Sliding electric contact material for low current

A sliding electrical contact, weak current technology, applied in contact materials, metal/alloy conductors, etc., can solve problems such as low hardness and wear resistance, reduced contact reliability, and unstable contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] According to the configuration described in Table 1, take the material of the present invention, smelt in a vacuum induction melting furnace, use argon protective gas, smelt, cast ingot at 600-700°C / 3h, homogenize, hot-roll, surface treatment, medium Rolling, intermediate heat treatment at 500-700°C / 1h (vacuum), and finish rolling to obtain the sliding electrical contact material for weak current according to the present invention

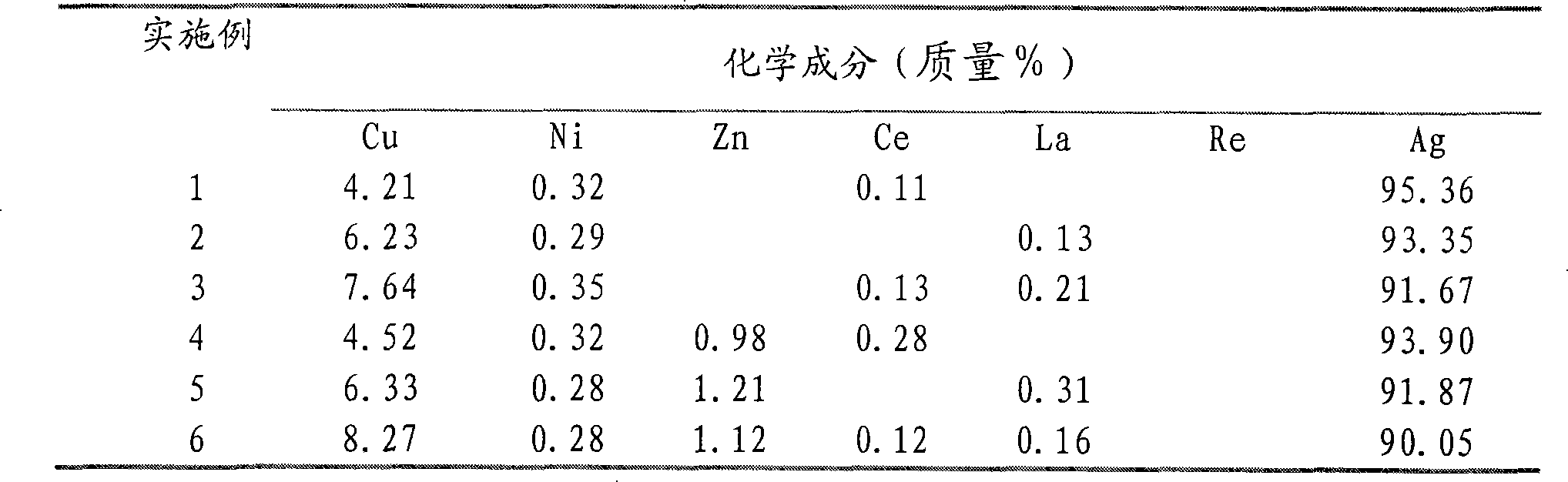

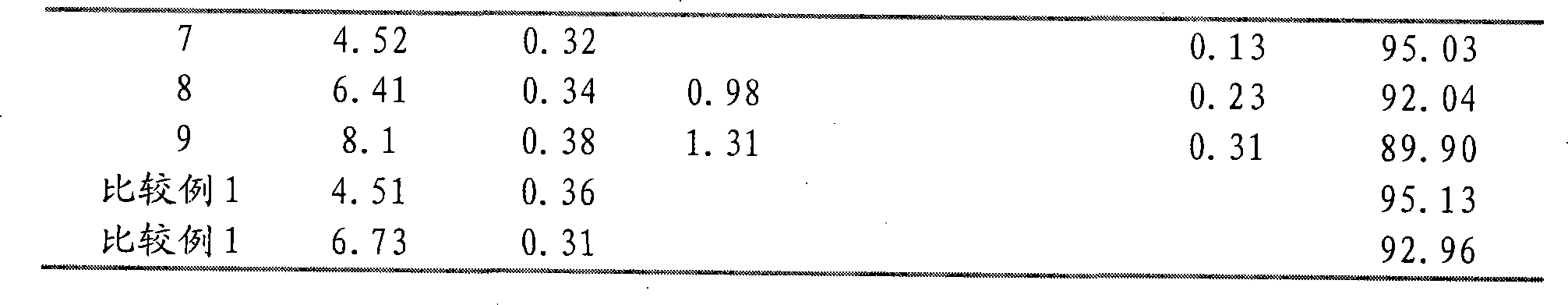

[0016] Table 1 Example composition of the sliding electrical contact material for weak current of the present invention

[0017]

[0018]

[0019] Note: Here Re is a mixed rare earth element containing Ce and La

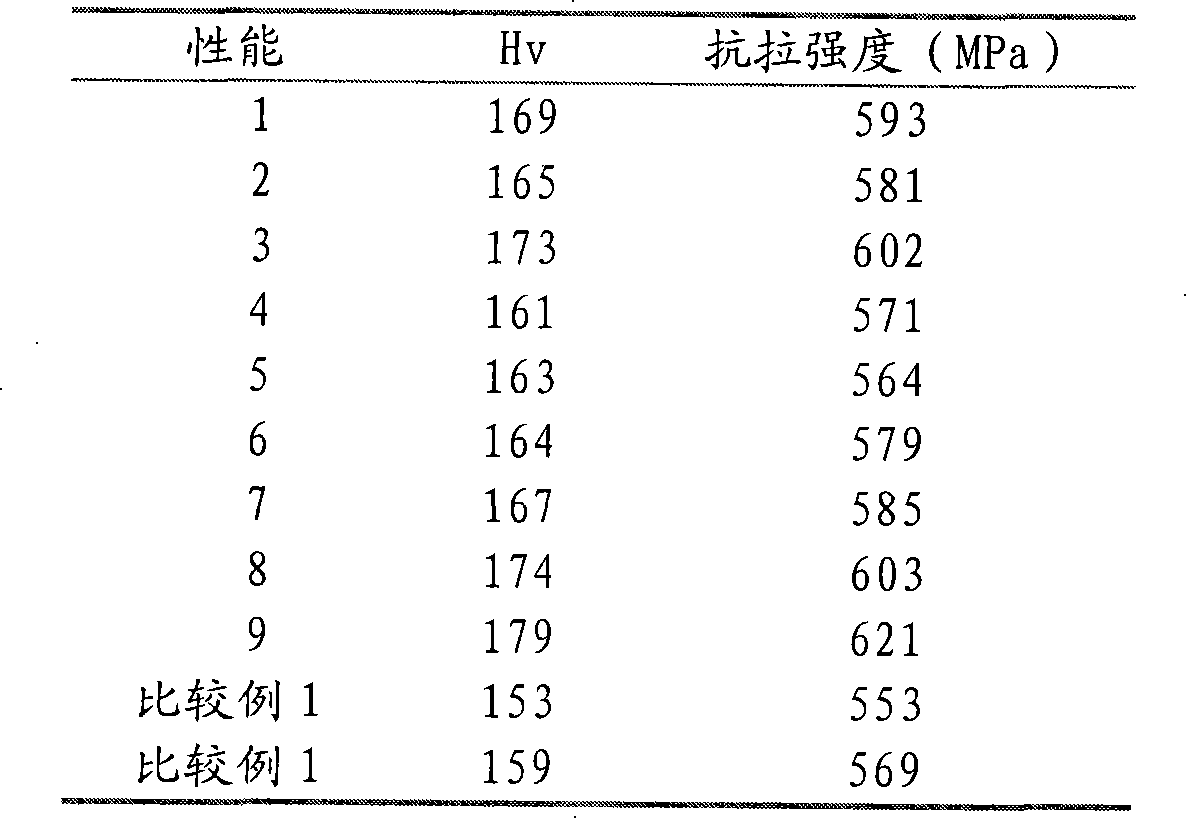

[0020] Table 2 Main properties of the sliding electrical contact material (processed state) for weak current of the present invention

[0021]

[0022] Compared with the Ag-Cu-Ni alloy comparative example finished product, the finished product of the material of the invention has improved hardness and tensile strength, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com