Arc-less switch and manufacturing method and using method thereof

An arc-free switch and switch technology, applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of arcing, easy heating, and arcing of auxiliary circuits, and achieve stable contact resistance, shock resistance, etc. The effect of high breakdown voltage and large current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

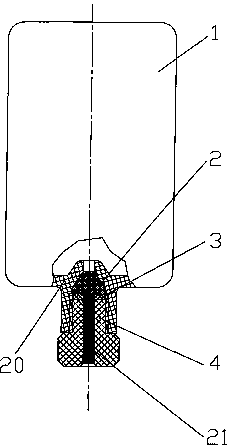

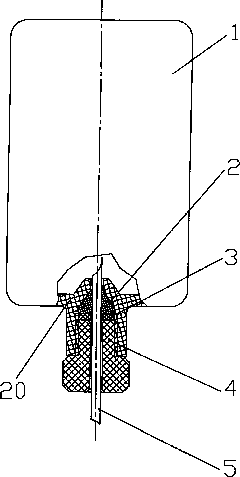

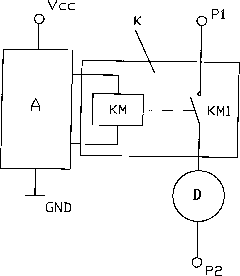

[0055] Example 1, such as figure 1 , image 3 Shown:

[0056] An arcless switch is provided, the arcless switch K is composed of a known relay 1 and an exhaust gas; its structural features are:

[0057] On the shell 20 of a known closed relay 1, a raised cylindrical exhaust platform is set, and a conical exhaust hole runs through the inside and outside. The inner shape of the cylindrical exhaust platform is that the lower part is cylindrical, and the upper part is conical. , wherein the cylindrical inner hole is provided with an internal thread; inside the vent hole, a flame-retardant elastic soft material 2, an annular circular gasket 3, a hollow bolt 4, and a flame-retardant adhesive 21 are arranged from top to bottom, Constitute the exhaust gas; the flame-retardant elastic soft material is tightly squeezed in the tapered hole, and the annular circular gasket is against the elastic soft material at one end, and the hollow bolt at the other end, and the hollow bolt is conne...

Embodiment 2

[0060] Example 2, such as Figure 4 , Figure 5 , Image 6 Shown:

[0061] An arcless switch is provided, the arcless switch K is composed of a switch cover 23, a spring 6, a sliding contact 7, a left fixed contact 8, a right fixed contact 9, an elastic soft film 10, an annular gasket 11, an inner hexagon It is composed of hollow bolt 12, mallet bolt 13, cylindrical nut 14 and exhaust body; its structural features are:

[0062]On the main body 22 of a switch housing, a raised cylindrical exhaust platform is set. There is a conical through exhaust hole in the cylindrical exhaust platform. The inner shape of the cylindrical exhaust platform is that the lower part is cylindrical. The upper part is conical, and the cylindrical inner hole is an internal thread; inside the vent hole, there are respectively provided with a flame-retardant elastic soft material 2, an annular circular gasket 3, a hollow bolt 4, a flame-retardant Sexual adhesive 21, the flame-retardant elastic soft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com