Patents

Literature

446 results about "Diaphragm structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

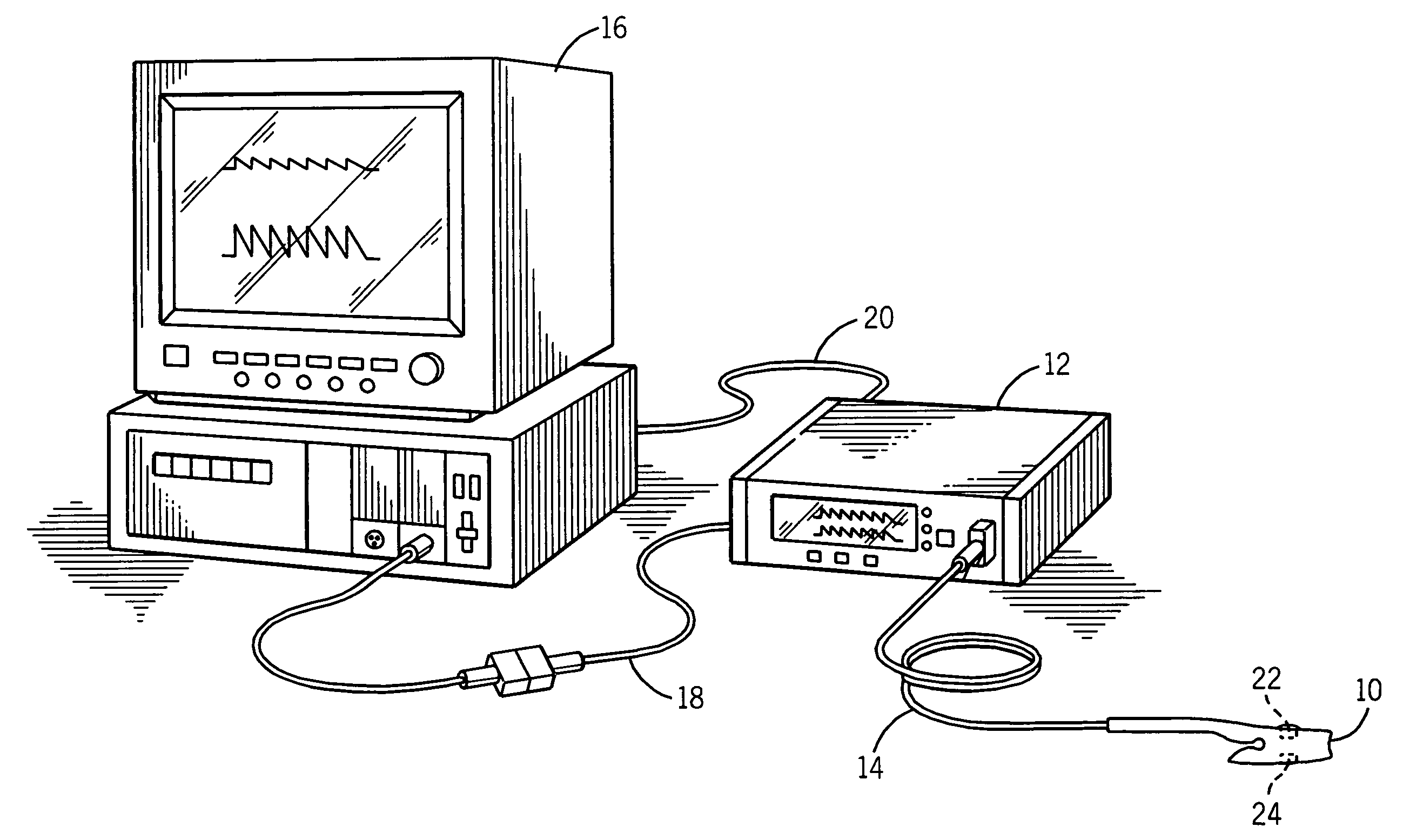

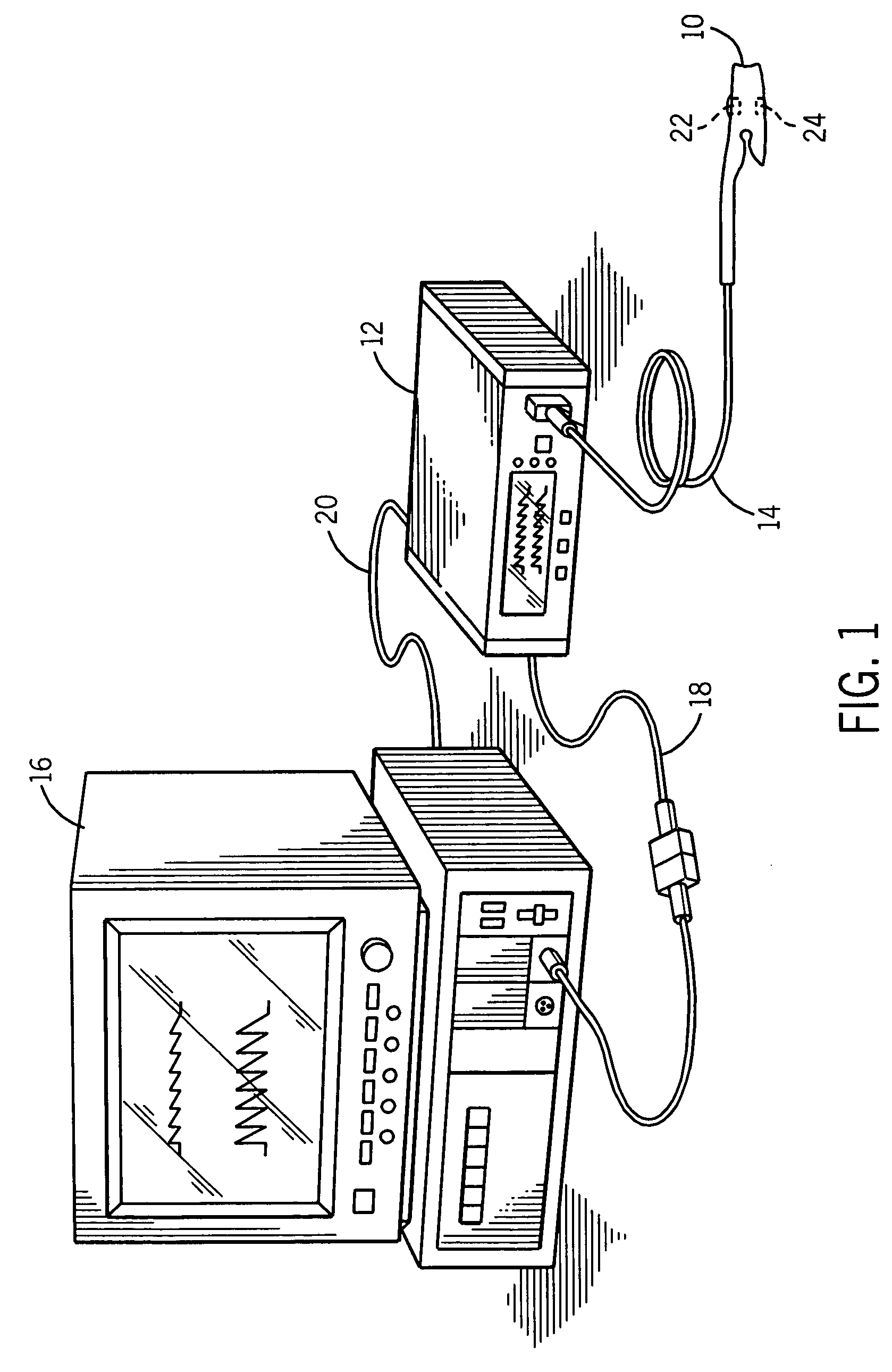

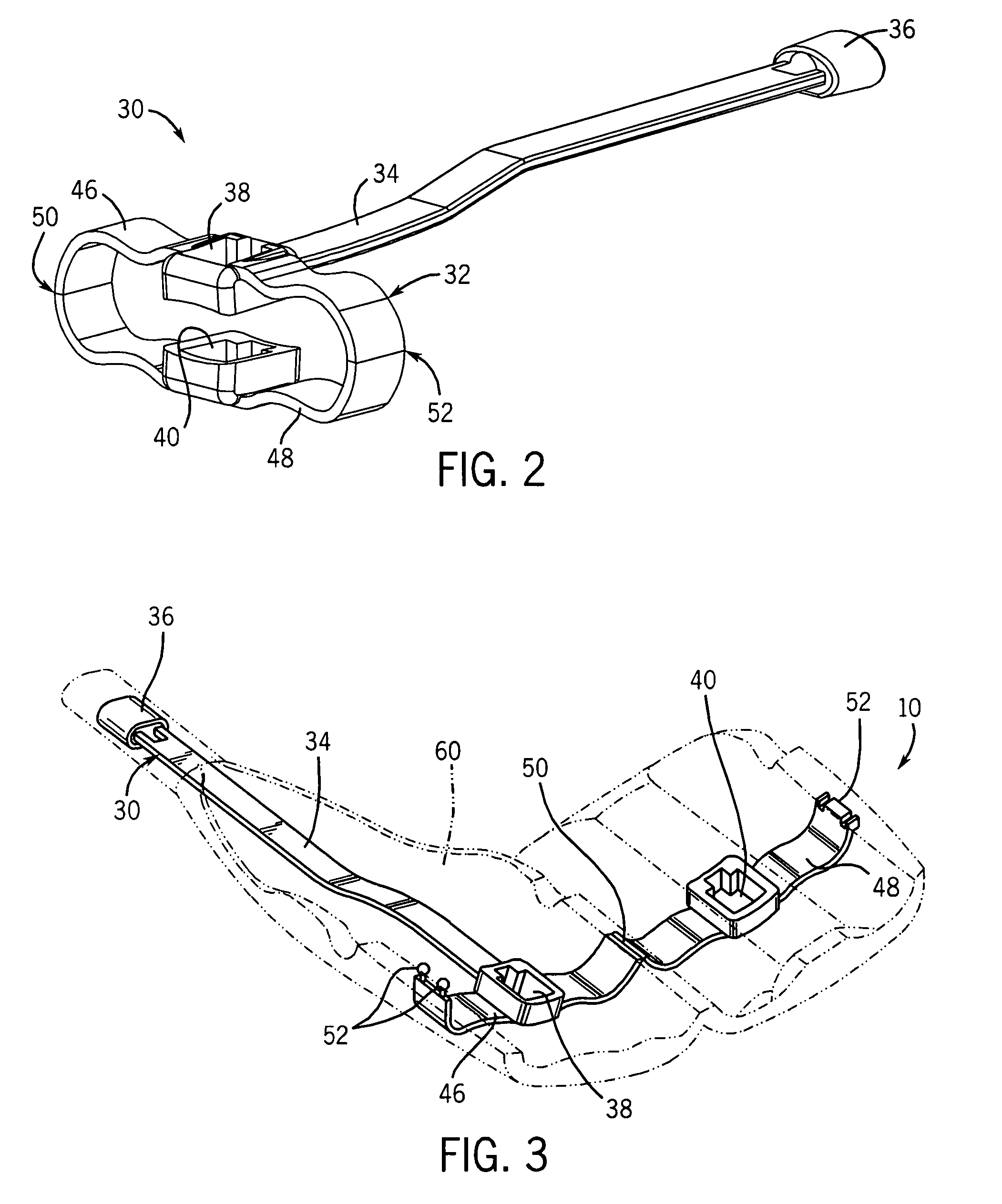

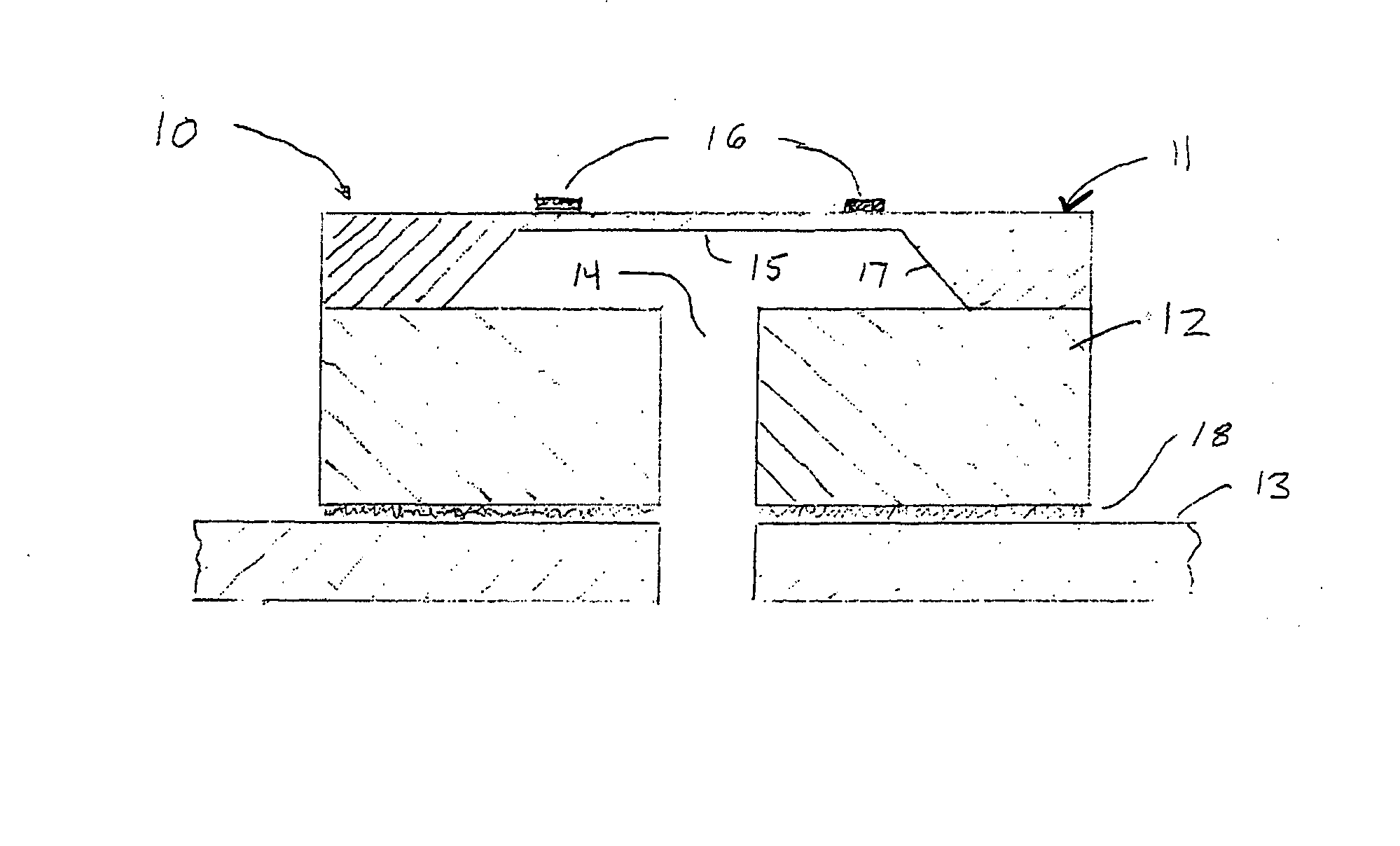

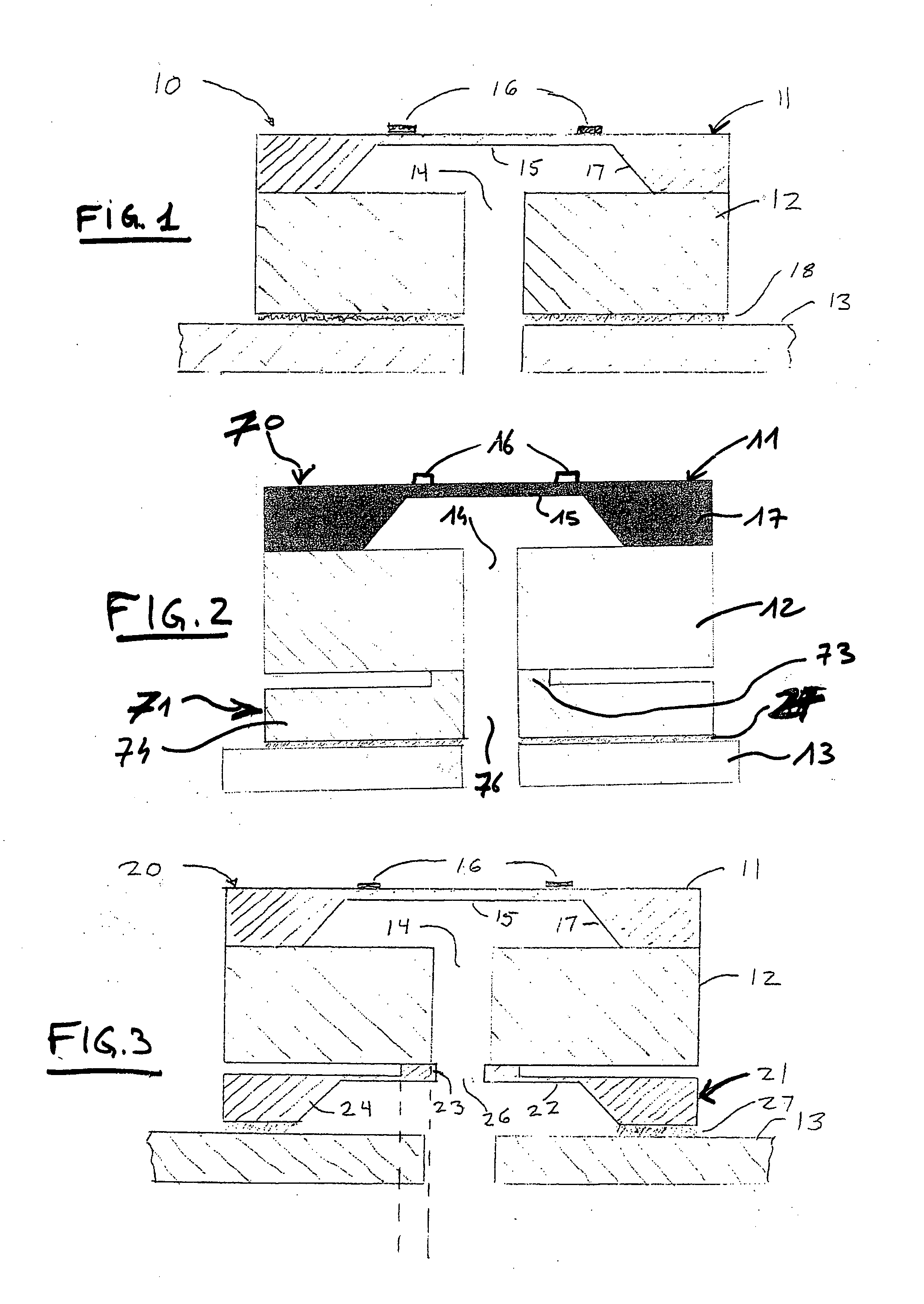

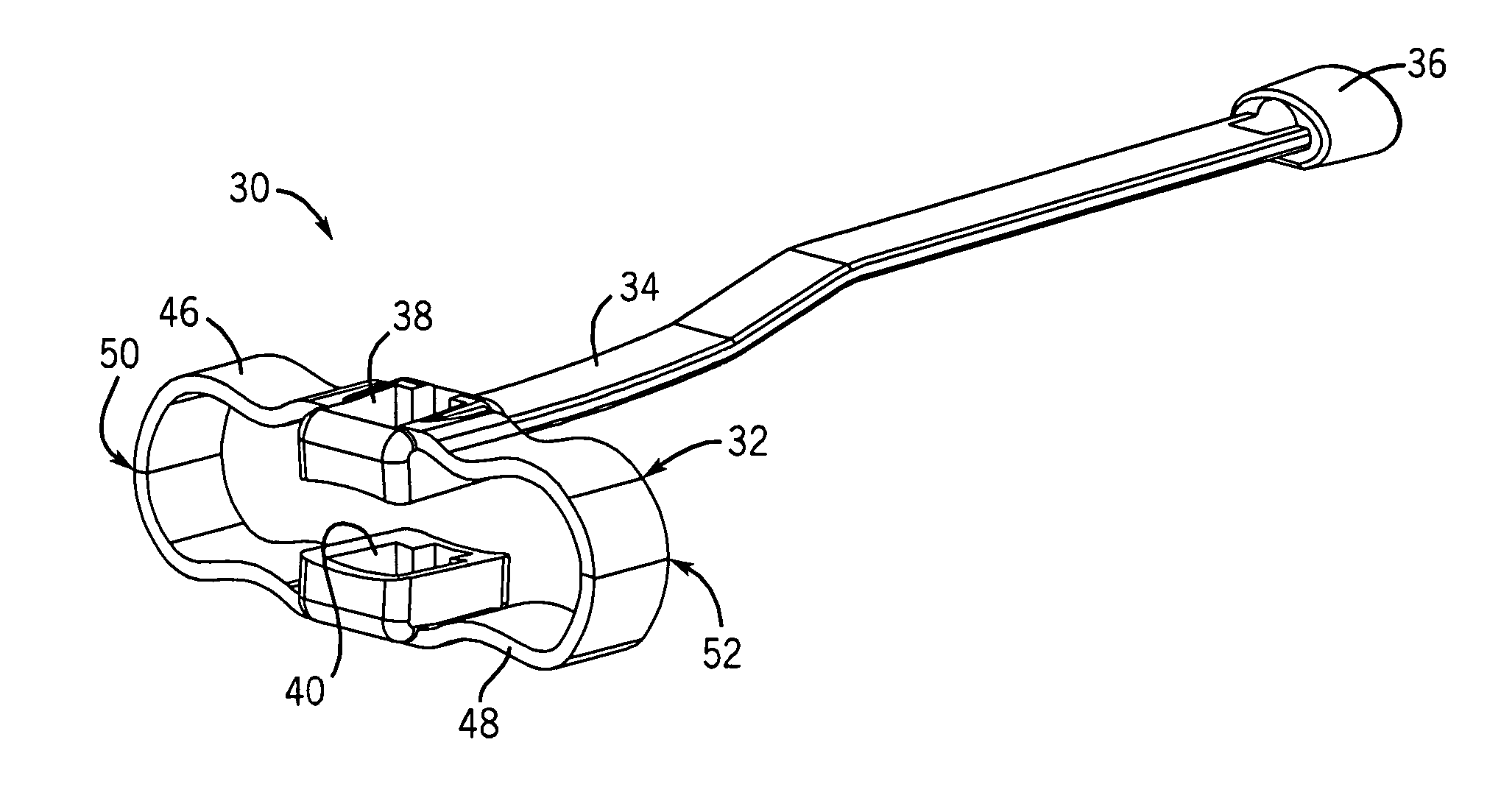

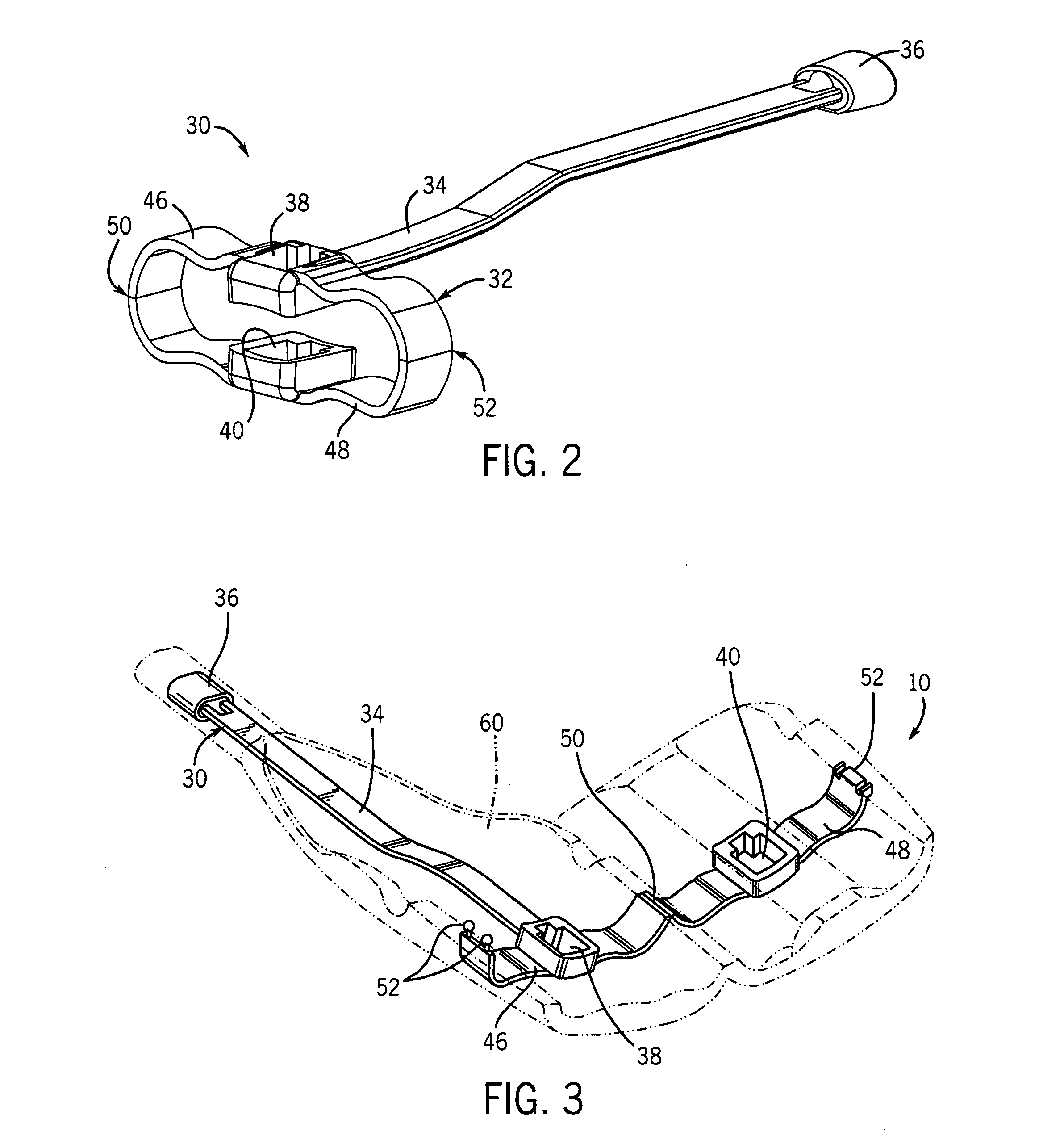

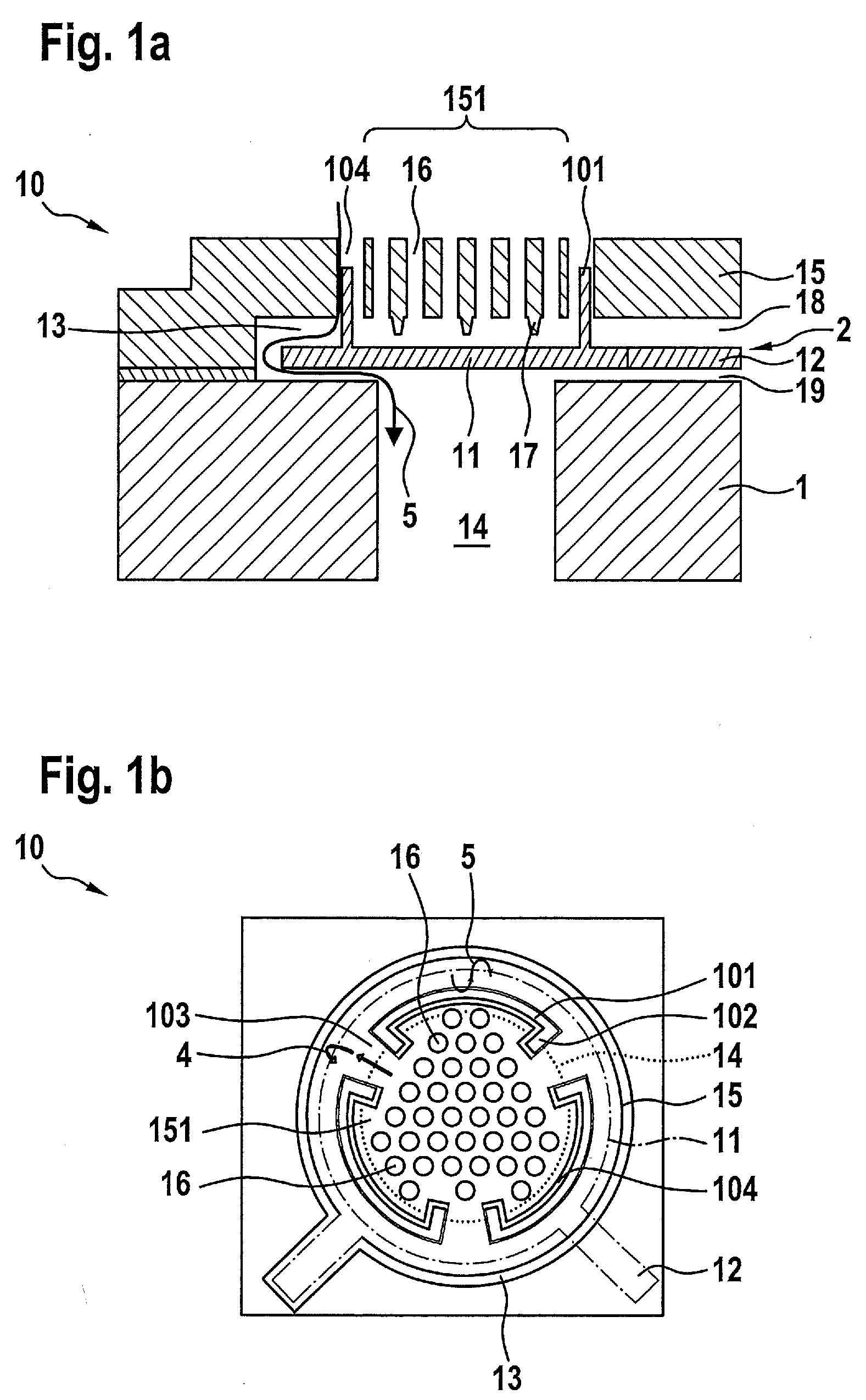

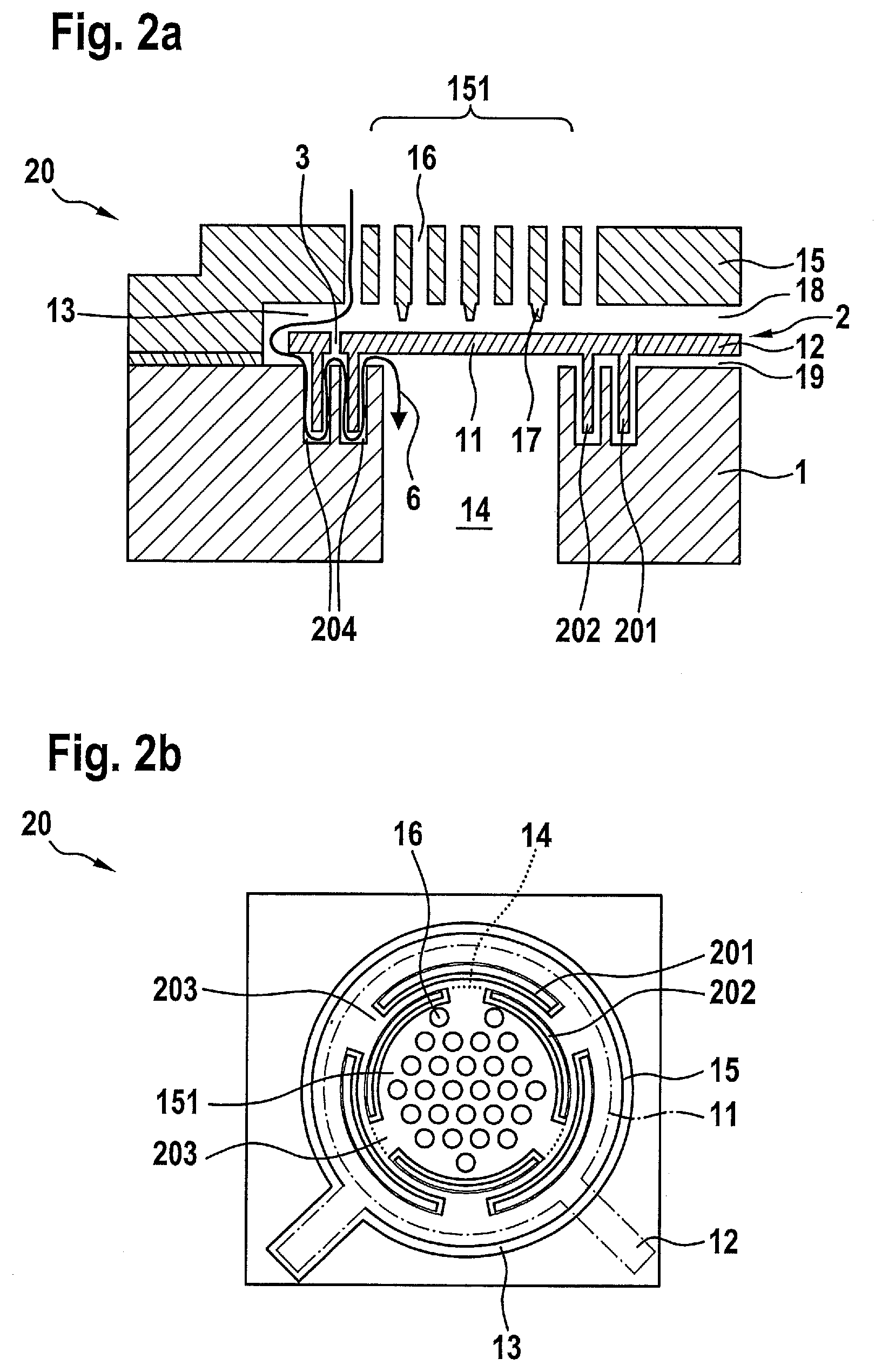

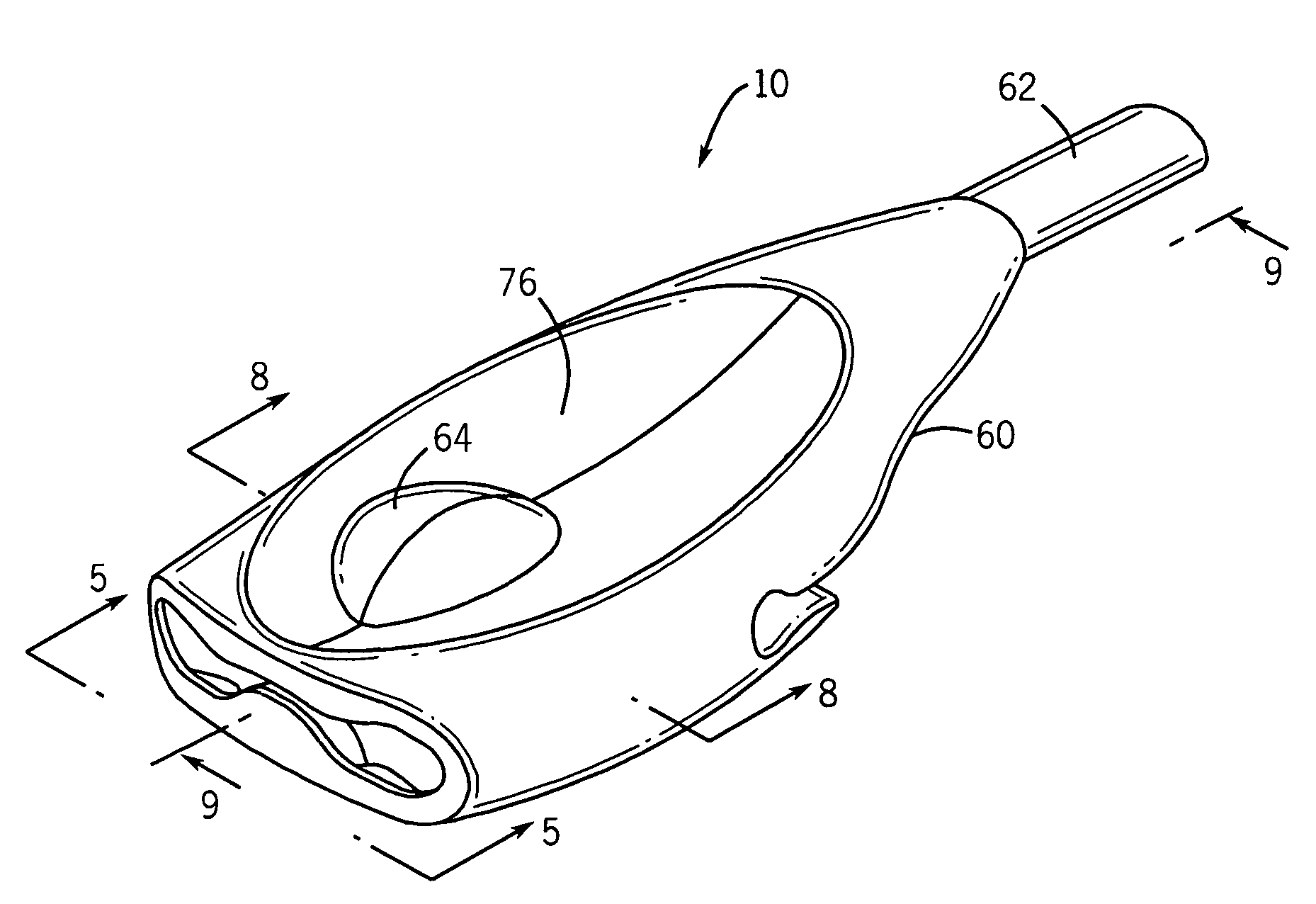

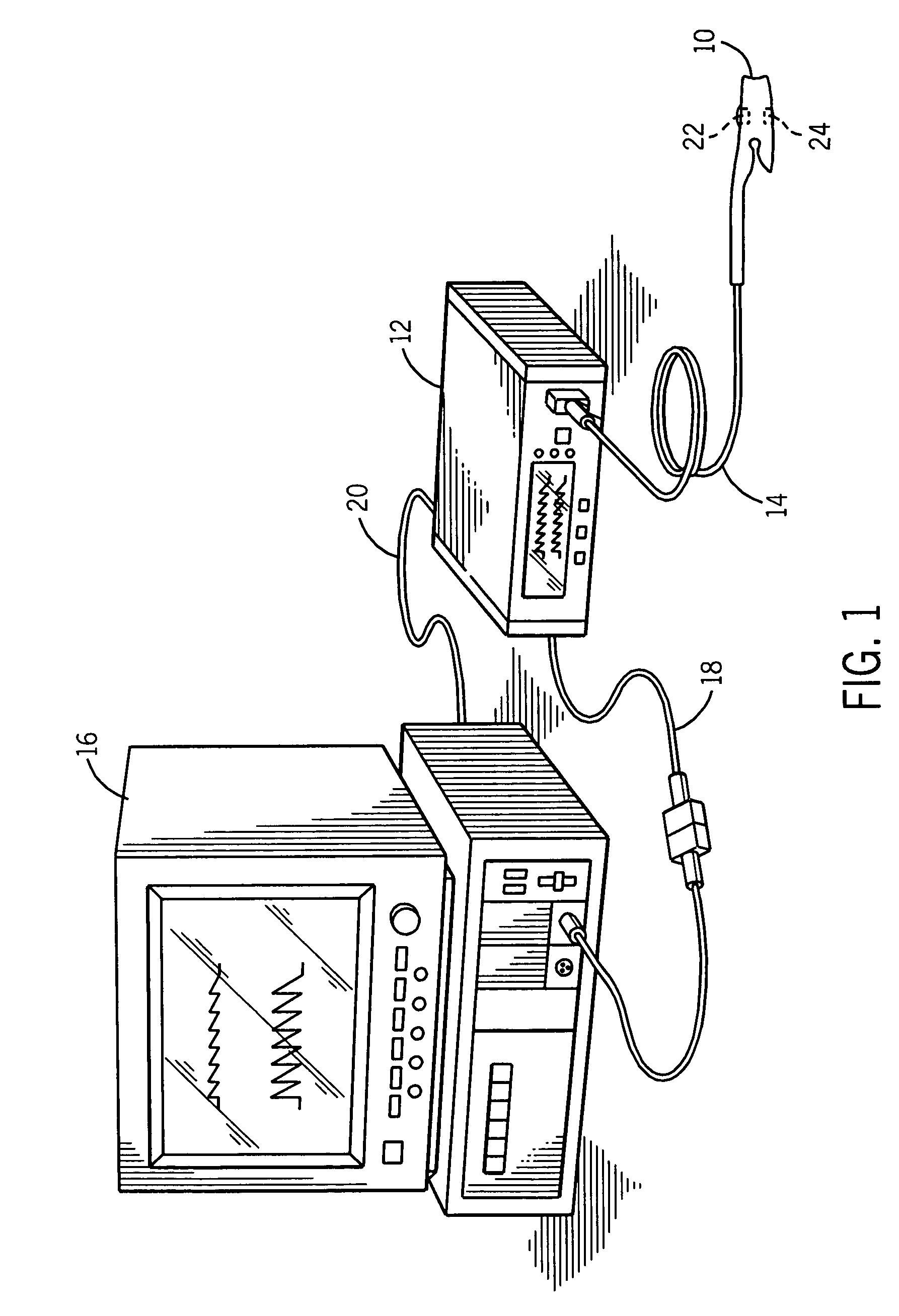

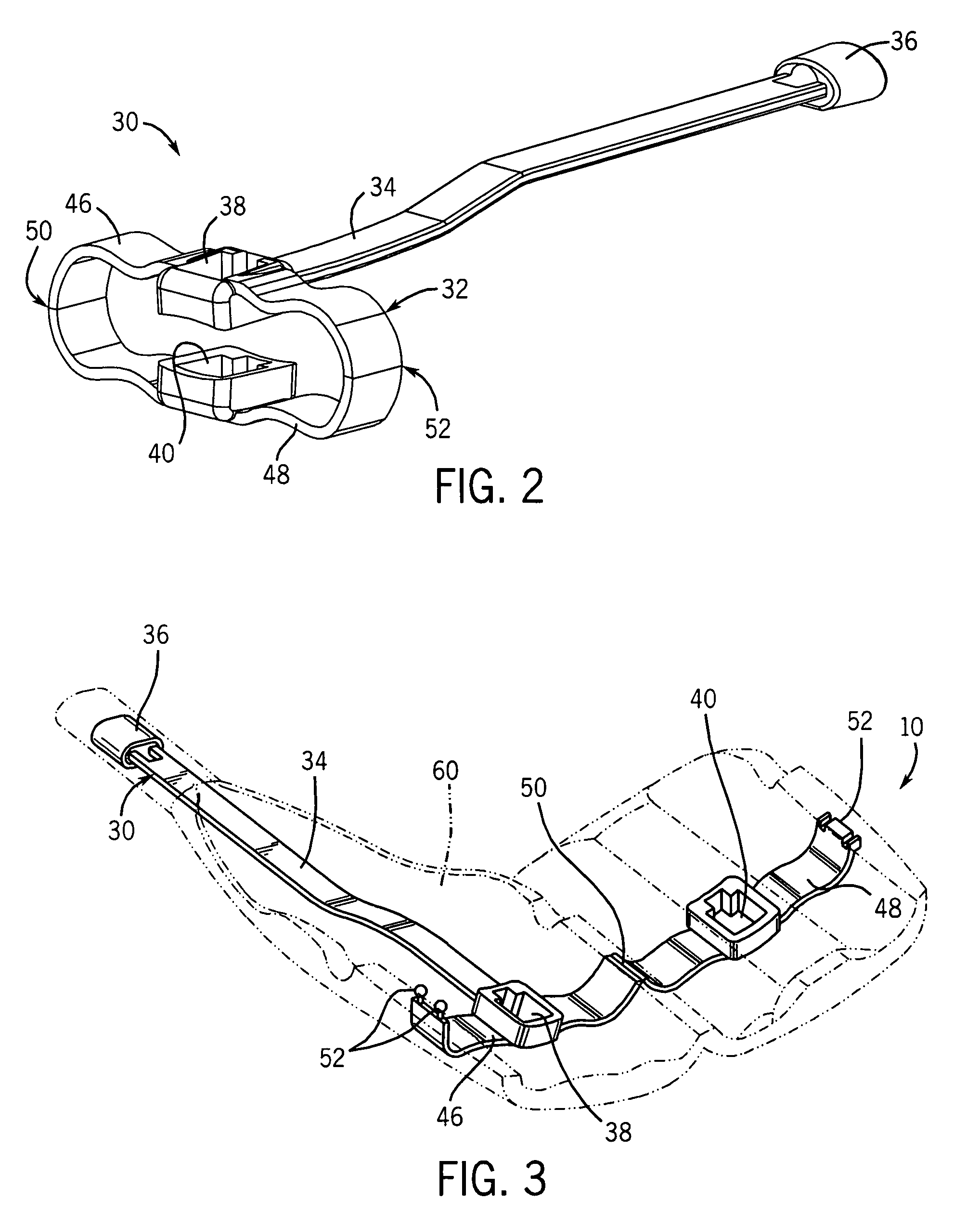

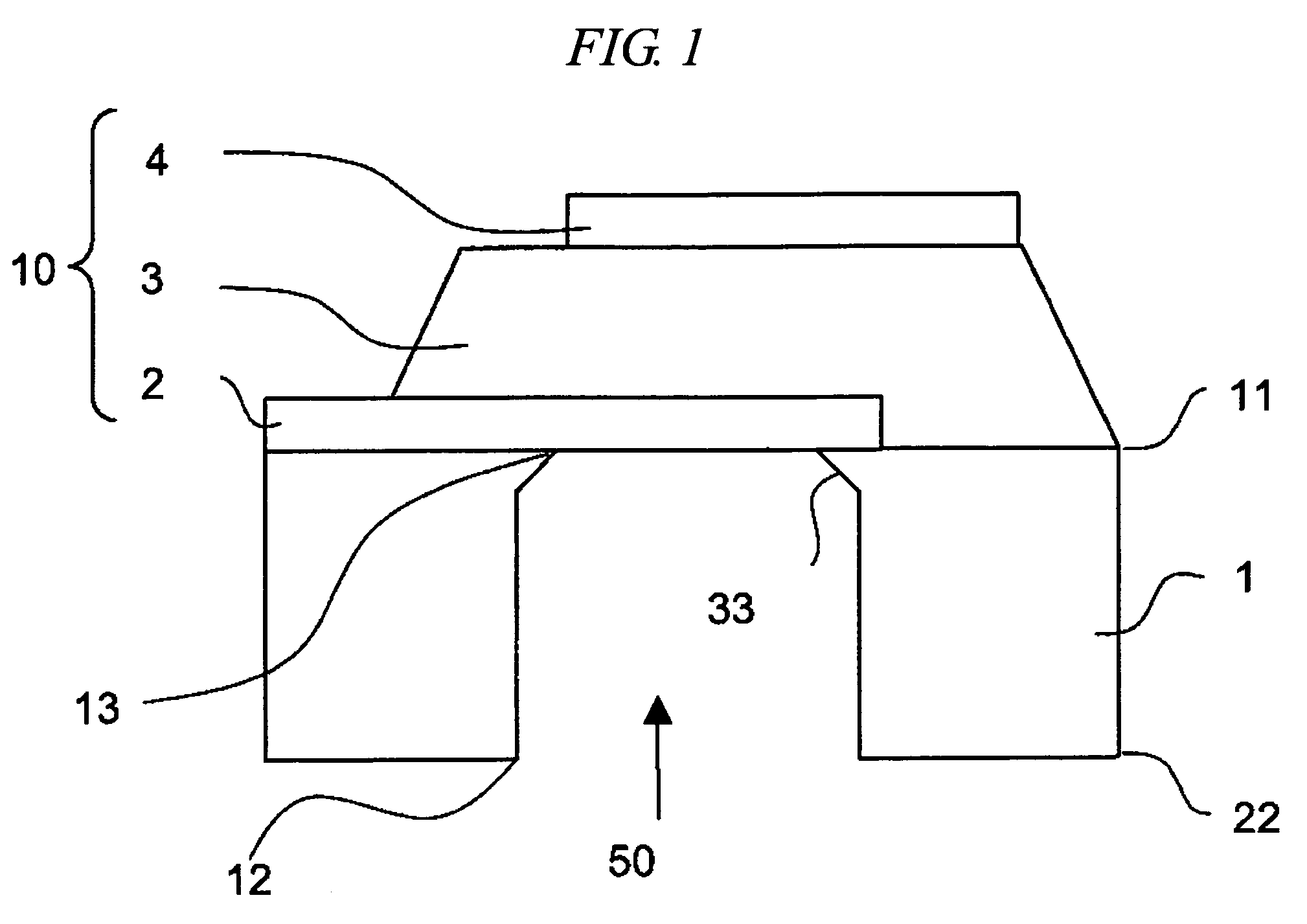

Compliant diaphragm medical sensor and technique for using the same

A sensor assembly is provided that includes a frame having a loop structure. An emitter and detector are disposed on opposite sides of the loop structure. A coating is provided over the frame. The coating includes at least one diaphragm structure disposed such that at least one of the emitter and detector can move along an axis running between the emitter and detector. The sensor may thereby be placed on a patient's finger, toe, and so forth to obtain pulse oximetry or other physiological measurements. A sensor frame and method of manufacturing the frame are also provided.

Owner:TYCO HEALTHCARE GRP LP

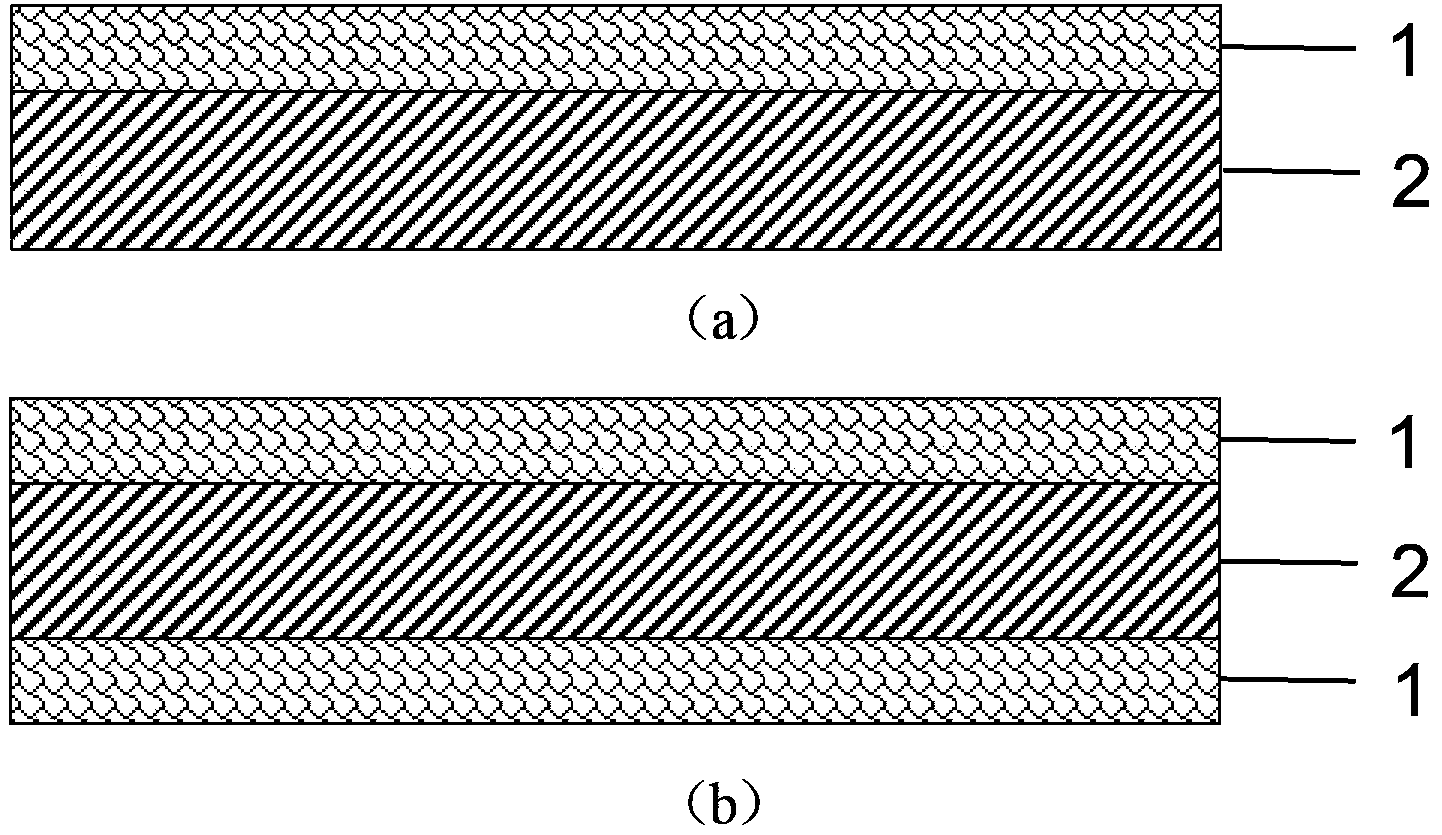

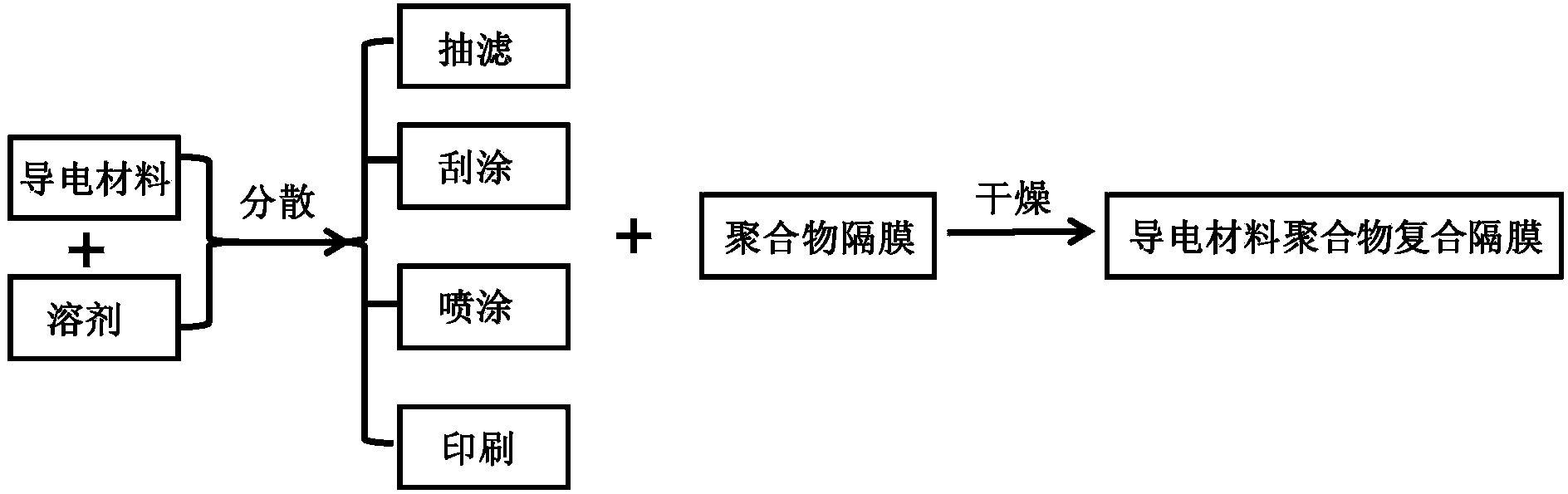

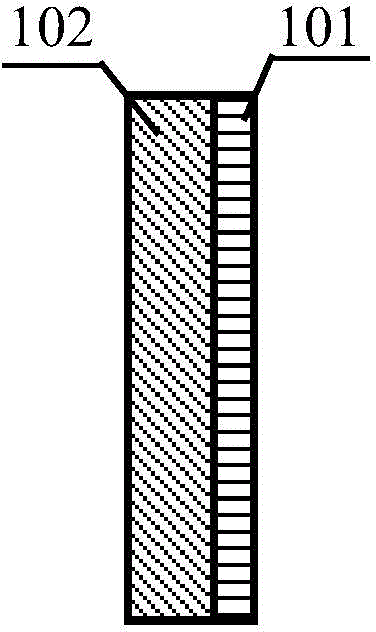

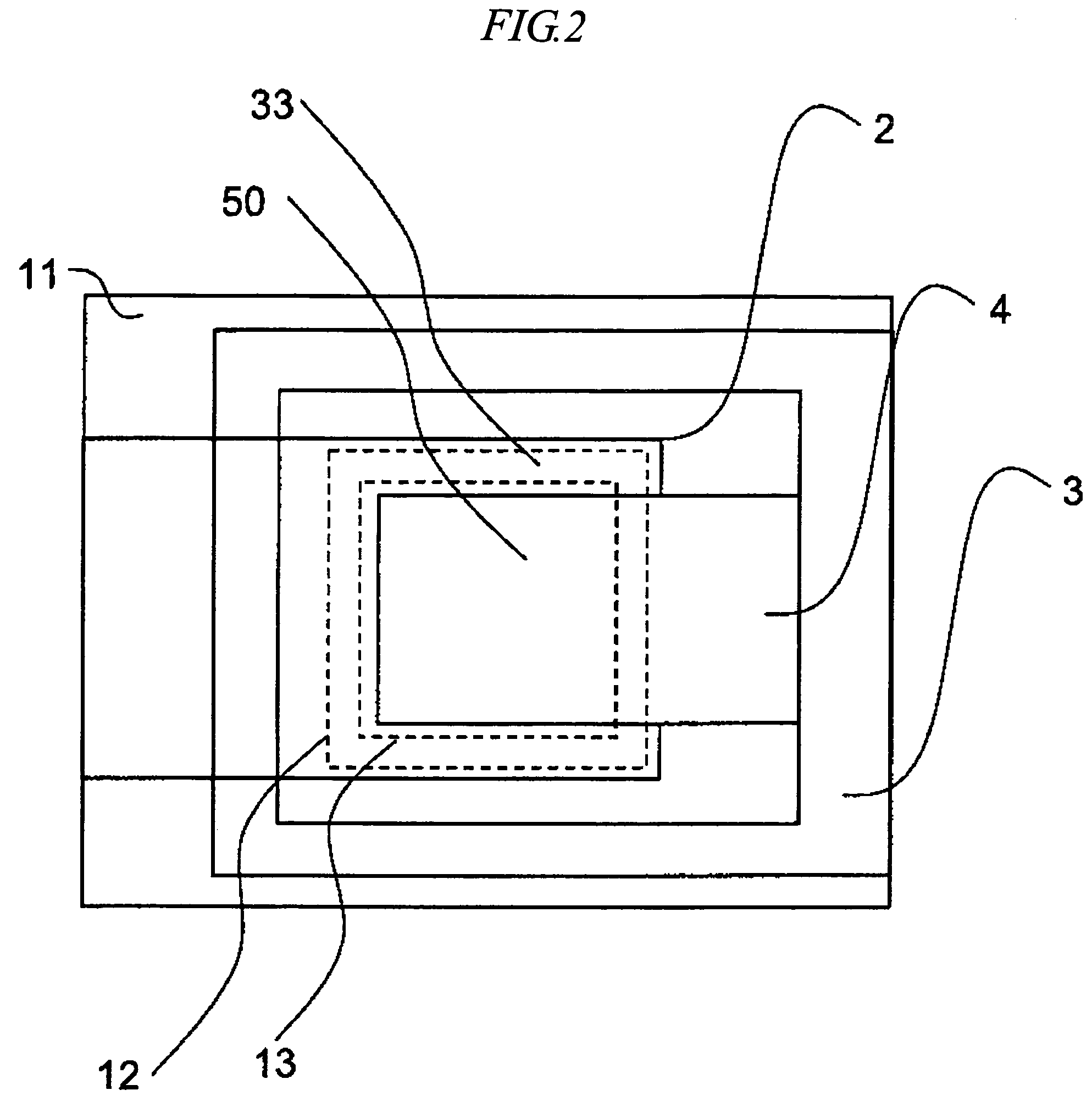

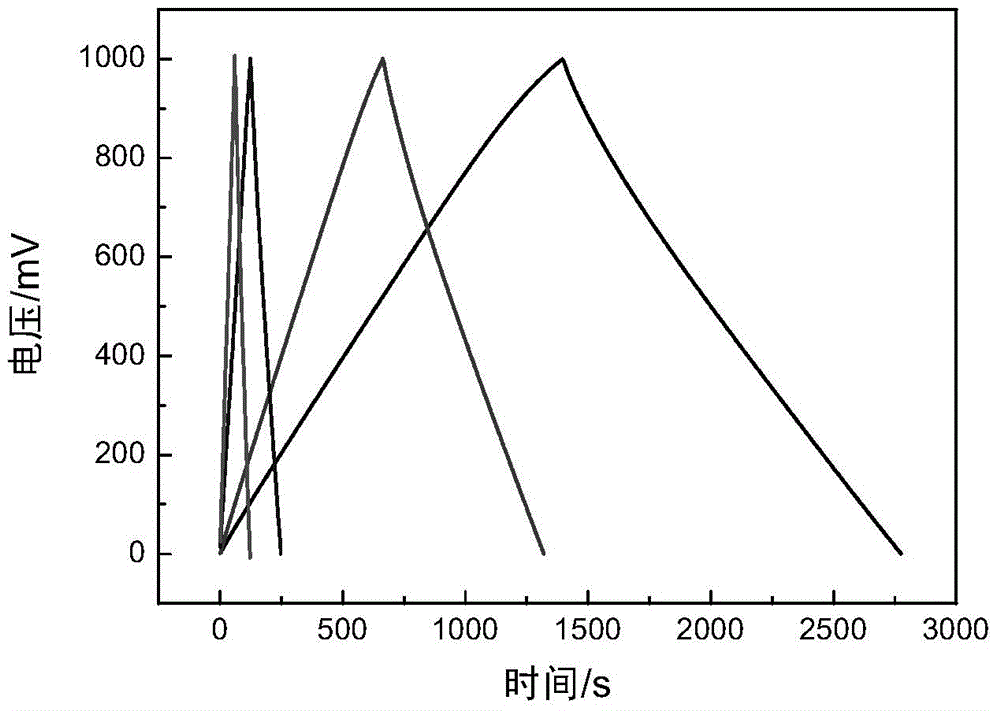

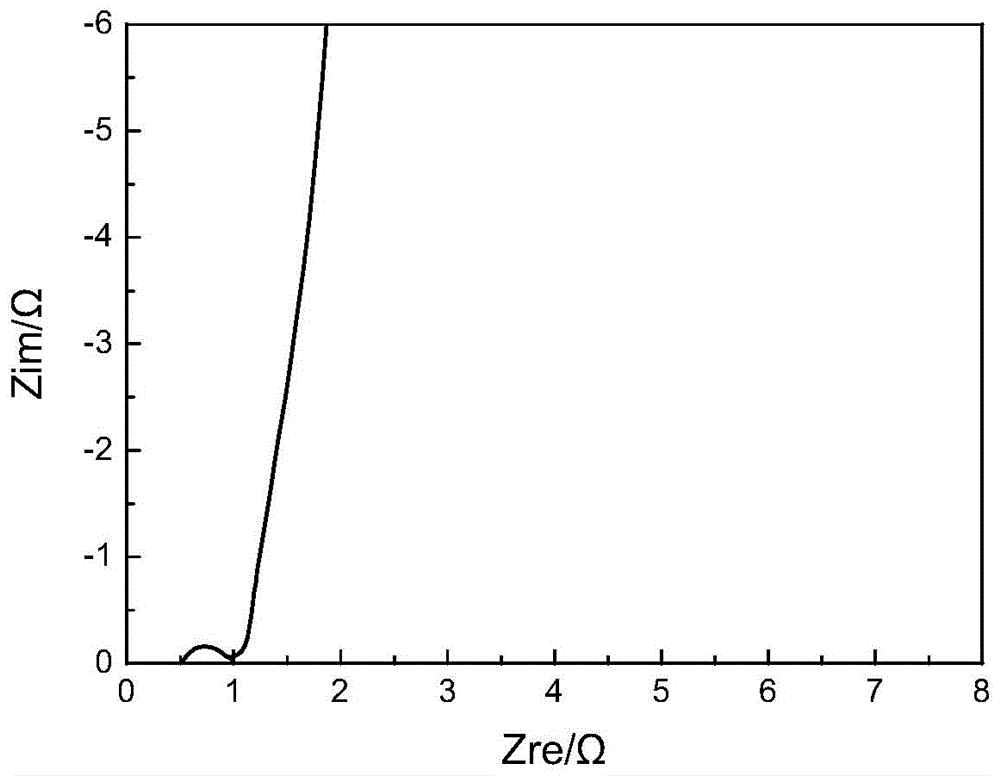

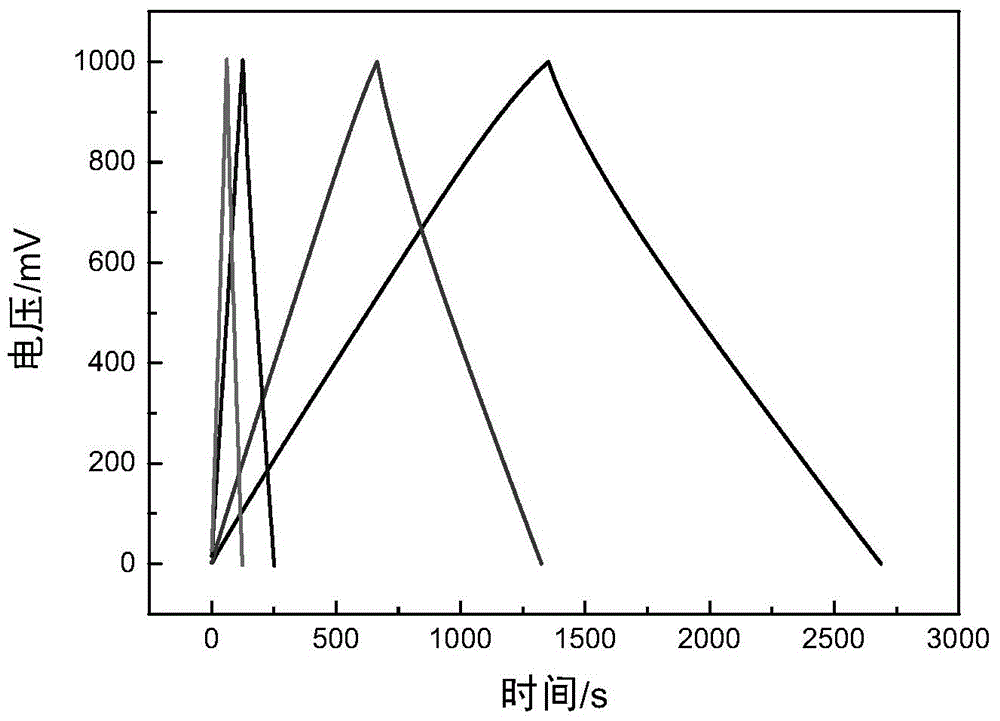

Composite diaphragm for battery and preparation method thereof

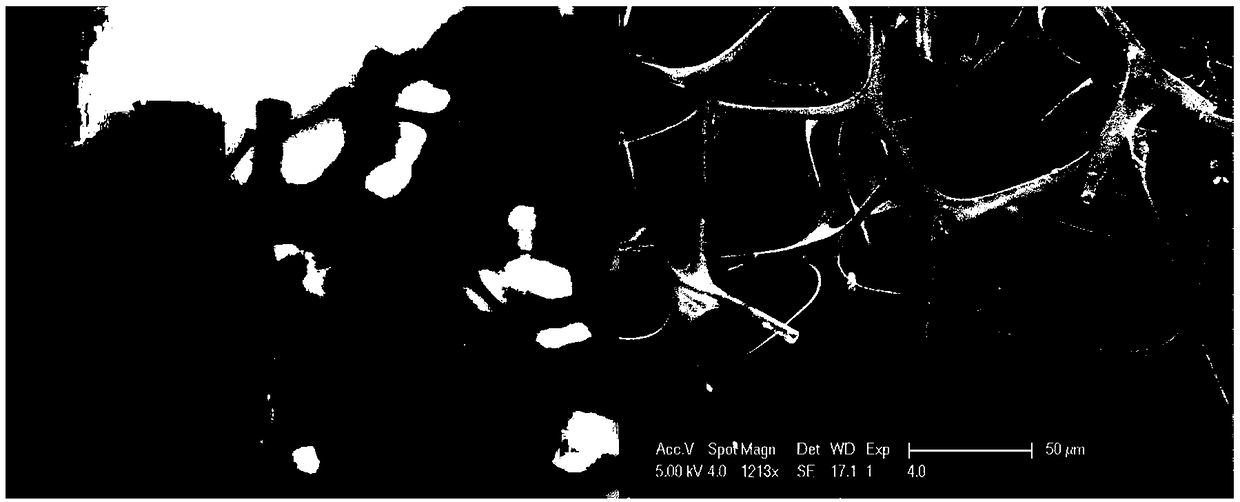

InactiveCN104103791ALower internal resistanceIncrease contactCell component detailsMetallic lithiumDiaphragm structure

The invention discloses a composite diaphragm for a battery and a preparation method thereof, belonging to the field of electrochemical cells. The composite diaphragm is a multilayer composite diaphragm structure composed of a conducting layer / a polymer layer or a conducting layer / a polymer layer / a conducting layer, wherein the conducting layer mainly comprises a carbon material or a conductive polymeric material and forms a film on a single surface or double surfaces of a polymer diaphragm. The composite diaphragm has the following characteristics: the conducting layer has strong electrolyte adsorption and storage capability, the process of ion transport is shortened, and large-current charge and discharge performance of the battery is improved; when the composite diaphragm is used in a metallic lithium battery, the conducting layer in the composite diaphragm contacting with metallic lithium can alleviate nonuniform corrosion on the surface of lithium and inhibit formation of lithium dendrite crystals. The preparation method for the composite diaphragm is simple and easily controllable, can realize large-quantity and low-cost industrial preparation of the composite diaphragm and has a high application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

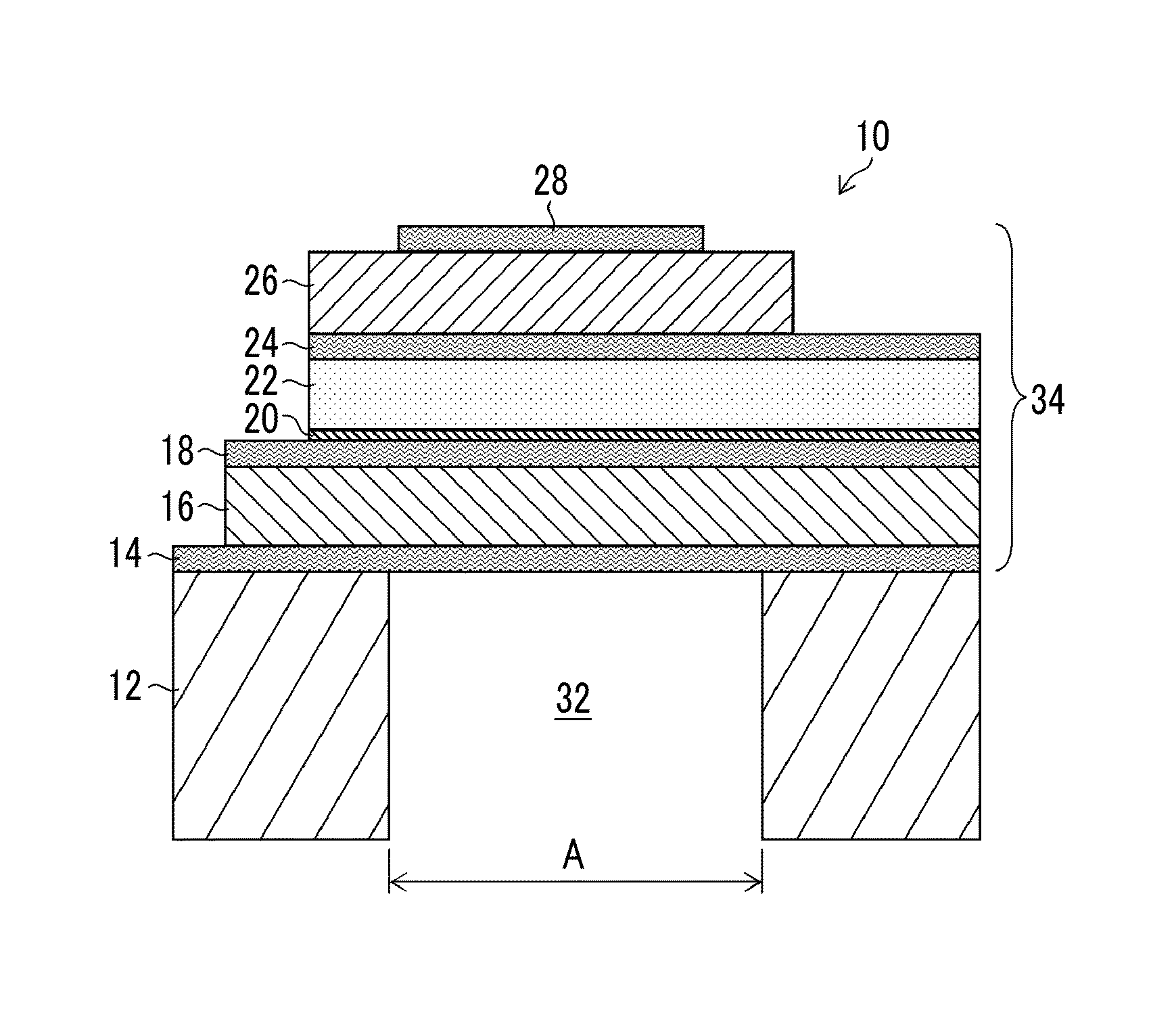

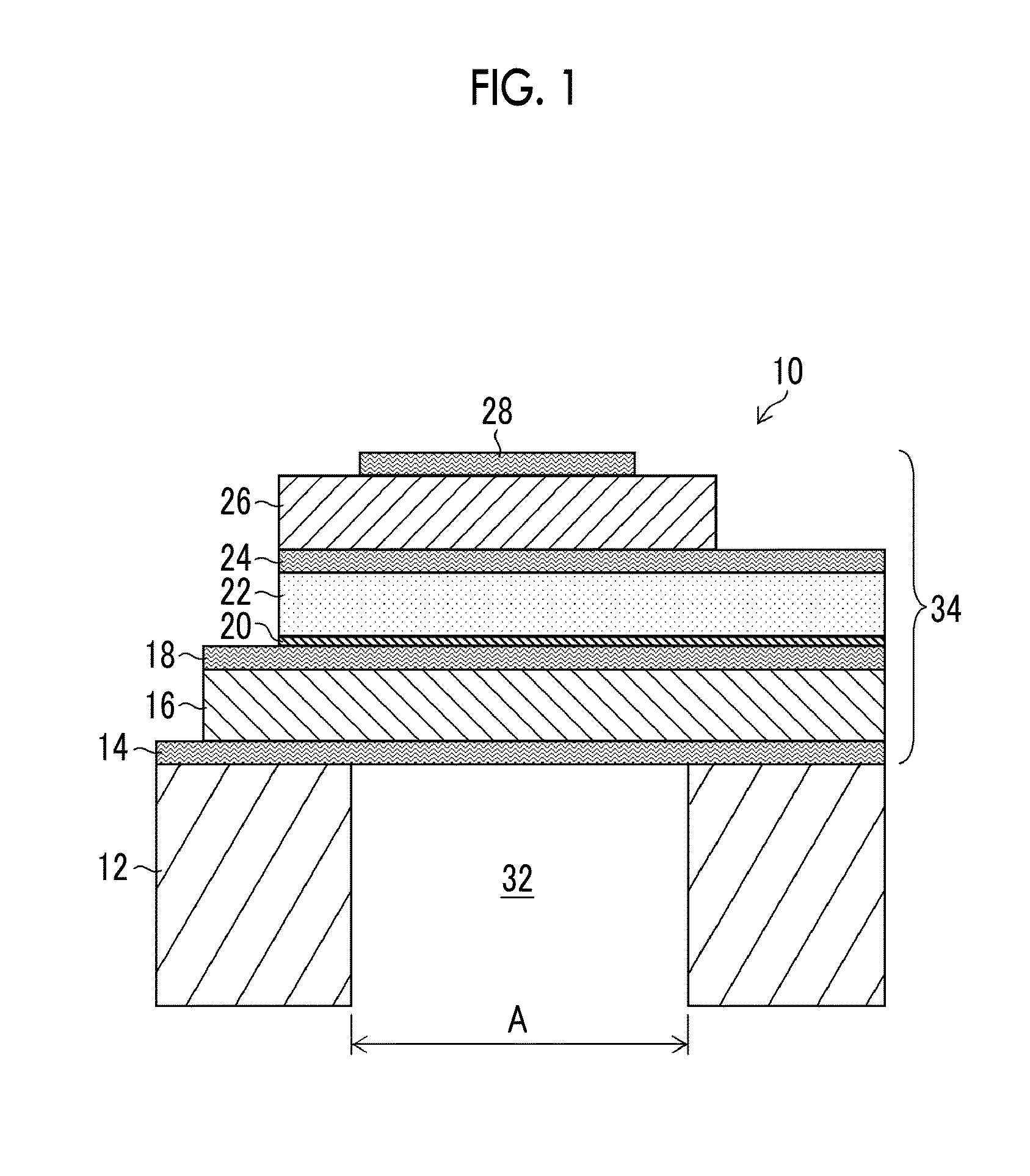

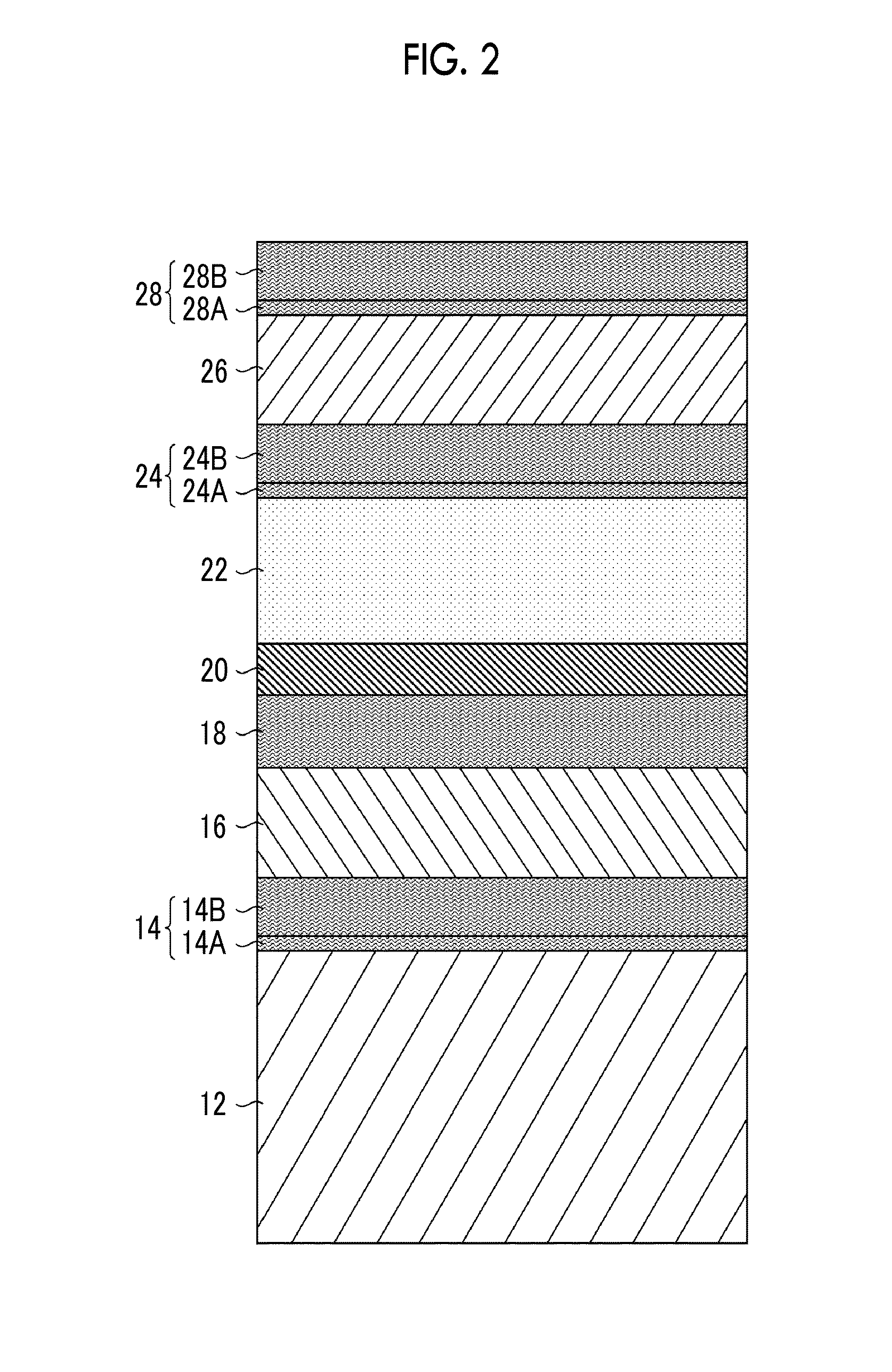

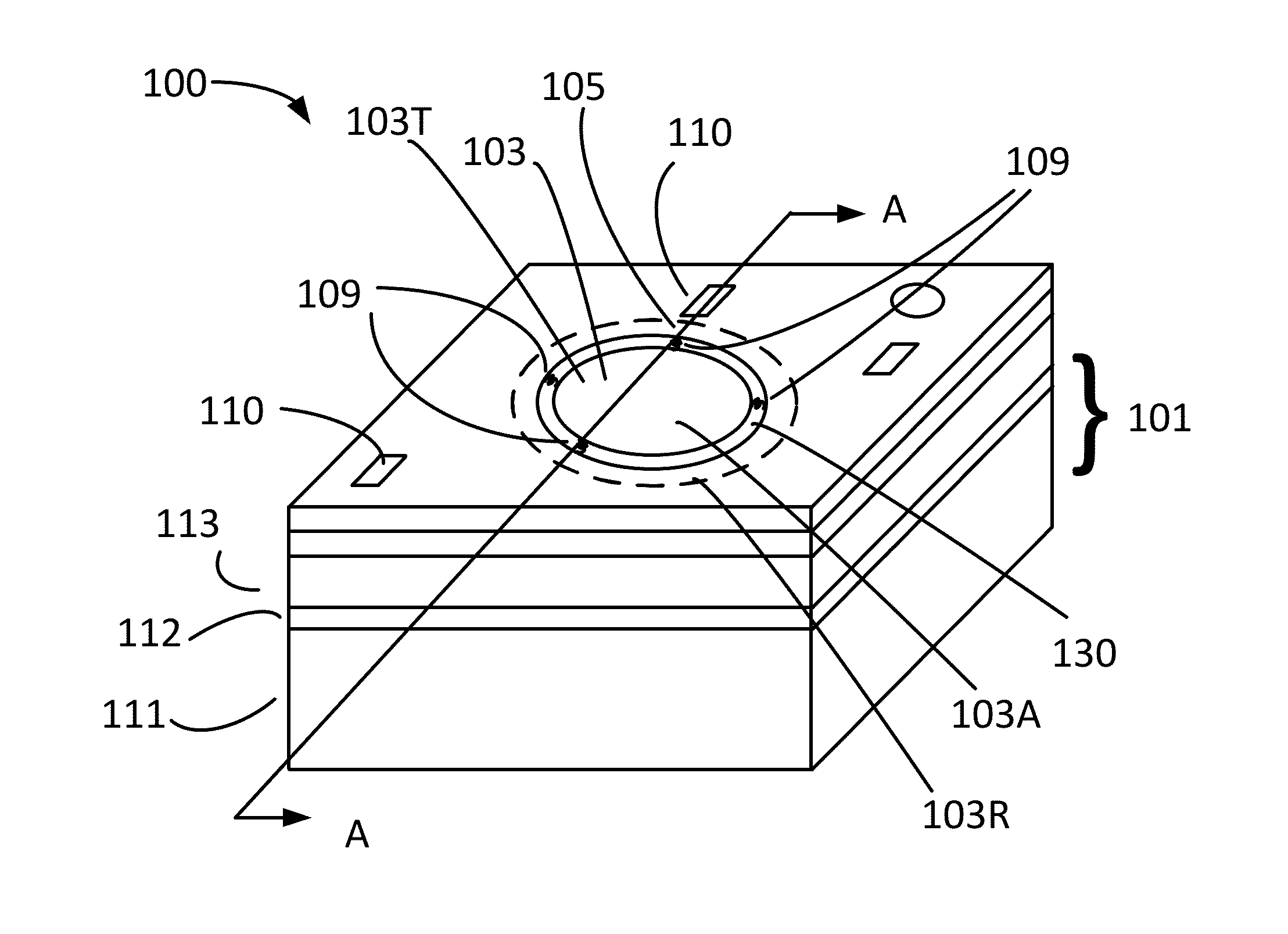

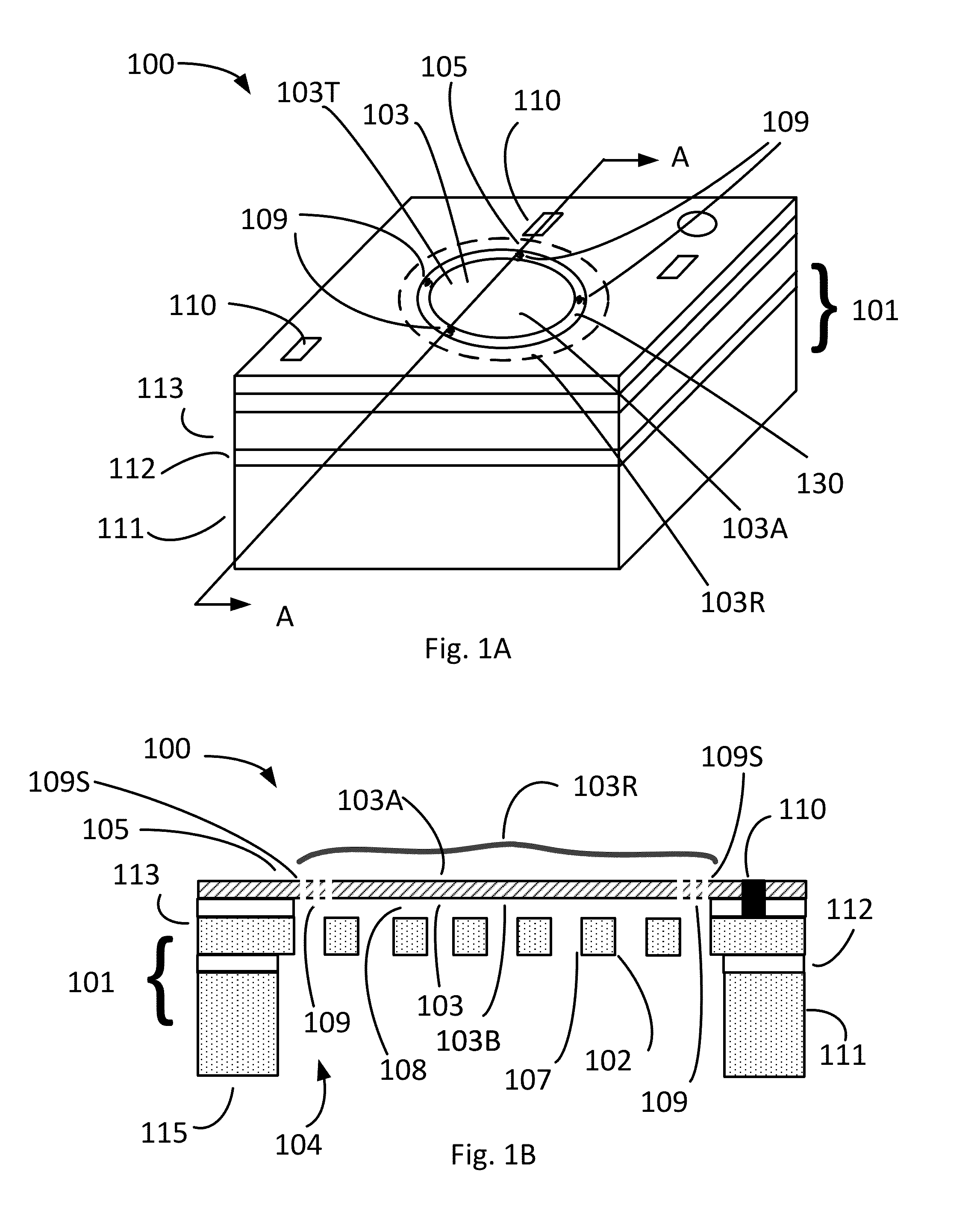

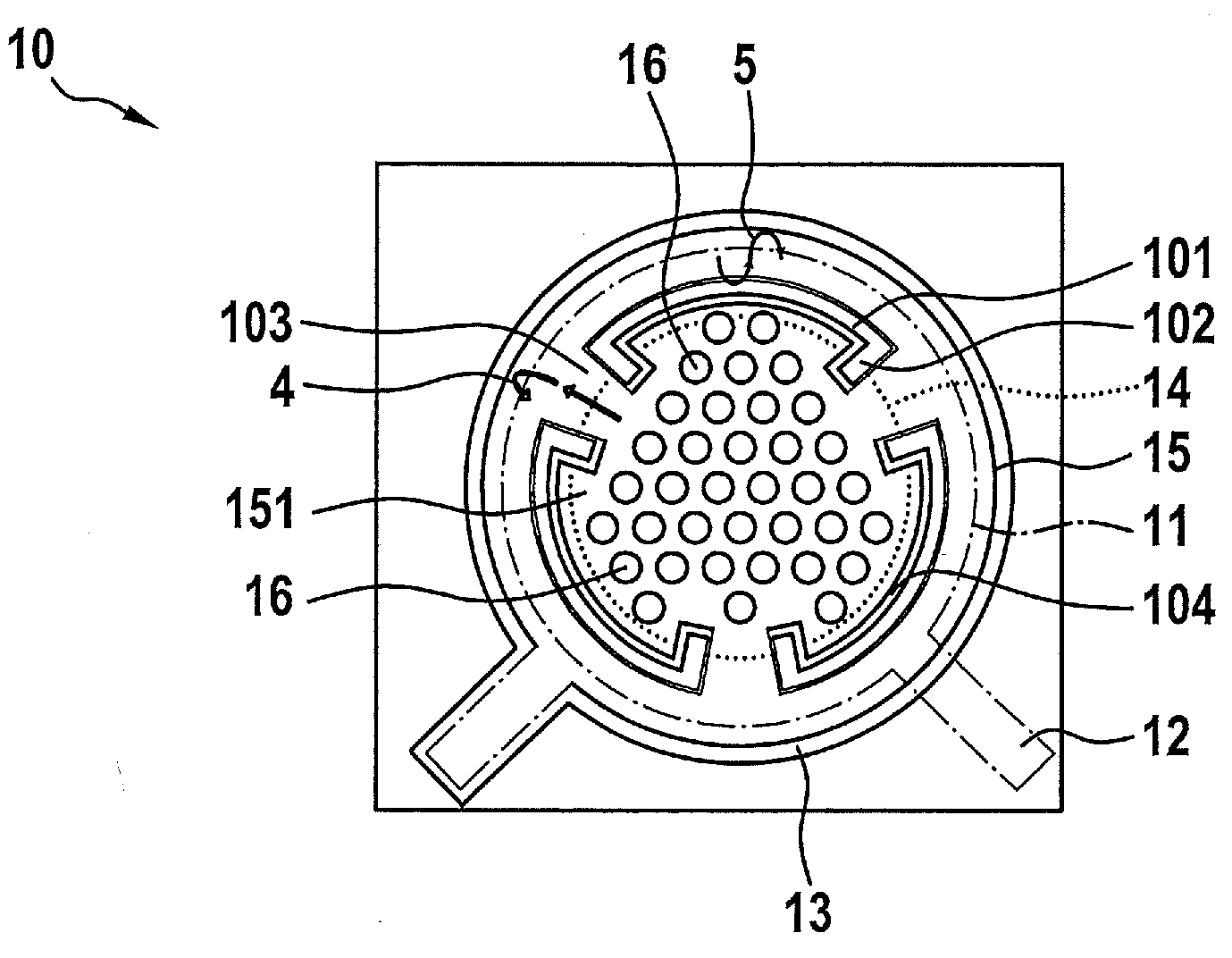

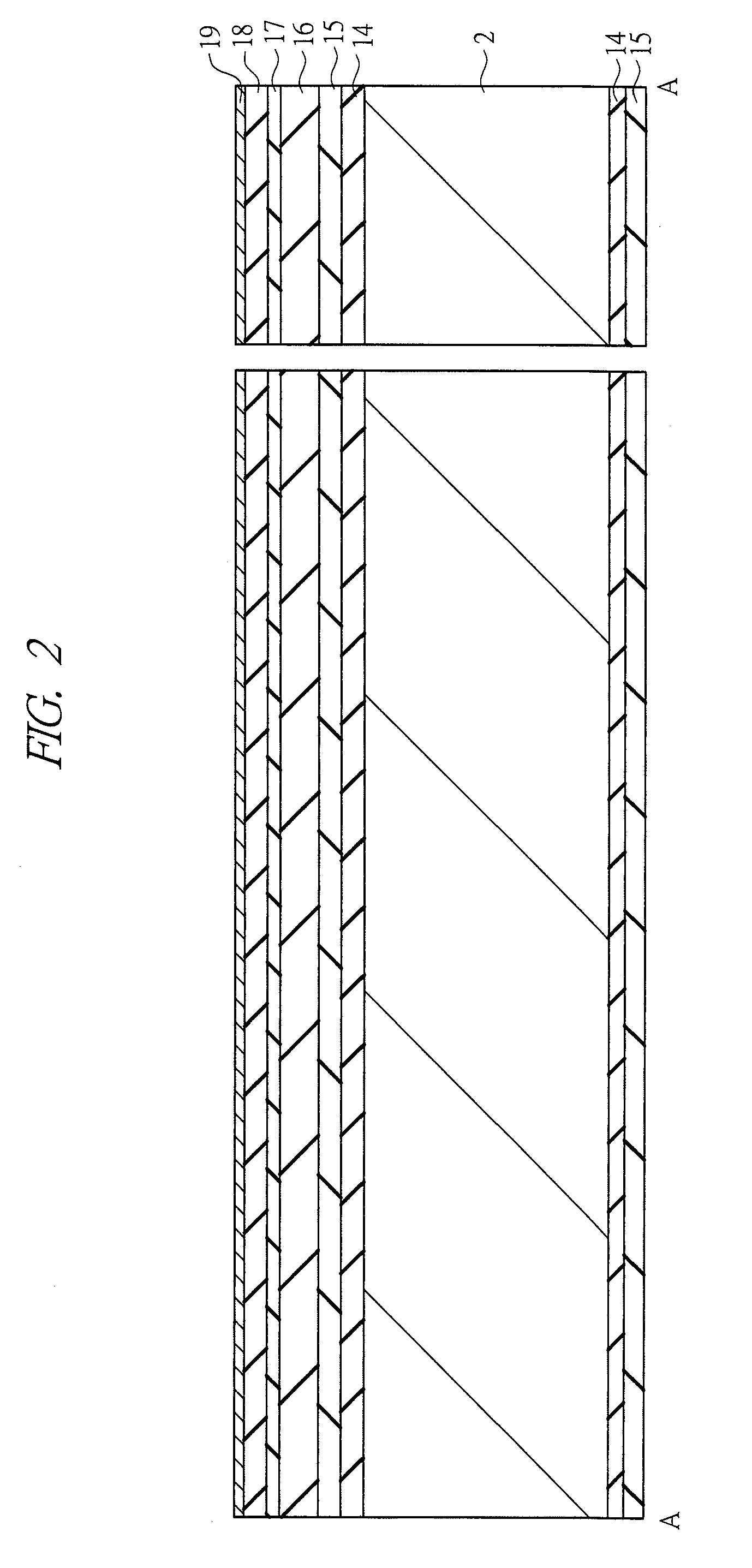

Piezoelectric element and method for manufacturing piezoelectric element

InactiveUS20160240768A1Improve efficiencySimple processPiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationDiaphragm structureEngineering

Provided are a piezoelectric element having high stability, which operates with high efficiency, and a method for manufacturing the piezoelectric element. The piezoelectric element (10) has a laminate structure in which a first electrode (14), a first piezoelectric film (16), a second electrode (18), an adhesion layer (20), an interlayer (22), a third electrode (24), a second piezoelectric film (26), and a fourth electrode (28) are laminated in this order on a silicon substrate (12). The interlayer (22) is formed of a material different from that of the second electrode (18) and has a thickness of 0.4 μm to 10 μm. A device having a diaphragm structure or a cantilever structure is formed by removing a part of the silicon substrate (12). The respective layers (14 to 28) laminated on the silicon substrate (12) can be formed using a thin film formation method represented by a vapor phase epitaxial method.

Owner:FUJIFILM CORP

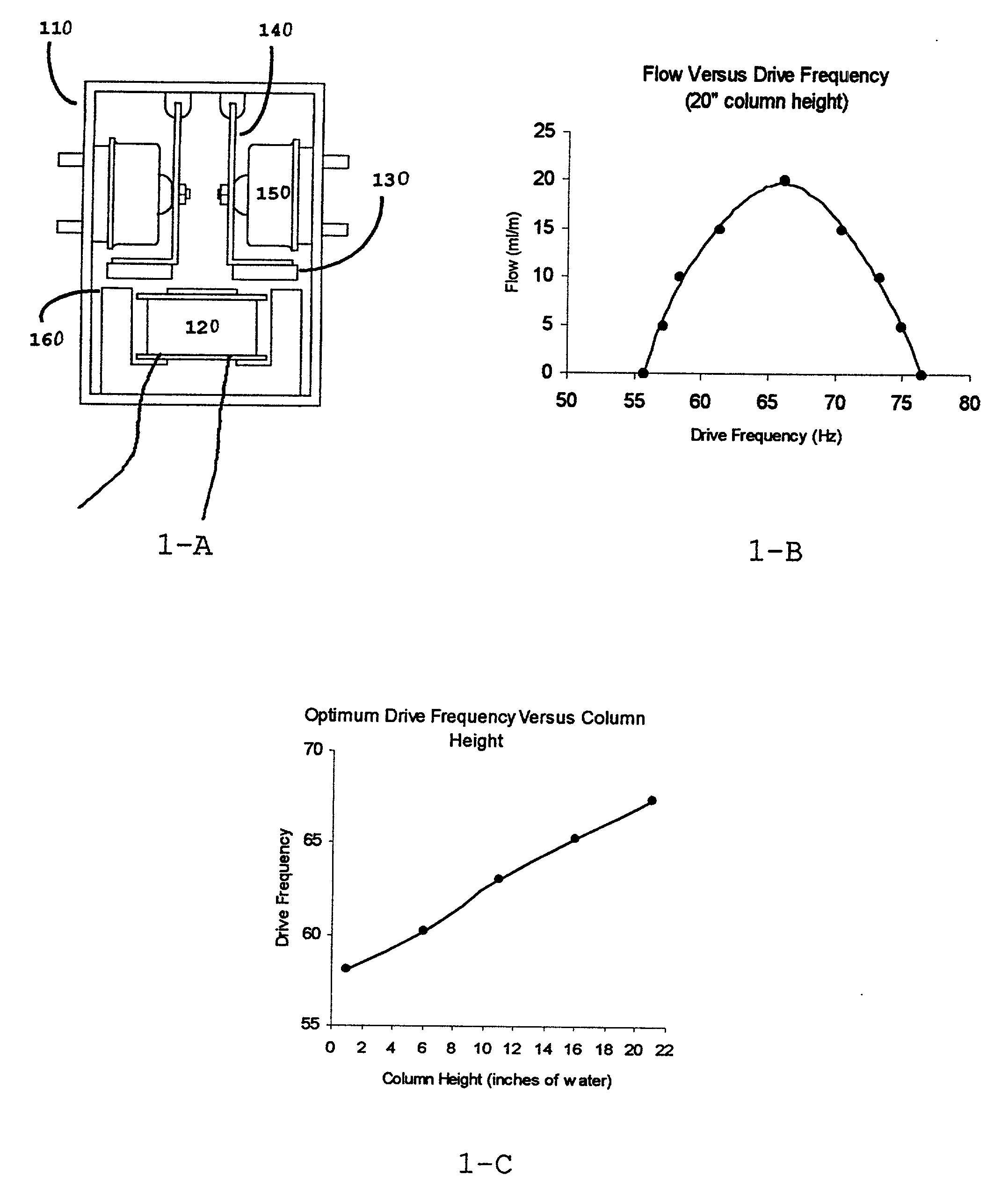

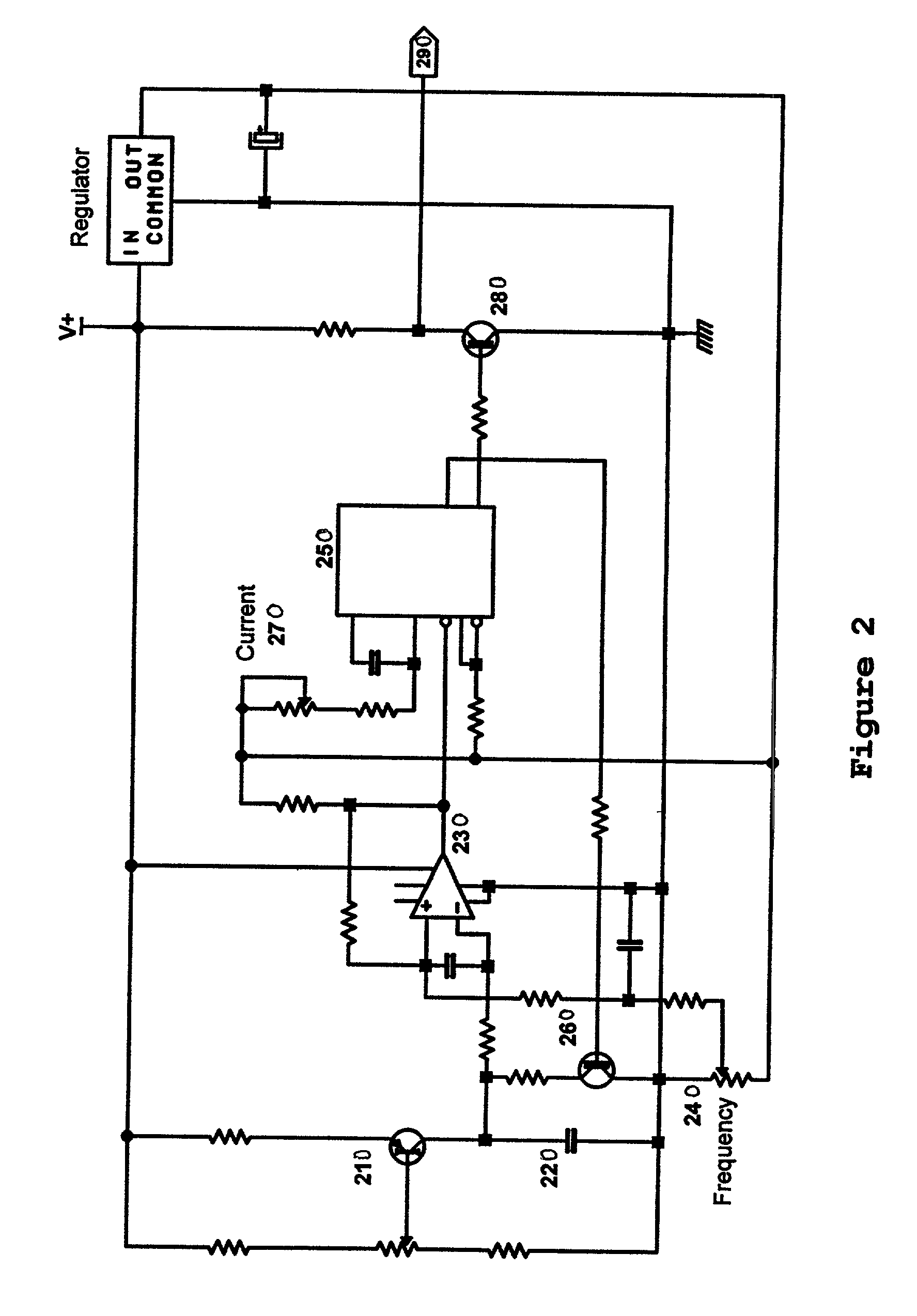

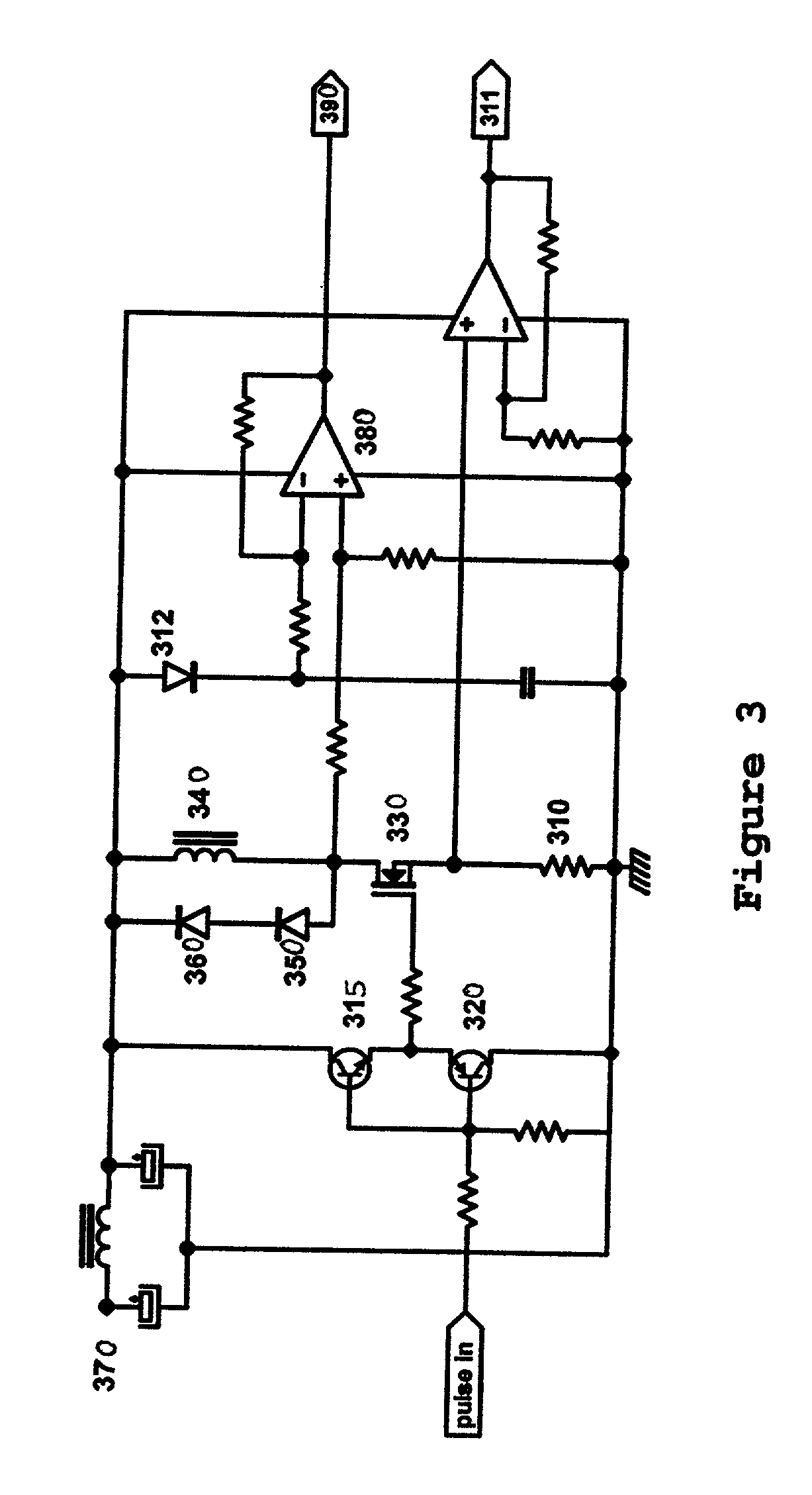

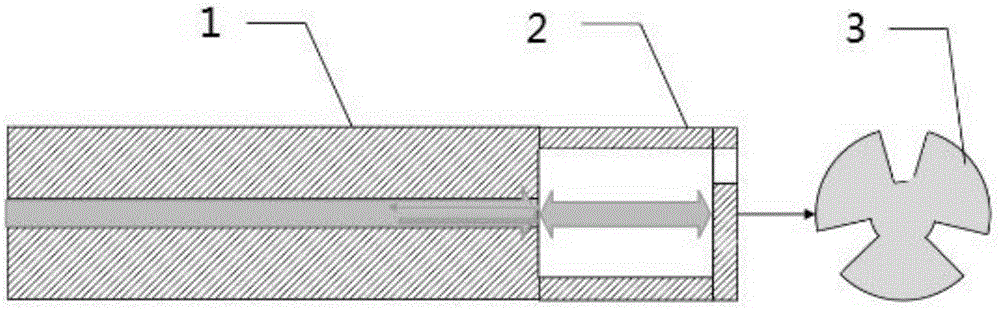

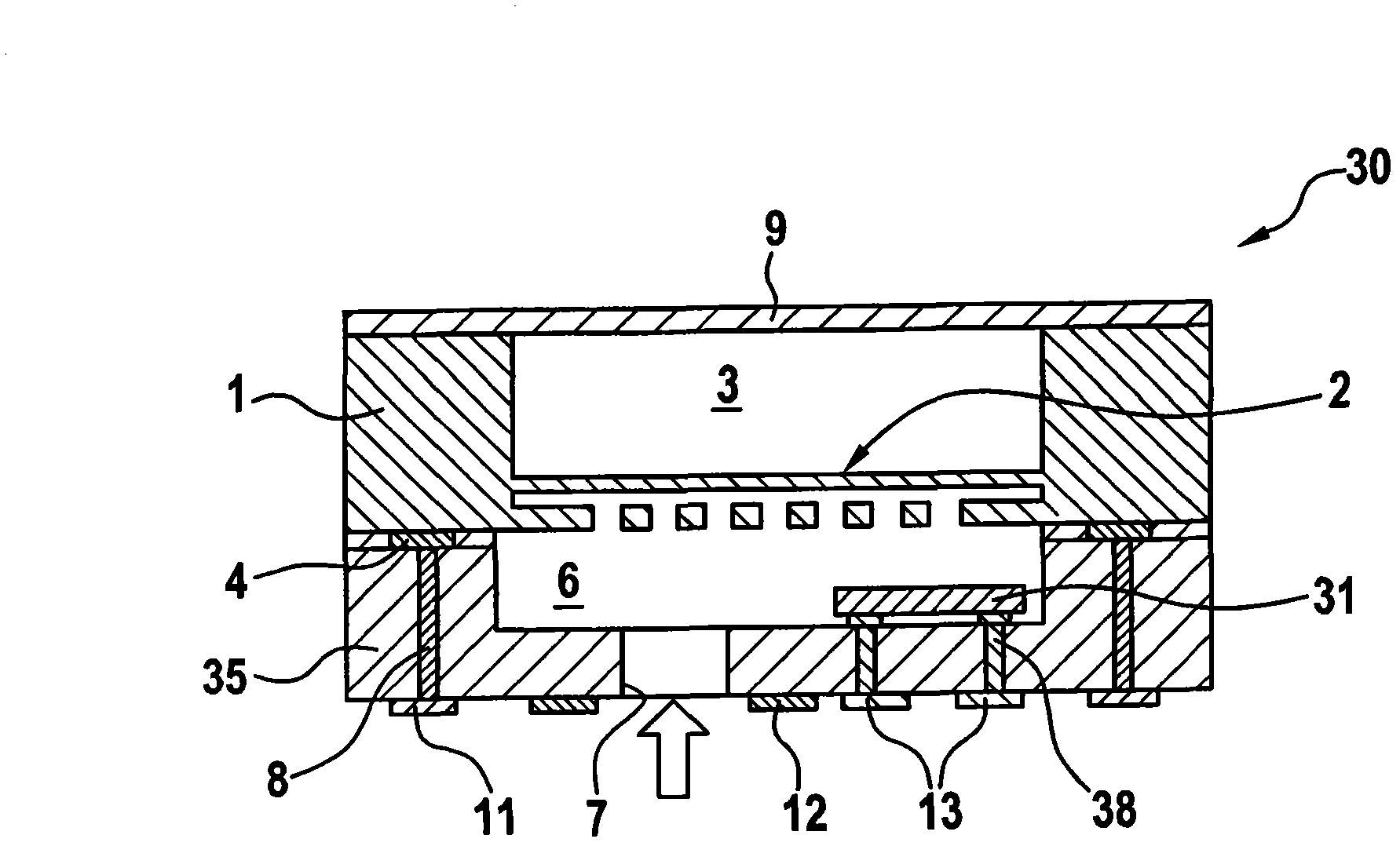

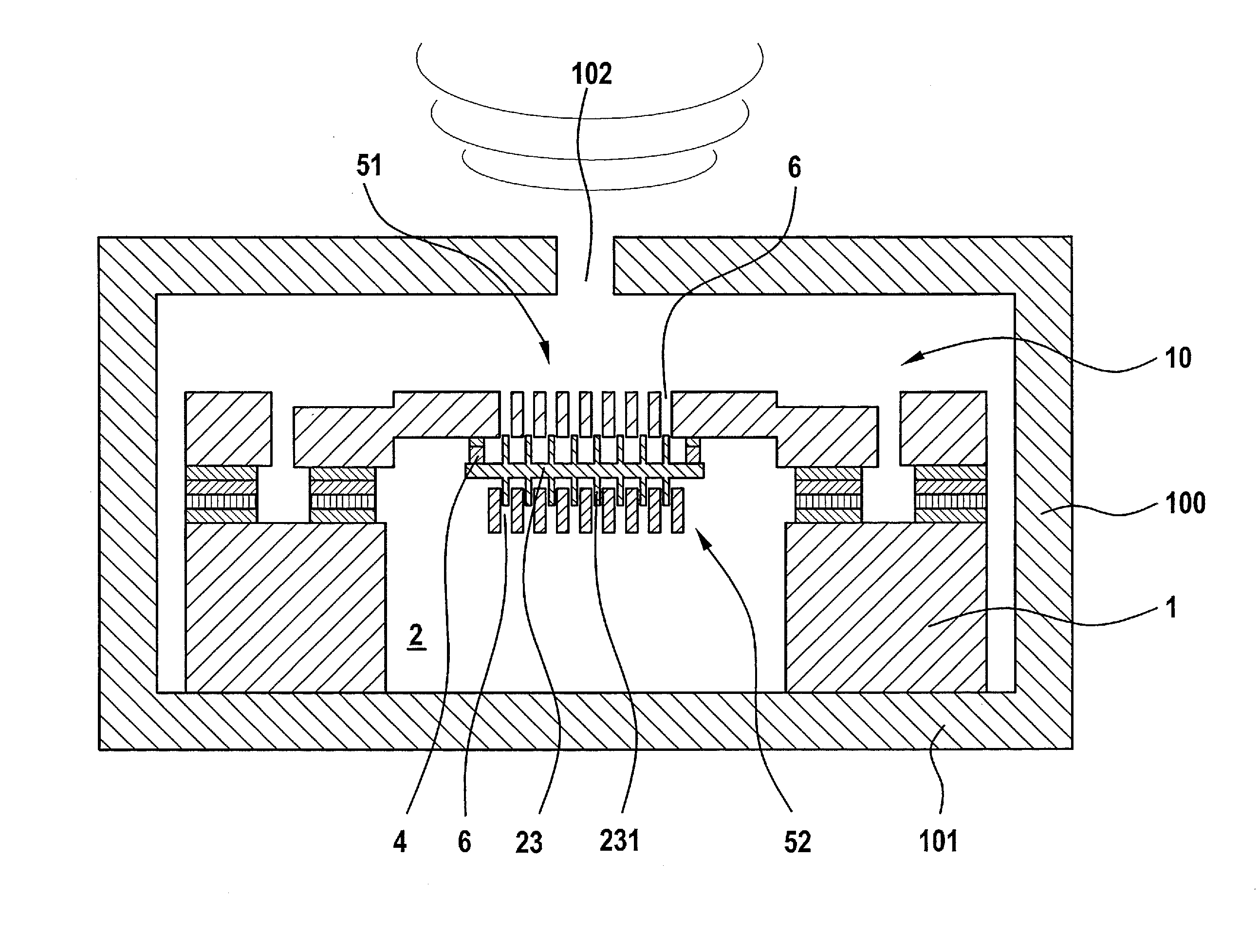

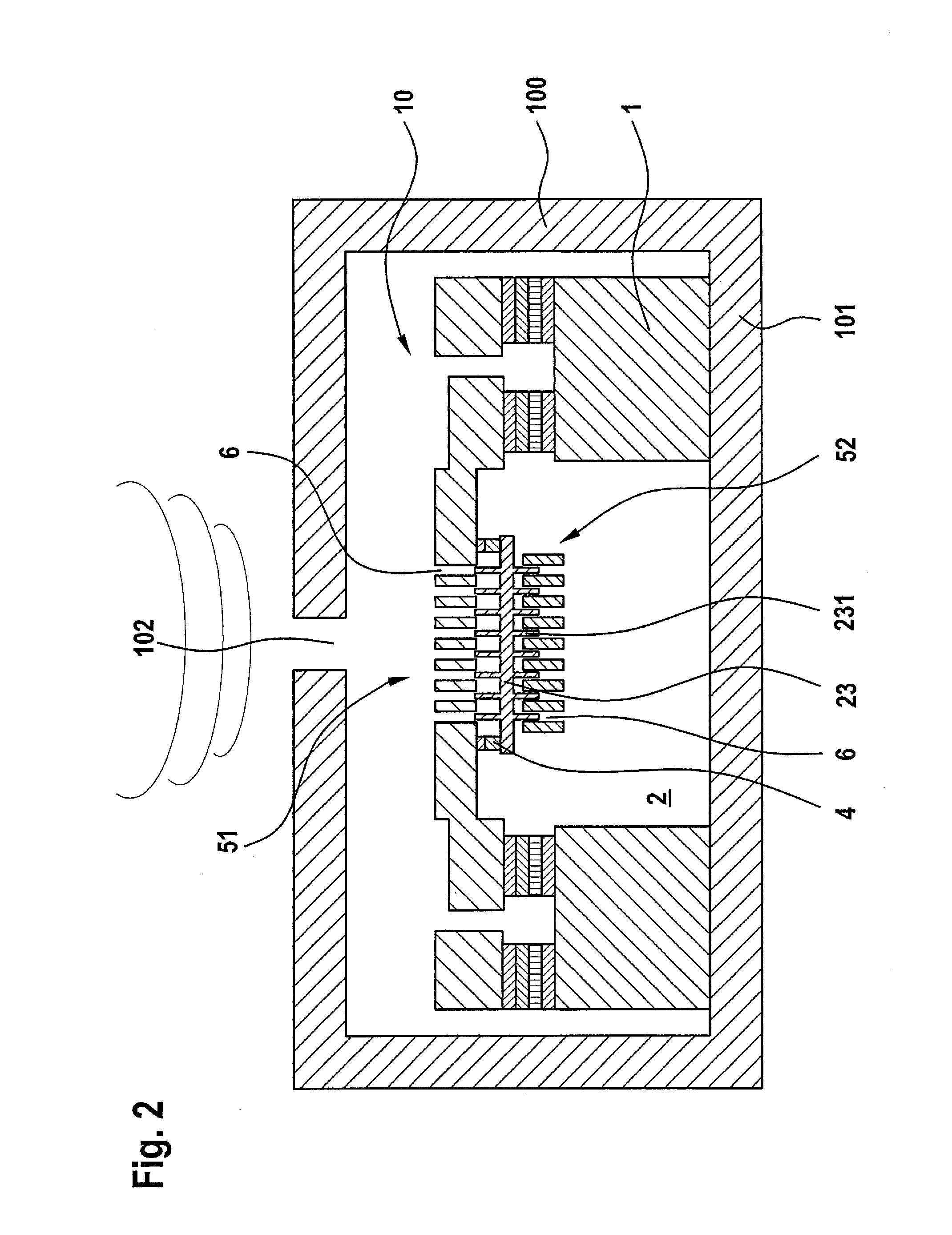

Automatic optimizing pump and sensor system

InactiveUS20010033795A1Easy to de-installEasy to transportFlexible member pumpsPump controlDiaphragm structureEngineering

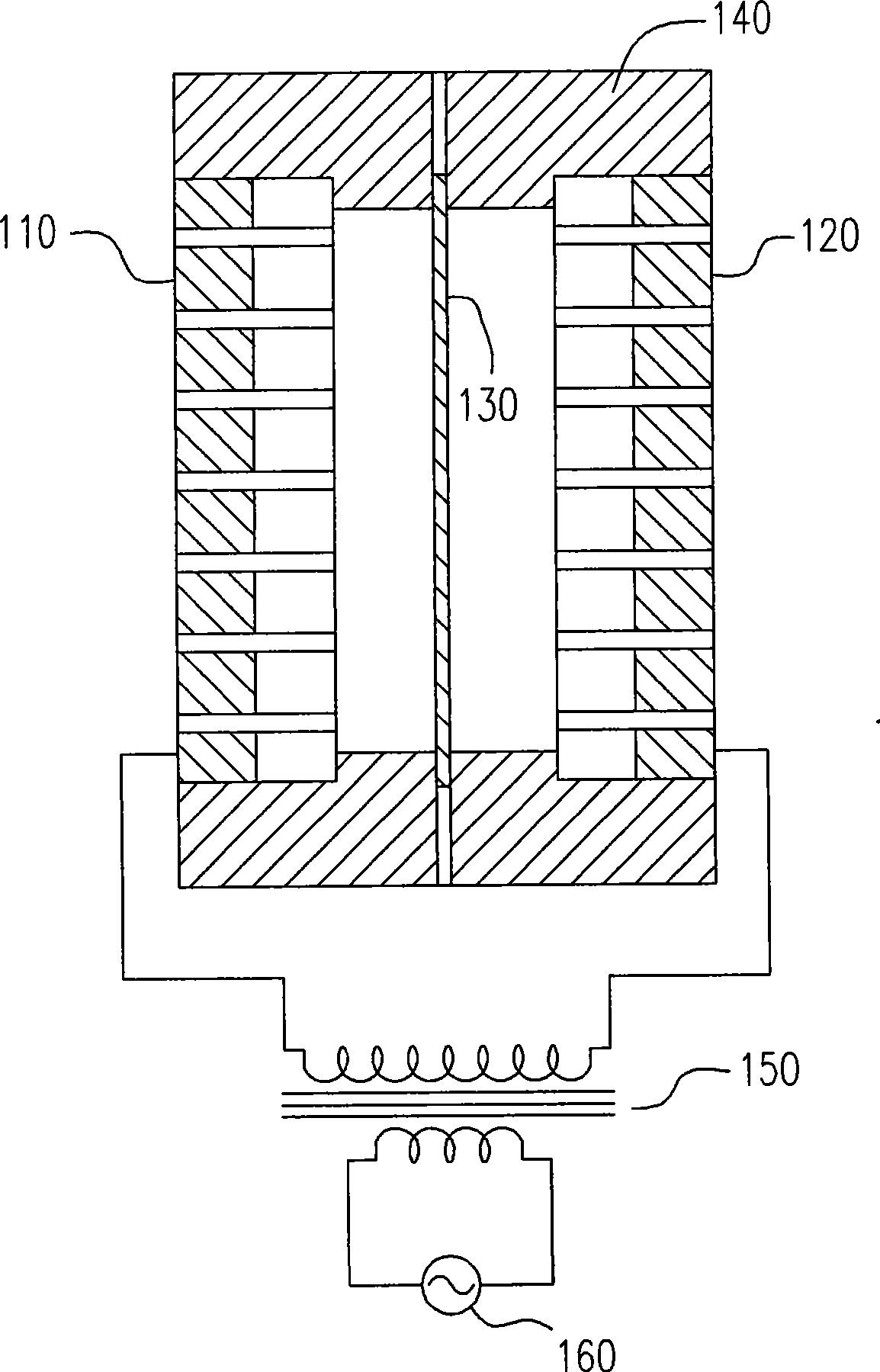

A reciprocating electromagnetic pump comprising a coil wound about a bipolar or tripolar core, a diaphragm structure mechanically coupled to at least one arm with a magnet attached to one end of the arm and a controller electronically connected to the coil. The arm is vibrated under the influence of a periodic electromagnetic field to produce flow. The flow of current through the electromagnet is interrupted so that the magnets are impelled during either a vacuum or a pressure stroke, but are not impelled during the reciprocal stroke. A microprocessor houses the controller which analyzes amplitude and frequency components of a signal produced in the electromagnet coil during the reciprocal stroke to provide a pump flow rate, a pumping efficiency, a pumping load and a height of the fluid column into which the pump mechanism is operating. The controller employs automatic feedback such that an operating frequency is controlled to match a self-resonant frequency of the pump and a coil current is controlled to a minimum value required to provide the desired flow. The microprocessor further comprises a pulse generator and a solid state switch that interrupts current flow through a pump electromagnet.

Owner:HUMPHERIES JAMES C

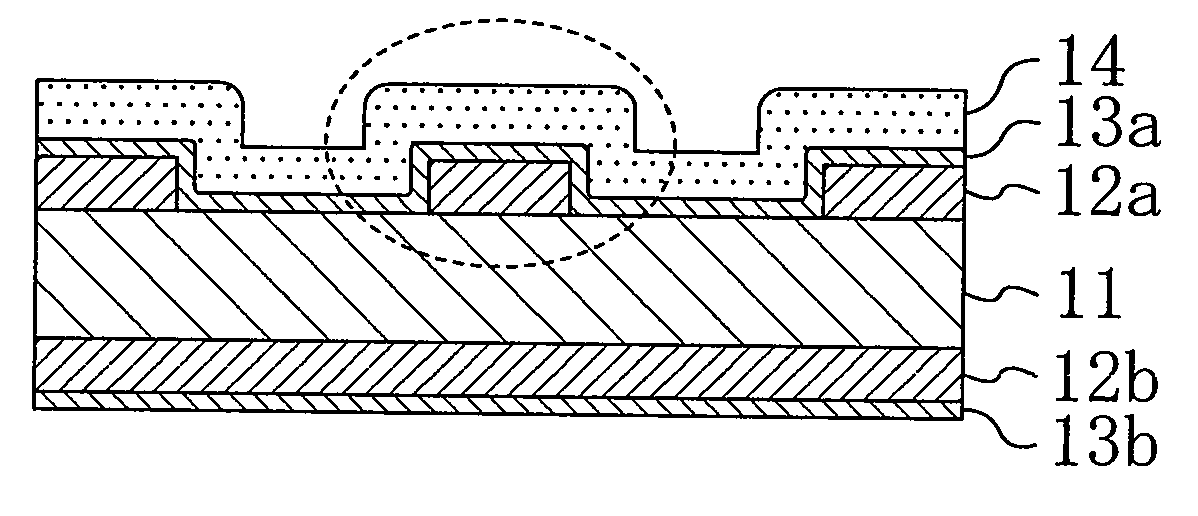

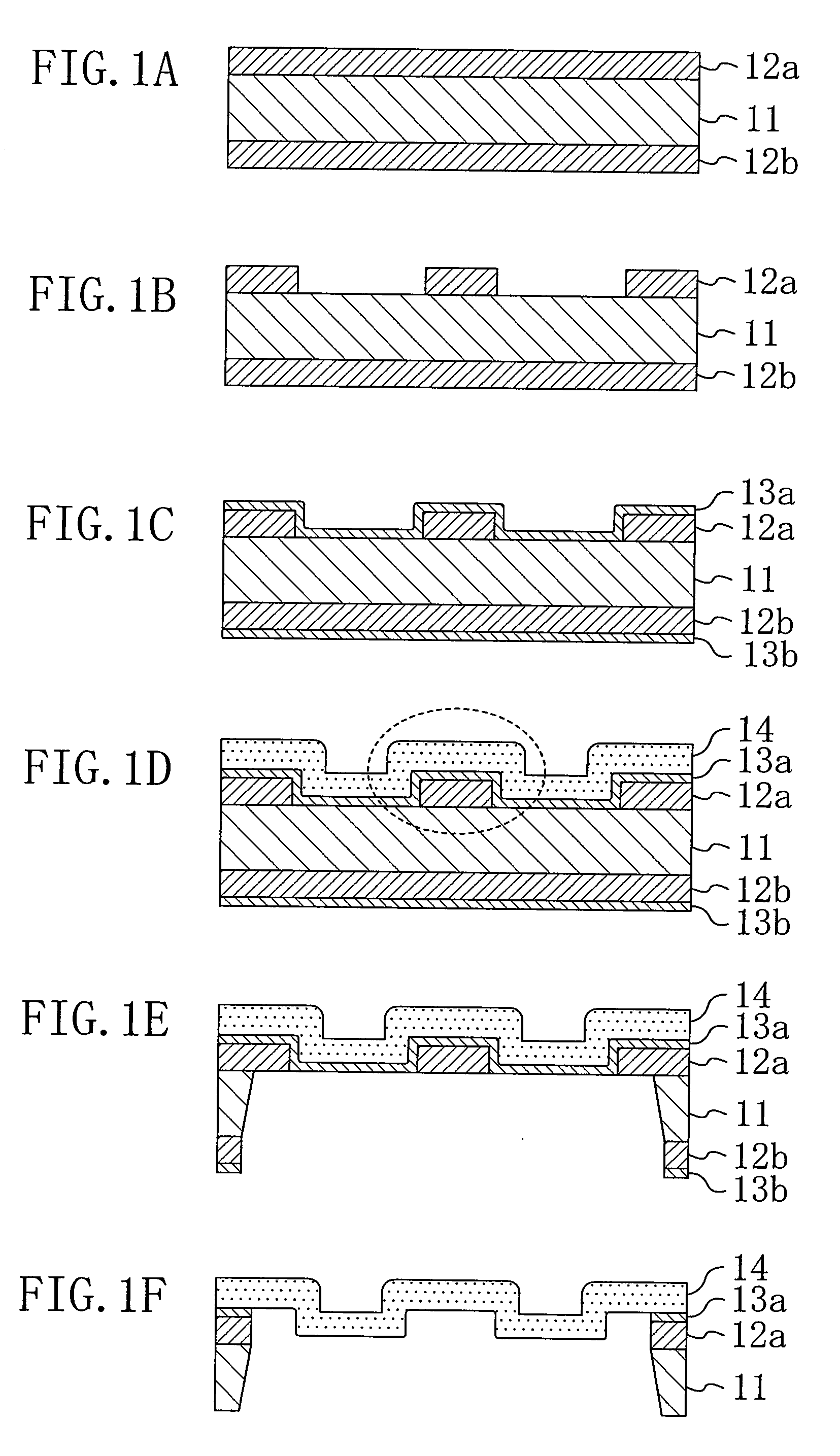

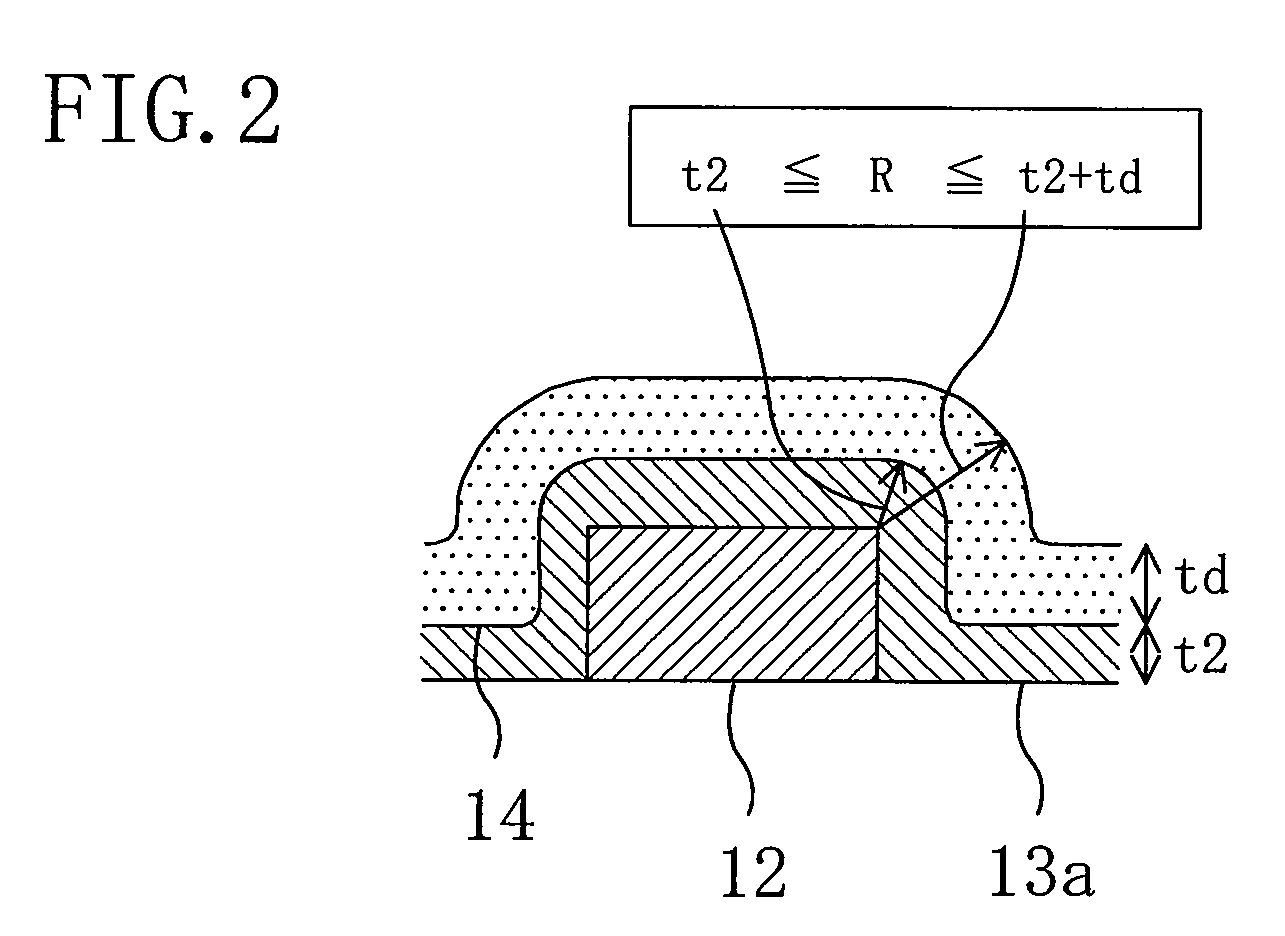

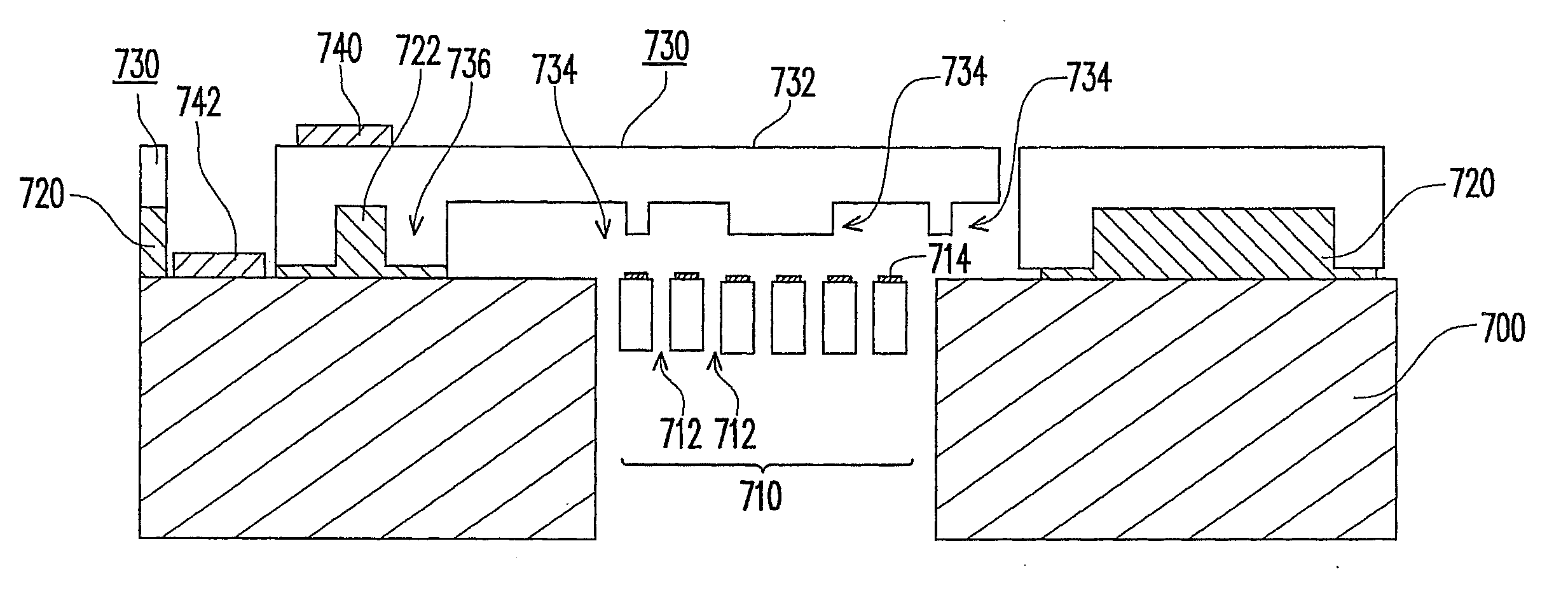

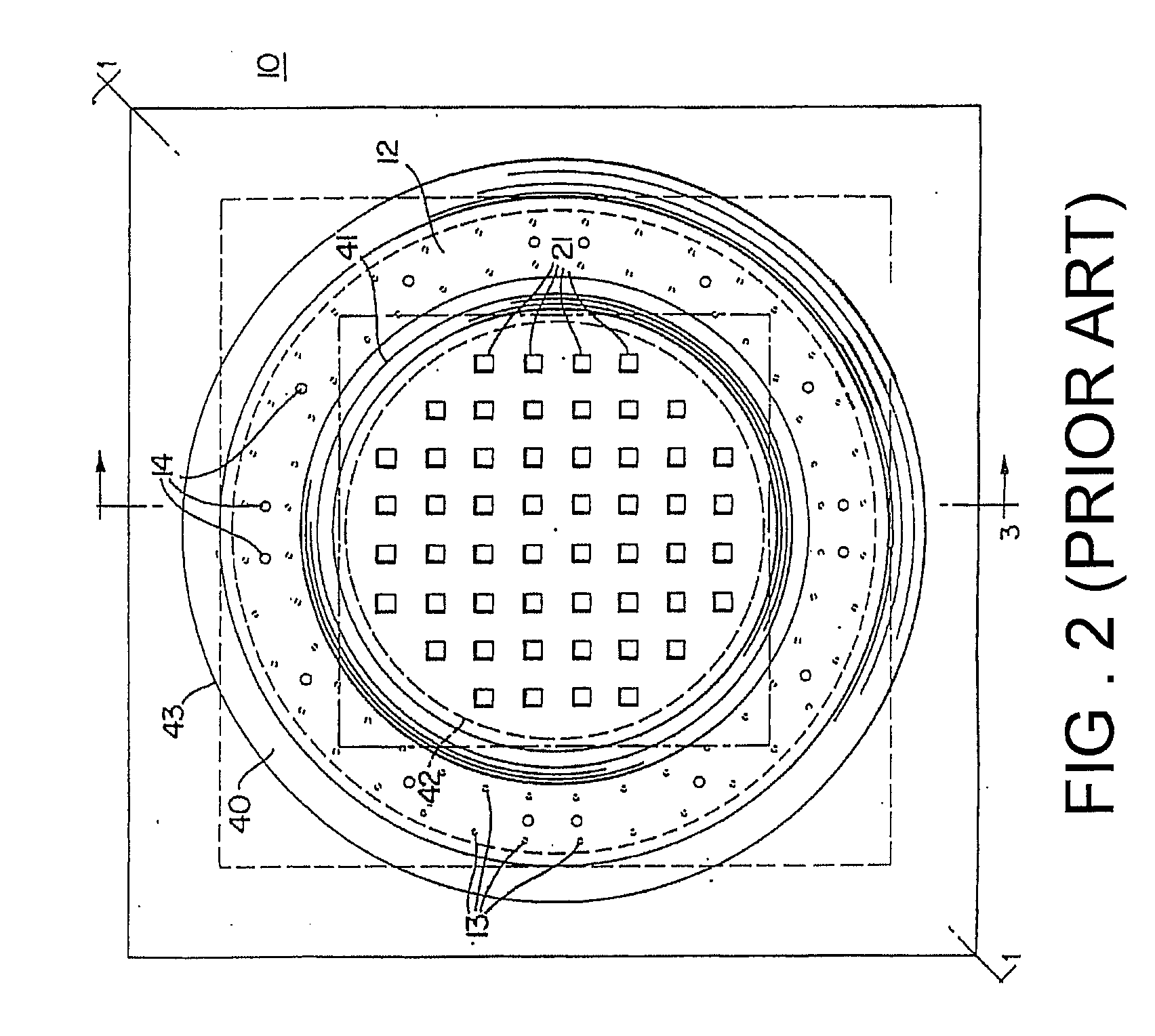

MEMS diaphragm structure and method for forming the same

InactiveUS20090116675A1Well formedEasily roundedPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersDiaphragm structureEngineering

Owner:PANASONIC CORP

Optical fiber F-P multifunctional sensor based on microporous optical reflection diaphragm

ActiveCN104596559AAvoid tearingAvoid damageSubsonic/sonic/ultrasonic wave measurementPhase-affecting property measurementsOptical reflectionDiaphragm structure

The invention provides an optical fiber F-P multifunctional sensor based on a microporous optical reflection diaphragm. The optical fiber F-P multifunctional sensor based on the microporous optical reflection diaphragm is characterized in that the design of an F-P cavity structure formed by sequentially connecting a single-die optical fiber, an optical capillary tube and the microporous optical reflection diaphragm and a special microporous optical reflection diaphragm structure is adopted to develop a built-in optical fiber F-P multifunctional sensor which can highly sensitively detecting liquid refractive index, air humidity and ultrasound under common air pressure and external high pressure conditions. The sensor has a micro size, is simple in structure, integrated, high in sensitivity, fast to respond, high in resistance to electromagnetic interference, applicable to the fields of environmental monitoring, and biochemical detection and ultrasonic detection, has a good market prospect, and is high in market value.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

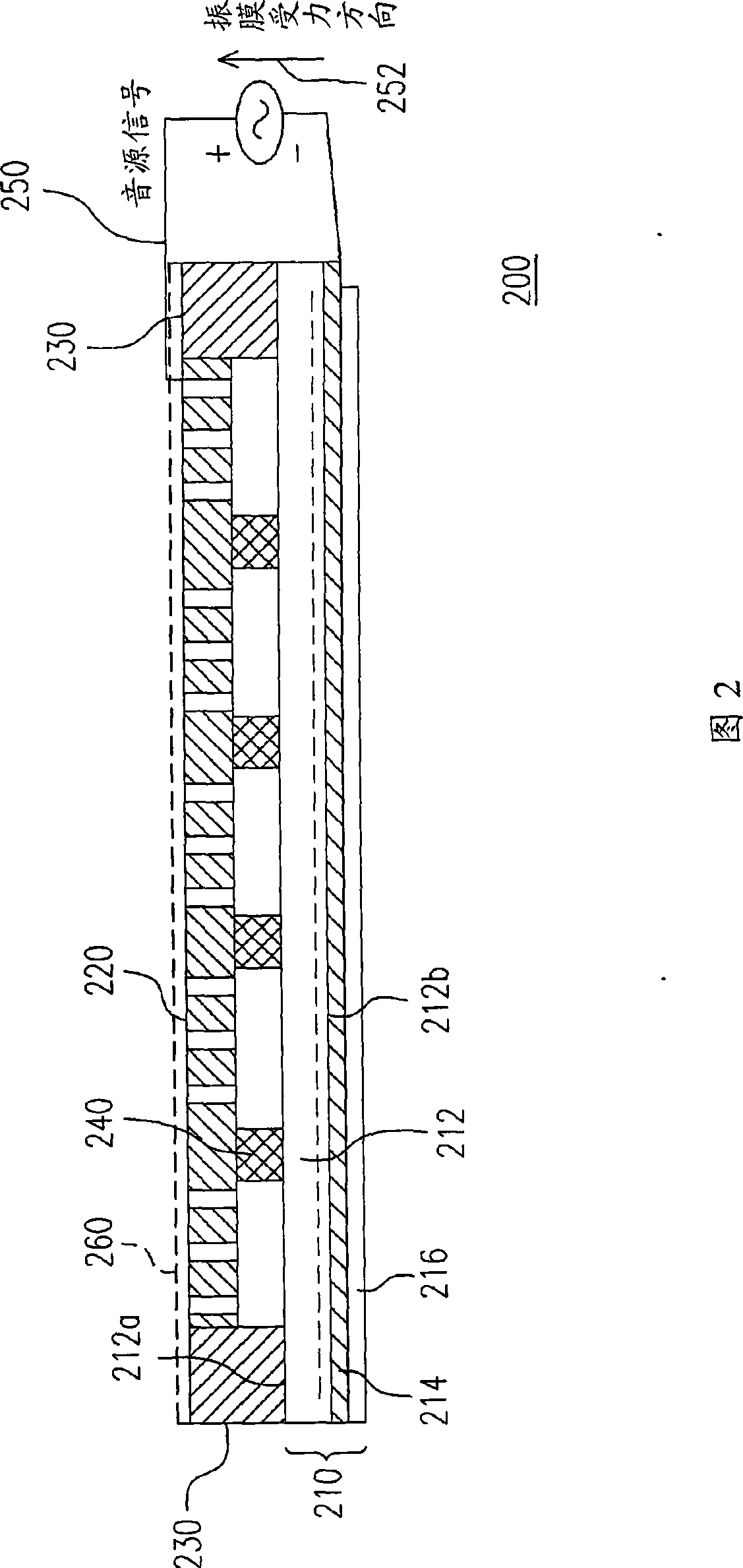

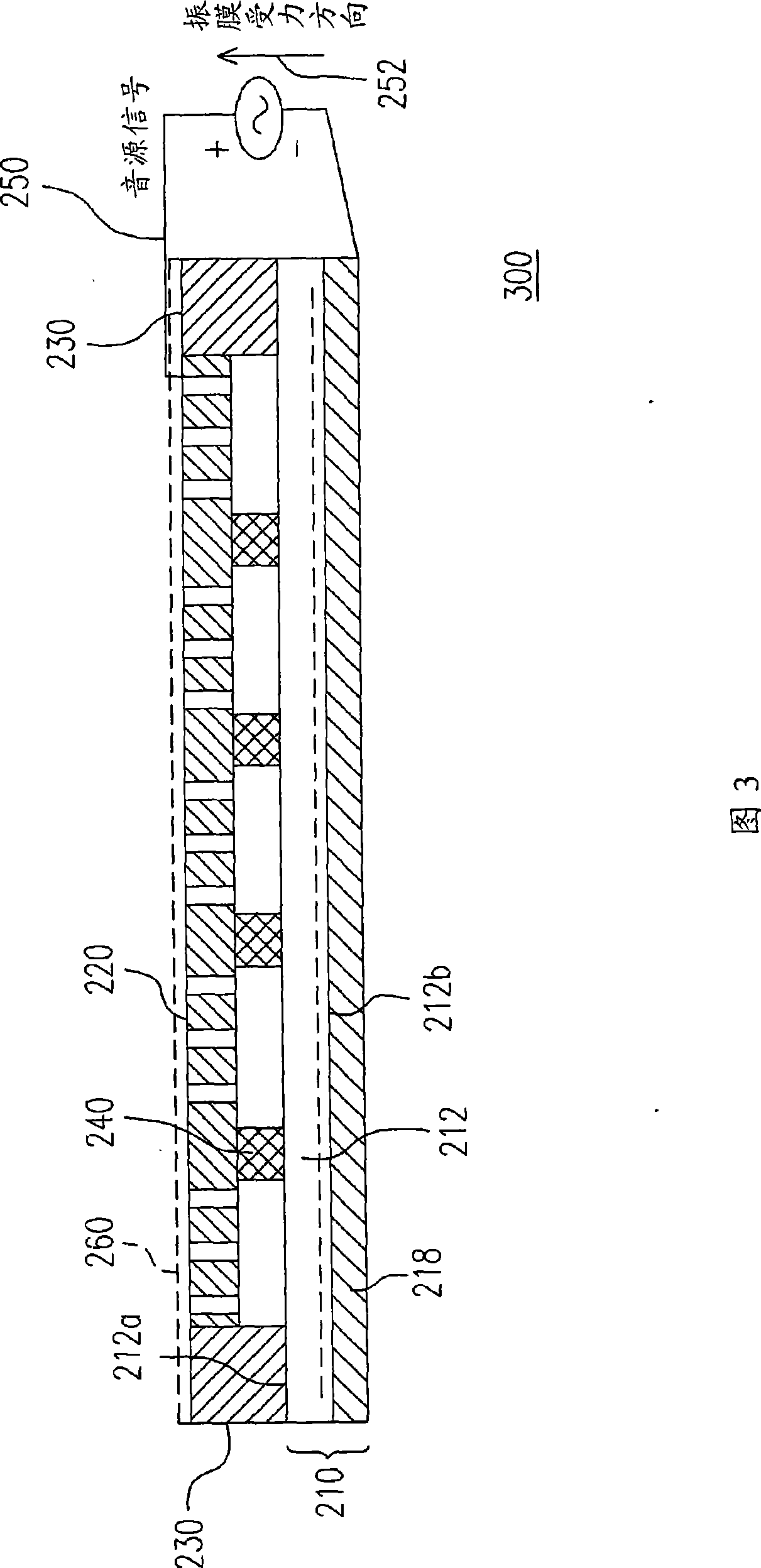

Miniature acoustic transducer

ActiveUS20070291964A1High complianceHigh deformationElectrostatic transducer microphonesDeaf-aid setsMicro structureParallel plate

A technique using a new diaphragm structure and support design is provided herein for microphones or structure designs for pressure sensing. The structure includes a set of capacitive structures. The capacitive structure has a combination of a diaphragm structure, a back plate structure and a surrounding micro-structure for fixing the diaphragm. After the diaphragm structure has deformed due to a pressure load, a gap between the back plate and the diaphragm is changed accordingly, and variation occurs in the capacitance value between the two parallel plates. By using the principle of the effect of capacitance value variation, the capacitive sensor causes the capacitance value to vary with the change in the sound, thus accomplishing the object of measuring.

Owner:IND TECH RES INST

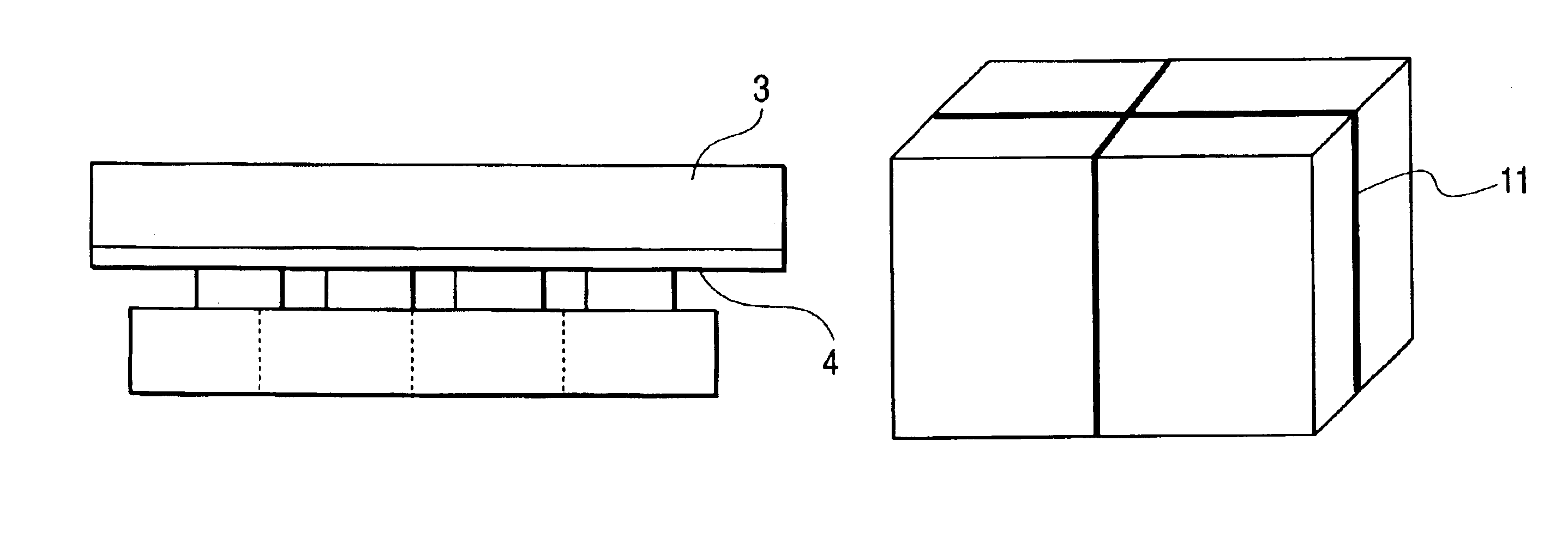

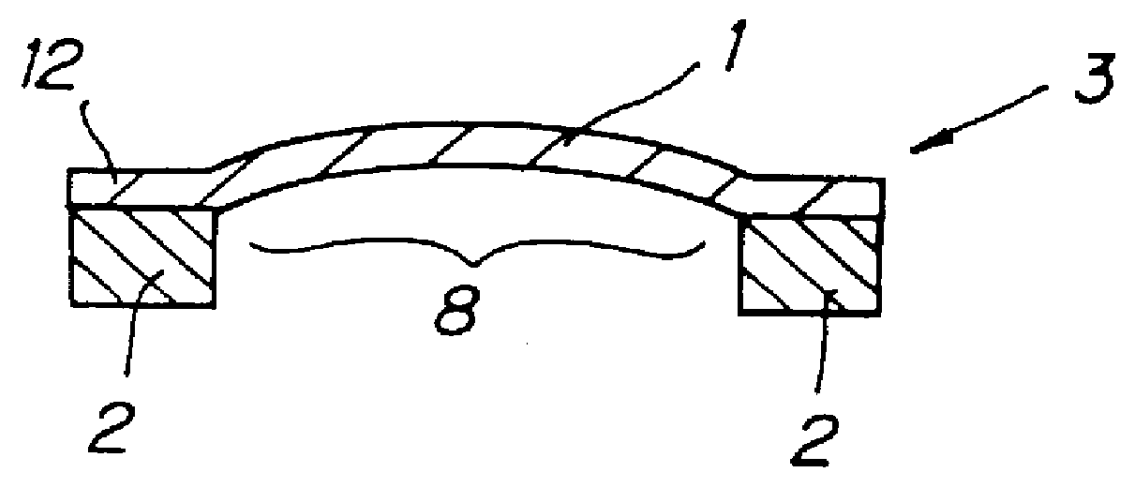

Method of manufacturing actuator and ink jet head

InactiveUS6927084B2Maintain good propertiesExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblySemiconductor/solid-state device manufacturingDiaphragm structureSingle crystal substrate

A method of manufacturing an actuator comprises the steps of bonding a piezoelectric film formed on a single crystal substrate to a diaphragm structure member and removing the single crystal substrate therefrom to manufacture the actuator. The single crystal substrate is a substrate having bonded portions where a plurality of single crystal substrates are bonded together.

Owner:CANON KK

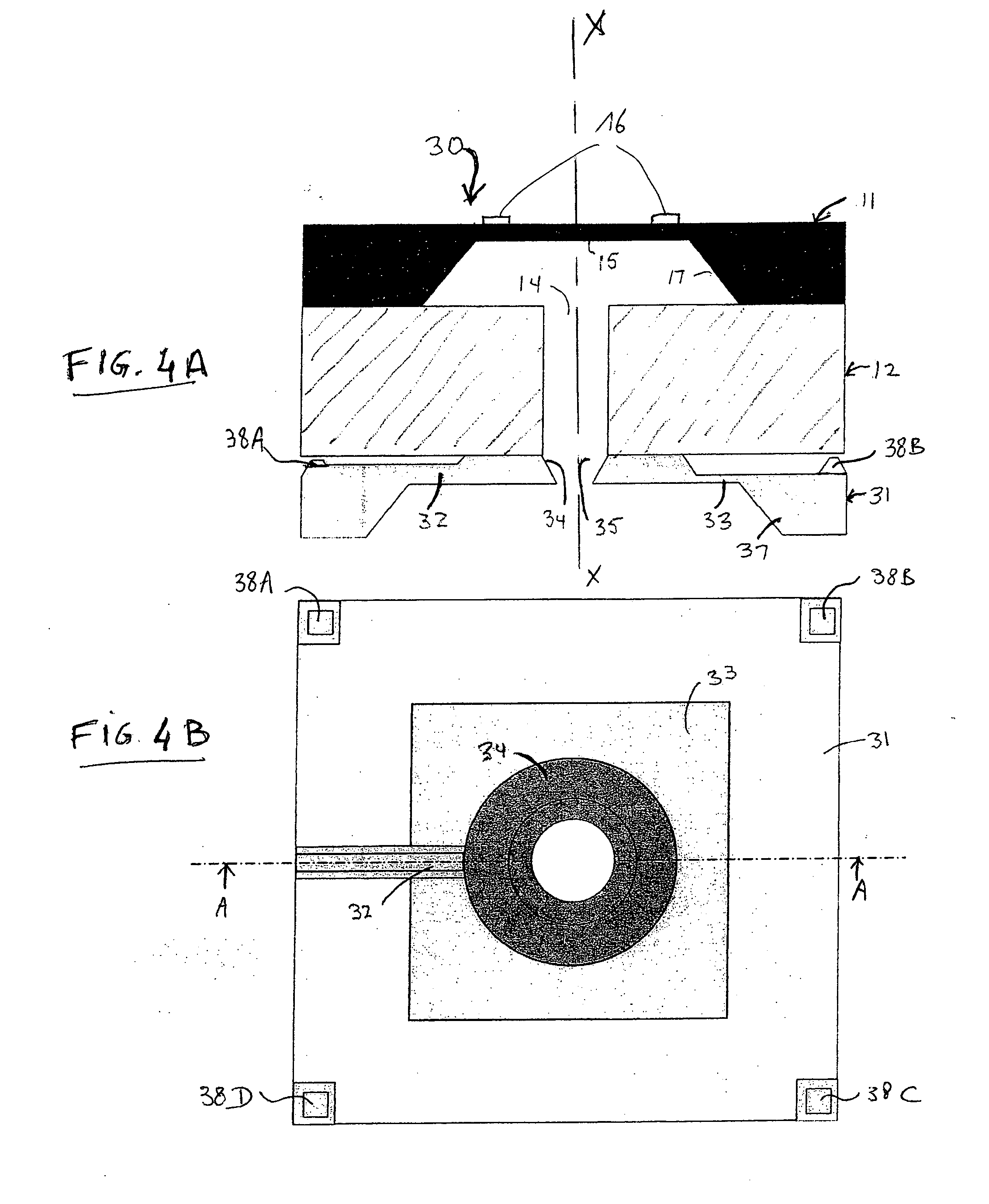

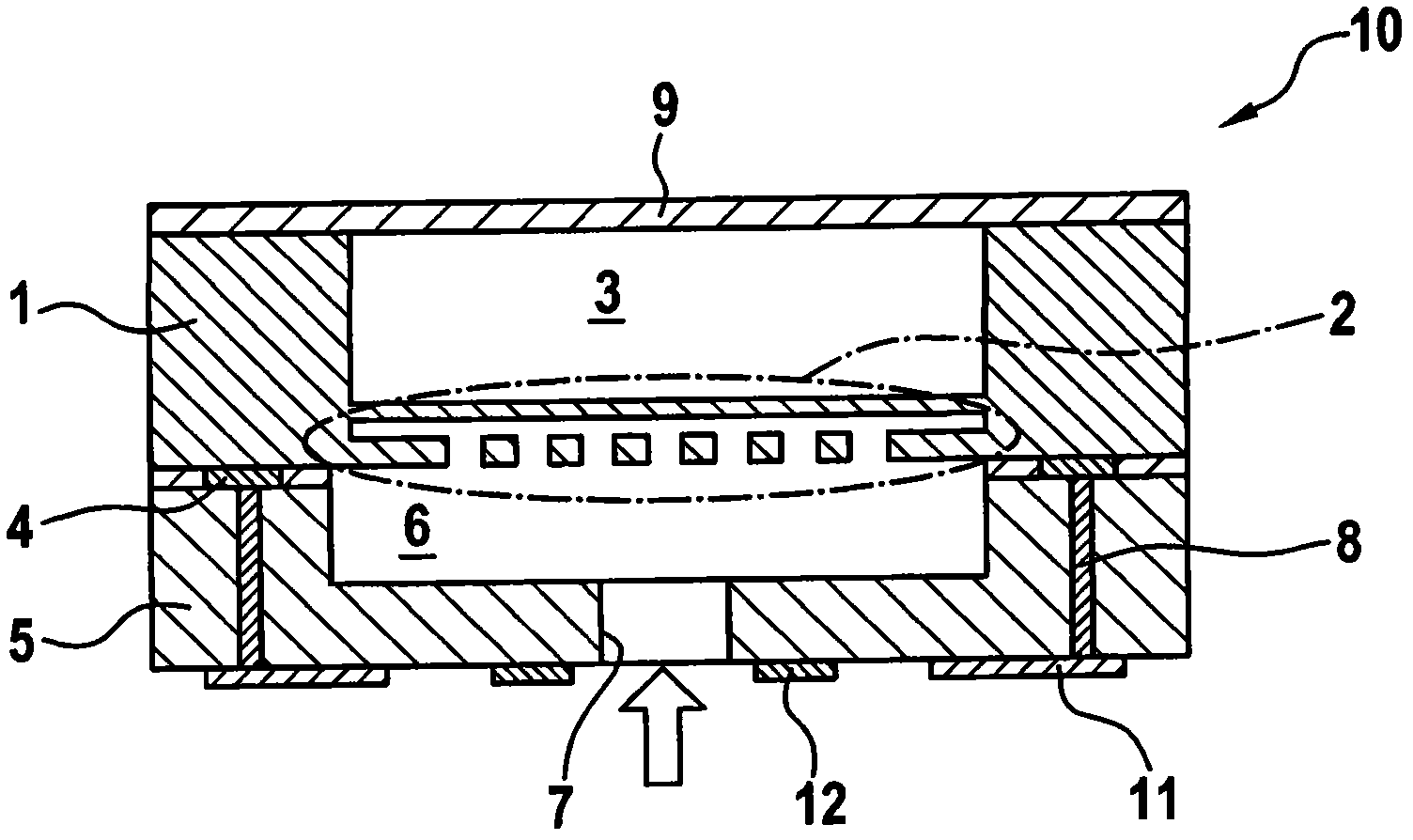

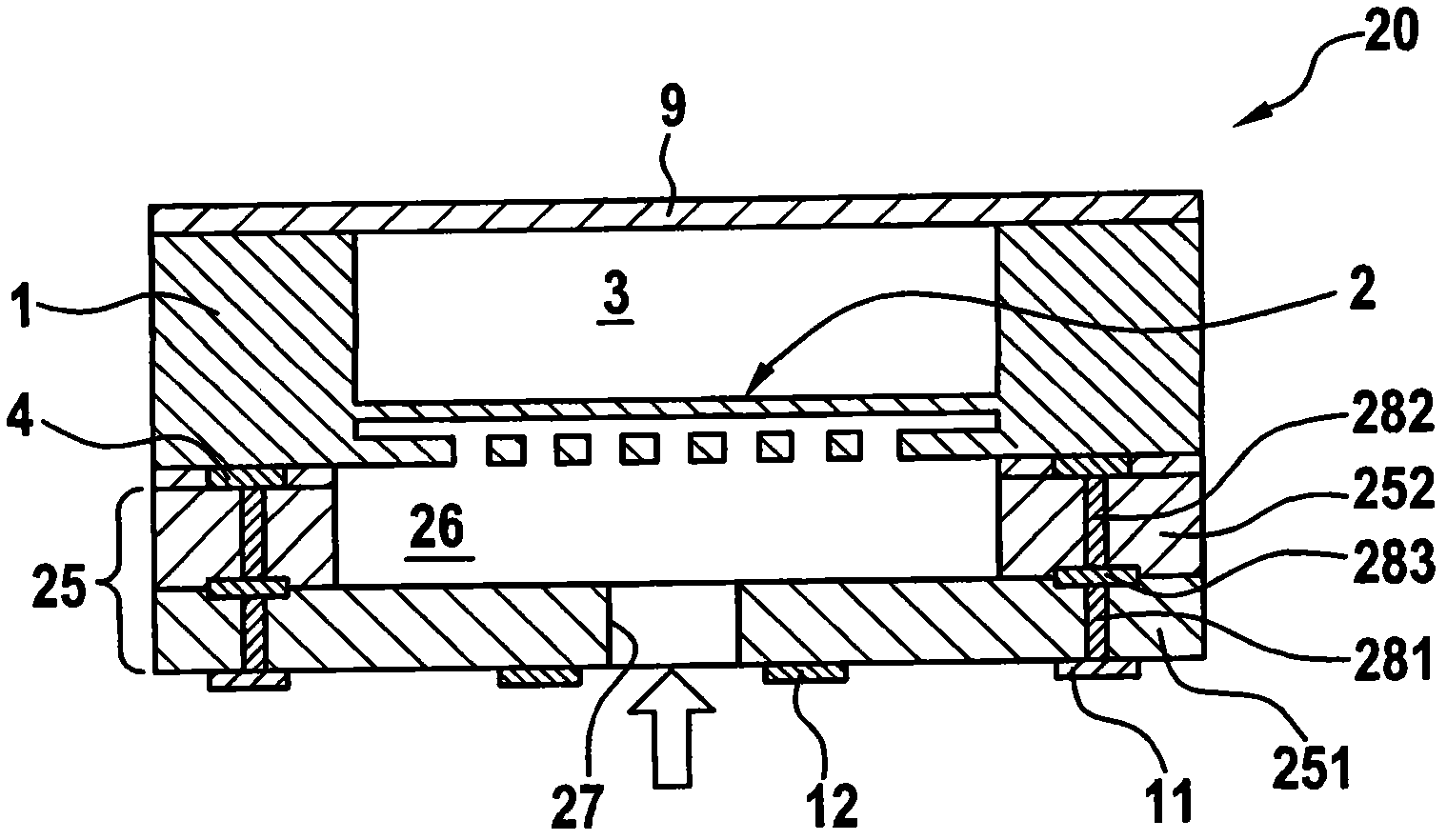

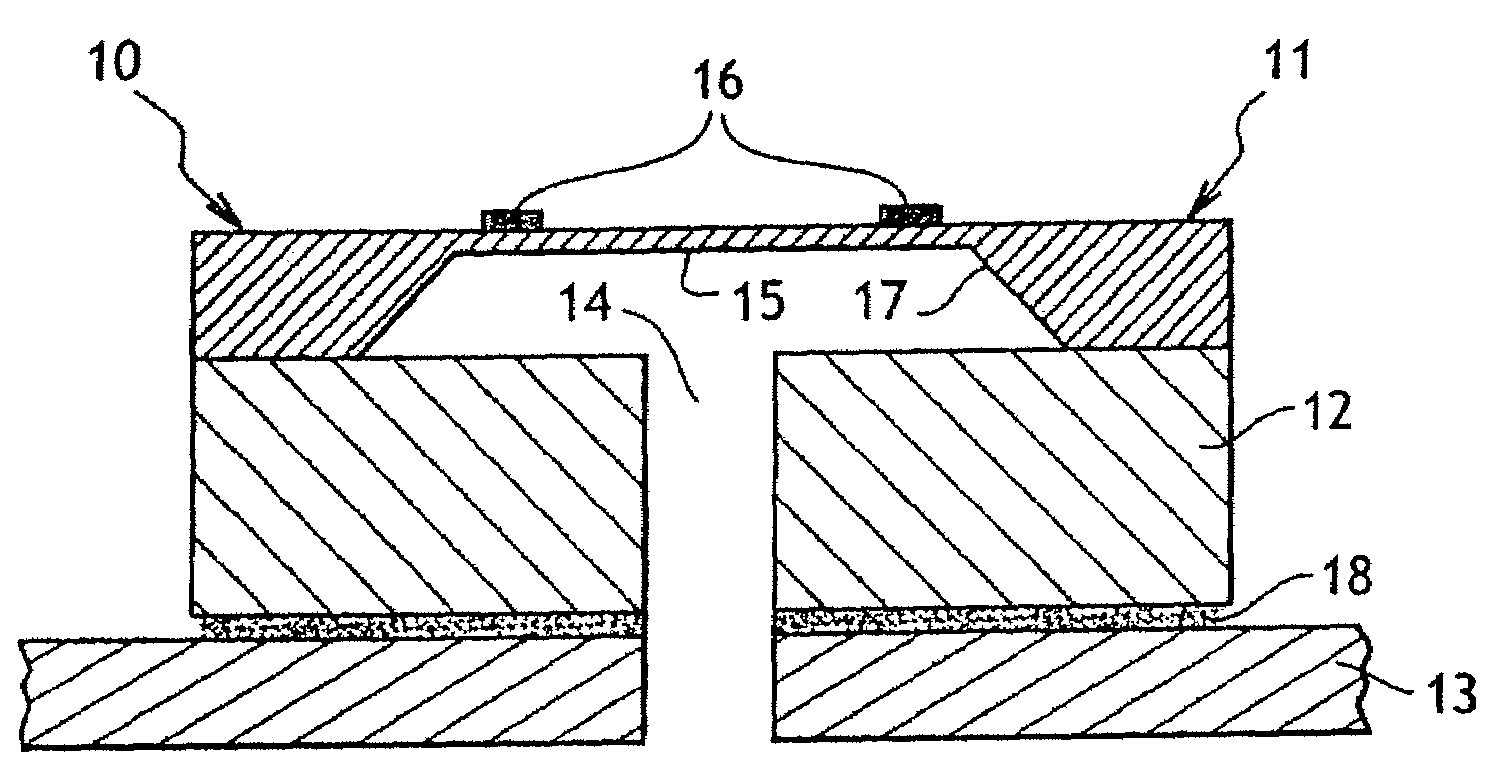

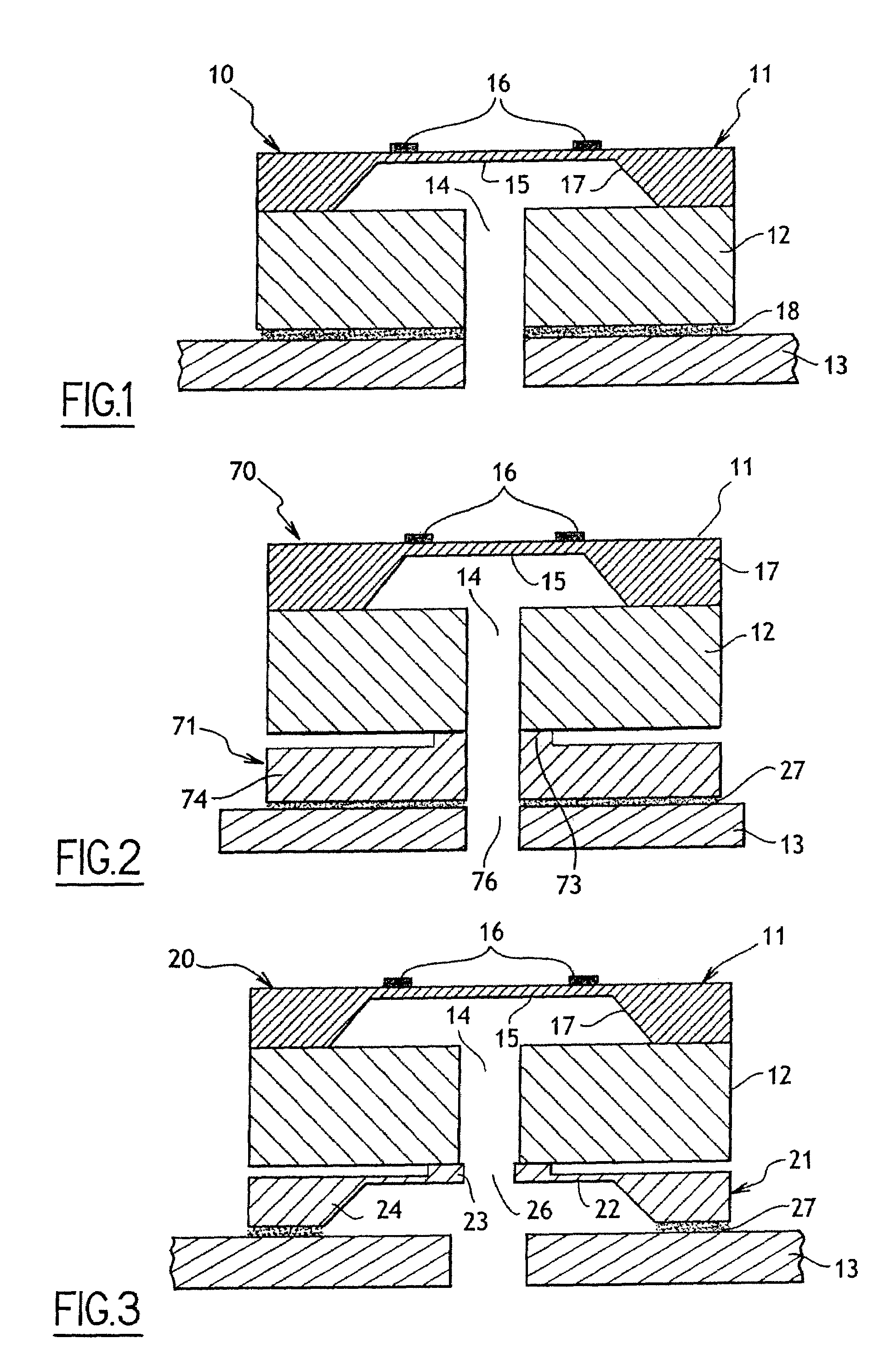

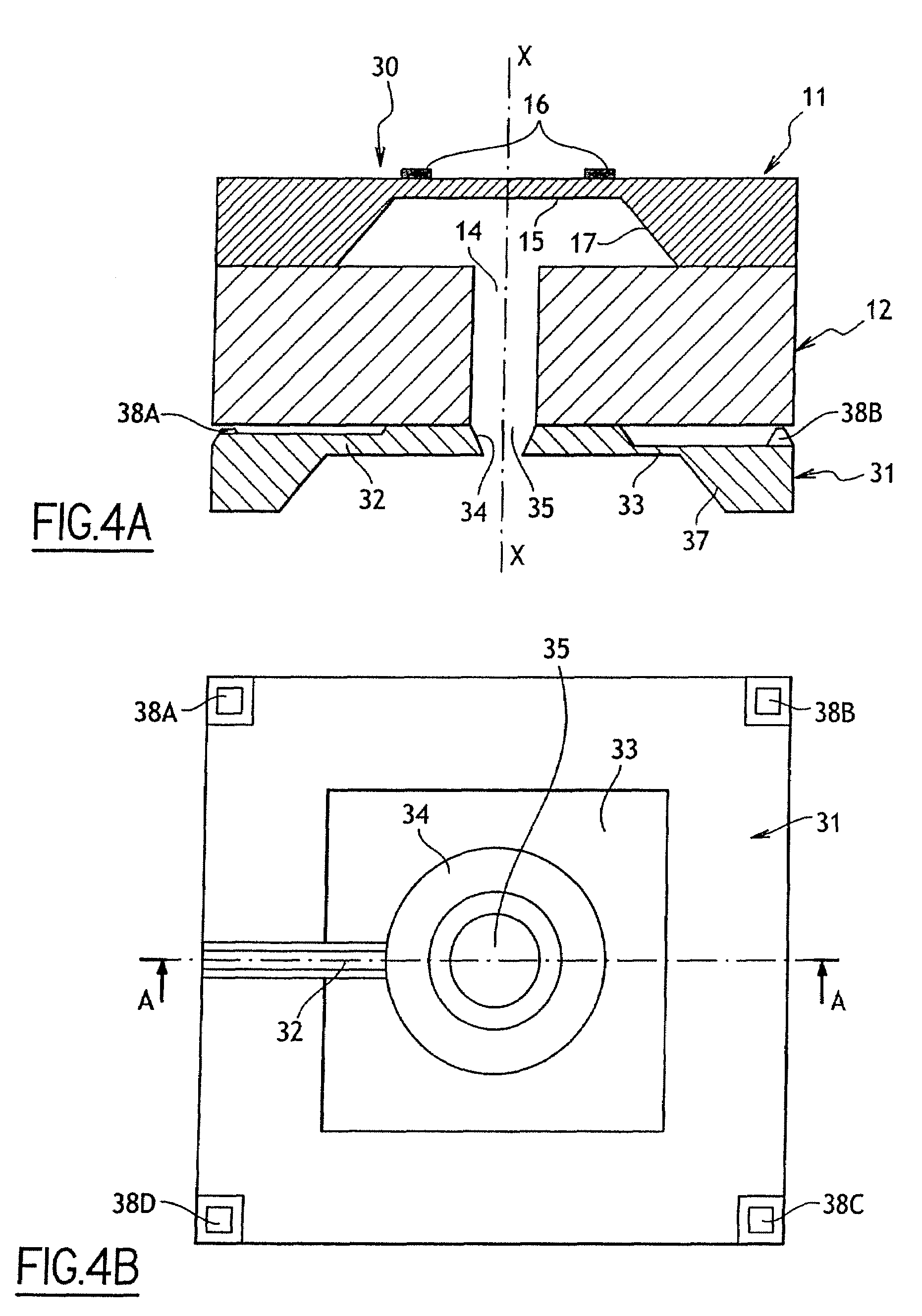

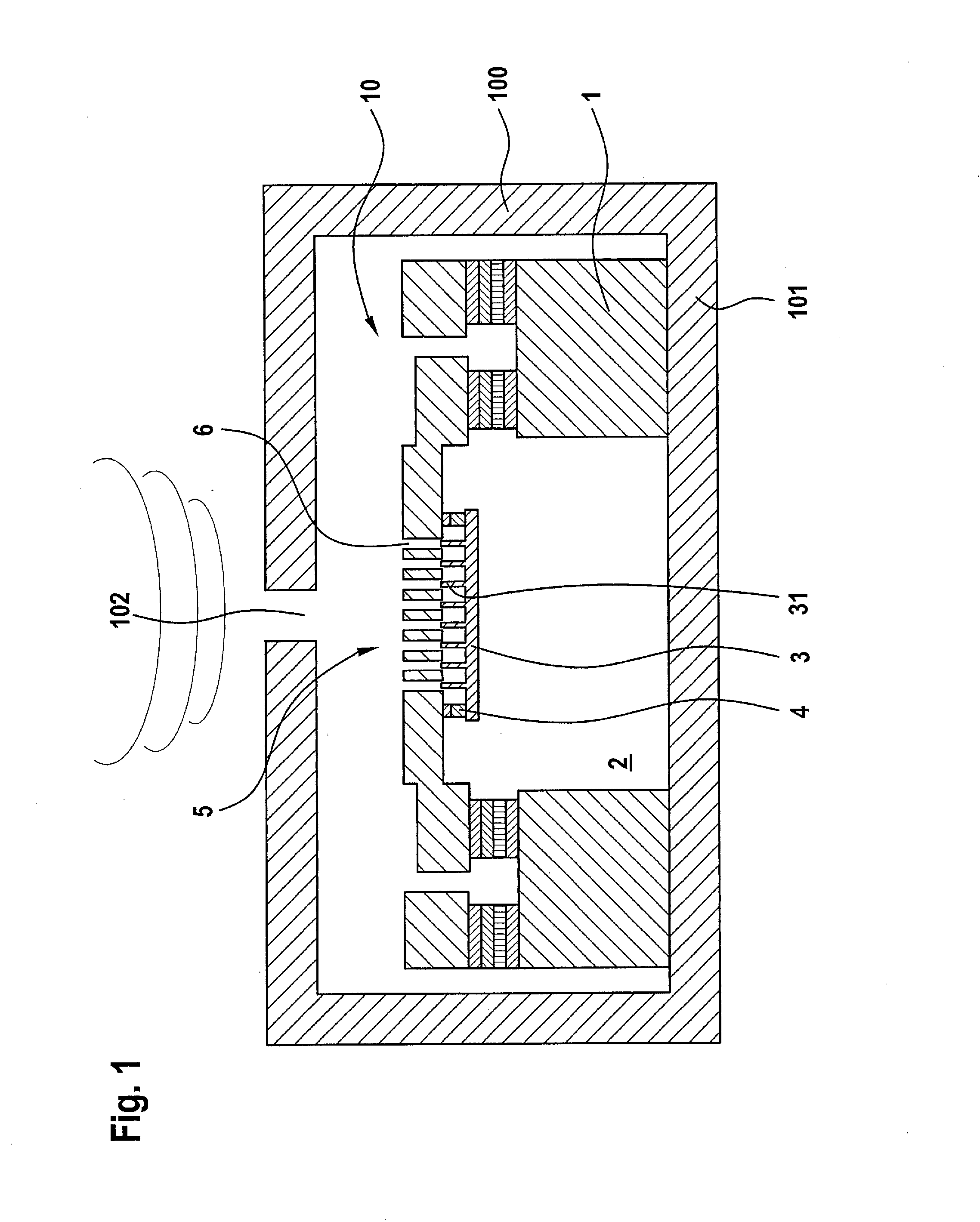

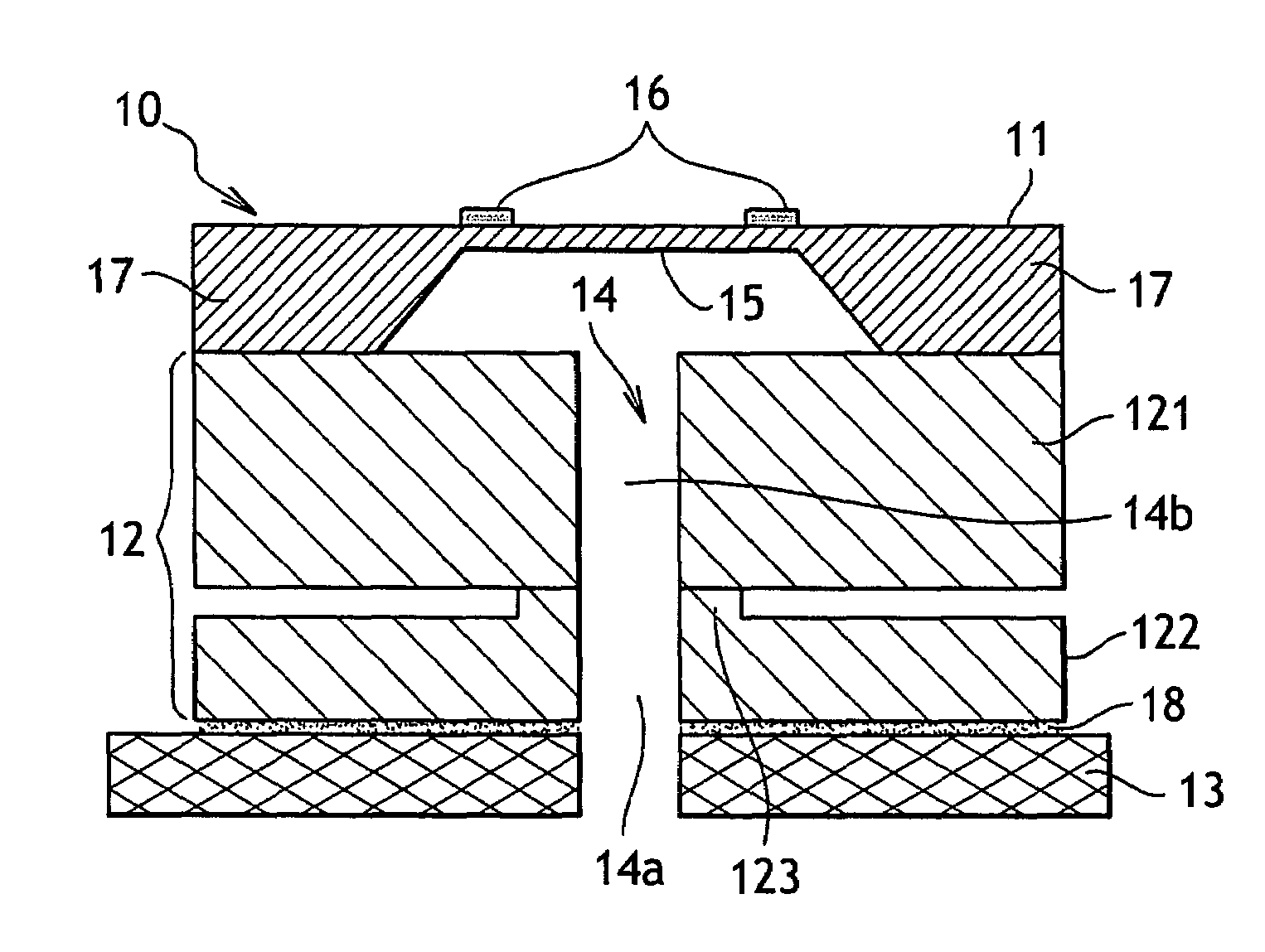

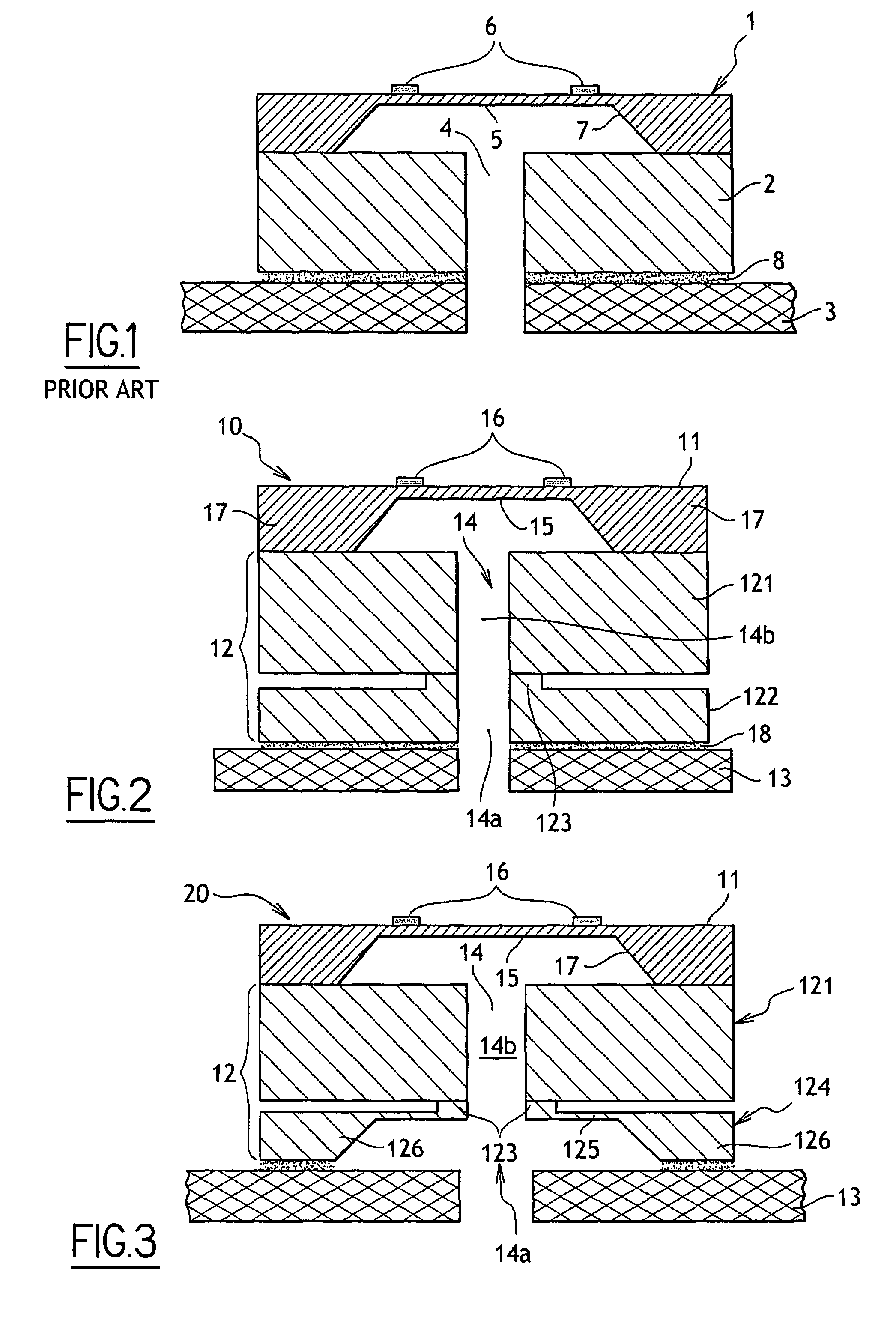

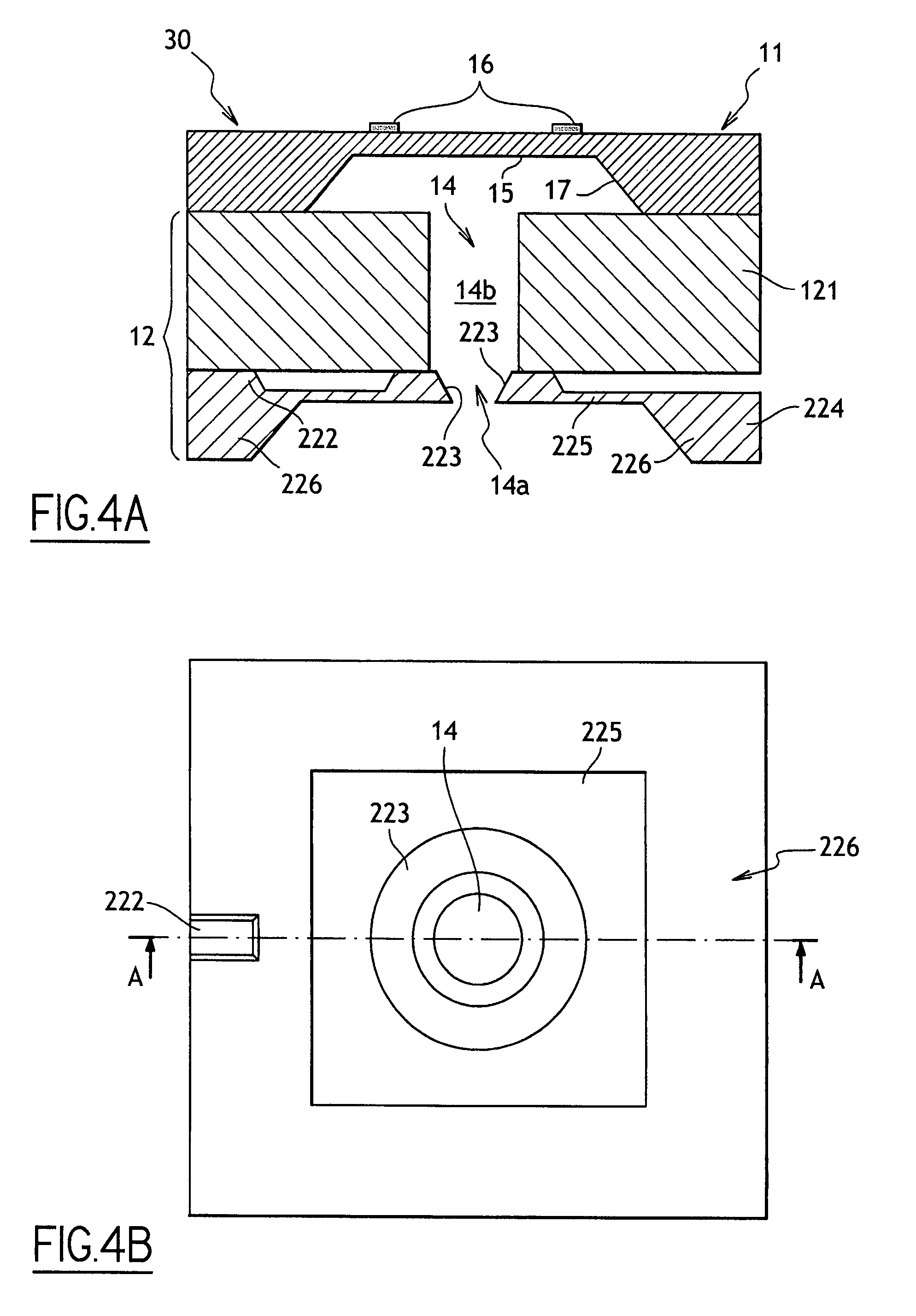

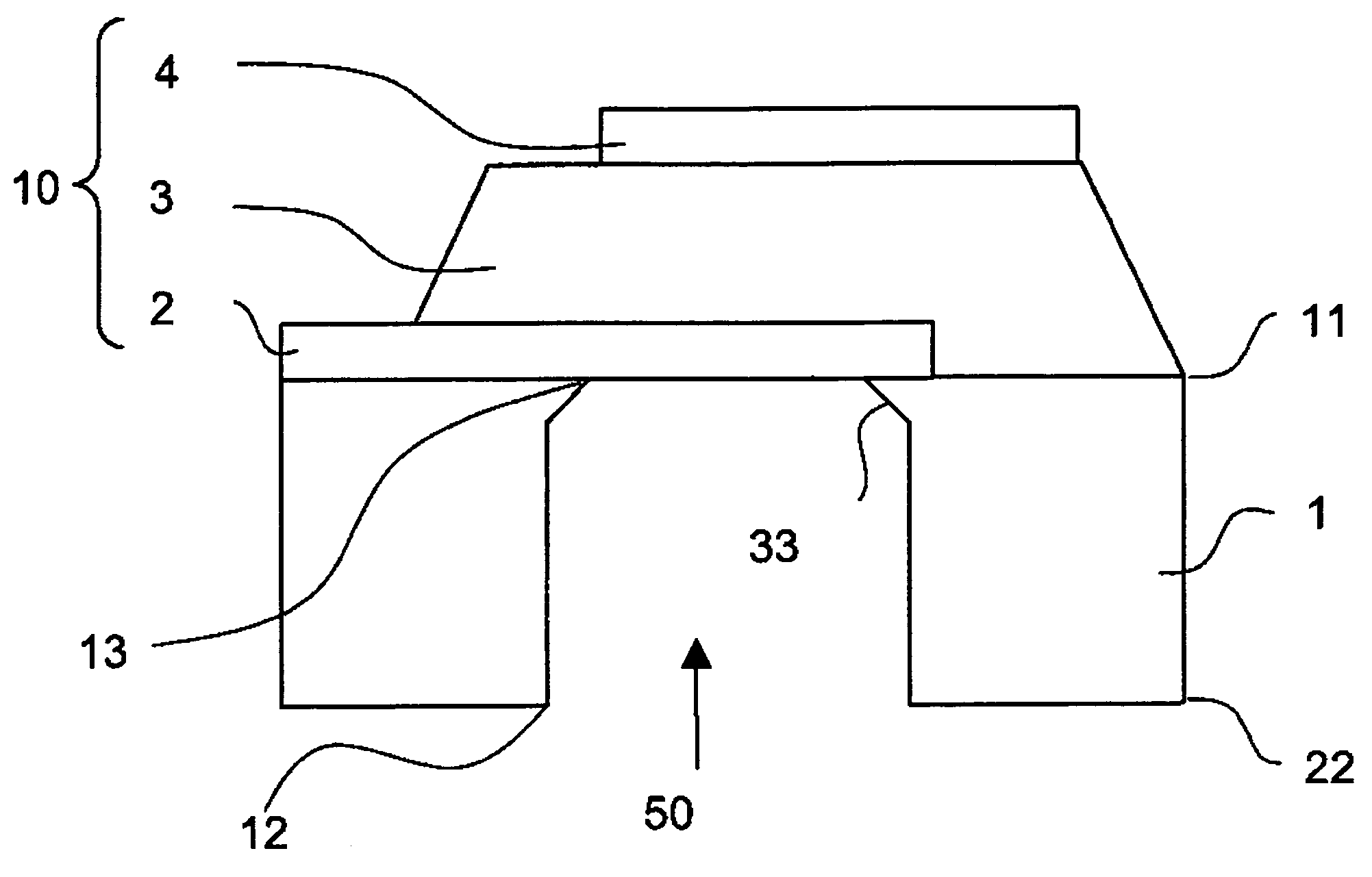

Stress isolated pressure sensing die

ActiveUS20080006092A1Avoid deformationReduce transferFluid pressure measurement using elastically-deformable gaugesDiaphragm structurePressure sense

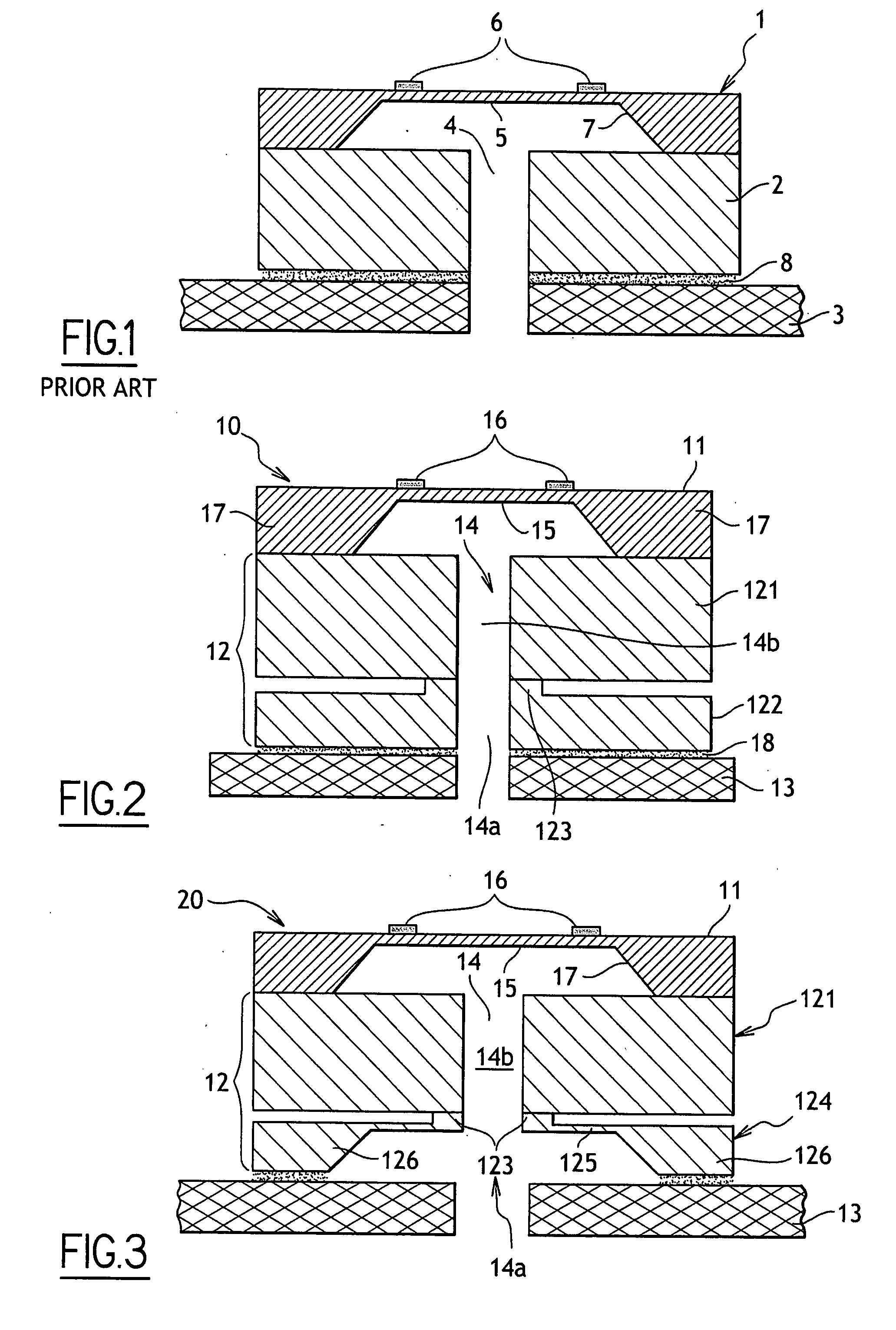

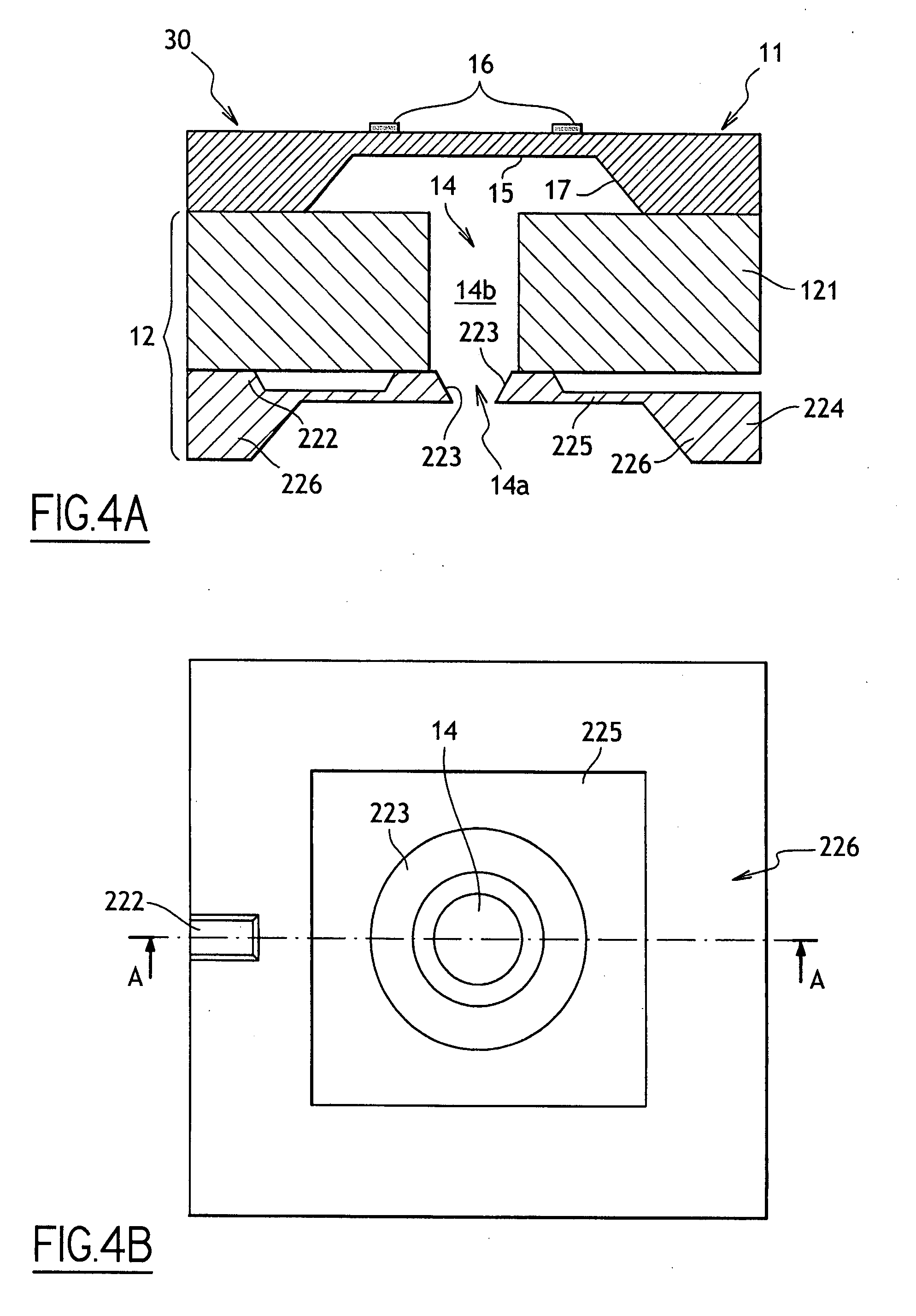

The invention relates to a pressure sensing die to be mounted on a base, comprising: a sensing structure comprising: a diaphragm structure with a deflectable sensing diaphragm whose deflection is representative of the pressure and sensing elements for detecting the deflection of the sensing diaphragm, a pedestal supporting the diaphragm structure, a linking structure for isolating at least some of the stresses caused by the mounting of the sensing die on the base from said deflectable sensing diaphragm, the linking structure being linked on one side to a bottom surface of the pedestal and to be linked, on an opposite side, to a top surface of the base, wherein the linking structure comprises at least one linking element extending between the base and the pedestal and having a mean cross-section smaller than the said bottom surface and top surface so as to constitute a small link between the base and the pedestal. The invention further relates to a method of manufacturing such a sensing die.

Owner:AUXITROL

Stress isolated pressure sensing die, sensor assembly inluding said die and methods for manufacturing said die and said assembly

ActiveUS20080016683A1Improve stabilityMinimize deflectionFluid pressure measurement using elastically-deformable gaugesMetal working apparatusDiaphragm structurePressure sense

The invention concerns a pressure sensing die to be mounted on a base, comprising: a diaphragm structure with a deflectable pressure sensing diaphragm whose deflection is representative of the pressure and sensing elements for detecting the deflection of the sensing diaphragm; a pedestal supporting the diaphragm structure; wherein the pedestal is a composite pedestal comprising top and bottom platforms connected by at least one small link having a mean cross-section smaller than the cross-section of the top platform, said small link isolating at least some of the stresses, produced by the mounting of the pressure sensing die on the base, from said deflectable pressure sensing diaphragm.

Owner:AUXITROL

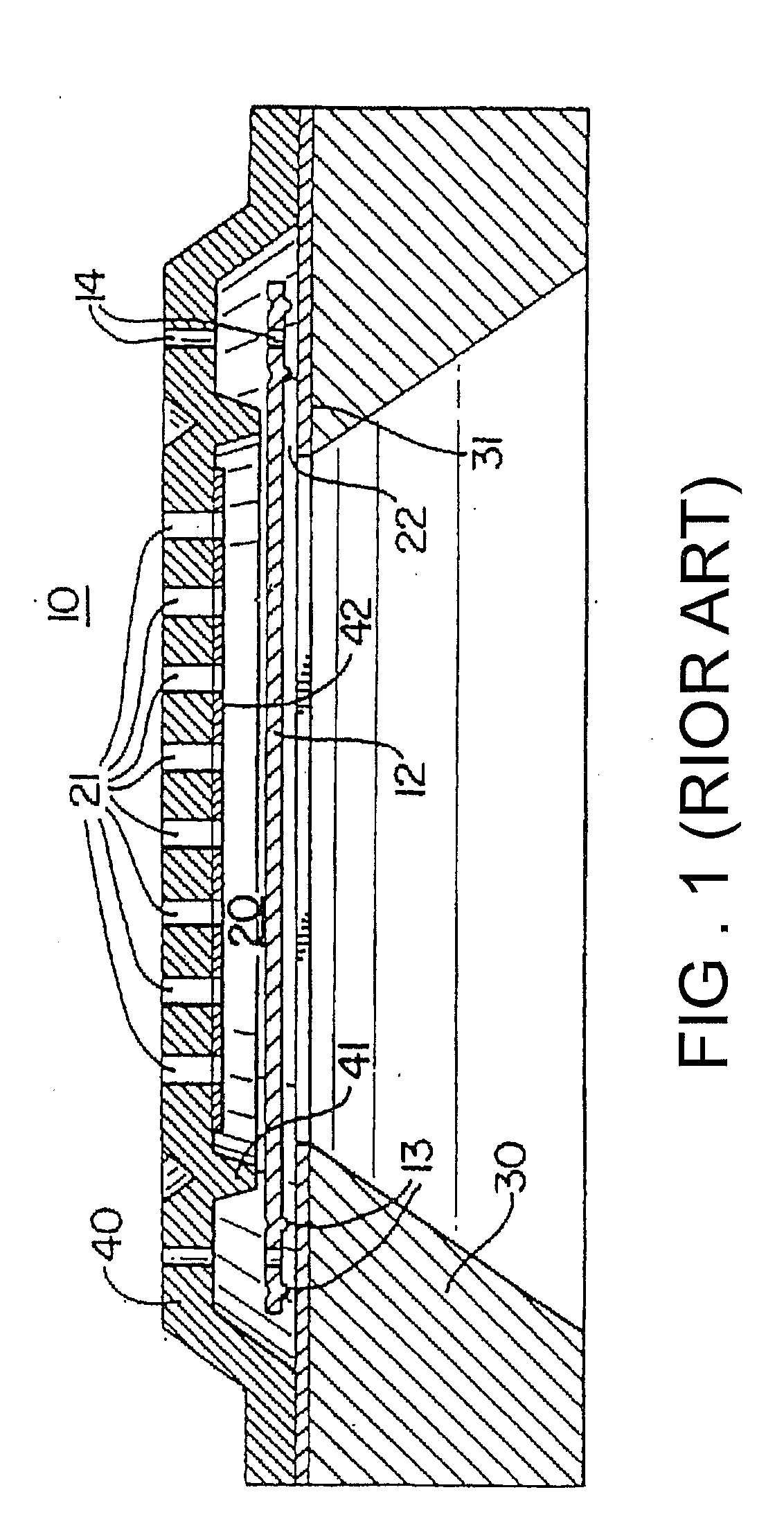

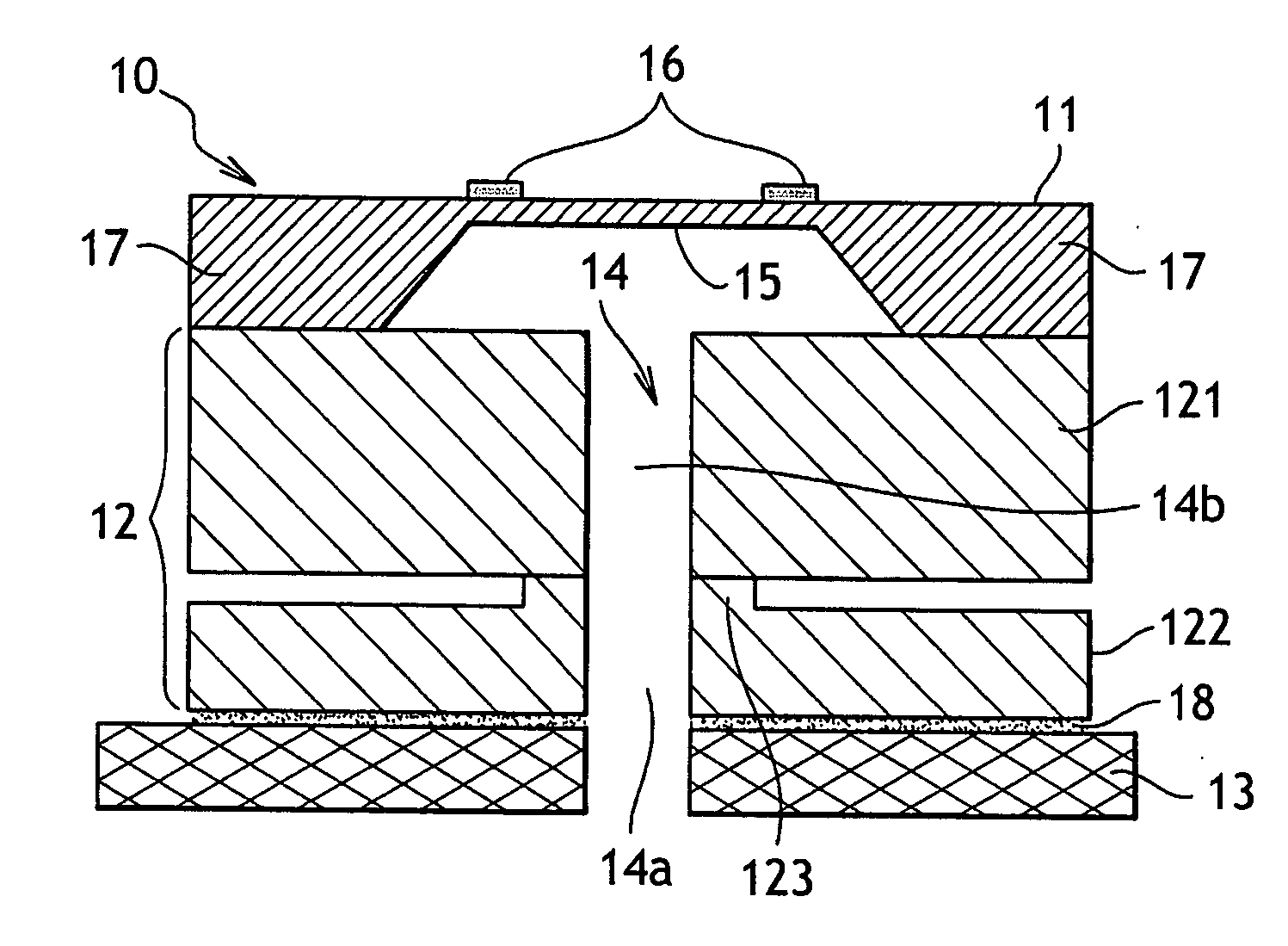

Compliant diaphragm medical sensor and technique for using the same

ActiveUS20070032708A1Provide supportDiagnostic recording/measuringSensorsDiaphragm structurePulse oximetry

A unitary sensor is provided that includes a frame upon which electrical and optical components may be disposed and a coating, such as an overmolded coating provided about the frame. The unitary sensor includes one or more diaphragm structures formed from thin regions of the coating material and disposed generally about at least one of the optical components. The diaphragm structure or structures allow the optical components to be separated, such as by application of an opposing force to the lateral sides of the sensor, such that the sensor may be placed on a patient. The sensor may thereby be placed on a patient's finger, toe, and so forth to obtain pulse oximetry or other physiological measurements.

Owner:TYCO HEALTHCARE GRP LP

Low Frequency Response Microphone Diaphragm Structures And Methods For Producing The Same

ActiveUS20140264650A1Decorative surface effectsSemiconductor/solid-state device manufacturingDiaphragm structureEngineering

A microphone system includes a diaphragm suspended by springs and including a sealing layer that seals passageways which, if left open, would degrade the microphone's frequency response by allowing air to pass from one side of the diaphragm to the other when the diaphragm is responding to an incident acoustic signal. In some embodiments, the sealing layer may include an equalization aperture to allow pressure to equalize on both sides of the diaphragm.

Owner:INVENSENSE

Lithium metal battery, electrode plate for same and method for preparing electrode plate

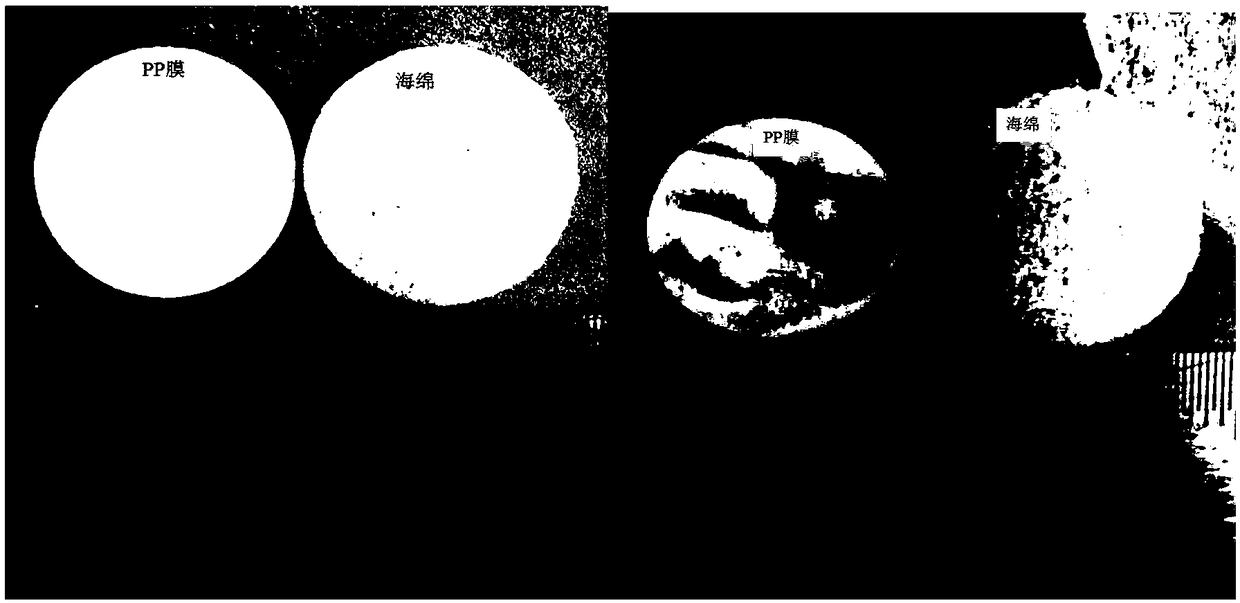

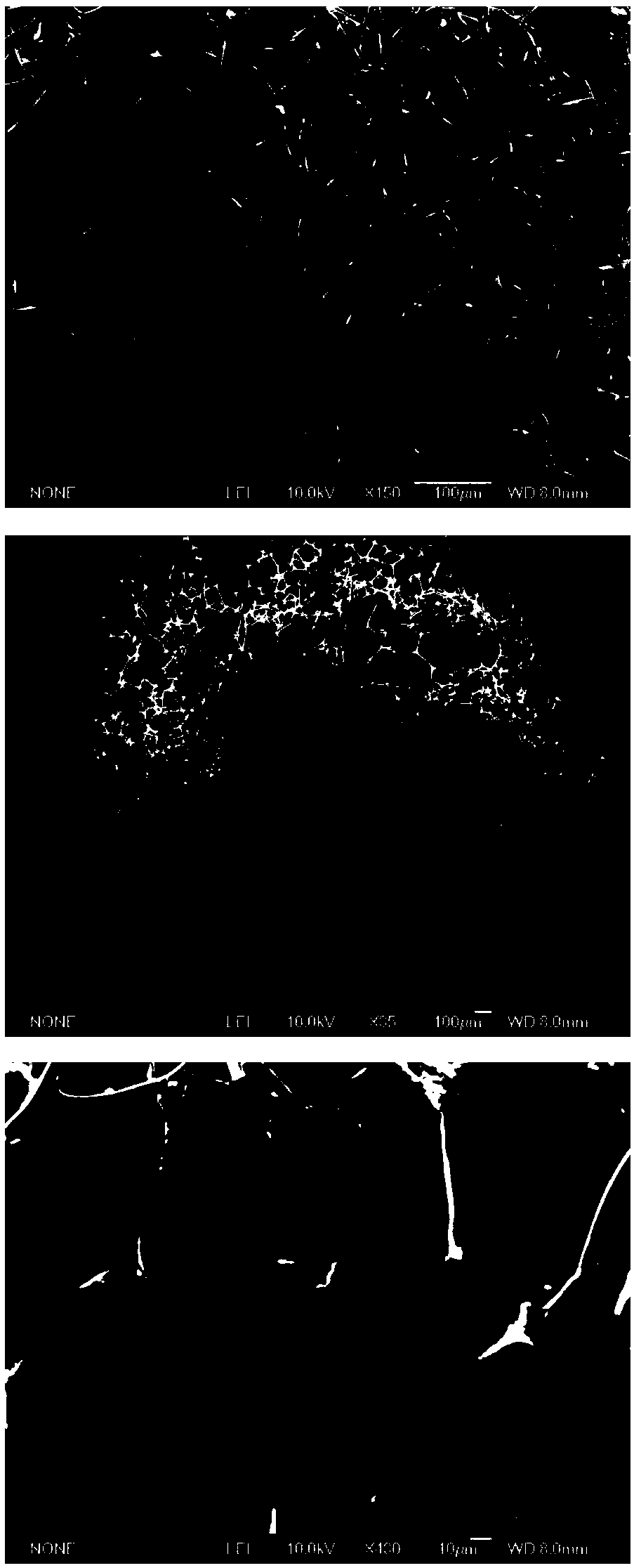

ActiveCN108899472ASimple structureAlleviate interface instabilitySecondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumElectrical battery

The invention provides a negative electrode plate for a lithium metal battery. Metallic lithium plates and sponges are compressed to obtain the negative electrode plate. The negative electrode plate has the advantages that the traditional lithium metal battery structures can be simplified when the negative electrode plate is applied to the lithium metal battery, electron barrier effects can be realized by sponge elastic interface layers instead of diaphragms, and volume change and the instability of interfaces inside the battery can be relieved by elastic interface materials in battery cycle;sponge medium layers are excellent in electrolyte solution wettability, and are high in thermal deformation resistance as compared with common polypropylene diaphragms; elastic three-dimensional framework structures of the sponges are favorable for inhibiting dendrite growth in lithium metal battery cycle procedures and relieving the volume change of negative electrodes, and accordingly further development of the lithium metal battery can be promoted from another angle by composite metal lithium negative electrodes which are designed by the aid of sponge materials and are free of diaphragm structures.

Owner:UNIV OF SCI & TECH OF CHINA

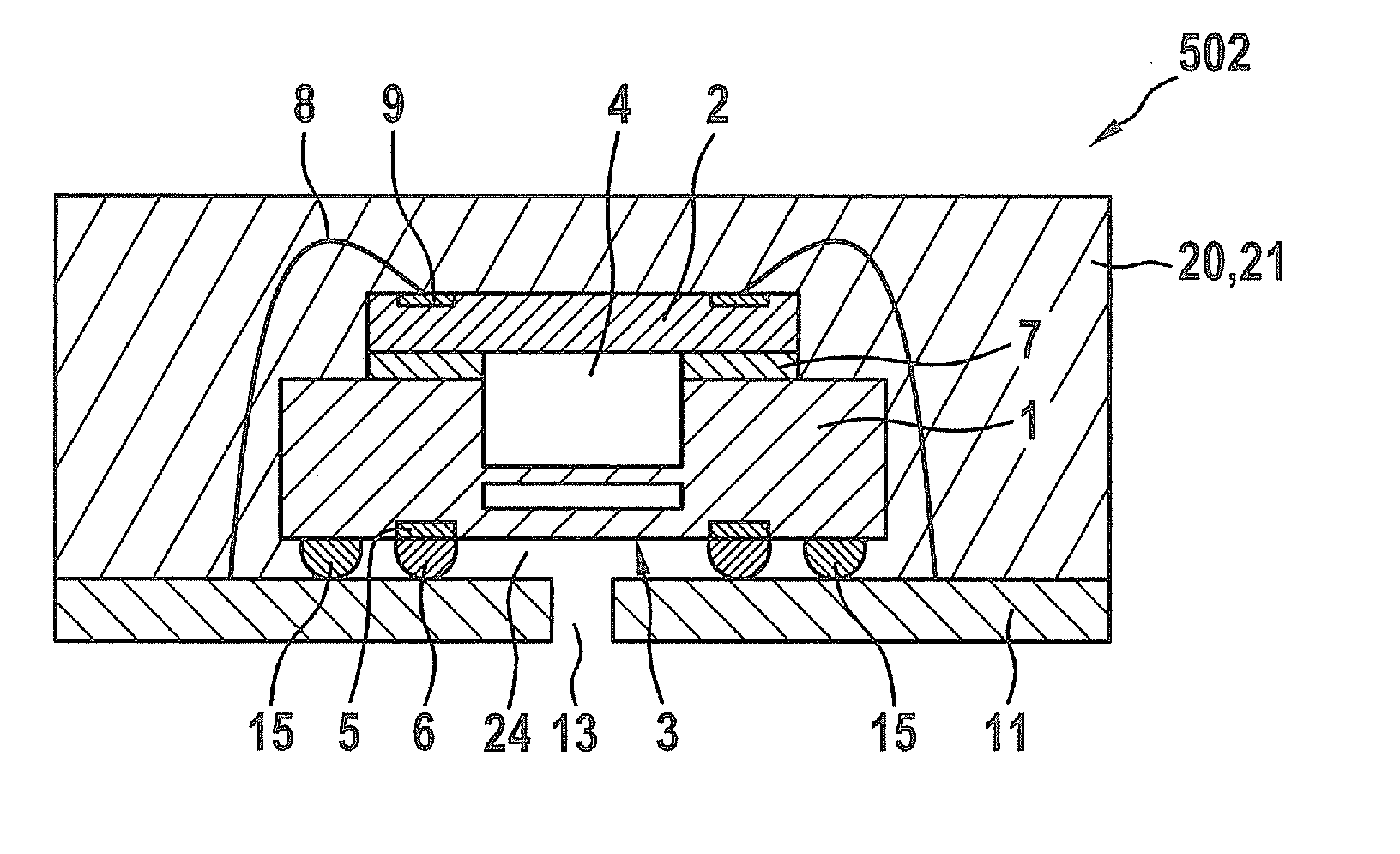

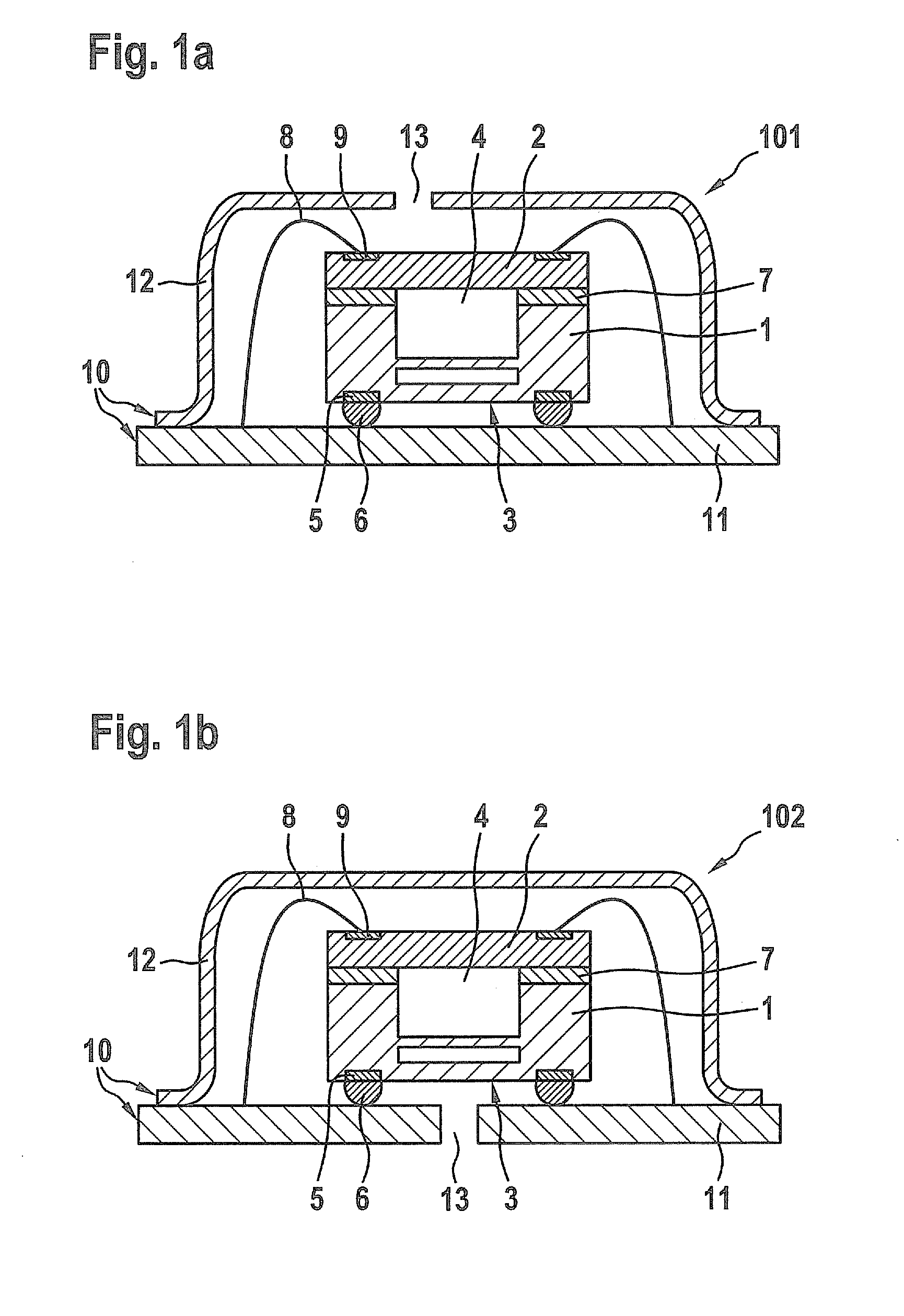

Component

ActiveUS20120280335A1Good flexibilityReduce horizontal sizeSemiconductor electrostatic transducersSolid-state devicesDiaphragm structureChip stacking

A component includes at least one MEMS component and at least one additional semiconductor component in a common housing having at least one access opening. On the front side of the MEMS component, at least one diaphragm structure is provided, which spans a cavity on the backside of the MEMS component. The housing includes a carrier, on which the MEMS component is mounted. The MEMS component is mounted, using its front side, on the carrier, so that there is a standoff between the diaphragm structure and the carrier surface. The at least one additional semiconductor component is connected to the backside of the MEMS component, so that the MEMS component and the semiconductor component form a chip stack.

Owner:ROBERT BOSCH GMBH

Component

ActiveCN102685657ASemiconductor electrostatic transducersElectrostatic transducer microphonesDiaphragm structureInterposer

A wafer-level-based packaging concept for MEMS components having at least one diaphragm structure formed in the component front side is described, according to which an interposer is connected to the front side of the MEMS component, which has at least one passage aperture as an access opening to the diaphragm structure of the MEMS component and which is provided with electrical through contacts so that the MEMS component is electrically contactable via the interposer. The cross-sectional area of the at least one passage aperture in the interposer is to be designed as significantly smaller than the lateral extension of the diaphragm structure of the MEMS component. The at least one passage aperture opens into a cavity(6) between the diaphragm structure (2) and the interposer(5).

Owner:ROBERT BOSCH GMBH

Stress isolated pressure sensing die

ActiveUS7475597B2Reduce transferCost effectiveFluid pressure measurement using elastically-deformable gaugesDiaphragm structurePressure sense

The invention relates to a pressure sensing die to be mounted on a base, comprising:a sensing structure comprising:a diaphragm structure with a deflectable sensing diaphragm whose deflection is representative of the pressure and sensing elements for detecting the deflection of the sensing diaphragm,a pedestal supporting the diaphragm structure,a linking structure for isolating at least some of the stresses caused by the mounting of the sensing die on the base from said deflectable sensing diaphragm, the linking structure being linked on one side to a bottom surface of the pedestal and to be linked, on an opposite side, to a top surface of the base,wherein the linking structure comprises at least one linking element extending between the base and the pedestal and having a mean cross-section smaller than the said bottom surface and top surface so as to constitute a small link between the base and the pedestal.The invention further relates to a method of manufacturing such a sensing die.

Owner:AUXITROL

Single body construction for loudspeaker

ActiveCN101426165ASimple structureSuitable for mass productionElectrets selectrostatic transducerElectrostatic transducer microphonesThin metalMetallic electrode

Proposed is a speaker in the monomer structure, including a single electret diaphragm structure, a single metallic electrode with a plurality of openings and a frame support. In an embodiment, the electret diaphragm structure is composed by stacking an electret diaphragm layer, a super thin metal film electrode and an insulating layer, wherein, the super thin metal film electrode is located between the electret diaphragm layer and the insulating layer. In another embodiment, the electret diaphragm structure is composed of an electret diaphragm layer and a conductive electrode layer with oxidation conductive material. The frame support is located between the electret diaphragm structure and the metallic electrode, forming a space for vibrating as an electret diaphragm structure, to producesound.

Owner:IND TECH RES INST

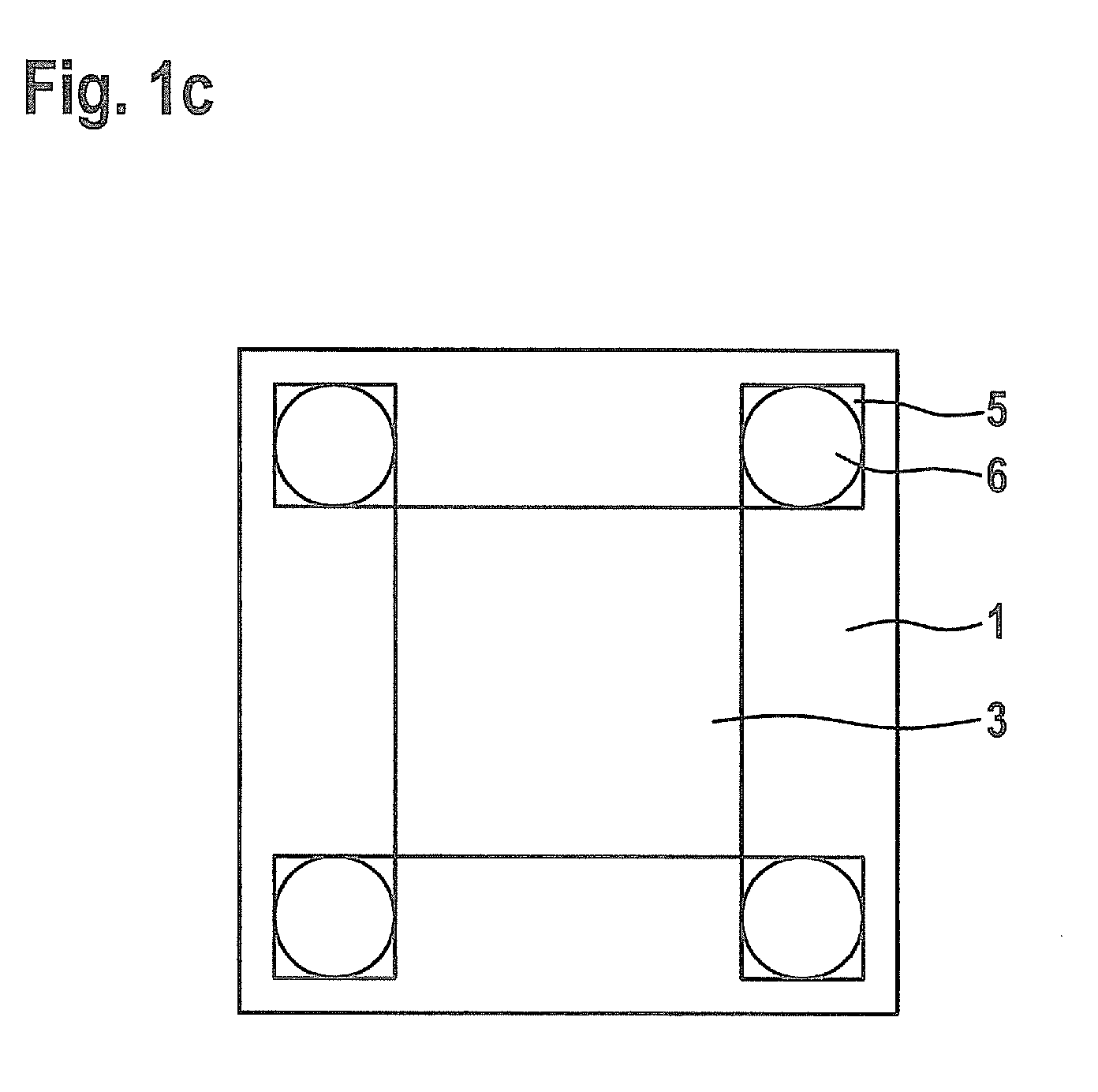

Component having a micromechanical microphone structure

InactiveUS20130243234A1Improved acoustic sealingImprove performancePiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersDiaphragm structureEngineering

A micromechanical microphone structure configured as a layered structure includes: a semiconductor substrate; a diaphragm structure having an acoustically active diaphragm which at least partially spans a sound opening in the back side of the substrate and is provided with a movable electrode of a microphone capacitor, which diaphragm structure has openings via which pressure compensation occurs between the back side and the front side of the diaphragm; a stationary acoustically permeable counterelement having vents, which counterelement is situated in the layered structure above the diaphragm and which functions as a carrier for a nonmovable electrode of the microphone capacitor; and at least one ridge-like structural element which is situated at the outer edge area of the diaphragm, and which protrudes from the diaphragm plane into corresponding recesses in an adjoining layer.

Owner:ROBERT BOSCH GMBH

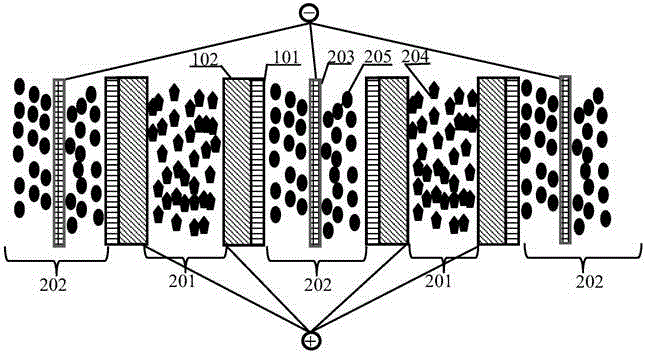

Lithium slurry battery reactor

ActiveCN106159302AThe height of the cavity can be adjusted arbitrarilySolve consumptionFuel cell auxillariesRegenerative fuel cellsLithiumDiaphragm structure

The invention provides a lithium slurry battery reactor. The lithium slurry battery reactor comprises positive pole reaction cavities, negative pole reaction cavities, unipolar diaphragms, negative pole current collectors, positive pole slurry and negative pole slurry, wherein each unipolar diaphragm is formed by an isolating layer and a positive pole porous current collector layer located on a single side of the isolating layer through close contacting, and a plurality of unipolar diaphragms are sequentially stacked in the sequence that isolation layers are placed oppositely; the distance between every two adjacent positive pole porous current collector layers is larger than 0 and preferably ranges from 1 mm to 10 mm, a gap between the every two adjacent positive pole porous current collector layers forms one positive pole reaction cavity, and the positive pole slurry is located in the positive pole reaction cavity; the distance between two adjacent isolating layers is larger than 0 and preferably ranges from 1 mm to 20 mm, and a gap between the adjacent isolating layers forms one negative pole reaction cavity; the negative pole current collectors are located in the negative pole reaction cavities, and the negative pole slurry is located between the negative pole current collectors and the isolating layers. With the adoption of the unipolar diaphragm structure, the problems of consumption of lithium ions and increasing of polarizing internal resistance due to deposition of metal lithium on the negative pole porous current collector layers in a bipolar diaphragm structure are solved.

Owner:南京竞予能源有限公司

Compliant diaphragm medical sensor and technique for using the same

Owner:TYCO HEALTHCARE GRP LP

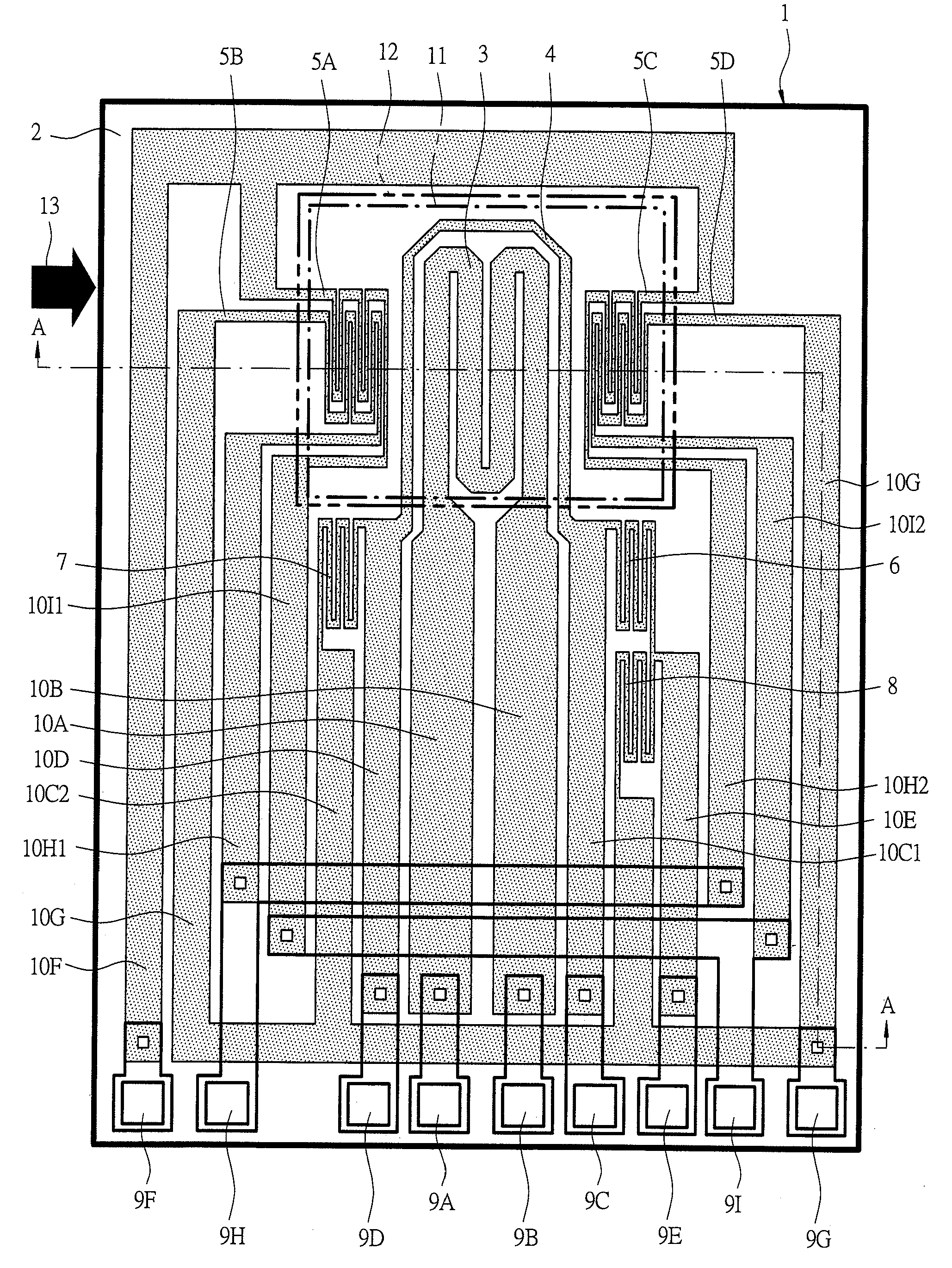

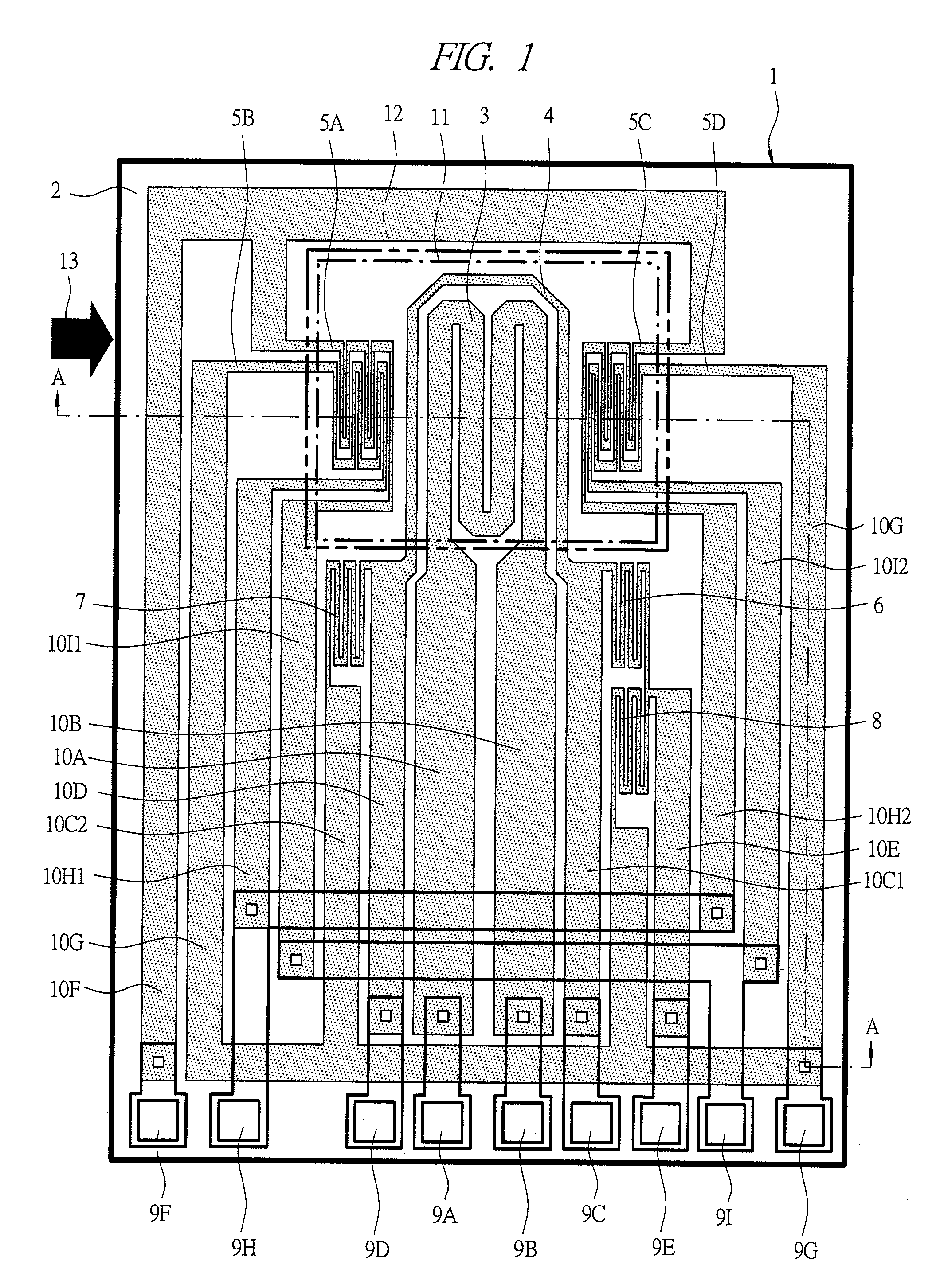

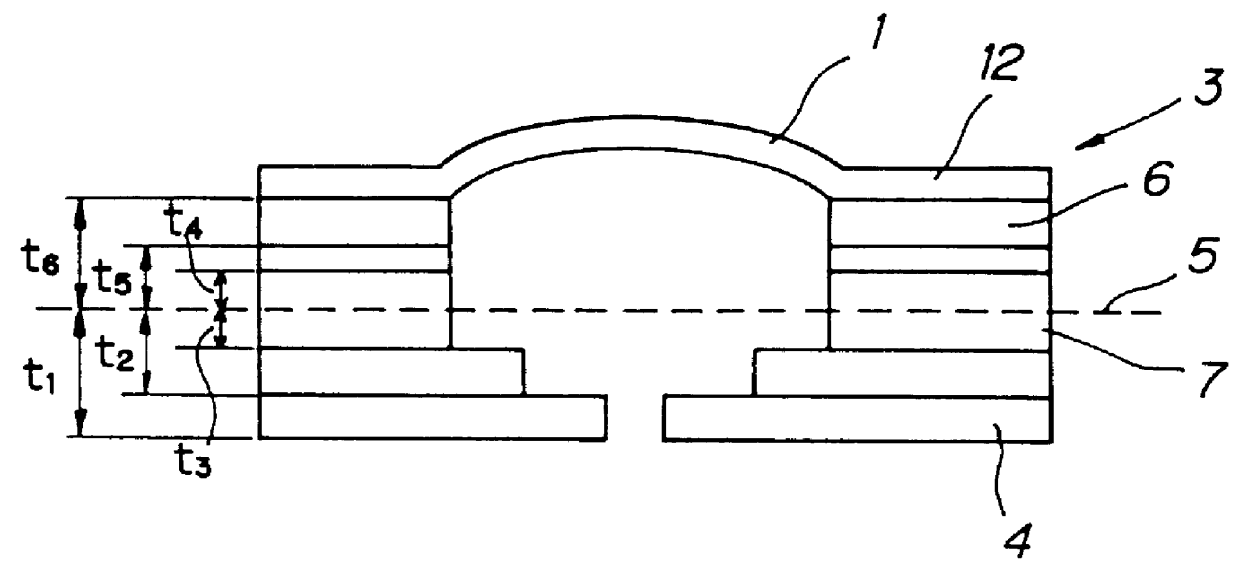

Thermal fluid flow sensor and method of manufacturing the same

ActiveUS20100139391A1Reduce unevennessLarge in densenessVolume/mass flow by thermal effectsVolume flow proportion measurementFlow transducerDiaphragm structure

A thermal fluid flow sensor having a diaphragm structure body configured by an insulating film formed by stacking a film having compressive stress and a film having tensile stress on the top and bottom of a temperature-measuring resistive element and a heater resistive element which are processed by microprocessing is provided. The insulating film at a lower layer of the heater resistive element, a temperature-measuring resistive element for heater resistive element, upstream temperature-measuring resistive elements, and downstream temperature-measuring resistive elements, has films having compressive stress (a first insulating film, a third insulating film, and a fifth insulating film) and films having tensile stress (a second insulating film and a fourth insulating film) being alternately arranged, and two layers or more of the films having tensile stress are arranged.

Owner:HITACHI ASTEMO LTD

Component having a micromechanical microphone structure

ActiveUS20140105428A1Increase in microphone sensitivityHigh possible change in capacitanceMicrophonesTransducer detailsDiaphragm structureMems microphone

A capacitive MEMS microphone structure is provided, which micromechanical microphone structure of component is realized in a layer construction and includes: a diaphragm structure sensitive to sound pressure, which is deflectable in a direction perpendicular to the layer planes of the layer construction; an acoustically penetrable counter-element which has through holes and is formed above or below the diaphragm structure in the layer construction; and a capacitor system for detecting the excursions of the diaphragm structure. The diaphragm structure includes a structural element in the middle area of the diaphragm structure, which structural element projects perpendicularly from the diaphragm plane and which, depending on the degree of excursion of the diaphragm structure, variably extends into a correspondingly formed and positioned through hole in the counter-element.

Owner:ROBERT BOSCH GMBH

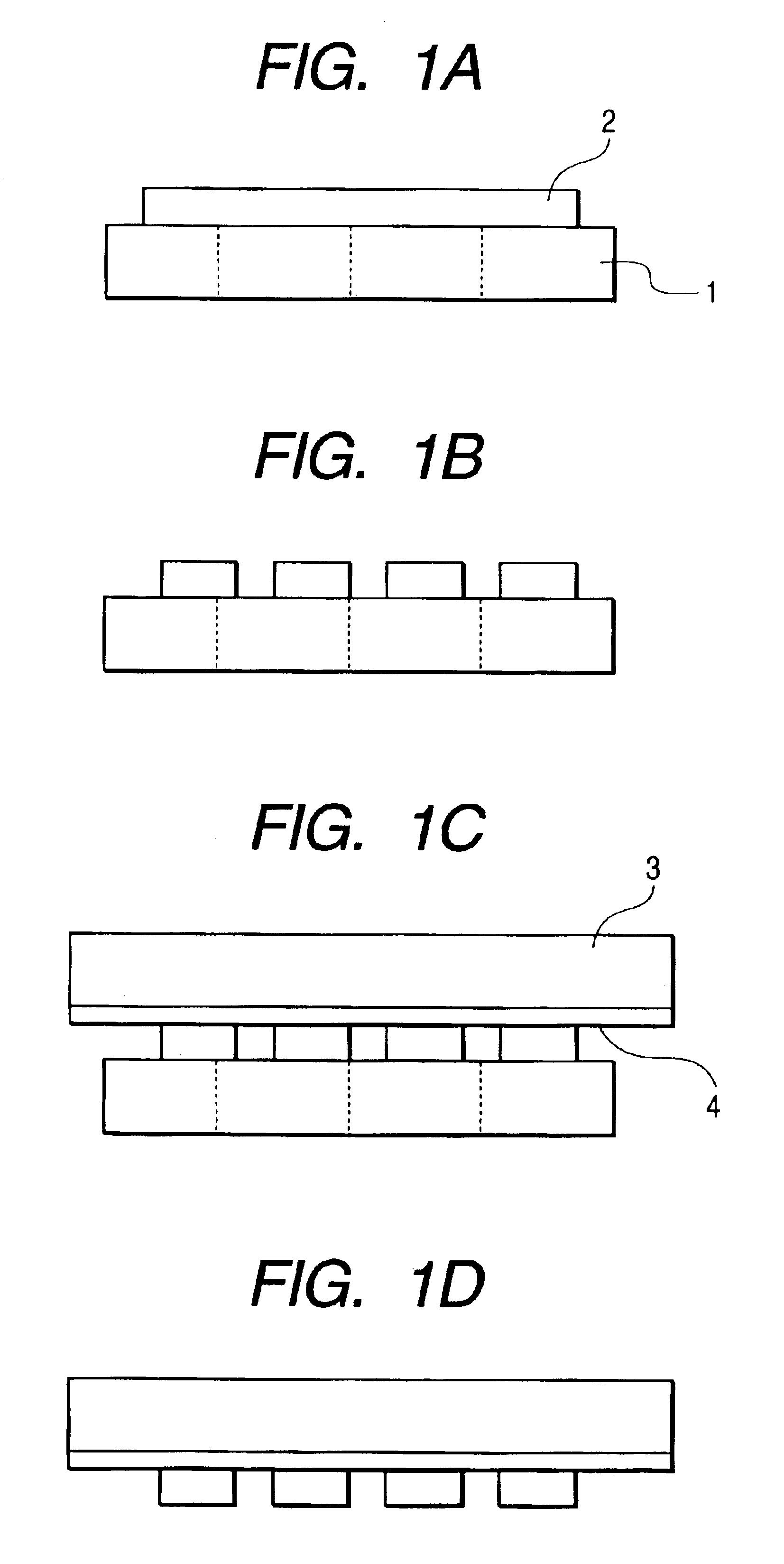

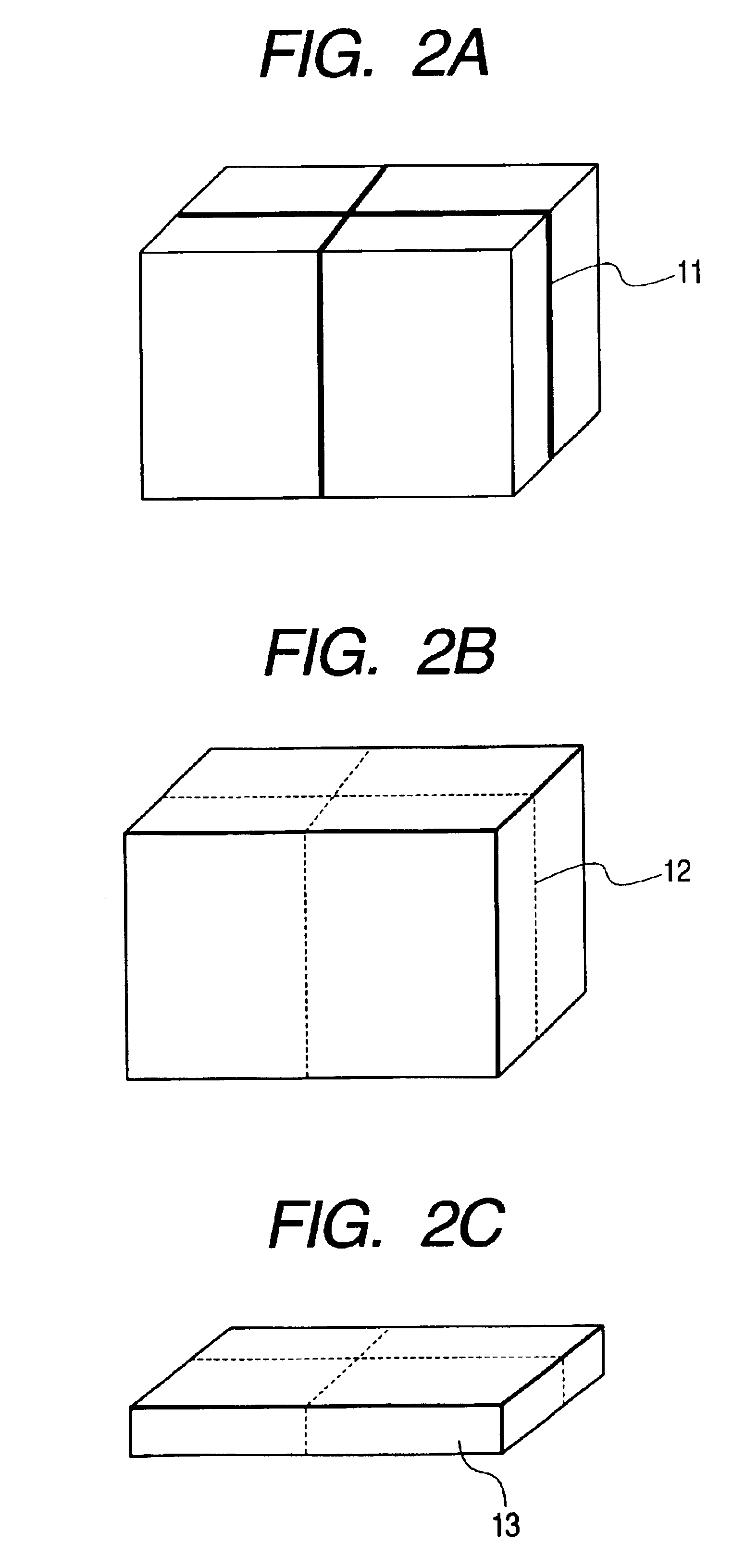

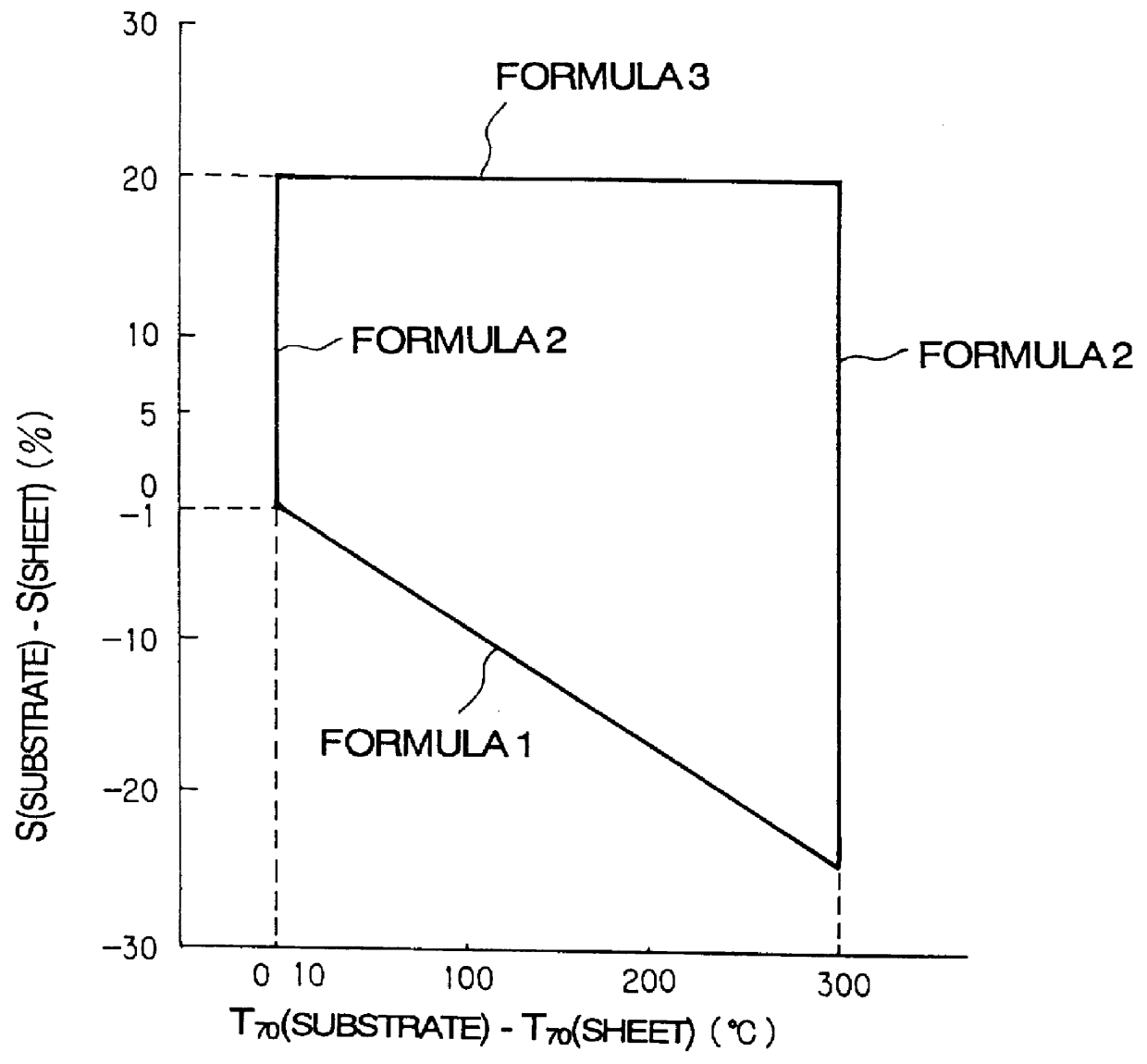

Method for producing ceramic diaphragm structure

InactiveUS6045642AStructure miniaturizationPiezoelectric/electrostriction/magnetostriction machinesLayered productsMetallurgyShrinkage rate

A method for producing a ceramic diaphragm structure includes preparing a ceramic green substrate having at least one window and a plurality of layers, and a thin ceramic green sheet. The ceramic green sheet is superposed on the ceramic green substrate to cover the window and thereby provide a unitary laminate. The laminate is then fired so that the ceramic green sheet provides a diaphragm portion which protrudes in a direction away from the window. The average sintering temperature difference or the average shrinkage-rate difference, of the layers of the ceramic green substrate, is larger than zero.

Owner:NGK INSULATORS LTD

Stress isolated pressure sensing die, sensor assembly inluding said die and methods for manufacturing said die and said assembly

ActiveUS7661318B2Minimize deflectionReduce outputFluid pressure measurement using elastically-deformable gaugesMetal working apparatusDiaphragm structurePressure sense

The invention concerns a pressure sensing die to be mounted on a base, comprising:a diaphragm structure with a deflectable pressure sensing diaphragm whose deflection is representative of the pressure and sensing elements for detecting the deflection of the sensing diaphragm;a pedestal supporting the diaphragm structure;wherein the pedestal is a composite pedestal comprising top and bottom platforms connected by at least one small link having a mean cross-section smaller than the cross-section of the top platform, said small link isolating at least some of the stresses, produced by the mounting of the pressure sensing die on the base, from said deflectable pressure sensing diaphragm.

Owner:AUXITROL

Bulk acoustic wave resonator and manufacturing method thereof, filter using the same, semiconductor integrated circuit device using the same, and high frequency module using the same

InactiveUS7221242B2Improve featuresIncrease production costImpedence networksPiezoelectric/electrostriction/magnetostriction machinesDiaphragm structureAcoustics

Owner:HITACHI MEDIA ELECTORONICS CO LTD

Lithium double-fluid flow battery

ActiveCN105280942AAvoid cloggingReduce circulationRegenerative fuel cellsFuel cell detailsLithiumDiaphragm structure

The invention provides a lithium double-fluid flow battery, which comprises a porous positive current collector, a positive reaction cavity, a diaphragm, a metal lithium negative plate, a negative reaction cavity, a positive suspension and a negative electrolyte, wherein a gap with a certain distance exists between the diaphragm of the battery and negative metal lithium; the gap is fully filled with the negative electrolyte which continuously or intermittently flows; and a solid-liquid composite dual-diaphragm structure is formed by the diaphragm and the negative electrolyte. Through continuous or intermittent washing by the electrolyte, the problem of potential safety hazards caused by lithium dendrites generated by a metal lithium negative electrode in charge-discharge processes is solved; and meanwhile, the lithium double-fluid flow battery plays roles in purifying the negative electrolyte, cleaning the diaphragm and adjusting the concentration of the positive suspension.

Owner:南京竞予能源有限公司

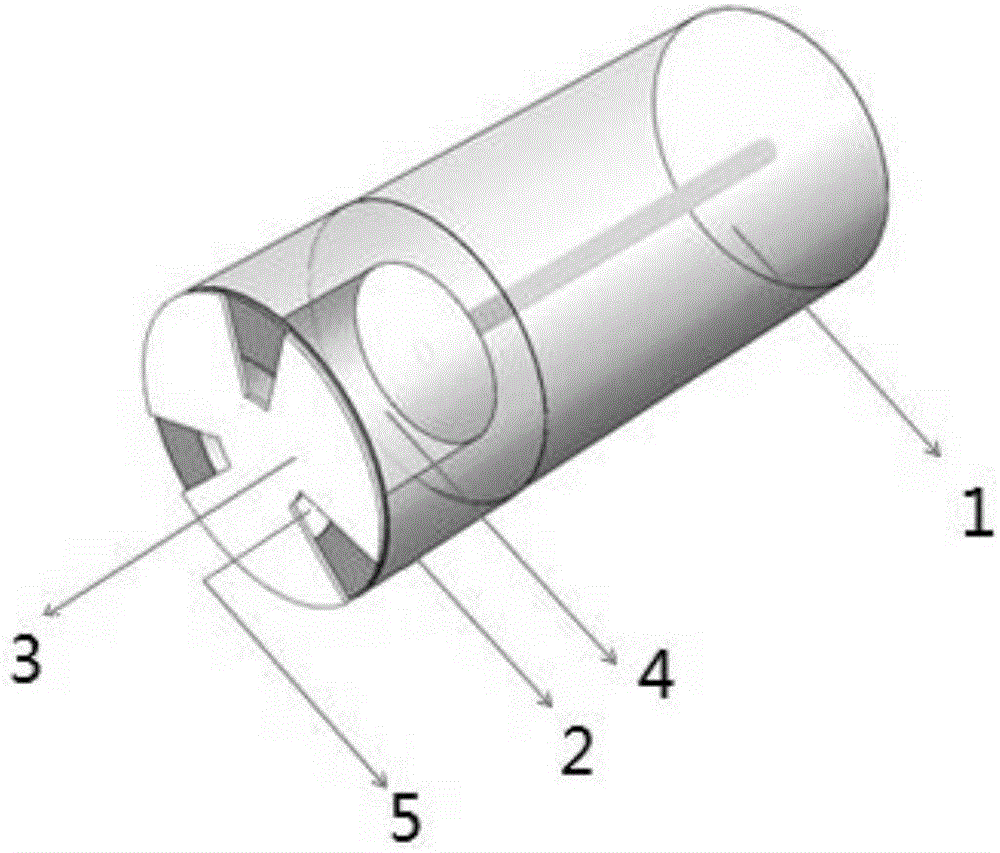

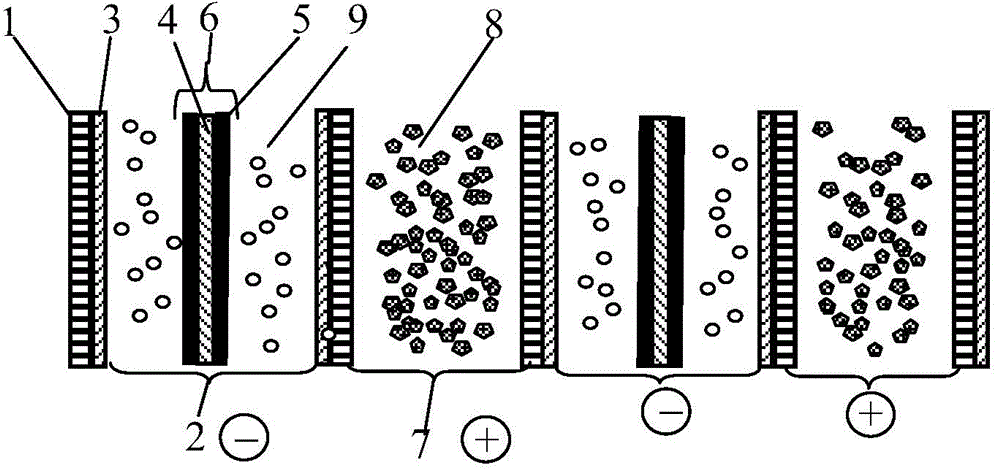

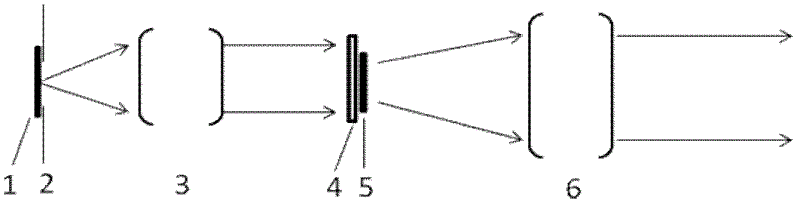

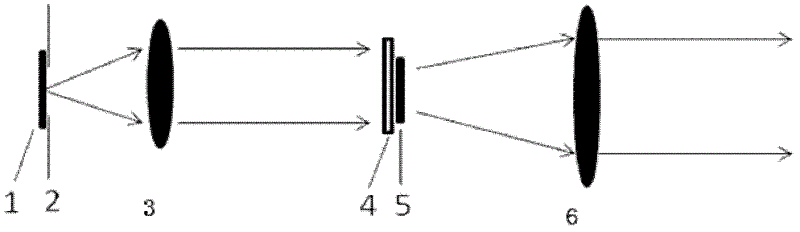

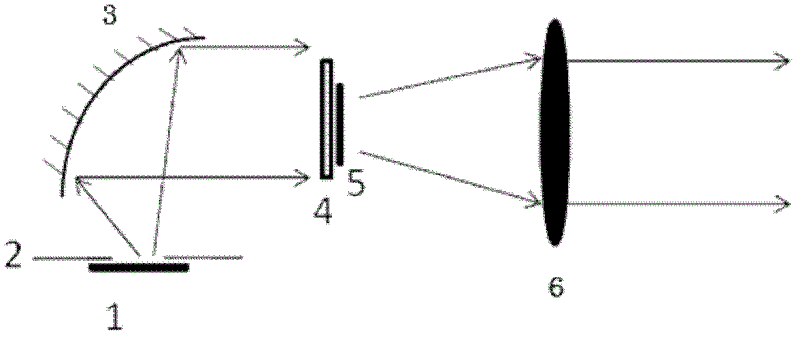

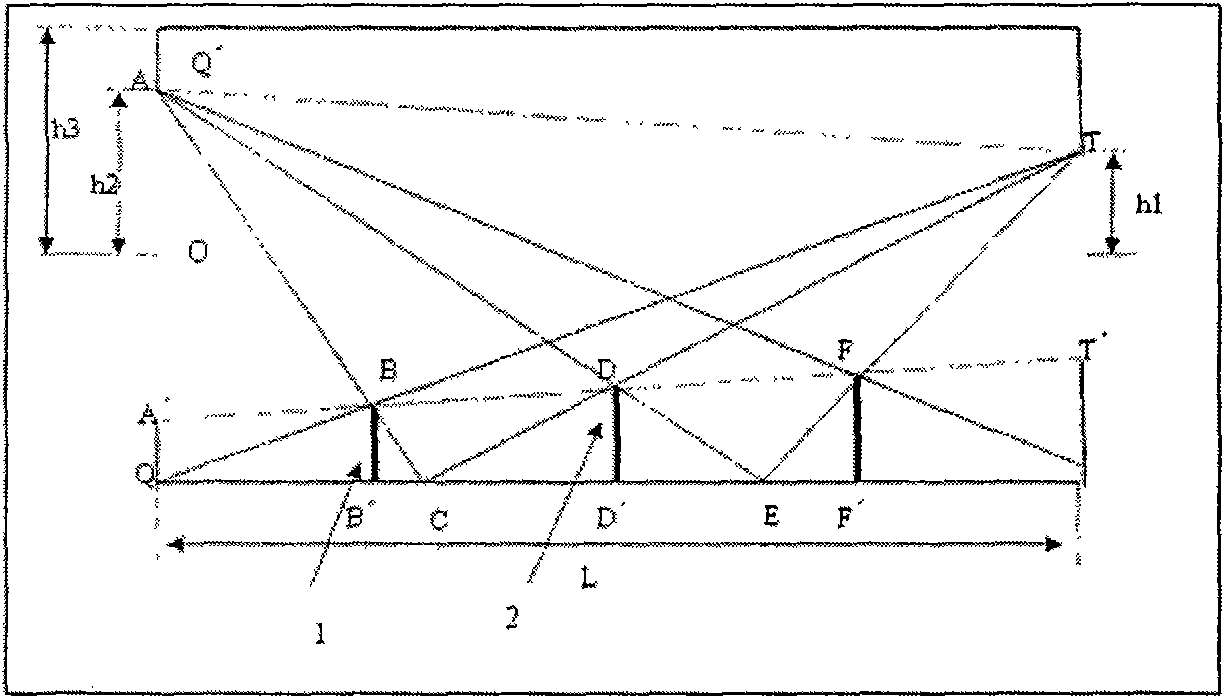

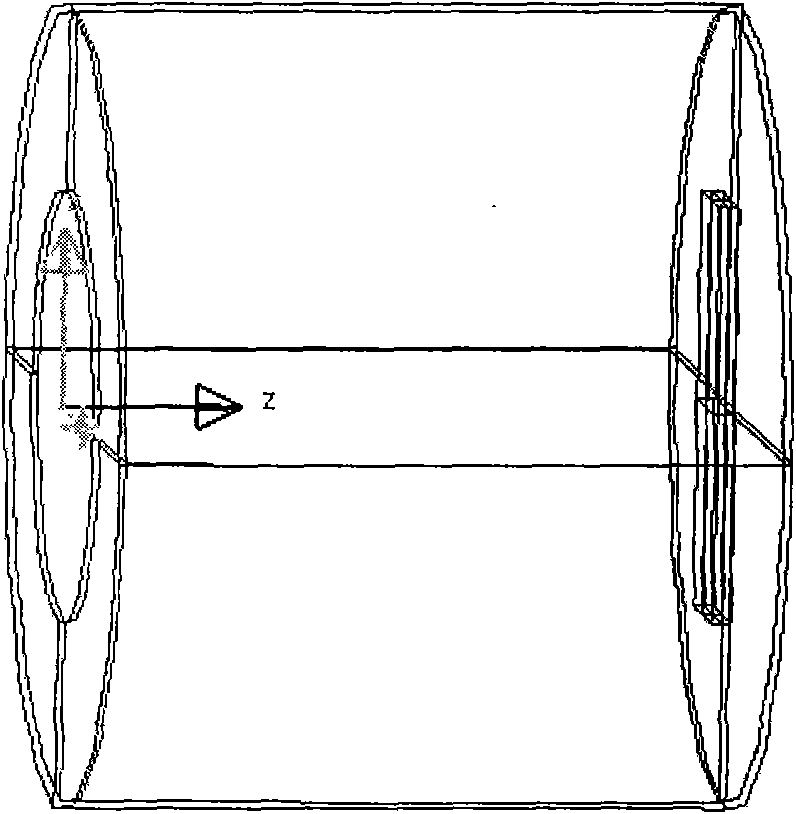

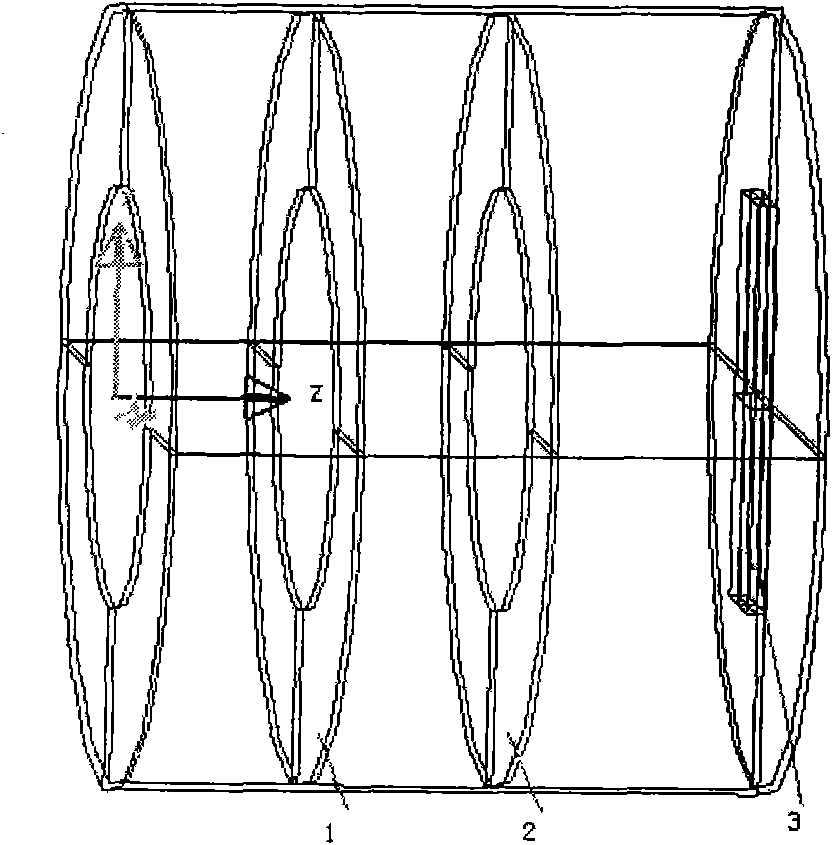

Energy-adjustable infrared target simulation system

InactiveCN102621692ARealize continuous change of energyAiming meansOptical elementsCamera lensEnergy regulation

The invention discloses an energy-adjustable infrared target simulation system, which belongs to the field of optical techniques, and relates to a broadband and energy-adjustable-continuously infrared target simulation system. The infrared target simulation system comprises a black body 1, an energy diaphragm 2, a lighting lens 3, an infrared dodging system 4, an infrared target 5 and a projection lens 6, wherein the infrared radiation emitted by the black body 1, after passing through the energy diaphragm 2 and being collimated by the lighting lens 3, enters the infrared dodging system 4; then, after being dodged by the infrared dodging system 4, the infrared radiation enters the infrared target 5 and finally is collimated and outputted by the projection lens 6. The emergent face of the black body 1 is arranged on the focal plane of the lighting collimating lens 3; and the infrared target 5 is arranged on the focal plane of the projection lens 6, and the emergent energy of the target is controlled by the energy diaphragm 2, when the diaphragm largens, the system energy increases, and when the diaphragm is reduced, the system energy decreases. According to the invention, the energy adjustment on an infrared target simulator is performed by using a diaphragm structure, so that the continuous change of infrared broadband energy can be realized, therefore, the system can carry out simulation test on the infrared systems under different energy requirements.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

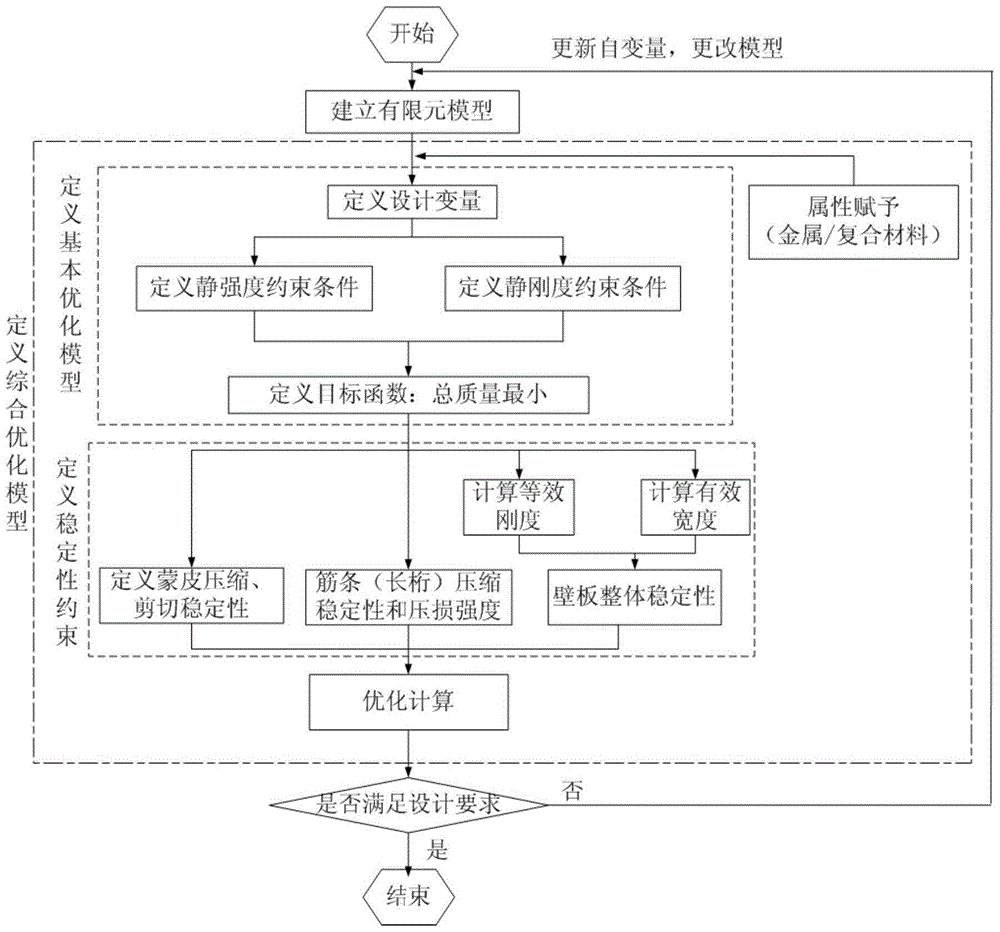

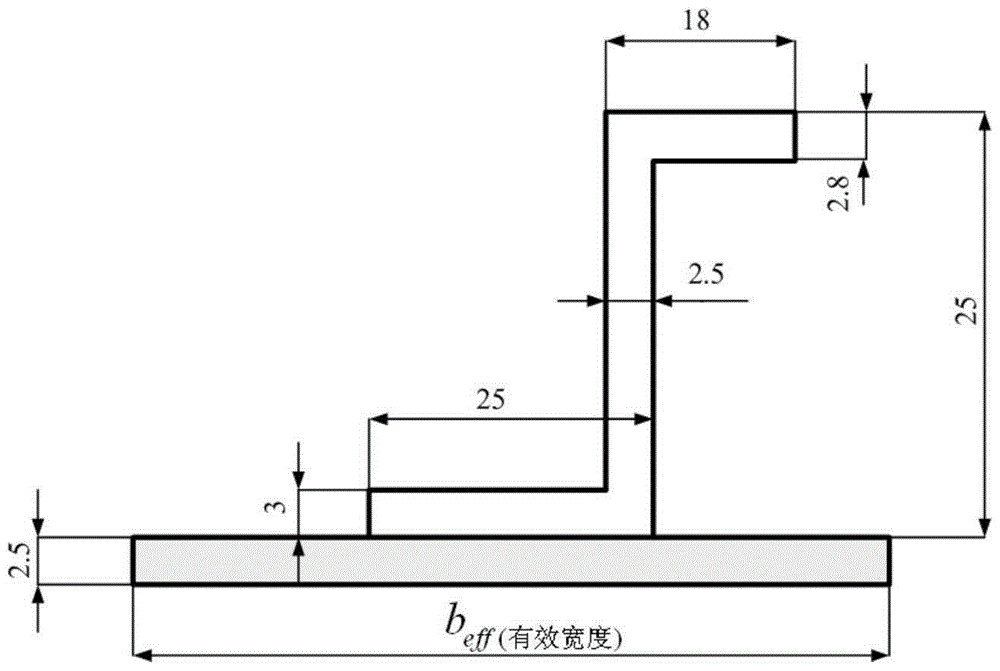

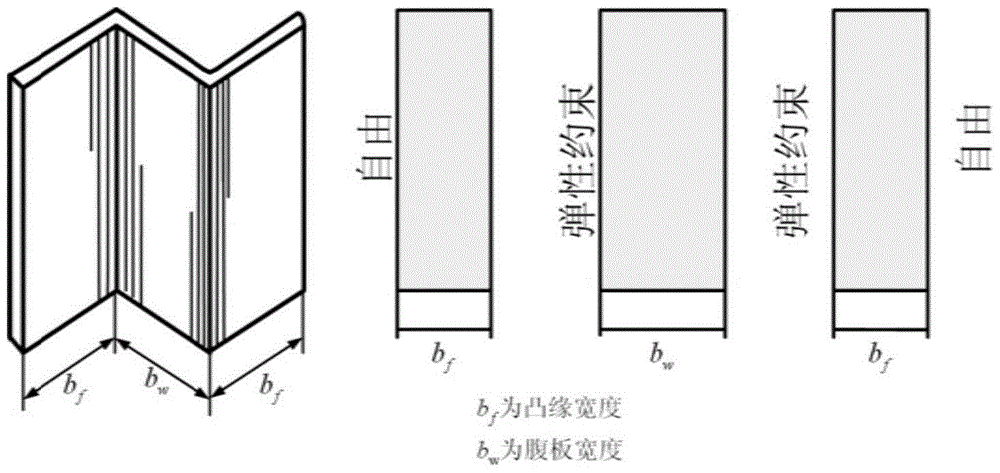

Integrated optimization method of static strength, rigidity, stability of wallboard structure

The invention discloses an integrated optimization method of static strength, rigidity, stability of a wallboard structure. In an optimization design process, apart from conventional static strength and rigidity, an integrated stability determination coefficient of the wallboard structure is introduced as a constraint condition, i.e., in an iteration process, automatic calculation and determination are performed on multiple instability modes including wallboard rib compression stability, pressing damage strength, compression stability of a skin diaphragm structure, cutting stability, integrated wallboard stability and the like, minimization of the total weight of the structure is taken as an object, dimension parameters of the wallboard structure are optimized, under the condition that the static strength, the rigidity and the integrated stability performance of the wallboard structure after the optimization satisfy design requirements, the weight of the structure is the lightest, recalculation on various stability of the structure after conventional engineering design and optimization is avoided, the problems of increased calculation cost and design change risks which are caused by using a conventional method are solved, and the design efficiency is substantially improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Colloidal electrolyte super capacitor adopting reticular diaphragm

ActiveCN104916455APrevent leakageAvoid short circuitHybrid capacitor separatorsHybrid capacitor electrolytesInternal resistanceDiaphragm structure

The invention provides a colloidal electrolyte super capacitor adopting a reticular diaphragm. The colloidal electrolyte super capacitor is characterized in that the reticular diaphragm is adopted to replace a conventional diaphragm; the reticular diaphragm is located between a positive electrode and a negative electrode, so that the positive electrode and the negative electrode can be separated from each other; and channels of positive electrode and negative electrode active materials are filled with colloidal electrolyte and are communicated with each other through holes of the reticular diaphragm, and therefore, electrolyte ion migration channels can be formed. The reticular diaphragm is adopted, and therefore, short circuit of the positive electrode and the negative electrode can be avoided, and the transfer resistance of electrolyte ions between the positive electrode and the negative electrode can be effectively decreased. Compared with a super capacitor without a diaphragm structure and colloid electrolyte, the super capacitor of the invention has the advantages of high security and diverse packaging modes; and compared with a colloidal electrolyte super capacitor adopting a conventional diaphragm such as polypropylene non-woven fabric, the colloid electrolyte super capacitor adopting the reticular diaphragm has the advantages of low internal resistance and high power density.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cold diaphragm with light blocking ring structure

InactiveCN101614834AStray light energy reductionEasy to makeRadiation pyrometryOptical elementsDiaphragm structureTransmittance

The invention discloses a cold diaphragm with a light blocking ring structure. The invention is characterized in that two light blocking rings are reasonably added into the internal wall of the cold diaphragm, and the surfaces of the light blocking rings are coated with a layer of black coating with excellent performance, thus effectively reducing stray light. The design can excellently improve the signal-to-noise ratio of the system, enhances the contrast ratio and improves the exploring and recognizing capacities of the whole system. Compared with cold diaphragms without the light blocking ring structure, the invention can effectively reduce stray light, and causes point source transmittance PST value to be attenuated corresponding to several orders of magnitude, the manufacture is easy, and the cost is low, thus being suitable for any cold diaphragm structures.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com