Component

A component and component technology, applied in the field of packaging of MEMS components, can solve the problems of high risk of contamination or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

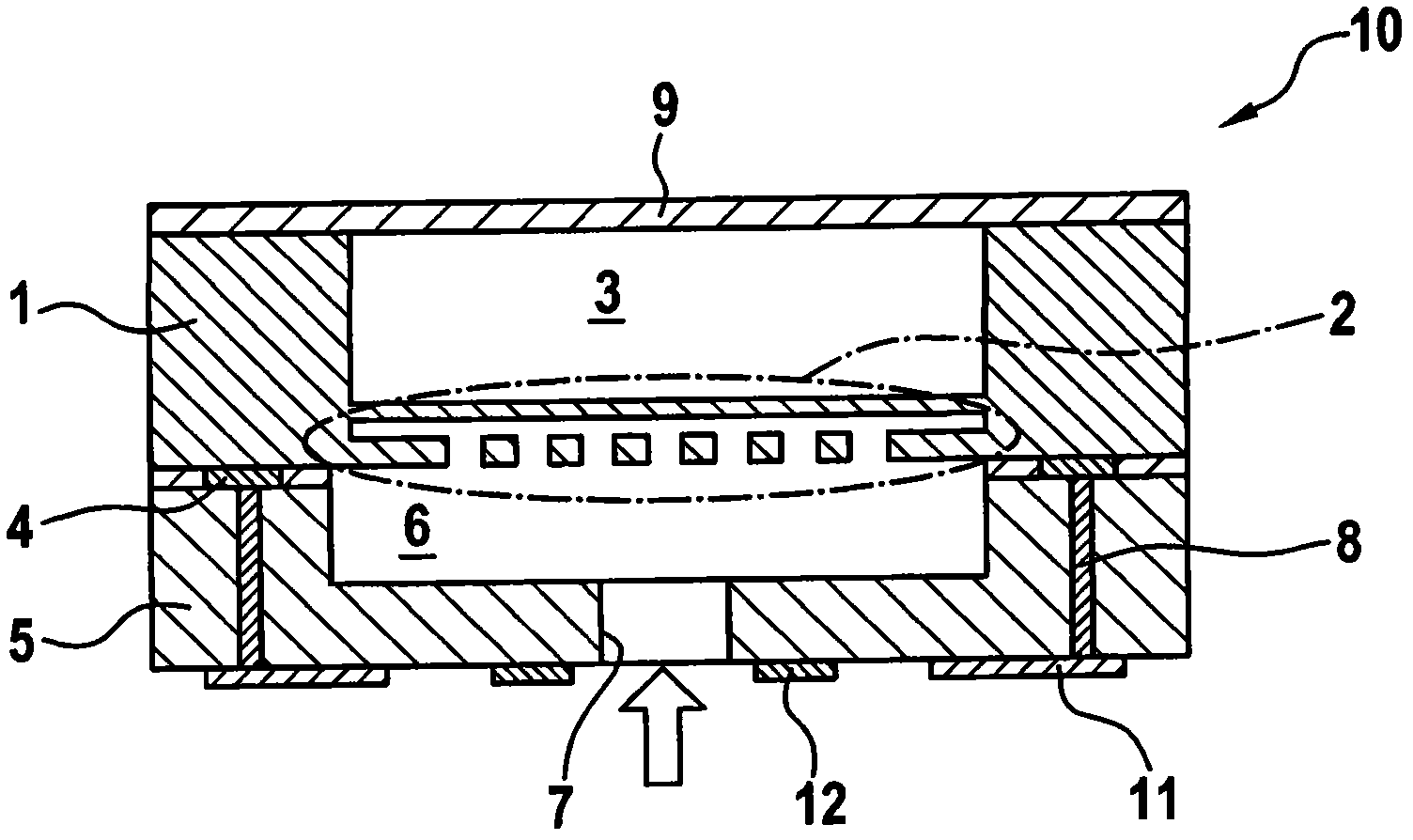

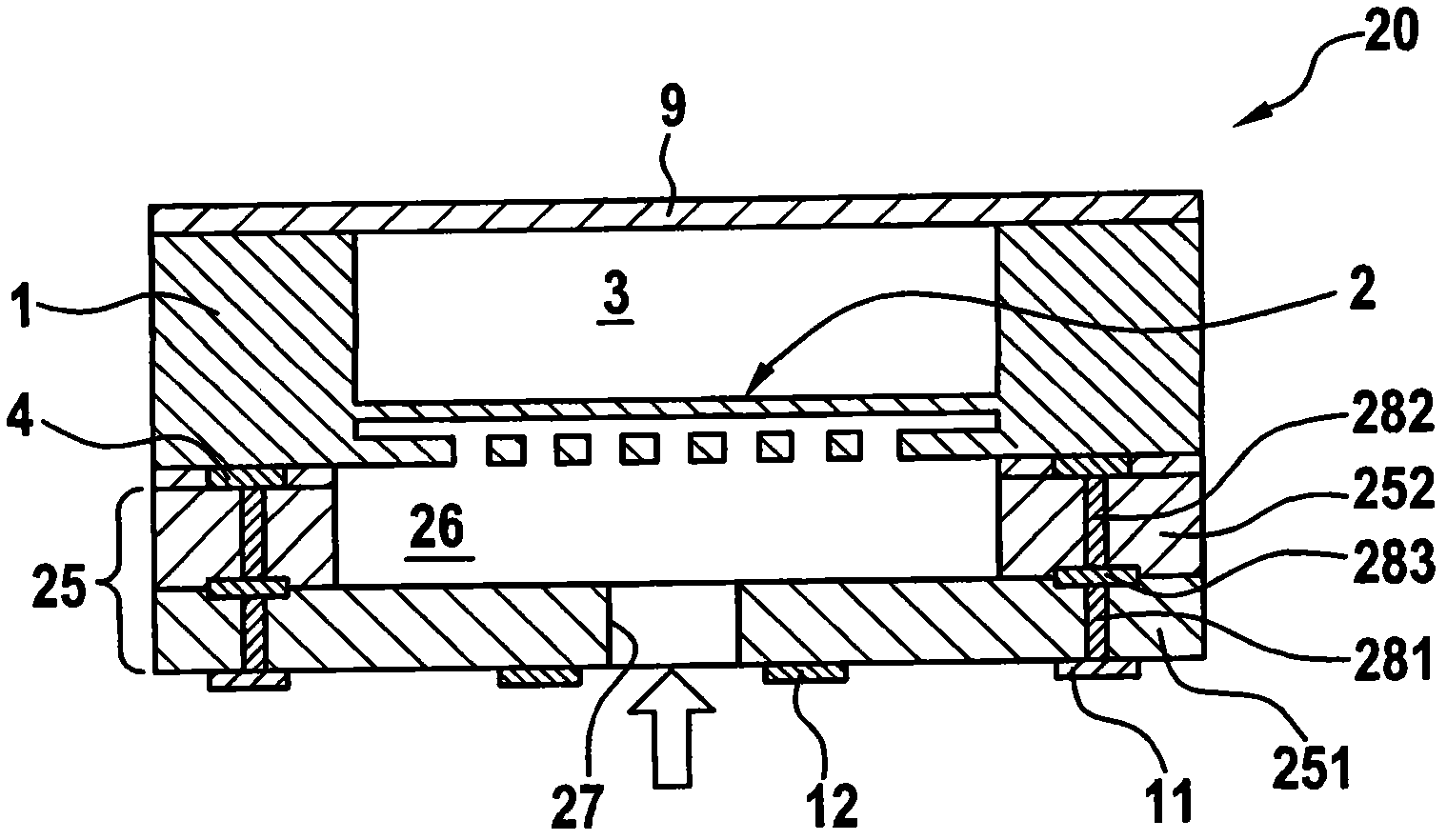

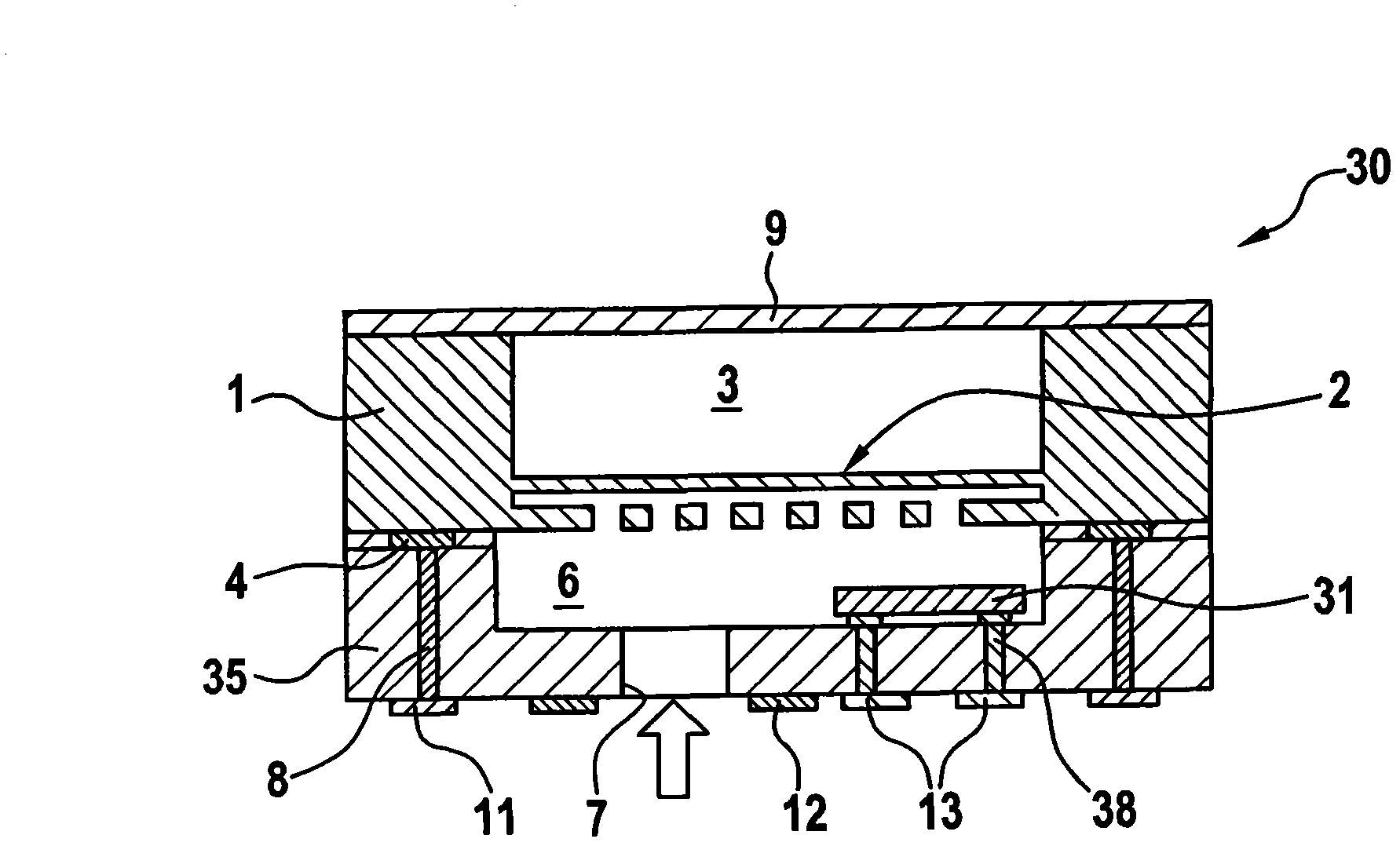

[0019] exist figure 1 The MEMS microphone package 10 shown in is implemented in the form of a wafer level package (WLP), ie in the form of a stack of wafers. The MEMS microphone package 10 includes a microphone component 1 , which is hereinafter referred to as a microphone chip 1 . A sound-sensitive membrane structure 2 in the form of a membrane with a counter-electrode is formed in the front side of the microphone chip 1 and covers the cavity 3 on the rear side of the chip. Usually there are also circuit elements on the front side of the microphone chip, but are not shown here for reasons of clarity. Only the electrical contacts 4 for signal transmission are shown.

[0020] Furthermore, the package 10 includes an interposer 5 which is arranged on the front side of the microphone chip 1 . A groove 6 is formed in the surface of the interposer 5 facing the microphone chip 1 , which groove extends over the entire diaphragm area. The interposer 5 can be, for example, a backsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com