Lithium slurry battery reactor

A slurry battery and reactor technology, applied in the direction of fuel cell additives, regenerative fuel cells, fuel cell components, etc., can solve the problems of increasing, lithium ion consumption, polarization internal resistance, etc., to increase the internal resistance of the battery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

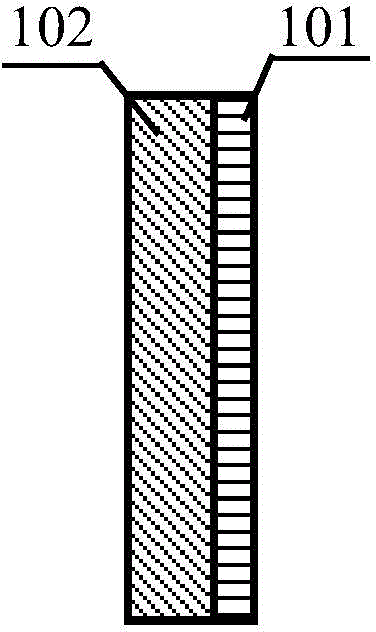

[0026] Such as figure 1 As shown, the unipolar separator includes a positive electrode porous collector layer 102 and a separator layer 101 , wherein the positive electrode porous collector layer 102 is located on one side of the separator layer 101 and is in close contact with the separator layer 101 . In this embodiment, the positive electrode porous collector layer 102 is a 200-mesh stainless steel mesh that can pass through lithium ions with a surface composite conductive carbon black, the isolation layer 101 is a polyethylene porous polymer separator, and the positive electrode porous collector layer 102 and The isolation layer 101 is fixed at the edge by bonding.

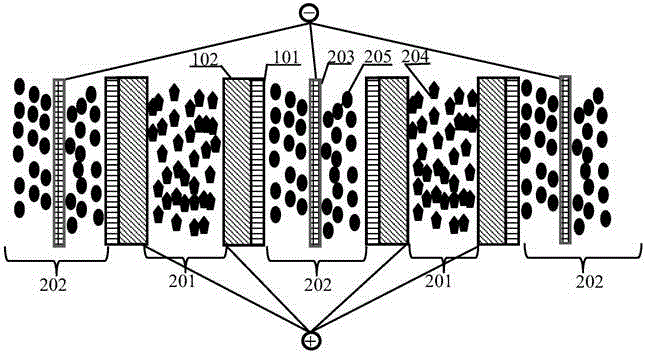

[0027]as attached figure 2 As shown, several unipolar separators are stacked sequentially according to the order in which the isolation layer 101 is placed relative to the isolation layer 101, wherein the gap between two adjacent positive electrode porous collector layers 102 constitutes the positive electro...

Embodiment 2

[0030] The structure of the battery reactor is the same as in Example 1. The difference is:

[0031] The unipolar separator in this embodiment is composited by bonding the positive electrode porous current collector layer 102 and the separator layer 101 through edge positions;

[0032] The unipolar separator is compounded with a polyethylene porous membrane with a thickness of 10um on the outside of the isolation layer;

[0033] The positive electrode porous current collector layer 102 is a porous mixture composed of conductive carbon black and a binder, wherein the mass fraction of conductive carbon black is 80%;

[0034] The isolation layer 101 is polypropylene material;

[0035] The negative electrode current collector 203 is carbon fiber conductive cloth;

[0036] The cavity heights of the positive electrode reaction chamber 201 and the negative electrode reaction chamber 202 are both 5mm;

[0037] In this embodiment, the positive electrode slurry 204 is an organic ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com