Production equipment of multi-H-shaped coarse-denier porous POY filament and manufacturing method thereof

A production equipment and a coarse denier technology, which are applied to the production equipment and the field of preparation of multi-H-shaped coarse denier porous POY filaments, can solve the problems of slow heating speed, increased melt waste discharge consumption, long discharge time, etc., and achieve accurate Control and balance uniform temperature, reduce the number of heat medium additions, good hair-like effect and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

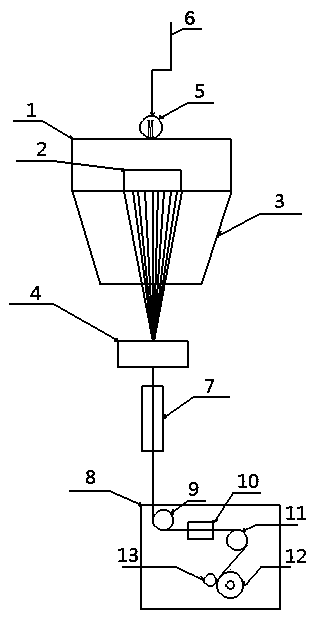

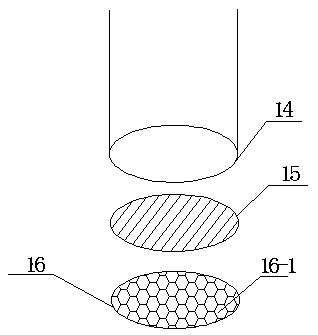

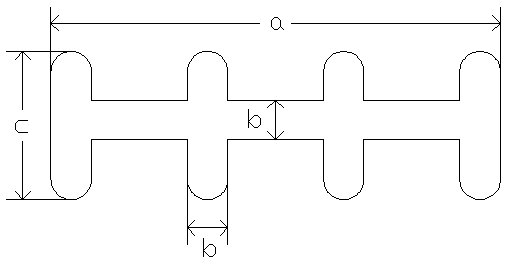

[0038] Such as Figure 1 to Figure 7 As shown, a method for preparing multi-H-shaped coarse denier porous POY yarns is produced by the above-mentioned production equipment, and specifically includes the following steps: passing the molten polyester melt through the melt pipeline of one of the heat medium pipeline system devices into each In the spinning box, the melt entering each spinning box is accurately metered by the corresponding metering pump, and then flows into each spinning assembly through the melt pipeline of another heat medium pipeline system device, and then passes through the sand cup in turn. The metal sand, filter screen, twill net and spinneret hole of the spinneret are extruded into primary fibers, and the primary fibers are cooled and formed by the ring blowing cooling device. The temperature of the cooling air in the ring blowing cooling device is 19°C and the humidity is 75%. , the pressure is 30Pa, and after the completion, the oiling device is clustere...

Embodiment 2

[0040] Such as Figure 1 to Figure 7 As shown, a method for preparing multi-H-shaped coarse denier porous POY yarns is produced by the above-mentioned production equipment, and specifically includes the following steps: passing the molten polyester melt through the melt pipeline of one of the heat medium pipeline system devices into each In the spinning box, the melt entering each spinning box is accurately metered by the corresponding metering pump, and then flows into each spinning assembly through the melt pipeline of another heat medium pipeline system device, and then passes through the sand cup in turn. The metal sand, filter screen, twill net and spinneret hole of the spinneret are extruded into primary fibers, and the primary fibers are cooled and formed by the ring blowing cooling device. The temperature of the cooling air in the ring blowing cooling device is 19°C and the humidity is 85%. , the pressure is 45Pa, and after the completion, the oiling device is clustere...

Embodiment 3

[0042] Such as Figure 1 to Figure 7 As shown, a method for preparing multi-H-shaped coarse denier porous POY yarns is produced by the above-mentioned production equipment, and specifically includes the following steps: passing the molten polyester melt through the melt pipeline of one of the heat medium pipeline system devices into each In the spinning box, the melt entering each spinning box is accurately metered by the corresponding metering pump, and then flows into each spinning assembly through the melt pipeline of another heat medium pipeline system device, and then passes through the sand cup in turn. The metal sand, filter screen, twill net and spinneret hole of the spinneret are extruded into primary fibers, and the primary fibers are cooled and formed by the ring blowing cooling device. The temperature of the cooling air in the ring blowing cooling device is 19°C and the humidity is 80%. , the pressure is 40Pa, and after the completion, the oiling device is clustere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com