Patents

Literature

77results about How to "Conducive to subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

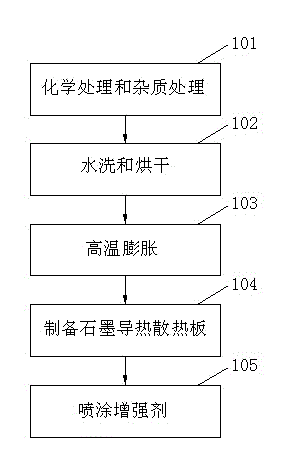

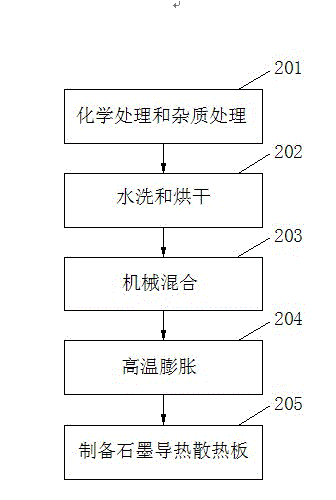

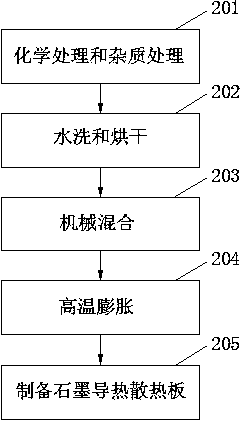

Method for preparing high-thermal conductivity graphite radiating fins

InactiveCN101951751ANo pollution in the processNo sheddingCooling/ventilation/heating modificationsStrong acidsPhysical chemistry

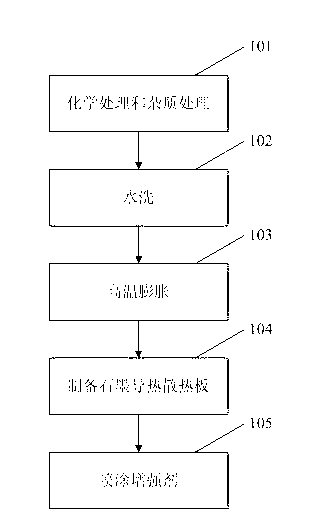

The invention provides a method for preparing high-thermal conductivity graphite radiating fins. The method comprises the following steps of: a, soaking graphite powder serving as a raw material in acid treatment solution obtained by mixing sulfuric acid and hydrogen peroxide at the temperature of between 20 and 100 DEG C for 20 to 120 minutes; or treating the graphite powder by a high-temperature purification method; or soaking the graphite powder in mixed solution obtained by mixing fluorides and strong acid for 20 to 150 minutes; b, washing the treated graphite powder until the pH value is 5 to 6.5; c, putting the washed graphite powder into a graphite expansion furnace for expansion at the temperature of between 800 and 1,000 DEG C for 3 to 20 hours, and slowly cooling the graphite powder to room temperature; and d, in the mass ratio of the graphite powder to compound particles of 2-8:1, preparing the graphite radiating fins with the thickness of 0.05 to 5mm by using graphite coiled material manufacturing equipment.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

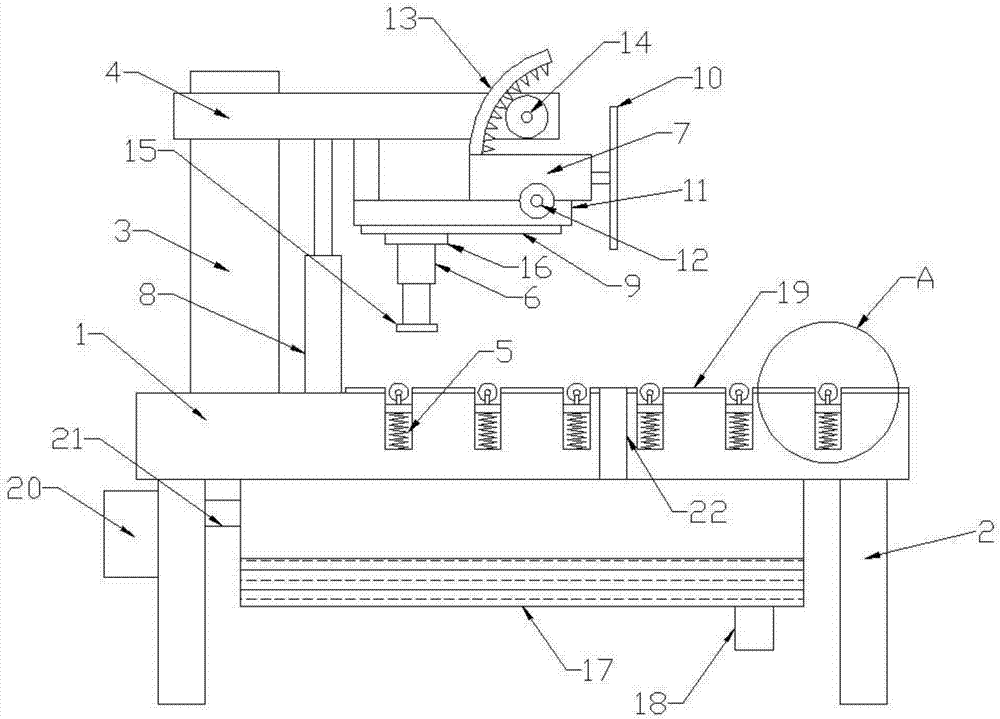

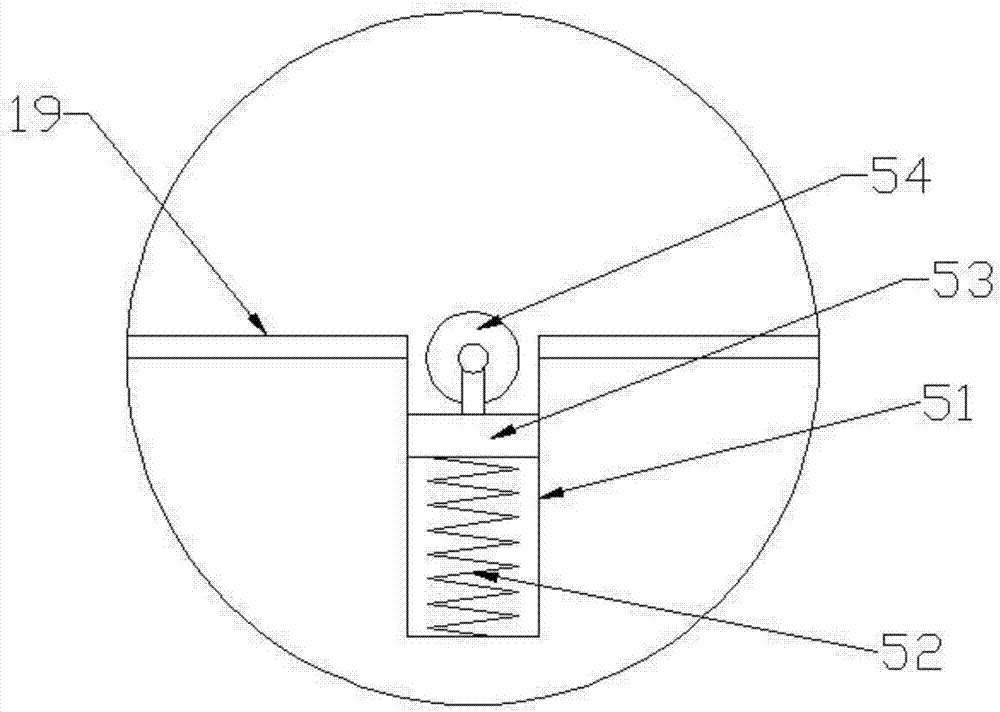

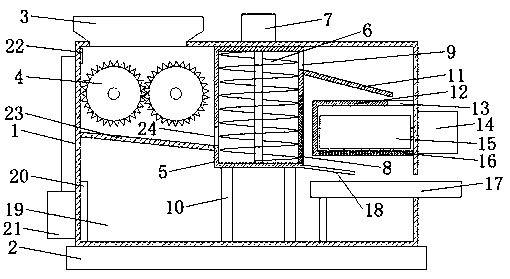

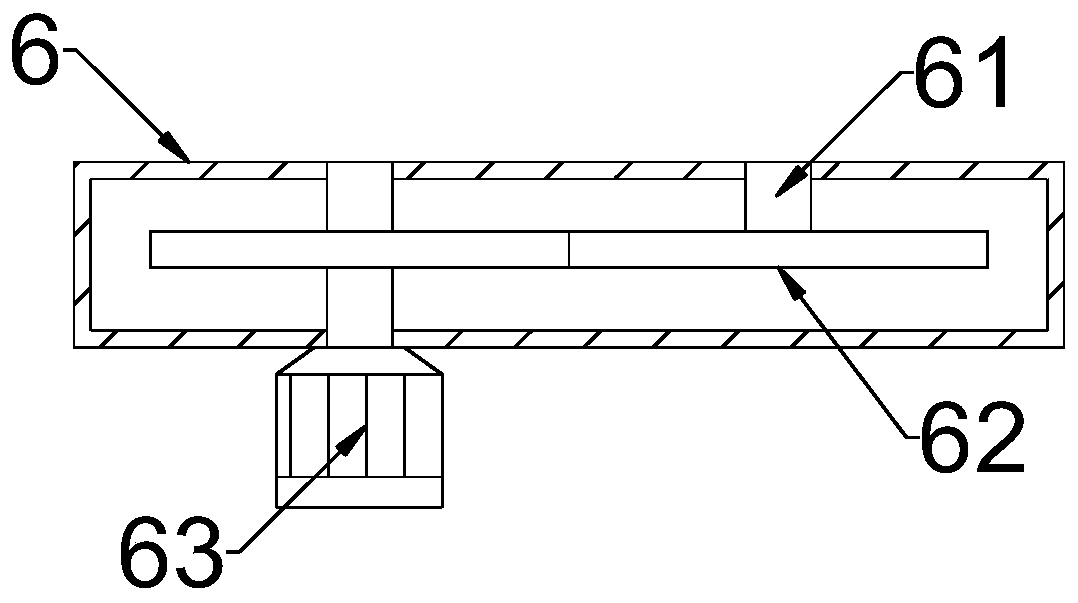

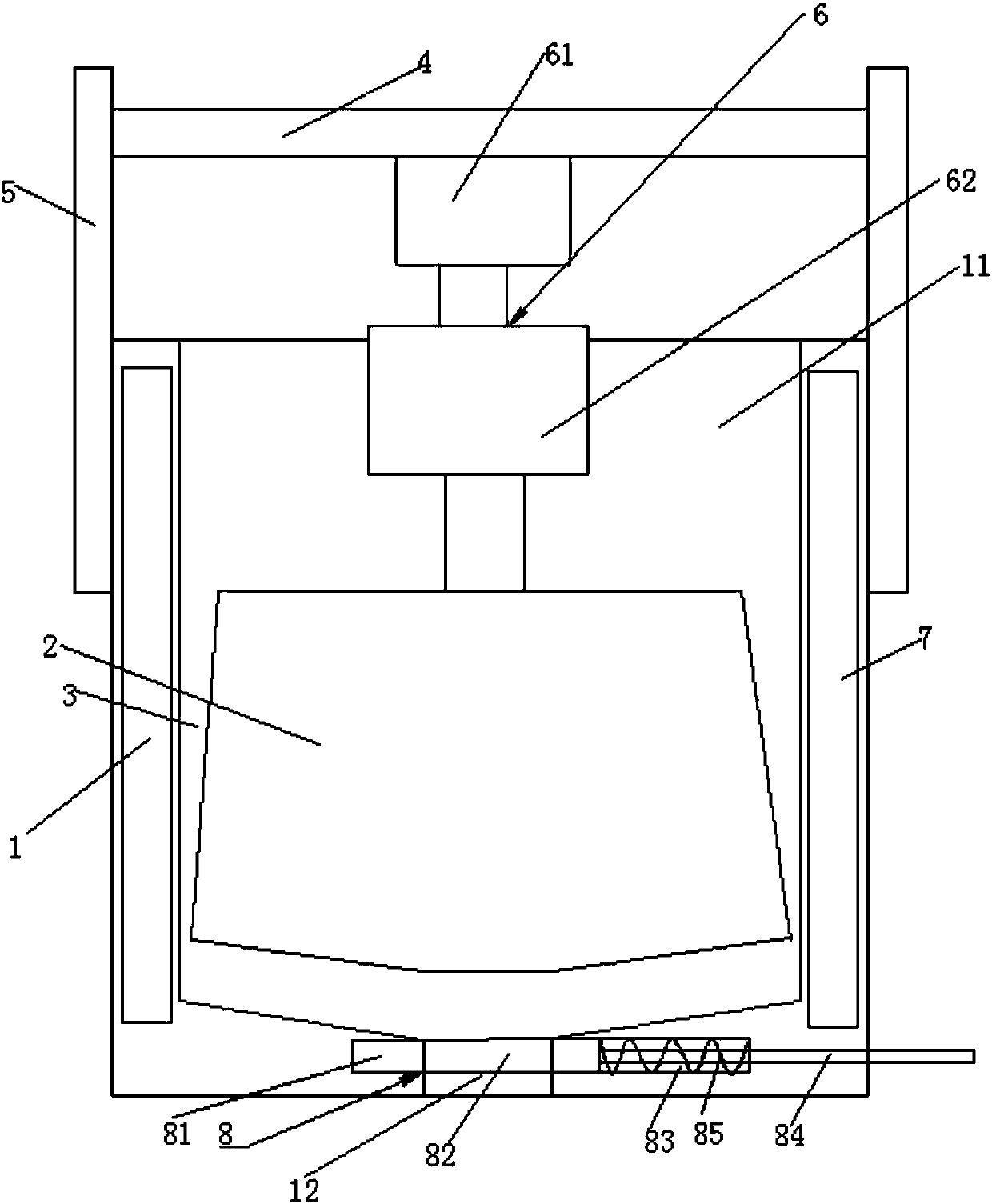

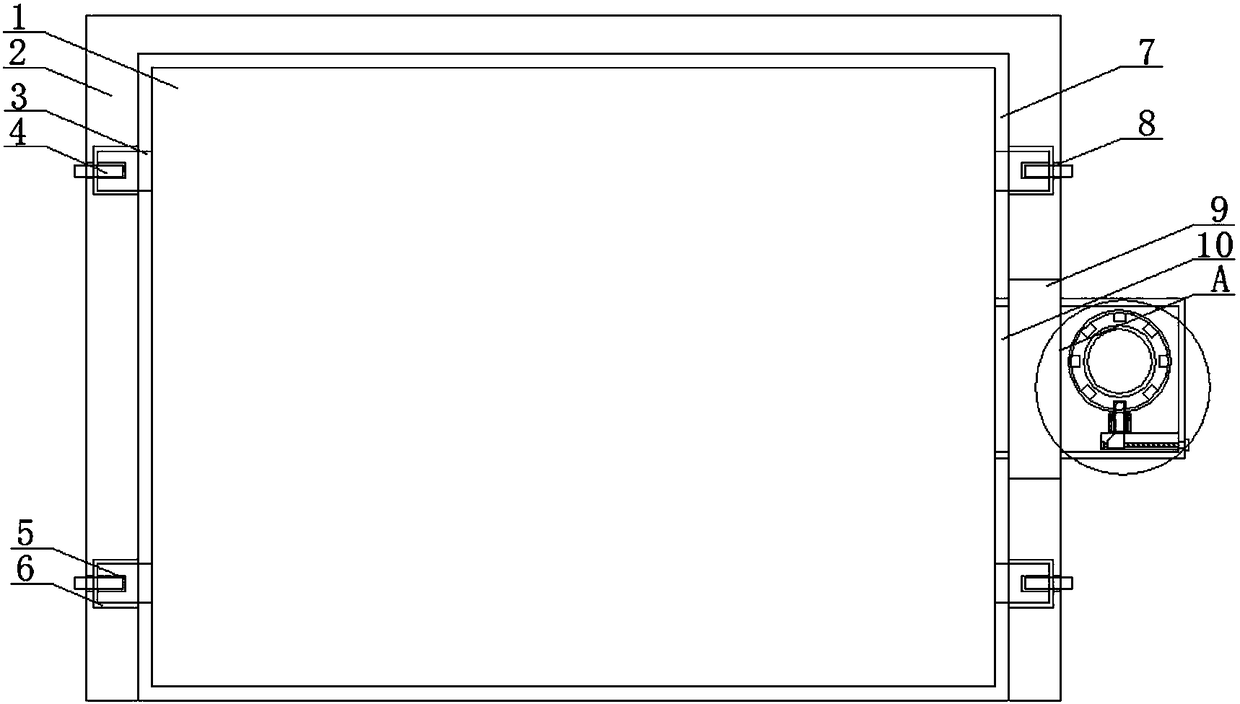

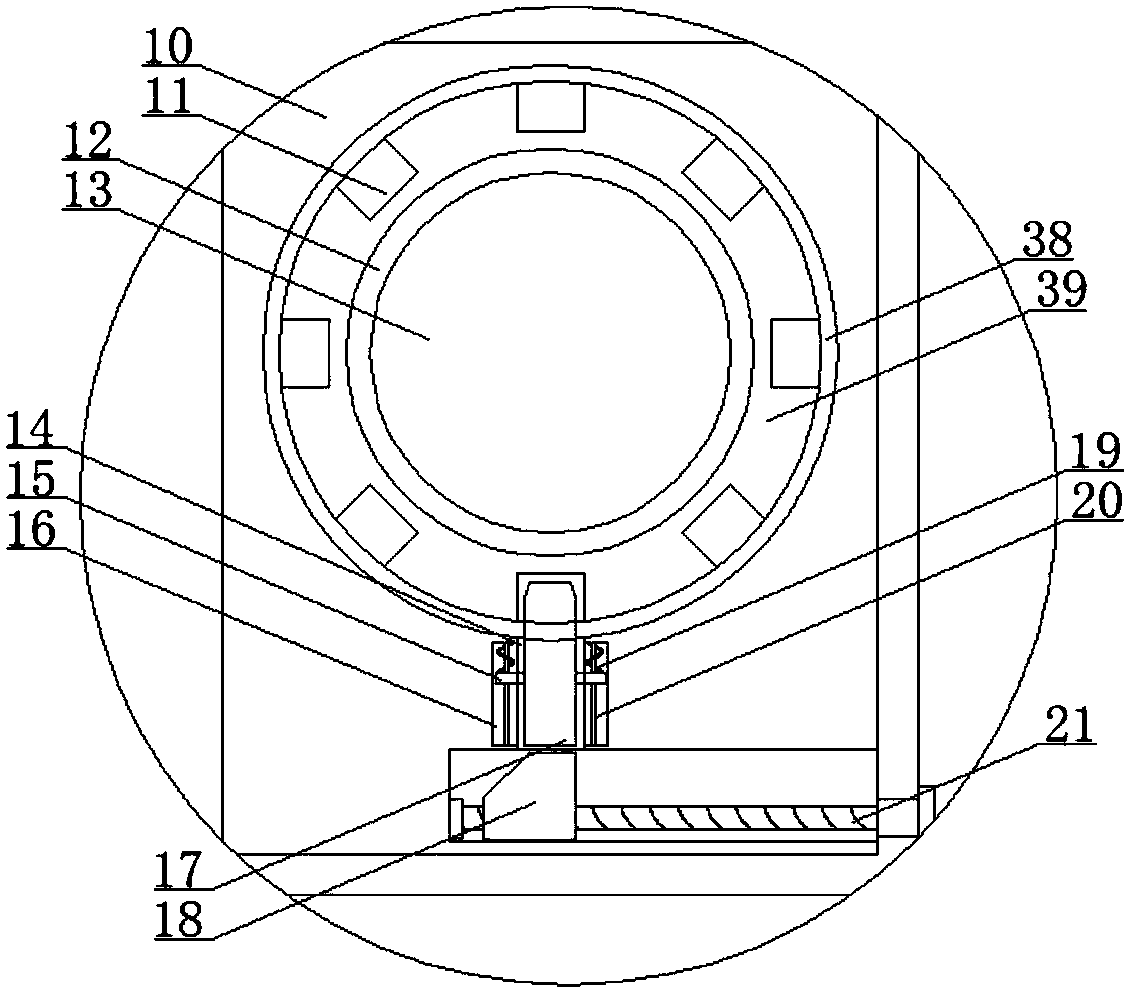

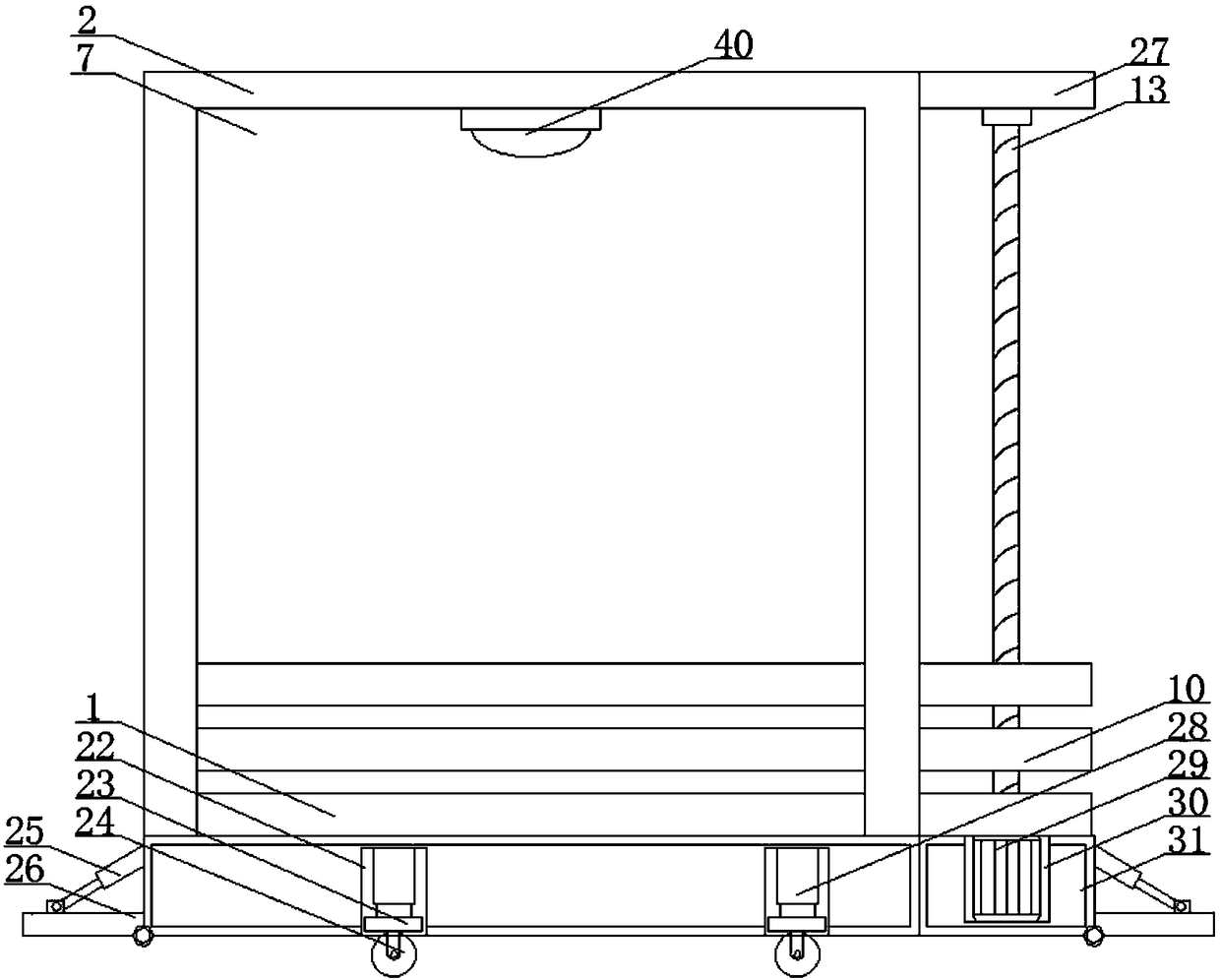

Angle-adjustable steel plate cutter

InactiveCN106964833ADoes not affect the fixedConducive to subsequent processingShearing machinesMaintainance and safety accessoriesGear driveSheet steel

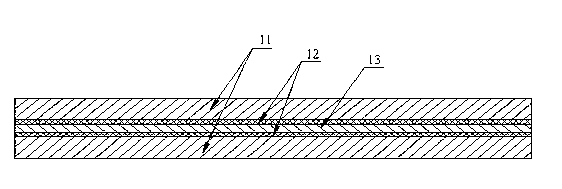

The invention discloses an angle-adjustable steel plate cutting machine, which comprises a platform, supporting legs, uprights and beams; a mounting frame is fixedly installed on the lower side of the beam; a rotating shaft is installed on the end of the mounting frame; ; The upper side of the motor is fixedly connected with an arc-shaped guide rod, and a plurality of equidistant teeth are arranged on the lower side of the guide rod, and a gear is connected through the meshing of the teeth, and a water tank is communicated below the cutting opening; Several supporting mechanisms are arranged on the platform and on both sides of the cutting opening, and the supporting mechanisms are composed of grooves, springs, supporting plates and guide wheels. The invention supports the steel plate through the support mechanism, so that the steel plate can easily move left and right on the platform, reducing the labor intensity of workers; the gear drives the guide rod to move, so that the motor rotates around the rotating shaft, and the cutting of the steel plate forms an angle with the horizontal plane. Surface cutting, so that the cutting machine has a variety of functions to meet more production needs.

Owner:惠安县鑫泰信息科技有限公司

Preparation method of heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin

InactiveCN102700230AImprove mechanical propertiesHigh strengthSemiconductor/solid-state device detailsSolid-state devicesFiberCarbon fibers

The invention provides a preparation method of a heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin, comprising the following steps of: pretreating graphite powder; processing the pretreated graphite powder by using graphite foil production equipment to prepare a graphite heat conducting and radiating plate; and spraying and sticking the graphite heat conducting and radiating plate and chopped graphite fiber, carbon fiber cloth or carbon fiber as a reinforcing agent by using a binder to prepare the heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin. The preparation method of the heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin is used for overcoming the defects such as low mechanical property, short service life, easiness for fall off and the like existing in the traditional preparation process; the mechanical strength and the purity of the heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin are greatly improved and the convenience is provided for the following machining; the heat-conducting fiber reinforced high-heat-conducting graphite heat radiating fin has the advantages of small weight, high intensity, high heat conducting property and the like; and the application range of a graphite sheet is expanded.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

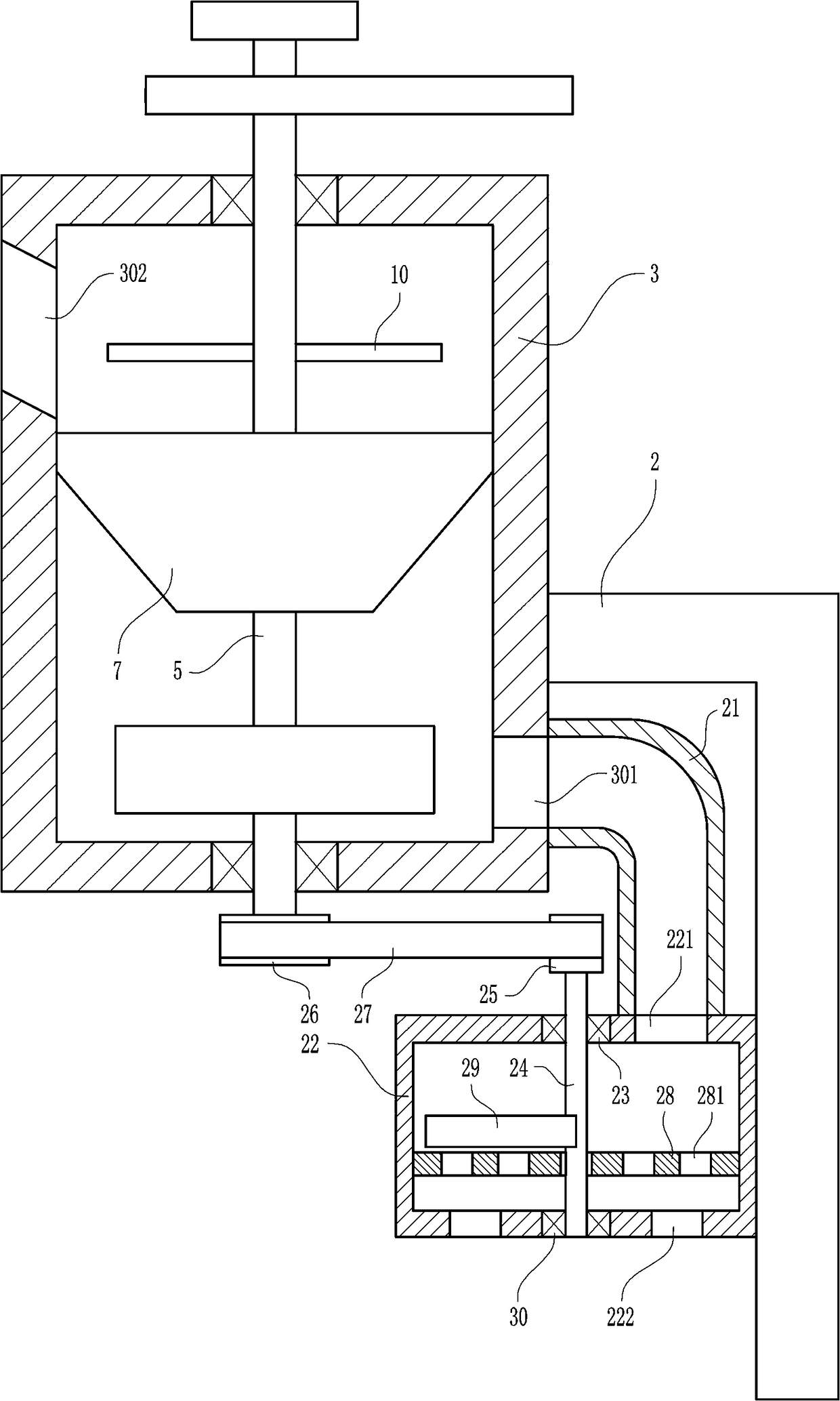

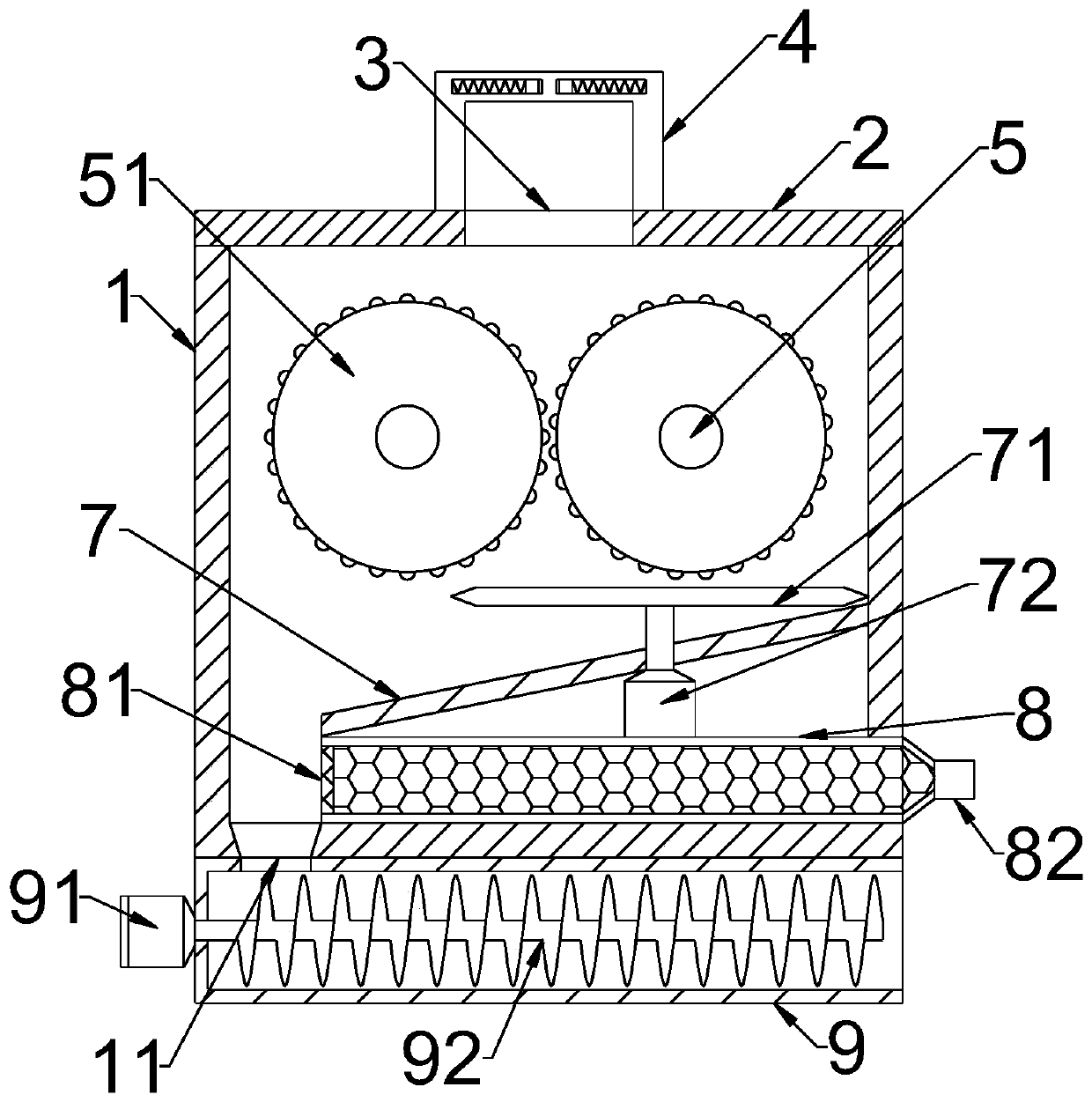

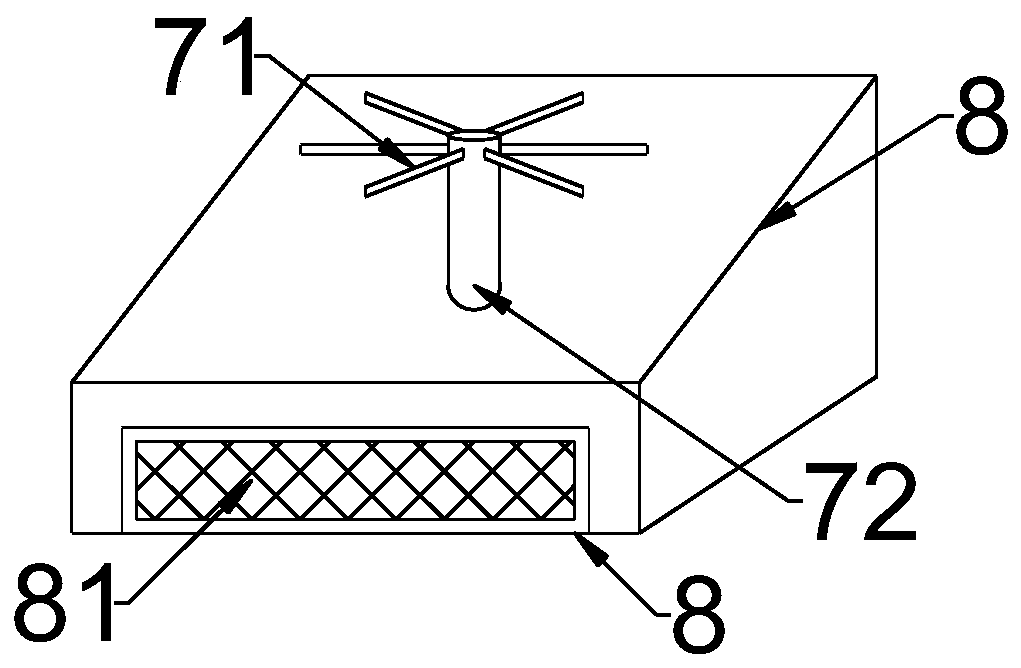

Waste carton recycling, reusing and crushing device

InactiveCN108855474AComplete and compact structural designCrush helpsCleaning using liquidsGrain treatmentsCartonHigh pressure

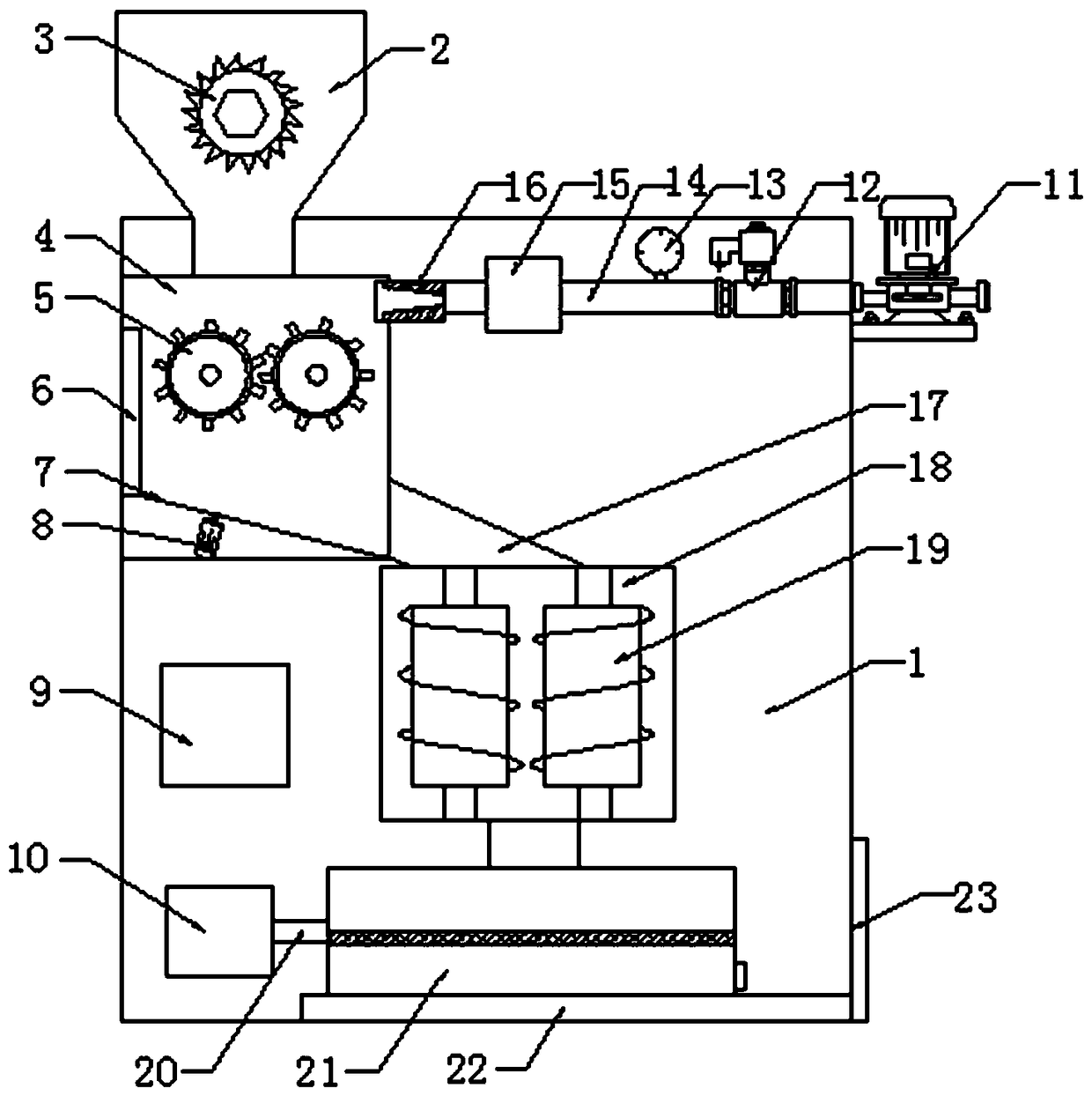

The invention discloses a waste carton recycling, reusing and crushing device. The waste carton recycling, reusing and crushing device comprises a box body, a waste paper input mouth and a collectionbox, the top of the box body is fixedly provided with the waste paper input mouth, the waste paper input mouth is internally and fixedly provided with a tear-up blade, a first crushing chamber is internally and parallelly provided with two crushing rollers, the bottom of the first crushing chamber is fixedly provided with an inclined plate, one side of the lower end of the first crushing chamber is provided with a transmission pipeline, the tail end of the transmission pipeline is connected with a second crushing chamber in a communicating manner, the second crushing chamber is internally andparallelly provided with two rolling shafts, the bottom end of the second crushing chamber is provided with a material outlet, the collection box is placed below the material outlet, the lower portionof the collection box is fixedly provided with a sliding rail, the side, away from an observation window, of the upper portion of the box body is provided with a high-pressure pump, the high-pressurepump is connected with the first crushing chamber through a water pipe, and the water pipe is provided with a high-pressure stop valve, a pressure gage, a pressure stabilizing box and a high-pressurenozzle in sequence. According to the waste carton recycling, reusing and crushing device, by means of the arrangements of the tear-up blade, the crushing rollers and the rolling shafts, waste cartonsare crushed more thoroughly, and the waste carton recycling, reusing and crushing device is reasonable in design and suitable for popularization and use.

Owner:东台市天时利包装有限公司

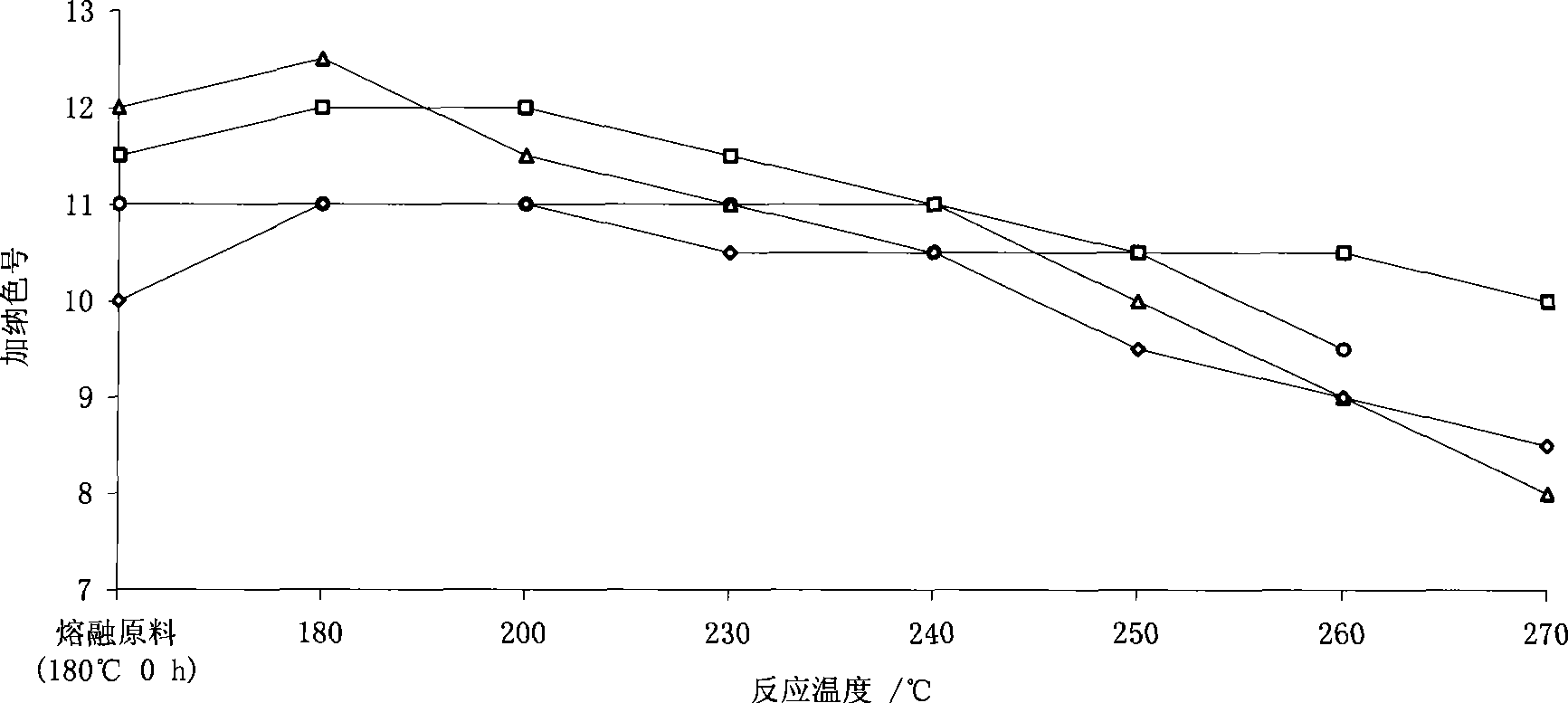

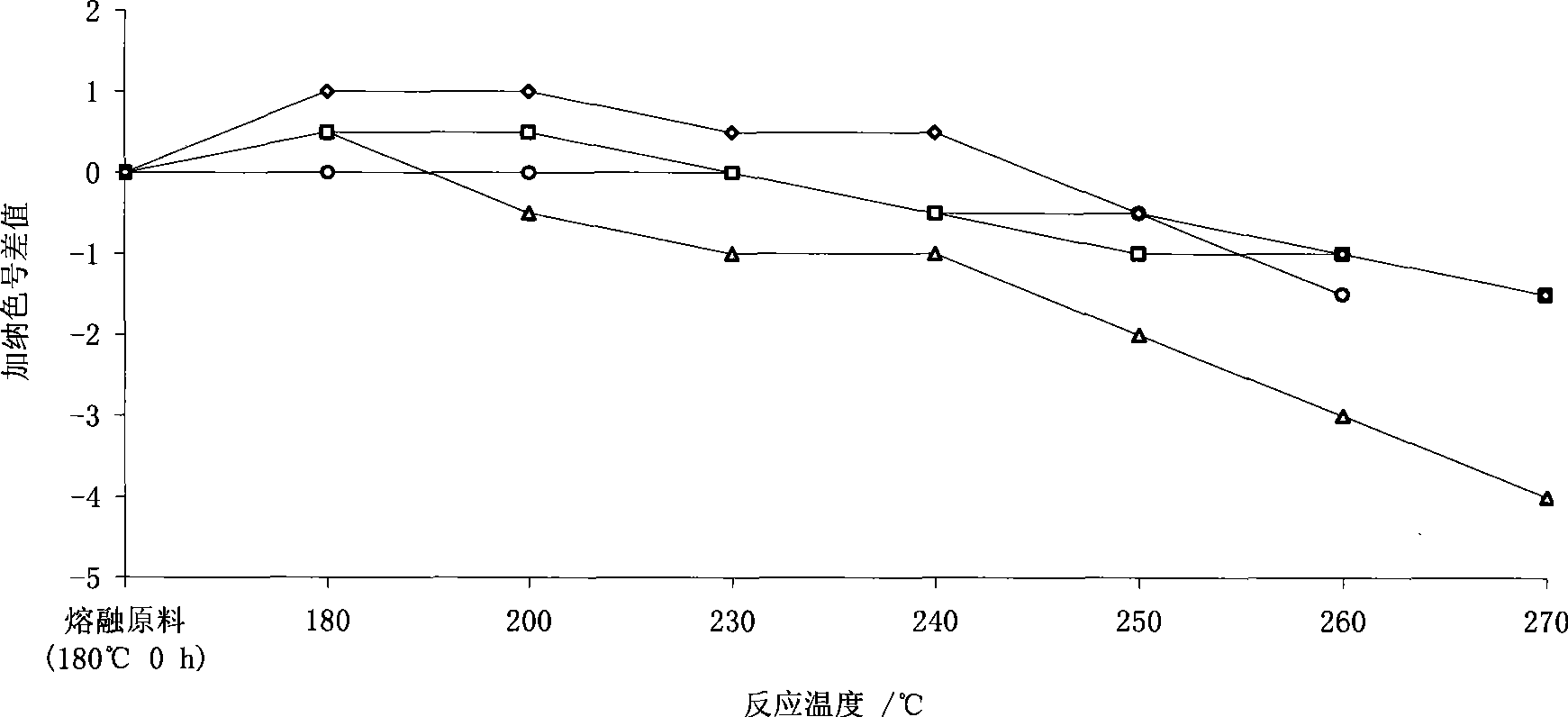

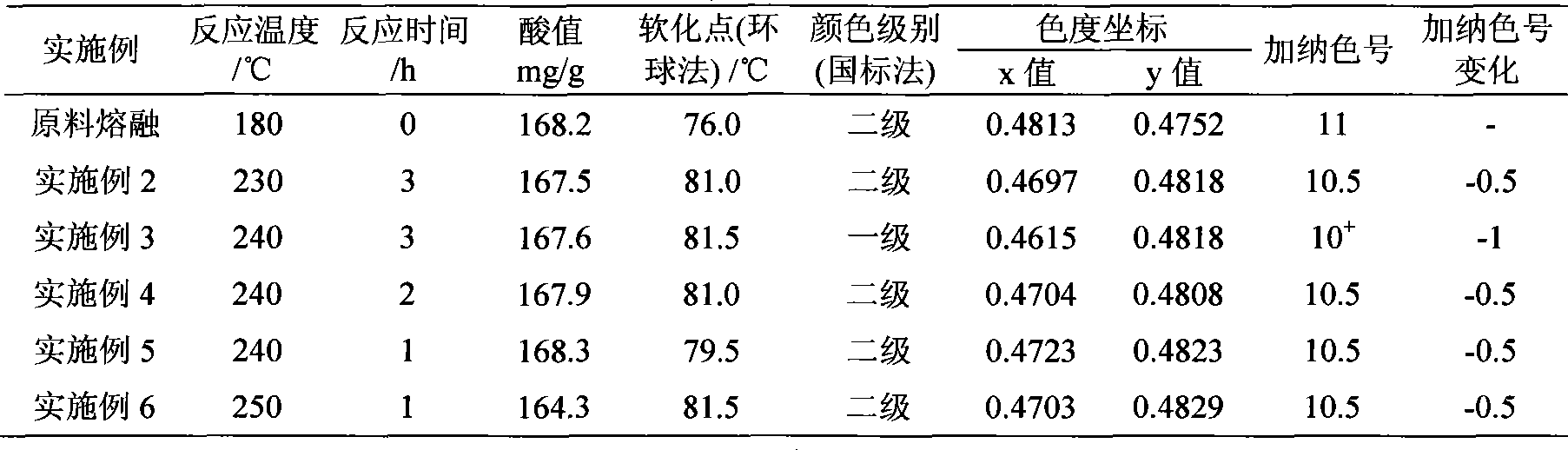

Method for decolorization preparation of pale rosin by rosin containing non-decoloring agent

The invention discloses a method used for preparing light-colored rosin by a rosin light-coloring way without adding decoloring agent, which is mainly characterized in that under the condition without the decoloring agent, colored composition in the rosin is decomposed by a thermo-chemical bleaching action, thus achieving the object of light-coloring decoloring of the rosin; namely, under the condition of protective gases such as nitrogen, and the like, the rosin keeps the temperature for a certain time at the temperature of 180-270 DEG C; after the reaction is finished, the rosin is cooled to the temperature below 180DEG C, and the light-colored rosin can be prepared by feeding. The color of the rosin prepared by the method is better than the raw material rosin; when being presented by Gardner color grade, the color of the product is shallower by 0.5-4 color grade than the initial color; the best color is equivalent to national standard special grade which is gained by lightening from national standard class 4; the light-colored rosin is not needed to be distilled in a high vacuum state, has simple and convenient operation, little energy consumption, low expense and high product yield, and has no adding of external additive composition; the gained light-colored rosin product is beneficial for the deep processing and utilization of the rosin, and is applicable to being directly taken as the raw material of various rosin resins.

Owner:湖南松本林业科技股份有限公司

Method for preparing honeysuckle flower extract by jointly adopting membrane separation and column chromatography

ActiveCN102391115AHigh content of active ingredientsConducive to subsequent processingCarboxylic acid esters separation/purificationMedicinal herbsChlorogenic acid

A method for preparing a honeysuckle flower extract by jointly adopting membrane separation and column chromatography includes the steps as follows: after preparation of filtrate A and filtrate B, membrane separation, ethanol recycling, column-giving sample-adding and impurity washing, eluting a macroporous resin column by ethanol in volume percentage concentration of 5%-25%, allowing the eluent to pass through a 700-Dalton membrane, conducting pressure reduction and concentration on membrane concentrate in the temperature of 50-80DEG C, and then conducting spray drying, thus obtaining a chlorogenic acid extract; and eluting the macroporous resin column by ethanol in volume percentage concentration of 55%-85%, conducting pressure reduction and concentration on the eluent in the temperature of 50-80DEG C, and then conducting spry drying, thus obtaining a flavone extract. Compared with the prior art, the method adopts the membrane separation technology and the column chromatography technology jointly to prepare the honeysuckle flower extract and can obtain the chlorogenic acid extract and the flavone extract in the honeysuckle flower simultaneously; and the method has such advantages as follows: the utilization rate of medicinal materials is high and the content of the obtained active ingredients is high, so that the subsequent processing and using are facilitated; and the method is simple in technology, low in energy consumption during operation, and convenient for large-scale industrial production and popularization.

Owner:GUANGDONG APOLLO GRP

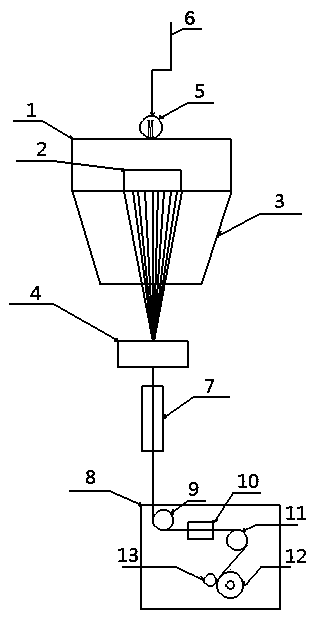

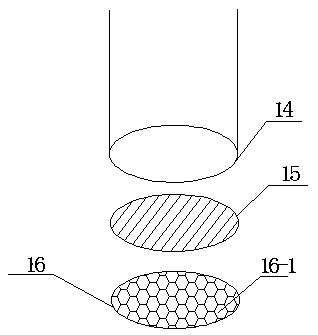

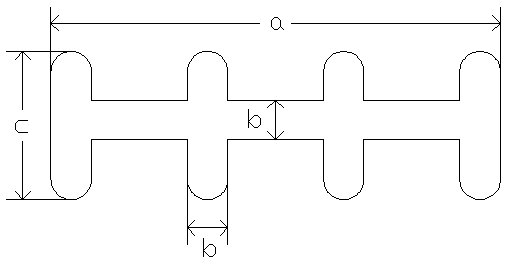

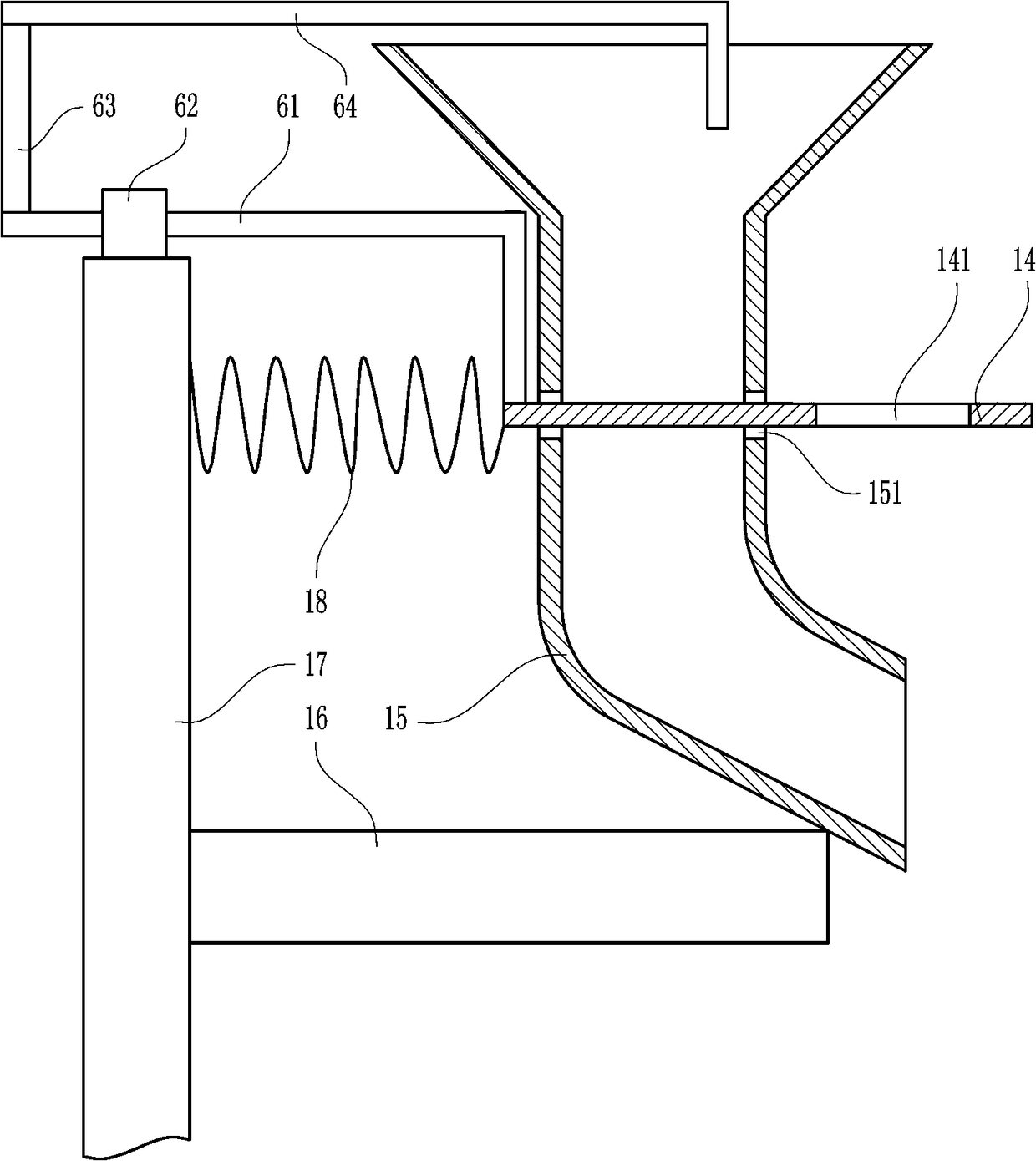

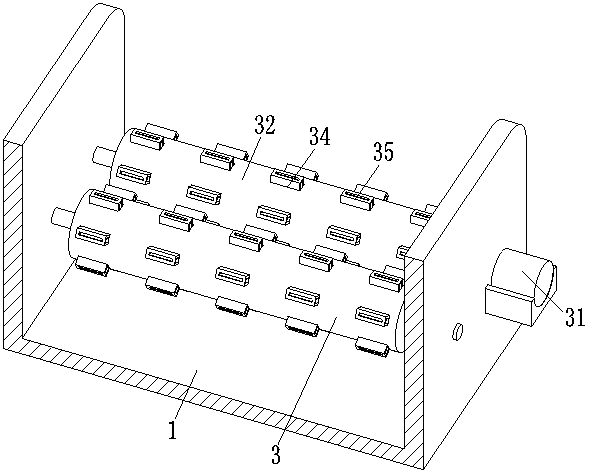

Production equipment of multi-H-shaped coarse-denier porous POY filament and manufacturing method thereof

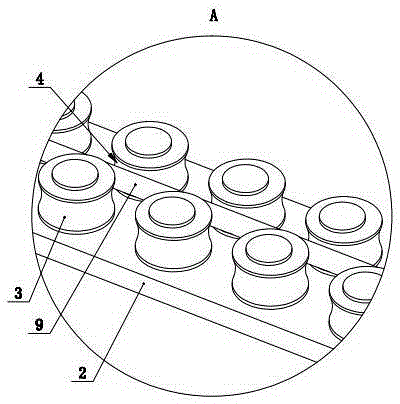

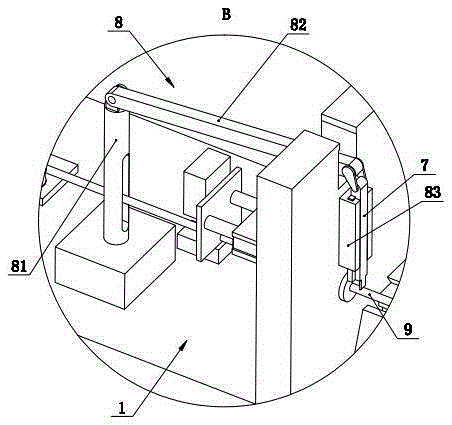

InactiveCN109137109ANovel structural designReduce unevennessSpinning head liquid feederArtificial thread manufacturing machinesPolyesterWinding machine

The invention discloses the production equipment of a multi-H-shaped coarse-denier porous POY filament and a manufacturing method thereof. The production equipment comprises spinning box bodies, a ring blowing cooling device, an oiling device, a spinning channel, a winding machine and a plurality of heating medium pipeline system devices used for melt conveying in a spinning process, wherein the spinning box bodies, the ring blowing cooling device, the oiling device, the spinning channel and the winding machine are successively arranged from top to bottom. The manufacturing method comprises the following steps of using the above production equipment to produce; making molten polyester melt pass through the melt pipes of the heating medium pipeline system devices to enter into each spinningbox body; after passing through a metering pump and a spinning component, extruding a nascent fiber; and passing through the ring blowing cooling device, the oiling device and the spinning channel, finally winding into a spinning cake. A temperature in the spinning box bodies can be rapidly increased, and the temperature can be accurately controlled, balanced and uniformed, product quality is ensured, energy consumption is reduced, and production efficiency and the abnormity degree of products are increased, which is good for rear channel processing.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Crushing device for medical waste glass medicine bottles

InactiveCN108787041ACause some damagesImprove crushing effectGrain treatmentsMedical wasteMedical treatment

The invention relates to a crushing device for medical medicine bottles, in particular to the crushing device for the medical waste glass medicine bottles and aims to achieve the technical effect of providing the crushing device for the medical waste glass medicine bottles, wherein the crushing device is simple and convenient in operation, small in labor intensity, safe and reliable. According tothe technical implementation scheme, the crushing device for the medical waste glass medicine bottles comprises a base, an L-shaped supporting plate, a big barrel body, a first bearing, a big rotatingshaft, a stirring plate, a conical funnel, a first crushing rod, a second crushing rod, a third crushing rod and the like. The L-shaped supporting plate is located on the base and is connected with the base, and the big barrel body is located on the left side of the L-shaped supporting plate and is connected with the L-shaped supporting plate. The crushing device for the medical waste glass medicine bottles provided by the invention is simple and convenient in operation, small in labor intensity, safe and reliable in performance, time-labor saving, high in crushing efficiency, good in effect,simple in structure, easy to maintain and repair, low in maintenance and repair cost and easy to produce and manufacture.

Owner:HEBI CITY PEOPLES HOSPITAL

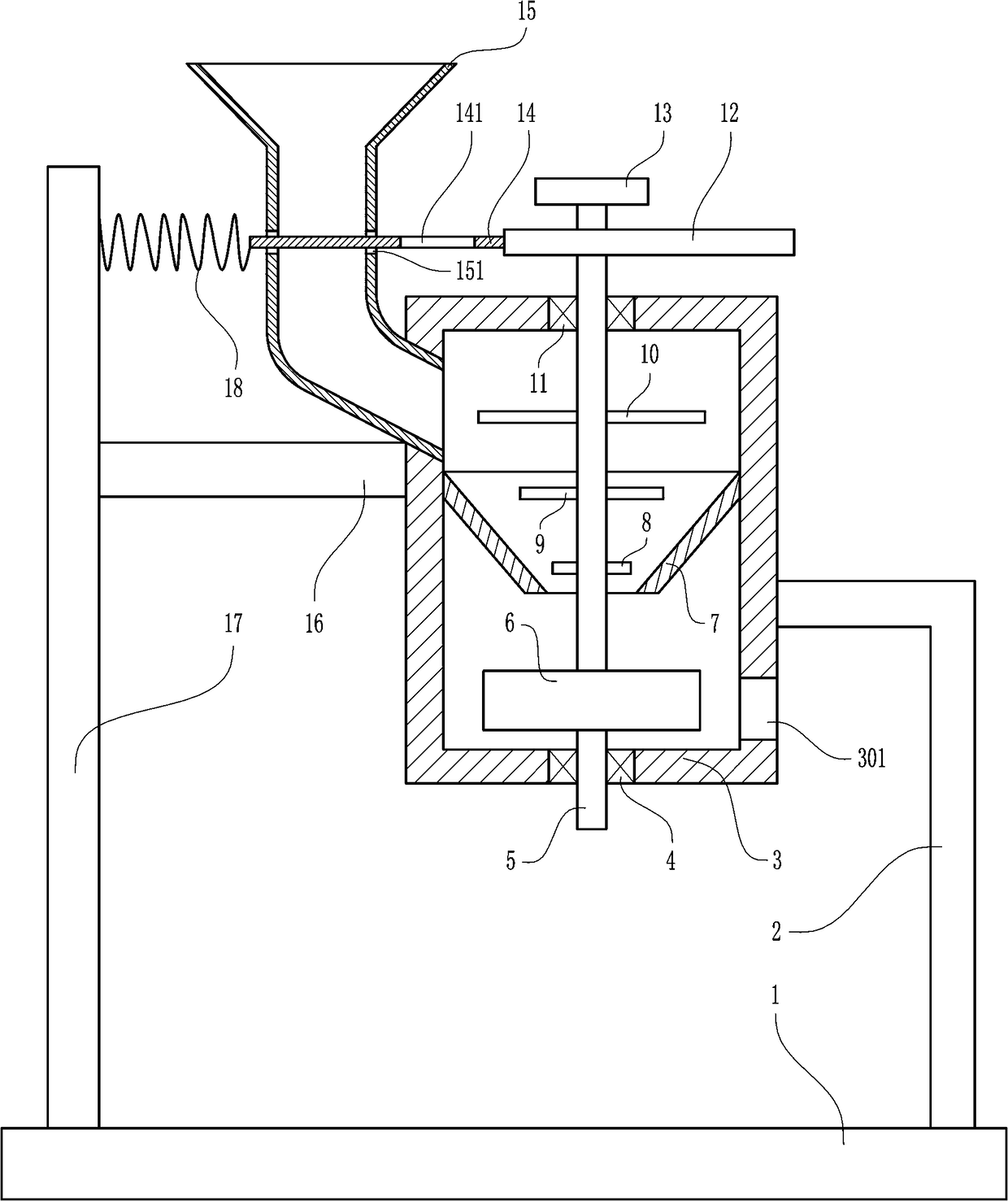

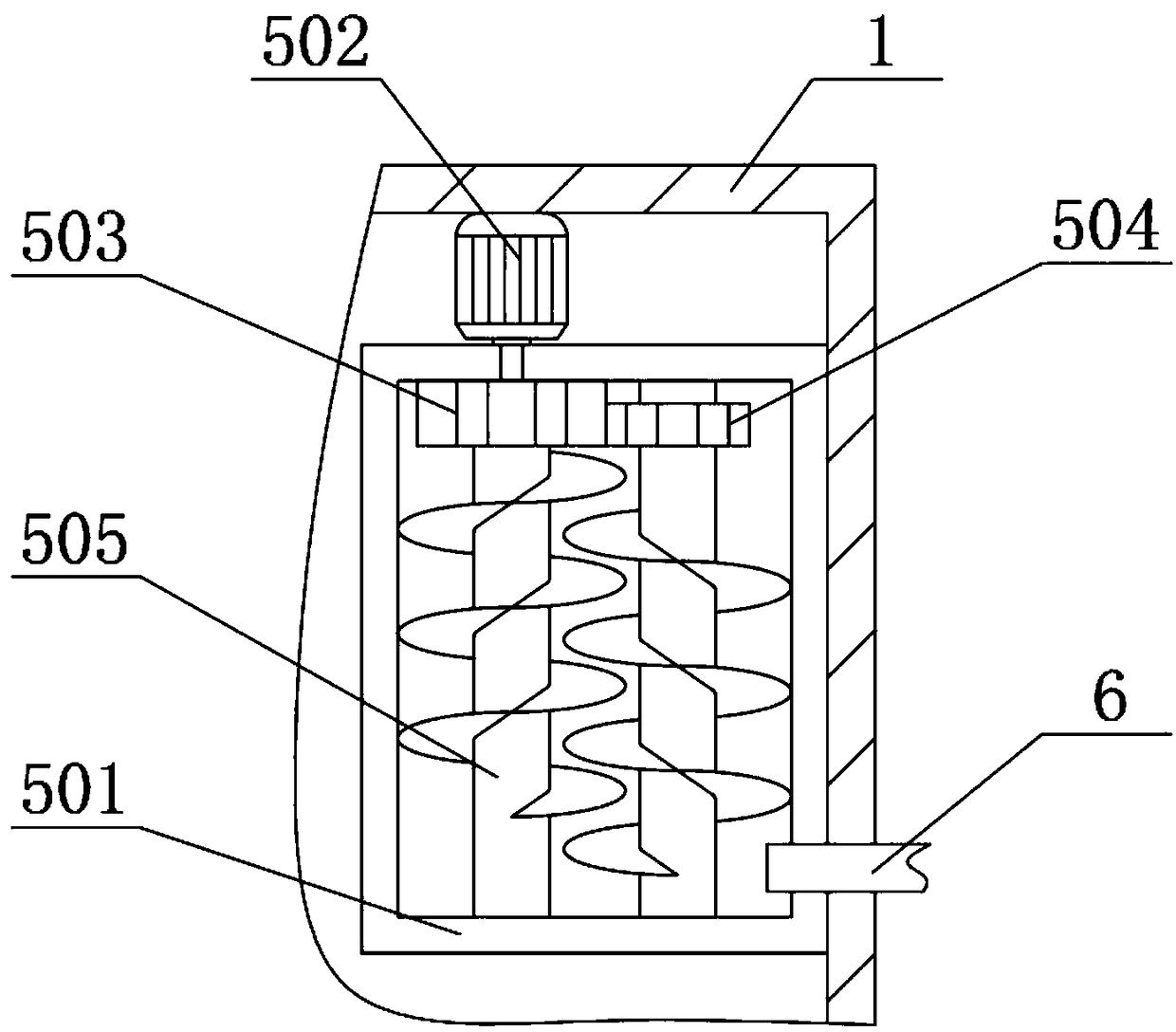

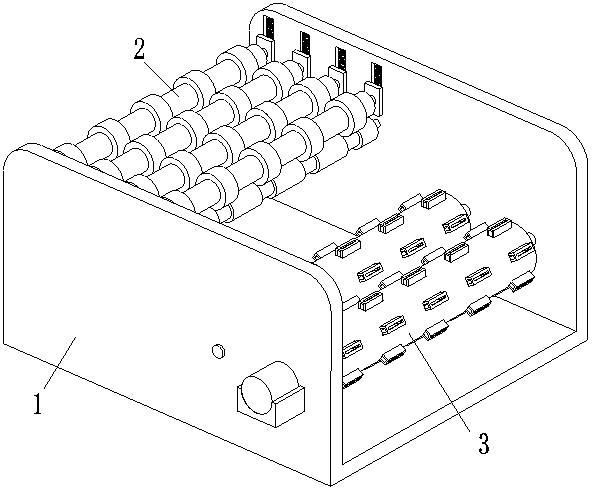

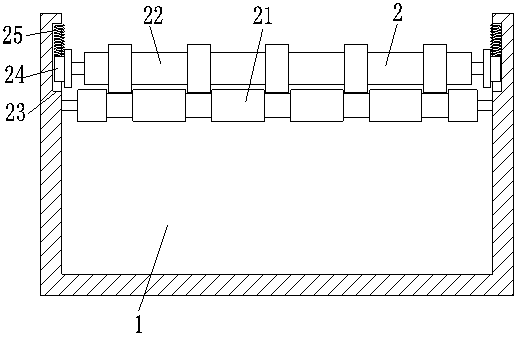

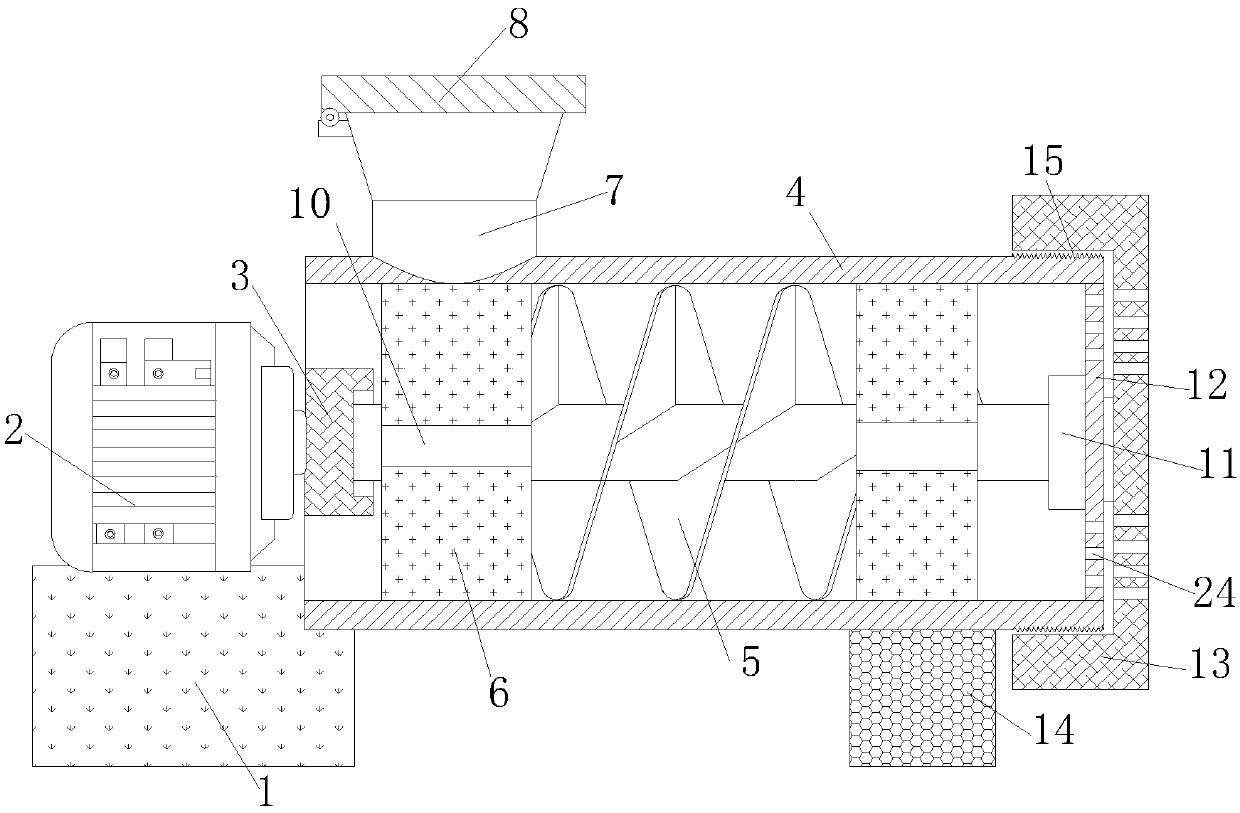

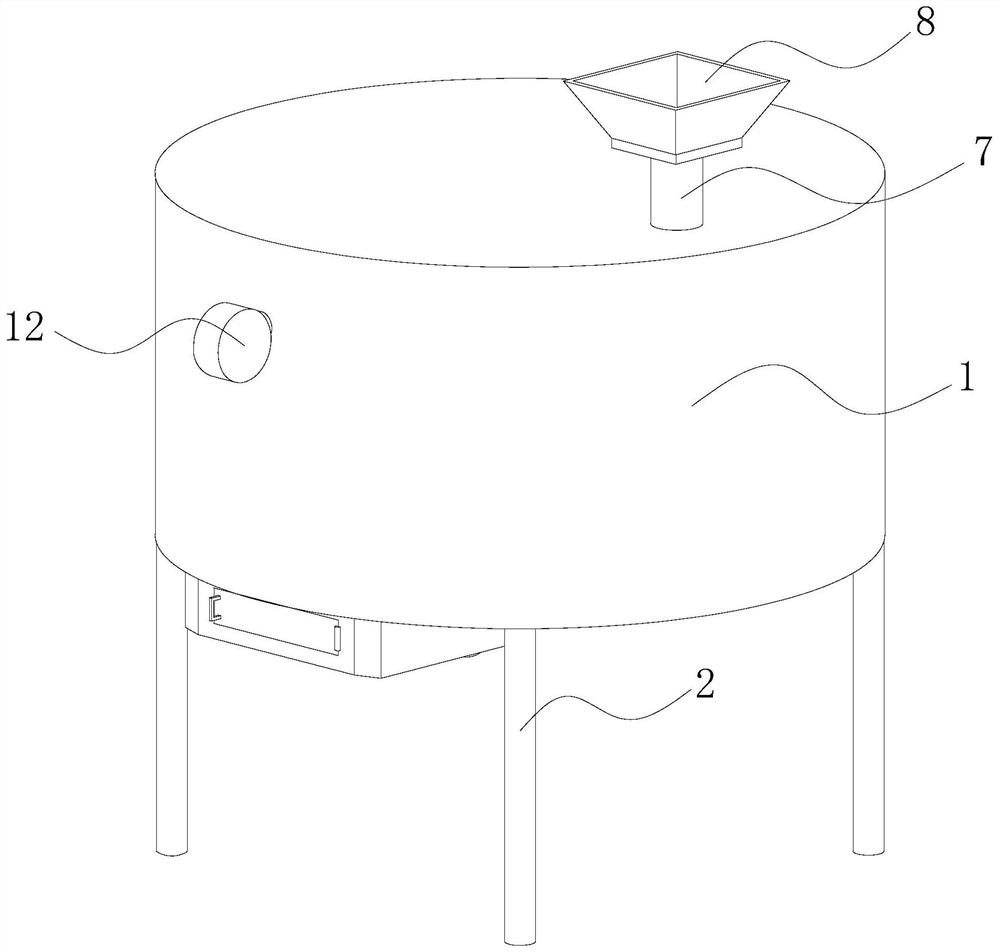

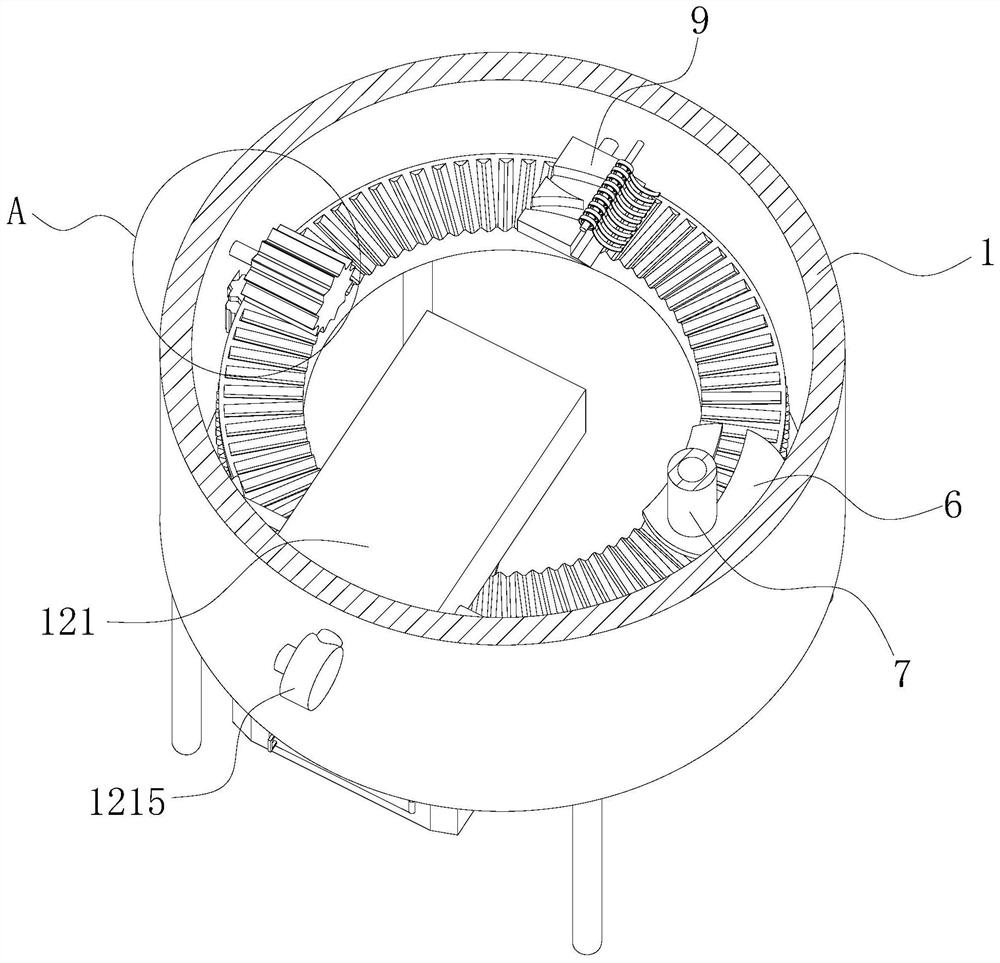

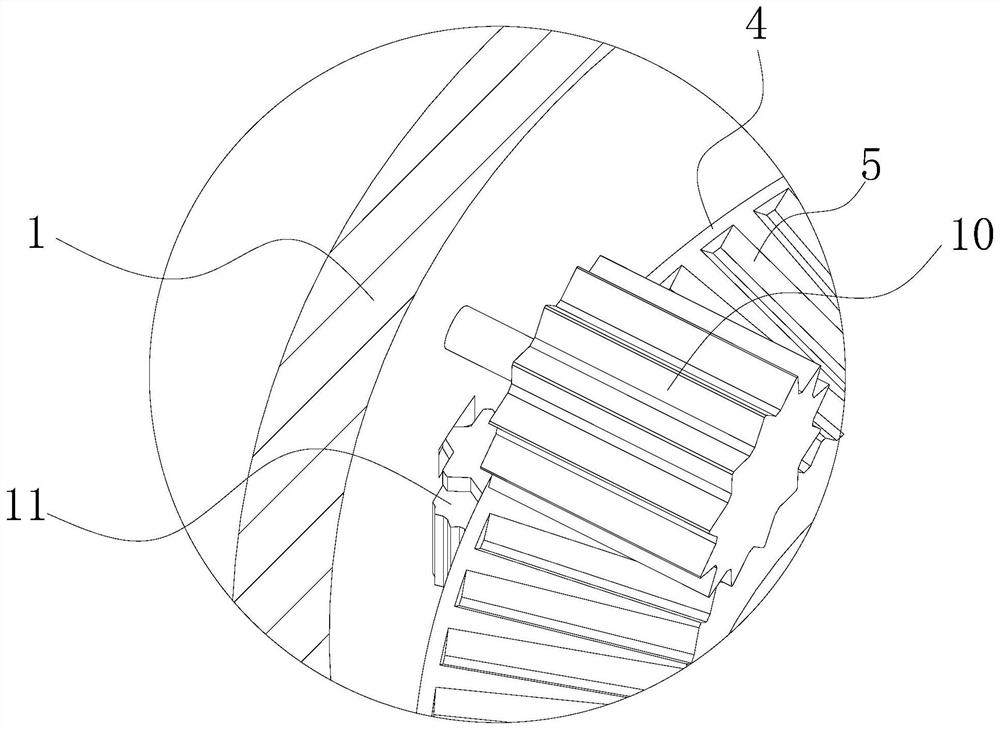

Grinding device for production and manufacture of panax notoginseng powder

InactiveCN109317288AEasy to cleanImprove work efficiencySievingScreeningPANAX NOTOGINSENG ROOTEngineering

The invention relates to the technical field of medicine manufacture and especially relates to a grinding device for production and manufacture of panax notoginseng powder. The device provided by theinvention comprises a box body and a feeding hopper, wherein the top end of the box body communicates with the feeding hopper; a washing device, a drying device and a grinding device are firmly connected in succession on the inner side of the box body from top to bottom; the washing device comprises a first washing box and a first electric motor; the first washing box is firmly connected on the inner side of the rear end face of the box body; the first electric motor is firmly connected to the left end of the first washing box; a first gear is firmly connected to the tail end of a main shaft of the first electric motor; and a second gear is in engaged connection with the rear end of the first gear. According to the invention, with spiral cleaning blades, the first gear and the second geardisposed in the device, less dirty panax notoginseng can be effectively cleaned; the spiral cleaning blades not only can be used to convey the panax notoginseng, but can also be used to wash the panaxnotoginseng; and the washing effect is good and the working efficiency is high.

Owner:湖南龟寿堂健康产业发展有限公司

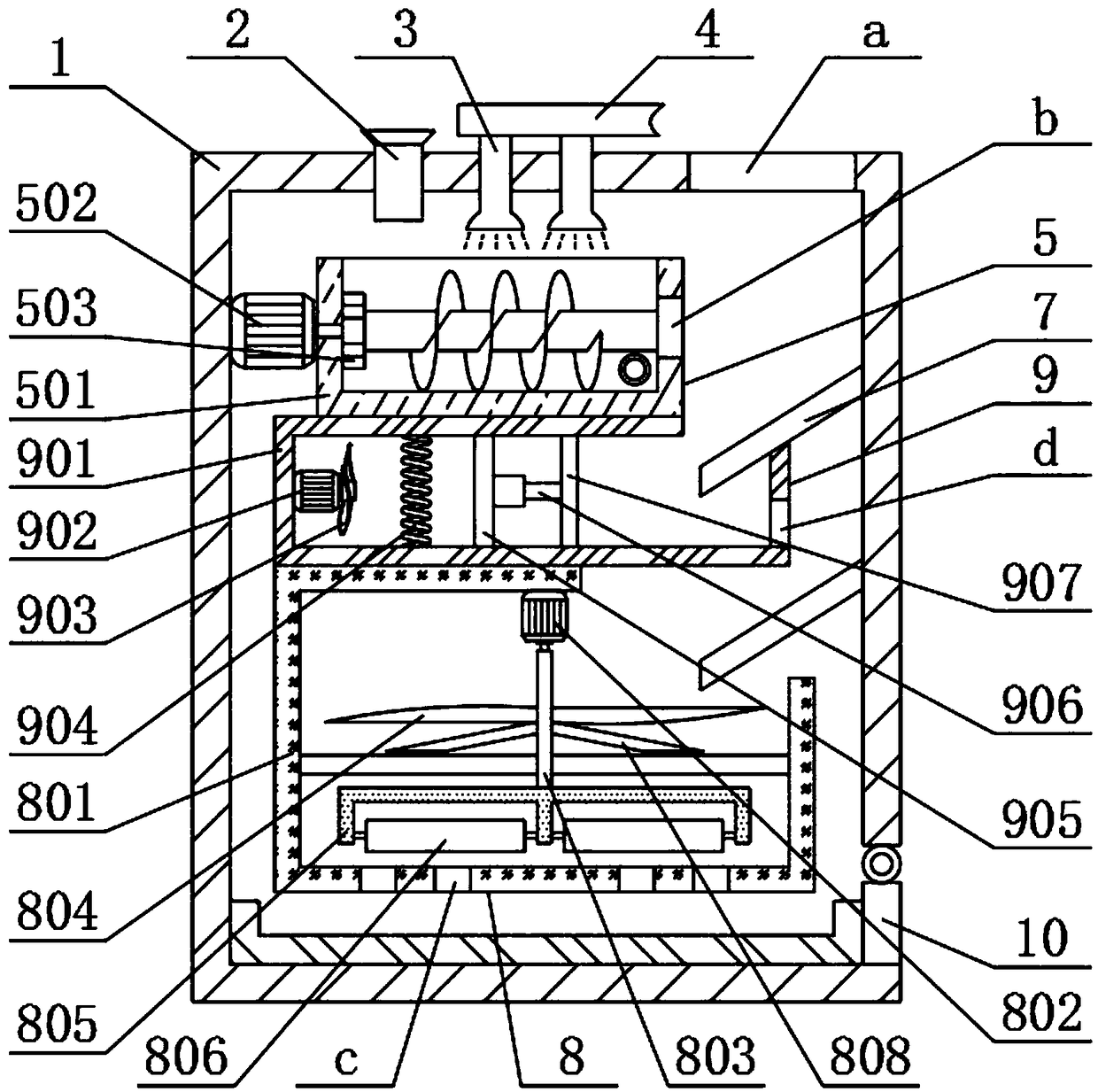

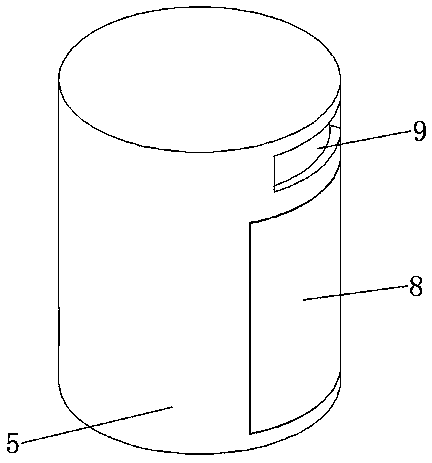

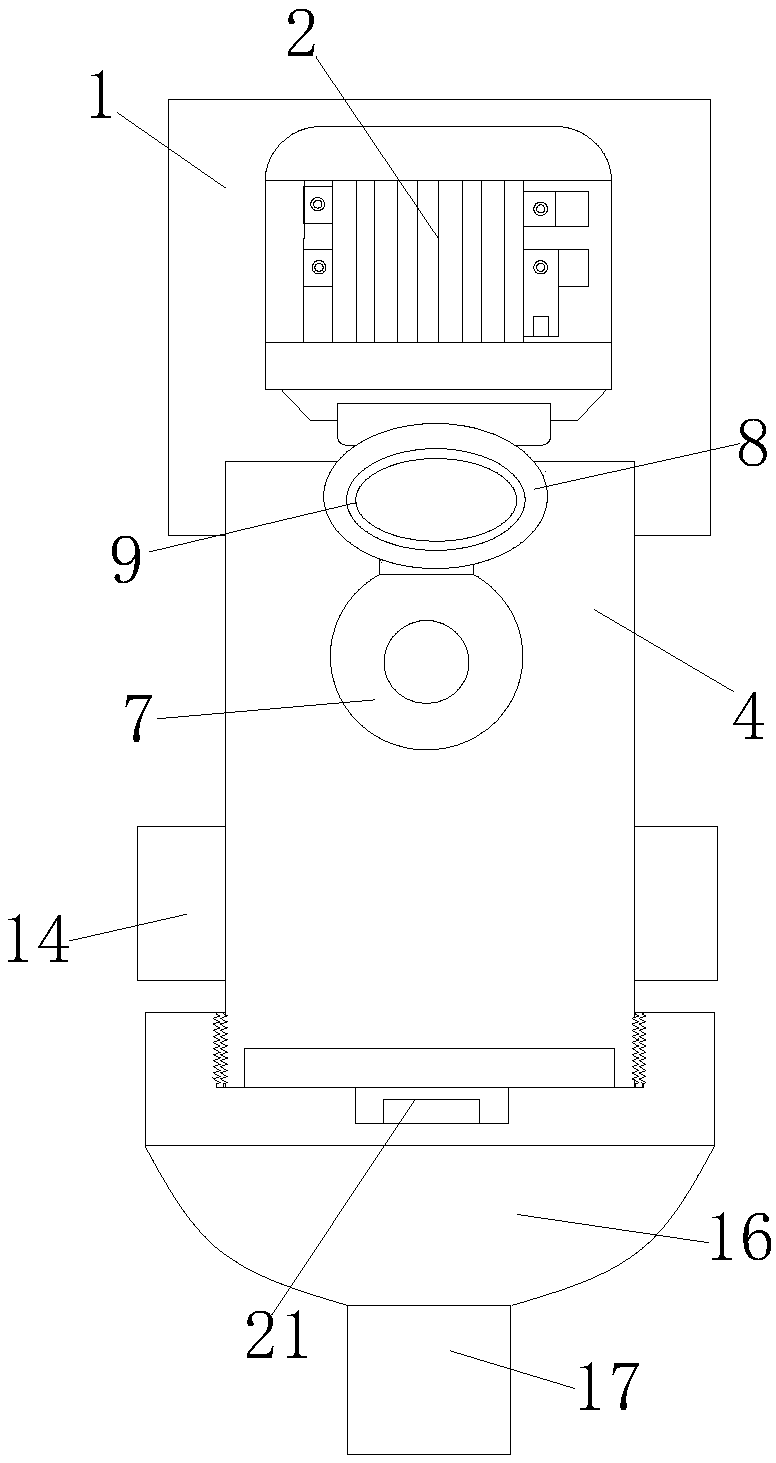

Eccentric structure-based stone material crusher with fine grinding function

ActiveCN110898906AImprove crushing efficiencyGrind evenlyGrain treatmentsSpiral bladeStructural engineering

The invention belongs to the field of stone processing and discloses an eccentric structure-based stone material crusher with a fine grinding function. The stone material crusher comprises a shell, adamping base, a feeding hopper and crushing rollers; vertical spiral blades are coaxially mounted in a separation cylinder; a powder discharging screen plate is mounted on the right side wall of the separation cylinder in an embedded manner; a grinding mechanism is arranged below a second material guide plate and comprises a grinding cylinder, a second motor and a grinding roller; the grinding cylinder is internally provided with the horizontal grinding roller; the center axis of the grinding roller and the center axis of the grinding cylinder are eccentrically arranged; and a plurality of discharging holes are formed in the bottom of the grinding cylinder. According to the eccentric structure-based stone material crusher with the fine grinding function of the invention, the powder discharging screen plate arranged on the side wall of the separation cylinder discharges stone materials which meet requirements and have been subjected to primary crushing, so that the stone materials can be separated in time; the grinding mechanism gradually grinds and crushes large stone materials; the stone materials will not be stuck in the grinding mechanism, so that grinding is smooth; the groundstone materials are discharged from the bottom of the grinding mechanism so as to be collected; and continuous grinding and crushing can be conducted.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

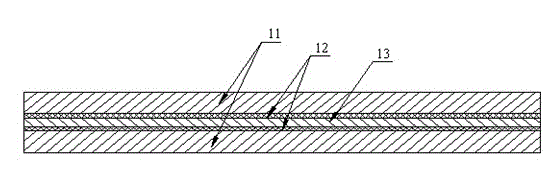

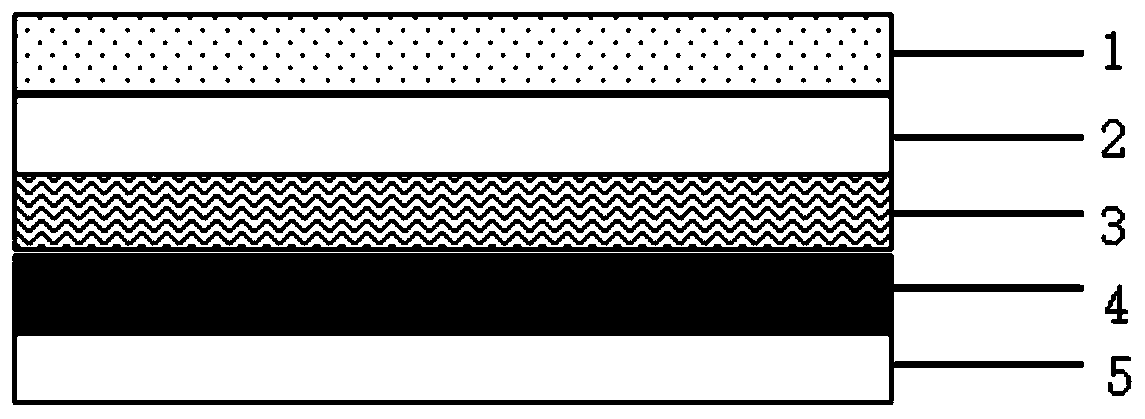

Substrate-free heat-conducting double-faced adhesive tape

InactiveCN103881597AImprove thermal conductivityEasy to punchNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingColloid

The invention discloses a substrate-free heat-conducting double-faced adhesive tape which comprises an adhesive tape and release films, wherein both sides of the adhesive tape are provided with the release films; the adhesive tape is composed of a colloid matrix and a heat-conducting material; and the colloid matrix is pressed into a sheet. The substrate-free heat-conducting double-faced adhesive tape has the advantages of high reliability, favorable heat conductivity, high temperature resistance, low price and the like, is convenient to manufacture, easy for adhesion and convenient die cutting, and has wide market prospects in electronic industry.

Owner:TAICANG TAIBANG ELECTRONICS TECH

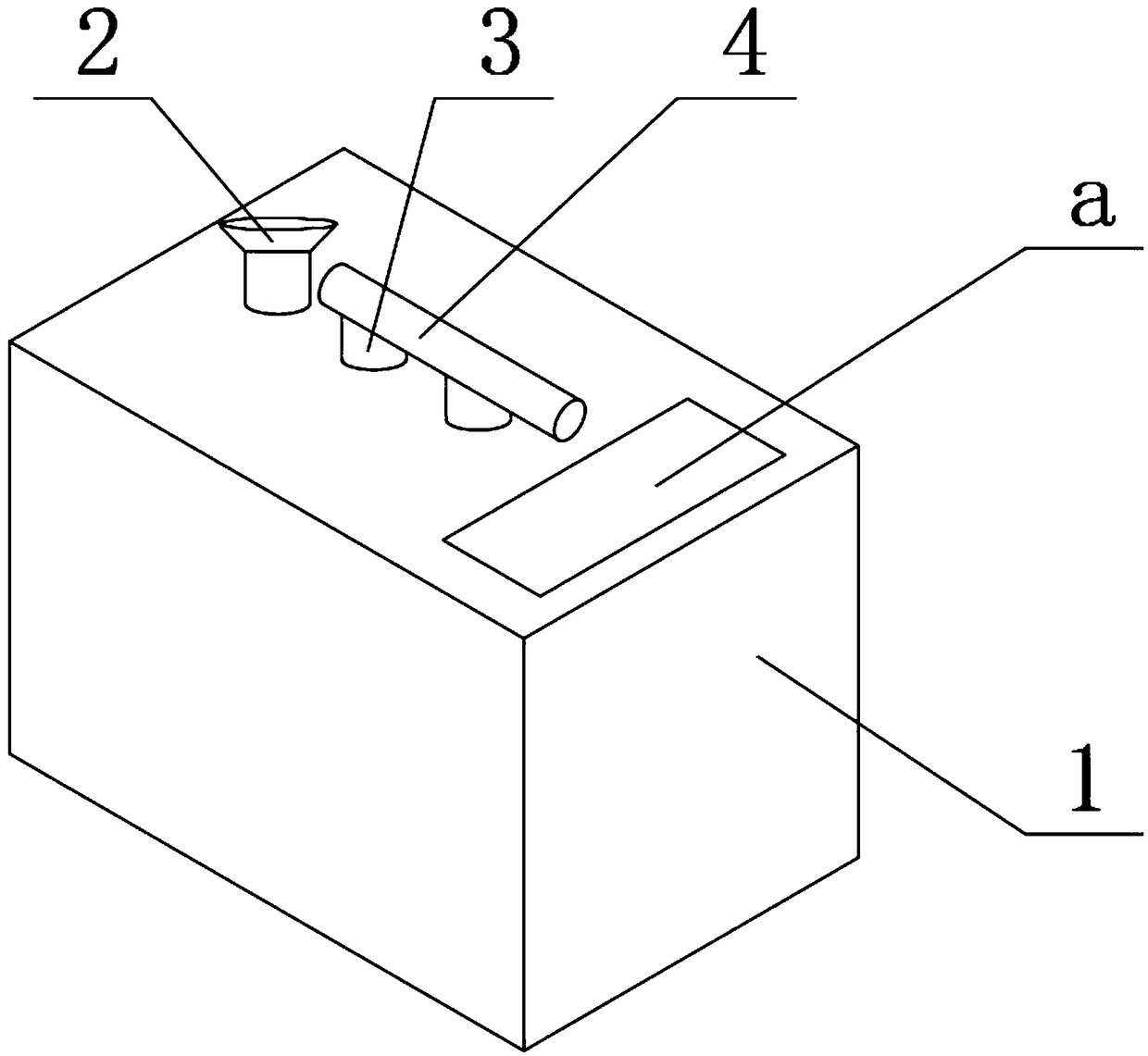

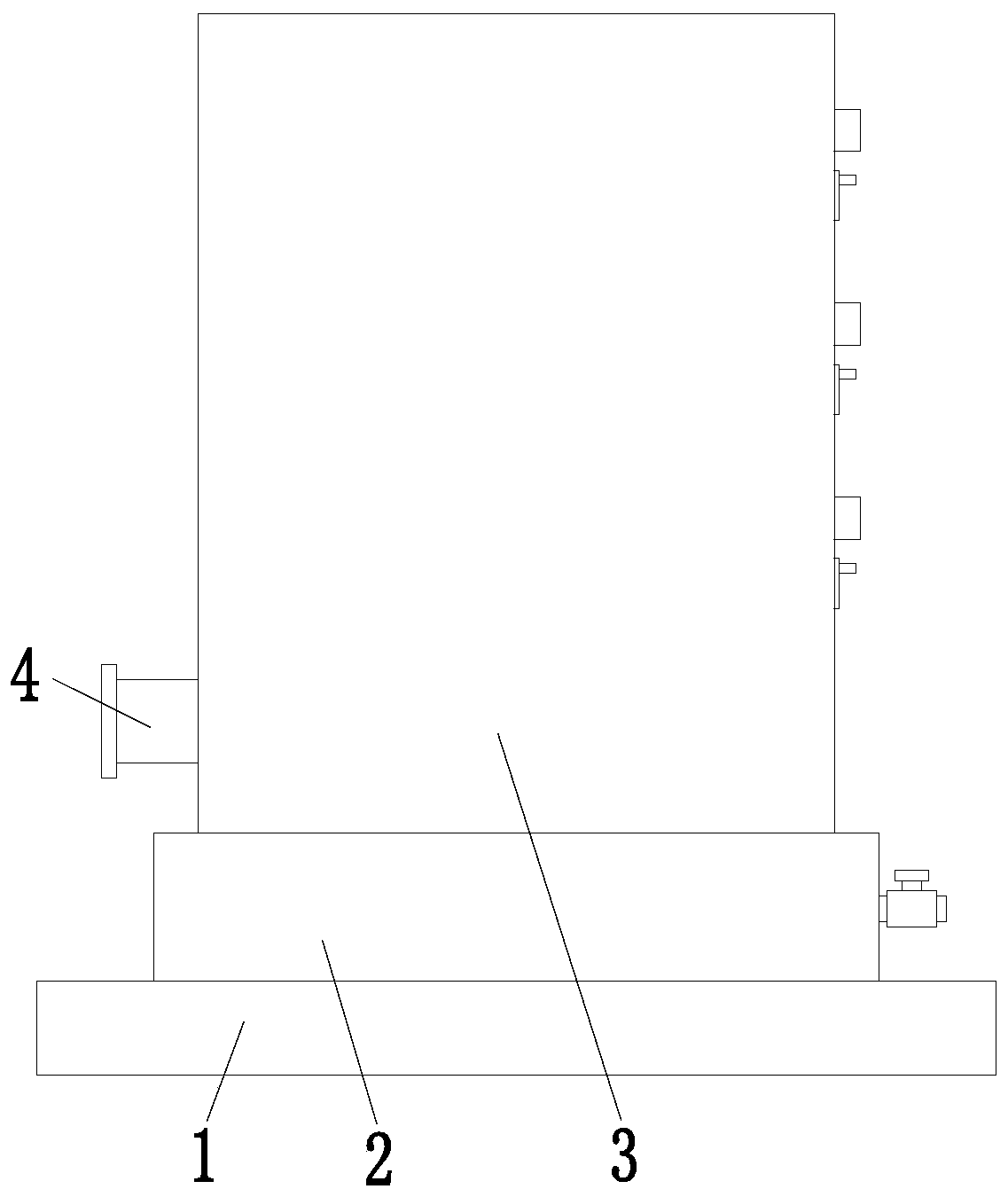

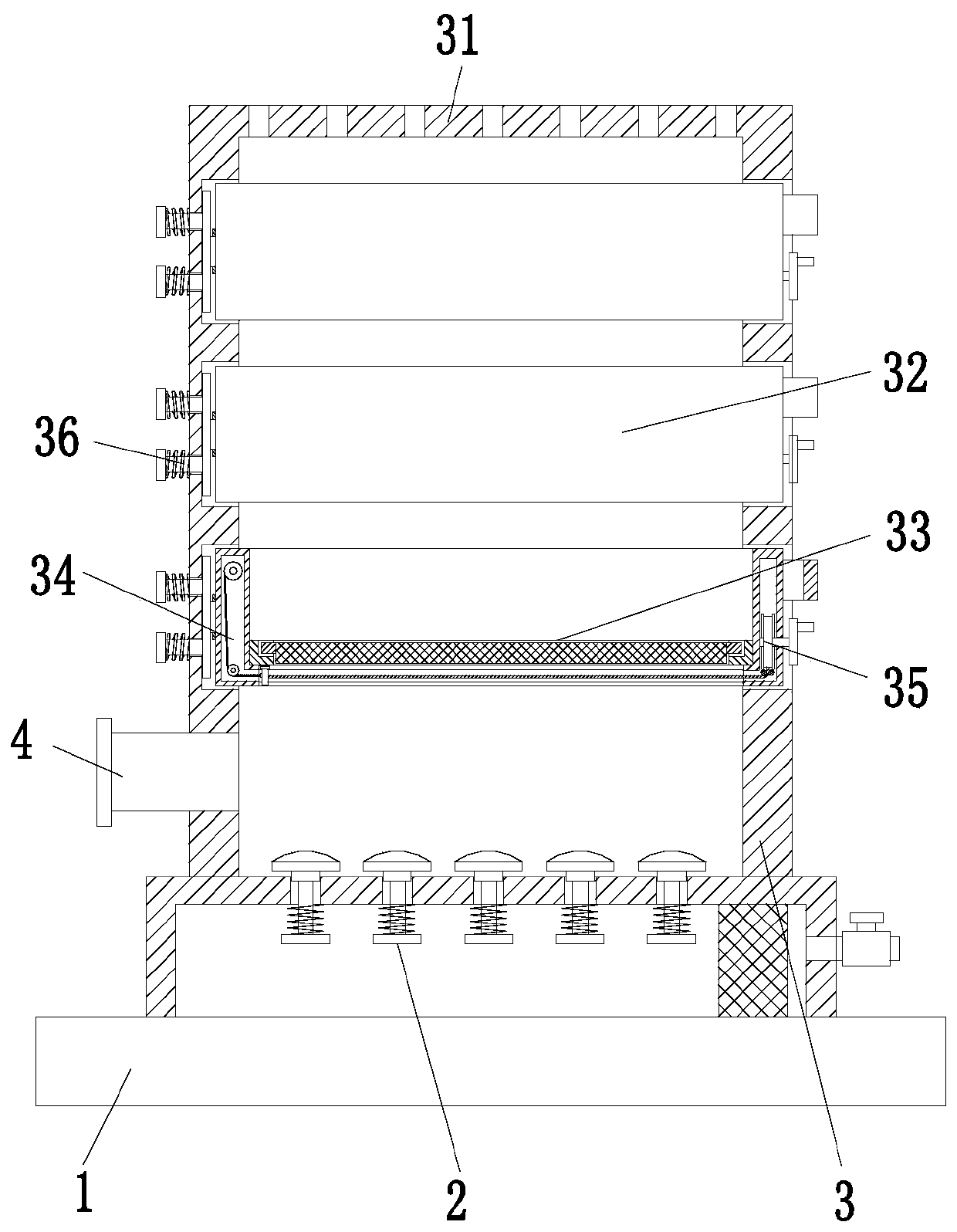

Crushing and compressing treatment device for woody wastes of construction engineering

InactiveCN110152856ASolve the problem of generating dust and dustHave the effect of elastic positioningWood working apparatusGrain treatmentsArchitectural engineeringSawdust

The invention discloses a crushing and compressing treatment device for woody waste of construction engineering. The crushing and compressing treatment device comprises a shell body, a grinding rollerlocated on the shell body, a material guide mechanism and a material guide base which is arranged at the lower end of the shell body in a communication manner and communicates with the lower end through a material guide hole; the upper end of the shell body is movably connected with an upper cover; a feeding opening is formed in the upper cover in a penetrating manner; a material guide frame is arranged above the feeding opening; and a dust collection cavity for collecting tiny wood dust is further movably assembled in the shell body. According to the crushing and compressing treatment devicedisclosed by the invention, after materials are crushed and processed through the grinding roller, the materials are further crushed through a crushing blade when falling off; after the crushing is finished, a conveying spiral shaft is rotated under the driving of a conveying motor so that the materials can be effectively led out and are convenient to collect intensively; meanwhile, the problem that crushed material smoke dust is generated through sawdust in a processing process is solved by driving an air pump and a wood processing product is also convenient to collect sufficiently; and limiting rollers at two sides are matched to realize an elastic positioning effect and wood is more stable to stretch, so that grinding is facilitated after cooperation.

Owner:孙哲西

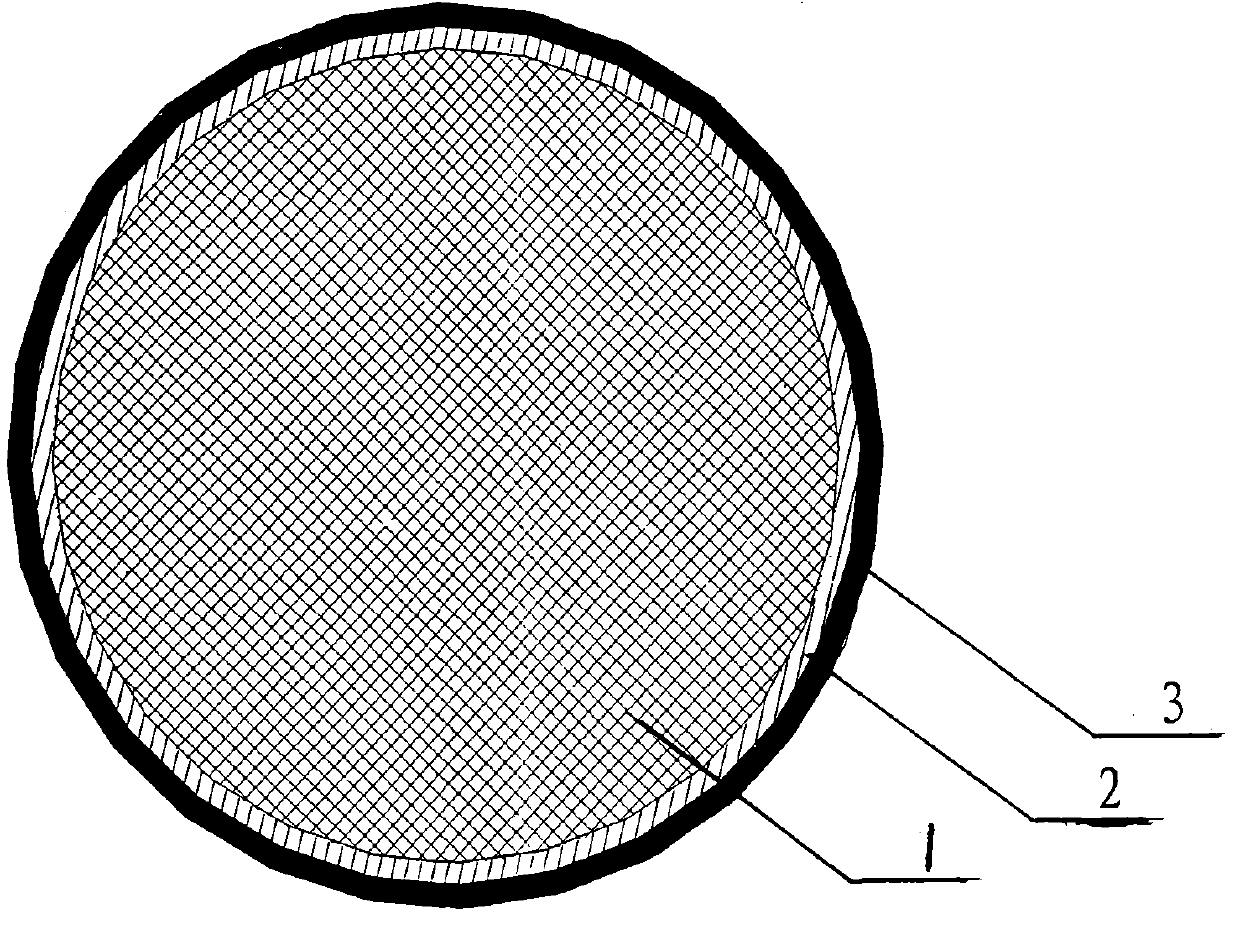

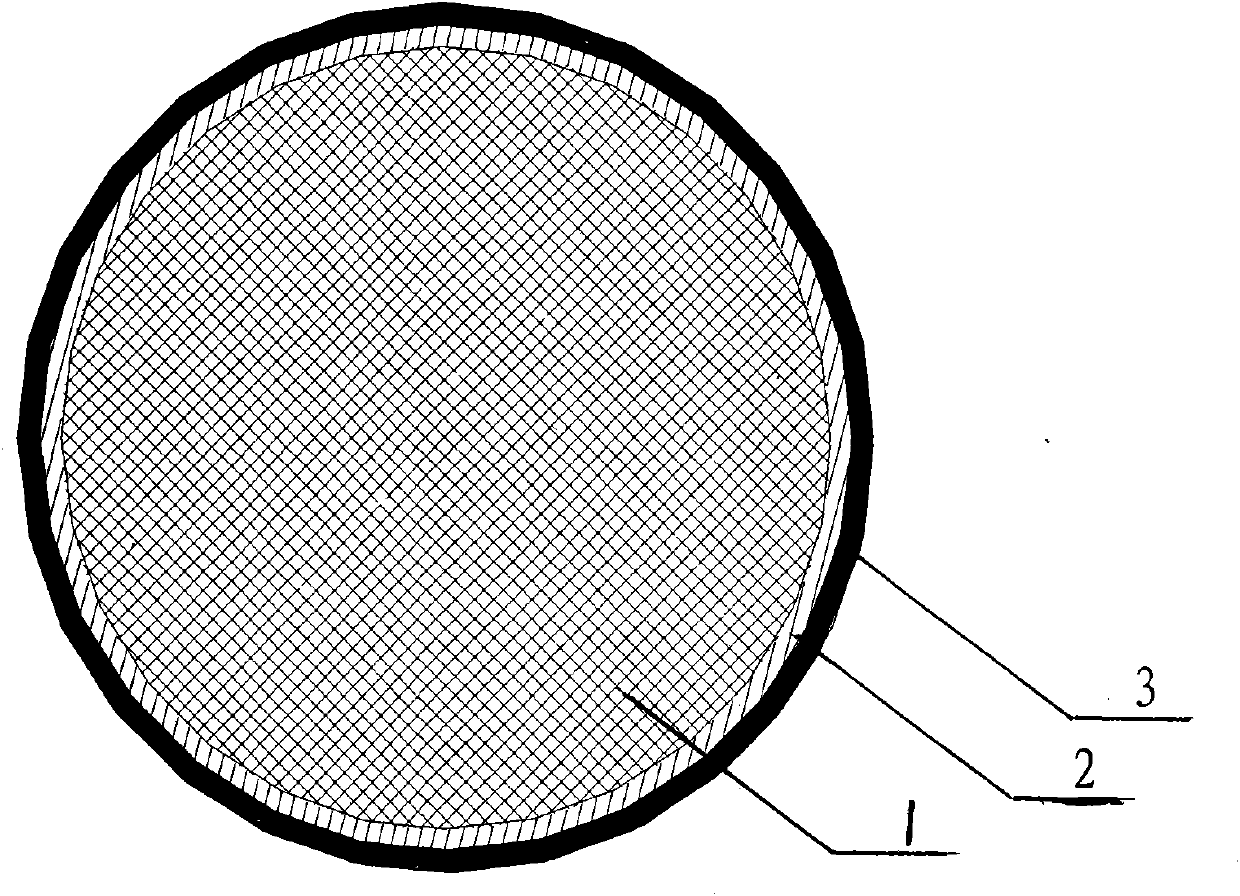

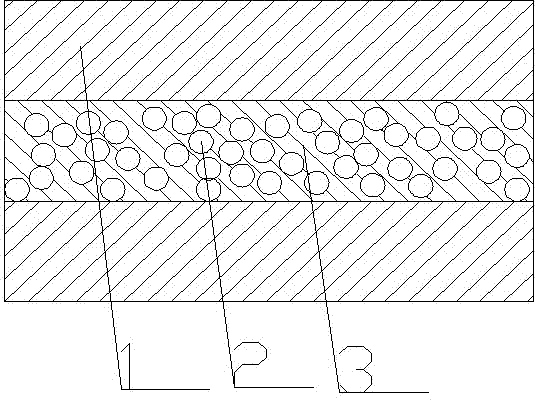

Thermal-conducting fiber reinforced high-thermal-conductivity graphite radiating fin and preparation method thereof

ActiveCN102975417AImprove mechanical propertiesHigh strengthSemiconductor/solid-state device detailsSolid-state devicesFiberCarbon fibers

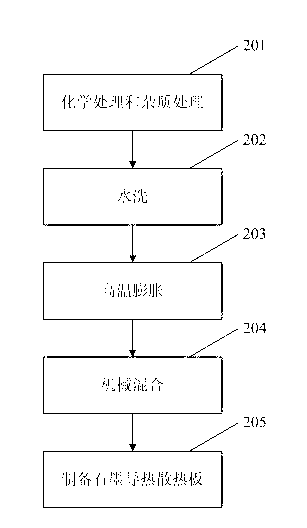

The invention provides a thermal-conducting fiber reinforced high-thermal-conductivity graphite radiating fin and a preparation method thereof. The preparation method of the thermal-conducting fiber reinforced high-thermal-conductivity graphite radiating fin comprises the following steps: carrying out pretreatment on graphite powder; processing the graphite powder subjected to pretreatment by using a graphite coiled material production device, thereby obtaining a thermal-conducting graphite radiating plate; and taking short graphite fibers, carbon fiber cloth and carbon fibers as a reinforcing agent, and carrying out coating and laminating on the thermal-conducting graphite radiating plate and the reinforcing agent by using an adhesive so as to obtain the thermal-conducting fiber reinforced high-thermal-conductivity graphite radiating fin. According to the preparation method of the thermal-conducting fiber reinforced high-thermal-conductivity graphite radiating fin, the defects of low mechanical properties, short service life and easy falling and the like existing in the conventional preparation process can be overcome, and the mechanical strength and the purity of the radiating fin are greatly improved, thereby facilitating subsequent processing; and the radiating fin has the advantages of light weight, high strength, high thermal conductivity, and the like, and enlarges the application range of graphite flakes.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

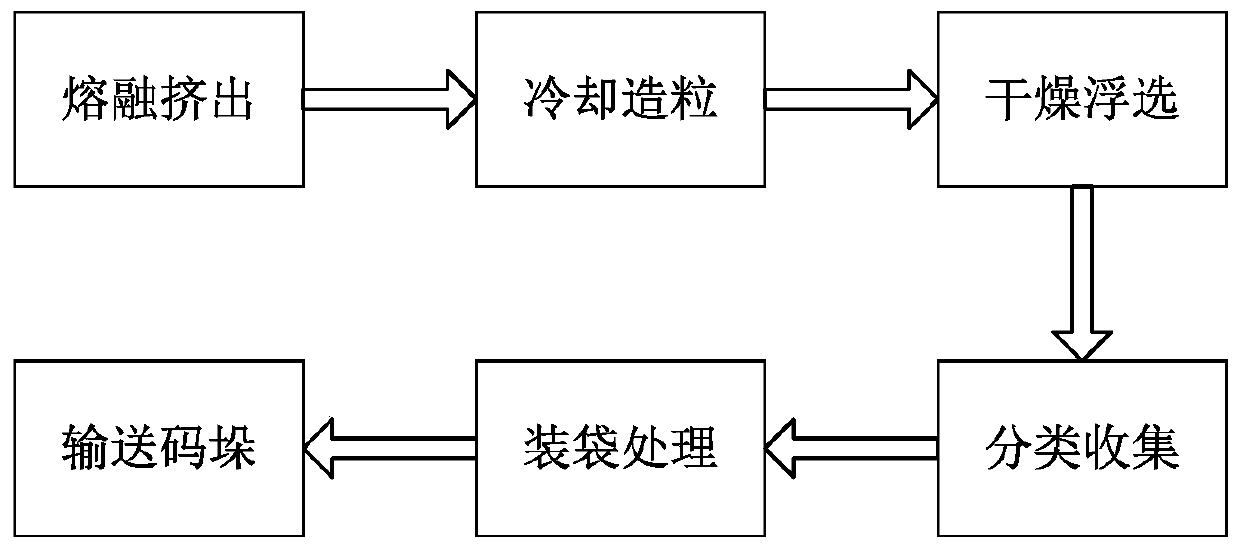

Plastic granulation post-treatment process

InactiveCN110435038AAvoid easy bondingConducive to subsequent processingCoatingsScreening effectEngineering

The invention relates to a plastic granulation post-treatment process which comprises a bottom plate, an air jetting rack, a flotation device and a feeding inlet. The air jetting rack is mounted at the upper end of the bottom plate. The flotation device is mounted at the upper end of the air jetting rack. The feeding inlet is mounted at the lower end of the left side of the flotation device and communicates with the flotation device. The plastic granulation post-treatment process can solve the existing problems that when granules are subjected to post-treatment, the dehumidification drying effect of the granules is poor, the granules are prone to have bubbles and cracks, and newly extruded plastic is liable to be bonded together, so that the granules have poor using effect and are unfavorable for subsequent processing use; and meanwhile, when the granulated granules are screened, the screening effect is poor, the sorting precision is low, and the granules can not be collected quickly after being sorted. The process has the advantages of good drying dehumidification effect, high precision of sorting, high efficiency and the like.

Owner:东莞市三润塑胶科技有限公司

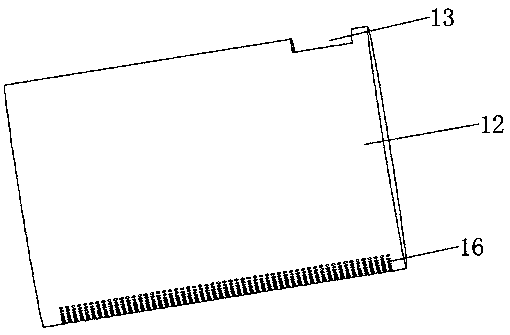

Die-cutting equipment for lithium battery electrode material processing

ActiveCN111070316AAvoid errorsGuaranteed accuracyMetal working apparatusElectric machineryEngineering

The invention relates to die-cutting equipment for lithium battery electrode material processing. The die-cutting equipment for lithium battery electrode material processing comprises a fixed frame, aflat-pressing device and a die-cutting device; the fixed frame is of a U-shaped structure; the flat-pressing device is mounted on the left side in the fixed frame; the die-cutting device is arrangedon the right side of the flat-pressing device; and the die-cutting device is mounted on the right side in the fixed frame. According to the die-cutting equipment for lithium battery electrode materialprocessing, the difficult problems that the phenomenon that burrs are easily produced at the edges and corners of an electrode material when stamping and cutting are performed because the electrode material is commonly cut in a stamping mode, the edge cutting effect of the electrode material is poor and the electrode material is cut unevenly to affect subsequent processing and using of the electrode material, moreover, a motor is prone to cumulative errors because a stepping motor is commonly adopted for driving and stretching when the electrode material is subjected to fixed-length stretching, and the fixed length may be inaccurate after long-time use, so that the phenomenon that the lengths of the cut electrode materials vary is easily caused when the electrode material is cut by the existing equipment can be solved.

Owner:QUZHOU UNIV

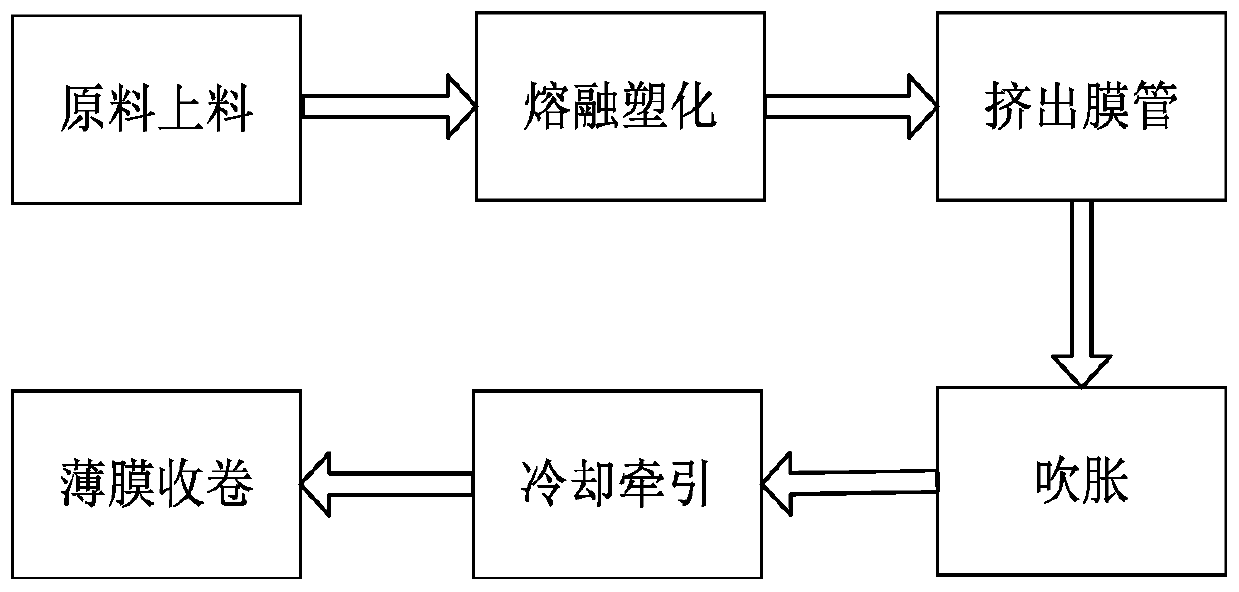

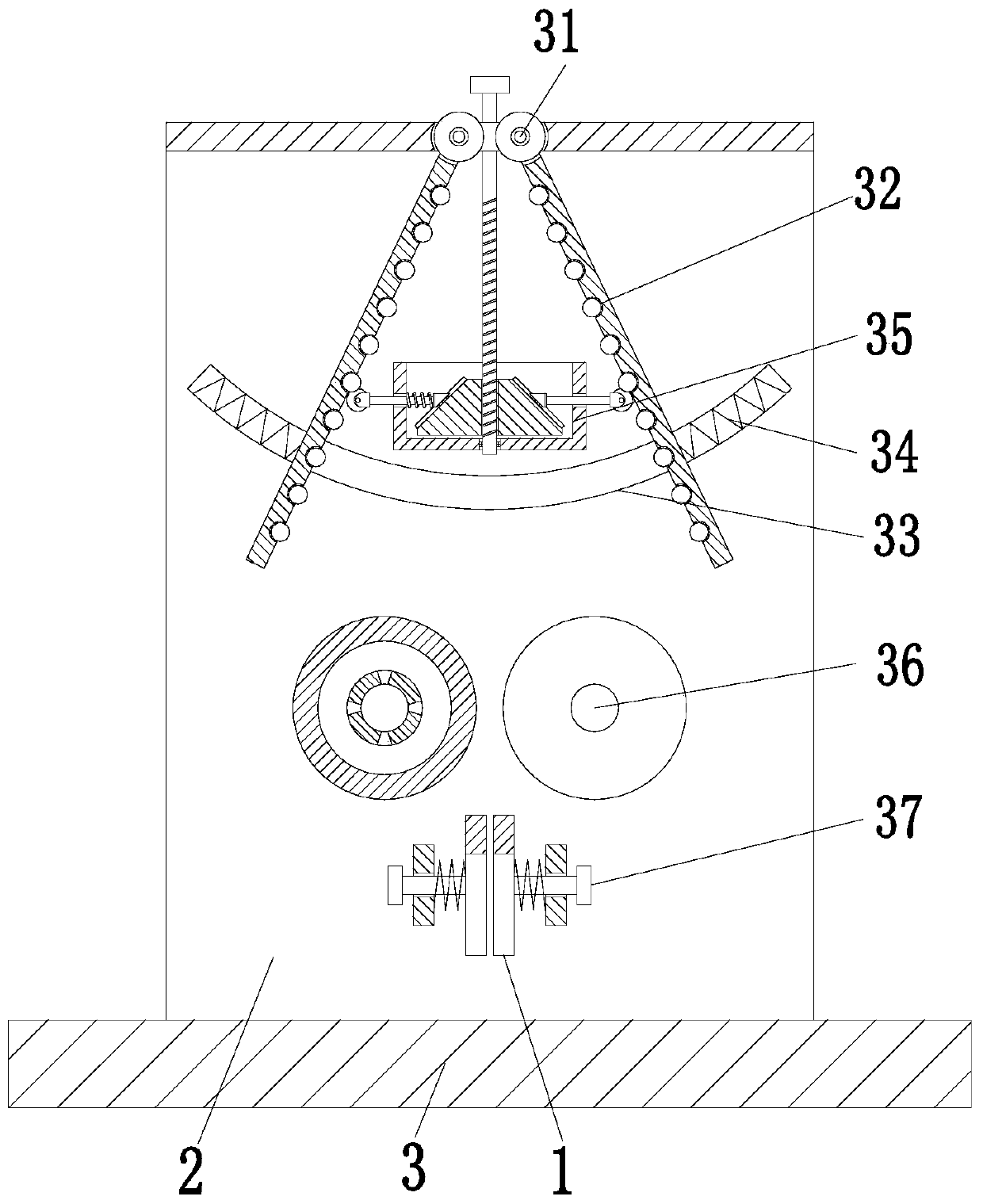

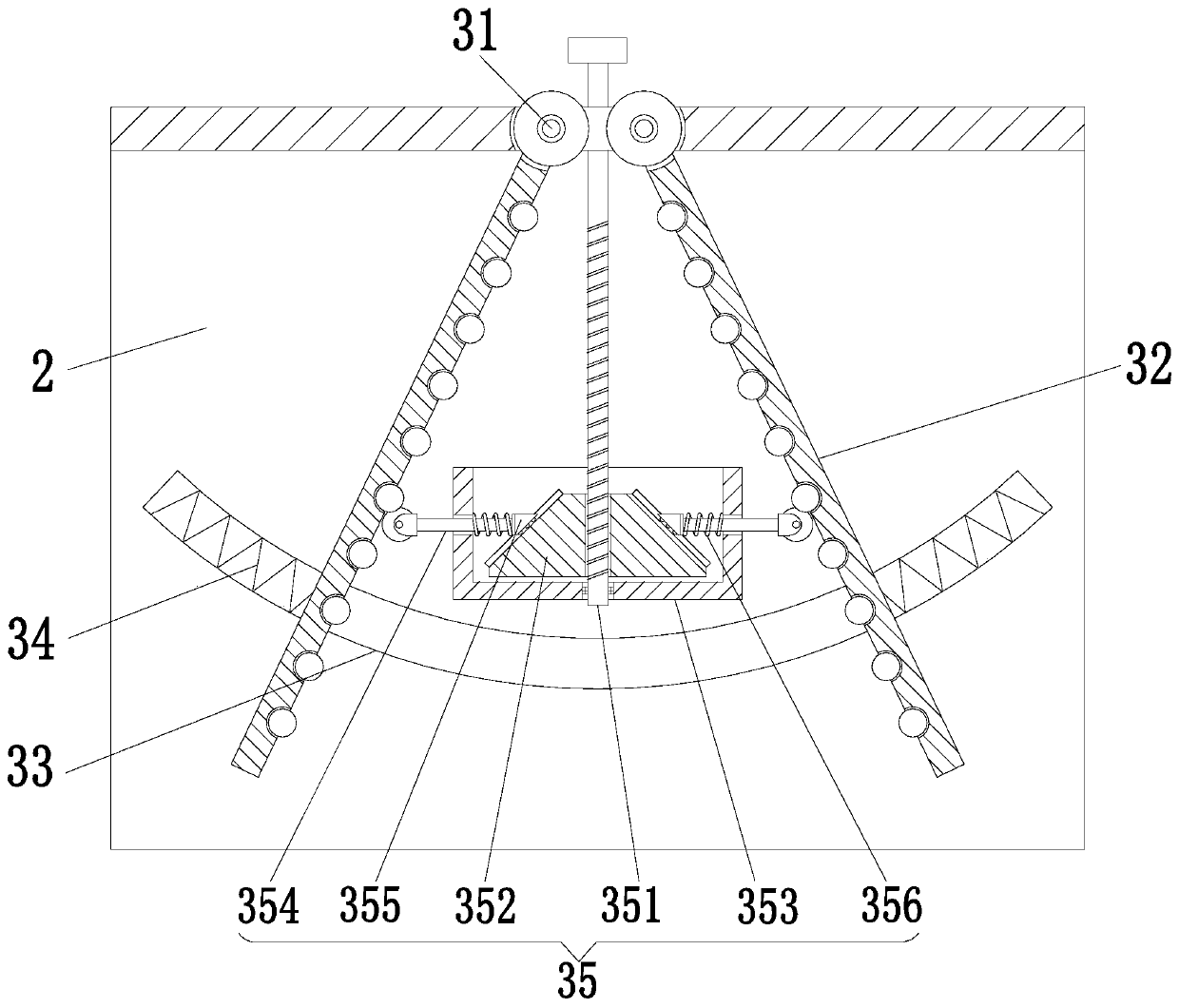

Preservative film production process

InactiveCN111590857AEfficient cooling and coolingEasy to processFlat articlesWebs handlingMolten stateThin membrane

The invention relates to a preservative film production process. The preservative film production process comprises a bottom plate, a supporting frame and a traction device, wherein the supporting frame is installed at the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, and the traction device is installed in the supporting frame. The preservative film production process disclosed by the invention can solve the problems that a film in a molten state is likely to adhere to the surface of a guide roller due to the fact that the guide plate cannot berapidly cooled generally when the existing equipment cools and guides the preservative film, so that the prepared film is likely to damage, and more folds easily exist on the surface of the film whenthe existing equipment is used for winding the prepared film, and the gas in the film cannot be effectively exhausted, so that the wound film is easily broken and the subsequent use of the film is affected are solved.

Owner:侯哲宇

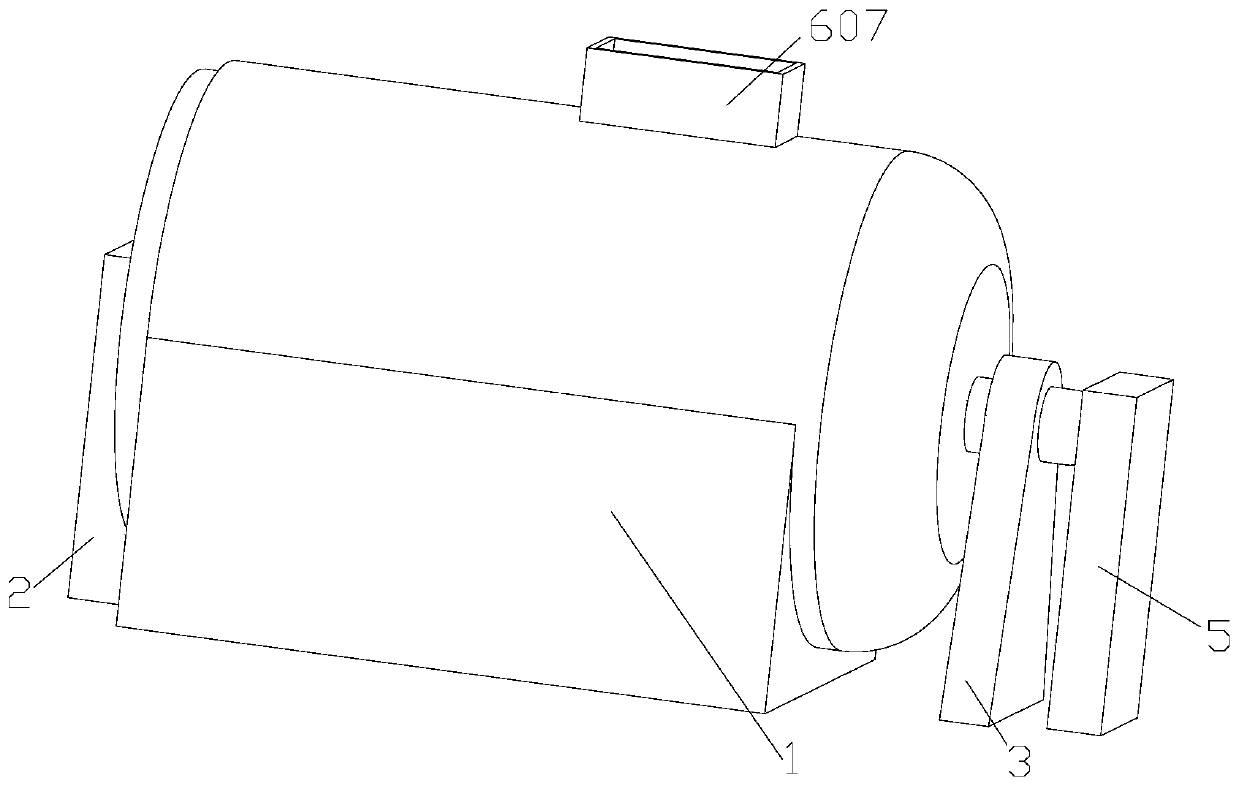

Feed grinding device

InactiveCN109569788AAchieve smashConducive to subsequent processingGrain treatmentsHeating arrangementGas cylinderDrive motor

The invention provides a feed grinding device. The feed grinding device comprises a barrel body, a grinding roller, a charge hole, a discharge hole and a drive device, wherein the grinding roller is tapered; the grinding roller is arranged in the barrel body; a gap is formed between the grinding roller and the inner side wall of the barrel body; the gap is gradually reduced from the upper side ofthe barrel body to the lower side of the barrel body; supporting rods are arranged at the two sides of the barrel body; a beam is arranged between the two supporting rods; the drive device comprises adrive motor and an electric gas cylinder; the base of the drive motor is arranged on the beam; the output end of the drive motor is connected with the base of the electric gas cylinder; the output end of the electric gas cylinder is fixedly connected with the middle part above the grinding roller; the charge hole is formed in the upper portion of the barrel body; the discharge hole is formed in the lower portion of the barrel body; and the discharge hole is equipped with a sealing device. The feed grinding device realizes feeding of large-particle feed, and is convenient for follow-up processing use.

Owner:陆左琴

Efficient meat product processing equipment

InactiveCN110710558AEasy to processConducive to subsequent processingSausage filling/stuffing machinesMeat processing devicesBiotechnologyCoupling

The invention discloses efficient meat product processing equipment. The efficient meat product processing equipment comprises a base, a motor is arranged at the top end of the base, a coupling is connected to a rotating head end of the motor, the coupling penetrates through a side wall of a conveying pipe and is coaxially connected with a spiral conveyor arranged in the conveying pipe, a left side of a bottom end of the conveying pipe is fixed to the base, a vertical column is arranged on the right side of the bottom end of the conveying pipe, cutting devices are arranged on the inner walls of the two sides in the conveying pipe correspondingly, each cutting device comprises a sleeve, sliding blocks in inverted-T shapes are arranged on the outer walls of the two sides of each sleeve correspondingly, and every two sliding blocks are matched with a sliding groove formed in the inner wall of the conveying pipe. According to the efficient meat product processing equipment, through the twoarranged cutting devices, meat pieces are subjected to first-time cutting and mincing when falling into the conveying pipe from a feeding pipe, and are chopped again by the cutting devices when conveyed to the other side of the conveying pipe by the spiral conveyor, the meat pieces are chopped more evenly through two times of cutting treatment, and the processing efficiency is improved.

Owner:漳州市好亦鲜食品有限公司

Gluing device of coating machine

InactiveCN103301989AEasy to rewindEasy to useLiquid surface applicatorsCoatingsCoated surfaceMechanical engineering

The invention relates to a gluing device of a coating machine. The gluing device comprises a gluing roller and a glue feeding roller which are meshed with each other, wherein the two ends of the glue feeding roller are respectively wound with more than one tape layer; the two tape layers correspond to the two wound and coated ends on the gluing roller respectively; relative to the outer side edges of the coated ends, the inner edges of the tape layers are retracted by 0.5-1.5mm. The gluing device has the advantages that the glue feeding roller is additionally provided with the tape layers matched with the coated side edges on the gluing roller, so that the fast and stable gluing in coating is realized, and the phenomenon of fat edges in coating is avoided; the structure is simple and compact, the use is convenient, the phenomenon of waste edges on the side edge of the coated surface is effectively avoided, the coating efficiency and the coating quality are high and the subsequent processing and use are convenient.

Owner:泰兴联创绝缘材料有限公司

Profile steel splicing, machining and welding process

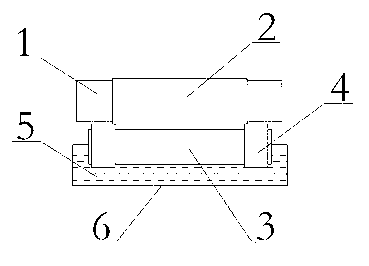

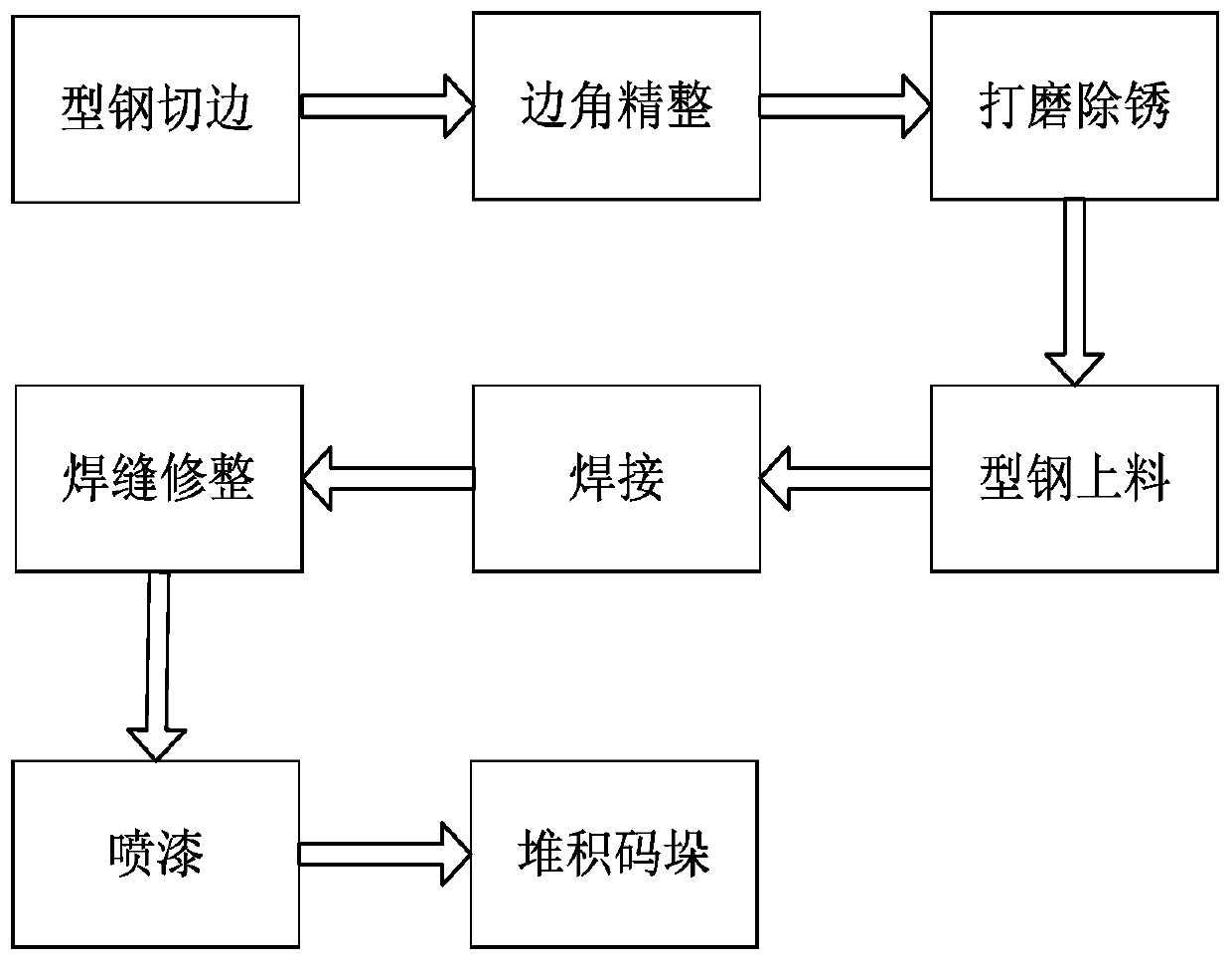

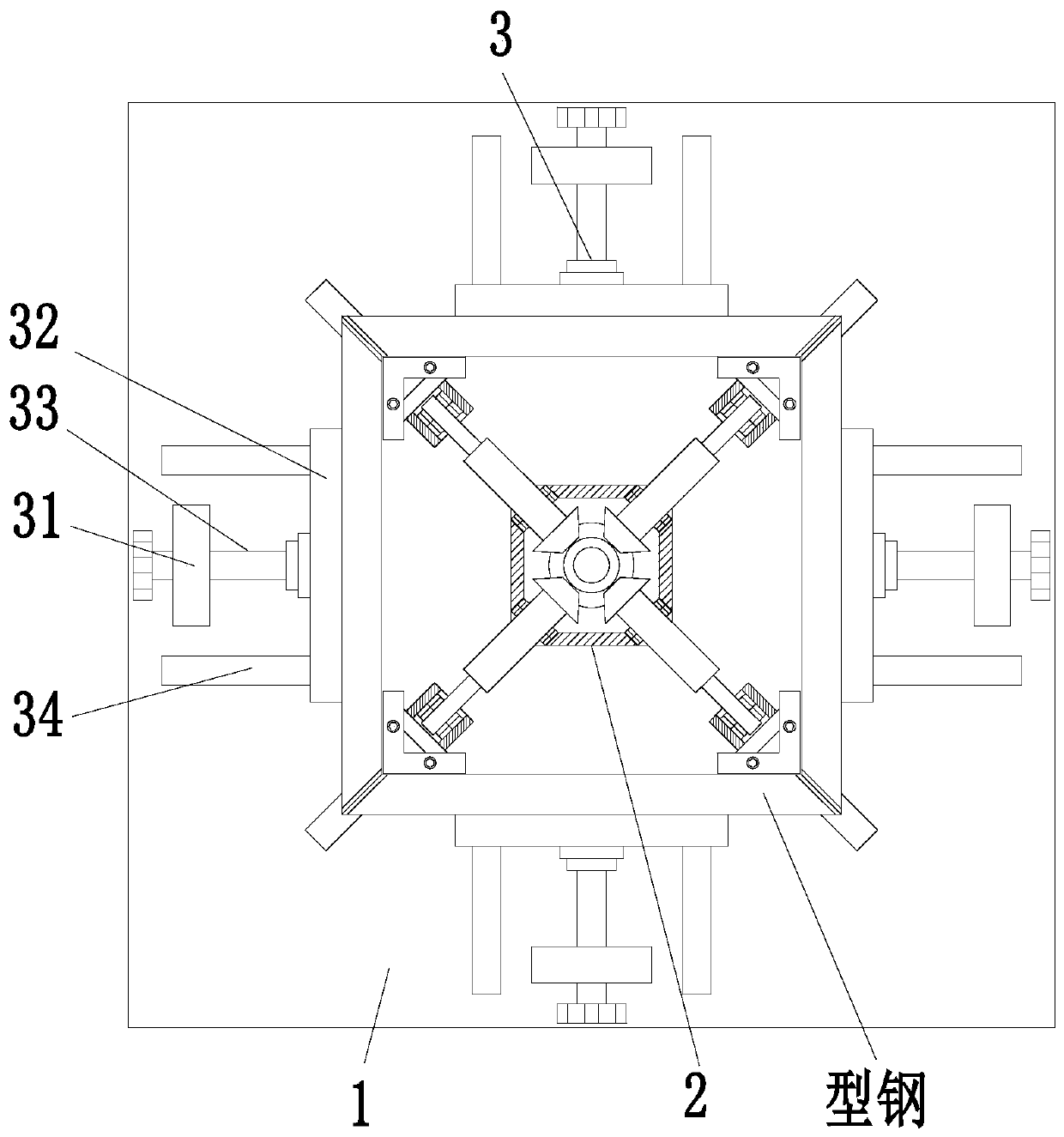

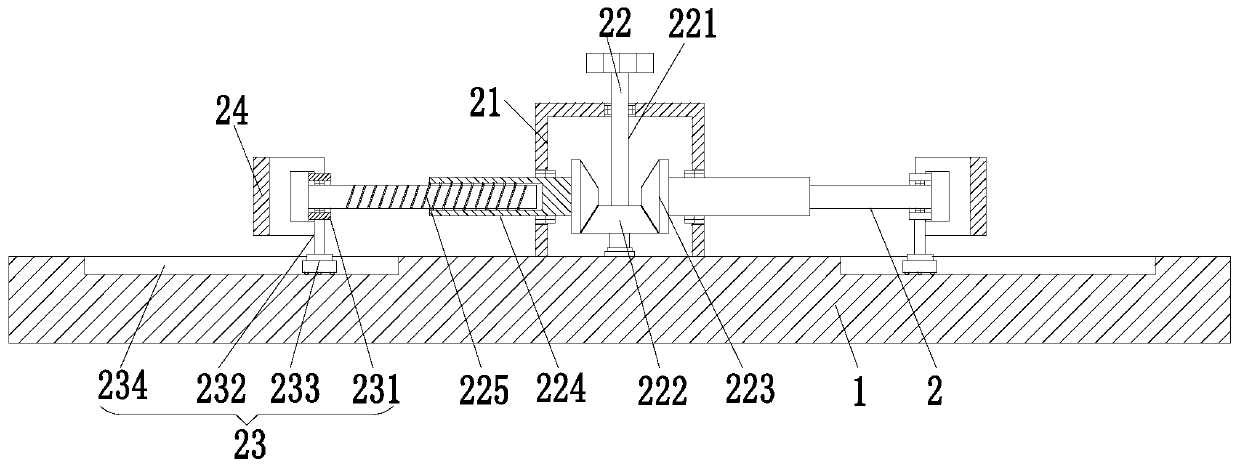

InactiveCN110744215APrecise positioningAvoid driftingWelding/cutting auxillary devicesAuxillary welding devicesMachiningMaterials science

The invention relates to a profile steel splicing, machining and welding process. The profile steel splicing, machining and welding process adopts a base plate, an inner supporting device and outer supporting devices; the inner supporting device is installed at the middle part of the upper end of the base plate; the outer supporting devices are uniformly arranged at the outer side of the base plate; and the outer supporting devices are installed at the upper end of the base plate. The profile steel splicing, machining and welding process can solve the problems that the existing equipment is poor in positioning effect on profile steel before the profile steel is welded and cannot realize accurate clamping and positioning on the profile steel, the profile steel is easily deviated in a welding process, thus a steel structure is poor in welding effect and low in accuracy and can be easily scrapped; when the existing equipment is used for clamping the profile steel, the clamping effect is poor, a clearance between the profile steel cannot be accurately regulated, so the welded profile steel is low in rigidity and poor in stability; subsequent machining of the steel structure is affectedand the like.

Owner:郑文豪

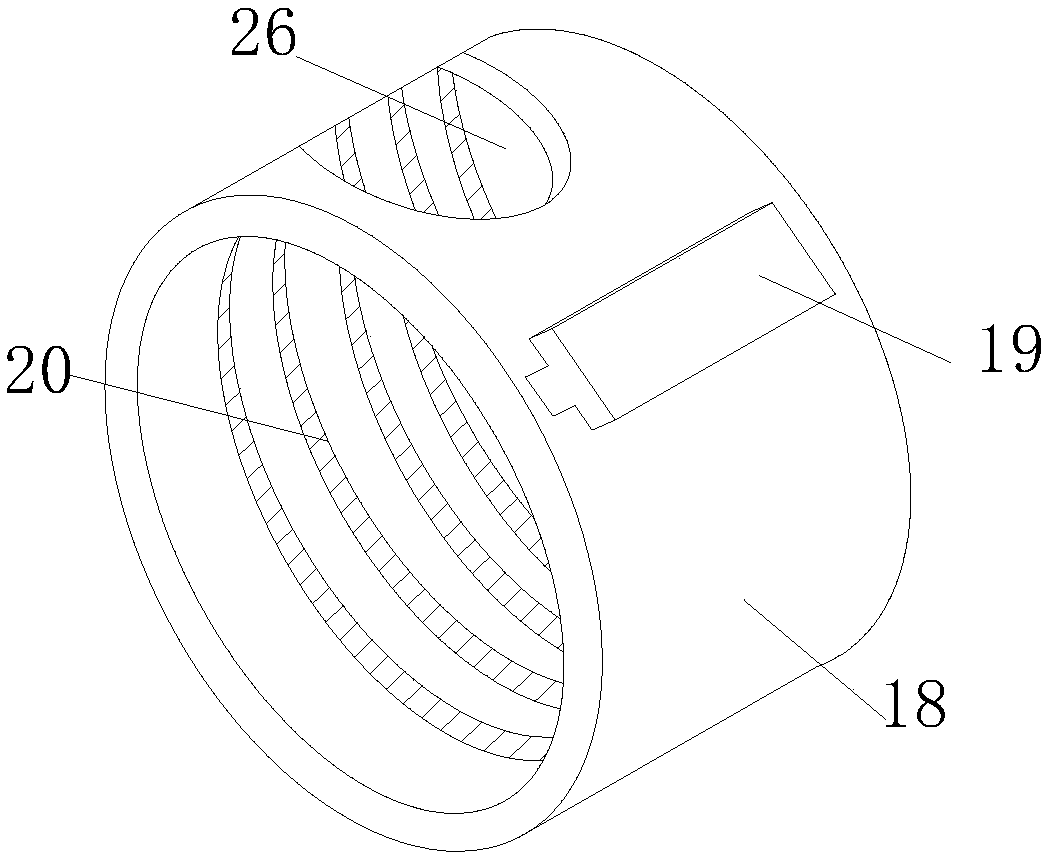

Chemical fertilizer crushing and screening device with drying function

ActiveCN113368967AImprove crushing effectConducive to subsequent processingSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to the technical field of chemical fertilizer processing, and discloses a chemical fertilizer crushing and screening device with a drying function; the chemical fertilizer crushing and screening device comprises a shell; a supporting frame is fixedly connected to the position, close to the outer side, of the bottom of the shell; a supporting ring is fixedly connected to the inner wall of the shell through the supporting frame; the top of the supporting ring is rotationally connected with a base through a bearing; and clamping grooves are formed in the top of the base. According to the chemical fertilizer smashing and screening device with the drying function, during crushing, chemical fertilizer raw materials are cut off through a preliminary crushing device and evenly distributed; then the evenly distributed chemical fertilizer raw materials are ground and crushed through a grinding roller; the smashed chemical fertilizer raw materials are screened and dried through a screening and drying device; subsequent processing of chemical fertilizer raw materials is facilitated; caking is prevented; processing is directly completed at a time; processing efficiency is improved; and the advantages of being easy to operate and convenient to use are provided.

Owner:济宁中农大化肥业股份有限公司

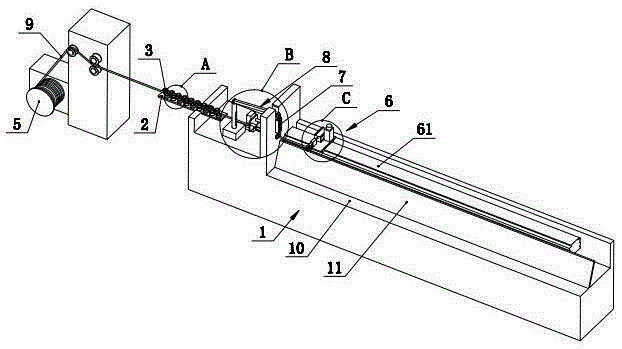

Steel cable cutting mechanism

The invention discloses a steel cable cutting mechanism which comprises a machine frame. A flat plate is fixed to the machine frame and provided with two rows of rolling wheels which are linearly arranged in a staggered manner; a steel cable straightening channel is formed between the two rows of rolling wheels; the portion, in front of the input end of the steel cable straightening channel, of the machine frame is provided with a steel cable output roller; the portion, behind the output end of the steel cable straightening channel, of the machine frame is provided with a steel cable stretching traction device; a steel cable cutter and a driving mechanism used for driving the steel cable cutter to cut a steel cable are arranged between the output end of the steel cable straightening channel and the steel cable stretching traction device; the steel cable stretching traction device comprises a linear slide rail installed on the machine frame; a slide base is installed on the linear slide rail in a sliding manner; and the slide base is provided with a mechanical arm used for grabbing the steel cable. By means of the structure, the steel cable cutting mechanism can substantially improve production efficiency and achieve full-automatic operation.

Owner:温州豪华汽车配件有限公司

Crushing equipment for cotton fiber reprocessing

ActiveCN113578469ANot easy to floatIncrease weightUsing liquid separation agentDrying gas arrangementsCotton fibreStructural engineering

The invention relates to the technical field of cotton fiber processing, and discloses crushing equipment for cotton fiber reprocessing. The crushing equipment comprises a crushing box; a vertically arranged central shaft is rotatably mounted at the center in the crushing box; a crushing motor is mounted on the top surface of the crushing box to drive the central shaft to rotate; a plurality of crushing cutters are arranged on the outer side of the central shaft; a plurality of hollow parts are distributed in the circumferential direction of a shell of the crushing box; separation pads are installed in the middles in the hollow parts and divide the hollow parts into installation cavities and liquid storage cavities; a plurality of liquid outlet holes are distributed in the shells, adjacent to an inner cavity of the crushing box, of the liquid storage cavities; an atomization nozzle is installed at each liquid outlet hole; an extrusion mechanism is arranged in each installation cavity, so that liquid in the liquid storage cavities is sprayed into the crushing box through the atomization nozzles; and the extrusion mechanisms are in transmission connection with the center shaft through transmission mechanisms. The crushing equipment can improve the cotton fiber smashing efficiency and smashing effect, and is simple in structure and convenient and fast to use.

Owner:安徽省农业科学院棉花研究所

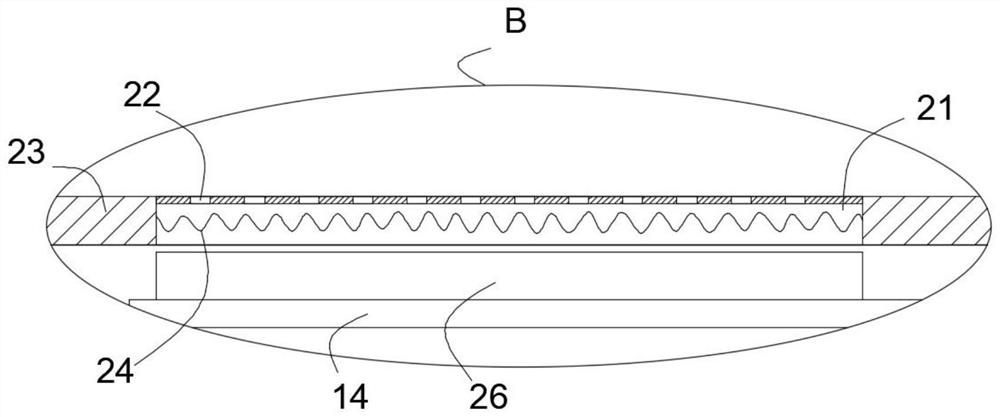

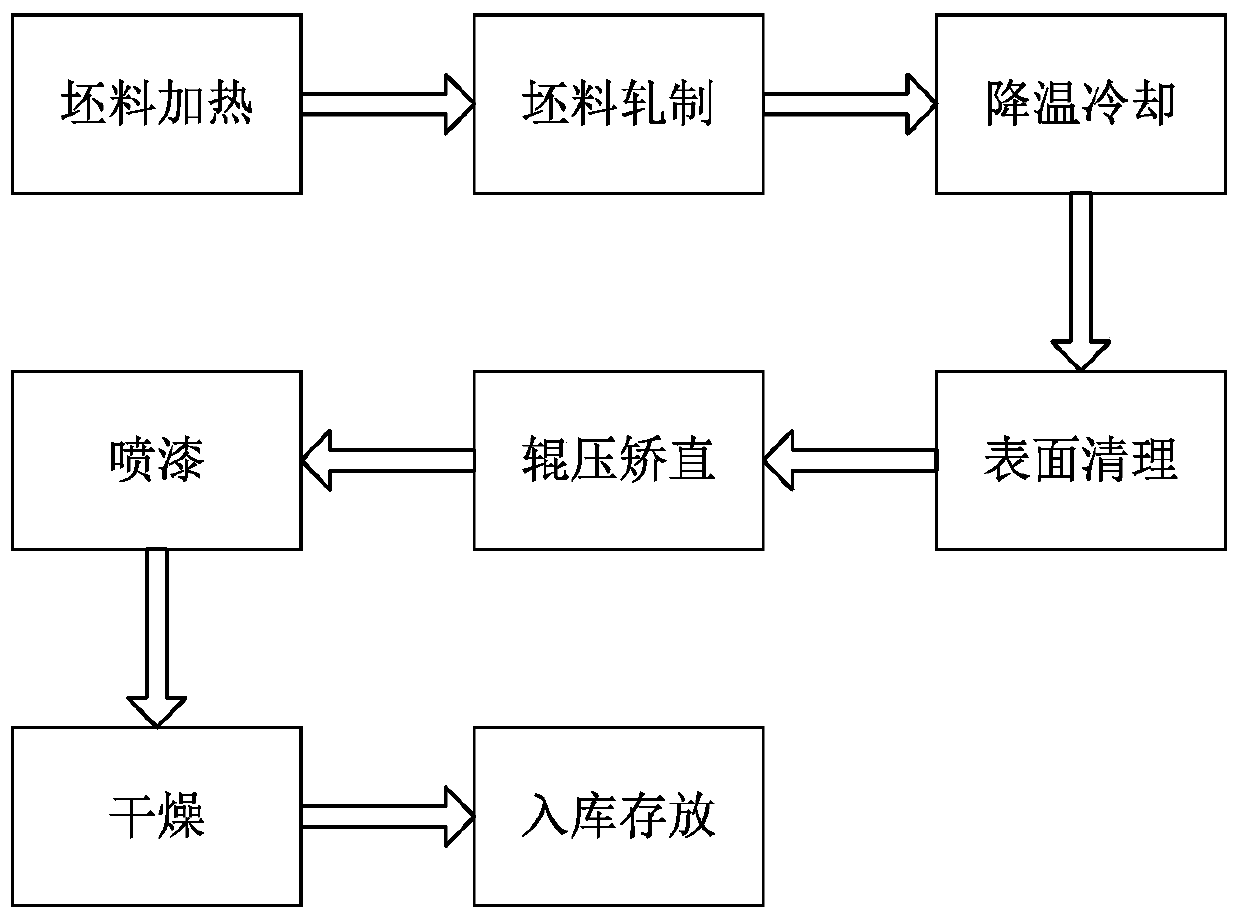

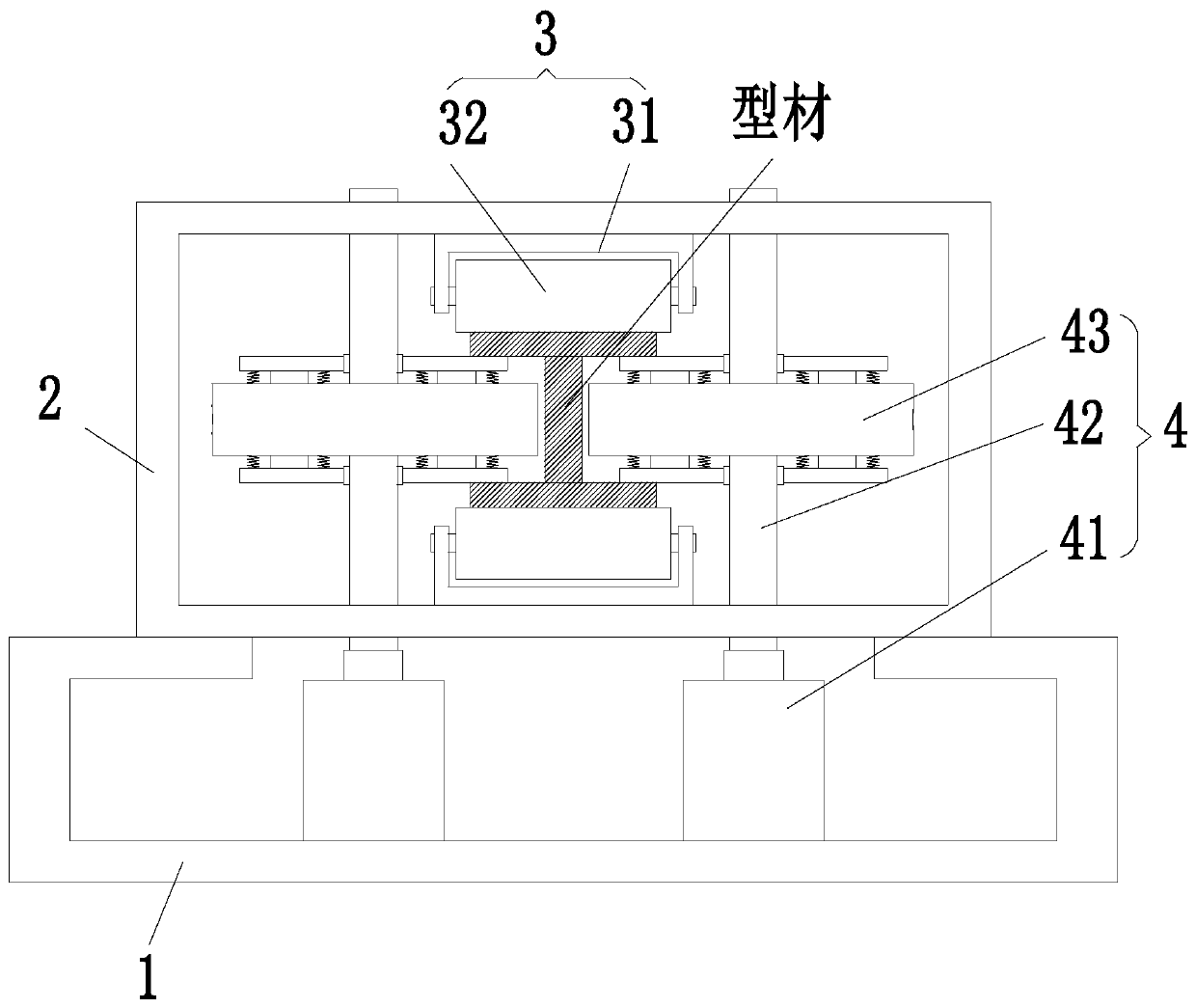

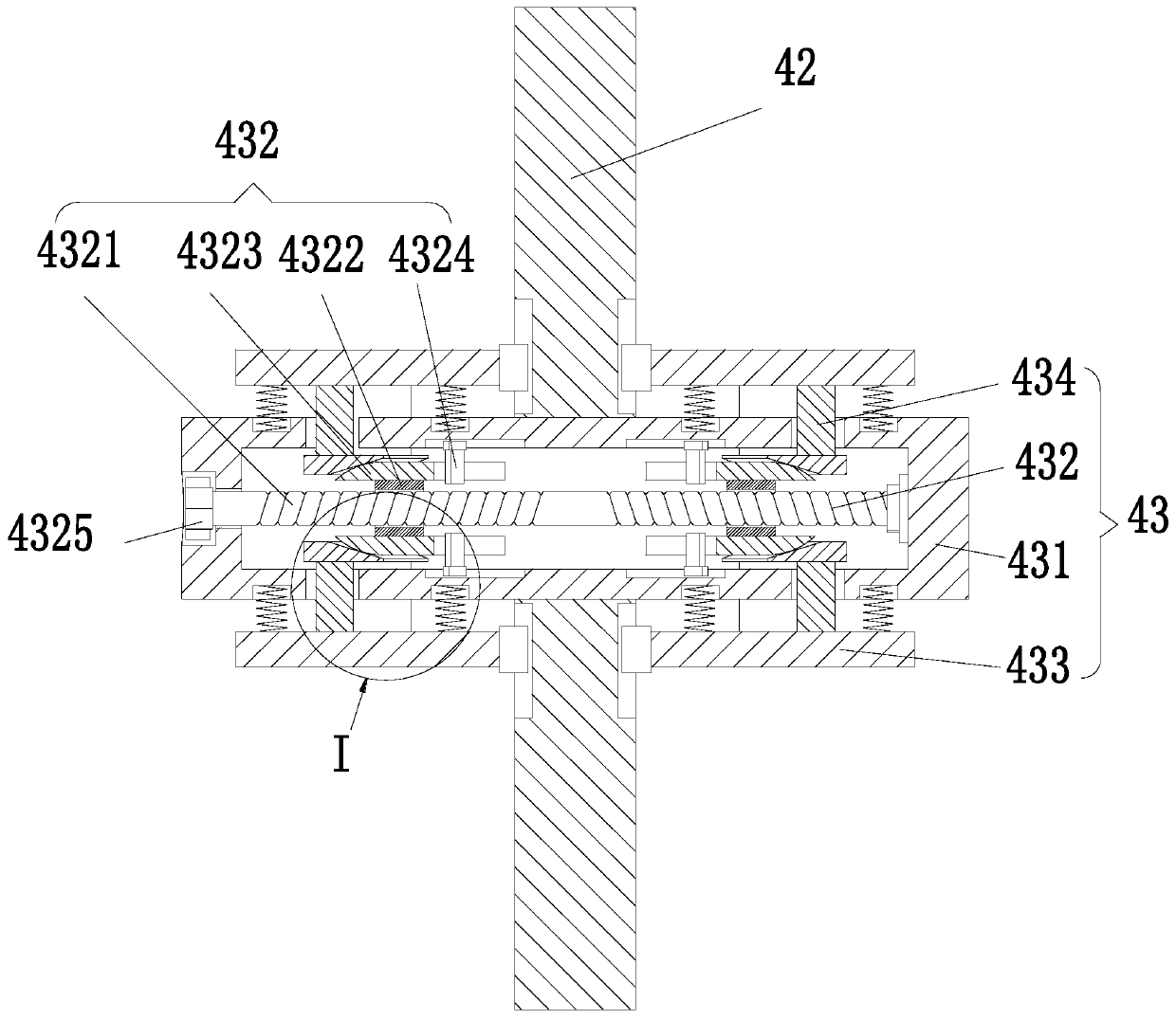

Finishing process for sectional material rolling

ActiveCN110449462AGood adaptabilityReduce inefficiencyMetal rolling arrangementsMechanical engineeringEngineering

Owner:ZHUMADIAN ZHONGDUO ALUMINUM

Fur storage device

The invention discloses a fur storage device which comprises a bearing block. A bearing groove is formed in one side of the bearing block. Two parallel first slide grooves are formed in the opposite side walls in the bearing groove respectively. A plurality of first sliders are installed in the first slide grooves from top to bottom. The four first sliders on the same side form a group, and a bearing plate is fixed among the first sliders in the same group. A plurality of second limiting holes are formed in the side wall of one end in each first slide groove at equal intervals. Fur is conveniently stored and is prevented from being affected by the external environment, the quality of the fur is protected, movement is convenient, subsequent processing and using are facilitated, the qualityof the finished product is effectively ensured, the fur can be conveniently put away and placed on the bearing plate by an operator, the space can be effectively used, the waste of the high layer space cannot be caused, the use rate of the storage space is increased, the storage amount is increased, the structure is simple, operation is convenient, and the fur storage device is suitable for popularization.

Owner:吕彬

Heat-conduction-fiber-enhanced high heat conductivity graphite cooling fin and manufacturing method

ActiveCN104144597AImprove mechanical propertiesHigh strengthCooling/ventilation/heating modificationsFiberGraphite

The invention provides a heat-conduction-fiber-enhanced high heat conductivity graphite cooling fin and a manufacturing method. The graphite cooling fin is a sheet product formed in the mode that mixed raw materials are expanded by a graphite expansion furnace at a high temperature and pressed by a graphite coiled material double-roller device, wherein the mixed raw materials comprise graphite powder and graphite fibers, the proportion of the graphite powder to the graphite fibers is 2-1000:1. The manufacturing method of the heat-conduction-fiber-enhanced high heat conductivity graphite cooling fin overcomes the defects that in a traditional manufacturing process, the mechanical property is low, the service life is short, and dropping is easily caused, the mechanical strength and the purity are greatly improved, convenience is brought to follow-up machining and use, the heat-conduction-fiber-enhanced high heat conductivity graphite cooling fin has the advantages of being light in weight, high in strength, high in heat-conduction performance and the like, and the using scope of graphite sheets is expanded.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

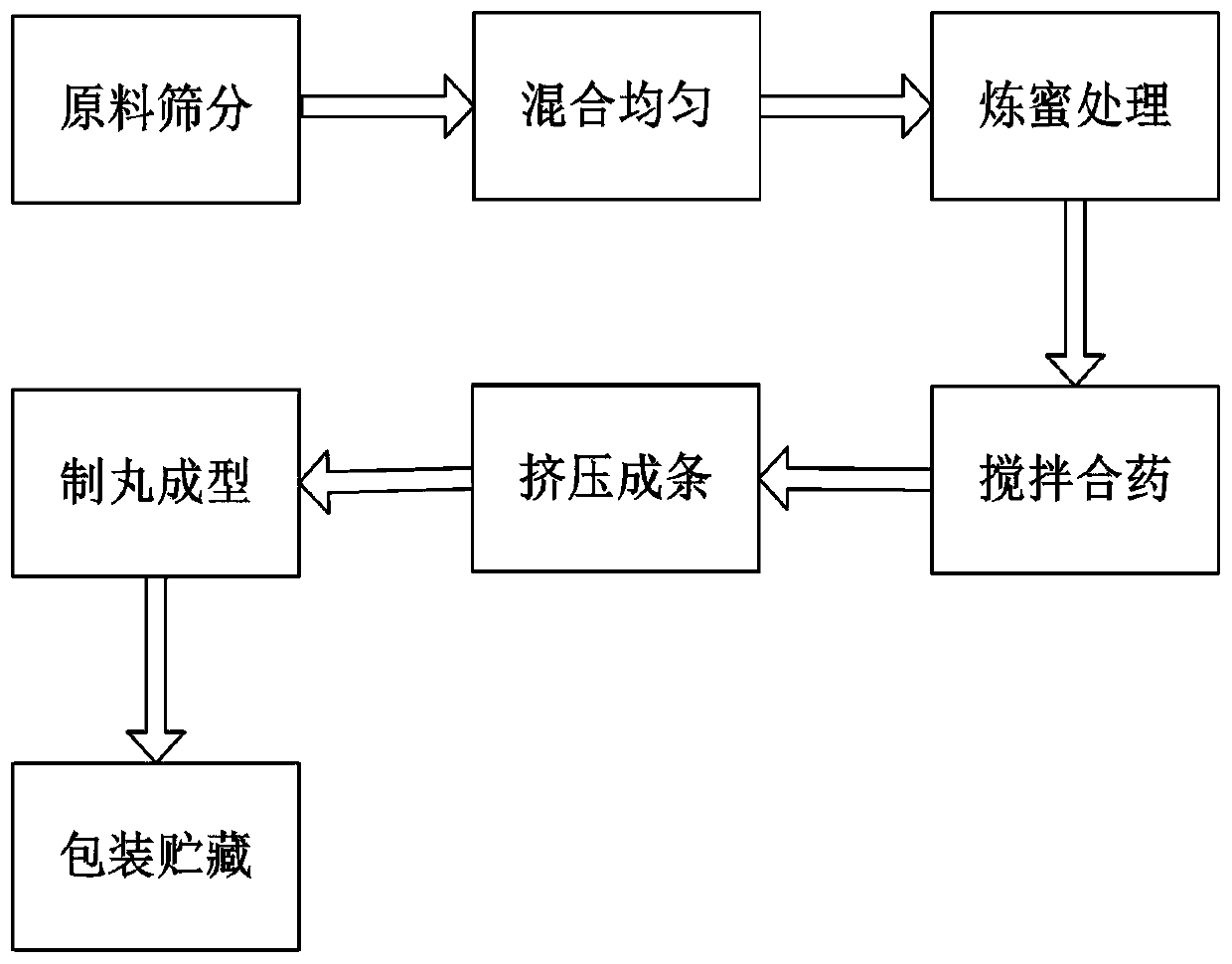

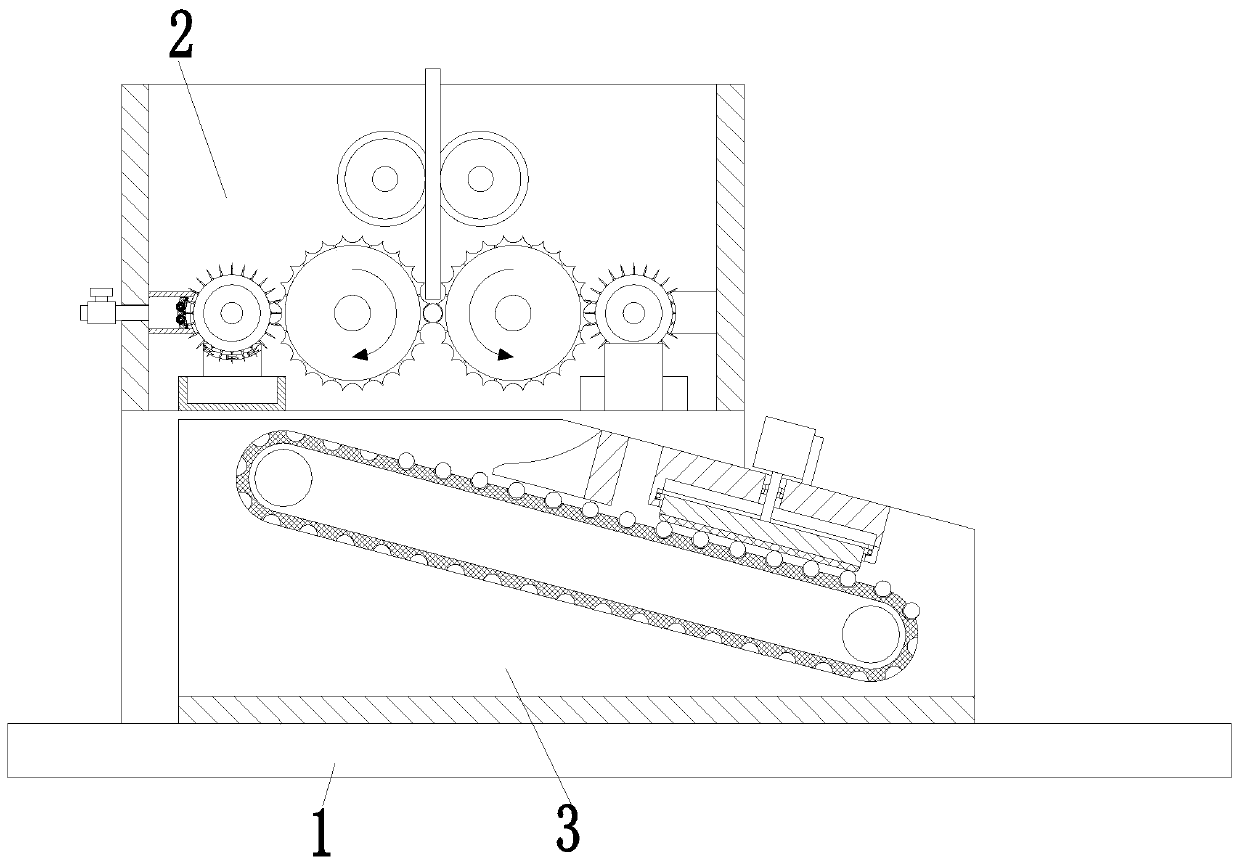

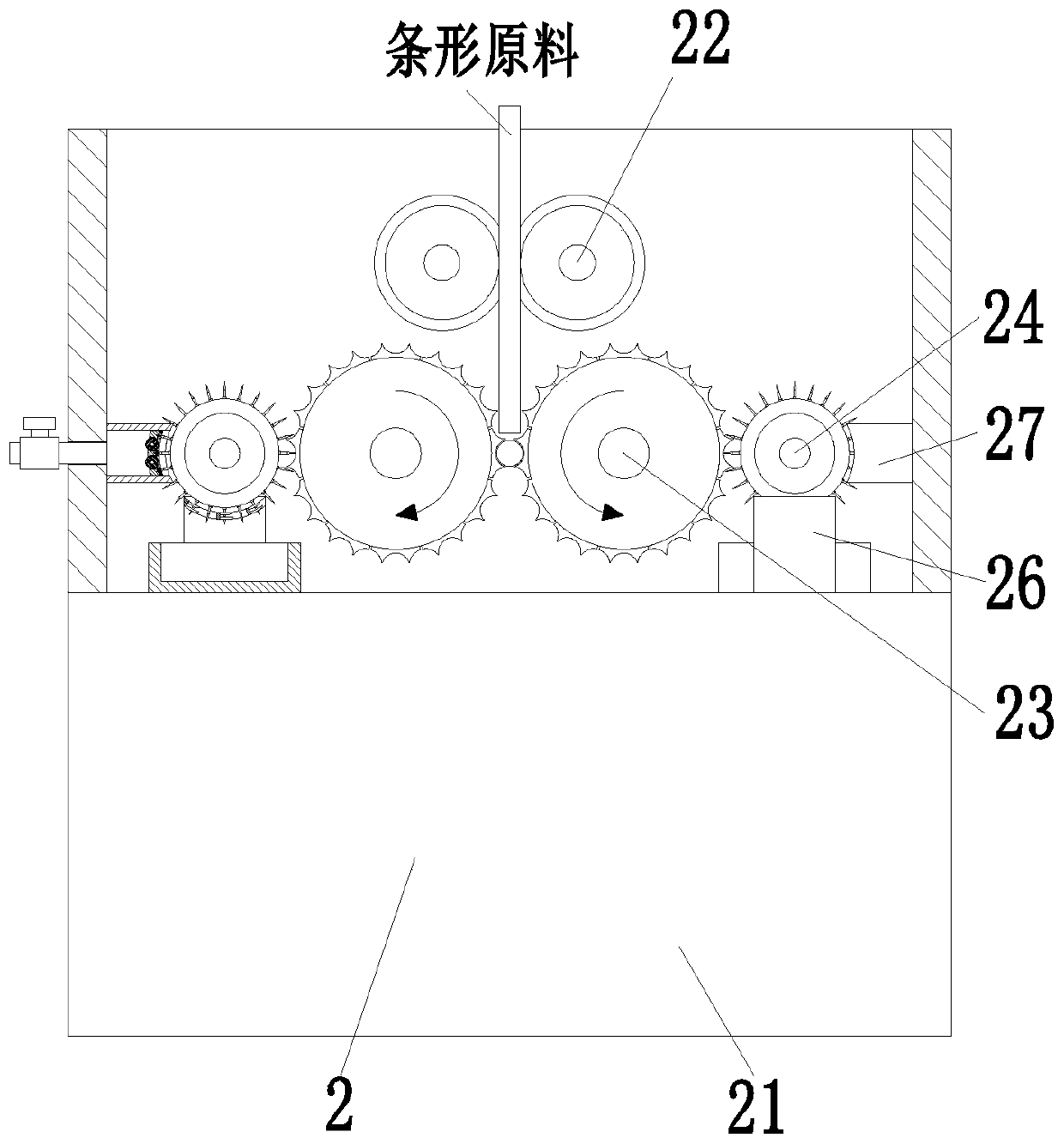

Preparation process of eight-material pills

ActiveCN111590950AGood cutting effectEvenly dicedPharmaceutical product form changeShaping pressStructural engineeringMechanical engineering

The invention relates to a preparation process of eight-material pills. The preparation process comprises a bottom plate, a granulating device and a rubbing device, wherein the granulating device is mounted at the upper end of the bottom plate; an empty groove is formed in the middle of the lower end of the granulating device; the rubbing device is arranged in the empty groove; and the rubbing device is mounted on the bottom plate. By adopting the preparation process provided by the invention, the difficulties that the diameters of the prepared eight-material pills are not uniform, a cutting roller after cutting cannot be rapidly cleaned, a lot of impurities are easily accumulated on the cutting roller and the cutting effect is influenced, and meanwhile, when existing equipment is used forprocessing the eight-material pills, the cut raw materials cannot be effectively finished, so that the prepared pills are irregular, subsequent processing of the pills is influenced and the like, caused by the fact that the existing equipment is used for cutting the raw materials and the cutting is not uniform can be solved.

Owner:池州市九华府金莲智慧农业有限公司

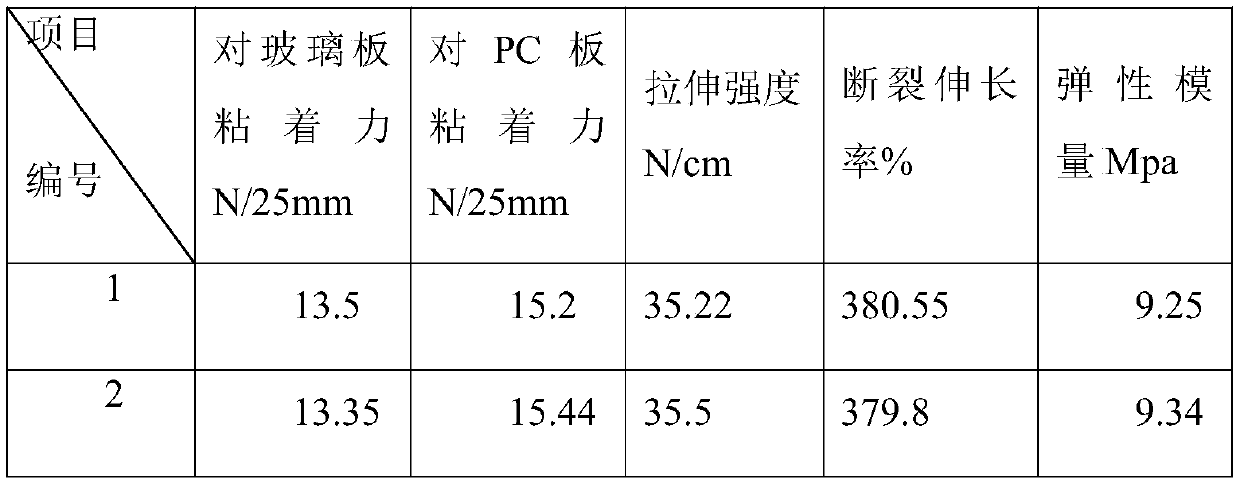

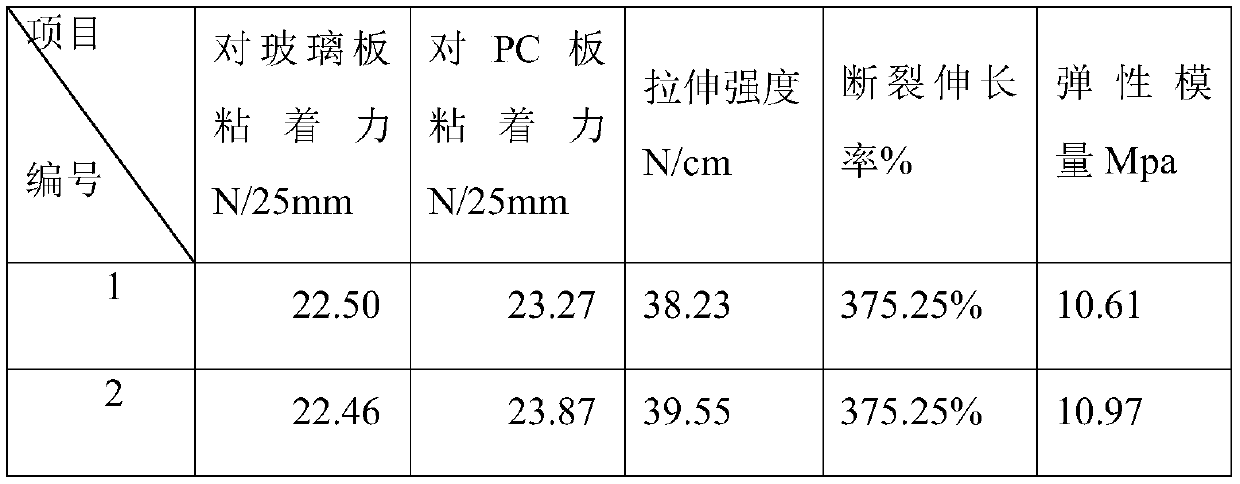

Film material and preparation method thereof

PendingCN111100566AImprove production yieldWon't breakPolyureas/polyurethane adhesivesHeat-activated film/foil adhesivesPolymer scienceThin membrane

A film disclosed by the invention comprises a multilayer structure which is arranged in sequence. The multilayer structure at least comprises a hot melt adhesive layer, a TPU substrate layer and a UVadhesive microstructure coating, wherein the UV adhesive microstructure coating is provided with a surface microstructure, and the microstructure comprises CD lines or drawn wires or concave-convex lines, an NCVM plating layer and an ink layer. The film provided by the scheme of the invention has good toughness, is beneficial to subsequent processing, and has good matching and fitting performancefor PC, glass materials and other materials.

Owner:江苏晶华新材料科技有限公司

Straw drying equipment

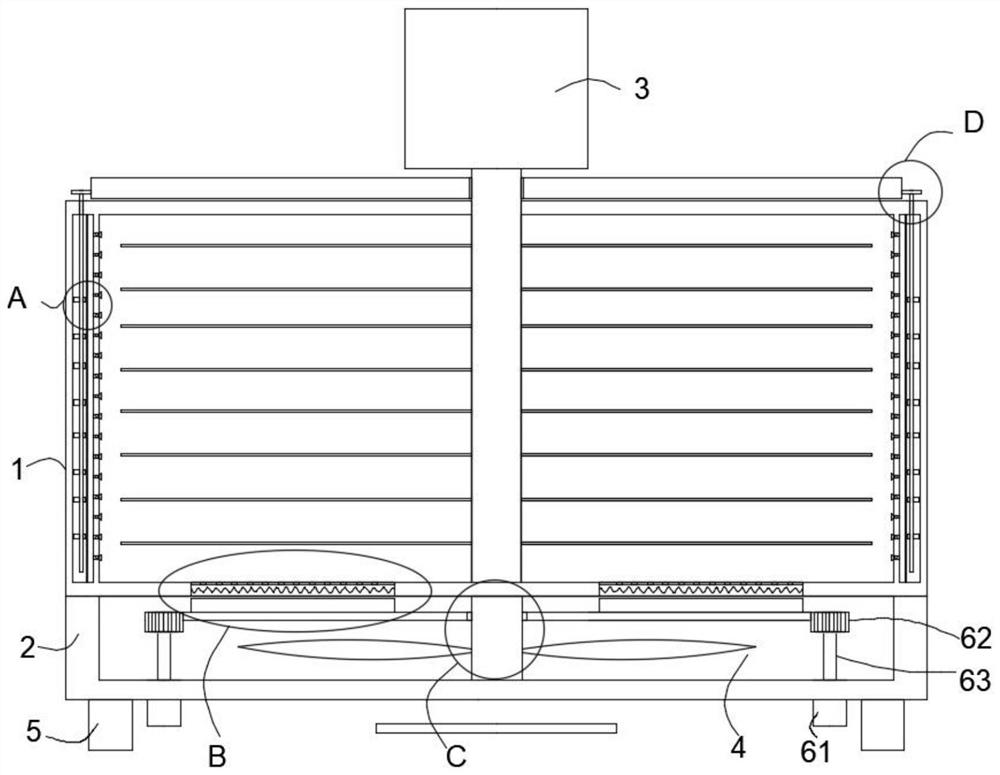

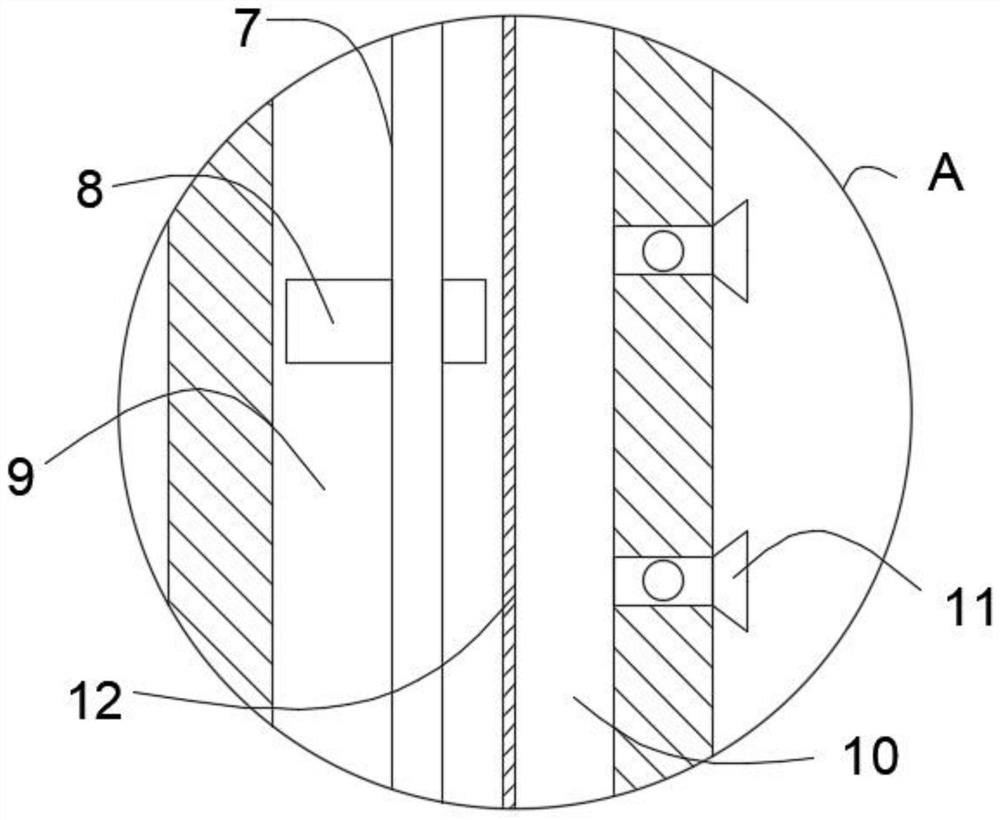

ActiveCN111121418ASimple equipment structureConducive to subsequent processingDrying gas arrangementsDrying solid materialsRotational axisIndustrial engineering

The invention discloses straw drying equipment which comprises a base, a first supporting plate arranged on the left side of the base, an electric motor fixedly arranged in the first supporting plate,a base space arranged in the base, a discharge trough formed in the lower end wall of the base space, a second supporting plate arranged on the right side of the base, a hot-air blower arranged on the right side of the base, a ventilating pipe arranged on the left end surface of the hot-air blower in a communicating manner, a base space arranged in the base, a feeding pipe arranged at the upper end of the base space in a communicating manner, a rotating shaft fixedly arranged at the output end of the electric motor, a fan device arranged in the base space and three pushing devices separatelyarranged on the rotating shaft from left to right.

Owner:ANJI YUHONG CLAY CHEM

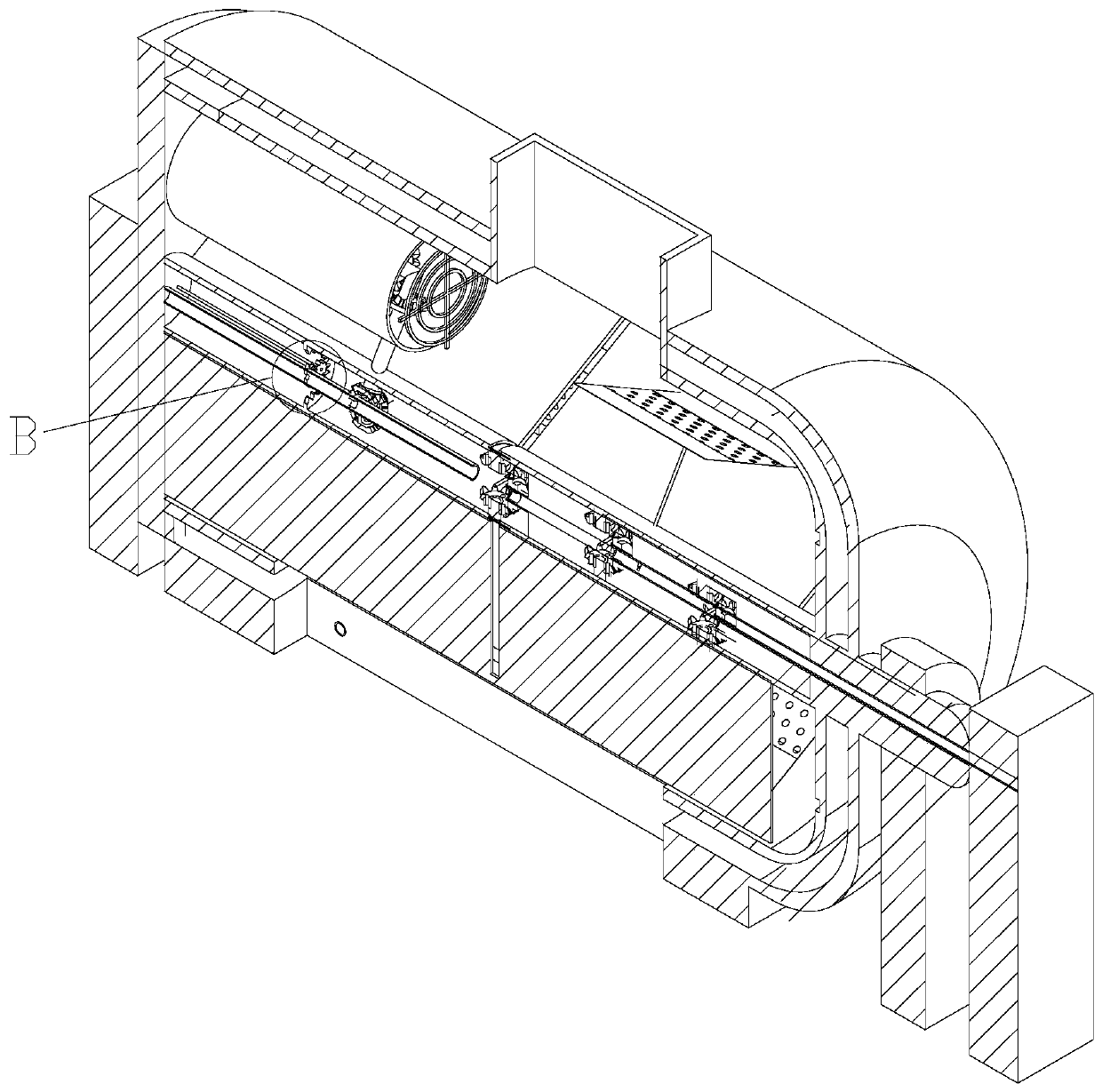

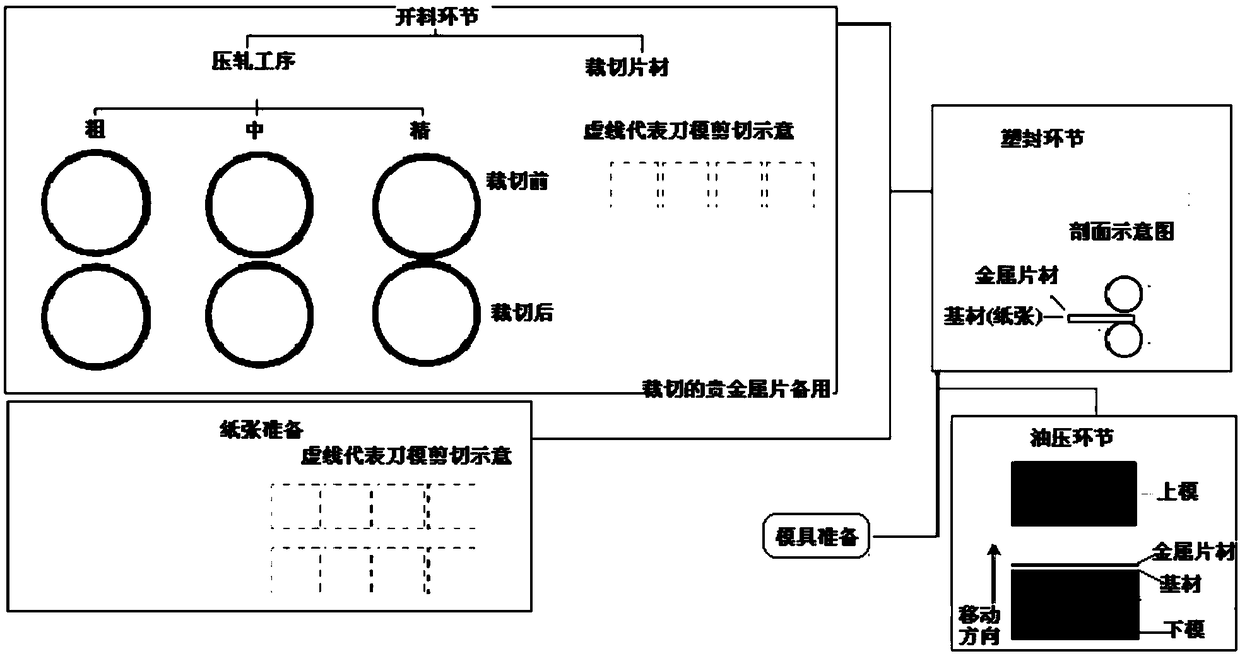

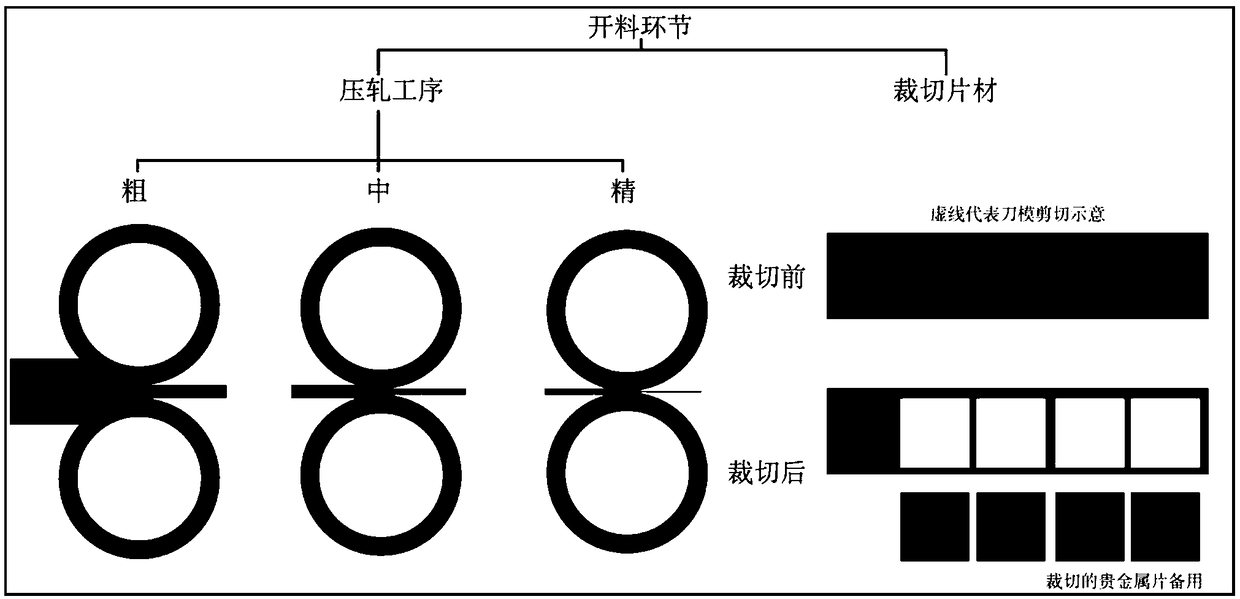

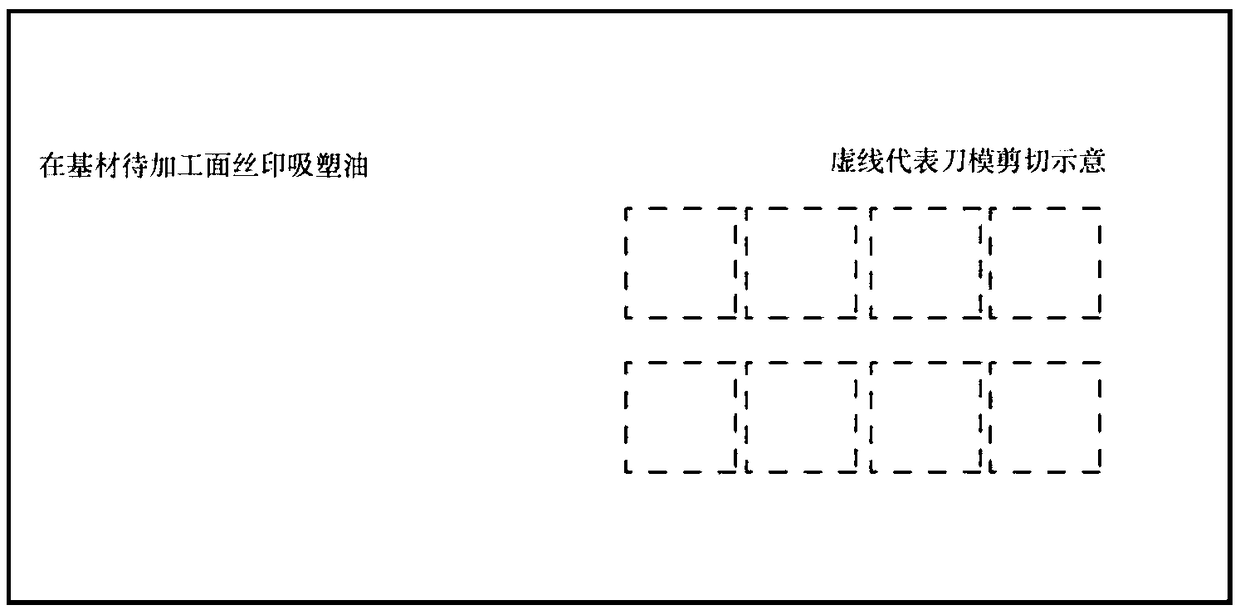

Noble metal and base material compound embossing process method and process product thereof

PendingCN109397961ANot easy to damageWon't breakDecorative surface effectsSpecial ornamental structuresWaxPentaerythritol

The invention provides a noble metal and base material compound embossing process method. The method comprises the steps of 1, a material cutting procedure, wherein sheets are obtained and cut; 2, preparation of a base material, wherein blister varnish is bonded to a to-be-processed surface of the base material, and the base material and the noble metal sheets are cut according to a certain size ratio and shape; 3, heating and plastic sealing, wherein the cut noble metal sheets are compounded with the cut base material; 4, oil pressing, wherein a compounded product is placed on a mold formingsurface for oil pressing to achieve a preset surface effect on the surface of the product. The corresponding noble metal and base material compound embossing process product is also disclosed and comprises a noble metal layer, the base material and a blister varnish layer, wherein the base material is disposed on one side of noble metal and used for supporting the noble metal layer, and the blister varnish layer is disposed between the noble metal layer and the blister varnish layer and used for connecting the noble metal layer with the blister varnish layer and is a mixture of butadiene styrene, a polystyrene butadiene copolymer, rosin pentaerythritol ester, ethyl acetate and synthetic wax.

Owner:SHENZHEN JINBAOYING CULTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com