Straw drying equipment

A technology for drying equipment and straw, applied in the field of straw drying, can solve problems such as poor drying effect, and achieve the effect of simple structure of the equipment and favorable subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

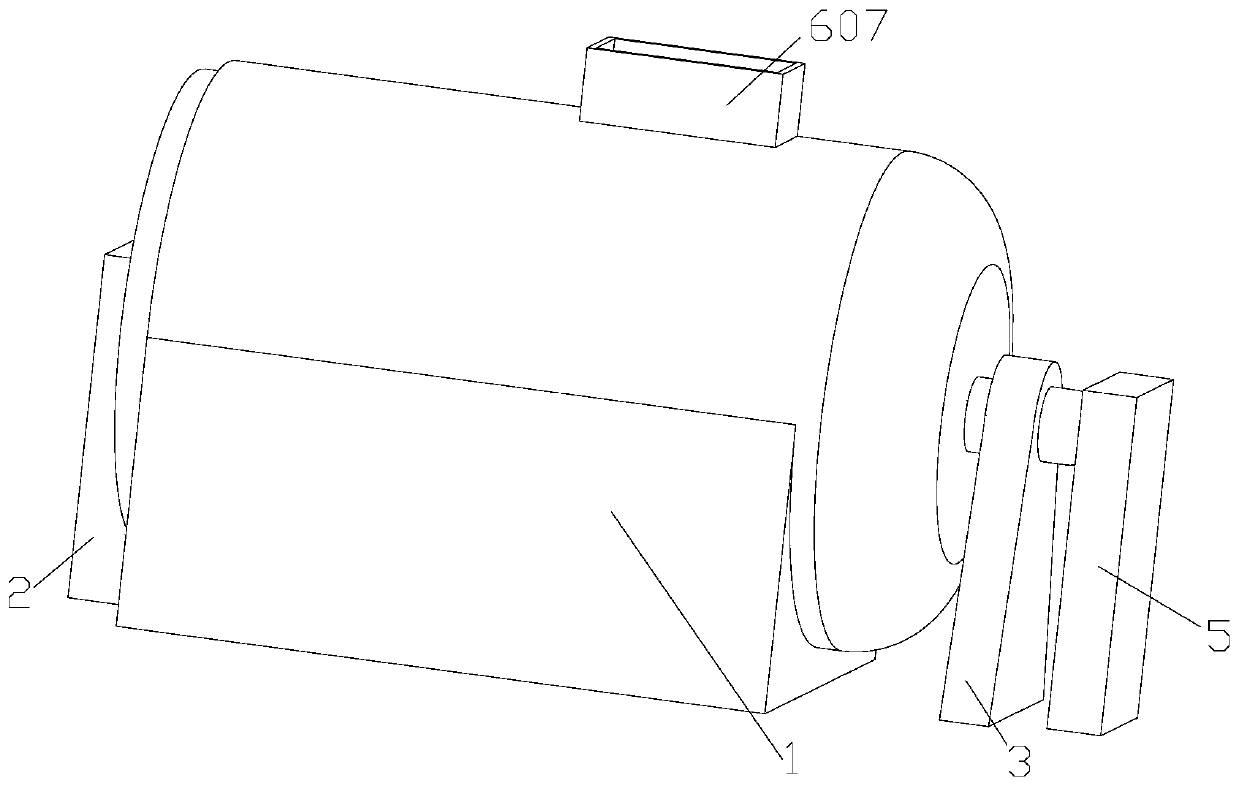

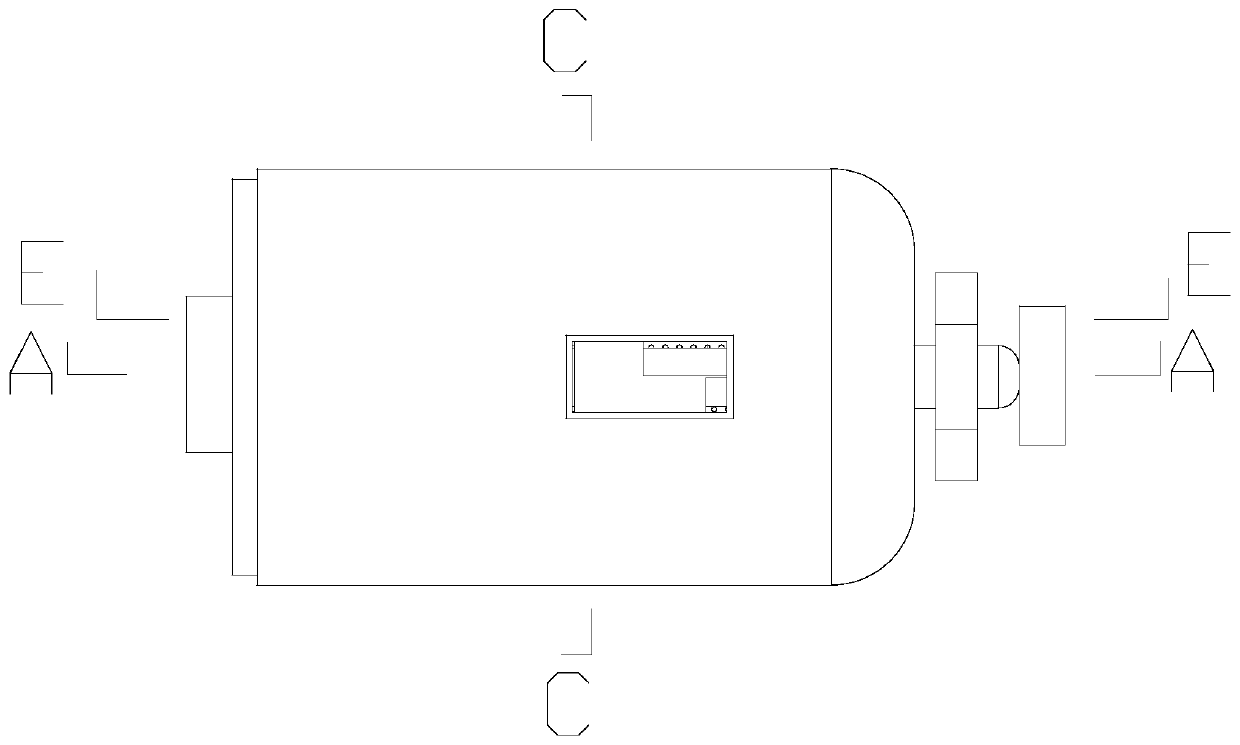

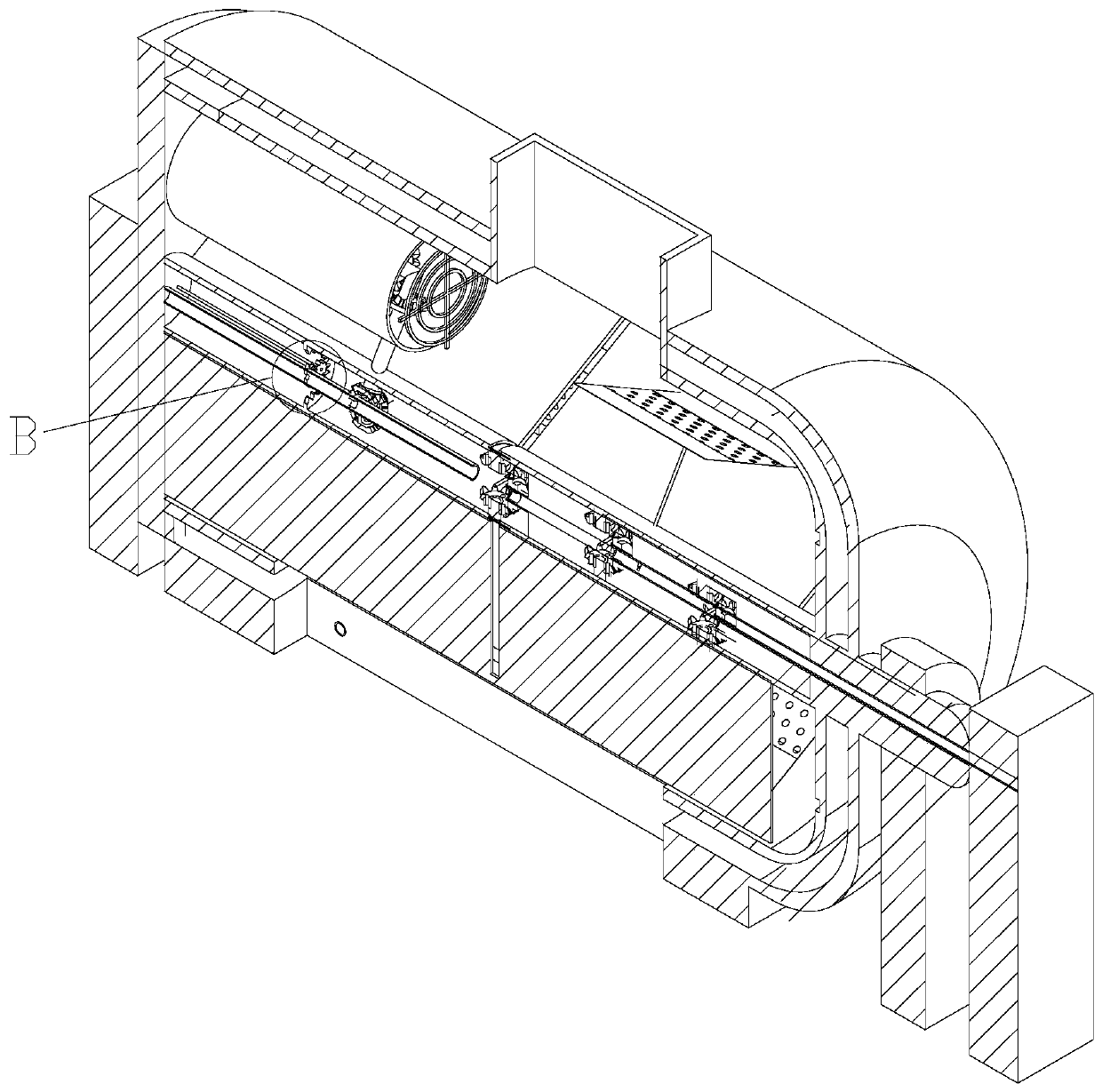

[0022] Such as Figure 1-10 As shown, a straw drying equipment includes a machine base 1, a first support plate 2 arranged on the left side of the machine base 1, a motor fixedly arranged in the first support plate 2, and a machine base set in the machine base 1 Space, the discharge chute arranged on the lower end wall of the machine base space, the second support plate 3 arranged on the right side of the machine base 1, the hot air blower 5 arranged on the right side of the machine base 1, and the ventilation pipe arranged on the left end surface of the hot air blower , the base space arranged in the base 1, the feeding pipe 607 arranged at the upper end of the base space, the rotating shaft 7 fixedly arranged at the output end of the motor, the fan device arranged in the base space, from left to right respectively Three pushing devices arranged on the rotating shaft 7, the processing box body 101 fixedly arranged on the rotating shaft 7, the processing space arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com