Bottom feed type gas method and equipment for preparing gas with no tar products through oxygendeficient fluid bed combustion

A fluidized combustion and gasification device technology, applied in the direction of granular/powdered fuel gasification, bulk chemical production, etc., can solve the problem of incomplete fuel gasification gasification efficiency, difficulty in applying large-scale processes and systems, and high equipment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

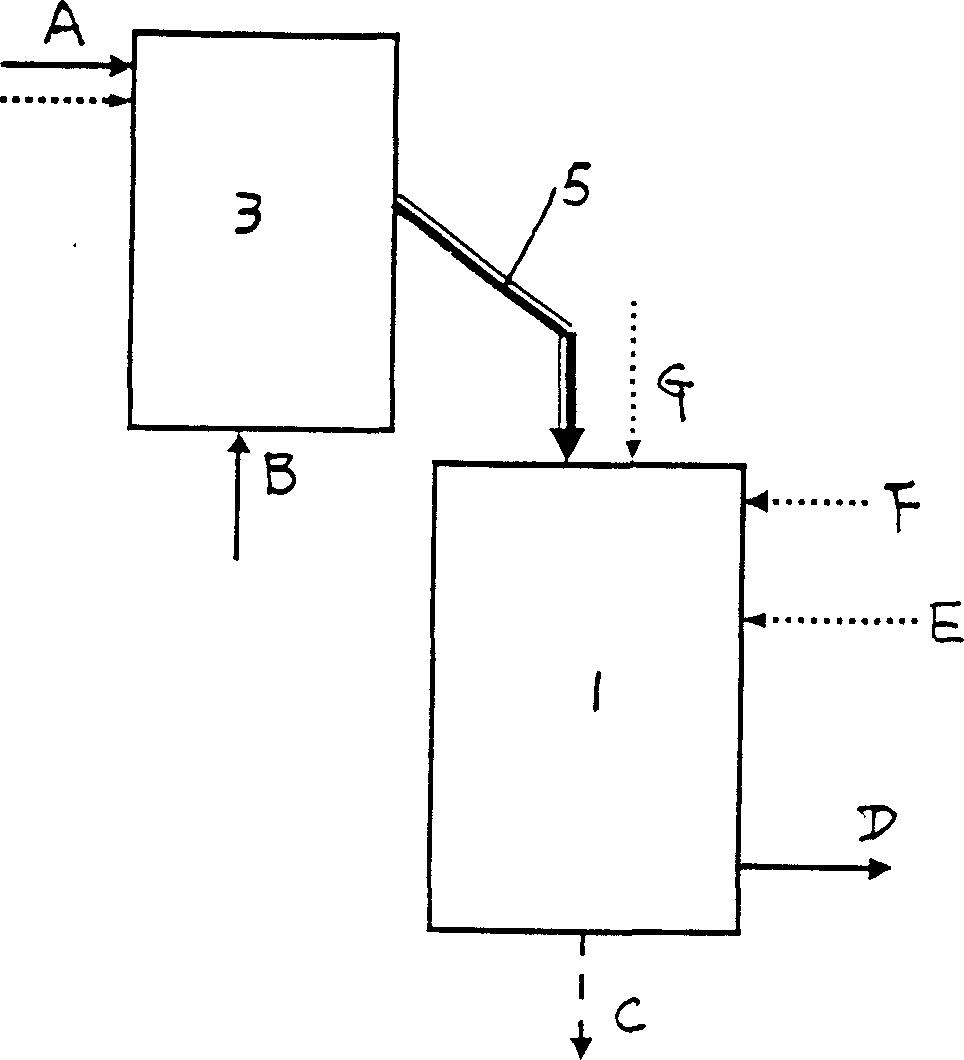

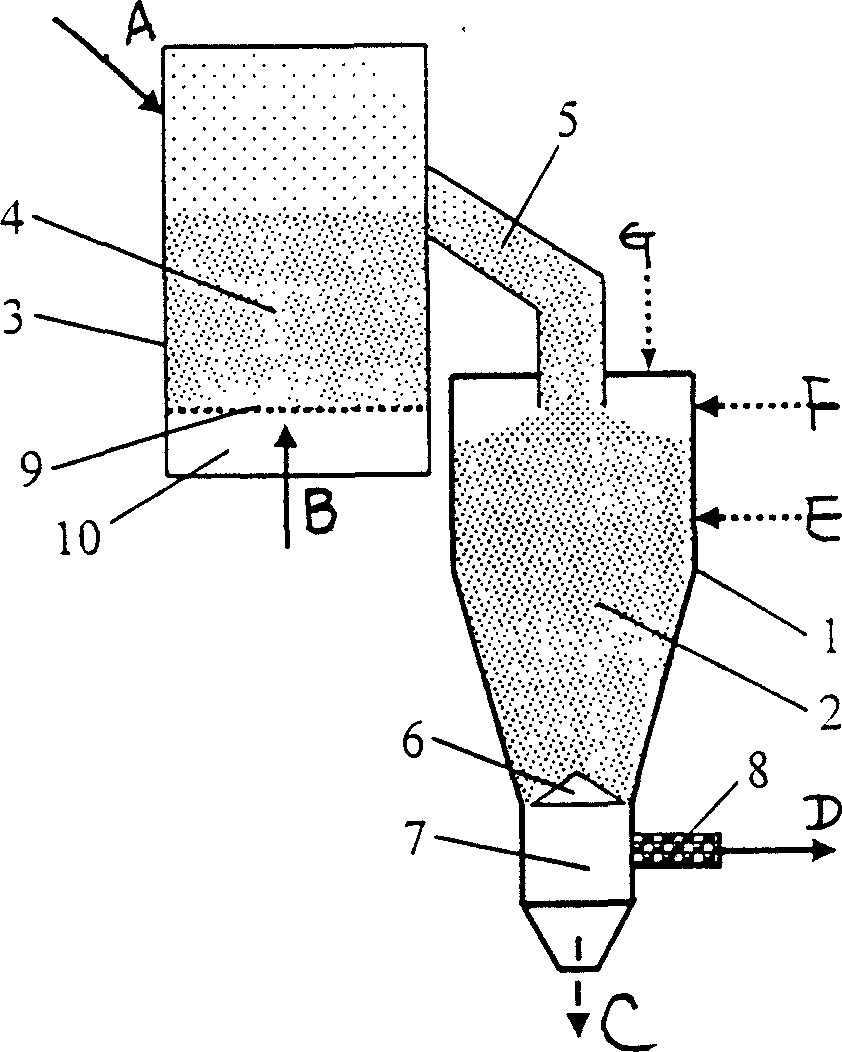

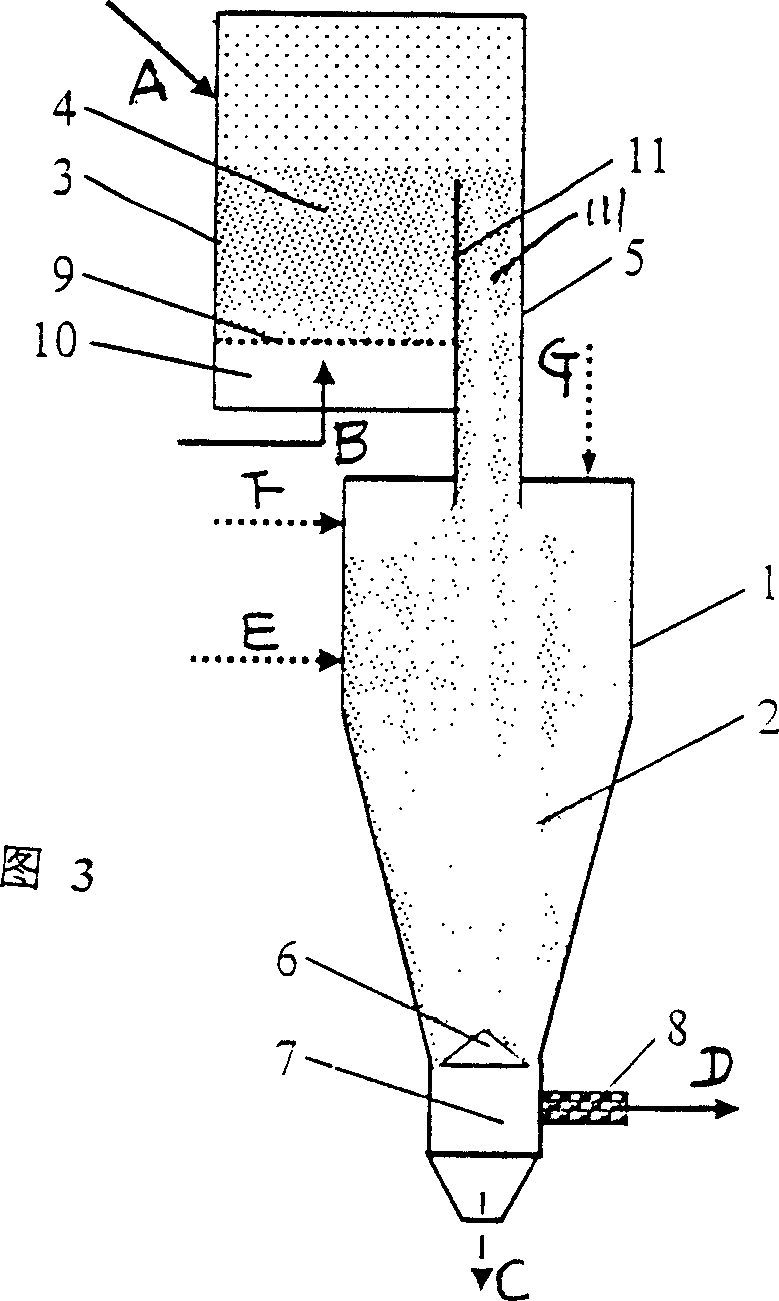

[0073] attached figure 2 For the implementation of figure 1 A schematic structural diagram of a gasification device for the gasification method of the present invention is shown. The device comprises: a downdraft fixed-bed gasifier 1, a fluidized-bed burner 3 and a delivery channel 5 connecting the two reactors. Here, the burner 3 referred to constitutes the pre-gasification stage, and the downdraft gasifier 1 constitutes the post-gasification stage. The transfer channel 5 is provided outside the fluidized bed combustor 3 . Fuel is fed into the fluidized bed reactor from the other side with respect to the channel 5 (to prevent the fed fuel from reaching the delivery channel 5 too quickly via a possible short circuit). According to the principle of the invention, the proportion of oxidant (detailed in the summary of the invention) is supplied into the fluidized bed gas dispersion chamber 10, and after being distributed by the gas dispersion plate 9, the fuel particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com