Patents

Literature

1020 results about "Organic solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic wastes are often disposed of with other wastes in landfills or incinerators, but since they are biodegradable , some organic wastes are suitable for composting and land application. Organic materials found in municipal solid waste include food, paper, wood, sewage sludge , and yard waste .

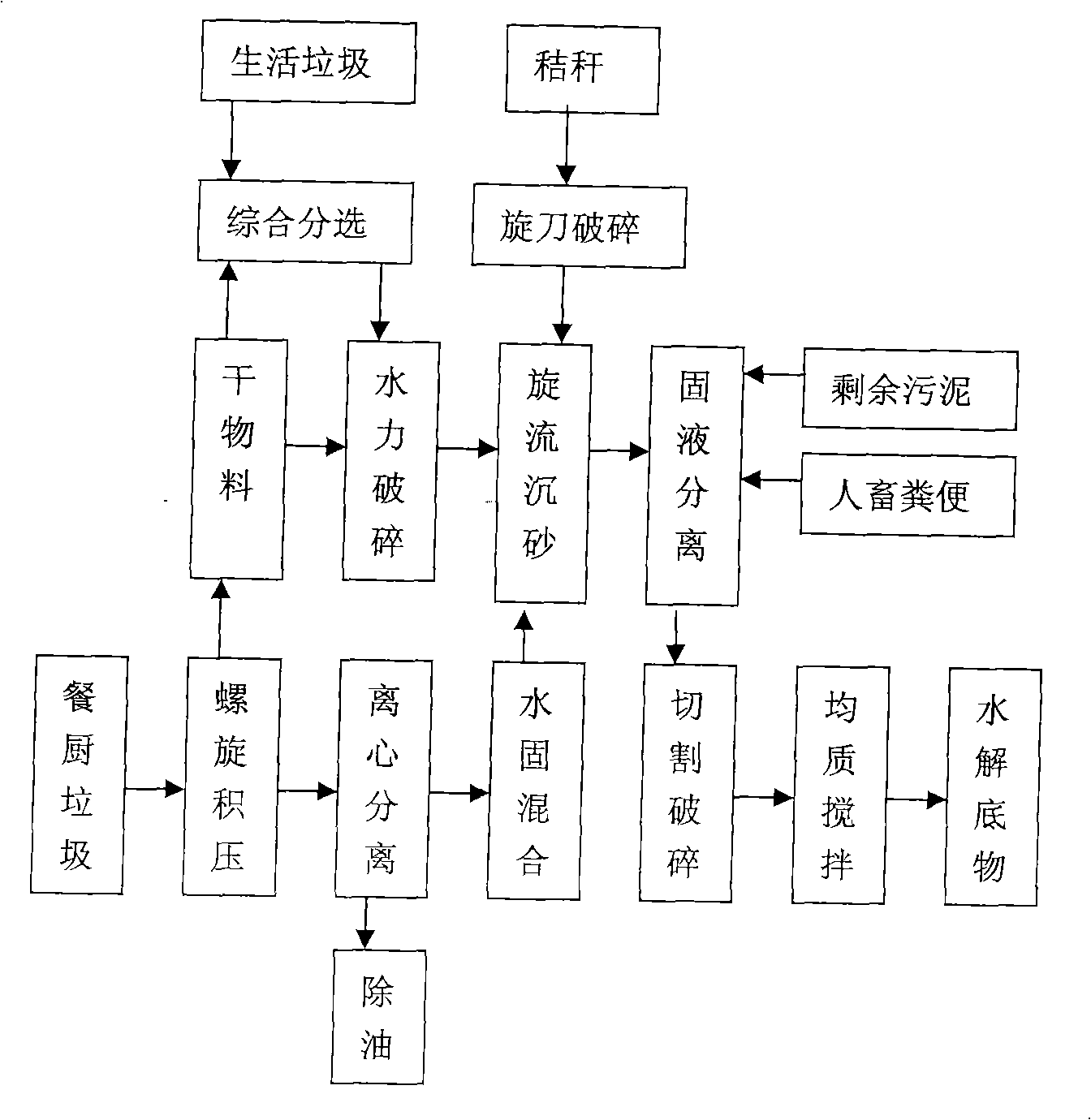

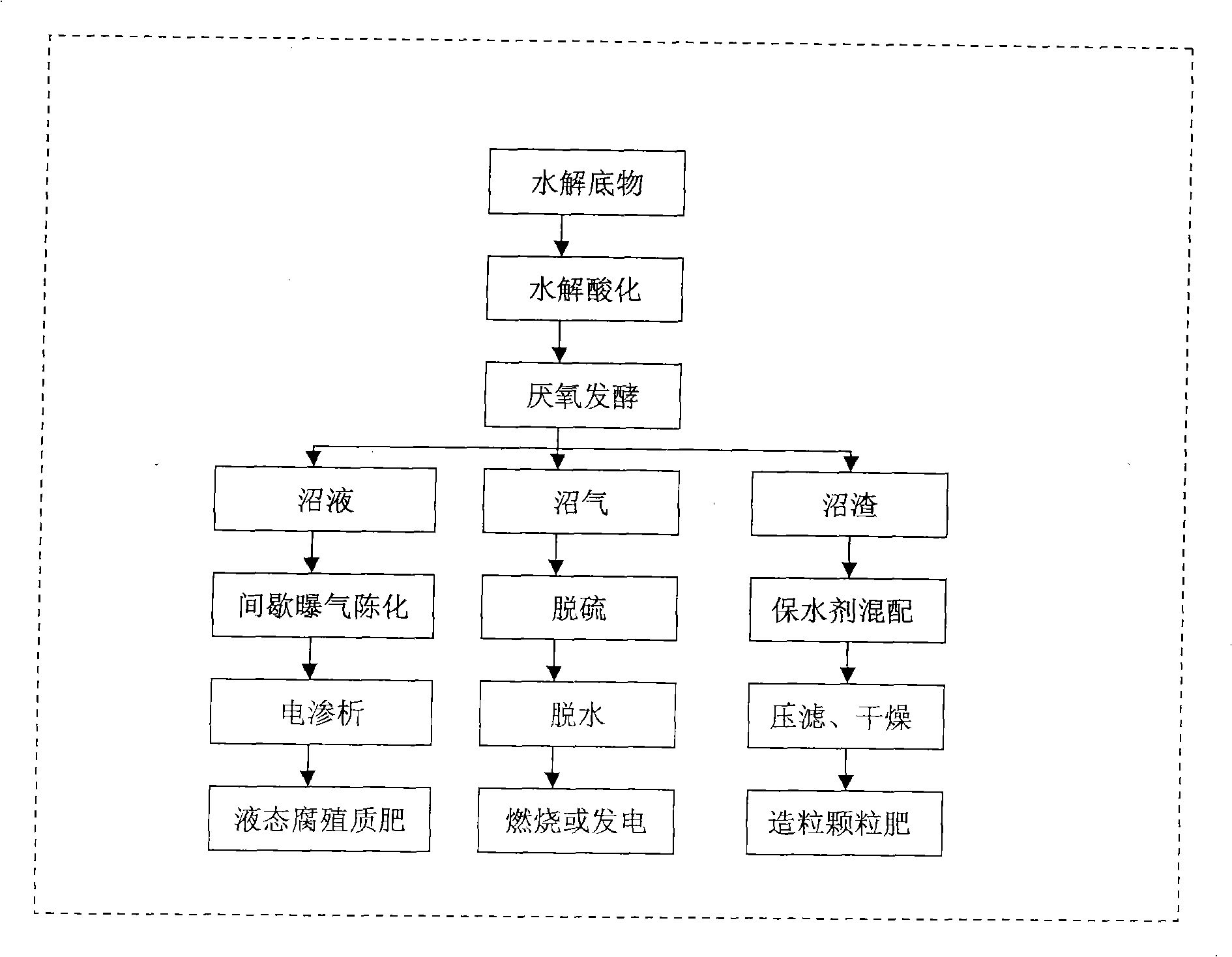

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

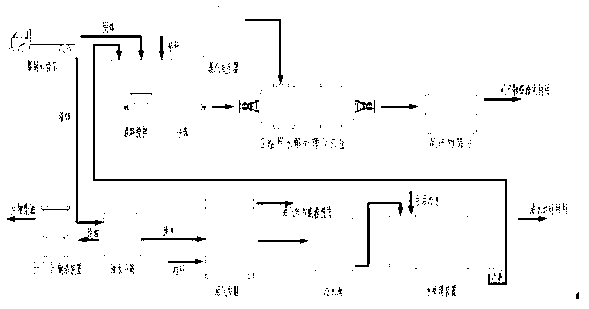

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

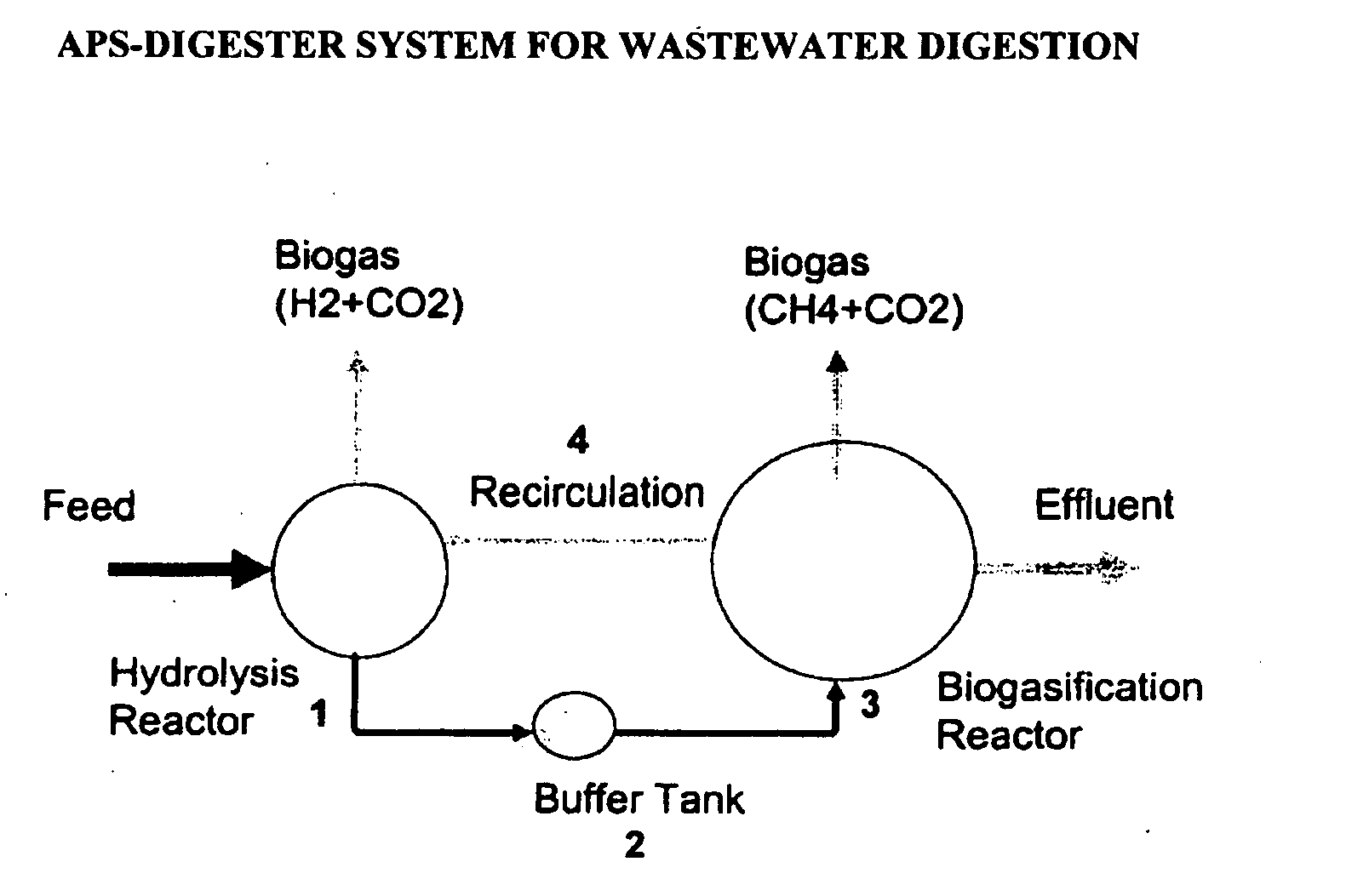

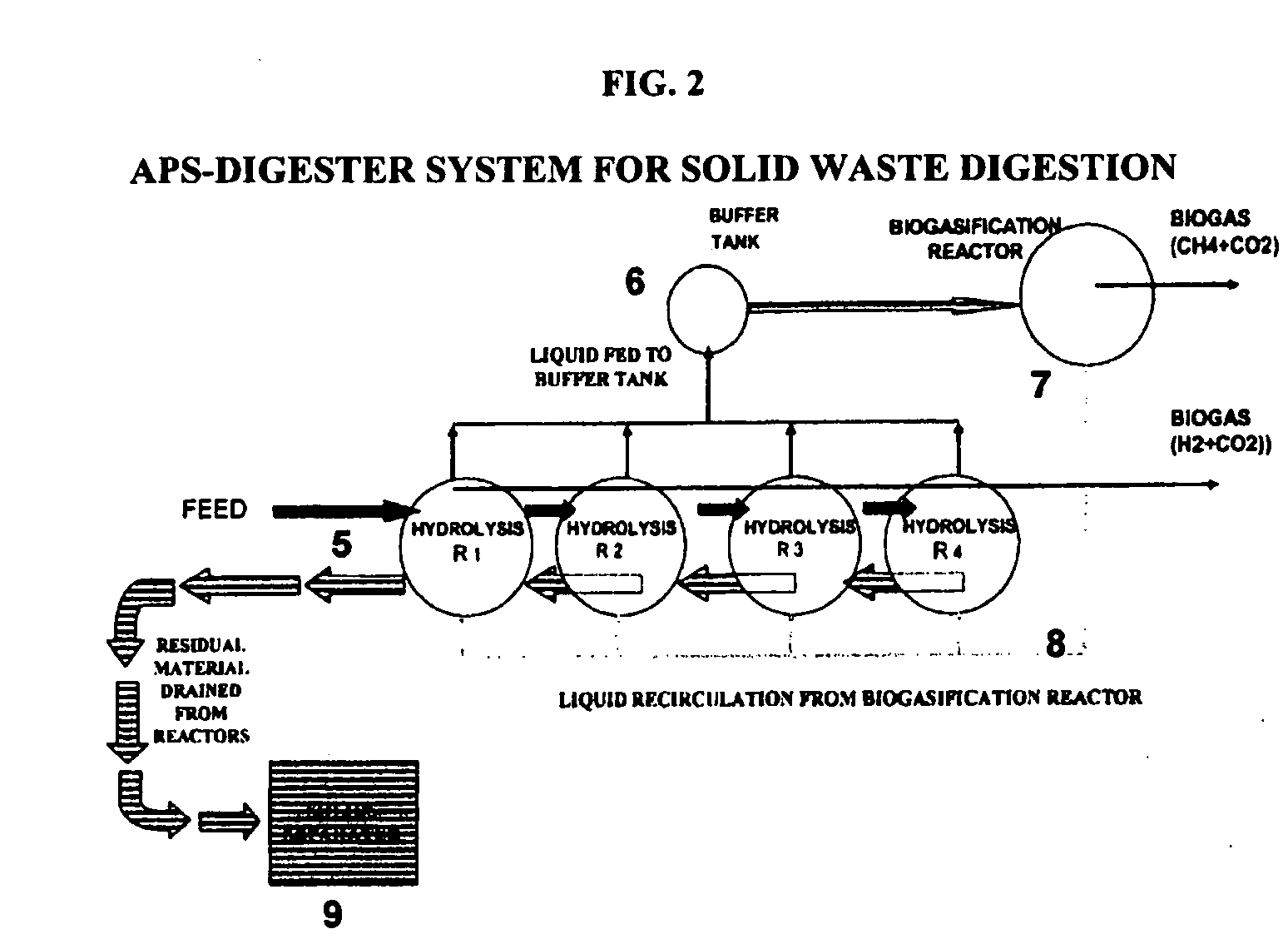

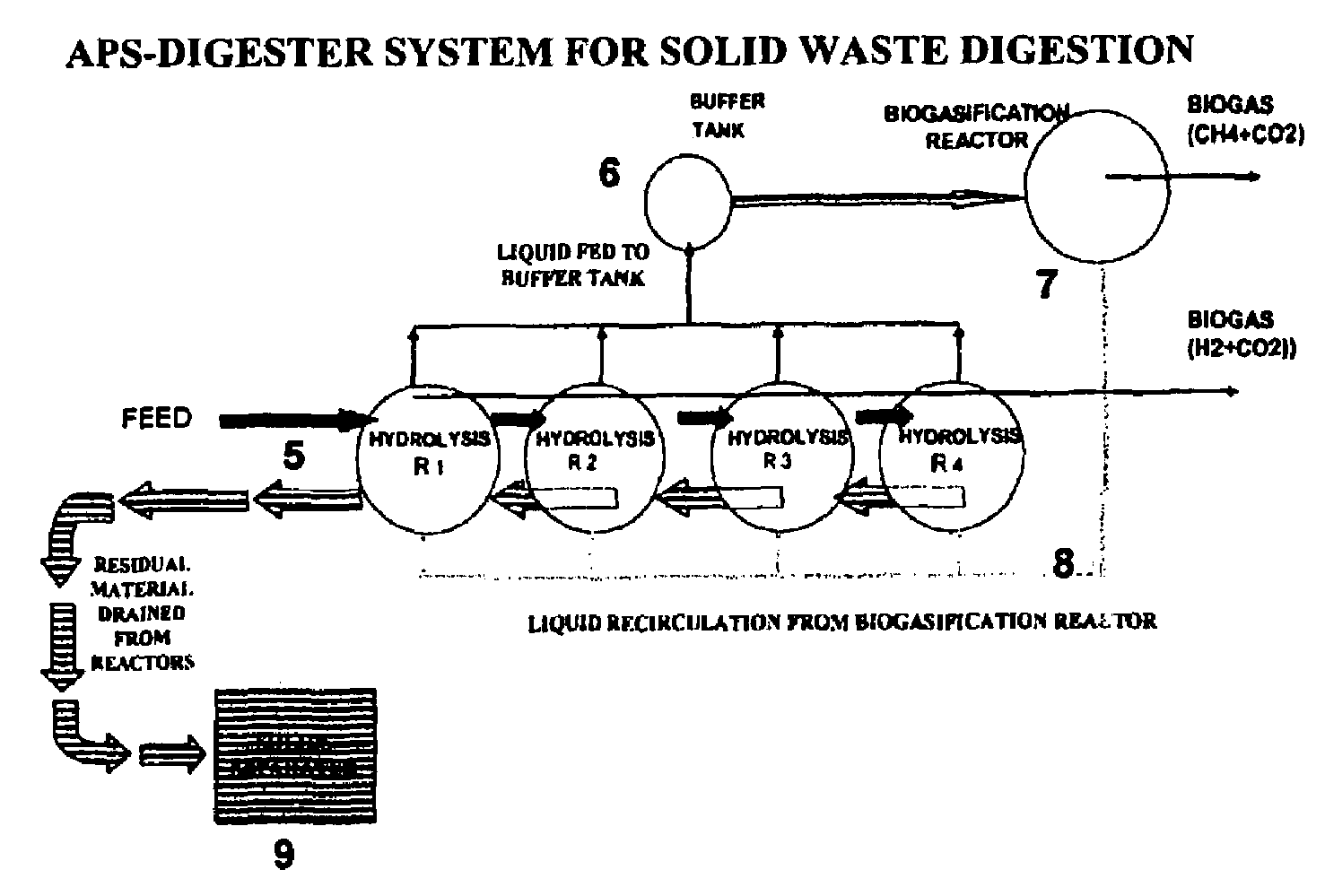

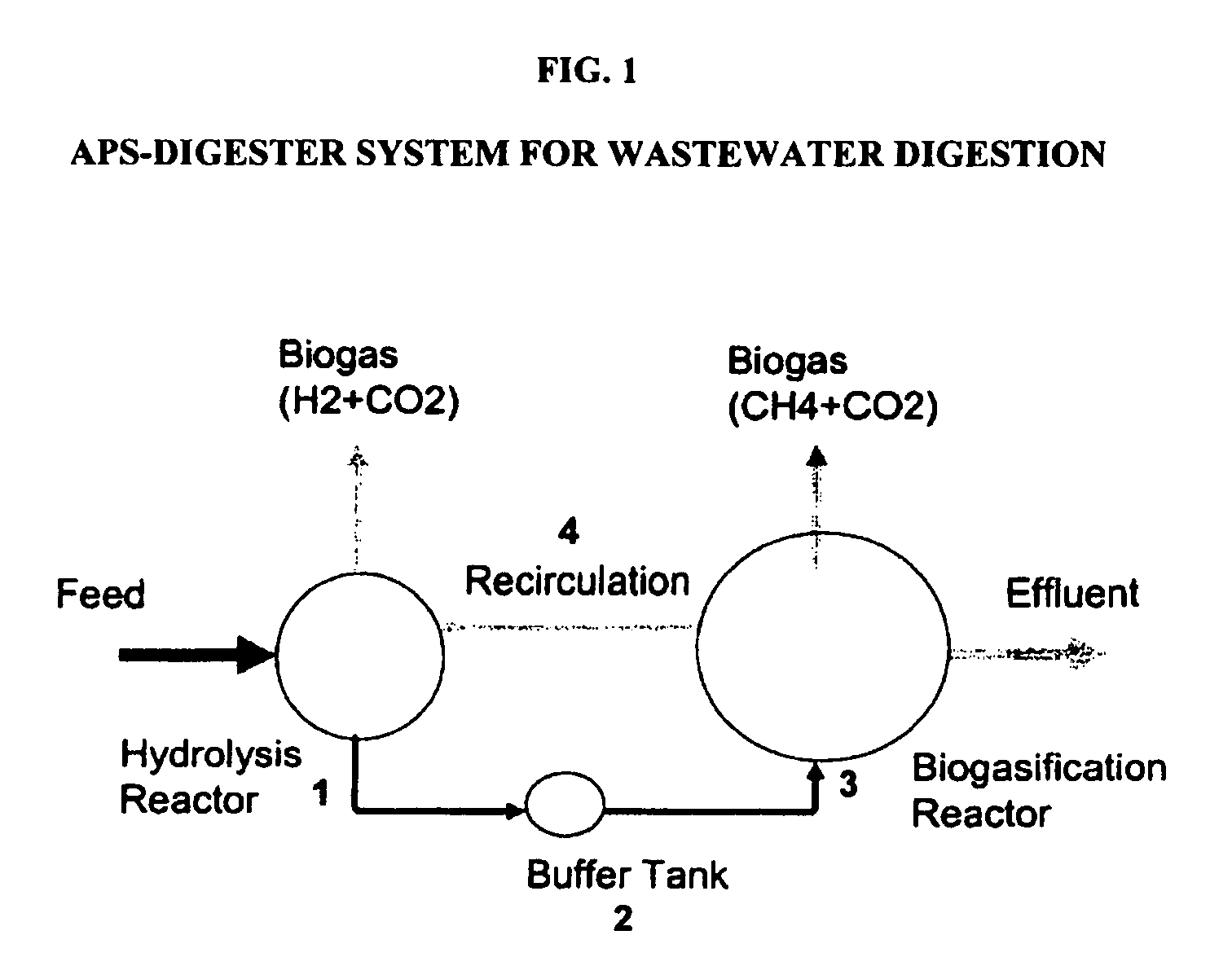

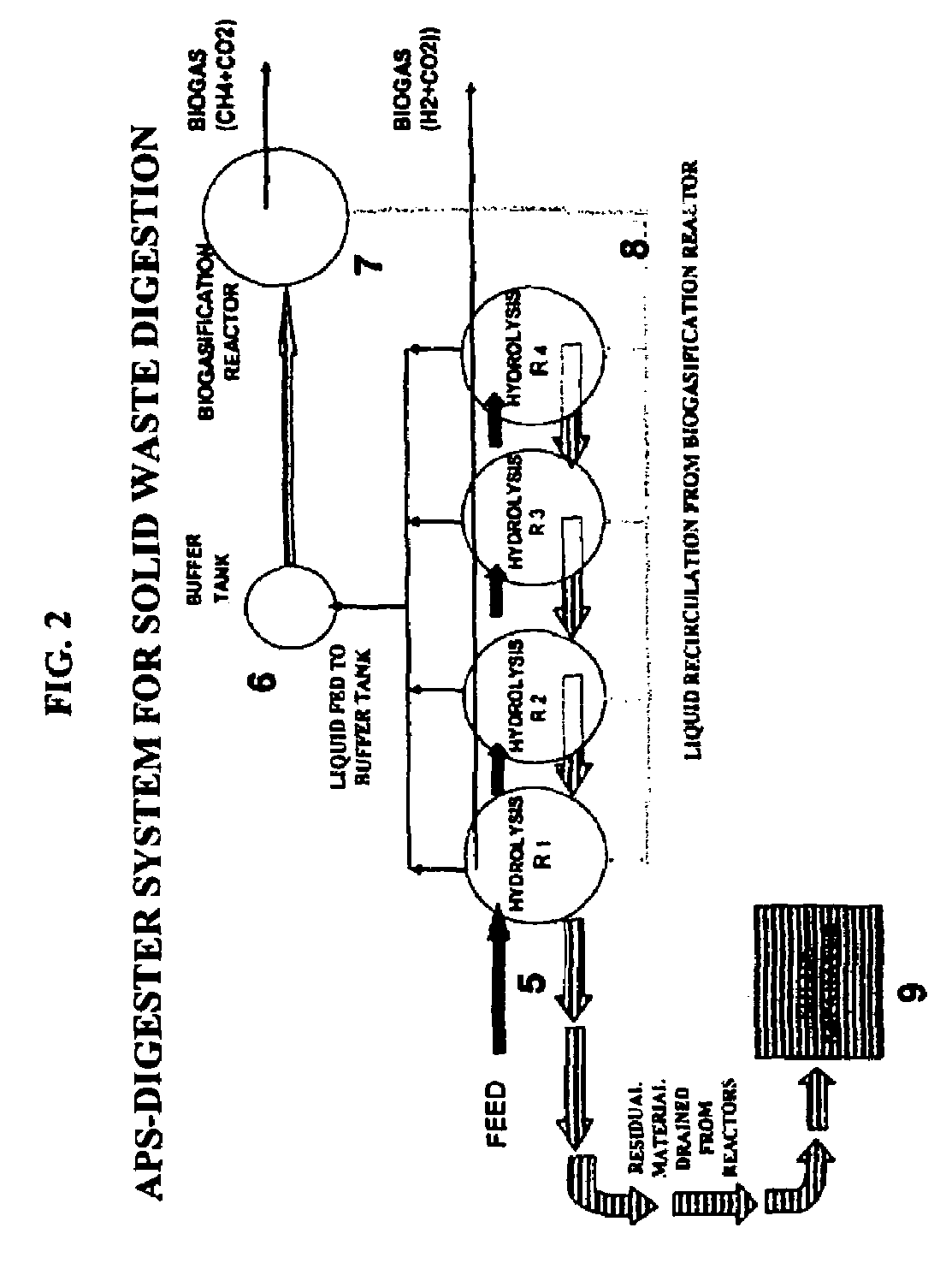

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS20070158264A1Improve energy conversion efficiencyLess air emissionLiquid degasificationBiological substance pretreatmentsHigh rateBuffer tank

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

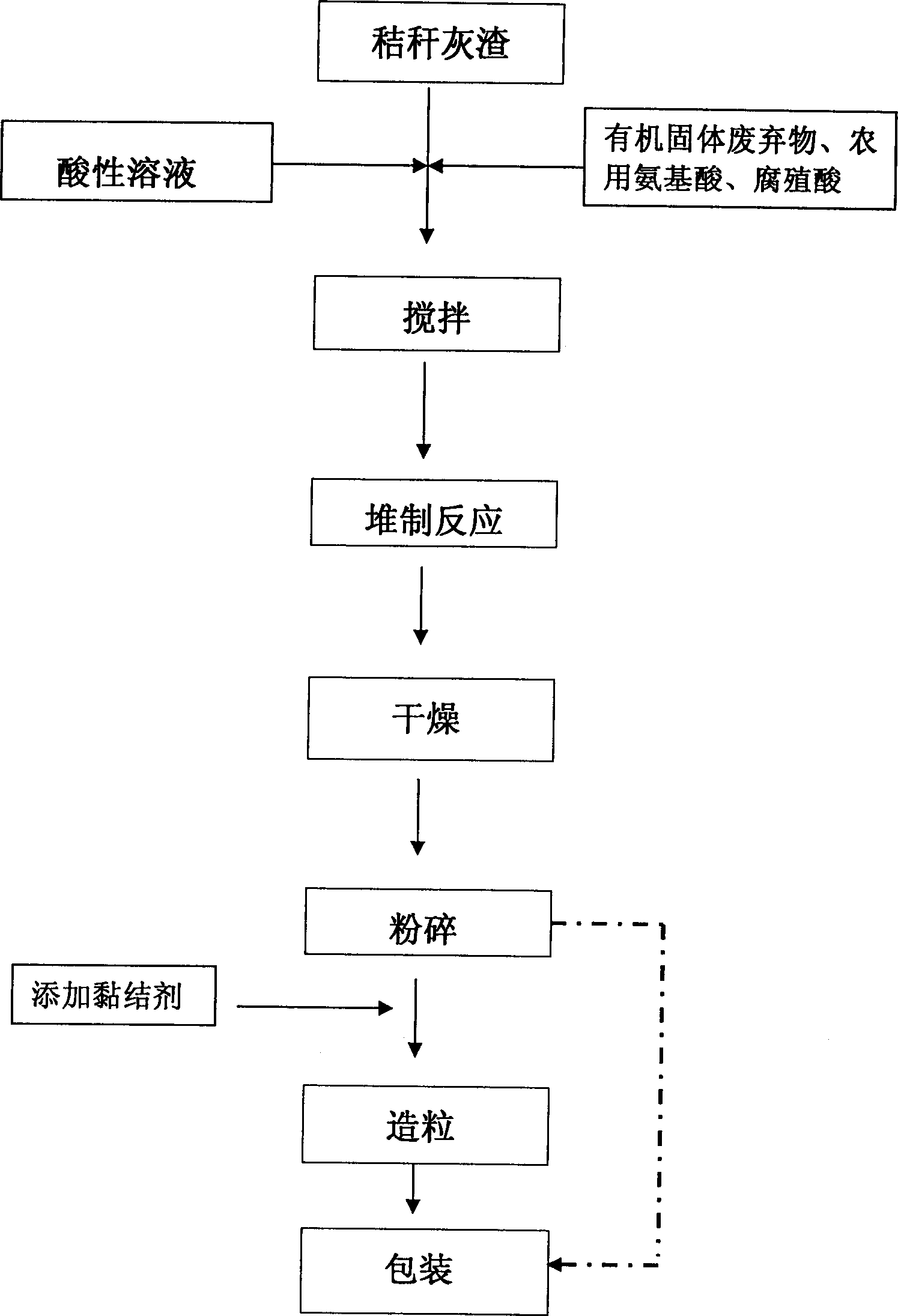

Process for producing multielement fertilizer by plant straw ash

InactiveCN1793074AImprove Nutrient Utilization EfficiencyHigh activityBio-organic fraction processingOrganic fertiliser preparationOrganic acidPlant efficiency

The invention relates to a plant straw ash multi-element fertilizer manufacturing method that use simple device, low invest, low producing cost. It could supply P, K, Ca, Mg, Fe, Zn, Cu, Mn and Mo to plant. It has high plant efficiency nutrient. It uses ash that is produced by firing, cracking and gasifying the plant straw as main raw material adding inorganic waste pickle liquid, agricultural use organic acid and / or organic solid waste to make the pH value of raw material decrease below 6.0-7.5, fermenting for 1-10 days, adding 3-10% binding agent after drying and smashing to grain finished fertilizer. The invention is especially suited for the ash fertilizing process and commercial process in straw generating process.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

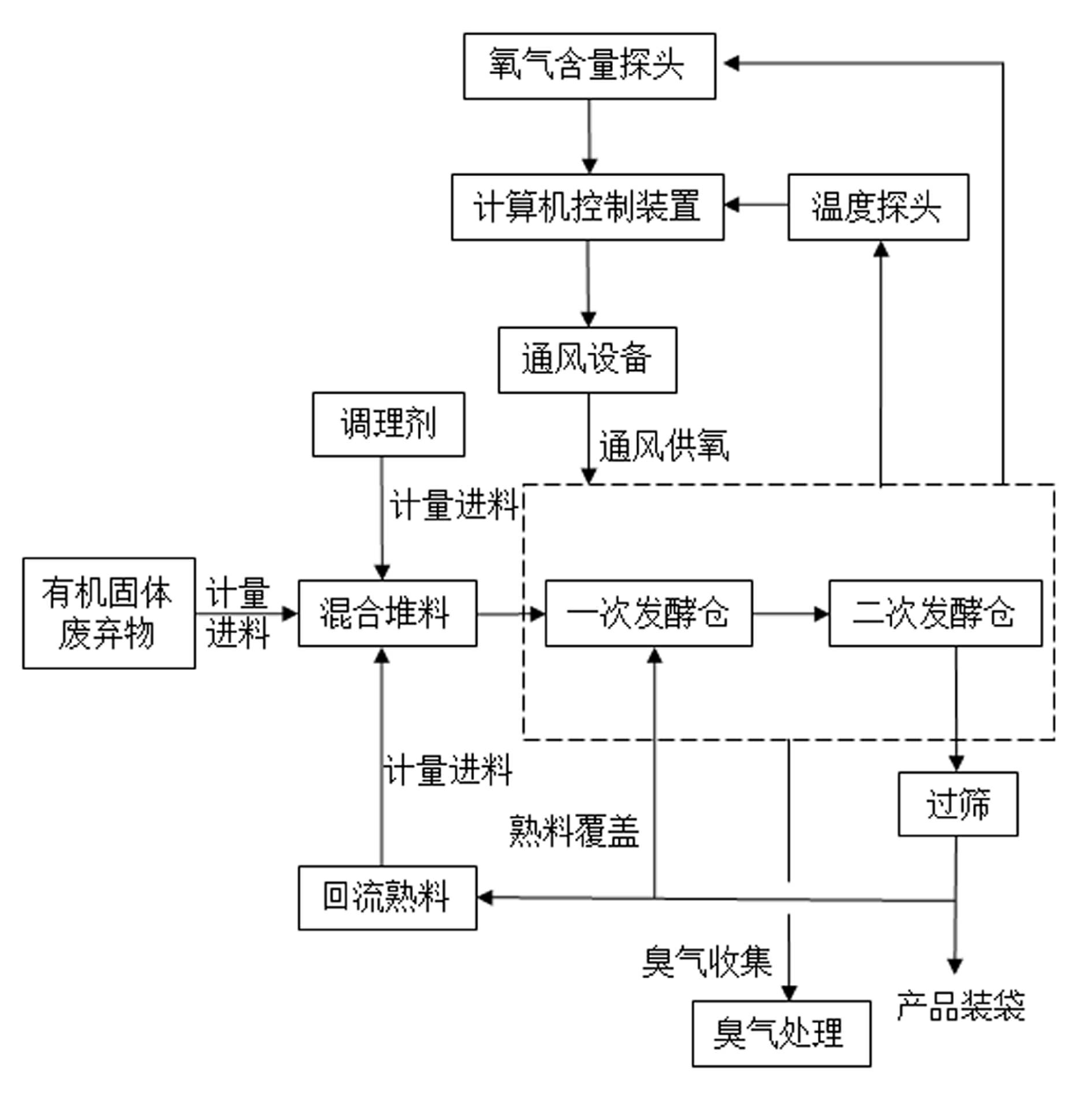

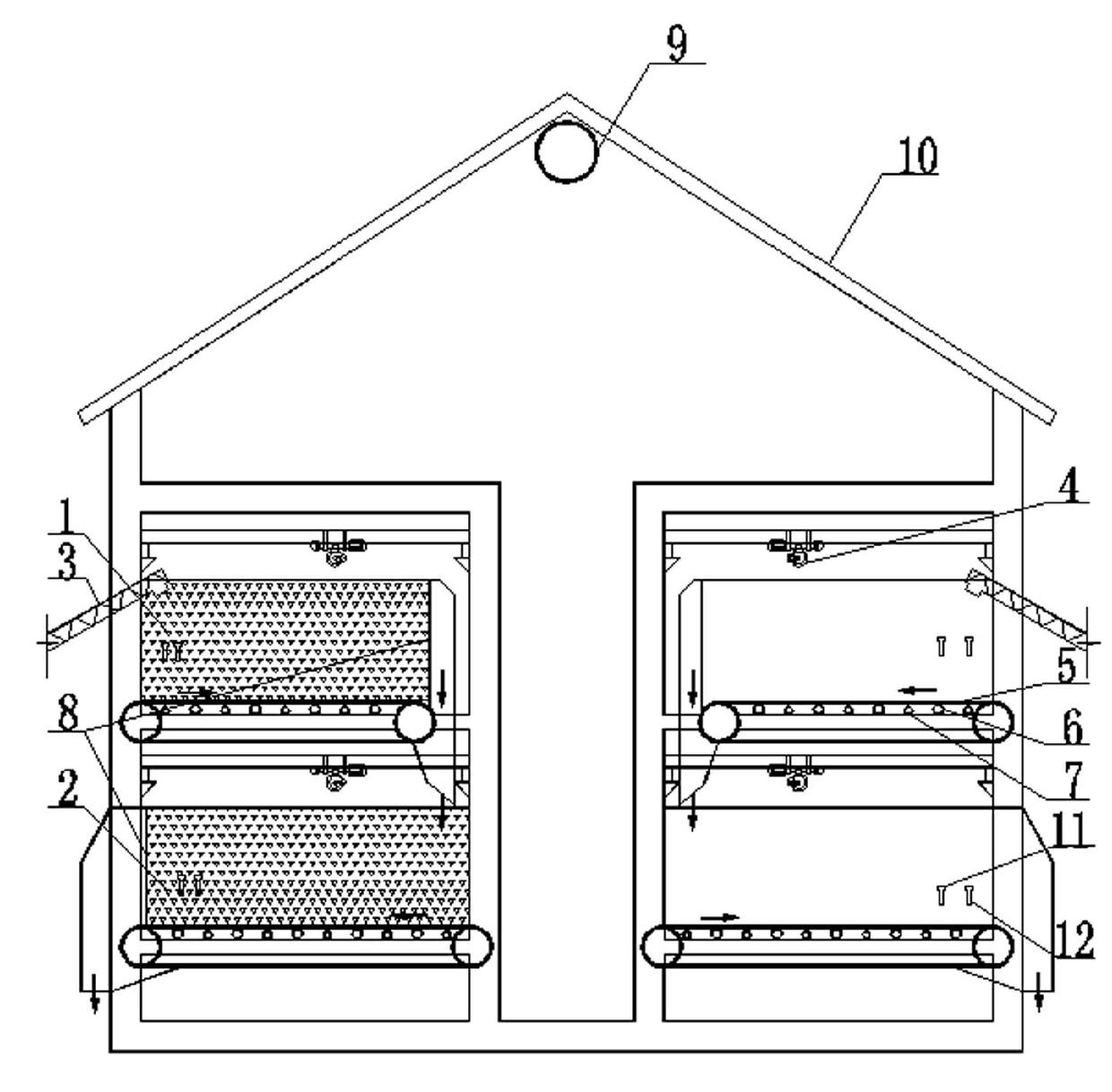

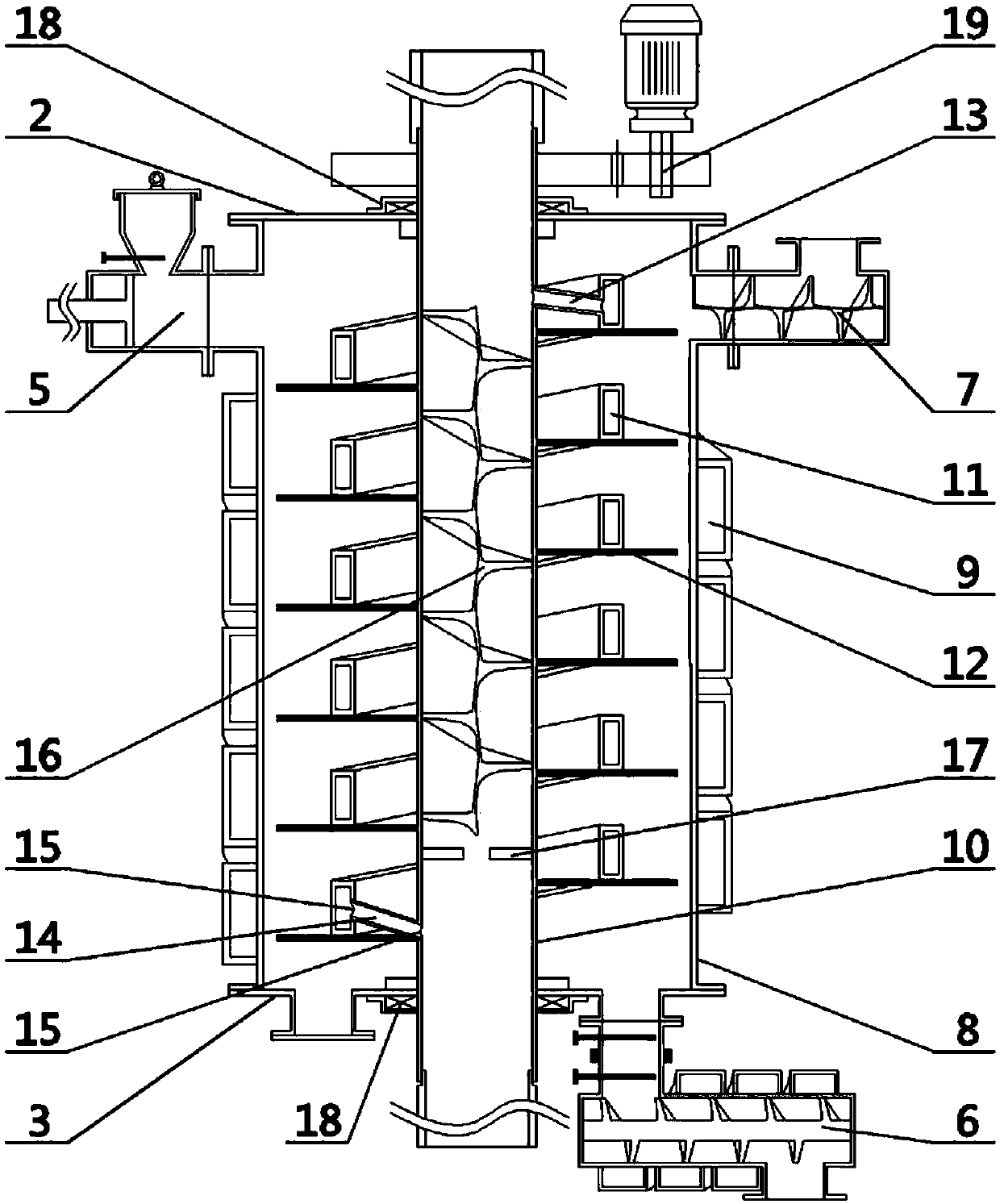

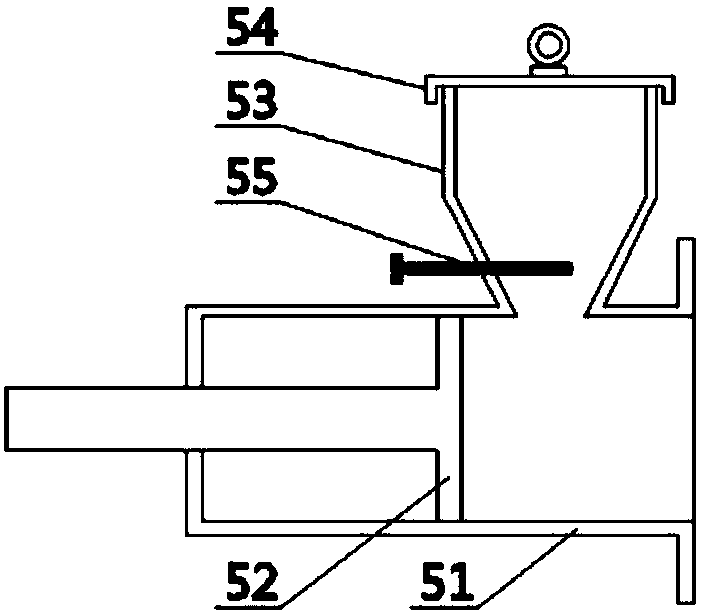

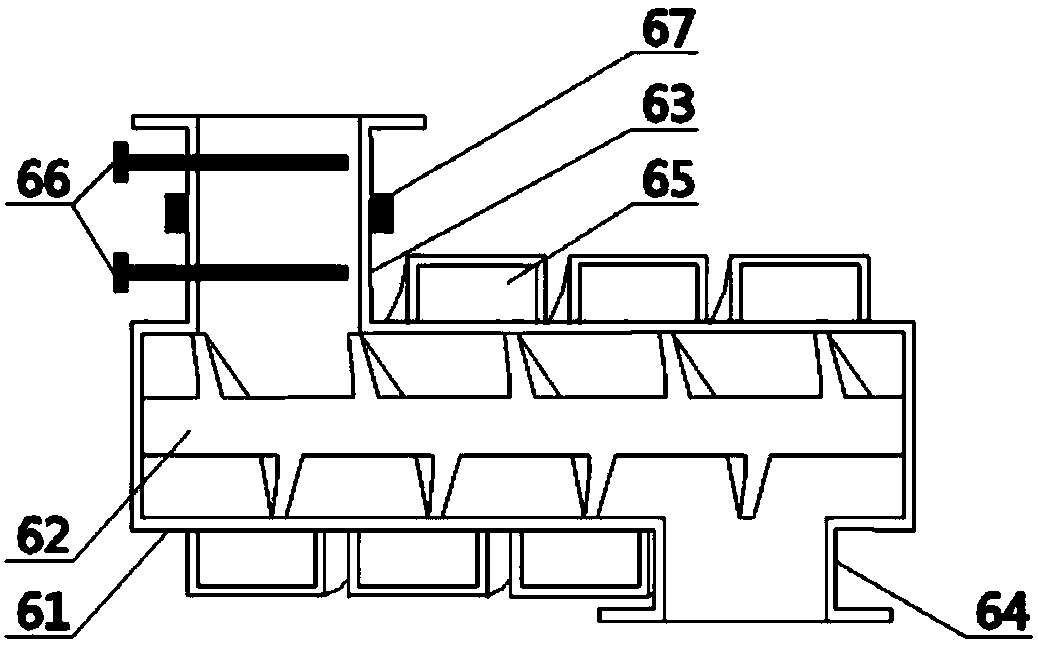

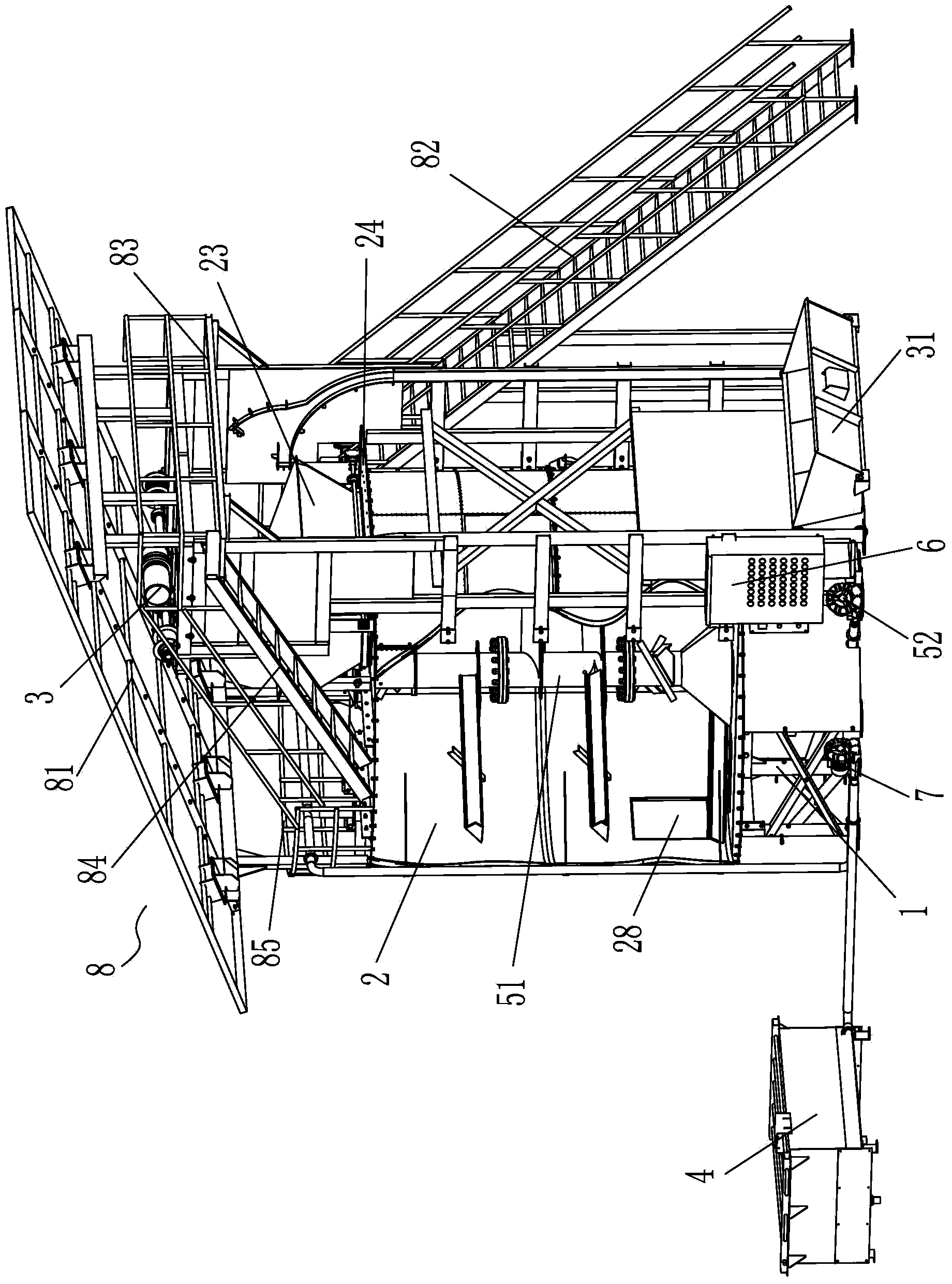

Aerobic fermentation fertilizer making device for organic solid waste and method thereof

InactiveCN102603384ARealize resource utilizationShort fermentation cycleBio-organic fraction processingClimate change adaptationTransmission beltEngineering

The invention discloses an aerobic fermentation fertilizer making device for organic solid waste, which comprises fermentation cabins, a plant, multifunctional pile turning machines, a feeding device and a screening machine, wherein multiple groups of fermentation cabins are arranged in the plant; each group of fermentation cabin comprises a primary fermentation cabin and a secondary fermentation cabin which are correspondingly arranged on an upper position and a lower position; the bottoms of the two fermentation cabins are respectively provided with a transmission belt, an idler wheel and an aeration pipe; the discharging end of the feeding device is positioned on the primary fermentation cabin; the multifunctional pile turning machines are arranged in the two fermentation cabins; the bottoms of the two fermentation cabins are respectively provided with a movable baffle; one end of the transmission belt of each fermentation cabin corresponds to the position of the movable baffle of the fermentation cabin; the outlet of the movable baffle of the primary fermentation cabin is positioned above the transmission belt of the secondary fermentation cabin; the outlet of the movable baffle of the secondary fermentation cabin is positioned above the screening machine; the top of the plant is provided with an odor centralizing pipe provided with a plurality of air inlets; and the odor centralizing pipe is connected with a deodorization device arranged out of the plant. The aerobic fermentation fertilizer making device for the organic solid waste has the advantages of small occupied land, high mechanized degree and low operation cost and is simple to operate.

Owner:中国市政工程西北设计研究院有限公司

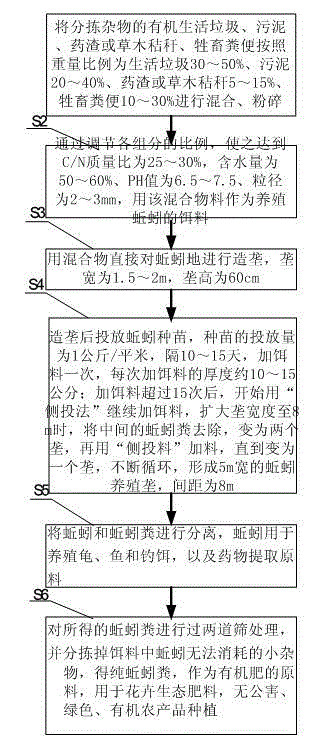

Organic solid waste bio-treatment technology based on earthworm breeding

InactiveCN104082251ALarge amount of processingAchieve biological purificationFood processingClimate change adaptationLivestock manureFeces

The invention discloses an organic solid waste bio-treatment technology based on earthworm breeding. The organic solid waste bio-treatment technology based on earthworm breeding comprises the following steps that household garbage, sludge, medicine residuals or vegetation straws, animal excrement, fruit and vegetable leaves and the like, rich in organics, of sorted impurities are mixed and fermented according to a weight proportion; the mixture serves as the bait for breeding earthworms; ridges are built on a earthworm field through the mixture; young earthworms are put into the field after ridge building, and the input quantity of the young earthworms is 1 kilogram per square meter, bait is added every 11-16 days, the thickness of bait added each time is about as high as 10-15 cm, the earthworms are collected when the ridges are heightened to 60 cm, then bait continues to be added through a lateral input method, the earthworms are collected every two times of bait adding, and the work is repeated. The organic solid waste bio-treatment technology based on earthworm breeding saves energy, protects the environment, carries out treatment through a pure biological method, is high in processing efficiency and large in processing amount, develops a new treatment method for domestic garbage, and achieves perfect combination of social benefits, ecological benefits and economic benefits.

Owner:西安市沣东新城康运种养殖专业合作社

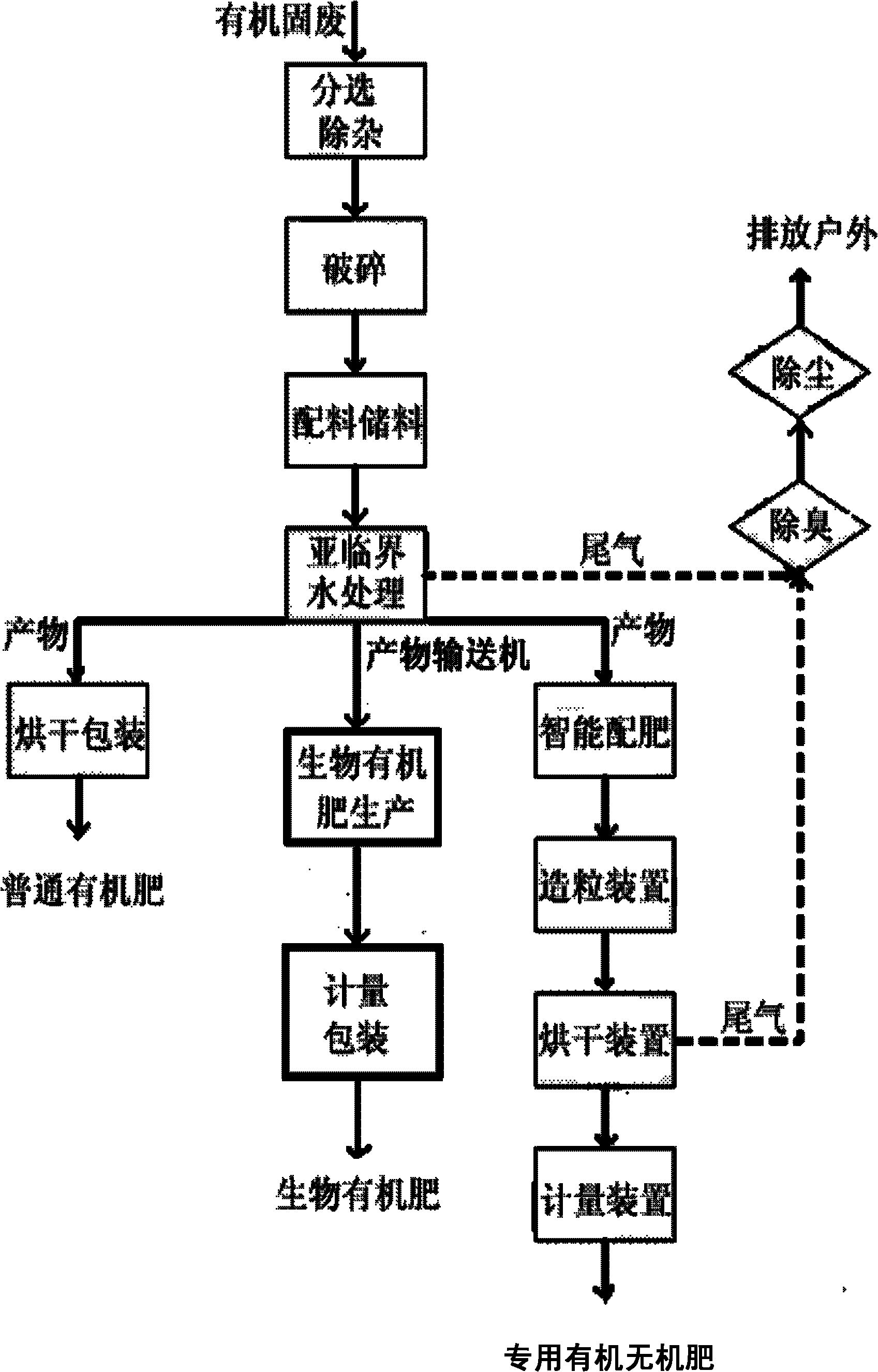

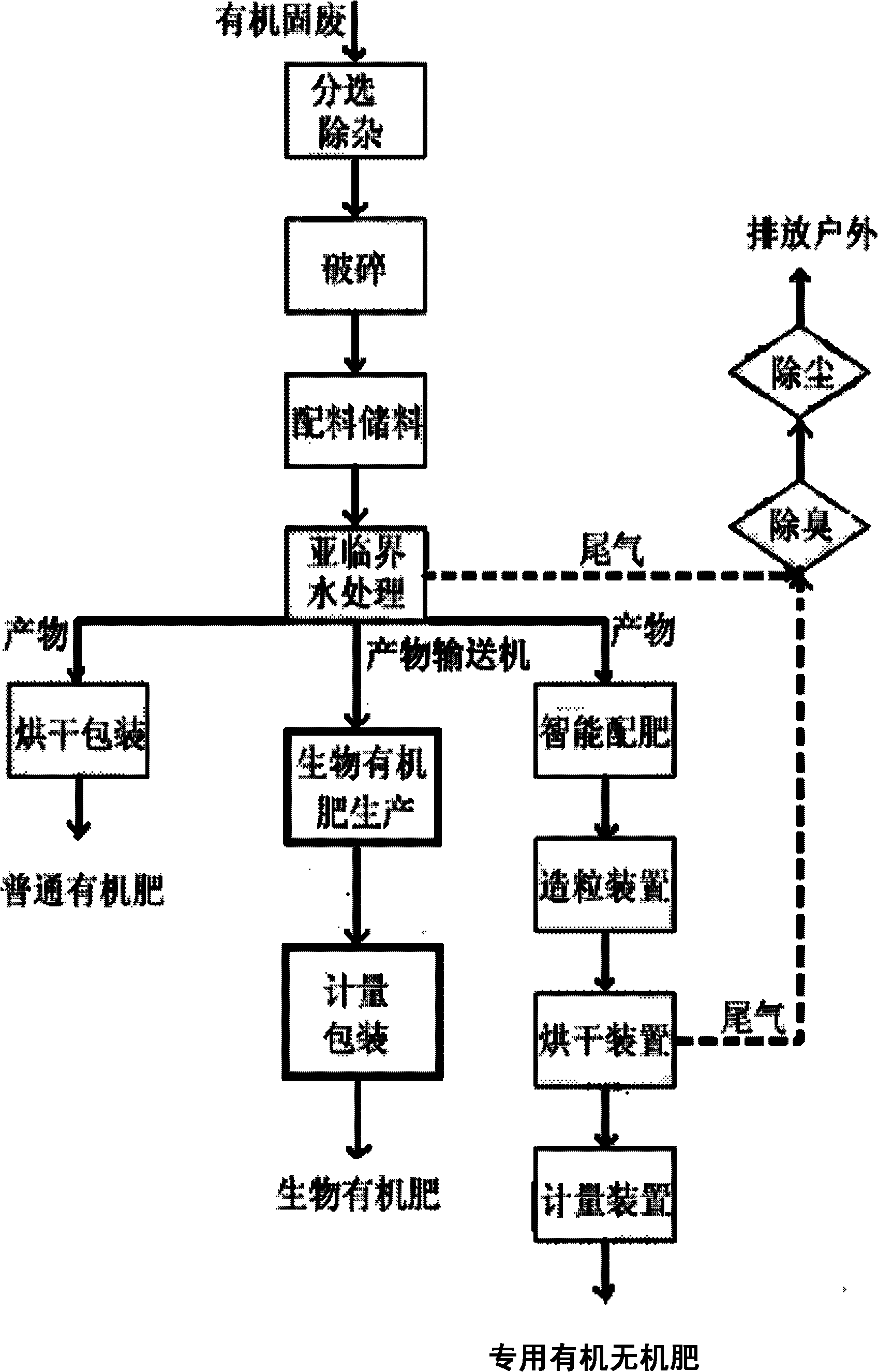

Method and equipment for producing organic fertilizer by utilizing subcritical water to process rural-urban organic solid waste

ActiveCN102146002AAdaptableHigh activityClimate change adaptationExcrement fertilisersHigh activityImpurity

The invention discloses a method and equipment for producing an organic fertilizer by utilizing subcritical water to process rural-urban organic solid waste. The method is characterized in that the method is implemented by the following technical scheme that (1) carrying out separation to remove impurities in the organic solid waste, grinding the separated organic solid waste, adding auxiliary materials into the ground organic solid waste and storing the materials to be processed; (2) feeding the materials to be processed into subcritical water treatment and carrying out the treatment of subcritical water organic solid waste by adopting an intelligent control method through a plurality of main reaction kettles and buffering kettles, which are connected in parallel, so as to obtain a processed product; and (3) as required, preparing the processed product into a common organic fertilizer, a biological organic fertilizer or special organic and inorganic fertilizers used for different soil and crop conditions. In the invention, the organic solid waste is processed and is prepared into the fertilizer by the subcritical water so as to realize full-equipment production and intellectualization. The method and the equipment are energy-saving, have high efficiency and compact layout, and are environmental-friendly and safe. The fertilizer has high activity and is quick-acting and long-acting.

Owner:国环电气科技(上海)有限公司

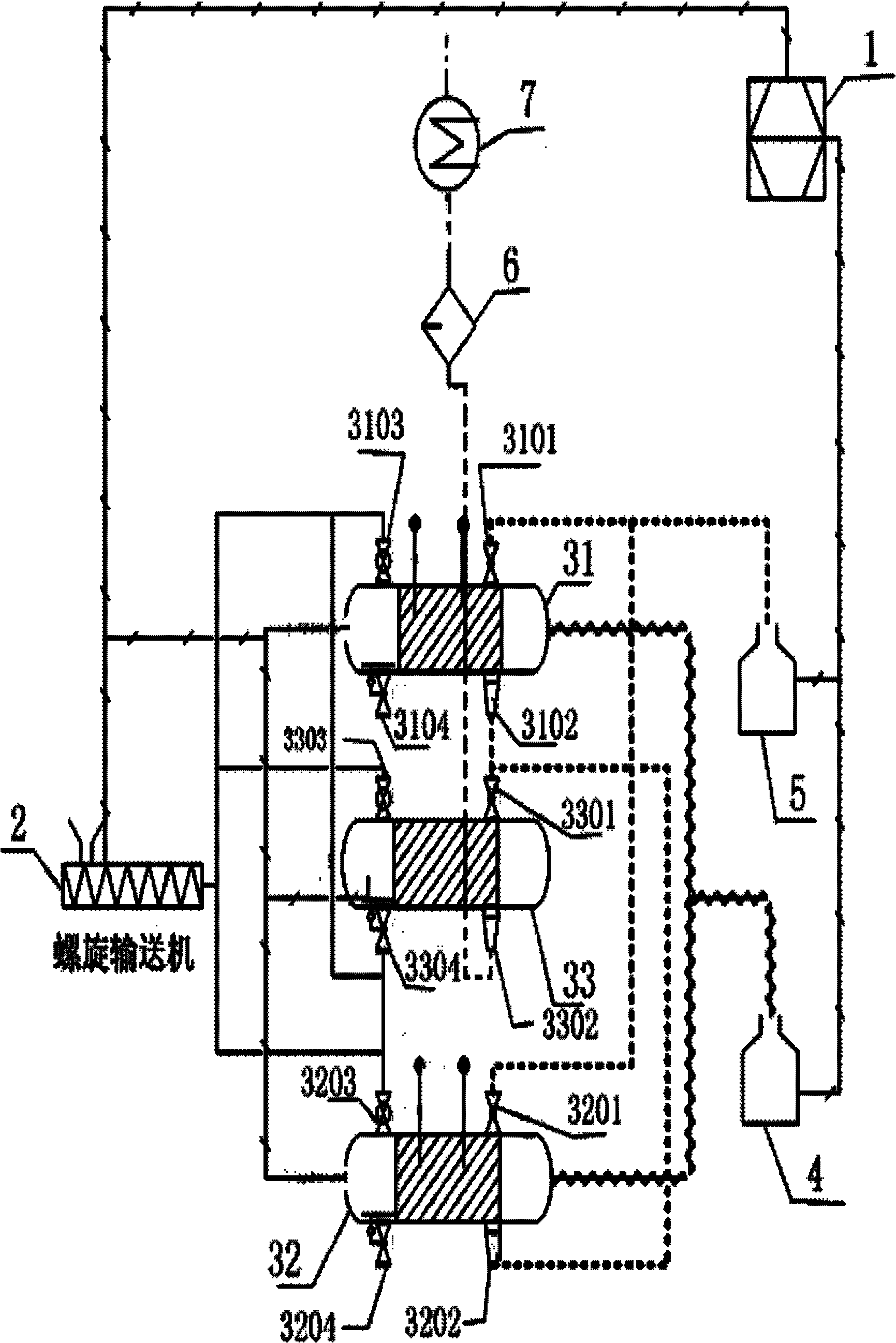

Method for producing methane by two-phase multi-stage anaerobic fermentation of organic solid wastes

ActiveCN101565719AAvoid reactionAvoid phase effectsWaste based fuelFermentationWater dischargeSludge

The invention provides a method for producing methane by two-phase multi-stage anaerobic fermentation of organic solid wastes and belongs to the field of the treatment of organic solid wastes, namely the field of renewable energy resources. The prior art has the problems that the yield of the methane is unstable, and the continuous operation can not be achieved. The method comprises the following steps that: the organic solid wastes are put in n(n is more than or equal to 2) acidification reactors in parallel connection and subjected to hydrolytic acidification at a pH value of between 5.8 and 6.5 and a temperature of between 50 and 55 DEG C, and the materials in each hydrolytic acidification reactor are changed after the materials are reacted for n*m(m is more than or equal to 1) days; the percolate generated due to acidification is collected, the pH value of the percolate is adjusted to be between 7.0 and 8.0, the percolate is pumped into a methane reactor filled with inoculation sludge in a mode of batch feeding, and the generated gas is collected at the pH value of between 7.0 and 8.0 and at a temperature of between 50 and 55 DEG C; and finally, the water discharged from the methane reactor is pumped into the acidification reactors. The method has the advantages of high gas-producing efficiency, short period, the realization of stable and continuous gas production, no emission of waste water, and the like.

Owner:BEIJING UNIV OF CHEM TECH

High-speed composting process and apparatus

ActiveCN101508603AImprove fat retentionFast water absorptionBio-organic fraction processingOrganic fertiliser preparationHigh rateThermal insulation

The invention relates to a high rate composting method and equipment thereof. The method comprises the following steps: sending organic solid waste to separation equipment for separation and recycling; making the waste into grains and sending the grains into a materialized pretreatment groove; adding a wetting agent, a bond dissociation agent and water beyond saturation state of materials; after stirring, sending the mixture into a high speed stable kettle for heating and pressurizing; maintaining the material in the reaction kettle at liquid and solid state; adding an oxidizer and a heavy metal remover; after reducing pressure to reduce pressure in a vessel, sending the mixture to a high speed activation kettle; adding a softening agent and an activation agent for an activation reaction under the condition of increasing temperature and pressure; and carrying out steam instant explosion operation by leading material to a product finery and controlling humidity, granularity and nutriment in a fertilizer within a range as required. By the method, the organic waste can be transferred to high quality compost in an hour and hydroscopic property, moisture retaining quality, adsorptivityof N, P, K and trace elements needed by plants, ventilation property, thermal insulation, flood-resistance and desertification resistance can be improved greatly, bacterium and parasites can be killed completely, poisonous organic compound can be decomposed and excess heavy metal in material can be stabilized or removed.

Owner:北京绿创生态科技有限公司

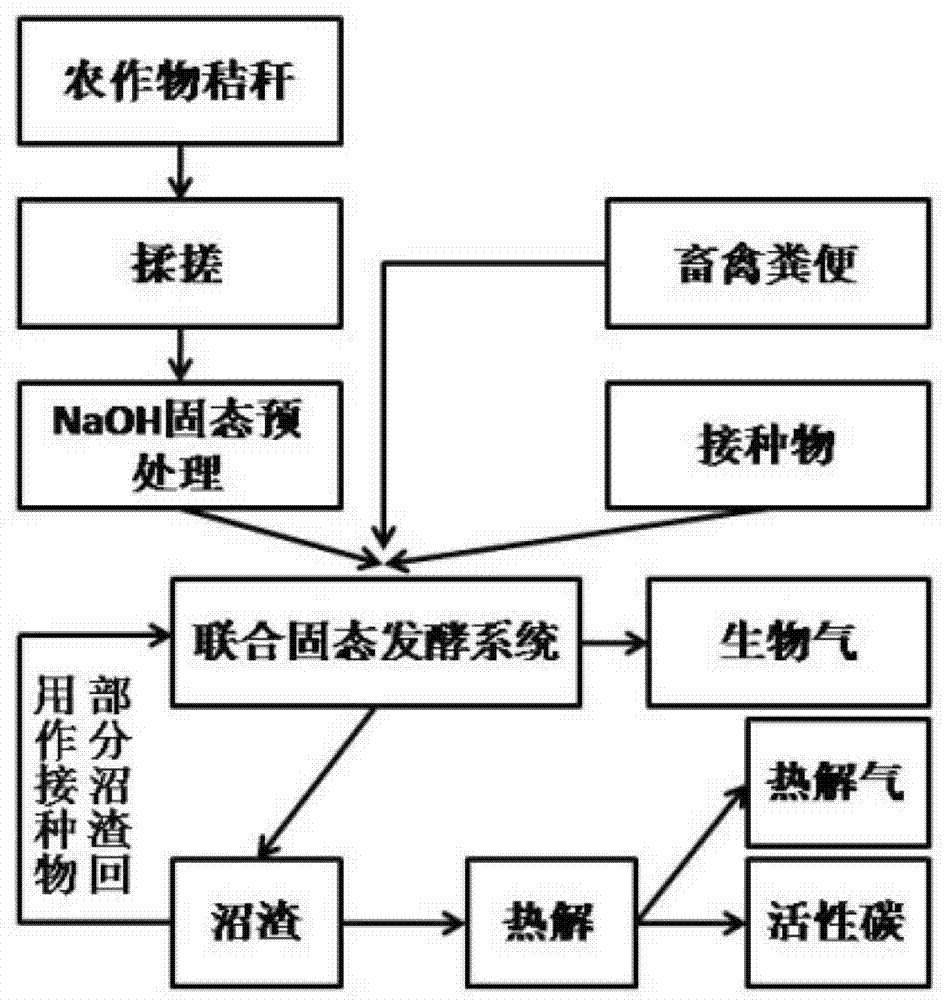

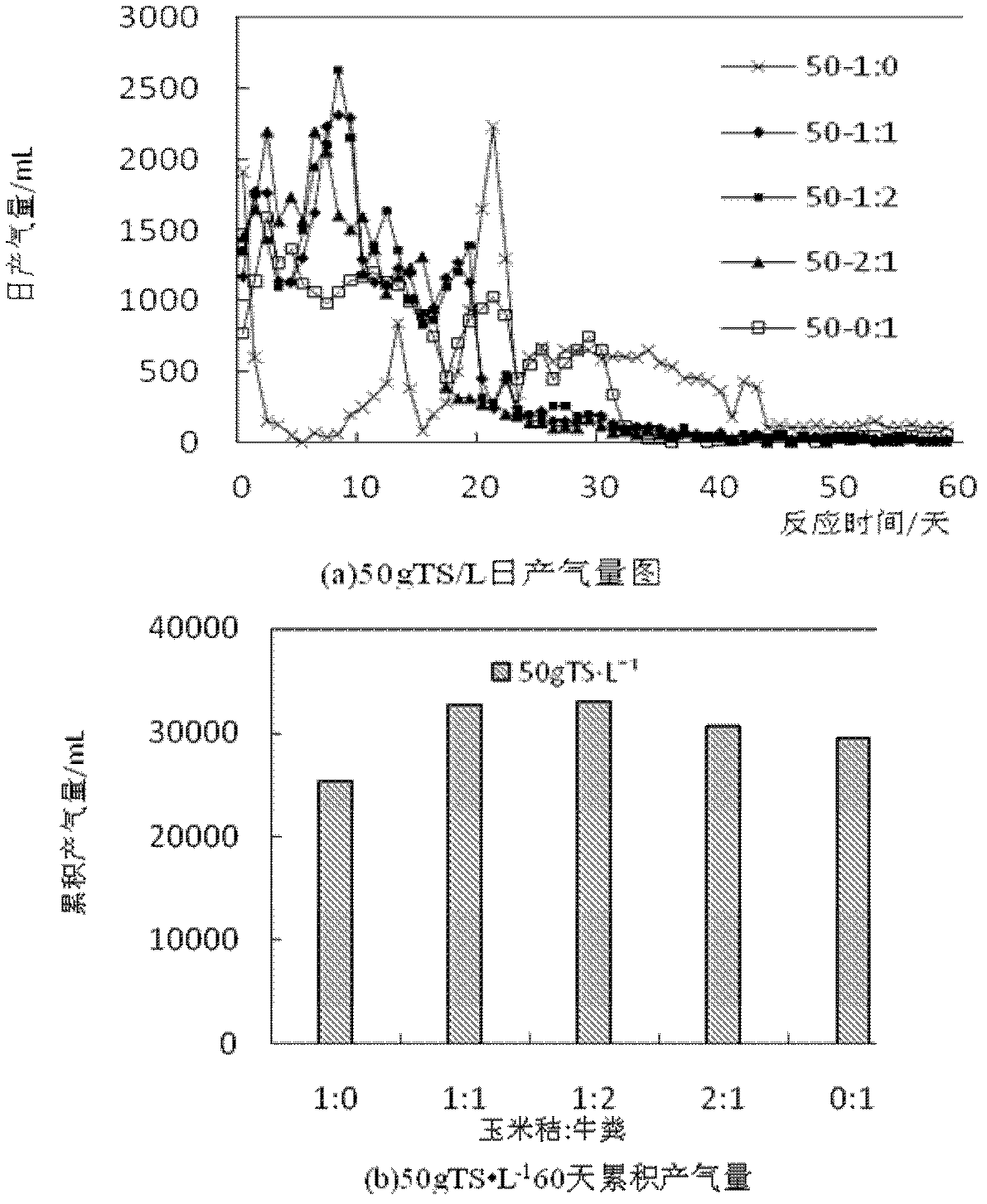

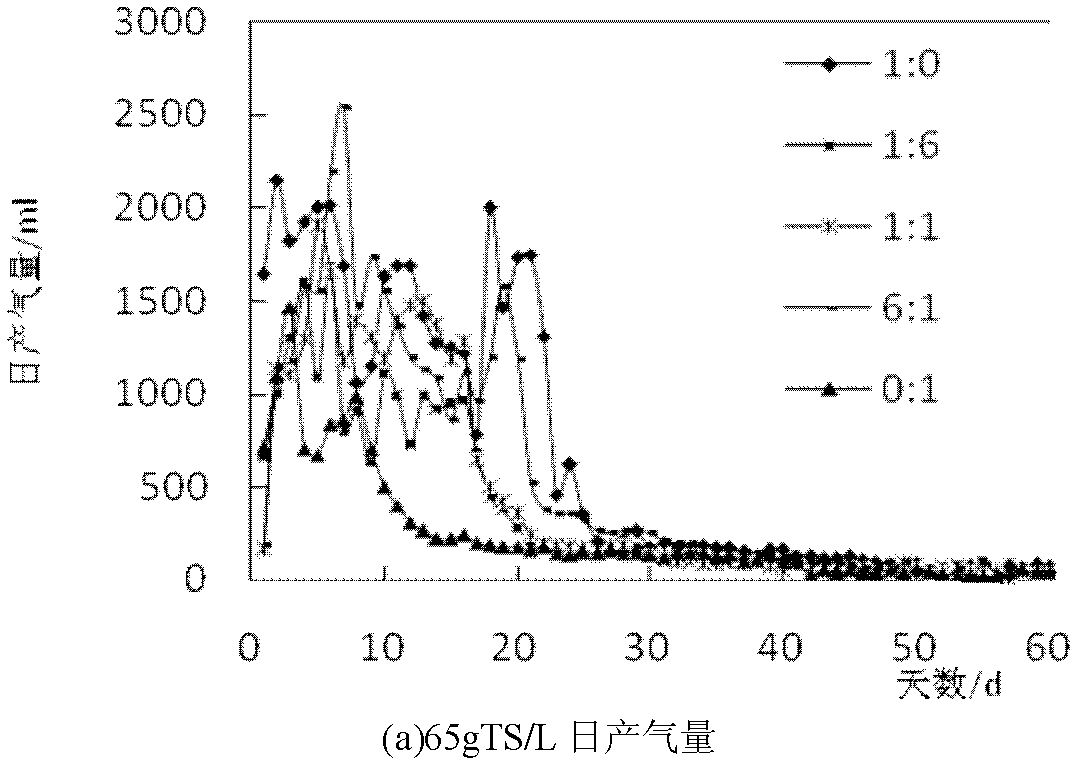

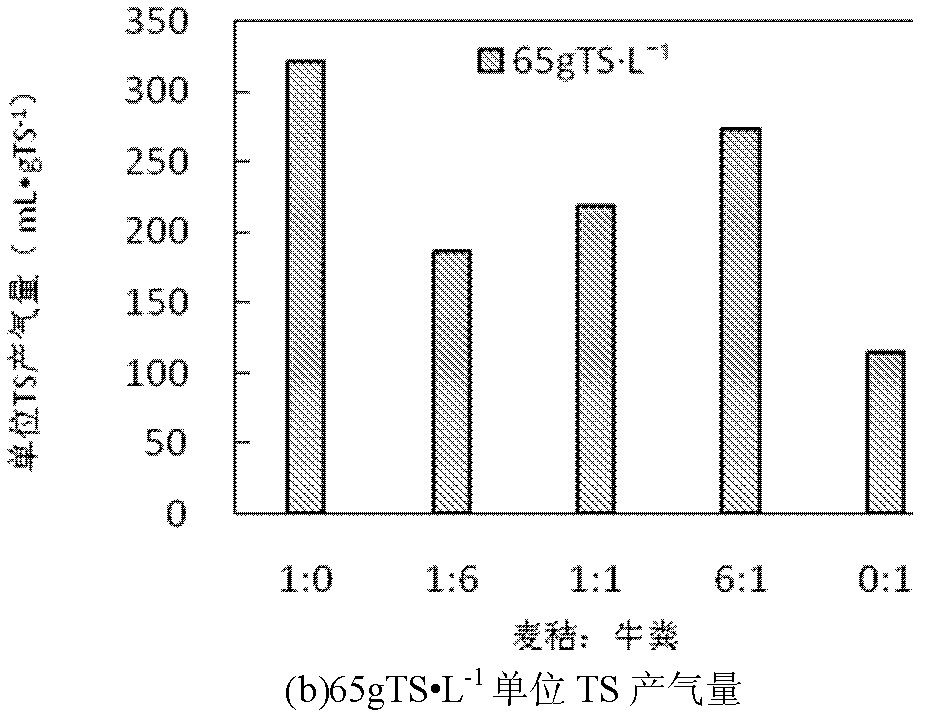

Method for producing biogas by combined solid state fermentation of crop straws and excrements of livestocks

ActiveCN103088070ASolve the difficulty of usingOptimize preprocessing timeWaste based fuelFermentationFecesResource utilization

The invention belongs to the field of efficient resource utilization of organic solid wastes, and particularly relates to a method for producing biogas by combined solid state fermentation of crop straws and excrements of livestocks. The method for producing biogas comprises the following steps of: rubbing the crop straws by a rubber; adding NaOH aqueous liquor, and uniformly mixing for pretreatment; then, performing combined solid fermentation on mixed crop straws, excrements of livestocks and inoculums; performing anaerobic fermentation to produce biogas at 50-60 DEG C; and finally, taking out residue after solid fermentation. 30% of the residue is used for newly added inoculums and the rest enters into a pyrolysis reactor for pyrolysis to product biogas. The pyrolysis gas generated can be used to supply heat to the system, and the solid product after pyrolysis can be used as an active adsorbing material or a catalytic material, so that comprehensive utilization of organic wastes is realized. Compared with the prior art, the method for producing biogas provided by the invention has the characteristics of no biogas slurry, convenience and rapidness, safety, stability and high biogas producing efficiency.

Owner:BEIJING UNIV OF CHEM TECH

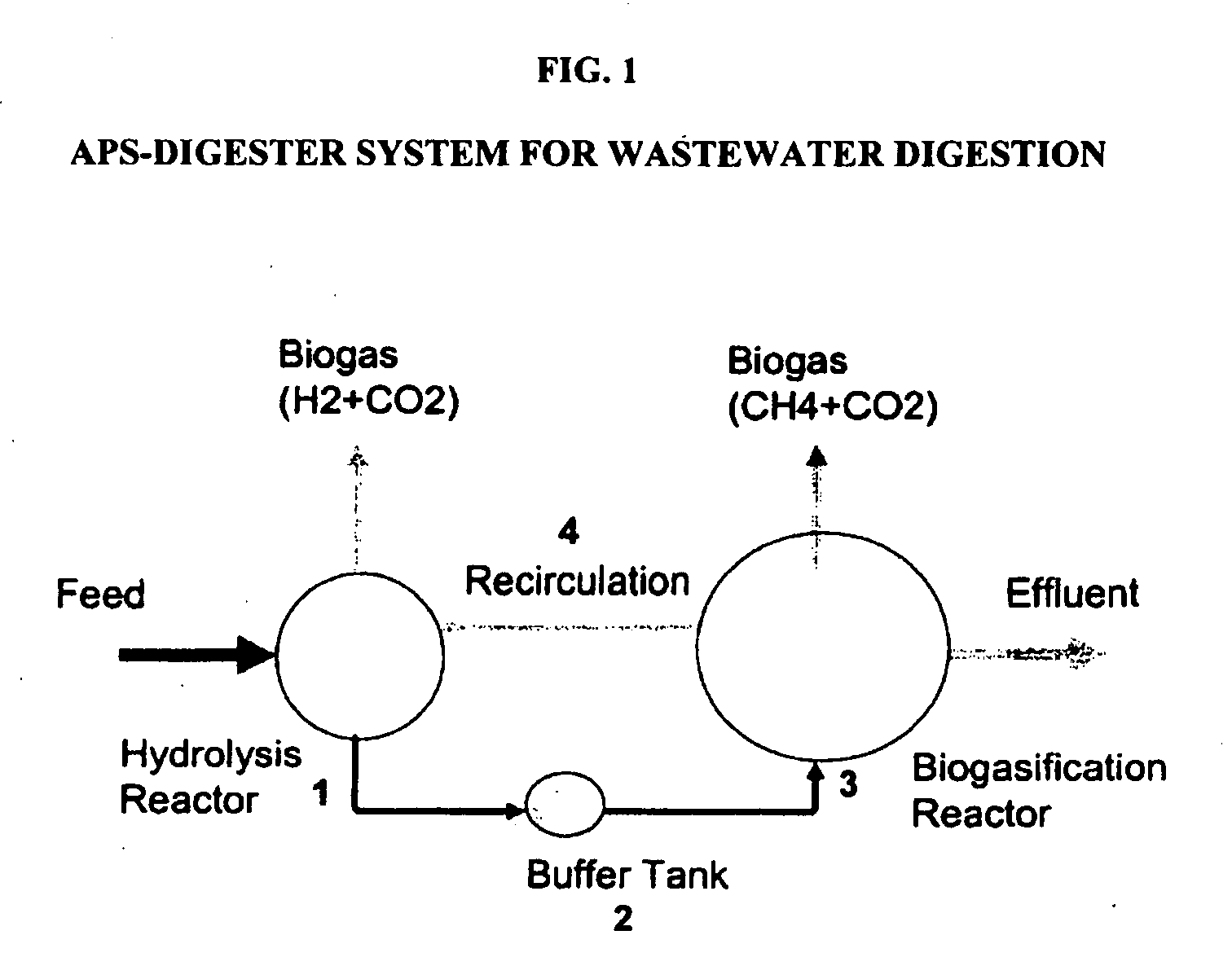

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS7556737B2Less air emissionImprove conversion efficiencyBiological substance pretreatmentsLiquid degasificationBuffer tankBiogas production

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

Multi-effect soil conditioner and preparation method thereof

ActiveCN102925162AImprove water absorption and retention capacityStrong resistance to external physical pressureAgriculture tools and machinesOrganic fertilisersWater holdingFluoride

The invention discloses a multi-effect soil conditioner and a preparation method of the multi-effect soil conditioner. The multi-effect soil conditioner comprises the raw materials, by weight, 600-740 parts of organic solid waste, 150-210 parts of flyash and 110-190 parts of polyamino acid superabsorbent. The 600-740 parts of the organic solid waste, the 150-210 parts of the flyash and the 110-190 parts of the polyamino acid superabsorbent are mixed sufficiently and dried to granulate. The soil conditioner has various advantages of being water-holding and fertilizer-saving, and increasing plant soil nutrient and improving soil physico-chemical property and the like. The soil conditioner can be applied to various qualitative soils and play a crucial role in restoring special soils such as high level of fluoride soil and clayey soil, and also play a crucial role in wind prevention and sand fixation.

Owner:NANJING UNIV OF TECH

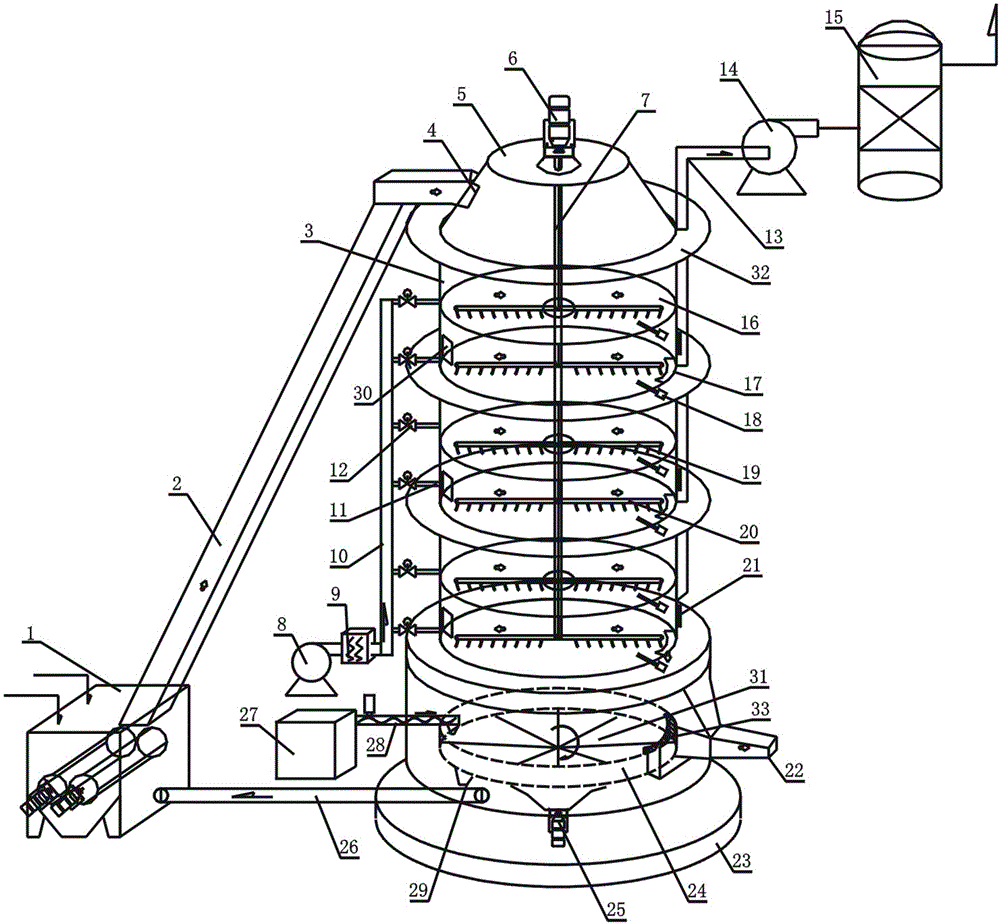

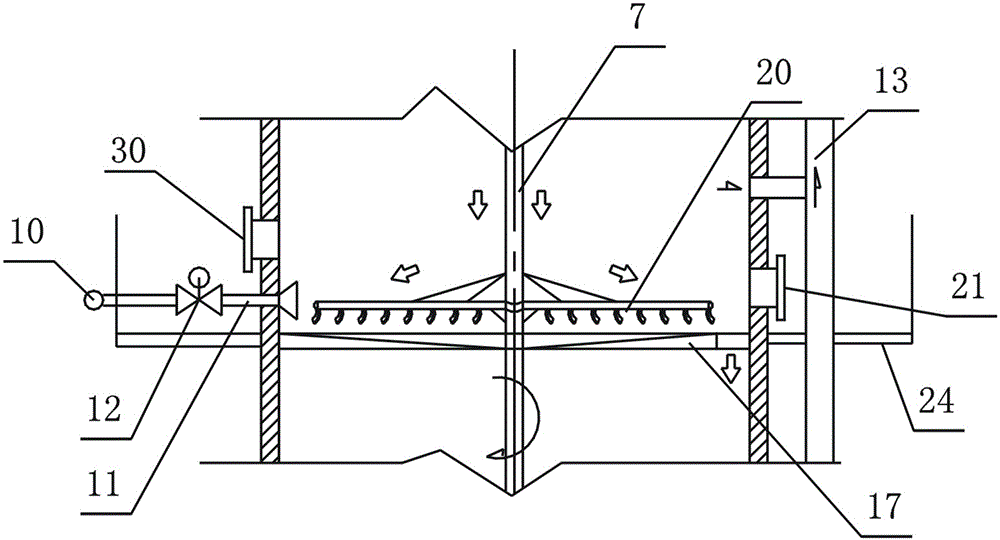

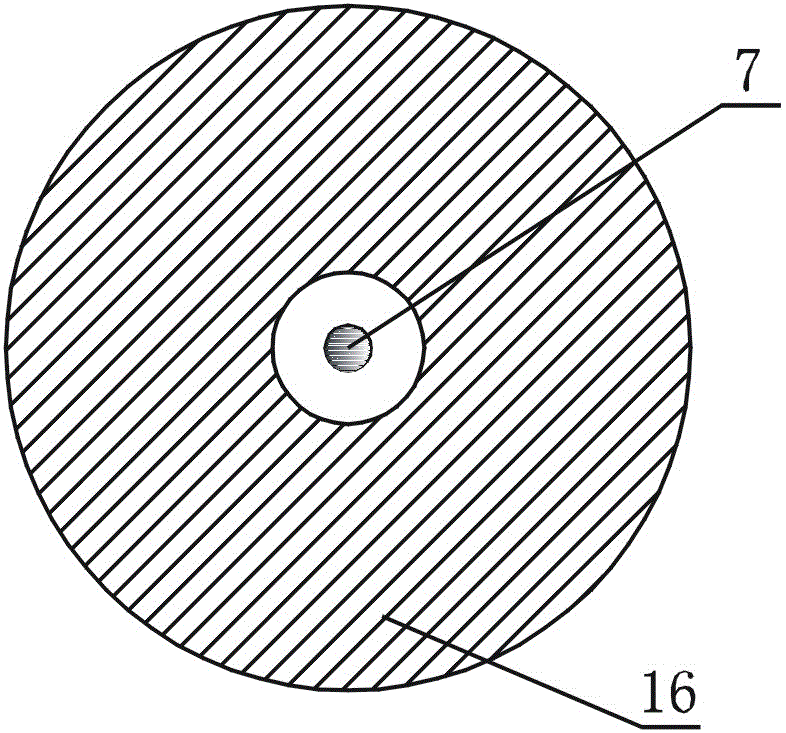

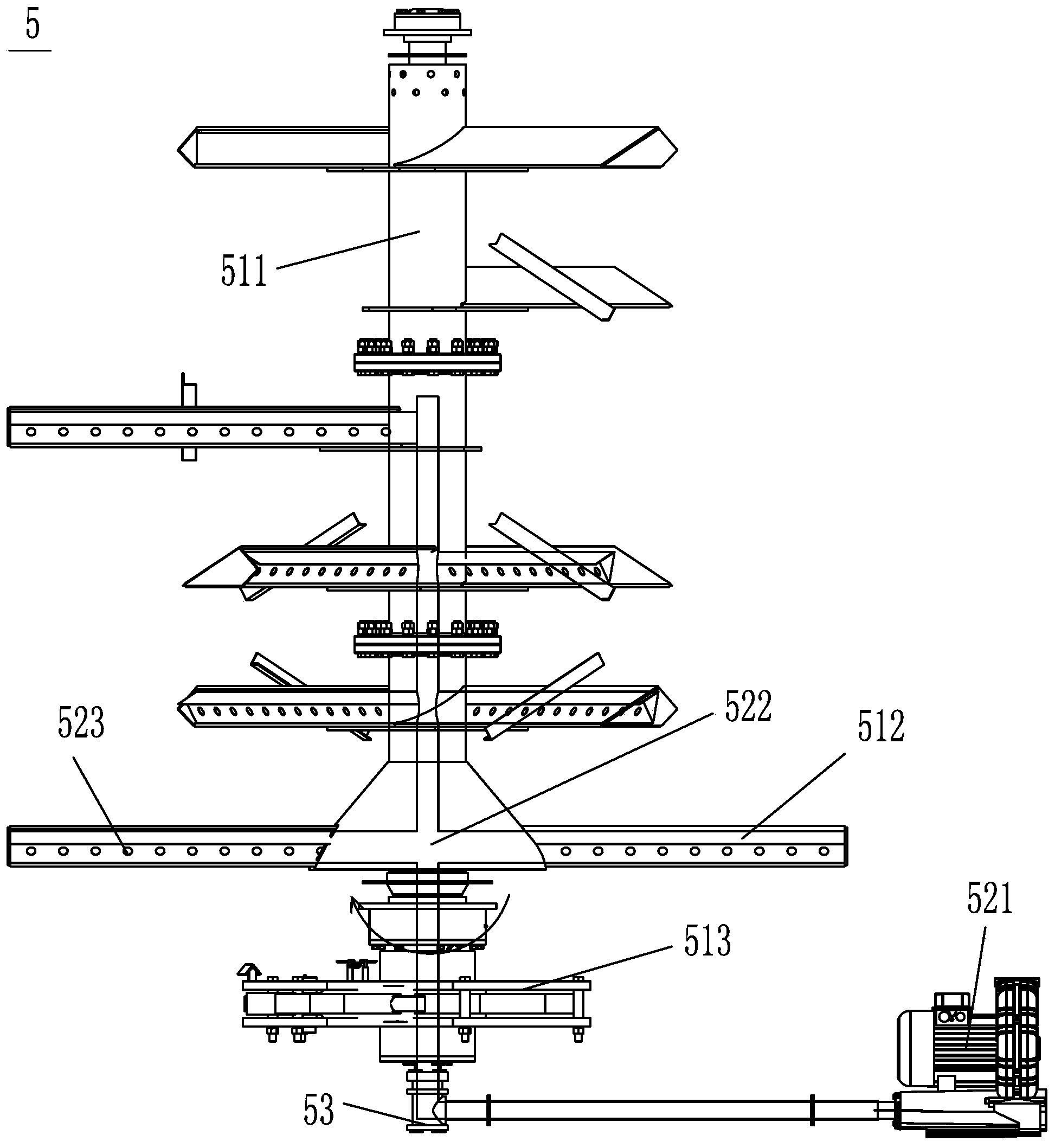

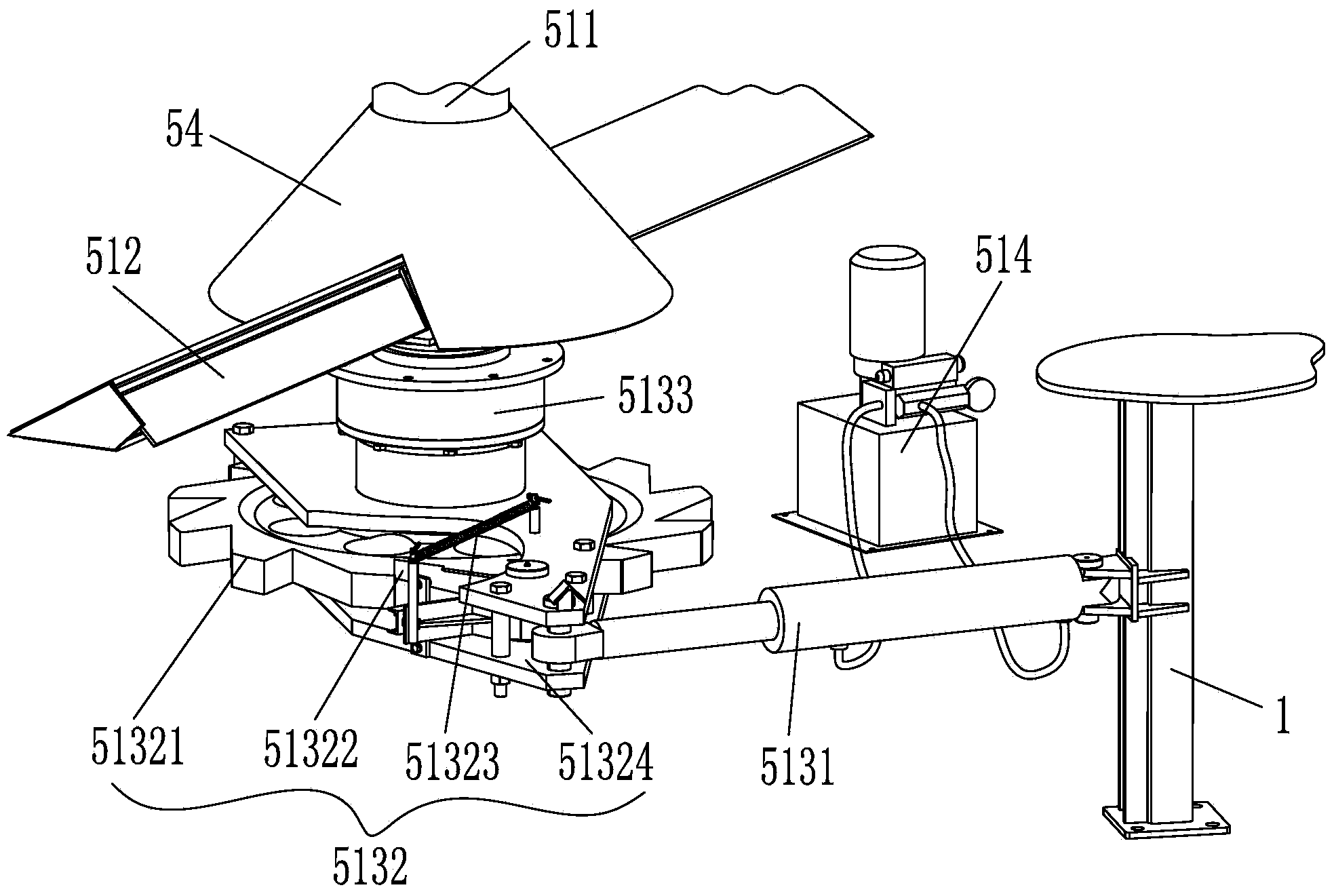

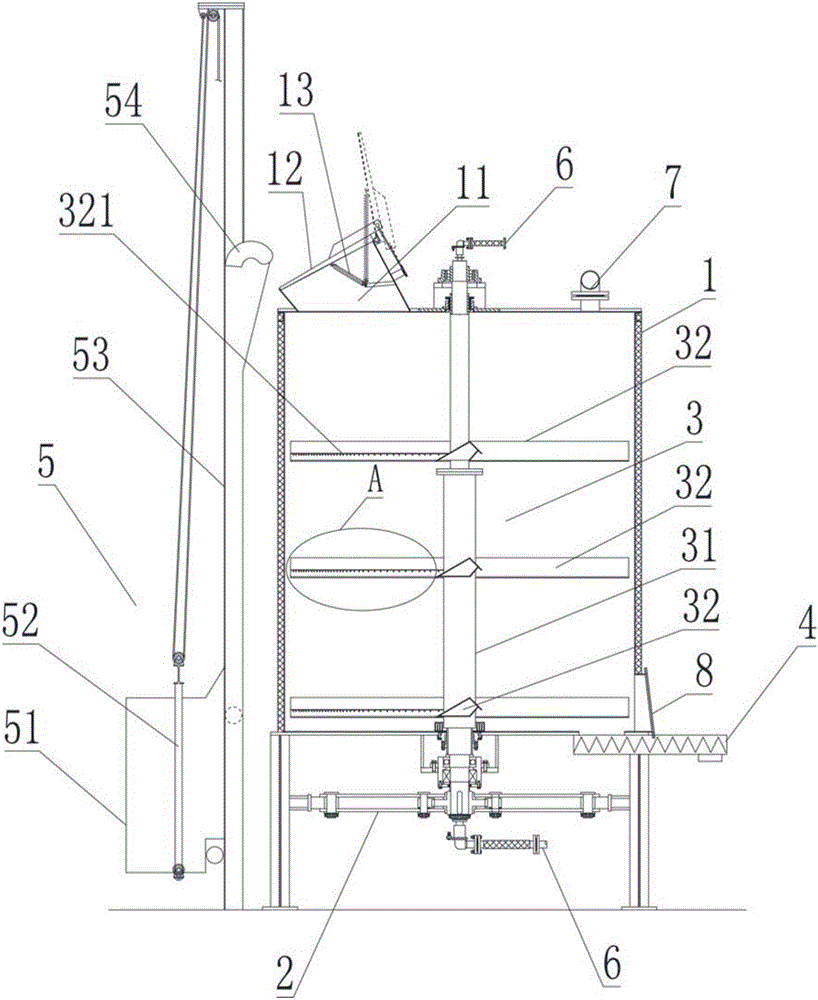

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

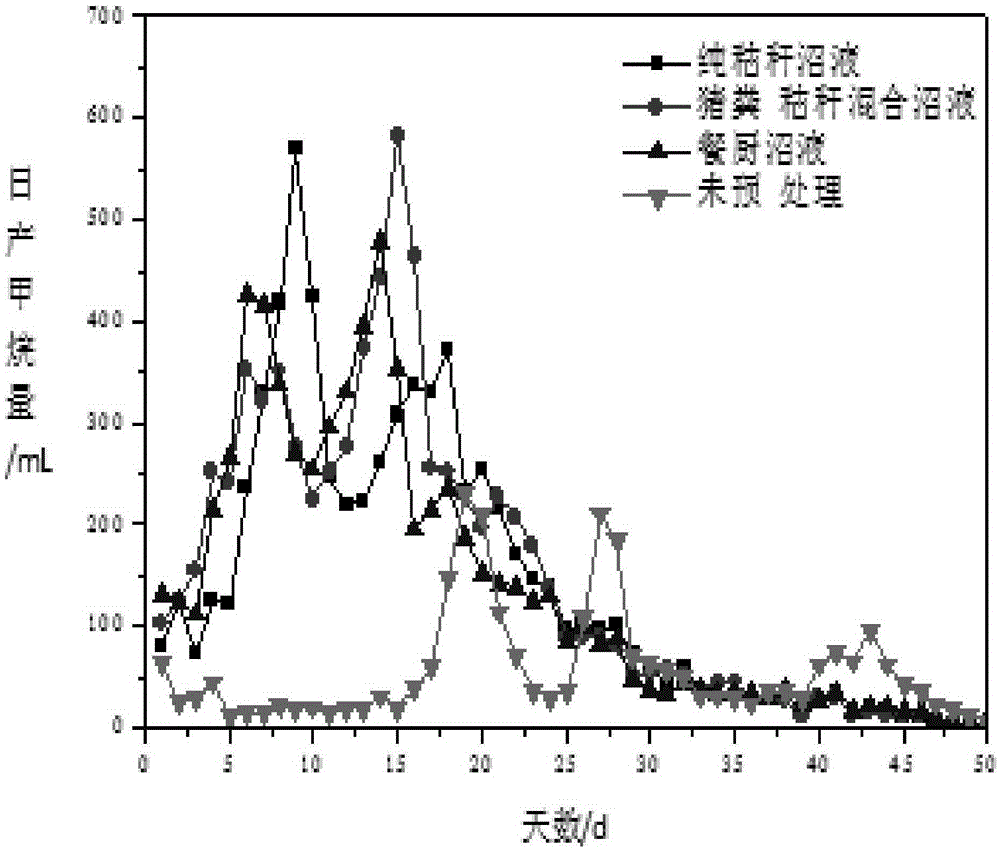

Method for improving methane-producing performance under synergistic action of mixed quasi-synchronous fermentation of multiple raw materials

ActiveCN102559773AExcellent digestionExcellent stabilityWaste based fuelFermentationMethane yieldOperability

The invention belongs to the field of treatment of organic solid wastes, and discloses a method for improving anaerobic gas-producing performance under the synergistic action of the mixed quasi-synchronous fermentation of multiple raw materials. By the method, organic wastes (straw, domestic garbage, excrement and the like) are subjected to the quasi-synchronous fermentation of multiple raw materials, namely the organic wastes are pretreated, so that the fermentation period of materials (such as the straw and the like) with a long fermentation period is shortened and is close to an average fermentation period of the mixed materials; the fermentation period of materials (such as garbage in restaurants and kitchens, excrement and the like) which are easy to digest is prolonged appropriate; and the pretreated materials are mixed, inoculated and subjected to anaerobic digestion to produce methane, so that the methane-producing period of the materials with the anaerobic digestion period is synchronous with that of the materials with the short anaerobic digestion period to realize the quasi-synchronous fermentation of the materials. The method is simple and high in operability; and by the method, two and more than two organic solid wastes are treated simultaneously, and the accumulative methane yield of unit volatile solid (VS) substances is improved by 15 to 60 percent averagely.

Owner:BEIJING UNIV OF CHEM TECH

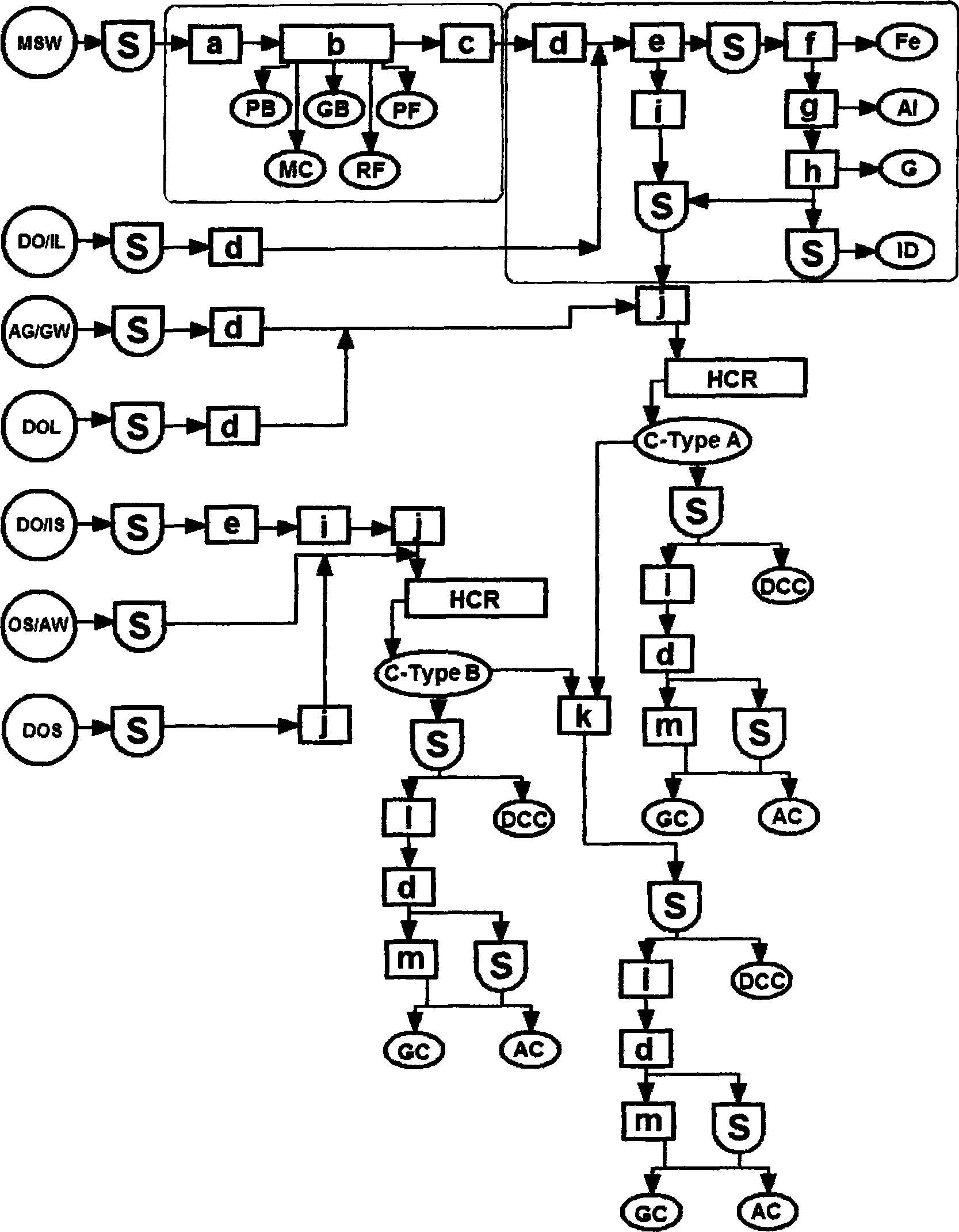

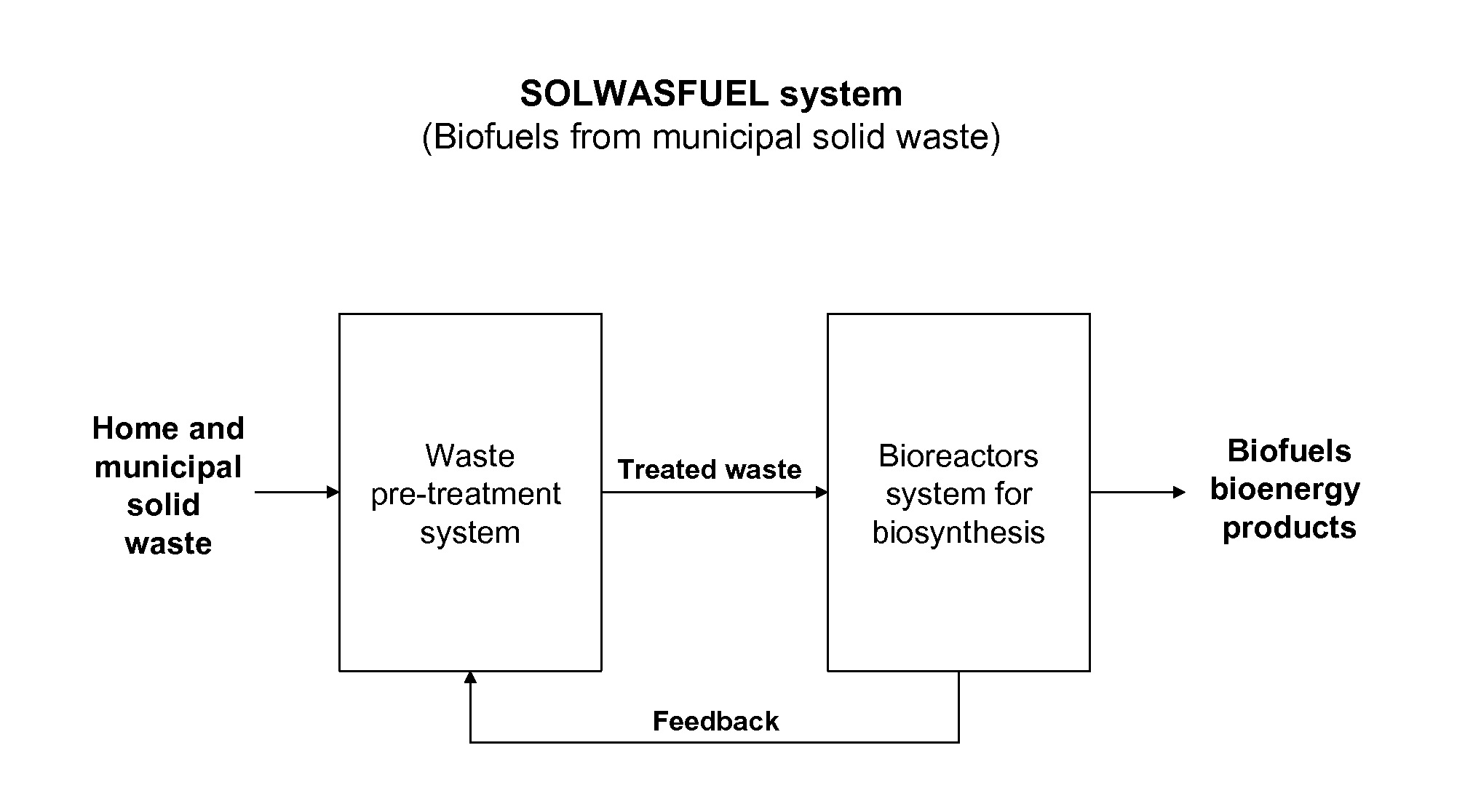

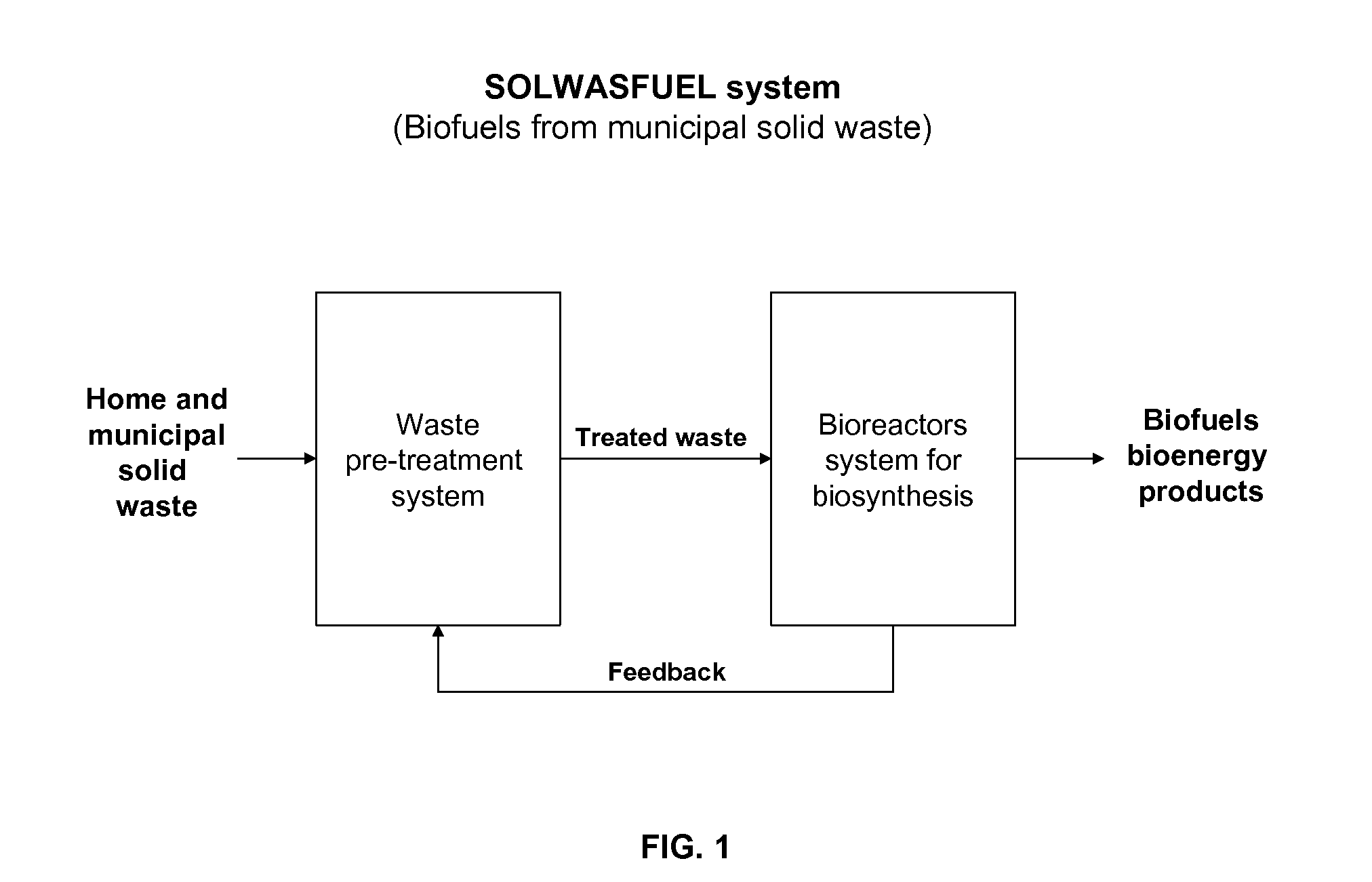

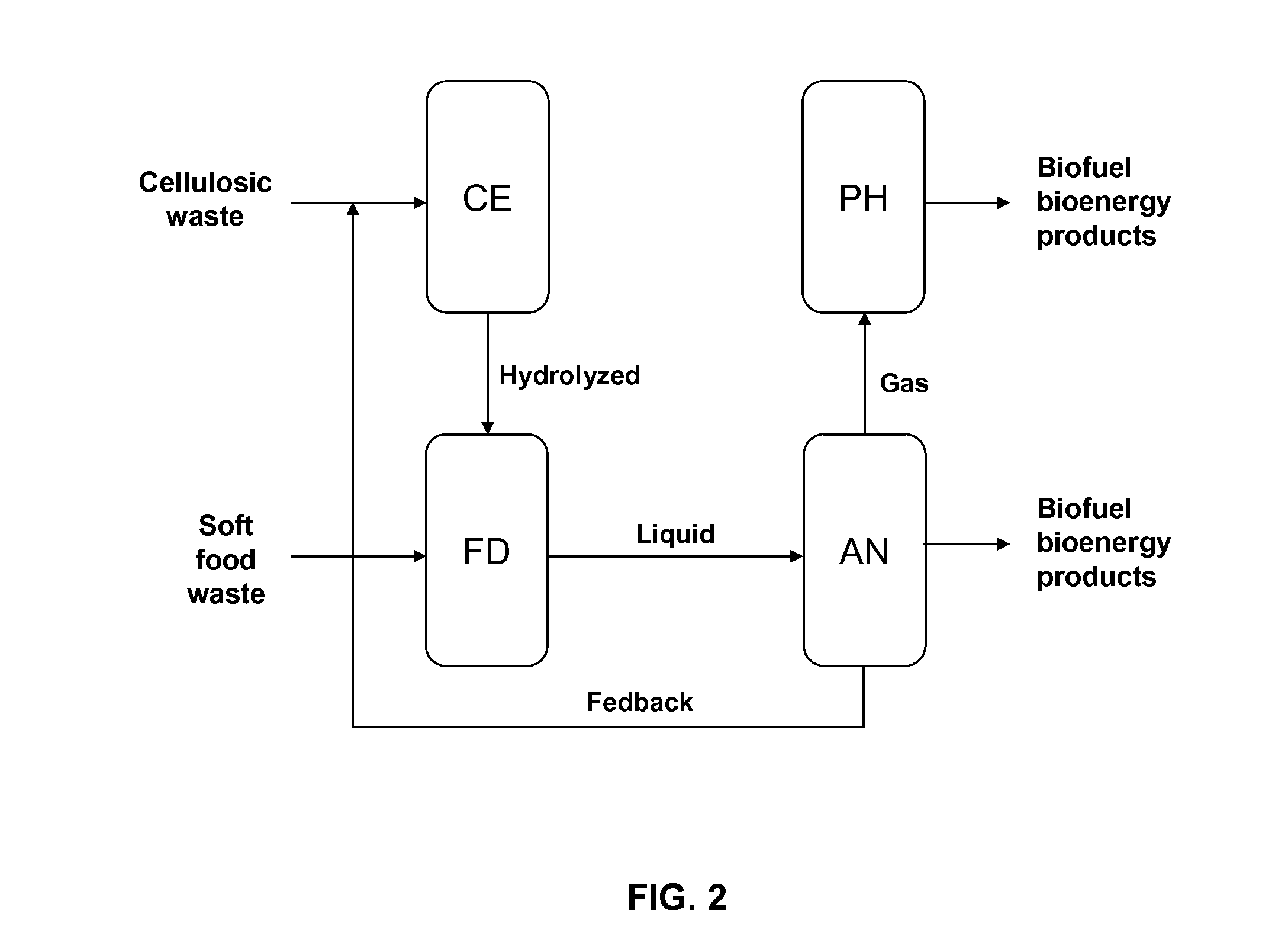

Refinery process to produce biofuels and bioenergy products from home and municipal solid waste

InactiveUS20110165639A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCardboardCellulose

The present invention provides methods of a process (SOLWASFUEL system) for producing biofuel and bioenergy products using, as starting raw material, home and municipal organic solid waste, including recalcitrant lignocellulosic materials of paper, cardboards, organic plastics, cellulose plants, and food waste. In accordance with the invention, home and municipal solid waste, can serve as a carbon source to support the metabolism of synthetic microorganisms to produce biofuels and bioenergy products.

Owner:BRIJEN BIOTECH

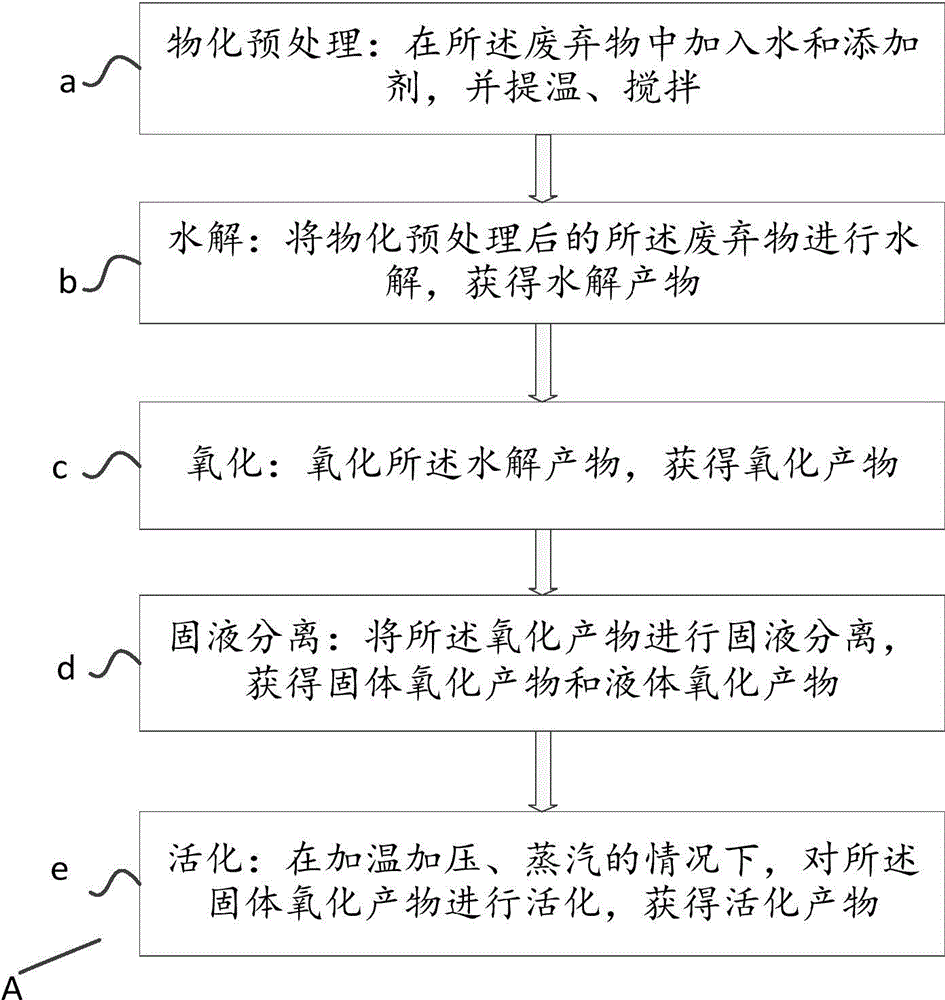

Method and device for treating organic solid waste

ActiveCN104148358AComplete oxidationAvoid lostSolid waste disposalClimate change adaptationCompound (substance)Biological activation

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely hydrolyzing the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; (d) carrying out solid-liquid separation, namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product; and (e) carrying out activation, namely activating the solid oxidization product in the case of heating, pressurizing, steaming and additive adding, thereby obtaining an activated product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

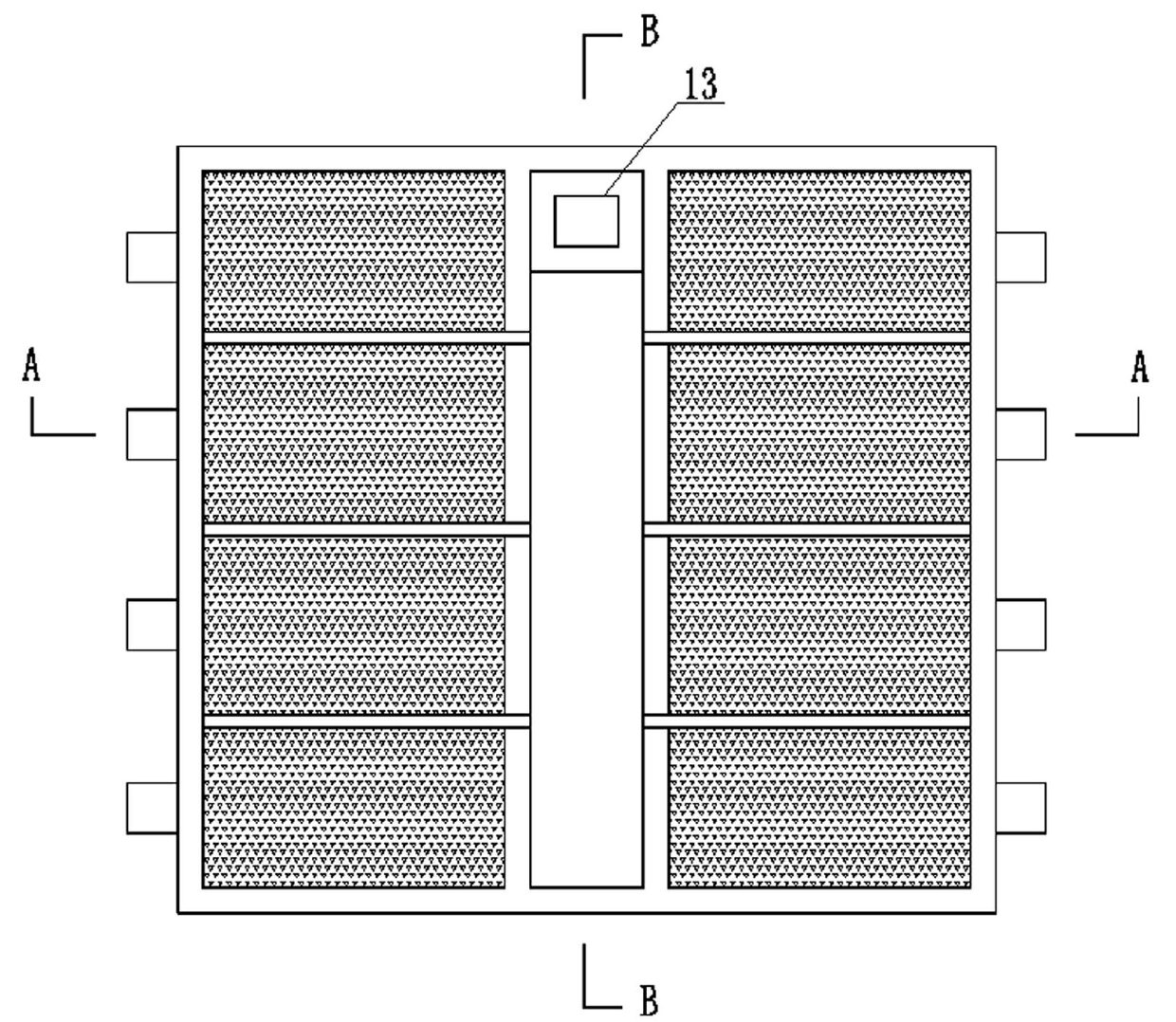

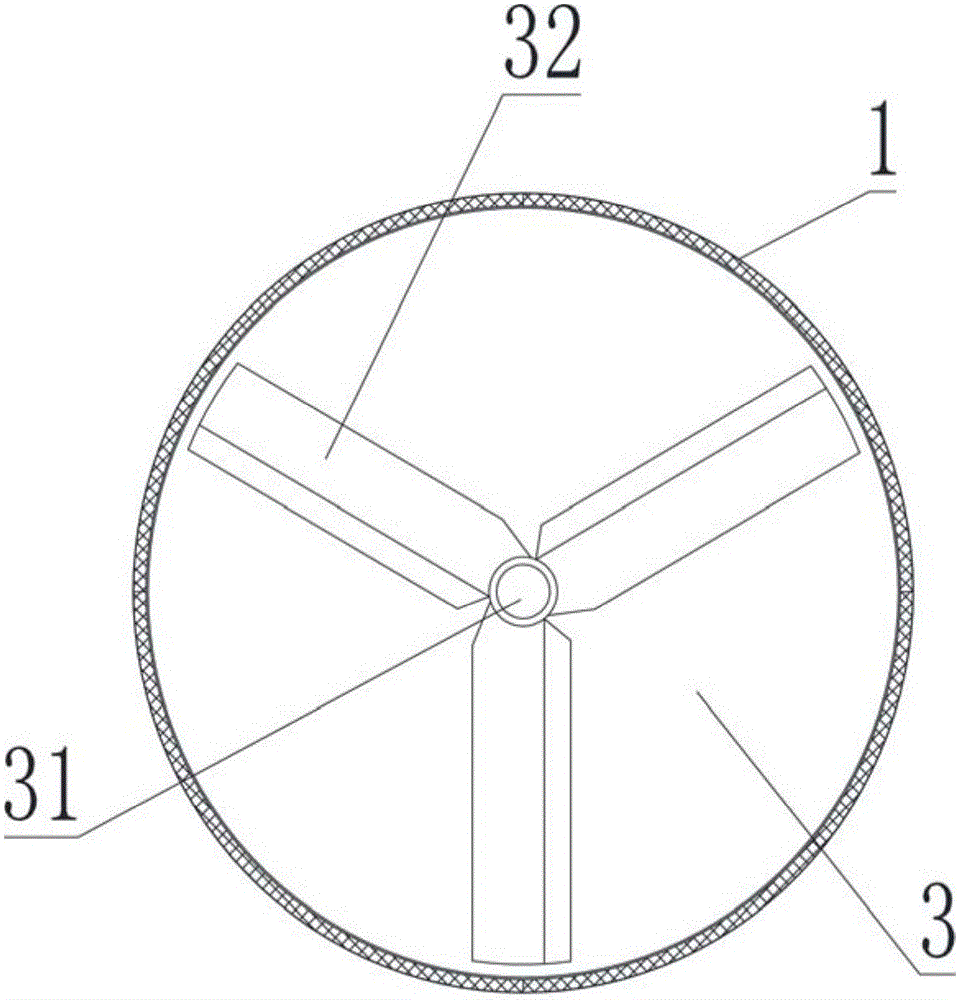

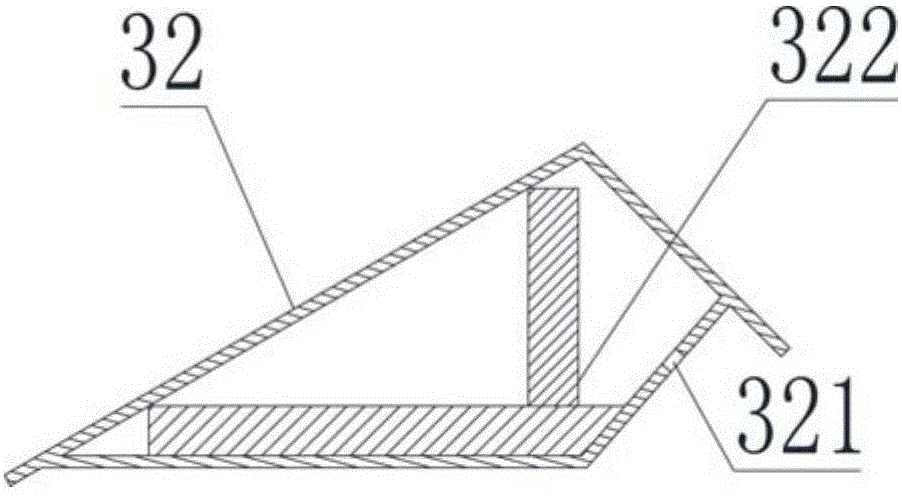

Aerobic composting device for organic solid waste

ActiveCN103145467ARealize resource utilizationAchieve reductionBio-organic fraction processingOrganic fertiliser preparationTemperature controlAir blower

The invention discloses an aerobic composting device for organic solid waste, which comprises a feeding mixer, a conveyor, a fermentation tower, a scraper blade drive device, an air blower, a heating device, an exhaust fan, a waste gas processing device, centre discharge trays, periphery discharge trays, a swivel type granulator, a granulator drive device, a return conveyor, a granulating agent adding device and a spiral conveyor. The aerobic composting device is characterized in that a conical sealing cover is arranged above the fermentation tower, the swivel type granulator is arranged below the fermentation tower; the feeding mixer is connected with the feeding opening in the side surface of the sealing cover through the conveyor; an inward scraper blade is arranged above the centre discharge tray, and an outward scraper blade is arranged above the periphery discharge tray; and two or more groups of the centre discharge trays and the periphery discharge trays are arranged in the fermentation tower from top to bottom. The aerobic composting device for the organic solid waste disclosed by the invention has the characteristic of processing the organic solid waste in a quantity-reduction, stable and harmless manner to realize resource recycling; in addition, the device occupies a small space and also has the characteristics of automatic feeding, granulating, self-control venting, temperature controlling and tail gas processing.

Owner:湖南洁源生物能源科技有限公司

Composting reactor

ActiveCN104072226AHigh degree of automationCompact structureChemical industryOrganic fertiliser preparationBiological filterFresh air

The invention relates to a composting reactor for organic solid waste composting production, which comprises a reactor frame, a closed reaction chamber, a charging device, an aeration and stirring system and a biological filter tank, wherein the closed reaction chamber is installed on the reactor frame and provided with a feed port; the charging device is positioned on one side of the closed reaction chamber, arranged relative to the feed port, and used for delivering an organic solid waste raw material into the closed reaction chamber; the aeration and stirring system is partially installed in the closed reaction chamber, and comprises a stirring device and an aerator which are connected with each other; the stirring device is used for slowly and intermittently stirring the organic solid waste raw material which is delivered into the closed reaction chamber; the aerator is used for delivering fresh air to the inside of the organic solid waste to accelerate the aerobic fermentation; and the biological filter tank is communicated with the closed reaction chamber through an induced draft fan, and used for further treating tail gas generated in the organic solid waste aerobic fermentation process. The composting reactor has the advantages of compact structure, high efficiency, energy saving, no odor pollution in the treatment process, and high automation degree.

Owner:MAE WELLFUL IND

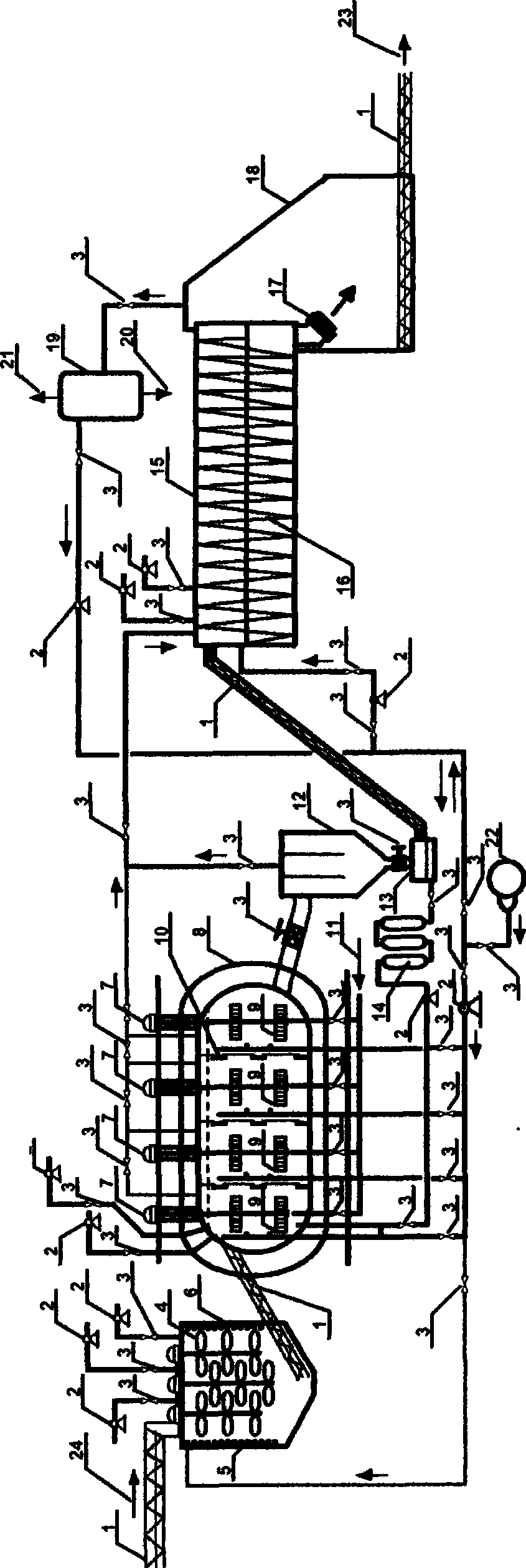

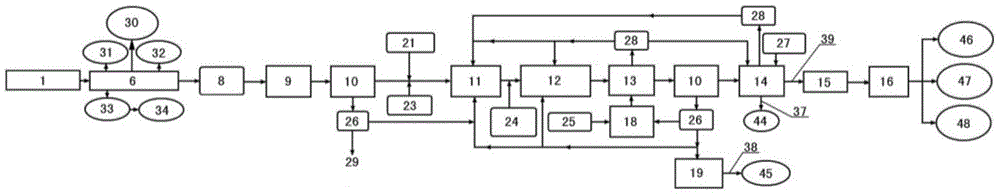

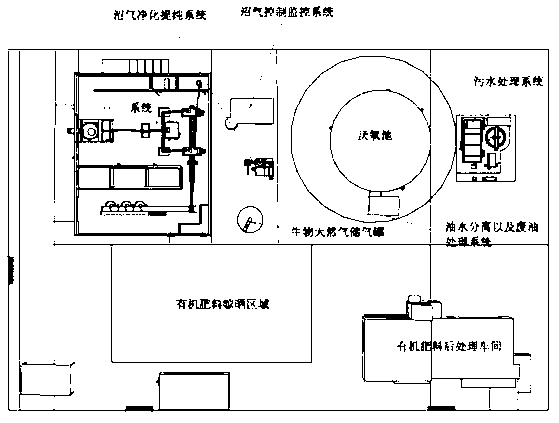

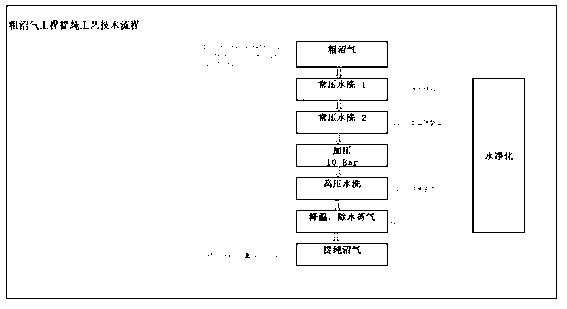

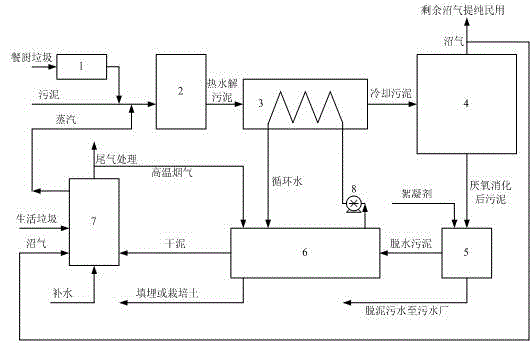

Organic solid waste regeneration resource treatment method and apparatus system thereof

ActiveCN102921711AReduce moistureReduce salt contentBio-organic fraction processingSolid waste disposalEnvironmental engineeringEnergy supply

The invention provides an organic solid waste regeneration resource treatment method, which has a subcritical hydrolysis process and an anaerobic fermentation process, wherein the anaerobic fermentation process supplies energy for the subcritical hydrolysis process, and the subcritical hydrolysis process is an end treatment process, and comprises treatment of biogas residues generated by anaerobic fermentation. With the organic solid waste treatment method and the apparatus system thereof, energy self-circulation within the system can be achieved, wherein biogas generated by the anaerobic fermentation system is adopted as energy supply of the subcritical hydrolysis system, and the biogas residues generated by anaerobic fermentation can be treated into a fertilizer by the subcritical hydrolysis system, such that problems in the prior art are solved, energy consumption is substantially reduced, and environmental protection and pollution reduction are easily achieved, wherein the problems in the prior art comprise that: the biogas residues generated by anaerobic fermentation do not have a discharging way, and the subcritical hydrolysis system requires the external function.

Owner:国环电气科技(上海)有限公司

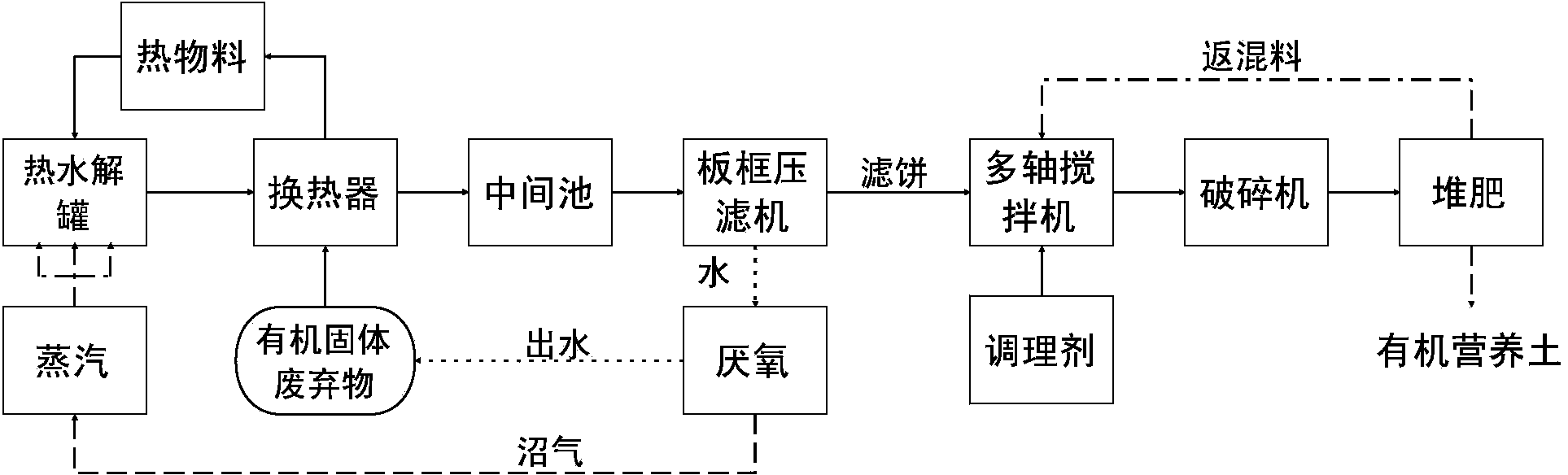

Thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes

ActiveCN104177145ASpeed up fermentationImprove dehydration effectBio-organic fraction processingClimate change adaptationOxygenFilter press

The invention discloses a thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes. The process comprises the following steps: preheating the organic solid wastes with the solid content of 10%-15% by virtue of a heat exchanger, performing thermal hydrolysis on hot steam with pressure of 0.4-1.0MPa and temperature of 150-190 DEG C, dehydrating the treated materials in a plate-and-frame filter press to form filter cakes with the water content of 35%-50%, adding proper conditioners and back-mixing materials into the filter cakes, and finally performing high-temperature aerobic composting treatment in a composting system to form organic nutritional soil. Compared with a conventional composting system, the process has the characteristics that the conditioner consumption is greatly reduced, the composting speed is relatively high, the composting effect is relatively good, and the treating capacity of the composting system is increased by 2-3 times.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

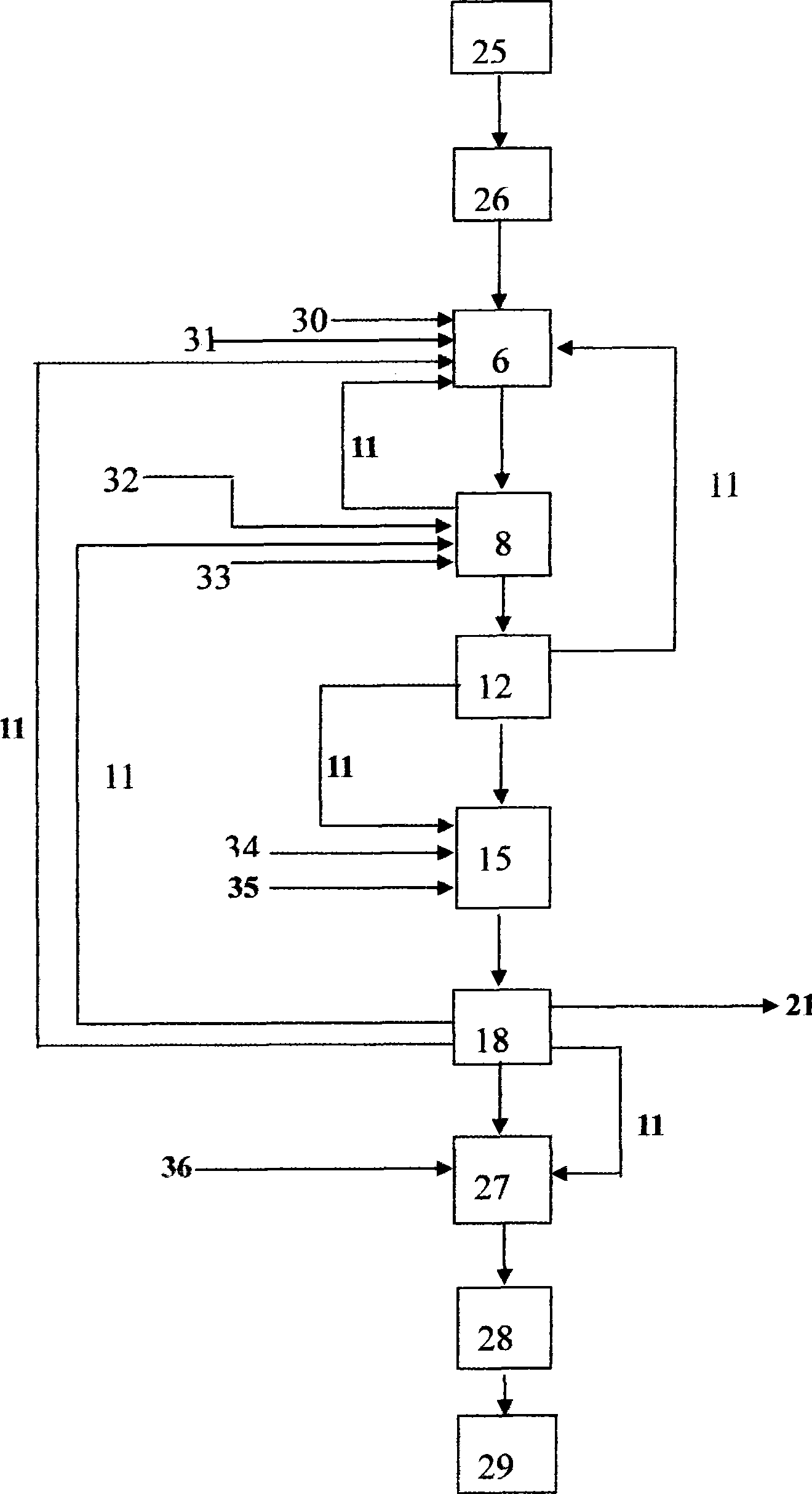

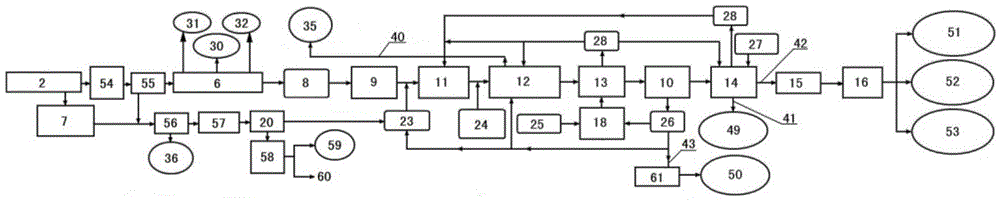

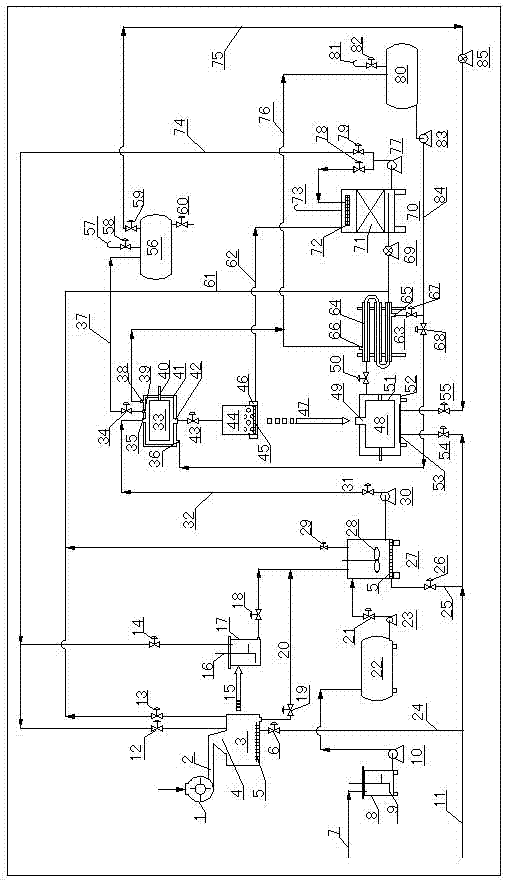

Low-emission solid organic waste treatment system realizing methane and active carbon production

ActiveCN103240264AEasy to handleReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsTreatments waterClean energy

The invention discloses a low-emission solid organic waste treatment system realizing methane and active carbon production. The technical method of the low-emission solid organic waste treatment system realizing methane and active carbon production uses a waste crushing treatment system, an anaerobic digestion raw material pre-treatment and blending system, an anaerobic digestion reactor system, an anaerobic digestion residuum dehydrating system, an anaerobic digestion residuum carbonizing system, a carbonized gas collecting, heat-exchanging and purifying system, and a treatment water recycling system. The technical integration of the low-emission solid organic waste treatment system realizing methane and active carbon production is capable of finishing the optimal treatment of the biomass solid organic waste, and the final product is the clean energy methane and environment-friendly material active carbon. The partial required energy can be produced by the technical method, the energy recycling rate is high, and the treatment on the exhaust gas and effluent can be finished in the production link, the system is energy-saving and environment-friendly. By sufficiently considering the influence of various factors and the coherence among various links, the period of anaerobically treating the biomass organic solid waste can be obviously shortened, and the treatment efficiency of the organic solid waste can be sufficiently improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

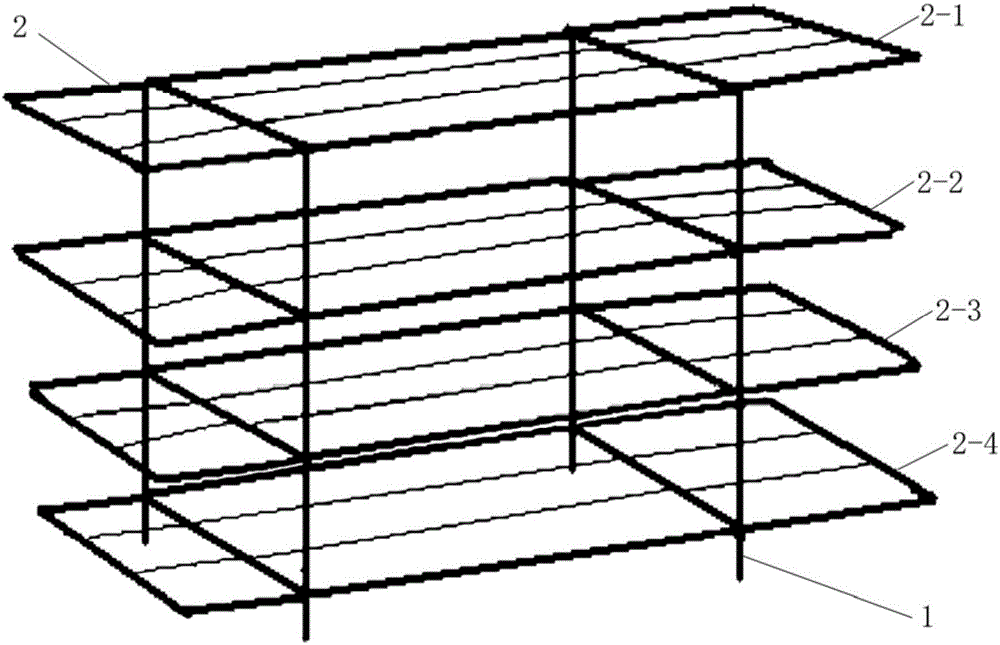

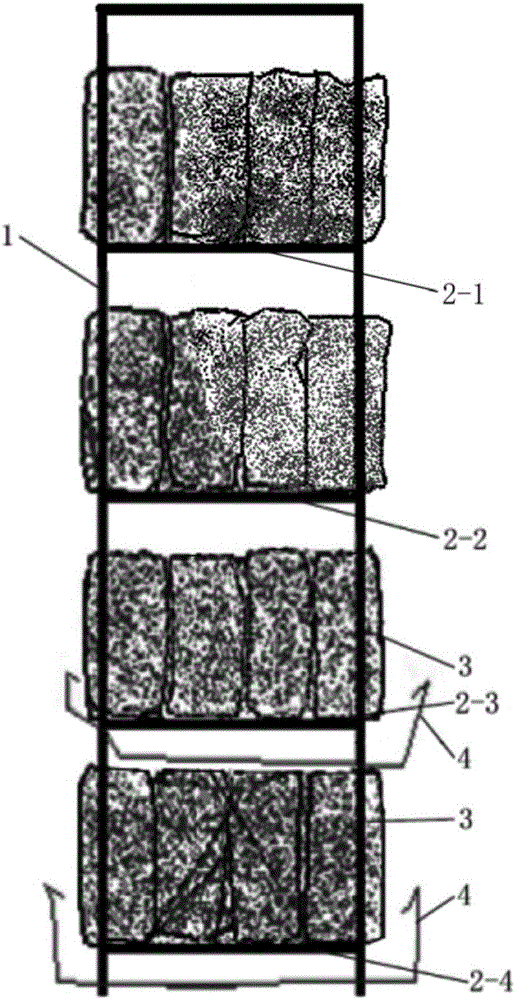

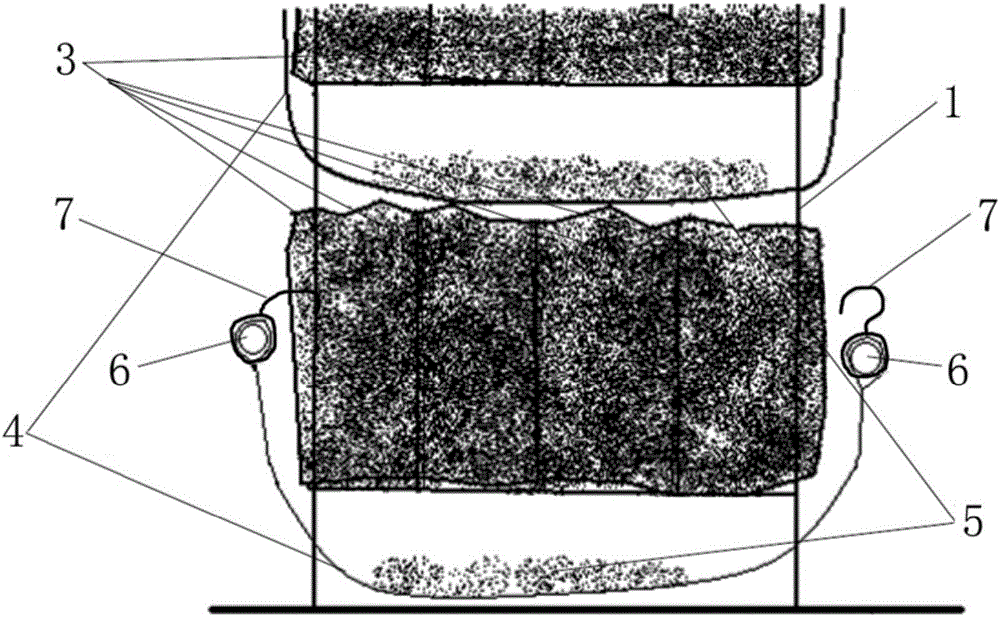

Culture medium for breeding earthworms and stereoscopic earthworm breeding method and device

ActiveCN106577556ASuitable for growthSuitable for breedingFood processingAnimal feeding stuffFiberFeces

The invention relates to a culture medium for breeding earthworms and a stereoscopic earthworm breeding method and device and belongs to the technical field of earthworm breeding. The culture medium is prepared through the following method that firstly, a base material and EM bacterium liquid are mixed, humidity is adjusted to 80%-90% to obtain a mixed material, and the base material is mainly composed of livestock feces, coarse fiber materials and sludge; secondly, the mixed material is subjected to closed anaerobic fermentation for 22-26 h, and after temperature is lowered to 28-32 DEG C, the EM bacterium liquid is added to continue the closed anaerobic fermentation for 22-26 h, and a fermented material is obtained; and thirdly, net bags are filled with the fermented material, and after compacting, the culture medium is obtained after piling and thorough decomposing are performed for 1-3 days. The culture medium achieves that pollution is treated through cultivation and achieves effective recycling of organic solid waste, nutrient substances in the base material are reserved to the maximum extent, and the culture medium is suitable for growing and breeding of the earthworms; and a three-dimensional stereoscopic space is provided for activity and breeding of the earthworms, adult earthworms are not needed to be separated manually, and intensified stereoscopic breeding of the earthworms in a greenhouse or in an indoor environment can be achieved easily.

Owner:海南晟延农业投资有限公司

Energy-saving recycling treatment disposal system and energy-saving recycling treatment disposal process for organic solid waste

InactiveCN104944732AImproved anaerobic biodegradabilityImprove the efficiency of anaerobic digestionSludge treatment by de-watering/drying/thickeningSolid waste disposalExternal energyWaste treatment

The invention relates to an energy-saving recycling treatment disposal system and an energy-saving recycling treatment disposal process for an organic solid waste. The energy-saving recycling treatment disposal process mainly comprises a continuous sludge pyrohydrolysis anaerobic digestion section, a sludge dehydration heat drying section and a dry sludge, domestic garbage and biogas mixing incineration section. Due to the energy-saving recycling treatment disposal system and process disclosed by the invention, the innocent treatment of kitchen garbage, municipal sludge and the domestic garbage can be thoroughly realized by combining a high-temperature sludge anaerobic digestion technology with the high-organic matter characteristic of the kitchen garbage by utilizing respective characteristics of three solid wastes, applying a solid waste high-temperature incineration technology of mixed biogas, adopting a reasonable energy resource integrated means and applying an advanced high-temperature continuous pyrohydrolysis pretreatment technology. In addition, the energy-saving recycling treatment disposal process disclosed by the invention can also be used for realizing the recycling of the three solid wastes, improving the energy resource utilization efficiency of an integrated system, effectively reducing the input of external energy resources and reducing the operation cost. The energy-saving recycling treatment disposal process disclosed by the invention is capable of realizing the continuous operation of solid waste treatment, simple and reliable, simple in equipment, small in initial investment and has good environmental and economic benefits.

Owner:TONGJI UNIV

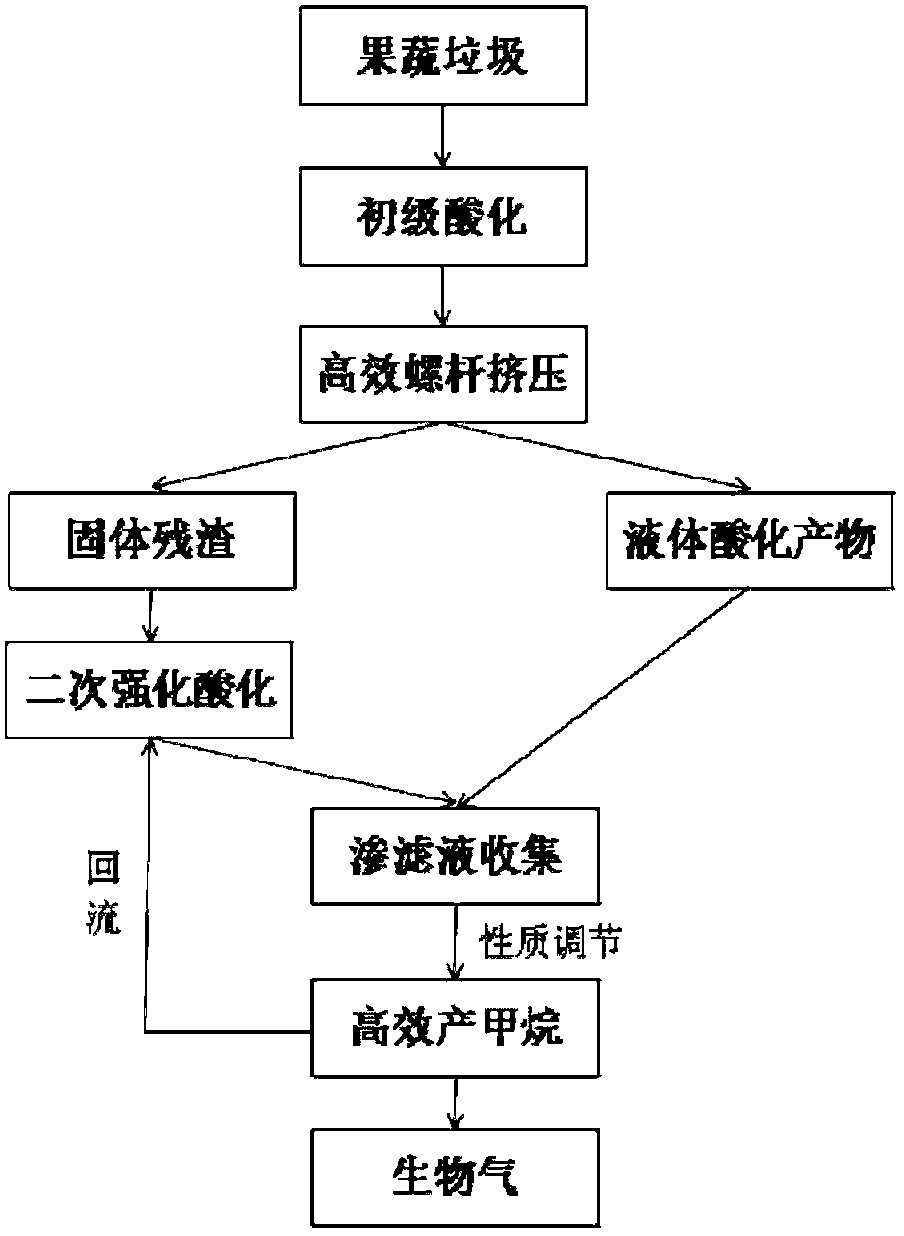

Method for producing biogas through anaerobic digestion of fruit and vegetable waste

ActiveCN102703515AHigh efficiency of hydrolysis and acidificationReduce consumptionWaste based fuelFermentationMethanationAerobic digestion

The invention discloses a method for producing biogas through anaerobic digestion of fruit and vegetable waste, and belongs to the field of high-efficiency recycling of organic solid waste. The fruit and vegetable waste is firstly subjected to acidification as well as a high-efficiency extrusion process to realize solid-liquid separation, and then a solid-state product and a liquid-state product are treated respectively. Solid-state residue is subjected to secondary reinforcing acidification to enter a high-efficiency anaerobic digestion methane production reactor together with a liquid-state acidification product; and meanwhile, effluent water of the methanator is used as reflux liquid to be circulated in a solid-state residue secondary reinforcing hydrolytic acidification reactor to speed up the hydrolytic acidification reaction. According to the method, high-efficiency transformation of the waste is realized, and the effluent water in the methanator is pumped into the secondary reinforcing acidification reactor for recycling. The method has the advantages of high treatment rate, high gas production rate, short period, capability of realizing continuous stable gas production, no wastewater discharge and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

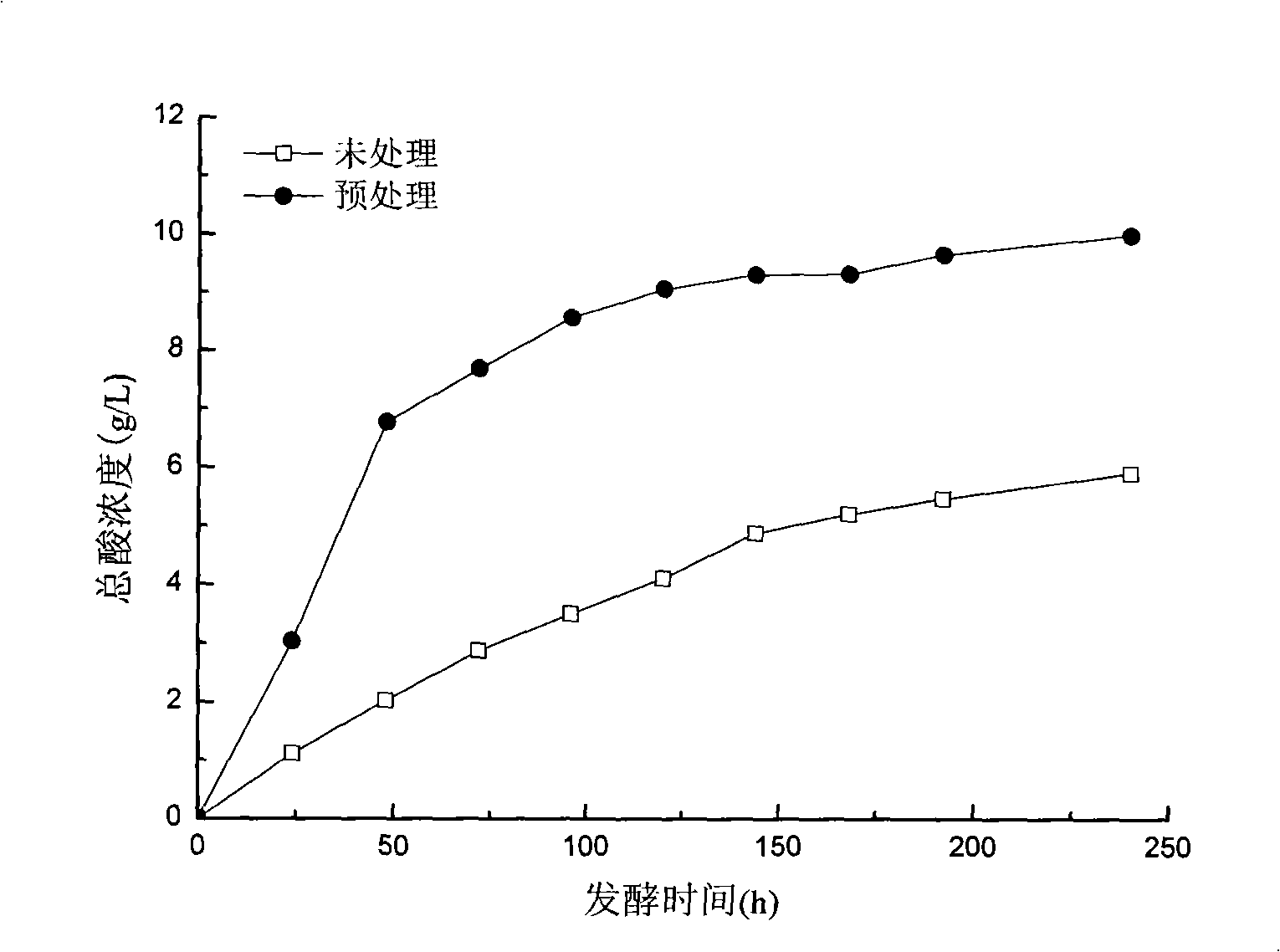

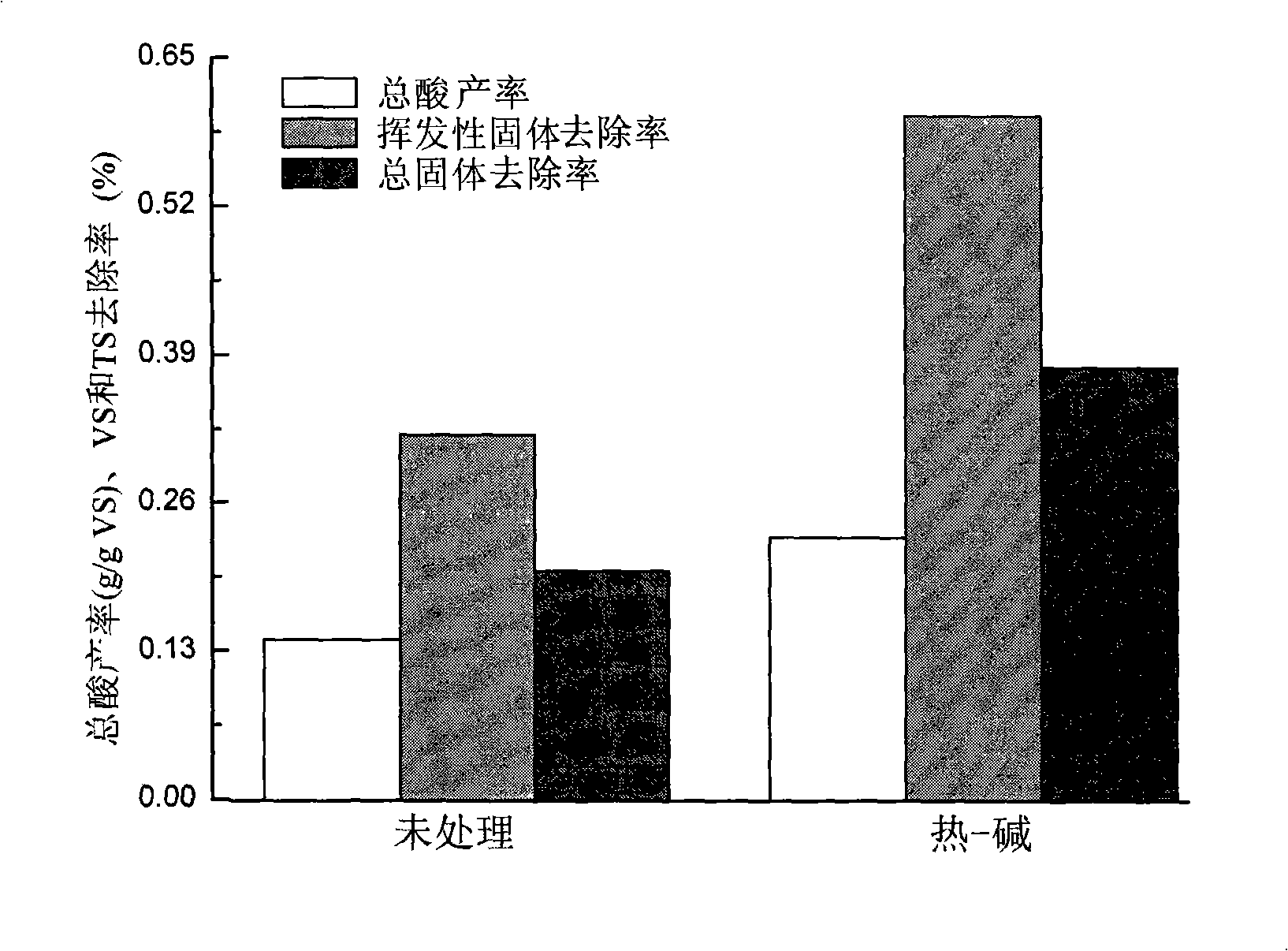

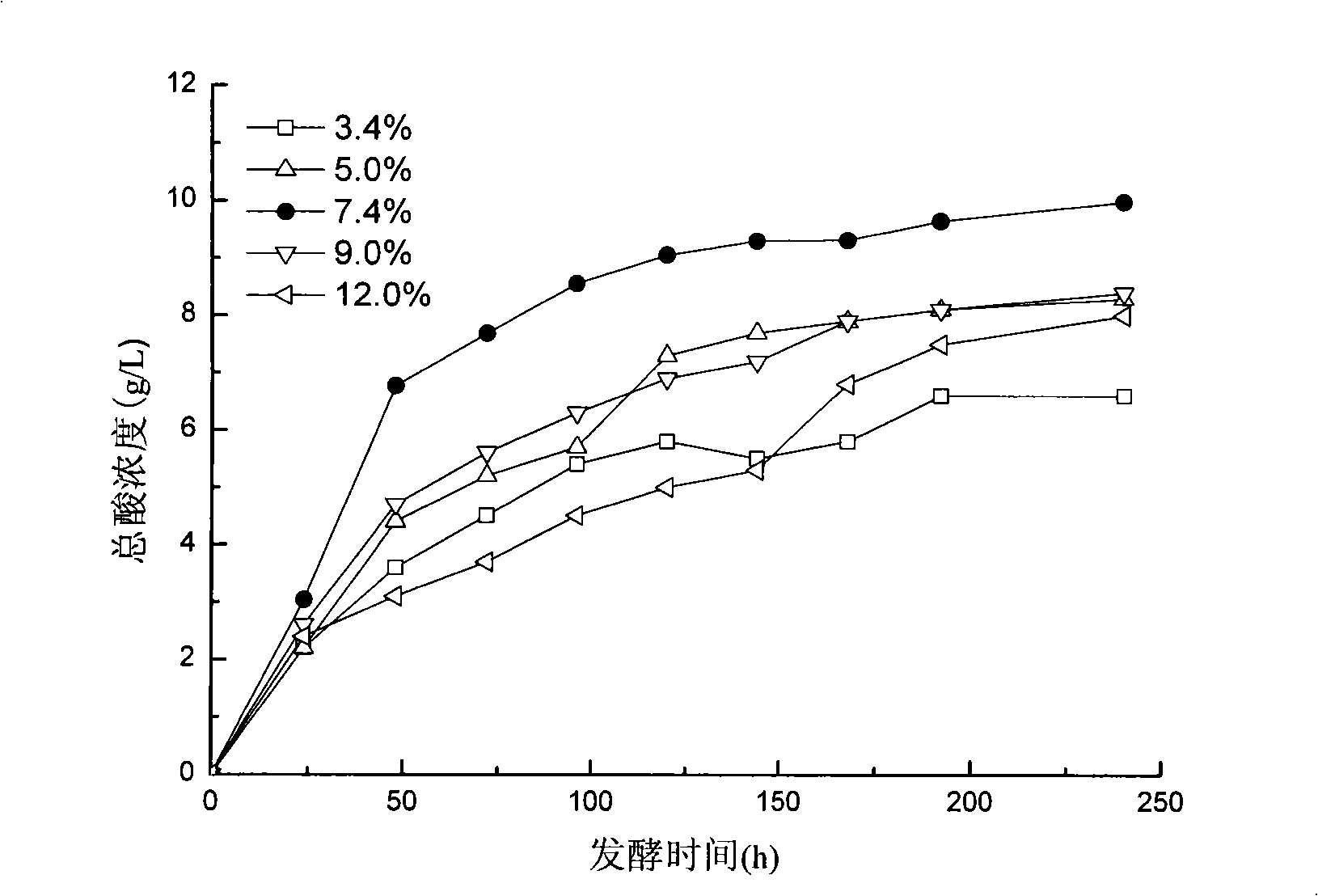

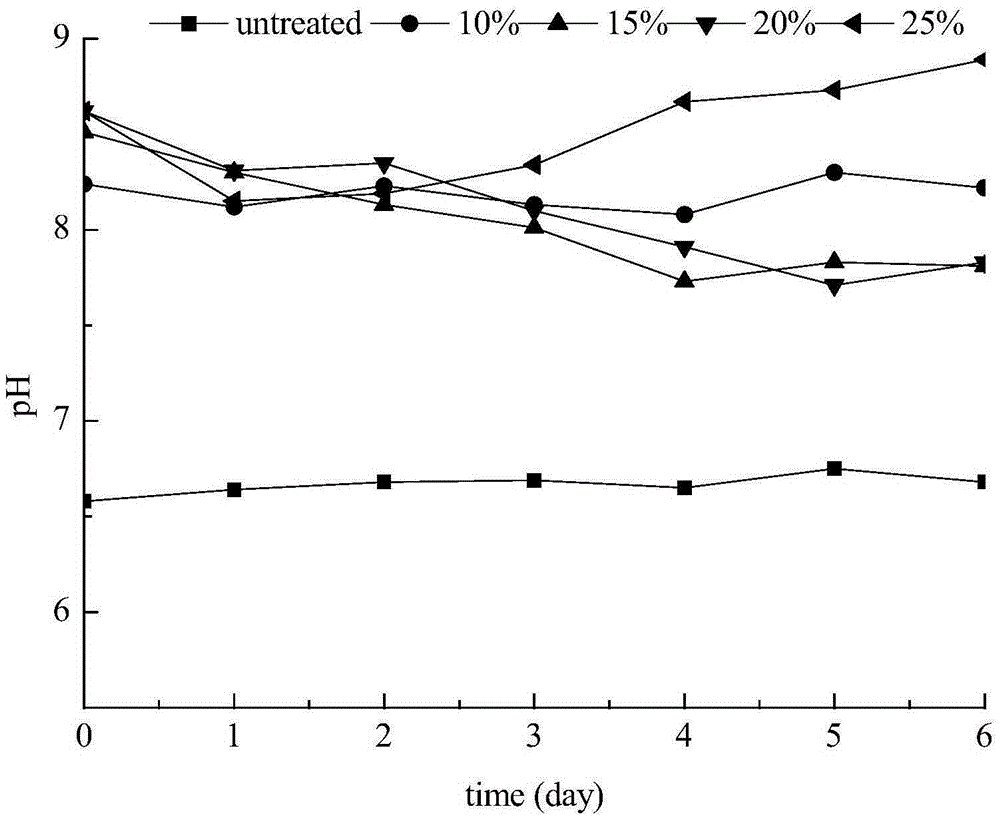

Method for preparing volatile fatty acid with high solid concentration organic castoff heat-alkali preprocessing post anaerobic fermentation

InactiveCN101314783AHigh yieldShorten the fermentation cycleWaste based fuelFermentationVolatile fatty acidsGram

Owner:JIANGNAN UNIV

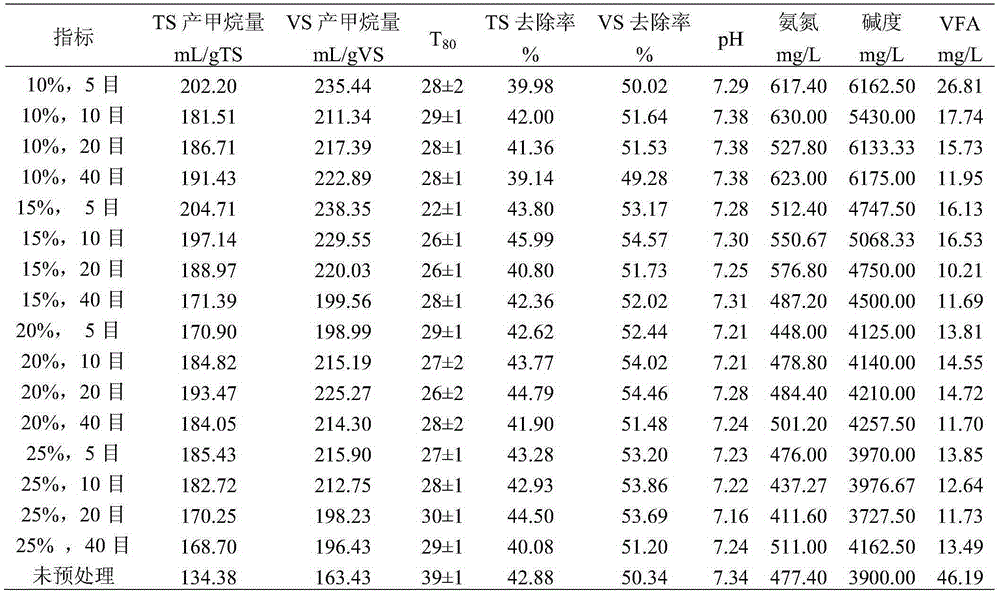

Method for improving straw and excrement mixed anaerobic digestion gas production performance by biochemical pretreatment of maize straw

ActiveCN105420282AReduce preprocessing timeEasy to operateWaste based fuelFermentationFecesThermostat

A method for improving straw and excrement mixed anaerobic digestion gas production performance by biochemical pretreatment of maize straw belongs to the field of anaerobic digestion of organic solid waste, and comprises the following steps: extracting biogas liquid from a biogas liquid pool, and sieving with a sieve; crushing straw, uniformly mixing the crushed straw with the biogas liquid, placing the obtained mixture in a closed vessel, and pretreating in a thermostat at 35 DEG C for 1 to 3 days; uniformly mixing the obtained material with excrement, inoculating anaerobic digestion sludge, adjusting the pH, adding water for dilution and performing moderate-temperature anerobic fermentation. Compared with the prior art, the method has the following benefits: (1) the pretreatment time is remarkably shortened by 5-14 days; (2) the anerobic fermentation period is remarkably shortened by 23.08-43.59%; (3) the yield of methane is remarkably improved by 25.72-36.55%; (4) the process is simple, the cost is low, and the operation is easy.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of biological organic fertilizer

ActiveCN105418172AImprove filtration efficiencyImprove resource utilizationBio-organic fraction processingClimate change adaptationBacillus licheniformisFiber

The invention provides a preparation method of a biological organic fertilizer. The preparation method comprises the steps of fermentation substrate providing, fermentation substrate stacking and substrate fermentation, wherein the step of fermentation substrate stacking comprises the steps that a fermentation substrate and a fermentation liquid microorganism bacterium agent are evenly mixed and stacked to a rectangular fermentation substrate pile with the height of 0.5-0.8 m according to the proportion that 0.9-1.1 L of the fermentation liquid microorganism bacterium agent is added to every 1,000 kg of the fermentation substrate. The fermentation liquid microorganism bacterium agent comprises bacillus subtilis liquid, bacillus licheniformis liquid, saccharomyces cerevisiae liquid, lactic acid bacillus liquid and aspergillus niger liquid. By means of the preparation method of the biological organic fertilizer, waste materials can be changed into treasure, and the generally existing environmental pollution problems that when resourceful treatment of organic solid waste is conducted, the capacity for decomposing macromolecular protein and coarse fibers is weak, nitrogen is prone to loss, and pungent odors are produced can be solved.

Owner:鹤壁市人元生物技术发展有限公司

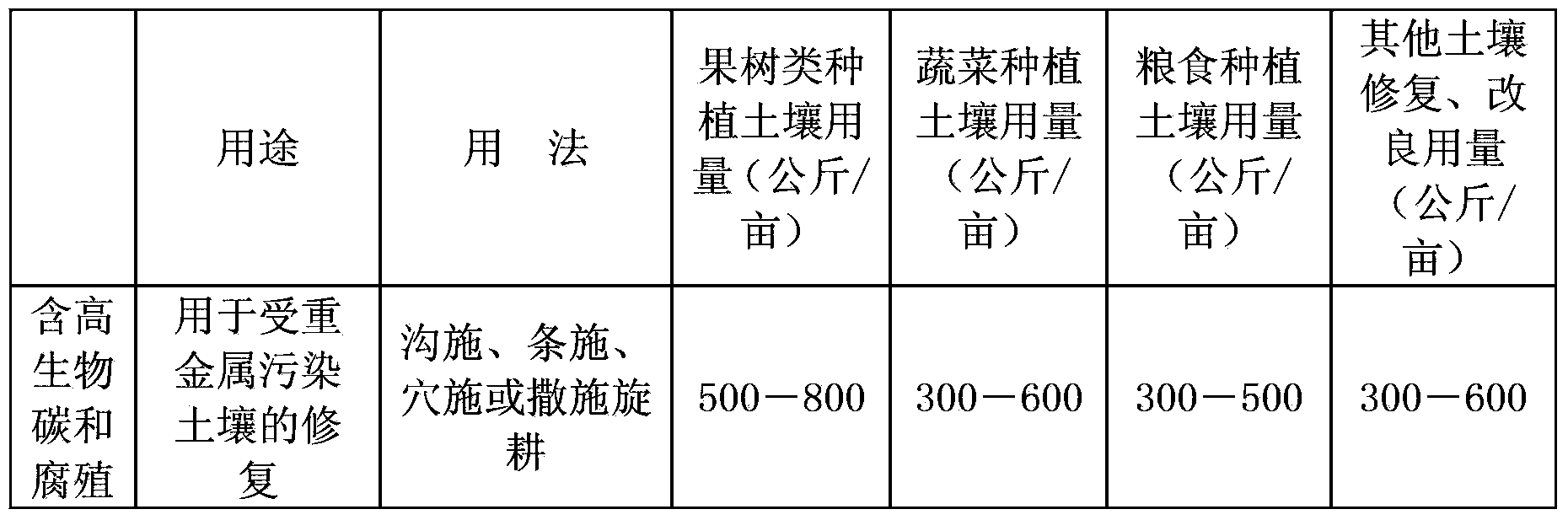

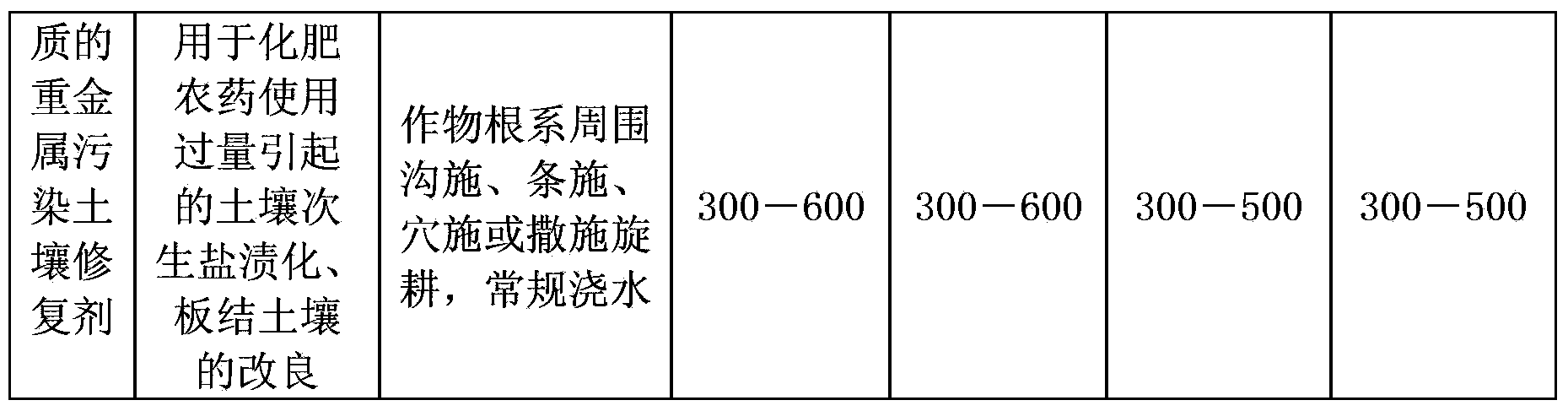

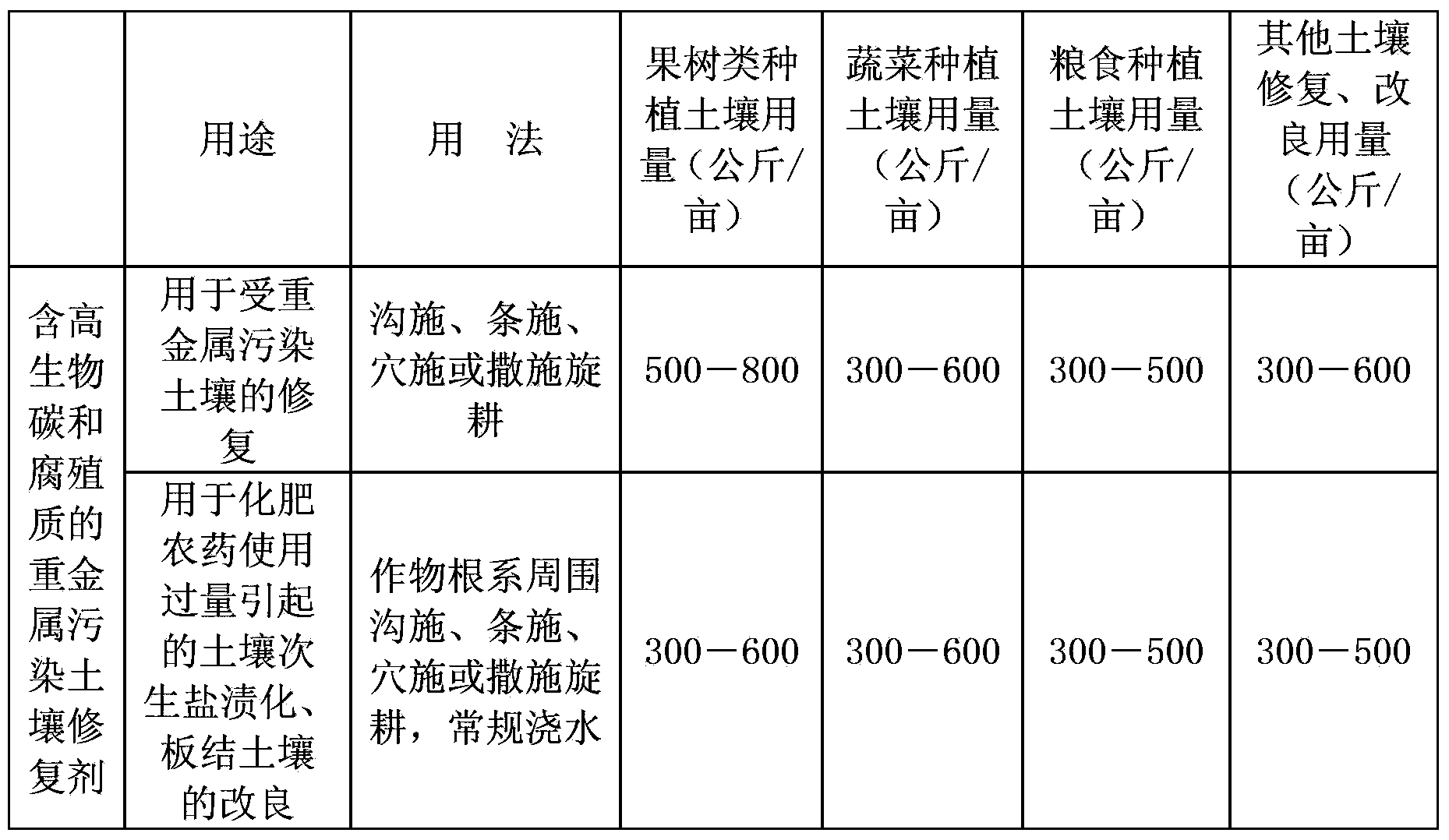

Heavy metal polluted soil repairing agent with high content of biocarbon and humus and application method thereof

InactiveCN104338741AAvoid absorptionBarrier migrationContaminated soil reclamationDiseaseResidual body

The invention discloses a heavy metal polluted soil repairing agent with a high content of biocarbon and humus, and an application method thereof. The repairing agent is composed one or more of kitchen garbage, blue algae, livestock and poultry manure, straw, wood chip, rice husk, plant wastes, dead animal due to diseases and residual body of livestock and poultry. The raw materials mentioned above is subjected to steps of impurity removing, grinding, and proportioning, and then the mixture is subjected to a sub-critical water treatment for 90 to 150 minutes at a temperature of 180 to 360 DEG C under a pressure of 1.8 to 5.8 MPa so as to obtain the tail product; wherein the biocarbon content accounts for not less than 45% of the dry substrate, the total nutrient content is 4 to 6%, the amino acid content is not less than 20%, the humus content is not less than 40%, the trace element content is not less than 0.5%, and the pH value of the repairing agent is 5 to 7. The provided repairing agent can be used to repair polluted soil, and can also be used to treat the soil secondary salinization and hardened soil caused by over application of chemical fertilizer and pesticides. The organic solid waste pollutants are processed to produce the repairing agent, thus the environment pollution problem is solved, and at the same time, the biocarbon and humus in the tail product can repair and improve the soil polluted by metals, chemical fertilizers, and pesticides.

Owner:上海国环生态科技股份有限公司

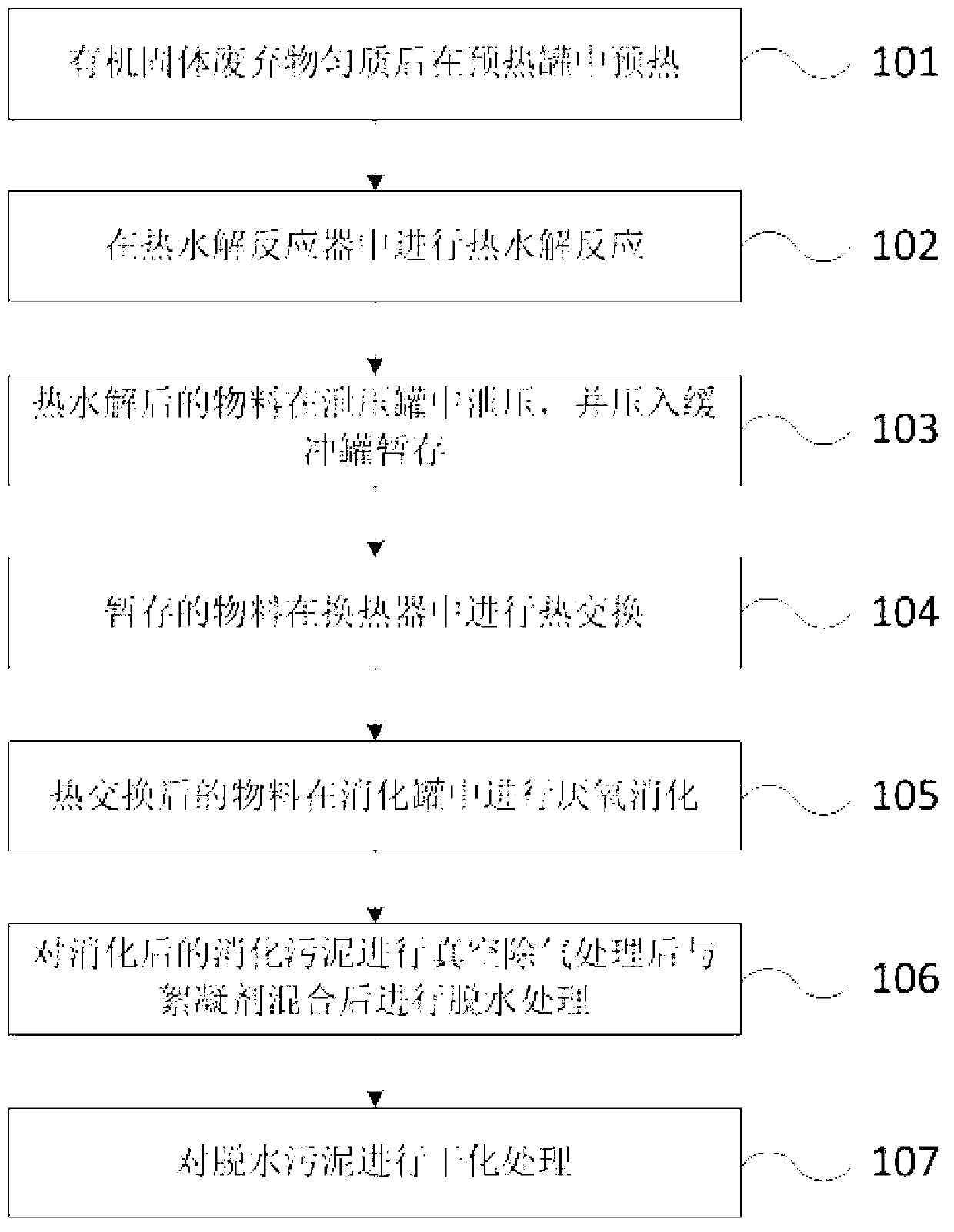

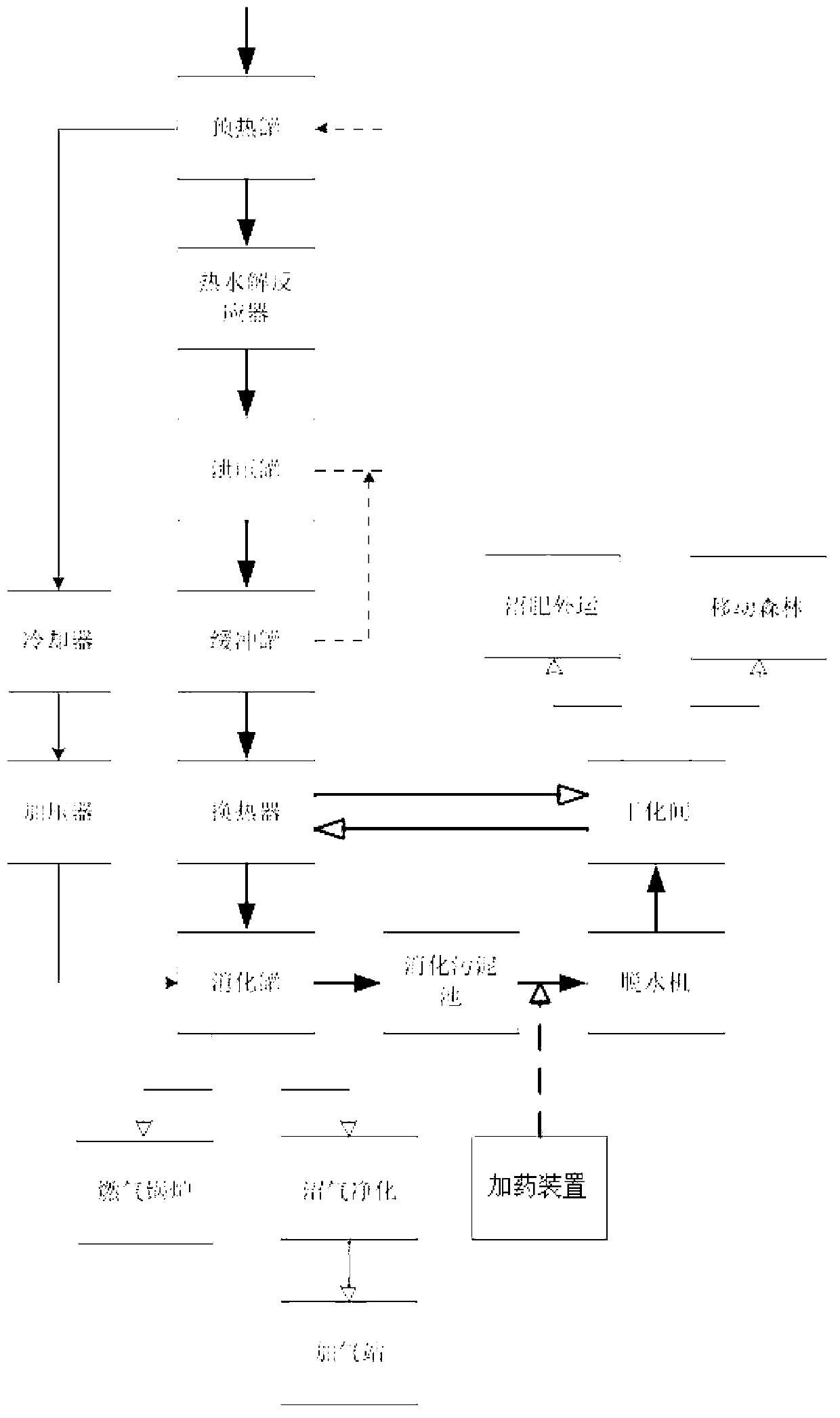

Treatment method of organic solid waste

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

Closed silo composting reactor

InactiveCN105060962APrevent compactionRaise the fermentation temperatureBio-organic fraction processingOrganic fertiliser preparationEffective volumeFermentation

The invention relates to the technical field of organic solid waste treatment, in particular to a closed silo composting reactor. The closed silo composting reactor comprises a composting silo, a stirring device, a hydraulic drive device and a discharge screw conveyor, wherein a feed port and an exhaust port are formed in the top of the composting silo; a discharge port is formed in the bottom of the composting silo; the discharge screw conveyor corresponds to the discharge port; the stirring device is arranged in the composting silo; the hydraulic drive device drives the stirring device to rotate and stir. The composting silo adopts vertical closed design, has high effective volume and can increase fermentation temperature, so that the fermentation period is greatly shortened; the stirring device performs continuous dynamic stirring, thereby having stirring, mixing and loosening effects and avoiding material compaction; with the adoption of rotating aeration, effectiveness and uniformity of aeration are improved.

Owner:北京沃土天地生物科技股份有限公司

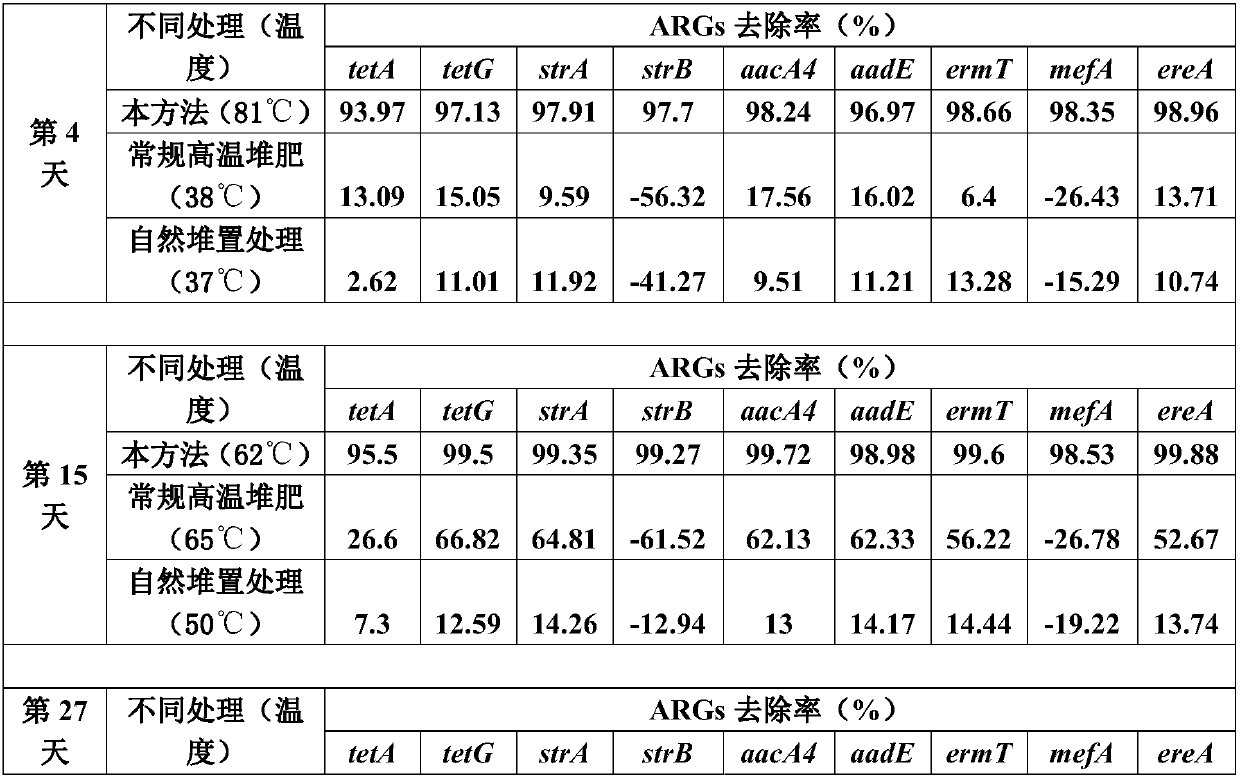

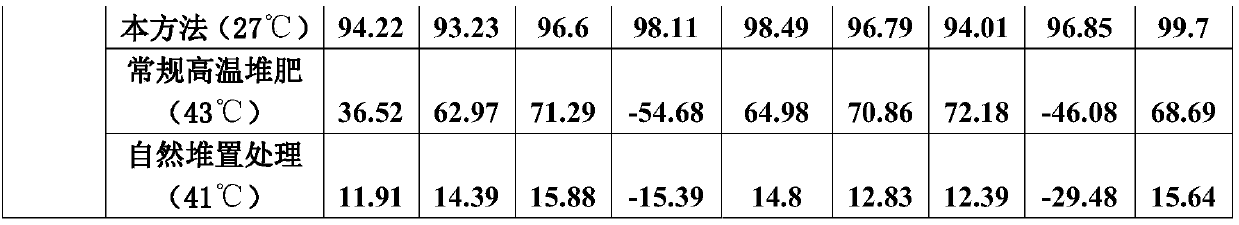

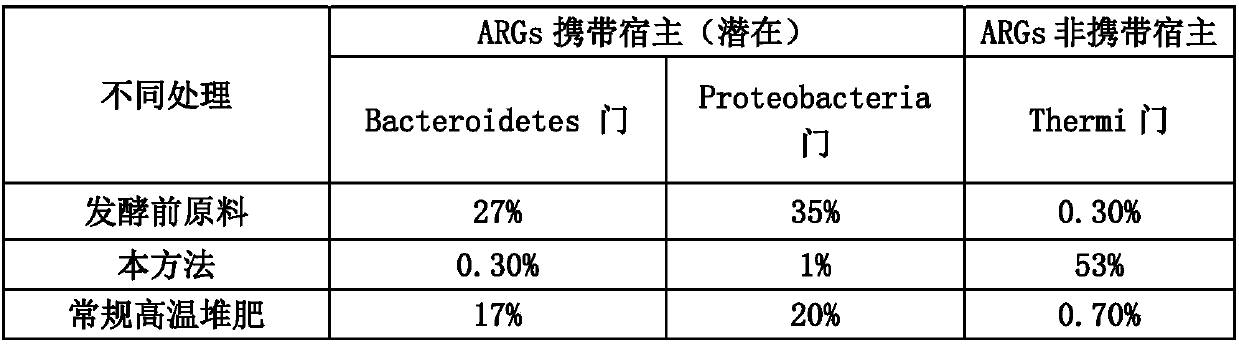

Method for quickly reducing antibiotics and resistance genes in organic solid waste

ActiveCN108033817AReduce the risk of gene transferNo reboundBio-organic fraction processingBacteriaGene transferBacteroidetes

The invention discloses a method for quickly reducing antibiotics and resistance genes in organic solid waste, and belongs to the field of organic solid waste treatment. The method has the advantagesthat ultrahigh-temperature aerobic fermentation is carried out on the organic solid waste by the aid of aerobic zymocyte capable of tolerating the temperatures of at least 80 DEG C under the conditionthat pile temperatures are not lower than 80 DEG C under the control for at least 5-7 days, and accordingly effects of quickly and stably reducing the antibiotics and the resistance genes in the organic solid waste can be realized; the antibiotics and the ARGs (antibiotic resistance genes) can be quickly degraded by means of ultrahigh-temperature aerobic fermentation, integral microbial communitystructures in piles further can be changed, 90% of microorganisms (mainly including Proteobacteria and Bacteroidetes) which carry the ARGs can be killed, risks of gene transfer of the ARGs can be reduced, diffusion of the ARGs can be controlled from the source, and the ARGs can be guaranteed against rebounding; the organic solid waste can be treated, and double effects of efficiently removing antibiotic residues and resistance gene pollution can be realized; exogenous heating can be omitted, energy can be produced only by the aid of metabolism of thermophilic microorganisms to reach the highfermentation temperatures, and accordingly the method is low in energy consumption and is environmentally friendly.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com