Energy-saving recycling treatment disposal system and energy-saving recycling treatment disposal process for organic solid waste

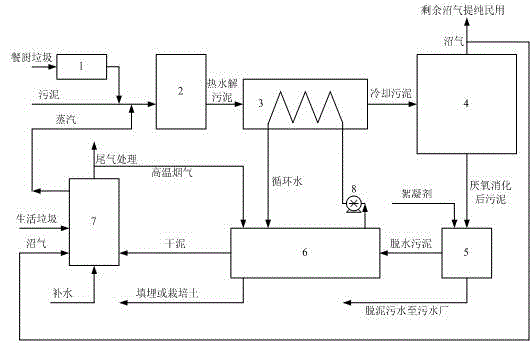

A technology for organic solids and wastes, which is applied in the fields of solid waste removal, biological sludge treatment, waste fuel, etc., and can solve the difficult harmless treatment of solid waste, difficult treatment of kitchen waste, and low anaerobic gas production rate To achieve the effect of shortening the peak of gas production and sludge residence time, improving the treatment capacity and avoiding the production of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028]The kitchen waste collected by the city is transported to the crusher 1 for crushing, and then mixed with the municipal sludge with a water content of 80% in the urban sewage treatment plant through a screw pump and mixed in the pipeline. Before entering the thermal hydrolysis tank 2, high-temperature and high-pressure steam is continuously fed into the mixed sludge, and the steam transfers heat energy to the mixed sludge, which cools itself and mixes with the sludge, and the mixed sludge is heated by steam to a state of high temperature and high pressure, containing water The rate is increased, the viscosity is reduced, and the fluidity is improved. The high-temperature and high-pressure mixed sludge enters from the bottom of the thermal hydrolysis tank 2, is mixed evenly by the mixer equipped in the thermal hydrolysis tank 3, and slowly rises from the bottom to the top outlet. The high-temperature and high-pressure sludge stays in the thermal hydrolysis tank 3 for more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com