Method for preparation of organic fertilizer from organic solid waste

A technology of organic solids and organic fertilizers, applied to the preparation of organic fertilizers, organic fertilizers, biochemical equipment and methods, etc., can solve the problems of poor dehydration performance of mud cakes, long hydraulic retention time, and insufficient killing of pathogenic bacteria, and achieve effective results Good, more mature compost, and improved processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

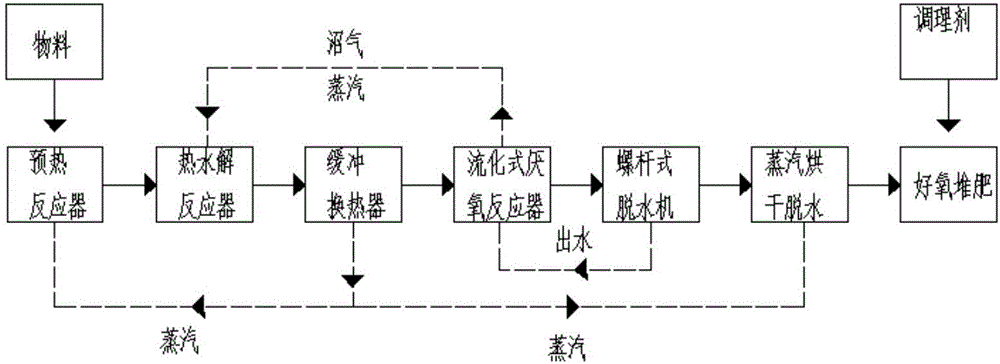

Method used

Image

Examples

Embodiment 1

[0036] Dewatered sludge with a moisture content of 97.5% in urban sewage treatment plants is sent to the preheating heat exchanger, and the steam from the buffer heat exchanger preheats the sludge to a temperature of 90°C; then it is intermittently and quantitatively sent to the thermal hydrolysis tank Inside, the sludge in the thermal hydrolysis tank is treated with steam at a temperature of 190°C and a pressure of 1.0Mpa at multiple points, and the temperature in the tank is 170°C and the pressure is 0.6Mpa for thermal hydrolysis treatment for 30 minutes; The treated sludge has a solid content of 15%. After thermal hydrolysis, the material enters the buffer heat exchanger to flash and release preheated steam, so that the sludge temperature drops to 55°C and then enters the anaerobic reactor. The anaerobic reactor adopts buffer The heat source of the heat exchanger is kept warm, and the anaerobic reactor is pumped into the anaerobic reactor under the double action of the agita...

Embodiment 2

[0038] Dewatered sludge with a water content of 97.5% and kitchen waste with a water content of 85% in urban sewage treatment plants are blended into 88% mixed organic waste (that is, the solid content is 12%), which is transported to the buffer heat exchanger, and the waste heat steam After the mixture is preheated, the temperature is 80°C; then it is intermittently and quantitatively transported to the thermal hydrolysis tank, and the sludge in the thermal hydrolysis tank is fed with steam at a temperature of 190°C and a pressure of 1.0Mpa at multiple points, the tank The internal temperature is 170°C, the pressure is 0.6Mpa, and the thermal hydrolysis treatment is carried out for 50 minutes; the solid content of the sludge after thermal hydrolysis treatment is 25%. After thermal hydrolysis, the material enters the buffer heat exchanger to flash and release preheated steam. The sludge temperature is lowered to 55°C and then enters the anaerobic reactor. The anaerobic reactor ...

Embodiment 3

[0040]Dewatered sludge with a water content of 97.5% and chicken manure with a water content of 75% in urban sewage treatment plants are blended into 80% mixed organic waste (that is, the solid content is 20%), which is transported to the buffer heat exchanger, and the waste heat steam will After the mixture is preheated, the temperature is 90°C; then it is intermittently and quantitatively transported to the thermal hydrolysis tank, and the sludge in the thermal hydrolysis tank is fed with steam at a temperature of 190°C and a pressure of 1.0Mpa at multiple points. The temperature is 170°C, the pressure is 0.6Mpa, and the thermal hydrolysis treatment is carried out for 40 minutes; the solid content of the sludge after thermal hydrolysis treatment is 25%. After thermal hydrolysis, the material enters the buffer heat exchanger to flash to release preheated steam, so that the After the mud temperature drops to 55°C, it enters the anaerobic reactor. The anaerobic reactor adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com