Modified slag/chitosan composite capable of reducing water content of domestic sludge and preparation method thereof

A technology of domestic sludge and chitosan, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of polluting the atmosphere, endangering human health, etc. Improved dehydration performance and enhanced adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of modified slag / chitosan composite, the method is as follows:

[0022] (1) Modification of slag

[0023] 1) Crush the slag, sieve it through a 200-mesh sieve, and take the sieve to obtain slag powder.

[0024] 2) Soak a certain amount of slag powder in 4mol / %L sulfuric acid according to the ratio of material to liquid: 1g:1mL, stir and soak for 2h under the condition of stirring speed of 30r / min, filter, and put the obtained solid into the temperature of 200°C Dry in an oven for 20 minutes to obtain modified slag.

[0025] (2) Compound preparation

[0026] 1) Put the chitosan into an oven with a temperature of 200° C., and dry it for 15 minutes.

[0027] 2) According to the mass ratio of modified slag: chitosan=200:1, take the modified slag and chitosan, and stir for 90min under the condition of stirring speed of 100r / min to obtain the modified slag / chitosan composite.

Embodiment 2

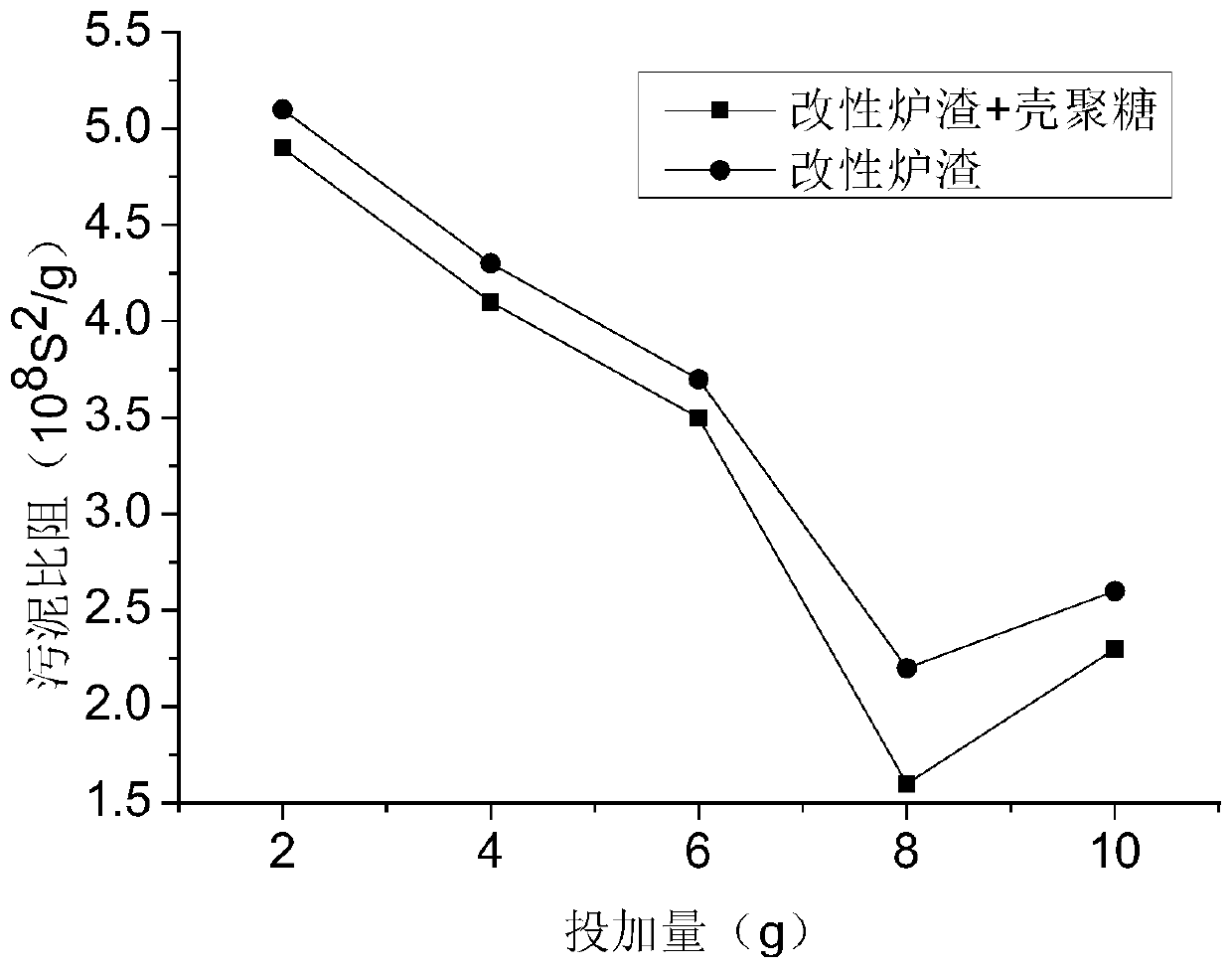

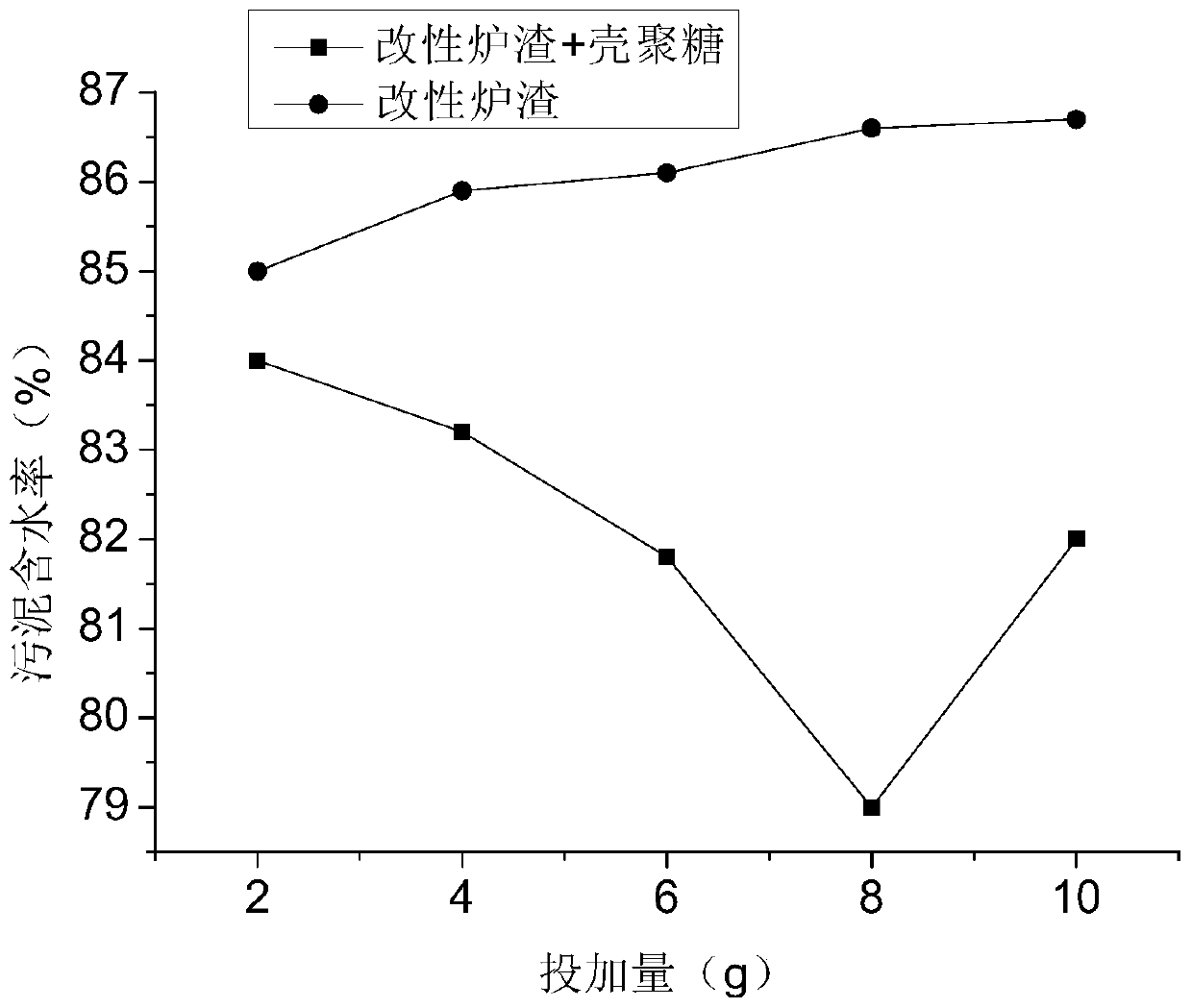

[0028] Application of Example 2 Modified Slag / Chitosan Compound in Sludge Dewatering

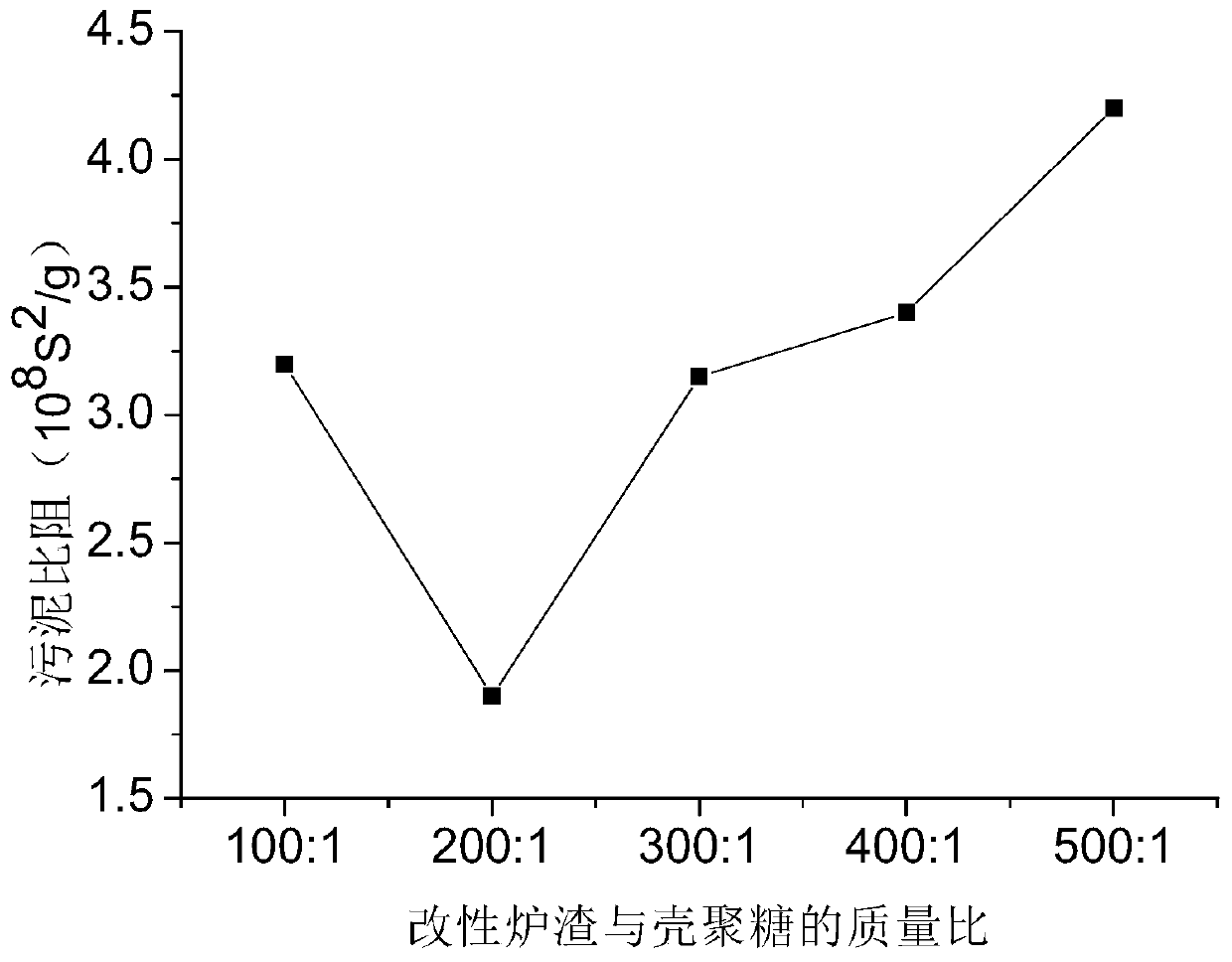

[0029] (1) Effect of mass ratio of modified slag to chitosan on sludge specific resistance

[0030] The domestic sludge selected in this experiment comes from a sewage treatment plant, and its water content is as high as 92%.

[0031] The preparation of modified slag / chitosan compound: method is the same as embodiment 1, just changes modified slag: the mass ratio of chitosan is respectively 100:1, 200:1, 300:1, 400:1, 500:1 , prepared into five different mass ratios of modified slag / chitosan composites.

[0032] Sludge dehydration method: Take 100mL of domestic sludge and pour it into a 250mL beaker, then take 8g of the above-mentioned modified slag / chitosan compound in different proportions and add them to the beaker respectively, and stir at 30r / min After uniformity, pour it into the Buchner funnel, turn on the vacuum pump to carry out the suction filtration experiment, and calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com