Patents

Literature

81results about How to "Reduce harm to the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

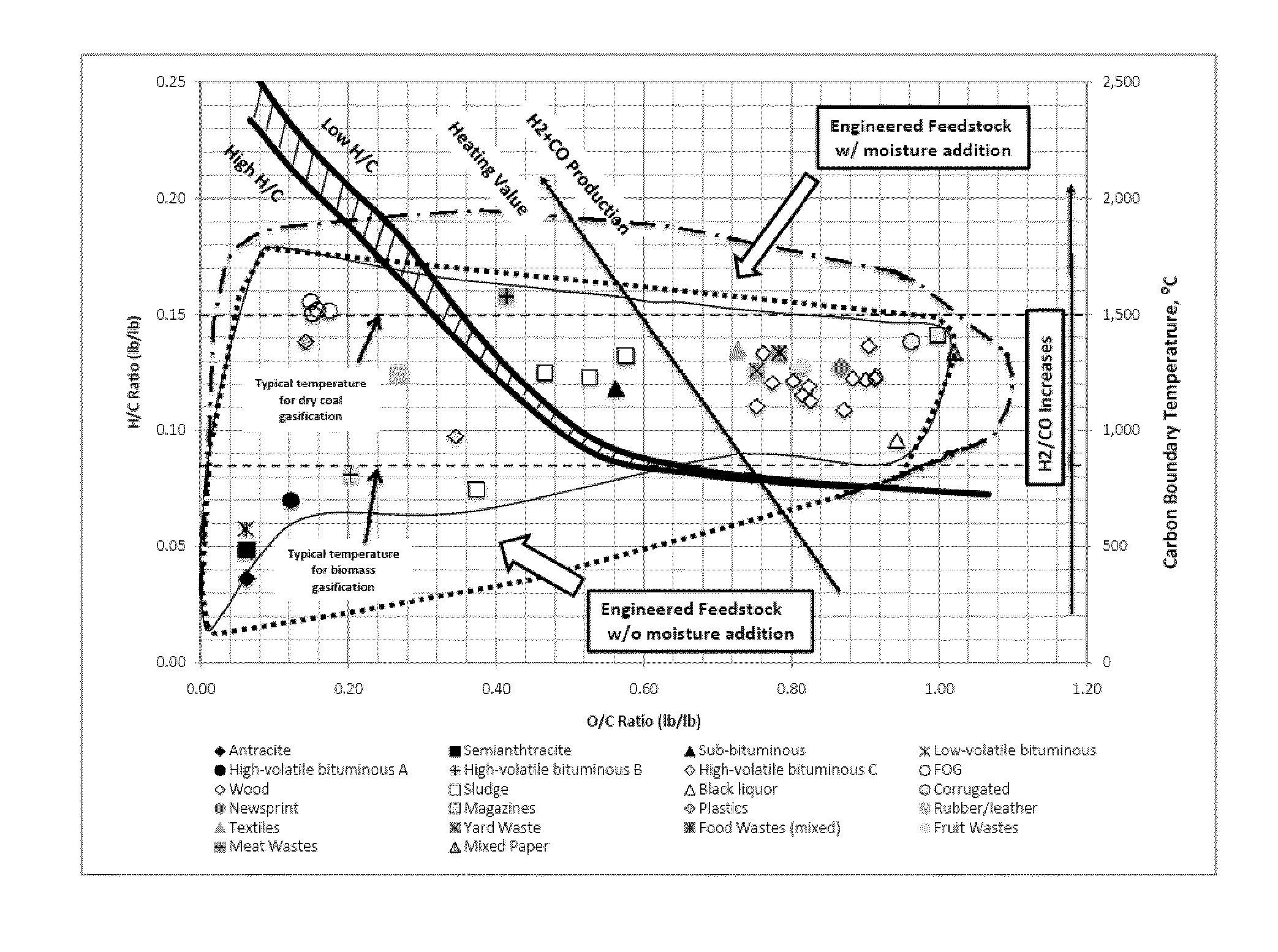

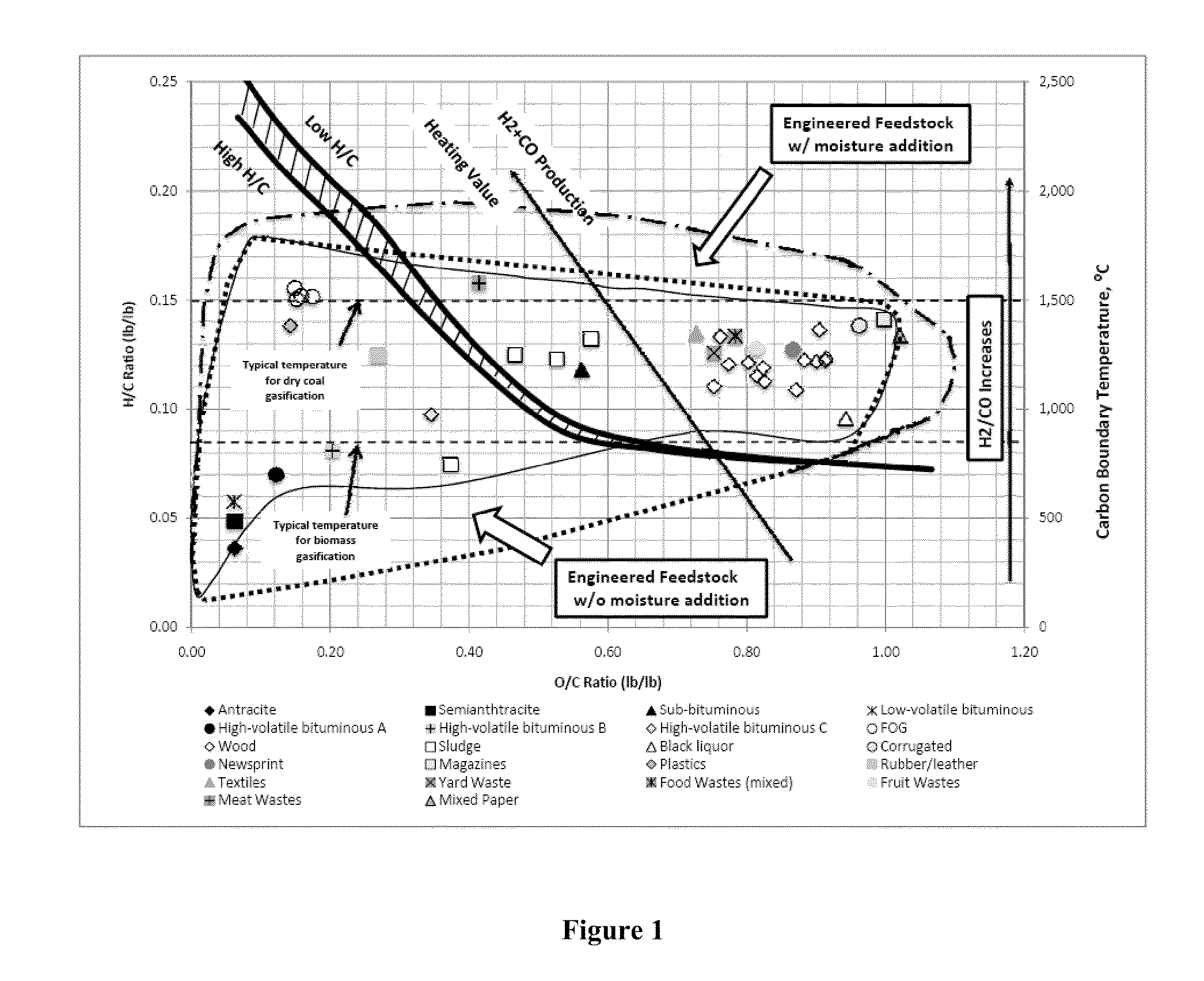

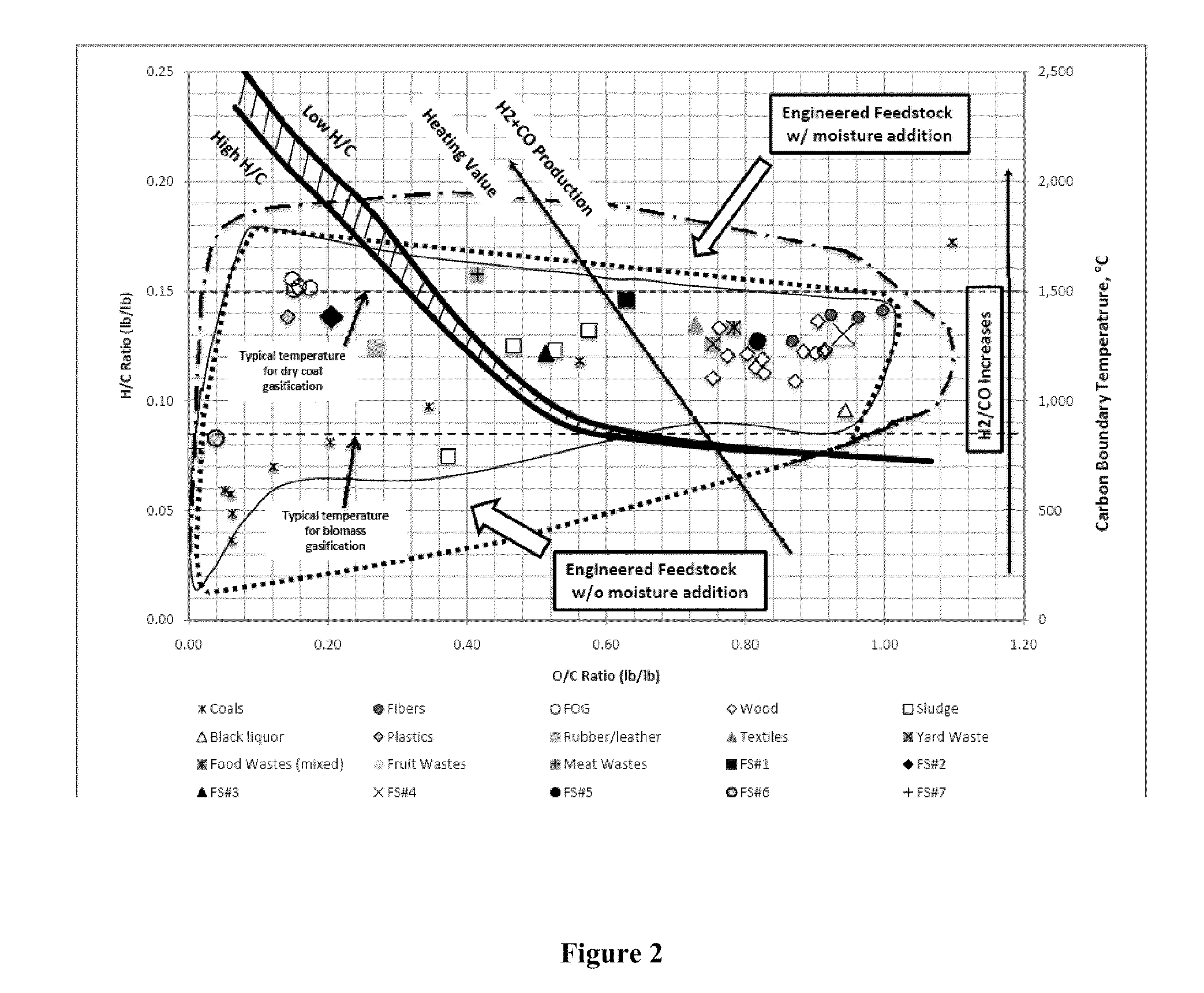

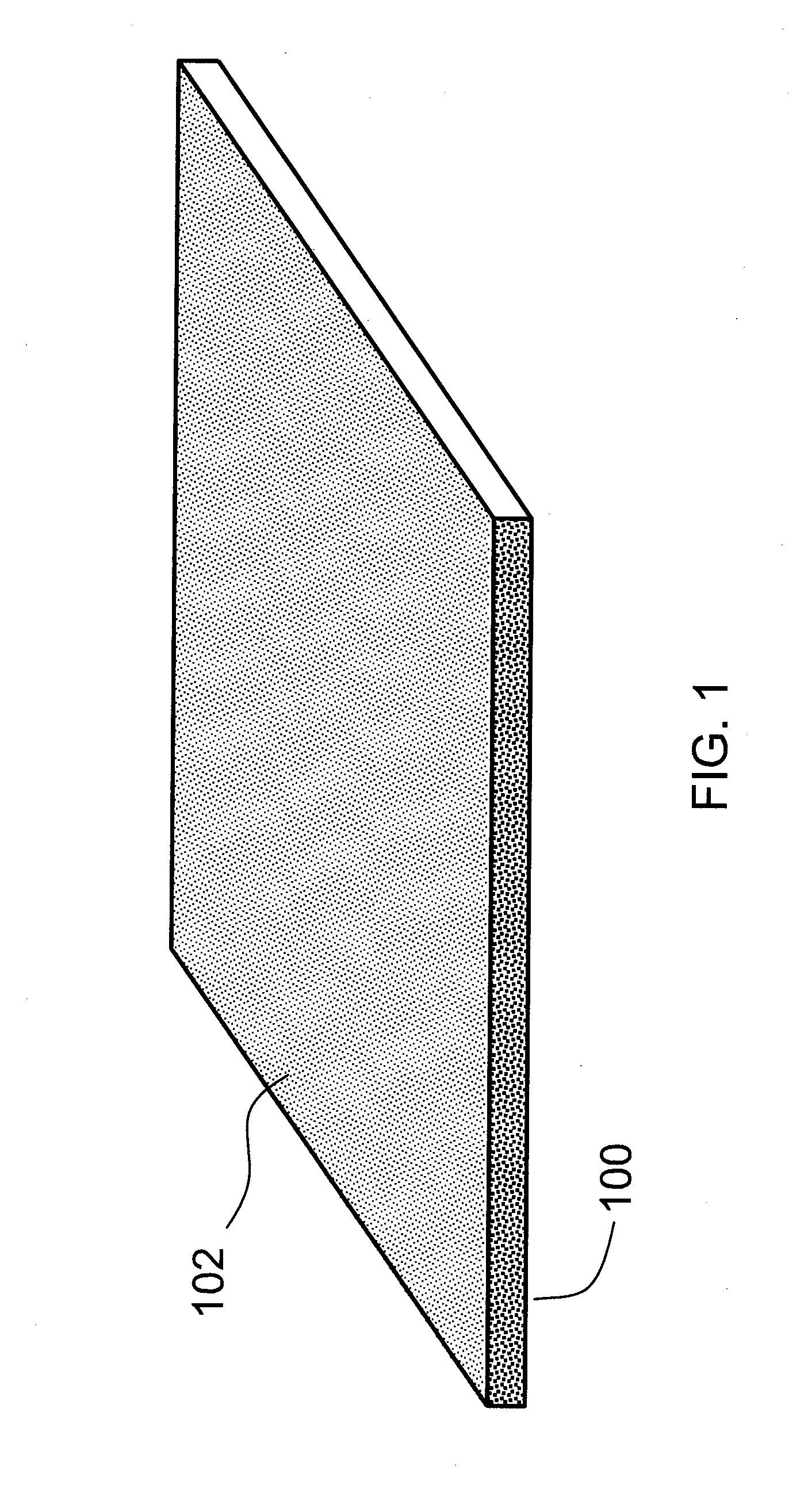

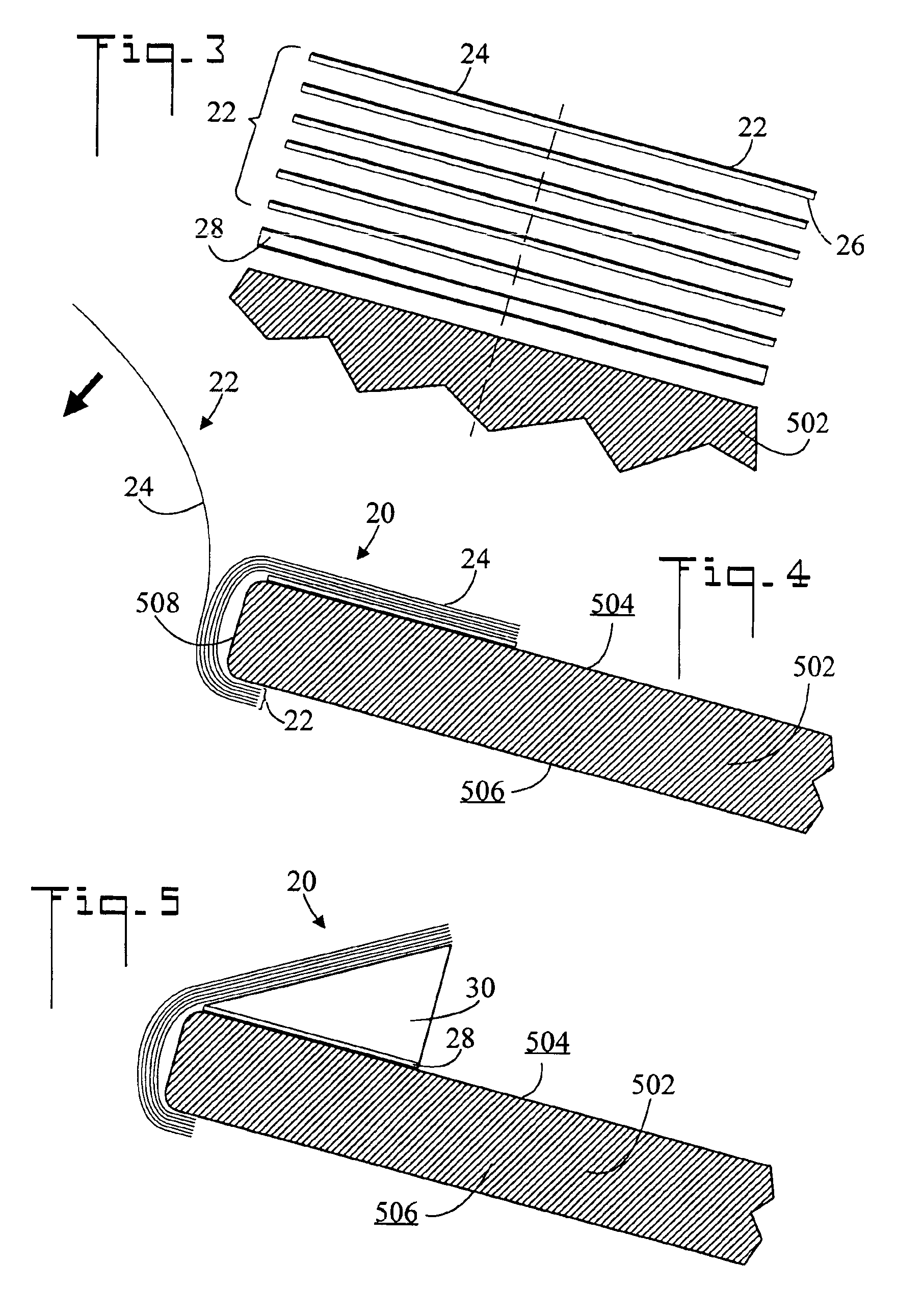

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS20100031560A1Reduce harm to the environmentQuality improvementMechanical working/deformationBiofuelsEngineeringCoal fired

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

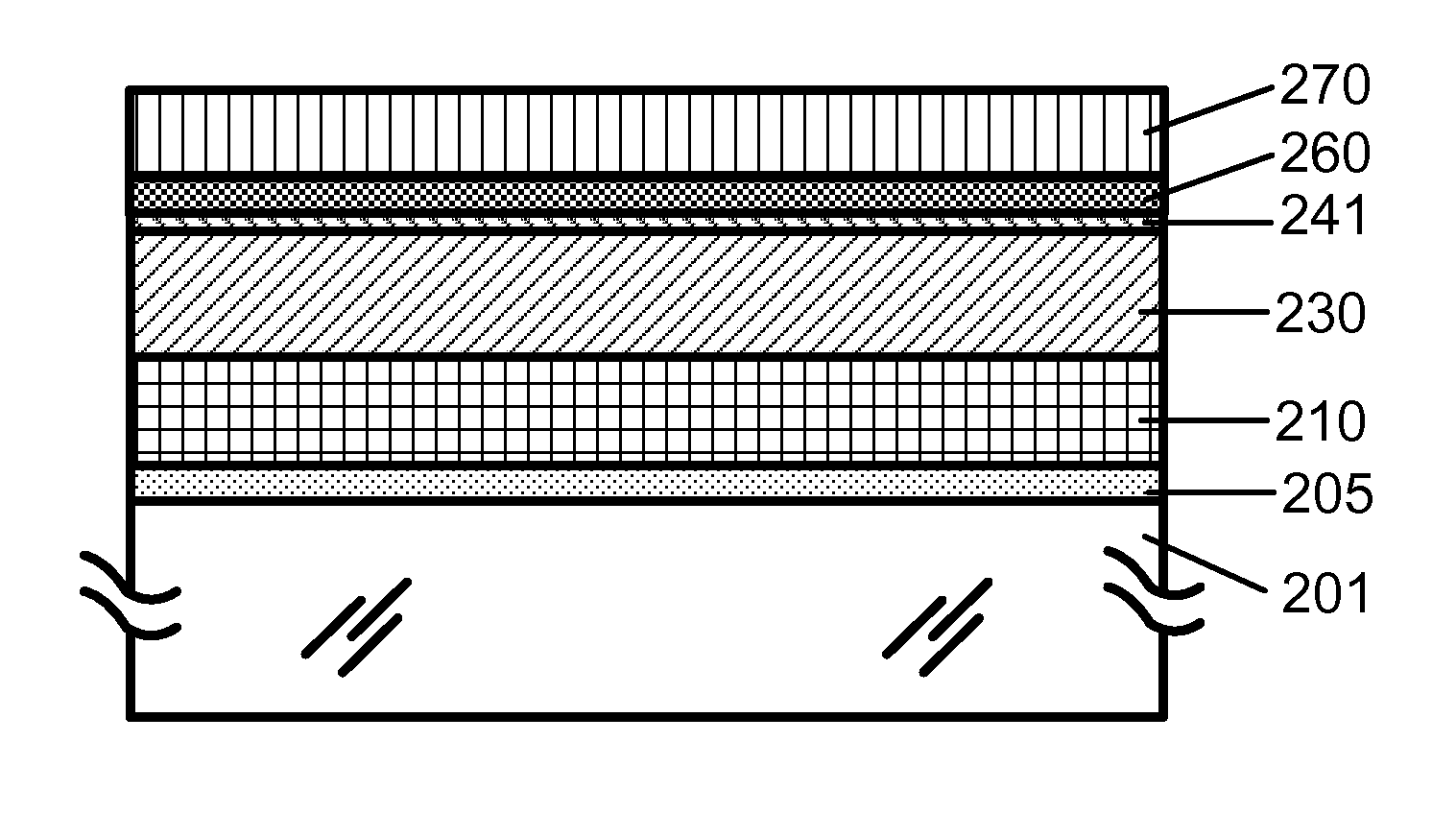

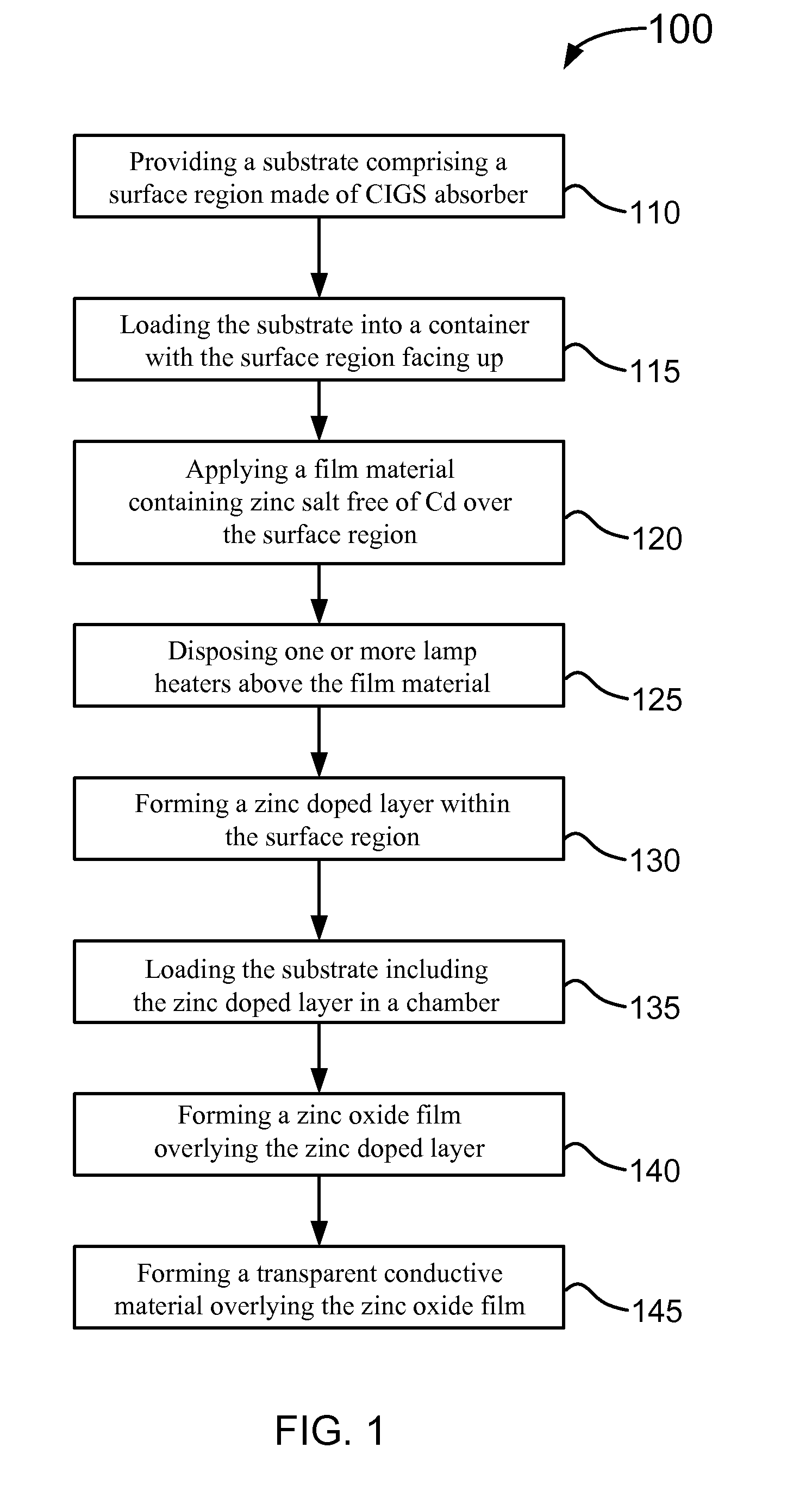

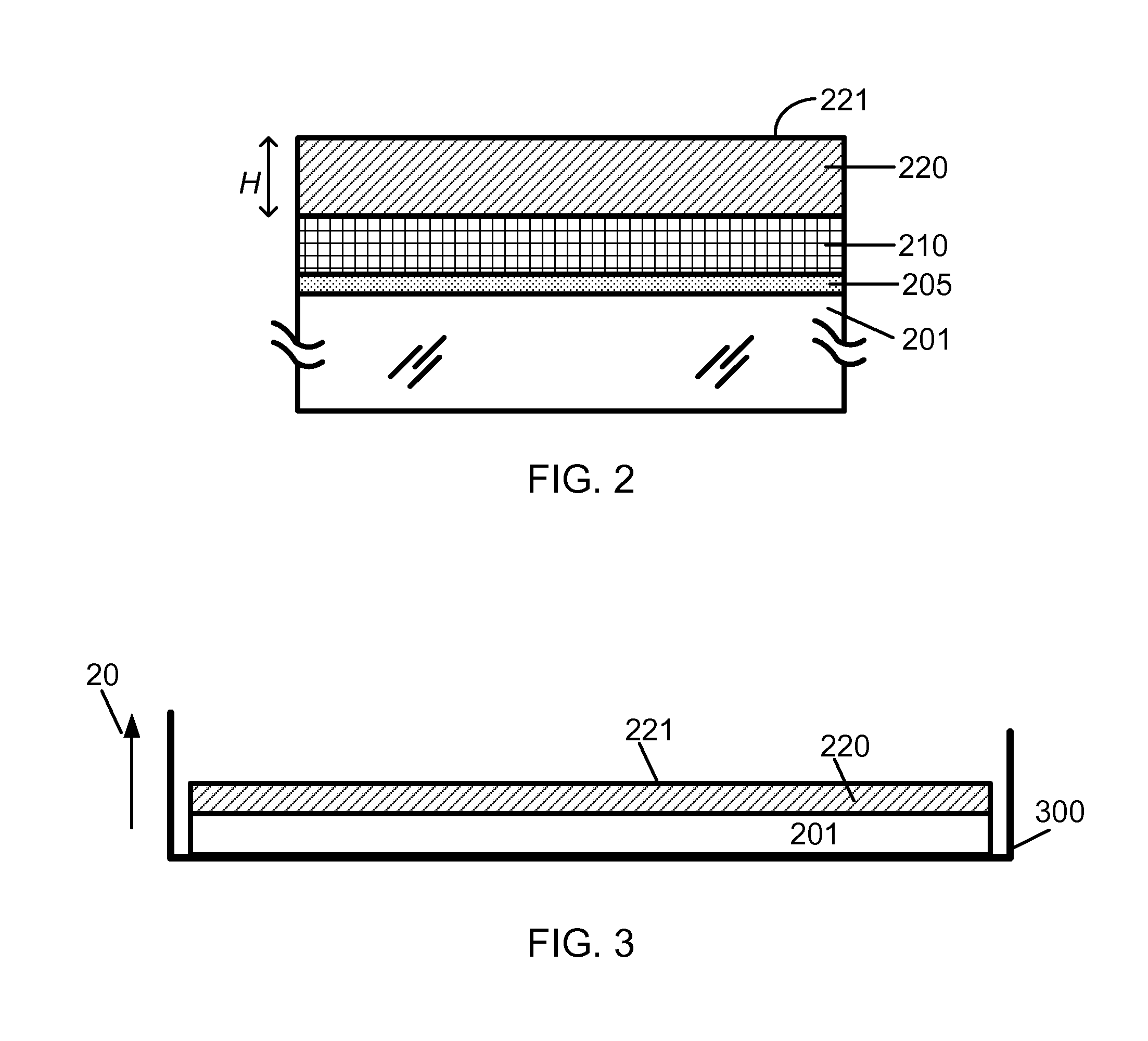

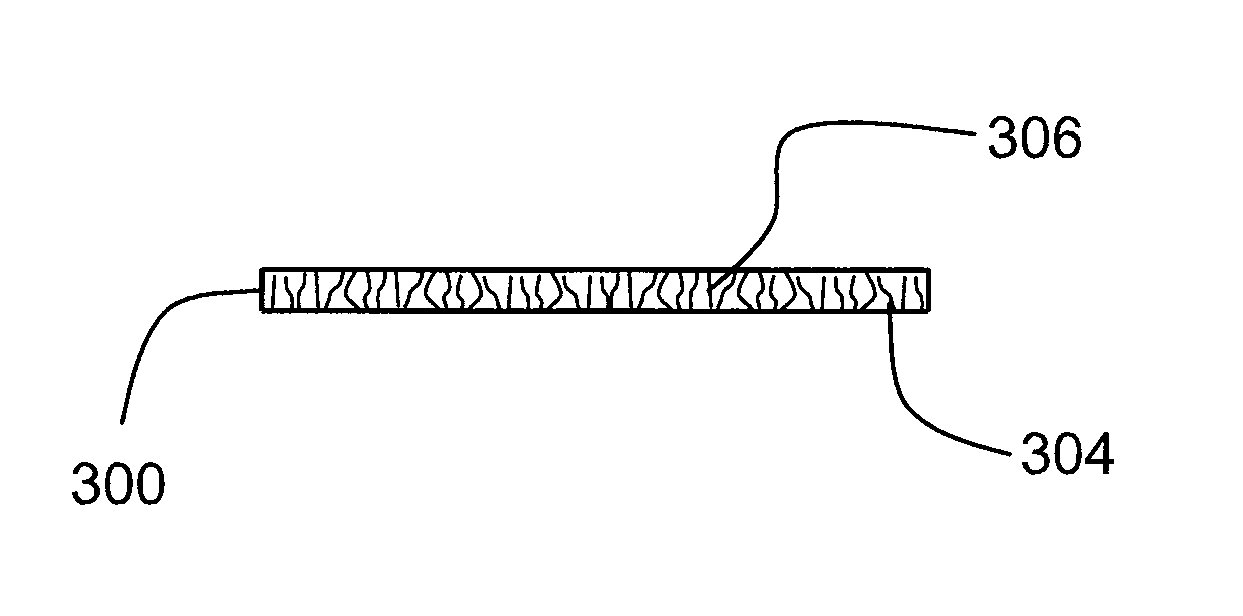

Method and Device for Cadmium-Free Solar Cells

InactiveUS20120240989A1SaveReduce harm to the environmentSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSulfur

A method for fabricating a thin film photovoltaic device is provided. The method includes providing a substrate comprising a thin film photovoltaic absorber which has a surface including copper, indium, gallium, selenium, and sulfur. The method further includes subjecting the surface to a material containing at least a zinc species substantially free of any cadmium. The surface is heated to cause formation of a zinc doped material. The zinc doped material is free from cadmium. Furthermore the method includes forming a zinc oxide material overlying the zinc doped material and forming a transparent conductive material overlying the zinc oxide material.

Owner:CM MFG

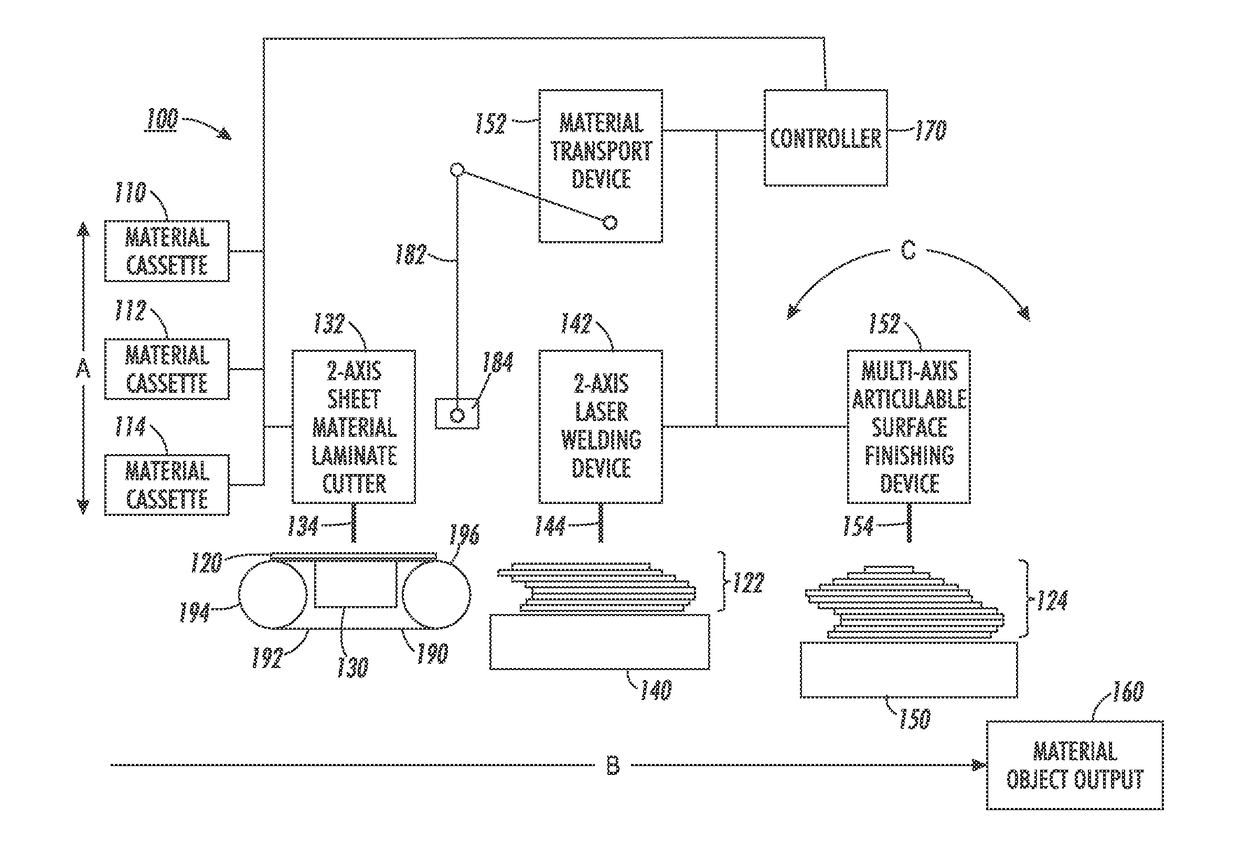

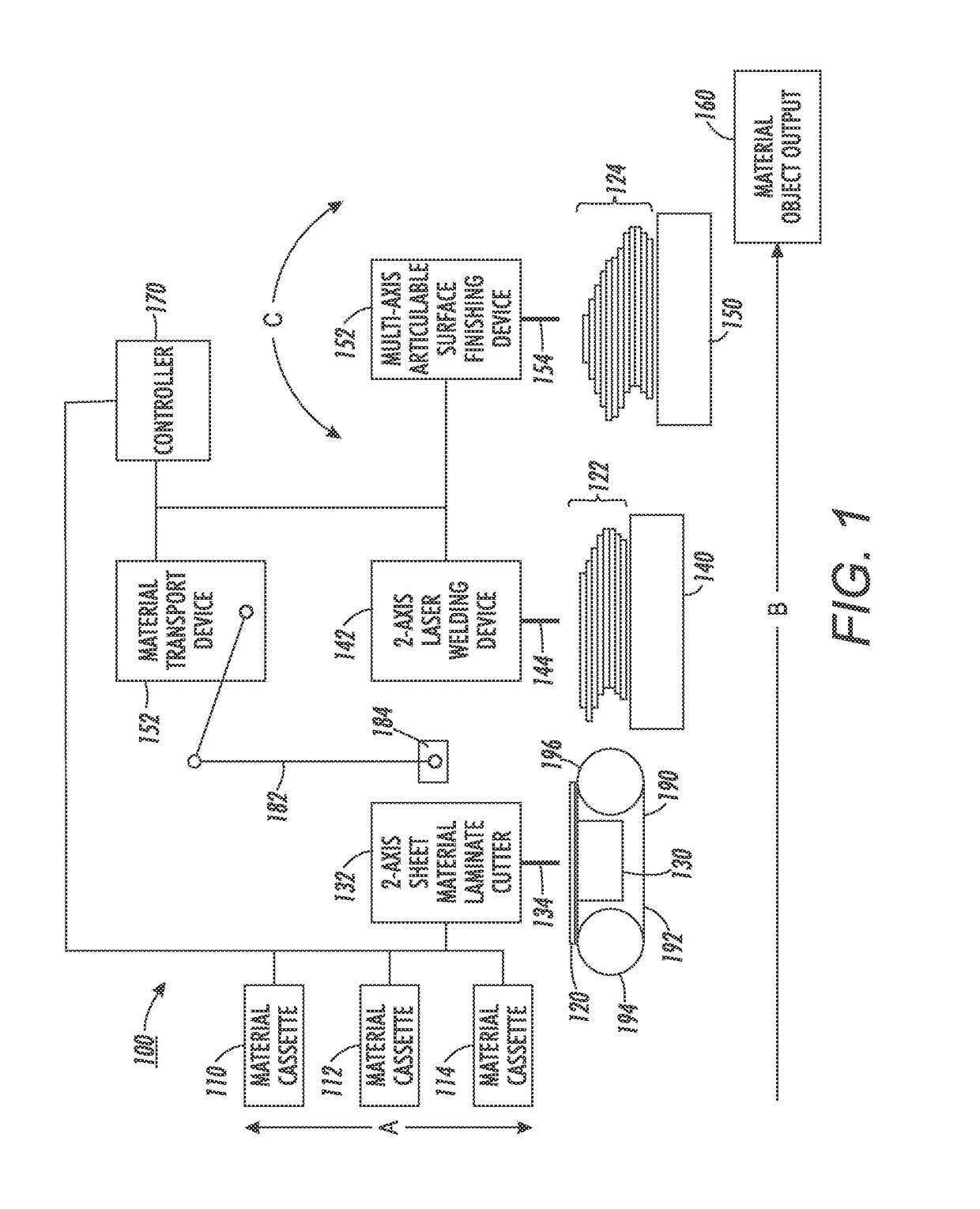

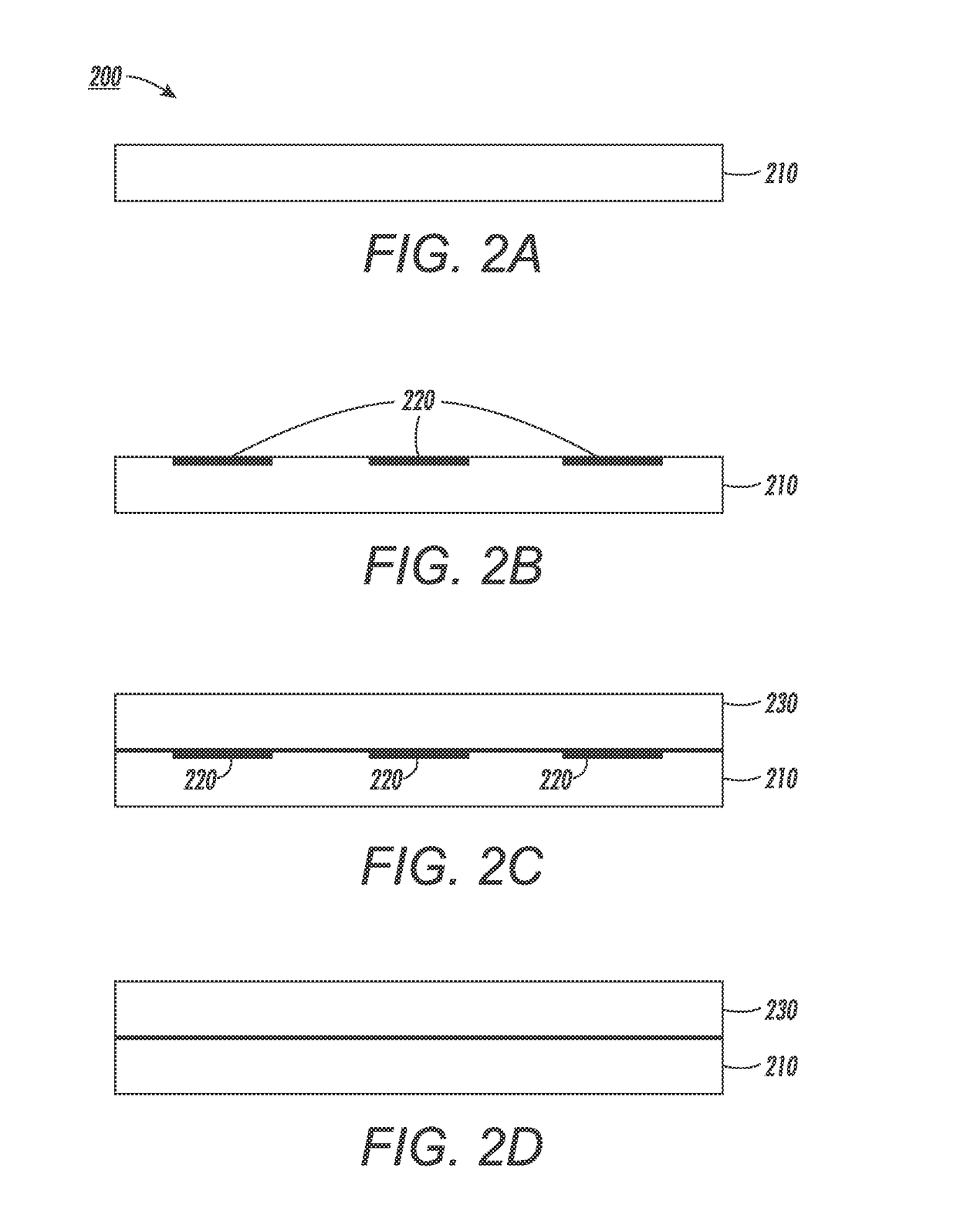

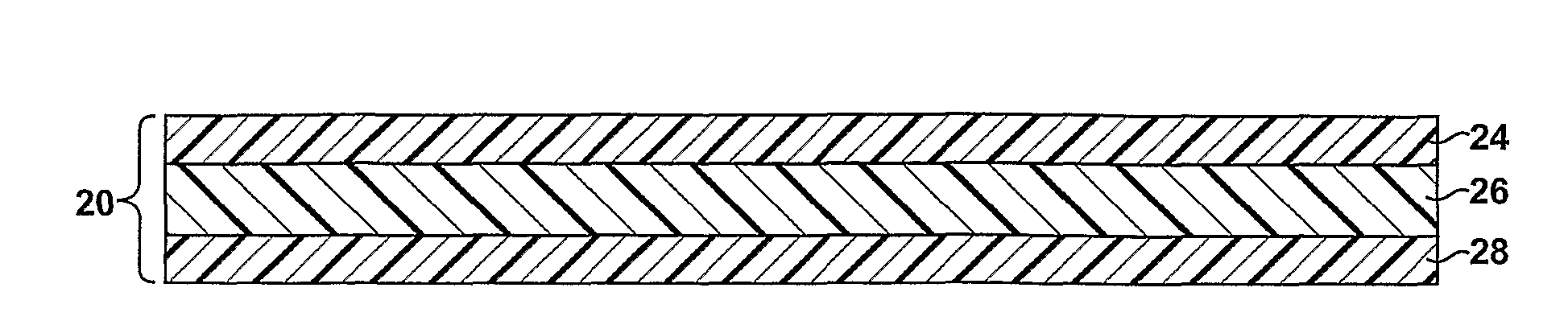

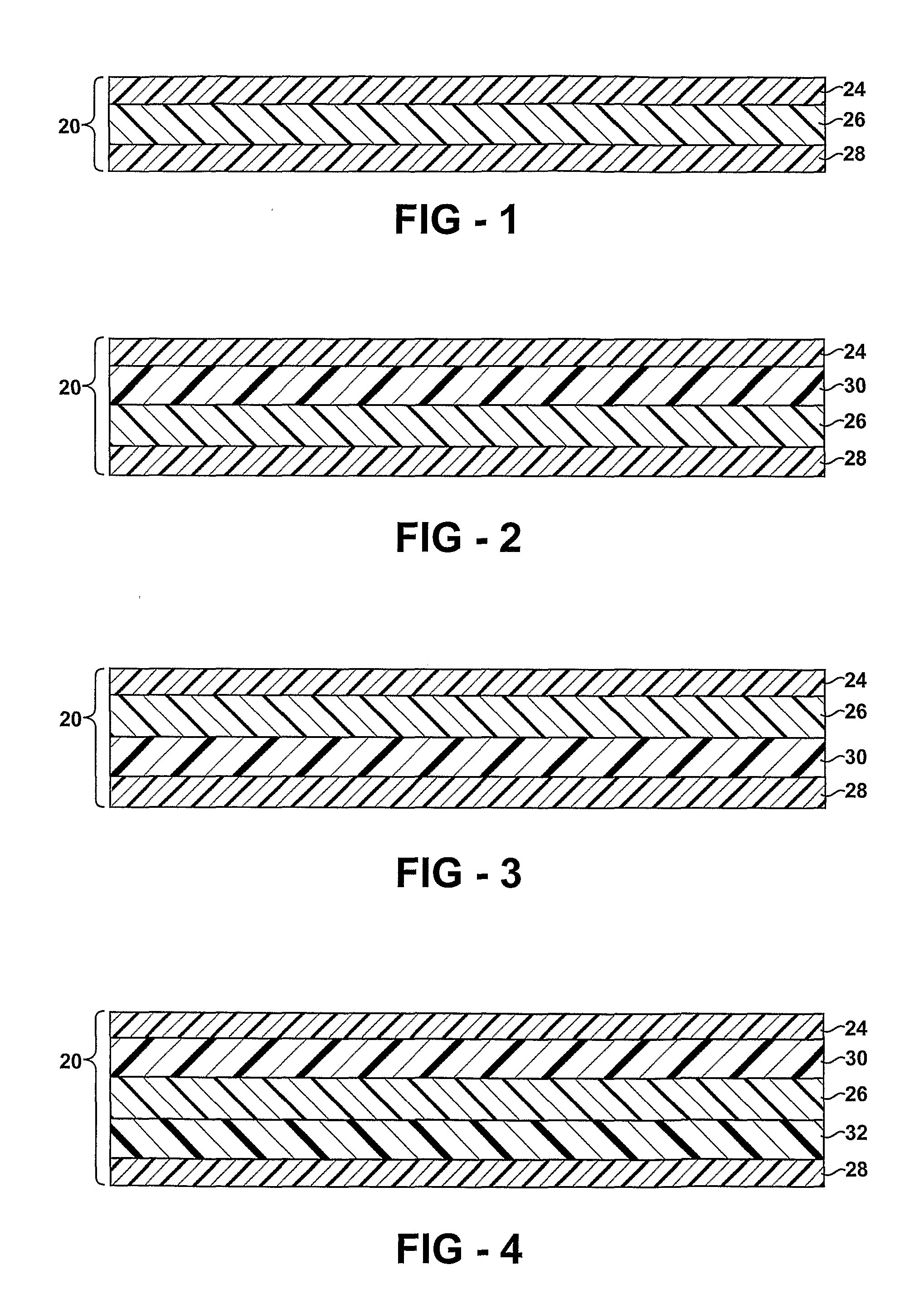

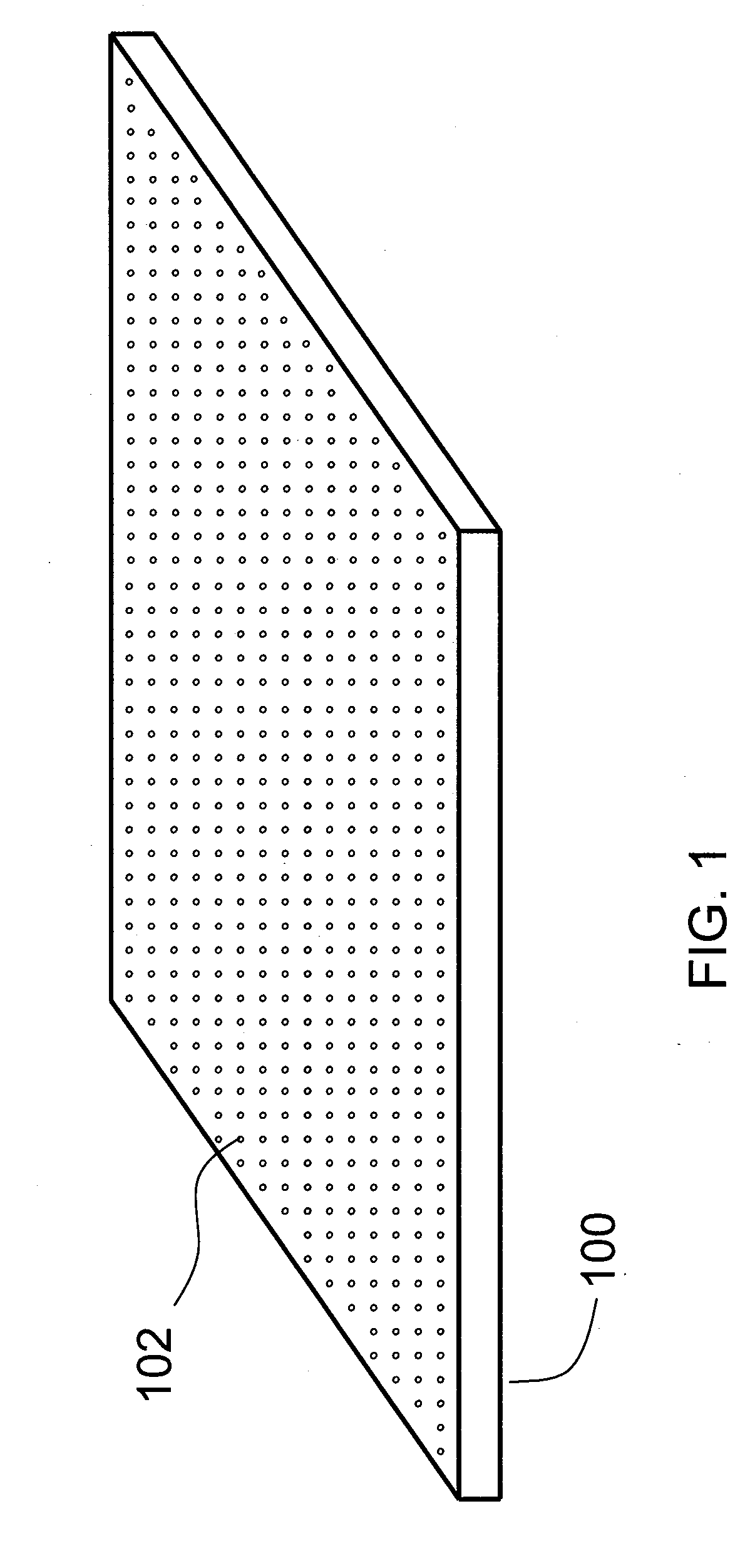

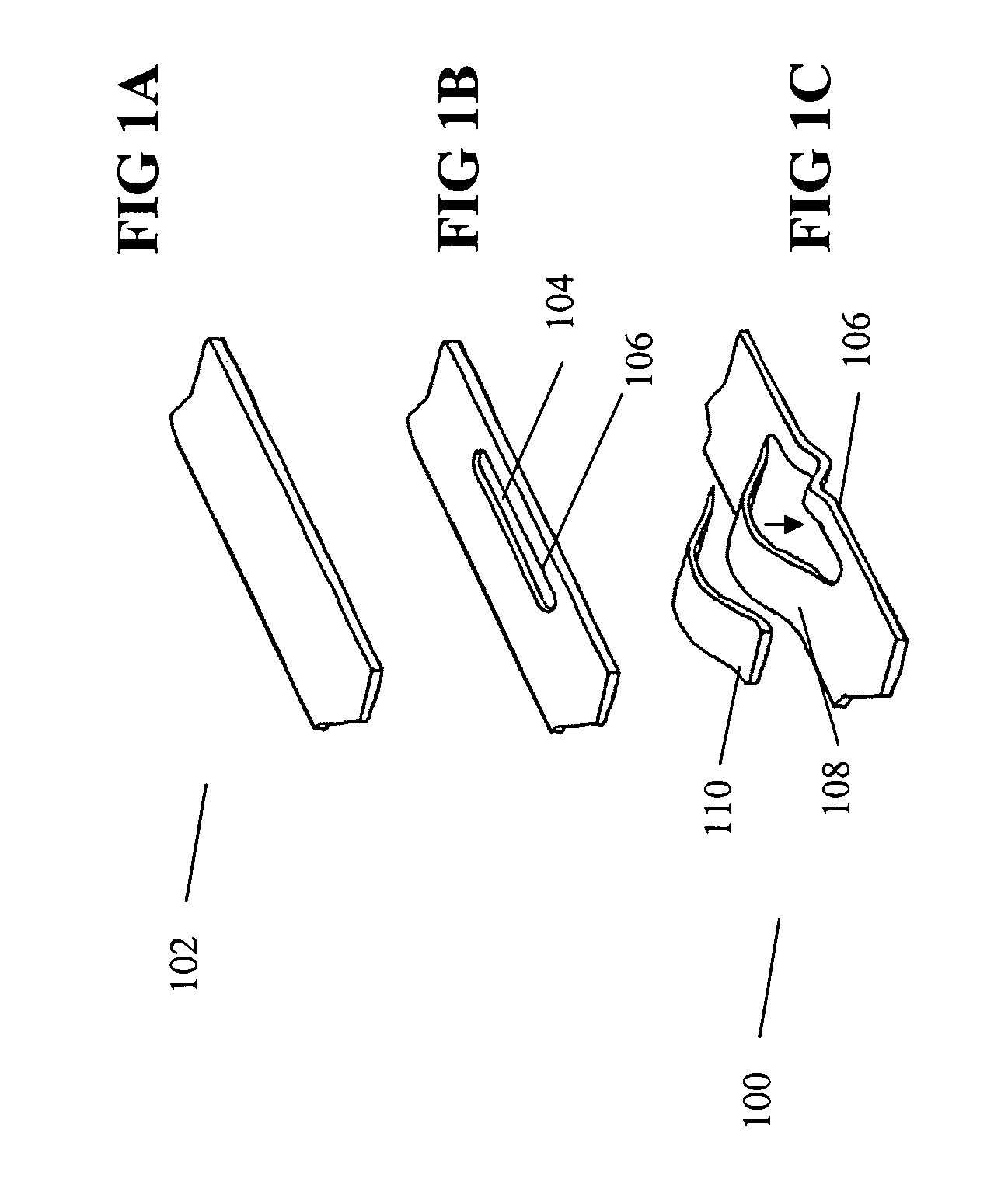

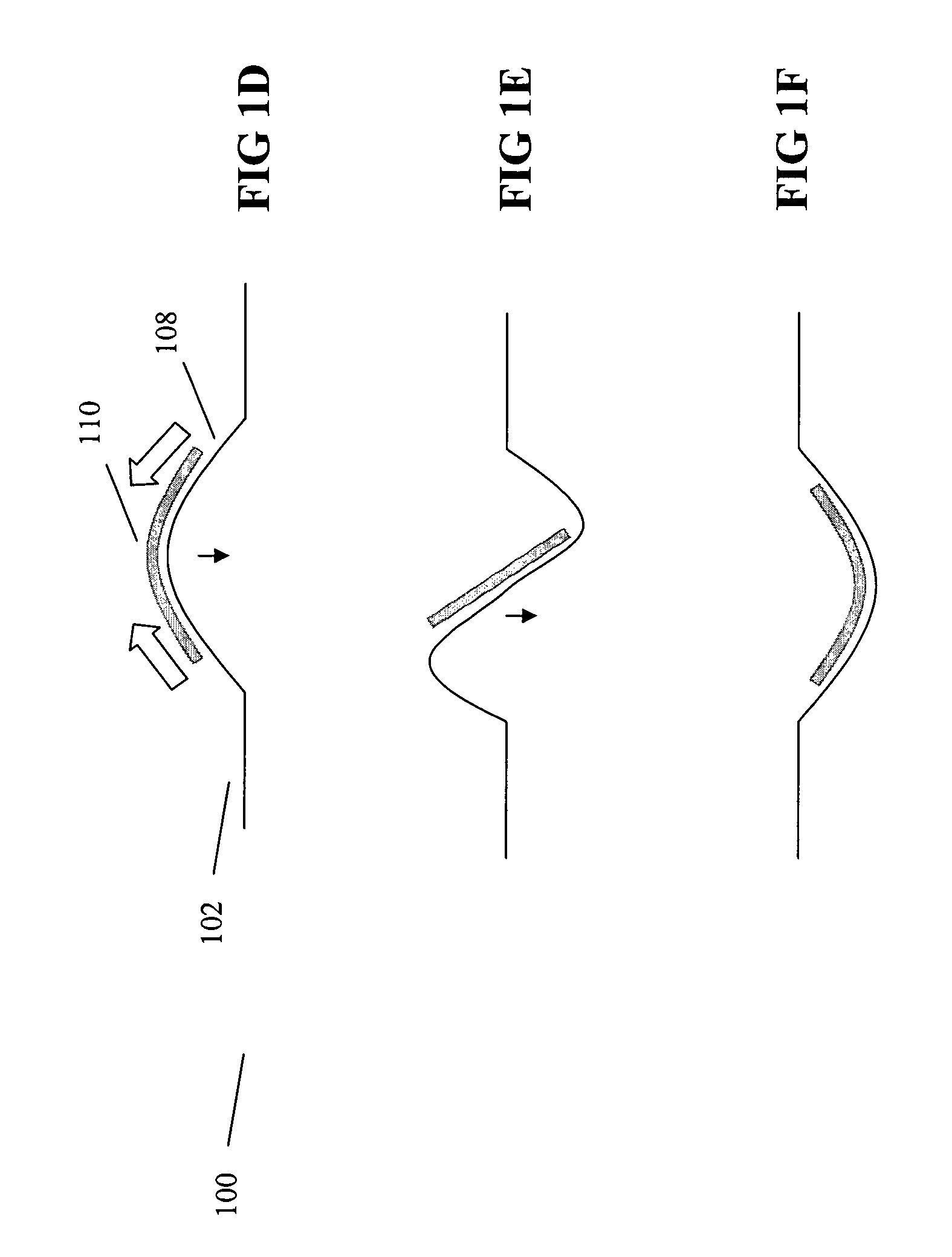

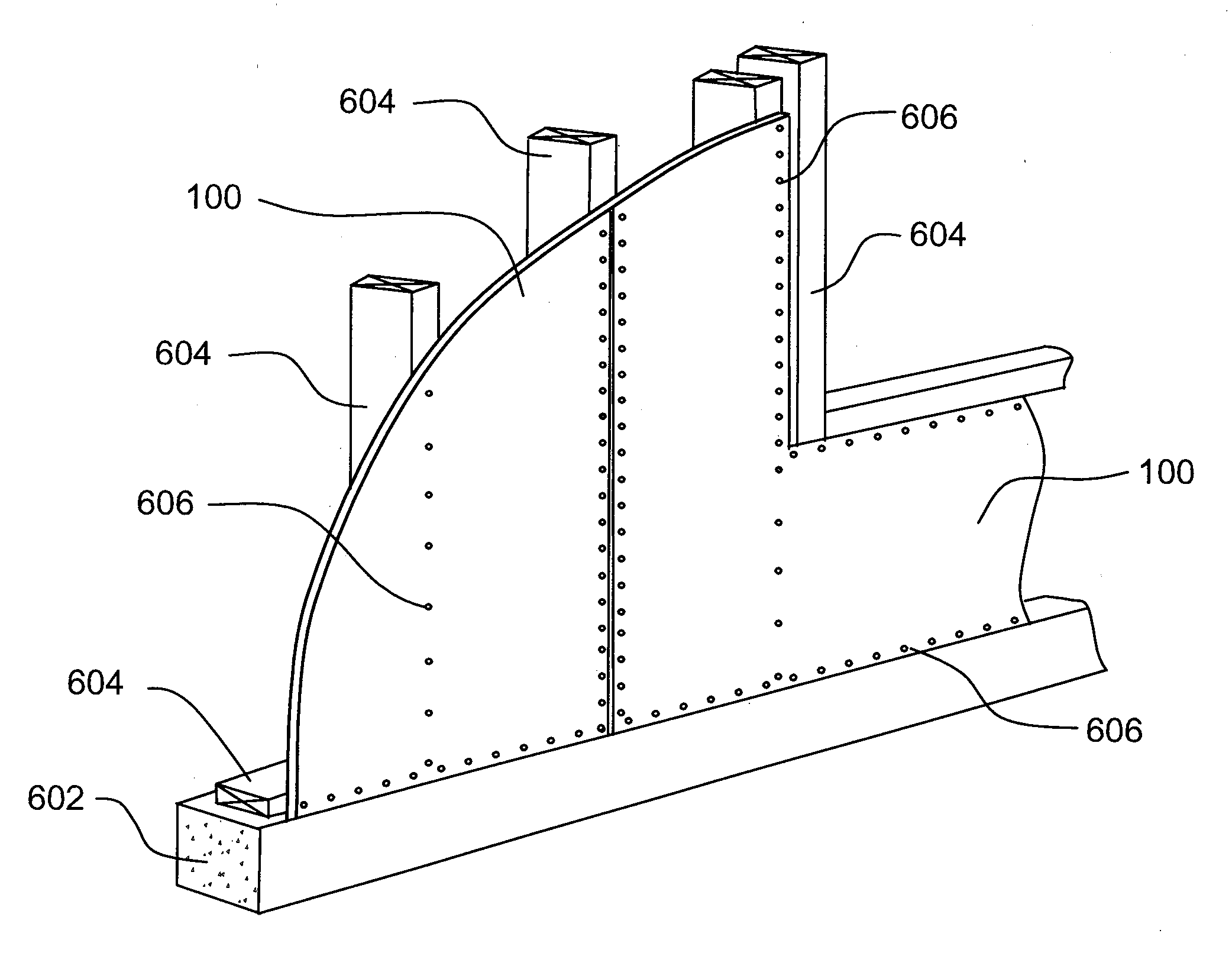

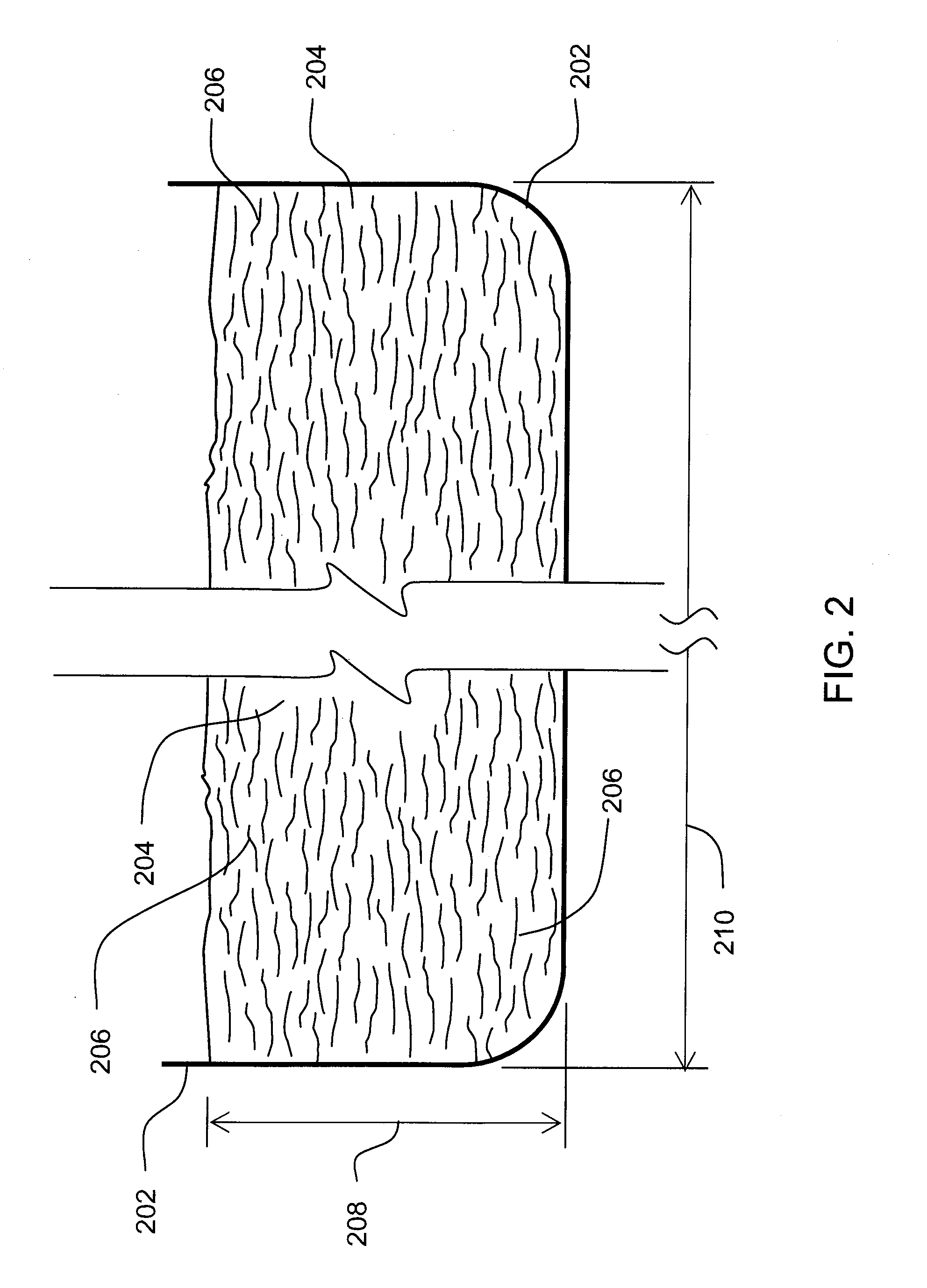

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including locally laser welded laminates

ActiveUS20170144370A1High build rateSolve the slow construction speedAdditive manufacturing apparatus3D object support structuresSurface finishMachining

A system and method are provided for implementing localized and directed laser welding joining techniques in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components (3D objects). A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through a targeted laser welding technique; and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

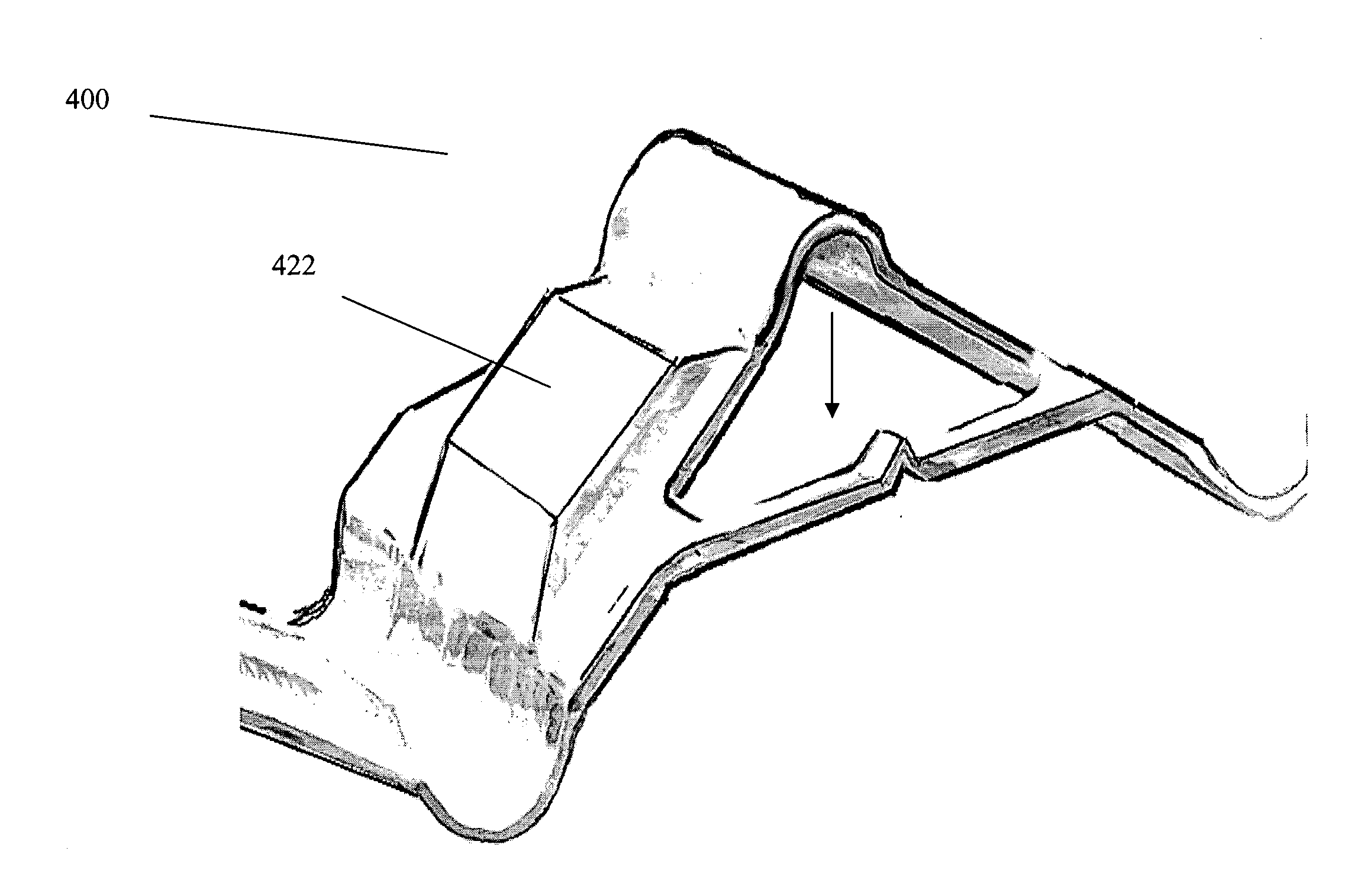

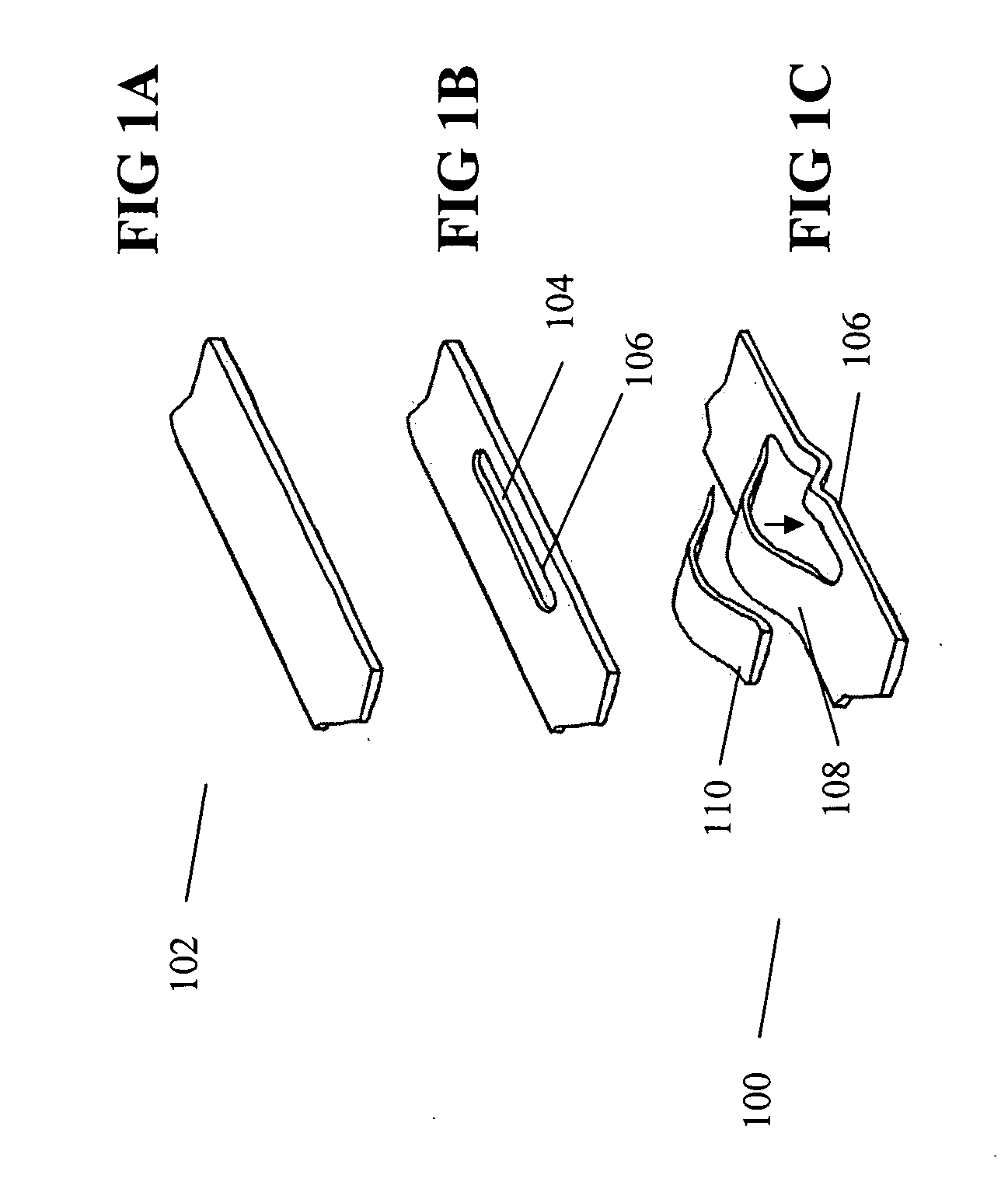

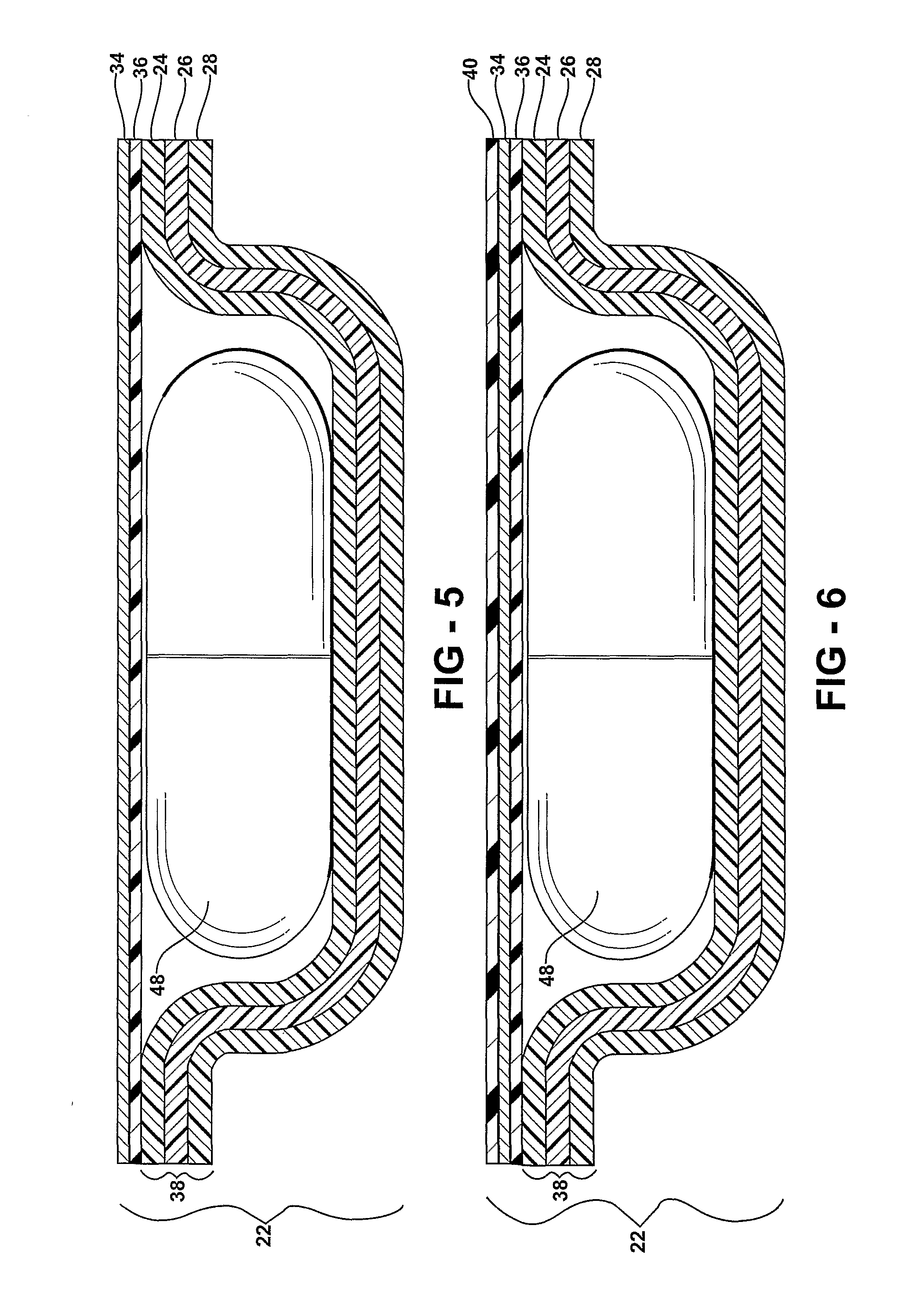

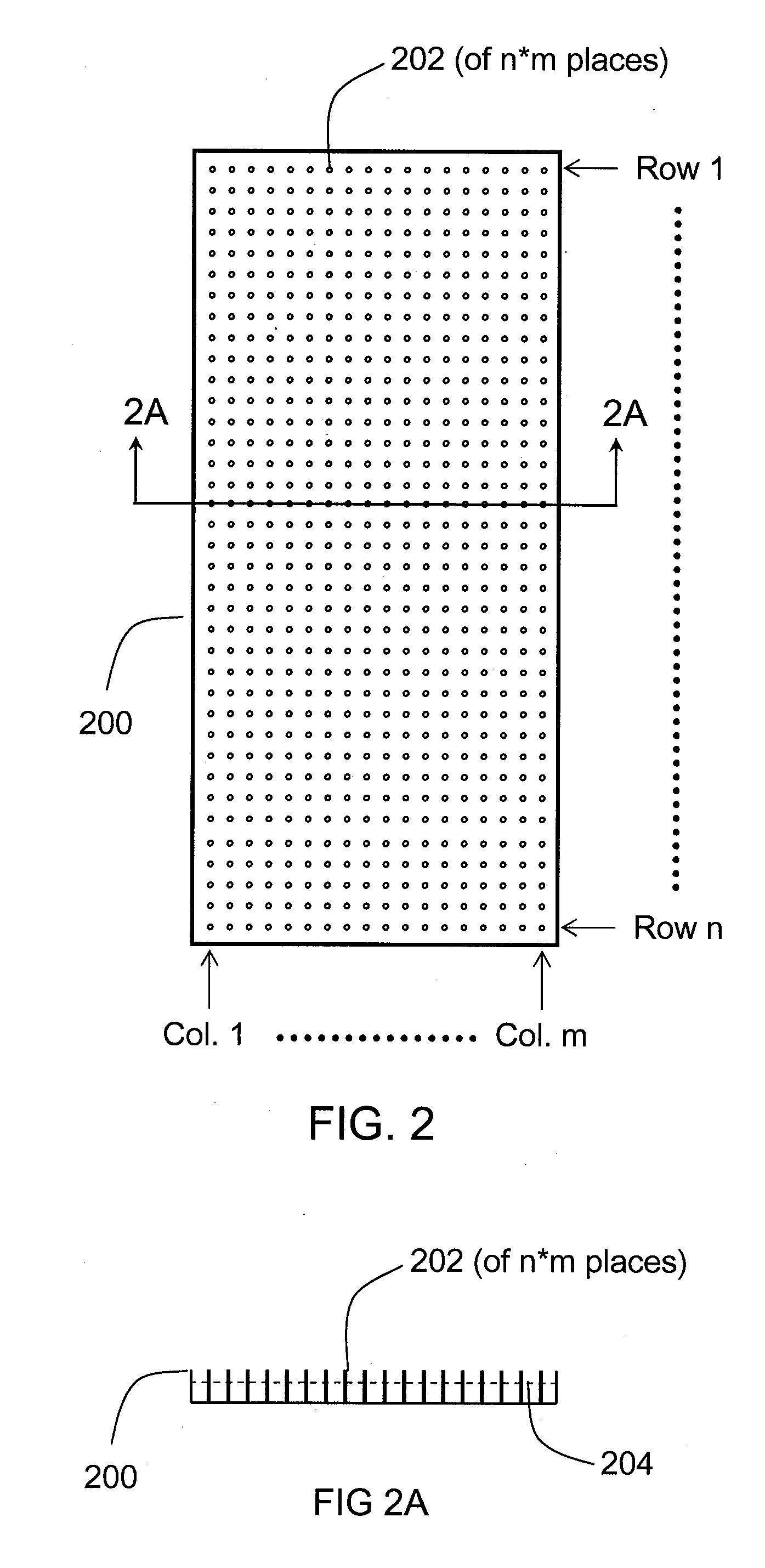

Thin, flexible actuator array to produce complex shapes and force distributions

InactiveUS20060201149A1Large specific surface areaMore surface areaElectrothermal relaysThermally actuated switchesEngineeringDisplay device

An actuator includes a bistable mechanism having a tension beam and a compression beam defined by a relief slit in a flexible substrate; and a first shape memory element that upon heating actuates the actuator from a first position to a second position. A heat source can be thermally coupled to actuate the first shape memory element, or the first shape memory element can be heated by passing current through the element. The actuators can be formed in an array. Such arrays can be useful for tactile displays, massagers, and the like. Also included are methods of operation and manufacturing.

Owner:MASSACHUSETTS INST OF TECH

Multilayer Films Including Cycloolefin Copolymer and Styrene-Butadiene Copolymer

InactiveUS20080075901A1Superior optical propertyLow produce costSynthetic resin layered productsGlass/slag layered productsButadiene-styrene rubberCo extrusion

A packaging film or sheet having a styrene-butadiene block copolymer directly melt-bonded to at least one layer of a cyclo-olefin copolymer is disclosed. The films may be made by means of co-extrusion. The packaging film is amenable to thermoforming processes and is particularly suitable for forming blister packaging used in pharmaceutical applications.

Owner:TOPAS ADVANCED POLYMERS +1

Low embodied energy sheathing panels and methods of making same

InactiveUS20100101457A1Reduce environmental impactHigh energyButtonsSolid waste managementSource materialPhosphoric acid

Sheathing panels are produced by methods which do not require natural resources such as wood and use significantly reduced embodied energy when compared with the energy used to fabricate gypsum sheathing panels. A novel binder, consisting in one embodiment of monopotassium phosphate and magnesium oxide, and combined with various fillers, is used to provide a controlled exothermic reaction to create a gypsum board-like core which can be formed into a suitable sheathing panel handled and installed in a typical manner. The panel is manufactured to have a desirable shear resistance and water vapor permeability, important performance elements in building envelope design. The manufacturing process results in a panel that does not require mature trees as source material, does not off gas, and involves much lower greenhouse gas emissions than the processes used to make traditional wood or gypsum-based sheathing panels.

Owner:PACIFIC COAST BUILDING PRODS

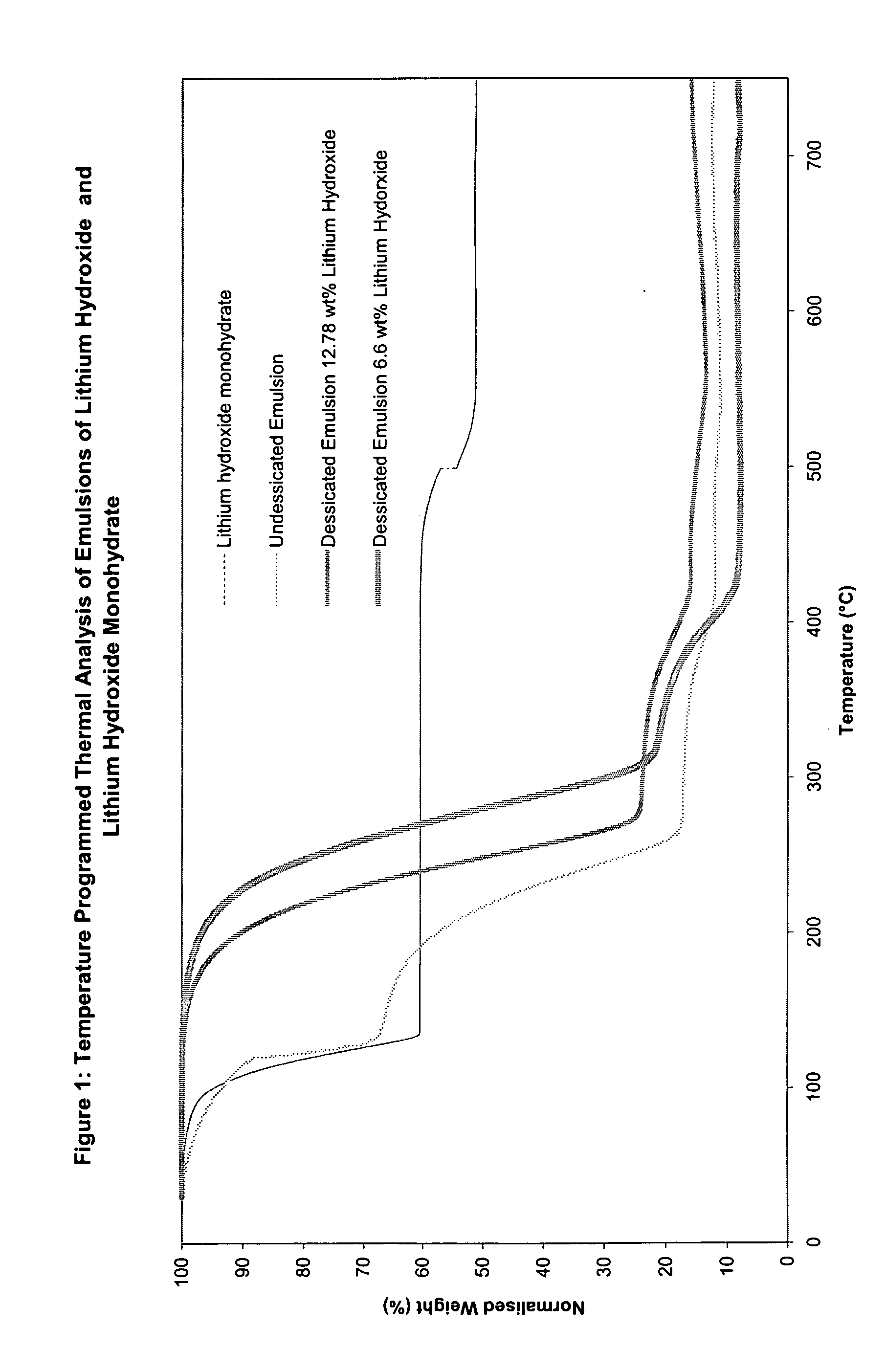

Metal hydroxide desiccated emulsions used to prepare grease

InactiveUS20060100292A1Reduce harm to the environmentIncrease productionOrganic chemistryOther chemical processesEmulsionCarboxylic acid

The invention provides a grease composition comprising a stable dispersion of a metal hydroxide with a number average particle size in the range 20 nanometres to 2 micrometres, a surfactant with a HLB of less than 10, a mono- or poly-carboxylic acid, and an oil of lubricating viscosity. The method of preparing a grease composition is also disclosed with benefits including a reduction in reaction time, amount of foam produced and environmental hazards.

Owner:THE LUBRIZOL CORP

Chromium plating method

InactiveUS7052592B2Reduce harm to the environmentImprove the level ofCellsElectrodesElectrolyteChromium

An electrolyte bath and method of electrolytically plating a layer of metallic chromium on a substrate comprises providing an electrolyte bath of a trivalent chromium, passing a current through the bath from an anode to a cathode which receives the substrate, maintaining the electrolyte bath at a desired temperature and a desired pH and depositing the trivalent chromium onto the substrate at a desired rate.

Owner:YEDIGARIAN GUEGUINE +1

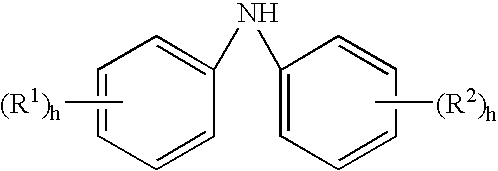

Manufacture of conjugated linoleic salts and acids

InactiveUS6897327B2Delayed reaction timeIncrease productivityFatty acid chemical modificationOrganic compound preparationIsomerizationDouble bond

A process to manufacture conjugated linoleic acid (CLA)-containing materials such as conjugated linoleic salts and acids that are enriched in desirable cis-9, trans-11- and trans-10, cis-12-CLA isomers and are low in certain undesirable isomers. The process generally entails isomerization of an alkyl ester of a linoleic acid-containing material at a temperature typically between about 90 to 140° C. to effectuate conjugation of the double bonds, followed by saponification of the resultant CLA-containing fatty acid ester to produce a CLA-containing fatty acid salt, optionally followed by neutralization of the CLA-containing fatty acid salt with an acid source to produce a CLA-containing fatty acid.

Owner:STEPAN SPECIALTY PRODS

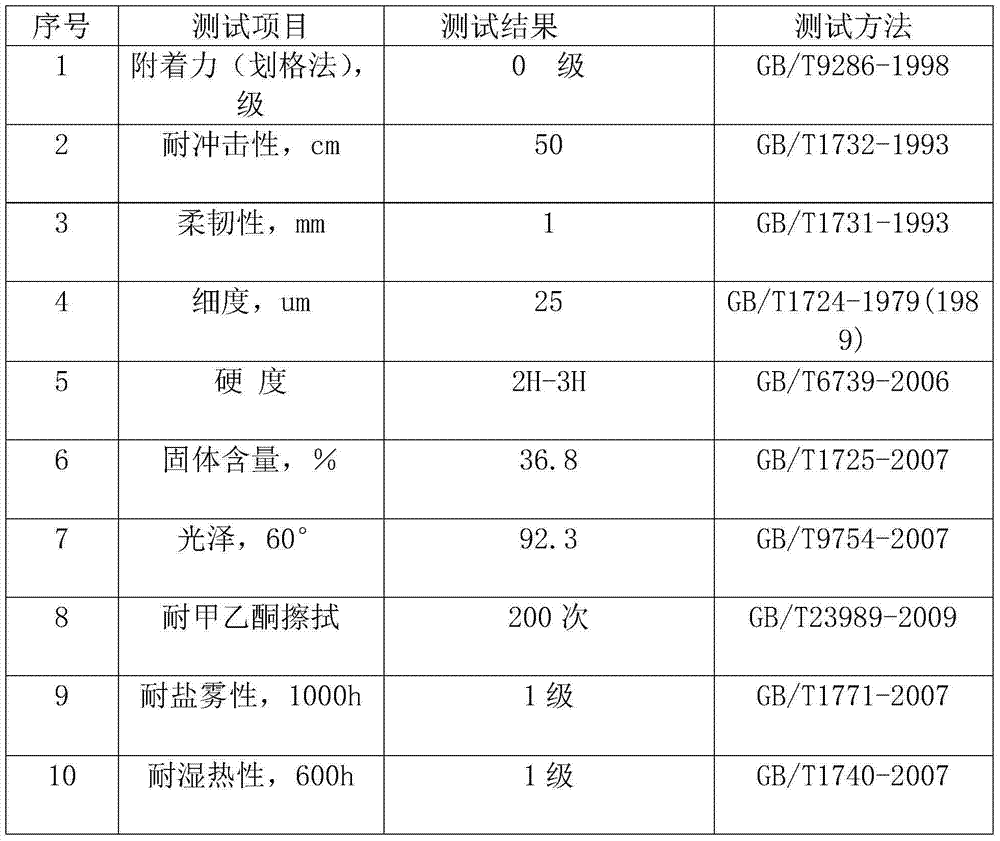

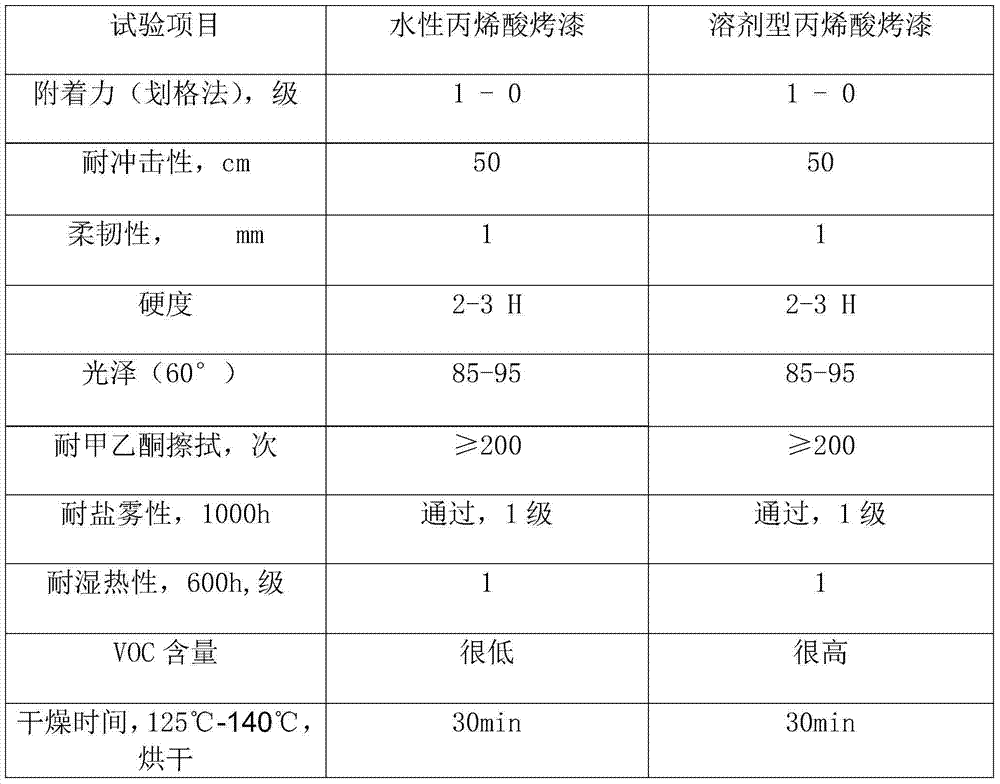

Water-based amino acrylic stoving varnish

The invention relates to water-based amino acrylic stoving varnish which is prepared from the following raw materials in parts by weight: 38-51 parts of water-based hydroxyl acrylic resin, 1.5-6.3 parts of dimethylethanolamine, 35-45 parts of deionized water, 0.3-0.5 part of a defoamer, 1.2-2.0 parts of a dispersant, 5.0-6.8 parts of high color carbon black and 5.5-7.5 parts of amino resin. A water-based environment-friendly and efficient decorative protective coating is obtained to meet the performance requirements of solvent type stoving varnish, and volatilization of organic solvents is greatly reduced, the environmental damage is reduced, and the production cost can be saved, so that the water-based amino acrylic stoving varnish satisfies the industrial policy requirement on national environment protection and energy saving, and can effectively replace related solvent based coatings.

Owner:CHANGZHOU CITY LATE COATINGS

Chromium plating method

InactiveUS20050284769A1Reduce harm to the environmentImprove the level ofCellsElectrodesElectroplatingElectrolyte

An electrolyte bath and method of electrolytically plating a layer of metallic chromium on a substrate comprises providing an electrolyte bath of a trivalent chromium, passing a current through the bath from an anode to a cathode which receives the substrate, maintaining the electrolyte bath at a desired temperature and a desired pH and depositing the trivalent chromium onto the substrate at a desired rate.

Owner:YEDIGARIAN GUEGUINE +1

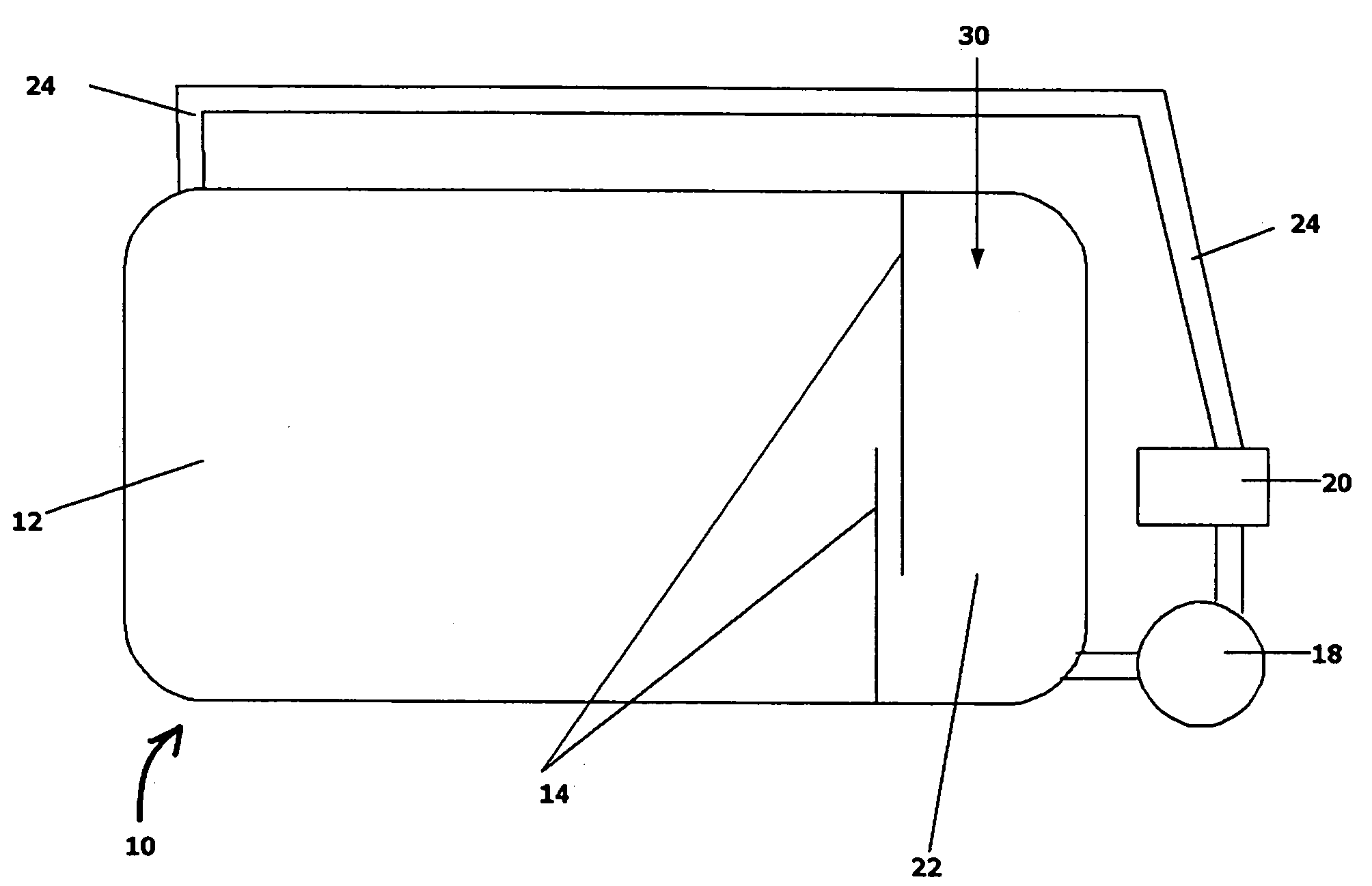

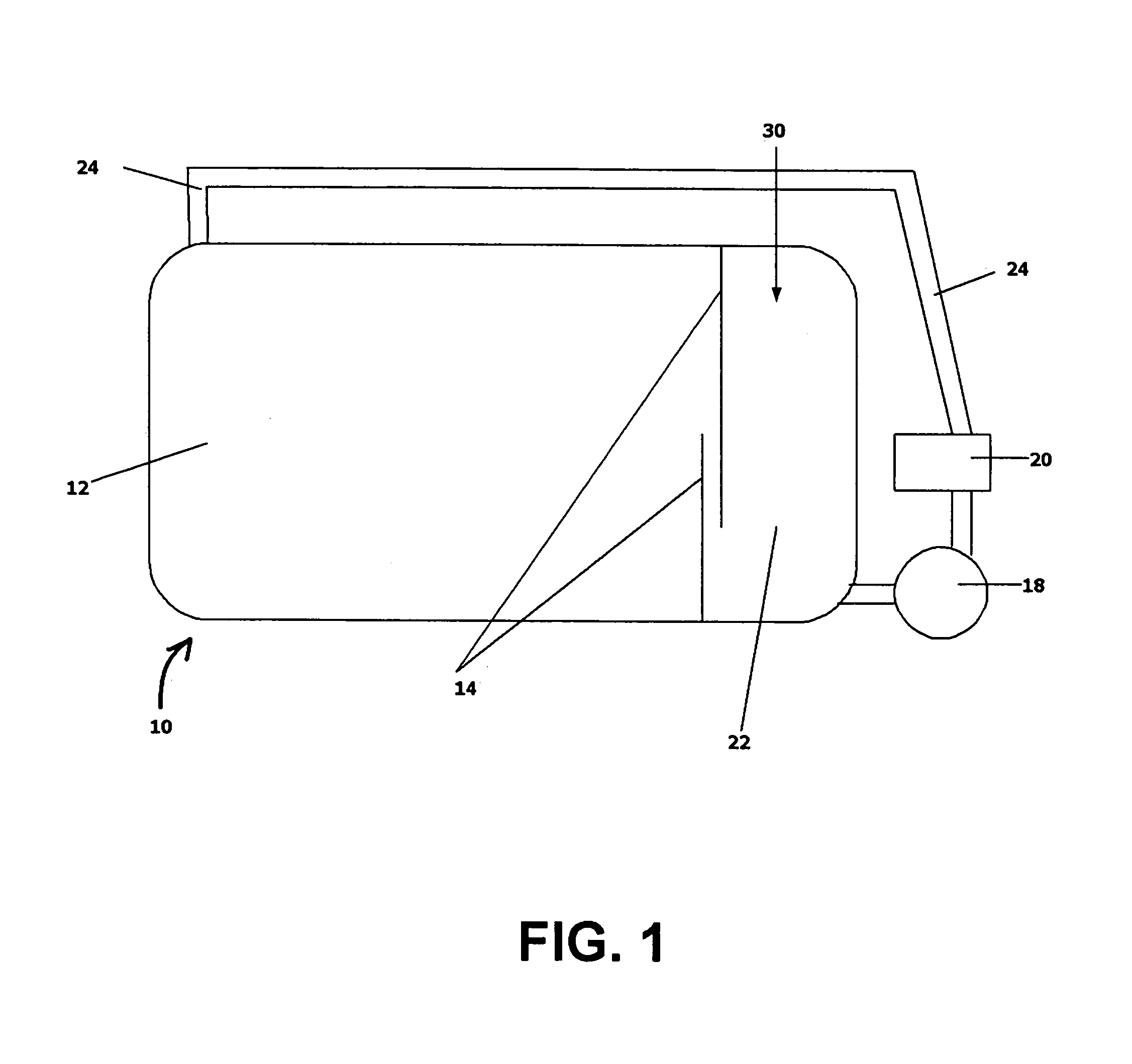

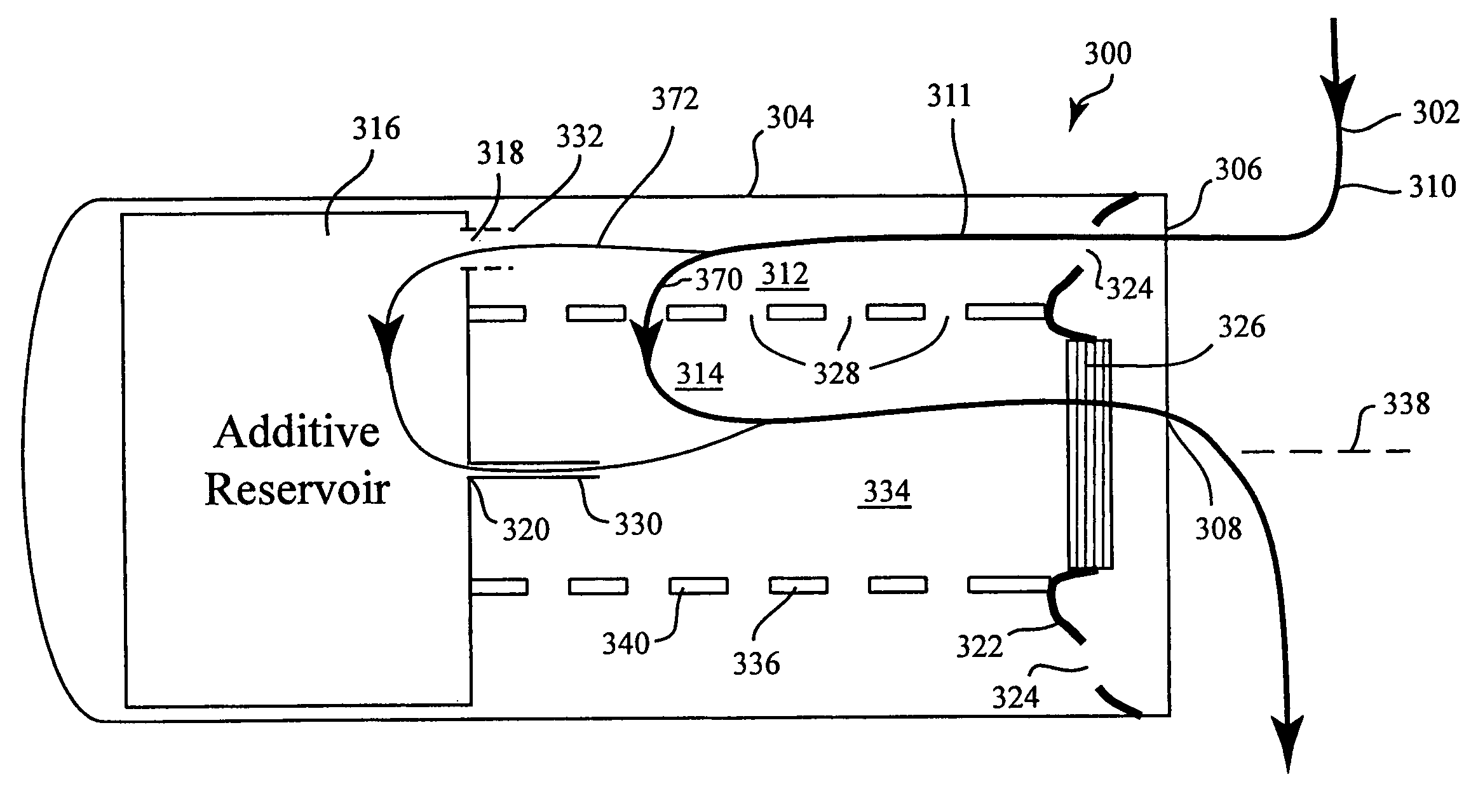

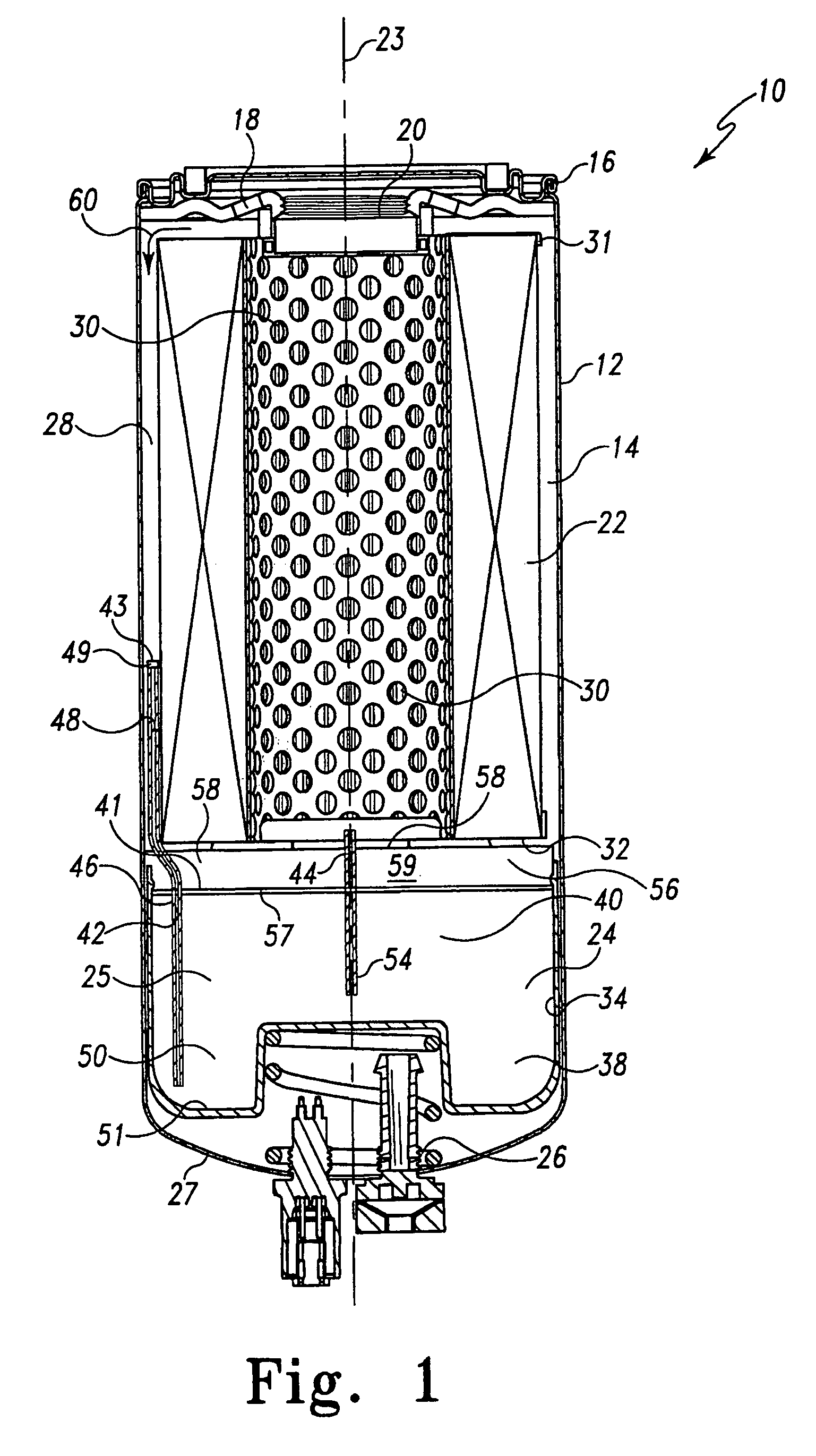

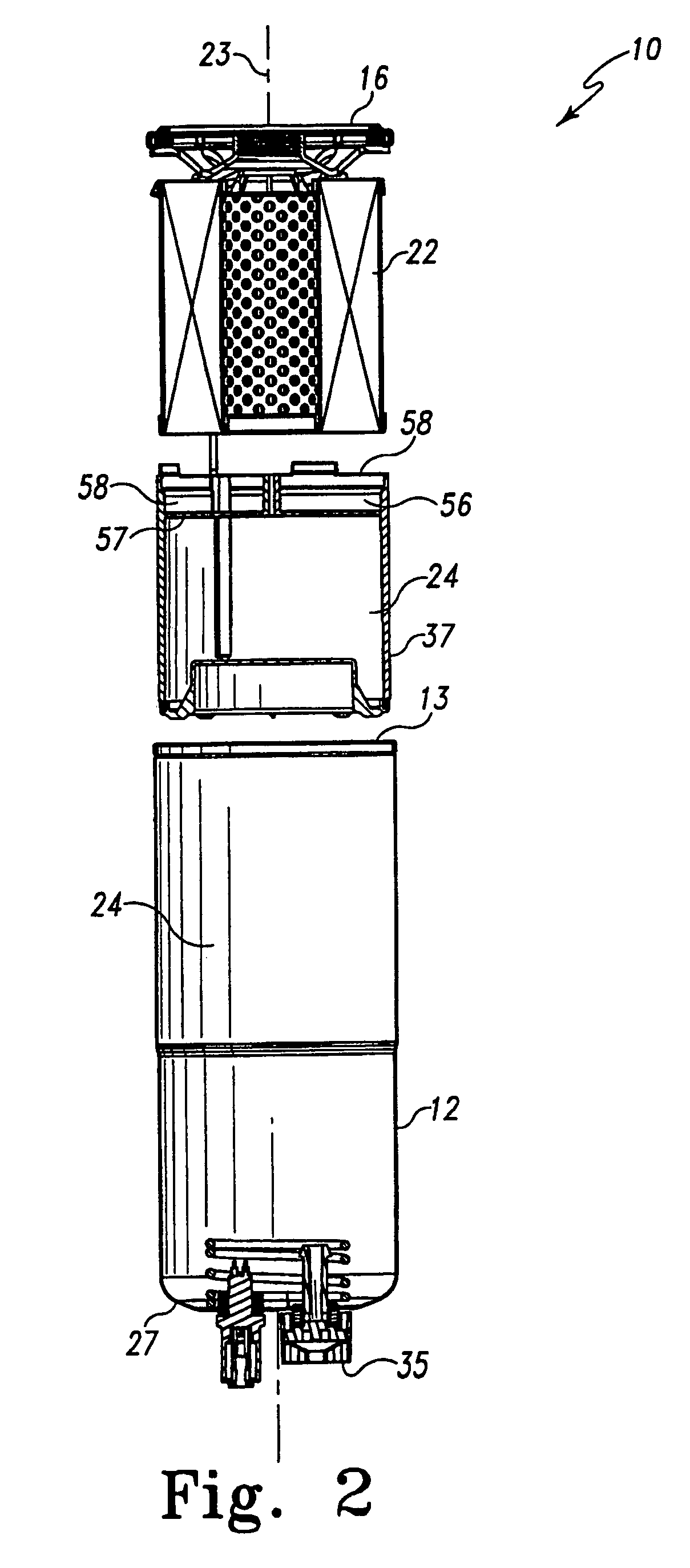

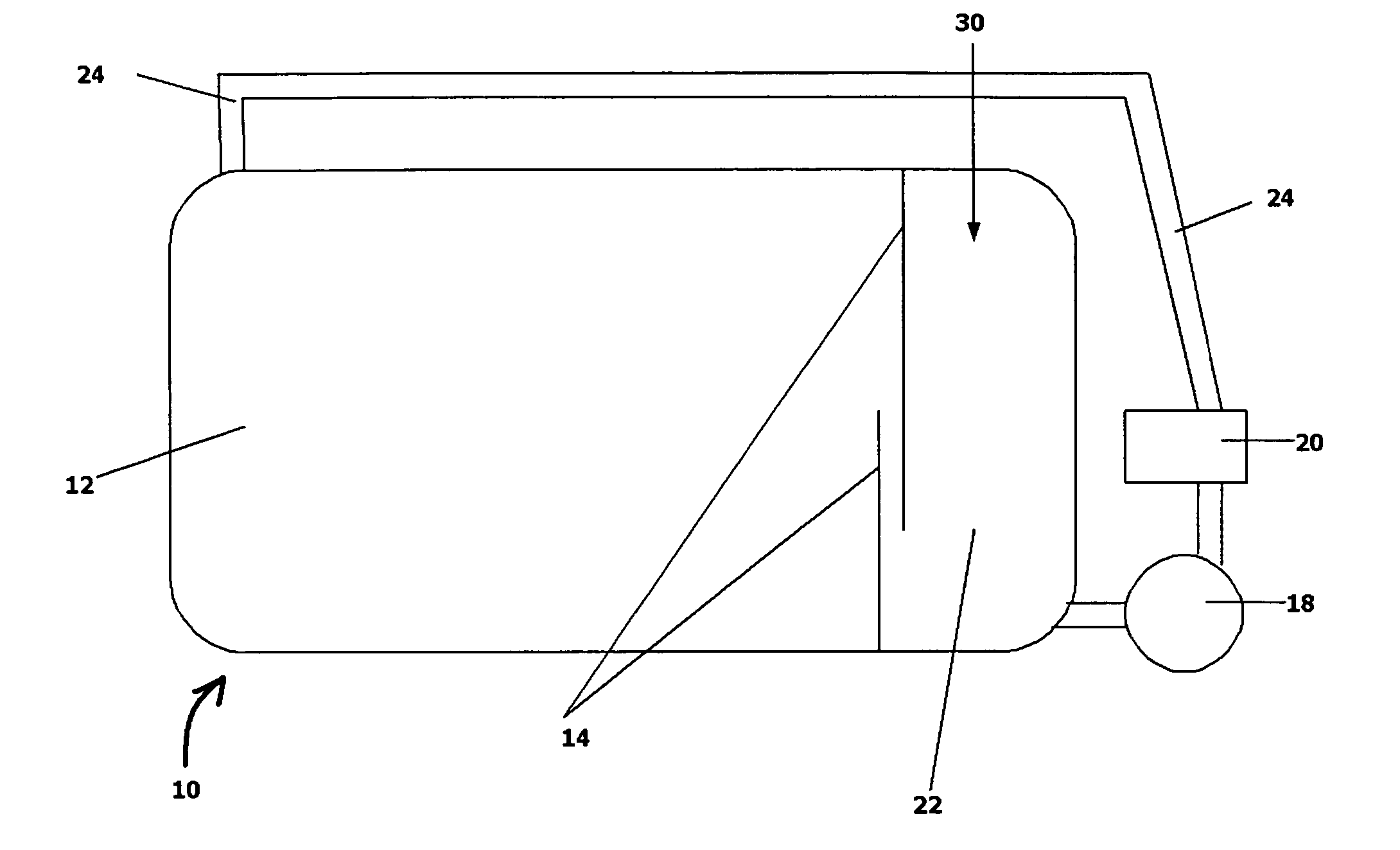

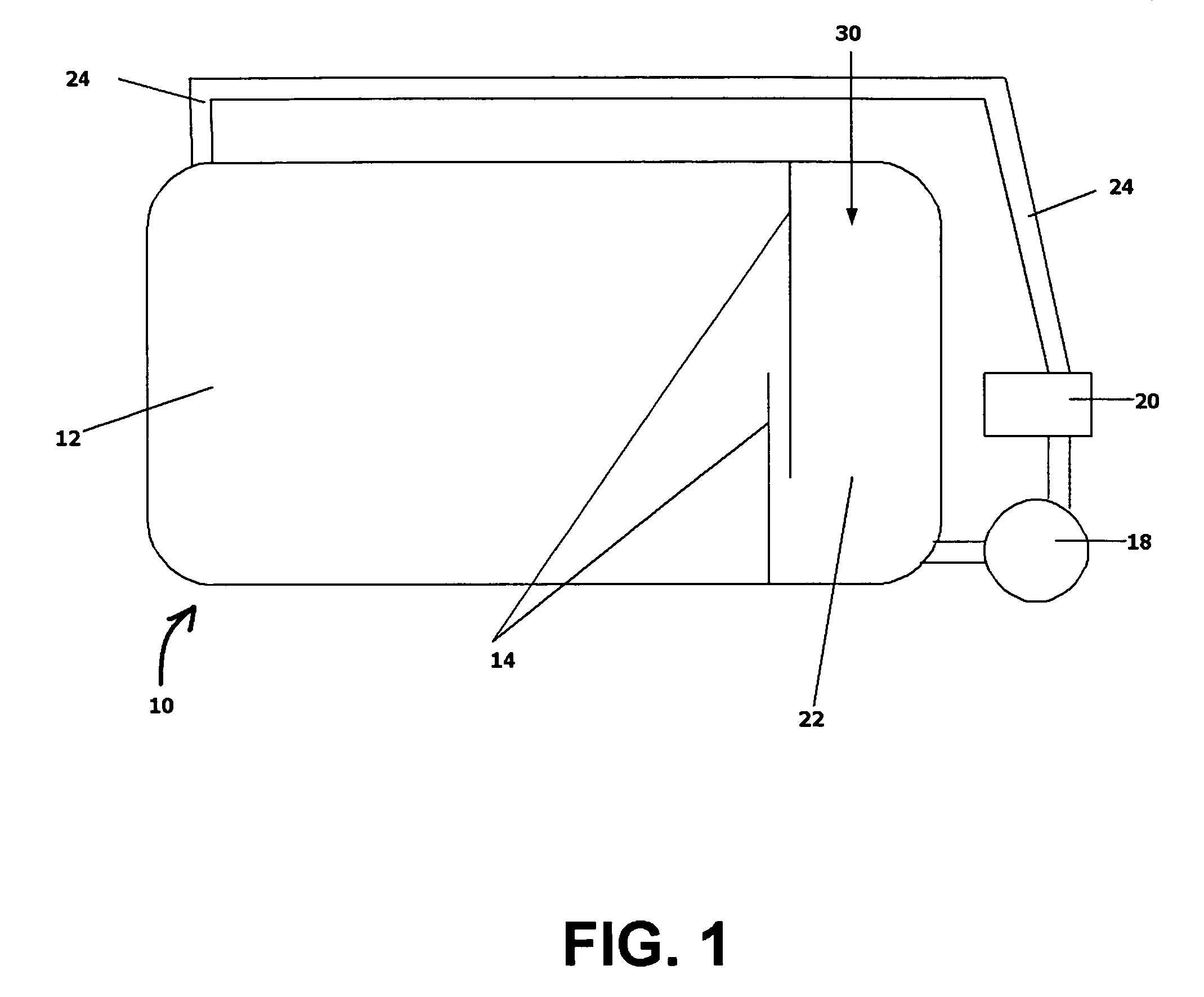

Pressure gradient dosing system for fluid supply

ActiveUS7297256B2Avoid damageReduce componentsSolid sorbent liquid separationLiquid displacementDelivery systemFluid supply

A pressure gradient dosing system is provided for a fluid supply system. A flow passage has first and second pressure zones having a pressure gradient therebetween. An additive reservoir in an additive delivery system responds to the pressure gradient to release additive to the flow passage.

Owner:CUMMINS FILTRATION INC

Electrolyte bath for trivalent chromium plating

InactiveUS20060118427A1Reduce harm to the environmentImprove the level ofCellsElectrodesElectroplatingElectrolyte

Owner:EDIGARYAN ARAMAYIS

Thin, flexible actuator array to produce complex shapes and force distributions

InactiveUS7665300B2Less expensiveReduce harm to the environmentElectrothermal relaysThermally actuated switchesPower flowEngineering

An actuator includes a bistable mechanism having a tension beam and a compression beam defined by a relief slit in a flexible substrate; and a first shape memory element that upon heating actuates the actuator from a first position to a second position. A heat source can be thermally coupled to actuate the first shape memory element, or the first shape memory element can be heated by passing current through the element. The actuators can be formed in an array. Such arrays can be useful for tactile displays, massagers, and the like. Also included are methods of operation and manufacturing.

Owner:MASSACHUSETTS INST OF TECH

Low embodied energy sheathing panels with optimal water vapor permeance and methods of making same

InactiveUS20100077698A1Reduce environmental impactReduce usageConstruction materialCovering/liningsFiberWater vapor

Sheathing panels are produced by methods which do not require natural resources such as wood and use significantly reduced embodied energy when compared with the energy used to fabricate gypsum sheathing panels. A novel binder, consisting in one embodiment of monopotassium phosphate and magnesium oxide, and combined with various fillers, is incorporated with hollow tubes or water soluble fibers to create a gypsum board-like core which can be formed into a suitable sheathing panel handled and installed in a typical manner. The panel is manufactured to have a desirable shear resistance and water vapor permeability, important performance elements in building envelope design. The manufacturing process results in a panel that does not require mature trees as source material, does not off gas, and involves much lower greenhouse gas emissions than the processes used to make traditional wood or gypsum-based sheathing panels.

Owner:ASHTECH IND LLC

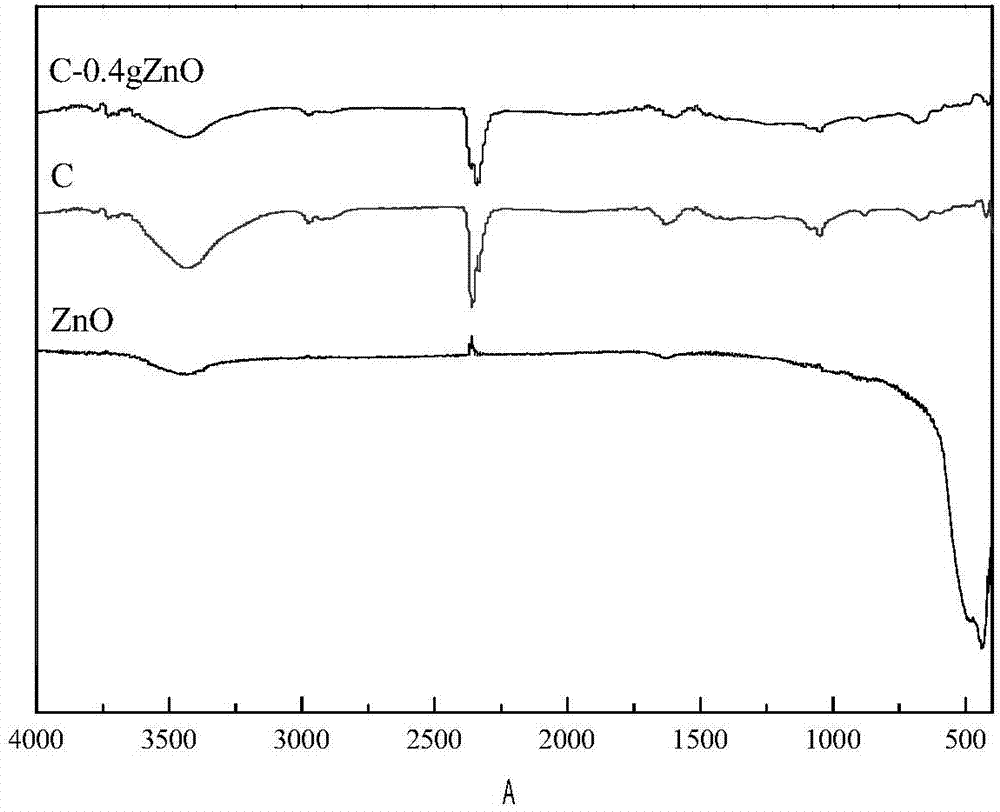

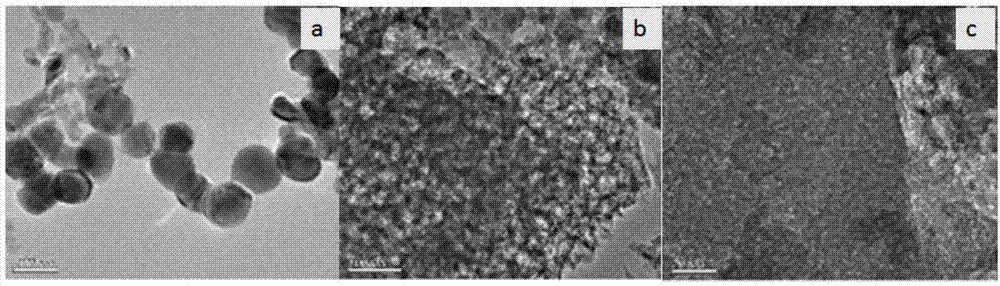

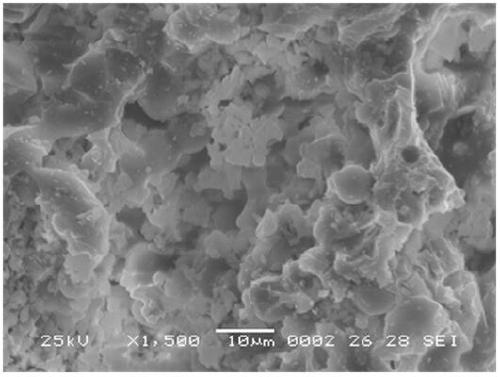

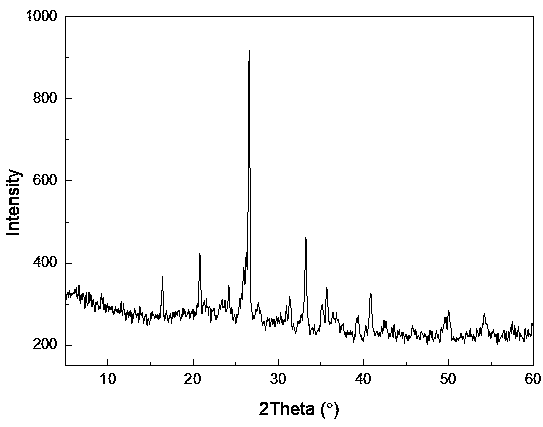

A method of preparing porous carbon by adopting spherical zinc oxide as a template and applications of the porous carbon

InactiveCN104759252AReduce harm to the environmentHarm reductionOther chemical processesZinc oxides/hydroxidesSolventOxide

The invention belongs to the technical fields of functional material preparation and environment protection applications, and discloses a technique of preparing a micro-nano carbon material having a porous structure by a hard template method. A technical scheme of the technique includes subjecting a zinc-source composite material to high-temperature calcination, low-temperature self-assembling and curing to obtain nanometer spherical zinc oxide, adding the spherical zinc oxide which is adopted as a template into an alcohol solution containing phenolic resin, subjecting the composite material to solvent self-volatilization assembling, low-temperature heat curing and high-temperature carbonization, fully dissolving with a prepared diluted hydrochloric acid solution, filtering, washing with water, washing with an alcohol, drying to obtain the porous carbon material, and performing effective adsorption treatment for ciprofloxacin by utilization of the prepared porous carbon material.

Owner:JIANGSU UNIV

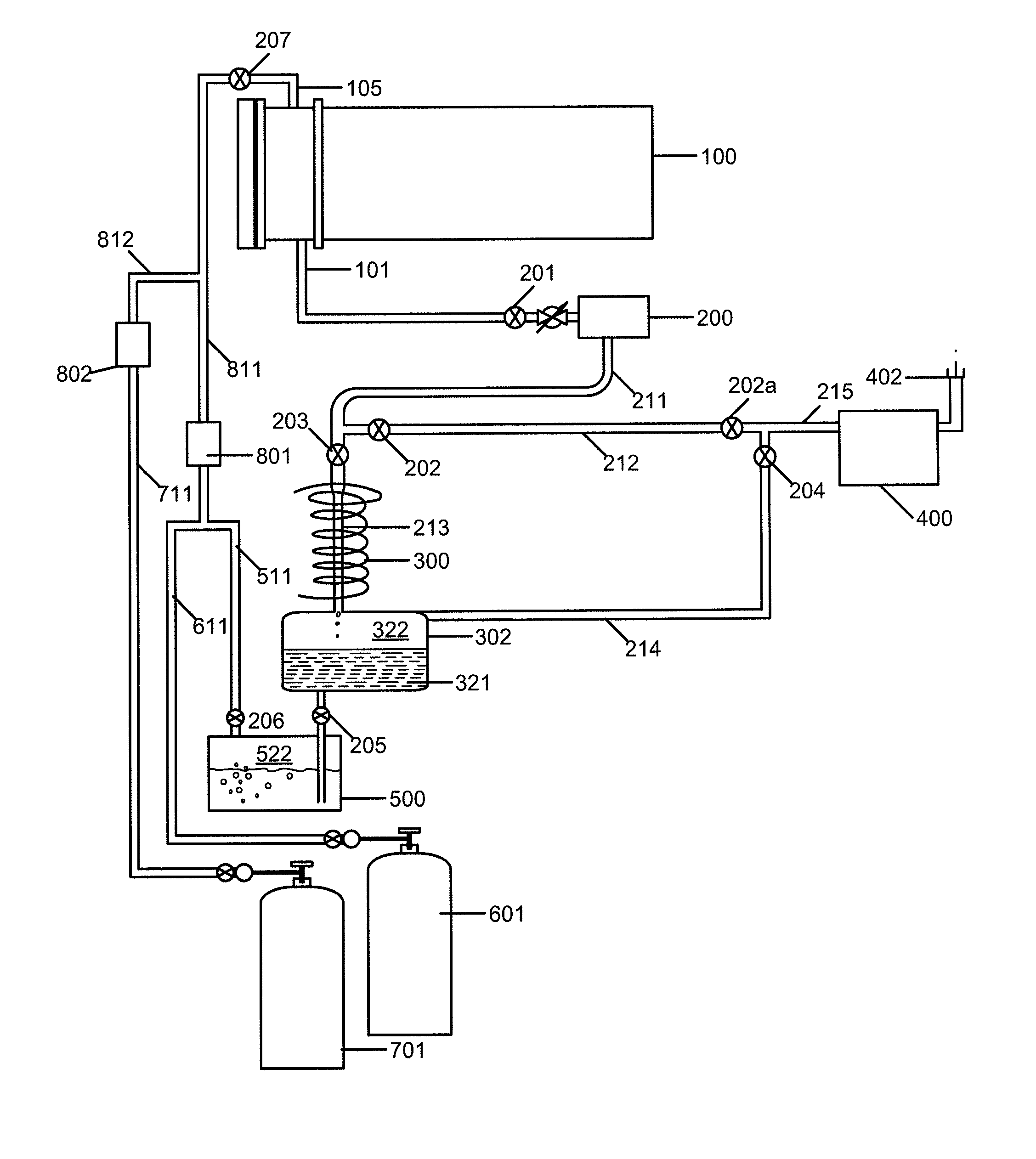

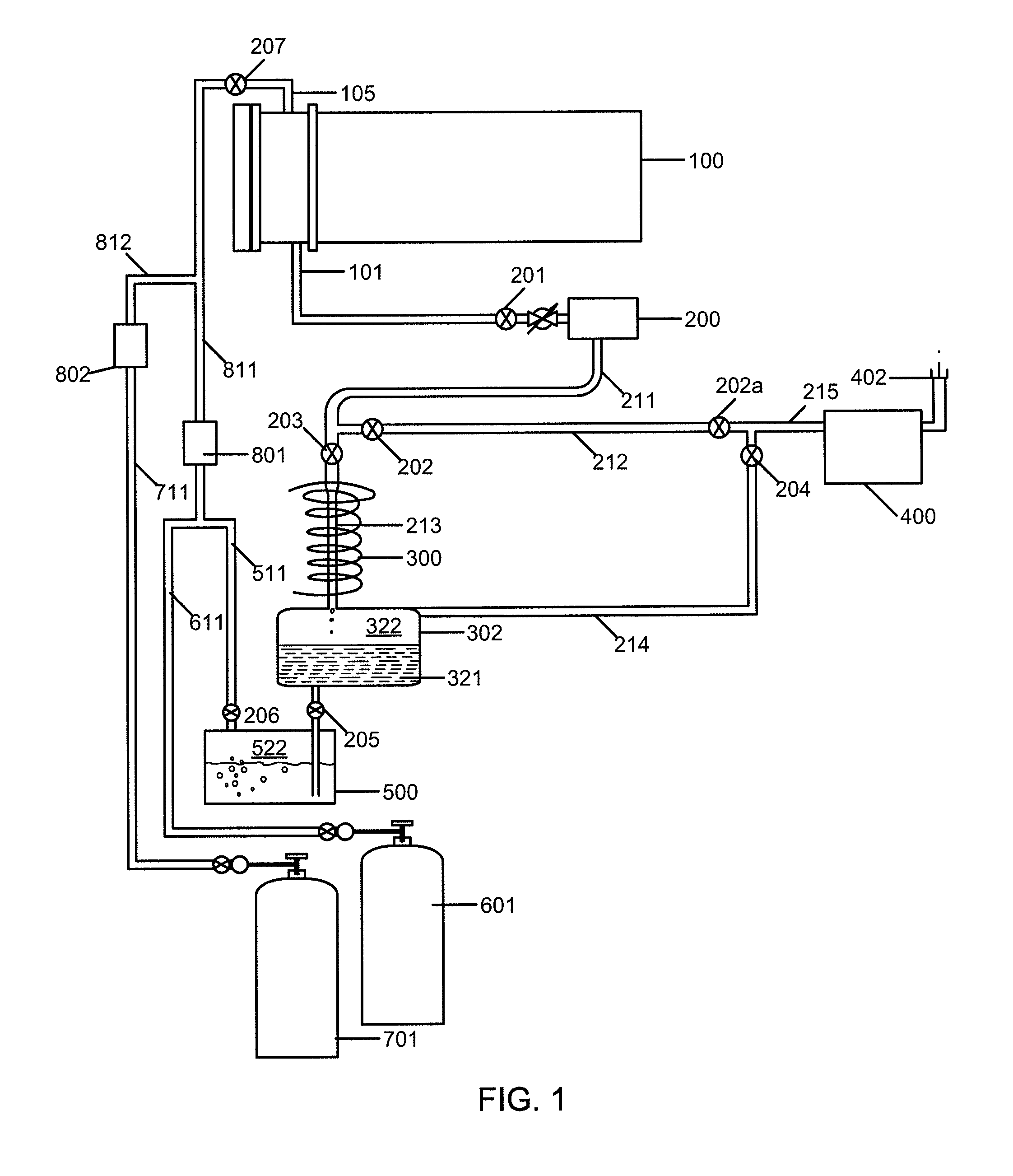

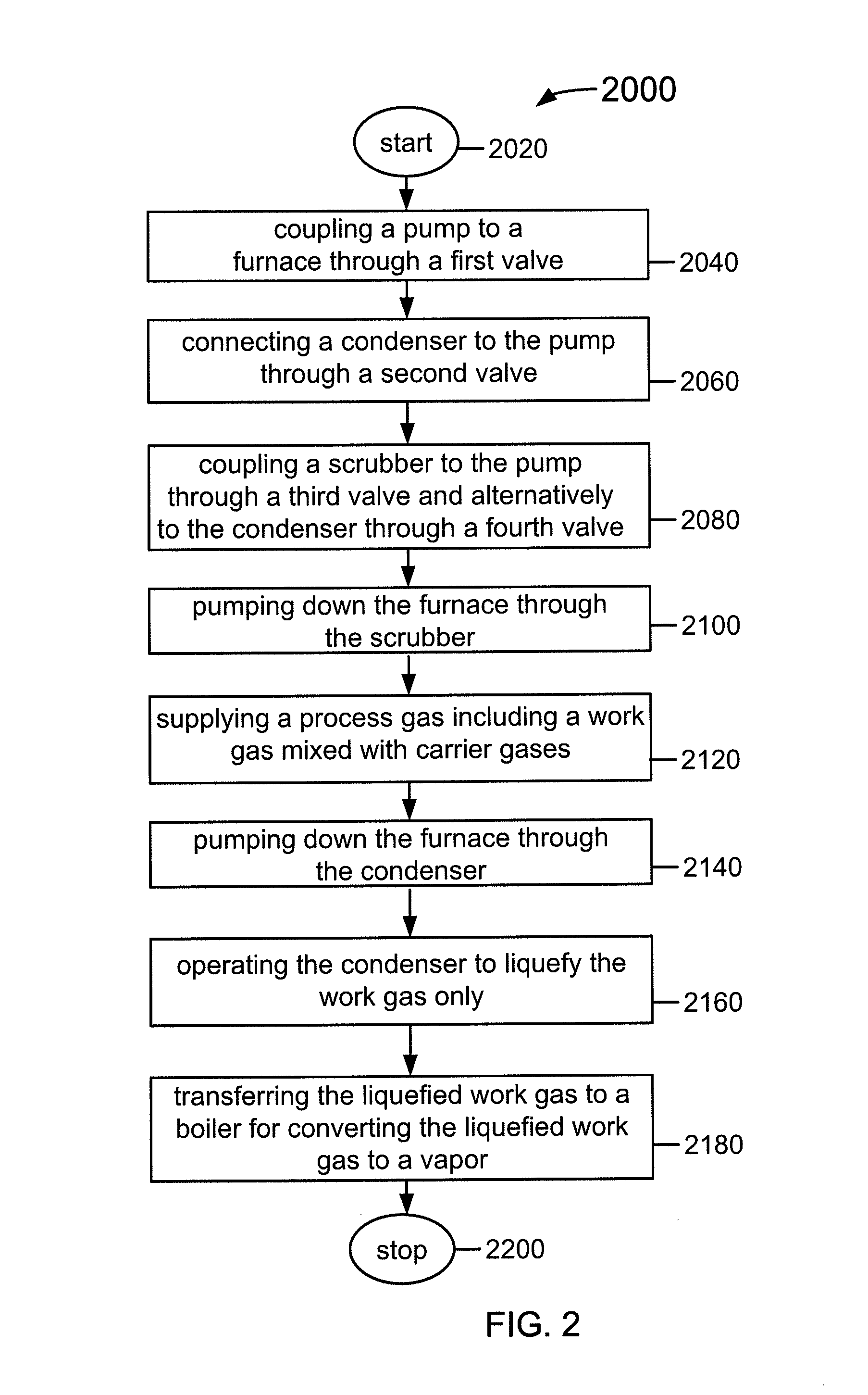

Method and system for recycling processing gas for selenization of thin film photovoltaic materials

InactiveUS8728200B1Cut down wasteMitigate environmental hazardsGas treatmentVacuum condensationScrubberBoiling point

A system for recycling a work gas used in a thermal reactor for treating sample materials includes a thermal reactor using a work gas from a first source mixed with carrier gases. The work gas has a boiling point higher than the carrier gases. The system includes a pump, a condenser which converts the work gas into a liquid, and a scrubber.

Owner:CM MFG

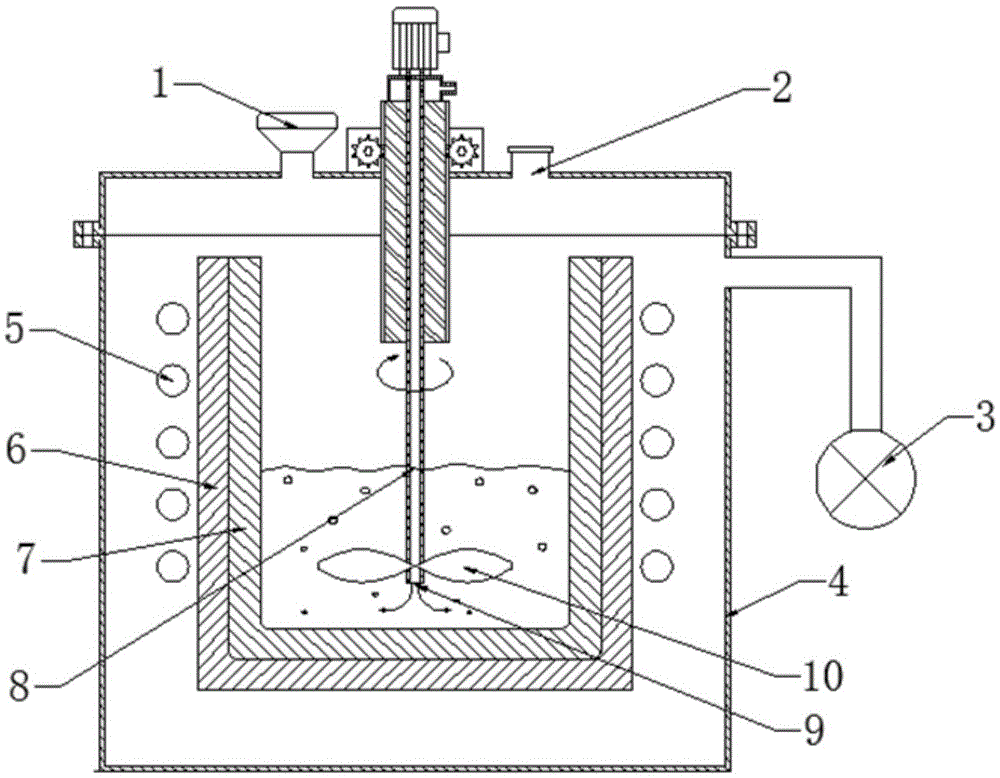

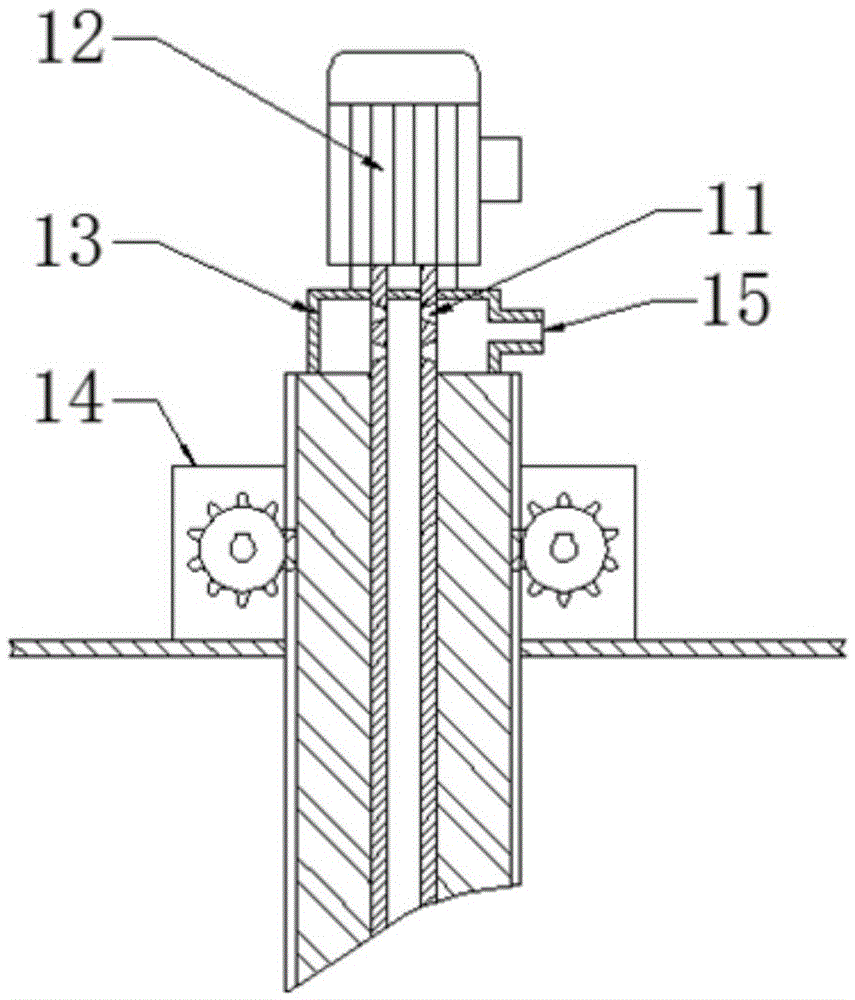

Boron removal method and device through activated slag agent

ActiveCN105540593AReduce the amount of slag agentReduce harm to the environmentSilicon compoundsSlagIntermediate frequency

The invention discloses a boron removal method and device through an activated slag agent, and belongs to the fields of semiconductor materials and metallurgy. The device is provided with a lobe pump, a furnace base, a medium-frequency induction coil, an insulating layer, a graphite crucible, a stirrer and a lifting device. The method comprises the steps that raw silicon is put into the graphite crucible from a feed port, the lobe pump is started to perform vacuumizing, a medium-frequency induction power supply is started to perform heating, and when the temperature is increased to 1500 DEG C, silicon blocks are completely molten; inert gas is charged into a furnace cavity to enable the temperature to be kept at 1550 DEG C-1650 DEG C, the slag agent is added, the stirrer is started, and first-time slagging is completed; the power of the medium-frequency induction power supply is increased to enable the temperature in the furnace cavity to reach 1700 DEG C-1800 DEG C, the feed port is opened, active components of the slag agent are put into the furnace cavity for the first time, vacuumizing is performed, the stirrer is started, the inert gas is introduced, and second-time slagging is completed; after slagging is completed, silicon liquid is poured into a receiving crucible, standing and cooling are performed, a silicon ingot is taken out, purified low-boron high-purity silicon is obtained, and then boron removal achieved through the activated slag agent is completed.

Owner:XIAMEN UNIV

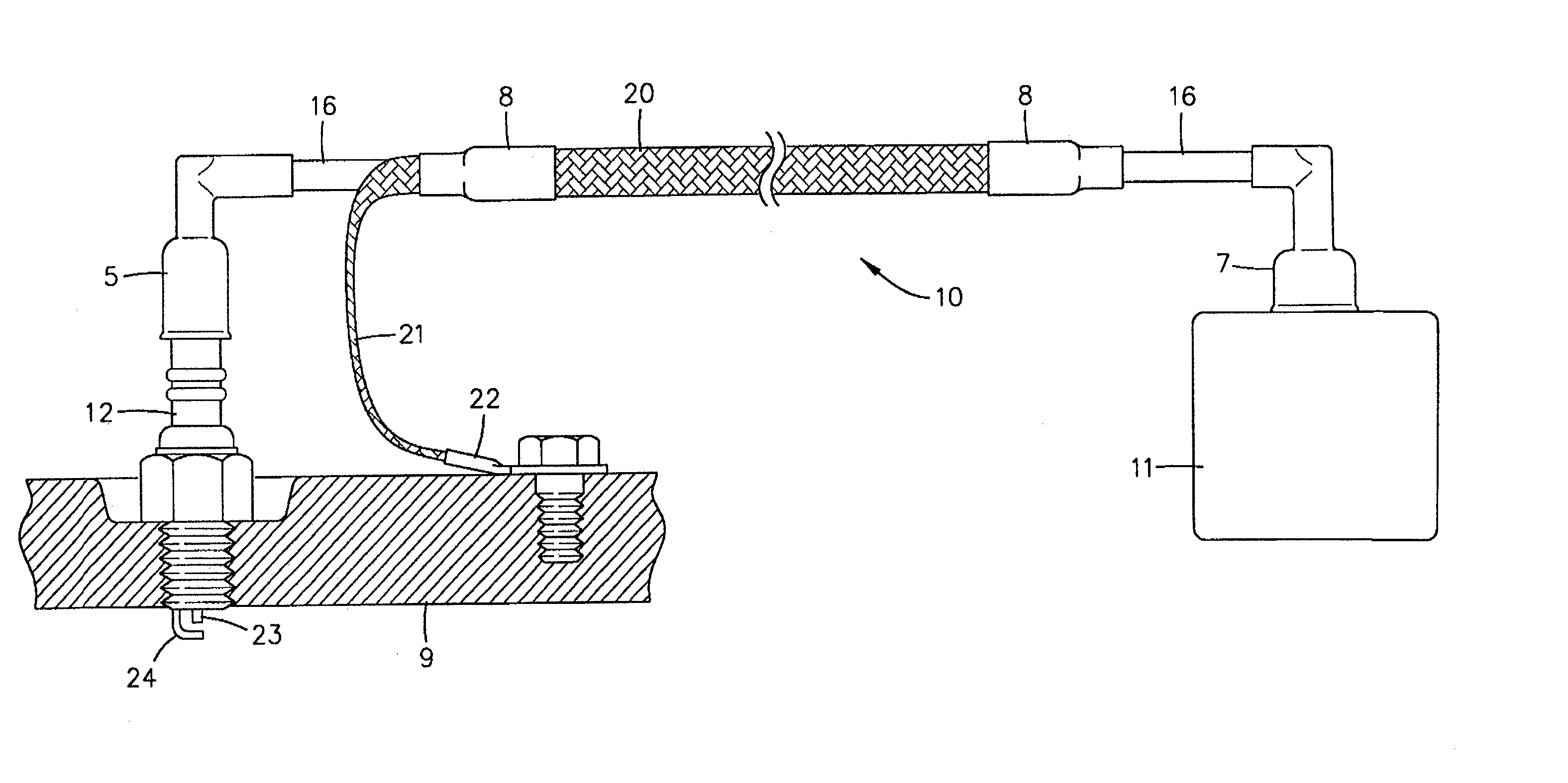

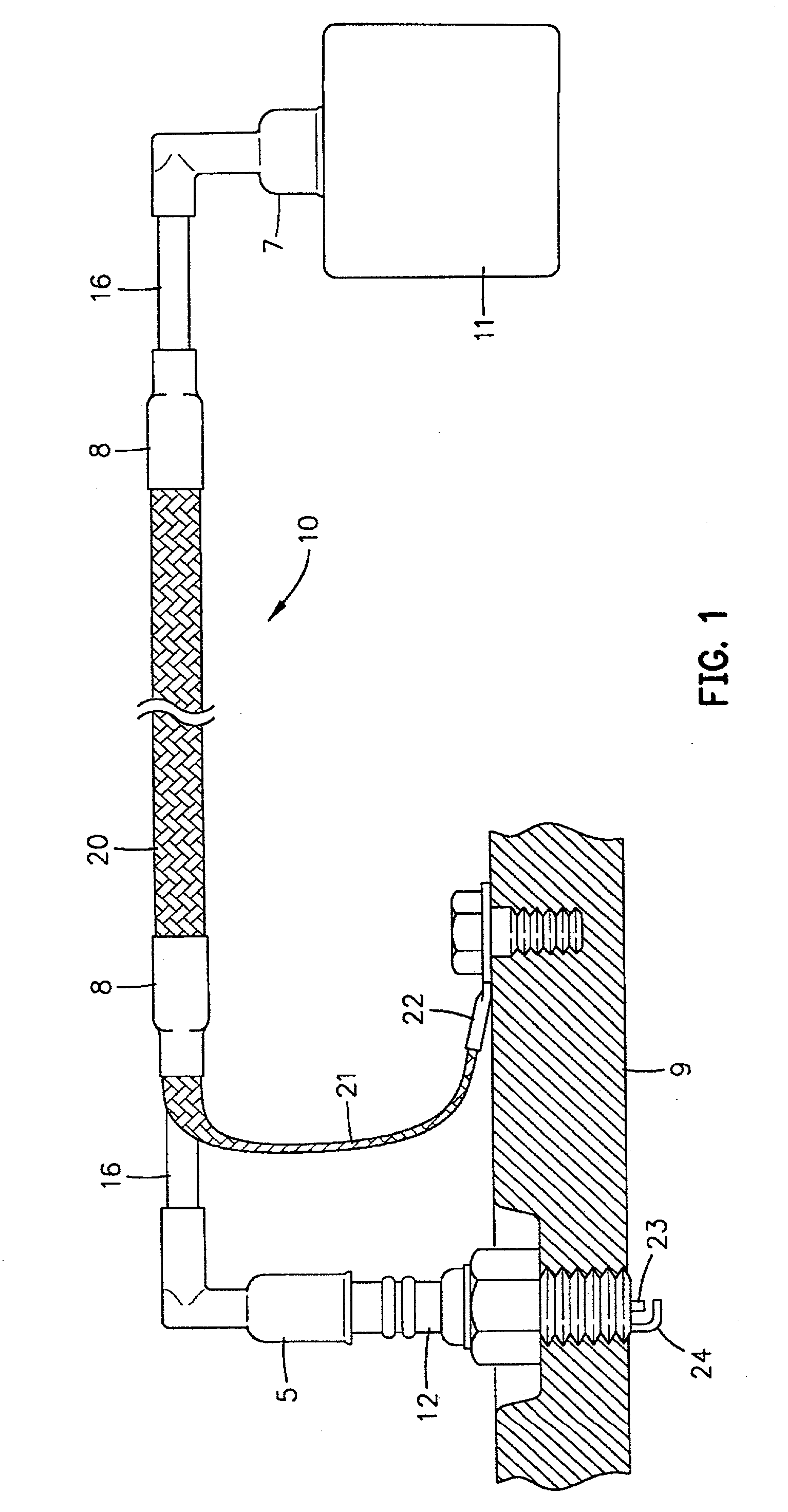

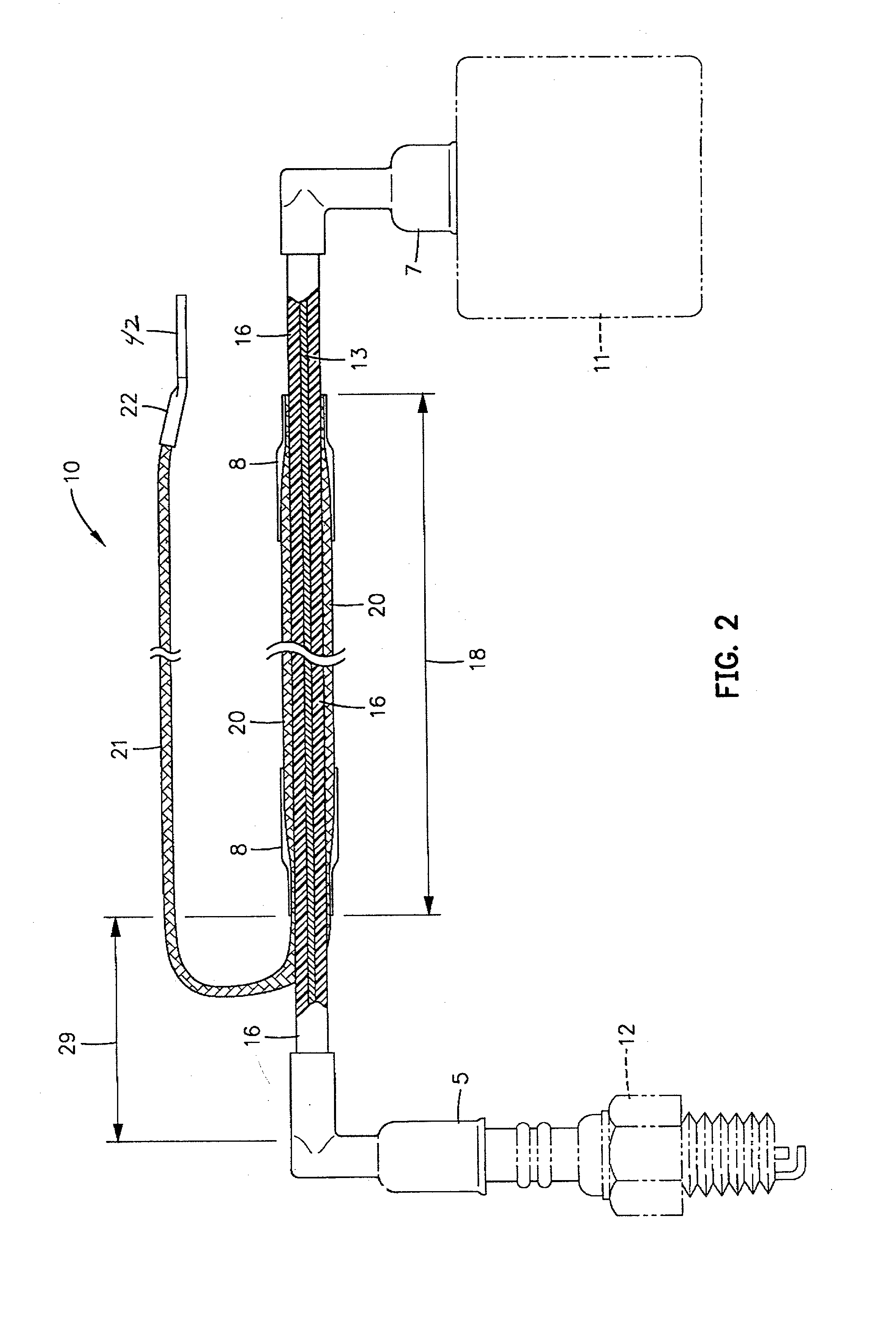

Combustion initiation device and method for tuning a combustion initiation device

InactiveUS20020129950A1Increase engine powerDecreasing harmful environmental emissionCoaxial cables/analogue cablesSparking plugsCapacitanceElectrical conductor

An ignition cable constructed according to a method for optimizing an ignition cable, the cable comprising at least a capacitor, where the ignition cable carries current from a power source to a spark plug located in a combustion chamber. The ignition cable comprises a center element structured to communicate electric current from the power source to the spark plug and an insulator surrounding the center element. The conductor removeably coupled to a ground, and surrounds at least a portion of the insulator. The center element, insulator and conductor comprise a capacitor having an optimal capacitance value that is determined by finding a maximum capacitance value and subtracting a safety margin.

Owner:NOLOGY ENG

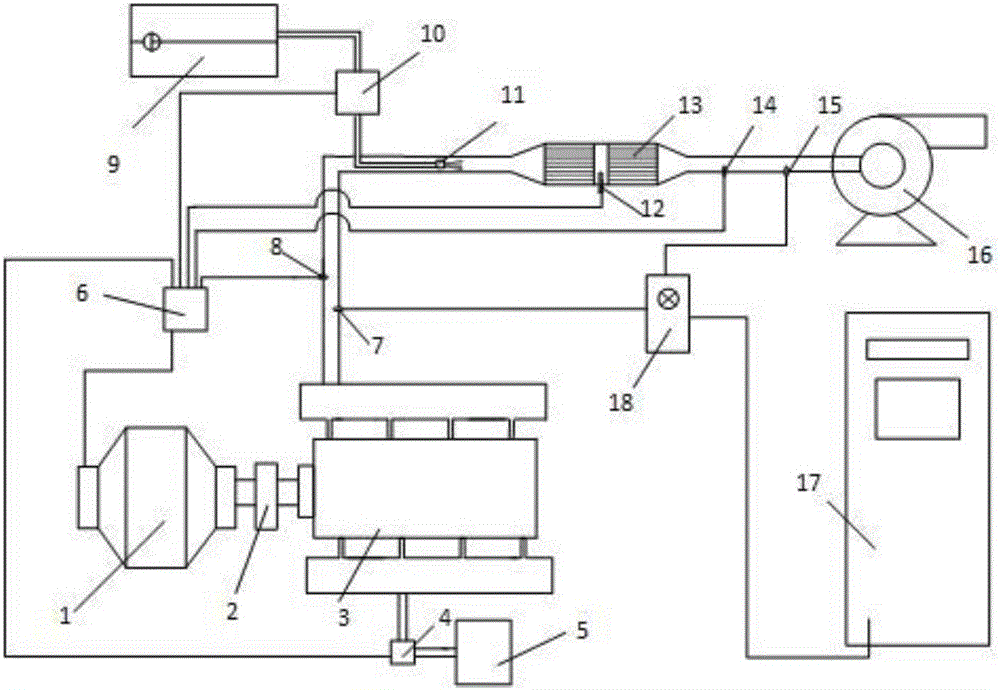

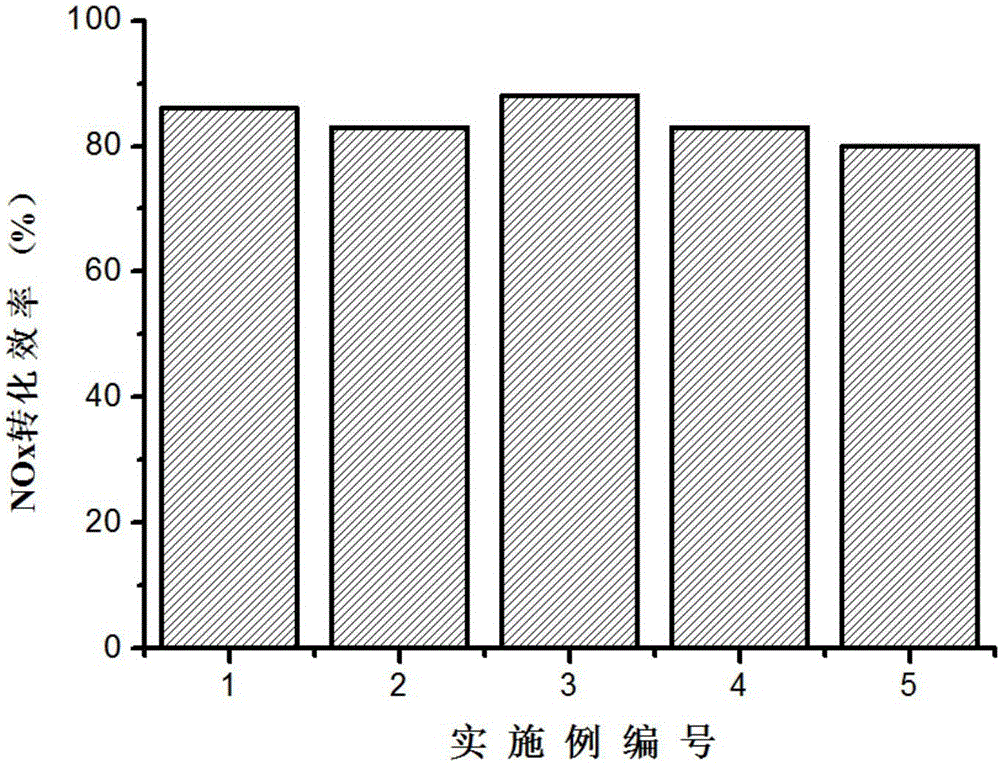

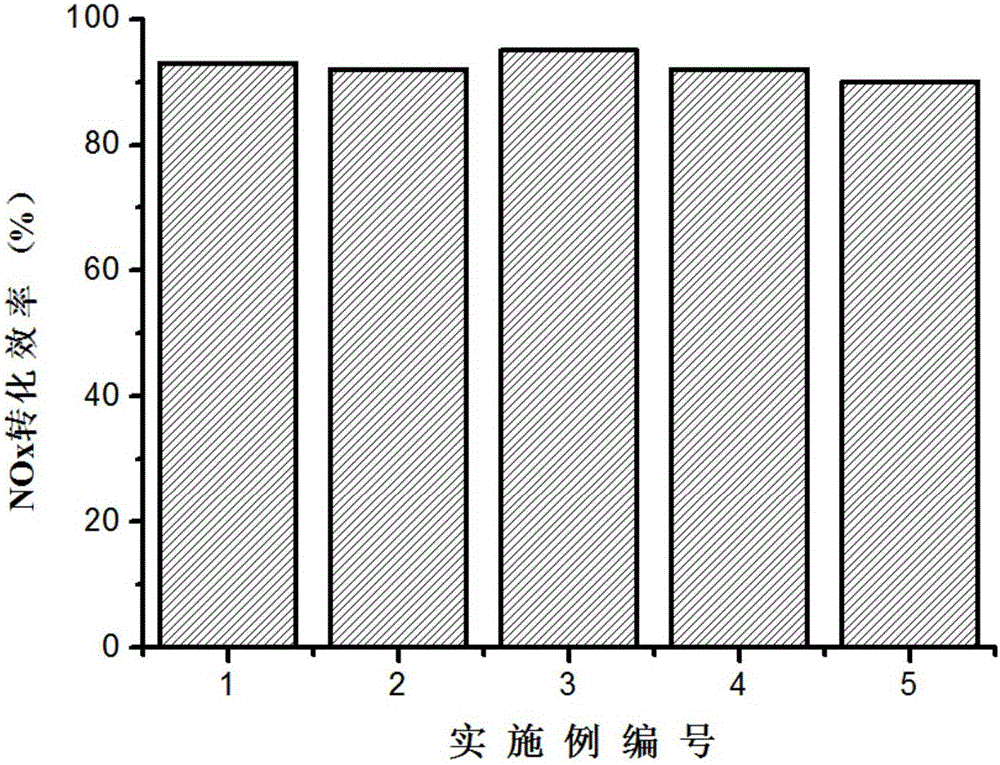

Ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst

ActiveCN106622348AImprove the catalytic activity of low temperature SCR reactionSuppress generationGas treatmentMolecular sieve catalystsCordieriteSlurry

The invention discloses a ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst. The catalyst is composed of a main catalyst, an auxiliary catalyst, a coating base material and a catalyst carrier, wherein a ferrous-La bimetallic modified ZSM-5 molecular sieve serves as the main catalyst; a CeO2-ZrO2 solid solution serves as the auxiliary catalyst; the coating base material is composed of SiO2, TiO2 and gamma-Al2O3; and a 400-mesh cordierite honeycomb ceramic serves as the catalyst carrier. A preparation process comprises the following steps: preparing and confirming the dosage of the supported catalyst raw materials; preparing the main catalyst, namely, the ferrous-La bimetallic modified ZSM-5 molecular sieve; and preparing the coating slurry and coating. The catalyst is packaged in a diesel engine SCR catalytic converter and is used for catalyzing the SCR reaction of the reducing agent and NOx, so as to realize the purification of NOx pollutants in the exhaust gas of the diesel engine. According to the invention, the environmental harm of the traditional catalyst is reduced, the generation of the secondary pollutants, such as SO3 derivatives, is restrained, and the low-temperature SCR reaction catalytic activity of the catalyst is obviously improved.

Owner:TIANJIN UNIV

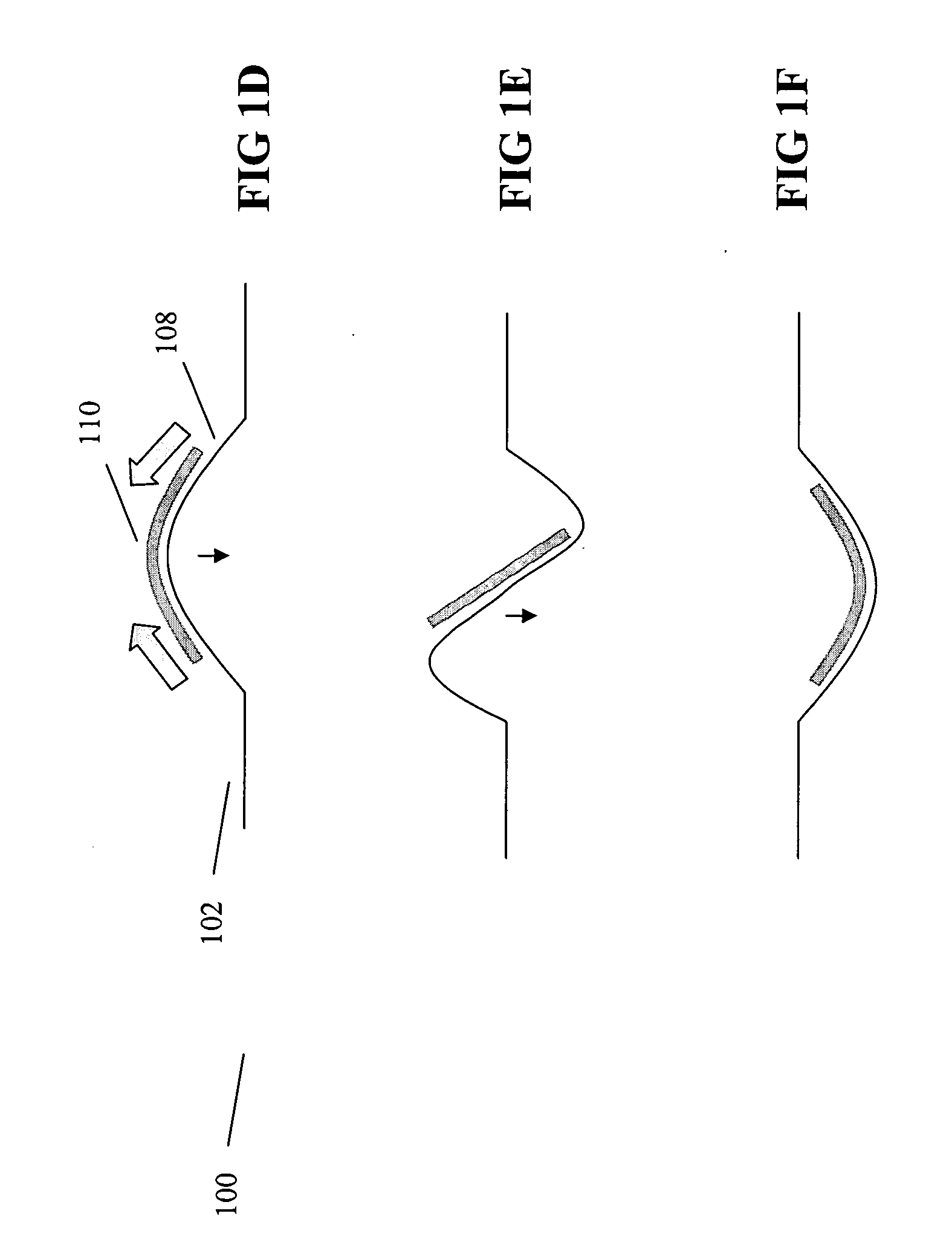

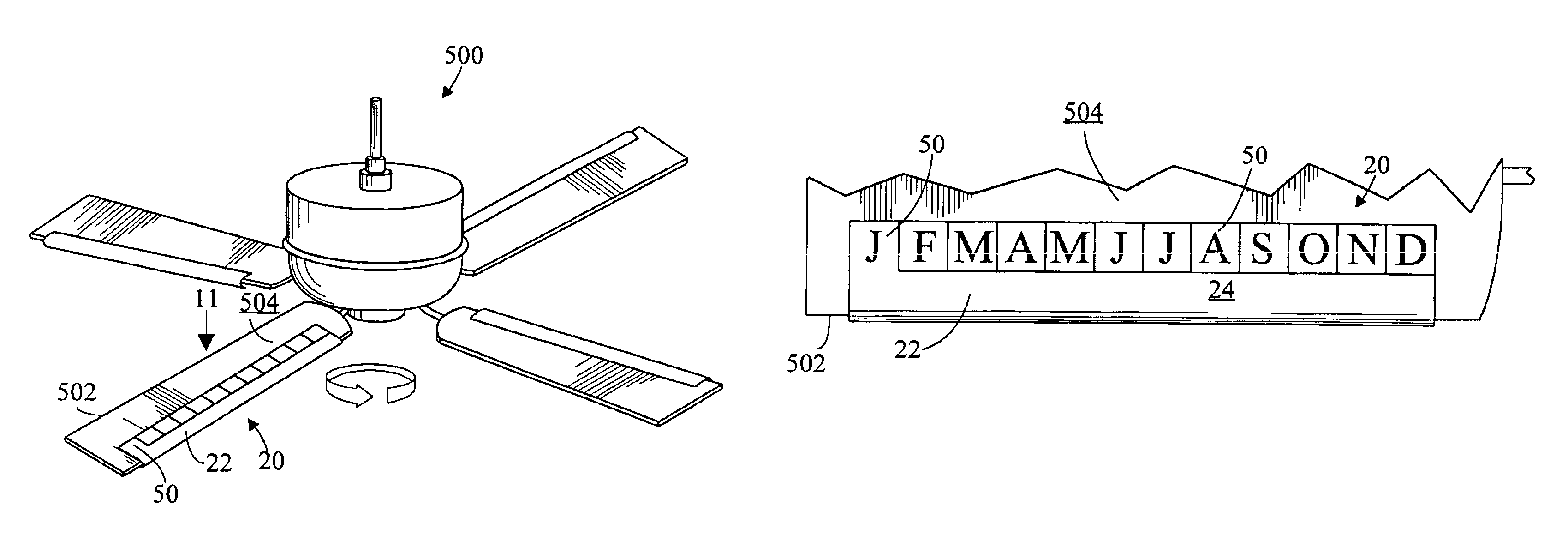

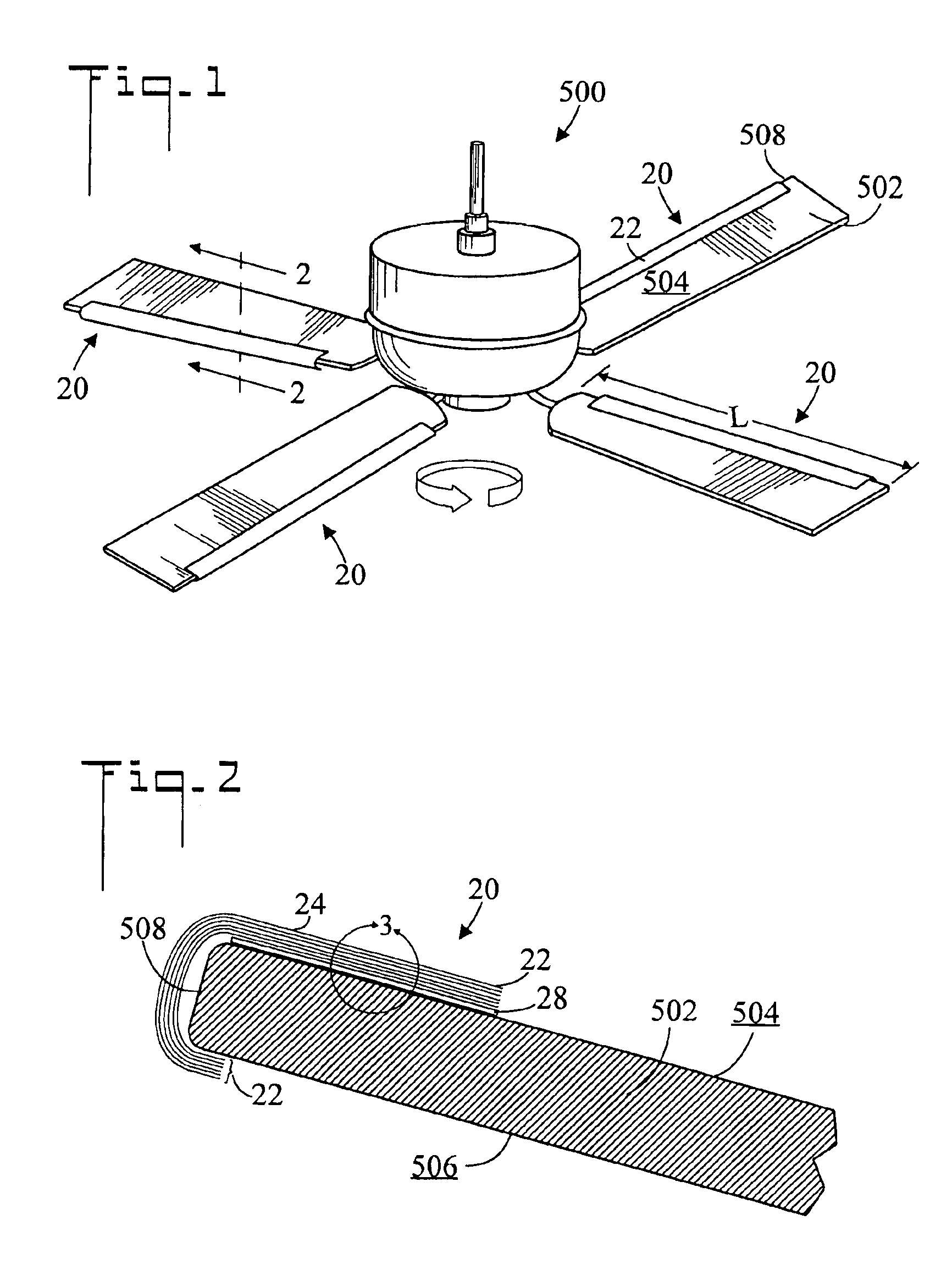

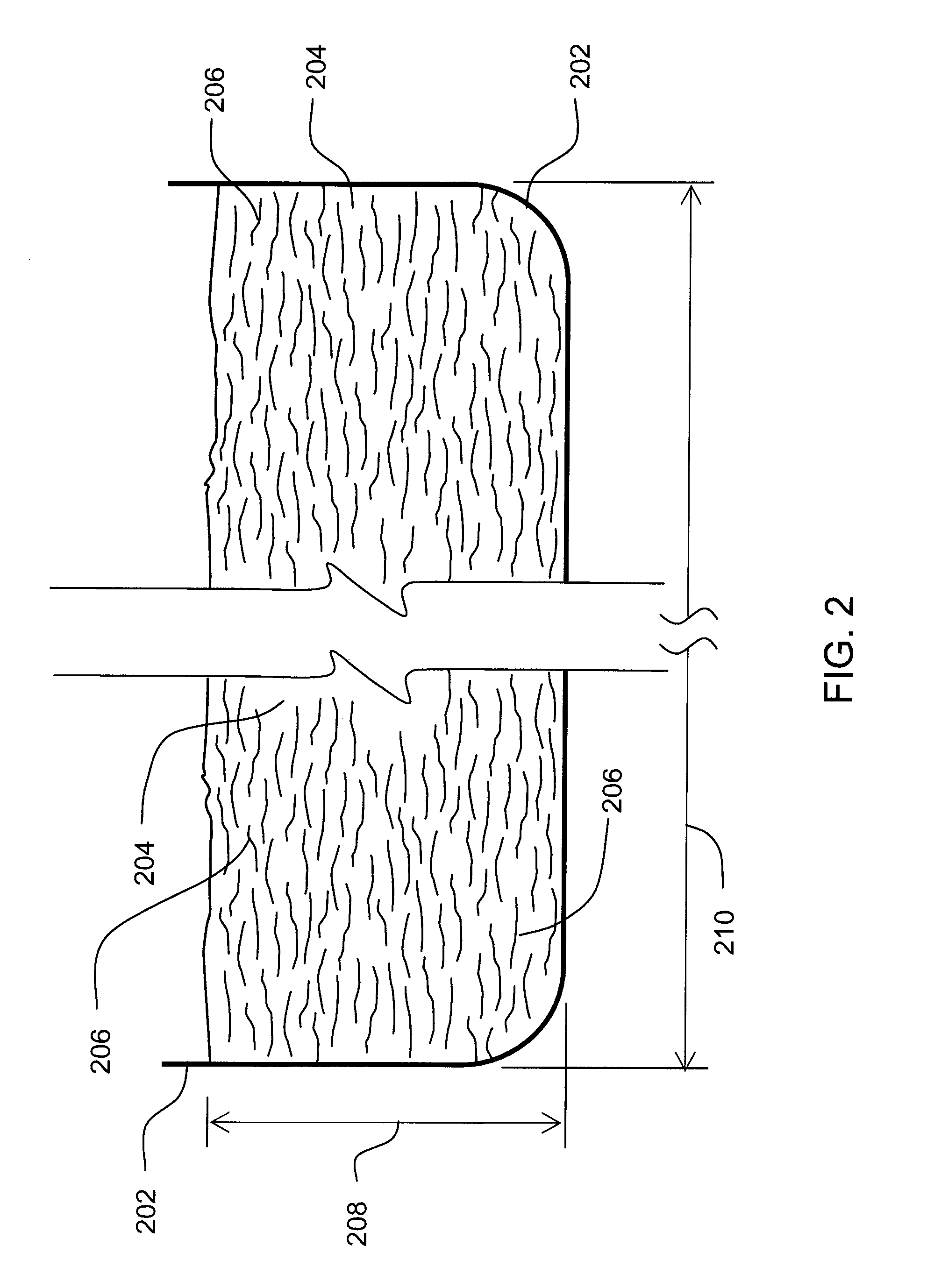

Method for removing pollutants from the air and apparatus therefor

InactiveUS6857852B1Improve air qualityImprove adsorption capacityPropellersPump componentsEnvironmental engineeringFan blade

A method for removing pollutants from a gas such as air includes attaching a multi-layer stack of sheets to the surface of a fan blade. The sheets have a tacky surface disposed on their outward facing side, so that as the fan blade rotates pollutants are captured by the tacky surface. When the tacky surface of the top most sheet becomes contaminated with pollutants, it is peeled off to expose a clean uncontaminated next lower sheet. In an embodiment of the invention, each sheet has a tab which facilitates the identification and removal of the topmost sheet when it becomes contaminated with pollutants.

Owner:CARFAGNA NANCY A +1

Low embodied energy sheathing panels with optimal water vapor permeance and methods of making same

InactiveUS7914914B2Reduce environmental impactReduce harm to the environmentConstruction materialCovering/liningsFiberWater vapor

Owner:ASHTECH IND LLC

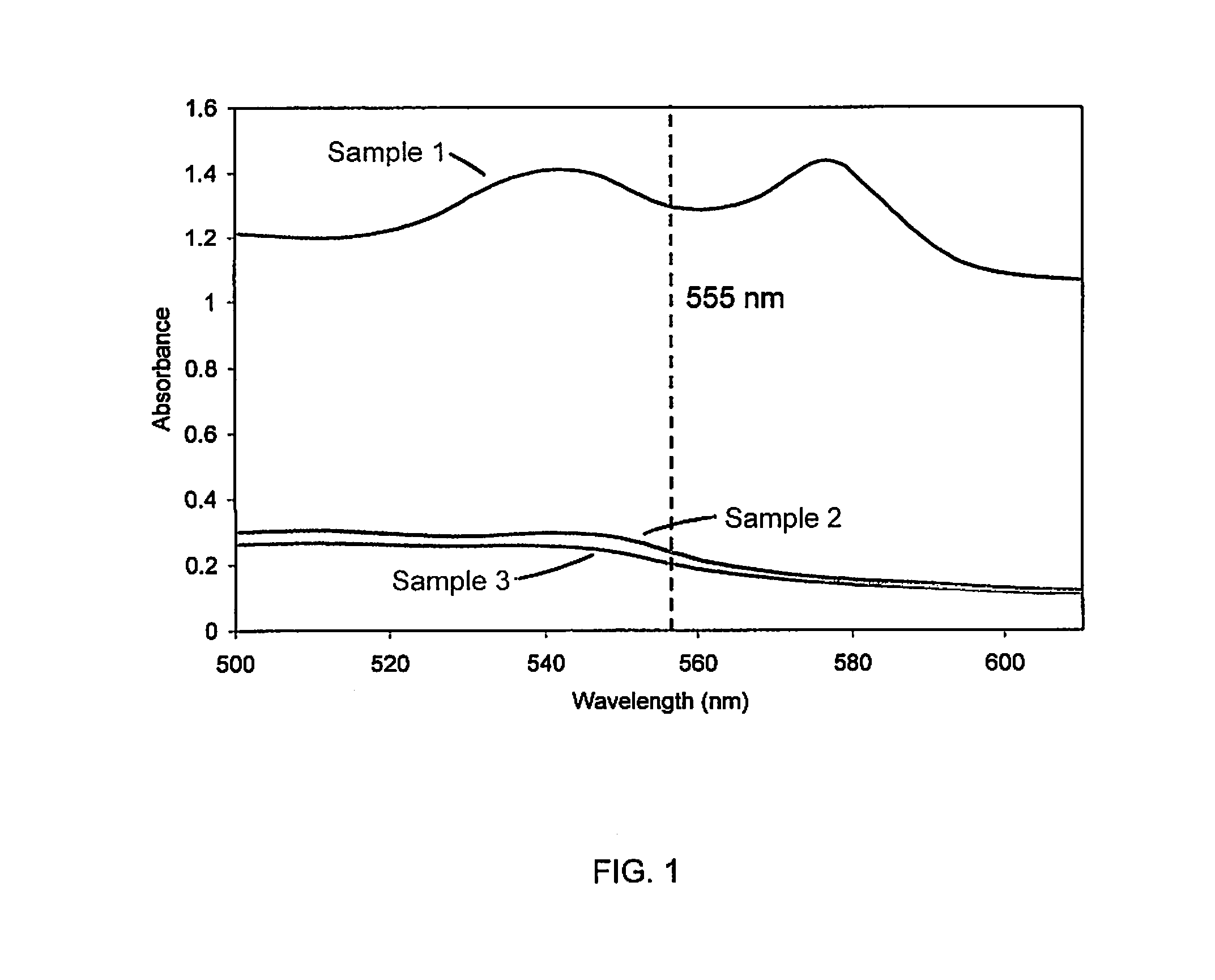

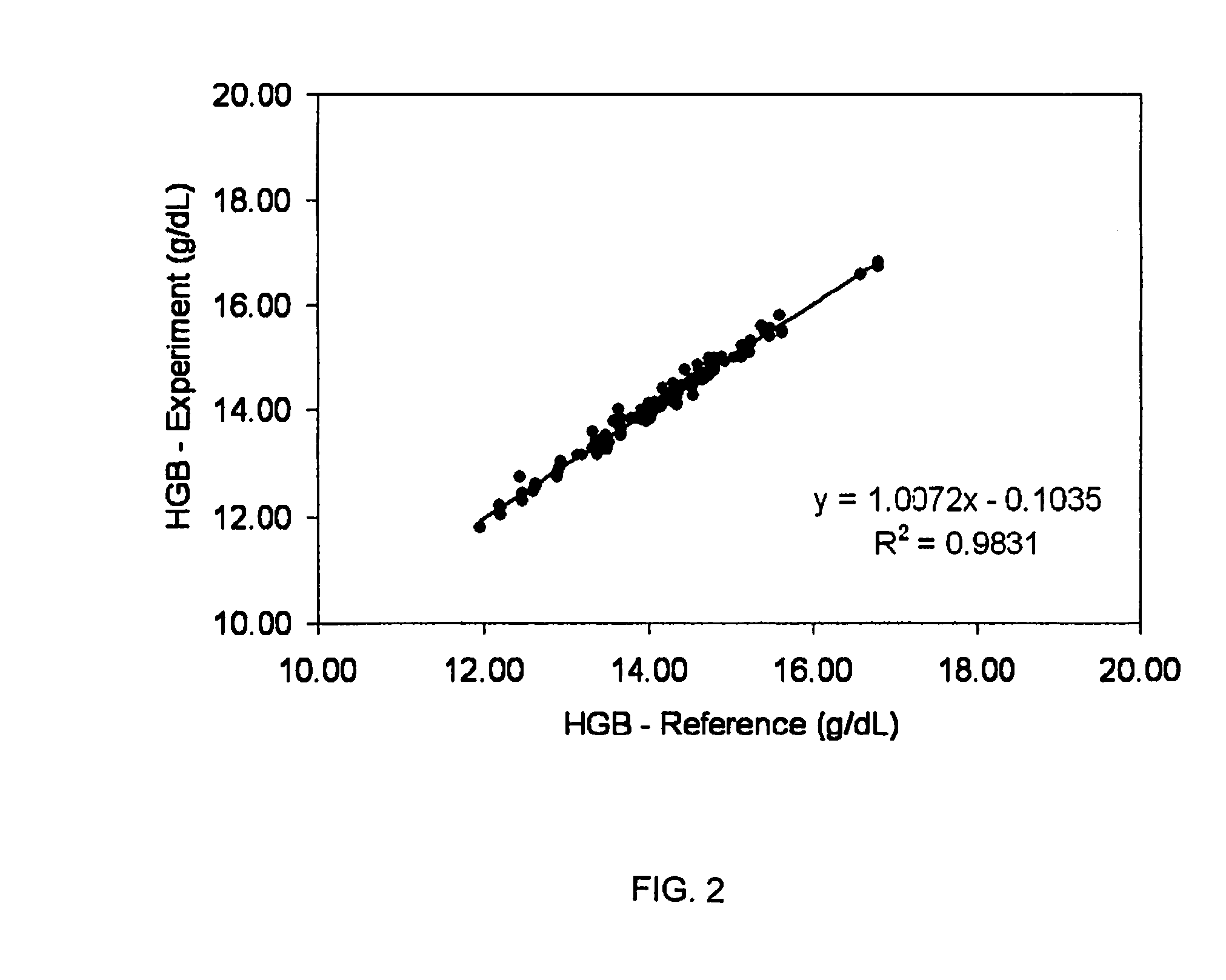

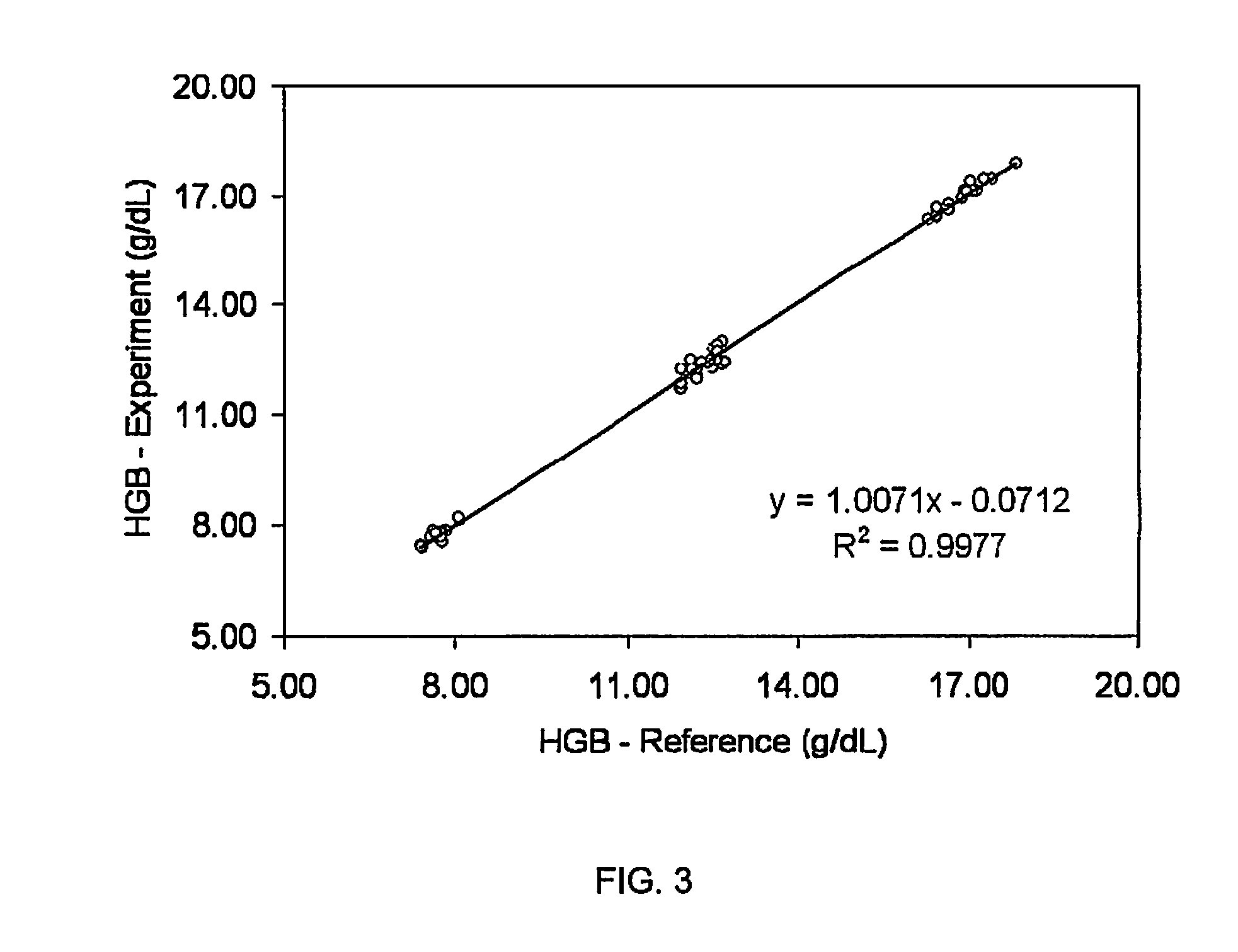

Method of using ligand-free lysing agent in hemoglobin analysis

ActiveUS8614066B2Accurately determinedReduce manufacturing costMicrobiological testing/measurementMaterial analysisCyanideHematology analyzer

Lysing agents that are free of ligands, including cyanide, for binding hemoglobin for hematology analyzers. The ligand-free lysing agents achieve accurate quantification of hemoglobin parameters, thereby replacing existing lysing agents for analysis of hemoglobin.

Owner:ABBOTT LAB INC

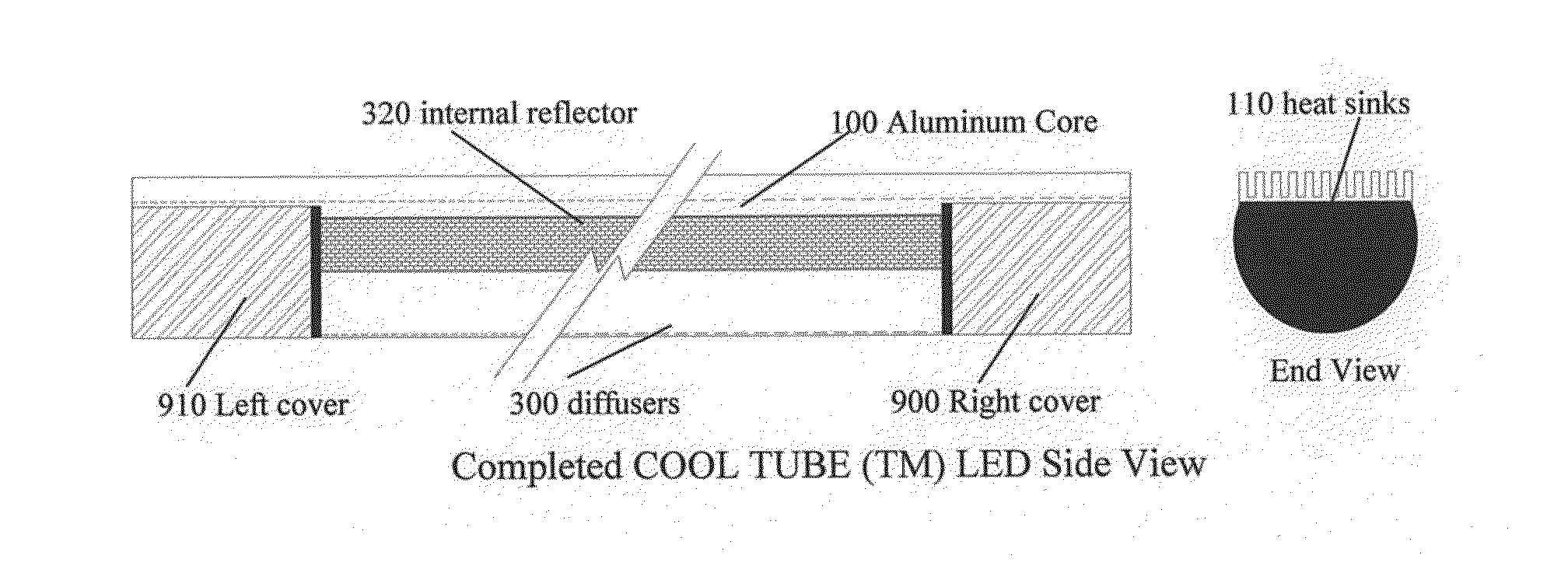

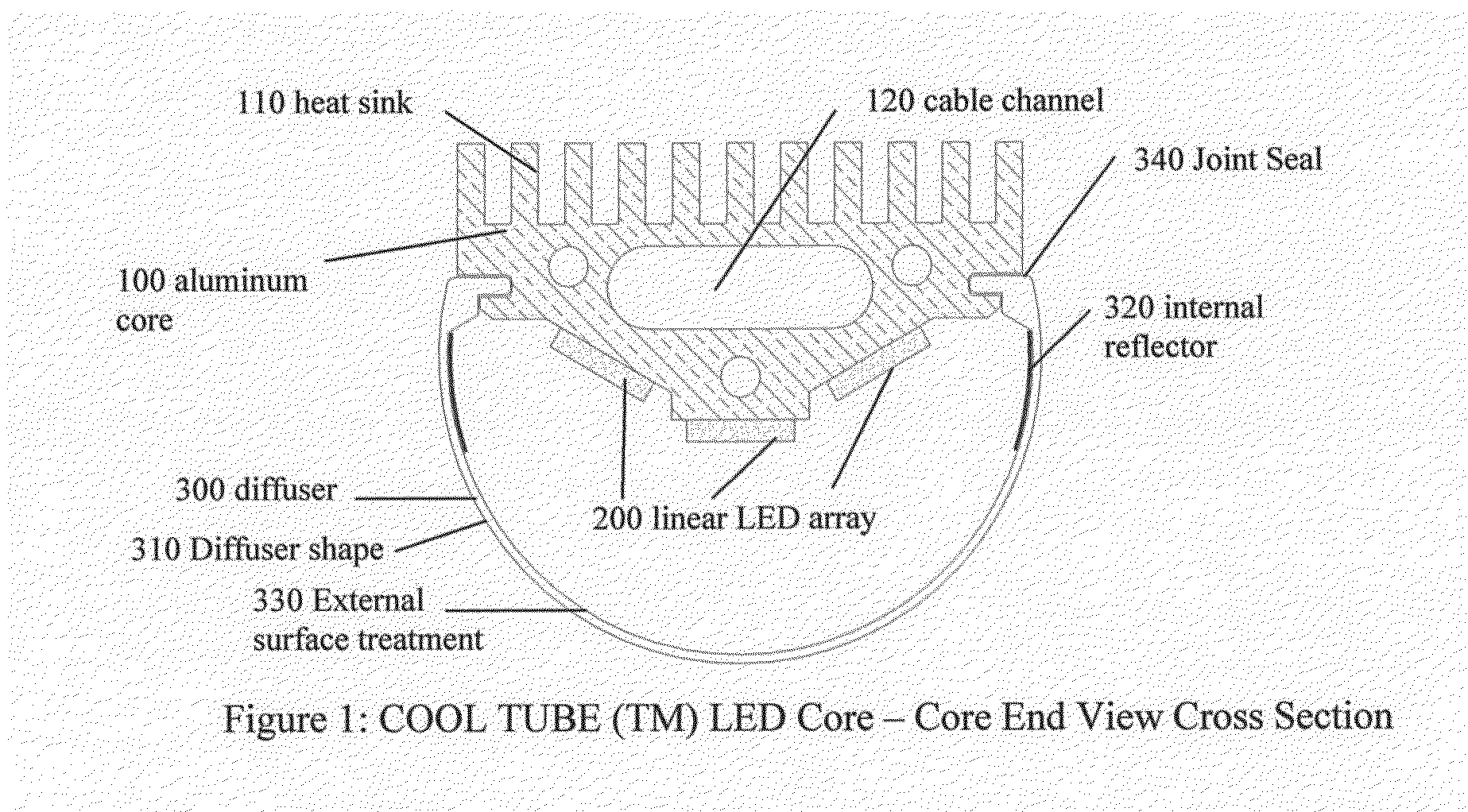

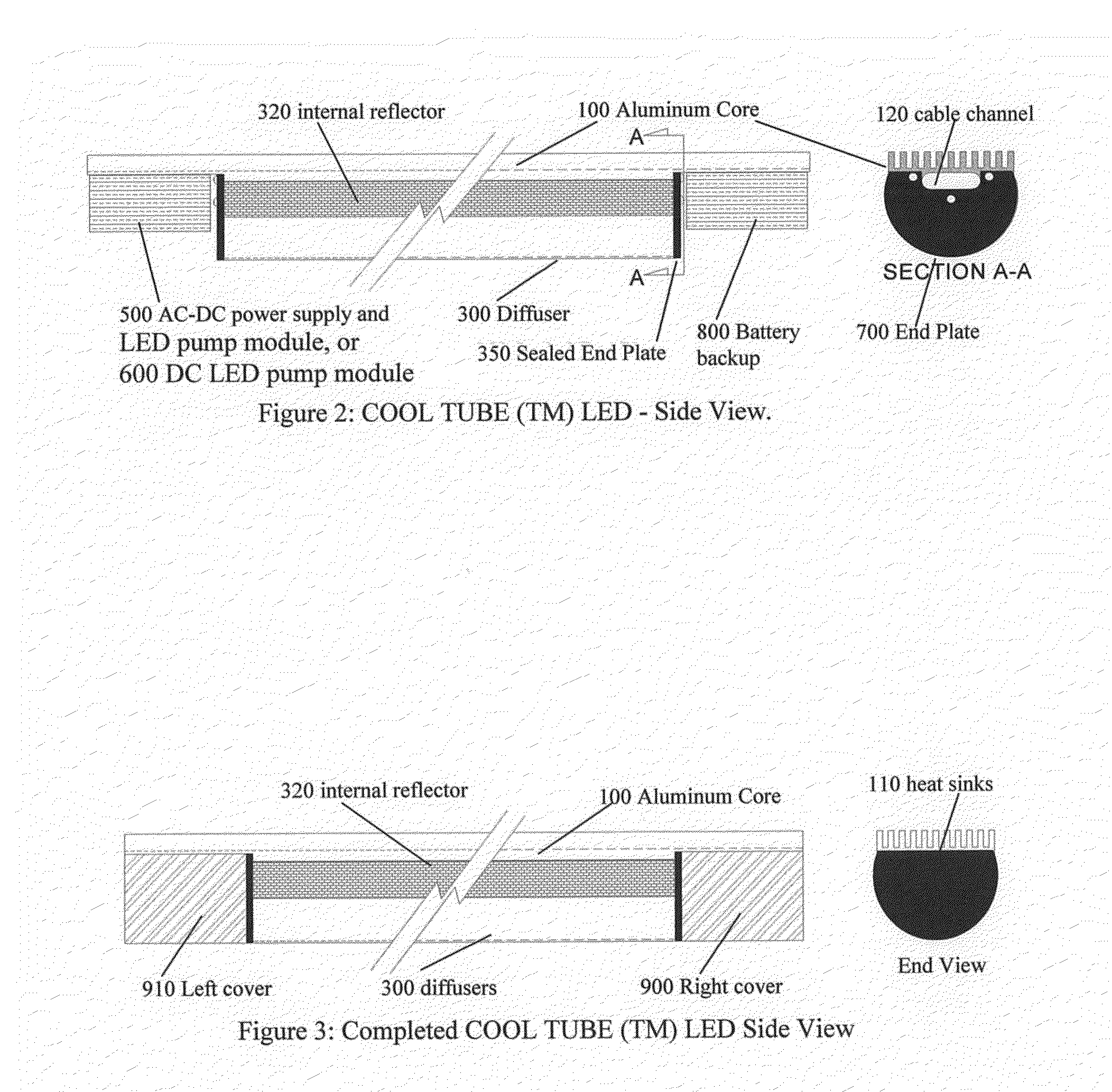

Cool tube (TM) LED lighting

InactiveUS20130335944A1Reduce installation costsImprove usabilityLighting support devicesElongate light sourcesEngineeringLinear array

Provided is a brilliant Humiliation light fixture using high efficiency white LEDs in a strip design that can replace many conventional single or multiple tube fluorescent lighting fixtures. This LED lighting fixture provides benefits in lower installation cost, lower cost of ownership, lower room heating, higher illumination availability, higher efficiency, elimination of faculae, flexibility in re-layout lighting and avoidance of hazard waste. The lighting fixture are not to be confused with “LED fluorescent tubes” which is a name common in the industry to describe a fluorescence tube shape containing a linear array of LEDs that is designed to replace individual fluorescent tubes.

Owner:DOBIN ANDREA

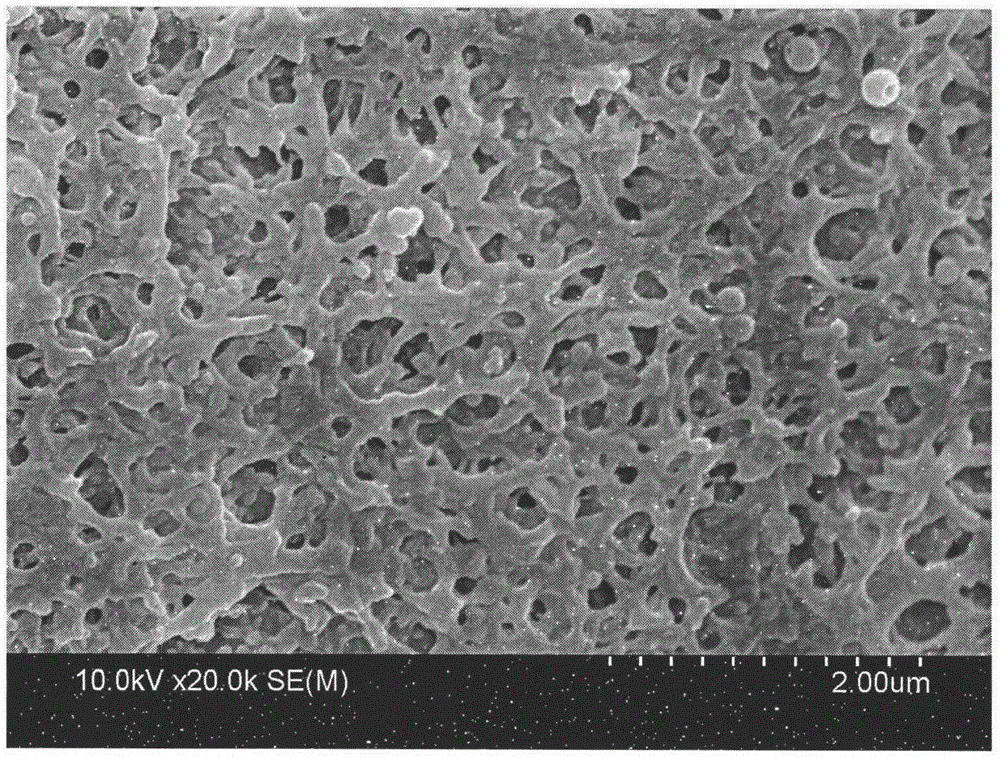

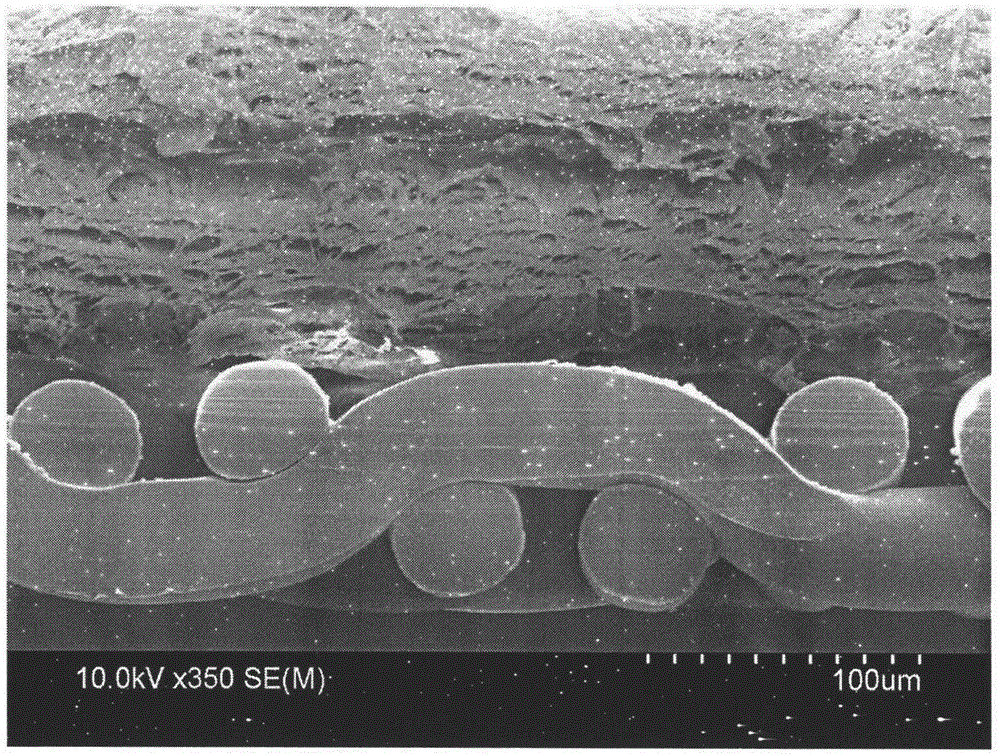

Novel preparation method of high-performance composite film

InactiveCN105233704AEmission reductionReduce harm to the environmentSemi-permeable membranesPropellerHigh intensity

The present invention provides a novel preparation method of a high-performance and high-strength composite film. The preparation method comprises: a) dissolving an organic polymer film preparing material in an organic solvent to obtain a homogeneous solution, adding a certain amount of an additive, uniformly mixing, and carrying out standing deaeration to obtain a film casting solution; and 2) placing the film casting solution in a constant pressure propeller, and spraying the film casting solution on a nonwoven fabric fixed on the surface of a rotation roller in a spray-coating manner by using a solution injection method while rotating the rotation roller, wherein the lower half portion of the rotation roller is immersed in the coagulation bath, and the constant pressure propeller speed, the injection distance, the rotation roller speed, the material feeding temperature, the atomizing pressure, and the air flow rate parameter are controlled to control the pore size and the distribution of the film so as to obtain the high-performance and high-strength fiber composite film. According to the present invention, the method has characteristics of simple preparation process, easy operation, low equipment requirements, energy saving and low cost, and is suitable for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

Method of preparing hierarchical pore ceramsite from red mud and coal ash

PendingCN109942274ALarge specific surface areaImprove removal efficiencyCeramic materials productionCeramicwareRed mudIon exchange

The invention discloses a method of preparing hierarchical pore ceramsite from red mud and coal ash and belongs to the technical field of solid waste reclamation and environment. The method comprisesthe following steps: uniformly mixing the coal ash, the red mud and agriculture and forestry waste residues, and adding water and uniformly stirring the mixture to obtain mixed mud B; granulating themixed mud B to obtain a ceramsite blank sample C; putting the ceramsite blank sample C at 90-120 DEG C to be treated for 60-180 min and then putting the ceramsite blank sample at 350-450 DEG C to be treated for 30-60 min at a constant temperature to obtain pre-ceramsite; putting the pre-ceramsite at 950-1150 DEG C to be roasted for 20-70 min and then carrying out furnace cooling to obtain hierarchical pore ceramsite D; and adding the hierarchical pore ceramsite D into an alkaline solution, then adding sodium metaaluminate to be uniformly mixed to obtain a ceramsite treatment system, heating the same at a uniform speed till the temperature of the ceramsite treatment system is 80-140 DEG C and treating the same for 6-24 hours, extracting the ceramsite, washing the same to be neutral and drying the ceramsite to obtain the hierarchical pore ceramsite. The hierarchical pore ceramsite has two duct structures: macropores and micropores and has good water absorption, water retaining property and ion exchange function.

Owner:KUNMING UNIV OF SCI & TECH

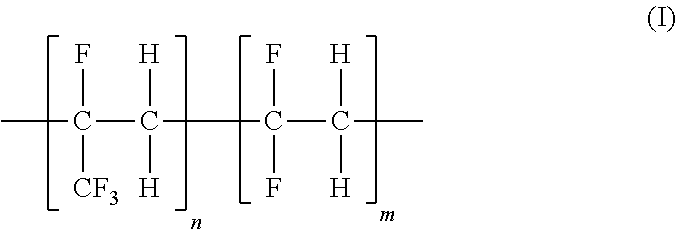

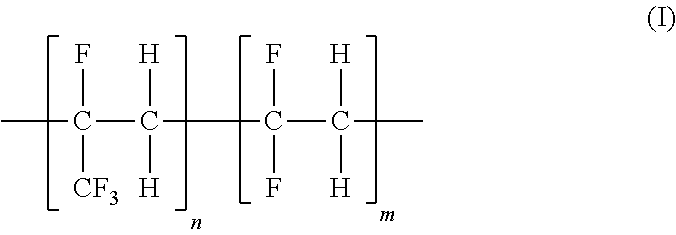

Blend polymeric membranes containing fluorinated ethylene-propylene polymers for gas separations

InactiveUS20140138317A1Low toxicityReduce corrosionSemi-permeable membranesGas treatmentPolymer scienceFluoride

The present invention generally relates to gas separation membranes and, in particular, to high selectivity fluorinated ethylene-propylene polymer-comprising polymeric blend membranes for gas separations. The polymeric blend membrane comprises a fluorinated ethylene-propylene polymer and a second polymer different from the fluorinated ethylene-propylene polymer. The fluorinated ethylene-propylene polymers in the current invention are copolymers comprising 10 to 99 mol % 2,3,3,3-tetrafluoropropene-based structural units and 1 to 90 mol % vinylidene fluoride-based structural units. The second polymer different from the fluorinated ethylene-propylene polymer is selected from a low cost, easily processable glassy polymer.

Owner:UOP LLC

Production method for preparing high-efficiency fluorine removal agent by using waste hydrochloric acid and aluminum-containing sludge and application

ActiveCN103833116AReduce waste dischargeReduce harm to the environmentWater/sewage treatment by flocculation/precipitationIndustrial wasteChemistry

The invention relates to a production method of a liquid fluorine removal agent, and particularly relates to a novel method for preparing high-efficiency fluorine removal agent by using waste hydrochloric acid and aluminum-containing sludge, belonging to the technical field of environment chemical engineering and wastewater treatment. The production method is characterized by comprising the steps: by using an industrial byproduct of the waste hydrochloric acid, calcium carbonate and an aluminum product industry of the aluminum-containing sludge as main raw materials, reacting according to a certain ration, adjusting pH by using calcium hydroxide, and polymerizing at a normal pressure after adding a stabilizing agent to obtain a colorless to faint yellow liquid. According to the production method, a production waste is treated in a hazard-free manner and is recycled, and is changed into valuable; zero emission is achieved in a production process, and the obtained product is stable in quality; the production method is simple in equipment, low in production cost and easy to popularize; through production testing, the production cost can be effectively lowered, so that the industrial waste acid and aluminum-containing solid waste are comprehensively utilized, and the economic and social benefits are remarkable.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

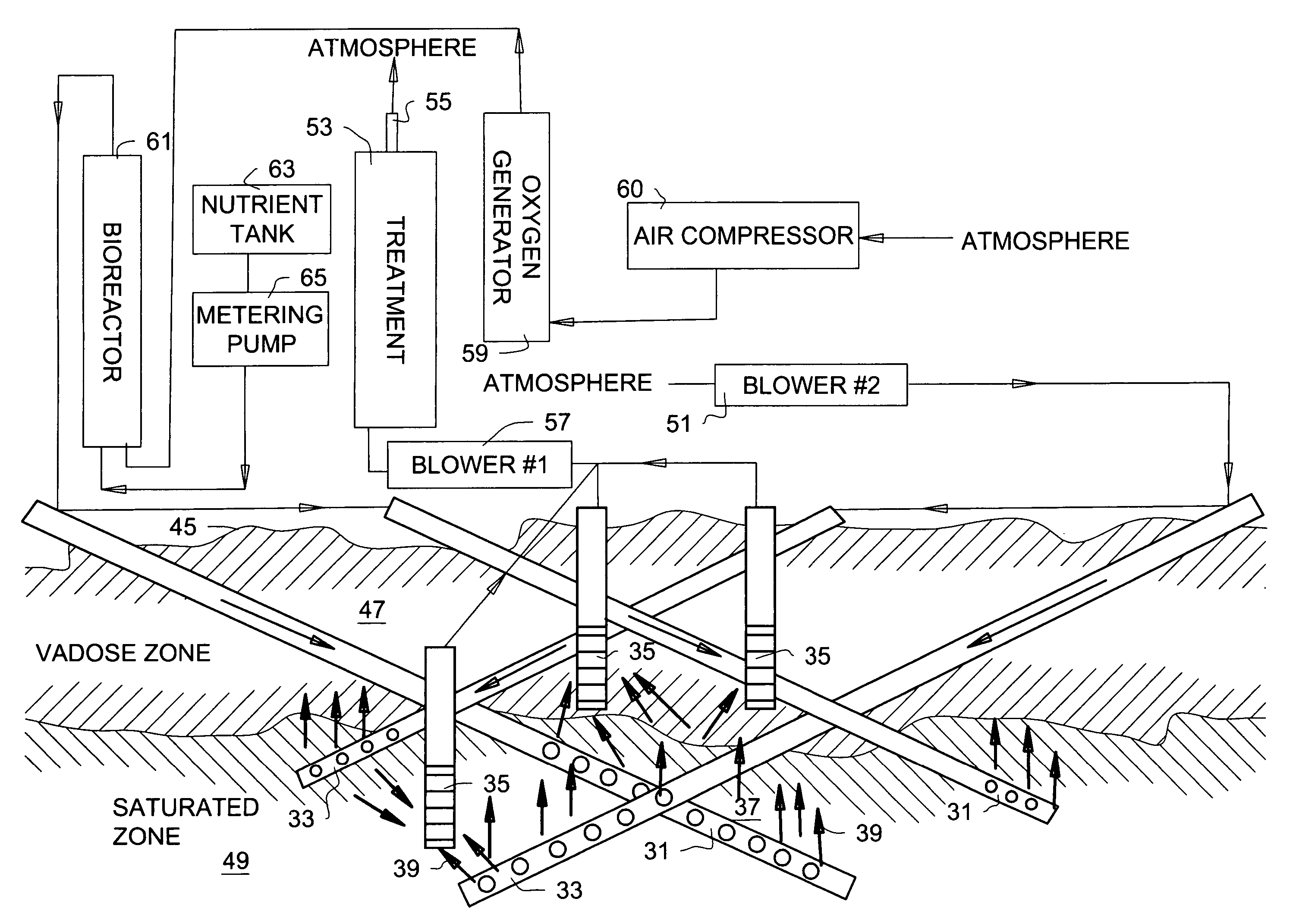

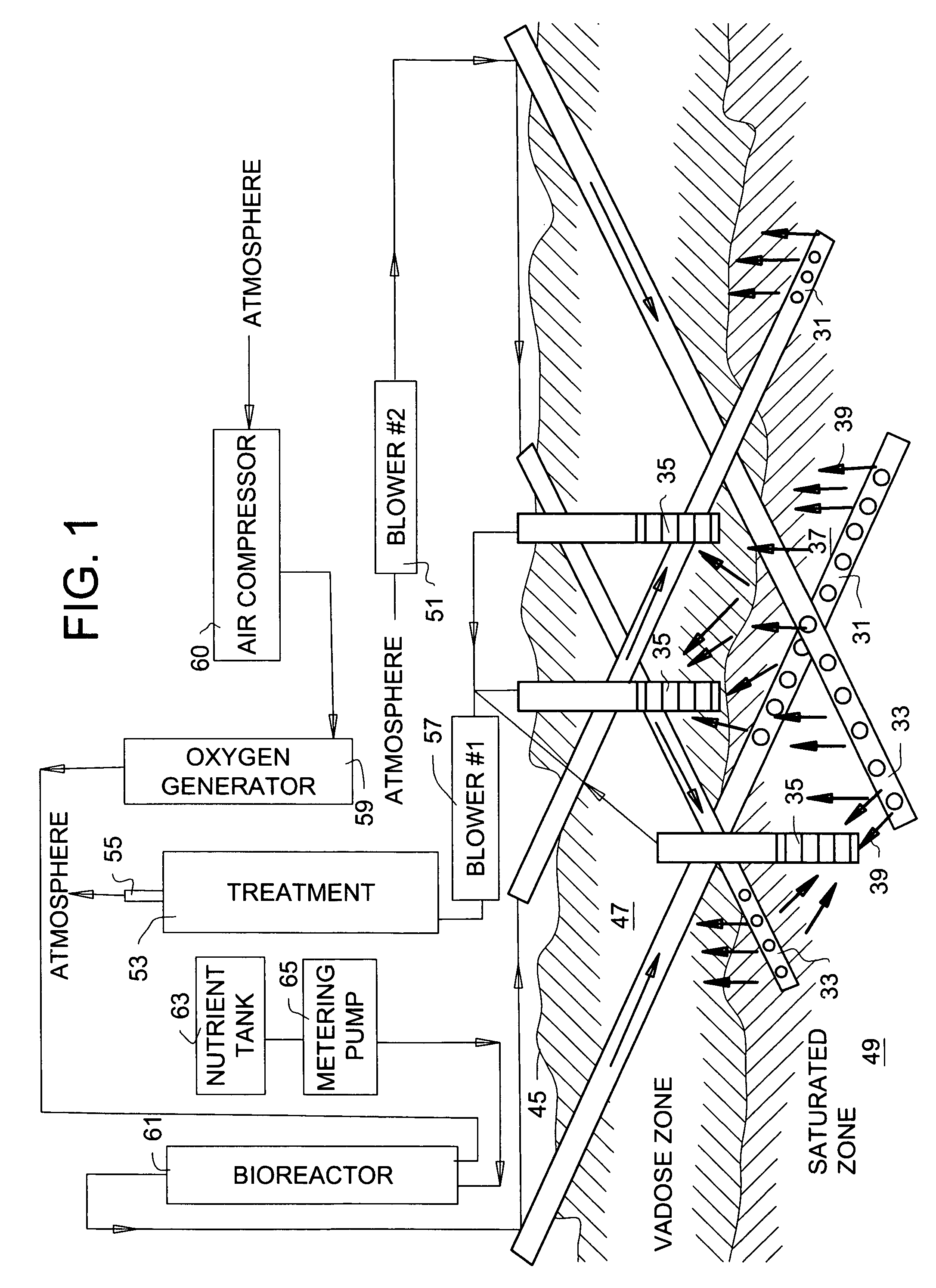

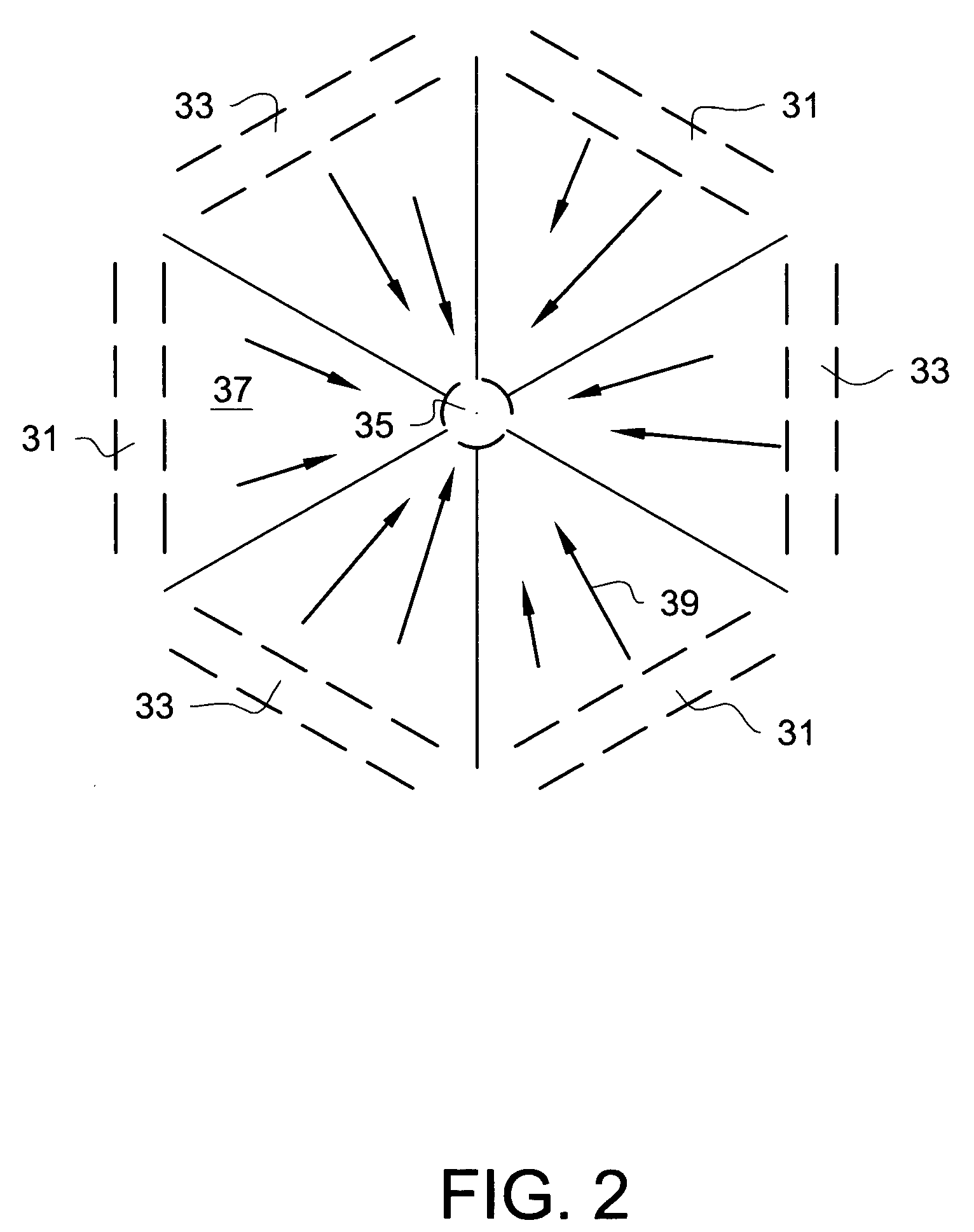

System and method for decontamination of contaminated soil in the vadose zone and/or groundwater

InactiveUS20050276662A1Increase productionIncrease ratingsTreatment using aerobic processesContaminated soil reclamationSoil gasFiltration

A system and method for the accelerated decontamination of contaminated soil, vadose zone and / or groundwater is described. Contaminates are removed from soil and from the groundwater via heat injection through trenching or directionally drilled or horizontally drilled and installed delivery plumbing, pure oxygen injection through separate plumbing installed in the same manner as the plumbing used to deliver the heat, bioventing, sparging, and bioremediation, all through the oxygen delivery plumbing, and soil vapor extraction through vertical wells, all contained in one mobile treatment system. Contaminants are separated from the soil gas via filtration or oxidation. Residual contaminants in the vadose zone and / or the in the groundwater are subjected to volatilization by increased temperature via heat injection and / or oxidation via contaminant degrading microorganisms.

Owner:SMITH KEITH L

Agricultural Pesticide Formulation

ActiveUS20140274693A1Improve stabilityLow toxicityBiocideOrganic active ingredientsAgricultural pesticidesPesticide formulation

The present invention provides a stable aqueous pesticide bifenthrin formulation having reduced toxicity and liquid fertilizer compatibility.

Owner:UNITED PHOSPHORUS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com