Boron removal method and device through activated slag agent

A technology of slag agent and lifting device, which is applied in the direction of chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of difficult degradation of waste slag, pollution of surrounding soil and water sources, and unfriendly environment, so as to reduce waste slag discharge and meet industrialization requirements. Production needs, the effect of improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Weigh 100kg of industrial silicon; the boron concentration is about 22ppmw;

[0041] 2) Weigh CaO and SiO according to the mass ratio of 1:3:1 2 , CaCl 2 , with a total mass of 20kg;

[0042] 3) Put the industrial silicon into the graphite crucible, evacuate, when the vacuum reaches 600Pa, turn on the induction power supply to heat, the temperature rises to 1500°C, heat for 30min, and the silicon block melts;

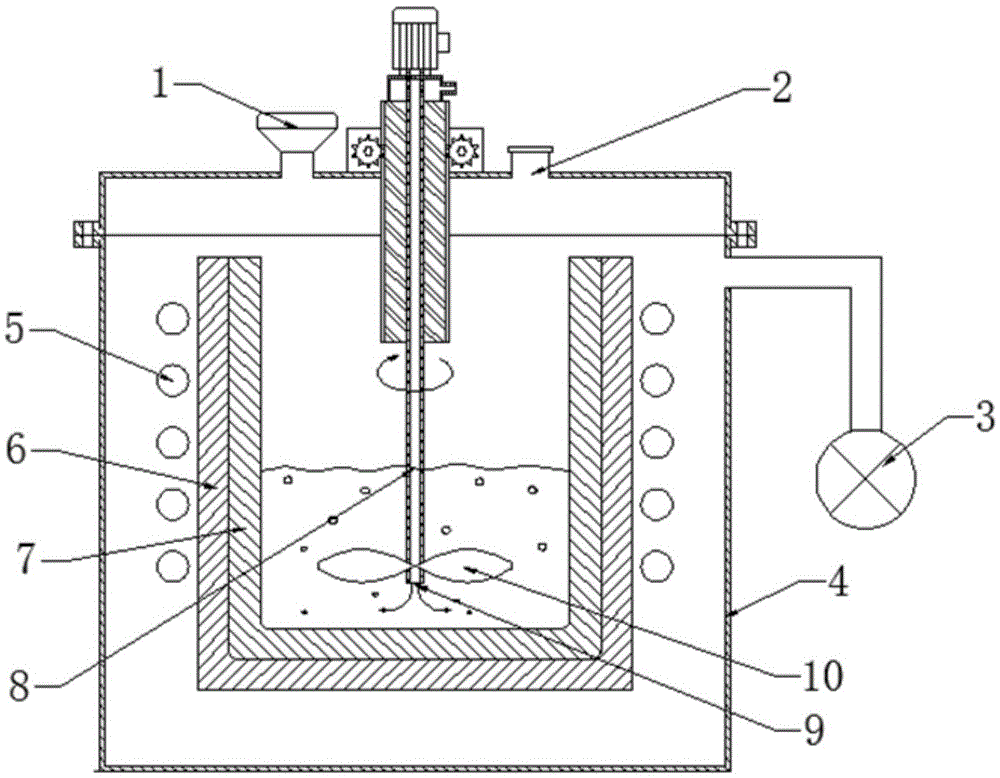

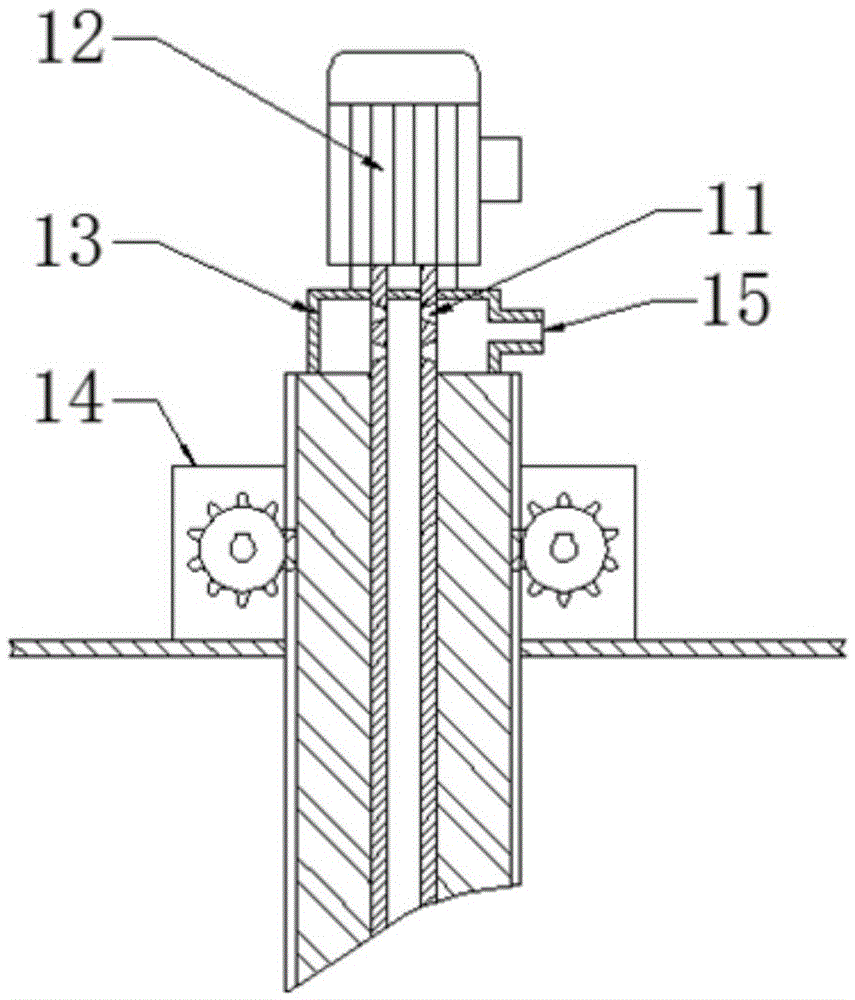

[0043] 4) Pass in inert gas, increase the temperature to 1600°C, add slag agent, start the vertical elevator to lower the agitator, and ventilate while stirring;

[0044] 5) After 45 minutes, stop stirring and ventilating, open the feed port, and put in 4kg of CaCl 2 , close the feed port, vacuumize, and when the vacuum reaches 600Pa, continue to stir and ventilate;

[0045] 6) The stirring rate in the whole process is 150r / min, and the ventilation rate is 35L / min during stirring;

[0046] 7) After 45 minutes, stop stirring and ventilation. After the slag...

Embodiment 2

[0048] 1) Weigh 100kg of industrial silicon; the boron concentration is about 22ppmw;

[0049] 2) Weigh CaO and SiO according to the mass ratio of 1:3:1 2 , CaCl 2 , with a total mass of 20kg;

[0050] 3) Put the industrial silicon into the graphite crucible, evacuate, when the vacuum reaches 600Pa, turn on the induction power supply to heat, the temperature rises to 1500°C, heat for 30min, and the silicon block melts;

[0051] 4) Pass in inert gas, increase the temperature to 1700°C, add slag agent, start the vertical elevator to lower the agitator, and ventilate while stirring;

[0052] 5) After 45 minutes, stop stirring and ventilating, open the feed inlet, and put in the active ingredient for the first time, and put in 8kg of CaCl 2 , close the feed port, vacuumize, and when the vacuum reaches 600Pa, continue to stir and ventilate, and ensure that the temperature is above 1600°C during the whole process;

[0053] 6) The stirring rate in the whole process is 150r / min, a...

Embodiment 3

[0056] 1) Weigh 100kg of industrial silicon; the boron concentration is about 22ppmw;

[0057] 2) Weigh CaO and SiO according to the mass ratio of 1:3:1 2 , CaCl 2 , with a total mass of 20kg;

[0058] 3) Put the industrial silicon into the graphite crucible, evacuate, when the vacuum reaches 600Pa, turn on the induction power supply to heat, the temperature rises to 1500°C, heat for 30min, and the silicon block melts;

[0059] 4) Pass in inert gas, increase the temperature to 1600°C, add slag agent, start the vertical elevator to lower the agitator, and ventilate while stirring;

[0060] 5) Stop stirring and ventilating after 45min, open the feed inlet, put in the active ingredient for the first time, and put in 4kg of CaCl 2 , close the feed port, vacuumize, and when the vacuum reaches 600Pa, continue to stir and ventilate, and ensure that the temperature is above 1600°C during the whole process;

[0061] 6) After 45 minutes, stop stirring and ventilate, open the feed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com