Patents

Literature

38results about How to "Meet content requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for enteric plant cellulose hard hollow capsules

ActiveCN103330695AGuaranteed functionKeep dryPharmaceutical non-active ingredientsCapsule deliveryFiber derivativeFiber

The invention provides a preparation method for hard hollow capsules from enteric plant cellulose derivatives and belongs to the technical field of pharmaceutic adjuvants. Plant cellulose is prepared from plant derivatives such as pine, purified cotton and the like. Colorless and transparent hard hollow capsules, colored hard hollow capsules, shading hard hollow capsules and the like can be prepared though the preparation method. The preparation method comprises steps of mixing of plant cellulose, surfactants, coagulant aids, coloring agents and water, molding, drying, coating and the like. The plant cellulose hard hollow capsules are advantaged by stable performances, low water content, environmental protection and safety. The plant cellulose hard hollow capsules can be filled by all kinds of contents.

Owner:SHAOXING KANGKE CAPSULE

Method for producing solar grade polycrystalline silicon by molten salt electrolysis and directional solidification combination technique

InactiveCN103774216AOvercoming the Difficulty in Removing Impurity Boron from SiliconSimple processPolycrystalline material growthSingle crystal growth detailsElectrolysisSilicon alloy

The invention relates to a method for producing solar grade polycrystalline silicon by molten salt electrolysis and directional solidification combination technique. The method is characterized by adopting the following processing steps: (1) preparing an aluminium-silicon alloy through eutectoid molten salt electrolysis; (2) separating aluminium from silicon through directional solidification; and (3) carrying out vacuum distillation and directional solidification on high-purity silicon. The phosphorus content of high-purity polycrystalline silicon obtained by the method is reduced to 0.08*10<-6>, the boron content is less than 0.1*10<-6> and the purity is more than 99.99995%, thus meeting the impurity content requirements (less than 0.5*10<-6>) of solar grade silicon.

Owner:INNER MONGOLIA TECHNICAL COLLEGE OF MECHANICS & ELECTRICS

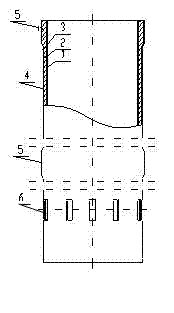

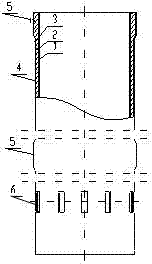

Glass fiber reinforced plastic flue gas jetting pipe used in desulphurization technology, and manufacturing method thereof

The invention discloses a glass fiber reinforced plastic flue gas jetting pipe used in a desulphurization technology. The glass fiber reinforced plastic flue gas jetting pipe comprises components of, from the inner side to the outer side: an inner antiseptic layer, a resin-rich structural layer, and an outer antiseptic layer. The inner antiseptic layer comprises a glass fiber surface felt layer and a glass fiber chopped strand felt layer manufactured from pasted oxirene-based resin. Oxirene-based resin takes 70-80wt% of the inner antiseptic layer. According to the weight of oxirene-based resin, 1-10% of silicon carbide and 1-2% of conductive carbon powder are mixed in oxirene-based resin. The resin-rich structural layer comprises normal thickness sections and thickened sections arranged along an axial direction of the jetting pipe. The thickened sections are arranged at connection positions between the glass fiber reinforced plastic flue gas jetting pipe and a separating plate, and between the glass fiber reinforced plastic flue gas jetting pipe and a grate. The resin-rich structural layer comprises alternately paved glass fiber check cloth layers and glass fiber chopped strand felt layers. The surfaces of the glass fiber check cloth layers and glass fiber chopped strand felt layers are pasted by using oxirene-based resin. Oxirene-based resin takes 55-70wt% of the resin-rich structural layer. Correspondingly, the invention provides a manufacturing method of the glass fiber reinforced plastic flue gas jetting pipe used in the desulphurization technology.

Owner:BAOSHAN IRON & STEEL CO LTD +1

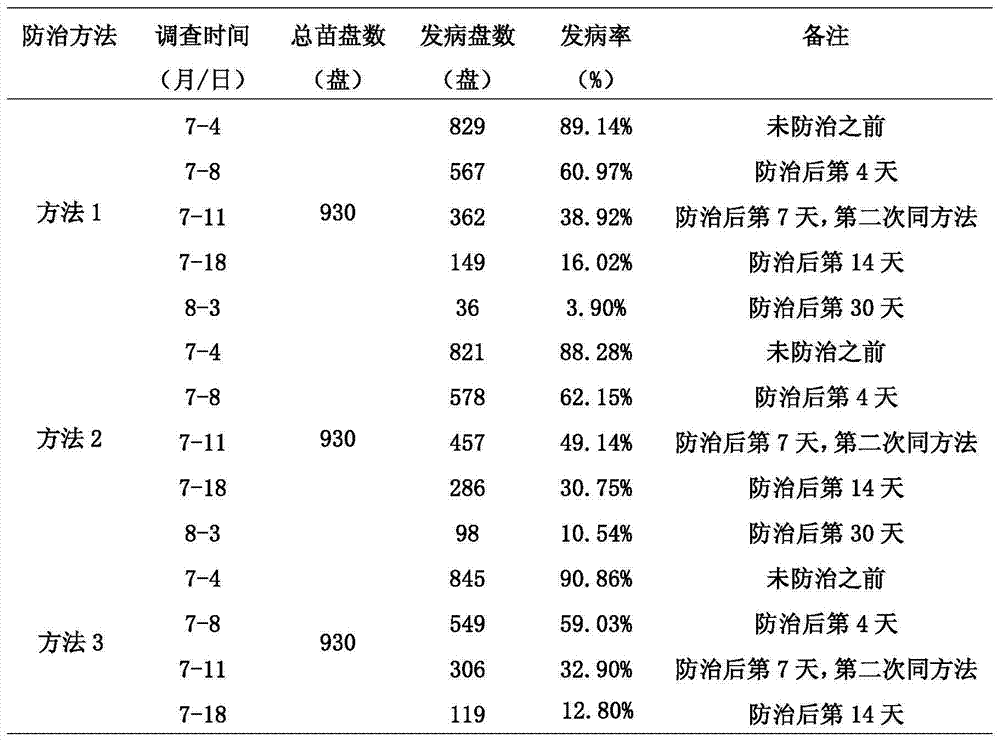

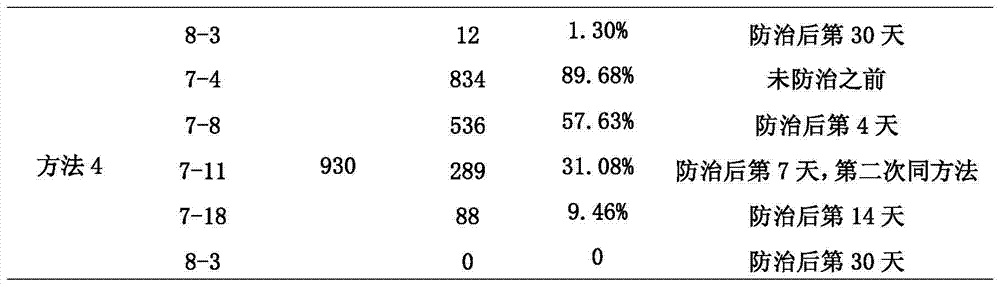

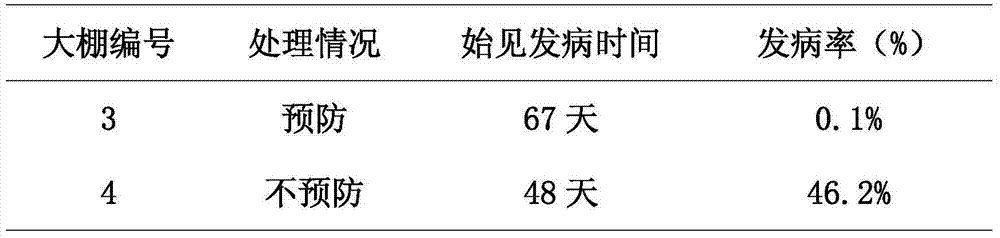

Saxifraga-stolonifera-meerb greenhouse-planting pest control method

ActiveCN104719049AQuality improvementImprove qualityPlant protectionChemicalsGreenhouseDisease damage

The invention discloses a saxifraga-stolonifera-meerb greenhouse-planting pest control method. The saxifraga-stolonifera-meerb greenhouse-planting pest control method includes the following steps: 1, carrying out matrix sterilizing; 2, sweeping a greenhouse before seedling growing; 3, selecting a disease-resistant variety; 4, using chlorothalonil or mancozeb-myclobutanil for mist spraying after planting is completed; 5, carrying out planting according to the planting spacing 15 cm*20 cm in each seedling disc, and carrying out ventilation in the greenhouse; 6, timely removing branches and leaves affected by diseases, thoroughly removing withered and rotted leaves, and cutting off disease and pest branches and disease and pest leaves; 7, after harvesting is carried out, timely removing stubbles, old leaves and weeds in the seedling discs. By means of the saxifraga-stolonifera-meerb greenhouse-planting pest control method, pest and disease damage during saxifraga-stolonifera-meerb planting can be effectively prevented, the attack rate can be reduced, the disease time can be set back, and the disease period can be shortened; when the pest and disease damage occurs, effective treatment and effective killing can be carried out; by means of the saxifraga-stolonifera-meerb greenhouse-planting pest control method, under the normal year condition, the yield of fresh semiannual saxifraga-stolonifera-meerb medicinal materials can be 1800 kg per mu, and the yield of dry semiannual saxifraga-stolonifera-meerb medicinal materials can be 180 kg per mu.

Owner:GUIZHOU BAILING GRP PARMACEUTIAL CO LTD

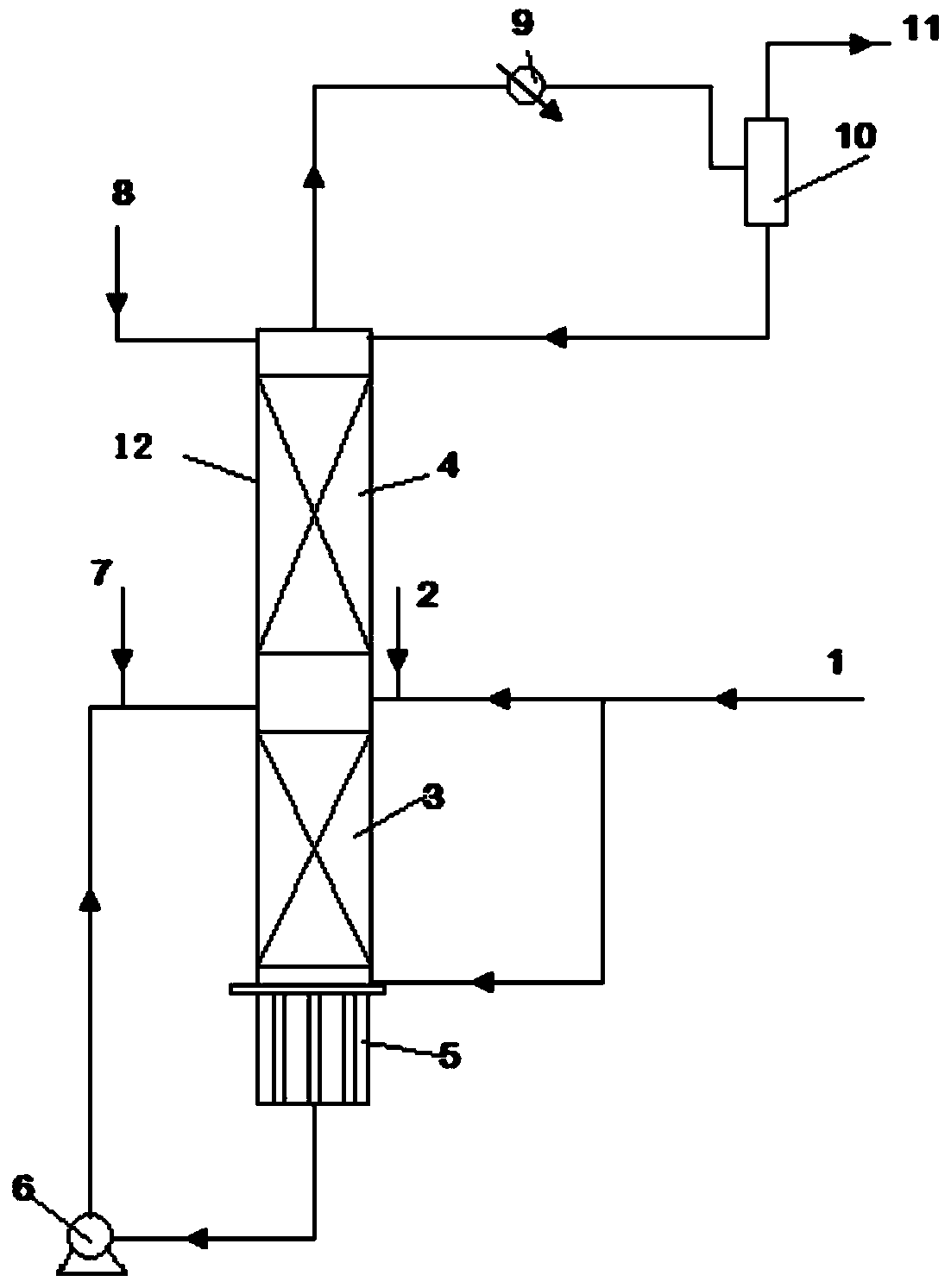

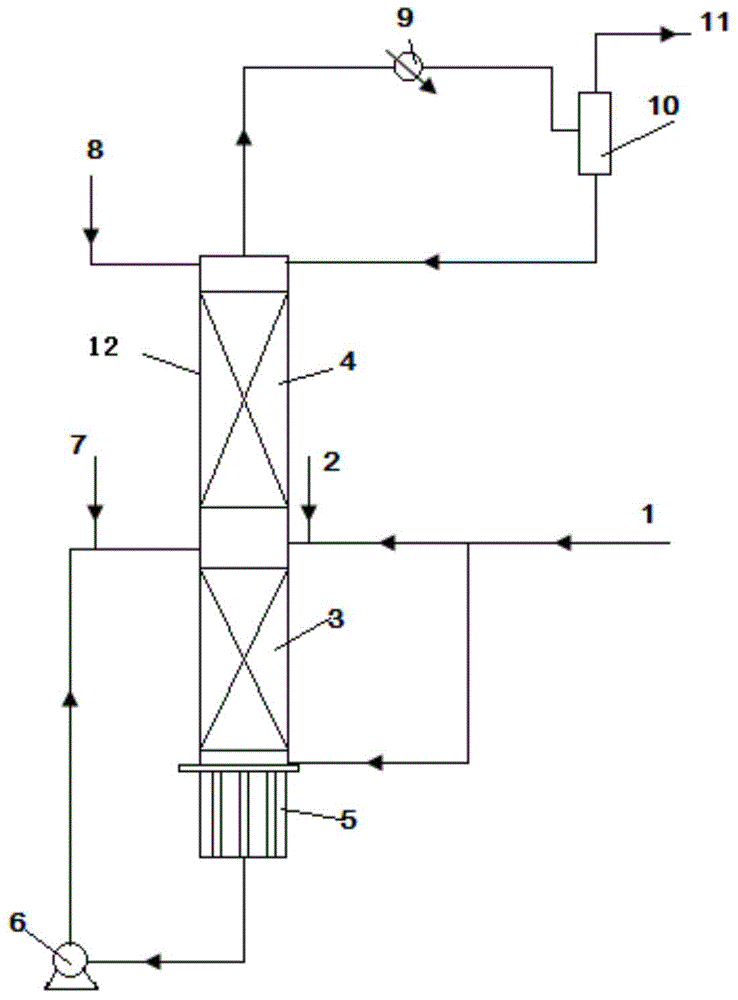

Methyl nitrite regeneration method

ActiveCN103936591AHigh regeneration rateFull recoveryChemical recyclingNitrous acid preparation ester preparationAlcoholReboiler

The invention discloses a methyl nitrite regeneration method, and is used for solving the problems of low regeneration rate of methyl nitrite, poor operational stability of a system caused by improper side reaction control, increase of operating cost and the like. The methyl nitrite regeneration method comprises the following steps: forming recycled gas containing 5-20% of nitric oxide after synthesis of methyl nitrite and carbon monoxide carbonyl, and entering the recycled gas to a methyl nitrite regeneration reactor in two parts, wherein a small part of recycled gas enters the lower section of the regeneration reactor from the bottom, the rest part of recycled gas and supplementing oxygen gas enter the upper section of the regeneration reactor from the middle part together; spraying fresh methyl alcohol into the tower top of the regeneration reactor, discharging methyl nitrite-containing gas from the tower top, pressurizing tower bottoms led out from the tower by using a pump and entering the tower bottoms to the lower section of the regeneration reactor from the middle part of the regeneration reactor; arranging a reboiler on the tower of the regeneration reactor, filling the lower section of the regeneration reactor with a catalyst, and arranging stuffing and / or a tower plate on the upper section of the regeneration reactor. The methyl nitrite regeneration method is simple in process, low in equipment investment and operating cost and high in regeneration rate of methyl nitrite and can be used for effectively solving the side reaction problem.

Owner:WUHUAN ENG +2

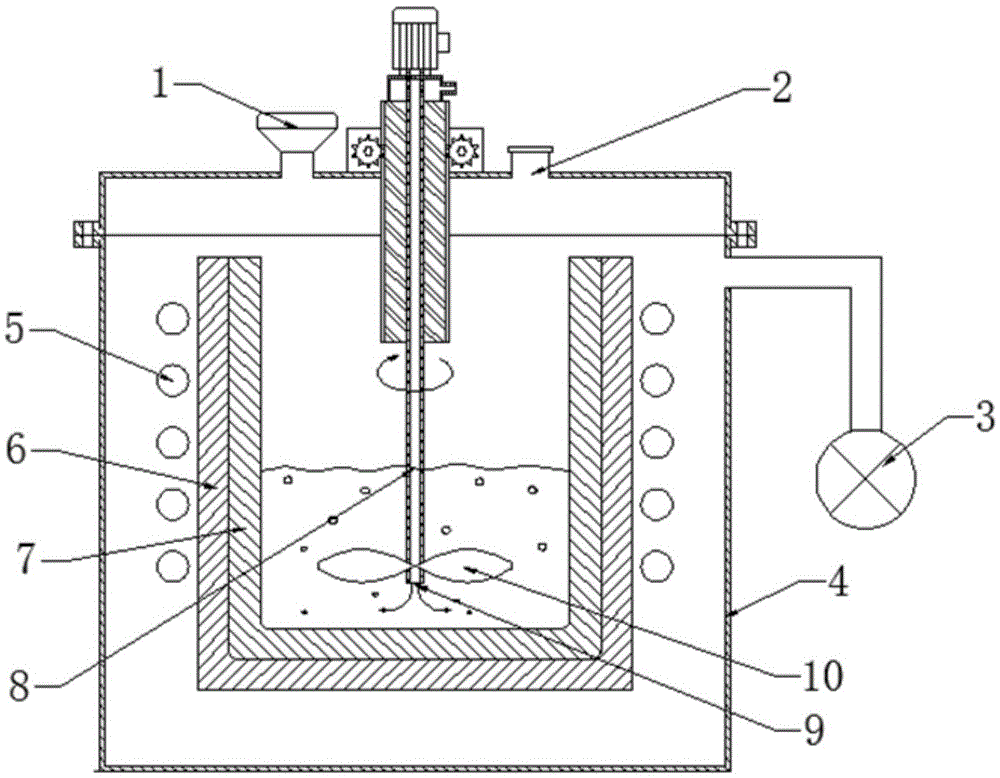

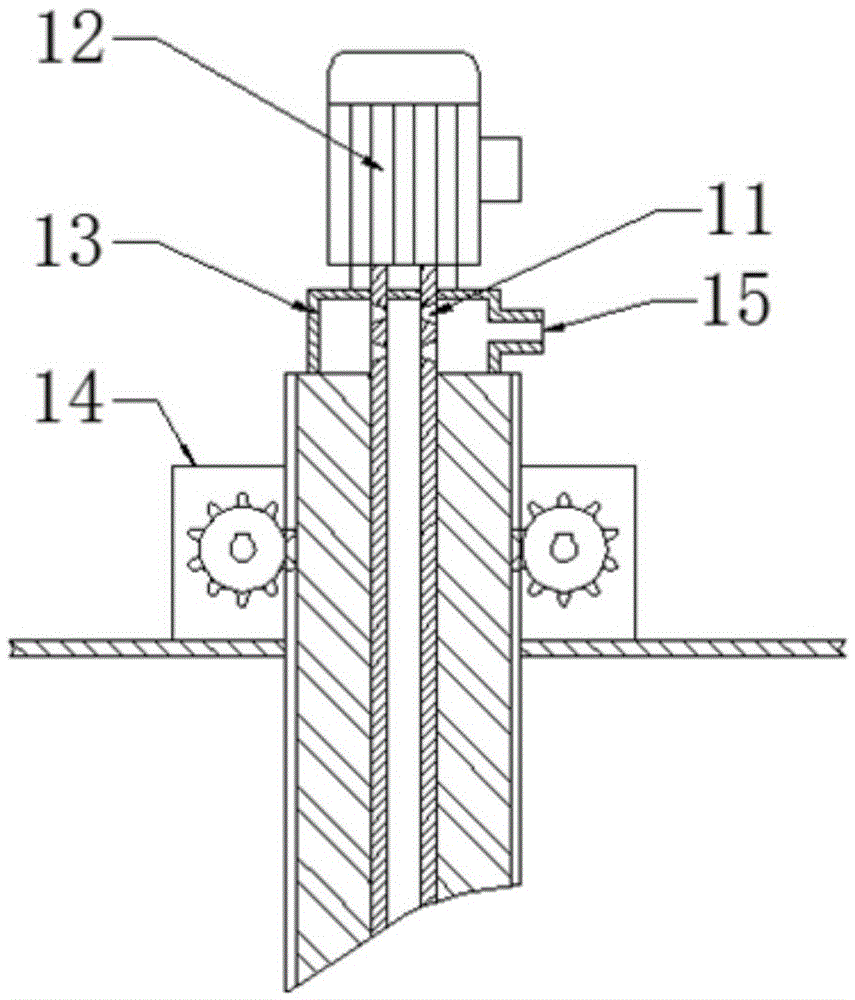

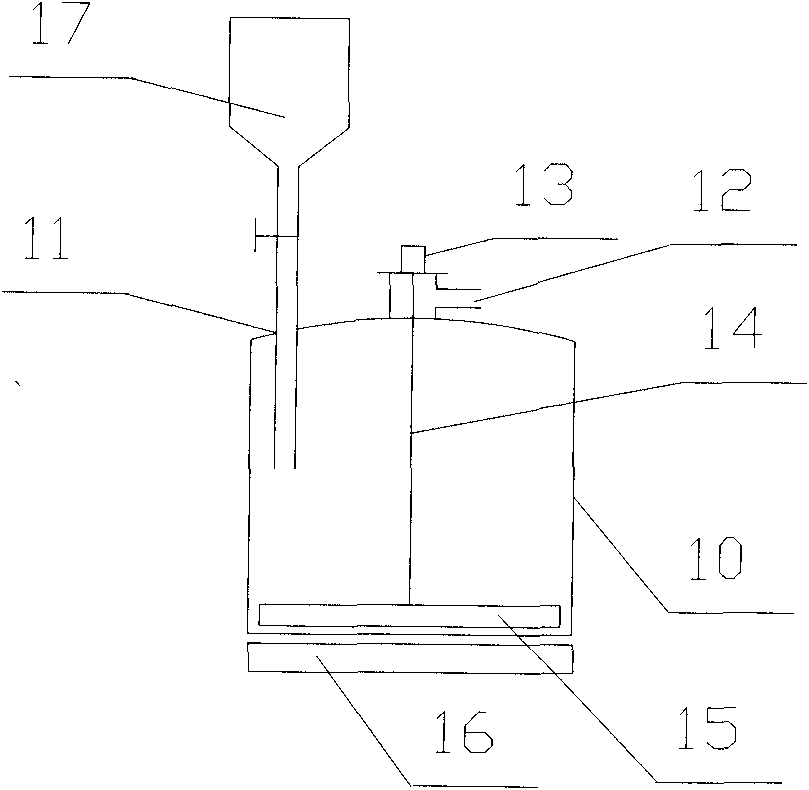

Boron removal method and device through activated slag agent

ActiveCN105540593AReduce the amount of slag agentReduce harm to the environmentSilicon compoundsSlagIntermediate frequency

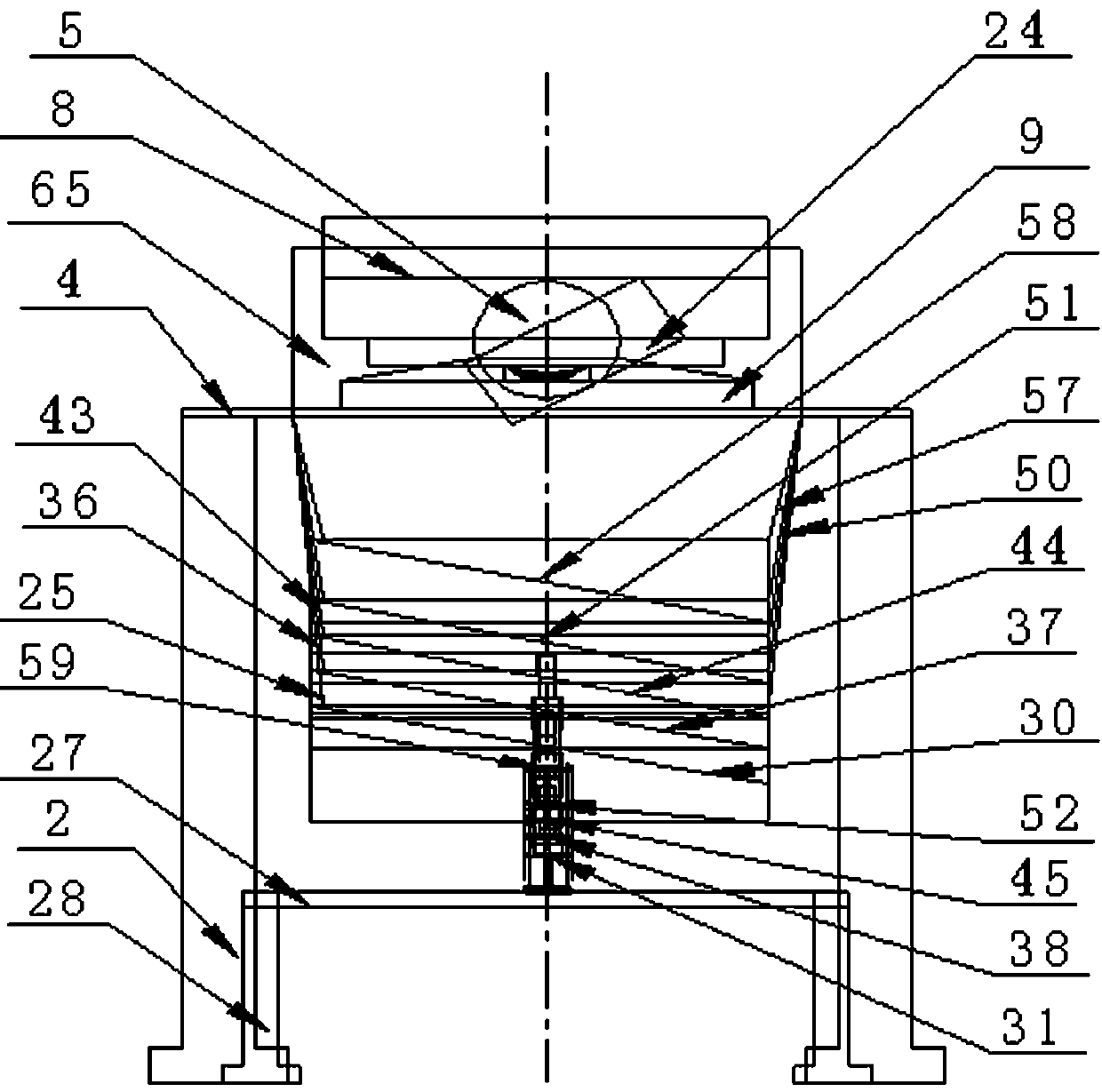

The invention discloses a boron removal method and device through an activated slag agent, and belongs to the fields of semiconductor materials and metallurgy. The device is provided with a lobe pump, a furnace base, a medium-frequency induction coil, an insulating layer, a graphite crucible, a stirrer and a lifting device. The method comprises the steps that raw silicon is put into the graphite crucible from a feed port, the lobe pump is started to perform vacuumizing, a medium-frequency induction power supply is started to perform heating, and when the temperature is increased to 1500 DEG C, silicon blocks are completely molten; inert gas is charged into a furnace cavity to enable the temperature to be kept at 1550 DEG C-1650 DEG C, the slag agent is added, the stirrer is started, and first-time slagging is completed; the power of the medium-frequency induction power supply is increased to enable the temperature in the furnace cavity to reach 1700 DEG C-1800 DEG C, the feed port is opened, active components of the slag agent are put into the furnace cavity for the first time, vacuumizing is performed, the stirrer is started, the inert gas is introduced, and second-time slagging is completed; after slagging is completed, silicon liquid is poured into a receiving crucible, standing and cooling are performed, a silicon ingot is taken out, purified low-boron high-purity silicon is obtained, and then boron removal achieved through the activated slag agent is completed.

Owner:XIAMEN UNIV

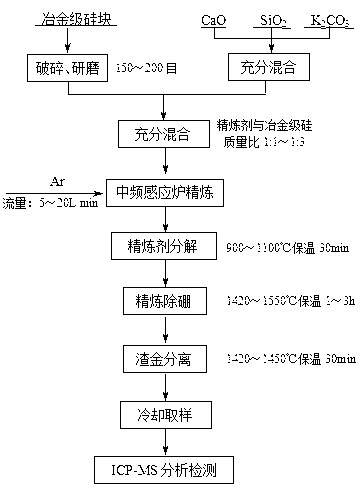

Method for removing impurity boron of metallurgical silicon by high-basicity refining agent

ActiveCN103073001AIncrease alkalinityImprove removal efficiencySilicon compoundsInduction furnaceSilica fume

The invention provides a method for removing impurity boron of metallurgical silicon by a high-basicity refining agent. The method comprises the following steps of: crushing and grinding the metallurgical silicon serving as a raw material; preparing the high-basicity refining agent from CaO, SiO2 and K2CO3 in a certain proportion; fully mixing silicon powder and the refining agent; placing the material in a medium-frequency induction furnace with Ar flow velocity of 5-20L / min, preserving heat at the temperature of 900 DEG C to 1100 DEG C for 30 minutes, then heating the material to 1420 DEG C to 1550 DEG C, preserving heat for 1 hour to 3 hours to remove boron and refine; then preserving heat at the temperature of 1400 DEG C to 1450 DEG C for 30 minutes to ensure that the impurity and the silicon are fully separated; and then cooling the material to obtain the refined silicon, wherein the removal rate of the boron is 97.2 percent. According to the method, the refining agent is obtained by adding high-basicity K2CO3 into CaO-SiO2, the method is more beneficial to removing the impurity boron of the metallurgical silicon, and has the advantages of innovation, good boron removal effect and high practicability, simple equipment, no need of complex blowing or a vacuum system, easiness in operation, simplicity in industrialization popularization and application, and can effectively reduce productive investment.

Owner:KUNMING UNIV OF SCI & TECH

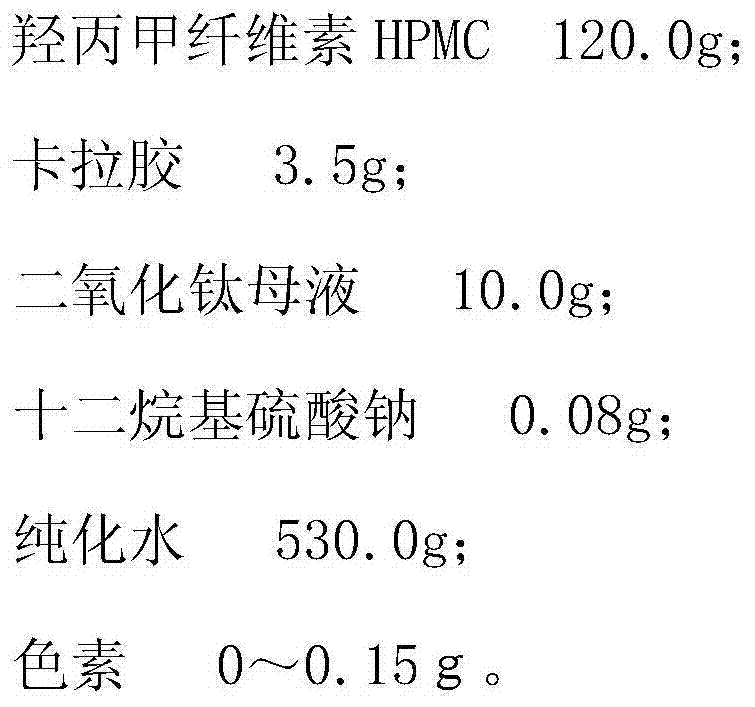

Hydroxypropyl methylcellulose hollow capsule and production process thereof

InactiveCN104324017AGood securityReduce pollutionPharmaceutical non-active ingredientsCapsule deliveryWater contentChemistry

The invention discloses a hydroxypropyl methylcellulose hollow capsule and a production process thereof. The glue solution of the hollow capsule is prepared from the following components: 120.0g of hydroxypropyl methylcellulose HPMC, 3.5g of carrageenan, 10.0g of titanium dioxide mother liquor, 0.08g of lauryl sodium sulfate, 530.0g of pure water and 0-0.15g of pigment. The production process comprises the following steps: preparing the titanium dioxide mother liquor; preparing HPMC sol; adding pigment into the glue solution; dipping glue, baking, demolding, cutting, registering, inspecting, packaging and putting in storage. The preparation process is simple and strong in operability, the capsule product has good molding property, high safety, good reliability and low water content, effectively takes the curative effect of content, is stable in molecule transmission, does not perform crosslinking reaction with the content, is sufficient in solubility, is little impacted by external temperature and humidity, has long preservation period, and is convenient for transporting and storing.

Owner:ZHEJIANG CHUNBAO CAPSULES

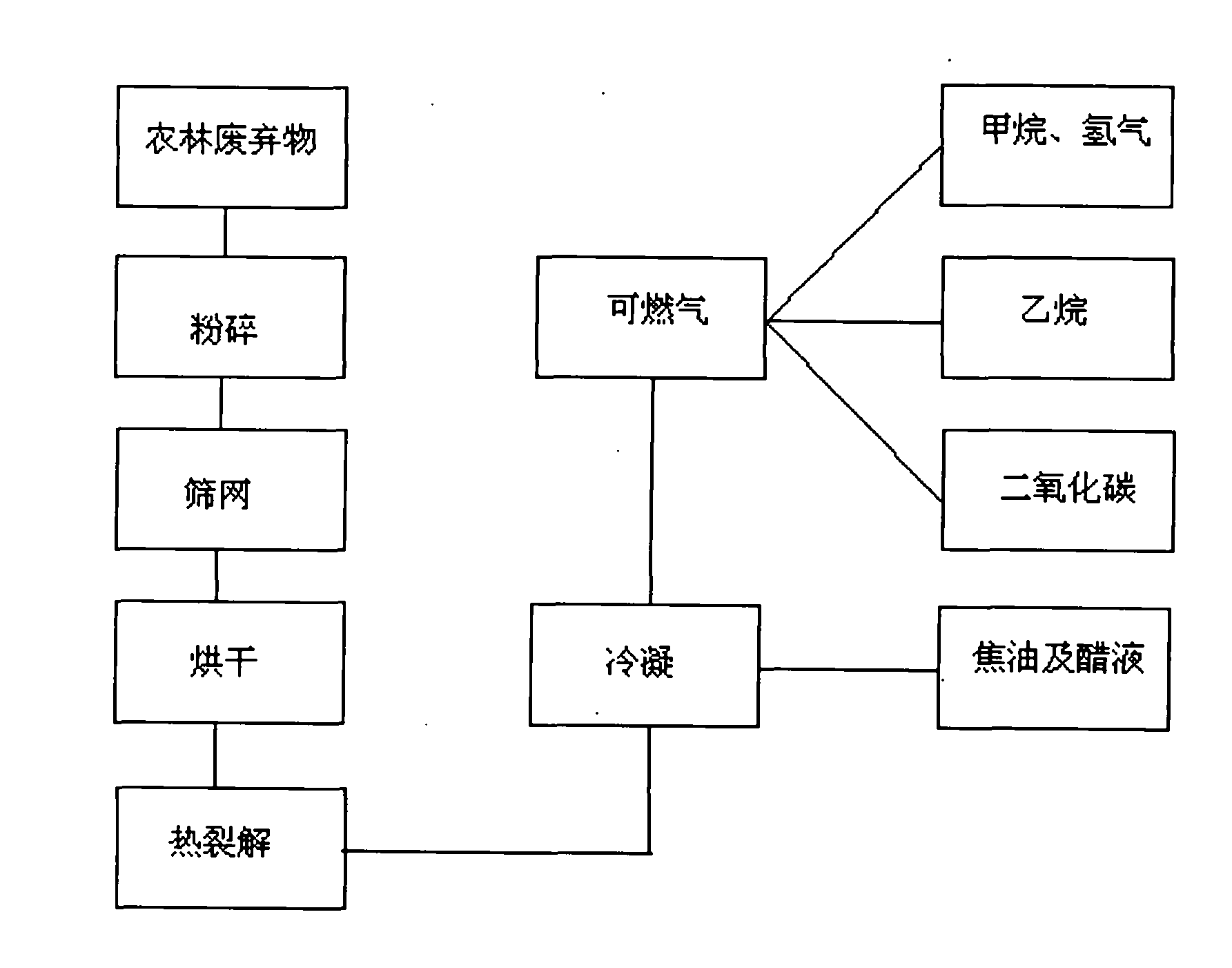

Method for preparing natural gas by biomass material thermal cracking and thermal cracking furnace used by same

InactiveCN101805647AReduced structureMeeting the energy needs of pyrolysisGaseous fuelsBiofuelsAgricultural residueFree state

The invention relates to a method for preparing natural gas by biomass material thermal cracking. The method comprises material smashing, material drying, thermal cracking in an oxygen-free state, cooling and separation and compressing separation steps and the like. The invention also provides a thermal cracking furnace in a thermal cracking process. The structure of the thermal cracking furnace can be simplified by using an oxygen-free thermal cracking environment, and the energy requirement of thermal cracking can be met by only using an electric heater. Compared with the prior art, the method can prepare more natural gas and obtain higher heat value based on the biomass material with the same quality, in particular forestry and agricultural residues.

Owner:倪建辉

Method for sub-critically extracting folium artemisiae argyi essential oil

The invention discloses a method for sub-critically extracting folium artemisiae argyi essential oil. The method comprises the following steps: (1) crushing a folium artemisiae argyi cake, putting into an extraction kettle under a vacuum environment, adding an extraction agent, namely tetrafluoroethane, into the kettle, and extracting for the first time under the conditions that the temperature is 40-60 DEG C and the pressure is 0.8-1Mpa; (2) extracting material residues for the second time in the extraction kettle with 80% ethyl alcohol under the conditions that the temperature is 40-60 DEG C and the pressure is 0.8-1Mpa; and (3) reducing pressure and concentrating the extract liquor acquired in the step (2) under the conditions that the temperature is 40-60 DEG C and the pressure is 0.09-0.095Mpa till the ethanol content is less than 5%, thereby acquiring the folium artemisiae argyi essential oil. The method disclosed by the invention can solve the technical problems of large loss of effective ingredients and low extraction efficiency of the present extraction technique.

Owner:梅跃进 +1

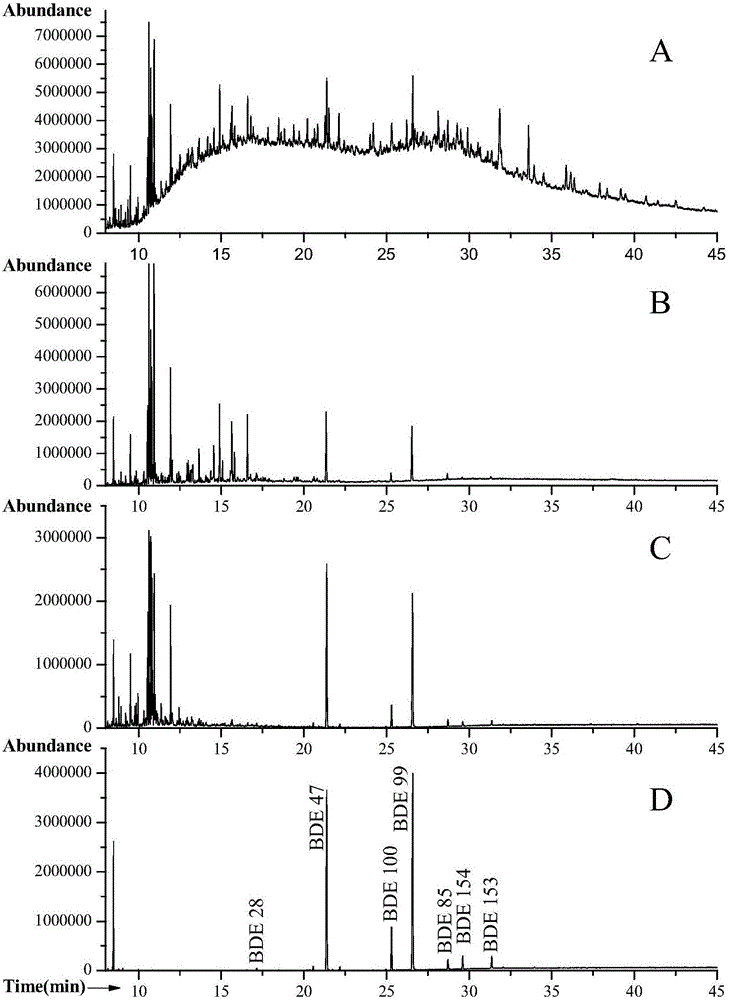

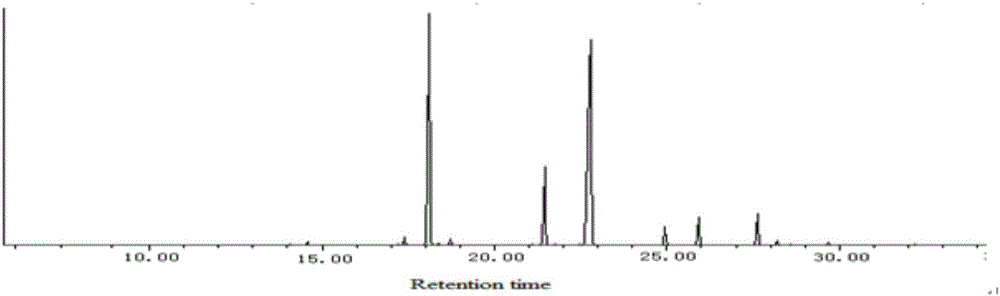

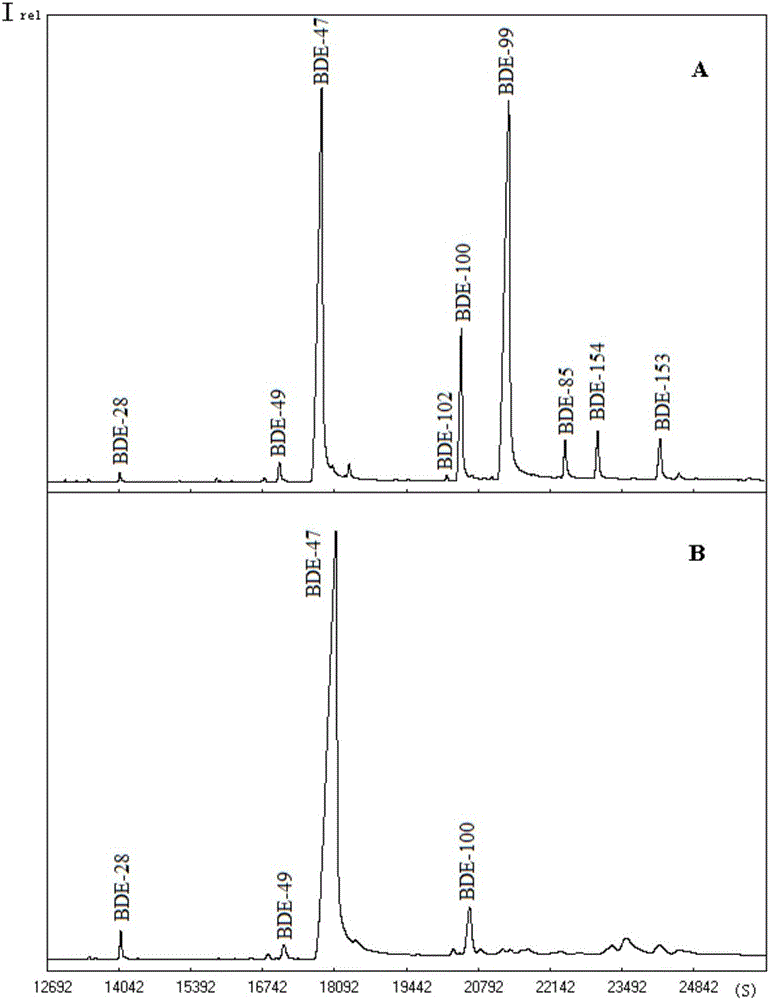

Analysis method of monomer stable carbon isotopes of polybrominated diphenyl ethers (PBDEs) in sediments

InactiveCN106124661AEfficient removalEasy to detect and analyzeComponent separationFreeze-dryingIsotope

The invention relates to an analysis method of monomer stable carbon isotopes of polybrominated diphenyl ethers (PBDEs) in sediments. The analysis method is characterized by comprising the following steps: step one, firstly freezing and drying a sediment sample, grinding the sediment sample and screening the sediment sample via a 200-mesh sieve; step two, placing the sediment sample in a Sohxlet extraction paper tube, and extracting for 48 hours at 60 DEG C via normal hexane / acetone to obtain an extraction solution; step three, purifying the extraction solution via acidic and neutral composite silica gel columns for a first time; step four, purifying the sample via an aluminum oxide composite silica gel column for a second time; step five, purifying the sample via a florisil column for a third time by pre-leaching via 10mL of normal hexane after feeding the sample to remove part of organic matter impurities, and eluting via 20mL of normal hexane to obtain an elution solution containing a target compound; step six, completing quantitative analysis of PBDEs; and step seven, completing analysis of monomer stable carbon isotopes of PBDEs. The analysis method is capable of effectively removing sulfur element impurities and some organic matter impurities in the sediment samples with high sample weight, and obtaining samples with clean matrixes; the method is suitable for analysis and detection of environmental pollutants.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

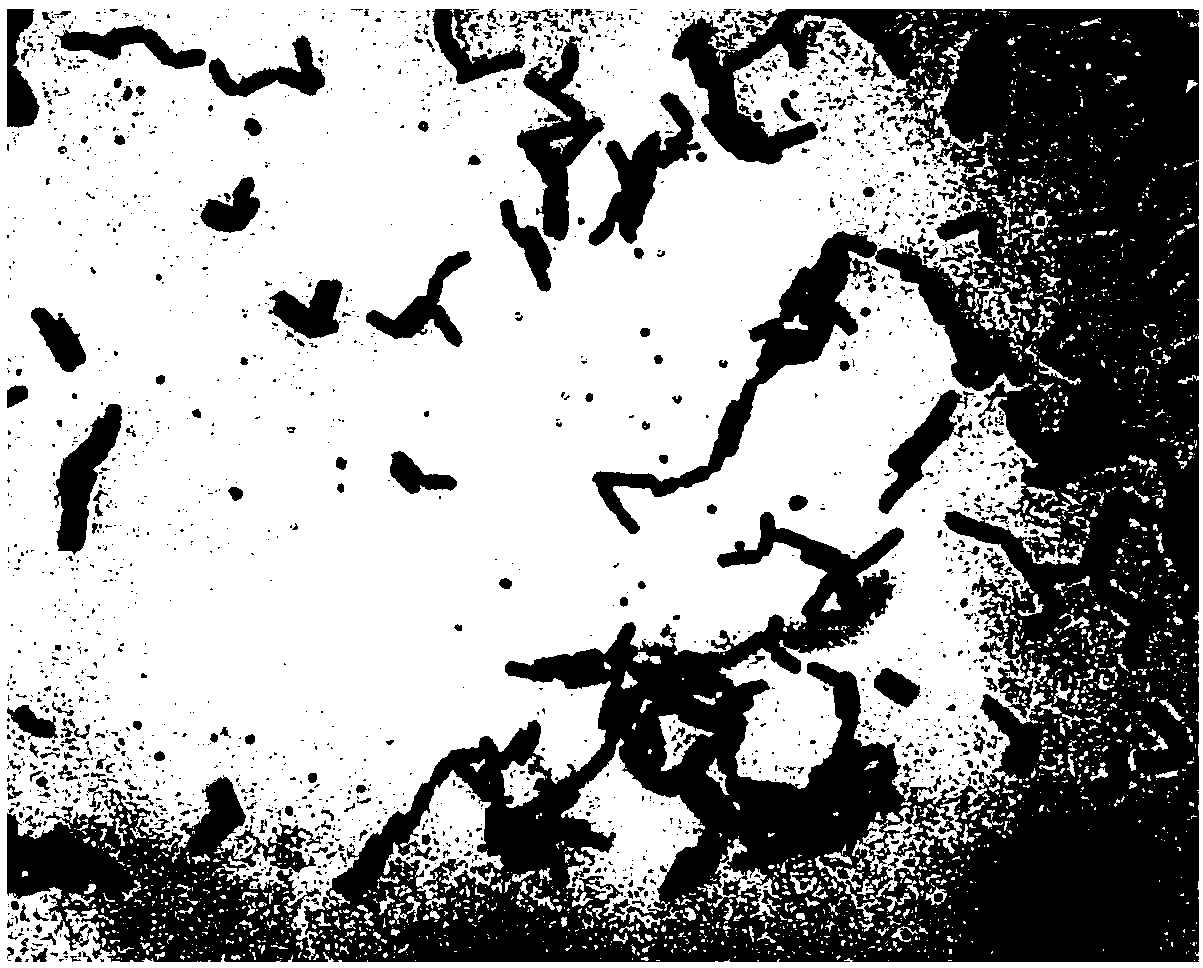

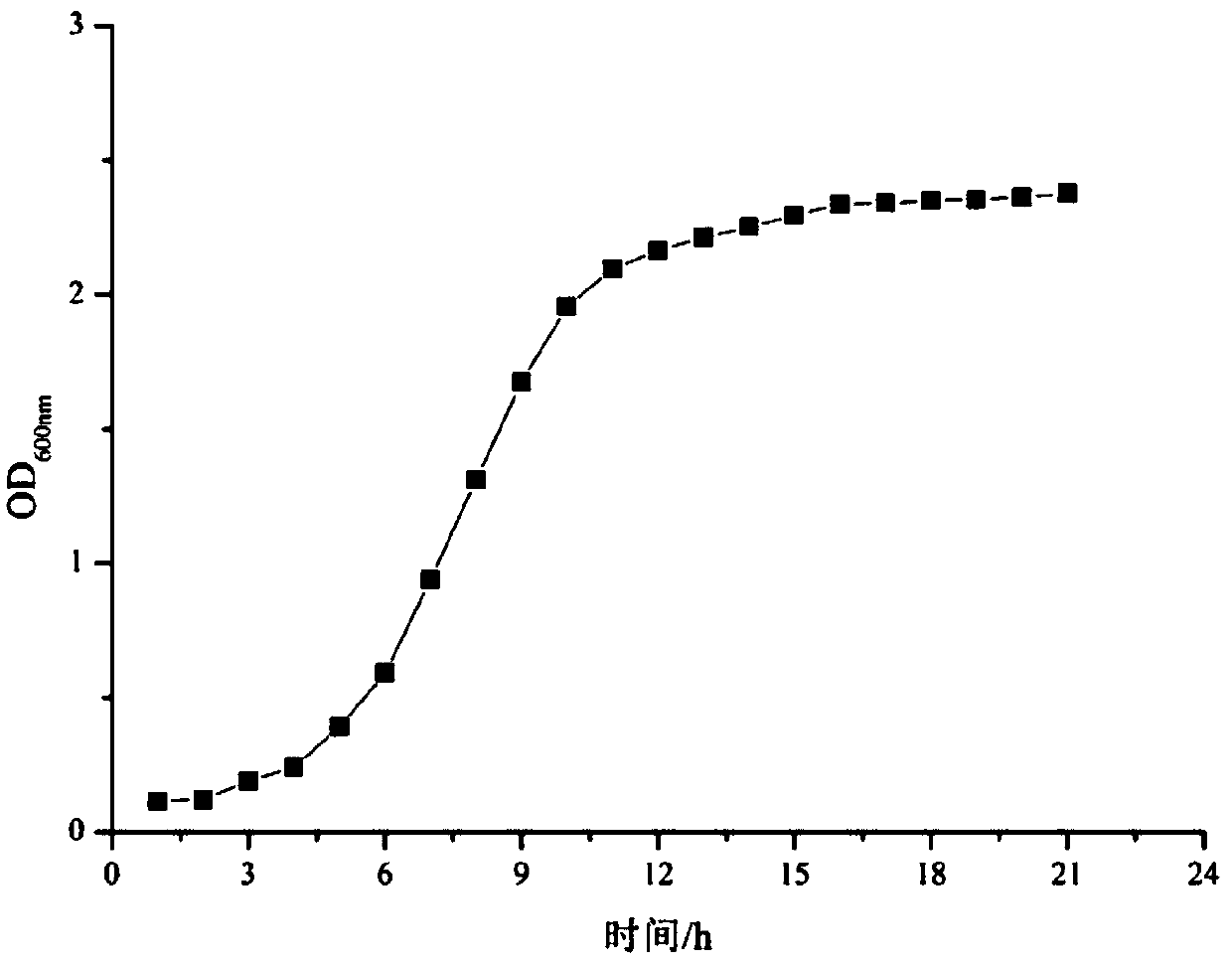

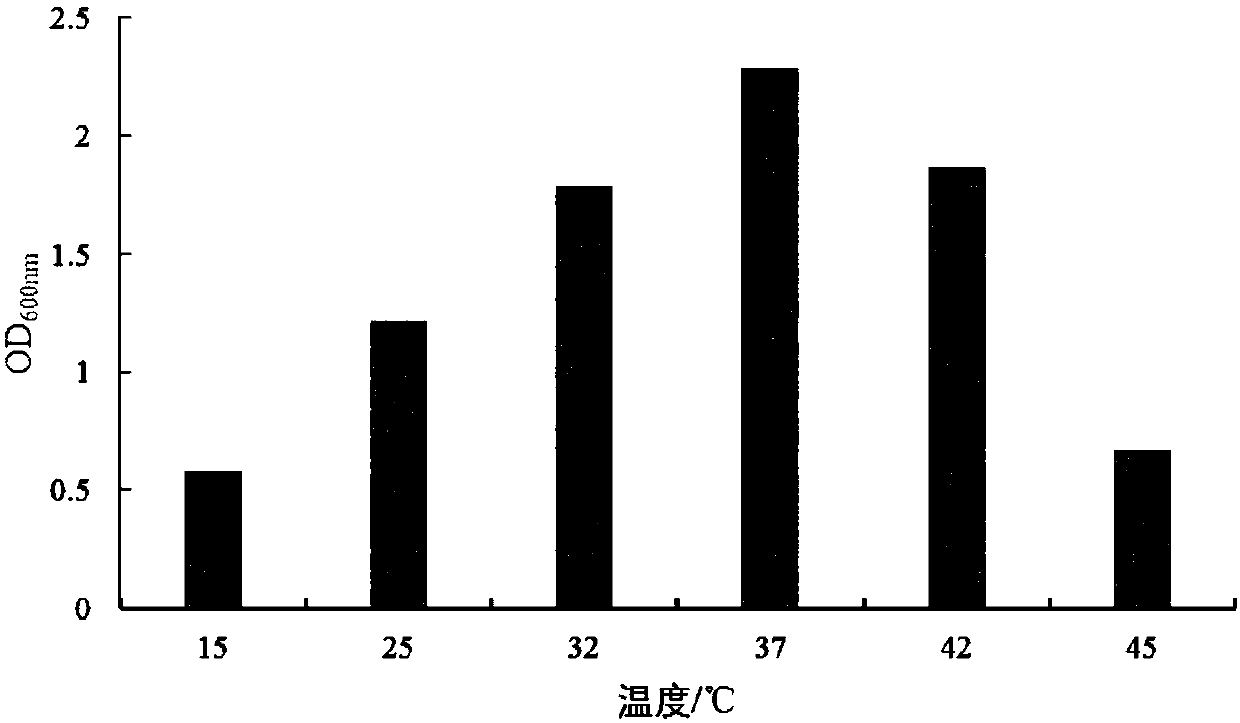

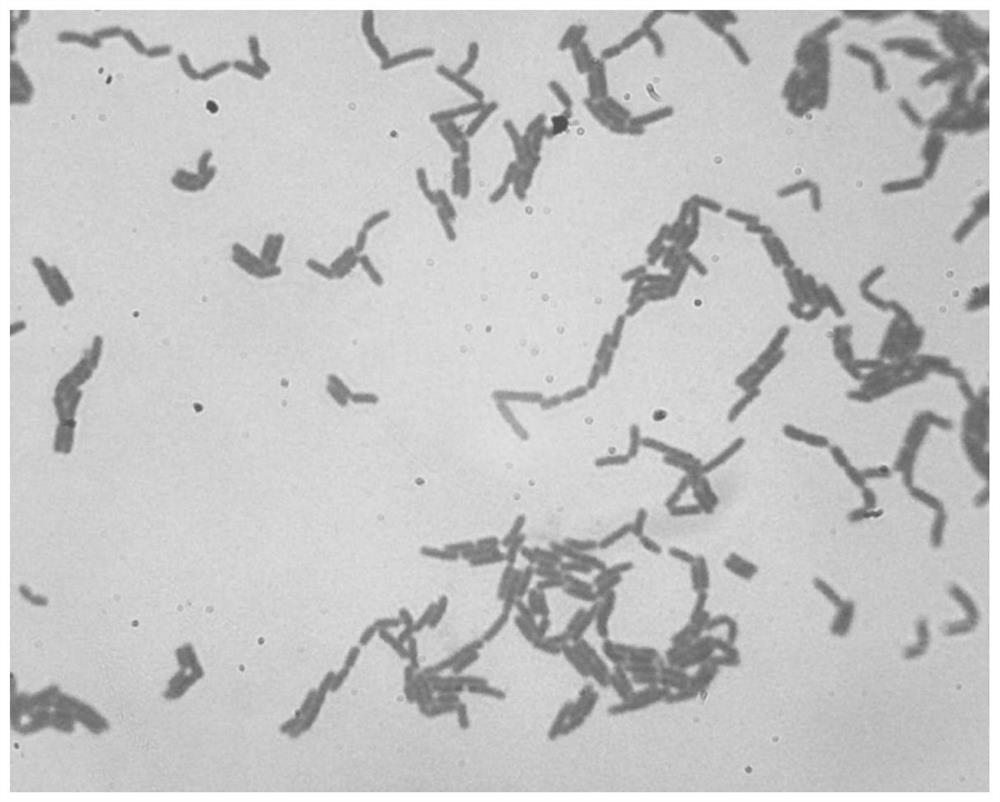

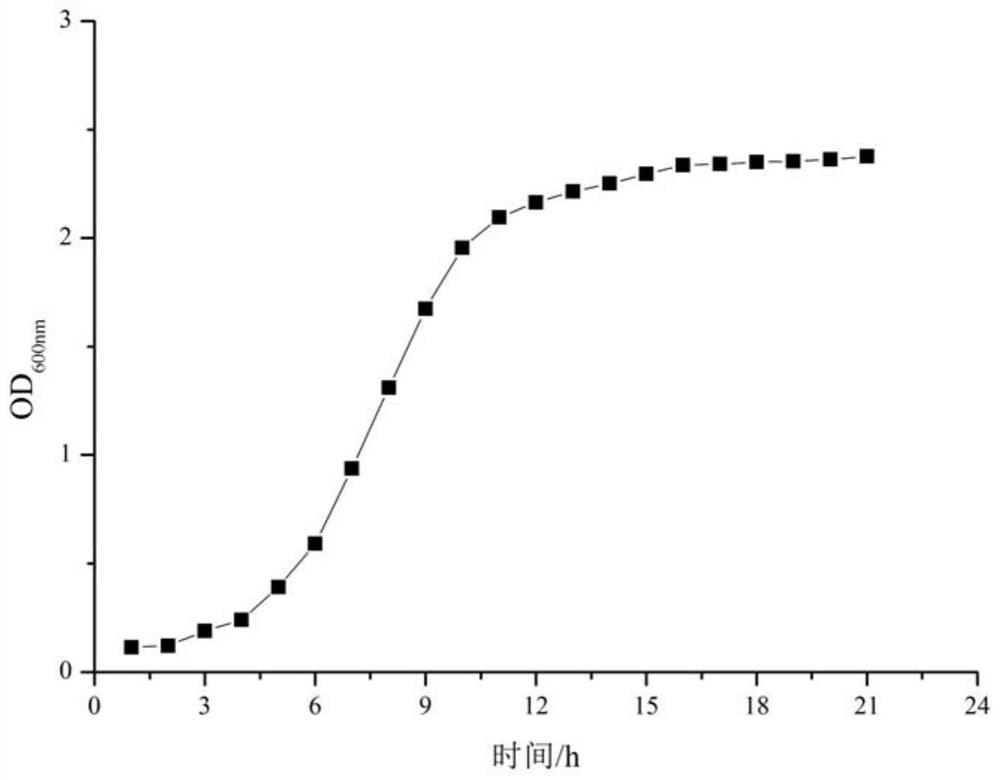

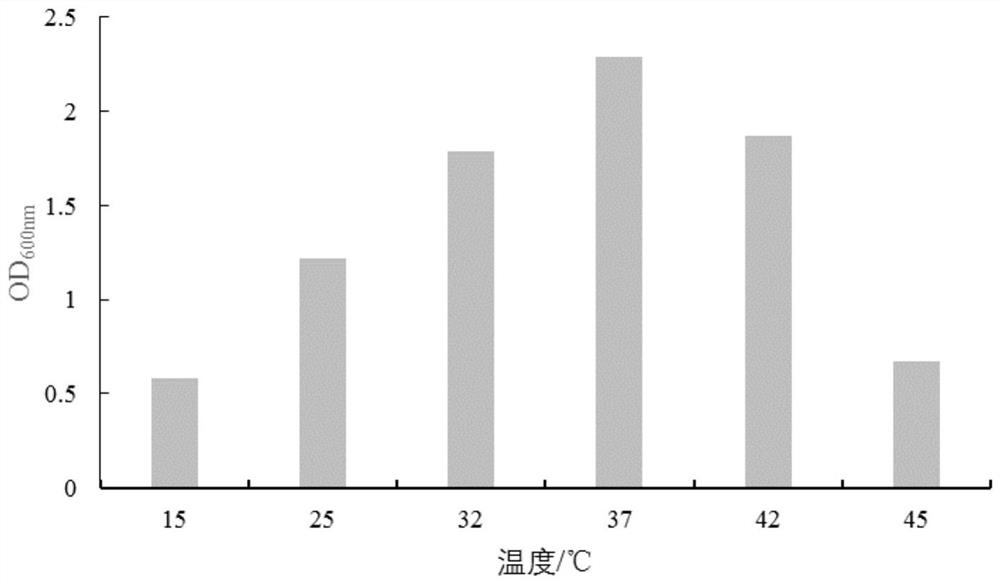

Lactobacillus casei SITCC No.10009

ActiveCN108676742AImprove the production effectMeet content requirementsMilk preparationBacteriaVolatile flavorSodium nitrate

The invention discloses lactobacillus casei SITCC No.10009 with the preservation number of CCTCC No.m2017364; the lactobacillus casei SITCC No.10009 has capability of producing high-yield butanedione;the lactobacillus casei SITCC No.10009 is applied to preparation of fermented milk or fermented milk beverage; in particular, the content of the butanedione in the fermented milk containing the lactobacillus casei SITCC No.10009 is 56.84 mg / L; due to the addition of sodium nitrate in the preparation process, the yield of the butanedione in the finally obtained fermented milk is up to 70.43 mg / L;moreover, when the lactobacillus casei SITCC No.10009 and the conventional fermenting agent are compounded, the varieties of volatile flavor substances in the fermented milk can be obviously increasedand the varieties of the volatile flavor compounds reach to 56, so that the fragrance quality of the fermented milk is improved, the improvement of the quality of the fermented milk is promoted, anda wide prospect is achieved in the field of fermented milk products.

Owner:SHANGHAI INST OF TECH

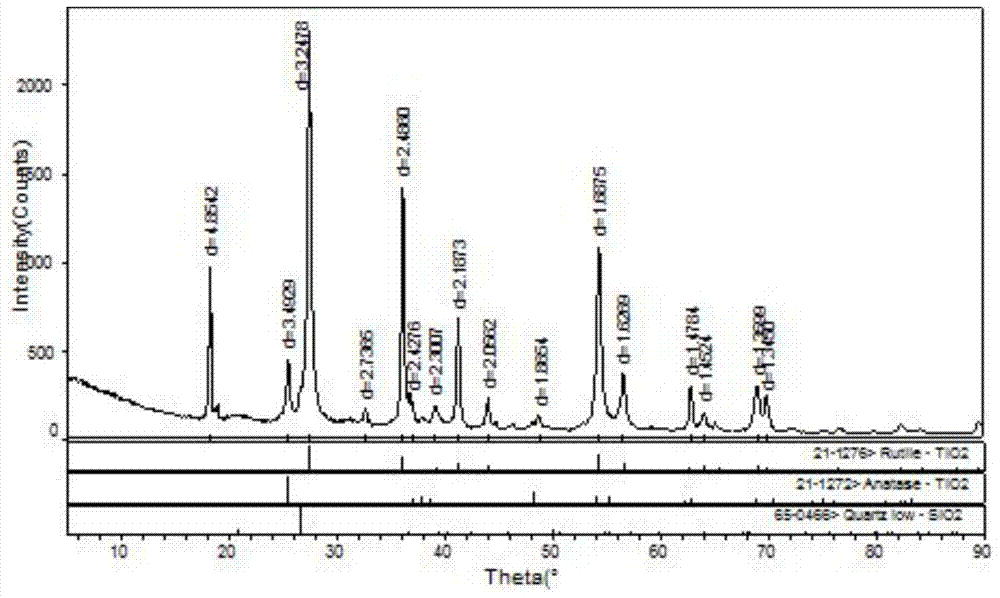

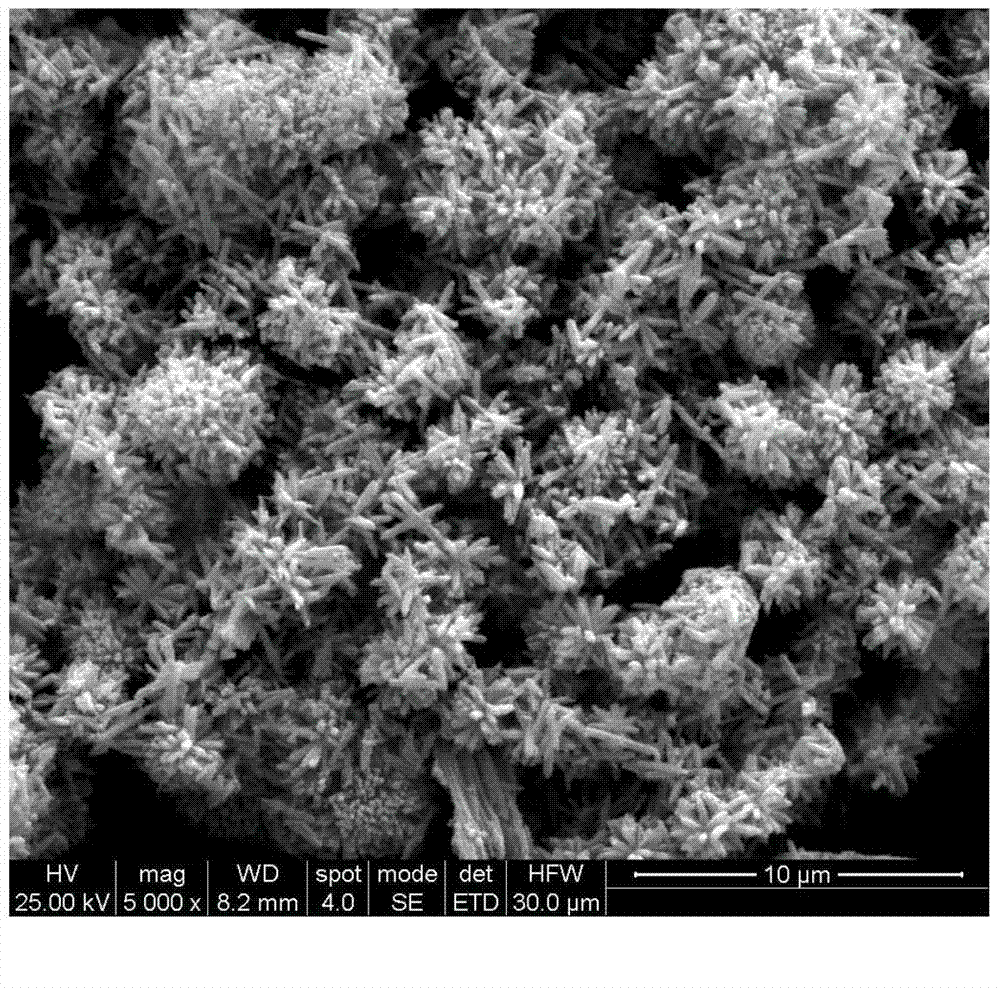

Method for preparing rutile titanium dioxide by titanium slag

ActiveCN104843777AHigh purityImprove resource utilizationTitanium dioxideResource utilizationSolvent

The invention discloses a method for preparing rutile titanium dioxide by titanium slag, which takes ironmaking byproduct-vanadium-titanium-iron concentrate for directly reducing to obtain a melting part titanium slag as a raw material, takes a hydrochloric acid solution as a solvent, and uses a hydrothermal method to prepare the titanium dioxide / silica intermediate products. The method comprises the following steps: using hydrochloric acid for leaching titanium from the titanium slag with high efficiency, then performing hydro-thermal synthesis on dissolved titanium to obtain titanium dioxide, finally using alkali lye to remove silicon from titanium dioxide to obtain rutile titanium dioxide with high purity, wherein a desilication solution can be used for preparing the byproduct white carbon black. The method uses simple process to obtain the rutile titanium dioxide at low temperature, a high temperature roasting process in a traditional technology can be avoided. The product titanium dioxide can be used for the fields of a catalyst or a catalyst carrier, the byproduct white carbon black can be used as a rubber additive, and hydrochloric acid can be returned for hydro-thermal synthesis and closed cycle usage. The whole technology has the advantages of high resource utilization rate, green environmental protection, low raw material cost, simple process, short flow and easy large-scale production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for efficiently removing boron and phosphorus in silicon

The invention relates to the field of treatment of industrial silicon materials, specifically to a method for efficiently removing boron and phosphorus in silicon. The method comprises the following concrete steps: mixing and smelting metallurgical-grade silicon, high-purity aluminum and an element I to obtain a melt I; cooling the melt I to obtain a solidified alloy I; soaking the solidified alloy I in hydrochloric acid to obtain a primary silicon wafer I, crushing the primary silicon wafer I into particles, then immersing the particles in hydrochloric acid, cleaning the particles with waterand drying the particles to obtain silicon without impurity boron; mixing and smelting the silicon without the impurity boron, the high-purity aluminum and an element II to obtain a melt II; cooling the melt II to obtain a solidified alloy II; and soaking the solidified alloy II in hydrochloric acid to obtain a primary silicon wafer II, crushing the primary silicon wafer II into particles, then immersing the particles in hydrochloric acid, cleaning the particles with water and drying the particles to obtain silicon without impurity phosphorus. The method of the invention is simple in process,low in smelting temperature and low in energy consumption; after treatment, a phosphorus content is less than 0.23 ppmw, and a boron content is less than 0.45 ppmw; and the method has high industrialvalue.

Owner:XINYANG NORMAL UNIVERSITY

Lactobacillus casei (lactobacillus casei) SITCC No.10009

ActiveCN108676742BImprove the production effectMeet content requirementsMilk preparationBacteriaBiotechnologyLactobacillus

The invention discloses a kind of Lactobacillus casei ( Lactobacillus casei ) SITCC No.10009, deposit number CCTCC No.M2017364, has the ability to produce high diacetyl, which is used in the preparation of fermented milk or fermented milk beverages, especially when containing Lactobacillus casei ( Lactobacillus casei ) The content of diacetyl in the fermented milk of SITCC No.10009 is 56.84 mg / L, especially the addition of sodium citrate in the preparation process makes the yield of diacetyl in the final fermented milk as high as 70.43 mg / L, and when combined with When the conventional starter is compounded, the types of volatile flavor compounds in fermented milk can be significantly increased, and the number of volatile flavor compounds reaches 56, thereby improving the aroma quality of fermented milk and promoting the improvement of the quality of fermented milk. In the field of fermented milk products Has broad prospects.

Owner:SHANGHAI INST OF TECH

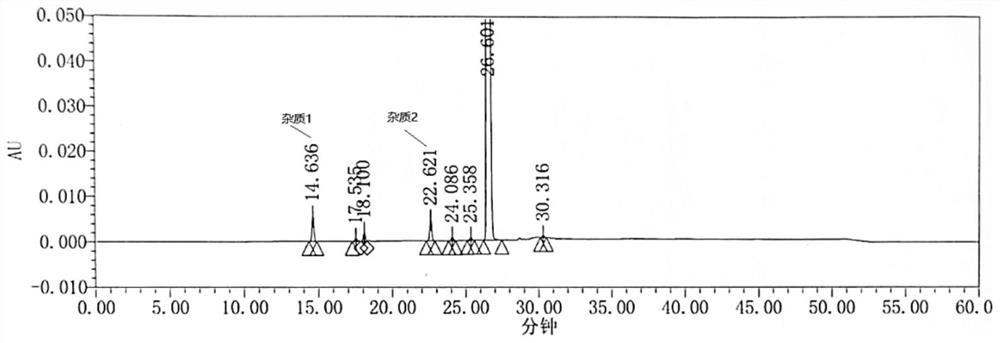

Separation and purification method of verbascoside

PendingCN114276391AGuaranteed synthetic qualityQuality improvementSugar derivativesSugar derivatives preparationBiotechnologyNew medications

The invention discloses a method for separating and purifying verbascoside, and relates to the technical field of biology, the method is separated and extracted from traditional Chinese medicine rehmannia glutinosa, and the method for separating verbascoside comprises the following steps: preparing materials and reagents; performing sample treatment; and separating and purifying the verbascoside. According to the method, beta-glucosidase which is high in price and difficult in source is not used as an enzymolysis reagent, the process route is simpler, industrial production is easier to realize, the content of verbascoside prepared by the method is higher than that of verbascoside prepared by the prior art, the requirement of new drug application on the content can be met, and the method is suitable for industrial production. The verbascoside product is derived from scrophulariaceae plants, the plant source of the verbascoside is expanded, the medicine source is rich, the extraction and preparation method of the verbascoside is optimized and improved, the operation is simple and convenient, the cost is low, only ethanol is used as an organic reagent during operation, toxic reagents such as methanol and acetone are not used, and the verbascoside product is green and environment-friendly.

Owner:TAIZHOU DANDING BIOTECH CO LTD

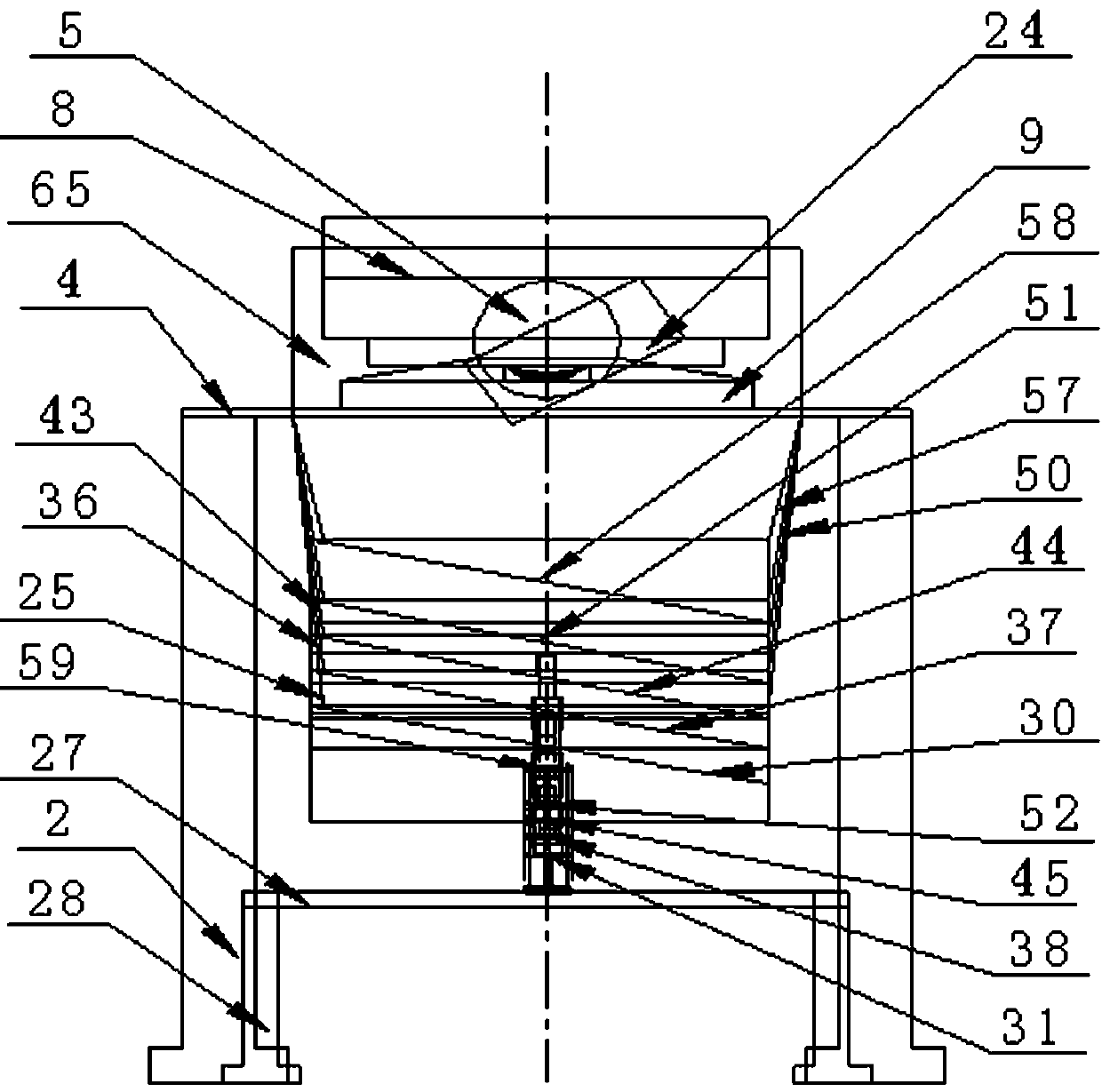

Integrated multi-stage dry permanent magnetic separator for classification and stepped sorting of coal

ActiveCN109530084AThe magnetic field strength can be adjusted steplesslyAchieve dischargeSievingScreeningAcute angleMagnetization

Provided is an integrated multi-stage dry permanent magnetic separator for classification and stepped sorting of coal. A pre-selection and classification cuboid squirrel cage is used to carry out pre-selection and classification. The entire pre-selection and classification cuboid squirrel cage is arranged right above a magnetic system located below a large support. An integrated magnetic separatorfor classification and sorting is constructed. The magnetic system adopts a stepped multi-stage tilted magnetizing variable movable magnetic field open magnetic system structure, and is composed of multiple single-stage pentahedron magnetic poles. The magnetization direction of permanent magnets is inclined. The value of the acute angle of the triangle can be changed according to the physical property change. Non-magnetic materials can automatically fall off the inclined surface, and magnetic materials can be turned over to a certain extent. The right upper part of each stage of permanent magnet is connected with a corresponding granular material sieve plate of the cuboid squirrel cage structure through a grading area chute. A vertical motion cylinder is arranged right under each stage ofpermanent magnet. A tapered non-magnetic material collector is arranged at the right end of each stage of permanent magnet. A magnetic material collector is arranged on the right side of each stage of permanent magnet and above the corresponding non-magnetic material collector.

Owner:河北地质大学

Comprehensive utilization of Chinese medicinal material magnolia bark

InactiveCN101485729APracticalChange limitationsMetabolism disorderAntinoxious agentsDiseaseNon toxicity

The invention relates to comprehensive utilization of traditional Chinese medicine magnolia officinalis. Active ingredients extracted on a platform with levels of genomics and proteomics from cortex, leaves, branches, root bark and twigs can be completely used for treating various diseases, such as tumor disease and the like, and have the advantages of obvious effect, definite target spot, small dosage and non-toxicity basically.

Owner:贺志弘

Enteric-coated vegetable cellulose hard hollow capsule and preparation method thereof

ActiveCN104288120BGuaranteed functionKeep dryPharmaceutical non-active ingredientsCapsule deliveryCarrageenanAdditive ingredient

The invention relates to enteric-coated plant cellulose hard empty capsules and a preparation method thereof. The hard empty capsules are prepared by mixing and processing the following raw materials in percentage by weight: 20-28 percent of plant cellulose derivatives, 10-16 percent of pectin, 0.2-0.25 percent of surfactant, 0.1-5 percent of coagulant aids, 0-0.05 percent of coloring agent, 0-5 percent of titanium dioxide, 0.1-0.5 percent of plasticizer and the balance of water, wherein the surfactant is selected from lauryl sodium sulfate or Tween 80; the plasticizer is selected from glycerin or polyethylene glycol; the coagulant aids are selected from any one or several out of sodium alga acid, agar, carrageenan and cooling gel; and the coloring agent refers to any one out of a synthetic coloring agent, a natural coloring agent and a plant coloring agent. The enteric-coated plant cellulose hard empty capsules disclosed by the invention comprise the main raw materials such as plant cellulose derivatives and pure natural plant polysaccharide pectin, the pectin serving as a main ingredient is uniformly distributed in the hard empty capsules, and the prepared hard empty capsules do not need outer coatings, so that gastric acid resistance can be realized, the hard empty capsules do not disintegrate in the stomach, the hard empty capsules and the contained drugs are not subjected to a cross-linking reaction, and thus the safety is high.

Owner:SHAOXING KANGKE CAPSULE

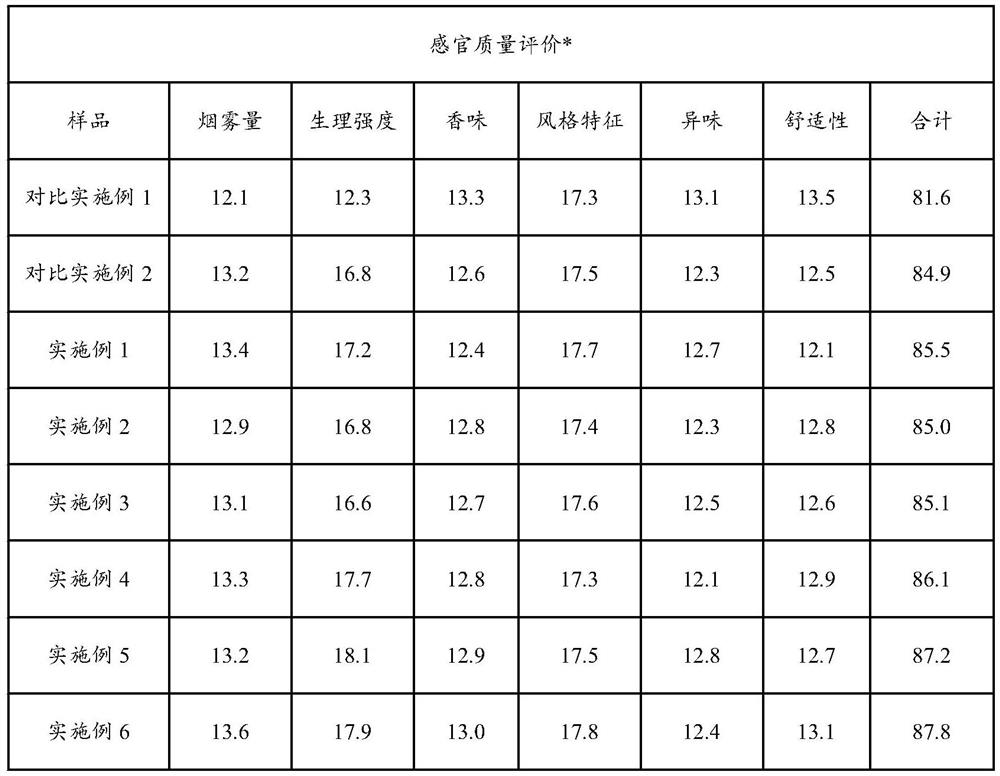

Electronic cigarette atomized liquid

PendingCN114468337AImprove application efficiencySimple preparation processTobacco preparationTobacco treatmentBiotechnologyArecoline

The invention relates to an electronic cigarette atomized liquid, which is composed of a mixed acid arecoline salt, propylene glycol, glycerol and a characteristic fragrance enhancer, and compared with a single organic acid arecoline salt electronic cigarette atomized liquid, the mixed acid arecoline salt electronic cigarette atomized liquid has the advantages of more stereoscopic physiological strength, better smoking experience and better smoking effect. Therefore, the mixed acid arecoline salt electronic cigarette atomized liquid better meets the physiological needs of consumers.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

A method for preparing high-titanium ferroalloy by electric thermite

ActiveCN109666793BMeet content requirementsIncrease the content of titanium componentsProcess efficiency improvementMetallic aluminumMagnetite

The invention relates to a method for preparing high-titanium ferroalloy by electric thermitic heating. The method involves uniformly blending ilmenite-containing minerals with titanium dioxide, slag-forming agent and metal aluminum particles as reducing agent, and then heating and maintaining the temperature in an electric furnace. After the smelting reduction reaction, the slag is separated to obtain a high titanium ferroalloy (Ti content ≥ 65wt%). The high-titanium-iron alloy prepared by the method of the present invention using titanium-containing minerals (such as ilmenite, vanadium-titanium magnetite, etc.) as raw materials can be exported as high value-added products or used as raw materials to enter subsequent production. Compared with the out-of-furnace thermite method, electric heating has lower production costs, does not require the use of heat-generating agents such as potassium chlorate, reduces flue gas treatment costs, and reduces the production of alumina. Therefore, it can reduce the consumption of metal aluminum and the amount of waste slag and slag components. Relatively simple, it is conducive to further utilization, such as being used as refractory materials.

Owner:NORTHEASTERN UNIV LIAONING

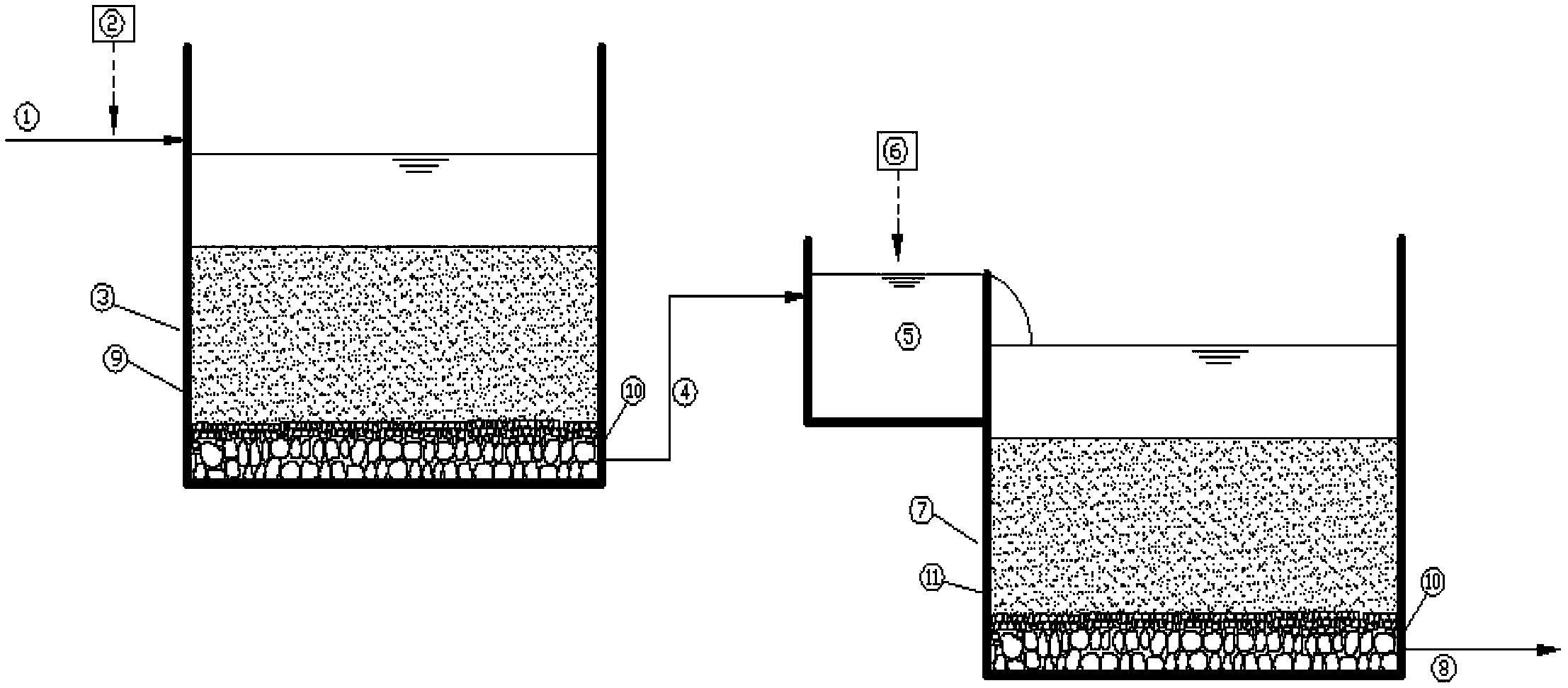

Device and method for biologically treating cadmium in wastewater

ActiveCN103193363BMeet content requirementsReduce processing costsWater contaminantsMultistage water/sewage treatmentSulfate-reducing bacteriaManganese

The invention discloses a device and a method for biologically treating cadmium in wastewater, and belongs to the technical field of water treatment. The method comprises the following steps: (1) constructing and starting a sulfate reducing biofilter; (2) constructing and starting an iron and manganese removing biofilter; (3) feeding cadmium-containing wastewater into the sulfate reducing biofilter, reducing hexavalent sulfur in the SO4<2-> into S<2-> through sulfate reducing bacteria, combining cadmium with sulfion to form insoluble substances of cadmium sulphide, and blocking most cadmium; feeding the unblocked cadmium into the iron and manganese removing biofilter, and adsorbung and removing cadmium by utilizing the adsorptivity of ecological manganese dioxide and ferrous oxides which are newly generated in the filter; and (4) feeding the raw wastewater into two levels of biofilters to be filtered sequentially. Cadmium in the produced water is less than 0.005mg / L, so that the national cadmium discharge requirements of second and third-class water in Environmental Quality Standards for Surface Water (GB3838-2002) are satisfied.

Owner:BEIJING UNIV OF TECH

Method for producing solar grade polysilicon by combined technology of molten salt electrolysis and directional solidification

InactiveCN103774216BOvercoming the Difficulty in Removing Impurity Boron from SiliconSimple processPolycrystalline material growthSingle crystal growth detailsElectrolysisSilicon alloy

The invention relates to a method for producing solar-grade polysilicon by combined technology of molten salt electrolysis and directional solidification. Silicon; (3) Vacuum distillation and directional solidification of high-purity silicon. The phosphorus content of the high-purity polysilicon obtained by the present invention is reduced to 0.08×10-6, the phosphorus content is less than 0.1×10-6, and the silicon purity reaches more than 99.99995%, which meets the content requirements of solar-grade silicon for impurities (less than 0.5×10-6 6).

Owner:INNER MONGOLIA TECHNICAL COLLEGE OF MECHANICS & ELECTRICS

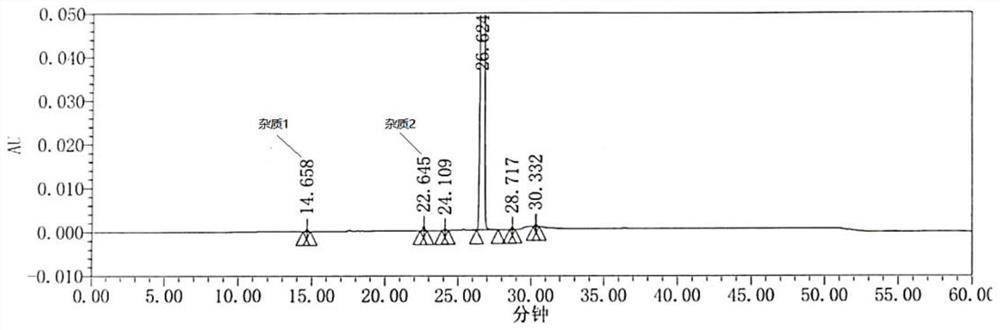

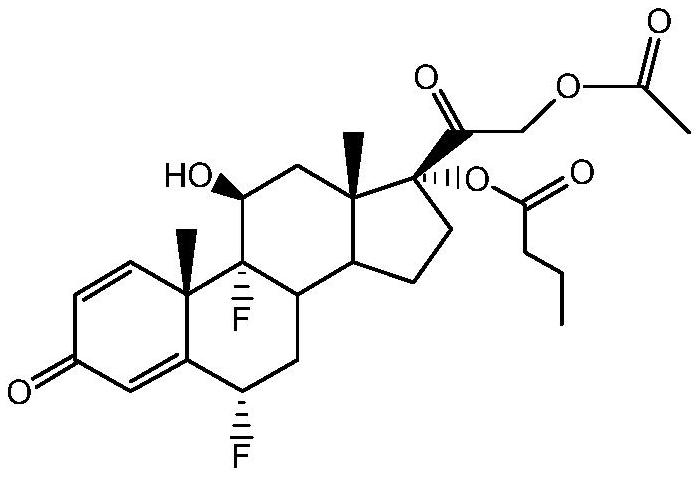

Refining method of difluprednate

The invention provides a refining method of difluprednate. The refining method of the difluprednate comprises the following steps: S1, adding dichloromethane into a difluprednate crude product, decolorizing, filtering and concentrating to obtain a concentrated difluprednate dichloromethane solution; s2, methanol is added into the concentrated difluprednate dichloromethane solution, and a concentrated difluprednate dichloromethane and methanol mixed solution is obtained through concentration; and S3, adding petroleum ether into the concentrated difluprednate dichloromethane and methanol mixed solution, concentrating, stirring for crystallization, standing, filtering and drying to obtain a refined difluprednate product. According to the refining method, the yield of the difluprednate is 95% or above, the content of the difluprednate is 99.7% or above, the impurity content is smaller than 0.1%, the high yield is guaranteed while the quality of the difluprednate product is improved, and the refining cost is reduced.

Owner:HENAN LIHUA PHARMA

A kind of method that catalyzes rosin to prepare rosin ester and p-cymene simultaneously

ActiveCN104530983BEmission reductionMeet content requirementsHydrocarbonsNatural resin chemical modificationP-isopropyltolueneCatalytic method

A method for simultaneously preparing abietate and cymene by catalyzing turpentine comprises the steps of (1) adding turpentine liquid into a reactor, adding a catalyst and alcohol for reaction at a temperature of 240-280 DEG C for 1-4 hours; (2) filtering, allowing the filtrate to stand for layering, performing reduced pressure distillation of the lower-layer liquid for 1-2 hours to obtain molten abietate and disproportionate turpentine; (3) performing reduced pressure rectification of the disproportionate turpentine, collecting fractions at 100-102 DEG C to obtain cymene. The method of the invention makes full use of the characteristics of large specific surface area and molecular sieve matrix of FCC waste catalysts to prepare a solid acid heterogeneous phase catalyst, simultaneously prepares the two fine chemicals of abietate and cymene by turpentine catalytic reaction, is simple in production process, solves the problems that homogeneous catalysts are difficult to separate from products and are difficult to regenerate for recycle in traditional abietate industrial preparation, decreases the content of trace metal zinc in abietate, and improves the product quality.

Owner:GUANGXI UNIV

A multi-stage dry-process permanent magnet magnetic separator integrating coal classification and step separation

ActiveCN109530084BThe magnetic field strength can be adjusted steplesslyAchieve dischargeSievingScreeningMagnetizationMagnetic poles

A multi-stage dry permanent magnet magnetic separator integrating coal classification and ladder separation, which uses a squirrel cage with a pre-selection and classification rectangular parallelepiped structure for pre-selection and classification. The entire pre-selection and classification cuboid structure of the squirrel cage is set in the magnetic system located under the large bracket. Directly above, build a magnetic separator integrated with grading and sorting; the magnetic system adopts a stepped multi-stage tilt magnetization variable movable magnetic field open magnetic system structure, which is composed of multiple single-stage pentahedral magnetic poles. The magnetization direction of the permanent magnet It is in an inclined direction, and the angle of the acute angle of the triangle can be changed according to changes in physical properties. Non-magnetic materials can automatically fall off on the inclined surface, and magnetic objects can achieve a certain flipping; the upper part of each level of permanent magnet passes through the classification area chute and the cuboid squirrel cage structure. The screening sieve plates for materials of corresponding granularity are connected correspondingly. A vertical motion cylinder is provided just below the permanent magnet of each stage; a conical non-magnetic collector is provided at the right end of the permanent magnet of each stage; the right side of the permanent magnet of each stage is located on the non-magnetic material collector. The upper part of the magnetic object collector is provided with a magnetic object collector.

Owner:河北地质大学

Monomer stable carbon isotope analysis method for polybrominated diphenyl ether in fish

InactiveCN106248815AEasy to detect and analyzeProcessing method saves timeComponent separationDiphenyl etherElution

The invention relates to a monomer stable carbon isotope analysis method for polybrominated diphenyl ether in fish. The monomer stable carbon isotope analysis method is characterized by specifically comprising: 1, extracting a target compound; 2, carrying out first purification on a fish sample; 3, carrying out second purification on the sample; 4, carrying out elution separation on the target compound, wherein the extraction liquid in the step 3 is injected, pre-leaching is performed with 22 mL of n-hexane, and then leaching is performed with 5 mL of n-hexane and 15 mL of dichloromethane-n-hexane having a volume ratio of 1:1 to obtain polybrominated diphenyl ether (PBDEs); 5, completing the quantitative analysis of the polybrominated diphenyl ether (PBDEs); and 6, completing the monomer stable carbon isotope analysis of the polybrominated diphenyl ether (PBDEs). According to the present invention, compared to the commonly used biological sample treatment method, the used experiment method of the present invention has advantages of time saving, solvent saving and good purification effect; and the prepared sample can effectively meet the target compound content required by CSIA analysis so as to easily develop the pollutant source analysis through the CSIA technology.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

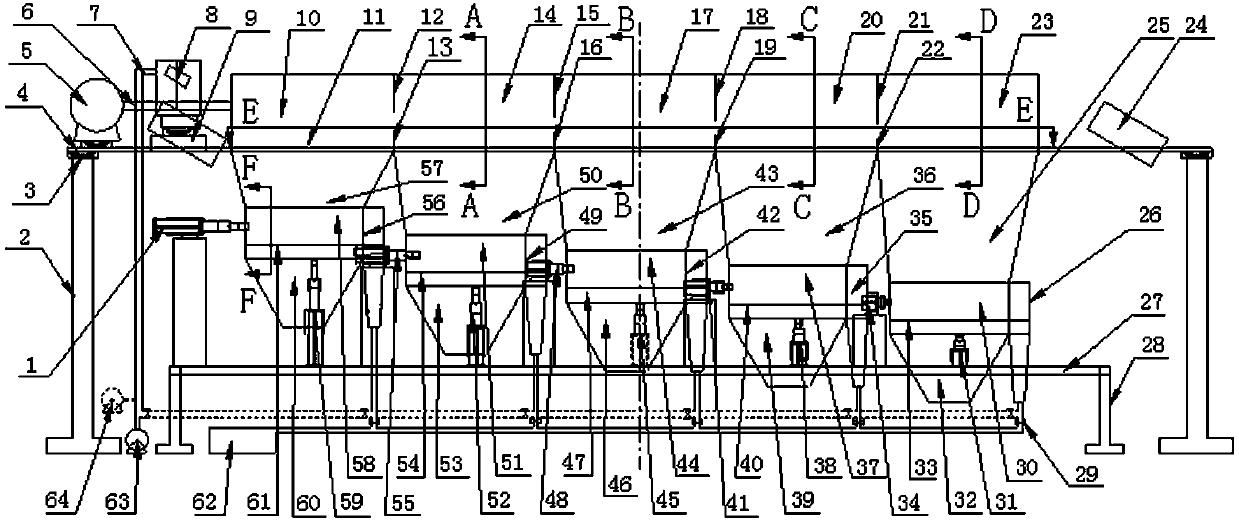

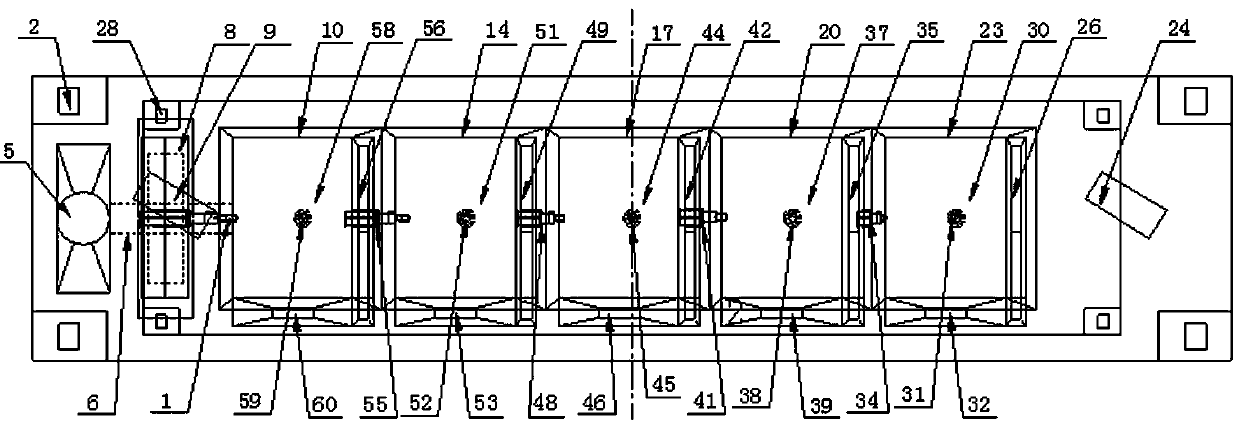

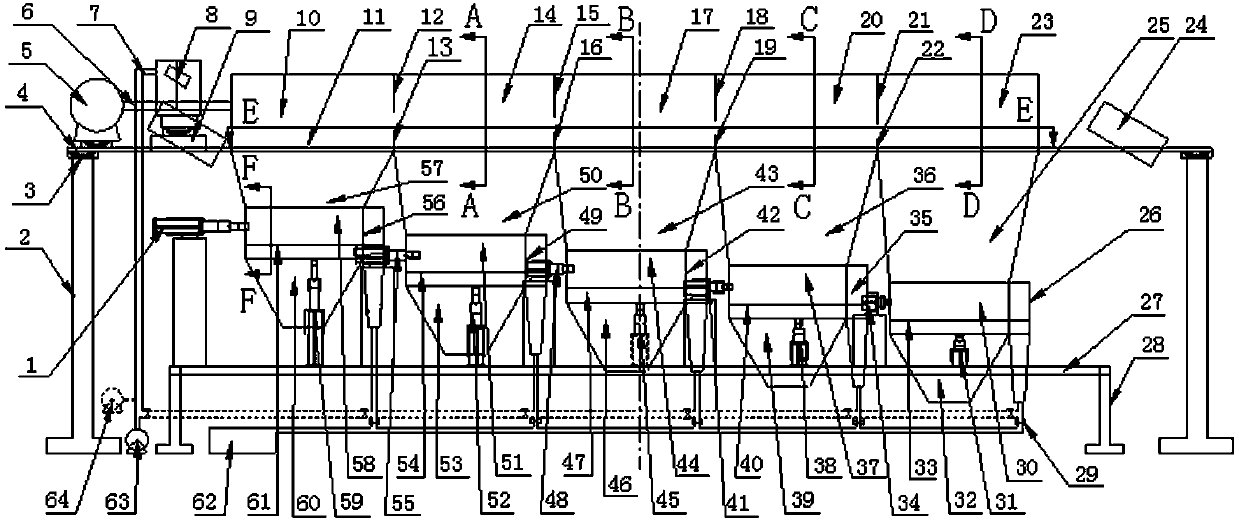

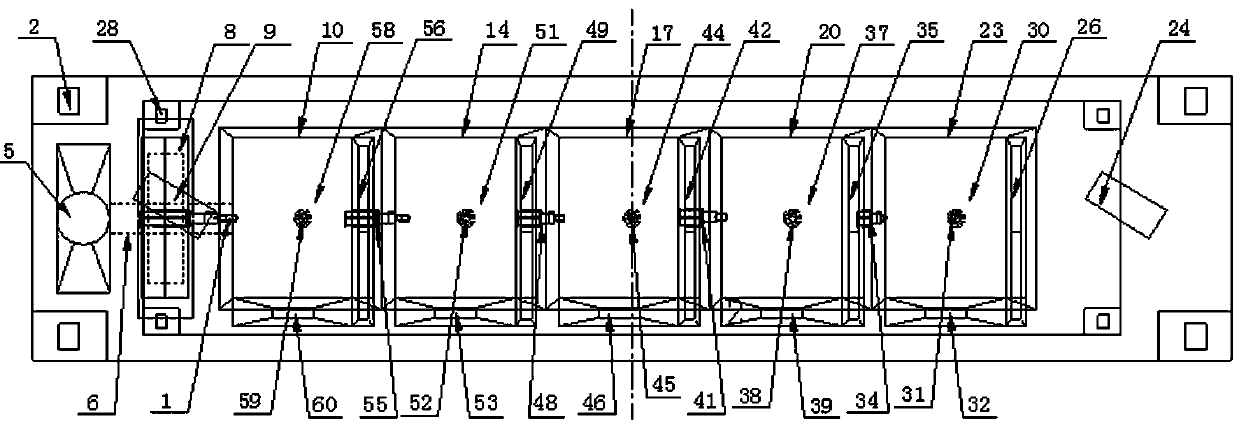

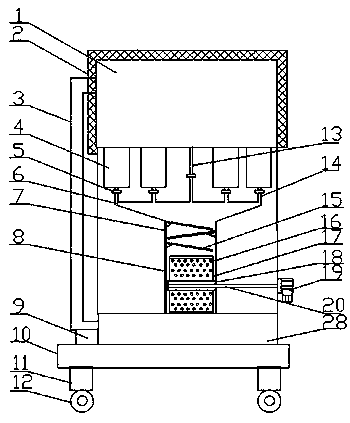

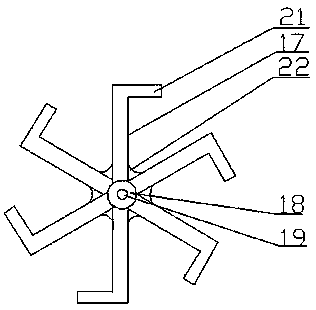

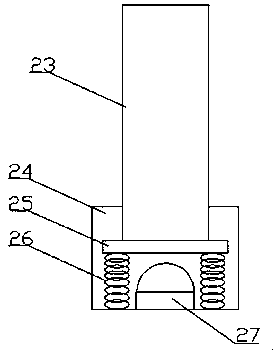

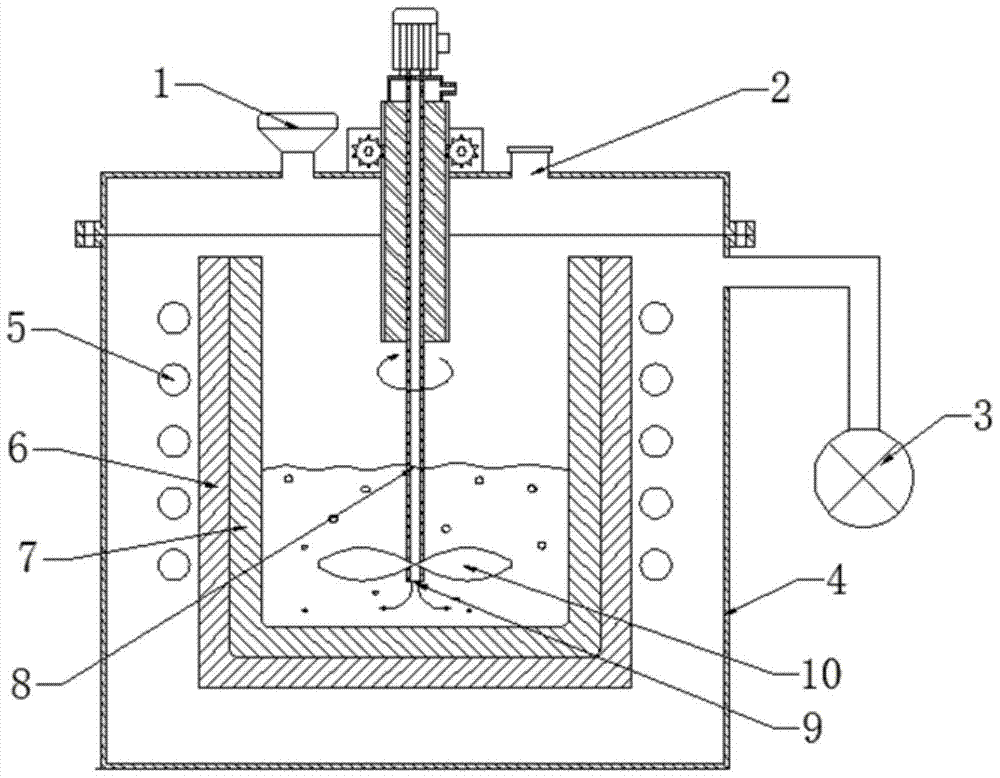

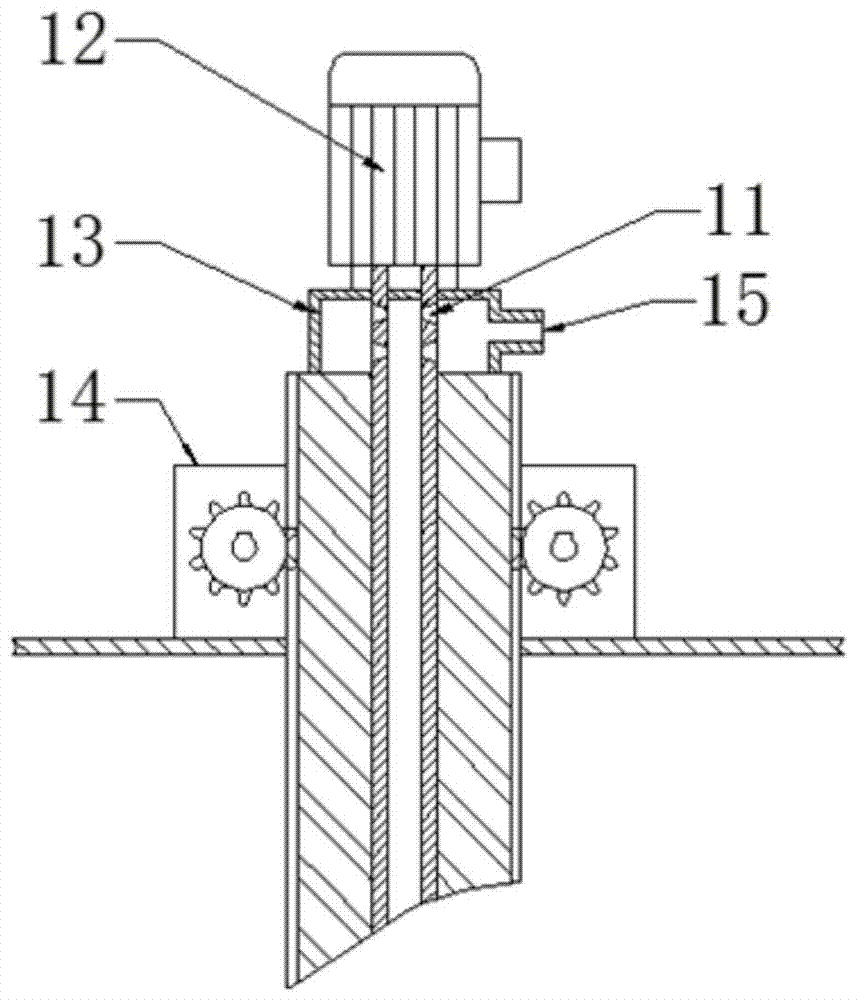

Soilless culture nutrient solution mixing device

InactiveCN109621767AMeet content requirementsGuaranteed production needsRotary stirring mixersTransportation and packagingNutrient solutionEngineering

The invention discloses a soilless culture nutrient solution mixing device, and belongs to the technical field of soilless culture. The device structurally comprises a box body. A culture chamber is arranged at the upper portion of the box body. A plurality of stock solution storing chambers are fixed to the lower portion of the culture chamber. A feed port is formed in each stock solution storingchamber. The bottom end of each stock solution storing chamber is connected with a mixing chamber through a second pipeline. The bottom end of the culture chamber is connected with a mixing chamber through a first pipeline. The bottom end of the mixing chamber is connected with a mixed liquid storing chamber through a conveying pipeline. A filtering area, a stirring area and a plurality of filtering plates in the filtering area are sequentially arranged in the conveying pipeline. The filtering plates are arranged in the filtering area. A stirring mechanism is fixed into the stirring area. Themixed liquid storing chamber is connected with the culture chamber at the upper portion of the box body through a water pump by means of a liquid conveying pipe. The mixed liquid storing chamber is fixed to a bottom plate. A control device is arranged on the wall of the box body. Stirring can be effectively conducted without losing time, the filtering plates are used for filtering out mediums, plant roots and stems and other large-particle waste left in a nutrient solution, and diseases are avoided.

Owner:SHANDONG FOREST SCI RES INST

Regeneration method of methyl nitrite

ActiveCN103936591BHigh selectivitySolve the real problemChemical recyclingNitrous acid preparation ester preparationAlcoholReboiler

The invention discloses a methyl nitrite regeneration method, and is used for solving the problems of low regeneration rate of methyl nitrite, poor operational stability of a system caused by improper side reaction control, increase of operating cost and the like. The methyl nitrite regeneration method comprises the following steps: forming recycled gas containing 5-20% of nitric oxide after synthesis of methyl nitrite and carbon monoxide carbonyl, and entering the recycled gas to a methyl nitrite regeneration reactor in two parts, wherein a small part of recycled gas enters the lower section of the regeneration reactor from the bottom, the rest part of recycled gas and supplementing oxygen gas enter the upper section of the regeneration reactor from the middle part together; spraying fresh methyl alcohol into the tower top of the regeneration reactor, discharging methyl nitrite-containing gas from the tower top, pressurizing tower bottoms led out from the tower by using a pump and entering the tower bottoms to the lower section of the regeneration reactor from the middle part of the regeneration reactor; arranging a reboiler on the tower of the regeneration reactor, filling the lower section of the regeneration reactor with a catalyst, and arranging stuffing and / or a tower plate on the upper section of the regeneration reactor. The methyl nitrite regeneration method is simple in process, low in equipment investment and operating cost and high in regeneration rate of methyl nitrite and can be used for effectively solving the side reaction problem.

Owner:WUHUAN ENG +2

A method and device for removing boron by activated slag agent

ActiveCN105540593BReduce contentMeet content requirementsSilicon compoundsSemiconductor materialsSlag

The invention discloses a boron removal method and device through an activated slag agent, and belongs to the fields of semiconductor materials and metallurgy. The device is provided with a lobe pump, a furnace base, a medium-frequency induction coil, an insulating layer, a graphite crucible, a stirrer and a lifting device. The method comprises the steps that raw silicon is put into the graphite crucible from a feed port, the lobe pump is started to perform vacuumizing, a medium-frequency induction power supply is started to perform heating, and when the temperature is increased to 1500 DEG C, silicon blocks are completely molten; inert gas is charged into a furnace cavity to enable the temperature to be kept at 1550 DEG C-1650 DEG C, the slag agent is added, the stirrer is started, and first-time slagging is completed; the power of the medium-frequency induction power supply is increased to enable the temperature in the furnace cavity to reach 1700 DEG C-1800 DEG C, the feed port is opened, active components of the slag agent are put into the furnace cavity for the first time, vacuumizing is performed, the stirrer is started, the inert gas is introduced, and second-time slagging is completed; after slagging is completed, silicon liquid is poured into a receiving crucible, standing and cooling are performed, a silicon ingot is taken out, purified low-boron high-purity silicon is obtained, and then boron removal achieved through the activated slag agent is completed.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com