A multi-stage dry-process permanent magnet magnetic separator integrating coal classification and step separation

A magnetic separator, ladder technology, applied in chemical instruments and methods, cleaning methods using tools, solid separation, etc., can solve problems such as accelerated application, loss, entrainment of magnetite powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below the present invention will be further described in conjunction with embodiment (accompanying drawing):

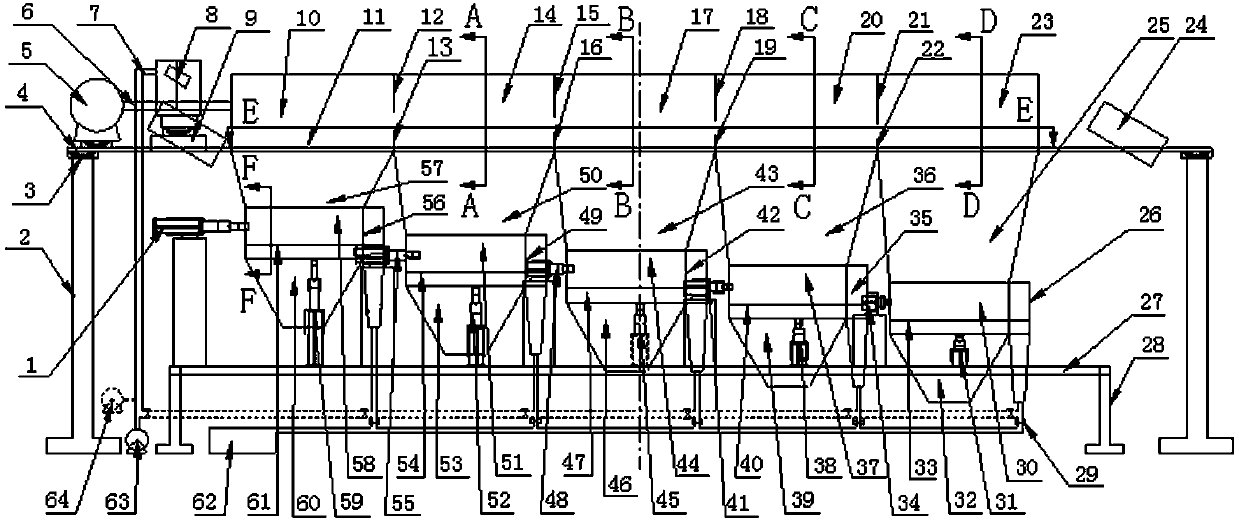

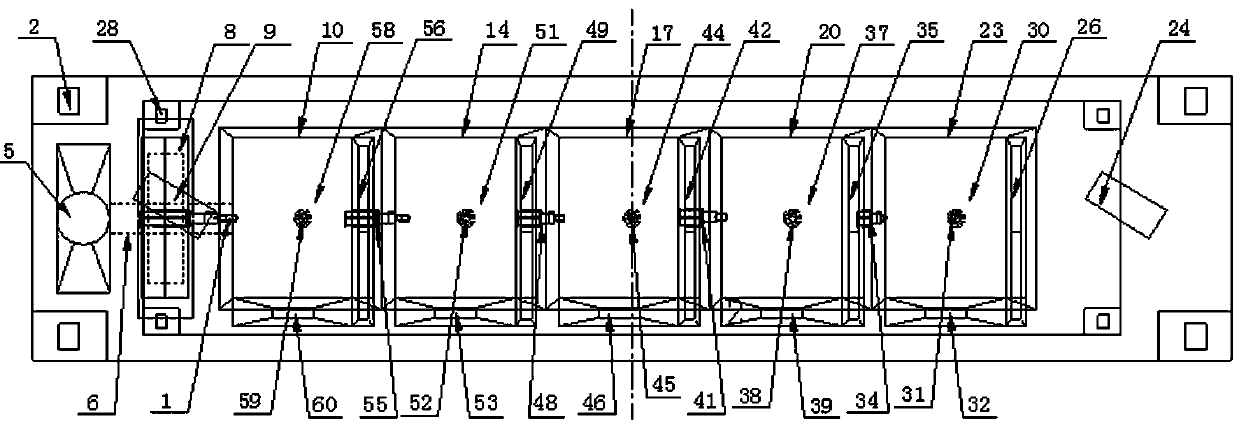

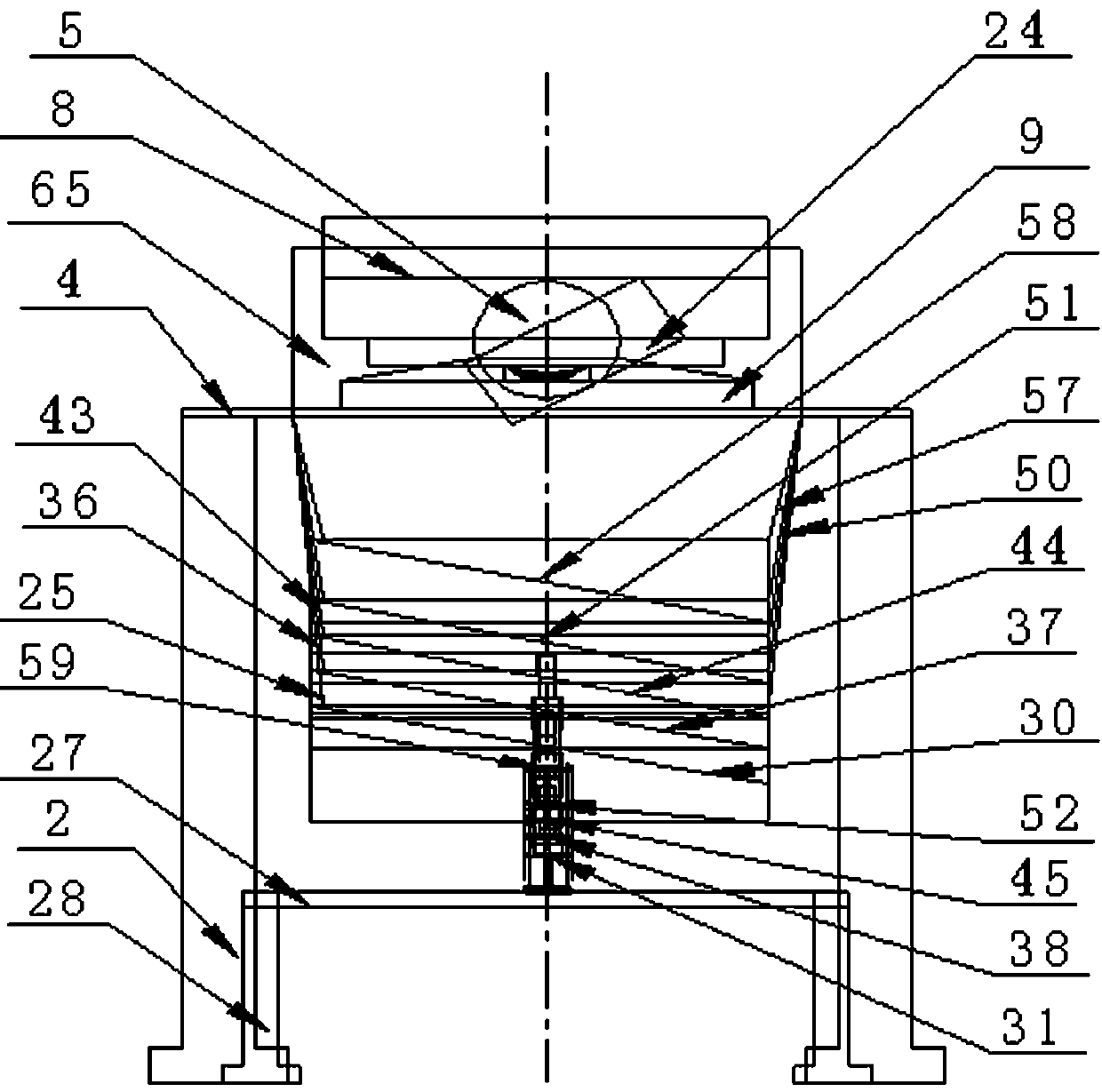

[0035] The coal classification and step separation integrated multi-stage dry-process permanent magnet magnetic separator of the present invention includes the following technical features:

[0036] a. Use pre-selected grading cuboid structure squirrel cages for pre-selection and grading. The entire pre-selection grading cuboid structure is set directly above the magnetic system below the large support to construct a grading and sorting integrated magnetic separator (mainly used for use) The one-time given material is conveyed and classified at the same time by means of the internal structure and fluidization of the squirrel cage), and the sieve plate of the squirrel cage at the bottom of the squirrel cage is set in a detachable and replaceable way (realized by the upper and lower flange pads), and is connected with each The sieve hole diameter of the sieve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com