Patents

Literature

135 results about "Pentahedron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a pentahedron (plural: pentahedra) is a polyhedron with five faces or sides. There are no face-transitive polyhedra with five sides and there are two distinct topological types. With regular polygon faces, the two topological forms are the square pyramid and triangular prism.

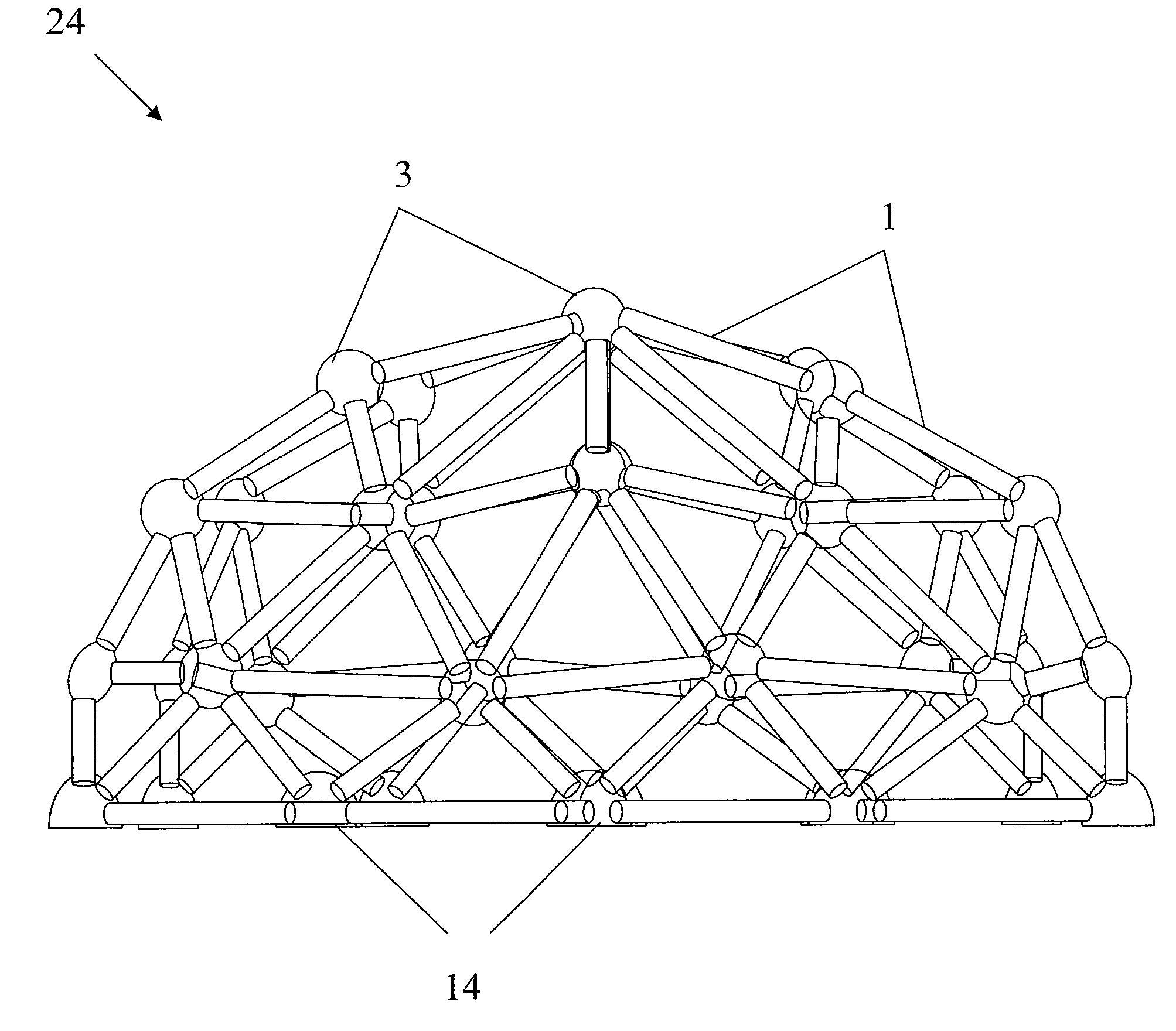

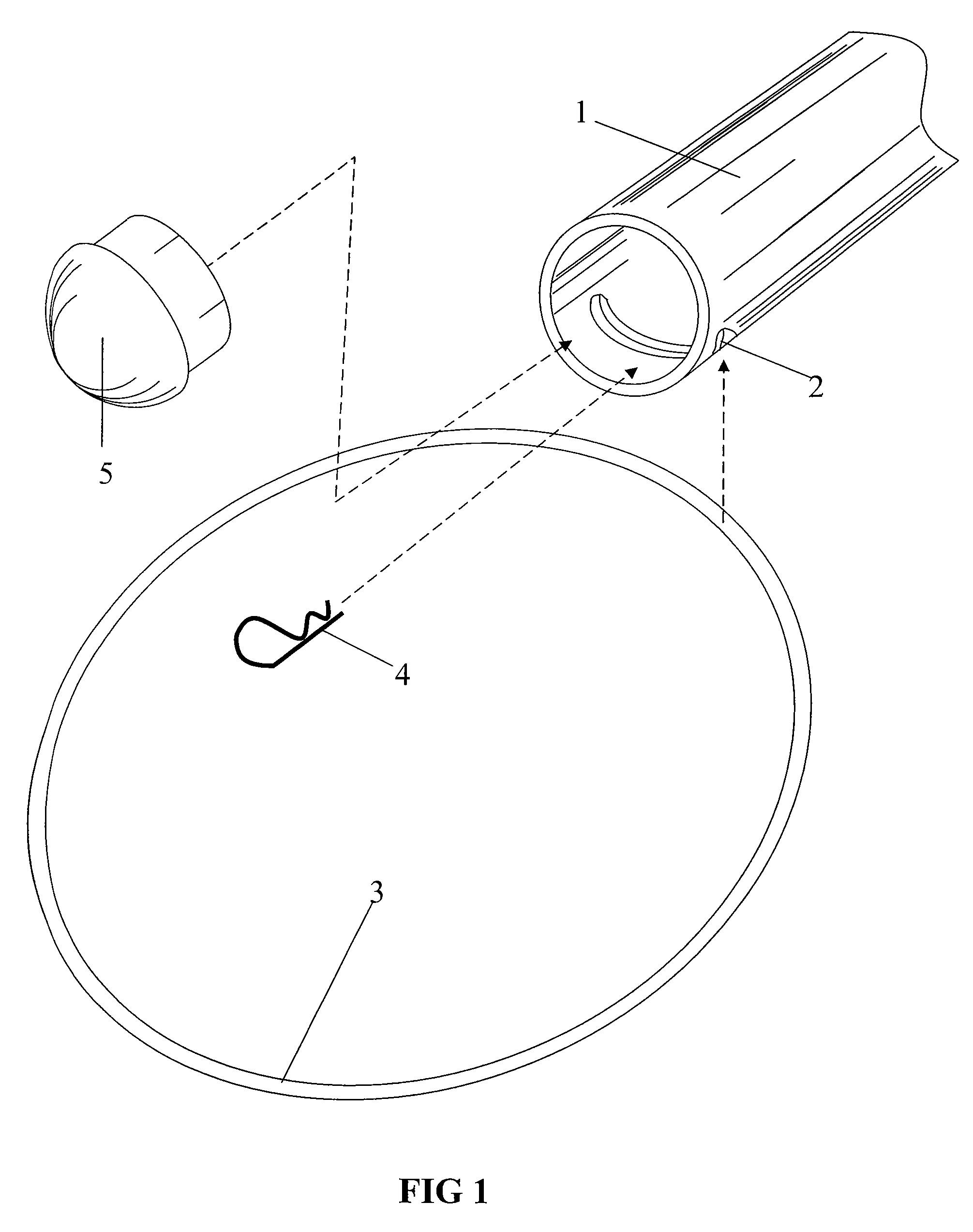

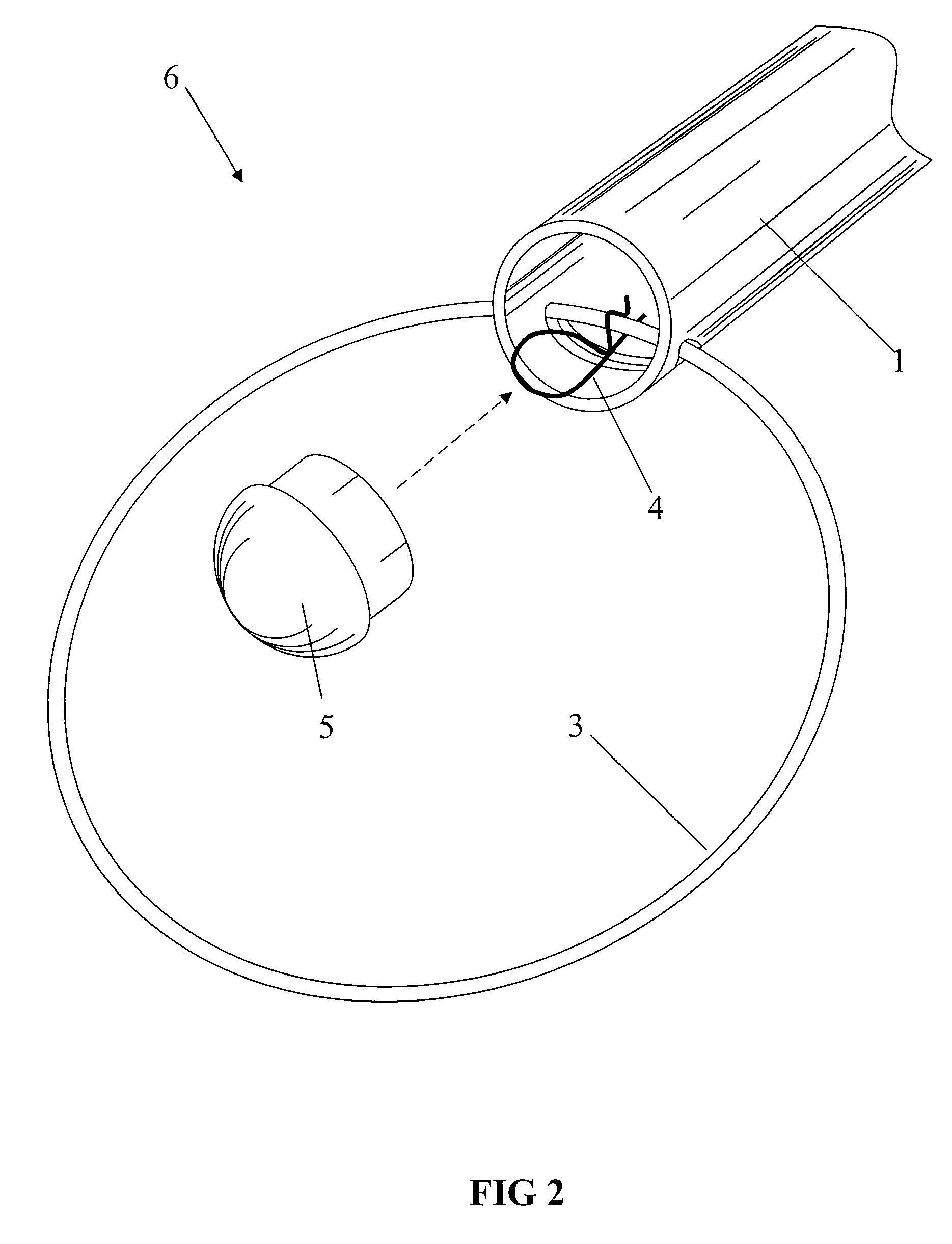

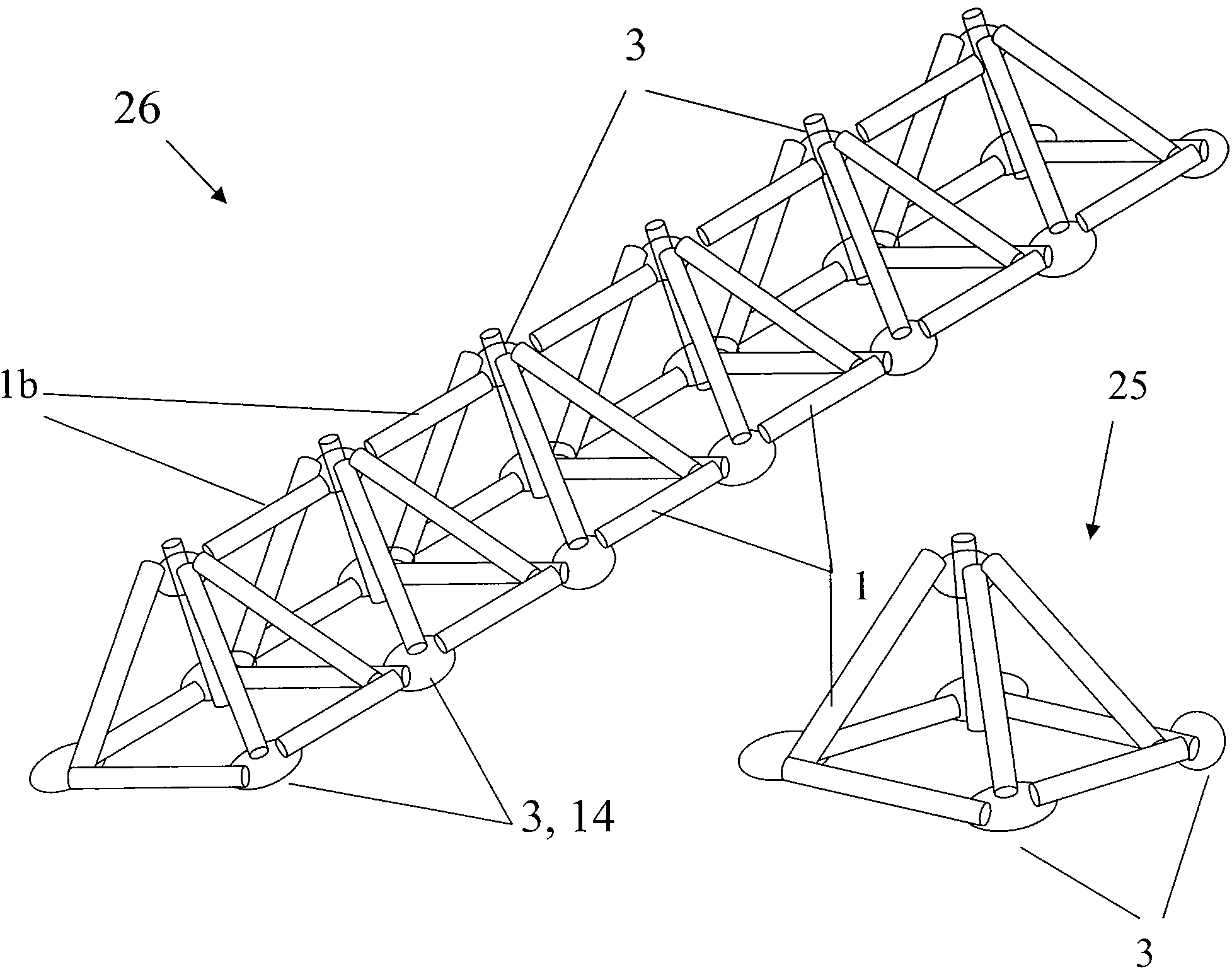

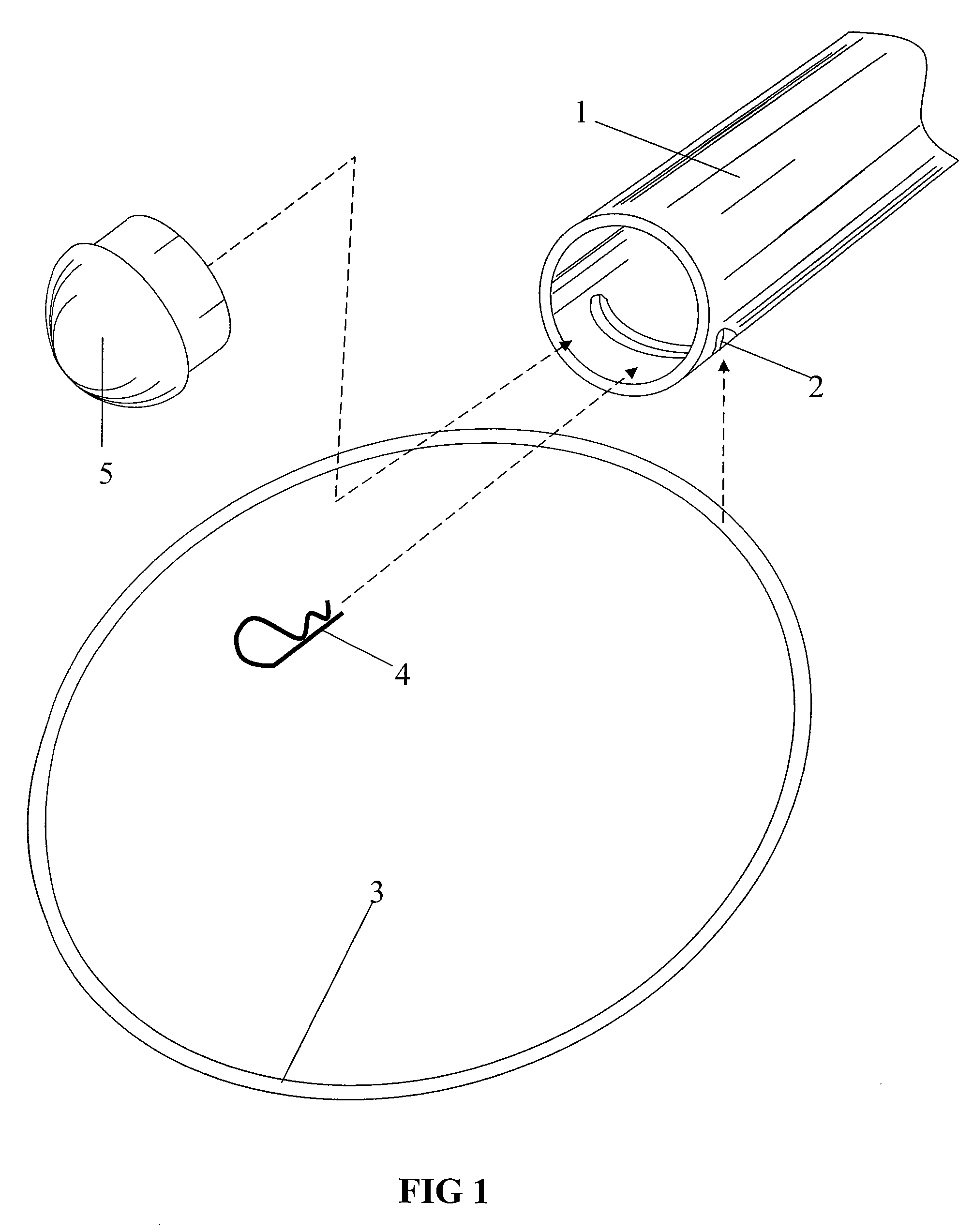

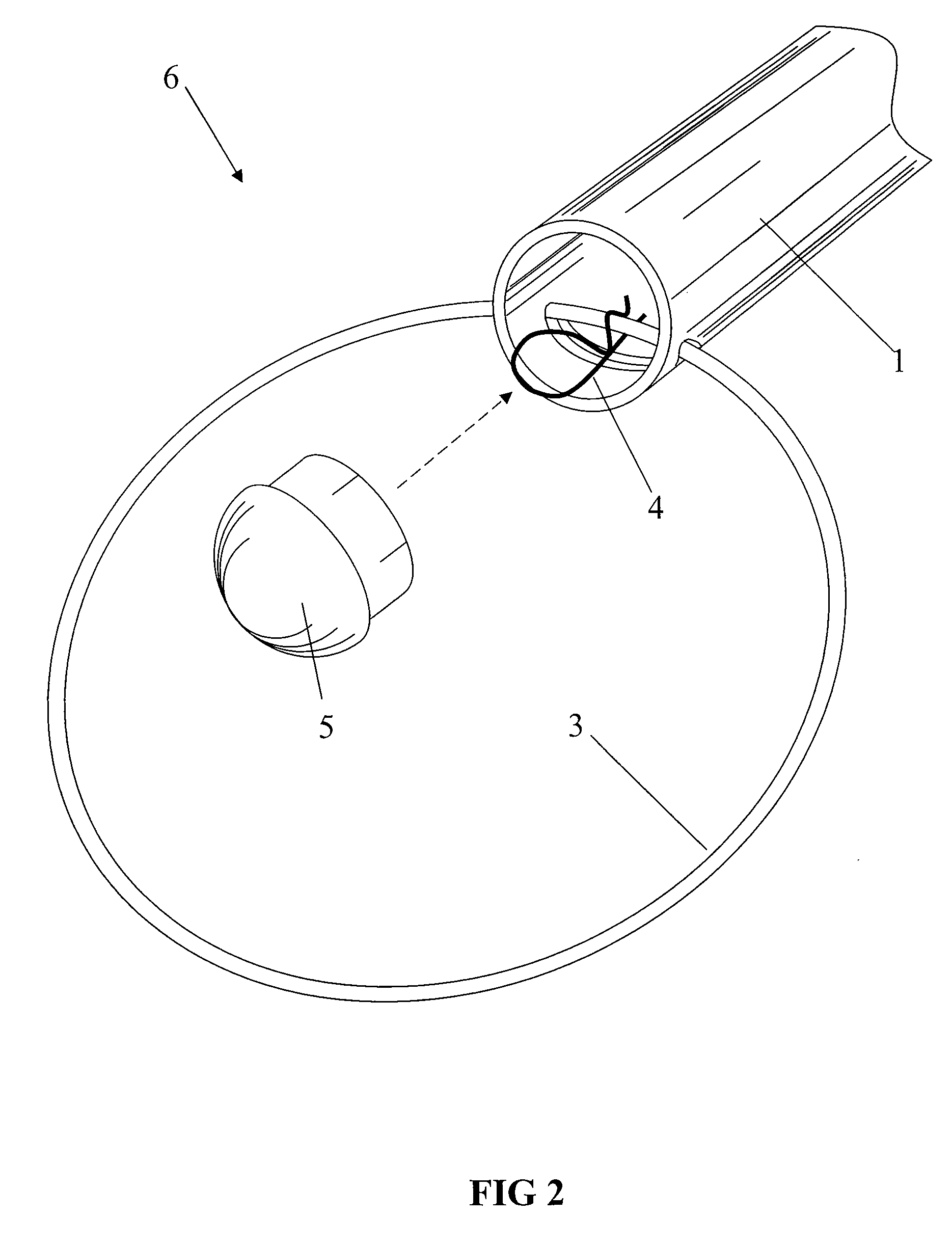

Space frame hub joint

A hub joint includes a metal rod and pin for joining tubular members in three-dimensional space for assembling a frame structure. The hub joint enables rapid assembly, rapid reconfiguration, and rapid disassembly without using any specialized tools. Multiple hub joints may be used to form geodesic domes, freestanding trusses, space frame slabs, tetrahedrons, and pentahedrons. The hub joints allow different frame configurations that are lightweight, strong, durable, scalable, expandable, and portable.

Owner:ATHAN STEPHAN P

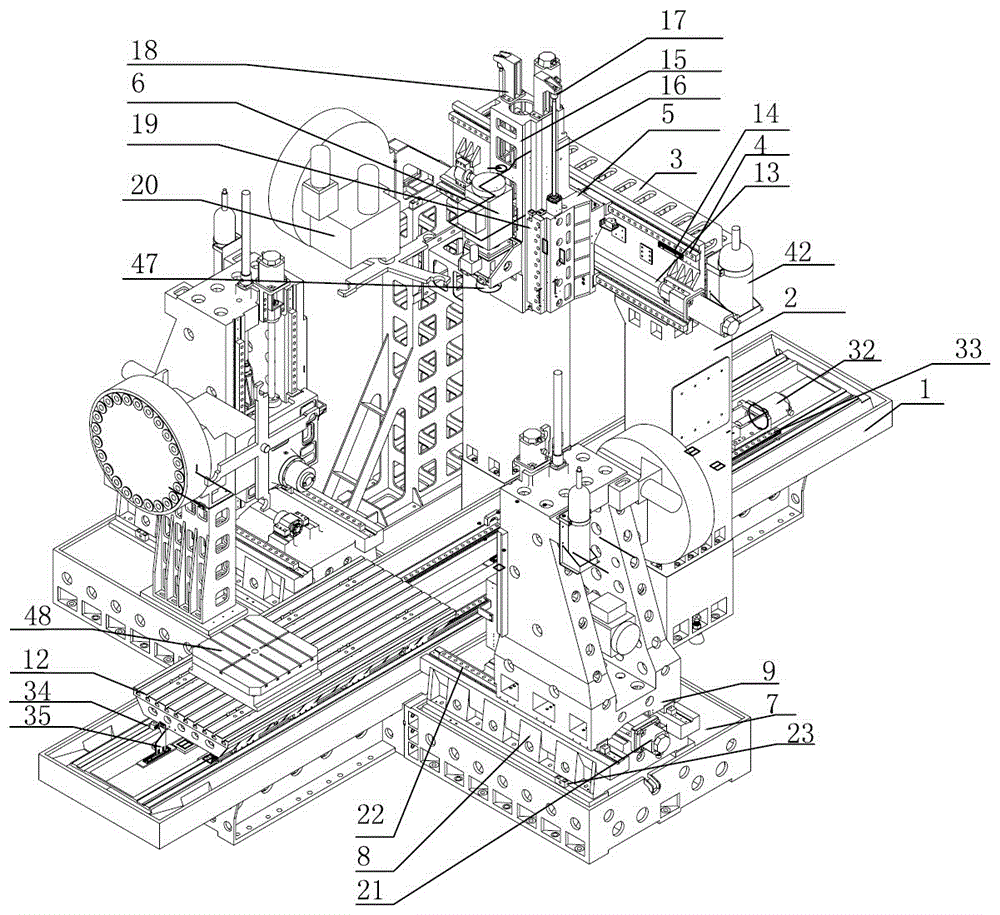

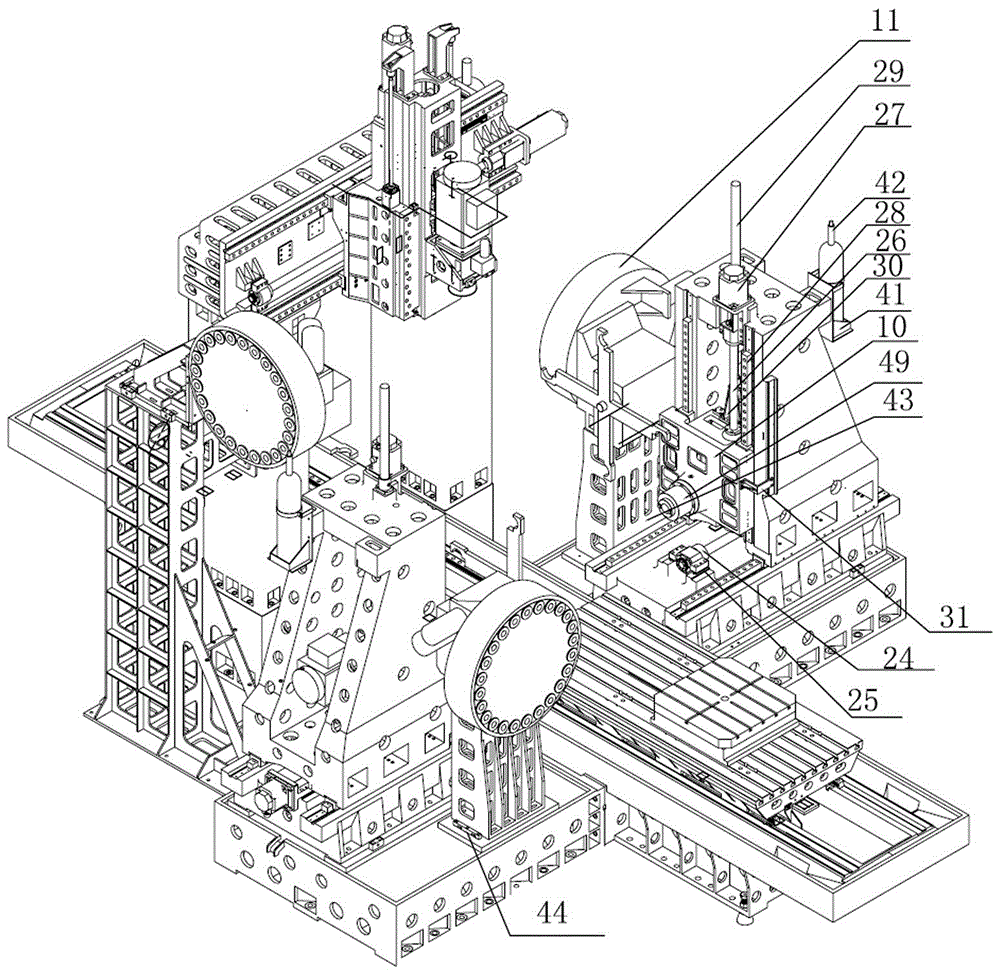

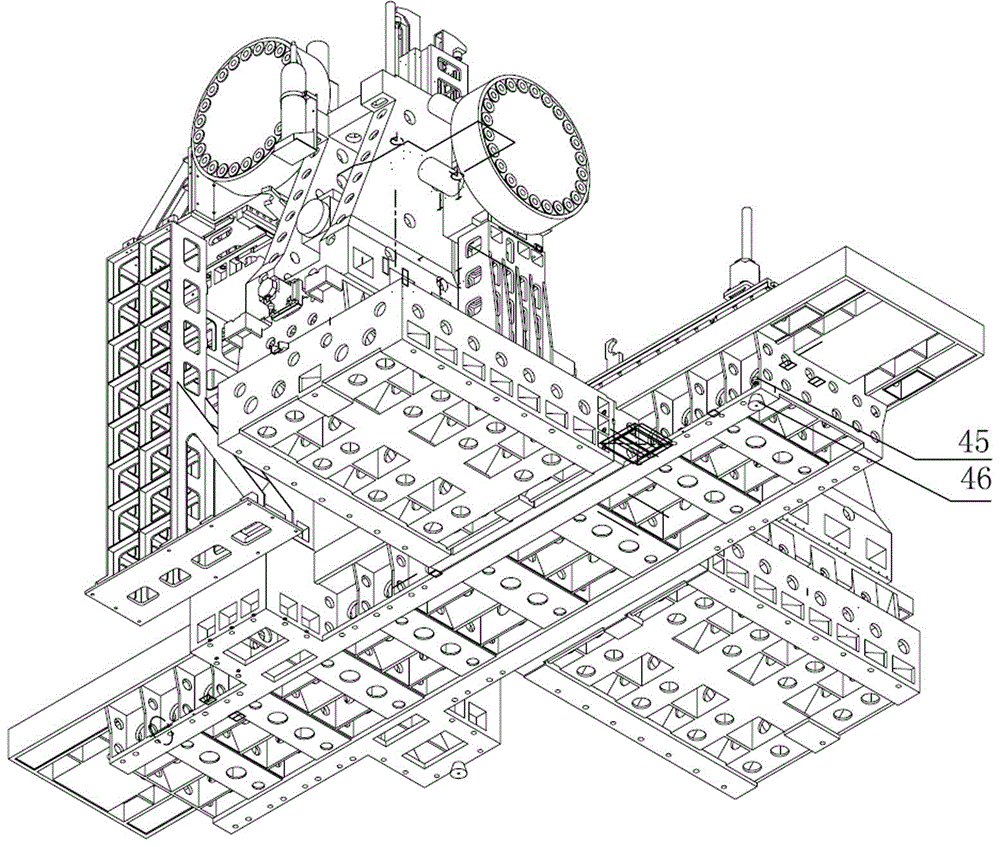

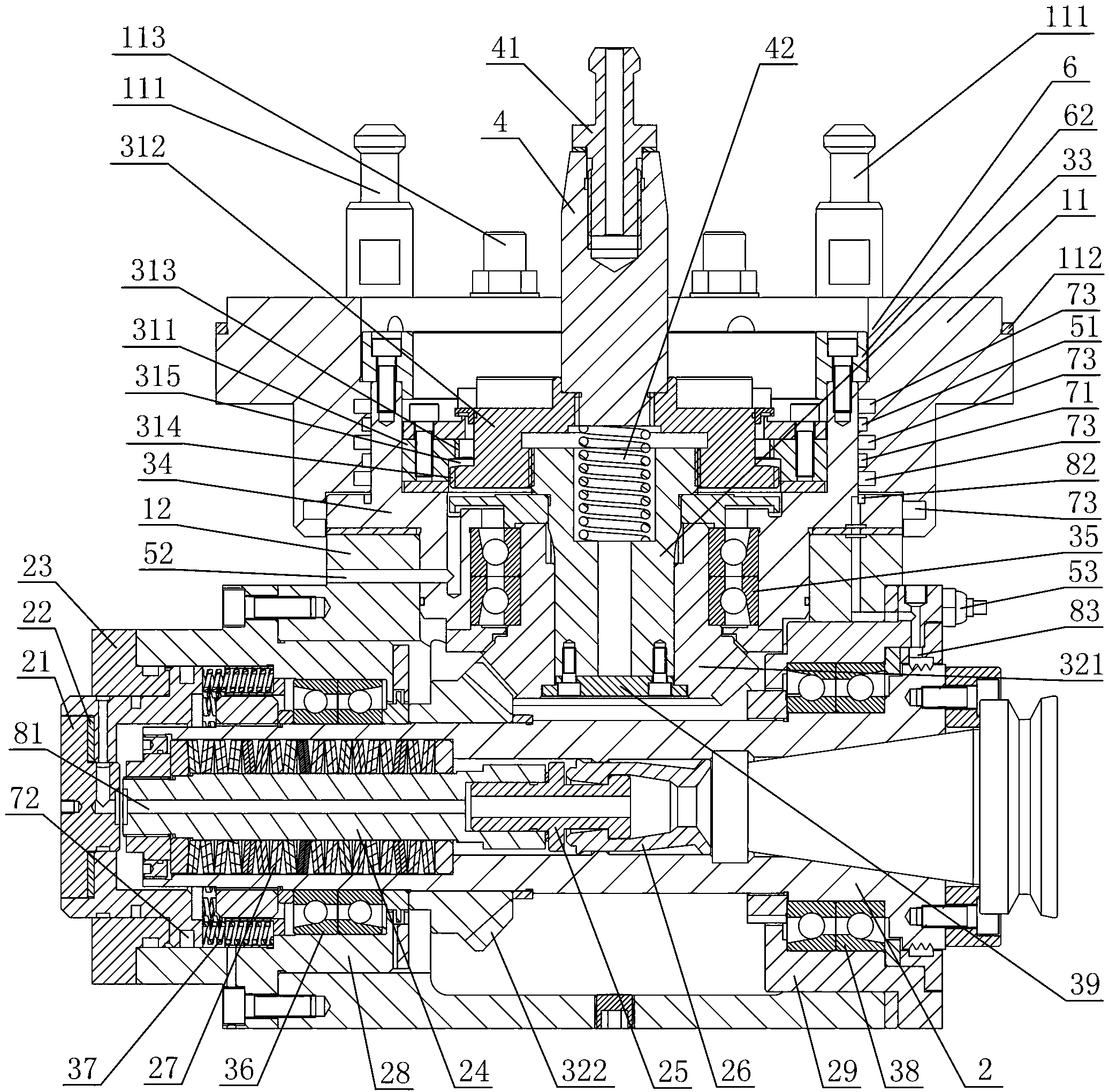

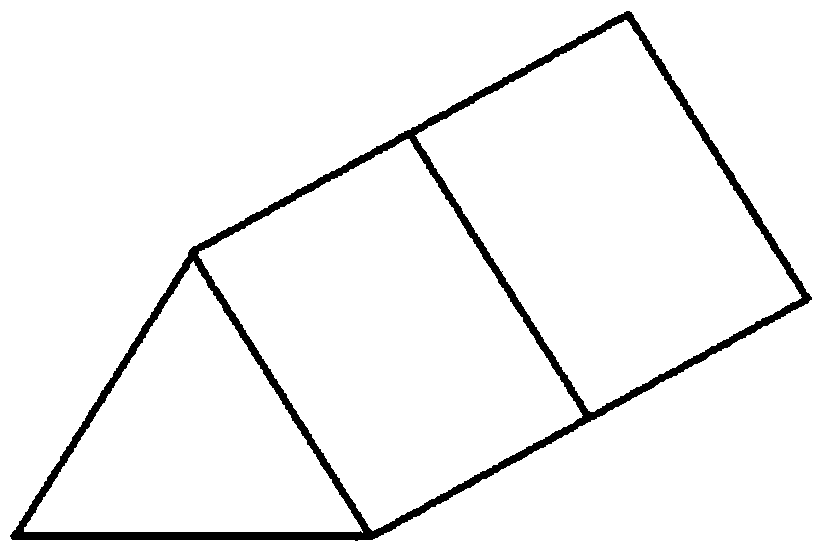

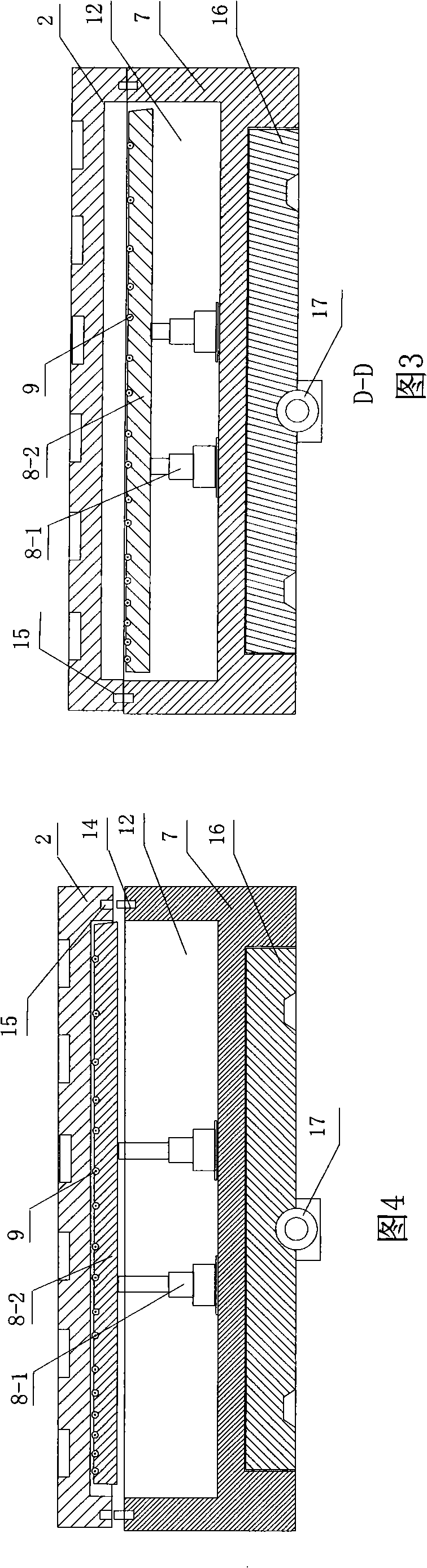

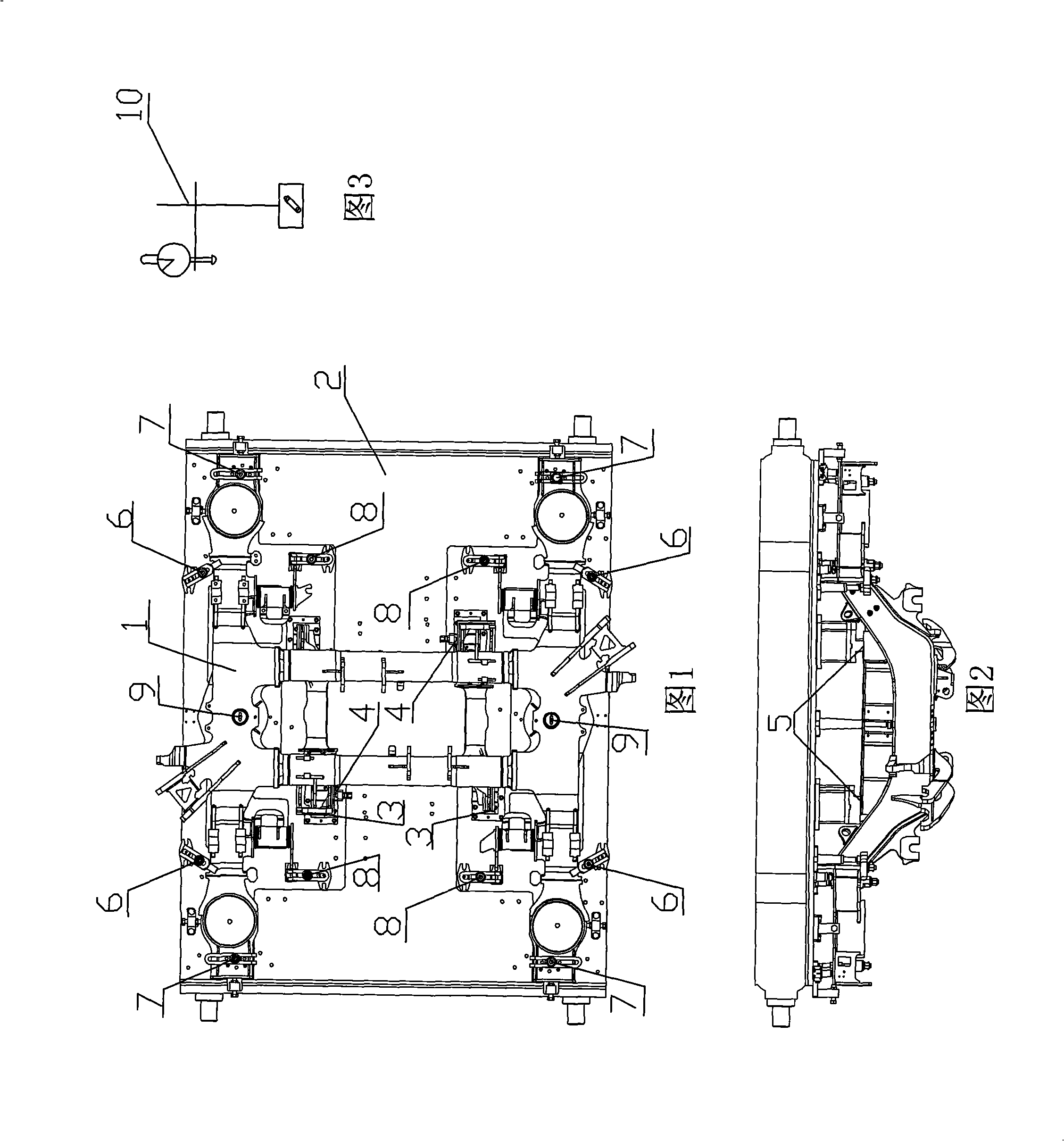

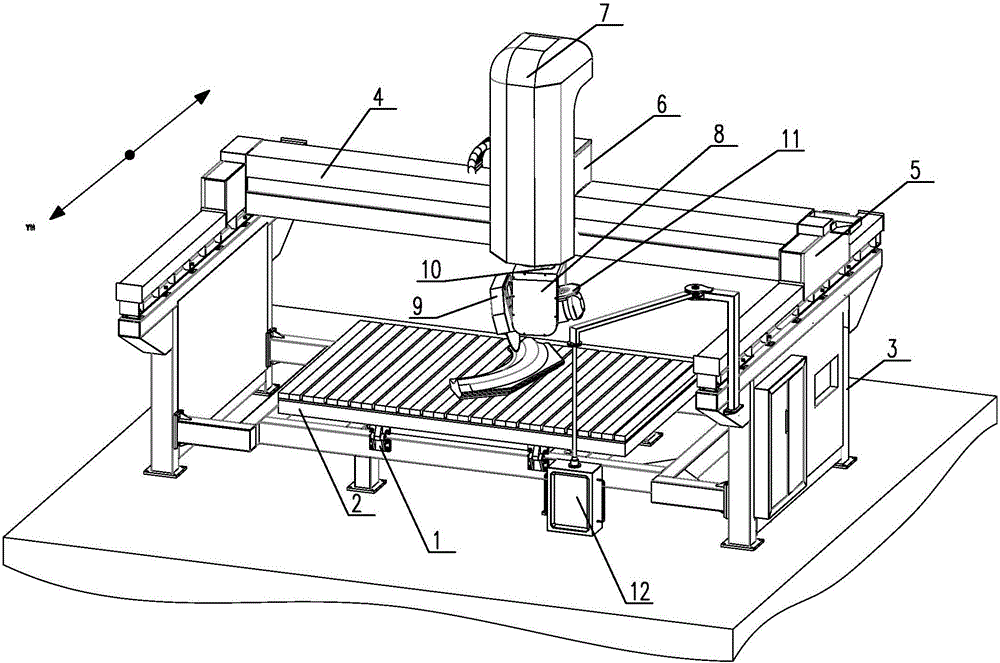

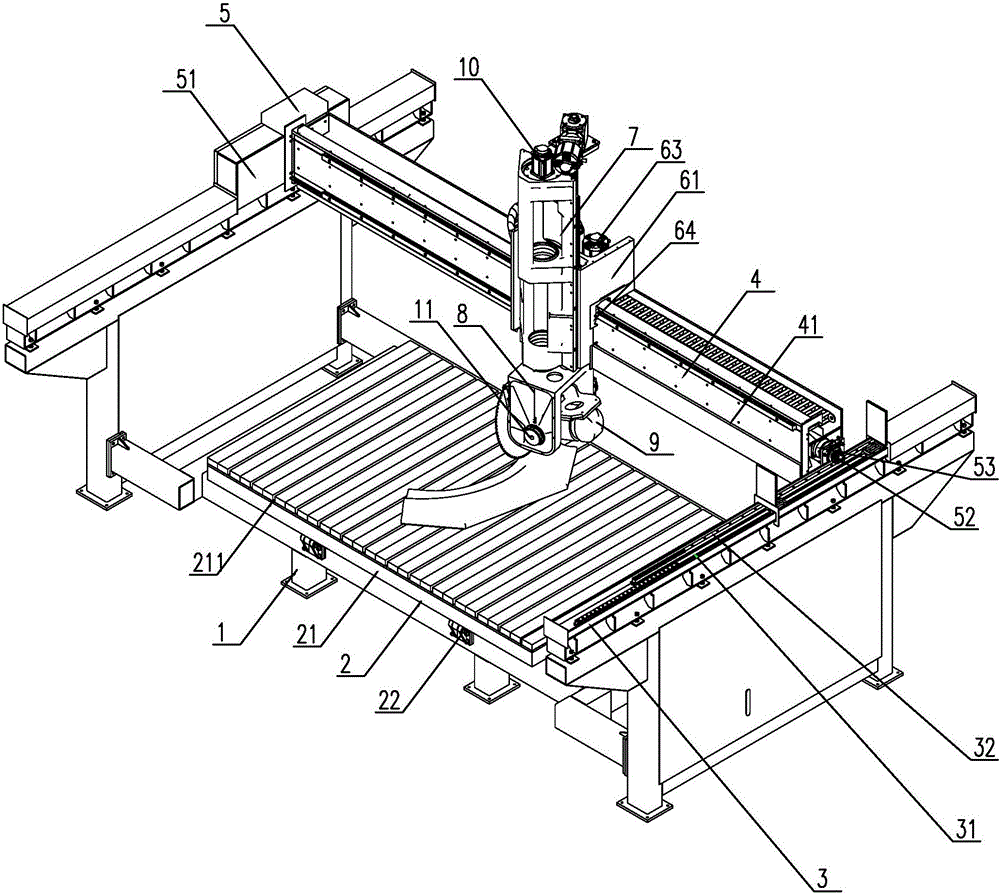

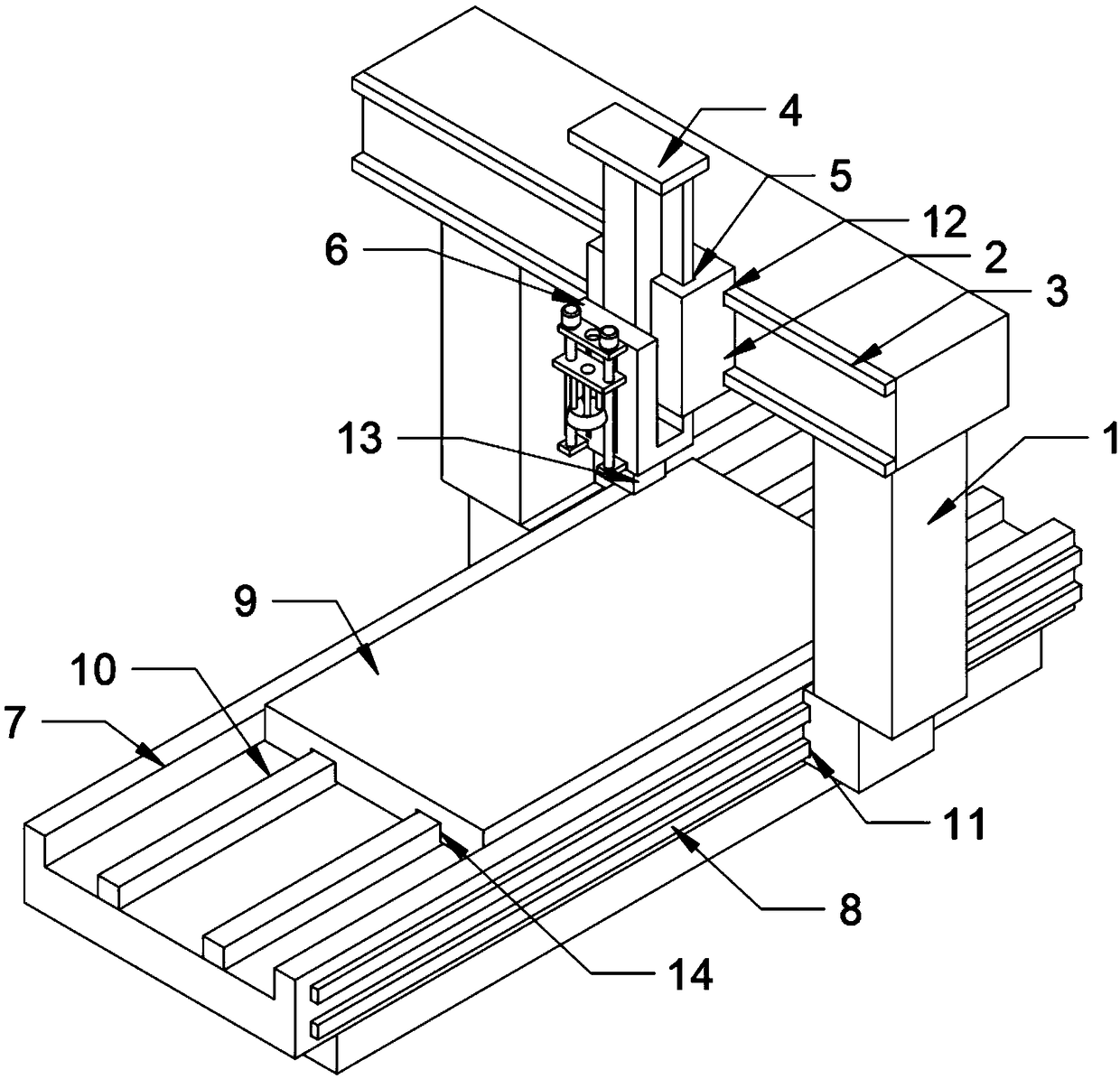

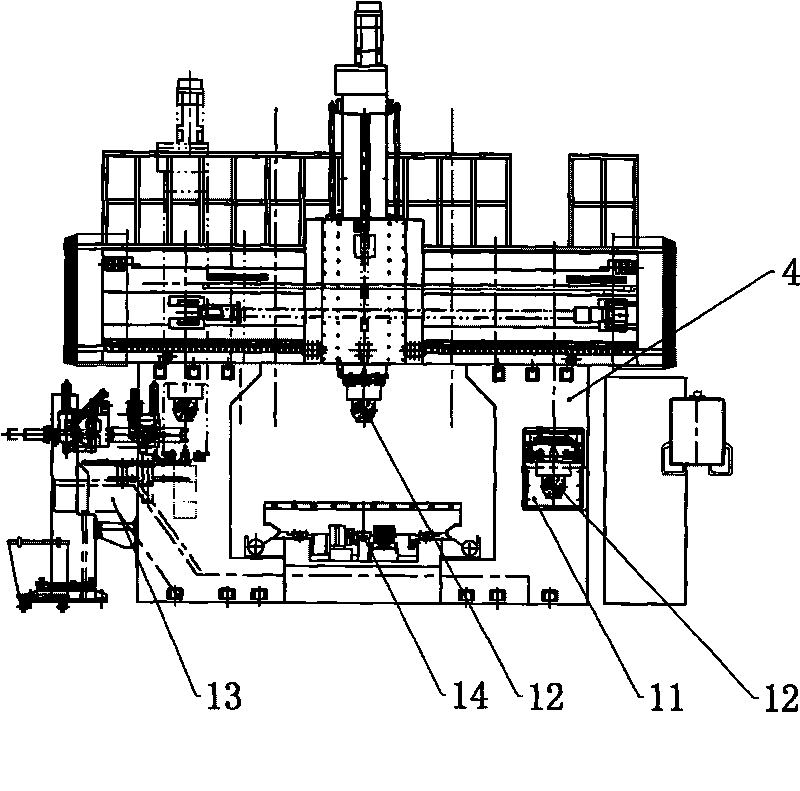

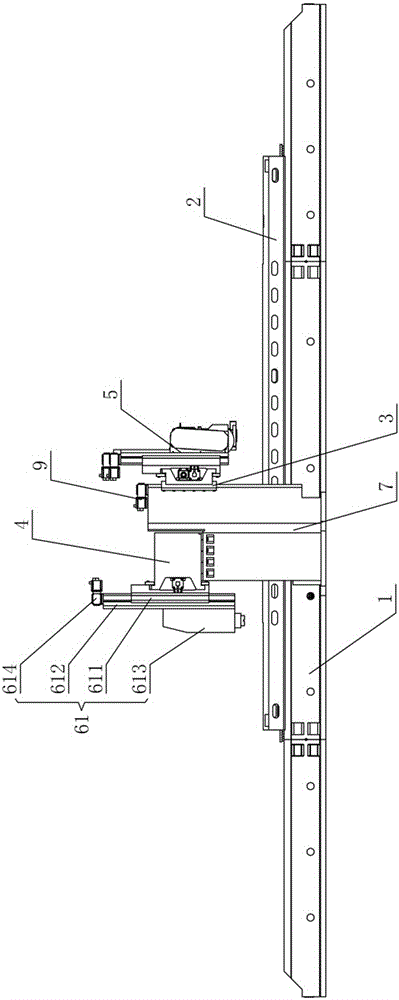

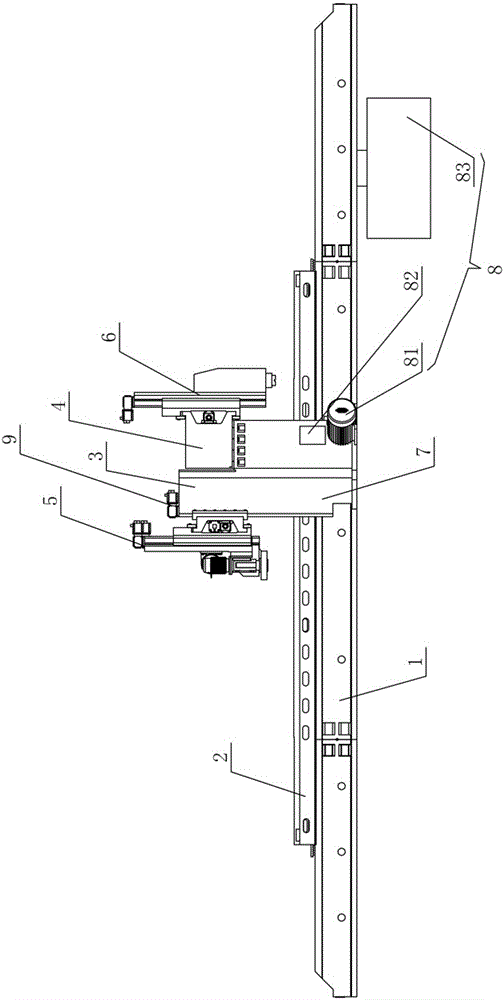

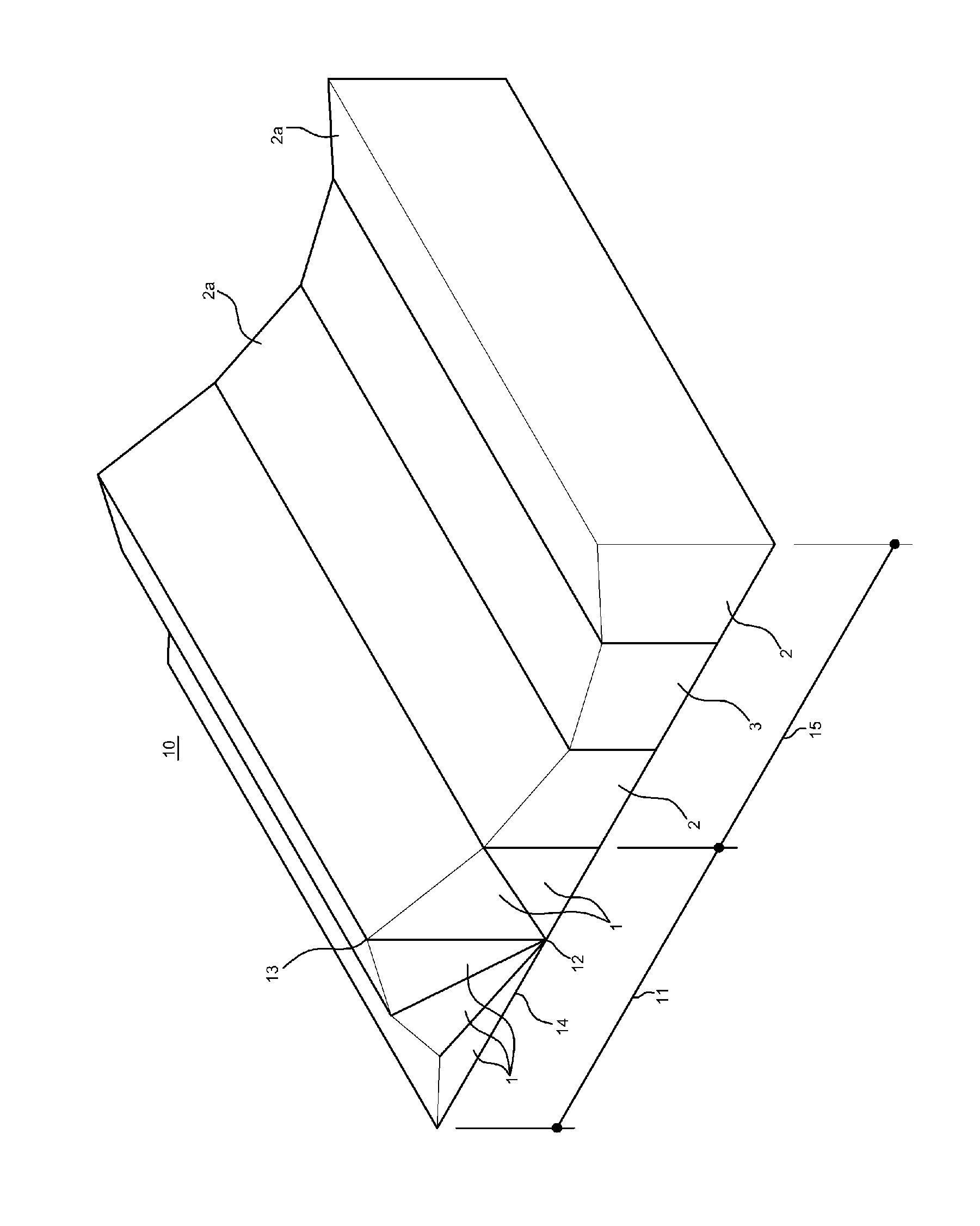

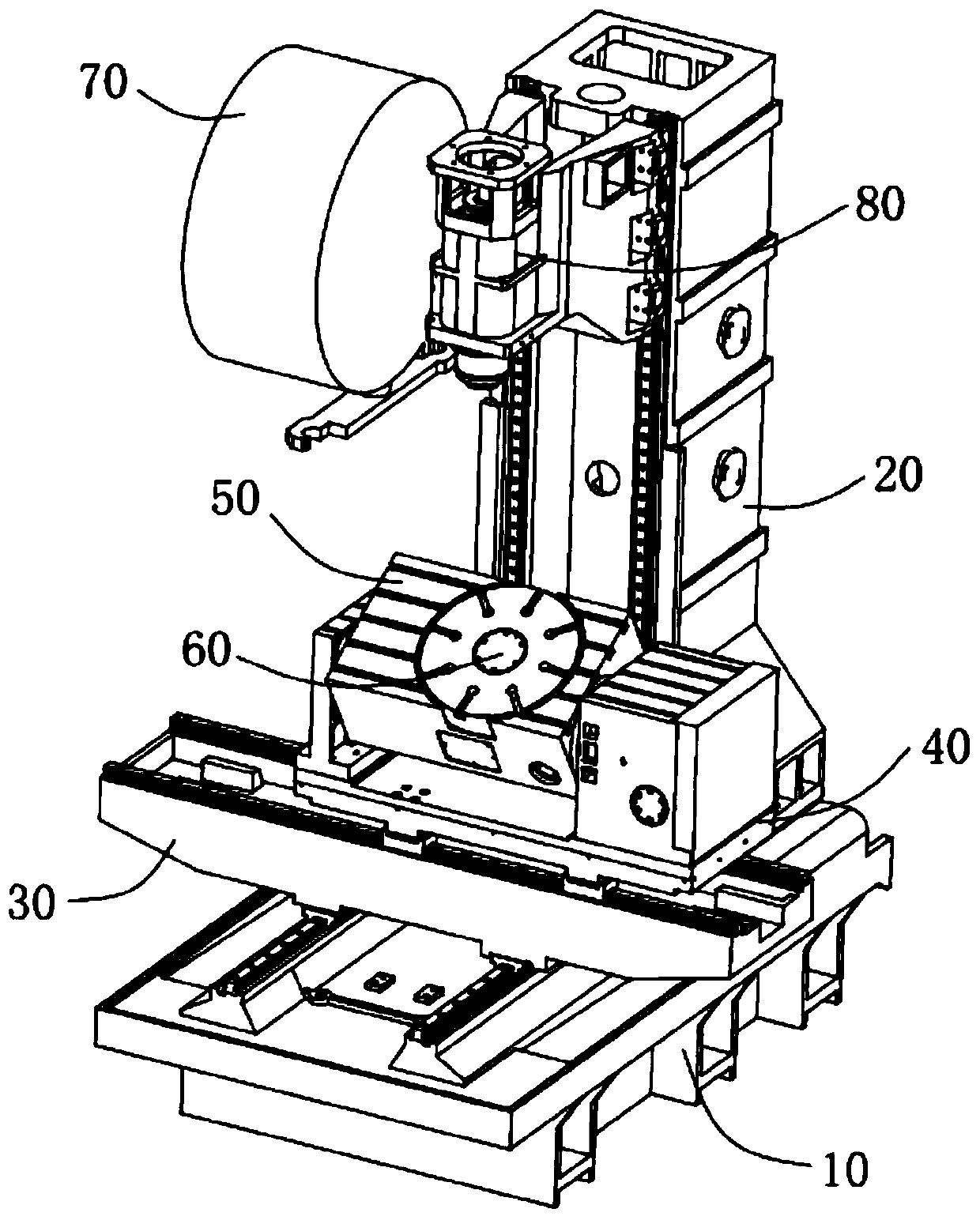

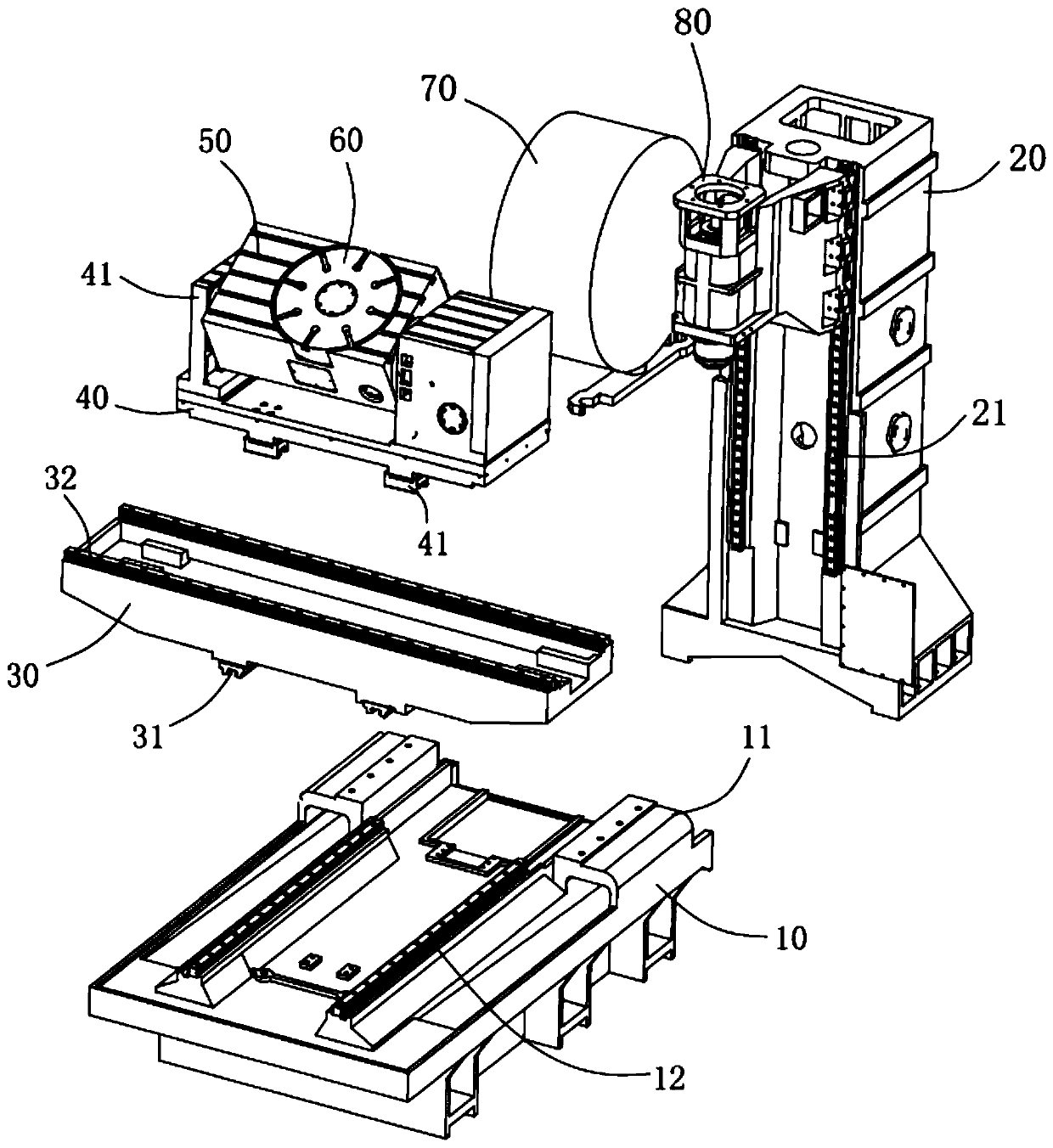

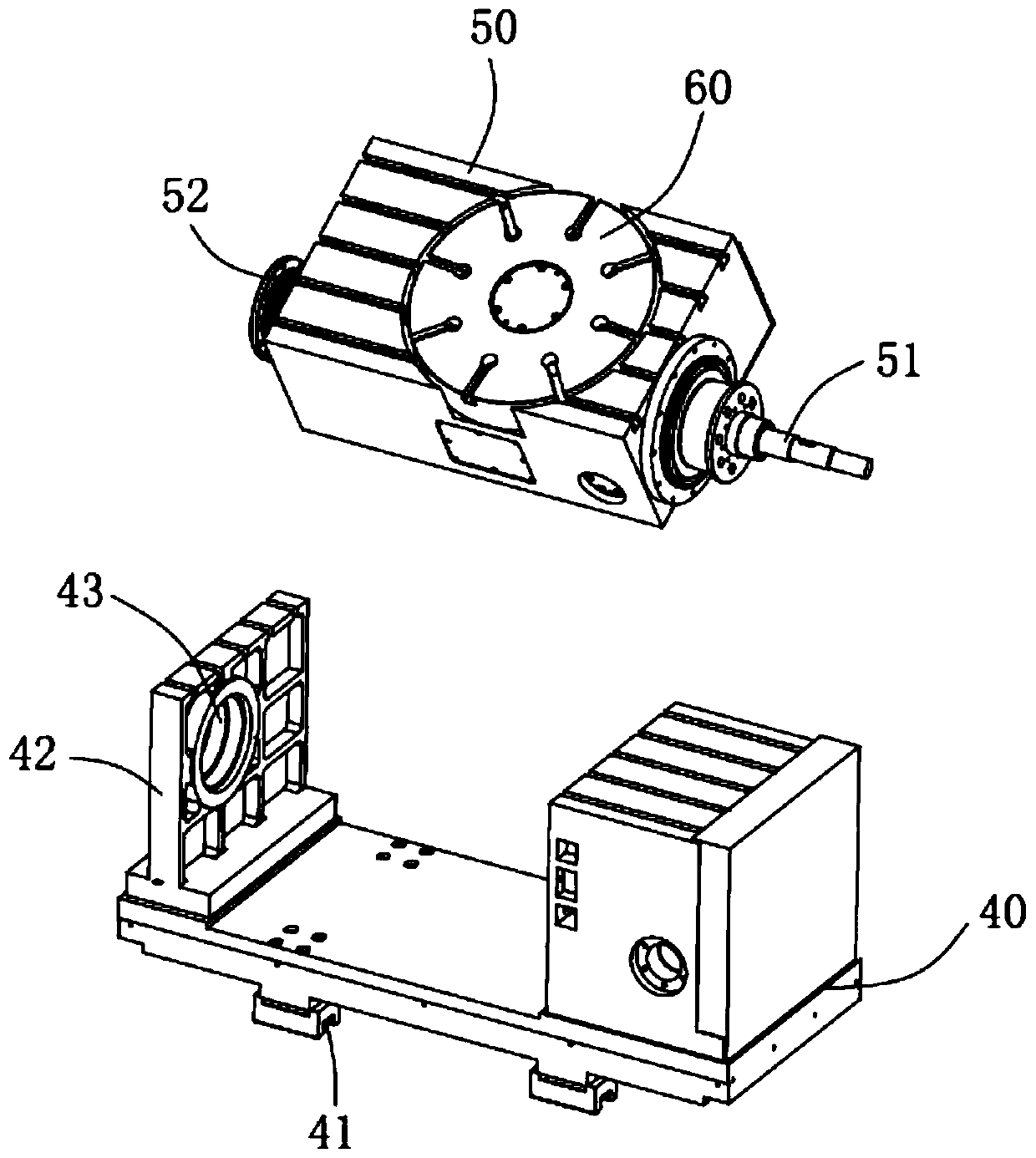

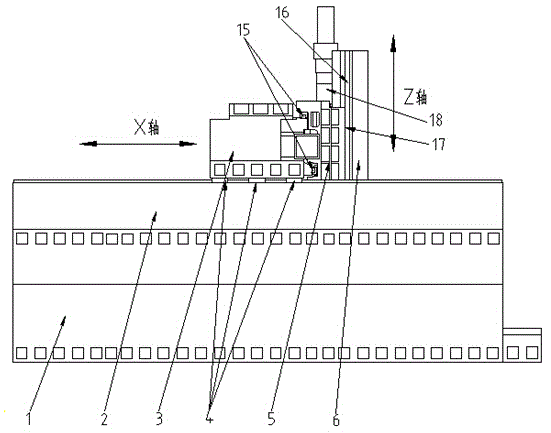

Vertical-horizontal composite pentahedron gantry machining center

InactiveCN105881107AImprove rigidityIncrease productivityFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a vertical-horizontal composite pentahedron gantry machining center which comprise a base; the base is mounted with a stand column; a cross beam is fixed at the upper end of the stand column; the cross beam is provided with a screw rod driving device and movably connected with at least one saddle through a cross beam guide rail; a ram is arranged on the saddle; a vertical spindle box and a vertical spindle are arranged on the ram; a screw rod driving device is arranged on the ram; a horizontal shaft base is fixed on at least one side of the base; a horizontal shaft lathe bed is located on the base; the horizontal shaft lathe bed is connected with a horizontal shaft saddle through a screw rod driving device; a horizontal shaft stand column is fixed on the horizontal shaft saddle; the horizontal shaft stand column is connected with a horizontal shaft spindle box and a horizontal spindle through a screw rod driving device; a horizontal shaft tool changer is fixed on one side of the horizontal shaft base; a longitudinal workbench is further arranged on the base and is driven by a screw rod; a rotating workbench is fixed on the longitudinal workbench; both the longitudinal workbench and the rotating workbench are connected with electrical numerical control devices.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

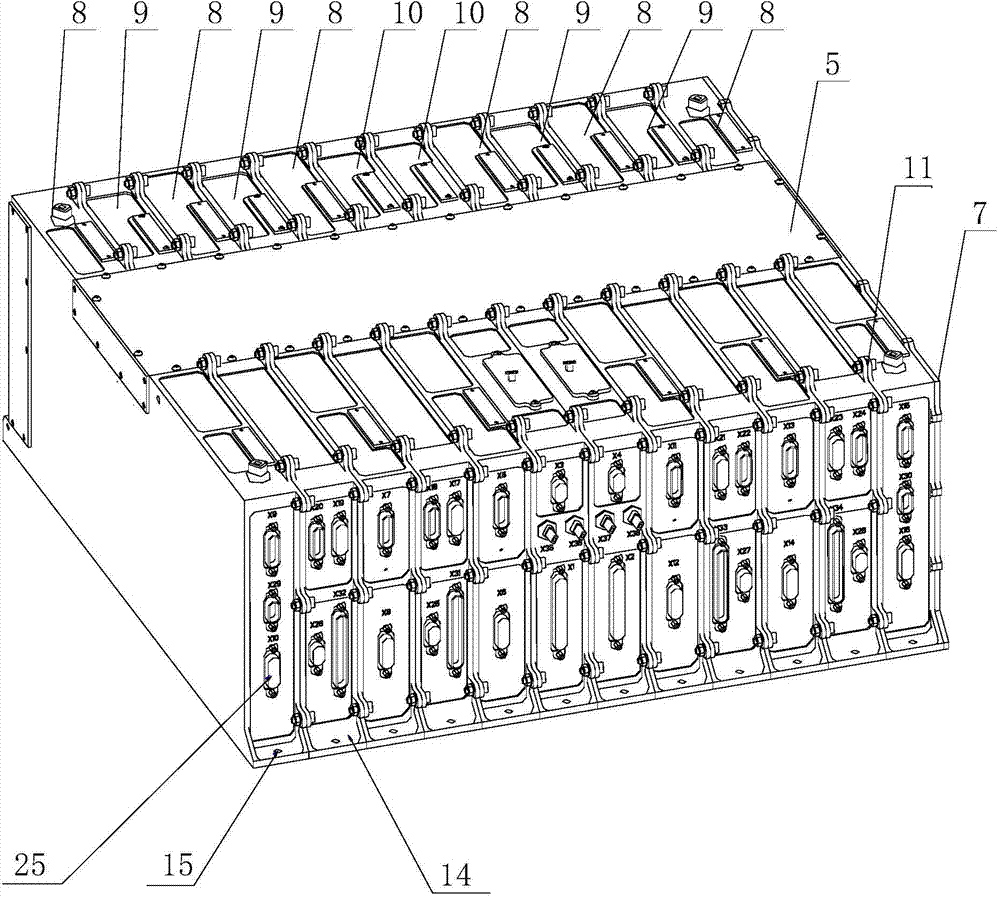

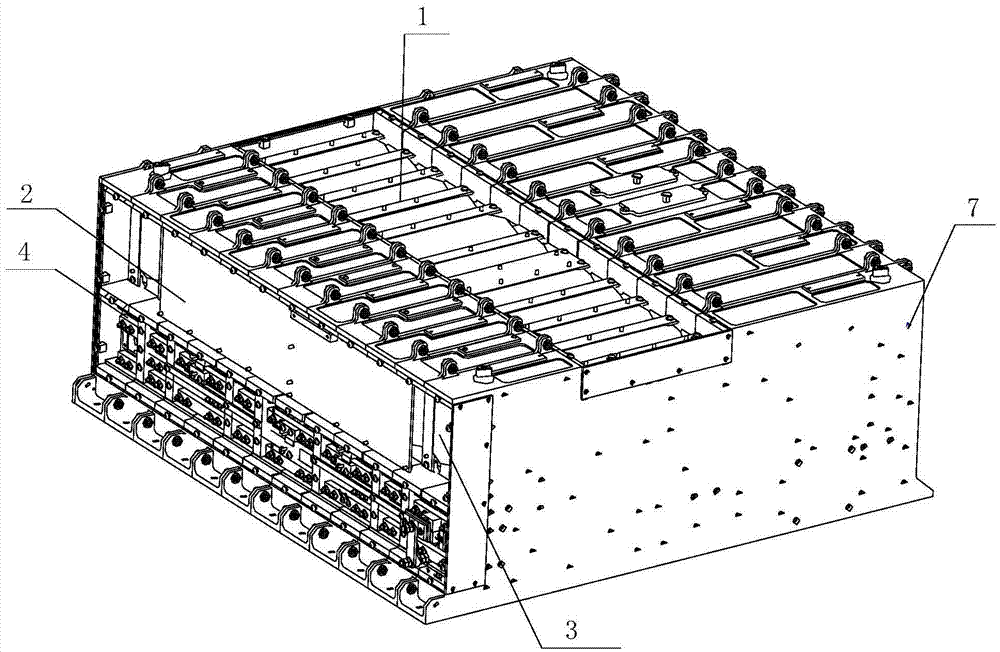

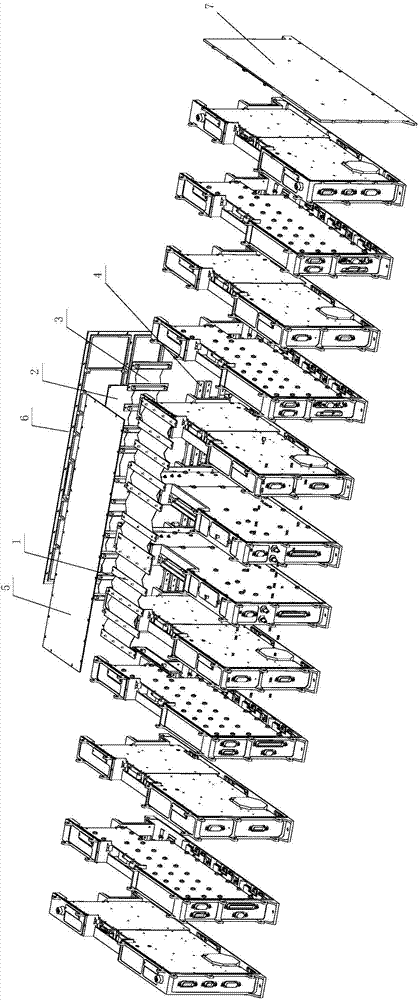

Satellite-borne high-power power conditioning unit platform of extensible structure

ActiveCN103619145AGood mechanical conditionMeet environmental test requirementsMagnetic/electric field screeningCircuit arrangements on support structuresPower controllerRemote control

The invention discloses a satellite-borne high-power power conditioning unit platform of an extensible structure. The satellite-borne high-power power conditioning unit platform of the extensible structure comprises a plurality of function modules, remote control and remote measurement flex-rigid printed boards, main error amplifier EMA modules, complete machine bus bars, an upper cover plate, a rear cover plate and side cover plates, wherein the function modules comprises the charge-discharge conditioning modules, the shunt conditioning modules and the remote control and remote measurement modules, the number of the charge-discharge conditioning modules and the number of the shunt conditioning modules are determined according to a power design objective, the main body of each function module is of a wholly-hollowed-out pentahedron structure, the side cover plates are installed after all the function modules are vertically arranged in a stacked mode, every two adjacent function modules are connected with each other through a protruding lug, each remote control and remote measurement flex-rigid printed board is installed in a cavity in the top of the corresponding function module, each error EMA module and each complete machine bus bar are installed in two cavities in the back side of the corresponding function module respectively, and the overall arrangement of the interior of each function module is layered and three-dimensional. The satellite-borne high-power power conditioning unit platform of the extensible structure can meet the environmental testing requirement of satellite-borne electronic equipment and can also meet the heat radiating requirement of a complete machine.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

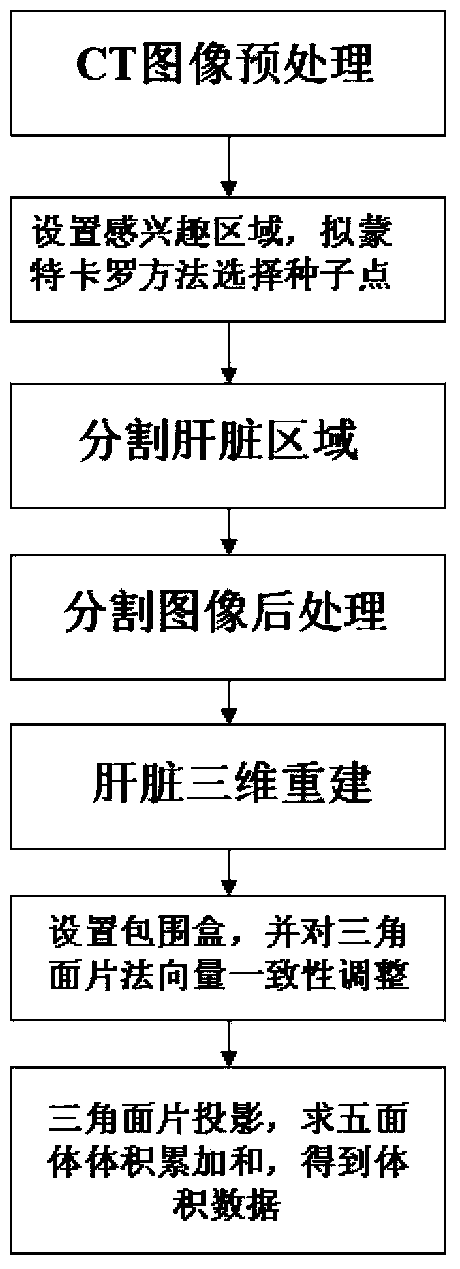

Method for measuring size of three-dimensional reconstruction liver model on basis of improved region growing algorithm

ActiveCN103473805AImprove calculation accuracyChange sizeImage analysis3D modellingProjection planeMeasurement precision

The invention discloses a method for measuring the size of a three-dimensional reconstruction liver model on the basis of an improved region growing algorithm. The method includes the steps that seed point selection and growth criteria in a traditional region growing algorithm are improved by means of a quasi-Monte Carlo method, and an abdomen CT image is segmented by means of an improved region growing segmentation method to extract a liver area; a segmented binary image is used for three-dimensional reconstruction to obtain the three-dimensional reconstruction liver model only provided with a surface mesh, and the model is sealed; a regular square bounding box is arranged, the bottommost face of the bounding box is provided with a projection plane, the sizes of pentahedrons defined by a triangle patch on the reconstruction model and a projection projected by the triangle patch on the projection plane in an enclosed mode are calculated, wherein the triangle patch is provided with a normal vector in the positive direction and a normal vector in the negative direction; finally, the algebraic sum of the sizes of the pentahedrons is the size of the liver model. The method can well represent the shape of the liver, and therefore size measurement is effectively carried out on the three-dimensional reconstruction liver model. Besides, the size of a part of the liver can be measured, and measurement precision is high.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Machining process for guaranteeing precision of external circle of shaft sleeve

The invention relates to the technical field of a shaft sleeve machining process, in particular to a machining process for guaranteeing the precision of an external circle of a shaft sleeve. The machining process comprises the following steps of: casting a steel piece blank; roughly milling each mounting surface, each positioning surface and each circular arc by using a planer type milling machine; roughly turning a front shaft neck, an inner hole and a back-end inner hole by using a vertical lathe; carrying out semi-precisely turning on the front shaft neck and precisely turning the inner hole and the back-end inner hole by using a vertical lathe face; by utilizing a pentahedron machining center, precisely milling and drilling each mounting surface, each positioning surface and holes and screw holes on faces, and precisely milling an circular-arc face; utilizing a rocker arm drill and a horizontal milling machine to ream a mounting hole circular arc and a plane lug boss; and utilizing an external circle milling bed to mill the external circle of the front end shaft neck. The machining process for guaranteeing the precision of the external circle of the shaft sleeve, disclosed by the invention, effectively ensures that the machining precision of the shaft neck is effectively ensured and the deformation amount of the shaft neck is controlled within 0.005 mm; and the machining process is suitable for machining parts with the similar structure, so that the machining process is easy to use and popularize.

Owner:CRRC QISHUYAN CO LTD

Space frame hub joint

A hub joint includes a metal rod and pin for joining tubular members in three-dimensional space for assembling a frame structure. The hub joint enables rapid assembly, rapid reconfiguration, and rapid disassembly without using any specialized tools. Multiple hub joints may be used to form geodesic domes, freestanding trusses, space frame slabs, tetrahedrons, and pentahedrons. The hub joints allow different frame configurations that are lightweight, strong, durable, scalable, expandable, and portable.

Owner:ATHAN STEPHAN P

Compact-structure high-speed automatic right angle head small and skillful in design

The invention discloses a compact-structure high-speed automatic right angle head. The compact-structure high-speed automatic right angle head comprises a box, a spindle and a transmission mechanism arranged between the box and the spindle. The compact-structure high-speed automatic right angle head is characterized in that the box is formed by an upper box body and a lower box body, a plurality of pull nails are arranged on the upper box body, the upper box body is connected with a puller oil cylinder via the pulling nails, the transmission mechanism comprises a first gear transmission mechanism, a transmission shaft and a second gear transmission mechanism, the first gear transmission mechanism is arranged at one end of the transmissions shaft, the second gear transmission mechanism is arranged at the other end of the transmission shaft and is connected with the spindle, the transmission shaft is arranged on a transmission shaft bearing seat, first angle contact ball bearings which are back-to-back are arranged between the transmission shaft bearing sat and the transmission shaft, the upper box body is sleeved at the upper end of the transmission shaft bearing seat, and the lower box body is sleeved at the lower end of the transmission shaft bearing seat. The compact-structure high-speed automatic right angle head has the advantages of compact structure and high rotating speed, and pentahedron lathes are enabled to be higher in cost performance.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

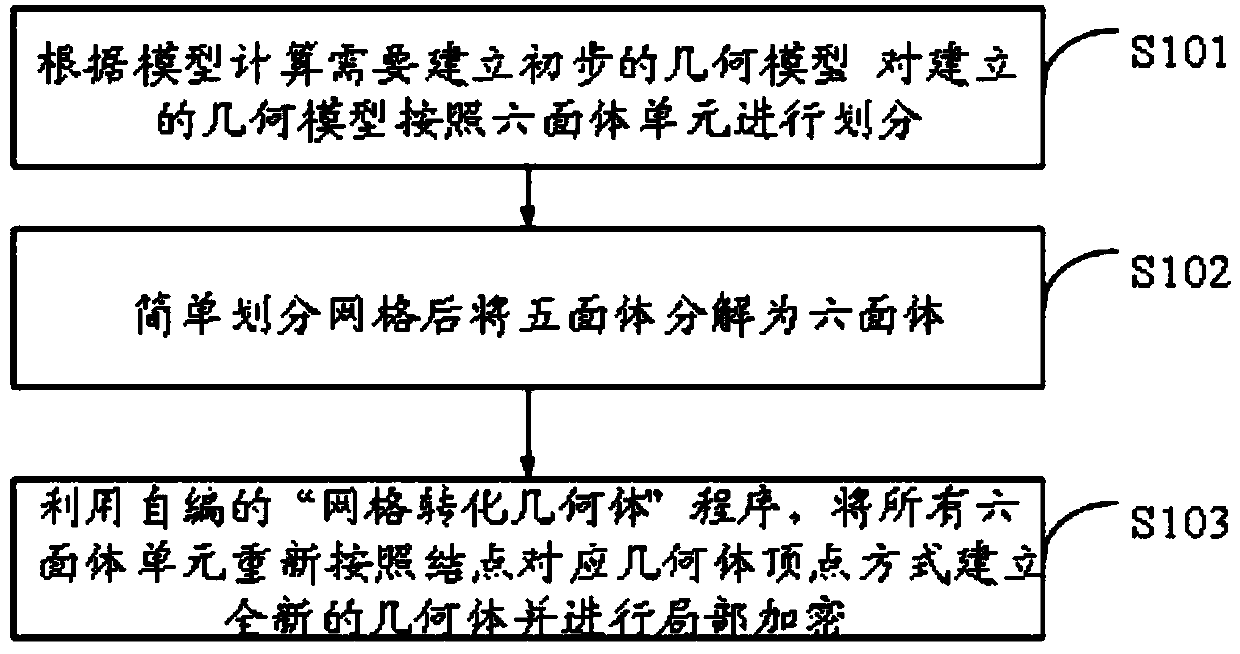

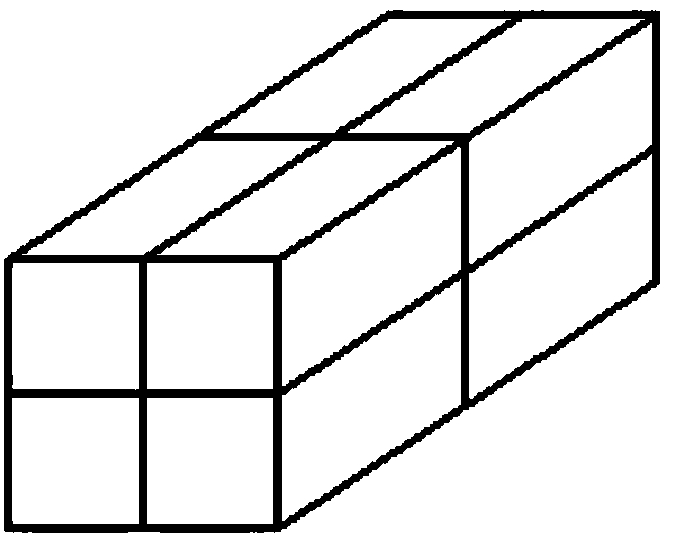

Complicated model complete hexahedron modeling and geometry remodeling and encryption method

ActiveCN103729506AQuick buildArbitrary control of local encryption densitySpecial data processing applicationsGeometric modelingSimulation

The invention discloses a complicated model complete hexahedron modeling and geometry remodeling and encryption method. The method includes: calculating geometry models required being built primarily according to models, and dividing the built geometry models according to hexahedron units; simply dividing grids, and then dividing transition units (pentahedron units) into hexahedron units; using a self-programmed grid-geometry conversion program to build all hexahedron units into brand new geometries according to a manner that nodes correspond to peaks of geometries, and performing local control encryption. By the method, a complete hexahedron network can be built fast, the local encryption density can be controlled optionally, precondition for performing large-scale scientific calculation is provided, and the build models are also suitable for other numerical methods.

Owner:DALIAN UNIV OF TECH

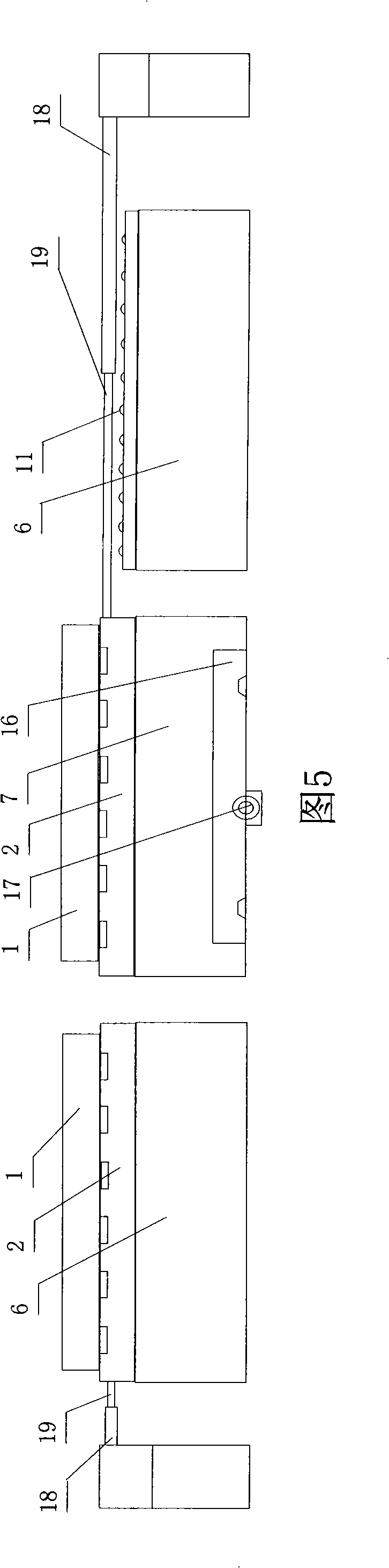

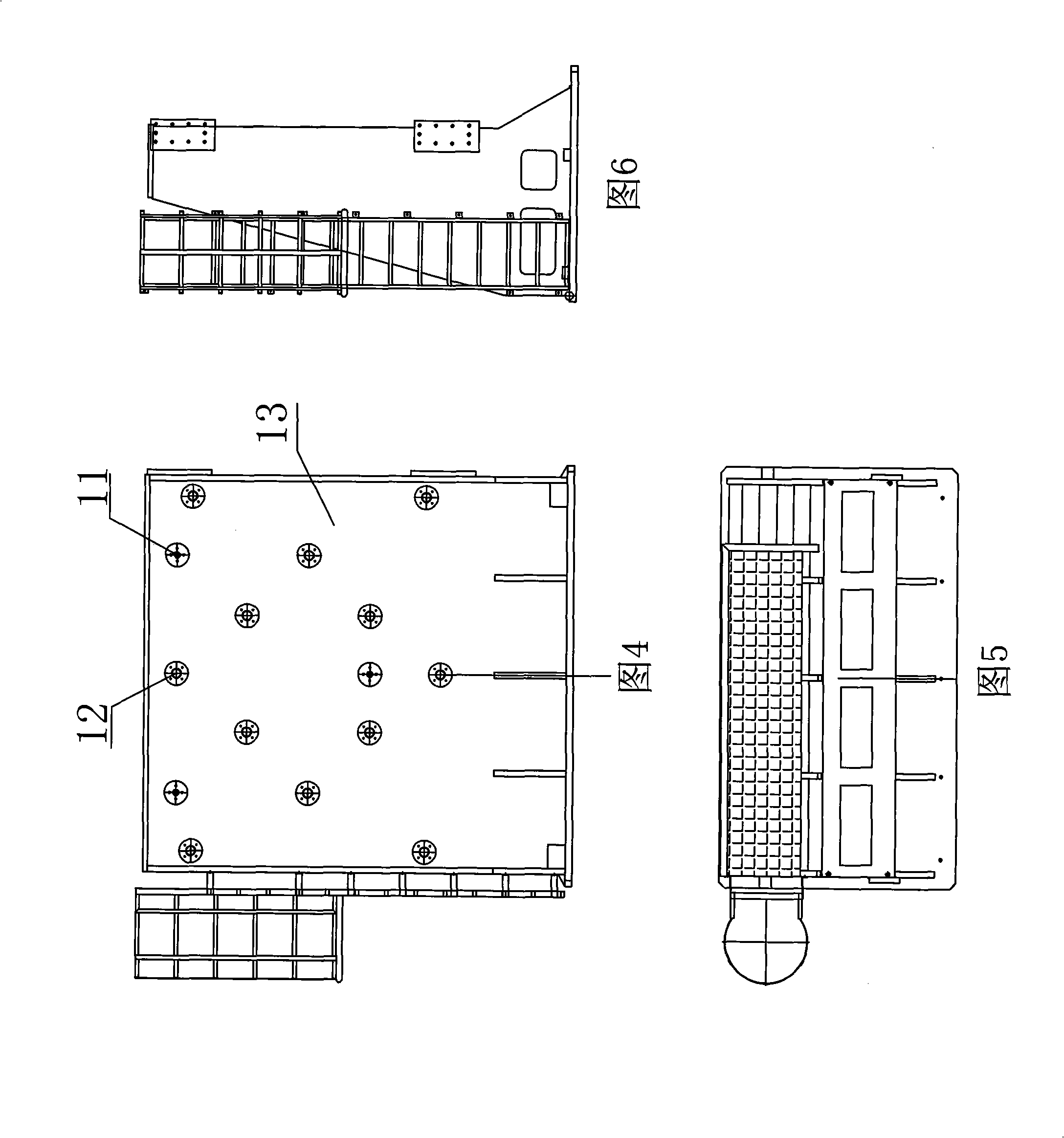

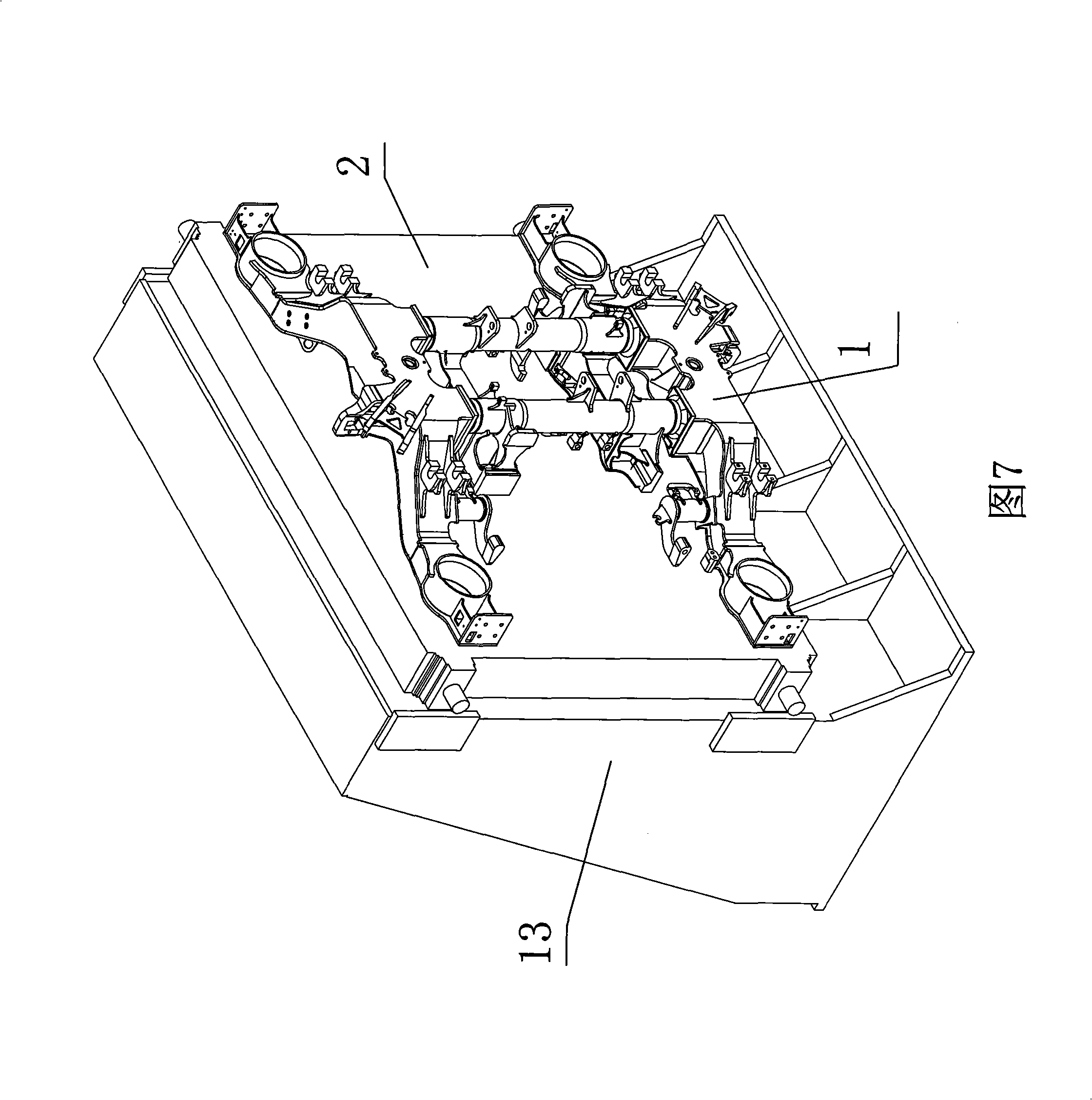

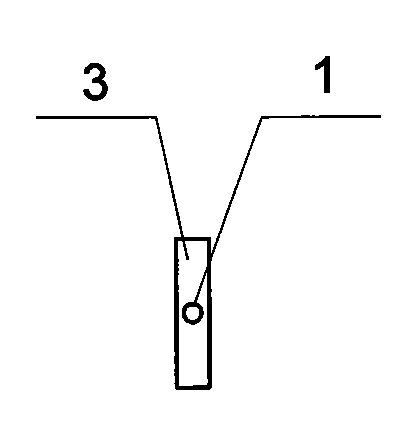

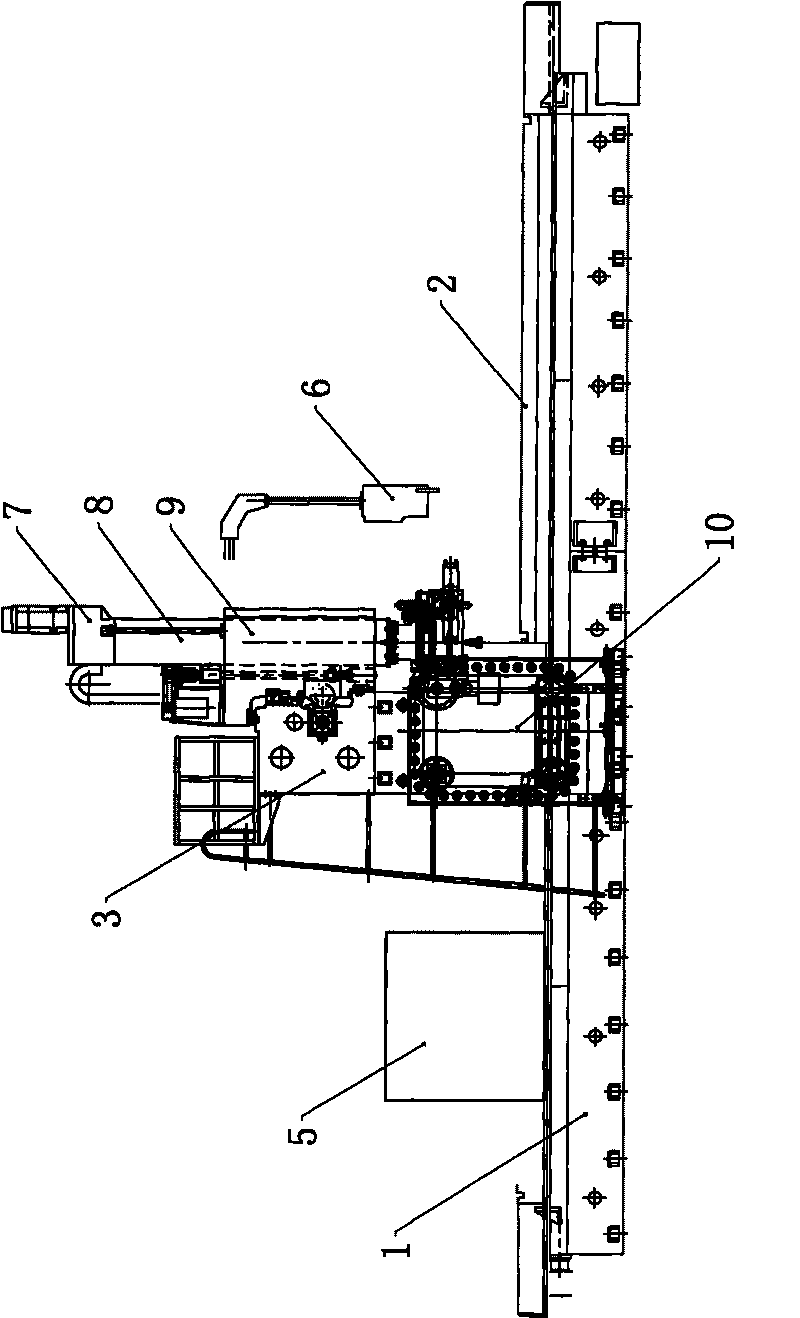

Pentahedron gantry processing center double-exchange workpiece conveying platform

InactiveCN101357439AShorten the processing cycleReduce the ratioLarge fixed membersMetal working apparatusEngineeringMachining

The invention relates to a center for processing a gantry, in particular to a transporting platform for transporting workpieces in and out used in the gantry machining center. The transporting platform is provided with a workpiece installation table used for fixing the workpiece and a vertical linear movement platform which is supported under the workpiece installation table and used for pushing or pulling the workpiece into or out of the machining center before or after the workpiece processing; a horizontal linear movement platform which bears the workpiece installation table and pushes the workpiece into or out of the vertical linear movement platform is arranged in front of the vertical linear movement platform; the vertical linear movement platform and the horizontal linear movement platform form a T-shaped structure; the horizontal movement mechanism comprises a transfer platform and two loading and unloading platforms arranged at the two sides of the transfer platform. The transporting platform greatly enhances the work efficiency and the structure of the whole transporting platform is compact, thus reducing the area occupied by the equipment; the structural improvement is based on the original transporting platform; thus the transporting platform has relatively simple structure and low improvement cost.

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

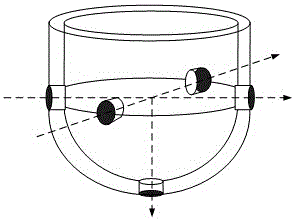

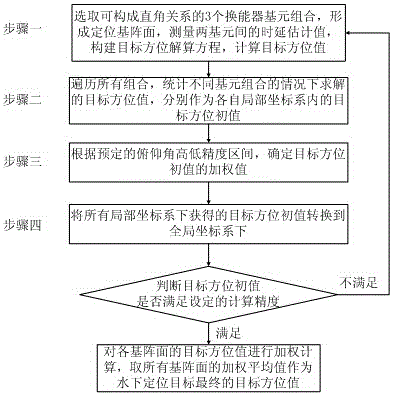

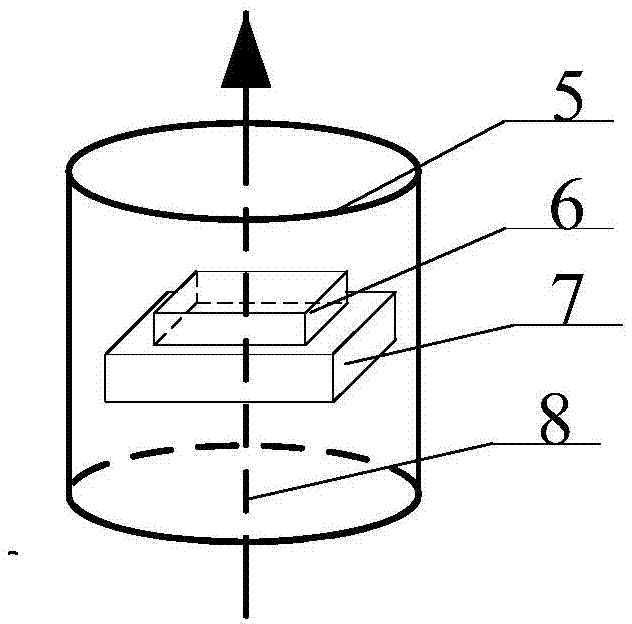

Ultra-short baseline five-element stereoscopic space array and underwater acoustic localization method

InactiveCN106199519AGuaranteed validityImprove effectivenessPosition fixationOrthogonal coordinatesClassical mechanics

The invention discloses an ultra-short baseline five-element stereoscopic space array including five underwater acoustic energy transducer elements that are respectively arranged at the vertexes of a spatial pentahedron, four of the underwater acoustic energy transducer elements are arranged at the four vertexes in a horizontal plane to form a square layout, and two diagonal elements of the four elements in the same plane and the fifth element respectively form positioning planes in the vertical direction, and thereby two positioning reference planes in the vertical direction are formed. When the localization is carried out, an orthogonal coordinate system can be formed by using any three points of the horizontal plane, and also a horizontal orthogonal coordinate system can be formed by four points; and meanwhile, any two diagonal elements on the horizontal plane and the fifth element form positioning array planes in the vertical direction, different array planes are combined for positioning to obtain target directional values, and then by means of coordinate transformation, the positioning result of each local coordinate system is converted to a unified overall positioning coordinate system for data fusion to be the final directional value of the target to be measured.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Integral processing method for truck frame of high-speed motor train unit

ActiveCN101342663AControl stressGuaranteed accuracyAutomatic control devicesFeeding apparatusBogieNumerical control

The invention discloses an integrated processing technology of a high speed motor train unit bogie frame, comprising a magnetic dial indicator which is used to quantize and control clamping deformation and clamping force, an integrated accompanying chemical device which is used for the integrated processing of the frame, a numerical control core milling processing center which is used for the integrated processing of the frame. By using the magnetic dial indicator to quantize and control clamping deformation and clamping force, the integrated processing technology effectively controls the stress produced by clamping frocks, and furthermore guarantees the precision of the size of the frame after finishing processing and loosening the clamp. By using the method for determining the relationship between the workpiece and the machine tool coordinate system through two positioning, the integrated processing technology improves the utilization rate of the machine tool, and ensures that the improvement of the clamping precision of the frame becomes possible on the other hand. By using the numerical control core milling processing center, the integrated processing technology fully utilizes all kinds of functions of the machine tool to process the frame with a pentahedron analogously type, with the result that the precision loss which may be produced by multiple step processing can be effectively avoided, and the processing precision and quality of the frame can be greatly improved.

Owner:CHINA RAILWAYS CORPORATION +2

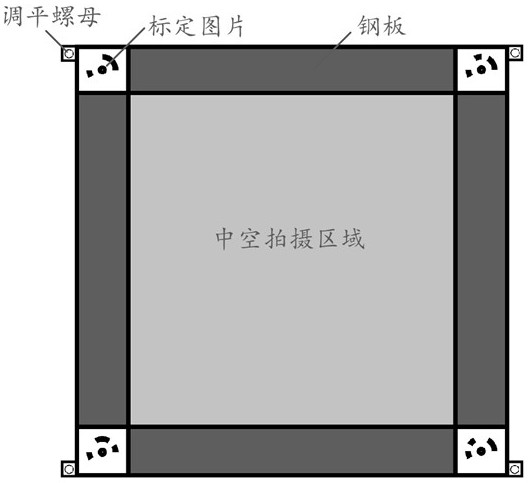

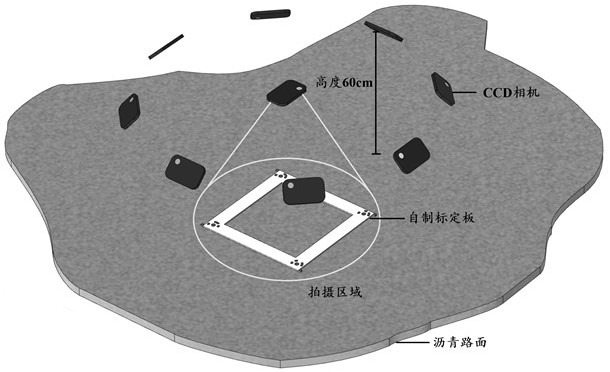

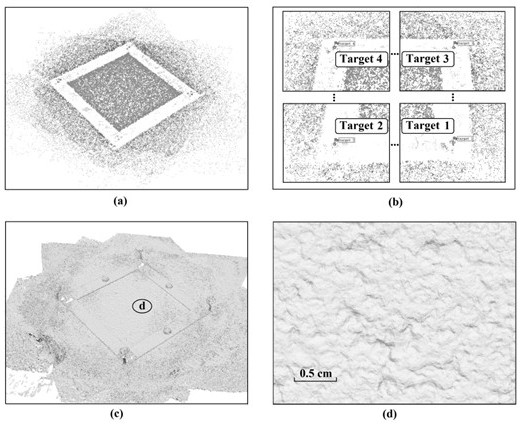

Asphalt pavement structure depth measuring method

ActiveCN112927366ADetails involving processing stepsUsing optical meansRight triangleClassical mechanics

The invention relates to a method for measuring the structure depth of an asphalt pavement. The method specifically comprises the following steps: S1, constructing a pavement texture model; S2, drawing up DRP and TRP by using an algorithm; S3, when the pavement texture model and the TRP are enclosed, dividing the pavement plane model, equally dividing a plurality of square grids, dividing the pavement plane model into two isosceles right triangle networks along a diagonal line, projecting three vertexes of each triangular grid along a Z-axis direction, and taking intersection points of the three vertexes and the pavement texture to form a triangle, generating pentahedrons by taking a triangular grid and a triangle defined by the triangular grid as a top surface and a bottom surface, abandoning all the pentahedrons of which the equivalent volume is a negative value when the equivalent volume of pavement texture filling is calculated, and superposing the volumes of the other pentahedrons in all grids, namely, the filling volume VFil of the pavement structure depth; S4, calculating the MTD', wherein MTD' IS is an approximate value of the MTD. The invention provides a pentahedron volume calculation method suitable for asphalt pavement structure depth.

Owner:CENT SOUTH UNIV

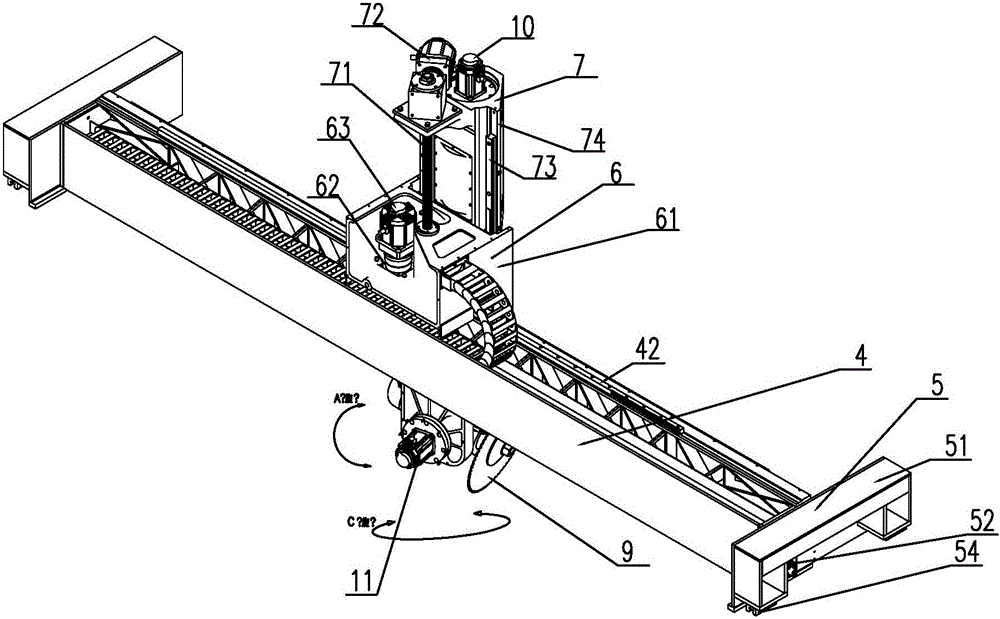

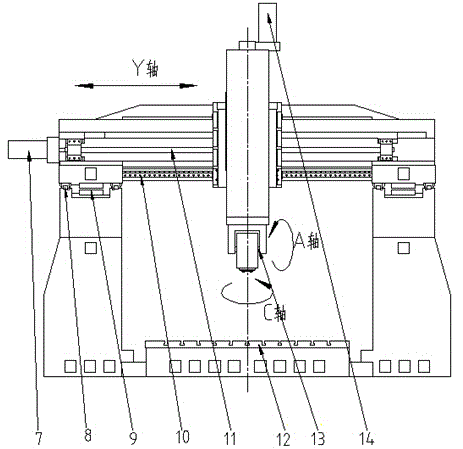

Numerical control five-shaft motion bridge type stone cutter

InactiveCN104985707AImprove efficiencyGuaranteed uptimeWorking accessoriesStone-like material working toolsLine shaftNumerical control

The invention relates to the stone processing machinery technical field, and especially relates to a stone multidimensional space heterotype curved surface processing five-shaft motion bridge type stone cutter comprising a pedestal, a work table, a side frame, a crossbeam, a vertical travel mechanism, a transverse travel mechanism, a lifting cutting mechanism, a cutting link seat, a cutter device, a C-shaft rotary drive mechanism, an A-shaft rotary drive mechanism, and a pc industrial control box; the vertical travel mechanism, the transverse travel mechanism, the lifting cutting mechanism, the C-shaft rotary drive mechanism, and the A-shaft rotary drive mechanism, are respectively connected with the pc industrial control box, and the cutter can be controlled on three linear shafts (X,Y and Z) and the two rotary shafts (A and C). the five-shaft motion bridge type stone cutter has five-shaft motion, real time linear, arc interpolation functions, can realize complex pentahedron curved surface processing, is mainly applied to multidimensional space heterotype curved surface stone decoration elaboration processing, thus doubling efficiency; the five-shaft motion bridge type stone cutter is stable in operation, and can reduce production and equipment maintenance cost.

Owner:FUJIAN JINJIANG SHENGDA MACHINERY

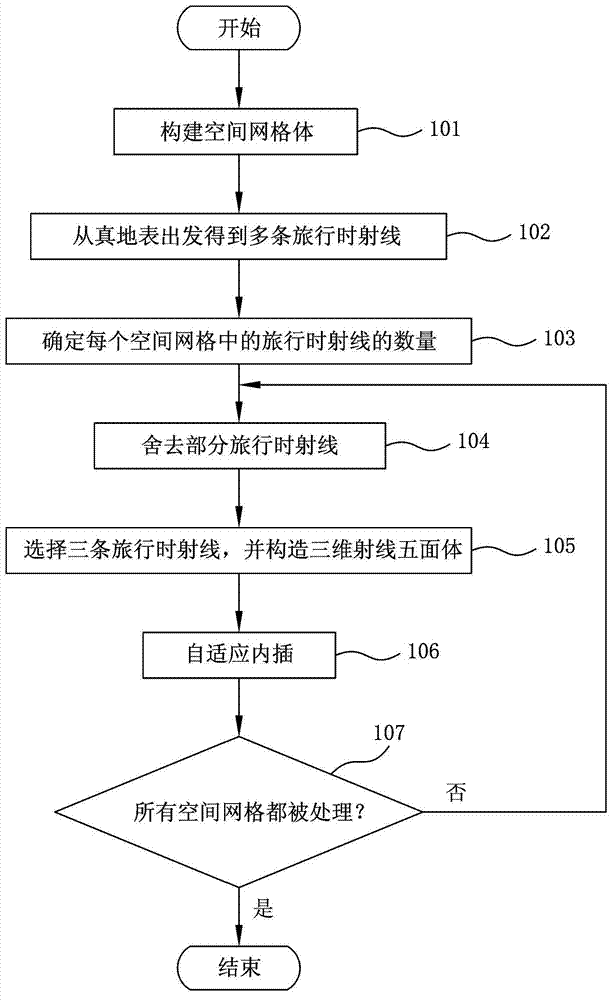

Self-adaption interpolating method for real ground-surface ray tracking

ActiveCN102830431AHigh precisionImprove efficiencySeismic signal processingSelf adaptiveComputer science

The invention provides a self-adaption interpolating method for real ground-surface ray tracking. The self-adaption interpolating method includes steps of (a), dividing a space required for travel-time ray tracking into spatial lattice bodies formed by a plurality of spatial lattices; (b) performing ray tracking computation from a real ground surface, and acquiring a plurality of travel-time rays in transmission of earthquake waves; (c) determining the number of travel-time rays penetrating through each spatial lattice; (d) selecting three travel-time rays penetrating through one or more spatial lattices adjacent to the spatial lattices with travel-time rays fewer than the preset number, and constructing a three-dimensional ray pentahedron on the basis of step length of the travel-time rays; (e) performing self-adaption interpolation via travel time of each control point at the six peaks arranged on the ray pentahedron, and accordingly, acquiring a travel-time ray penetrating through the spatial lattices; and (f), repeatedly executing the steps (d) and (e) until the number of the travel-time rays penetrating through the spatial lattices reaches the preset number.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

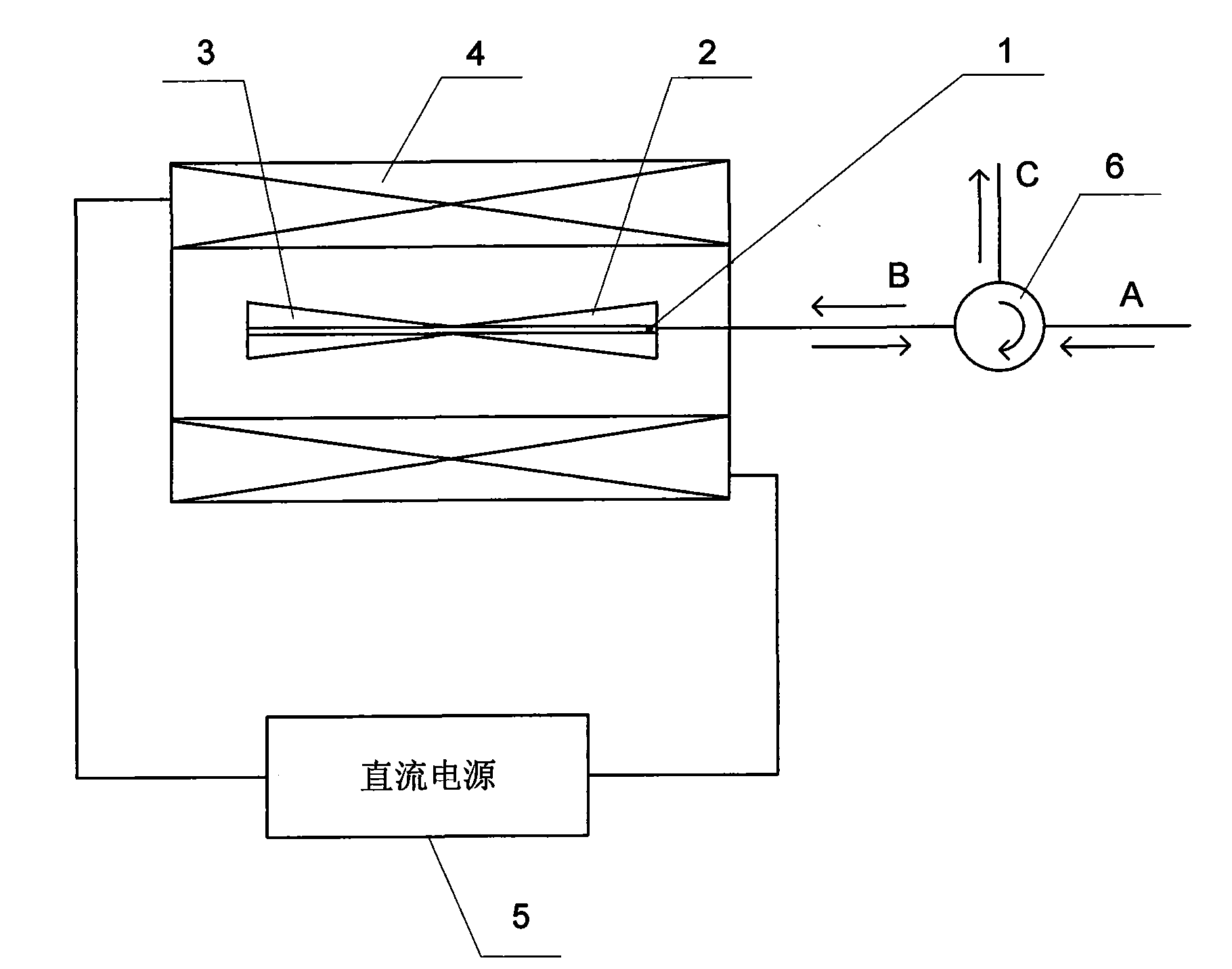

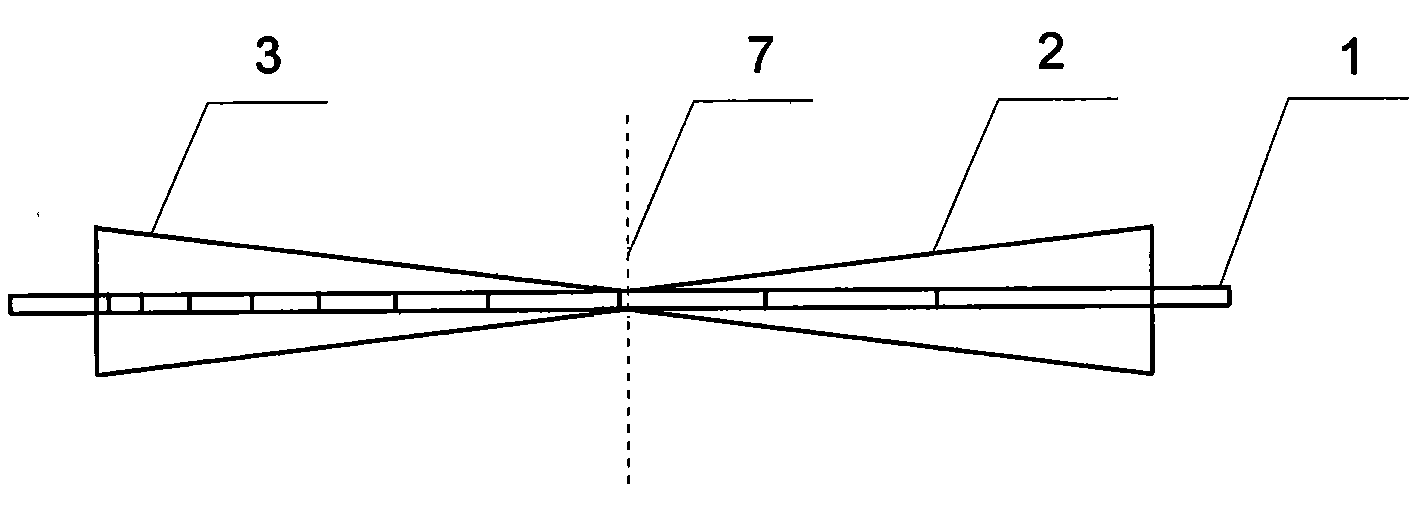

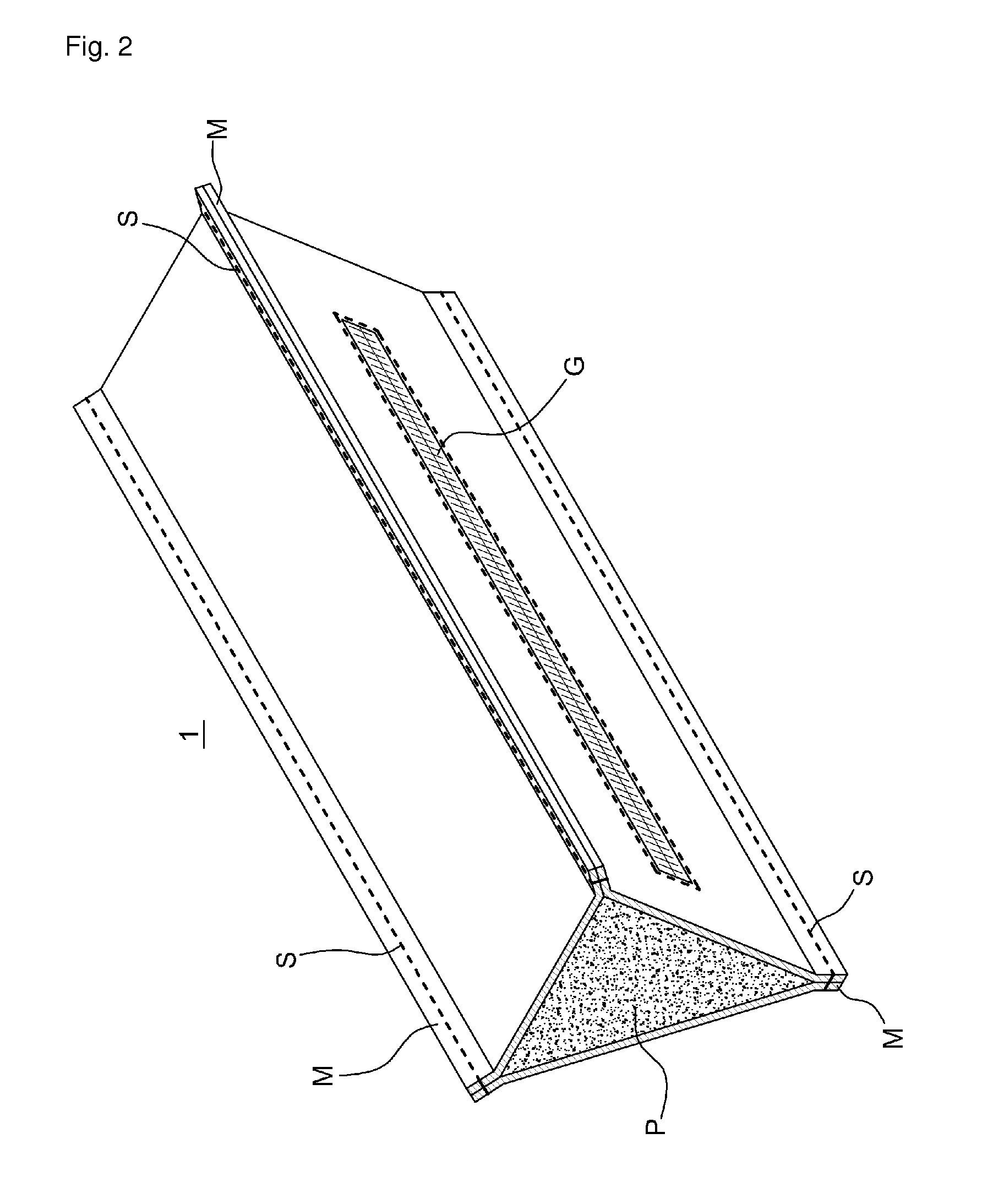

Chirp grating tuner based on magnetoconstriction

InactiveCN101581835AFast Dispersion CompensationDynamic Dispersion CompensationNon-linear opticsGratingOptical communication

The invention discloses a chirp grating tuner based on magnetoconstriction, belonging to the field of optical communication. The chirp grating tuner based on magnetoconstriction aims to solve the problem that response speed is low when chirp bragg grating is tuned with thermal tuning technology. The chirp grating of the invention is plated with a positive magnetostrictive film and a negative magnetostrictive film, wherein, the positive magnetostrictive film and the negative magnetostrictive film are both pentahedron whose cross section is isoceles triangle, and the positive magnetostrictive film and the negative magnetostrictive film are arranged along the perpendicular bisector of the axial line of the chirp grating in a mirror image mode; the symmetric lines of the positive magnetostrictive film and the negative magnetostrictive film are both in superposition with the axial line of the chirp grating, and the top of the positive magnetostrictive film and the top of the negative magnetostrictive film are in superposition with the central point of the chirp grating; the length of triangle hemline of the positive magnetostrictive film is 3.5 to 5 times of the diameter of the chirp grating, and the thickness of the positive magnetostrictive film is 1.1 to 1.5 times of the diameter of the chirp grating; chirp grating plated with the positive magnetostrictive film and the negative magnetostrictive film is arranged in a helix tube, and two ends of the helix tube loop are respectively connected with the positive pole and the negative pole of a direct current supply. The invention is used for chromatic dispersion compensation in optical communication.

Owner:HARBIN INST OF TECH

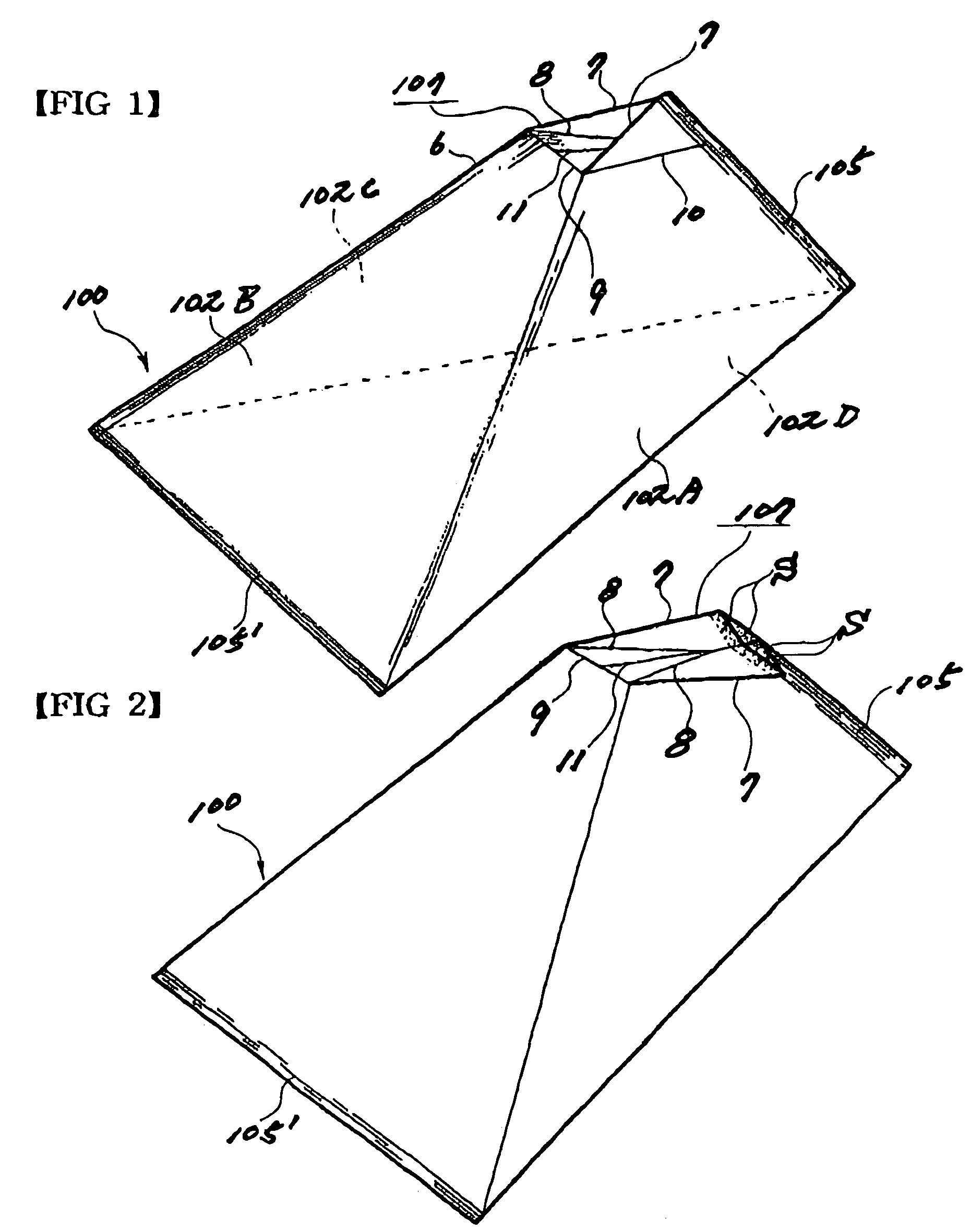

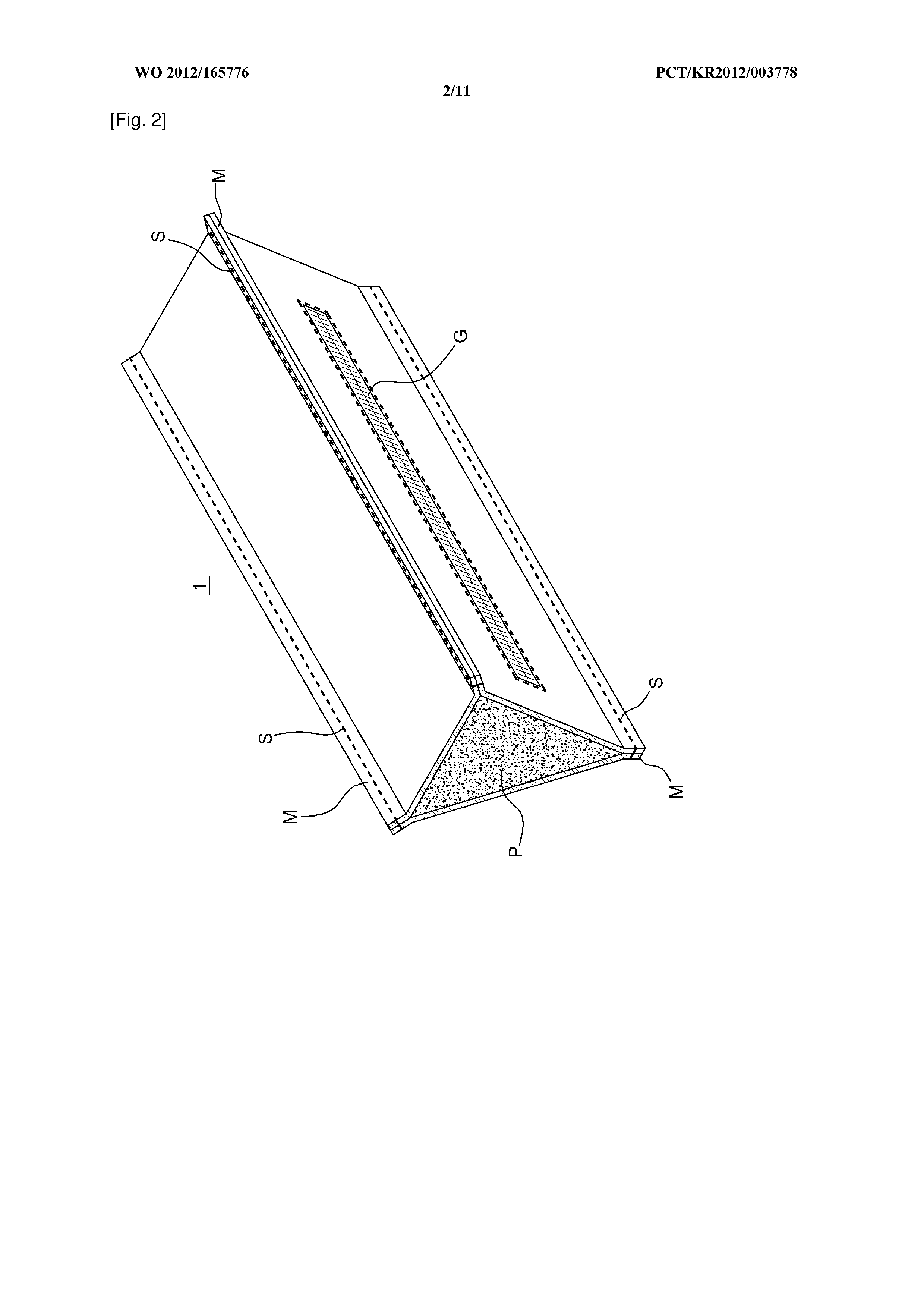

Pillow having a plurality of polygonal units

A pillow having a plurality of polygonal units, includes: a triangular pentahedron unit having a shape of a triangular prism; a one-side inclined square hexahedral unit having a shape of a square pillar; a rectangular hexahedron unit having a shape of a rectangular pillar; a both-side inclined rectangular hexahedron unit having a shape of a rectangular pillar; a rhombic hexahedron unit having a shape of a rhombic pillar; an isosceles-triangular pentahedron unit having a shape of an isosceles triangular prism; and a rectangular panel-shaped hexahedron unit having a shape of a rectangular pillar, whereby the units are sewn together in such a way so as to selectively come into surface contact with each other or be stacked, thus forming one pillow, with the respective units being filled with stuffing.

Owner:VENYGOOD

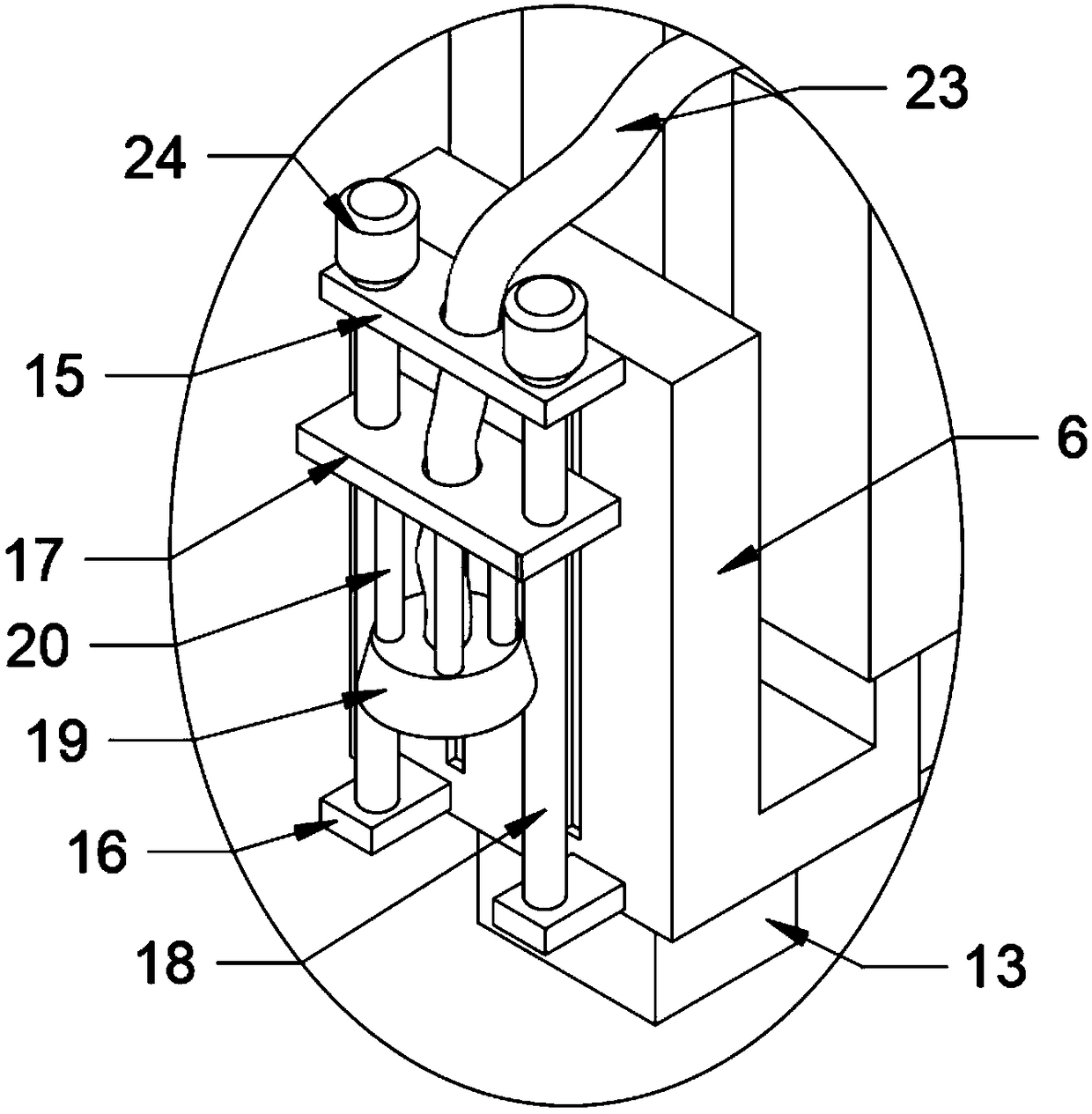

High-efficient scrap-removal pentahedron machining center

InactiveCN108907302AReduce usageCompact structureMilling machinesMaintainance and safety accessoriesEngineeringPortal frame

The invention discloses a high-efficient scrap-removal pentahedron machining center. The high-efficient scrap-removal pentahedron machining center comprises a portal frame, a transverse moving block,transverse guiding rails, a vertical moving block, a clamping slot, a mounting block, a base, longitudinal guide rails, a processing plate, sliding guide rails, longitudinal guide slots, transverse guide slots, a pentahedron processing block, sliding guide slots, an upper mounting plate, a lower mounting plate, a movable plate, a lifting lead screw, a scrap removal shell, electromagnetic telescopic rods, sliding slots, universal bearings, a telescopic guide pipe, a rotating motor, threaded holes and sliding rails, wherein the longitudinal guide rails are fixed to the two sides of the base; theportal frame is arranged above the base; the corresponding sides, close to the base, of the two-sided bottom ends of the portal frame are provided with the longitudinal guide slots matched with the longitudinal guide rails; a scrap-removal structure of the pentahedron machining center can be comprehensively moved along with a cutter fixing device, so that the use of an adjusting driving machine of the scrap-removal device is reduced and scraps are convenient to remove, and meanwhile, through cooperation application of the electromagnetic telescopic rods with different telescopic lengths, a scrap-removal shell and different inclined surfaces can be placed in parallel, so that the scrap-removal precision is improved.

Owner:深圳市钜人数控设备有限公司

High-precision pentahedral machining machine tool

InactiveCN101695769ANo loss of precisionDoes not decrease rigidityMilling equipment detailsElectrical controlEngineering

The invention relates to a high-precision pentahedral machining machine tool which comprises a machine tool body, a workbench, a beam, a left upright post, a right upright post, an electrical control body, a control board, a main transmission case, a slide pillow, a dragging plate, a cutter storeroom, an automatic head storeroom, a right-angle cutter head and a chip discharger. Guide rails respectively comprise linear rolling guide rails arranged at the left side and the right side of the machine tool body and an inserted steel rolling guide rail arranged in the middle of the machine tool body, wherein the inserted steel rolling guide rail comprises an inserted steel piece, a rolling piece and a fixing piece of the rolling piece. The center of a spindle of the right-angle cutter head is provided with a pull rod sleeved with a butterfly-shaped spring, and the right end of the pull rod is connected with a clamping claw. The inserted rolling guide rail also comprises an oil cylinder knife loosening device, and embedded parts of heat storeroom shells are embedded in the right upright post. The invention has the advantages of high processing precision, easy assembly, good interchangeability of machine tool parts, occupied space reduction of the machine tool and head replacement speed improvement.

Owner:GREATOO INTELLIGENT EQUIP INC

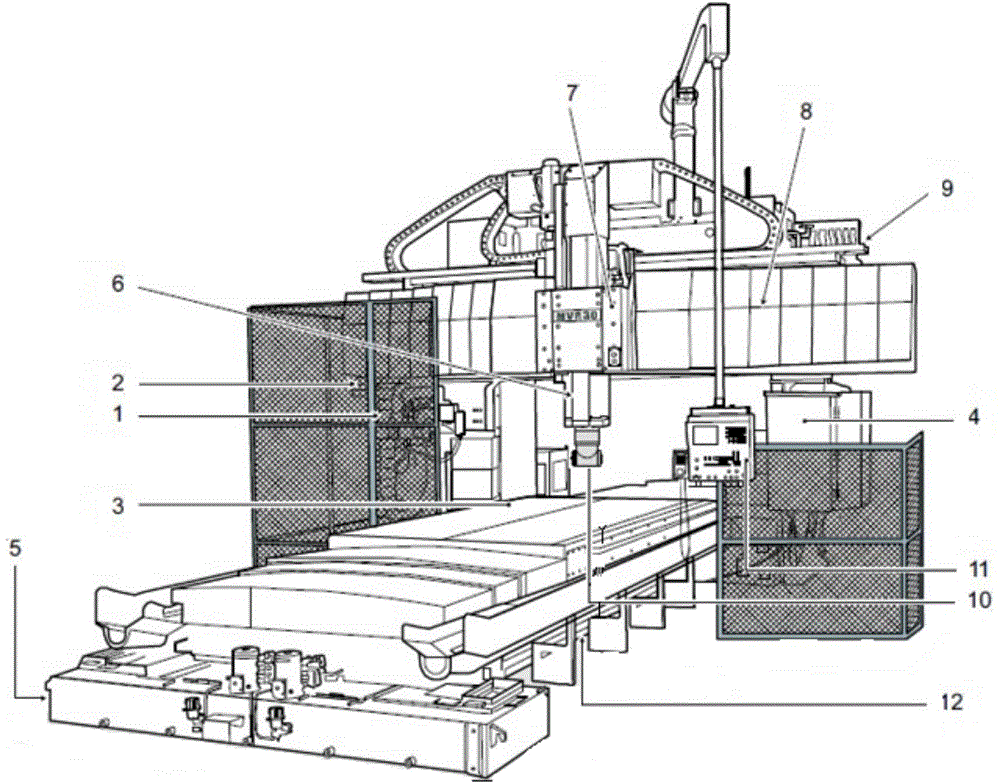

Gantry type milling processing center

InactiveCN106239165AFunction increaseEliminate setup errorsOther manufacturing equipments/toolsEngineeringPentahedron

The invention discloses a gantry type milling processing center. The milling processing center comprises a bed body, a worktable, a movable beam, a fixed beam, a grinding component, an all-purpose pentahedron milling component and two uprights, wherein the worktable is installed on the bed body, the two uprights are respectively arranged at two sides of the bed body and located at two sides of the worktable, the movable beam is arranged at one sides of the two uprights and capable of lifting along the uprights, and the fixed beam is fixedly arranged at the other sides of the two uprights; the grinding component is arranged on the movable beam and capable of transversely moving along the movable beam, and the all-purpose pentahedron milling component is arranged on the fixed beam and capable of transversely moving along the fixed beam; and the worktable comprises a linear movement platform and a rotary platform, the linear movement platform is arranged on the bed body, the rotary platform is embedded on the linear movement platform, the uprights are provided with driving components for driving the linear movement platform and the rotary platform to operate. The processing center disclosed by the invention has the advantages of being suitable for large complex part processing, high in processing precision, and capable of improving the processing efficiency and the automation degree.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

Deep hole machining method for numerical control machine tool gantry pentahedron

ActiveCN103551627ARealize precise machiningBreakthrough in machining accuracyMeasurement/indication equipmentsBoring/drilling machinesNumerical controlEngineering

The invention relates to a deep hole machining method for a numerical control machine tool gantry pentahedron. The method comprises the following steps of (1) detecting and regulating the levelness of a workbench; (2) detecting perpendicularity between axes X and Y; (3) detecting and regulating perpendicularity between an axis Z and each of the axes X and Y; (4) roughly boring and semi-finely boring a deep hole; (5) detecting and regulating the axial run-out, radial run-out and concentricity of the axis of a taper hole of a right-angled milling head and the concentricity of the axle center of the right-angled milling head in directions of 90 and 270 degrees; (6) clamping a fine boring tool on the right-angled milling head, feeding the fine boring tool from one end face of the deep hole in the direction of 90 degrees for machining, retracting the fine boring tool to a specified position when a half of the depth of the deep hole is finely bored, rotating the right-angled milling head to the direction of 270 degrees, and finely boring the other part from the other end face of the deep hole by using the fine boring tool. According to the method, accuracy parameters of the machine tool are detected and regulated before a workpiece is machined, and the axial and radial run-out of the axis of the taper hole of the right-angled milling head is detected and regulated before the deep hole is finely bored, so that the machining accuracy of equipment is improved, and a deep hole with a great diameter is accurately machined.

Owner:SUZHOU IND PARK ELECTROMECHANICAL EQUIP

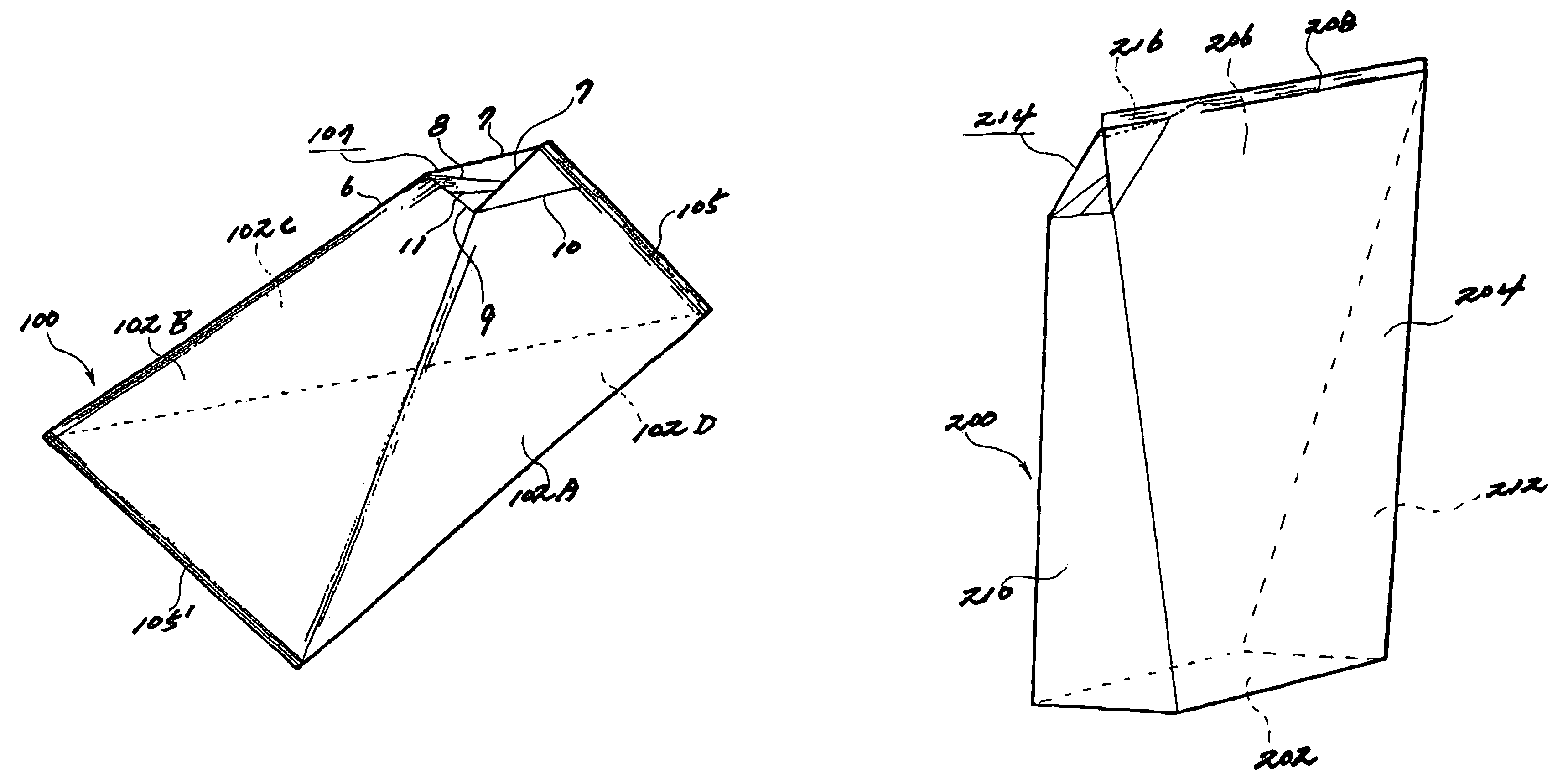

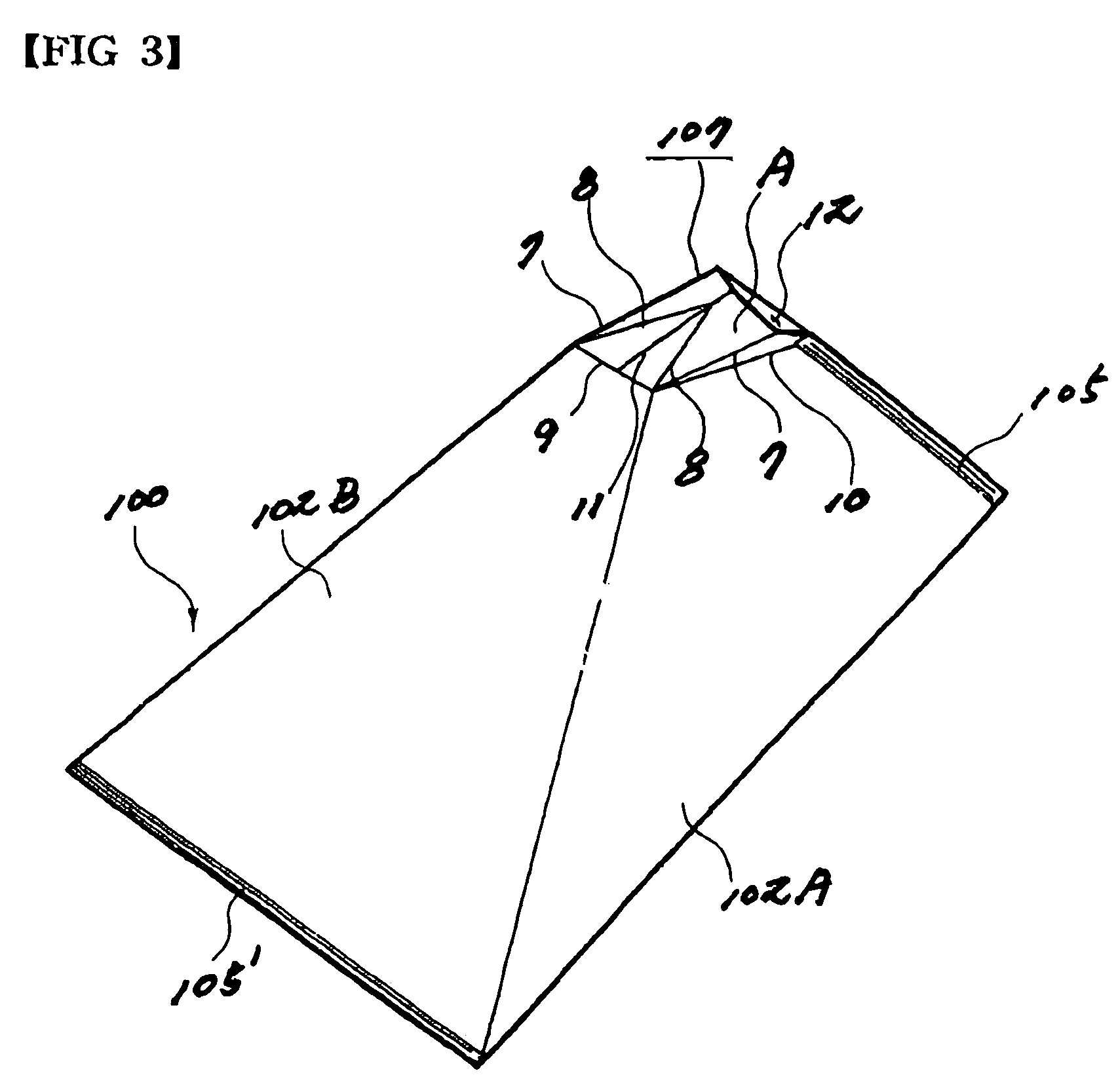

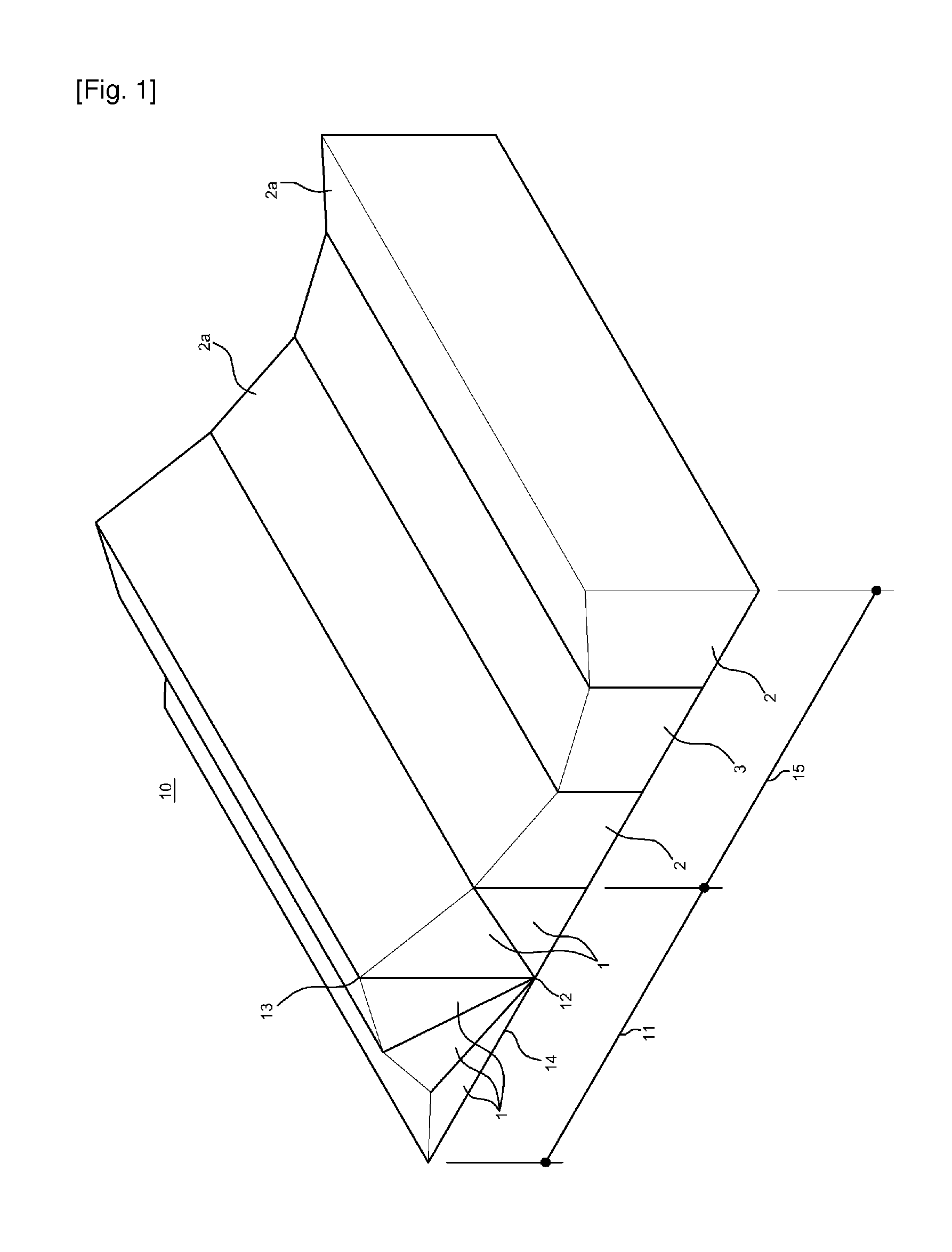

Tetrahedron/pentahedron container

A container includes at least one triangular surface, a sealing portion formed extending straightly from an angular point of the triangular surface, and an opening structure formed by folding a portion around the angular point of the container.

Owner:LEE IN OK

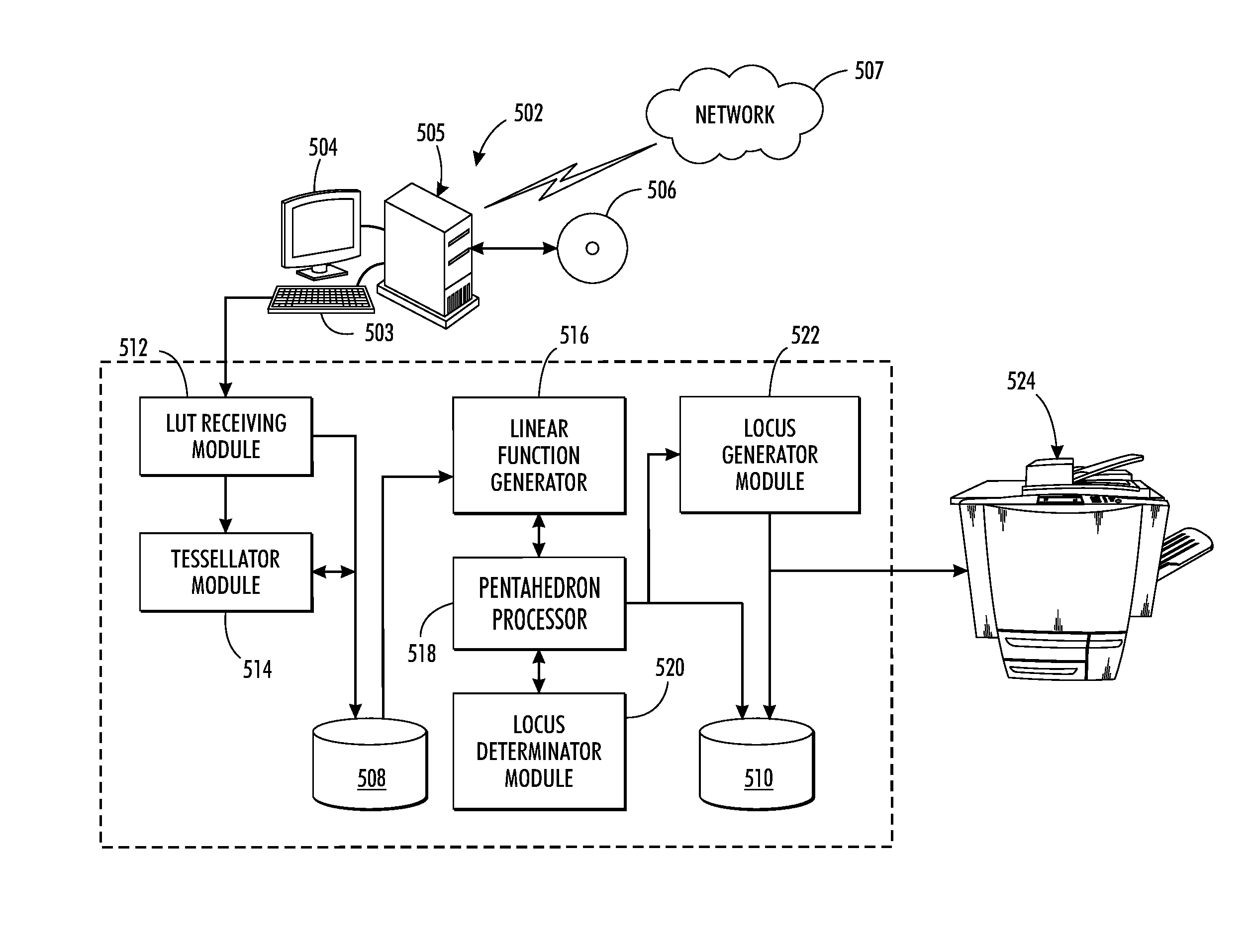

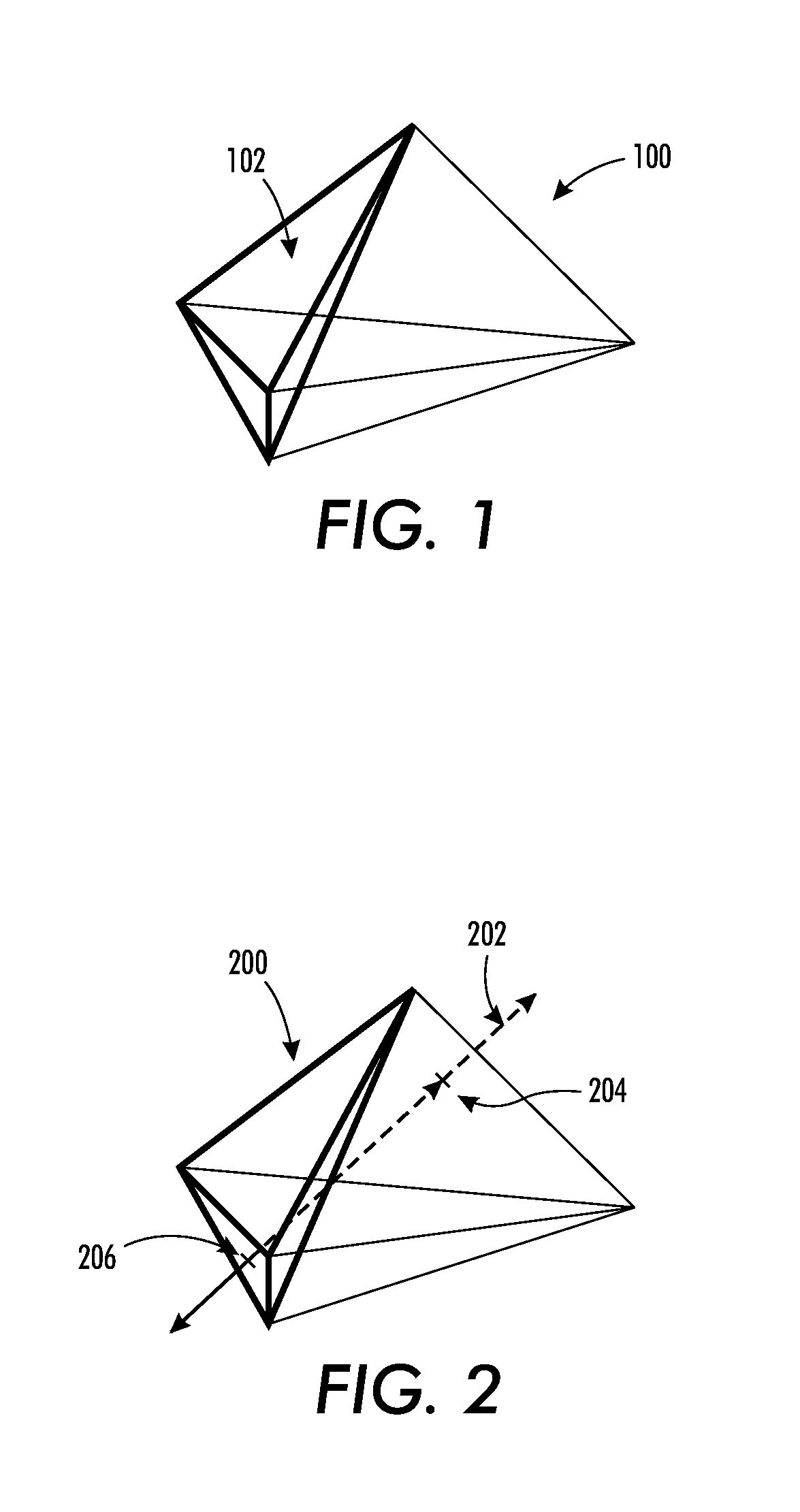

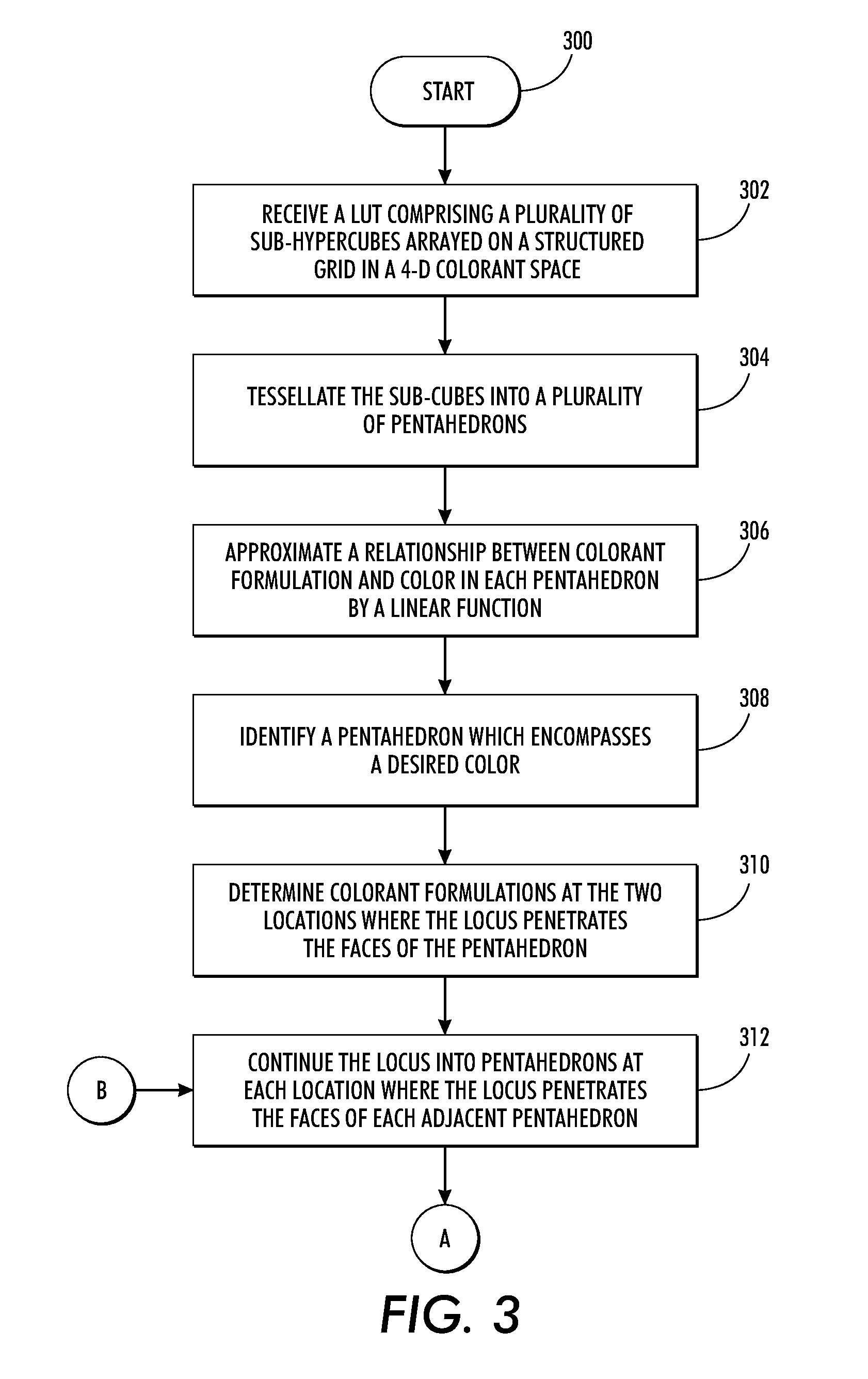

Finding a locus of colorant formulations that produces a desired color

InactiveUS20110286015A1Minimize cost functionFast and efficientDigitally marking record carriersDigital computer detailsGamutPresent method

What is disclosed is a novel system and method for converting a set of L*a*b* values to CMYK color space in which all CMYK formulations that produce each L*a*b* value are found and enumerated. The CMYK formulations are found through a search algorithm starting with the lightest L*a*b* values then visiting neighboring L*a*b* values until the entire L*a*b* color set has been processed. The CMYK space is tessellated into a set of pentahedrons, and for each L*a*b* value, an enclosing pentahedron is found and the CMYK values corresponding to where the locus of this point penetrates each surface is recorded. Adjacent pentahedrons are then visited and this process continues until the gamut boundary is reached. The result is a piecewise linear representation of the CMYK locus containing all values that will give the target L*a*b* value. The present method provides a flexible and powerful approach for solving color management problems.

Owner:XEROX CORP

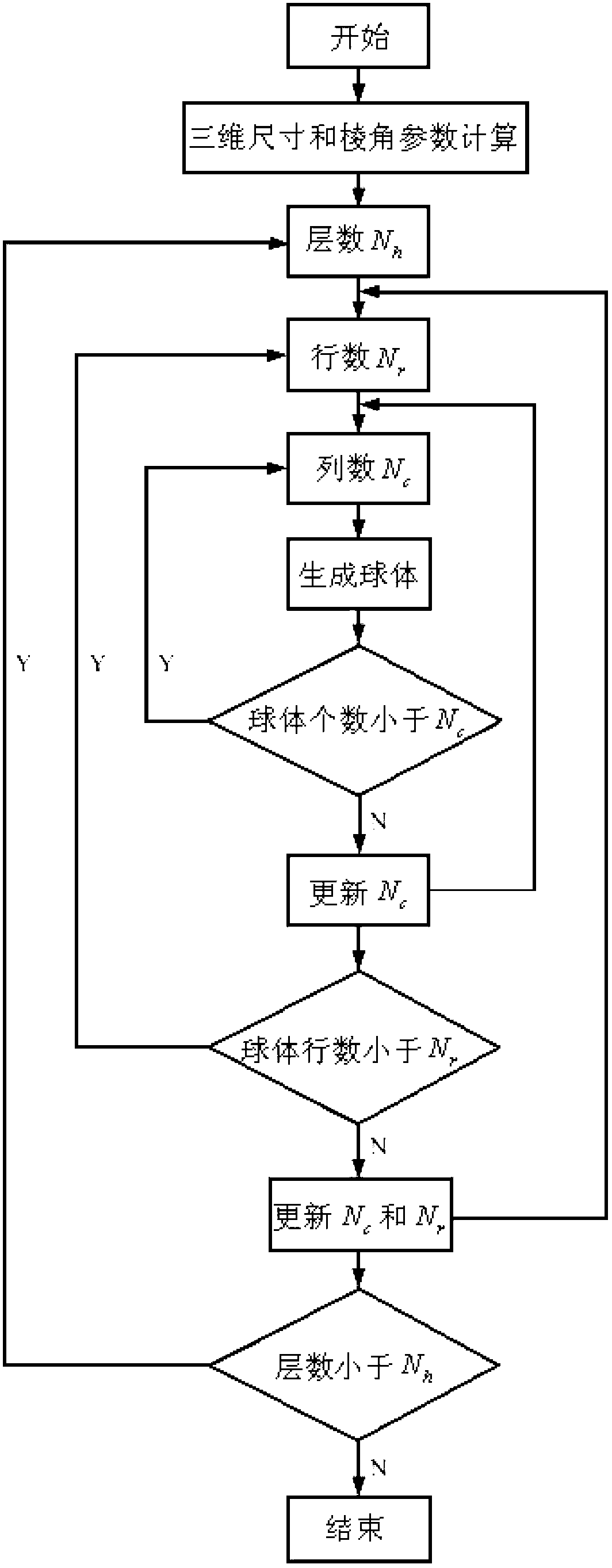

Aggregate three-dimensional structure discrete element generating method

The invention discloses an aggregate three-dimensional structure discrete element generating method. The method comprises the following steps: setting aggregate particles as a hexahedron, pentahedron or tetrahedron which is formed through several-layer arrangement of spheres having a same particle size, wherein at least three edges of the hexahedron, pentahedron or tetrahedron are mutually perpendicular to each other, and the three edges share an end point; and characterizing the three-dimensional dimension characteristics of the hexahedron, pentahedron or tetrahedron by the lengths of the three edges to include the characterization of the corner angle characteristics of the hexahedron, pentahedron or tetrahedron by three angles in the three vertical plane of the three edges. The aggregate three-dimensional structure discrete element generating method allows the dimension and corner angle parameters of the aggregates to be randomly selected based on the three-dimensional structure data of real aggregates according to the normal distribution, and can stimulate the real shapes, dimensions and the corner angles of the aggregate particles to establish a relationship with the real aggregates.

Owner:SOUTHEAST UNIV

Pillow having a plurality of polygonal units

A pillow having a plurality of polygonal units, includes: a triangular pentahedron unit having a shape of a triangular prism; a one-side inclined square hexahedral unit having a shape of a square pillar; a rectangular hexahedron unit having a shape of a rectangular pillar; a both-side inclined rectangular hexahedron unit having a shape of a rectangular pillar; a rhombic hexahedron unit having a shape of a rhombic pillar; an isosceles-triangular pentahedron unit having a shape of an isosceles triangular prism; and a rectangular panel-shaped hexahedron unit having a shape of a rectangular pillar, whereby the units are sewn together in such a way so as to selectively come into surface contact with each other or be stacked, thus forming one pillow, with the respective units being filled with stuffing.

Owner:VENYGOOD

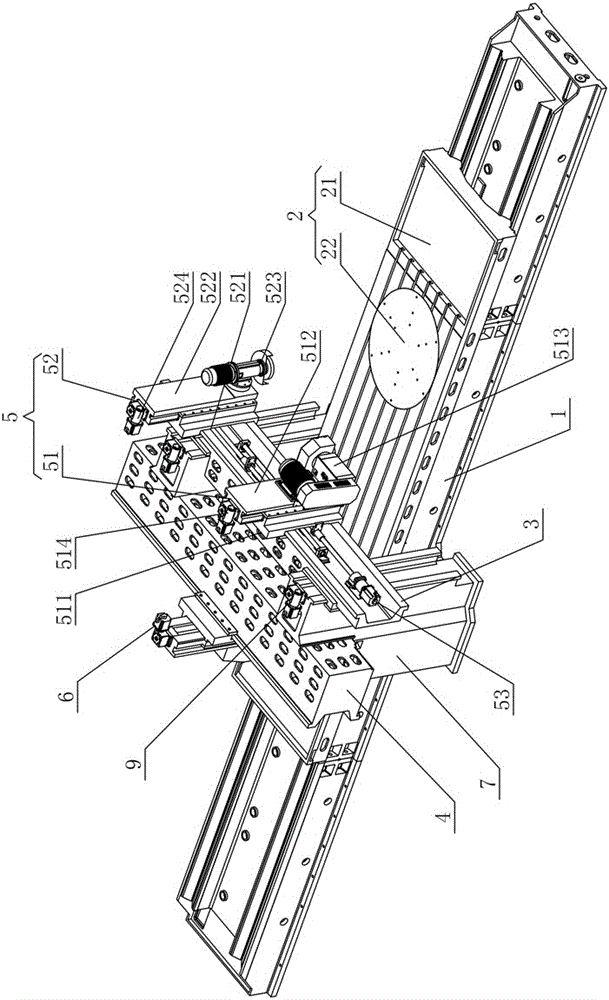

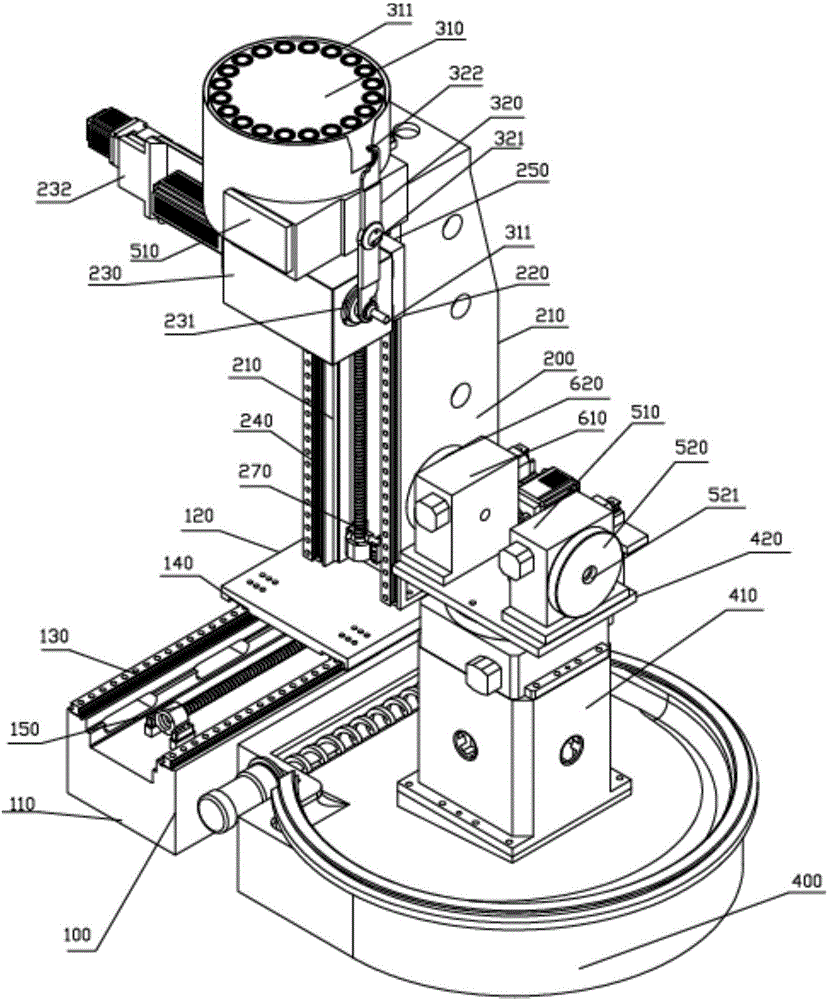

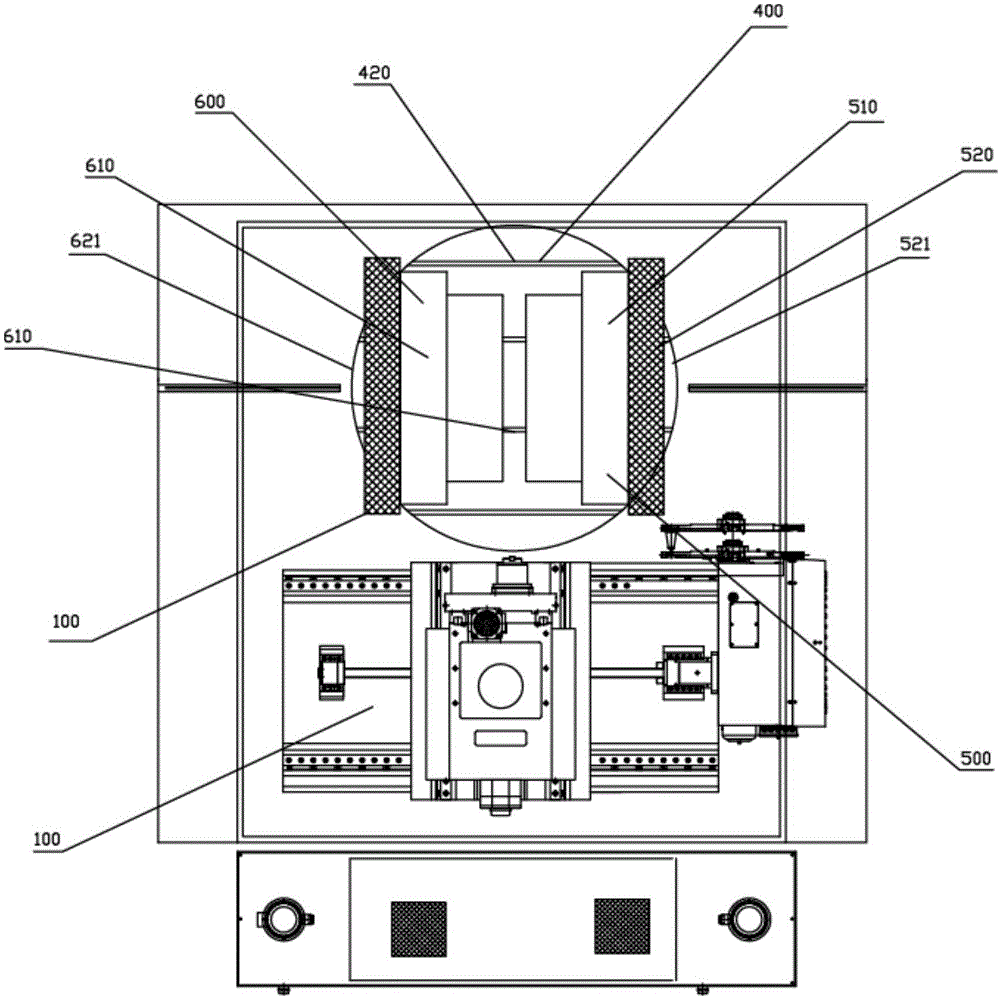

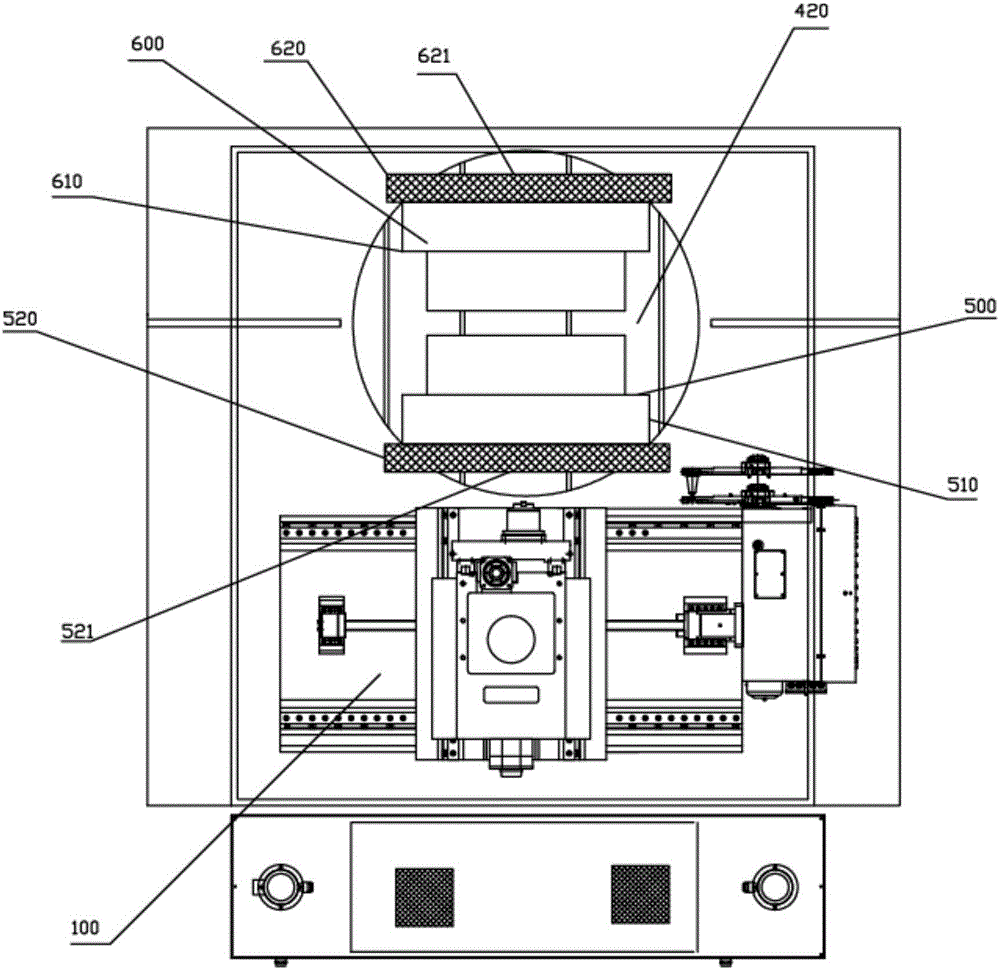

Efficient polyhedron processing machine tool

PendingCN109732409ASmall sizeGood accuracy and stabilityLarge fixed membersMetal working apparatusEngineeringMachine tool

An efficient polyhedron processing machine tool comprises a base, a machine frame, a Y-axis movement platform, an X-axis movement platform, a processing platform, a circular rotating platform, a toolmagazine and a cutting tool device. The machine frame is installed on the base, the Y-axis movement platform is installed on the base, and the X-axis movement platform is installed on the Y-axis movement platform. The processing platform is connected to the X-axis movement platform in a pivotal mode, the circular rotating platform is installed in the processing platform, and the tool magazine andthe cutting tool device are installed on the machine frame. According to the efficient polyhedron processing machine tool, due to the fact that the rotatable processing platform and the circular rotating platform are arranged, the processing operation of a single-axis pentahedron can be achieved only through one-time clamping operation of a workpiece. The forming accuracy is high, the accuracy stability of a part is high, and the part quality and the technology are also improved. In addition, the efficient polyhedron processing machine tool is compact in structure, simple, small in size, smallin occupied area and standard in operating position, the workpiece feeding and discharging clamping operation is quite convenient, the safety performance is high, the working efficiency can be greatly improved, the practicability is high, and the efficient polyhedron processing machine tool has the great popularization significance.

Owner:东莞市益格机械有限公司

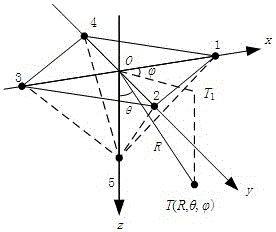

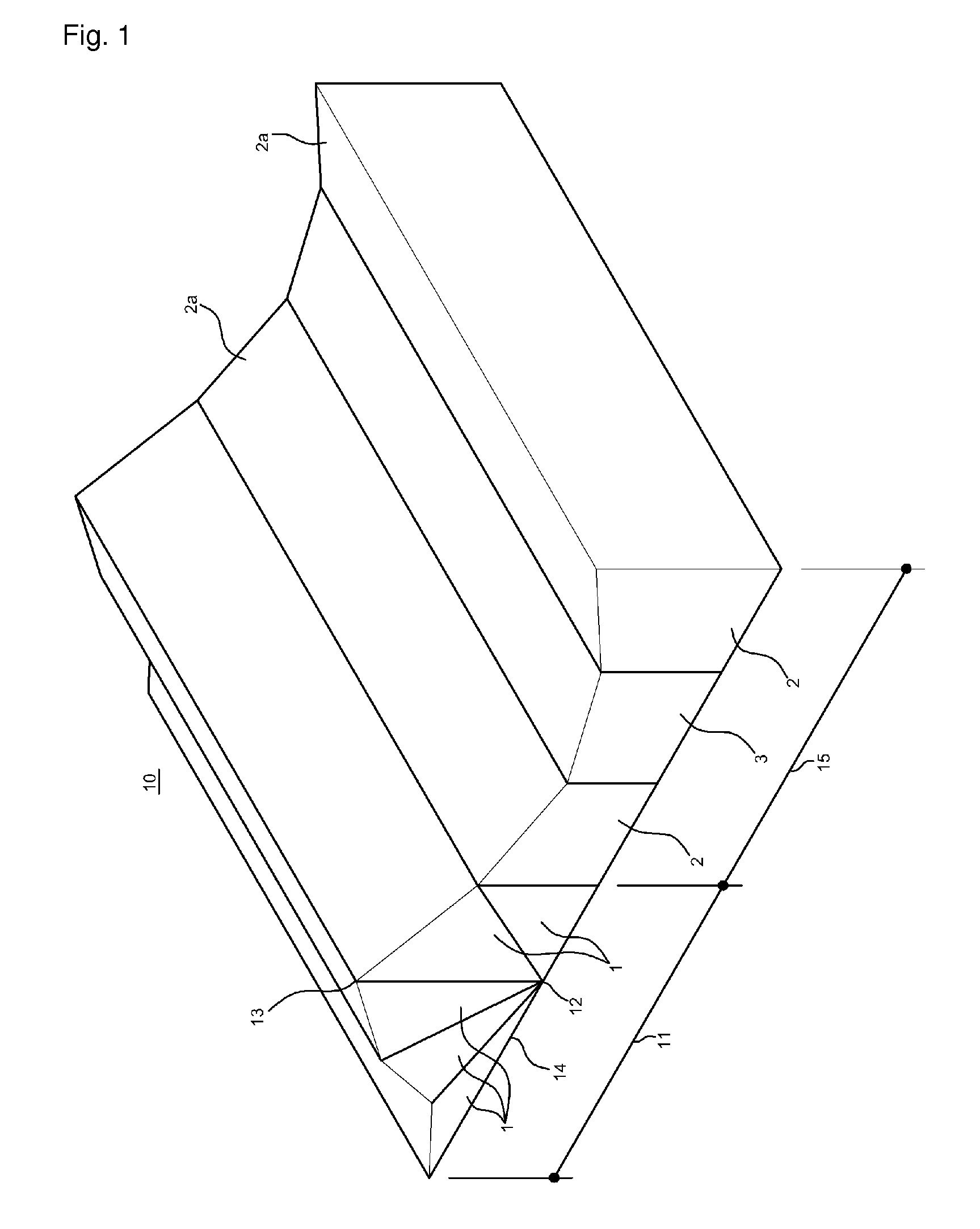

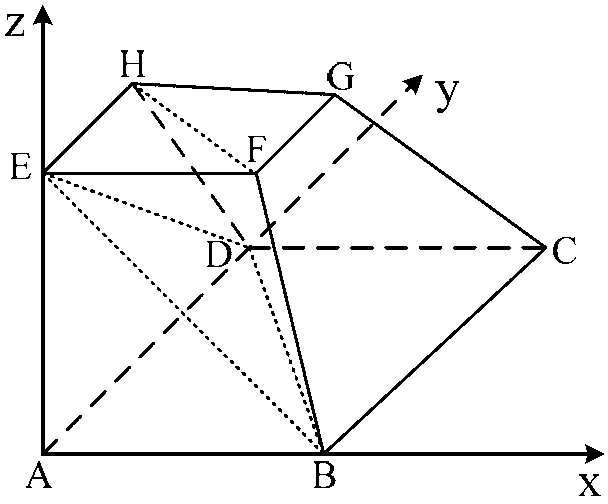

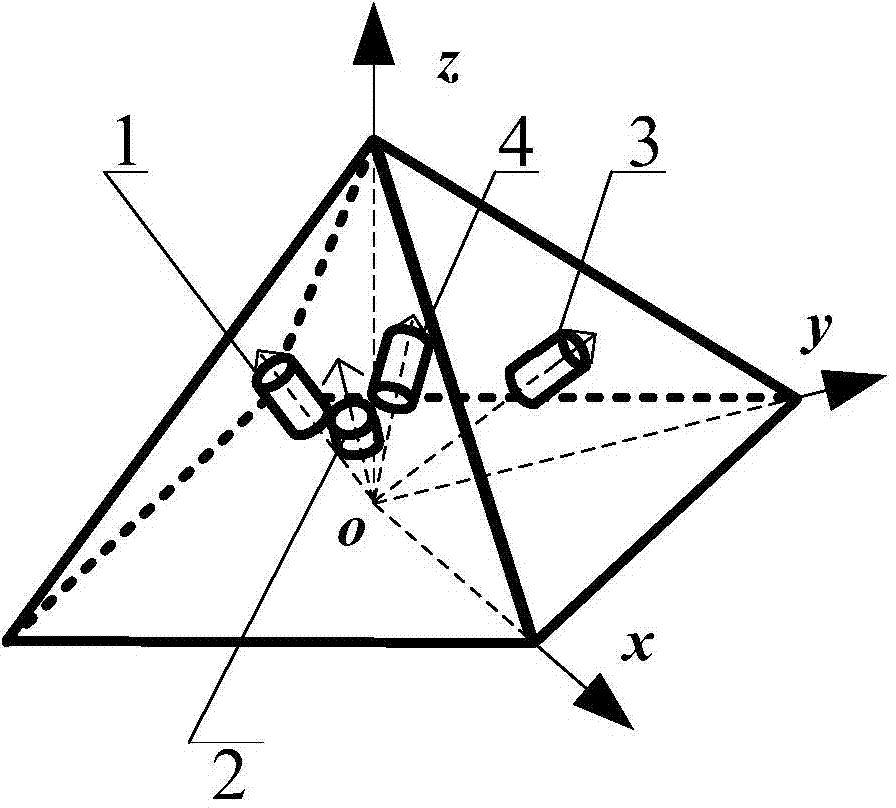

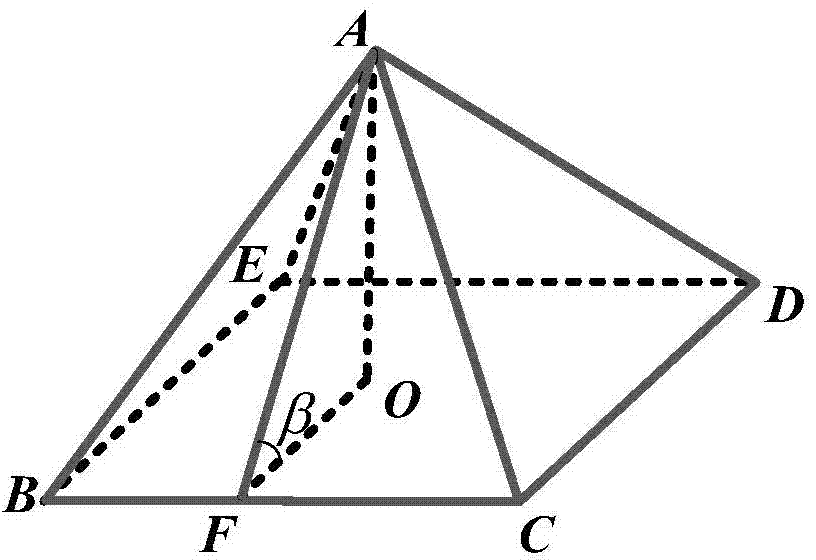

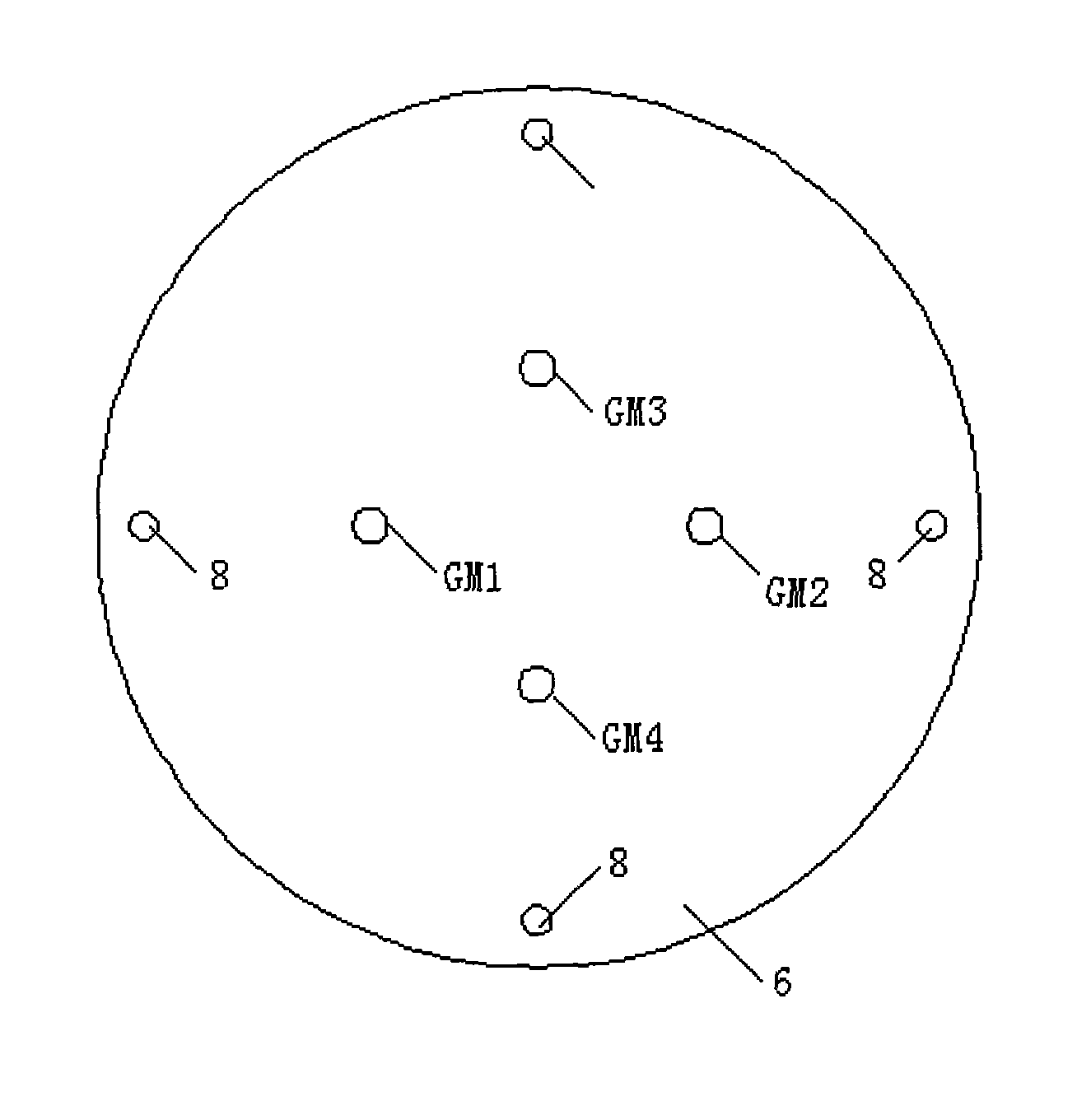

Symmetric diagonal configuration method based on pentahedron

InactiveCN104501810AReduce volumeReduce weightNavigation by speed/acceleration measurementsOrthogonal coordinatesAccelerometer

The invention relates to the technical field of inertial navigation, in particular to a symmetric diagonal configuration method based on a pentahedron. The symmetric diagonal configuration method based on the pentahedron is characterized in that directions of measuring axes of four inertial components are diagonal relatively to an orthogonal coordinate system, the directions of the measuring axes of the four inertial components are vertical to four side faces of the pentahedron, each inertial component comprises a spinning top and an accelerometer, the directions of each spinning top and each accelerometer keep consistent, intersection angles of the four side faces and the bottom face of the pentahedron are all 54.74 degrees, each side face of the pentahedron is an equilateral triangle, the bottom face of the pentahedron is a square, and an original point of the orthogonal coordinate system is the center of the bottom face of the pentahedron. According to the symmetric diagonal configuration method based on the pentahedron, the four inertial components in the configuration scheme are distributed in symmetric mode, and are all diagonally placed relatively to the orthogonal coordinate system, and when a single fault is caused on an arbitrarily one of the four inertial components, measuring accuracy of the orthogonal coordinate system can not change along with change of the inertial component which breaks down.

Owner:HARBIN ENG UNIV

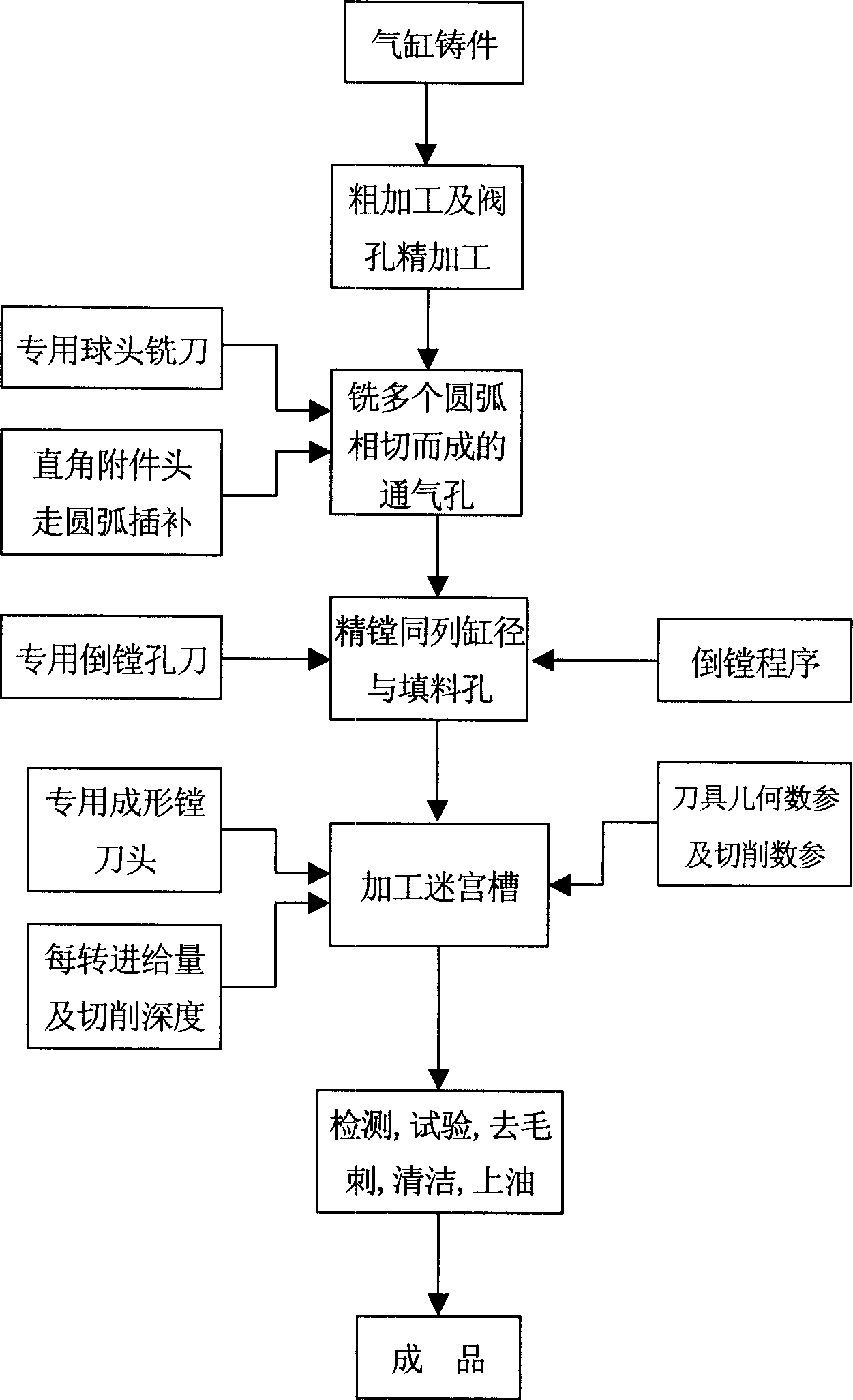

Production of labyrinth compressor cylinder

InactiveCN1854518AMeet the design requirementsGuaranteed coaxiality φ0.015 requirementPositive displacement pump componentsPositive-displacement liquid enginesMachine toolMachining

The invention encloses the following step of: rough machining of the labyrinth compressor cylinder on common machine tools and fine machining of the valve opening; setting separately the screw-pitch of the labyrinth groove and the depth of the helical groove on the wall of the cylinder to be the feeds per revolution and the cutting depth and then working on the labyrinth groove using a pentahedron working centre; fine boring of a same-line cylinder diameter and a filling hole in the pentahedron centre and milling a plurality of arc air vents on the pentahedron working centre.

Owner:WUXI COMPRESSOR CO LTD +1

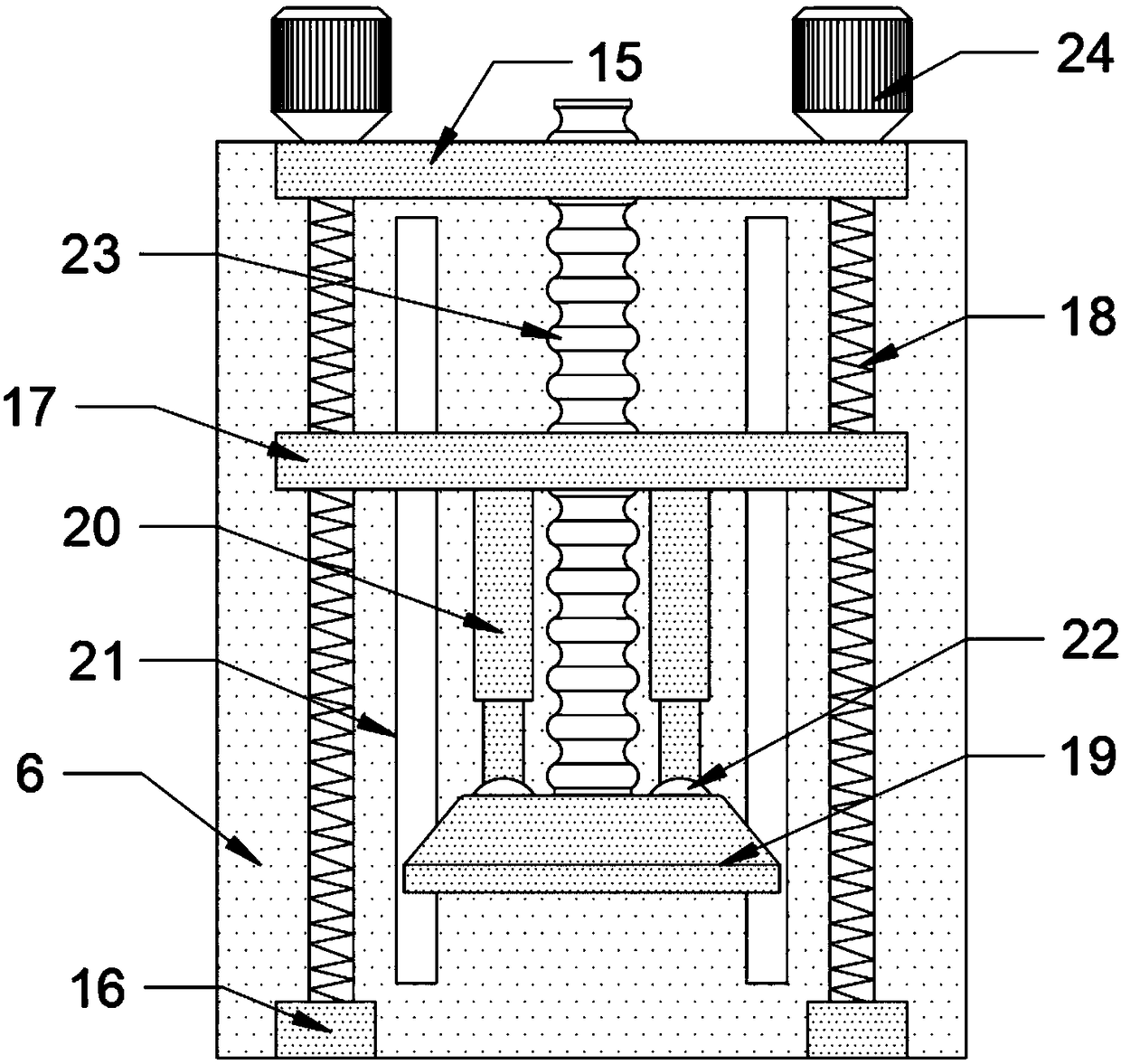

Pentahedron processing machine

ActiveCN106736630AOvercome the disadvantages of processingQuick tool changeFeeding apparatusLarge fixed membersThree-dimensional spaceMachine tool

The invention discloses a pentahedron processing machine which comprises an X-axis platform, a Z-axis platform, a tool magazine device, a first rotating table, a second rotating table and a third rotating table. Three-dimensional space rotation of a work piece is carried out by utilizing the rotating functions of the three rotating tables, and a good operation interface allows the programming difficulty of a pentahedron processing technique to be reduced; a tool changing arm, along with a tool changing library, is adopted for tool management, so that tools can be changed quickly and randomly, and the processing efficiency of a machine tool can be improved; and the three hydraulically driven rotating tables are adopted, the first rotating table is a base table, the second rotating table and the third rotating table that are hydraulically driven are additionally arranged on the upper surface of the first rotating table, the first rotating table allows the work piece to rotate at the Z-axis, the second rotating table and the third rotating table allow the work pieces to rotate at horizontal shafts, through the rotation of the three rotating tables, processing equipment capable of processing the five surfaces of the work pieces is formed, and the work pieces can be exchanged, so that the processing efficiency is higher.

Owner:SHENZHEN HUAYA CNC MASCH CO LTD

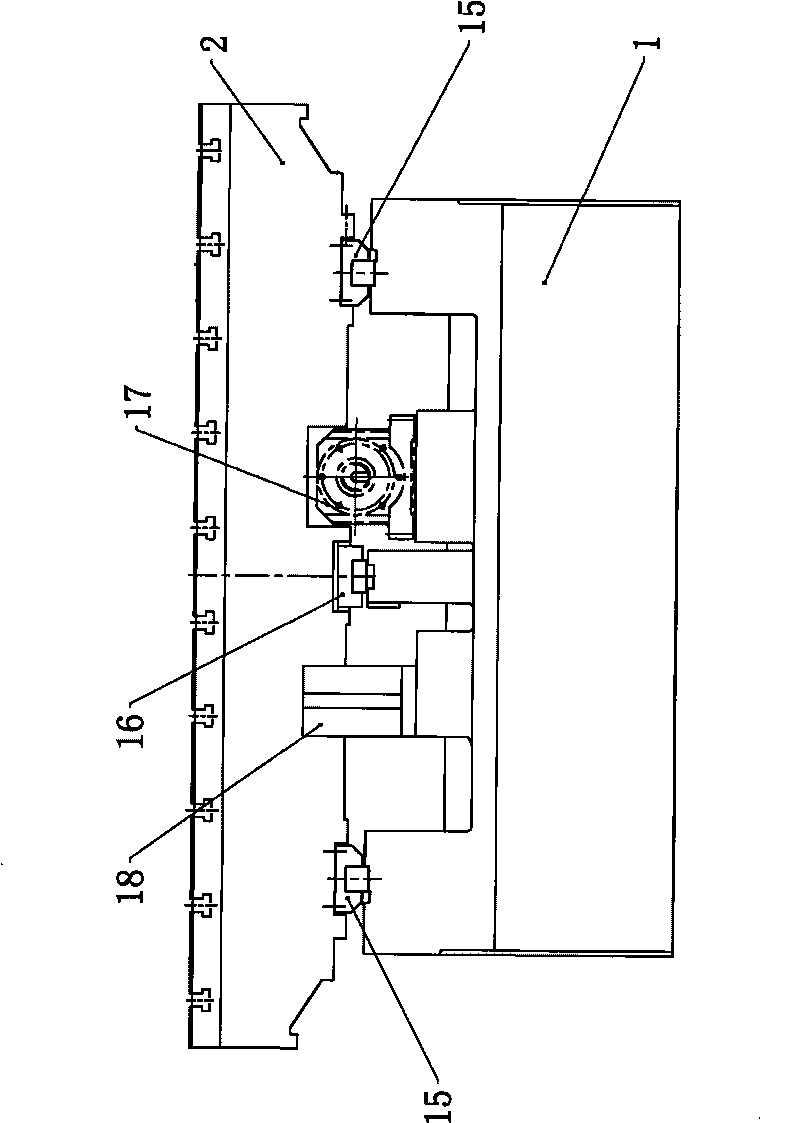

Large pentahedral gantry machining center and method for compensating deformation of movable cross beam

InactiveCN104801987AGuaranteed stabilityChange the shortcomings of not being able to carry large mold basesAutomatic control devicesFeeding apparatusEngineeringDrive motor

The invention discloses a large pentahedral gantry machining center and a method for compensating the deformation of a movable cross beam. The machining center comprises two fixed cross beams, a moveable cross beam, a workbench and the like, wherein the two fixed cross beams are respectively arranged on a left upright post and a right upright post; an X-axis linear guide rail is arranged on the fixed cross beams; X-axis slide blocks are arranged on the X-axis linear guide rail; the moveable cross beam is connected with the X-axis slide blocks; an X-axis linear motor drives the X-axis slide blocks to move along the X-axis linear guide rail; a Y-axis linear guide rail is arranged on the moveable cross beam; Y-axis slide blocks are arranged on the Y-axis linear guide rail; a slide saddle is connected with the Y-axis slide blocks; a Y-axis driving motor drives the Y-axis slide blocks to move along the Y-axis linear guide rail; a Z-axis linear guide rail is arranged on the slide saddle; Z-axis slide blocks are arranged on the Z-axis linear guide rail; a ram is connected with the Z-axis slide blocks; a Z-axis driving motor drives the Z-axis slide blocks to move along the Z-axis linear guide rail; a main shaft unit comprises an A-shaft rotary driving shaft and a C-shaft rotary driving shaft and is arranged on the ram. The machining center is applied to the high-speed and high-precision machining places of large parts.

Owner:GUANGDONG UNIV OF TECH

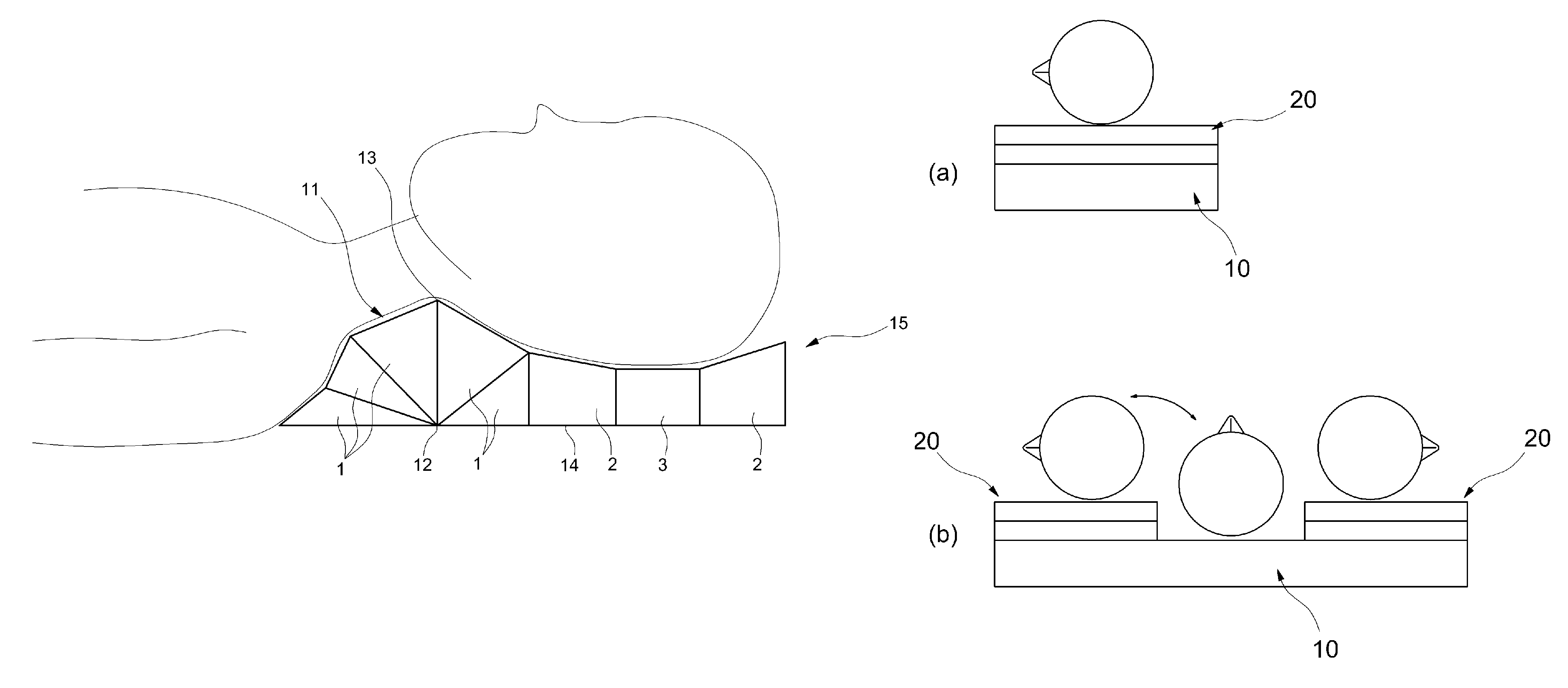

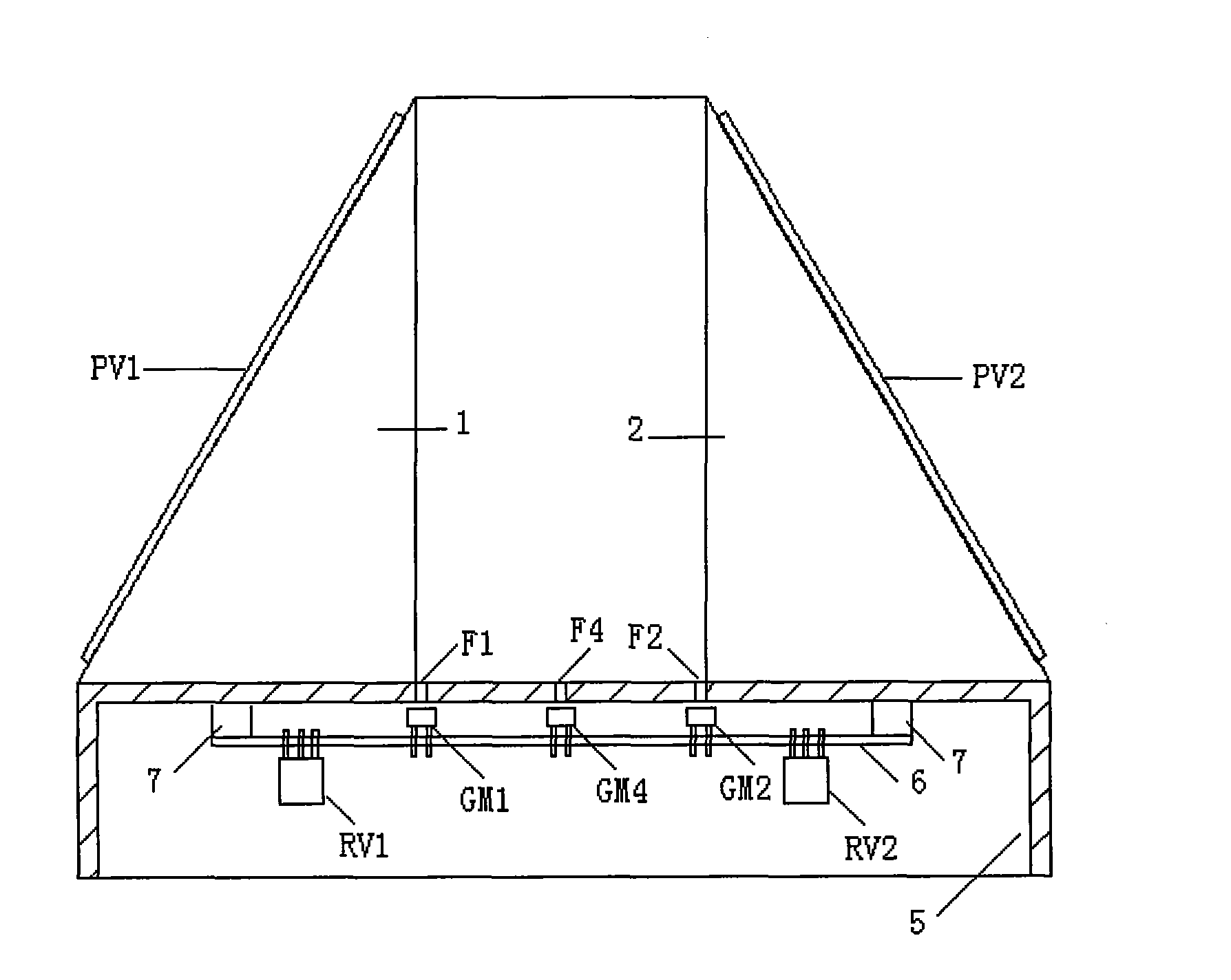

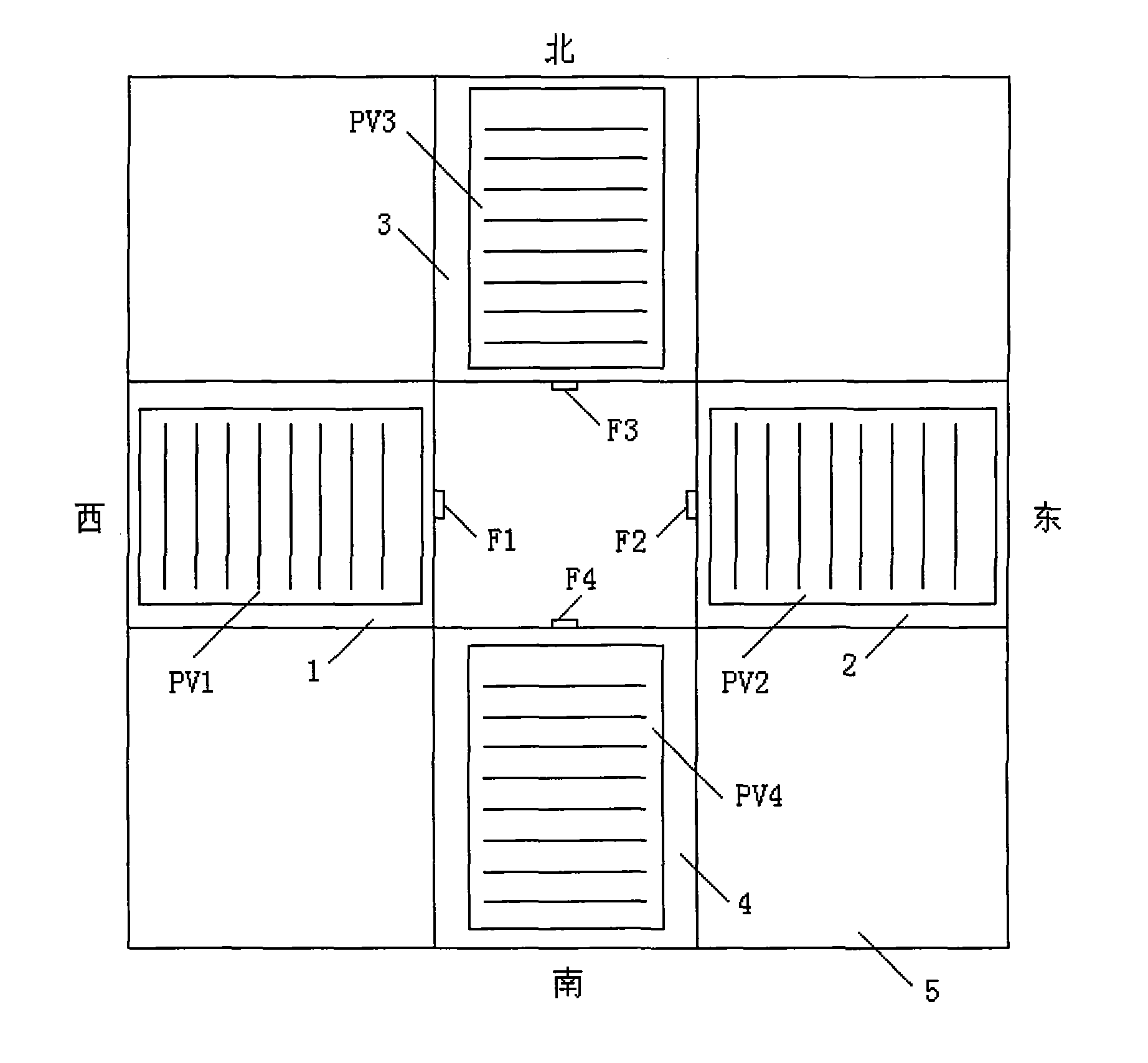

Sun-tracking detector having wide-angle capturing and precise tracking functions

The invention provides a sun-tracking detector having wide-angle capturing and precise tracking functions. In the sun-tracking detector, two sets of photosensors are adopted, wherein one set of photosensors is used for wide-angle low-precision tracking; and the other set of photosensors is used for high-precision positioning and tracking. In case of a large tracking angle difference, the sun-tracking detector firstly performs the wide-angle low-precision tracking, and then automatically performs the high-precision positioning and tracking to lock the tracking target (the sun) when the tracking error is reduced to a certain value. The sun-tracking detector comprises four triangular pentahedron brackets which are mounted on a base to form a well, wherein the well is positioned in the center of the base, four walls of the well form four shading regions, four small rectangular grooves are arranged in the centers of four sides at the bottom of the well to form four light-guiding holes, four photoresistors are correspondingly arranged at the four small rectangular grooves at the back side of the base, the sunlight can irradiate the four photoresistors by penetrating through the four small rectangular grooves, the four photoresistors and potentiometers composing an elevation angle and azimuth angle detecting circuit are mounted on a circuit board at the back side of the base, and four photosensitive cells are affixed onto the sloping planes of the four triangular pentahedron brackets and are used for wide-angle capturing. The four triangular pentahedron brackets and the circuit board are mounted on the base to form a whole, thus composing the sun-tracking detector having the wide-angle capturing and precise tracking functions. The sun-tracking detector has a detection angle more than 180 degrees, can not lose a tracking target (the sun) within the all-day tracking time and has the characteristics of simple structure, small volume and low cost, and operation is reliable.

Owner:WUXI HAOSOLAR TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com