Integral processing method for truck frame of high-speed motor train unit

A high-speed EMU and overall processing technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not being able to guarantee the overall processing accuracy, occupying equipment service time, and difficult secondary alignment, etc., to avoid Effects of loss of precision, improvement of machining precision, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

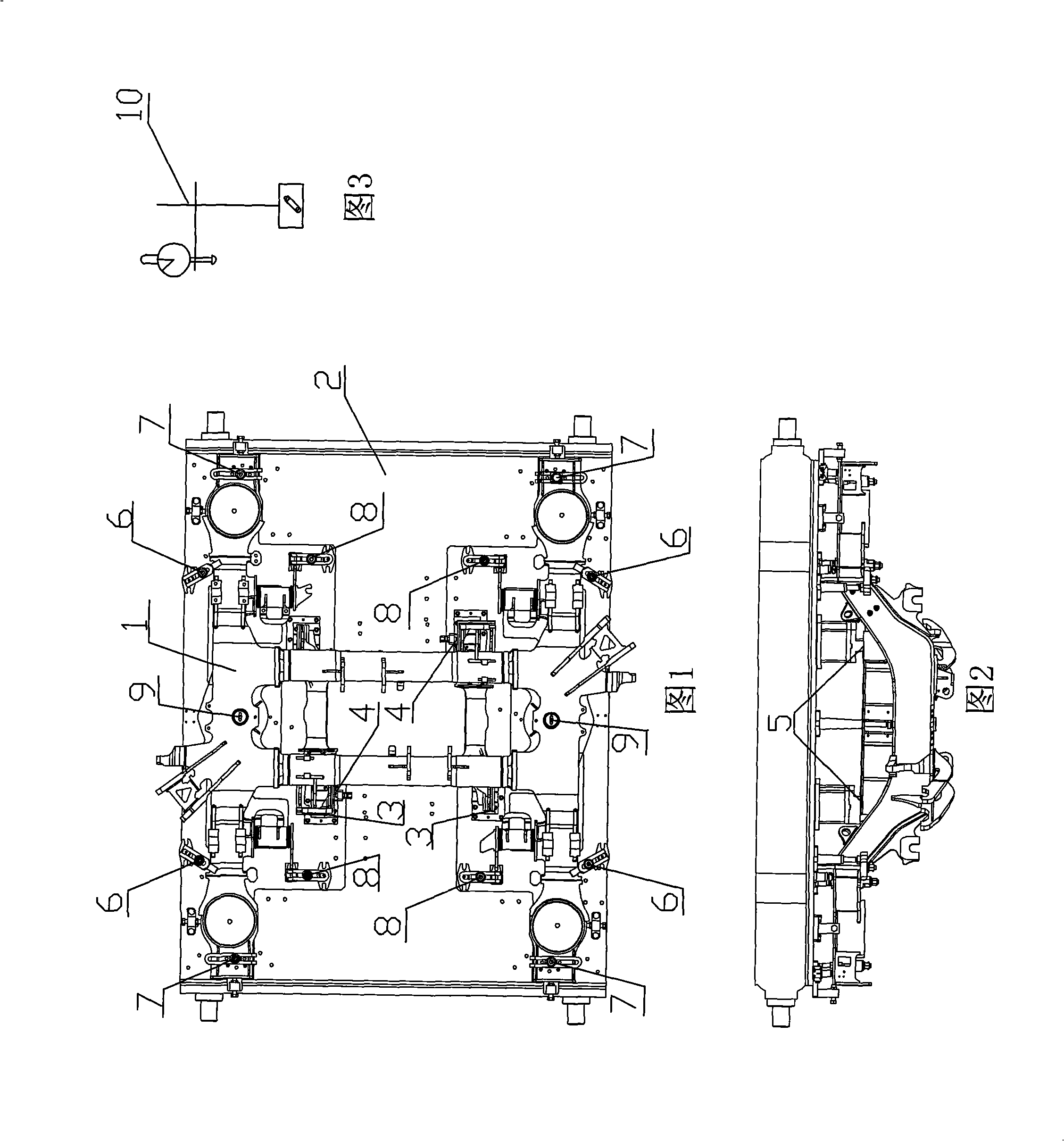

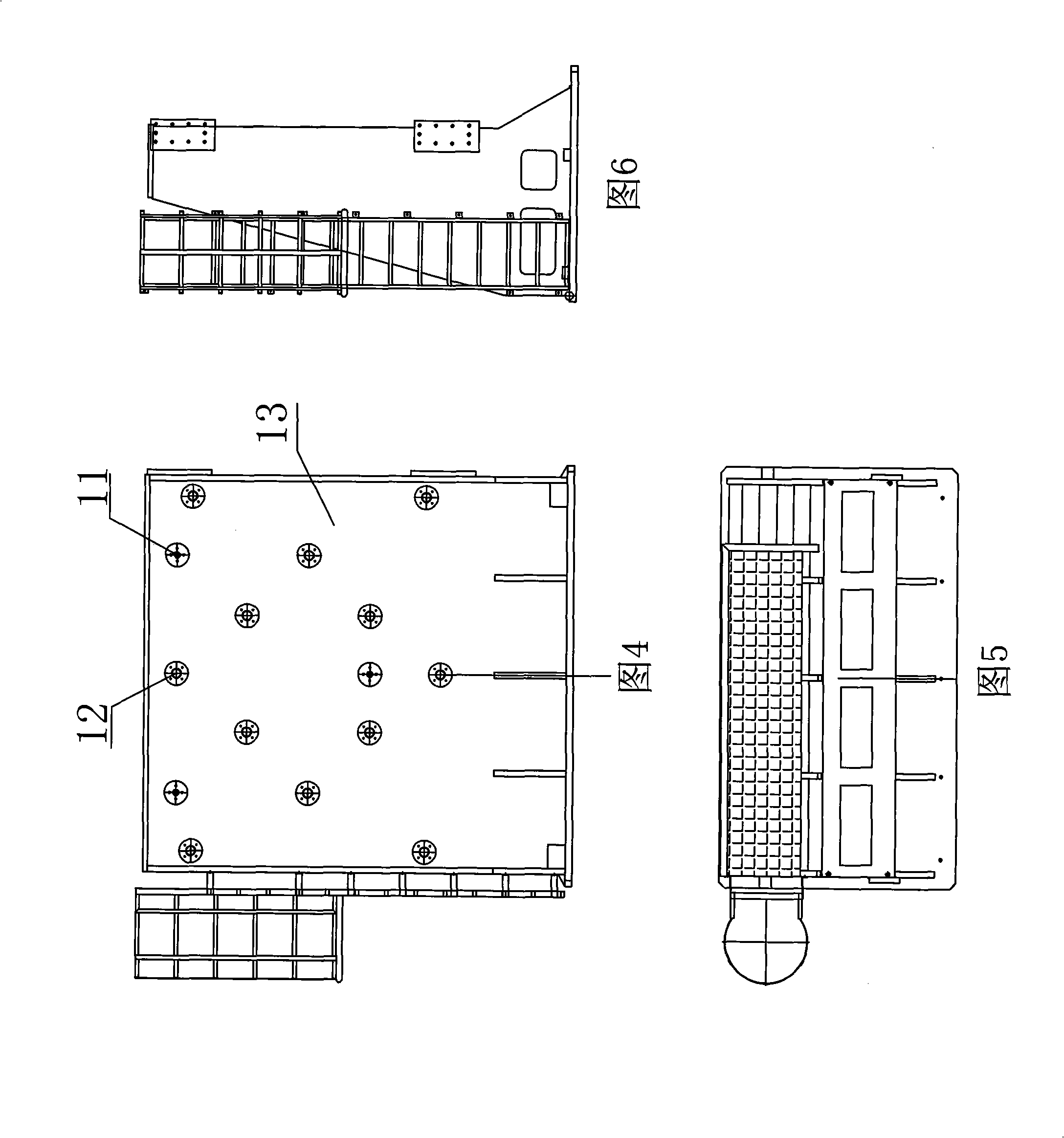

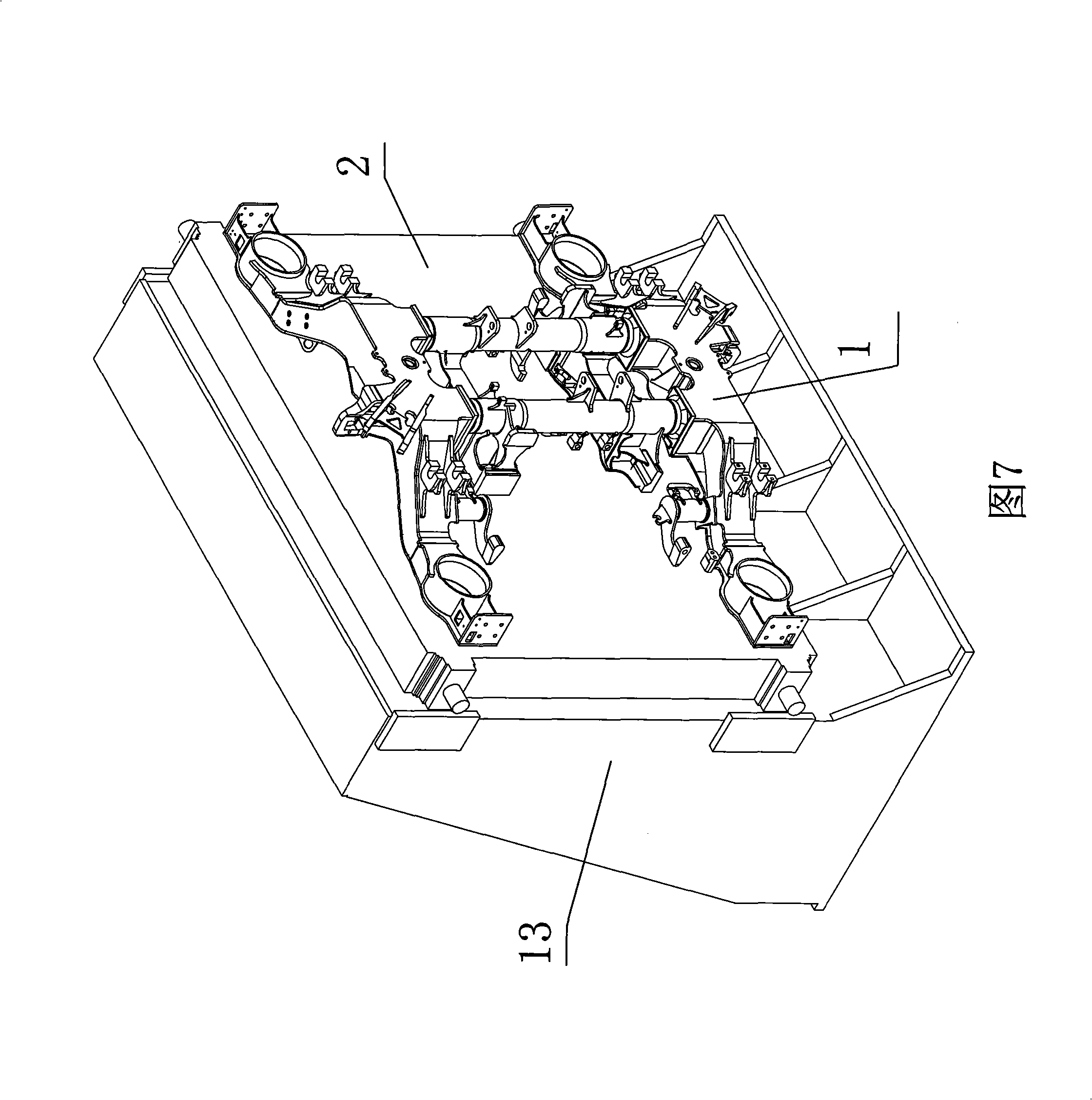

[0023] 1. Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, and Fig. 7, put the frame 1 to be processed on the back side up and horizontally on the accompanying foundation plate 2, and position the frame in the horizontal, vertical and height directions Datum plane 3, 4, 5 for positioning;

[0024] 2. Ensure that there is no force or moment between the frame and other clamping devices except for the contact with the positioning surface 3, 4, 5. When clamping, firstly attach the magnetic dial indicator 10 to the accompanying base plate 2, and the dial indicator head Contact the clamping devices 6, 7, 8, 9 of the frame, adjust the reading of the dial indicator to zero at the clamped position, and adjust the clamping devices 6, 7, 8, 9 composed of the pressing plate and the adjustable support, so that the dial indicator Change the reading of 10 to 20 (that is, support 0.2mm, which can be slightly increased according to different operators), and then press the frame thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com