Large pentahedral gantry machining center and method for compensating deformation of movable cross beam

A technology of machining center and moving beam, applied in the field of precision parts processing, can solve the problems of inability to guarantee the stability of machining accuracy, affecting machining accuracy and efficiency, and pressing and deforming the moving beam, so as to achieve stable and reliable transmission accuracy and follow-up. The effect of high error and fast compensation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The key technical points of the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

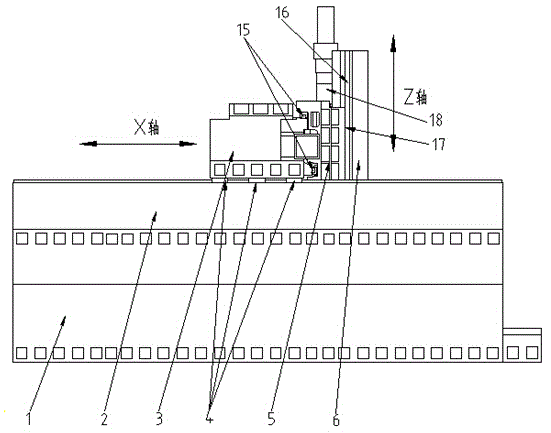

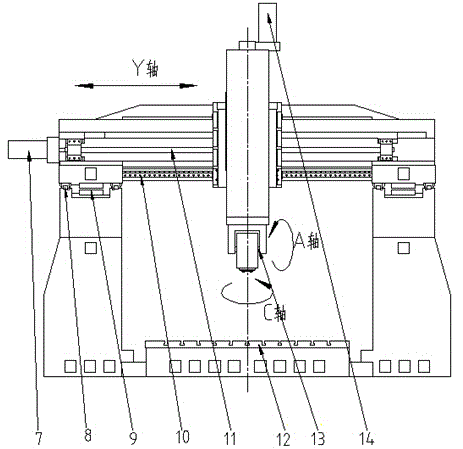

[0019] The structure diagram of the present invention is as figure 1 As shown, the large-scale pentahedron gantry machining center of the present invention includes left and right columns 1, fixed beam 2, moving beam 3, X-axis slider 4, sliding saddle 5, ram 6, Y-axis drive motor 7, and X-axis linear Guide rail 8, X-axis linear motor 9, Y-axis linear guide rail 10, worktable 12, spindle unit 13, Z-axis drive motor 14, Y-axis slider 15, Z-axis linear guide rail 16, Z-axis slider 17, of which the workbench 12 is installed on the ground, the left and right columns 1 are installed on both sides of the workbench 12, the left and right columns 1 support two fixed beams 2, and the two fixed beams 2 are respectively installed on the left and right columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com