Patents

Literature

1555results about How to "Eliminate internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-mode bending-resistant fiber and production method thereof

ActiveUS20110044596A1High mechanical reliabilityEasy to useOptical fibre with graded refractive index core/claddingOptical articlesMedicineRelative refractive index

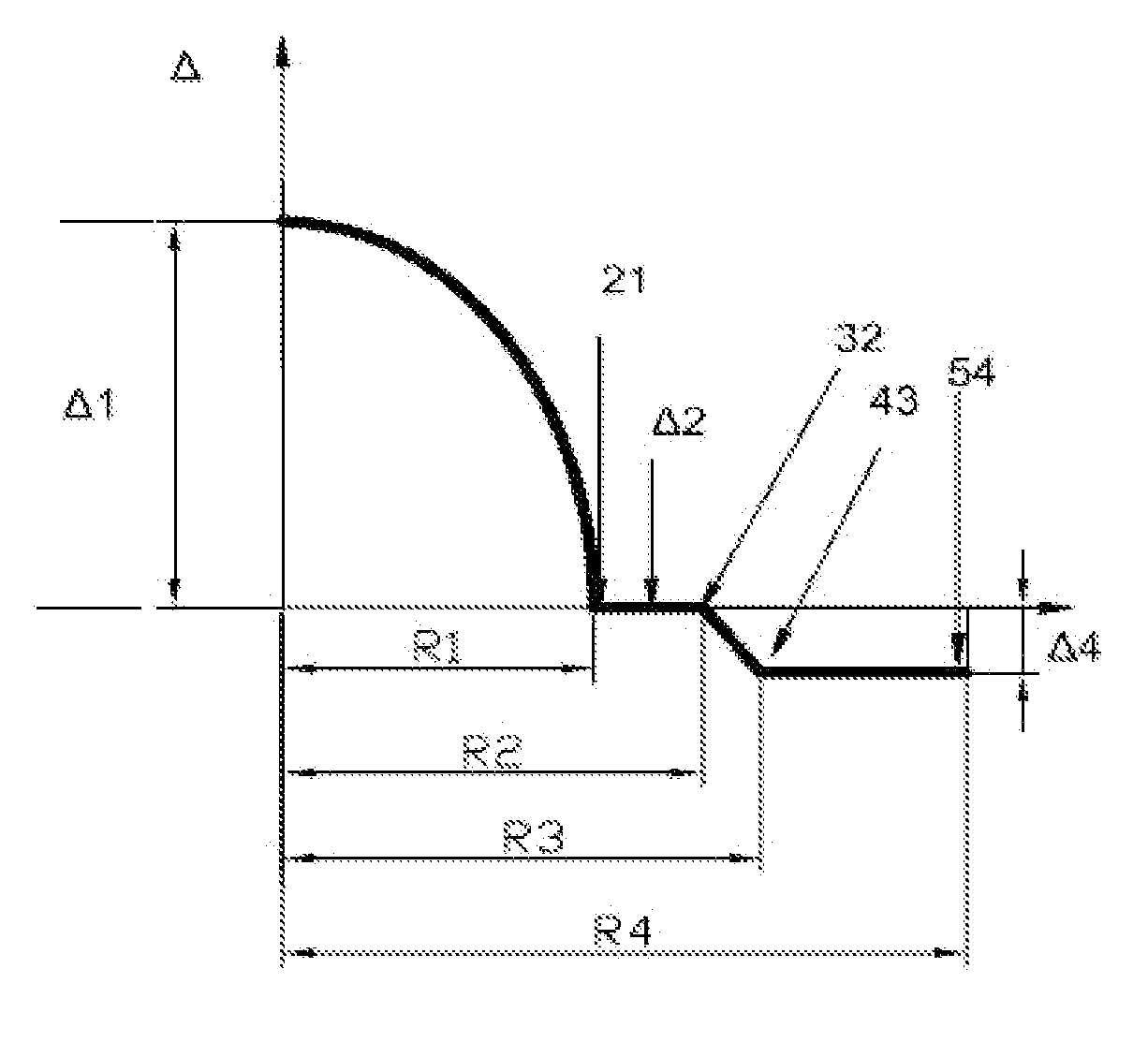

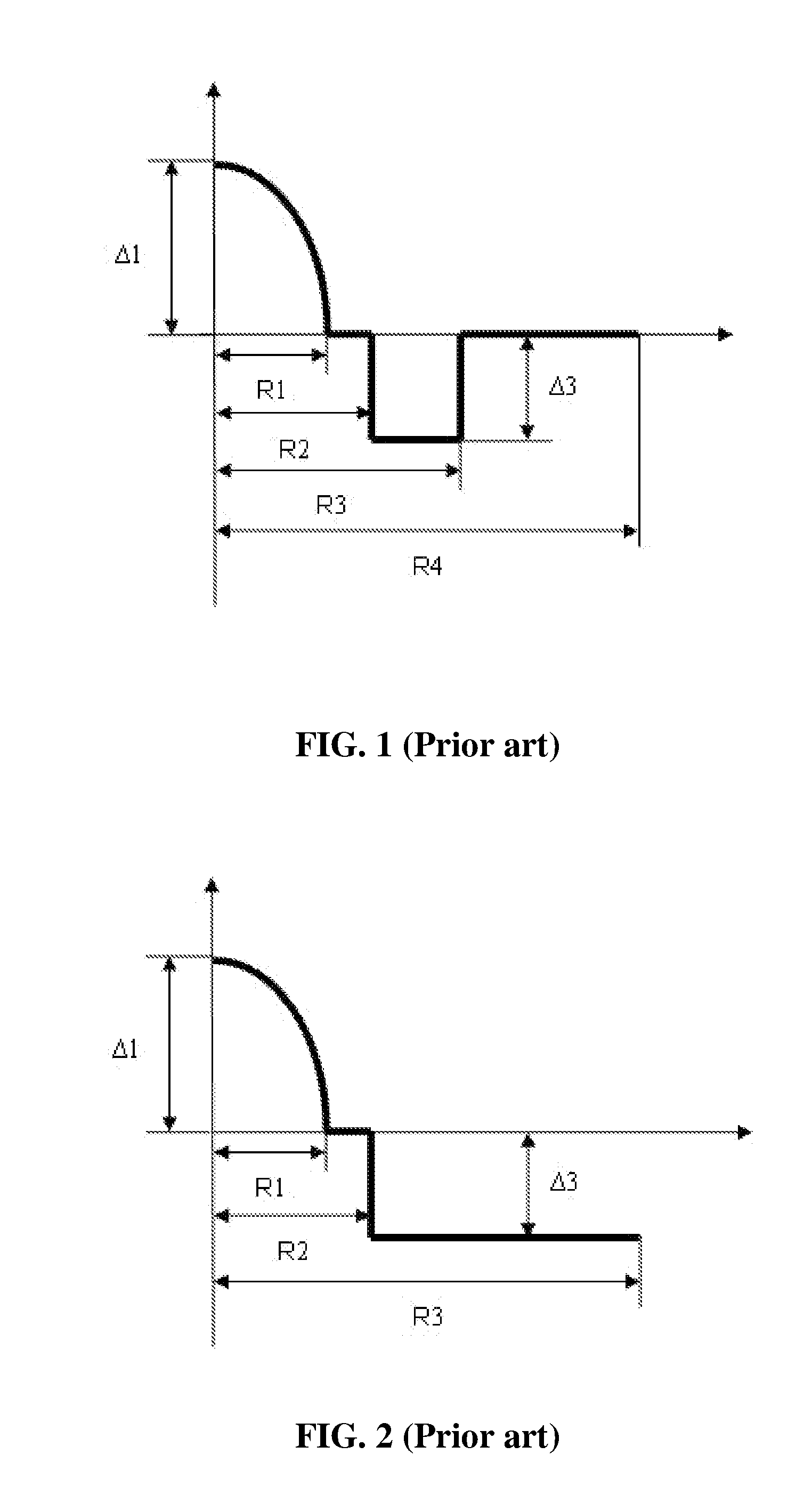

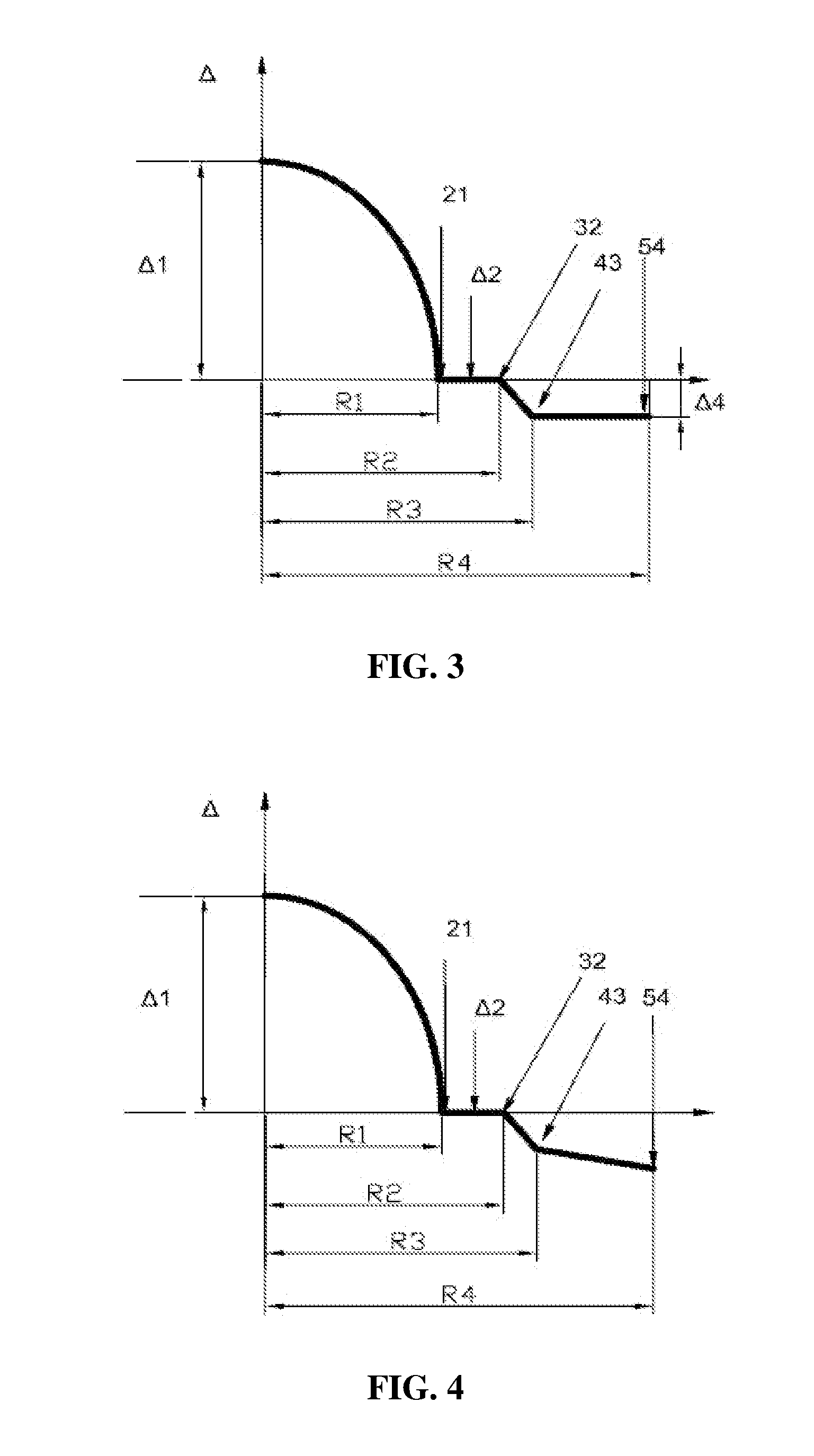

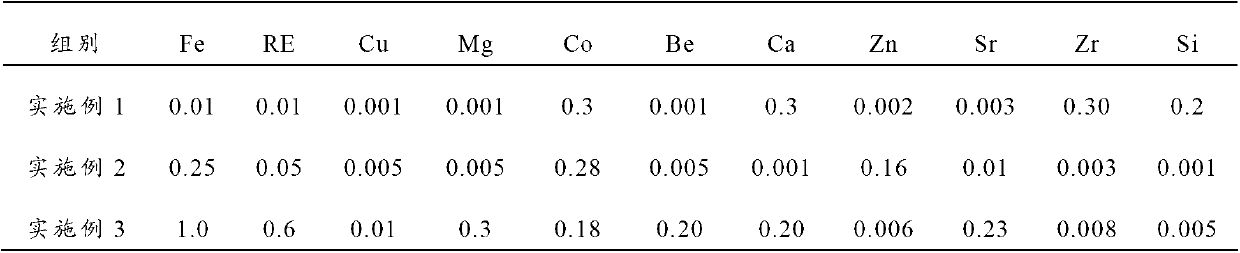

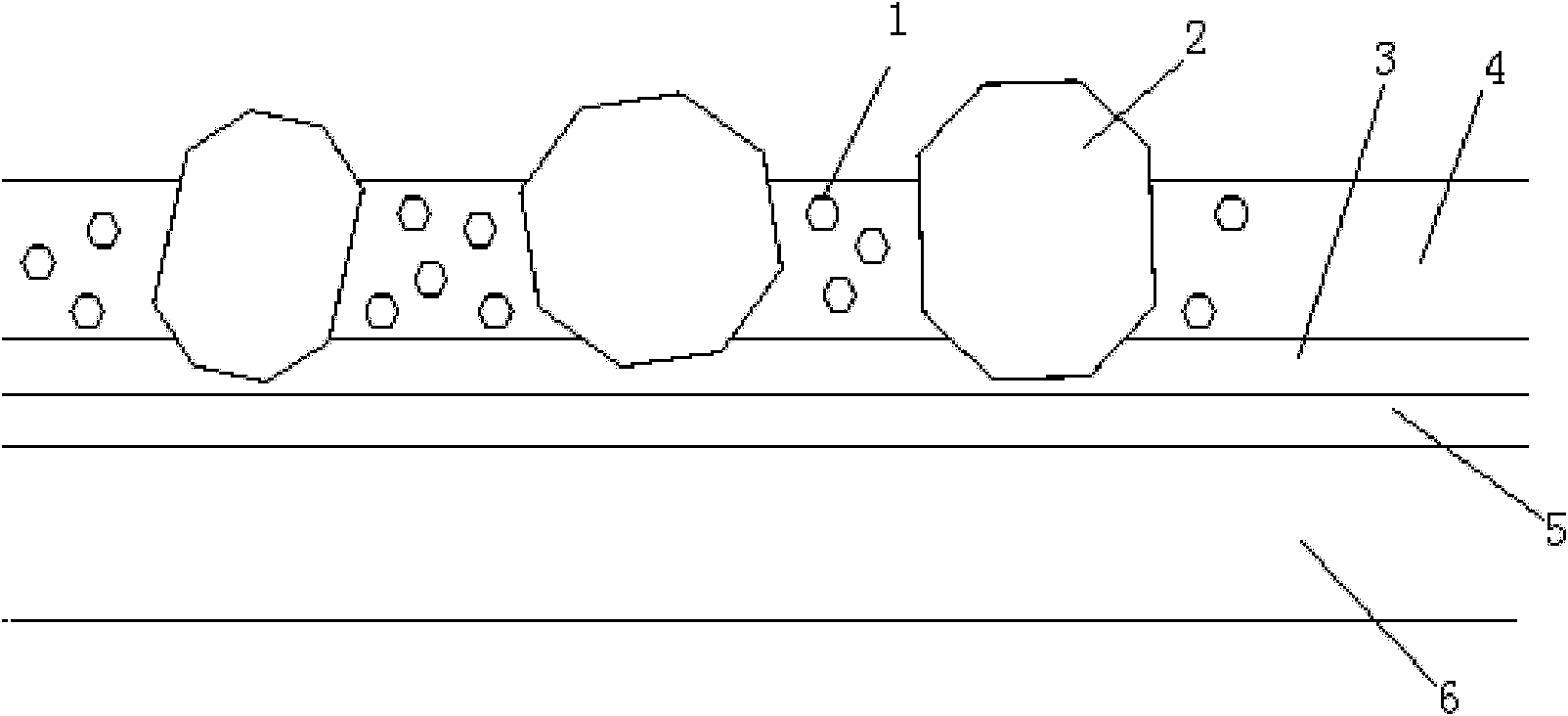

A multimode fiber including a core and a cladding. The core has a radius (R1) of 24-26 μm, the refractive index profile thereof is a parabola, and the maximum relative refractive index difference (Δ1) is 0.9-1.1%. The cladding surrounds the core and includes from inside to outside an inner cladding, a middle cladding, and an outer cladding; a radius (R2) of the inner cladding is 1.04-1.6 times that of the core, and a relative refractive index difference (Δ2) thereof is −0.01-0.01%; the middle cladding is a graded refractive index cladding whose radius (R3) is 1.06-1.8 times that of the core, and a relative refractive index difference thereof is decreased from Δ2 to Δ4; and a radius (R4) of the outer cladding is 2.38-2.63 times that of the core, and a relative refractive index difference (Δ4) thereof is between −0.20 and −0.40%. The invention reduces the additional bending loss of the fiber, improves the bending resistance and mechanical properties, basically eliminates the internal stress, and ensures the service life even working for a long term under the condition of low radius. The method for producing the fiber is simple, effective, and suitable for mass production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

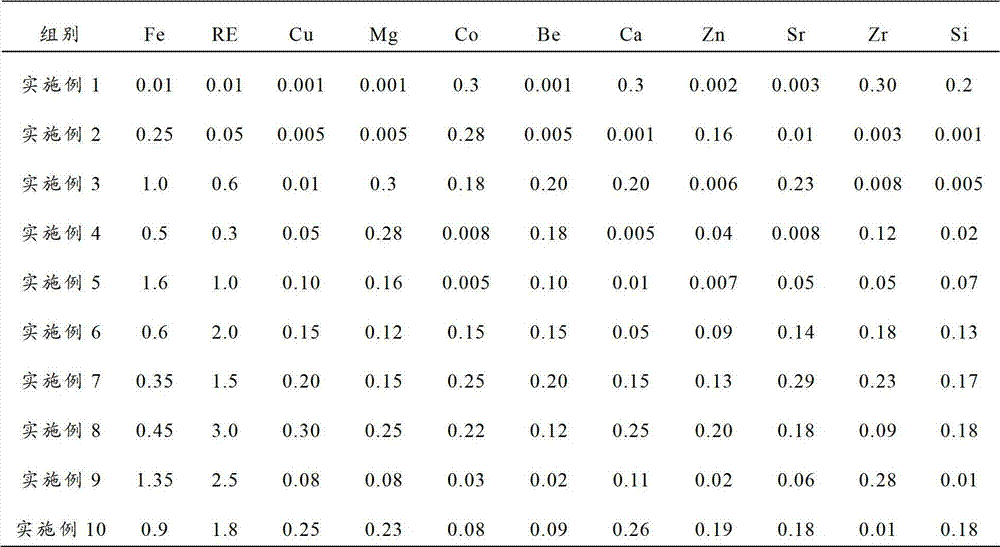

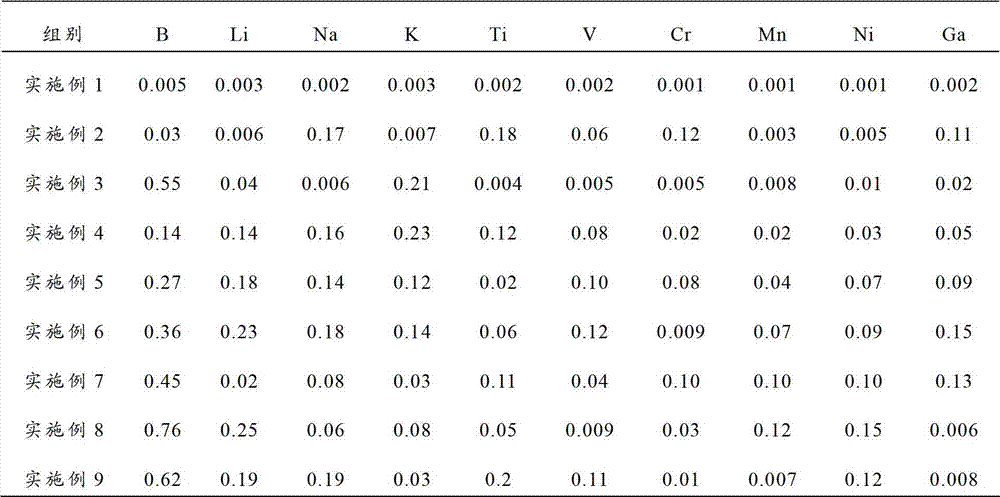

Al-Fe-C-RE aluminium alloy, preparation method thereof and power cable

ActiveCN103103387AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-C-RE aluminium alloy and a preparation method thereof. The preparation method comprises the following steps of: a) casting an aluminium alloy cast ingot; b) homogenizing the aluminium alloy cast ingot and rolling the homogenized aluminium alloy cast ingot to obtain an aluminium alloy rod material; c) intermittently annealing the aluminium alloy rod material obtained in the step b); and d) aging the aluminium alloy rod material obtained in the step c), thus obtaining the aluminium alloy. The invention also provides a power cable. The aluminium alloy has better overall performances by selecting and controlling the added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

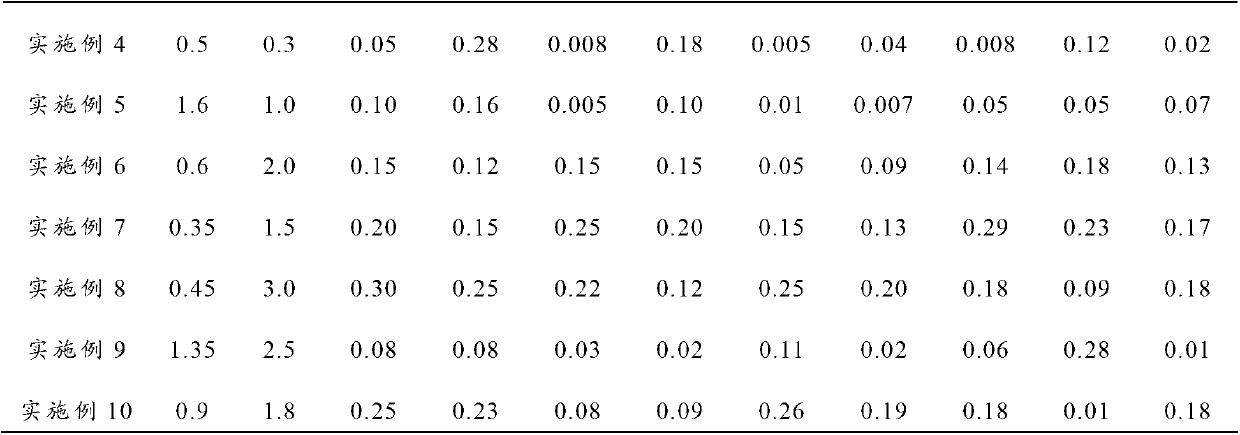

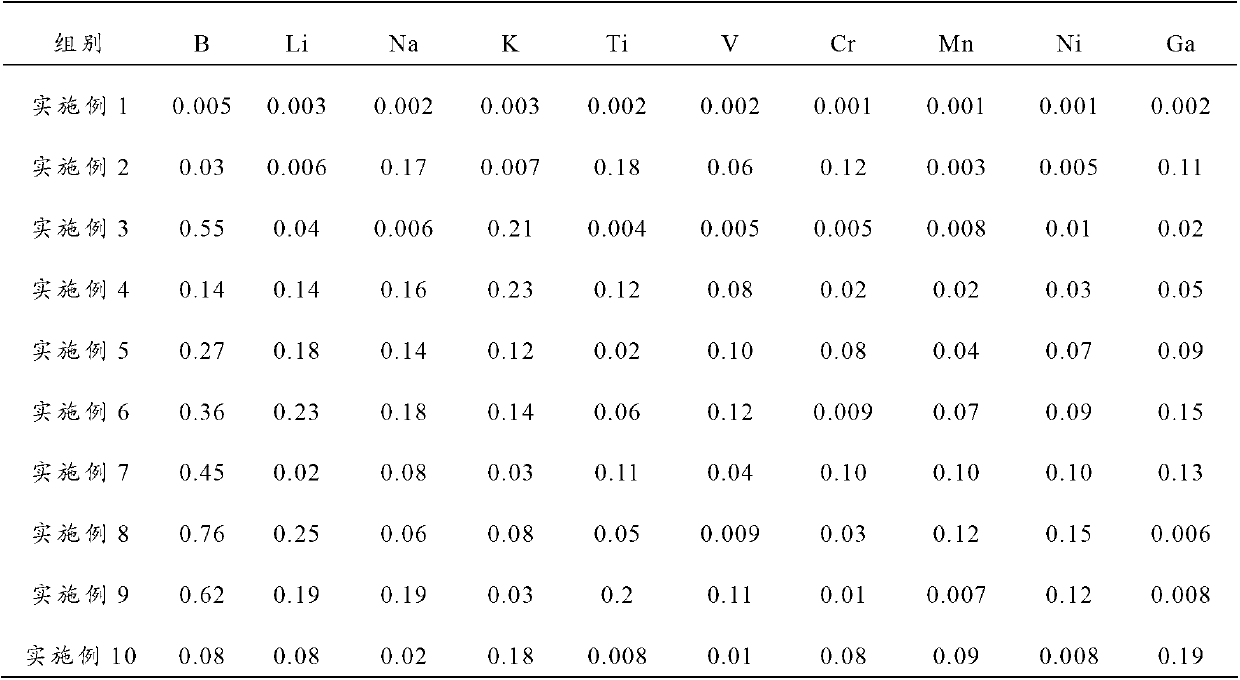

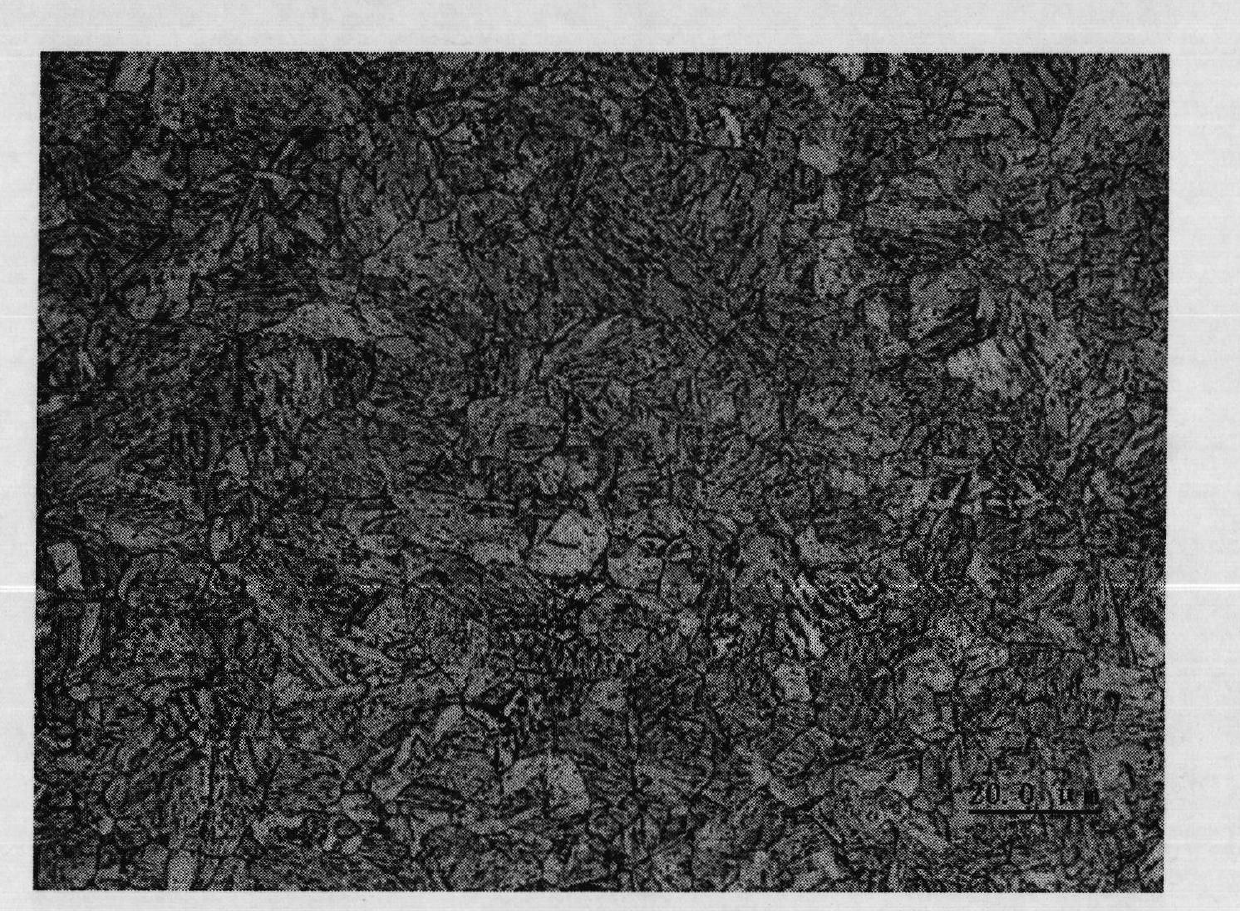

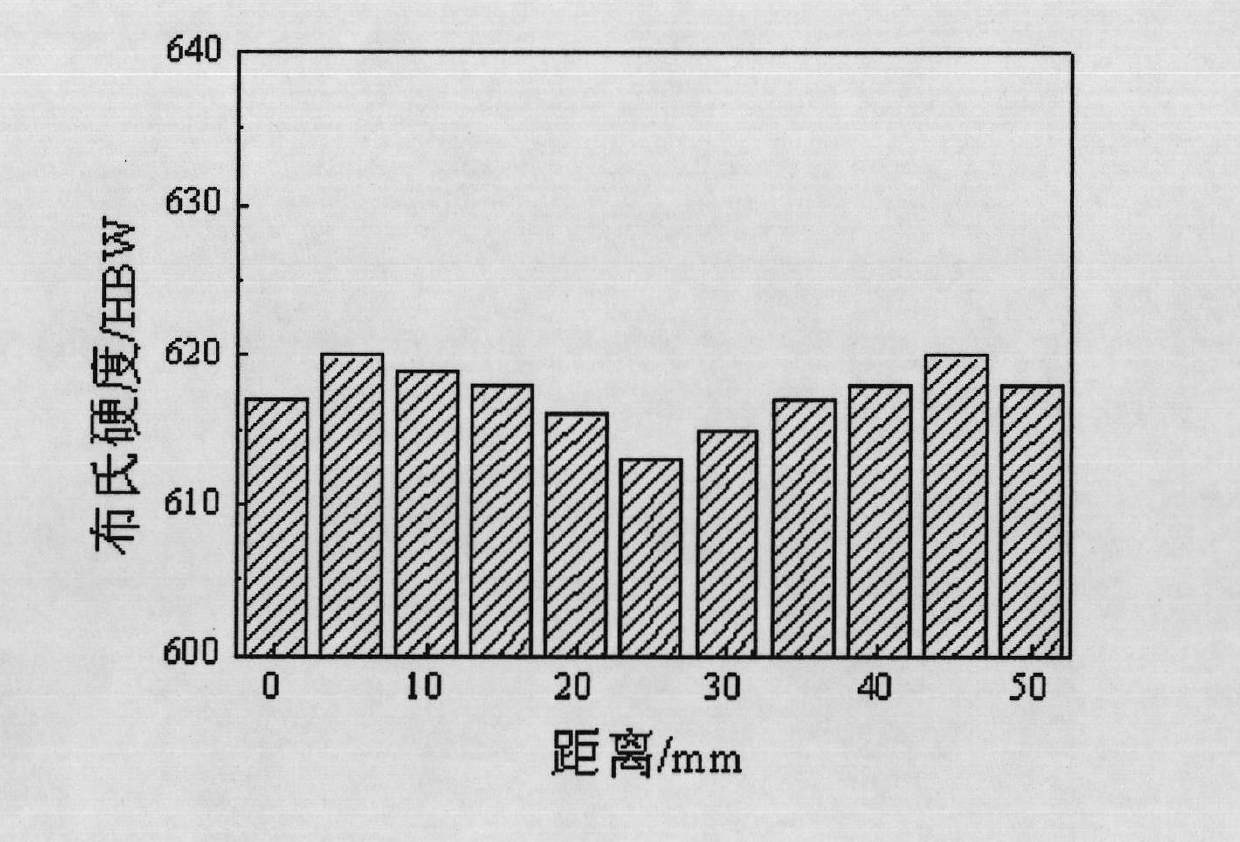

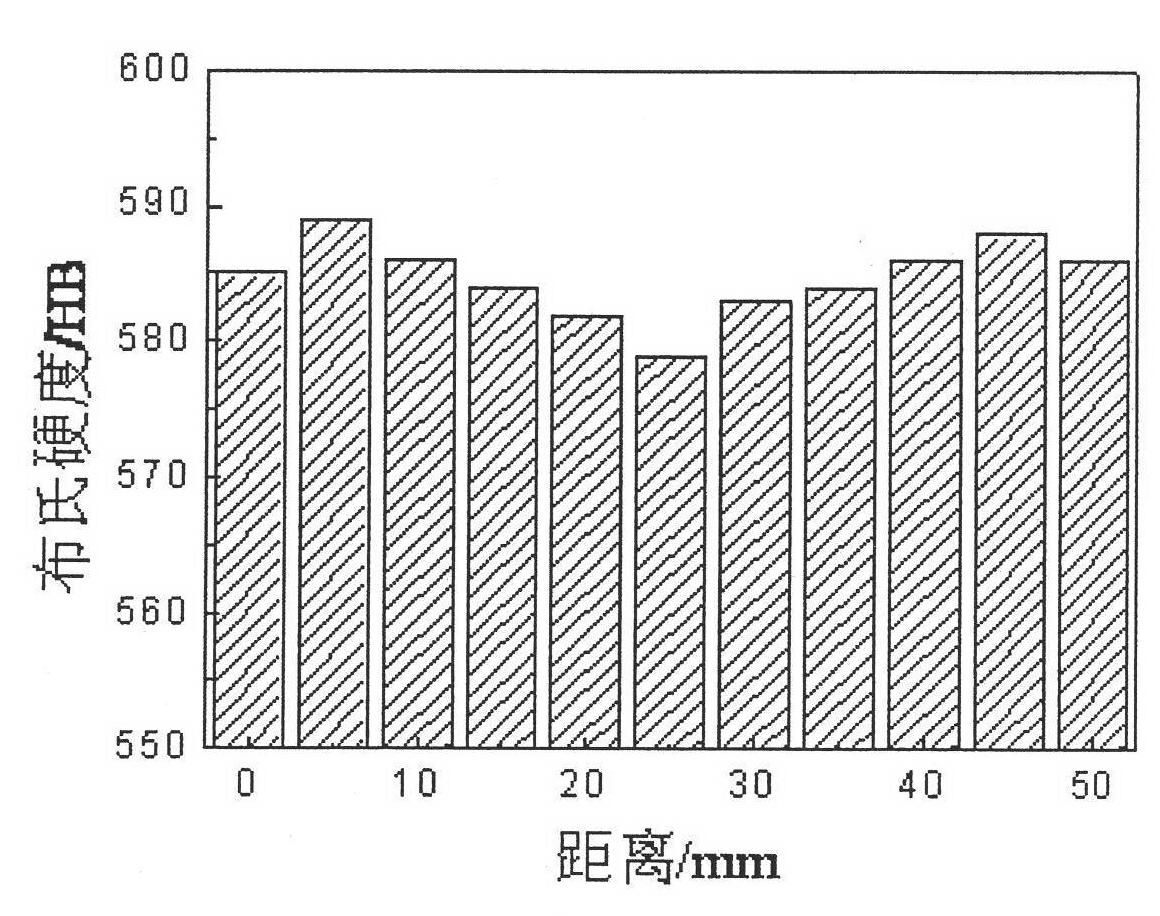

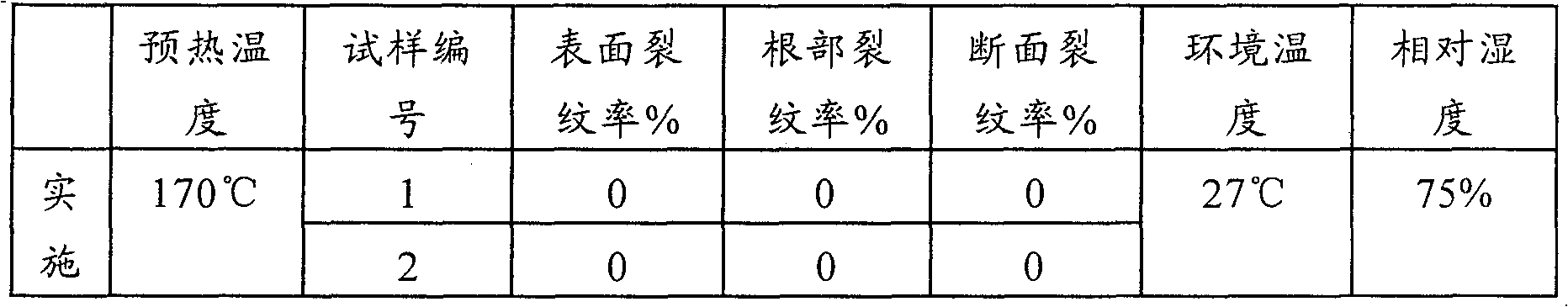

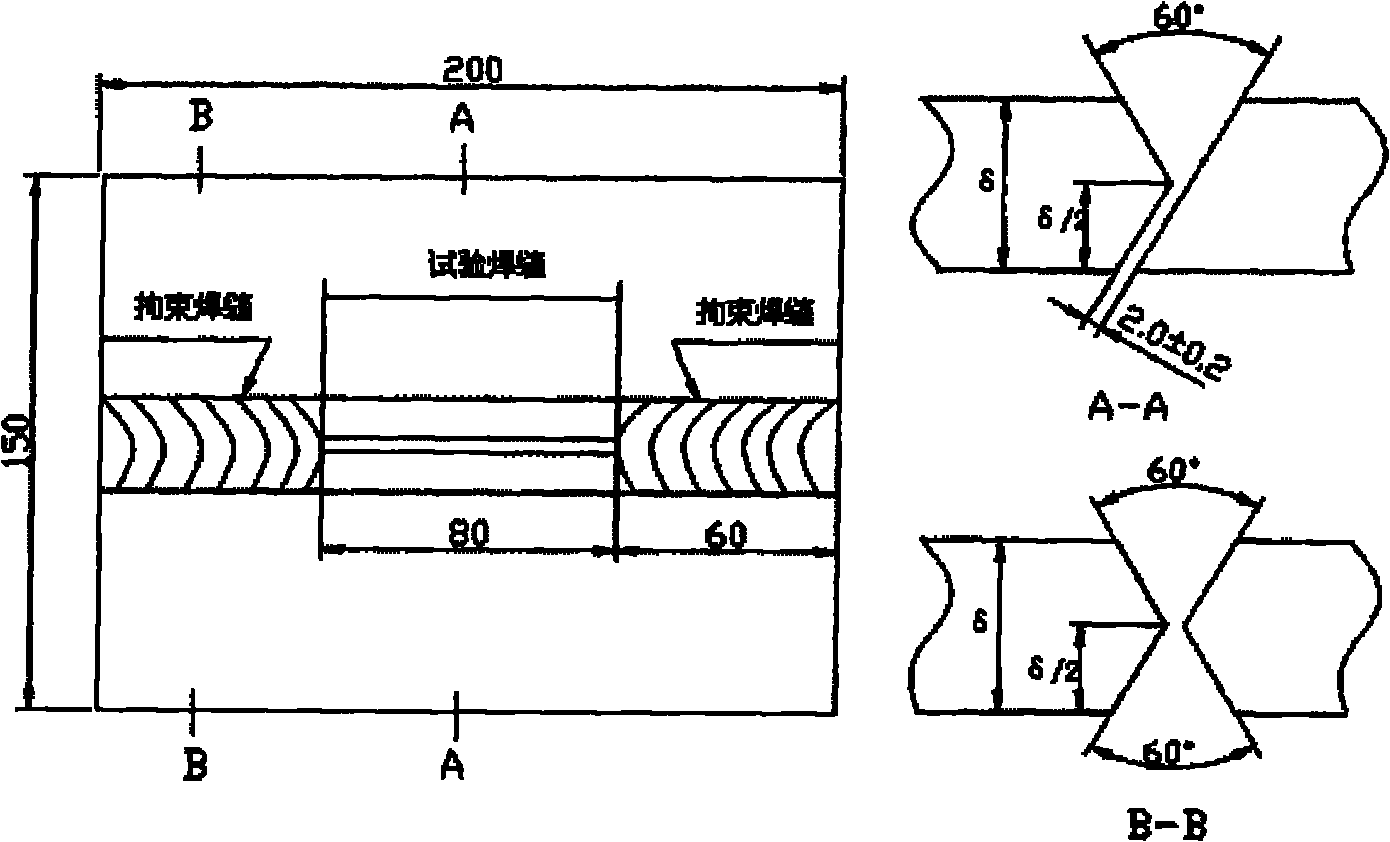

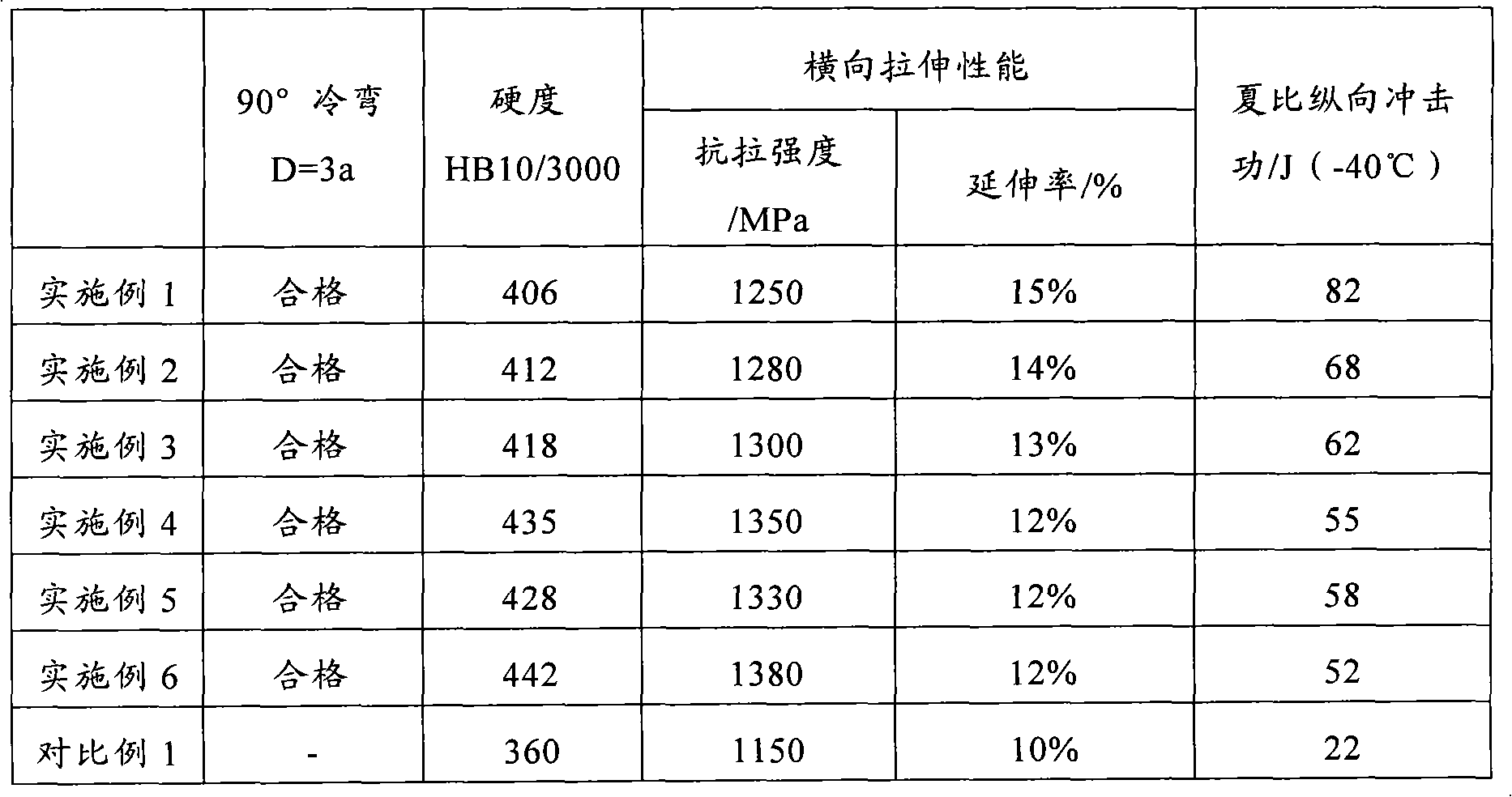

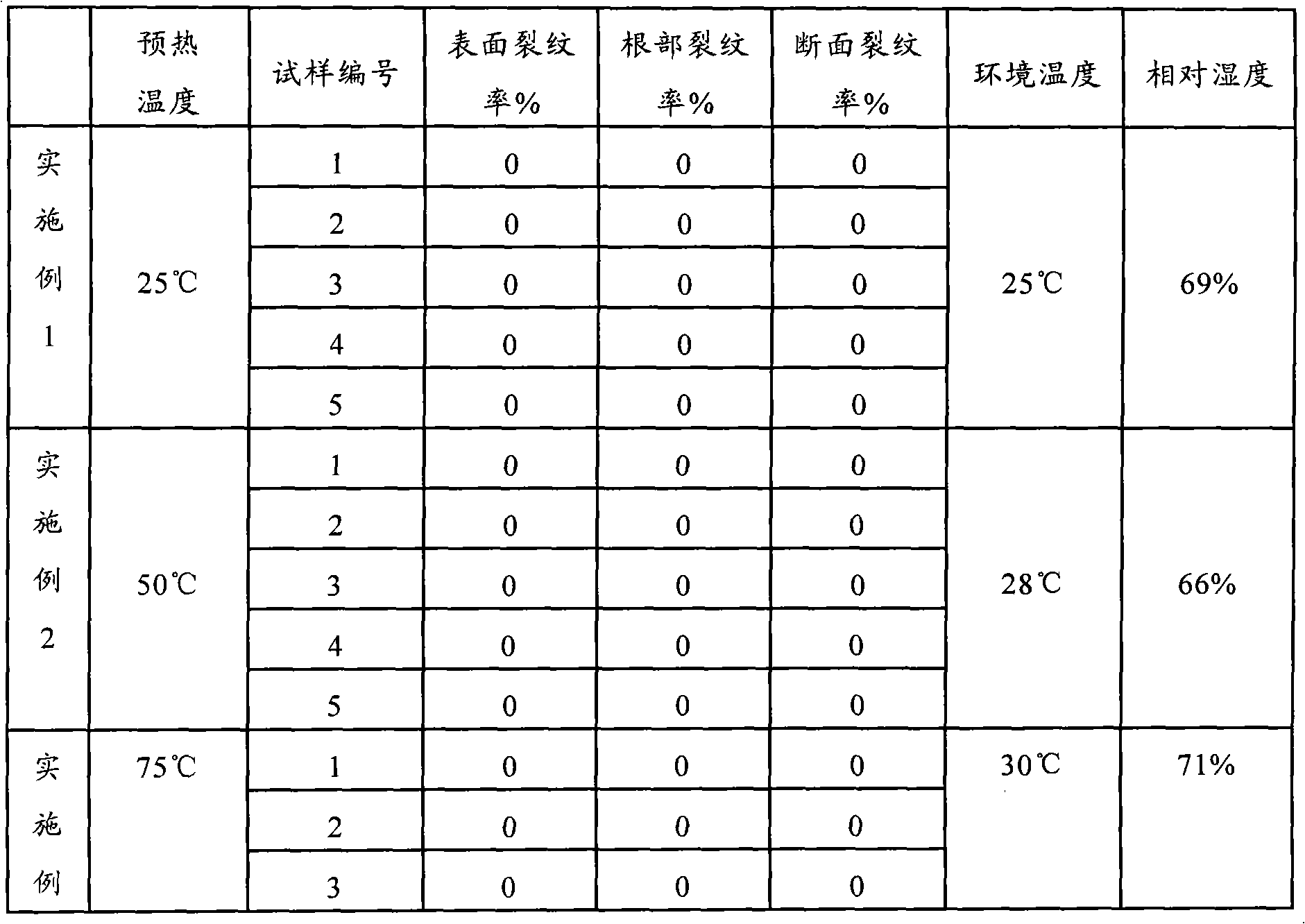

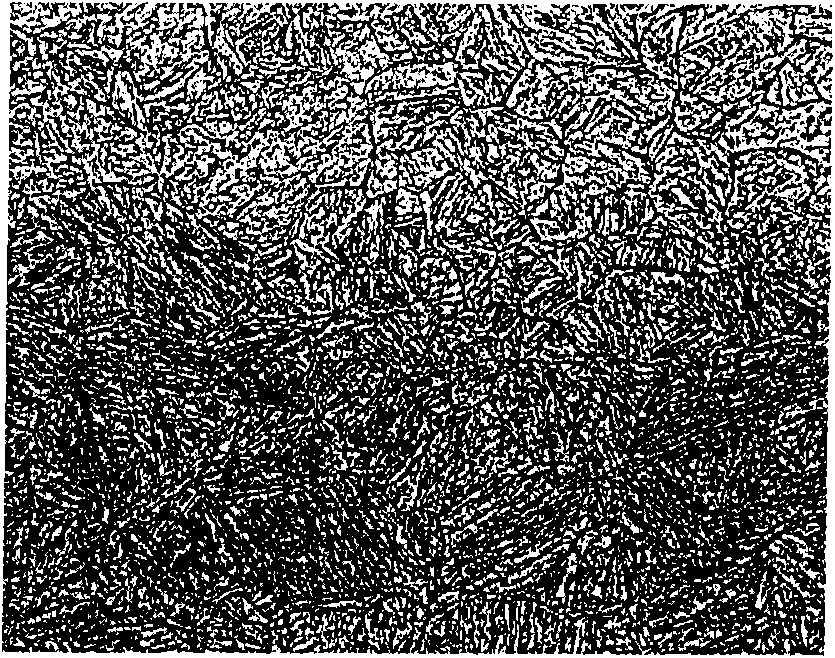

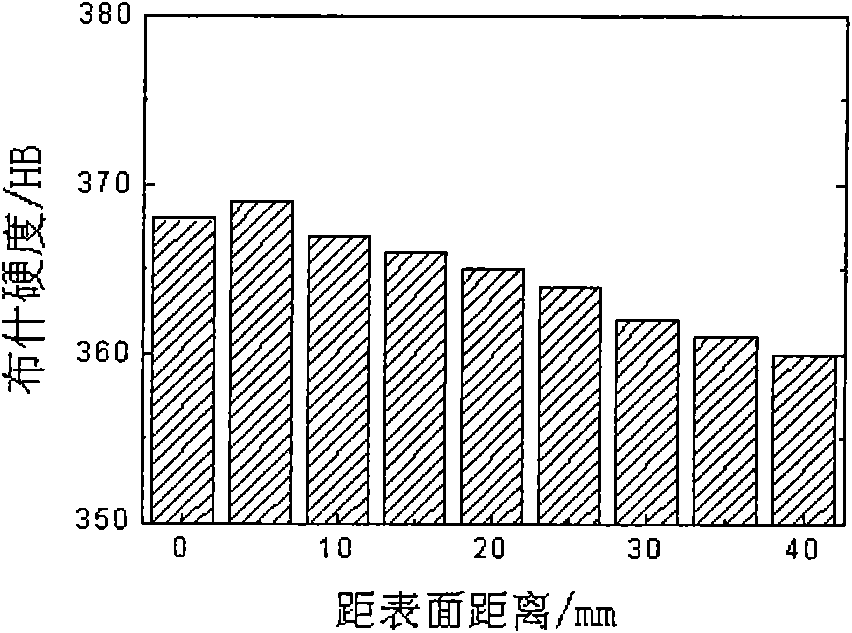

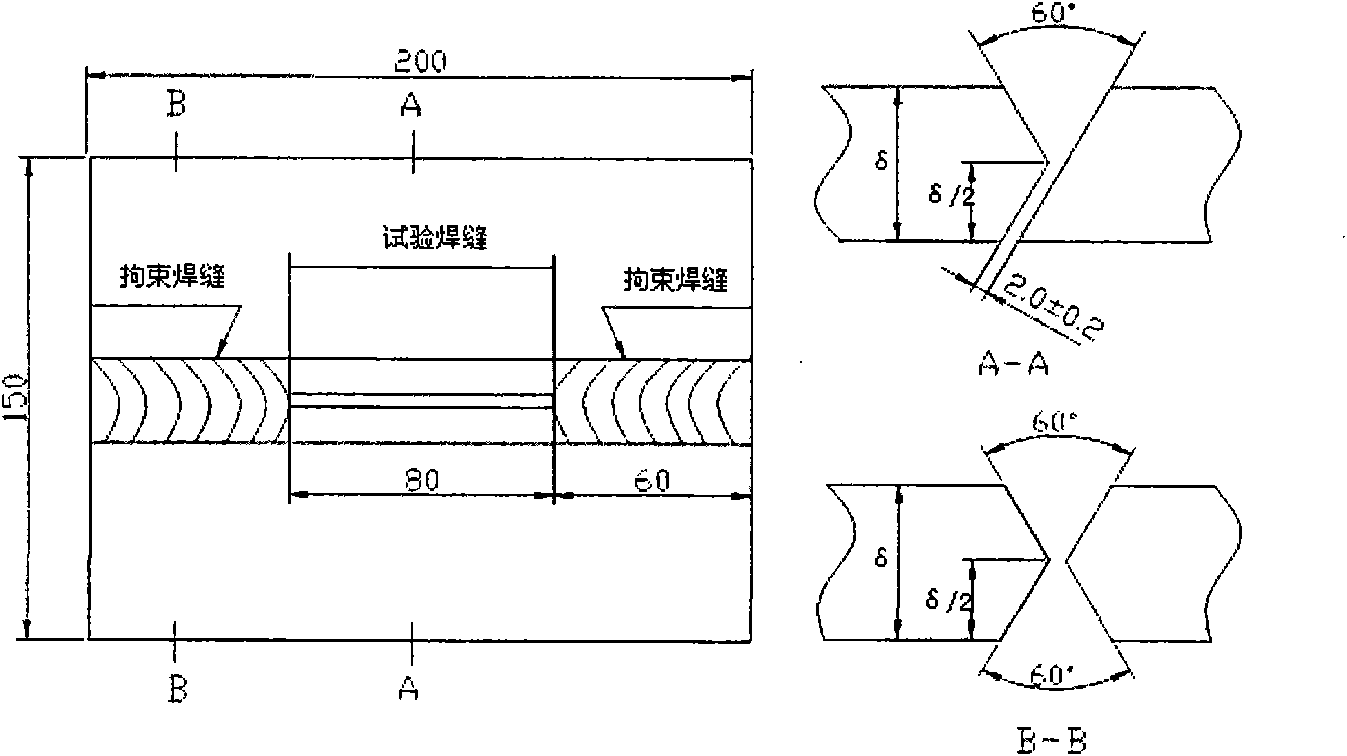

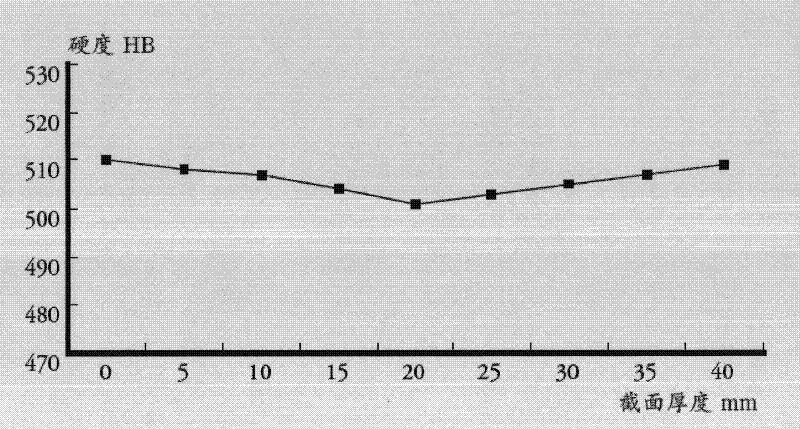

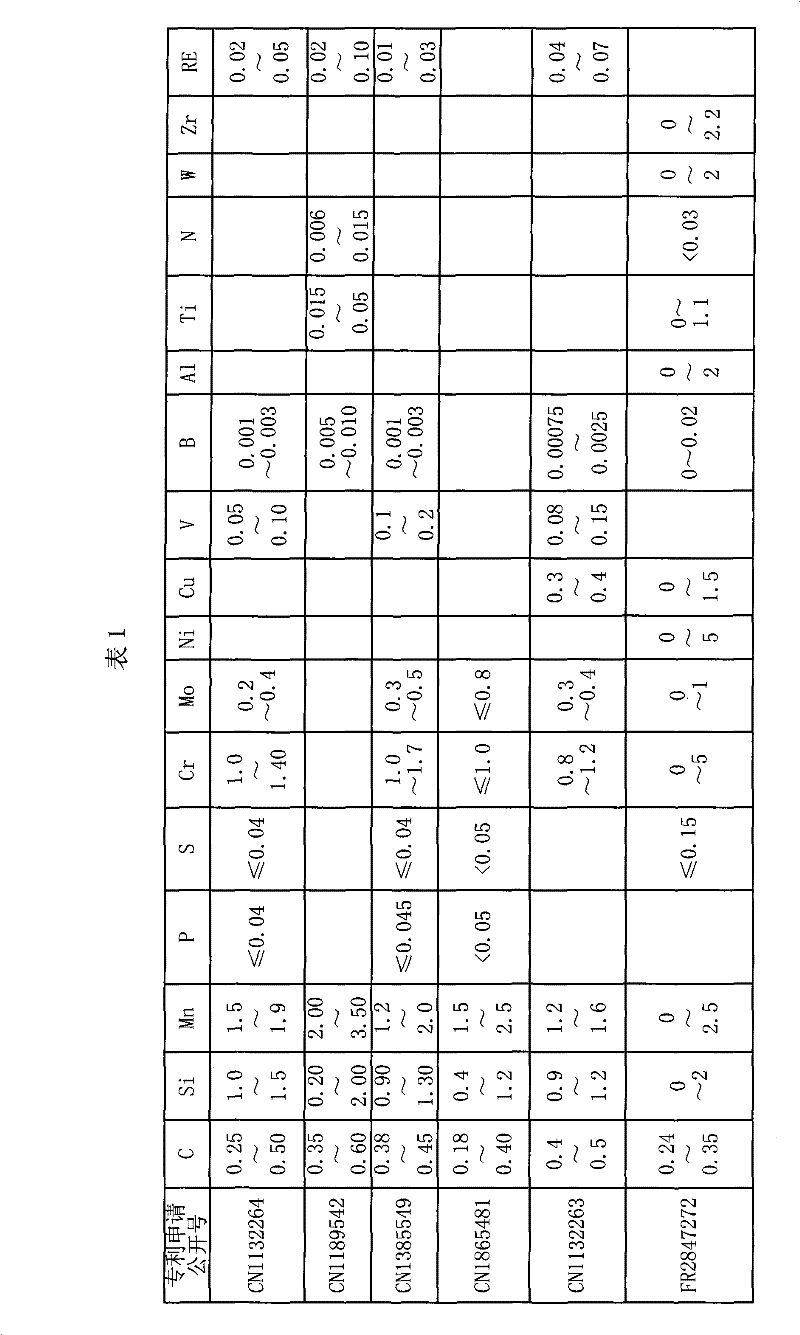

600HB-grade wear resistant steel plate and its manufacturing method

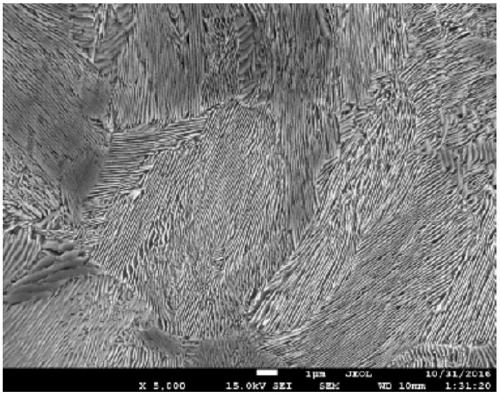

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balance Fe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance and excellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Al-Fe-Sb-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978449AEvenly heatedEliminate damagePower cables with screens/conductive layersMetal/alloy conductorsPower cableMetallurgy

The invention provides an Al-Fe-Sb-RE aluminum alloy, and a preparation method of the Al-Fe-Sb-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

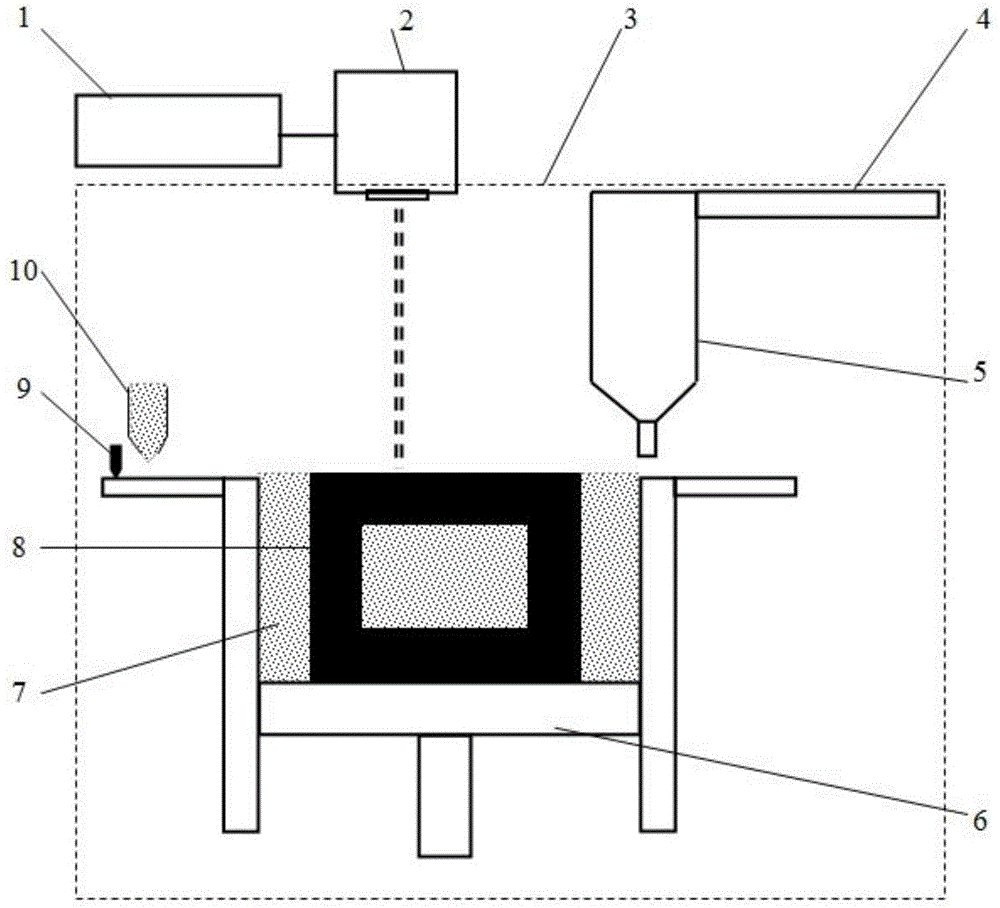

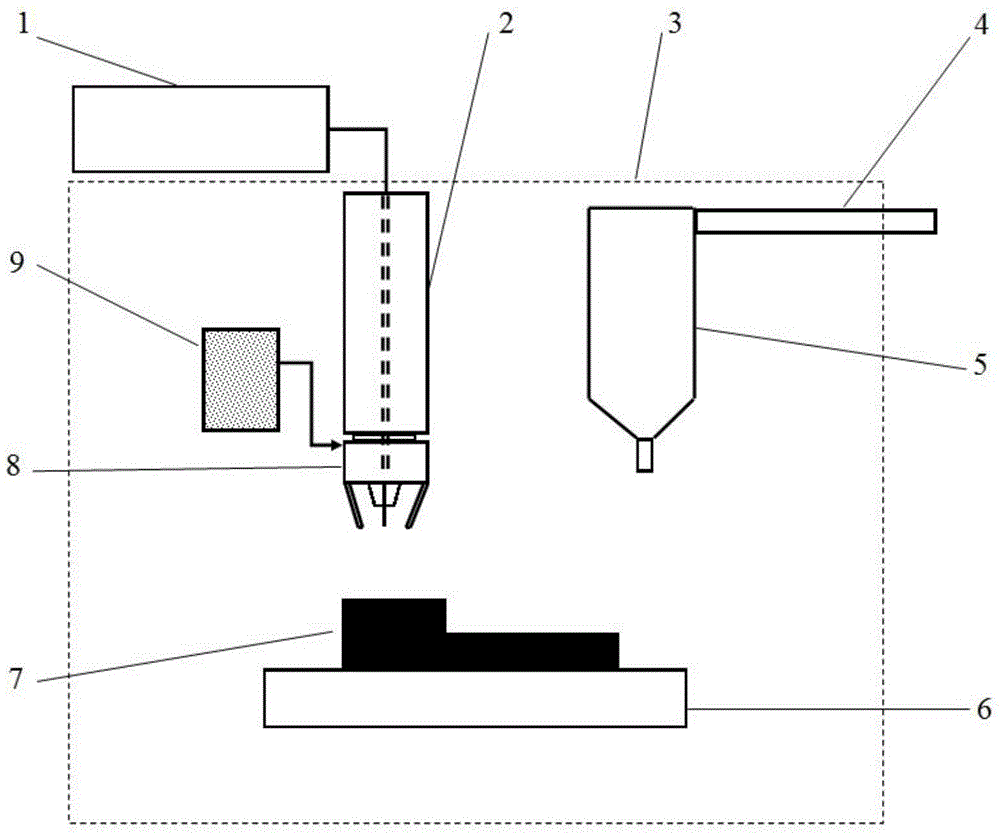

High-energy beam-ultrasonic composite additive manufacturing method for metal materials

InactiveCN104525944AHigh dimensional accuracyHigh performance controlIncreasing energy efficiencyHigh energyMechanical property

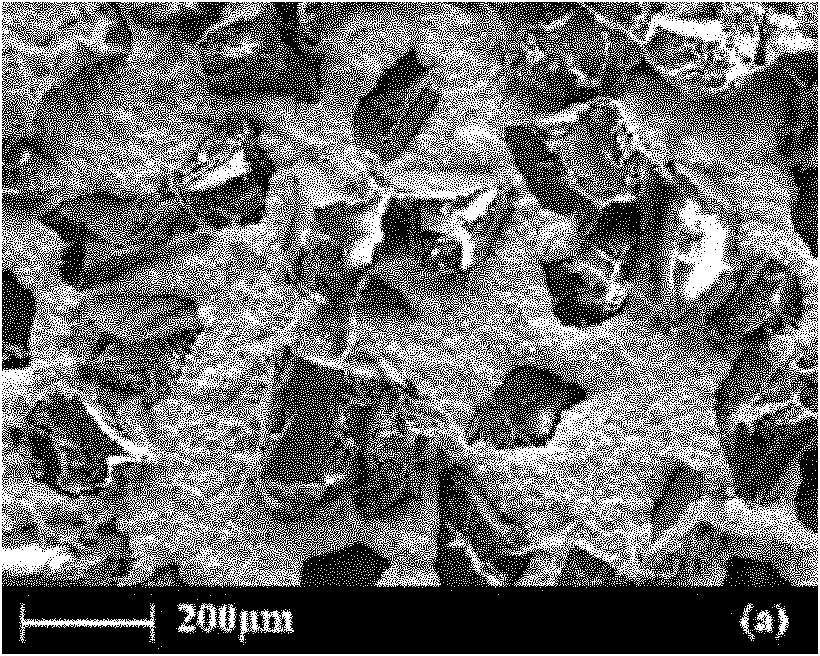

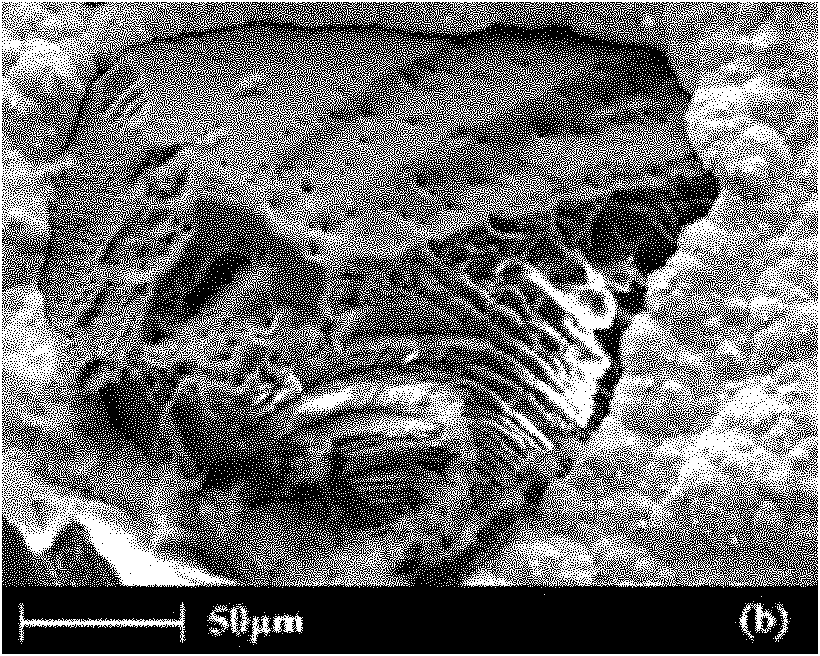

The invention discloses a high-energy beam-ultrasonic composite additive manufacturing method for metal materials and belongs to the field of additive manufacturing (3D printing) of metal materials. The method comprises the steps that based on the technical principle of layer-by-layer accumulation of additive manufacturing, metal forming materials are melted through high-energy beams; after the metal forming materials are melted / solidified layer by layer to accumulate to a certain number of layers, the solidified layers are subjected to ultrasonic peening to have compressive plastic deformation, so the internal stress and the internal defects of formed parts are eliminated, and crystalline grains are refined; afterwards, the process of layer-by-layer melting / solidifying accumulation and the process of ultrasonic peening are continued until the whole forming process of metal members is completed. According to the method, real-time layer-by-layer treatment is performed on the solidified layers through ultrasonic peening, so the internal stress and the internal defects can be effectively reduced or eliminated, the crystalline grains can be refined, and the mechanical property of the metal members through additive manufacturing can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Al-Fe-Ba-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Ba-RE aluminum alloy, and a preparation method of the Al-Fe-Ba-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Tl-RE aluminum alloy, and preparation method and power cable thereof

InactiveCN102978463AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-Tl-RE aluminum alloy, and a preparation method of the Al-Fe-Tl-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Bi-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Bi-RE aluminum alloy, and a preparation method of the Al-Fe-Bi-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Ni-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Ni-RE aluminum alloy, and a preparation method of the Al-Fe-Ni-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Ta-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978451AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-Ta-RE aluminum alloy, and a preparation method of the Al-Fe-Ta-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-W-RE aluminum alloy, and preparation method and power cable thereof

ActiveCN102978468AEvenly heatedEliminate damagePower cablesMetal/alloy conductorsAluminium alloyPower cable

The invention provides an Al-Fe-W-RE aluminum alloy, and a preparation method of the Al-Fe-W-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

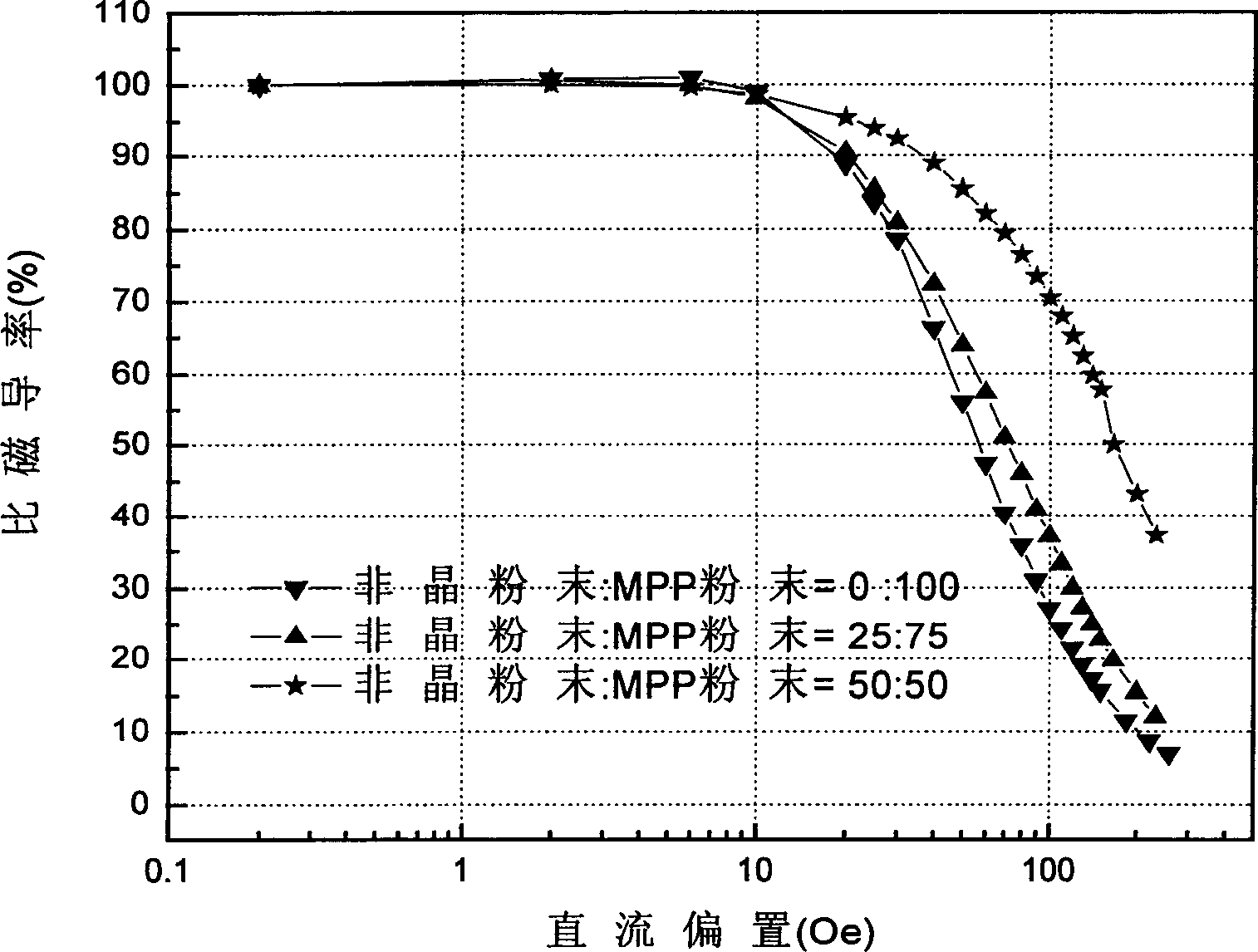

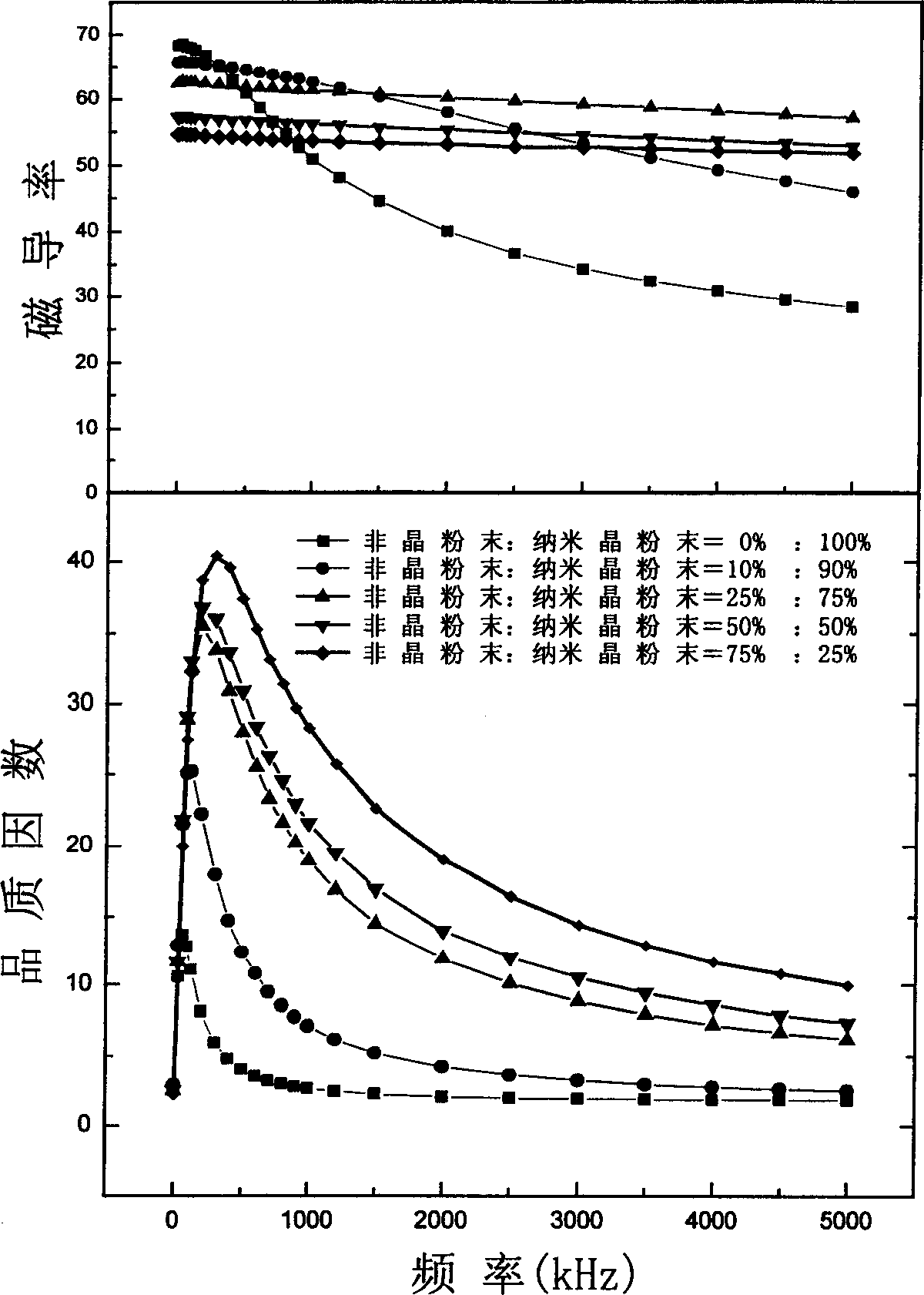

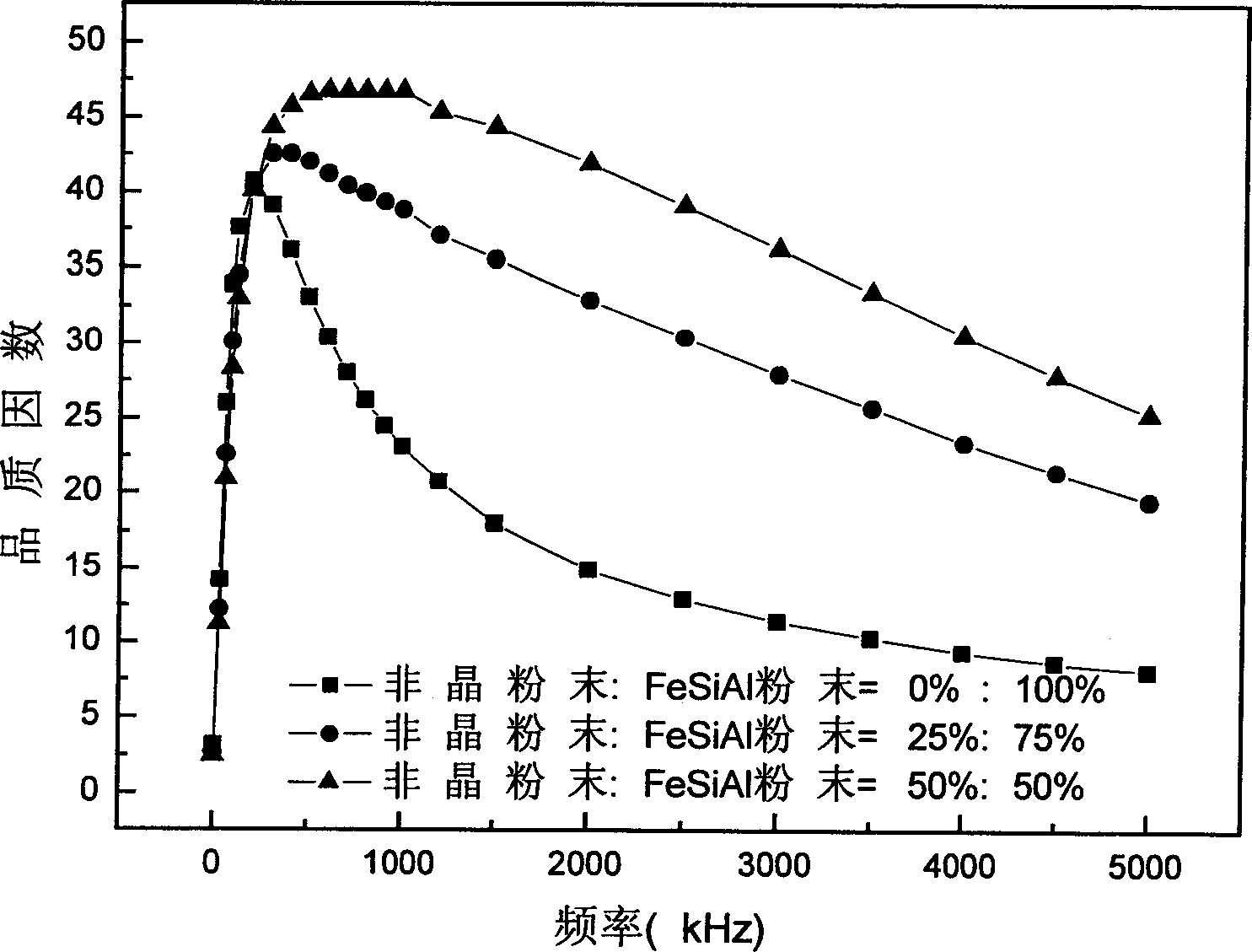

Composite powder for magnetic powder core and preparation process for magnetic powder core

InactiveCN1787127AEliminate internal stressImprove magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureIron powderNanocrystal

The invention provides a composite powder for magnetic powder core and the magnetic powder core preparing method thereof. The composite powder is mixed of powder A and powder B in the weight percents of 50-95wtúÑ and 50-95wtúÑ, respectively, where the powder A is one of the iron powder, iron-silicon powder, iron-silicon-aluminum powder, iron-base nano crystal powder, iron-base noncrystalline powder, iron-nickel powder, and iron-nickel-molybdenum powder; and the powder B has different demanded properties from the powder A and comprises at least one of the iron powder, iron-silicon powder, iron-silicon-aluminum powder, iron-base nano crystal powder, iron-base noncrystalline powder, iron-nickel powder, and iron-nickel-molybdenum powder. And the composite magnetic powder core preparing method anneals the powder A and powder B, respectively, so as to make both of them be in an excellent magnetic performance state, then mixes them uniformly, makes insulates and binding treatments, and finally makes press-forming and annealing treatments, thus obtaining the composite powder and the magnetic powder core thereof with synthetic and complete demanded properties.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Wear resistant steel plate

The invention provides a wear resistance steel plate, which contains the chemical ingredients (by weight percent) of: 0.31 to 0.40% of C, 0.10 to 0.80% of Si, 0.20 to 1.50% of Mn, not more than 0.050% of P, not more than 0.030% of S, 0 to 1.50% of Cr, 0 to 0.80% of Mo, 0.02 to 0.20% of Al, 0.0005 to 0.0040% of B, 0 to 0.10% of Ti, 0 to 0.030% of Ca, the balance of Fe and unavoidable impurities, wherein Cr+Mo is not less than 0.10% and not more than 1.80%, and Al+Ti not less than 0.05% and not more than 0.18%. A manufacturing method of the wear resistance steel plate comprises the steps of smelting, refining, casting, rolling, quenching, tempering and the like. The 550 HB-level wear resistance steel plate, which is obtained from the ingredients and process, has high hardness (not less than550 HB), can be welded and bent, and includes the microstructure of martensite or martensite and residual austenite. The steel plate has superior wear resistance and is extremely suitable for workingunder strong wear environment, especially on vehicles or facilities, like buckets, loaders, mining electric wheel dump tracks and the like, which come into contact with high-hardness materials, such as high strength ore and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

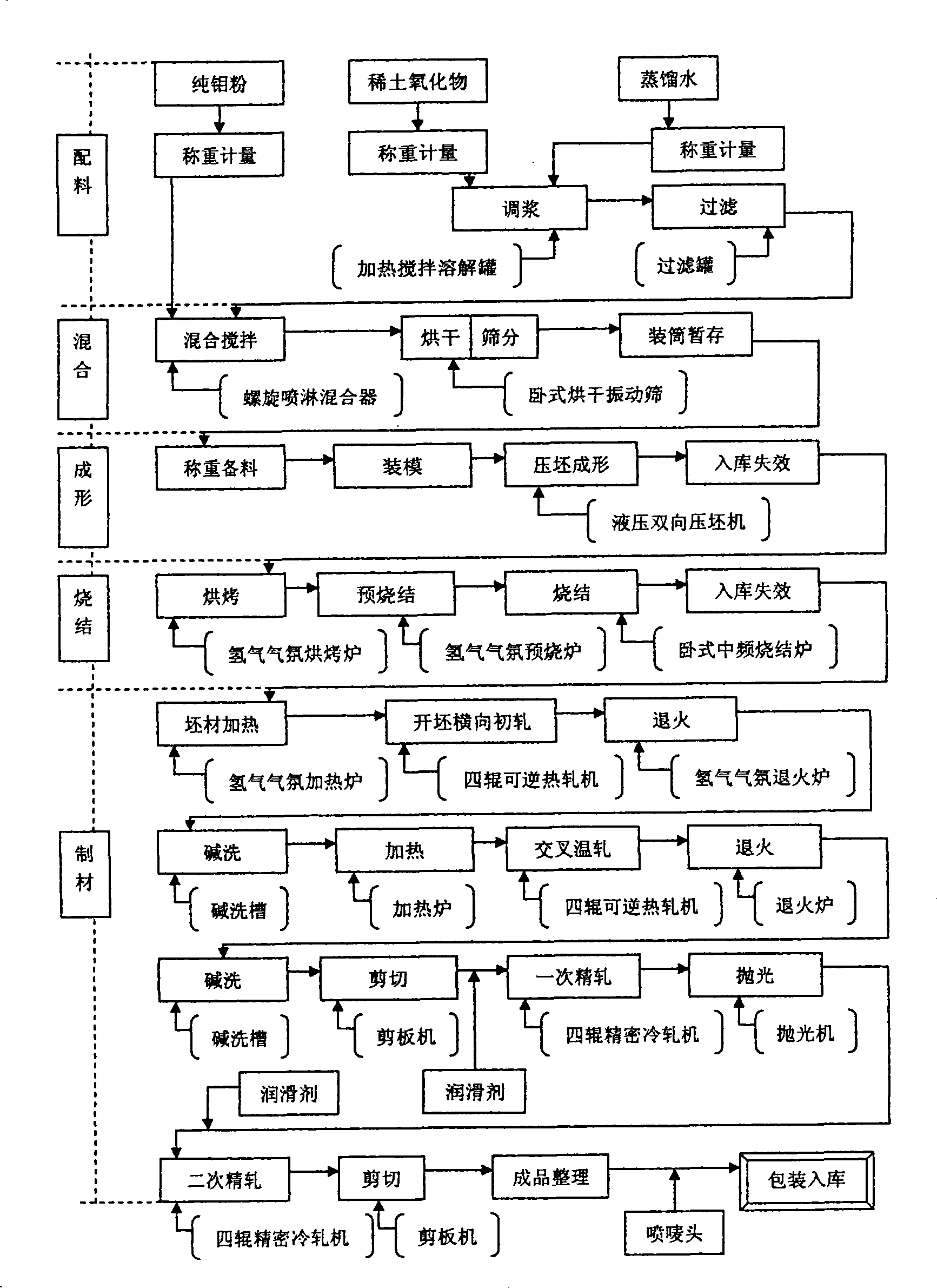

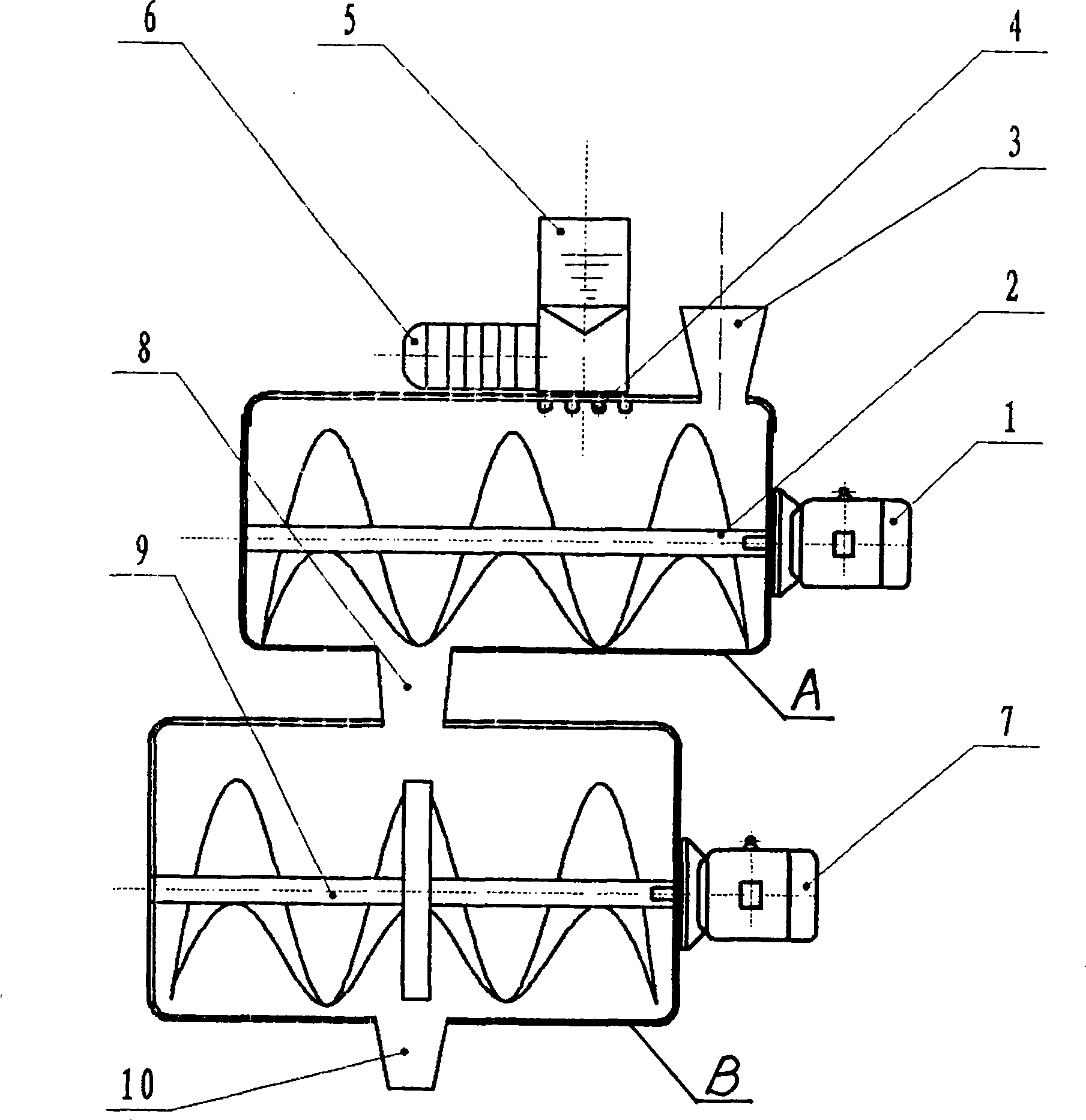

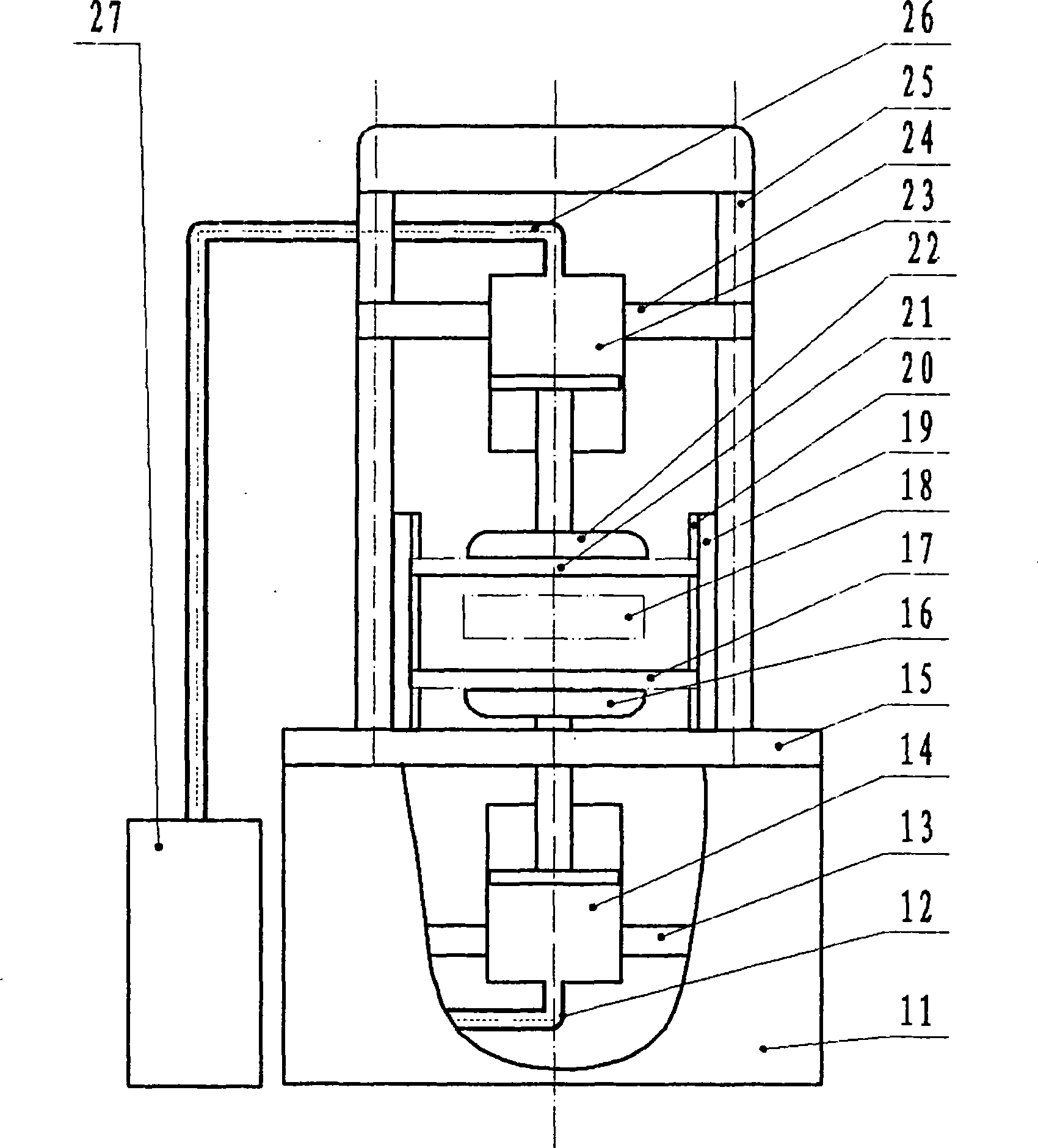

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

400HB-grade wear-resistant steel and method for manufacturing same

The invention provides a wear-resistant steel which comprises the following chemical components by weight percent (wt%): 0.08-0.24% of C, 0.10-0.30% of Si, 0.70-1.70% of Mn, 0.050% of P or less, 0.030% of S or less, 1.00% of Cr or less, 0.60% of Mo or less, 0.01-0.10% of Al, 0.0005-0.0040% of B, 0.005-0.06% of Ti and the balance of Fe and inevitable impurities, wherein the total weight percent of the Cr and the Mo is more than or equal to 0.15% and less than or equal to 1.20%, and the total weight percent of the Al and the Ti is more than or equal to 0.011% and less than or equal to 0.15%. A method for manufacturing the wear-resistant steel comprises the steps of smelting, casting, rolling, quenching and tempering. The 400HB-grade wear-resistant steel which is obtained by adopting the components and the process has high strength, good toughness and excellent machining performance, is easy to weld and bend and is suitable for the easily-worn equipment such as the bucket, the scraper conveyor and the mining electric-wheel dumper carriage of the engineering machinery.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

High-flexibility wear-resistant steel plate and manufacturing method thereof

ActiveCN101775539AImprove wear resistanceImprove low temperature toughnessMicro structureForeign matter

The invention provides a high-flexibility wear-resistant steel plate, which is characterized by comprising the following chemical components by weight percent: 0.04 to 0.11 percent of C, 0.10 to 0.50 percent of Si, 0.50 to 1.50 percent of Mn, less than 0.015 percent of P, less than 0.010 percent of S, 0 to 0.60 percent of Cr, 0 to 0.50 percent of Mo, 0 to 0.80 percent of Ni, 0 to 0.050 perent of Nb, 0.005 to 0.0040 percent of B, 0.010 to 0.060 percent of Al and 0.005 to 0.060 percent of Ti, and the surplus is Fe and inevitable foreign matters; and the content of Si, Mn and Cr satisfies that: Si+Mn+Cr is less than or equal to 2.4 percent and more than or equal to 1.30 percent; and the content of Mo, Ni and Nb satisfies that: Mo+Ni+Nb is less than or equal to 1.10 percent more than or equal to 0.10 percent. The hardness of the high-flexibility wear-resistant steel plate is more than 350 HB, the longitudinal impact power is more than 100J at the temperature of minus 40 DEG C, the micro-structure is of bainite or martensite, and the welding performance is excellent. The wear-resistant steel plate has simple and easy production technology and excellent low-temperature flexibility and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

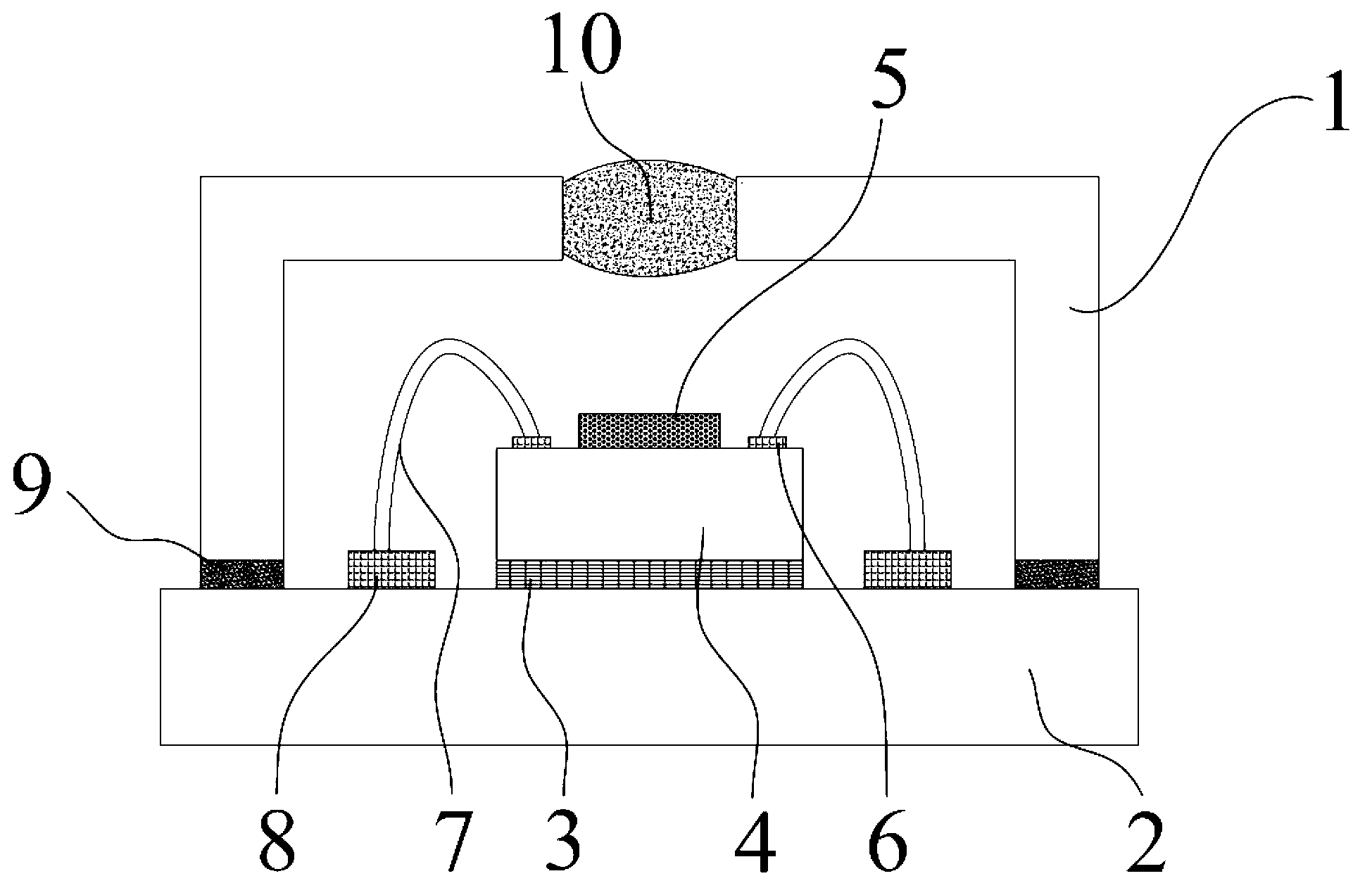

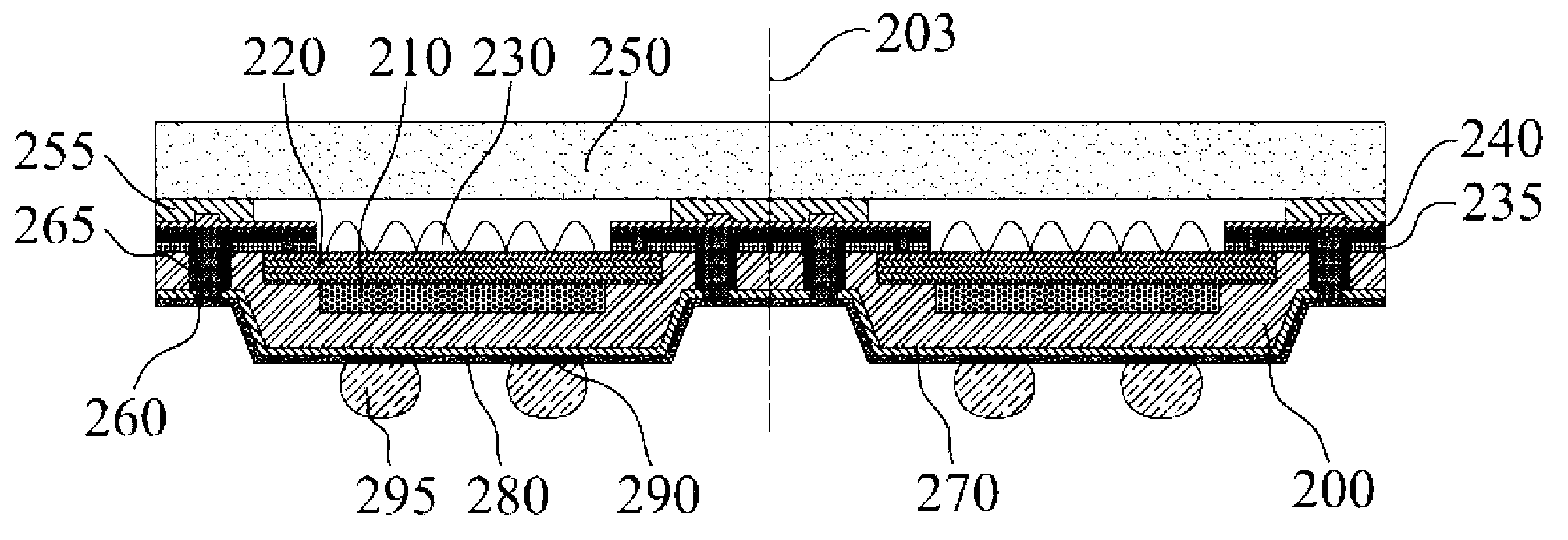

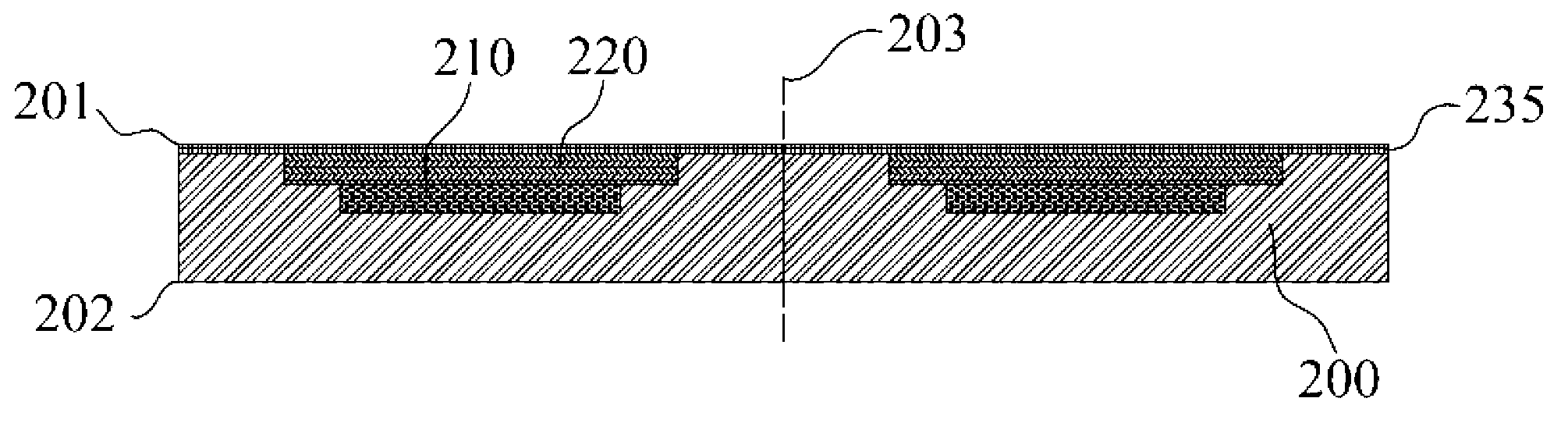

Wafer level chip size package and manufacturing method thereof

InactiveCN103021983AImprove bond strengthImprove layeringSemiconductor/solid-state device detailsSolid-state devicesMetalPolymer

The invention discloses a wafer level chip size package and a manufacturing method of the wafer level chip size package, belonging to the field of sensors. The wafer level chip size package comprises a wafer, wherein the positive surface of the wafer is a first surface which forms an image sensing region, the negative surface of the wafer is a second surface, and the first surface comprises a microlens, a metal interconnection layer and an optical interaction region from top to bottom; a silicon through hole which does not penetrate through a silicon substrate and a redistribution region are manufactured on the first surface, and I / Os at the periphery of the optical interaction region are connected with the silicon through hole; the wall of the silicon through hole is manufactured into a passivation layer and is filled; a polymer material is manufactured into a second protective layer on the redistribution region; the first surface is in bonding with a glass sheet, and a cavity is formed between the glass sheet and the wafer; the second surface is thinned and forms a groove structure through an etching process, and the silicon through hole is exposed; a line layer is manufactured on the second surface, and the silicon through hole is connected to a solder pad cushion; a welding prevention layer is manufactured on the line layer, and the solder pad cushion is exposed; and a solder ball is arranged on the solder pad cushion. With the adoption of the wafer level chip size package and the manufacturing method of the wafer level chip size package, the technological process is reduced, the reliability and the production efficiency of a product are improved, and the production cost is lowered.

Owner:BEIJING UNIV OF TECH

A kind of 500hb wear-resistant steel plate and its manufacturing method

ActiveCN102260829ASolderableStrong construction machinery applicabilityWear resistantChemical element

The invention discloses a 500 HB wear resistant steel plate, whose chemical elements contain, by weight, 0.23-0.33% of C, 0.10-0.50% of Si, 0.50-1.50% of Mn, Cr being less than or equal to 1.50%, Mo being less than or equal to 0.80%, 0.01-0.10% of Al, 0.01-0.10% of Ti, 0.0005-0.0040% of B, 0.01-0.08% of RE, 0.002-0.010% of Ca, Ni being less than or equal to 2.50%, P being less than or equal to 0.050%, S being less than or equal to 0.030%, and the balance being Fe and other unavoidable impurities. In addition, the mass percentages of the above chemical elements satisfy the following conditions: (Si+Mn) is less than or equal to1.50% and greater than or equal to 0.50%; (Al+Ti) is less than or equal to 0.15% and greater than or equal to 0.03%. Correspondingly, the invention also provides a manufacturing method of the 500 HB wear resistant steel plate. The steel plate prepared by the method has good mechanical processing property and its rigidity can reach over 500 HB.

Owner:BAOSHAN IRON & STEEL CO LTD

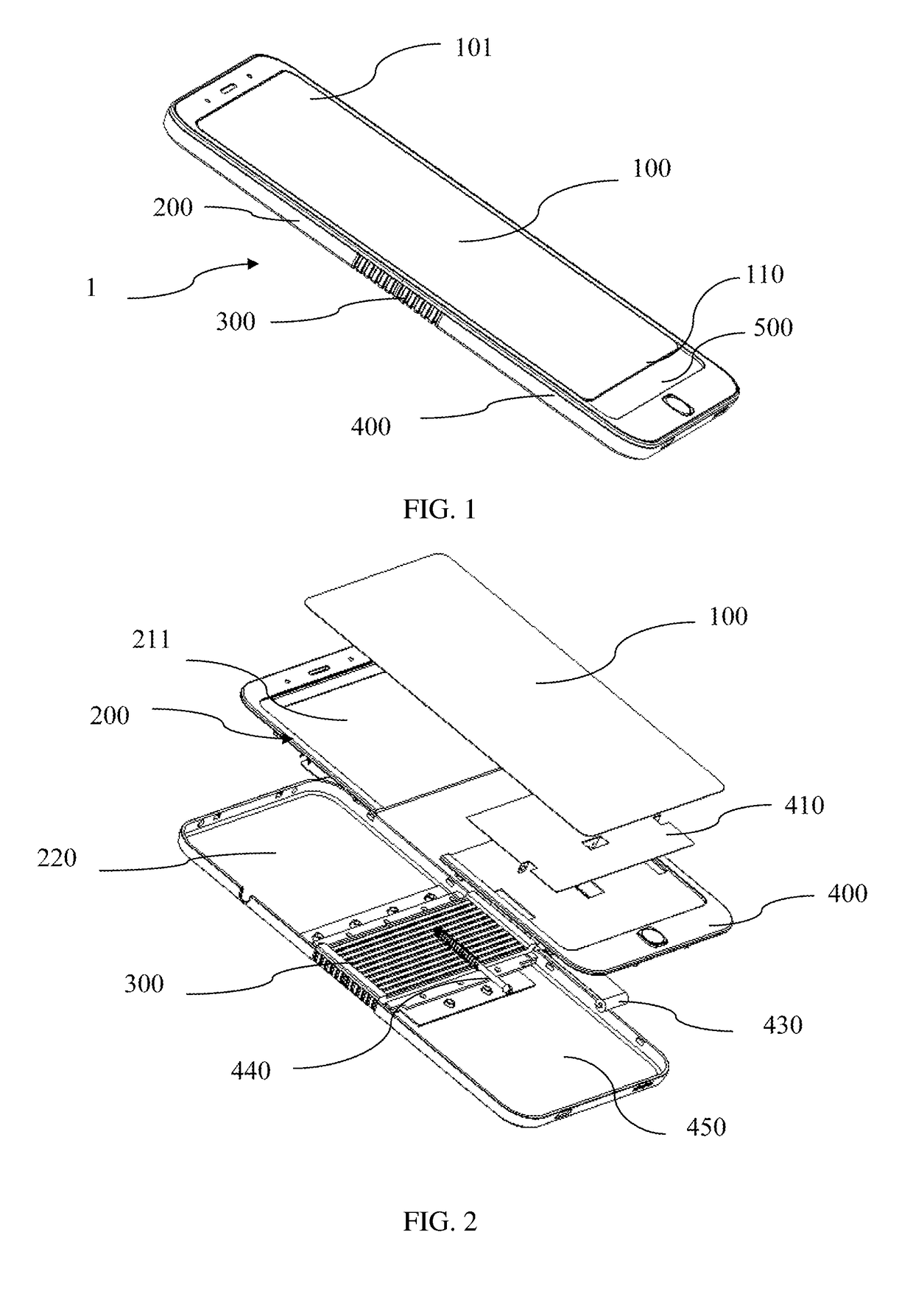

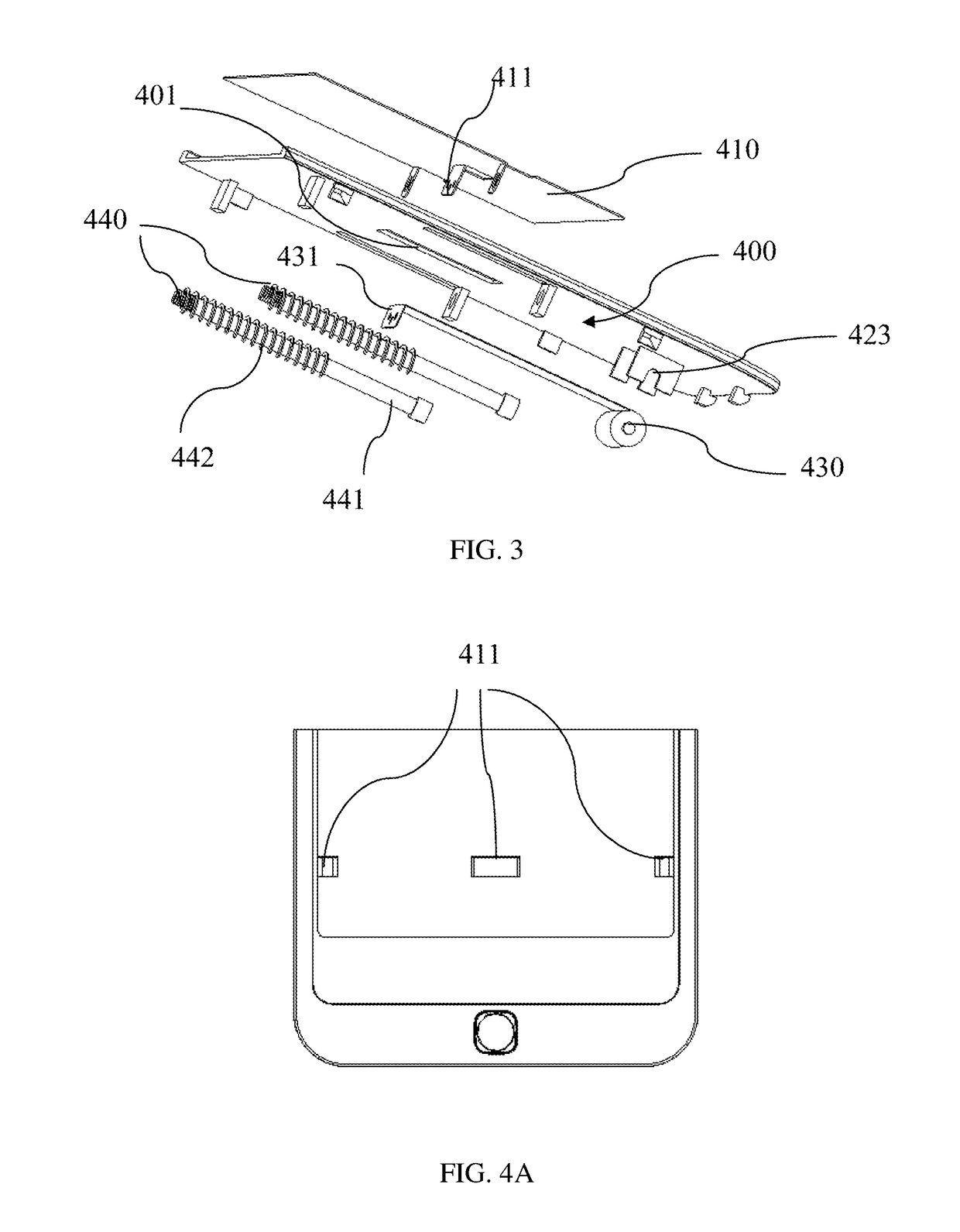

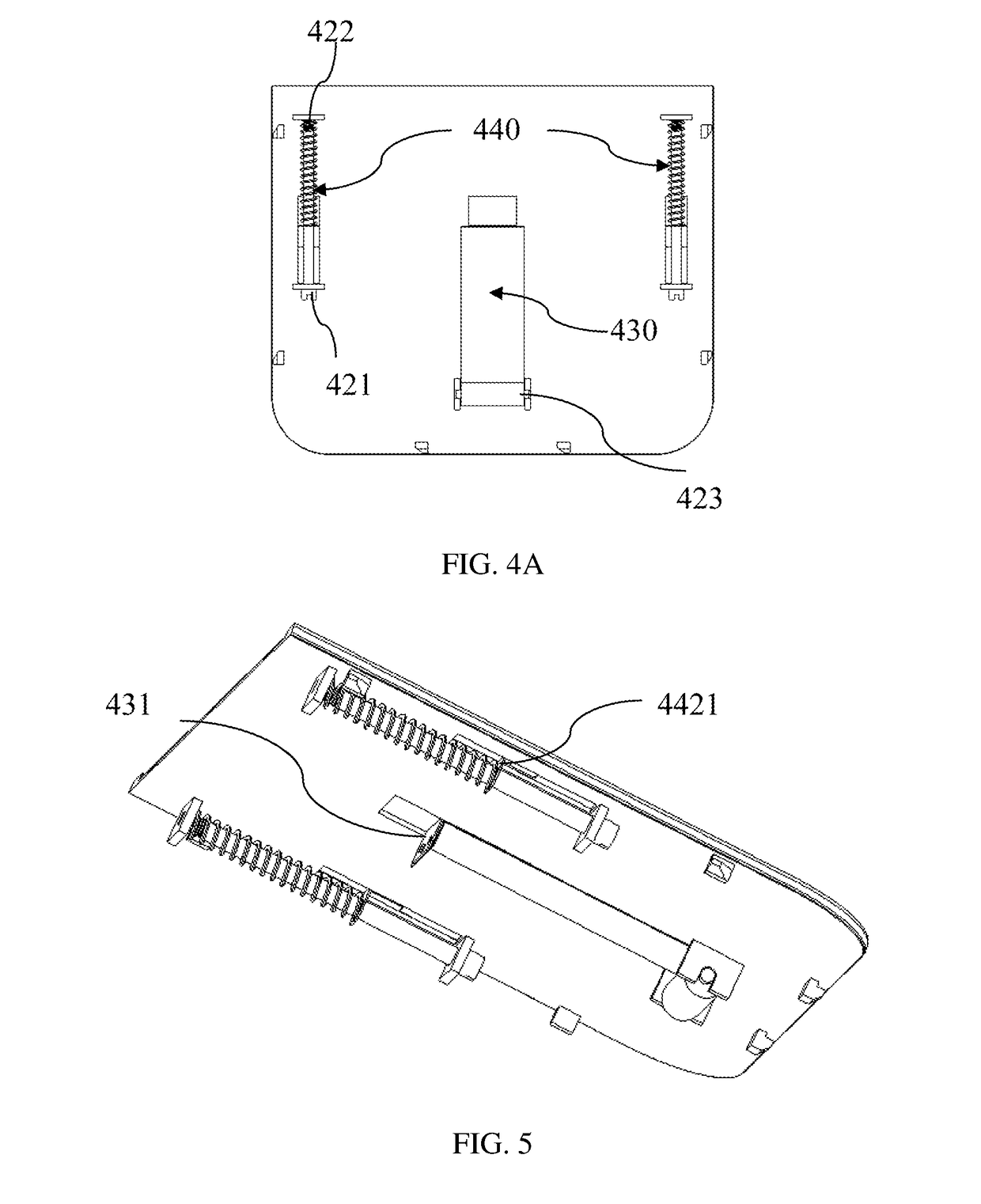

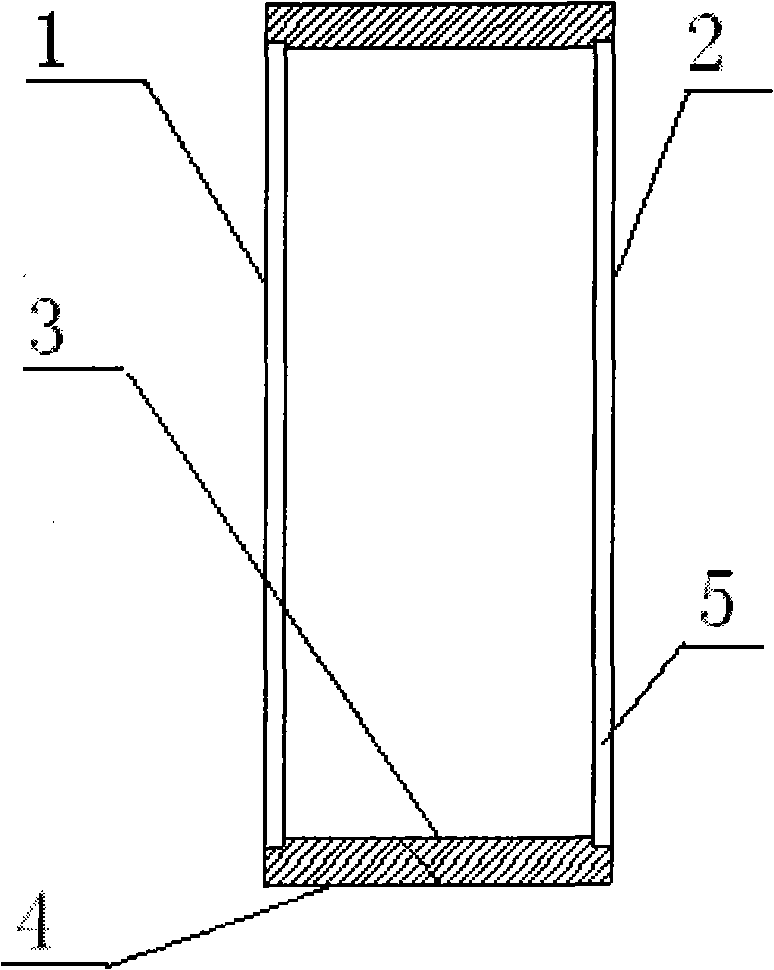

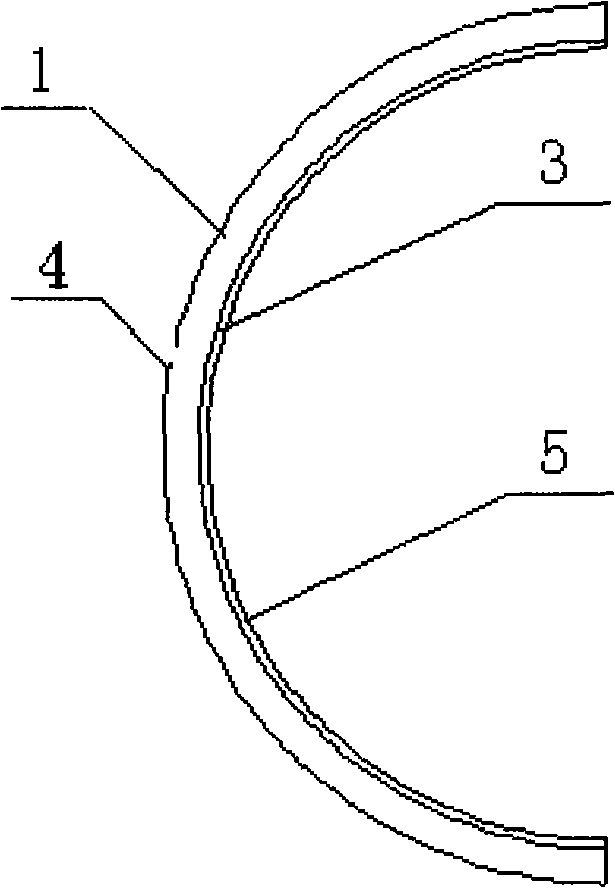

Foldable Display Device

ActiveUS20190073002A1Eliminate internal stressAvoiding compressive stress and tensile stressDetails for portable computersTelephone set constructionsDisplay deviceEngineering

The present application discloses a foldable display device, comprising a flexible screen and a support backplane cooperating therewith, the support backplane includes a first support plate and a second support plate hinged therewith by a rotary shaft system; a tension releasing mechanism is disposed at the first support plate or the second support plate, the flexible screen has a first end connected to the first support plate or the second support plate, and a second end opposite thereto, the second end is connected to the tension releasing mechanism, such that the second end of the flexible screen is slidable along a corresponding support plate between a first position in which the foldable display device is in an outward bending state and a second position in which the foldable display device is in a deployed state, and between the second position and a third position in which the foldable display device is in an inward bending state. This foldable display device can prevent the screen from damage as much as possible by providing a tension releasing mechanism.

Owner:BOE TECH GRP CO LTD

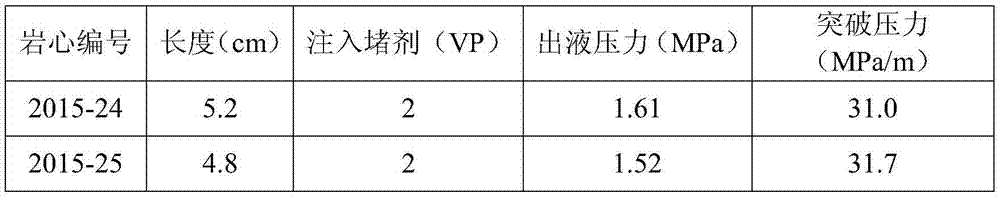

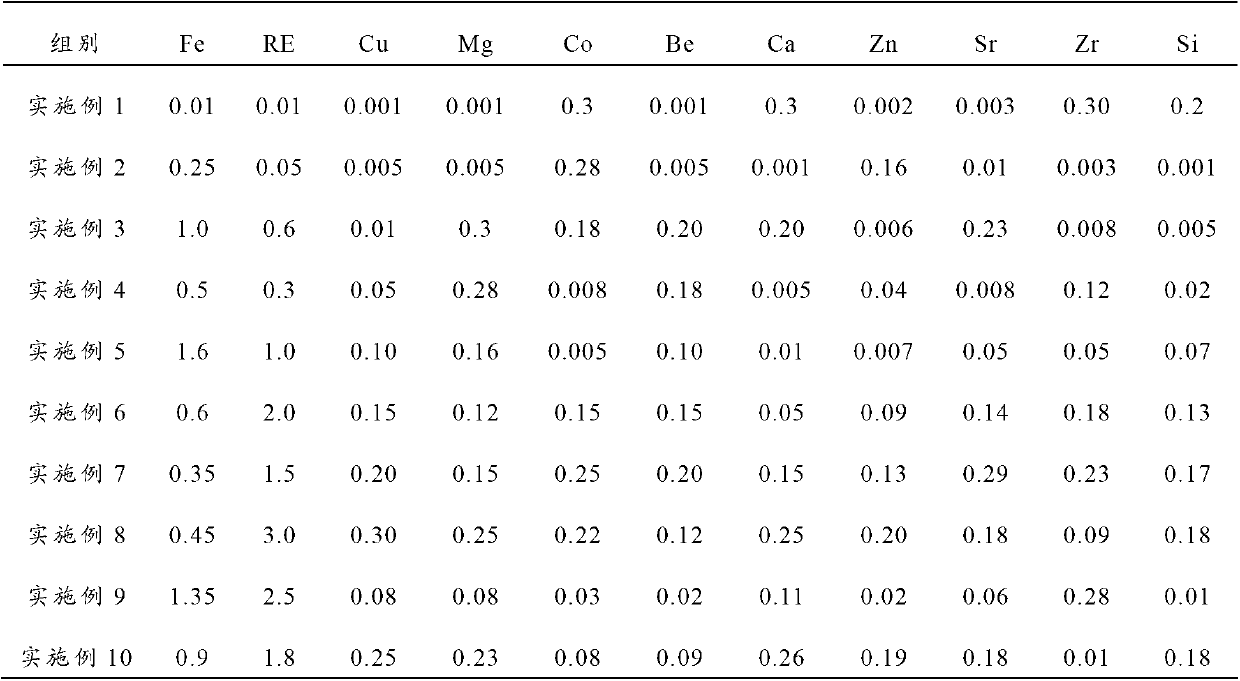

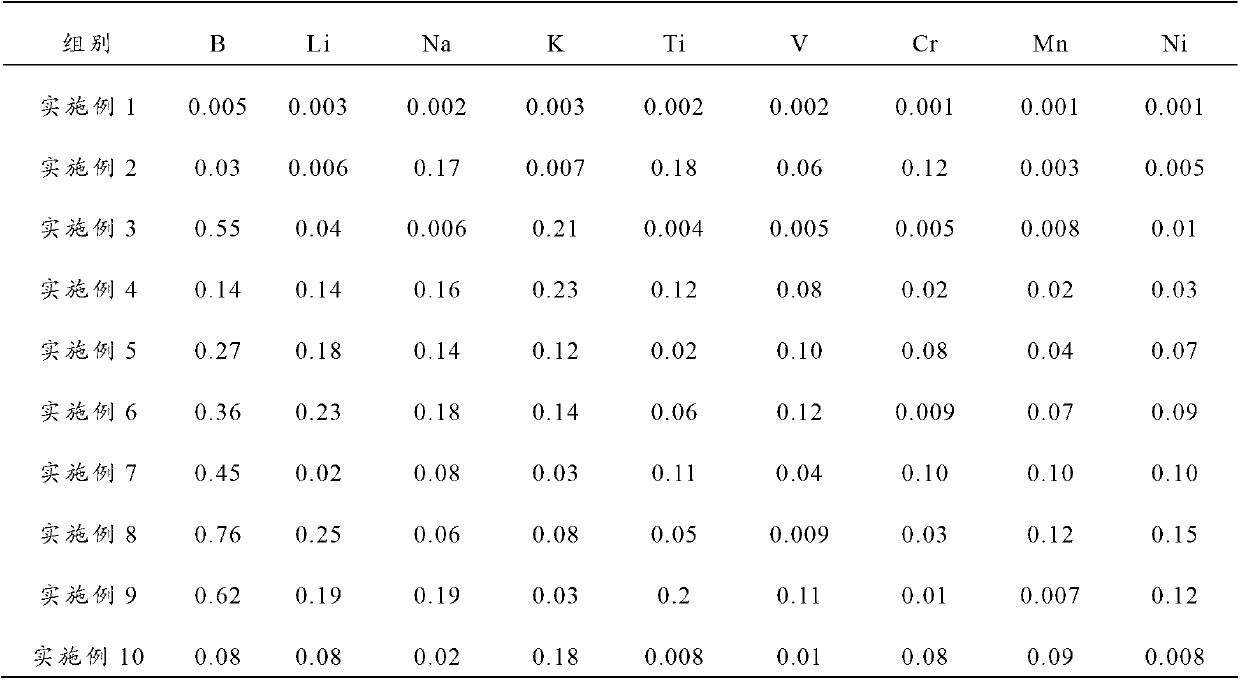

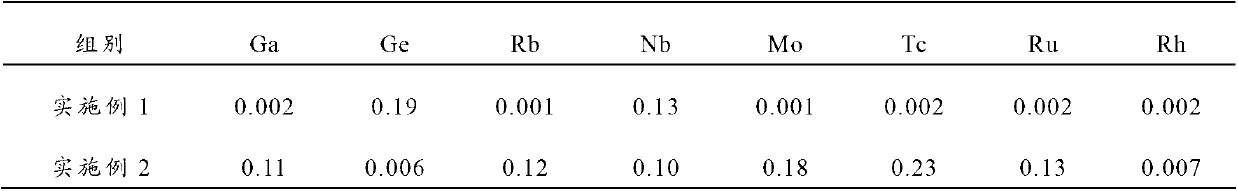

Fireflooding channeling sealing agent and preparation method thereof

ActiveCN105440233AHigh chemical activityHigh bonding strengthDrilling compositionNano al2o3Oleoresin

The invention provides a fireflooding channeling sealing agent and its preparation method. Raw materials for preparing the fireflooding channeling sealing agent contain, by weight, 0.5-3% of a melamine substance, 0.2-1% of phenol, 2-8% of aldehyde, 0.5-2% of a pH regulator, 0.2-1.2% of a nano-alumina oleoresin liquid XZ-LY102, 10-20% of ultrafine silicon dioxide and the rest of water. Sealing rate of the fireflooding channeling sealing agent can reach 93%; temperature resistance reaches 300 DEG C; the highest salinity tolerance reaches 150,000 mg / L; expriation data can reach 6 months and above under the steam condition of 300 DEG C; viscosity of a profile control agent before gel forming is 150-1,500 mPa.S; sealing strength can reach 31 MPa / m; and gel forming time can be controlled within 12-36h. By the use of the fireflooding channeling sealing agent, deep profile control of an oil layer can be realized.

Owner:PETROCHINA CO LTD

Al-Fe-Sn-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Sn-RE aluminum alloy, and a preparation method of the Al-Fe-Sn-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Electroplated diamond bur and manufacturing method thereof

InactiveCN102011168AImprove gripImprove cutting efficiencyElectrolytic coatingsDental toolsHardnessNickel base

The invention provides an electroplated diamond bur and a manufacturing method thereof. The electroplated diamond bur comprises a pure nickel base plated layer plated on a bur substrate, a sand plated layer plated on an alloy on the pure nickel base plated layer and a nano-diamond composite thickening plated layer plated on the sand plated layer on the alloy. The manufacturing method of the electroplated diamond bur comprises: the processing of the bur substrate, the treatment of the bur substrate and micron diamond and nanometer diamond powder before electroplating, preparation of a multi-component multi-layer composite plated layer at the head part of the bur and the heat treatment after electroplating. The electroplated diamond bur has higher hardness and wear resistance, the plated layers are difficult to wear during the using process, and the better holding force to diamond can be kept; on the one hand, the adoption of the heat treatment process after electroplating can eliminate internal pressure in the plated layers, on the other hand, the adoption of the heat treatment process can be simultaneously conductive to leading an interface between the bur substrate and the plated layer to form a diffusion layer, enhance the bonding force between the strengthening plated layer and the bur substrate, and greatly prolong the service life of the diamond bur.

Owner:HARBIN ENG UNIV

Hot-rolled steel wire rod for large bridge cable rope zinc-plated steel wire over 2000 MPa level and production method

ActiveCN109468530APlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWater bathsIngot

The invention relates to a hot-rolled steel wire rod for a large bridge cable rope zinc-plated steel wire over the 2000 MPa level. Chemical components of the steel wire rod comprise, by weight percentage, 0.90-1.10% of C, 0.20-0.60% of Si, 0.30-0.90% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.10-0.40% of Cr, 0.010-0.070% of Al, 0.02-0.15% of V, smaller than or equal to 0.05% of Cu, 20-40 ppm of Ca, 20-90 ppm of N and the balance Fe and inevitable residual elements. The content of sorbite texture of the steel wire rod is larger than or equal to 95%. Thethrough ring range of the tensile strength is smaller than or equal to 70 MPa (uniformity). After the steel wire rod is subjected to drawing and zinc plating, the tensile strength of the zinc-platedsteel wire is larger than or equal to 2000 MPa, and the number of torsions is larger than or equal to 12. According to the technical flow of the steel wire rod, pretreatment of molten iron is carriedout, steel is smelted through a converter or an electric furnace, LF refining is carried out, RH degassing treatment is carried out, continuous casting of 390*510 cogged ingot is carried out, a blankis reheated, the blank is rolled, the surface of an intermediate billet is subjected to finishing, the intermediate billet is reheated, the intermediate billet is rolled, the steel wire rod is subjected to EDC water bath toughening treatment, and the steel wire rod is collected and packed.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

Al-Fe-Re-RE aluminum alloy, and preparation method and power cable thereof

The invention provides an Al-Fe-Re-RE aluminum alloy, and a preparation method of the Al-Fe-Re-RE aluminum alloy. The method comprises the steps that: (a) an aluminum alloy ingot is cast; (b) the aluminum alloy ingot is subjected to a homogenization treatment; and the obtained aluminum alloy ingot is rolled, such that an aluminum alloy rod material is obtained; (c) the aluminum alloy rod material obtained in the step (b) is subjected to a batch-type annealing treatment; and (d) the aluminum alloy rod material obtained in the step (c) is subjected to an aging treatment, such that aluminum alloy is obtained. The invention also provides a power cable. According to the invention, through the selection and control over added elements and the adoption of a reasonable preparation process, the obtained aluminum alloy is provided with good comprehensive performance.

Owner:于贵良 +1

Al-Fe-Ir-RE aluminum alloy, preparation method thereof and power cable

ActiveCN103045913AEvenly heatedEliminate damagePower cables with screens/conductive layersMetal/alloy conductorsPower cableIngot

The invention provides Al-Fe-Ir-RE aluminum alloy, and also provides a preparation method of the Al-Fe-Ir-RE aluminum alloy. The preparation method comprises the following steps of: a) casting an aluminum alloy ingot; b) homogenizing the aluminum alloy ingot, and rolling the homogenized aluminum alloy ingot to obtain an aluminum alloy rod; c) intermittently annealing the aluminum alloy rod obtained in the step b); and d) performing aging treatment on the aluminum alloy rod obtained in step c) to obtain the aluminum alloy. The invention further provides a power cable. According to the invention, the aluminum alloy has a good comprehensive performance by choosing and controlling added elements and adopting a reasonable preparation process.

Owner:ANHUI JOY SENSE CABLE

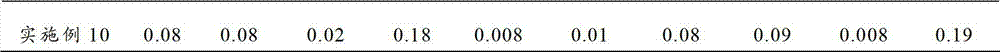

High-temperature resistance carbon fiber/epoxy resin composite material, preparation method and use

The invention discloses a high-temperature resistance carbon fiber / epoxy resin composite material, a preparation method and use. The method comprises the steps of preimpregnation material preparation and composite material curing forming. Through introducing a kind of latent accelerating agents of fatty amine hydrofluoride, the method reduces the forming time of the composite materials in a mold, effectively improves the production efficiency, reduces the production cost, and can not shorten the storage period of the preimpregnation materials. Through the high-temperature heat treatment, the invention further improves the crosslink density of the resin, and is favorable for improving the vitrification conversion temperature of the composite materials, and at the same time, the high-temperature heat treatment can effectively eliminate the inner stress produced by fast curing. The prepared composite material has good mechanical property and abrasion resistance performance, the vitrification conversion temperature of the composite material is between 190 and 210 DEG C, and the 180 DEG C high-temperature environment resistance requirements can be met.

Owner:SUN YAT SEN UNIV +1

Manufacturing process of high-power low-speed diesel shaft bushing

InactiveCN101275606AReduced edge defectsHigh bonding strengthBearing componentsManufacturing technologyLow speed

Owner:CHONGQING YUEJIN MACHINERY

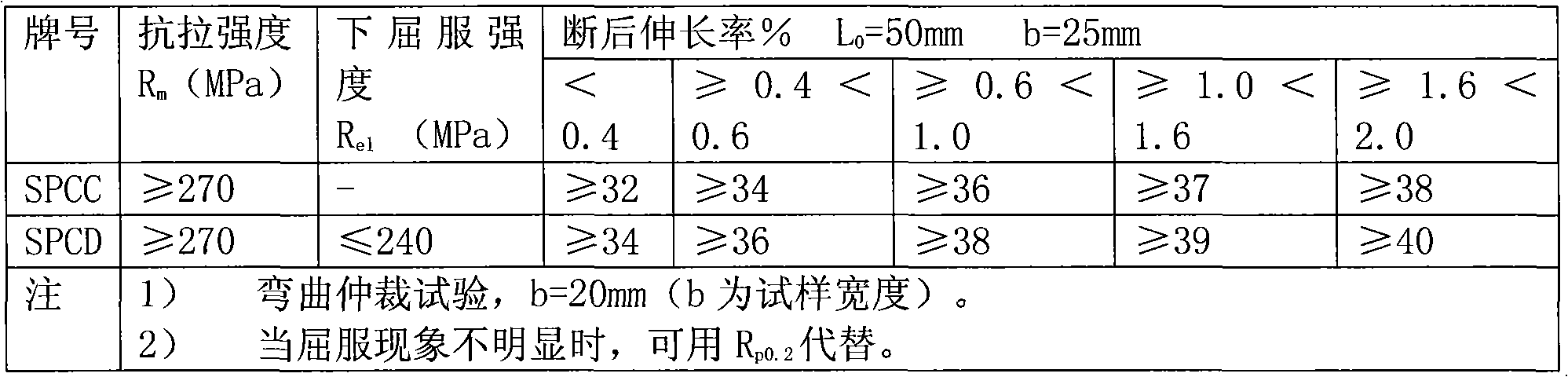

Anneal technique for producing SPCC steel grade with zincing wire annealing oven

InactiveCN101270409AEliminate internal stressHigh elongationFurnace typesHeat treatment furnacesCrystalliteDew point

An annealing process of producing SPCC steel in annealing furnace on galvanizing line belongs to the field of the heat treatment technology of metal. Using the process can also meet the strength and plasticity requirement of strip steel on continuous annealing line. The method comprises the following procedures: the steel is heated to 630 minus or plus 20 DEG C by open fire; the steel is heated to 760 minus or plus 20 DEG C by a radiant tube; dew point is controlled below minus 40 DEG C; the steel is maintained at 710 minus or plus 20 DEG C by radiant tube; dew point is controlled below minus 40 DEG C; the strip steel is sprayed to 210 minus or plus 20 DEG C, the dew point of the first area of the spray section is controlled below minus 60 DEG C; and is cooled to 160 minus or plus 20 DEG C. The method can be used on the annealing furnace of the galvanizing line and be suitable for annealing of SPCC steel. The method can eliminate the internal stress of the rolling processing of strip steel, promote the plasticity and the toughness of the strip steel, and meet the strength and the plasticity requirement of the strip steel on the continuous annealing line. The tensile strength of product is approximately at 380Megapascal, the yield strength is below 330Megapascal, and the elongation is more than 36 percent. The grain size of product stabilizes between 11 and 13 Mum, the elongation and the stamping property are all at the higher level. The method can avoid the idle of the production equipment of galvanizing line and reduce the depreciation loss of equipment.

Owner:HEBEI IRON AND STEEL

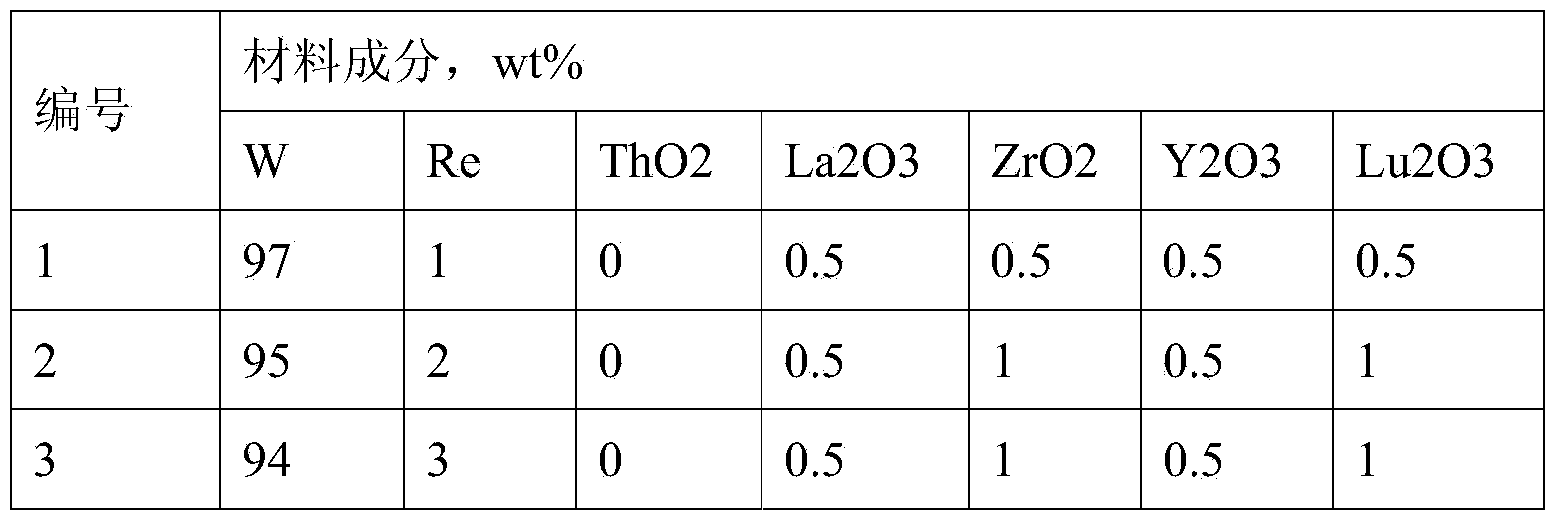

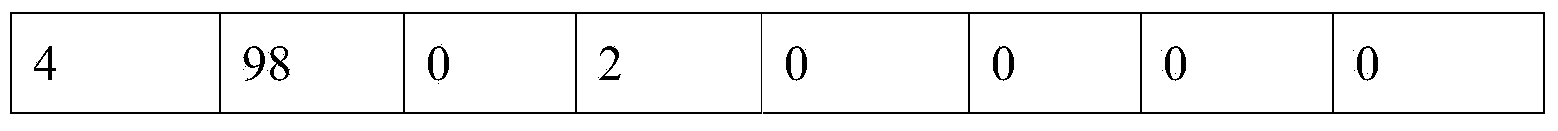

Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

InactiveCN103849804AImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumLutetium

The invention discloses a non-radiative multi-component composite tungsten negative material for a microwave oven magnetron and a preparation process of the negative material. The tungsten cathode material comprises lanthanum oxide, zirconium oxide, yttrium oxide, lutetium oxide, rhenium and tungsten, wherein the mass percent of each rare-earth oxide in the tungsten electrode material is 0.5%-1.5%, the mass percent of the total rare-earth oxides in the tungsten electrode is 2%-3%, the mass percent of the alloy element rhenium in the tungsten electrode material is 1%-4%, and the tungsten accounts for the rest mass percent. The tungsten cathode material is non-radiative, excellent in thermal emission performance, excellent in high-temperature creep resistance, thermal shock resistance and sag resistance, and long in service life. The preparation method of the non-radiative multi-component composite tungsten cathode material for the microwave oven magnetron comprises the steps of solution preparation, drying, reducing, isostatic cool pressing, sintering, incipient fusion, medium-frequency induction annealing, press working, winding and mechanical straightening. The non-radiative multi-component composite tungsten negative material for the microwave oven magnetron is better in usability. When heated periodically for a long time at a high temperature, the multi-component composite tungsten wire produced by virtue of the process is capable of going through large deformational resistance, and has the sag resistance.

Owner:深圳市威勒科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com