High-temperature resistance carbon fiber/epoxy resin composite material, preparation method and use

A technology of epoxy resin and composite materials, which is applied in the field of high-performance resin-based composite materials, can solve the problems of long-time resin and high curing reaction temperature, and achieve the effect of promoting curing reaction and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of promotor ethylamine hydrofluoride:

[0047] A polytetrafluoroethylene three-necked round-bottomed flask equipped with a constant-pressure dropping funnel was fixed in the middle of a magnetic heating stirrer, and the flask was filled with high-purity nitrogen for 30 minutes, and then 0.5 mol of anhydrous hydrofluoric acid (about 55 mL) was added to the flask, Use the low-temperature coolant circulation pump to control the reaction temperature between -5 and 0°C; at the same time, take a 500mL beaker, dissolve 0.5mol ethylamine in 200mL carbon tetrachloride, and then dissolve the ethylamine carbon tetrachloride solution Transfer to the constant pressure dropping funnel, and slowly add it dropwise into the round bottom flask within 30min. After the dropping is completed, quickly remove the constant pressure dropping funnel, seal the flask with a polytetrafluoroethylene stopper, continue to stir for 1h, and let it stand for 1 hour. Set layers. Ca...

Embodiment 2

[0049] The preparation method of accelerator n-butylamine hydrofluoride:

[0050] A polytetrafluoroethylene three-necked round-bottomed flask equipped with a constant-pressure dropping funnel was fixed in the middle of a magnetic heating stirrer, and the flask was filled with high-purity nitrogen for 30 minutes, and then 0.35 mol of anhydrous hydrofluoric acid (about 33 mL) was added to the flask, Use the low-temperature coolant circulation pump to control the reaction temperature between -5 and 0°C; at the same time, take a 500mL beaker, dissolve 0.3mol n-butylamine in 200mL carbon tetrachloride, and then tetrachloride n-butylamine Transfer the carbon solution to a constant-pressure dropping funnel, and slowly add it dropwise into a round-bottomed flask within 30 minutes. After the addition is complete, quickly remove the constant-pressure dropping funnel, seal the flask with a polytetrafluoroethylene stopper, and continue stirring for 2 hours. , standing layered. Carbon tet...

Embodiment 3

[0052] The preparation method of accelerator ethylenediamine hydrofluoride:

[0053] A polytetrafluoroethylene three-necked round-bottom flask equipped with a constant-pressure dropping funnel was fixed in the middle of a magnetic heating stirrer, and the flask was filled with high-purity nitrogen for 30 minutes, and then 0.7 mol of anhydrous hydrofluoric acid (about 77 mL) was added to the flask, Use the low-temperature coolant circulation pump to control the reaction temperature between -5 and 0°C; at the same time, take a 500mL beaker, dissolve 0.3mol ethylenediamine in 200mL carbon tetrachloride, and then ethylenediamine tetrachloride Transfer the carbon solution to the constant pressure dropping funnel, and slowly add it dropwise into the round-bottomed flask within 30 minutes. After the addition is completed, quickly remove the constant pressure dropping funnel, seal the flask with a polytetrafluoroethylene stopper, and continue stirring for 3 hours. , standing layered. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

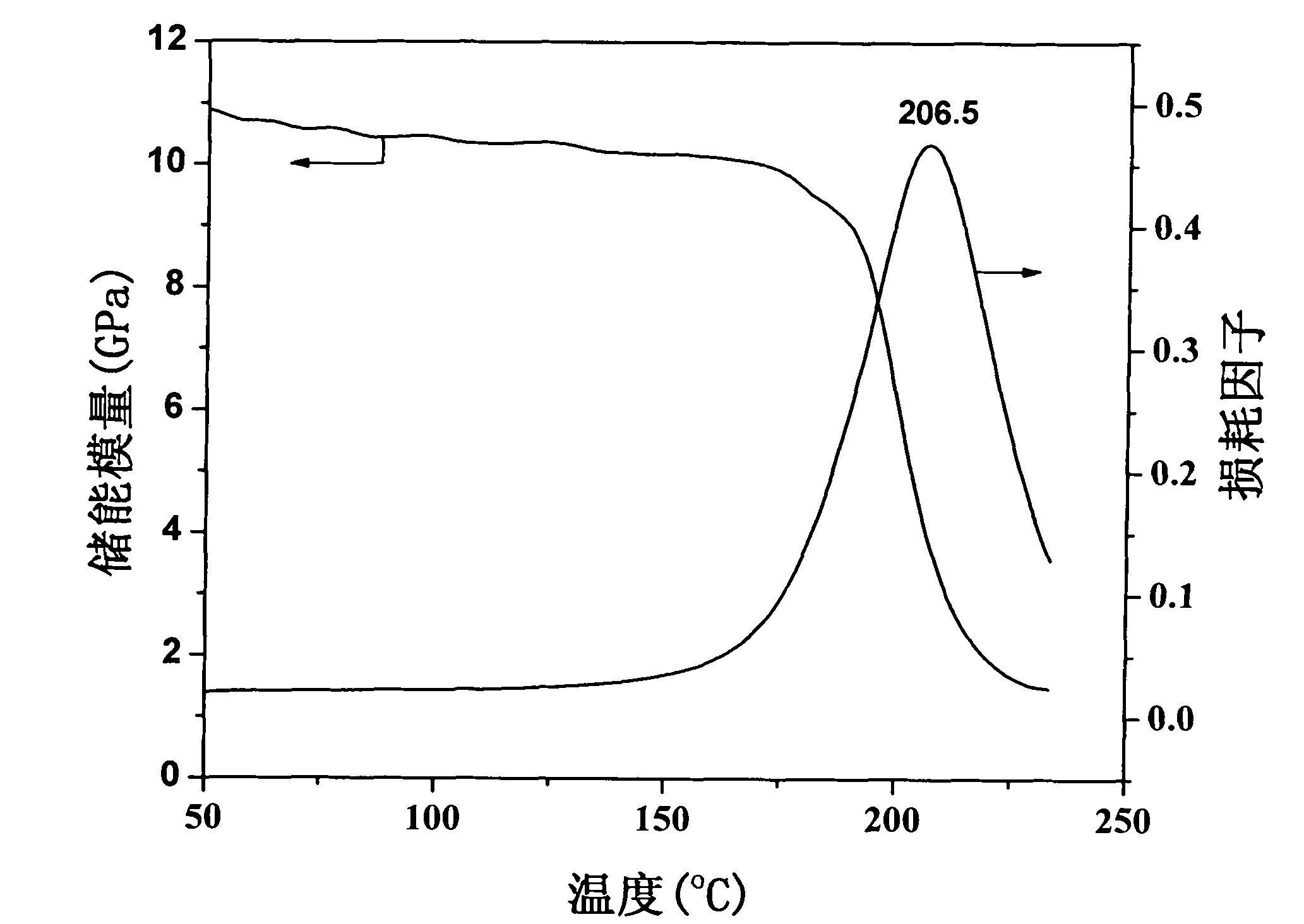

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com