Patents

Literature

103 results about "Tungsten cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

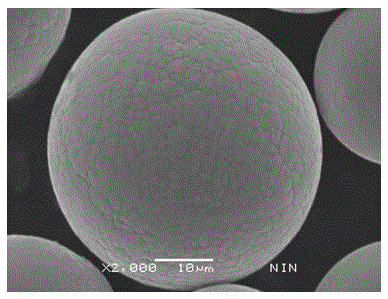

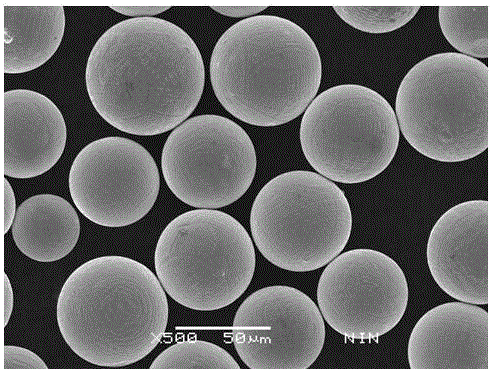

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

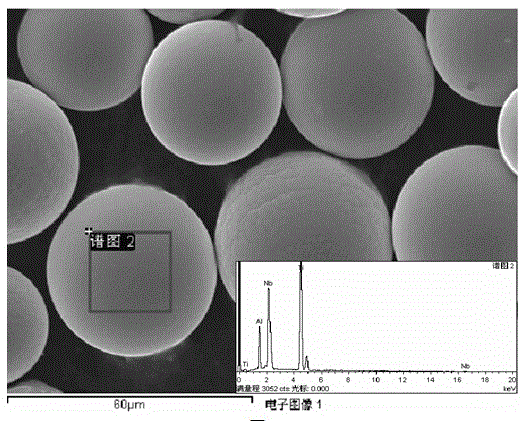

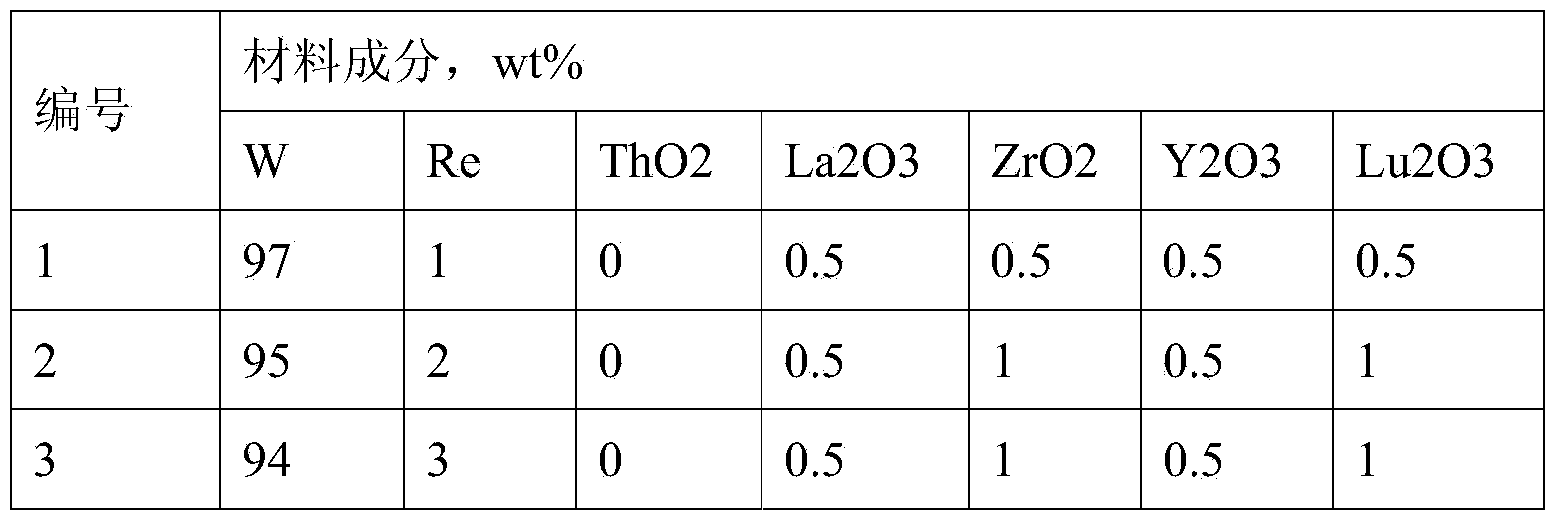

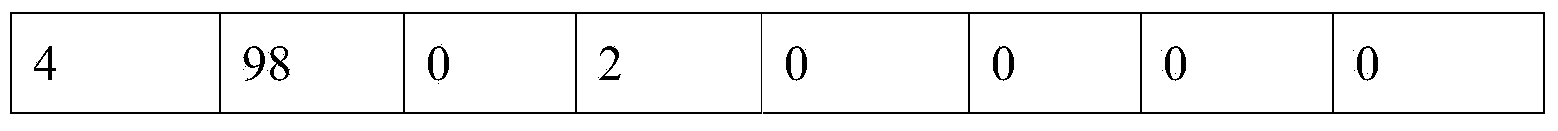

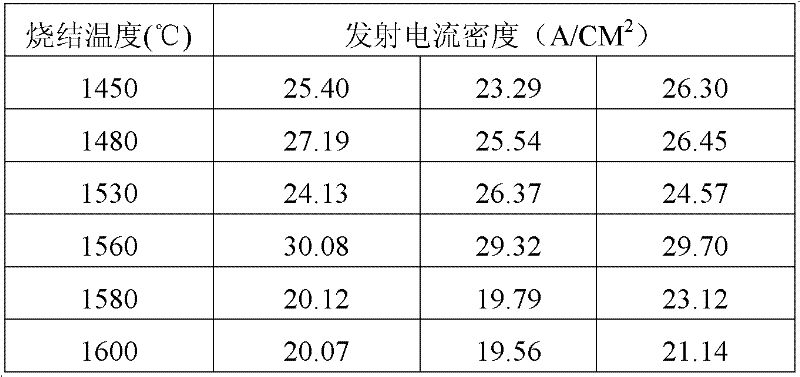

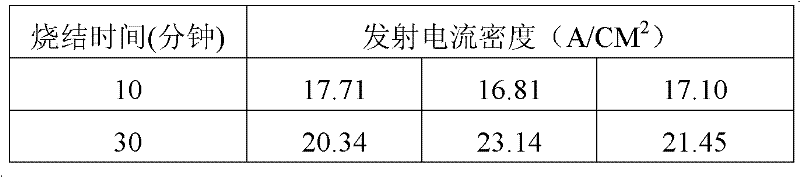

Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

InactiveCN103849804AImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumLutetium

The invention discloses a non-radiative multi-component composite tungsten negative material for a microwave oven magnetron and a preparation process of the negative material. The tungsten cathode material comprises lanthanum oxide, zirconium oxide, yttrium oxide, lutetium oxide, rhenium and tungsten, wherein the mass percent of each rare-earth oxide in the tungsten electrode material is 0.5%-1.5%, the mass percent of the total rare-earth oxides in the tungsten electrode is 2%-3%, the mass percent of the alloy element rhenium in the tungsten electrode material is 1%-4%, and the tungsten accounts for the rest mass percent. The tungsten cathode material is non-radiative, excellent in thermal emission performance, excellent in high-temperature creep resistance, thermal shock resistance and sag resistance, and long in service life. The preparation method of the non-radiative multi-component composite tungsten cathode material for the microwave oven magnetron comprises the steps of solution preparation, drying, reducing, isostatic cool pressing, sintering, incipient fusion, medium-frequency induction annealing, press working, winding and mechanical straightening. The non-radiative multi-component composite tungsten negative material for the microwave oven magnetron is better in usability. When heated periodically for a long time at a high temperature, the multi-component composite tungsten wire produced by virtue of the process is capable of going through large deformational resistance, and has the sag resistance.

Owner:深圳市威勒科技股份有限公司

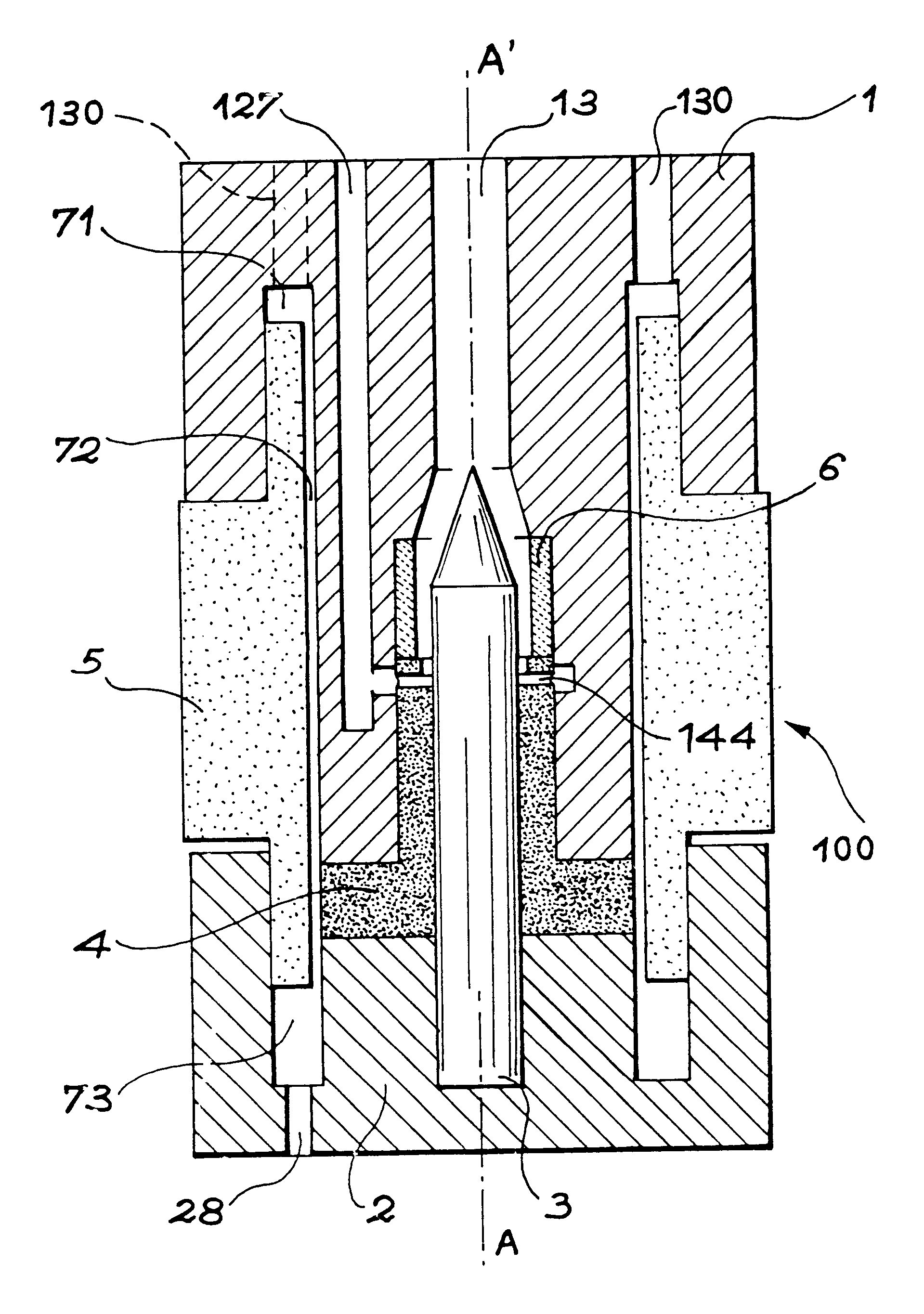

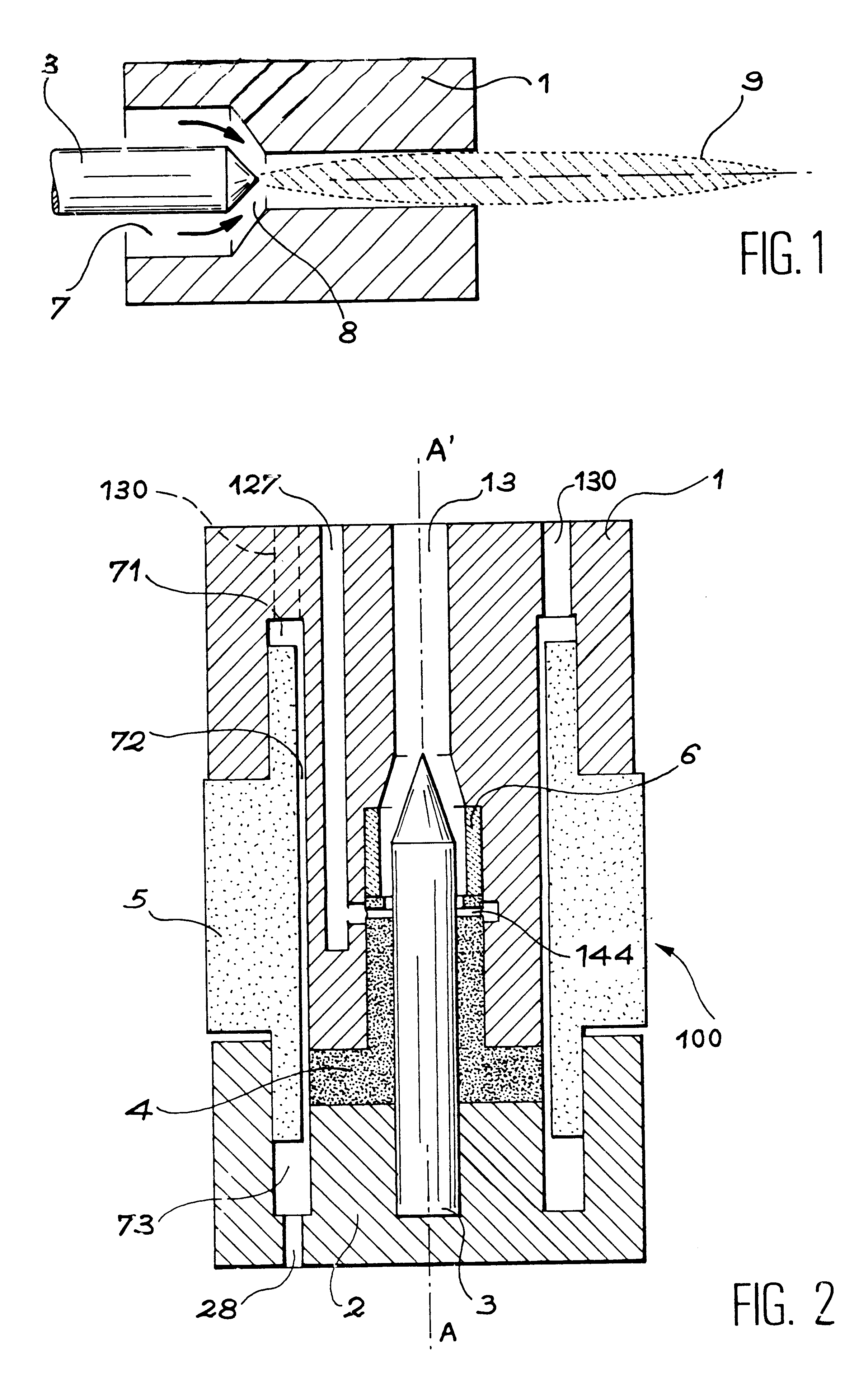

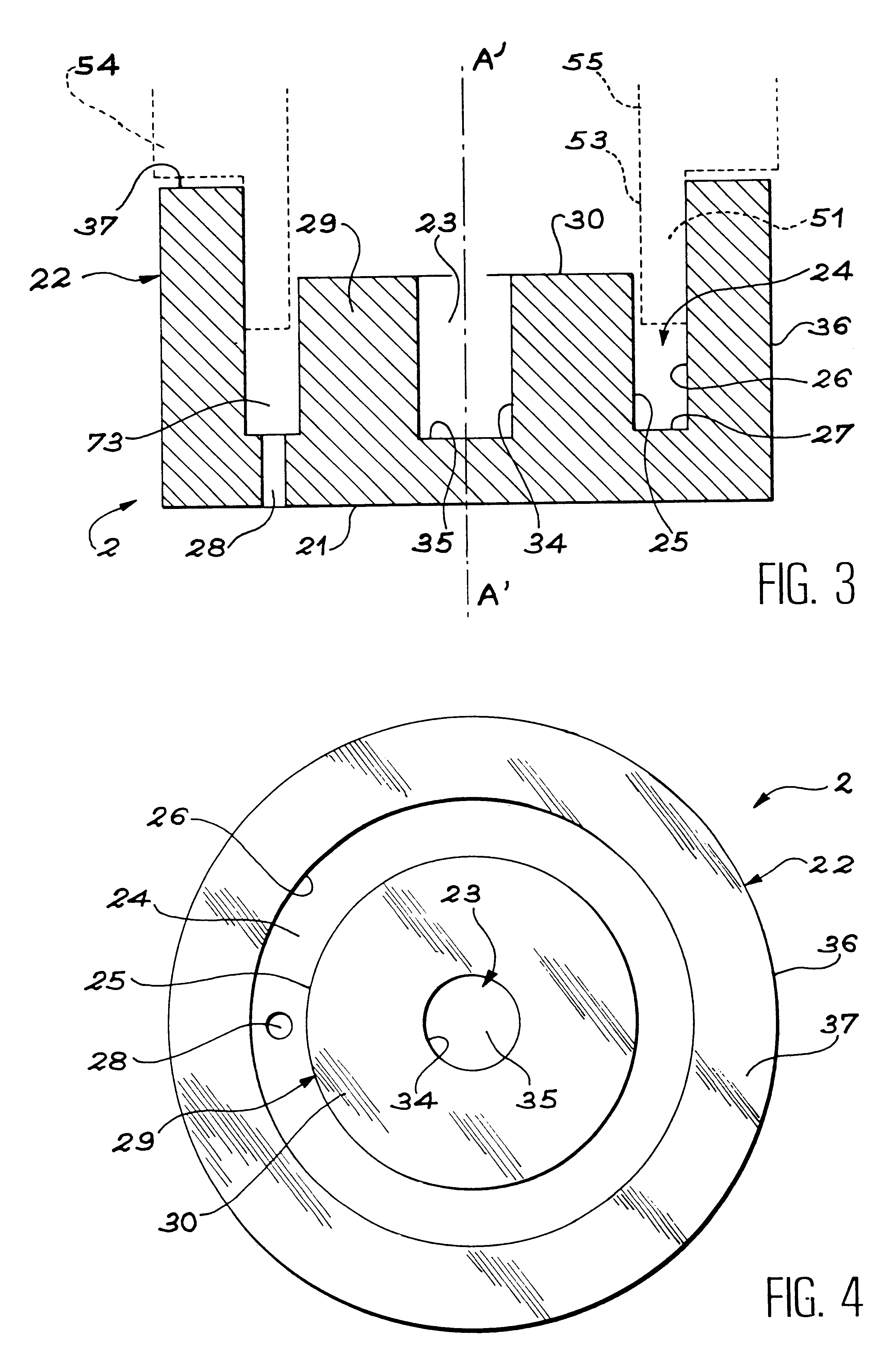

Plasma torch cartridge and plasma torch equipped therewith

InactiveUS6515252B1Simplify workShort timePlasma welding apparatusWelding/cutting media/materialsForming gasMetallurgy

The invention concerns a plasma torch comprising an interchangeable cartridge (100) consisting of six components only: an electroplating copper anode nozzle (1); an electroplating cathode support (2); a doped tungsten cathode (3); a plastic cathode diffusing-centring device (4); a plastic assembling device (5); a ceramic insert (6). Said components are assembled by pressing and the assembly of the components form volumes (71, 72, 73) constituting the anode cooling circuit and the plasma forming gas intake conduits (127, 44). The intake and discharge of fluid are provided by a connecting and maintaining structure designed for the easy mounting of the cartridge (100).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

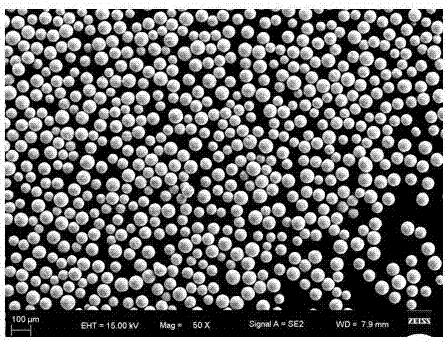

Preparation method of superfine high-grade spherical EP741NP alloy powder

The invention relates to a preparation method of superfine high-grade spherical EP741NP alloy powder. The method comprises the following steps: 1) proportionally preparing materials according to the EP741NP alloy composition, and smelting to obtain an EP741NP alloy bar; 2) processing the smelted EP741NP alloy bar into an electrode bar; 3) installing the electrode bar into a reaction chamber, vacuumizing the reaction chamber, and proportionally charging inert gas into the reaction chamber; 4) heating the end of an electrode bar to uniformly melt the end, throwing atomized liquid drops from the end of the electrode bar so that the liquid drops are quickly cooled into spherical particles in an inert gas atmosphere and fall into a collector, wherein a plasma torch comprises a tungsten cathode and a copper anode, and the electrode bar is not used as an electrode; and 5) carrying out electrostatic separation on the prepared EP741NP alloy powder in an inert gas protective atmosphere, screening, sampling and packaging. The EP741NP alloy powder prepared by the method is superfine, and has the characteristics of high purity, high-grade sphericity and no hollow powder or satellite powder.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

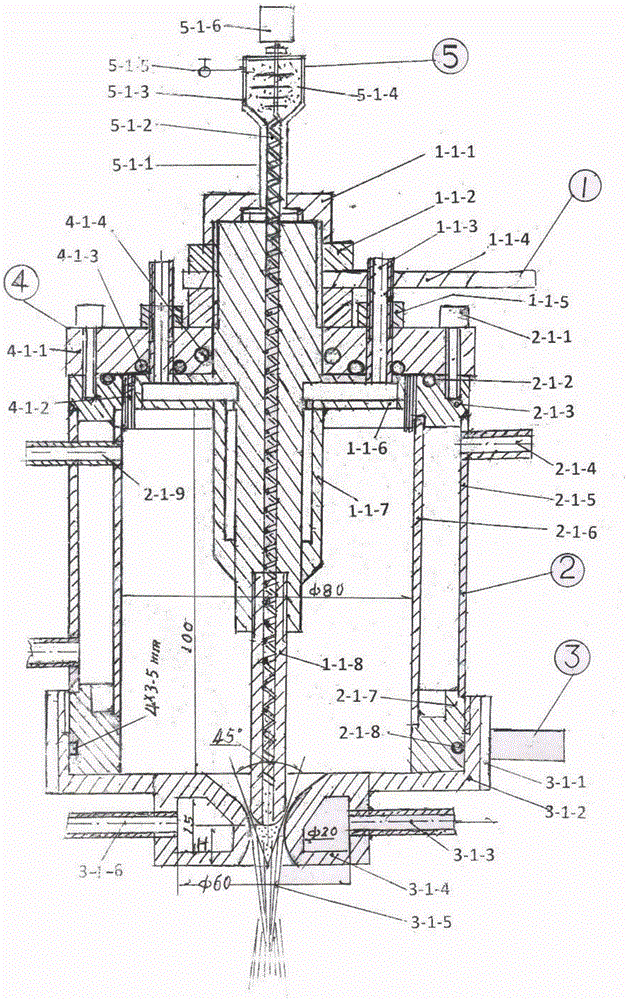

Direct-current argon arc plasma powder spray gun and manufacturing method

ActiveCN105755421AExpand the field of technology applicationImprove stabilityMolten spray coatingMetallurgyPlasma heating

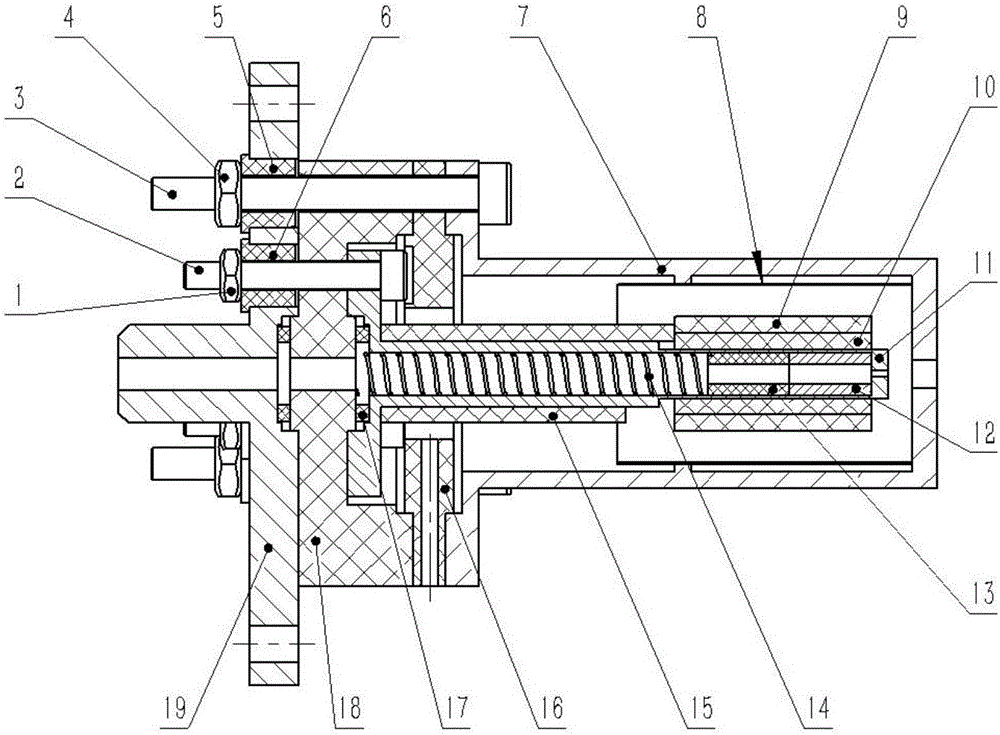

The invention discloses a direct-current argon arc plasma powder spray gun and a manufacturing method and belongs to the field of flame spraying equipment and technology of metal powder and metal ceramic powder.Two novel technologies including a hollow tungsten cathode outer surface annular arcing direct-current plasma heating method and an axial powder feeding mechanism penetrating the core of an argon arc are adopted, and position matching of a negative voltage pressure of the electric arc and the powder feeding mechanism is utilized, so that stability of the spray gun during long-time working is improved, and uniformity in heating temperature of metal powder particles, uniformity in spray speed and stability of spray layer quality are guaranteed.In addition, due to structural changing of a gun body, technology application field of the gun is expanded obviously, and the gun is expected to make a beneficial contribution to development of high technology in the future.

Owner:UNIV OF SCI & TECH BEIJING

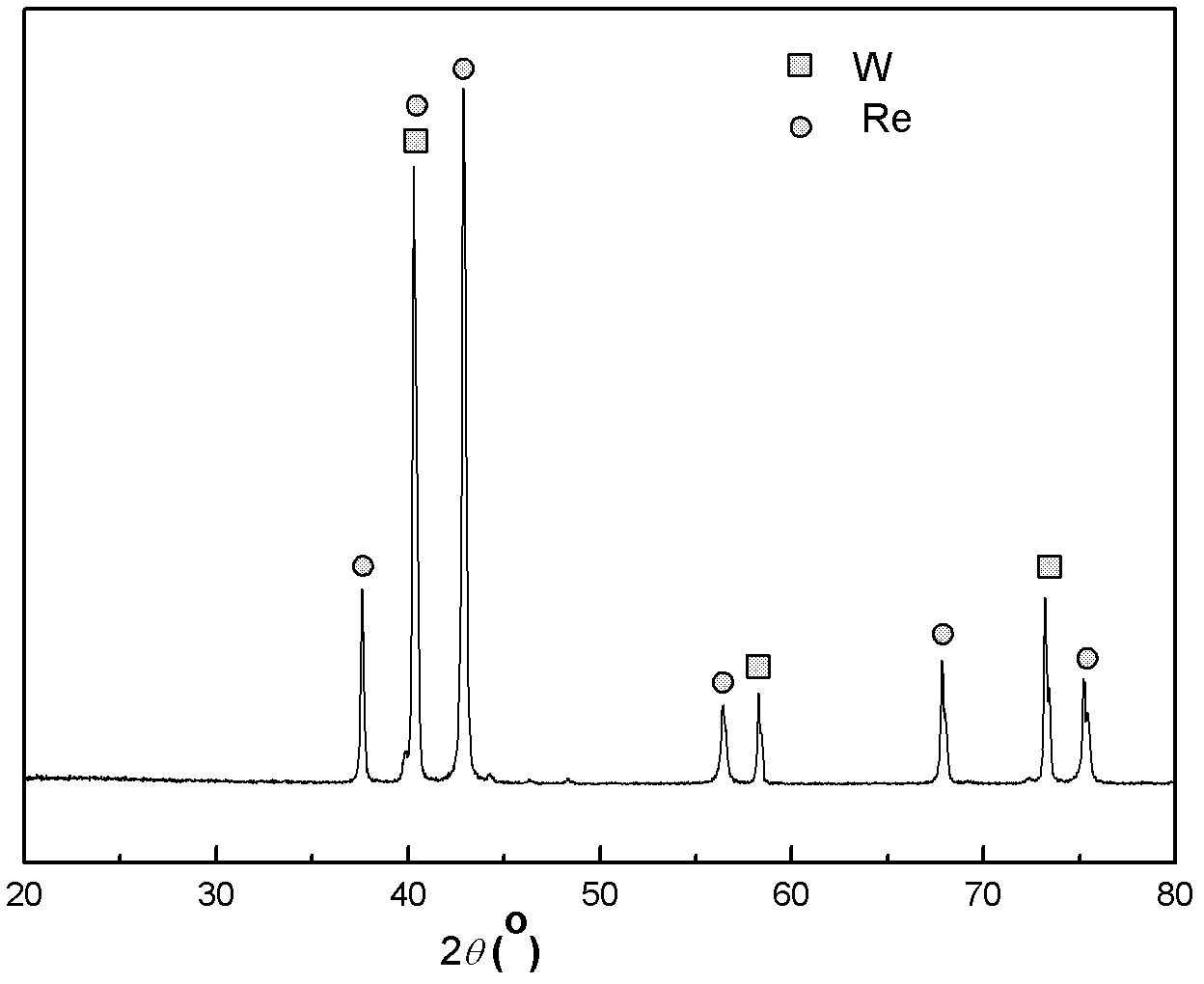

Rhenium tungsten based cathode material and preparation method thereof

The invention relates to a rhenium tungsten based cathode material and a preparation method thereof and belongs to the technical field of a refractory metal thermal cathode material. BaO, CaO and Al2O3 are loaded in pores of a porous rhenium tungsten base; the rhenium tungsten base is formed by coating tungsten grains by rhenium. The preparation method comprises the following steps: dissolving ammonium perrhenate in water, thereby preparing into a solution; adding tungsten powder into the ammonium perrhenate solution and stirring; drying; resolving and reducing in two steps under the hydrogen atmosphere, thereby obtaining rhenium tungsten powder; and pressing and sintering the rhenium tungsten powder under the hydrogen atmosphere, thereby obtaining a rhenium tungsten base and steeping into a molten barium aluminate calcium salt. The preparation method provided by the invention has the advantages that the preparation process is simple, the introduction of impurity element during the preparation process is avoided, the repeatability is strong, the prepared cathode material is excellent in emitting property, and the ion bombardment resistance of a traditional barium tungsten cathode is enhanced.

Owner:BEIJING UNIV OF TECH

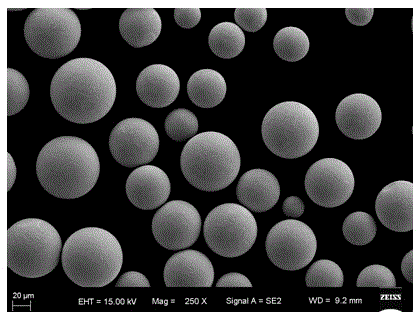

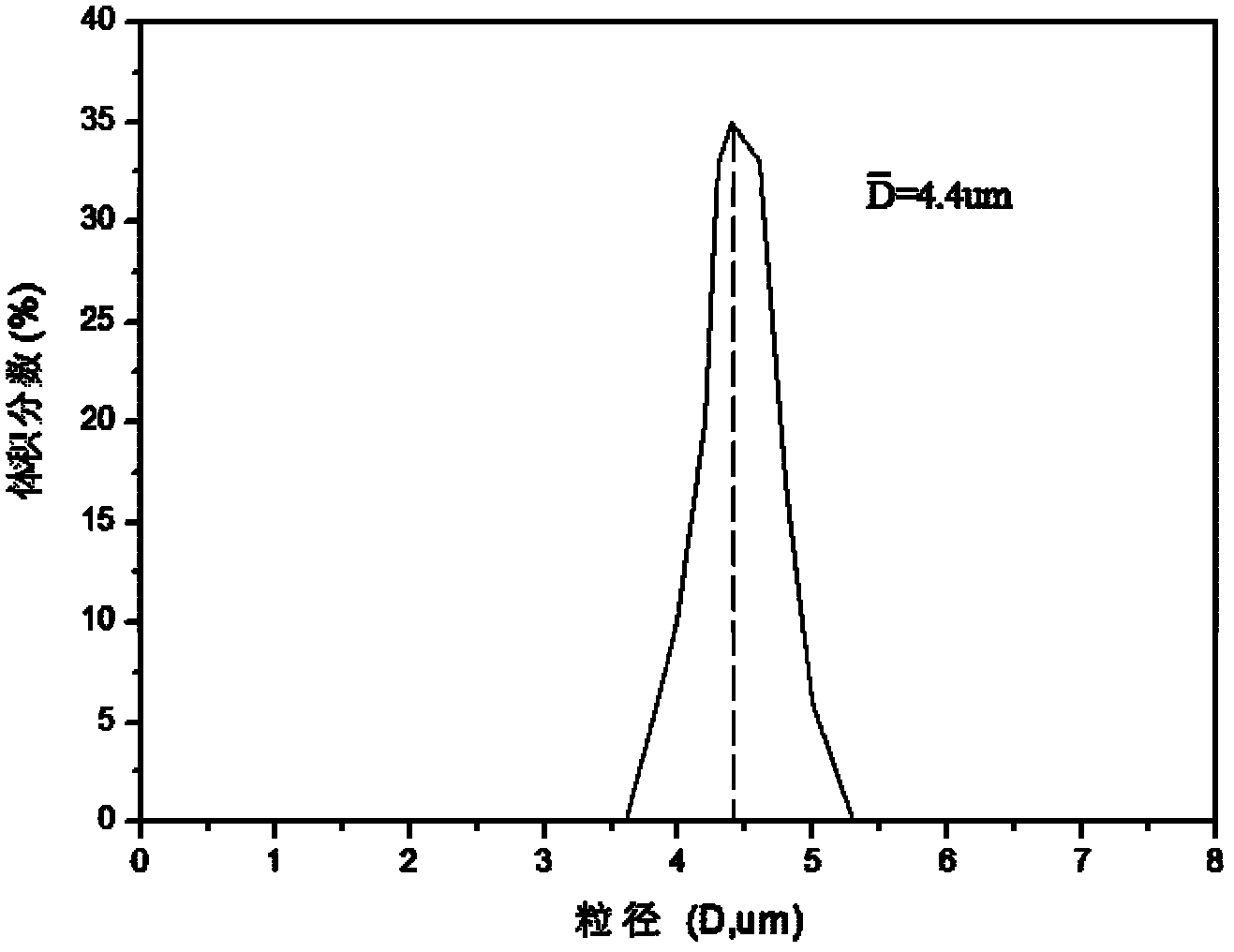

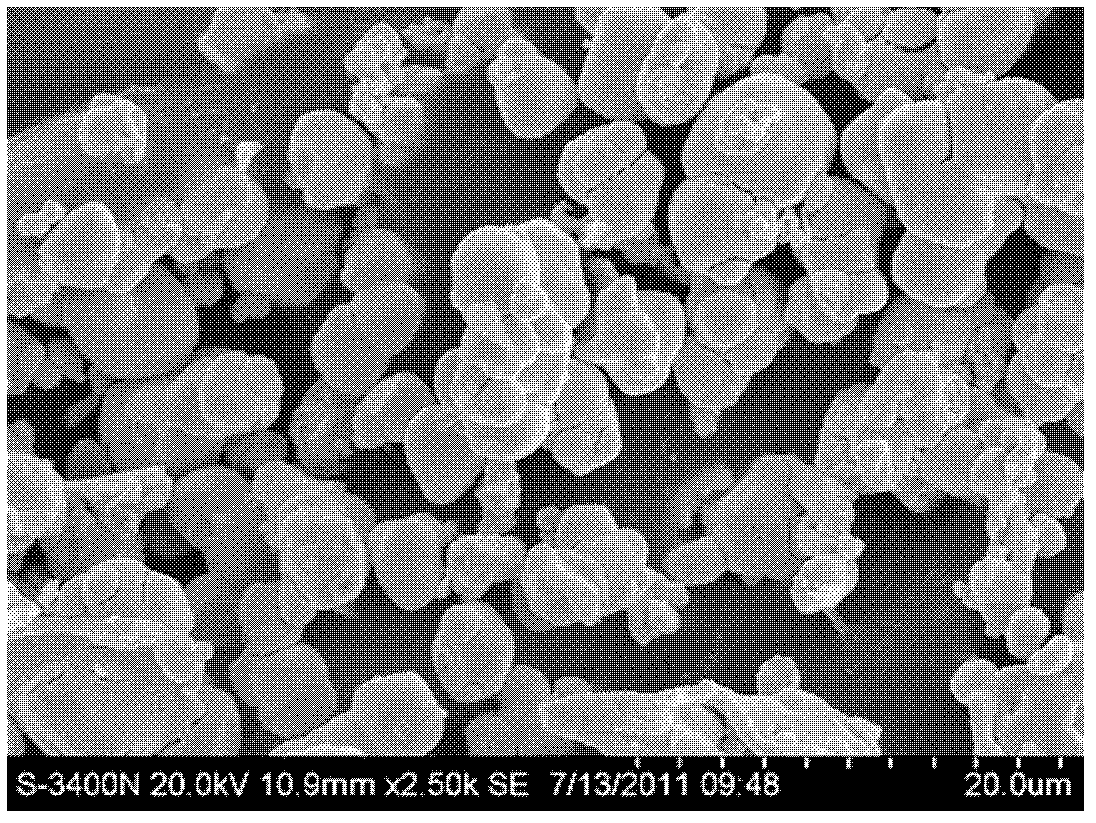

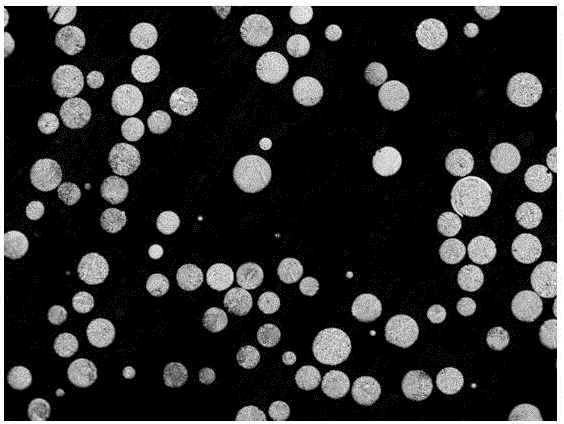

Preparation method for porous tungsten bulk material with uniform and controllable pores

The invention discloses a preparation method for a porous tungsten bulk material with uniform and controllable pores. The preparation method is characterized by comprising the following steps of: by taking tungsten powder as a raw material, obtaining spherical tungsten powder through plasma balling treatment and electric vibrating and screening treatment; and then, obtaining the porous tungsten bulk material by discharge plasma sintering. According to the preparation method, the porous tungsten bulk material with uniform and controllable pores is obtained by combining a plasma balling technology, an electric vibrating and screening technology and a discharge plasma sintering technology; the preparation method is simple and liable to realize; the control on pores of the product can be realized by regulating the process parameters, so that the porous tungsten bulk material with porosity of 17%-22.5% and pore size of 2-5 mum; the prepared porous tungsten bulk material can be used for remarkably improving the infiltration performance of the material, so that the launch stability of a barium-tungsten cathode is greatly improved, and the service life of the barium-tungsten cathode is prolonged.

Owner:HEFEI UNIV OF TECH

Method for preparing Mo powder and Mo alloy spherical powder for additive production

InactiveCN107876794AImprove qualityHigh sphericityAdditive manufacturing apparatusTransportation and packagingUltra fineAlloy

The method for preparing Mo powder and Mo alloy spherical powder for additive production includes the following steps that 1), smelted Mo rods and Mo alloy rods are finish-machined into Mo electrode rods and Mo alloy electrode rods; 2), the Mo electrode rods and the Mo alloy electrode rods are loaded to a reaction chamber, the reaction chamber is vacuumized, and inert gas is introduced into the reaction chamber according to a certain proportion; 3), a plasma gun contains a tungsten cathode and a copper anode, the Mo electrode rods and the Mo alloy electrode rods are not used as the electrode,the ends of the Mo electrode rods and the ends of the Mo alloy electrode rods are heated and uniformly melted, atomized droplets are thrown away from the ends of the Mo electrode rods and the ends ofthe Mo alloy electrode rods, and the droplets are rapidly cooled into spherical particles in an inert gas environment and fall into a collector; and 4), the obtained Mo powder and Mo alloy powder aresieved and packaged under the inert gas protection environment. The Mo powder and Mo alloy powder prepared through the method have the ultra-fine, high-purity, high-grade spherical, free-of-hollow-powder and free-of-satellite-powder characteristics.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

TWT impregnated Ba-W cathode and its preparation method

InactiveCN101145490AExtended service lifeLarge average pore sizeTransit-tube cathodesCold cathode manufactureRheniumPorosity

The invention discloses a dip-coated barium-tungsten cathode for traveling-wave tubes and a preparation method thereof. The dip-coated barium-tungsten cathode comprises a cathode drum, a cathode spongy body positioned inside the cathode drum. The invention is characterized in that the cathode spongy body is laminated by a tungsten spongy body and a tungsten-rhenium spongy body, wherein the tungsten-rhenium spongy body is coated with a noble metal film on the surface. With the above structure and preparation method, compared with the prior art, the cathode spongy body is a two-layered cathode spongy body laminated by the tungsten spongy body and the tungsten-rhenium spongy body, to replace the single-layer alloy substrate with uniform porosity in the prior art; the consumption of the noble metal Re is reduced; the porosity of the tungsten spongy body is increased; the storage level of cathode salts is increased; and the preferable proportion of the cathode salts allows both the emission behavior and the stability of salts better. With the noble metal Re coating, the cost of target materials is reduced. The consumption of noble metal is greatly reduced while ensuring the maximal emission and long service life of alloy substrate film-coated cathodes. The storage quantity of cathode salts is increased and the service life of cathode is prolonged.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Dipped barium tungsten cathode based on tungsten irridium alloy and its preparation method

InactiveCN1538482ASimple processShorten the production cycleDischarge tube solid thermionic cathodesCold cathode manufactureIridiumAluminate

Cathode is composed of 10-30% wt iridium powder and 70-90% wt tungsten powder, and dipping aluminate is in small opening. Preparation method is as following: annealing is carried out for iridium powder and tungsten powder in hydrogen furnace under 1000-1500deg.C; mixing iridium powder and tungsten powder and grinding the mixture evenly; pressing the mixture by stamper with molybdenum tube being inside so as to prepare flat-headed cathode; putting cathode in hydrogen furnace for heat preservation 1-10 hours under 1500-2000 deg.C; putting cathode in aluminate powder, at hydrogen atmosphere, 1500-2000 deg.C for 1-10 minutes and cleaning out float salt; installing heater obtains cathode needed.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

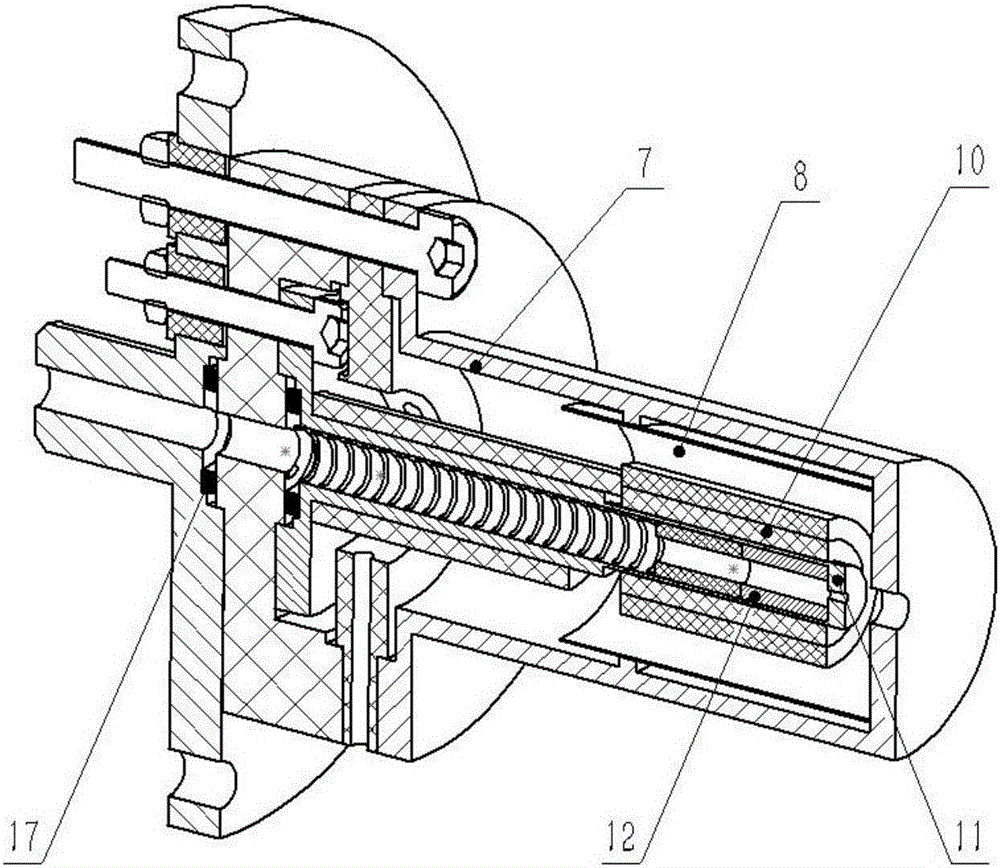

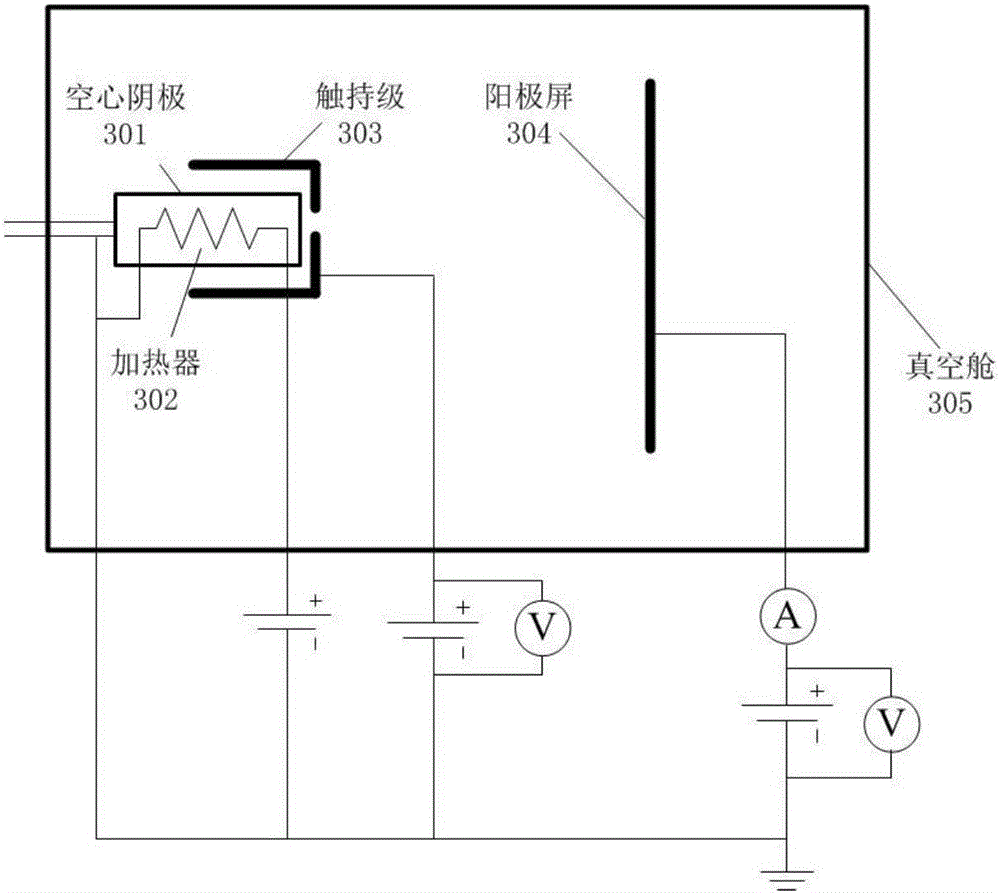

Small-size and miniwatt hollow barium-tungsten cathode

ActiveCN105788998AOptimizationIsolated contactDischarge tube solid thermionic cathodesMounting/support/spacing/insulation of electrode assembliesThermionic emissionHigh energy

The invention discloses a small-size and miniwatt hollow barium-tungsten cathode for an electric thruster. Barium-tungsten emissive material conducts thermionic emission through external heating. The small-size and miniwatt hollow barium-tungsten cathode is small and compactly structured, is mainly applied to low-power Hall thrusters and ion thrusters, and can provide high energy electrons for ionization of propellant and neutralize plume flows of the thrusters. A sidewise hole of a ceramic separation blade is used for introducing a heating wire, and a cathode pipe ceramic sleeve prevents contact of the wire and a cathode pipe to prevent short circuit due to contact of the wire and the cathode pipe. When the heating wire heats an emitter to 1100 DEG C, high voltage is applied on a contact holding stage for igniting. After successful ignition, the heating wire can be turned off and a self-holding heating mode is on. Electrons generated in the hollow cathode are sprayed to a high potential area on the downstream of the cathode, thereby completing thermionic emission.

Owner:BEIHANG UNIV

Preparing method for superfine high-grade spherical GH4133 alloy powder

The invention discloses a preparing method for superfine high-grade spherical GH4133 alloy powder. The method includes the steps that firstly, burdening is conducted according to components of a GH4133 alloy, and a GH4133 alloy bar is formed through smelting; secondly, the GH4133 alloy bar is subjected to finish machining to form an electrode bar; thirdly, the electrode bar is loaded into a reaction chamber, vacuum pumping is conducted on the reaction chamber, and the reaction chamber is inflated with inert gas according to a certain proportion; and fourthly, a plasma torque comprises a tungsten cathode and a copper anode, the electrode bar does not serve as the electrode, the end portion of the electrode bar is heated so that the end portion can be evenly melted; atomized liquid drops are thrown out from the end portion of the electrode bar so that the liquid drops can be rapidly cooled in the inert gas environment to form spherical particles and fall into a collector; and fifthly, the prepared GH4133 alloy powder is screened and subjected to electrostatic impurity removing in the inert gas protection environment. The GH4133 alloy powder prepared through the method has the beneficial effects of being superfine, high in purity capable of achieving a high-grade spherical shape and free of hollow powder and satellite powder.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Tungsten cathode laser multilayer cladding repairing method

ActiveCN105986266AConvenient and flexible process operationMetallic material coating processesElectrodesElectrolysisArgon atmosphere

The invention belongs to the technical field of laser cladding, particularly relates to a tungsten electrode laser multilayer repairing process used for rare earth fused salt electrolysis, belongs to the technical field of laser cladding and particularly relates to a tungsten cathode laser multi-layer repairing method. The tungsten cathode laser multi-layer repairing method is characterized in that a necking-down part of a tungsten electrode is cleaned and polished at the room temperature, and an oxide layer and a corrosion layer are removed thoroughly; then a 4 kW CO2 laser and a numerically-controlled worktable are used, a HUST-IV type high-precision powder feeding device and a coaxial powder feeding nozzle are used for cladding three kinds of mixed powder including SiC powder, Pd powder and pure W powder to the surface of a workpiece row by row and line by line under the protection of the argon atmosphere; a single-way multi-layer deposition manner is adopted for laser cladding, and a multi-layer coating with the thickness ranging from 6.0 mm to 10 mm is obtained; and finally, flaw detection is conducted, and it is ensured that the defects of cracks, air holes and inclusions are avoided in a cladding layer. The repairing method has the beneficial effects that the combining performance is high, operation is simple, and high temperature oxidability resistance and fused salt corrosivity resistance are good.

Owner:包头市三隆稀有金属材料有限责任公司

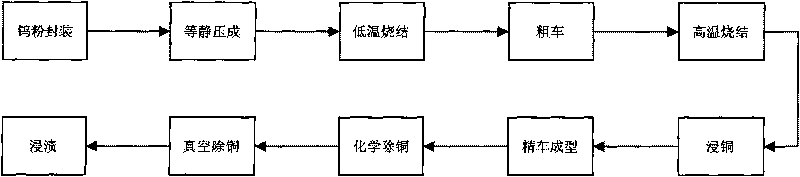

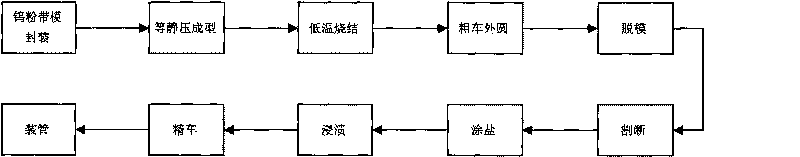

Manufacture method of annular barium-tungsten cathode emitter

The invention relates to a manufacture method of an annular barium-tungsten cathode emitter. The manufacture method comprises the following steps of: putting a molding mould in a latex sleeve, loading tungsten powder and then packaging; carrying out isostatic pressing; washing and removing the latex sleeve and putting the molding mould in a tungsten-mesh hydrogen furnace for heating and sintering at low temperature; roughly lathing, unloading mould, and cutting off to obtain a rough lathed tungsten blank; putting the tungsten blank in the tungsten-mesh hydrogen furnace and heating and sintering at high temperature; coating an active substance aluminate, putting the tungsten blank into a molybdenum-shell hydrogen furnace and heating and dipping; clamping and boring; and fine lathing the excircle and both end faces. The invention adopts a copper dipping free process and uses a molybdenum rod to process the tungsten molding mould. The method is simple and practical, saves resources and has low production cost, and because processes of dipping and removing the copper are saved, a horizontal hydrogen furnace used for dipping the copper and a vacuum degassing furnace used for removing the copper in practical production are saved, thus funds of about 500 thousands RMB can be saved. The method has quite obvious application prospect in the production of electric vacuum devices.

Owner:甘肃虹光电子有限责任公司

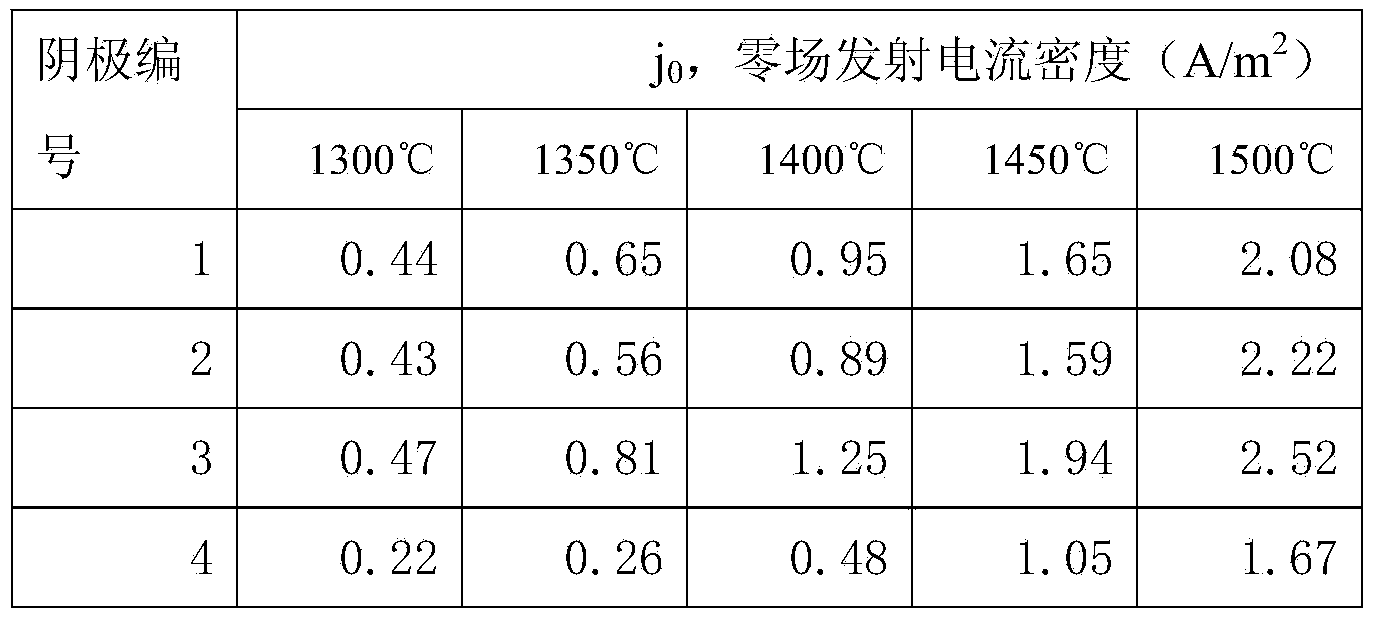

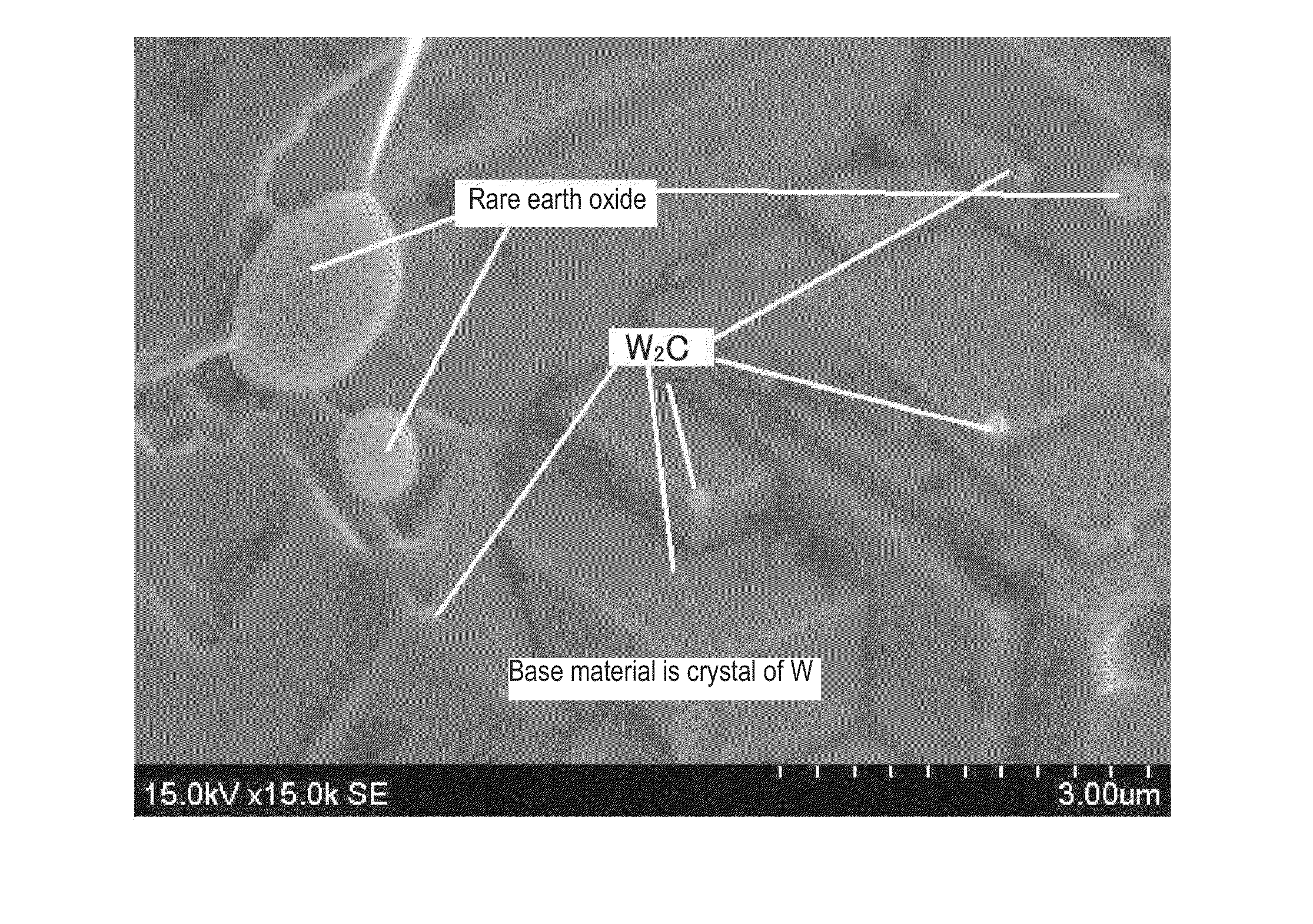

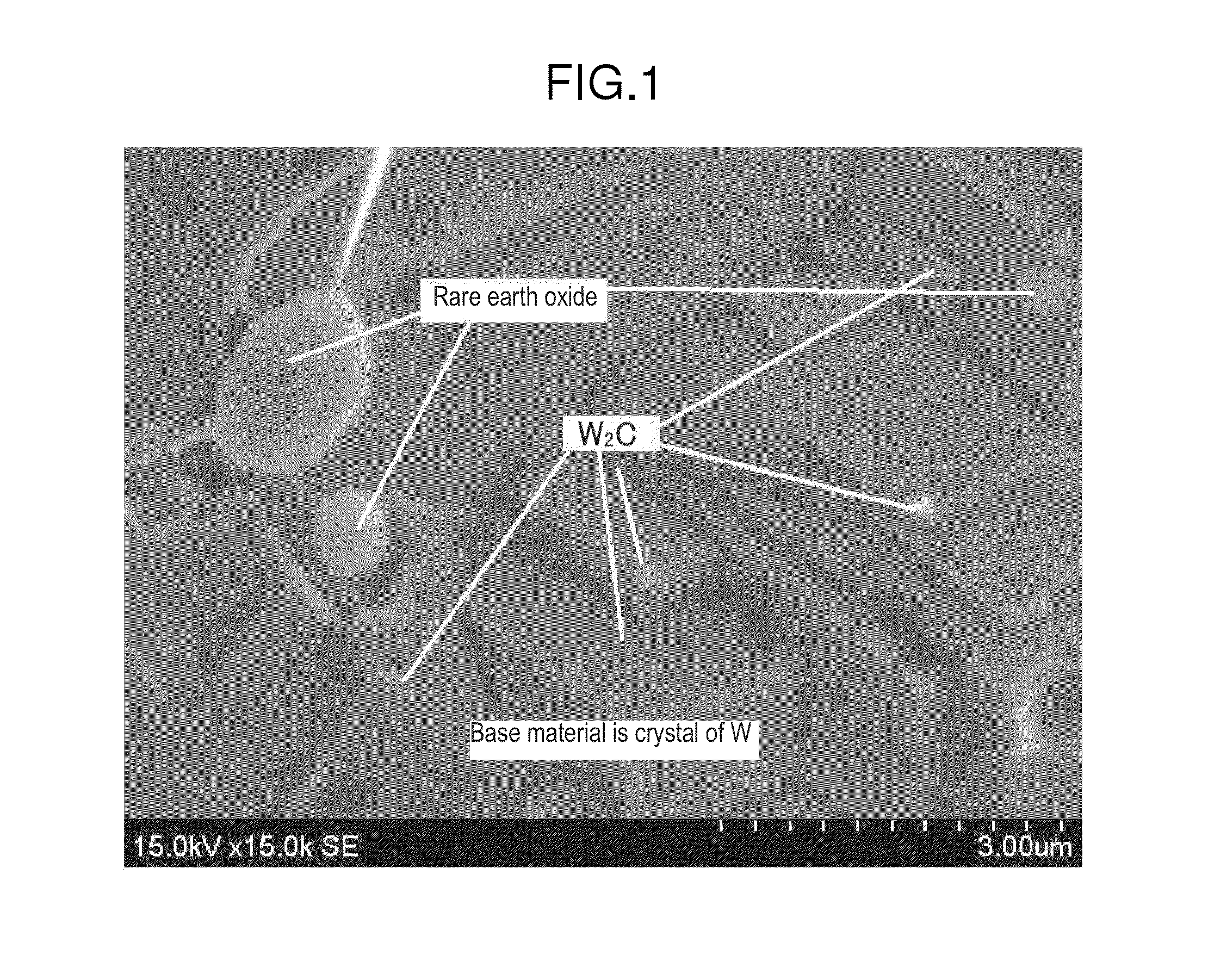

Tungsten cathode material

InactiveUS20140017114A1Easy to useImprove featuresGas discharge lampsDischarge tube/lamp detailsRare-earth elementPlasma sprayed

Provided is a cathode material which becomes an alternative material of a cathode material formed of a W—ThO2 alloy and is formed of a tungsten alloy that does not include thorium which is a radioactive element. When particles of a rare earth oxide and tungsten carbide are finely dispersed in a tungsten cathode material used as a discharge cathode material used in TIG, plasma spraying, plasma cutting, electrical discharge machining, discharge lamps and the like, reduction and diffusion of the rare earth oxide are accelerated, and supply of rare earth elements to a cathode surface is ensured, thereby improving discharge characteristics.

Owner:NIPPON TUNGSTEN CORP

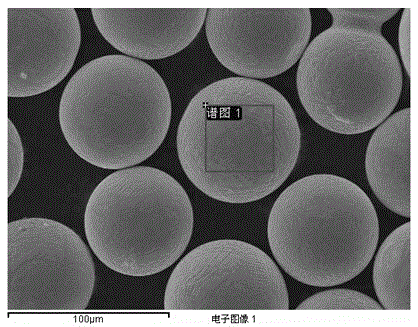

Method for preparing impregnated cathode matrix

InactiveCN102024640AUniform hole sizeWell distributed holesThermionic cathode manufactureMicrowavePrill

The invention discloses a method for preparing an impregnated cathode matrix and relates to technology of microwave devices. The method is used for preparing a tungsten sponge matrix of an impregnated barium and tungsten cathode. Tungsten particles of different sizes are prepared into uniform spherical particles by particle spray drying powder treating technology, so that the flowability of tungsten powder is enhanced; and after being filled into a rubber sleeve, the treated tungsten powder can be beat, tamped or vibrated to form a close-packed structure, and then the close-packed structure is pressed and sintered to prepare the tungsten sponge matrix. The method is simple and practicable, the prepared impregnated cathode matrix has the advantages of uniform hole size, uniformly distributed holes, few closed holes and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Impregnated barium tungsten cathode based on tungsten fibre and its preparation method

InactiveCN1536606ASimple processShorten the production cycleThermionic cathodesDischarge tube solid thermionic cathodesFiberAluminate

The invention provides a Wu fiber-based impregnated Ba-Wu cathode, its components in weight percent: Wu fiber 10-30% and Wu powder 79-90% and its hole is impregnated with aluminate. Its preparing method: place Wu fibe and Wu powder 1000-1500 deg.C in hydrogen furnaces for annealing, respectively; in weight percent, take Wu fiber 10-30% and Wu powder the rest to grind and mix uniformly and make all the fiber ports show certain directionality. Use press mould with Mo tube inside to press the mixture into flat-roofed cathode body; place the cathode body in hydrogen furnace: when the temperature reaches 1500-2000 deg.C, preserve heat for 1-10 hours; place in aluminate powder and in a hydrogen atmosphere, to dip for 1-10 minutes at 15000-2000 deg.C, and then eliminate the floating salt by Wu sleave group; install ohmic heating carrier getter to make it.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

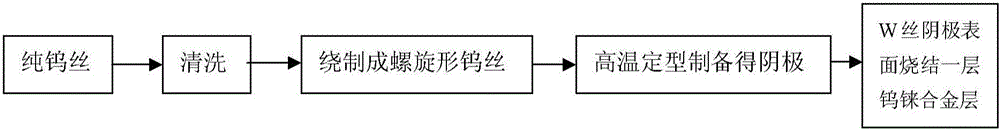

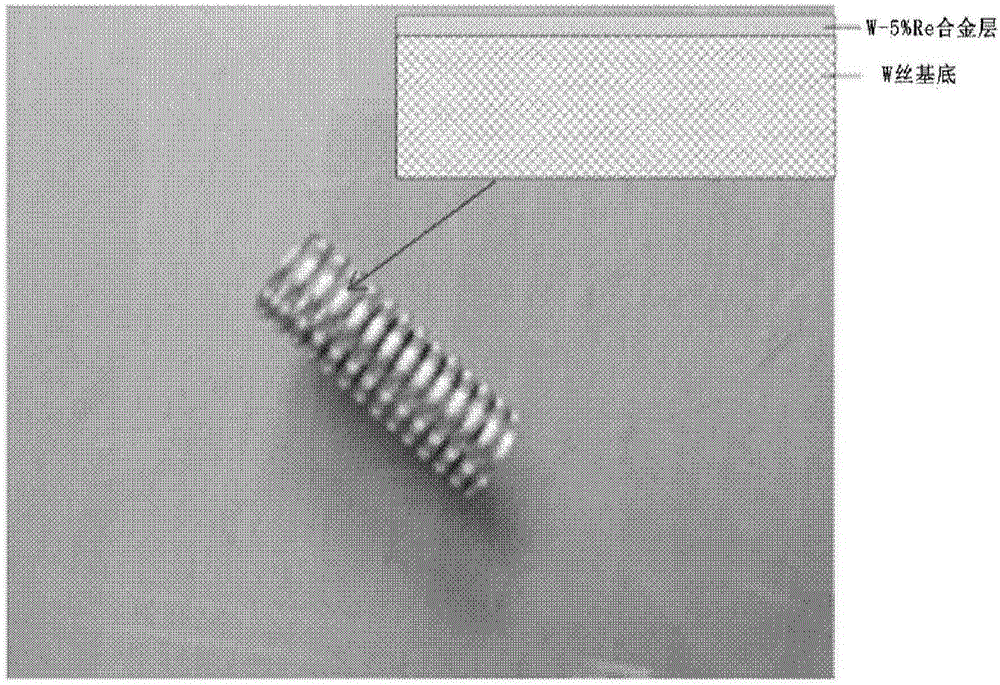

Rhenium doped tungsten-based alloy cathode and preparation method thereof

InactiveCN105702542AImprove launch stabilityLower working temperatureTransit-tube cathodesCold cathode manufactureRheniumHydrogen

The invention provides a preparation method of a rhenium doped tungsten-based alloy cathode. The preparation method comprises the steps of: mixing metal tungsten powder with rhenium powder to obtain evenly mixed tungsten-rhenium alloy powder; mixing the tungsten-rhenium alloy powder with 1.5wt% nitro-cotton solution evenly, applying the mixed solution to the surface of a tungsten cathode substrate, and baking; and placing a tungsten wire with the tungsten-rhenium alloy powder applied on surface into a high-temperature hydrogen furnace, and keeping the tungsten wire at the temperature of 1600+ / -50 DEG C for 10-15 minutes, thereby preparing the rhenium doped tungsten-based alloy cathode. The invention further provides the rhenium doped tungsten-based alloy cathode prepared by adopting the method. The rhenium doped tungsten-based alloy cathode provided by the invention can increase emission current density of a pure tungsten cathode used for a high-power continuous wave magnetron, reduce working temperature of the pure tungsten cathode, reducing surface evaporation rate of the cathode, and further prolonging service life of the cathode.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Alloy solder for dipping barium tungsten cathode and welding method thereof

InactiveCN102500954AImprove fluiditySmall evapotranspirationWelding/cutting media/materialsSoldering mediaWorking temperatureAlloy

The invention discloses alloy solder for dipping a barium tungsten cathode and a welding method thereof. The alloy solder consists of cobalt powder and tungsten powder which respectively have the average grain size of between 1 micrometer and 10 micrometers and the purity of between 99.0-99.99 percent and are fully mixed after hydrogen purification. The welding method mainly comprises the two steps of: preparing the alloy solder and welding a tungsten cake and a cathode cylinder. The invention has the beneficial effects that the melting point temperature of the alloy solder has good moderate flowing property and less evapotranspiration, is between the working temperature and the melting point temperature of a cathode activity material and can not cause the precipitation of the cathode activity material in the welding process; with the adoption of the alloy solder and the welding method, the tungsten cake dipped into the cathode activity material forms an effective welding with a molybdenum tube on a whole contact surface; and the alloy solder has high repeatability, stability and reliability.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

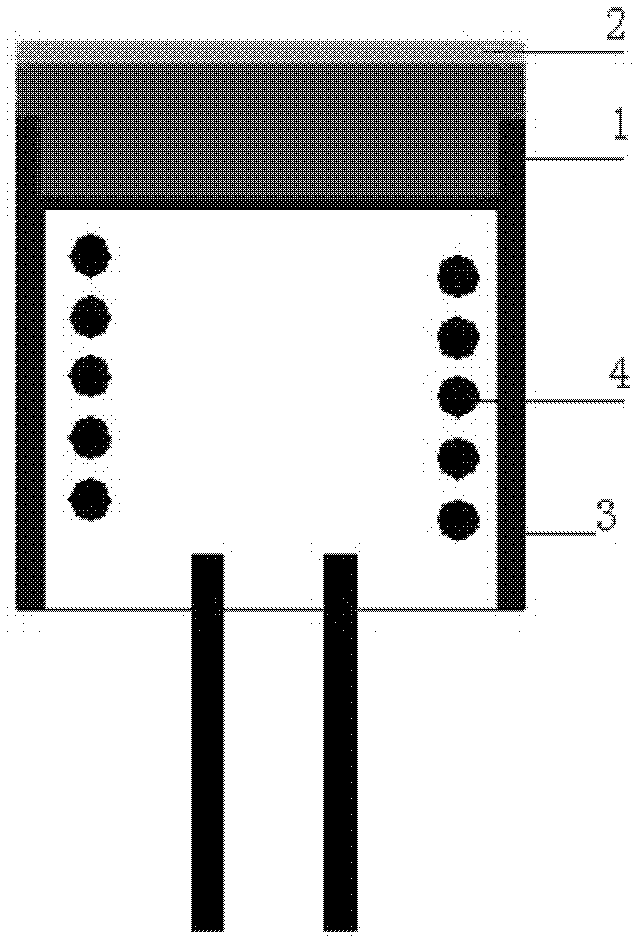

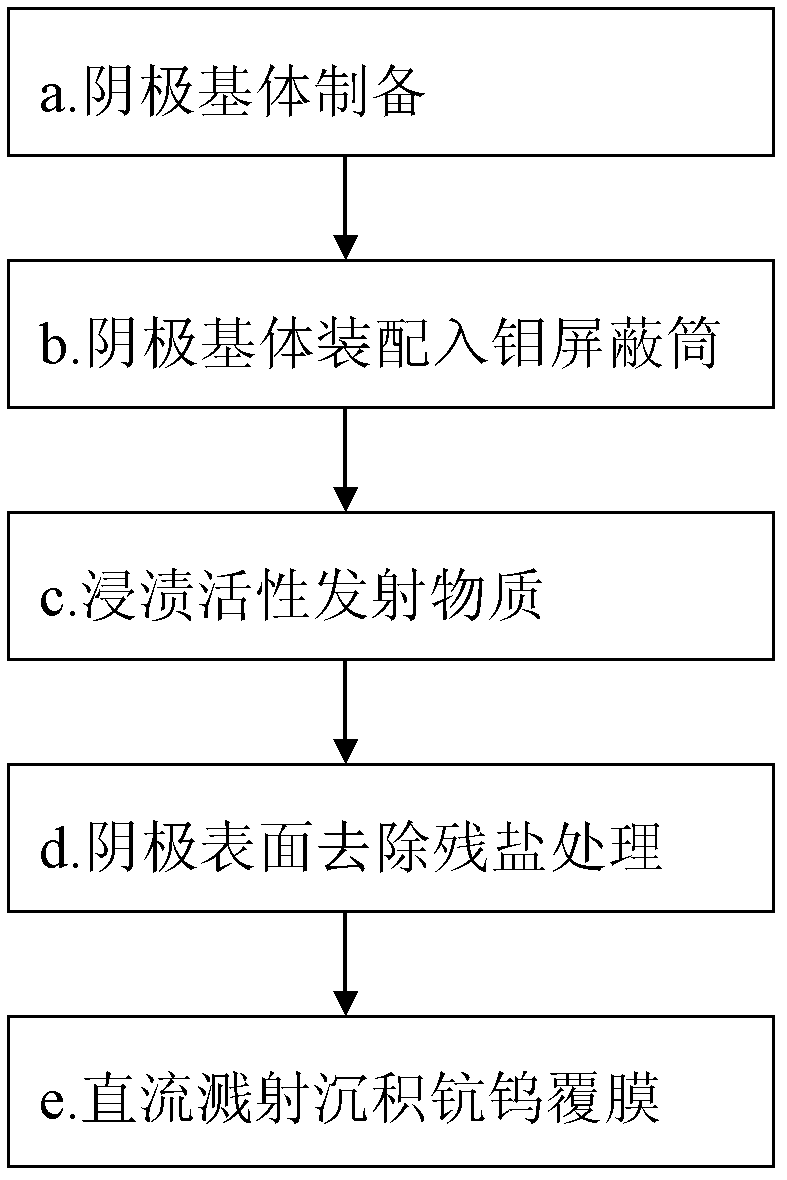

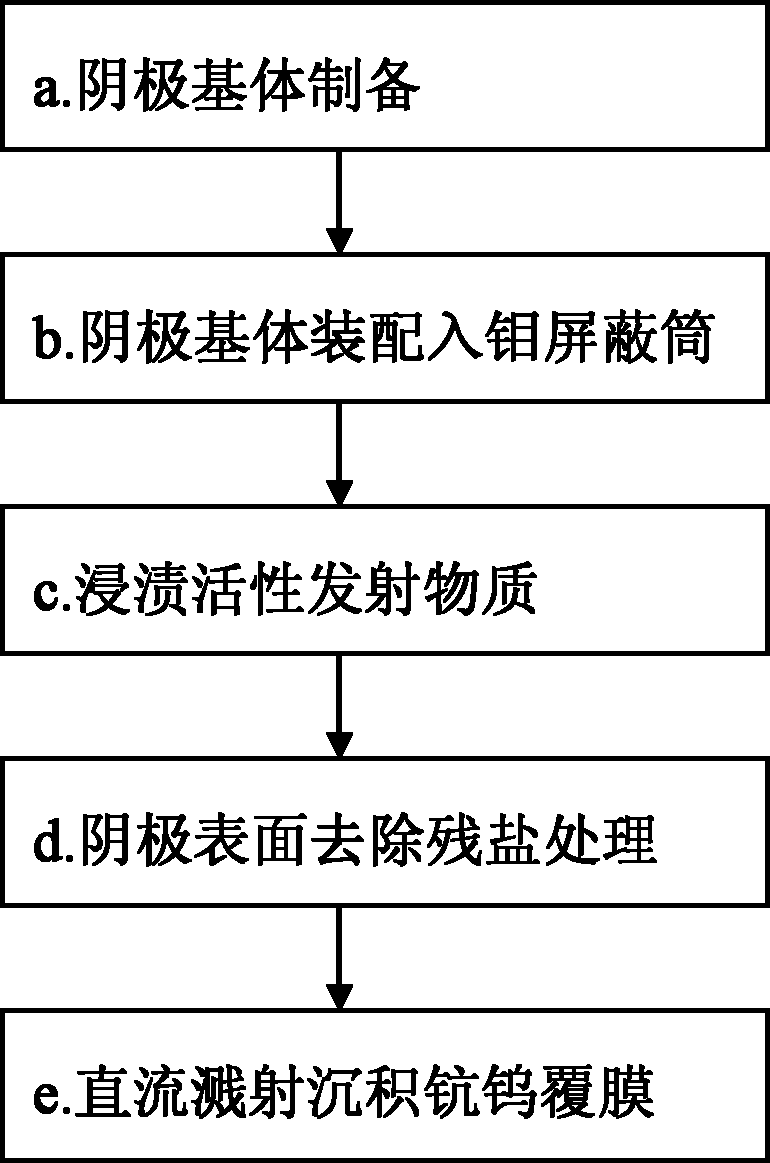

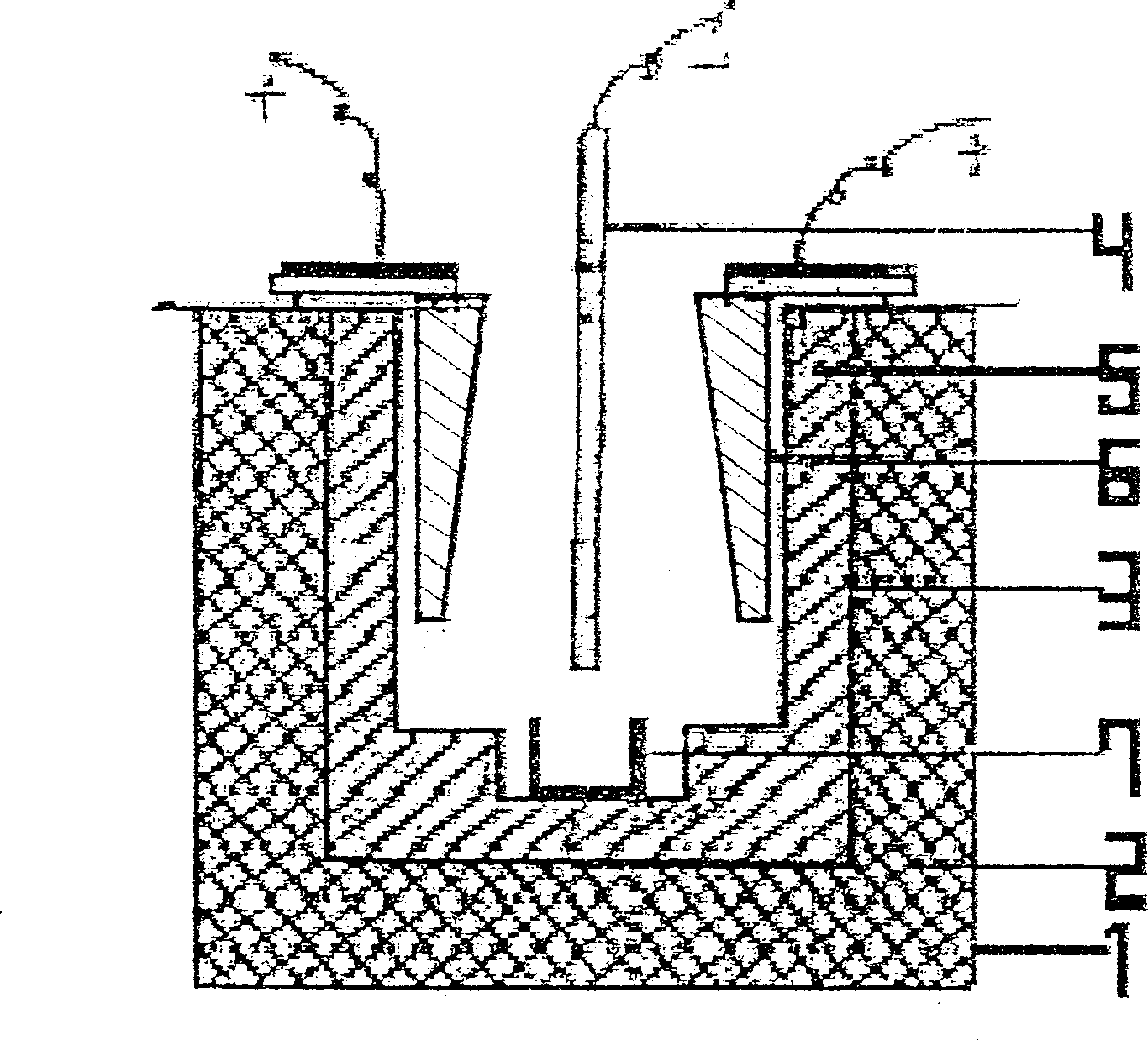

Thin film scandium-tungsten cathode and preparation method thereof

InactiveCN102522281ARemain oxidizedEvenly distributedDischarge tube/lamp detailsThermionic cathode manufactureMicrowaveOptoelectronics

The invention discloses a thin film scandium-tungsten cathode and a preparation method thereof, and the thin film scandium-tungsten cathode and the preparation method thereof belong to the field of microwave vacuum electronic apparatuses. The thin film scandium-tungsten cathode comprises a cathode matrix; a molybdenum shielding barrel is arranged at the lower part of the matrix; a heater assembly is arranged in the shielding barrel; and a synthetic scandium-tungsten covering film is arranged on the surface of the top of the cathode matrix. The preparation method of the thin film scandium-tungsten cathode comprises the following steps: preparing the cathode matrix, assembling the cathode matrix with the molybdenum shielding barrel, dipping an active emitting substance, processing the surface of the cathode, and sputtering a scandium-tungsten film in a direct current way. By using the cathode prepared by the method, the electron emission capacity is increased beneficially, and the emission uniformity is improved.

Owner:NO 12 RES INST OF CETC

Process for preparing cell-class mischmetal by fused salt electrolysis process and device therefor

The invention discloses a battery grade composite rare earth metal manufacturing technology and equipment of melting salt electrolytic method in the rare earth product preparing domain, which comprises the following steps: melting the blended rare earth oxide in the fluoride flux; ionizing; evolving Ren+ to reduce into Re on the tungsten cathode surface at (60-70V / M) DC electric field; oxidizing O2- into O2 on the graphite anode surface; reacting O2 and graphite to produce CO2 into the air. The electrolyser is made of carborundum connecting silicon nitride material, which reduces electrolyte fusing point and improves the fluidity and stability.

Owner:BAOTOU XIJUN RARE EARTH

Cathode salt, preparation method of cathode salt, barium tungsten cathode comprising cathode salt and preparation method of barium tungsten cathode

ActiveCN102637567AImprove launch performanceTo overcome the disadvantage of small emission currentTransit-tube cathodesCold cathode manufactureTungsten cathodeBarium carbonate

The invention discloses cathode salt, a preparation method of the cathode salt, a barium tungsten cathode comprising the cathode salt and a preparation method of the barium tungsten cathode. The cathode salt includes components, by weight, 3-4 parts of barium carbonate, 0.3-0.8 part of calcium carbonate and 1.5-2.5 parts of aluminum powder. The preparation method of the cathode salt includes weighing, ball milling, drying and synthesizing. The barium tungsten cathode prepared by the cathode salt has high emitting power which can be up to hundreds of amperes and meets the requirements of high-power and high-frequency development of microwave devices.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

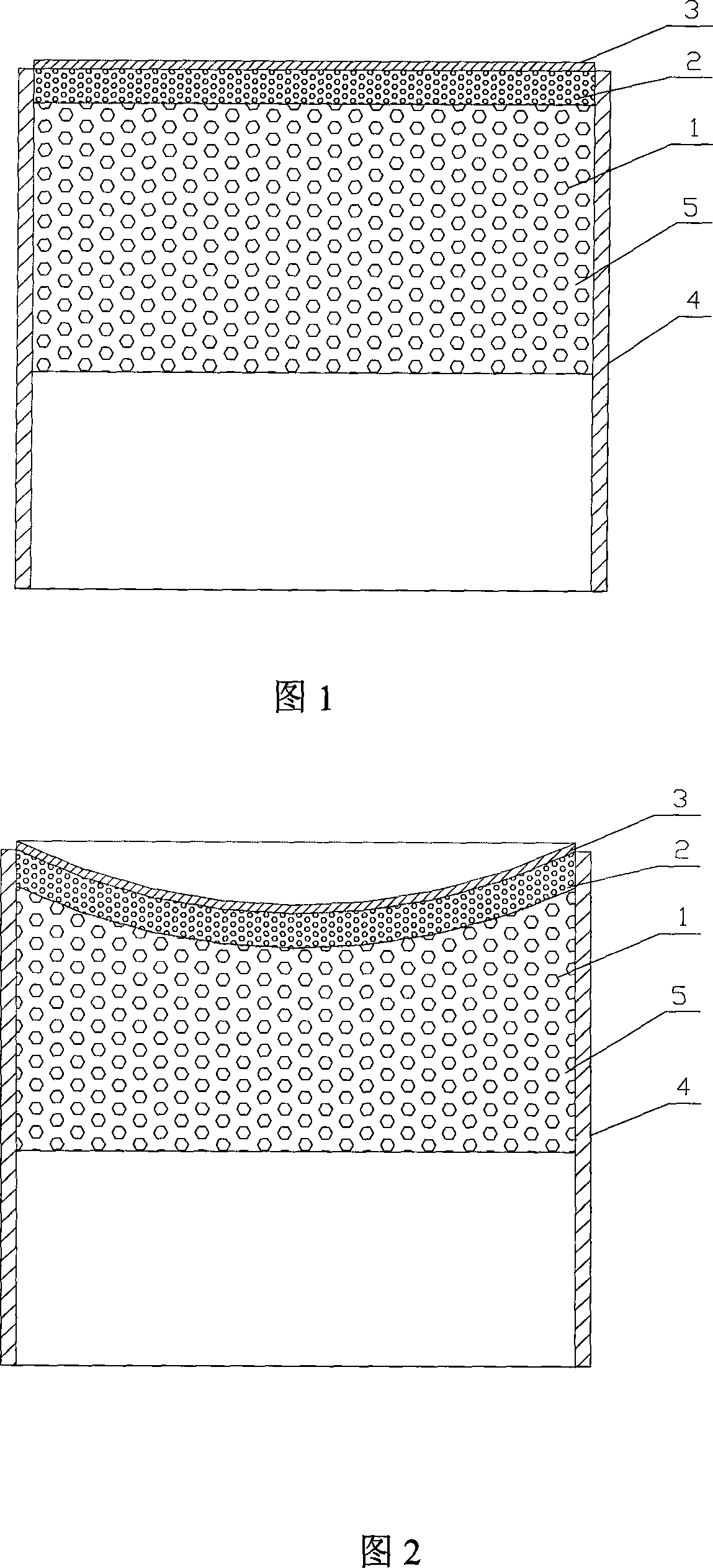

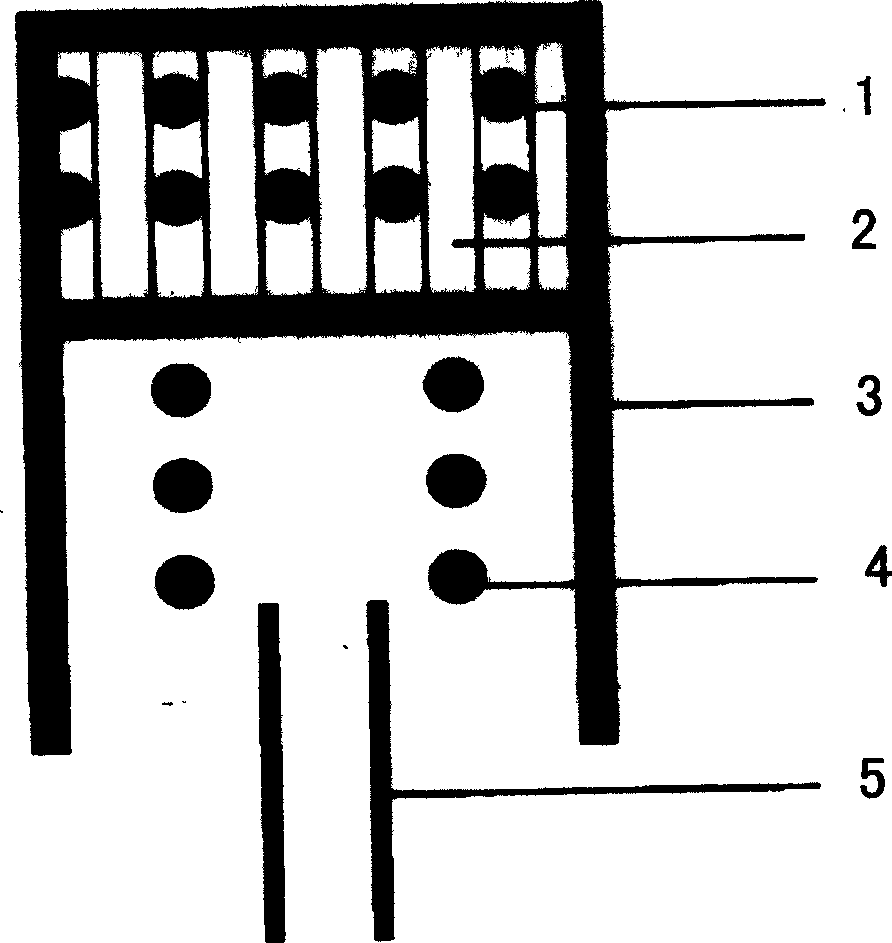

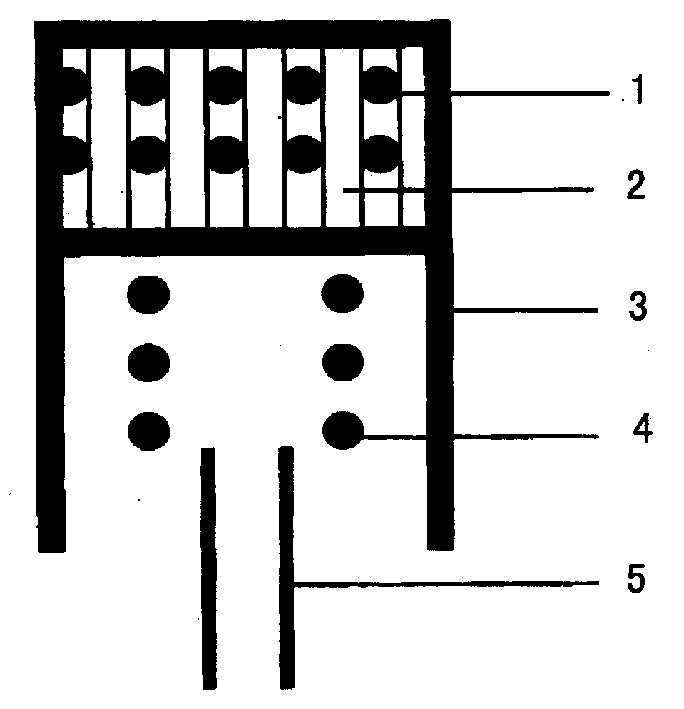

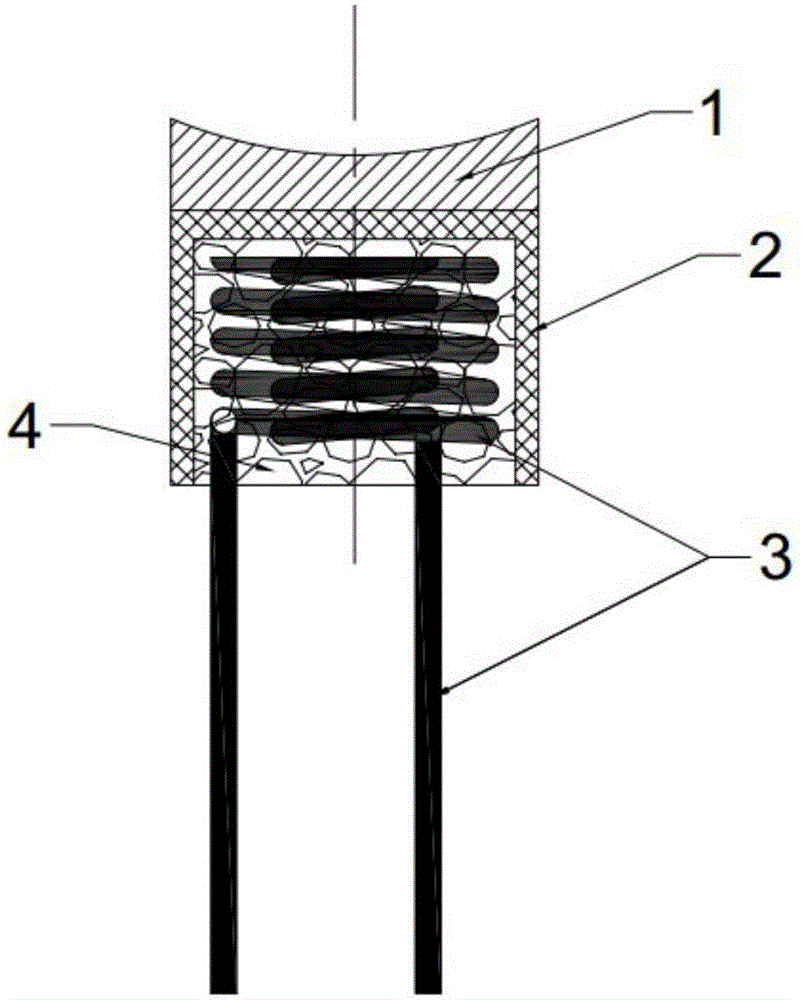

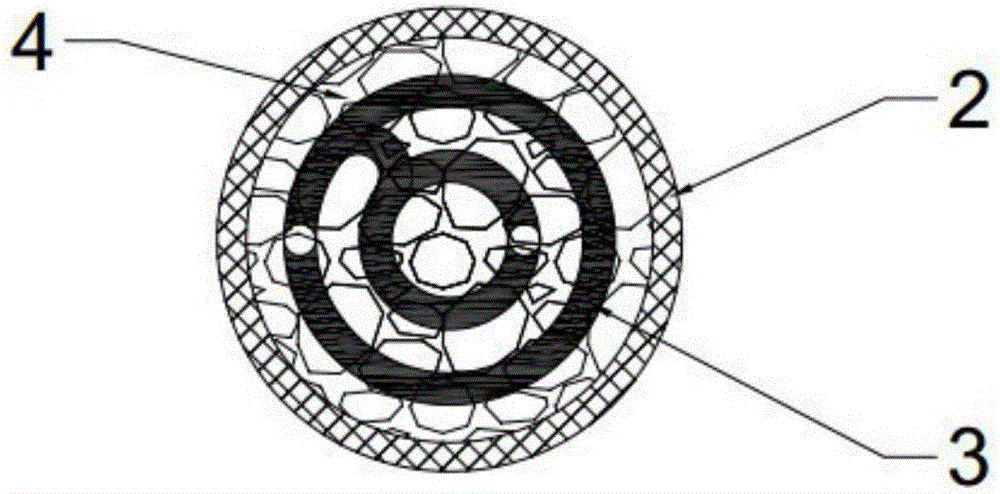

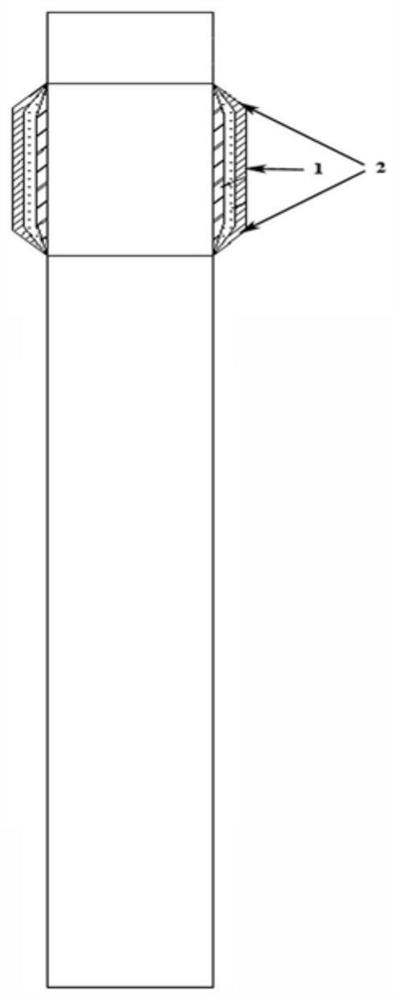

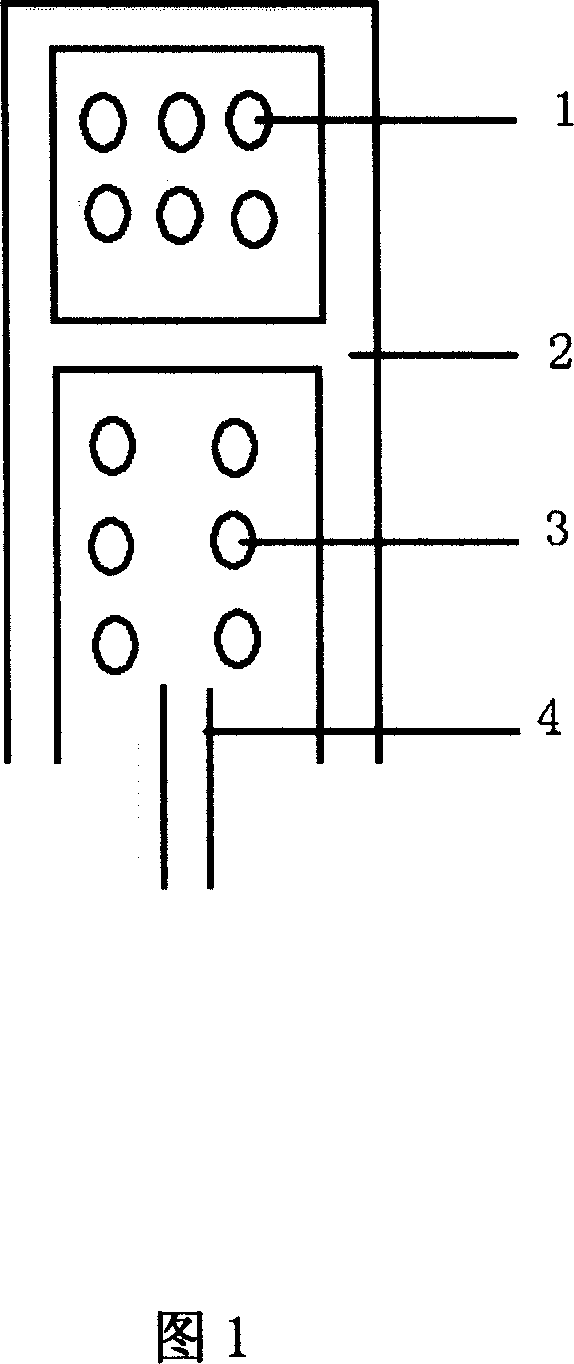

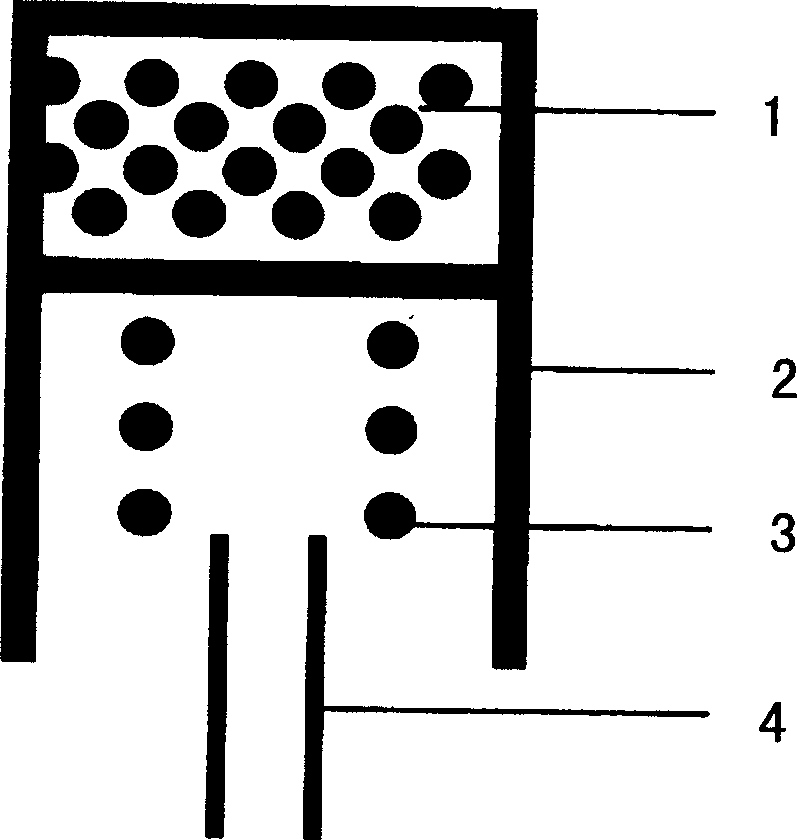

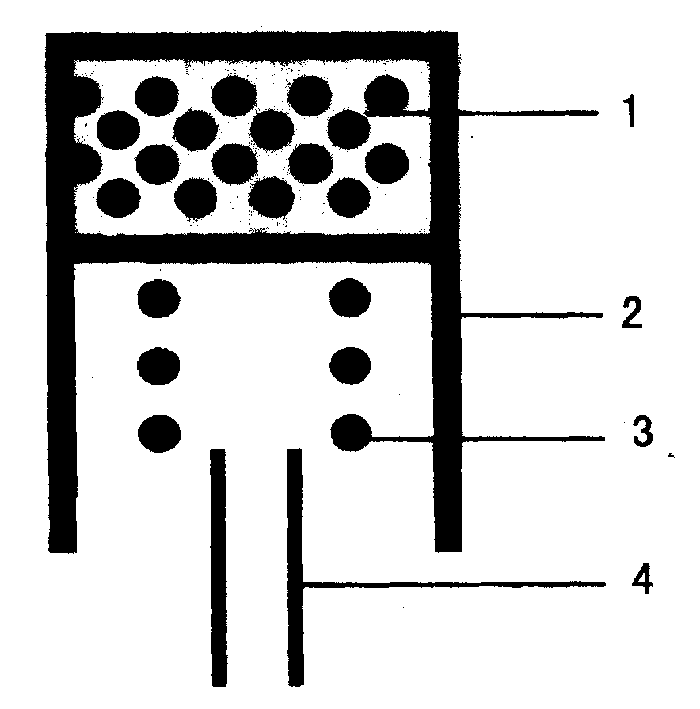

High-thermal-conductivity insulating medium fast-heating cathode hot wire assembly and preparation method thereof

InactiveCN105931935AImprove transfer efficiencyImprove heating efficiencyTransit-tube cathodesSlurryThermal transmittance

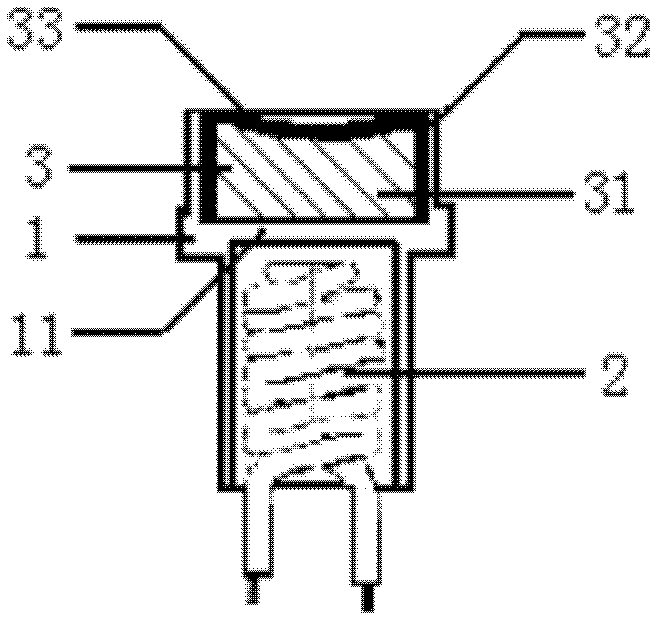

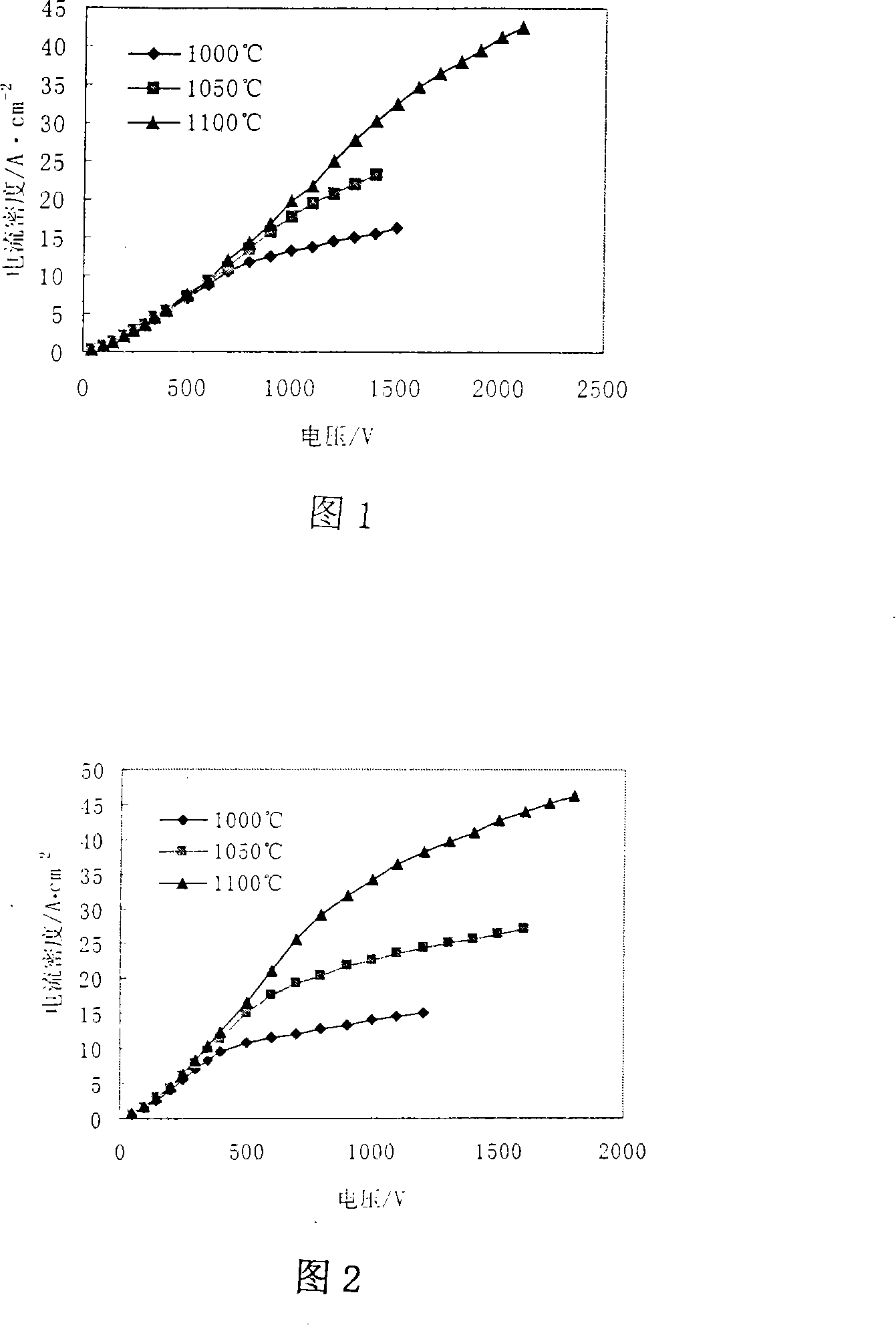

The invention provides a high-thermal-conductivity insulating medium fast-heating cathode hot wire assembly and a preparation method thereof. The high-thermal-conductivity insulating medium fast-heating cathode hot wire assembly comprises a tungsten cathode (1), a cathode tube (2), hot wires (3) and an insulating medium (4). The cathode tube (2) and the hot wires (3) are closely packaged into an integrated structure through the insulating medium (4). High-solid-content ceramic slurry is prepared by mixing organic solvents of alcohol and the like and aluminum nitride powders; the slurry is poured into the cathode tube and the hot wires are added to the cathode tube; and the high-thermal-conductivity insulating medium fast-heating cathode hot wire assembly is obtained through high-temperature sintering after centrifugal treatment and forming densifying. The high-thermal-conductivity insulating medium fast-heating cathode hot wire assembly is far higher in thermal conductivity than a conventional aluminum oxide ceramic assembly, and has higher heat transfer efficiency; the cathode hot wire assembly is shorter in preheating time, and can reach an operating temperature of 1050 DEG C within 5 s; the cathode hot wire assembly is higher in high-temperature strength and good in antiknock performance, meets the quick starting requirement under high shock vibration, is excellent in performance, high in reliability and long in service life, and can be widely applied to a quick start traveling-wave tube.

Owner:UNIV OF SCI & TECH BEIJING

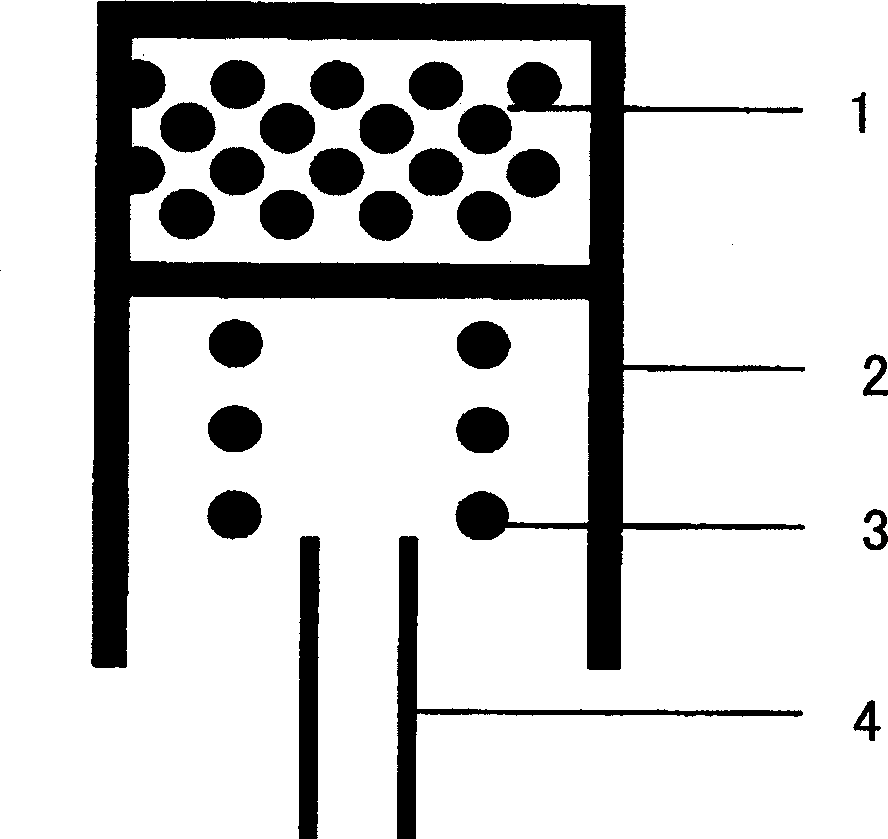

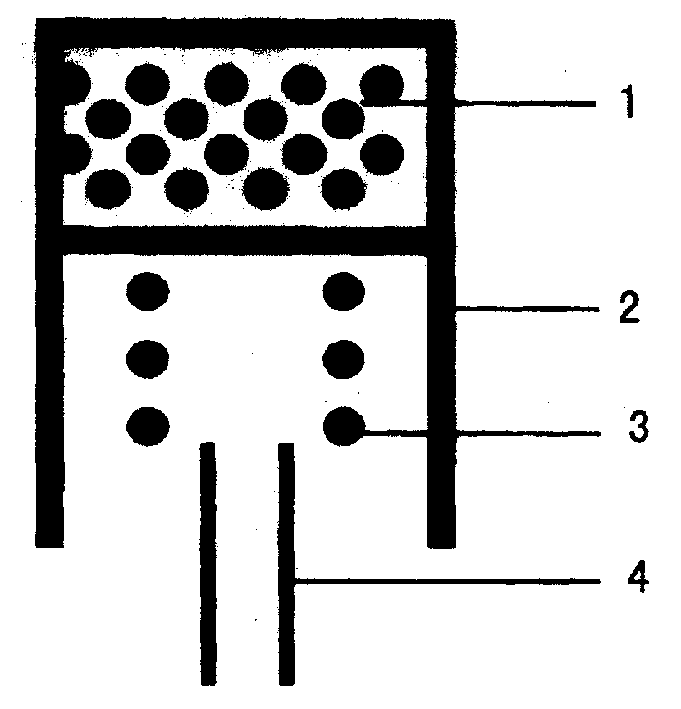

Storage film-coating dipped barium-tungsten cathode and preparation method

InactiveCN103050354AExtend your lifeIncreased emission current densityTransit-tube cathodesCold cathode manufacturePorosityWorking temperature

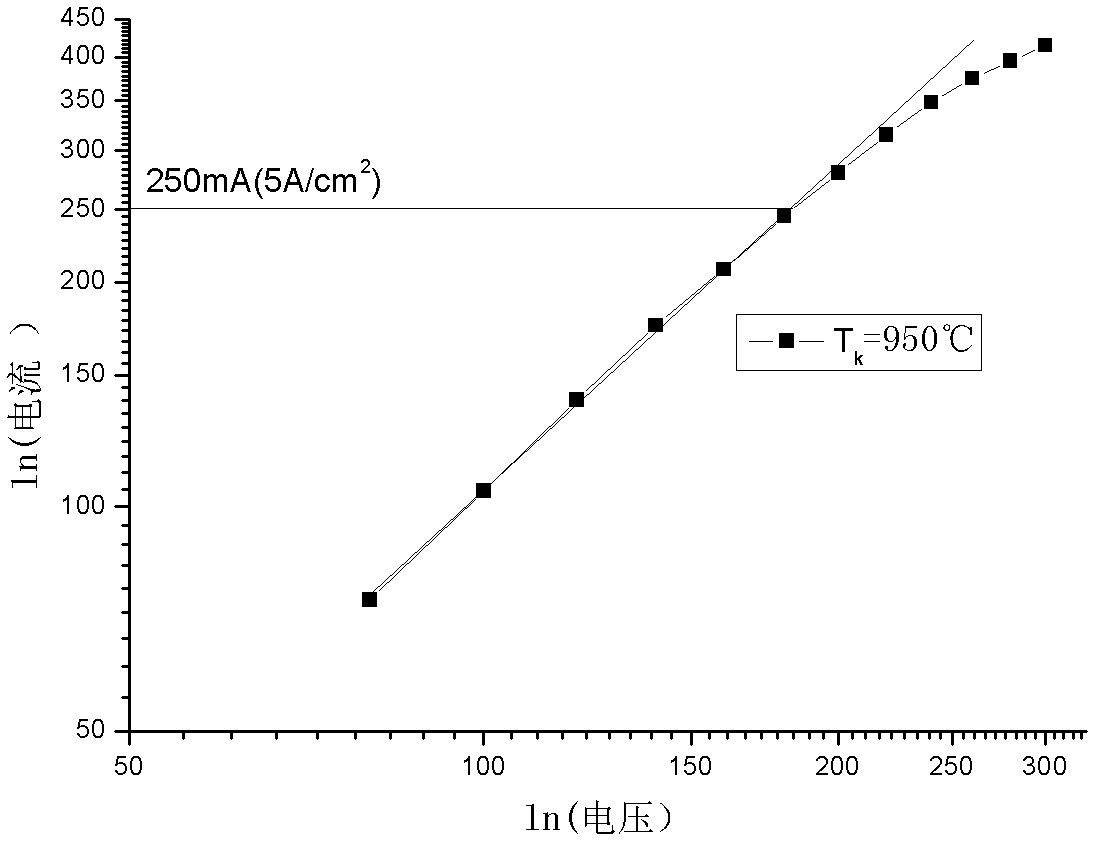

The invention discloses a storage film-coating dipped barium-tungsten cathode and relates to an electron device technology. The cathode adopts the following chamber tungsten sponge matrix structure: the cathode is divided into both inner and outer tungsten sponge matrixes; the inner end face of the inner tungsten sponge matrix is fixedly connected with a partition; the rest faces of the inner tungsten sponge matrix are coated with the outer tungsten sponge matrix; the lateral surface of the outer tungsten sponge matrix is fixedly connected with the inner wall of another accommodating cavity; the inner tungsten sponge matrix has porosity of 40 percent to 45 percent; the outer tungsten sponge matrix has porosity of 20 percent to 22 percent; and the outer end face of the outer tungsten sponge matrix is coated with a 0s-Ir-Al film. The cathode disclosed by the invention has the characteristics of large emission current density, long service life and the like; and a DC (Direct Current) emission volt-ampere characteristic curve result shows that when the working temperature of the cathode is 950 DEG C, a current of a deviated point can reach 5A / cm<2>. According to the invention, the emission current density of the barium-tungsten cathode is improved; storage of active materials is improved; the service life of the cathode is prolonged to 12 to 15 years; and the development requirement of a space travelling wave tube on the long service life of the hot cathode is met.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Negative electrode material for high intensity discharge lamp and manufacturing method thereof

ActiveCN103343275AIncrease in crystal defectsExtended service lifeGas discharge lamp detailsCold cathode manufactureManufacturing technologyThorium oxide

The invention relates to the field of metal material manufacturing technology, and specifically relates to a negative electrode material for a high intensity discharge lamp and a manufacturing method thereof. The negative electrode material comprises the following components: 1.5%-2.0% of thorium oxide, 0.0020%-0.0080% of potassium and 97%-98% of tungsten. Compared with a conventional negative electrode material, the negative electrode material provided by the invention has the following advantages that (1) thorium oxide particles of a thorium tungsten negative electrode even if 0.0020%-0.0080% of potassium is doped are fine and uniformly distributed; and (2) the thorium tungsten negative electrode contains a trace amount of potassium element, and by adopting the potassium-doped tungsten thorium negative electrode, the growth speed of crystal particles is slow, the tip shape of the electrode can be stably maintained, and the service life of the discharge lamp is prolonged.

Owner:威海多晶钨钼科技有限公司

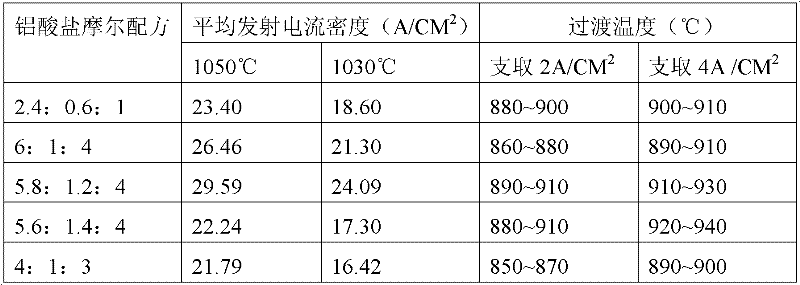

Aluminate for assembling barium-tungsten cathode of diode and preparation method thereof

InactiveCN102241412ASolution to short lifeGood launch performanceAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateAluminium hydroxide

The invention discloses aluminate for assembling barium-tungsten cathode of diode and a preparation method thereof. The aluminate is formed by 5.6 to 5.8 moles of barium carbonate, 1.2 to 1.4 moles of calcium carbonate and 4.0 moles of aluminium hydroxide. Experiment study indicates that the mixing ratio of the components is reasonable, that the prepared aluminate has high emission performance and high anti-poisoning performance, and that the service life of the assembled cathode is long. The preparation method of the aluminate has high operability and reasonable process design; and particularly, under optimal pressing mode, sintering temperature, sintering heat-preservation time, sintering atmosphere and the like, the preparation method can prepare the aluminate which has high emission performance and long service life and can meet requirements for high-standard traveling-wave diode cathode assembly.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Tungsten cathode for molten salt electrolysis, preparation method of tungsten cathode and application of laser cladding technology

PendingCN113897642AImprove corrosion resistanceFusion wellFurnace typesMetallic material coating processesElectrolysisMolten salt

The invention discloses a preparation method of a tungsten cathode for molten salt electrolysis, which comprises the following steps: sequentially carrying out laser cladding on the surface to be subjected to laser cladding of a tungsten substrate in copper, stainless steel and an anti-corrosion metal composite material to obtain the tungsten cathode with a copper cladding layer, a stainless steel cladding layer and an anti-corrosion metal cladding layer; wherein the surface to be subjected to laser cladding is the surface of the tungsten substrate in the area between the 1 / 10 position of the length of the tungsten substrate and the 1 / 4 position of the length of the tungsten substrate from the same end part of the tungsten substrate; the anti-corrosion metal composite material is prepared from the following components: 0.02 wt%-0.06 wt% of C, 1.5 wt%-2.5 wt% of Si, 2.5 wt%-3.5 wt% of W, less than or equal to 7 wt% of Fe, 10 wt%-20 wt% of Mo, 20 wt%-30 wt% of Cr, 8 wt%-20 wt% of ZrO, 0.4 wt%-0.8 wt% of B and the balance Ni. According to the method, the service life of a traditional tungsten cathode can be prolonged from about 200 days to 310-320 days.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

Dipped barium wolfram cathode and process for its manufacture

InactiveCN1925088AGood cathode stabilitySimple processDischarge tube solid thermionic cathodesCold cathode manufactureAluminateIridium

This invention discloses one dipping barium-tungsten cathode with multi functions and its process method, wherein, the cathode comprises addictive, molybdenum cylinder, heater, aluminates; the addictive is composed of iridium powder ruthenium powder and tungsten powder. The process method comprises the following steps: annealing the metal powder and weighting three materials less than 200 for mixing and using molybdenum powder mode to process cathode; heating to 1500-2000 degree less than one hour; putting it into aluminates powder for dipping for 0.5 to 10 minutes in 1500 to 2000 degrees.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

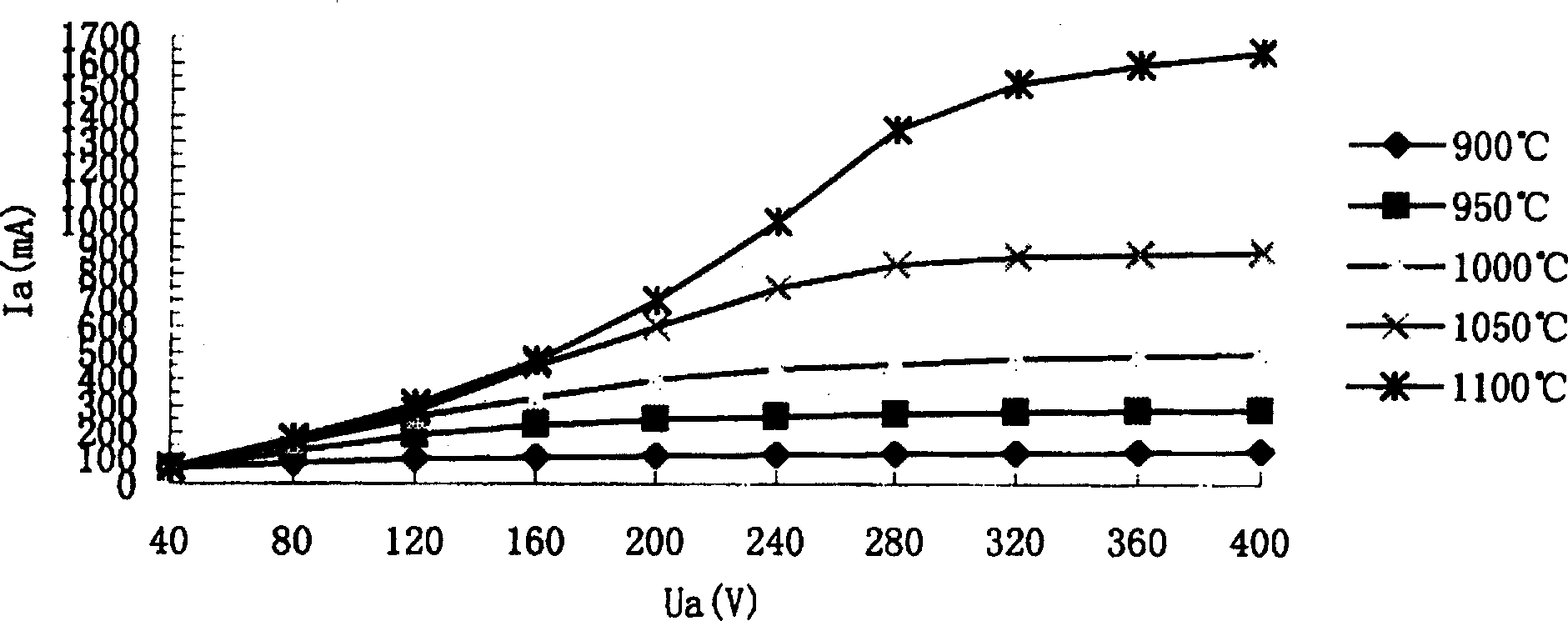

High electric current density electron emitter material containing zirconium tungsten base and production method thereof

InactiveCN101221869ASmall average pore sizeNarrow pore size distributionDischarge tube solid thermionic cathodesCold cathode manufactureZirconium hydrideHigh current density

The present invention relates to a high ampere density electron emitter material and a manufacture method thereof, in particular to a high ampere density electron emitter material having zirconium-tungsten matrix and the manufacture method thereof; the basal body of the material of the invention is zirconium dioxide and tungsten; tungsten powder is weighed, annealed in a hydrogen furnace, then grinded, and filtered with a screen of 80 meshes; the filtered tungsten powder and ZrO2are grinded to be even, then molded, and disposed in aluminate powder and immersed in hydrogen circumstance; after the floating salt is removed, the electron emitter material is made. The average pore diameter of the zirconium-tungsten basal body made by the invention becomes smaller, and the pore diameter distribution becomes narrower; when the working temperature is 1050 DEG C, the current density emitted by the cathode of the invention is 1.73 to 1.86 times larger than that of the traditional barium-tungsten cathode.

Owner:NANJING UNIV OF TECH

Dipped barium tungsten cathode based on nanometer material silicn dioxide and reparation method

InactiveCN1538483ASimple processShorten the production cycleDischarge tube solid thermionic cathodesCold cathode manufactureAluminateHydrogen atmosphere

Cathode is composed of 10-20% wt nano-silicon dioxide and 80-99% wt tungsten powder, and dipping aluminate is in small opening. Preparation method is as following: annealing is carried out for nano-silicon dioxide and tungsten powder in hydrogen furnace under 500-1500deg.C; mixing nano-silicon dioxide and tungsten powder and grinding the mixture evenly; pressing the mixture by stamper with molybdenum tube being inside so as to prepare flat-headed cathode; putting cathode in hydrogen furnace for heat preservation 1-10 hours under 1000-1500 deg.C; putting cathode in aluminate powder, at hydrogen atmosphere, 1500-2000 deg.C for 1-10 minutes and cleaning out float salt; installing heater obtains cathode needed.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com