Patents

Literature

798results about How to "Solve residual problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

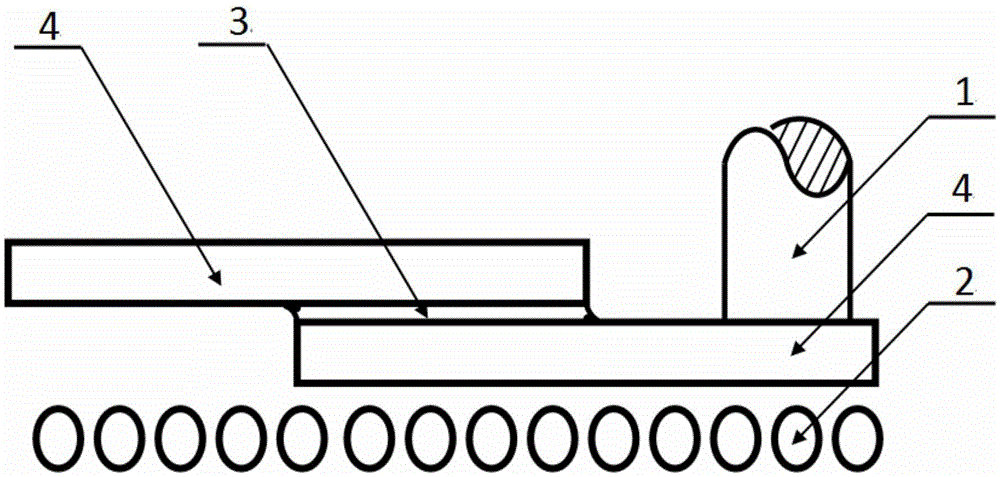

Method for manufacturing printed circuit board edge connector

ActiveCN101643927AAchieve preparationSolve residual problemsPrinted element electric connection formationEngineeringElectroplating

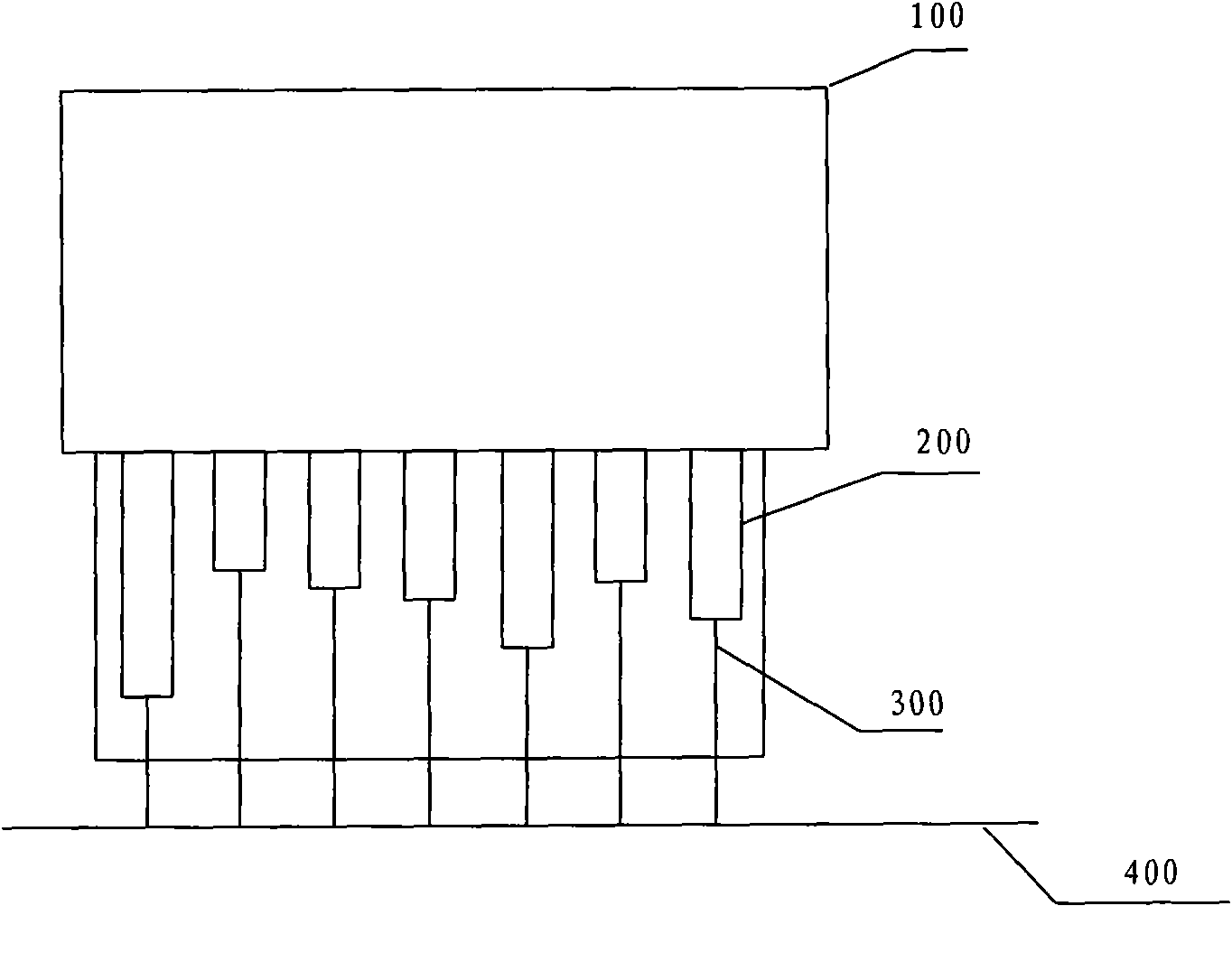

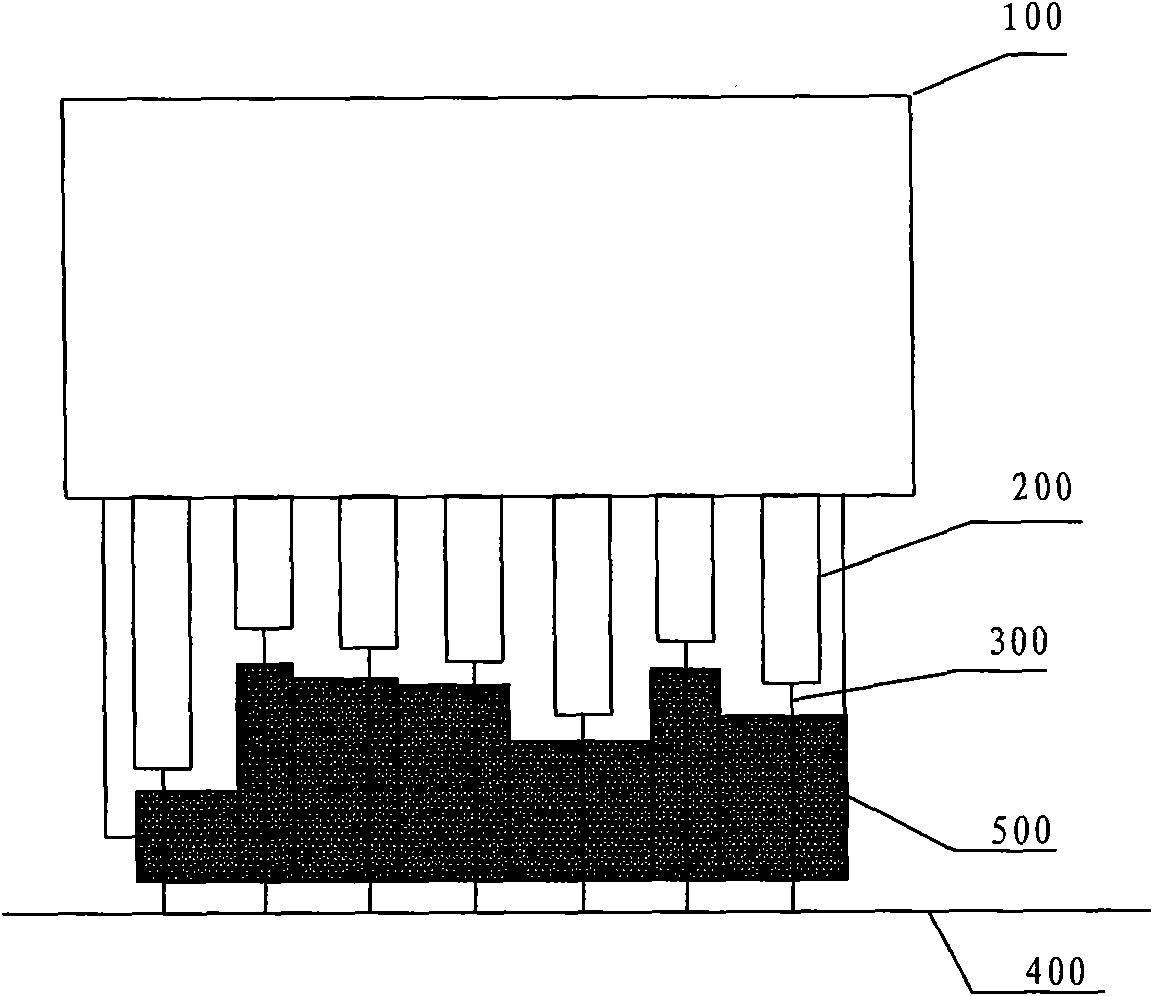

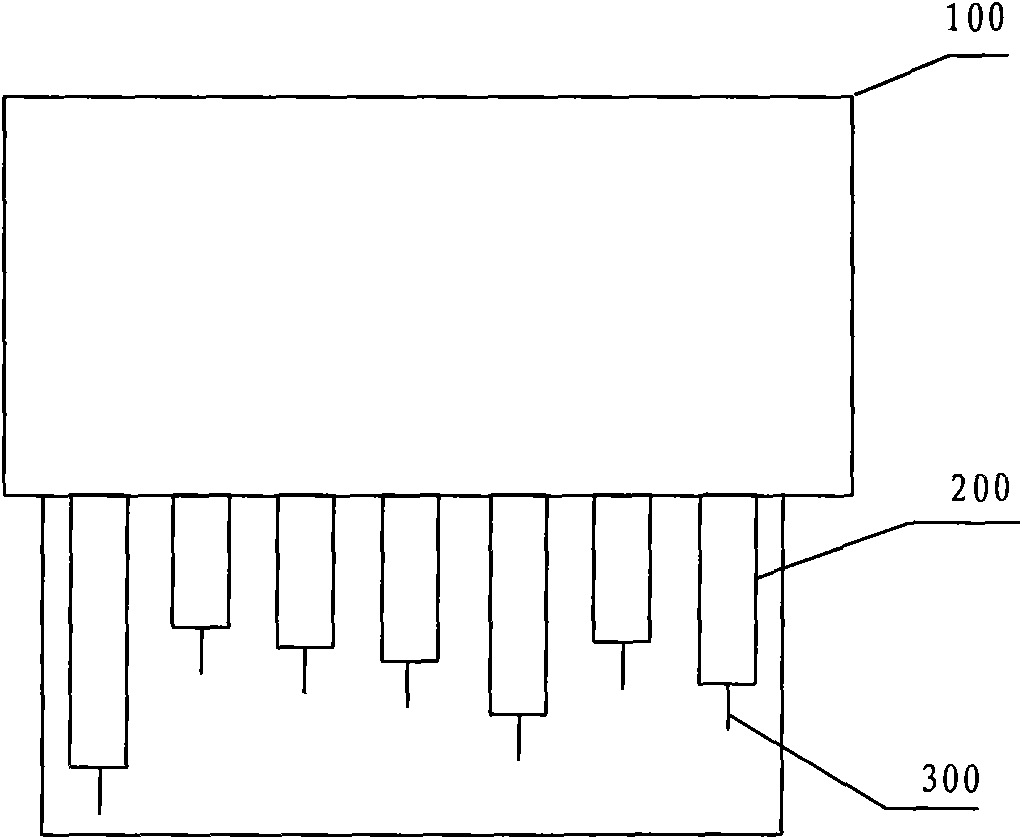

The invention discloses a method for manufacturing a printed circuit board edge connector, relates to the field of manufacturing process for a printed circuit board, and can solve the residue problemsof an edge connector plating lead of the printed circuit board. The method for manufacturing the printed circuit board edge connector comprises the following steps: forming the edge connector platinglead and an edge connector area on the printed circuit board once, wherein the width of adjacent parts of the edge connector plating lead and the edge connector area is equal to the width of the edgeconnector area; coating a covering substance to form an edge connector plating reserved area, and plating the edge connector plating reserved area to form the edge connector; and removing the covering substance, and etching the edge connector to obtain the edge connector without the plating lead. The method is suitable for manufacturing the edge connector without the lead for the printed circuitboard.

Owner:NEW FOUNDER HLDG DEV LLC +2

Method for extracting peony essence from fresh peony flowers

ActiveCN103305344APreserve the spice ingredientsRetain activityEssential-oils/perfumesBiotechnologyOrganic solvent

Owner:HEZE YAO & SHUN PEONY BIOTECH

Polyurethane synthetic leather cleaning production process based on direct coating method

ActiveCN102758359ASolve pollutionSolve residual problemsLamination ancillary operationsLaminationSurface layerSolvent free

The invention provides a polyurethane synthetic leather cleaning production process based on a direct coating method. The process comprises the steps of firstly spraying mixed double-component solvent-free polyurethane a nonwoven fabric or a knitted fabric through a reciprocating way of a spraying head by utilizing a double-spraying head material feeding machine, scrapping through a double-cutter scrapping machine so as to form a film, then drying and ageing the film through an oven, and ironing through a passing type roller ironing machine, thus forming a bottom layer having a plurality of holes and a flat surface on the nonwoven fabric or the knitted fabric; then coating waterborne polyurethane size on the upper face of the polyurethane bottom layer in a rolling coating way by utilizing a rolling coating machine, wherein the waterborne polyurethane size contains waterborne polyurethane, thickener and flatting agent; then drying through an oven so as to form a flat and smooth waterborne polyurethane surface layer; and finally embossing the upper face of the coating through a passing type roller type embossing machine, and levelly coating aqueous surface treating agent through a rotating type coating machine, thus obtaining the finished product of synthetic leather.

Owner:HENAN YONGHE PLASTIC

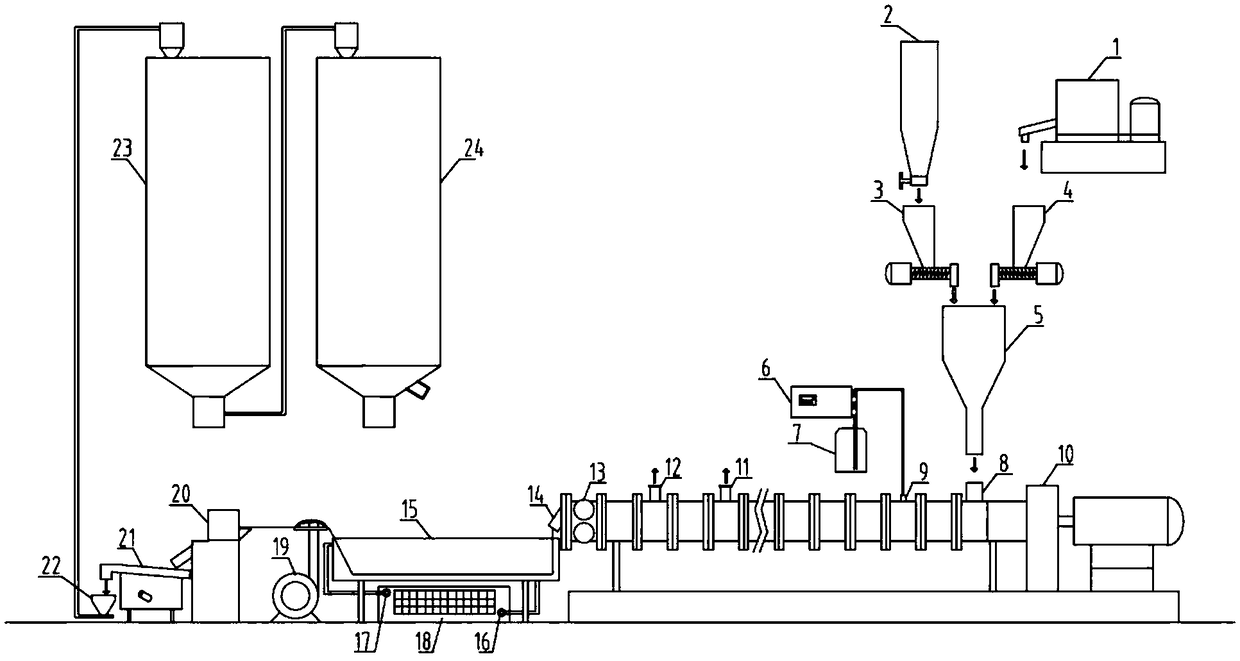

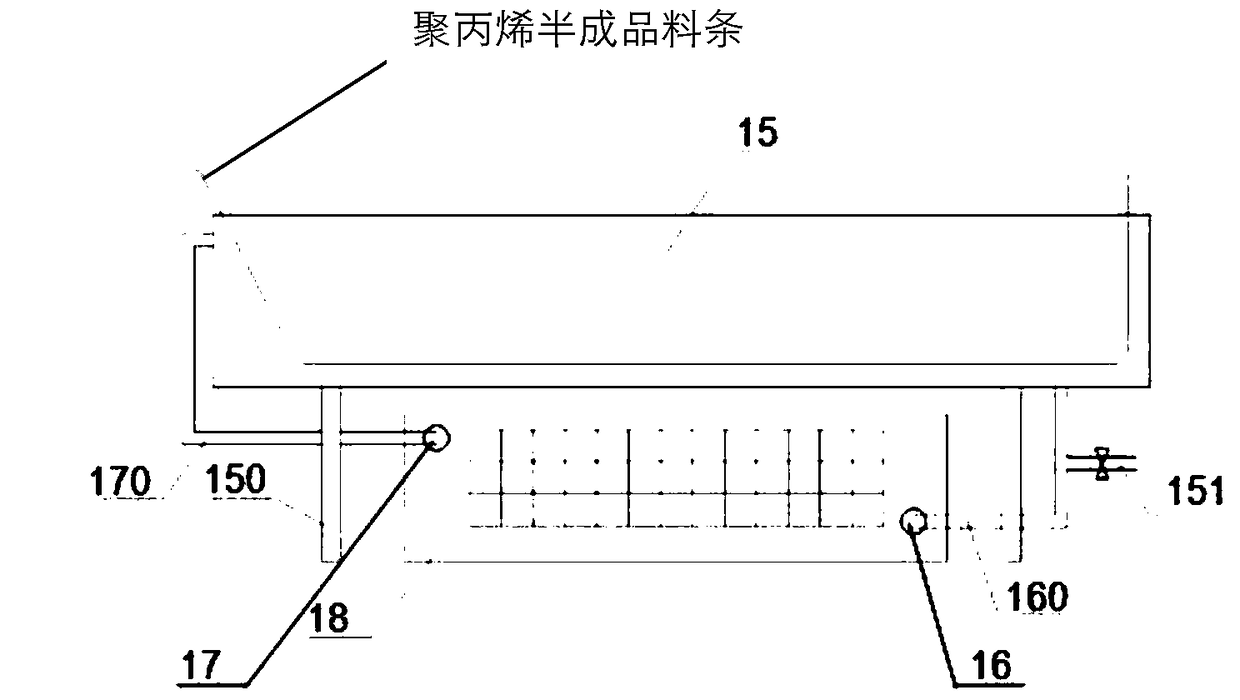

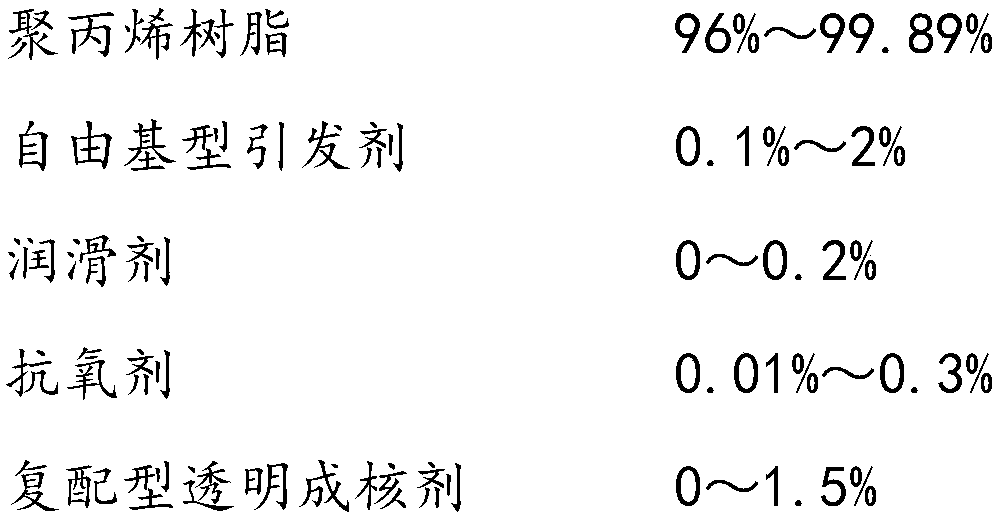

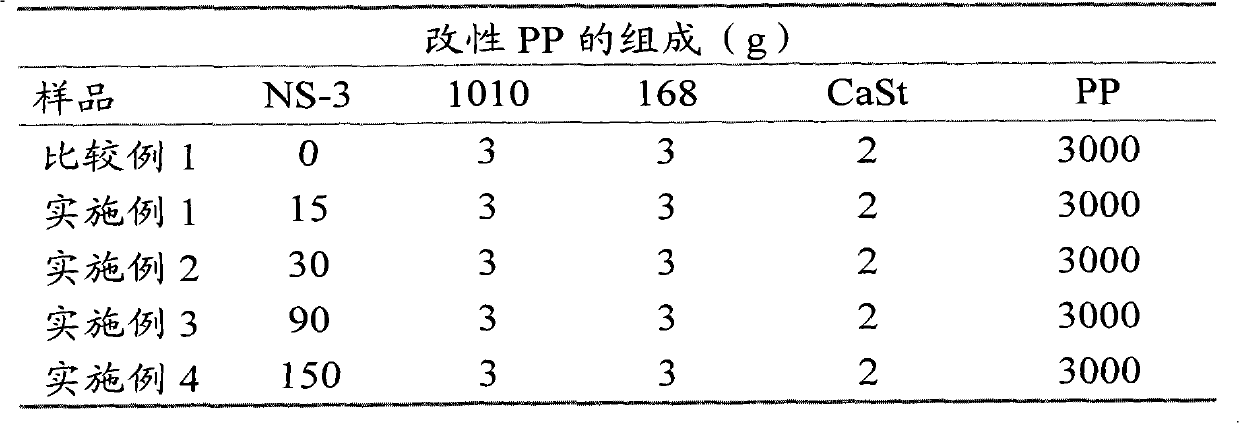

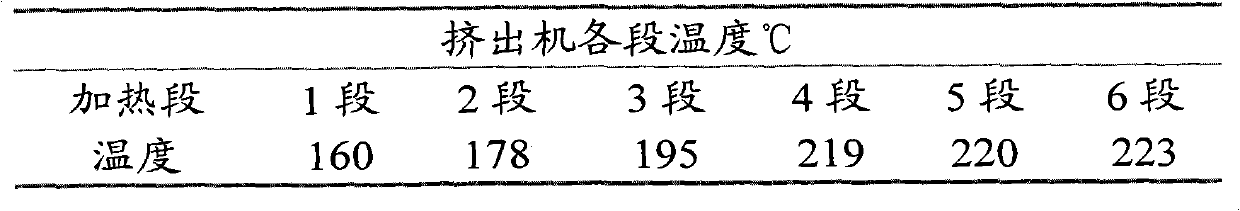

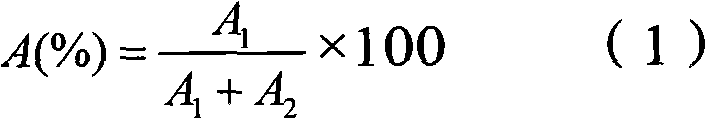

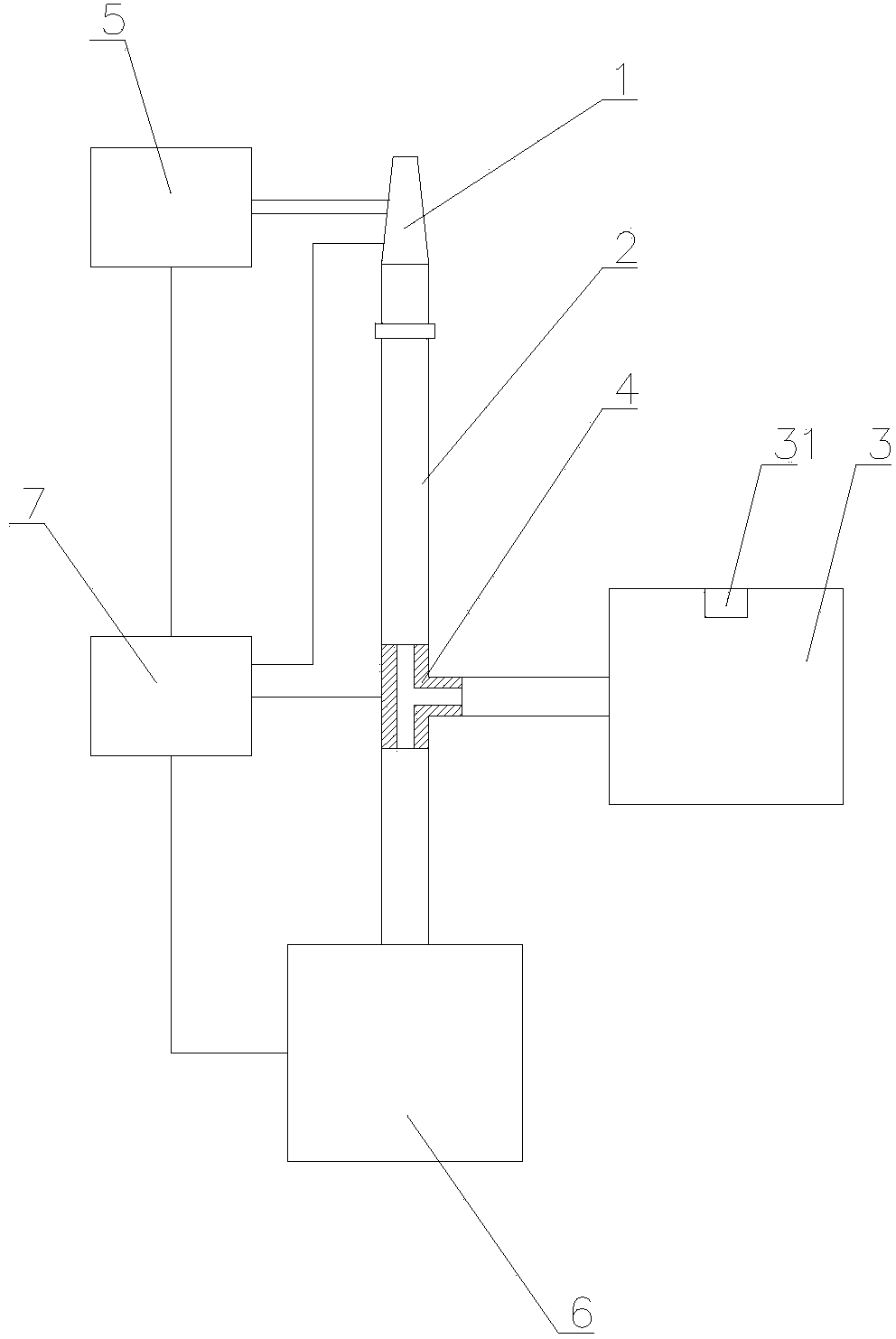

Low-odor high-transparency ultrahigh flowability polypropylene as well as preparation device and method thereof

The invention discloses low-odor high-transparency ultrahigh flowability polypropylene which comprises the following components in percentage by mass: 96-99.89% of a polypropylene resin, 0.1-2% of a free radical form initiator, 0-0.2% of a lubricant, 0.01-0.3% of an antioxidant and 0-1.5% of a compounded transparent nucleating agent. Due to adoption of the compounded transparent nucleating agent which is sufficiently reacted with the polypropylene resin, the initiator, the lubricant and the antioxidant synergistically, the ultrahigh flowability polypropylene which is high in transparency, lowin yellow index and low in haze is prepared. In addition, the invention further discloses a completely novel preparation device and process of the low-odor high-transparency ultrahigh flowability polypropylene. The transparency, the low odor and the low volatilization of the product in the preparation process can be further improved on the basis of a completely novel formula, the product can be prepared by using a one-step method, large-scale popularization and production in factories can be implemented, meanwhile, the problem of small molecule residues in the product is also solved to a largeextent, and aftertreatment processes of non-woven fabric manufacturing companies can be simplified.

Owner:大韩道恩高分子材料(上海)有限公司 +1

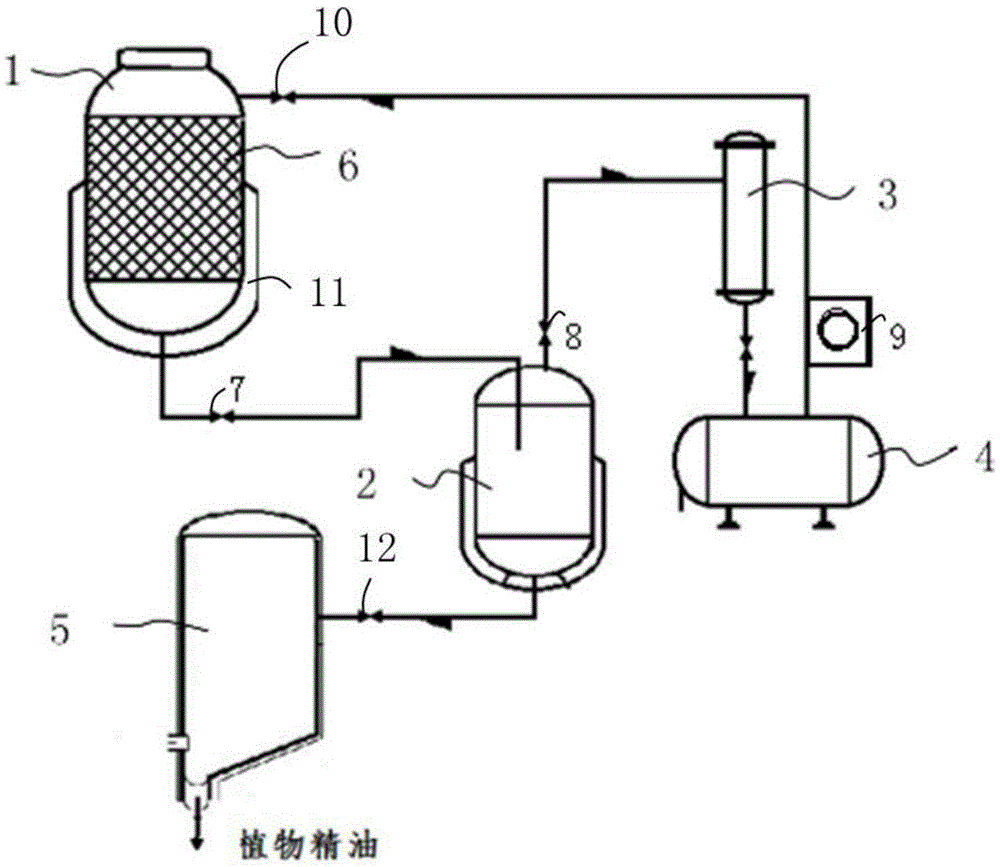

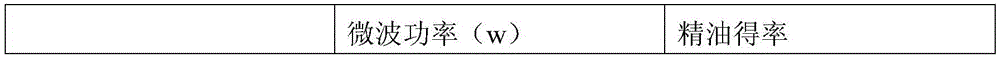

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

Method for extracting antarctic krill grease and separating biological active substance

InactiveCN102676291ARealize comprehensive utilizationHigh extraction rateFatty oils/acids recovery from wasteFatty-oils/fats productionSolubilityOrganic solvent

The invention discloses a method for extracting antarctic krill grease and separating other biological active substances, and belongs to the technical field of deep processing of marine food products. Aiming at the characteristics that the water content of antarctic krill is high and the antarctic krill is easy to autolyze, the grease can be directly extracted from the frozen antarctic krill at low temperature by using hydrophobic and hydrophilic mixed solvents; a salt solution and a common organic solvent are added into residues and an organic solvent / salt multi-phase salting-out extracting system is formed by using salting-out extracting effect; the distributions of biological active substances with different polarities in the antarctic krill in each phase are different according to a solubility difference; and furthermore, the residual grease is extracted to obtain astaxanthin; and shrimp meat proteins are separated and the solvents in the residues are recycled. The method disclosed by the invention is simple in operation and easy to realize, and has low cost, short period and moderate extracting conditions, and the organic solvents are cheap and easy to recycle, so that the method is easy to industrialize.

Owner:DALIAN UNIV OF TECH +1

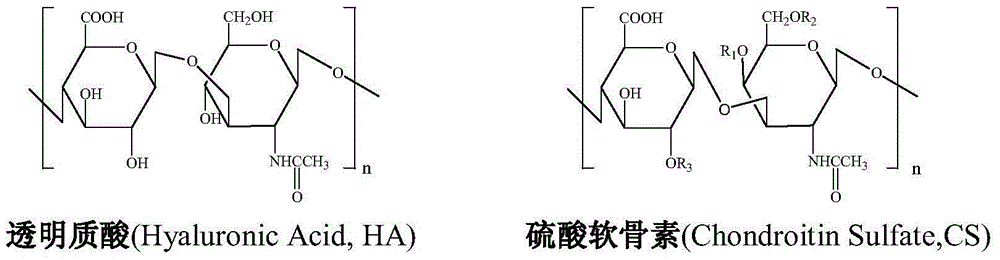

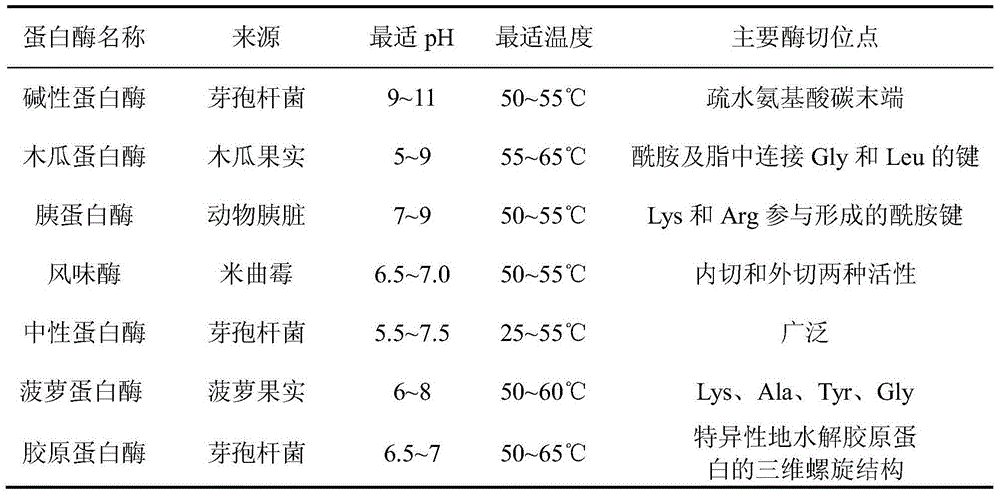

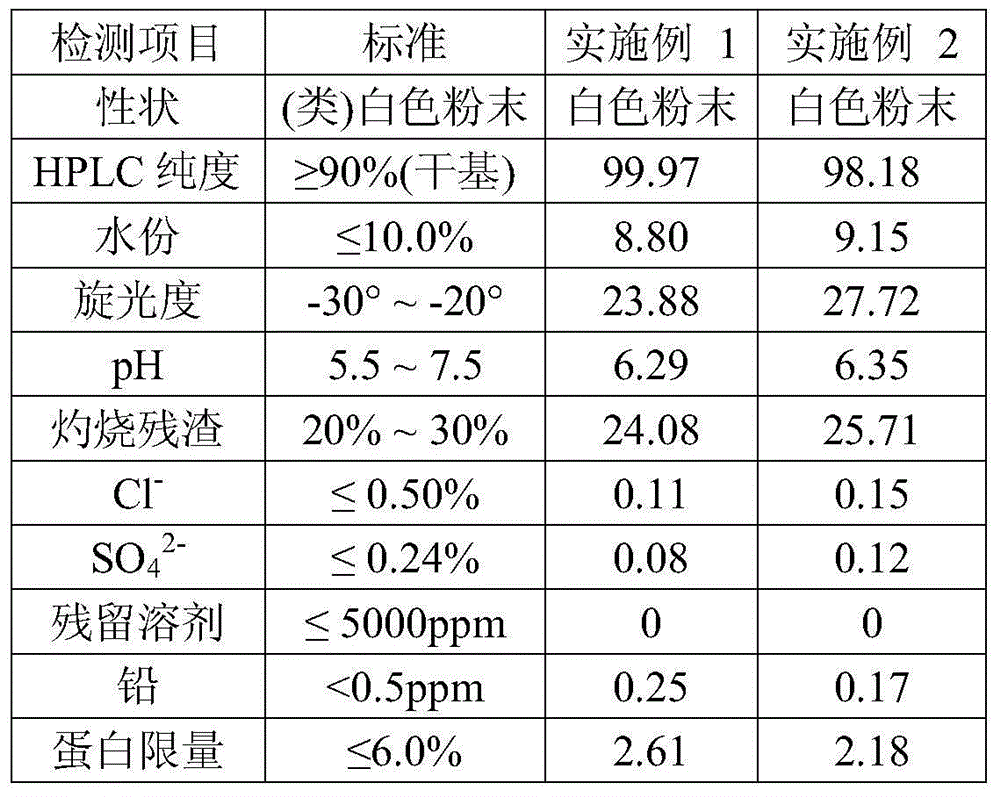

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Polyurethane synthetic leather cleaning production process based on release paper transfer coating method

ActiveCN102758360ASolve pollutionSolve residual problemsSynthetic resin layered productsLaminationProduction lineSolvent free

The invention provides a polyurethane synthetic leather cleaning production process based on a release paper transfer coating method. The process comprises the steps of firstly scrapping a top layer coating on a release paper; and then treating the release paper with a waterborne polyurethane coating at the top layer through dry-type production line which is provided with a multi-spraying head material supplying system and a multi-cutter scraping machine, coating the double-component solvent-free polyurethane on the upper face of the waterborne polyurethane coating through the multi-spraying head material supplying system; and finally jointly adhering the release paper with the solvent-free double-component polyurethane intumescent coating and a nonwoven fabric or a knitted fabric, and preparing into semi-finished product by pre-ageing in a parching channel, and then transferring the semi-finished product into a multi-layer folding ageing box for ageing, and finally separating the synthetic leather from the release paper so as to obtain the environment-friendly polyurethane synthetic leather. The polyurethane synthetic leather produced by the production process provided by the invention has a three-layer structure in which the surface is the waterborne polyurethane coating, the middle is the solvent-free double-component polyurethane intumescent coating, and the lower face is the nonwoven fabric or the knitted fabric.

Owner:HENAN YONGHE PLASTIC

Edible insect full-powder and the production process and application thereof

InactiveCN101116472ARich varietyIncrease the number ofAnimal proteins working-upAdditive ingredientInternational market

The present invention relates to a method to fabricate a full edible insect powder, with the main raw material as the edible insects with the represent of the flour weevil, the cicada, the cryptympana atrata, the locust and the silkworm pupa. The exploited products in both domestic and international markets at present include the specific animal feeds and the dishes of edible insects, as well as the animal feed made from a certain amount of raw materials of insects. The present invention aims to exploit a full edible insect powder as well as the fabrication method and application thereof to accomplish the industrialized production with a large scale. The technical proposal is that the insects which undergoes both elimination of foreign bodies, toxins and cleaning up in the latter phase of cultivation are killed, dehydrated, roasted, (or dried through refrigeration) dried and refrigerated in vacuum, and then smashed and filtrateed to be the final product. The effect of the present invention is that the full insect powder contains all nutritious elements thereof, including proteins, lipids, vitamins and various trace elements. The present invention has unique characteristic, safety without toxins, wide application fields, feasibility to be the nutrition of serious snacks, and feasibility to be the stuffing of food of various cakes and candies.

Owner:西安市轻工业研究所

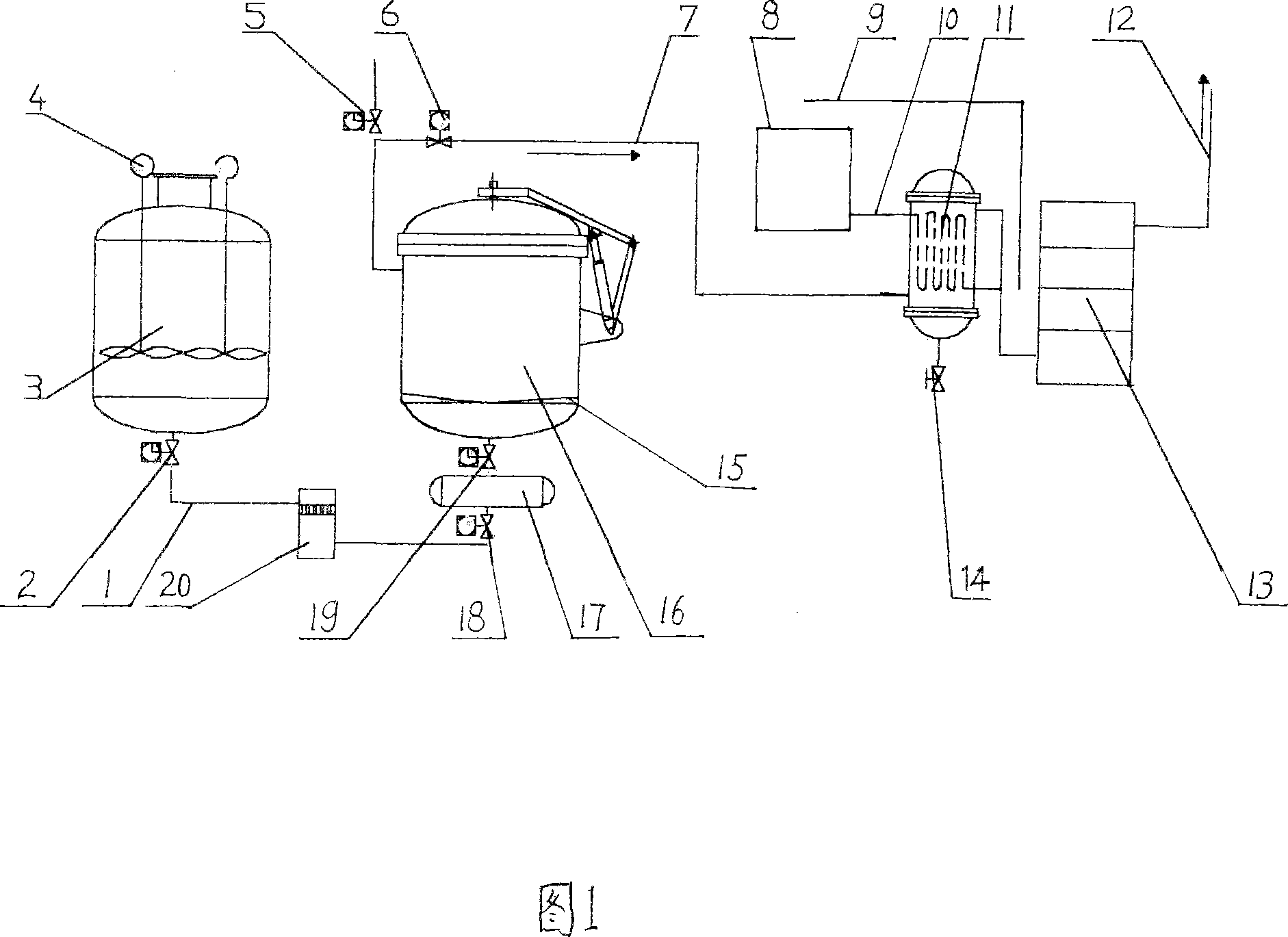

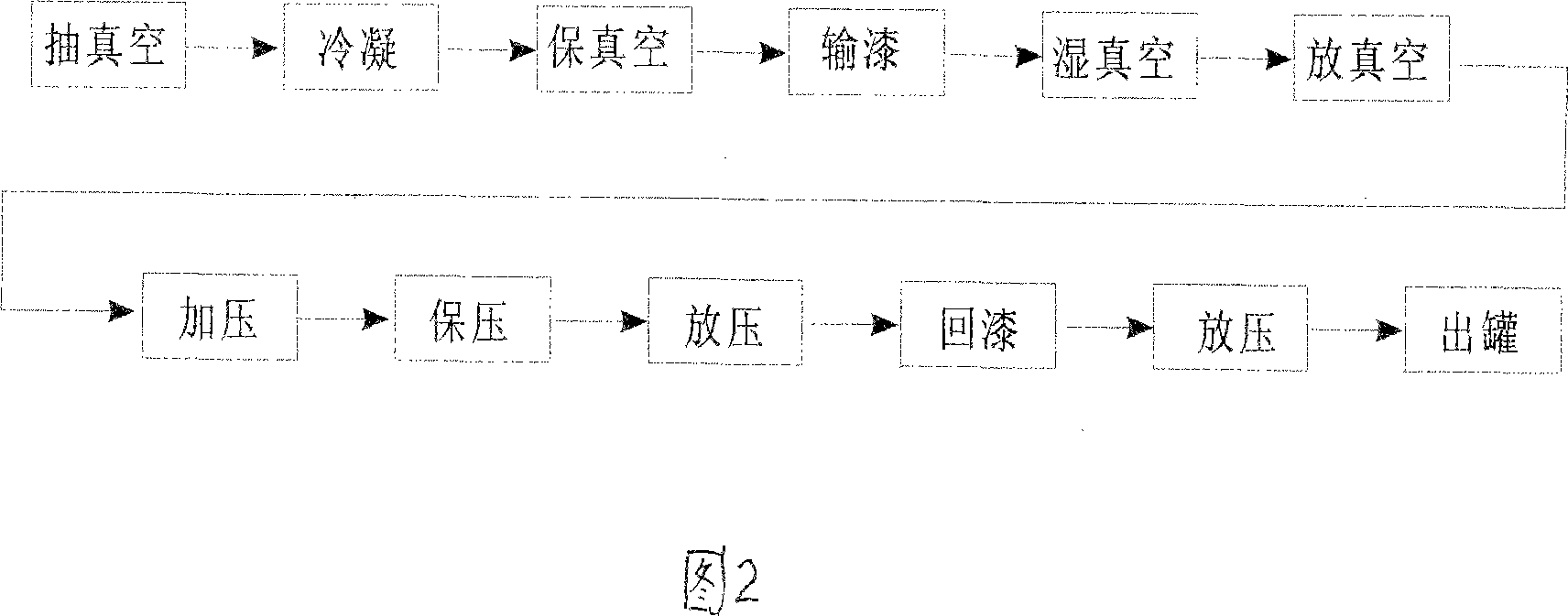

Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

InactiveCN101064456ASave raw materialsSmall dielectric lossLiquid surface applicatorsManufacturing dynamo-electric machinesSolventVacuum pressure

The invention relates to explosion-proof vacuum pressure impregnated insulation device and its process which is used in high-tension motor winding loop impregnated insulation paint, it characterized in that: condensator connected with refrigerator is set on the vacuum tube between the impregnating vessel and vacuum set, and collecting vessel is set on bottom of the impregnating vessel, one end of the collecting vessel is connected with the impregnating vessel, the another end is connected with the paint pipelines of storing vessel via transferring valve and returning valve. Using the device and the process, the remained insulation paint and dissolvent in the impregnating vessel can be solved, when the vacuum set vacuumizes the impregnating vessel, the explosive fuel phenylethene deflocculating agent can not be sucked to the vacuum set to gel and jam, it possesses practical effects of explosion-proof, safe reliability, saving raw material.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Spray-filmed composite material for fruit and vegetable or crop bagging, as well as preparation and application thereof

ActiveCN106172400AHas insect and disease resistanceEasy to useBiocideDead animal preservationDiseaseSide effect

The invention discloses a spray-filmed composite material for fruit and vegetable or crop bagging, as well as preparation and application thereof, and belongs to the field of functional composite materials and fruit and vegetable or crop bagging. The material is prepared from the following components in parts by mass: 5-30 parts of a film-forming substance, 58-94 parts of a dispersing agent, 1-10 parts of a pesticide-loading reinforcing material, 0.1-2 parts of an insect-proofing disease-resisting agent and 0-0.1 part of dye. The material has multiple colors and excellent insect-proofing disease-resisting performance, can be adhered to the surface of fruits and vegetables or crops to form a film to achieve the aim of bagging, does not influence growth of the fruits and vegetables or crops, does not have toxic or side effect, and can sustainably release insect-proofing disease-resisting substances. The material is simple in preparation method and low in raw material cost, can be used for replacing pesticide to solve the problem of pesticide residue, can be used for producing green organic foods, has long acting duration for 1-3 months, and can be used for preventing insects and resisting diseases for fruits, vegetables, crops, flowers, woods and the like.

Owner:SOUTH CHINA AGRI UNIV

Methanol gasoline heat value agent

InactiveCN101619250ASolve cold start difficultiesEasy to startLiquid carbonaceous fuelsAlcoholCombustion

The invention relates to a methanol gasoline heat value agent, belonging to the field of alcohol gasoline alternative fuel additives, and comprising the following components by weight percent: 2 percent to 4 percent of combustion catalyst, 2 percent to 4 percent of eduction agent, 83 percent to 90 percent of methanol heat value agent and 5 percent o 9 percent of gasoline heat value agent. The invention has the advantages of simple preparation, low cost, wide sources and the like, emphasizes on solving the problem that power of an engine is influenced by the descending of the heat value of methanol gasoline, and changes the difficulty of cold start of the methanol gasoline. Through a bench and road test, the use performance of the methanol gasoline after adding the heat value agent is close to burning commercial gasoline, is superior to the methanol gasoline of the same grade without adding the heat value agent, and the methanol gasoline after adding the heat value agent has equal oil consumption and power of agent with the burning commercial gasoline, better cold starting performance and acceleration quality than the commercial gasoline and lower pollution discharge than the commercial gasoline. The heat value agent has obvious effects on enhancing the heat value of the methanol gasoline and the power of the engine and easy cold start, and opens up a new path for all-round popularization with high ratio and large area of the methanol gasoline.

Owner:占小玲

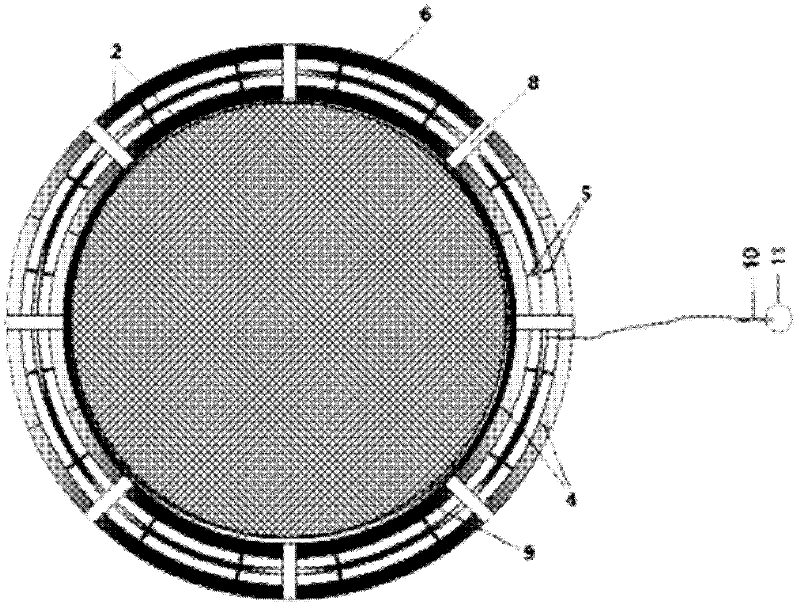

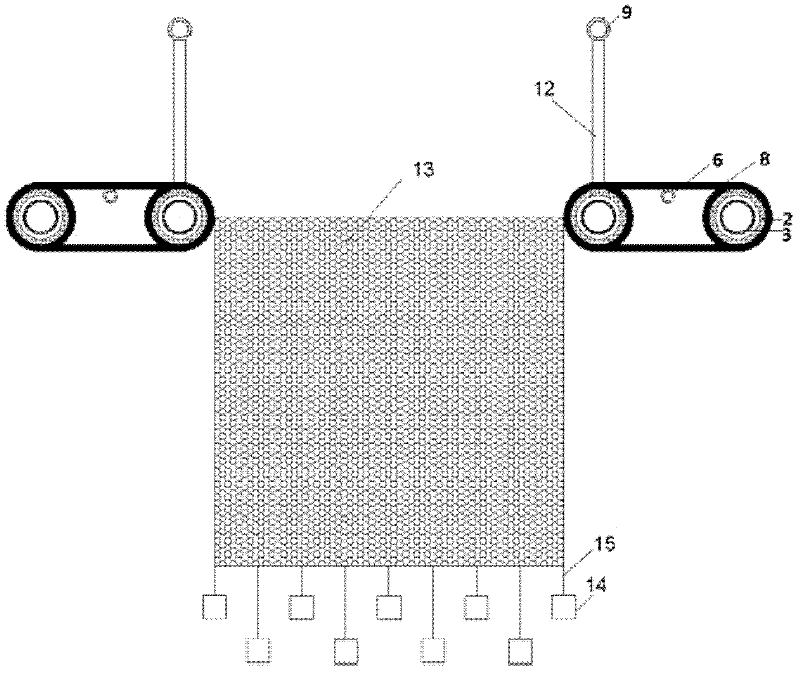

Lifting net box with inner liner and lifting support system of lifting net box

InactiveCN102640715AForce balanceImprove stabilityClimate change adaptationPisciculture and aquariaSupporting systemSiphon

The invention relates to a lifting net box with an inner liner and a lifting support system of the lifting net box. The invention consists of two parts: the net box with the lifting function and the lifting support system, wherein the net box is provided with the telescopic inner liner and mainly comprises a floating pipe, the inner liner, a separation plate, a ventilation main pipe, a ventilation hose, an air distribution pipe, a water communication pipe, a safety cap and the like, and the lifting support system mainly comprises an air pump, a communication pipe, an exhaust pipe, a valve, a flow rate distributor, an air distribution joint and an air pressure meter. The lifting support system on the sea level is connected to the ventilation main pipe through the ventilation hose and is then connected to the inner liner arranged in the floating pipe of the net box through the air distribution pipe, the inner liner can expand and contact under the effect of the air pump, a water body in the floating pipe is discharged when the inner liner expands, the upward floating of the net box is realized, the water body outside the net box enters the floating pipe from the water communication pipe through the siphon effect when the inner liner contacts, the downward sinking of the net box is realized, and the downward sinking is automatically stopped when the net box sinks down to a degree that a sinking element suspended at the bottom of a fishing net is in contact with the sea bed.

Owner:SHANGHAI JIAO TONG UNIV

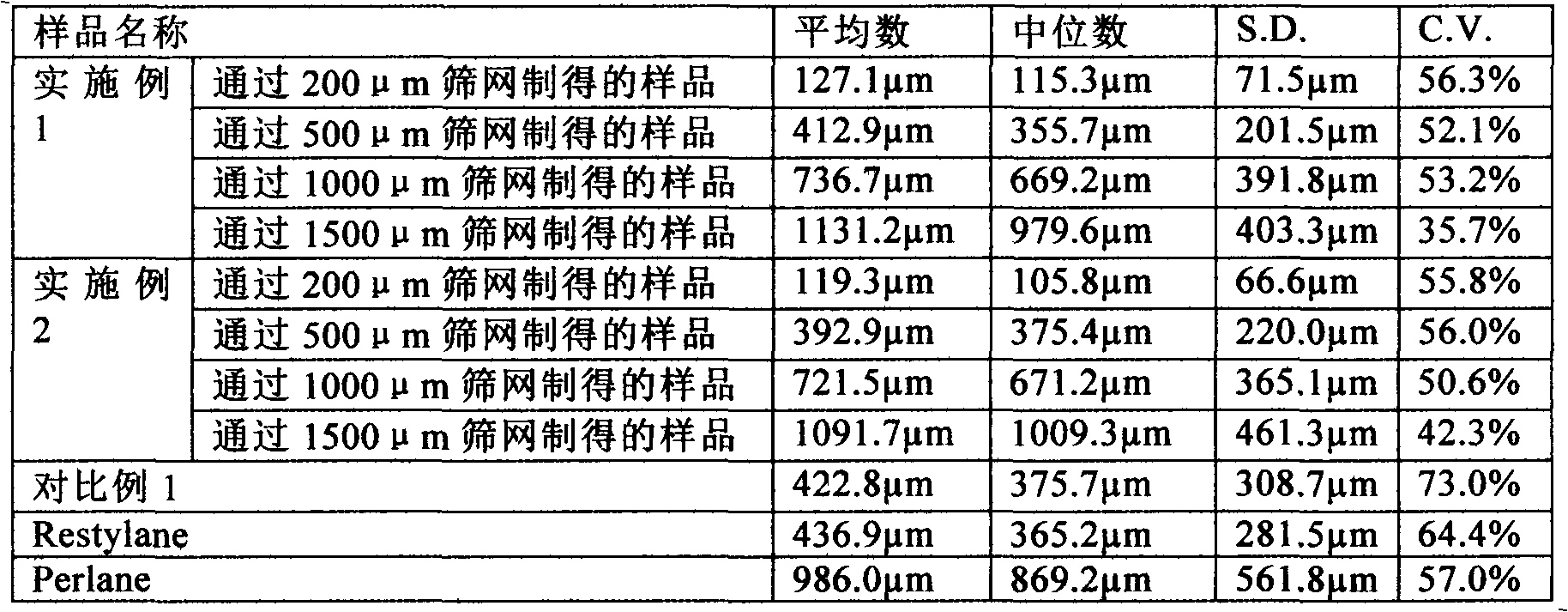

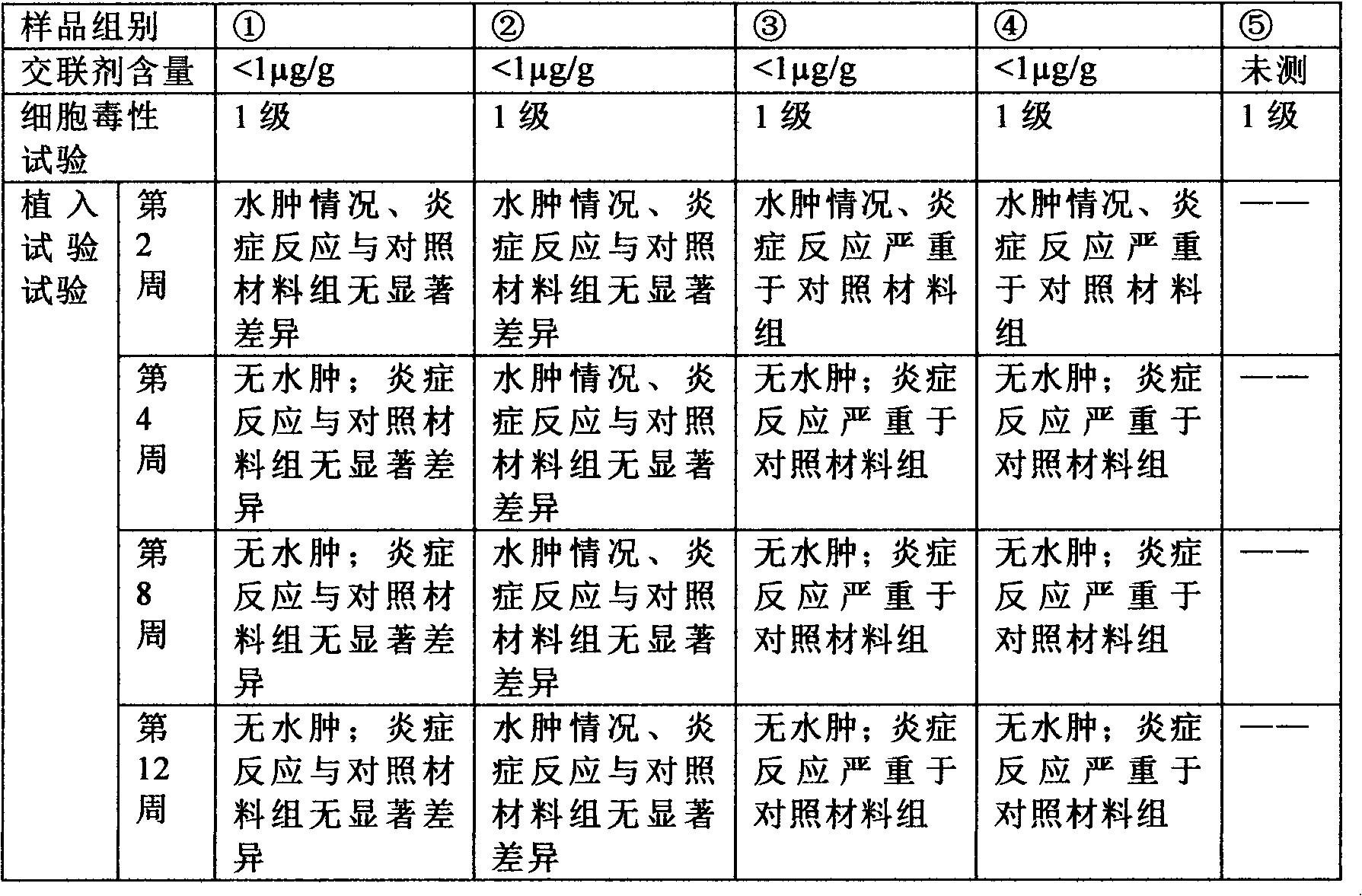

Gel composition for injection filling of skins and preparation method for gel composition

The invention discloses a method for preparing a gel composition for injection filling of skins. The method comprises the following steps of: performing cross-linking reaction on a hyaluronic acid raw material and a cross-linking agent to obtain a gel block, and cleaning and dialyzing the gel block; freezing the dialyzed gel block into a gel ice block, crushing by using a micro-pulverizer, and collecting gel ice particles with different particle size ranges by using a series of mesh sieves with different apertures; and swelling the gel ice particles with different particle size ranges by using a weakly alkaline hyaluronic acid solution respectively so as to close a residual free-state end of the cross-linking agent, and adding an acid solution to obtain the gel composition of which the pH value is within a physiologically acceptable range. By the method, the problem about the residue of the cross-linking agent of which one end is in a bonding state and the other end is still a free-state functional group after cross-linking reaction is solved; and the microgel composition with different particle size levels can be obtained by a simple preparation process so as to be suitable for the injection on different layers of the skins and achieve the beauty effects of filling, removing wrinkles and repairing depressions.

Owner:上海白衣缘生物工程有限公司

Preparation method and application of hydroxysafflor yellow A

ActiveCN102702150AReduce lossesReduce moisture contentOrganic chemistryChromatographic separationFreeze-drying

The invention discloses a preparation method for extracting, separating and purifying hydroxysafflor yellow A from a Chinese medicinal material safflower at high yield and purity. The method comprises the following steps of: performing ultrasonic water extraction on the safflower medicinal material, separating by using HZ801 macroporous adsorption resin, performing LH-20 sephadex chromatographic separation, performing ultrafiltration, and performing freeze drying. The content of the prepared hydroxysafflor yellow A dry powder is 99.8 percent, and the yield of the hydroxysafflor yellow A is 62.7 percent.

Owner:ZHEJIANG YONGNING PHARMA

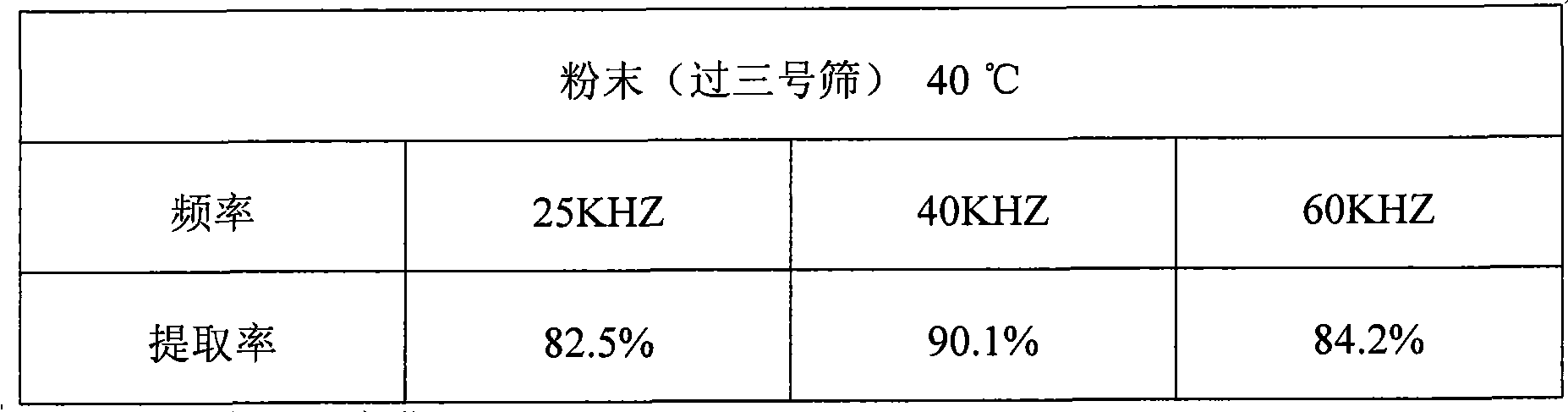

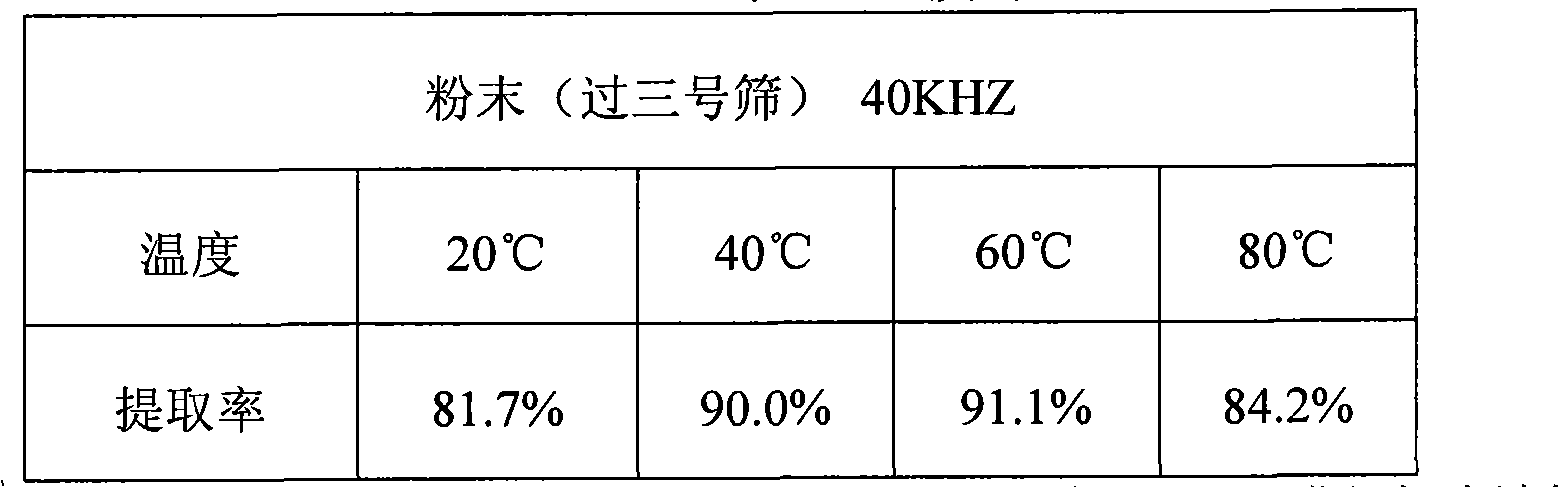

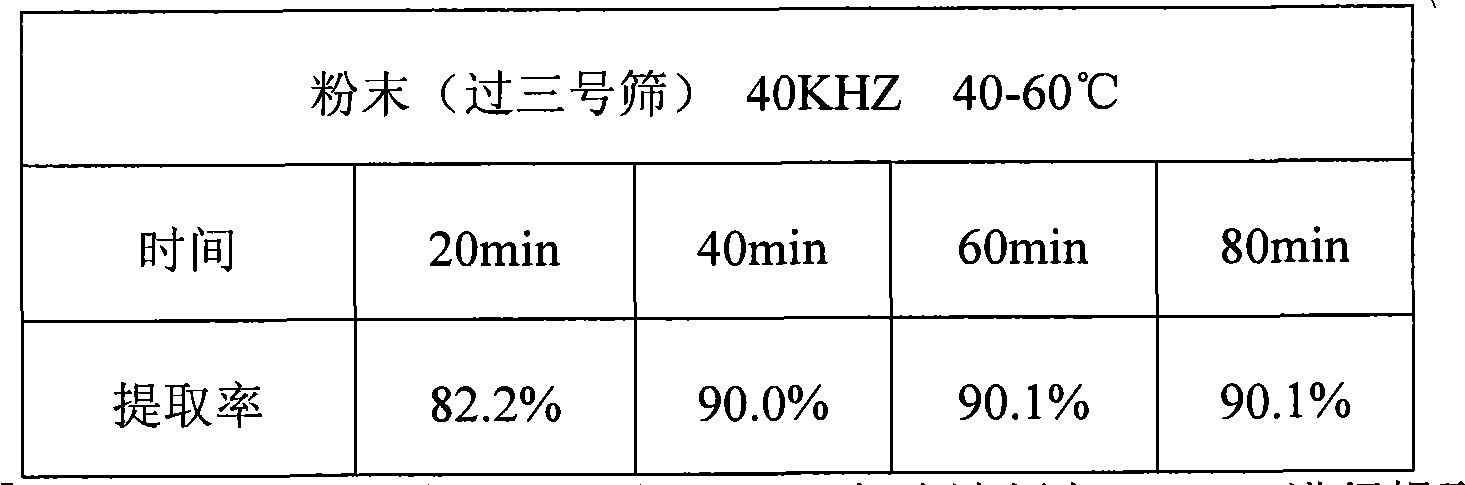

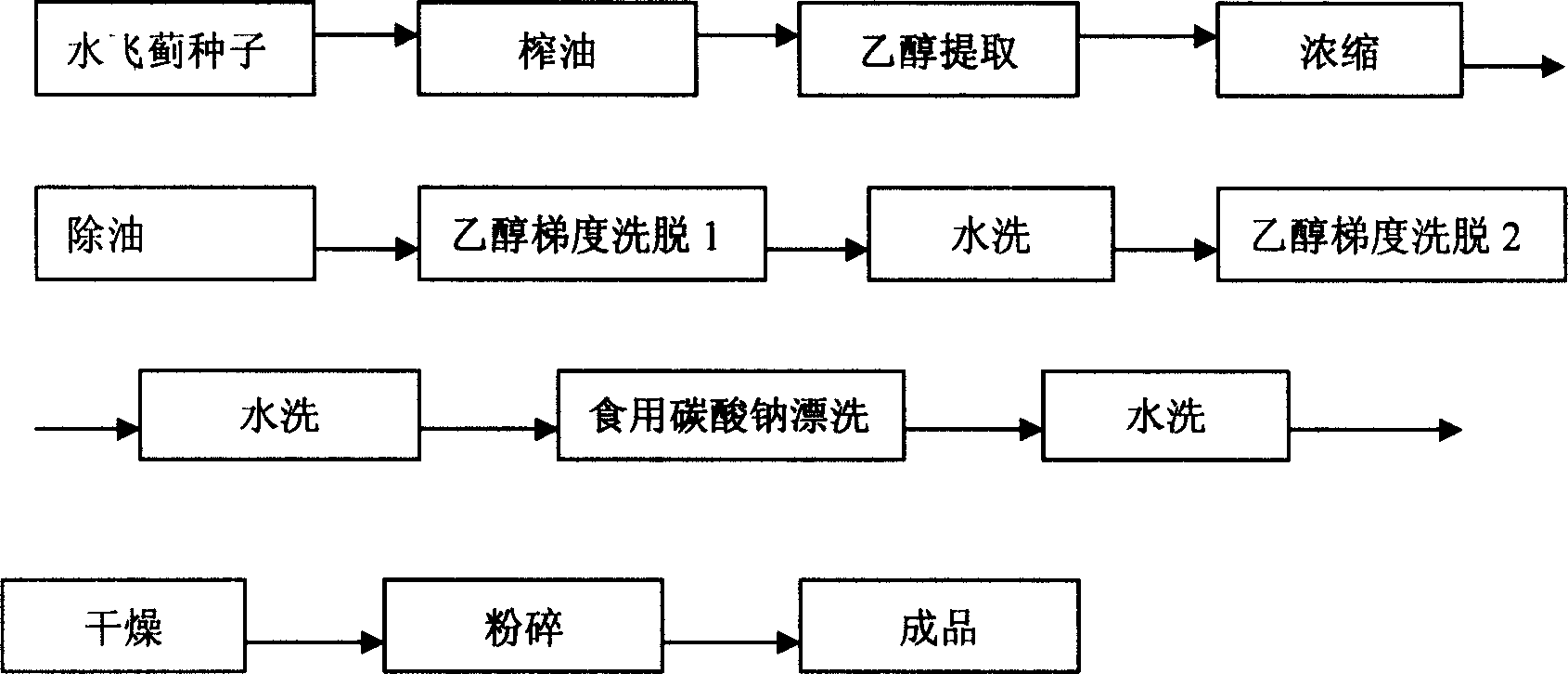

Process for extracting water grind thisvine using alcohole as single organic dissolvent

The invention discloses a process of extracting silymarine by using alcohol as a single organic solvent, adopting edible alcohol to extract silymarine, then adopting alcohol and water to wash twice so as to eliminate oil and impurities, using edible sodium carbonate for elution, drying the silymarine solids obtained by fulling and then crushing and obtaining the final product, where by the UV determination, the total flavone content in the silymarine has mass percent concentration of 70%-90%, the product yield is 2-3% of the quantity of silymarine seeds from which the oil has been extracted. It solves the problem of harmful solvent residues in current silymarine products, and it can obtain the silymarine products without harmful solvent residues.

Owner:XIAN UNIV OF TECH

Fence preservation method for prolonging shelf life of cold fresh poultry

InactiveCN101990930AAntibacterialImprove freshnessMeat/fish preservation using chemicalsBiotechnologyCold chain

The invention discloses a fence preservation method for prolonging shelf life of cold fresh poultry. The fence preservation method for prolonging the shelf life of the cold fresh poultry comprises the following steps of: placing fresh poultry which is obtained by slaughtering, washed completely and cut into a refrigeration storage at the temperature of between 2 and 5 DEG C and precooling the poultry for 1 to 2 hours, so that the surface temperature of the poultry is reduced below 5 DEG C and the internal temperature of the poultry is reduced below 10 DEG C; transferring the precooled poultry to a purification room and performing surface sterilization on the poultry through ozone or ozone solution of an ozone generator; immersing the poultry subjected to ozone sterilization into chitosan glutamate solution to retain freshness; taking out and draining the poultry; placing the poultry after corrosion prevention and freshness preservation into a food plastic packaging box; introducing carbon dioxide (CO2) and nitrogen (N2) into the food plastic packaging box and performing sealing package; and storing the packaged poultry into a cold chain at the temperature of between 2 and 5 DEG C. The fence preservation method for prolonging the shelf life of the cold fresh poultry has good effect and is suitable for retaining freshness of the fresh cut poultry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

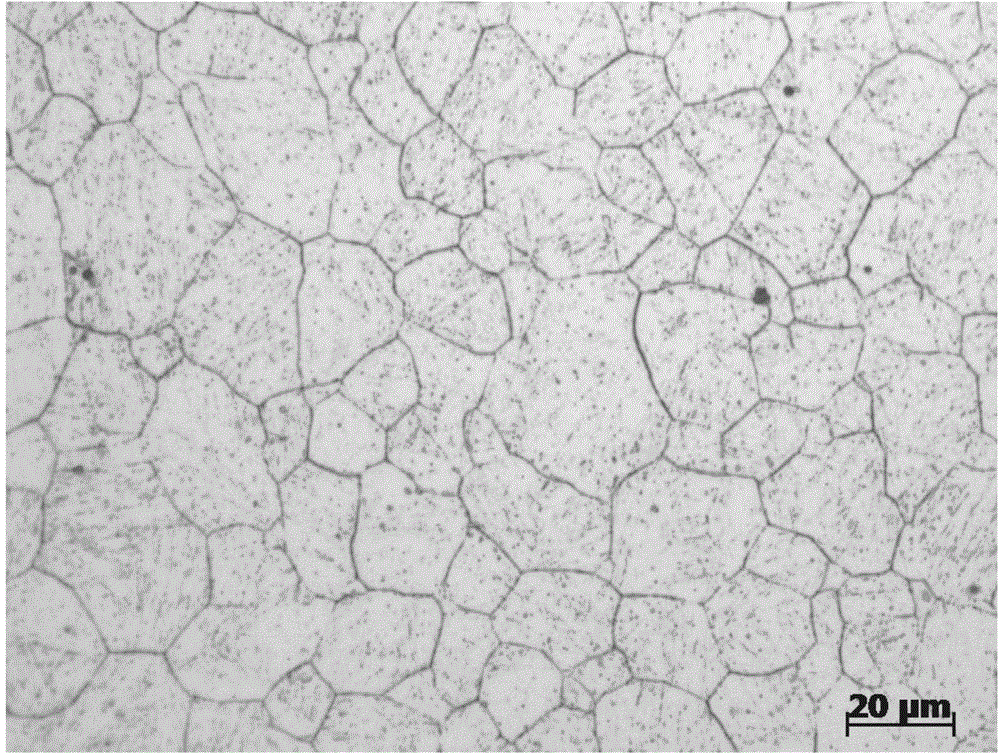

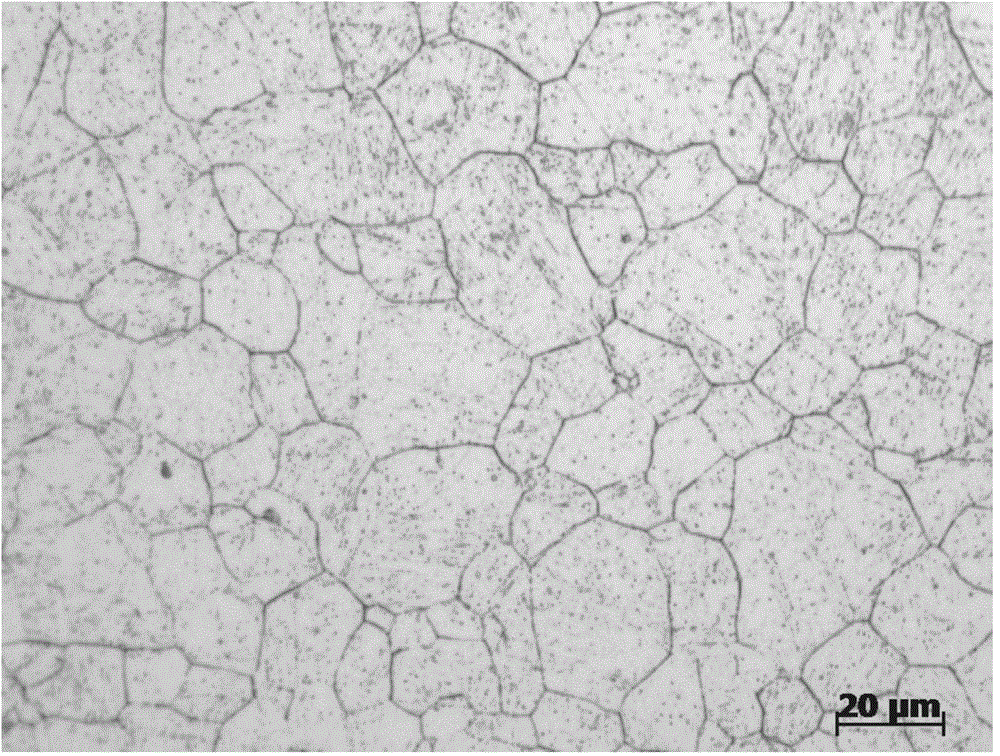

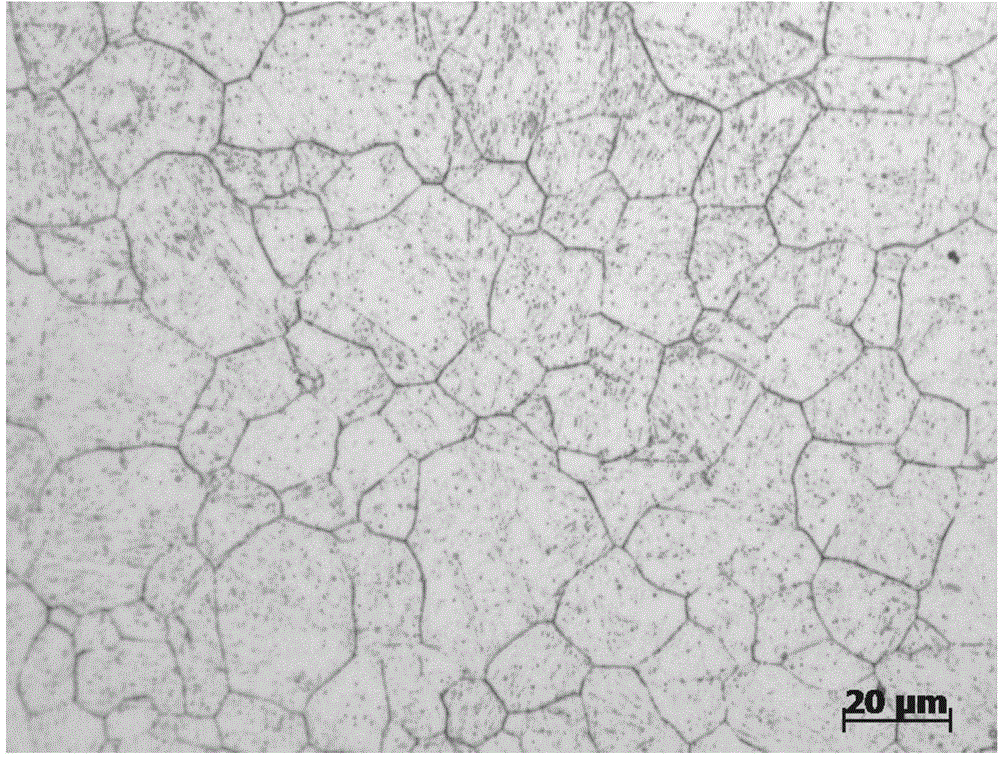

Method for displaying original austenite grain boundaries of maraging stainless steel

InactiveCN104483179AEffective displayDisplay clear and completePreparing sample for investigationMetallic material coating processesElectrolysisEtching

The invention provides a method for displaying original austenite grain boundaries of maraging stainless steel. The displaying of the original austenite grain boundaries is completed by three steps, namely, preparing a sample, carrying out passivation treatment with concentrated nitric acid and carrying out electrolytic etching with concentrated nitric acid. The method comprises the following steps: firstly preparing the sample, grinding and polishing one surface of the sample and grinding the other surfaces of the sample; placing the polished sample in 55-65% (volume fraction) aqueous nitric acid solution and carrying out passivation treatment for 3-5 minutes; carrying out electrolytic etching on the sample at room temperature for 3-5 minutes by adopting stainless steel sheet as a cathode and the passivated sample as an anode at the electrolytic voltage of 5-8V; after the electrolysis, completely rinsing the sample with tap water, rinsing the sample with alcohol and carrying out blow-drying and then observing the clear and complete microstructure-interference-free original austenite grain boundaries under the microscope. The method has the advantages that after the passivation treatment, the grain boundaries are preferentially displayed as compared with microstructures; no residual etching products are caused; the voltage is relatively low and the etching end point is easy to control.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Waterborne polyurethane decorative leather and manufacturing method thereof

The invention provides waterborne polyurethane decorative leather and a manufacturing method thereof. The manufacturing method includes the steps of 1), performing base cloth treatment; 2), coating; 3), agglomerating; 4), conducting washing and drying, namely removing residual solidification liquid on the base cloth through a washing trough, drying and setting so as to obtain waterborne polyurethane decorative leather base; 5), conducting dry-process direct coating, namely applying the waterborne polyurethane decorative leather base with waterborne direct coating topcoat slurry and drying; 6), subjecting the waterborne polyurethane decorative leather base obtained after dry-process direct coating to high-temperature embossing to shape surface effect grain so as to obtain the waterborne polyurethane decorative leather. The manufacturing method has the advantage that the waterborne polyurethane resin slurry and a waterborne environment-friendly auxiliary are used for enabling the decorative leather to be free of organic solvents during preparation and use, so that the problems of contamination and residues of solvent-type decorative leather are solved. The waterborne polyurethane decorative leather has the advantages of compact structure, less proneness to cracking and wear and flexibility in hand feel and can meet the demands of existing market on the decorative leather completely.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

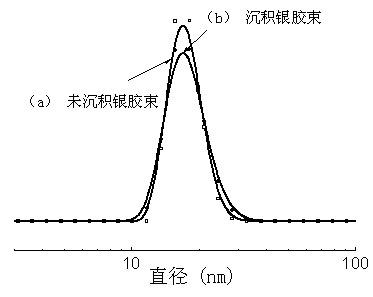

Antibacterial nano silver modified polymeric micelle and preparation method thereof

InactiveCN102671201AEasy to prepareAvoid Solvent Residue ProblemsAntibacterial agentsPowder deliverySelf-assemblyDrug

The invention belongs to the high-molecular nano biomedical materials, and specifically relates to a polymeric micelle in which the antibacterial nano silver is deposited at the core, and a preparation method of the polymeric micelle. Amphiphilic block copolymers form the micelle in a self-assembly manner through a direct dissolution method, and then, nano silver is generated at the core of the micelle in situ. The micelle has biocompatibility and also has certain temperature and pH sensitivity, the core-shell structure of the micelle can package multiple drugs, and simultaneously, with the existence of nano silver, the micelle has the curative effects of sterilization and bacterial inhibition.

Owner:TONGJI UNIV

Method for producing aqueous polyurethane synthetic leather for costume by using physically-foamed pore forming coating technology

InactiveCN102425069AImprove hygieneQuality improvementSynthetic resin layered productsTextiles and paperWater vapor permeabilitySolvent based

The invention relates to a method for producing aqueous polyurethane synthetic leather for costume by using a physically-foamed pore forming coating technology. According to the present invention, a physically-foamed polyurethane coating dry film transferring process replaces the original solvent-based polyurethane wet coagulation coating process, such that the problems of pollution and residue of the DMF solvent are solved; with adopting the aqueous polyurethane dry film transferring process to replace the solvent-based polyurethane dry film transferring process, the solvent pollution problem during the production process is eliminated; the synthetic leather for the costume is washed in hot water, the pore forming agent is lixiviated by the hot water, such that the penetrating pores are formed in the aqueous polyurethane coating of the synthetic leather, the water vapor permeability and the air permeability of the synthetic leather for the costume are improved, and the synthetic leather with the good-sanitary property is obtained; with the method, the DMF solvent recovery apparatus and the DMF solvent recovery process are saved, the production cost is reduced, and the technical process is simplified; when the conventional physical properties and the conventional mechanical properties are met, the water vapor permeability of the synthetic leather for the costume is more than or equal to 1.6 mg / cm<2>.h, and the air permeability of the synthetic leather for the costume is more than or equal to 2500 ml / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

Extraction process of rose essence for cigarette

ActiveCN102851118ANot destroyedSolve residual problemsTobacco preparationEssential-oils/perfumesFlavorDistillation

The invention discloses an extraction process of rose essence for cigarette, falling into the technical field of essence and flavoring extraction technique. The extraction process includes pretreating olive oil; immersing; ultrasonically extracting; filtering; extracting; freezing and concentrating under reduced pressure; and performing molecular distillation. In the extraction process, rose oil in rose leaves can be fully dissolved in the olive oil to improve extraction yield; and the olive oil is extracted by anhydrous ethanol for multiple times before being used to reduce impurities in the rose oil, thereby reducing or eliminating residue in oral cavity resulting from lipoids in essence for cigarette.

Owner:HUBEI CHINA TOBACCO IND +1

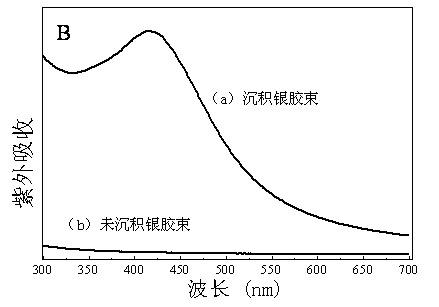

Method for extracting kelp iodine with comprehensive utilization of brown seaweed

ActiveCN101428761ARealize comprehensive utilizationSolve the problem of heavy metal residueHalogen/halogen-acidsBrown seaweedIodine

The invention provides a method for extracting iodine from kelp by comprehensively utilizing brown algae, and can solve the problems in the prior art that heavy metal is remained in the iodine from kelp. The invention adopts the brown algae as raw materials to prepare the iodine from kelp; in an extraction process, a principle that alginate from the brown algae absorbs the heavy metal is utilized, so as to solve the residue problem of the heavy metal in the iodine from kelp during the physical extraction process; and on the premise of ensuring the content of the iodine from kelp, the active ingredients of the kelp are remained to the maximum. At the same time of extracting the iodine from kelp, algae fine oil, algin and mannite are extracted by comprehensive utilization, so that the utilization rate of the kelp is increased to the maximum.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

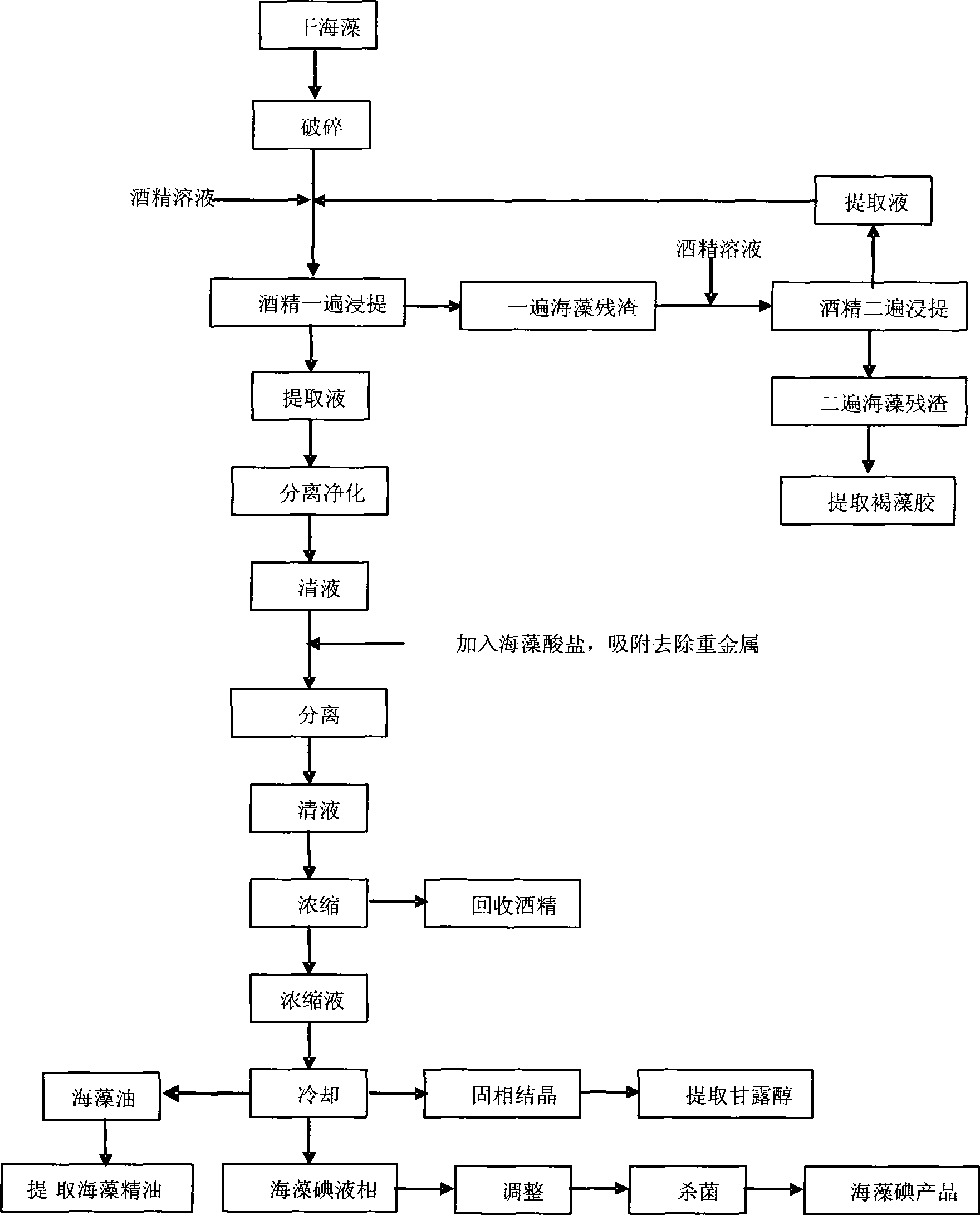

Pesticide sustained-release agent with modified MCM-41 as carrier, and preparation method thereof

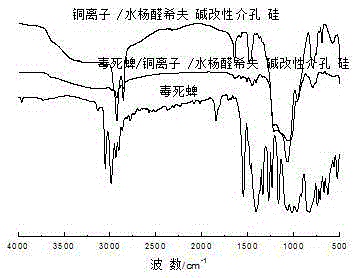

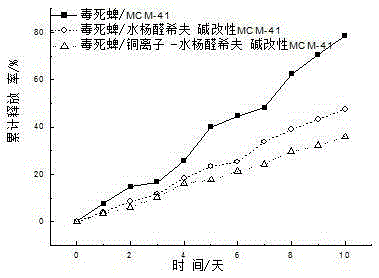

ActiveCN105230611AAvoid degradationAvoid the problem of easy decomposition when heatedBiocideArthropodicidesMesoporous materialOrganic chemistry

The invention relates to a pesticide sustained-release agent with modified MCM-41 as a carrier, and a preparation method thereof. The preparation method specifically comprises the following steps: S1, Schiff base silane is prepared; S2, Schiff base-MCM-41 is synthesized; S3, metal complex modified MCM-41 is prepared; and S4, the pesticide sustained-release agent with modified MCM-41 as carrier is prepared. According to the invention, the modified MCM-41 mesoporous material is prepared with a co-precipitation method and is used for adsorbing pesticide; the material is placed in a corresponding environment, such that the pesticide effect can be released slowly. Therefore, pesticide loading amount and utilization rate are improved. Also, with the pesticide sustained-release agent provided by the invention, environment pollution caused by pesticides is reduced.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Ultrasonic-assisted low-temperature glass brazing method

ActiveCN105522244AGood wettabilityOvercoming illiquiditySoldering apparatusSolder pasteUltrasonic assisted

The invention relates to an ultrasonic-assisted low-temperature glass brazing method. The ultrasonic-assisted low-temperature glass brazing method aims at solving the problems that in the existing process of brazing through low-temperature glass, as the viscosity of fusion glass under low temperature is large and a welding line is narrow, wetting spreading is not sufficient, and air hole remaining exists. The brazing method includes the steps that (1) low-temperature sealing glass powder and a binding material are mixed to obtain low-temperature glass brazing soldering paste; (2) a to-be-soldered raw material is cut and molded; (3) a soldered piece is subject to ultrasonic washing and polishing; (4) the low-temperature glass brazing soldering paste is coated to pre-connecting positions of the soldered piece; (5) the pre-connecting positions of the soldered piece are attached to form a to-be-soldered piece; and (6) heating is carried out to fuse the low-temperature glass brazing soldering paste, secondary ultrasonic vibration is applied to the surface of the to-be-soldered piece, and furnace cooling is carried out after vibration is stopped. The low-temperature sealing glass used in the method is low in sealing temperature, effective wetting spreading on the surface of the welded piece is carried out under the ultrasonication, obtained brazing connectors are free of macroscopic defects such as cracks and air holes, the residual stress is small, the strength is high, and the gas tightness is good.

Owner:HARBIN INST OF TECH

Nano-modified polypropylene soft packaging material

ActiveCN102020796AImprove mechanical propertiesImprove printing effectProcedure AgentsPolymer science

The invention provides a packaging polyolefin processing agent composition which is a mixture of nano silicon dioxide and ethylene-vinyl acetate copolymer, wherein the mass of the nano silicon dioxide accounts for 10-40% of the total mass of the processing agent composition, and the mass of the ethylene-vinyl acetate copolymer accounts for 60-90% of the total mass of the processing agent composition. The invention also provides packaging polyolefin modified by the processing agent composition. The modification of the nano silicon dioxide has greater influences on the mechanical property, the crystallization property, the polarity, the printing property, the composite property, the residue of organic solvent, and other indexes of the polypropylene. A result shows that after the polypropylene soft packaging material is subjected to nano modification, the toughness of the polypropylene soft packaging material is greatly enhanced; meanwhile, the polarity, the printing ink adhesive force and the peel strength of the material are improved; the adsorption of the modified polypropylene on toluene is greatly reduced. After nano modification, the using performance of the polypropylene used as the soft packaging material can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Three dimensions printing system and residual material recovery and nozzle cleaning device thereof

InactiveCN104385588AAvoid depositionAchieve recyclingHollow article cleaningAir pump3 dimensional printing

The invention provides a three dimensions printing system and a residual material recovery and nozzle cleaning device thereof. The three dimensions printing system comprises a nozzle, a connection pipe and a material tank and the material tank is provided with a discharge valve. The residual material recovery and nozzle cleaning device comprises an air pump, a water pump, a collection tank and a controller. A first end of the connection pipe is connected to the nozzle and a second end of the connection pipe is communicated with the material tank by the discharge valve. The air pump is communicated with the nozzle. The water pump is communicated with the second end of the connection pipe. The controller is respectively connected to the nozzle, the discharge valve, the air pump and the water pump and controls operation of the devices. The residual material recovery and nozzle cleaning device utilizes an air inflation method to realize primary flushing of the nozzle and the connection pipe, returns the residual printing material back to the material tank by air flows thereby realizing printing material recovery and recycle, and has the advantages of simple and fast recovery method, time and labor saving, waste reduction and cost saving. The residual material recovery and nozzle cleaning device utilizes a water feeding method to realize secondary flushing of the nozzle and the connection pipe thereby avoiding deposition of a less amount of the residual printing material in the nozzle and the connection pipe after air-operated flushing.

Owner:HEFEI SKE INTELLIGENT TECH

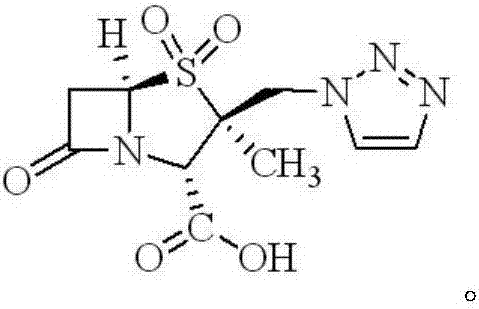

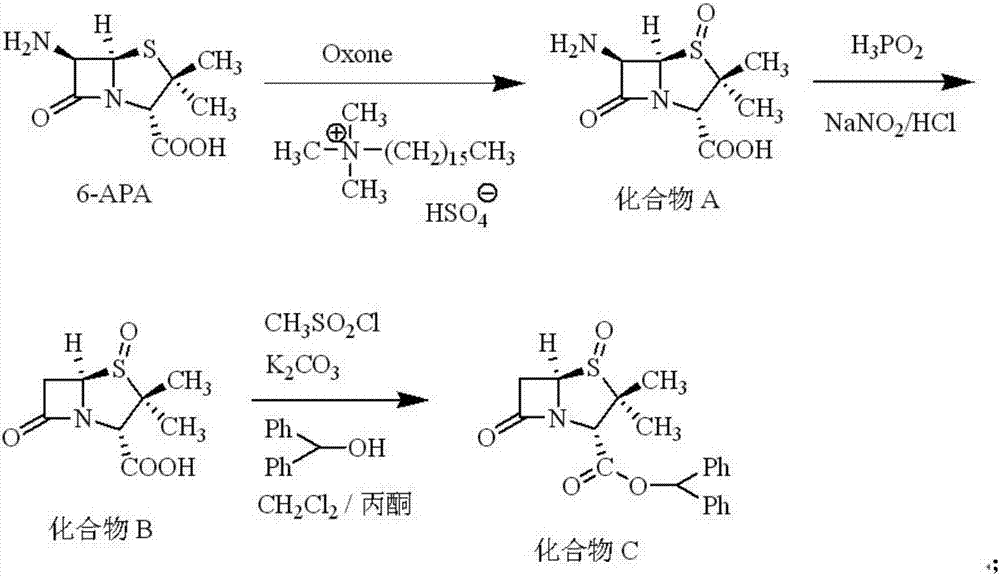

Synthetic method of tazobactam acid

The invention provides a synthetic method of tazobactam acid, comprising the steps of (a) using 6-APA (6-aminopenicillanic acid) as a starting material and cetyltrimethylammonium hydrogensulfate as a catalyst to oxidize with oxone to obtain compound A; subjecting the compound A to deamination reaction to obtain compound B; esterifying the compound B to obtain compound C; (b) subjecting the compound C and 2-mercaptobenzothiazole to reduced pressure backflow to obtain compound D; ultrasonically vibrating the compound D and copper bromide to obtain compound E; reacting the compound E and 1H-1,2,3-triazole to obtain compound F; (c) allowing hydrogen peroxide and acetic anhydride to act on the compound F to obtain compound G; reacting the compound G with anisole to obtain tazobactam acid. Amino groups in 6-APA are diazotized directly, diazo groups are then removed, reduced pressure backflow and ultrasonic vibration are performed, hydrogen peroxide and acetic anhydride are used as oxidants, less byproducts are generated, and the yield and quality of tazobactam acid are effectively increased.

Owner:SHIJIAZHUANG WANYE CHEM IND CO LTD

Modularized smokeless firework propellant and preparation method thereof

ActiveCN102219621ASolve residual problemsImprove securityNitrated explosive compositionsPrillFireworks

The invention discloses a modularized smokeless firework propellant which contains nitrocotton, a large quantity of tiny holes are arranged in the propellant and have block shape, and the size and shape of the holes are determined according to the caliber and shape of a firework transmitting barrel. The preparation method of the modularized smokeless firework propellant comprises the following steps: firstly mixing organic bond with granular pore firework powder, secondly preparing block-shaped solid by using the mixed materials through mould pressing, and then expelling volatilizing components in the block-shaped medicine by stoving. Compared with the granular pore firework powder, the modularized smokeless firework propellant can thoroughly solve the problem of propellant residue of granular propellant feeding, and simplifies the operation of transmitting propellant feeding, so that the stability and consistency of an end firework product are better; and in addition, the modularizedsmokeless firework propellant also avoids the mechanical friction action among granules, and improves the safety of manufacture, transmission, and storage of the firework products.

Owner:NANJING UNIV OF SCI & TECH

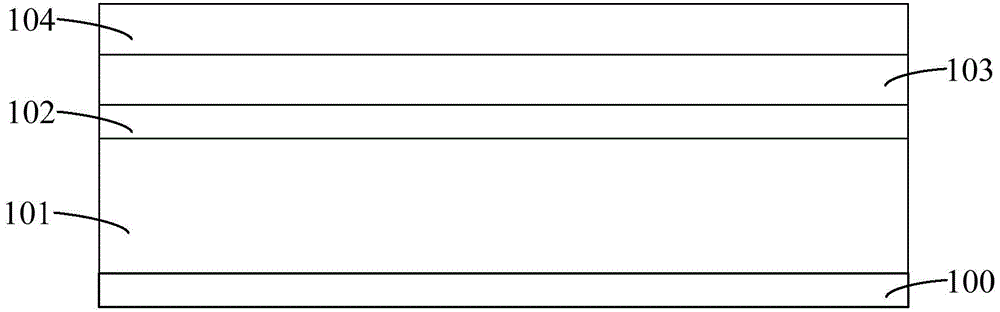

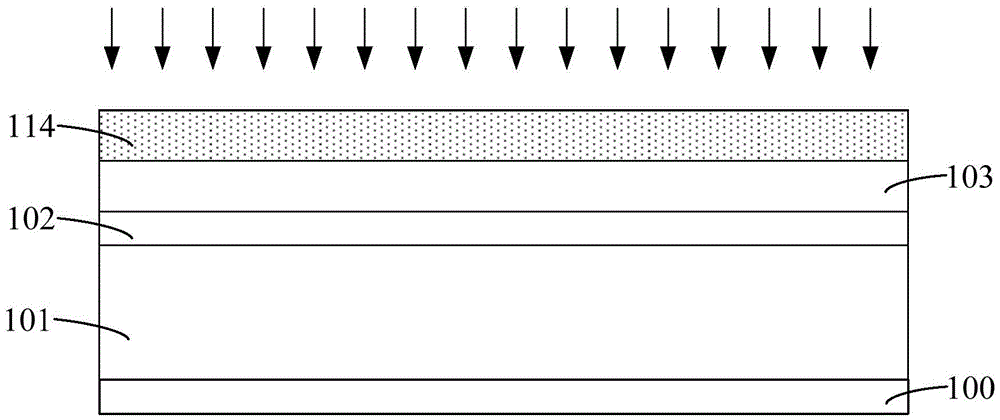

Formation method of semiconductor structure

ActiveCN105719956AHigh positioning accuracyEasy to shapeSemiconductor/solid-state device manufacturingSemiconductor structureDry etching

A method for forming a semiconductor structure, comprising: providing a base; forming an initial mask layer on the base; performing doping treatment on the initial mask layer to convert the initial mask layer into a doped mask layer; A first pattern layer having a first opening is formed on the surface of the doping mask layer; using the first pattern layer as a mask, a dry etching process is used to etch the doping mask layer along the first opening, forming a second opening through the doping mask layer, and the etching rate of the doping mask layer in the dry etching process is higher than the etching rate of the initial mask layer; removing the first pattern layer. The etching rate of the doped mask layer in the dry etching process of the present invention is greater than the etching rate of the initial mask layer, so there is no need to form an organic distribution layer, avoiding the problem of residual organic distribution layer materials, and improving the initial mask layer and the second mask layer. Second, the cleanliness of the opening improves the yield rate of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com