Patents

Literature

33 results about "6-APA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

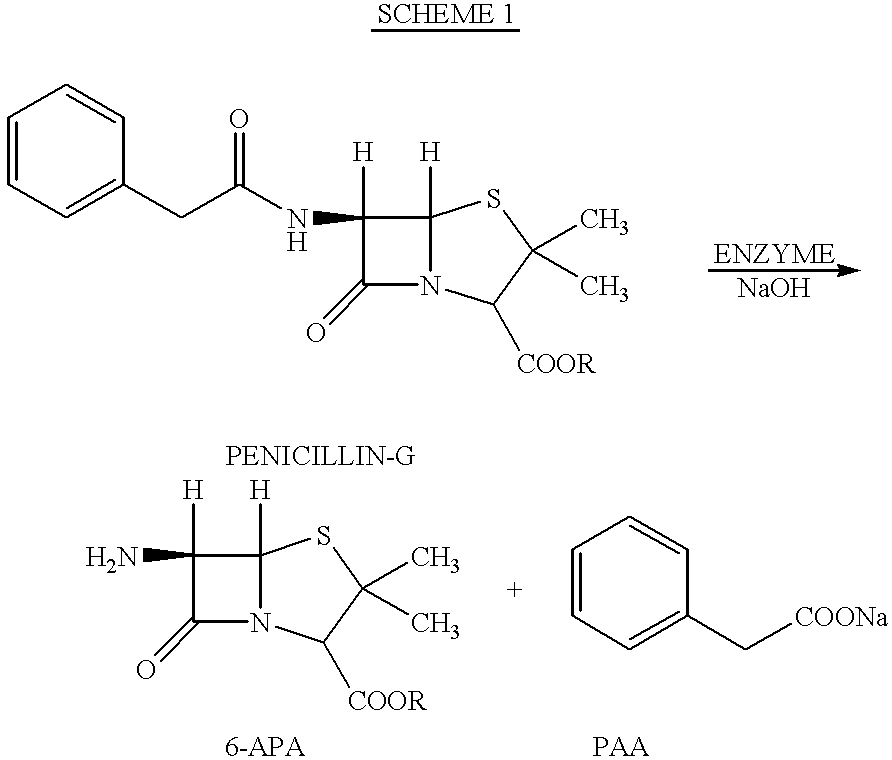

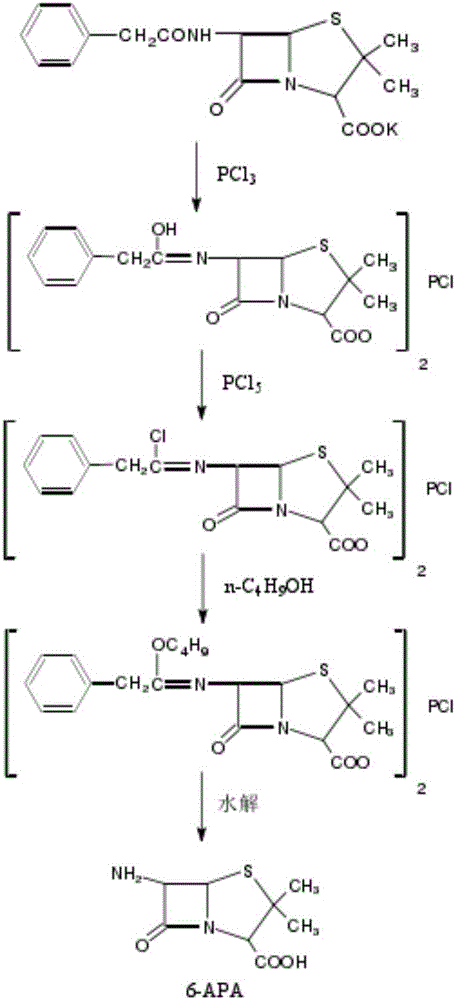

6-APA is the chemical compound (+)-6-aminopenicillanic acid.

Immobilized enzyme biological catalyst, preparation method and application

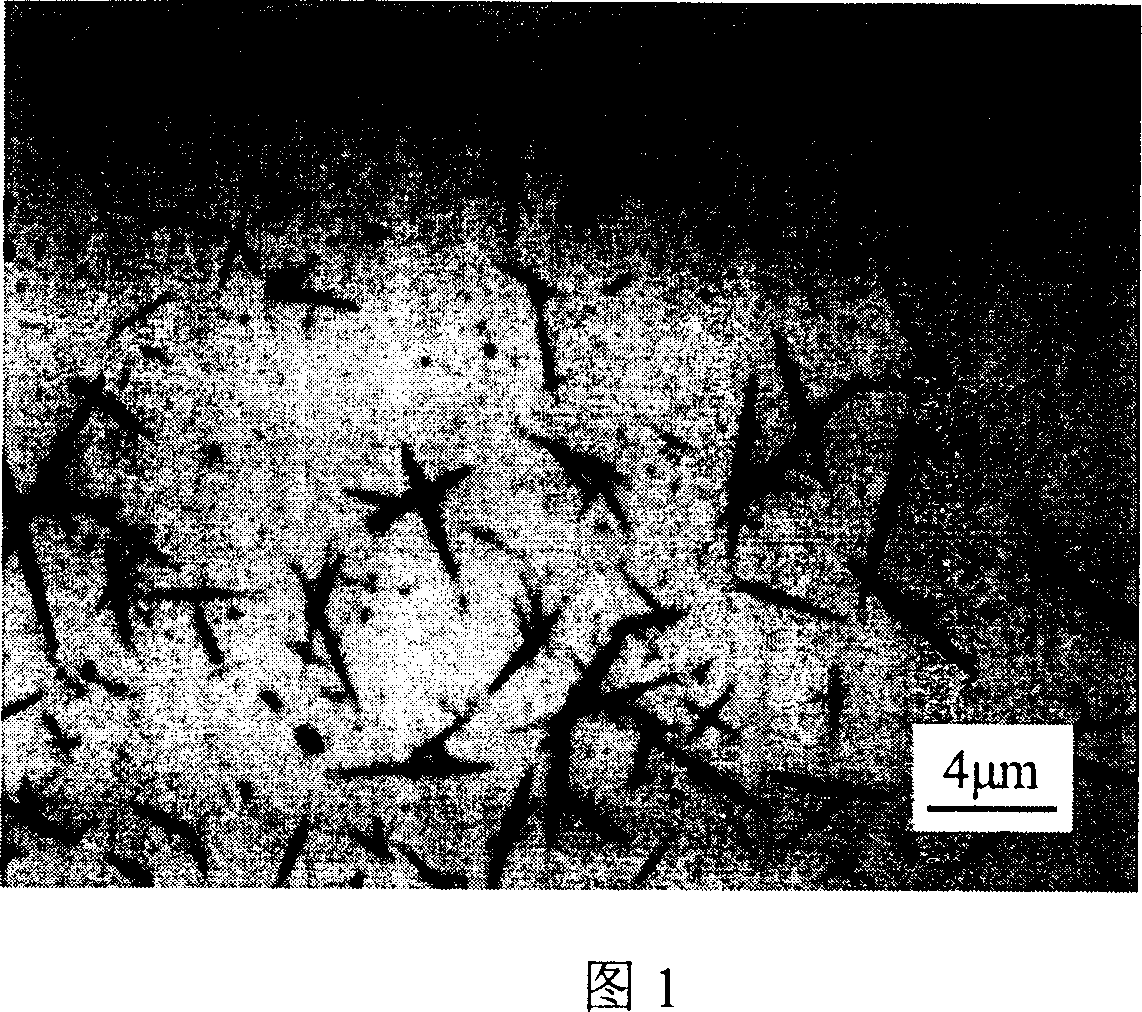

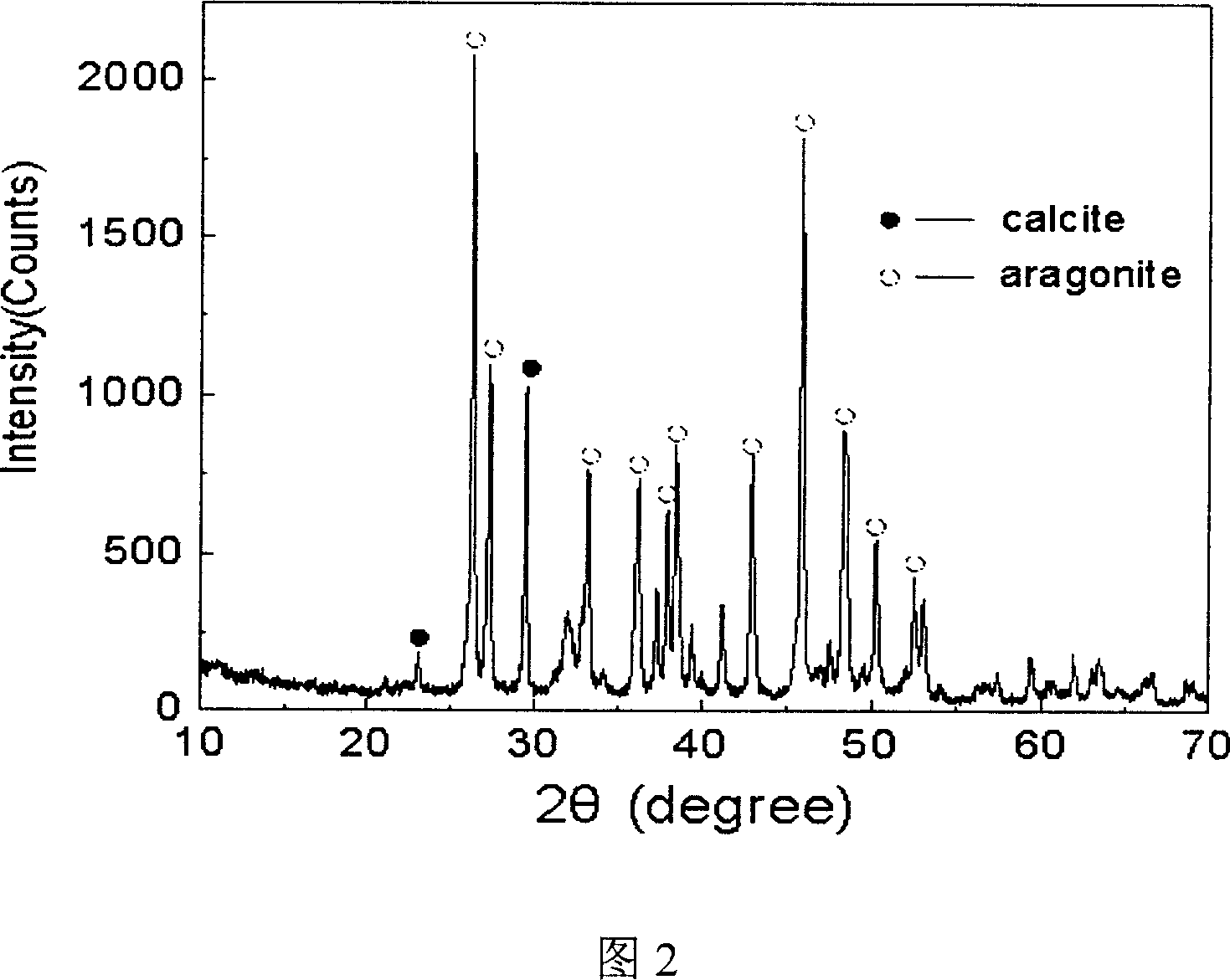

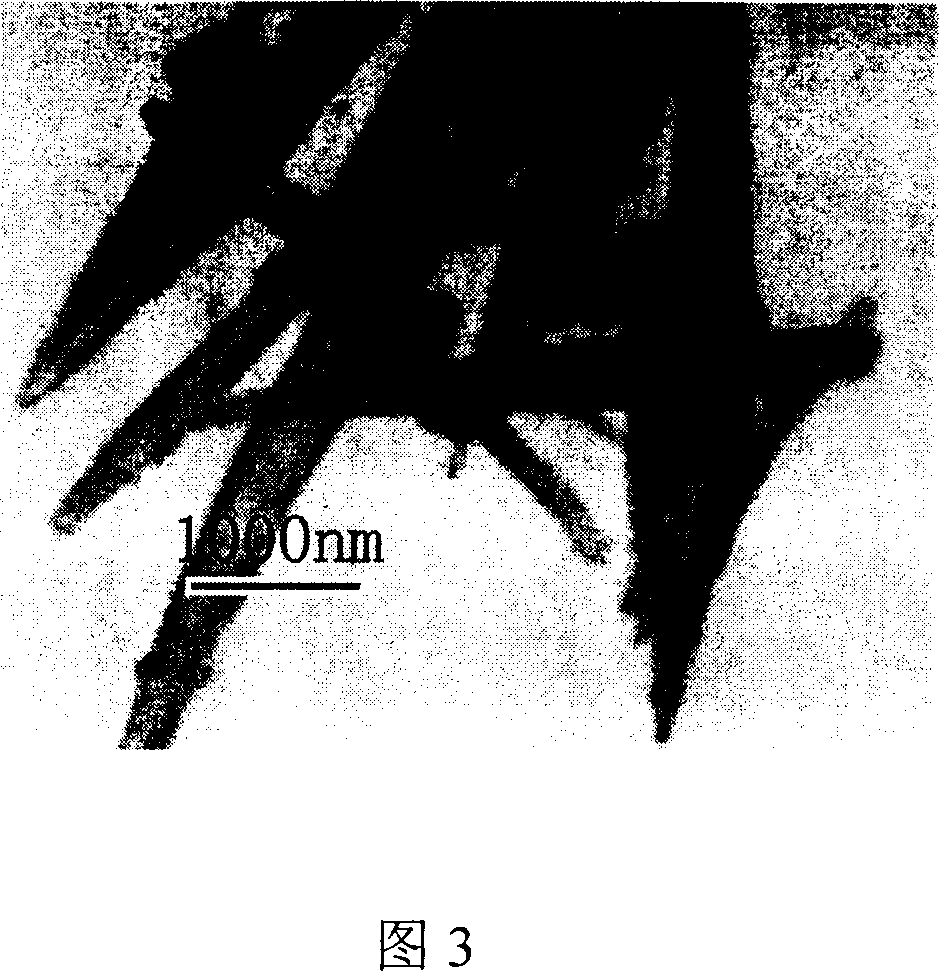

InactiveCN101058824AReduce dosageImprove distributionImmobilised enzymesChemical industryDielectricPotassium

The invention relates to an immobilized enzyme biocatalyst and the manufacturing method and application. The immobilized enzyme biocatalyst regards tubular hollow silica dioxide dielectric hole material as a carrier external surface, inner surface and micropore in the wall of which are fixed biological enzyme molecule. The method includes physical adsorption cast investment or chemical coupling / crosslinking method; the biocatalyst is provided with good enzyme dispersibility and high carrying quantity, high recovery ratio of enzymatic activity, low enzyme flow rate. The invention can fix penicillin acylating enzyme, glucose oxidase, peroxidase, cytase and so on, which also can be used for removing sugar in protein, removing sugar in total egg, removing oxygen in food , microbiological sensing device, antibiosis and disinfection reaction, wherein immobilized penicillin acylating enzyme biocatalyst can be used to hydrolyze penicillin potassium and manufacture 6-APA.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for 6-amino penicillanic acid

The invention discloses a preparation method for 6-amino penicillanic acid, which comprises the following steps: a, performing ultrafiltration membrane separation and nanofiltration membrane concentration on a penicillin fermentation liquor to obtain a concentrated filter liquor; b, placing the concentrated filter liquor into a reaction tank, adding an immobilized penicillin acylase 4MU / m<3> concentrated filter liquor and performing conversion reaction to obtain a 6-amino penicillanic acid conversion solution; c, performing actived carbon decoloration and filtering on the conversion solution to obtain a 6-amino penicillanic acid filter liquor; and d, adding seed grain into the 6-amino penicillanic acid filter liquor obtained through the procedures in the step c, growing the grain, crystallizing, filtering, washing and drying. The preparation method has the advantages of simple process flow, easiness for operation, safety, environmental protection, and capabilities of effectively improving the yield of 6-APA, reducing the production cost and improving the labor productivity.

Owner:NORTH CHINA PHARMA COMPANY

A kind of preparation method of amoxicillin sodium

The present invention relates to the field of drug synthesis, in particular to a method for preparing amoxicillin sodium. The method of the present invention comprises the following steps: (1) preparation of acid anhydride; (2) preparation of 6-APA solution; (3) condensation: Move the 6-APA salt solution into the mixed acid anhydride reaction bottle, and time it for 3 hours; (4) Hydrolysis: add the condensation solution of step (3) to the hydrolyzed solution; (5) Crystallization: Leave the crystal to grow for 1 hour and then stir to grow the crystal for 1 hour (6) Suction drying: wash with water first, then wash with acetone, and dry in vacuum at 40° C. for 3 hours to obtain amoxicillin.

Owner:HARBIN PHARMA GRP CO LTD GENERAL PHARMA FACTORY

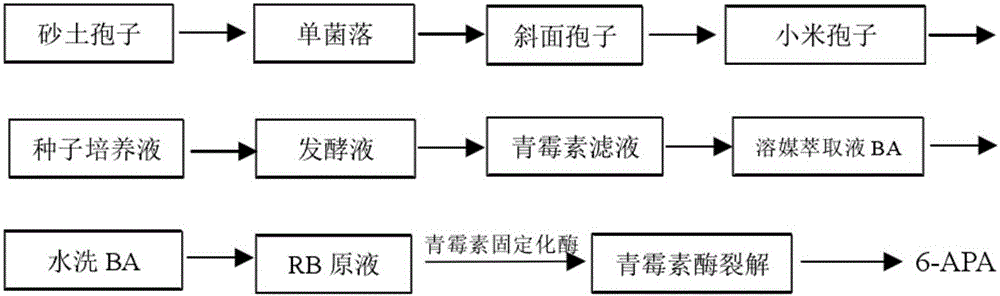

Process for preparing straight-through 6-aminopenicillanic acid

InactiveCN101735243AAvoid disadvantagesLarge amount of deesterificationOrganic chemistryFermentationGas phasePressure reduction

The invention discloses a process for preparing straight-through 6-aminopenicillanic acid, which comprises the following steps: a, filtering and acidizing penicillin fermentation solution, extracting the penicillin fermentation solution by using butanol, and concentrating and decoloring the extract to obtain butyl ester extracting solution of penicillin; b, back extracting the butyl ester extracting solution of the penicillin by using alkali solution to obtain brine solution of penicillin (heavy phase or RB for short); c, continuously injecting the brine solution of the penicillin into a degreasing tower in a vacuum pressure reduction state to convert the butyl ester into a gas phase from the brine solution of the penicillin, discharging the degreased brine solution of the penicillin out of a pressure reduction system from the bottom of the tower to a storage tank with a cooling device, and cooling the degreased brine solution of the penicillin for later use; and d, performing enzymatic conversion on the degreased brine solution of the penicillin, then adding 6-APA crystal seeds into the solution, growing the crystals, crystallizing the solution, and drying the crystals.

Owner:NORTH CHINA PHARMA COMPANY

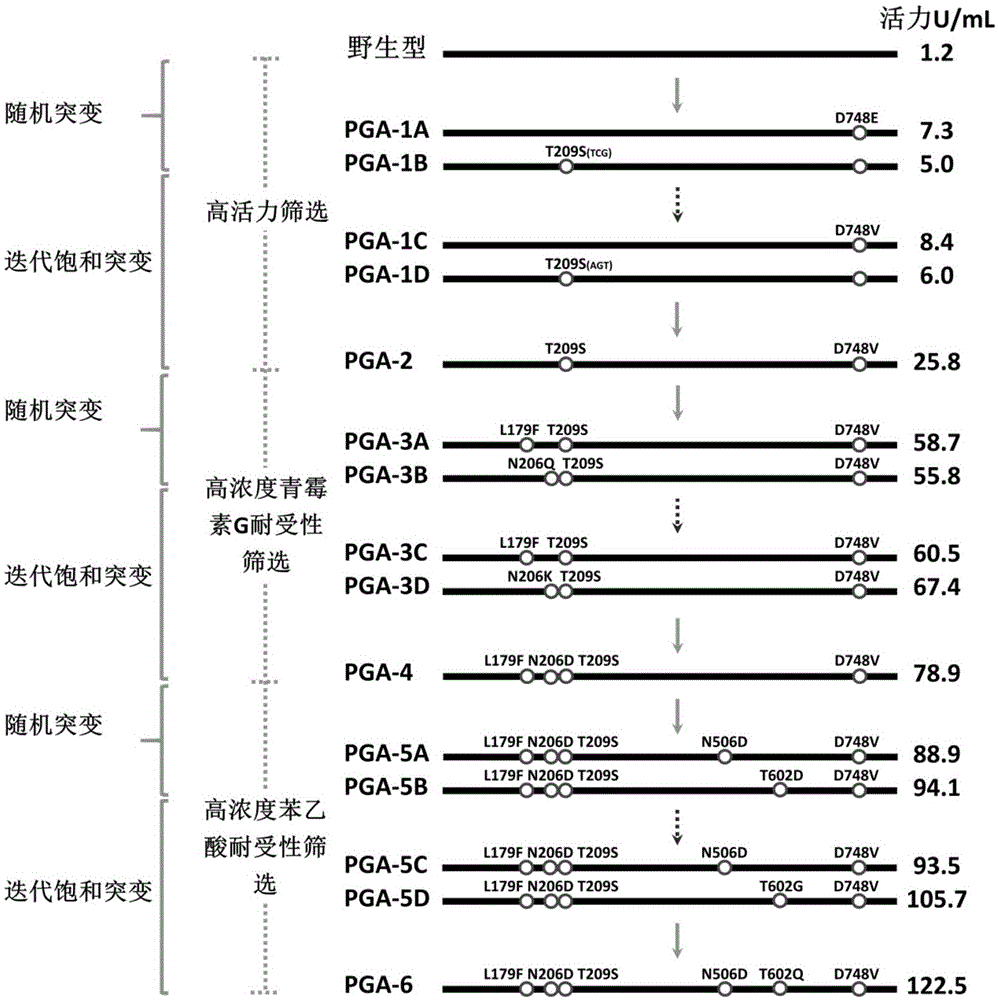

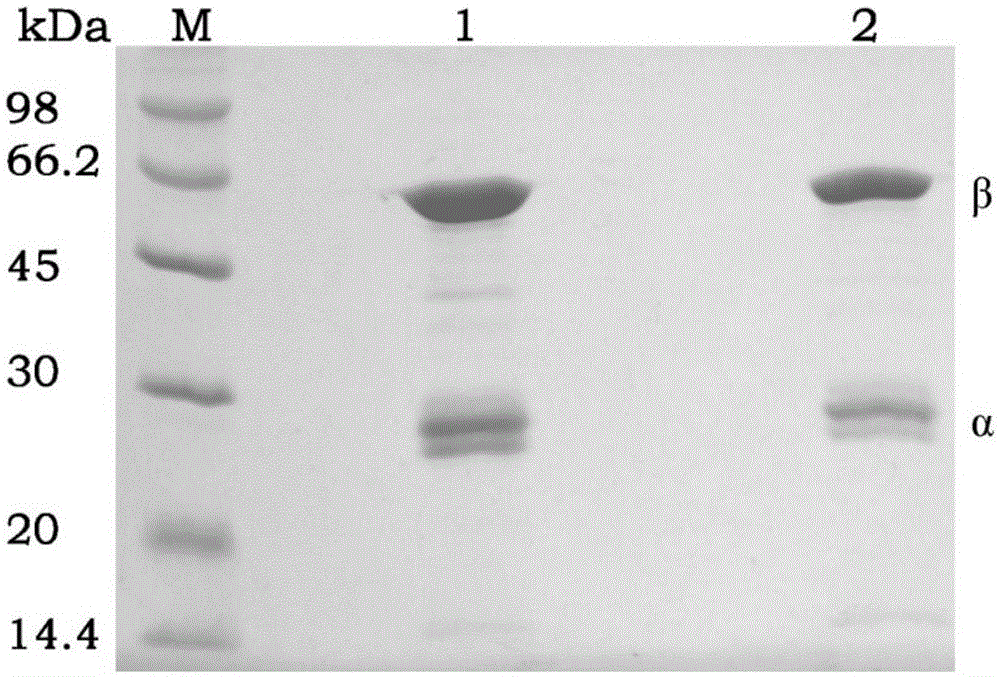

Mutant of penicillin G acylase (PGA) and preparation method and application of mutant

ActiveCN105087533AStrong concentration toleranceIncreased concentration toleranceHydrolasesFermentationPhenyl acetic acidEscherichia coli

The invention provides a mutant of penicillin G acylase (PGA) and a preparation method and application of the mutant. The non-rationally and semi-rationally designed enzyme engineering reconstruction technology is adopted for mutation of penicillin G acylase obtained from Escherichia coli ATCC 11105, so that a PGA mutant with higher reactivity, higher reaction rate, better conversion rate, stronger in penicillihe concentration tolerance, less substrate residue, and higher in phenyl acetic acid concentration tolerance; meanwhile, the mutant is subjected to recombinant expression, bacteria strain construction, fermenting cultivation, immobilization and application to prepare 6-amino-penicillanic acid (6-APA). The activity of the PGA-6 mutant prepared by the invention is increased by 102 times, the substrate penicillihe concentration tolerance is increased to 30%, and the phenyl acetic acid concentration tolerance is increased to 20 mmol / L; meanwhile, the immobilized PGA-6 mutant is used to decompose penicillihe with a concentration of 25% under the condition of pH 8.0 and 25 DEG C so as to prepare 6-APA, and the reaction time is shortened to 55 minutes, the substrate conversion rate is 98% or above, and after being used for 600 batches and above, the activity is not lost obviously, therefore, good operation stability is achieved.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

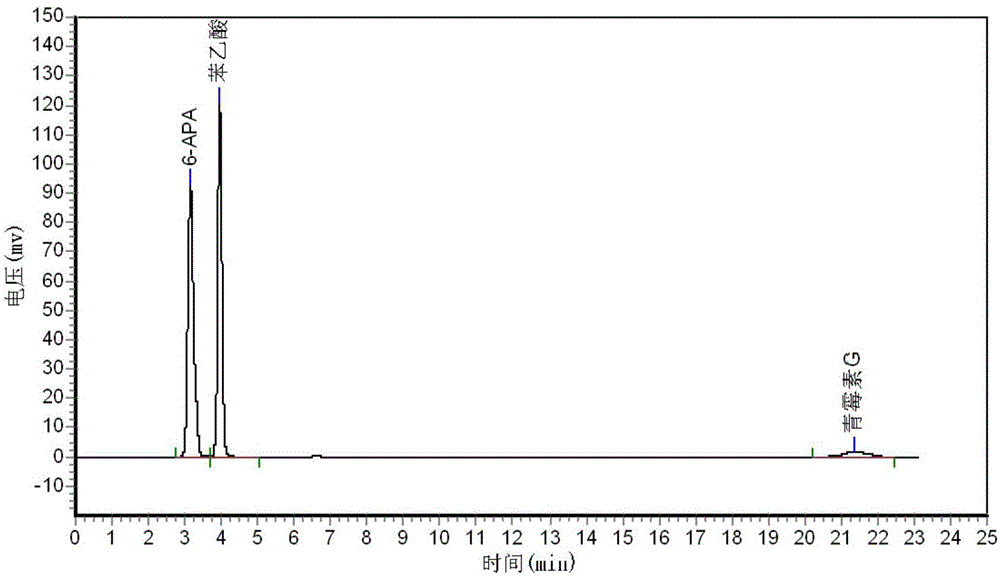

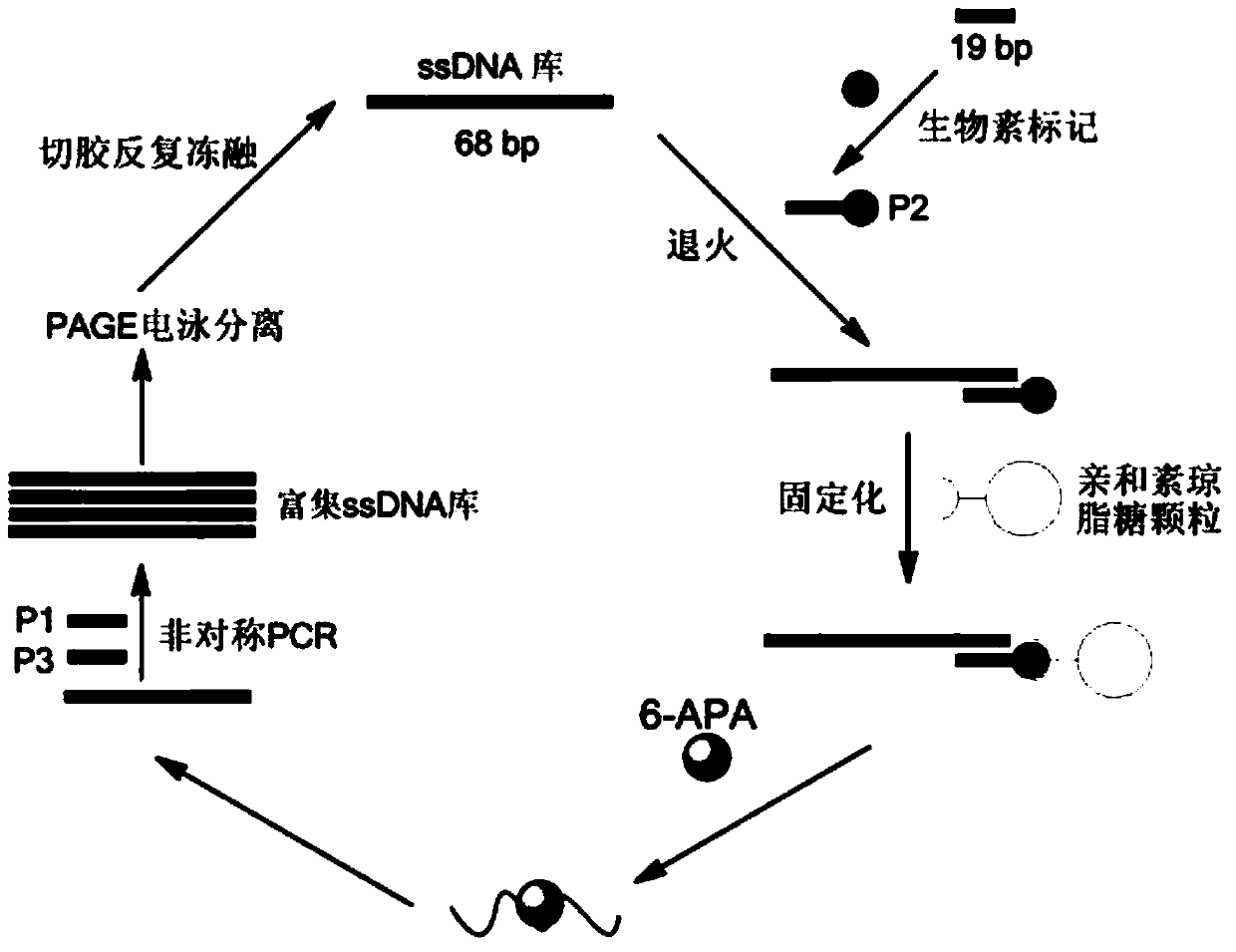

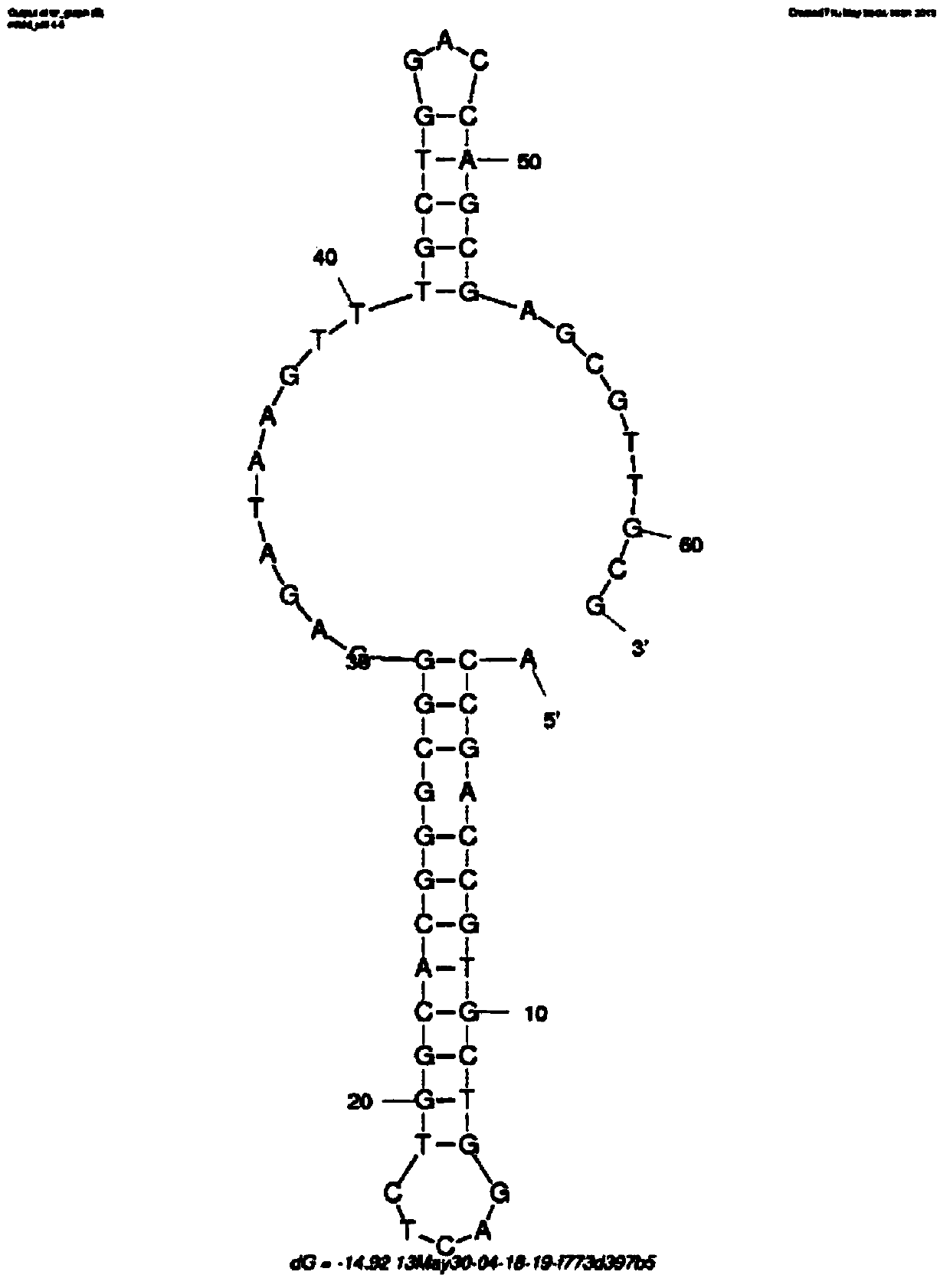

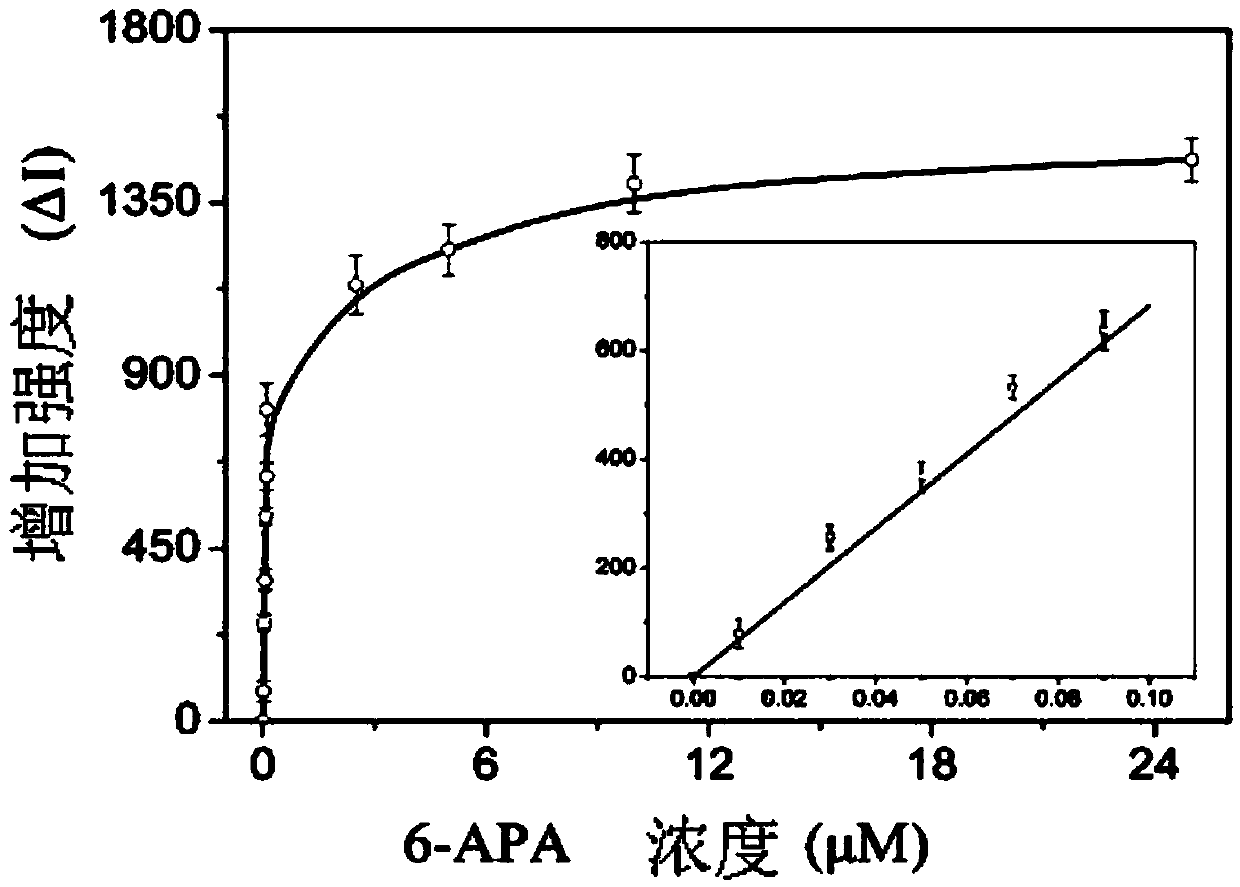

Improved penicillin antibiotic aptamer without fixed point target substance and application thereof

ActiveCN103387991AEasy to fixEasy to operateColor/spectral properties measurementsDNA/RNA fragmentationElutionMISCELLANEOUS ANTIBIOTICS

The invention discloses a penicillin antibiotic aptamer obtained by the screening technology for an improved aptamer without a fixed point target substance in the field of screening a penicillin antibiotic aptamer without a fixed point target substance, and an application thereof. The unfixed nucleic acid is eluted through a fixed oligonucleotide library; the parent nucleus 6-APA (6-aminopenicillanic acid) of the penicillin antibiotic is added in positive screening to act on the fixed nucleic acid; after eluting the nucleic acid molecules which can be combined with 6-APA, PCR (polymerase chain reaction) amplification is directly performed for next screening; and other antibiotics are added in negative screening, and the nucleic acid molecules in non-specific binding with the penicillin antibiotics are removed by elution. Through multiple rounds of positive and negative screening, 10 nucleic acid aptamers with high specificity and strong affinity with 6-APA are obtained; and the nucleic acid aptamer with a stable secondary structure is selected for developing a nucleic acid aptamer sensor for detecting 6-APA.

Owner:SHANGHAI JIAO TONG UNIV

6-aminopenicillanic acid preparation method

The invention discloses a process for preparing 6-aminopenicillanic acid, which comprises the following steps: (1) filtering the penicillin fermentation liquid, acidifying, extracting and concentrating with butanol, decoloring to obtain butyl extract of penicillin, (2) subjecting butyl extract of penicillin to back extraction with alkaline solvent, obtaining aqueous solution of penicillin salts, (3) degreasing the aqueous solution of penicillin salts, (4) loading the degreased aqueous solution of penicillin salts into penicillin acylated enzyme retort for enzyme conversion, charging 6-APA seeds, cultivating quartz, crystallizing and drying.

Owner:NORTH CHINA PHARMA GROUP CORP

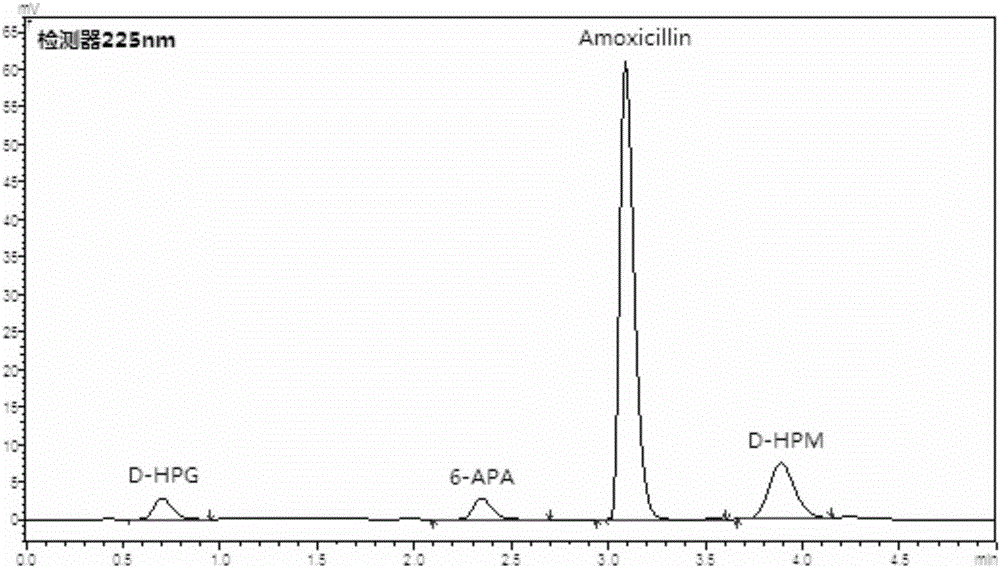

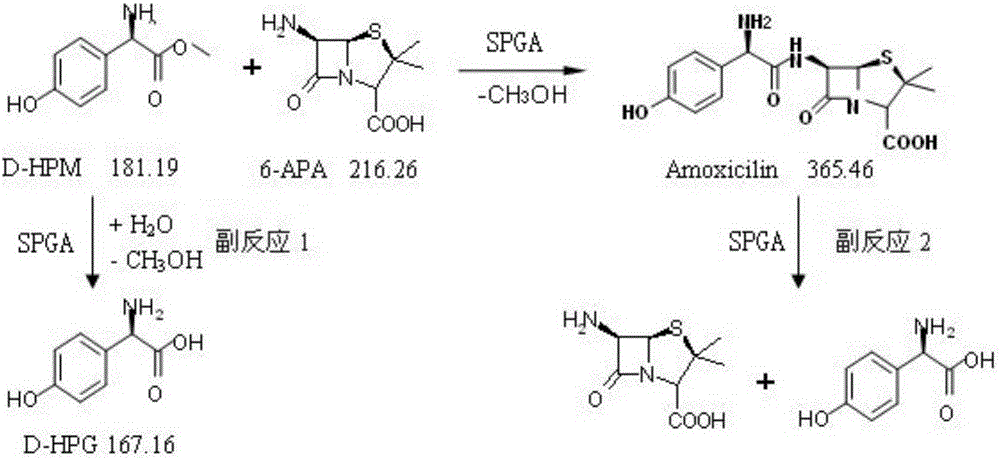

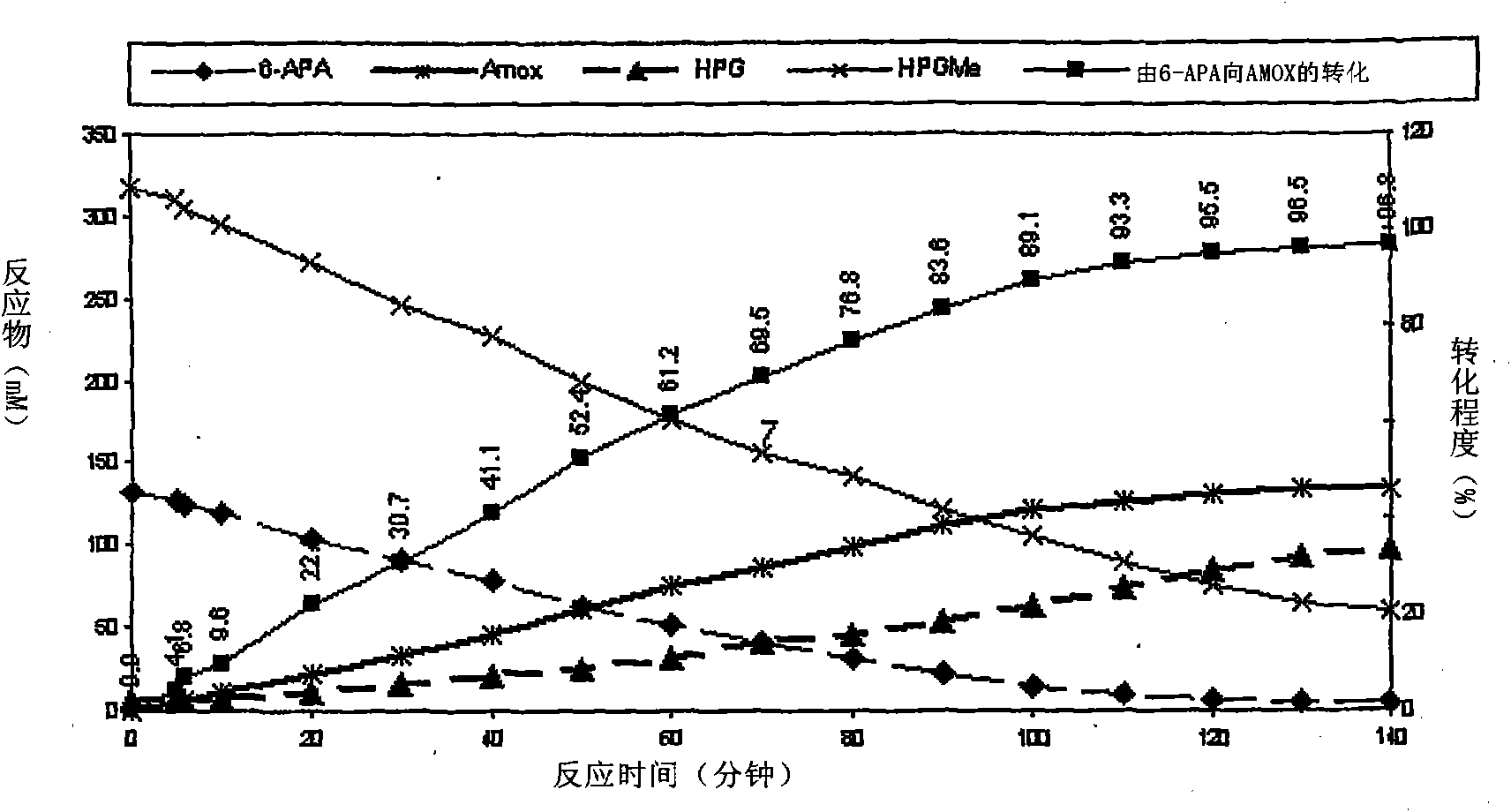

Penicillin G acylase mutant for synthesis and application thereof in preparation of amoxicillin

ActiveCN105274082ASynthetic activity is goodImprove stabilityHydrolasesFermentationContinuous useOrthogenesis

The invention provides a penicillin G acylase mutant for synthesis and an application thereof in the preparation of amoxicillin. Penicillin G acylase of Achromobacter xylosoxidans origin is mutated by computer aided design in connection with semi-rational design of site-saturation mutagenesis technique and enzyme engineering modification of orthogenesis, thus acquiring the penicillin G acylase mutant lower in hydrolytic activity, better in synthetic activity, higher in synthesis-hydrolysis ratio (S / H), higher in acid resistance and better in stability, and amoxicillin can be catalytically synthesized more effectively and quickly. Immobilized enzyme hydrolytic activity of the mutant SPGA-4 obtained is decreased by 8.7 times, synthetic activity is increased by 5.6 times, the S / H ratio is increased by 8 times, the activity remains at 79% for 60 min under the condition of pH 2.0, amoxicillin is catalytically synthesized by a solid method at 10 DEG C or 20 DEG C, substrates 6-APA and D-HPM are directly charged in a solid form without dissolving, reaction pH need not be controlled, substrate conversion rate is higher than 99%, continuous use is available in more than 300 batches, and good operational stability is given.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

Immobilized penicillin amidase carrier and its preparing method

The present invention discloses a kind of immobilized penicillin amidase carrier and its preparation process. The immobilized pencillin amidase carrier is prepared with surfactant as dispersant and vinyl compound as monomer and through crosslinking polymerization in reverse suspension technology. The carrier immobilized pencillin amidase has an apparat enzyme activity in preparing 6-APA with benzyl pencillin potassium as high as 125 IU / g. The polymer bead carrier containing epoxy group of the present invention has high apparent enzyme activity, simple technological process, easy operation andcheap material and may be used in industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

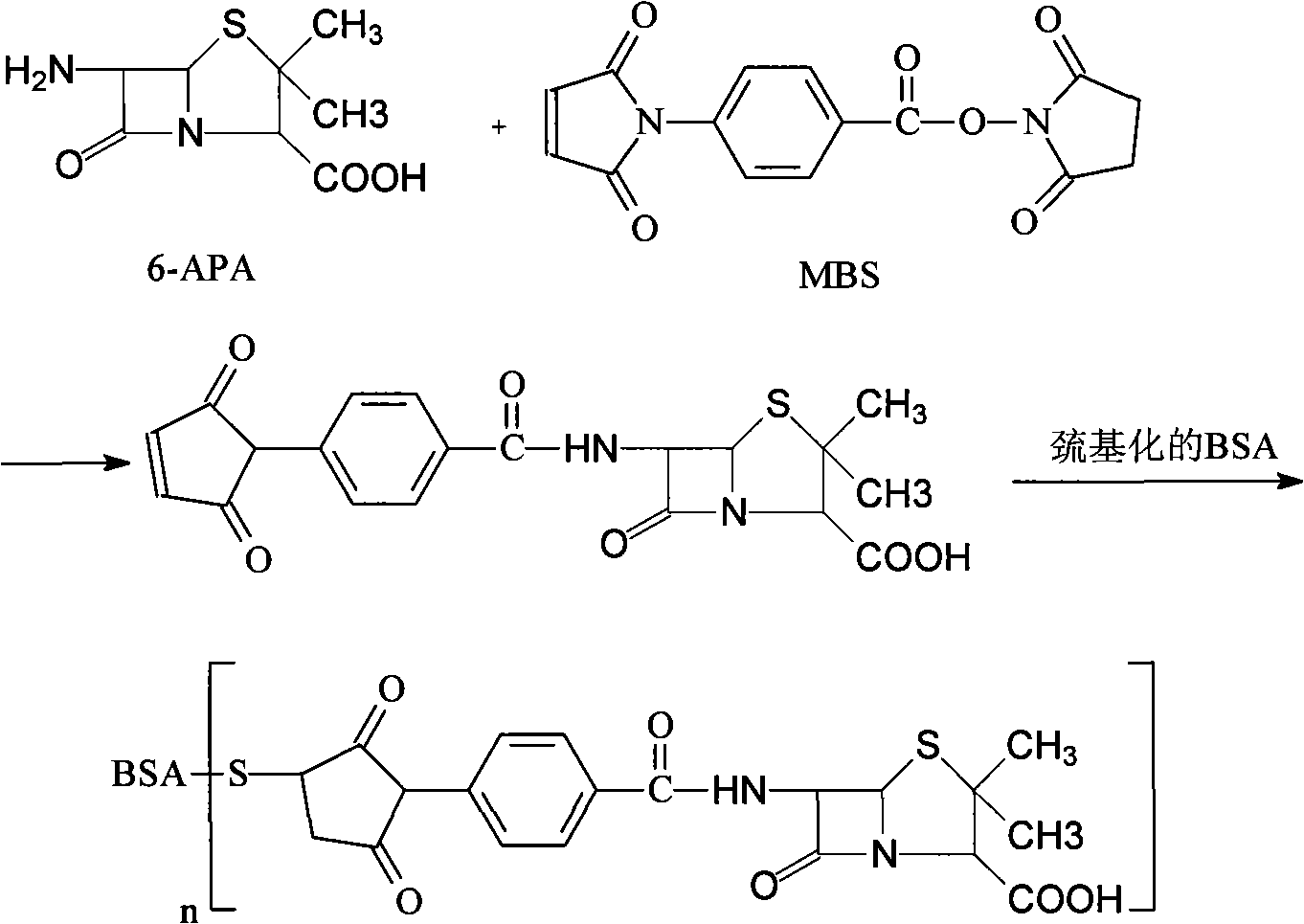

Method for synthesizing general artificial antigen of beta-lactam drugs

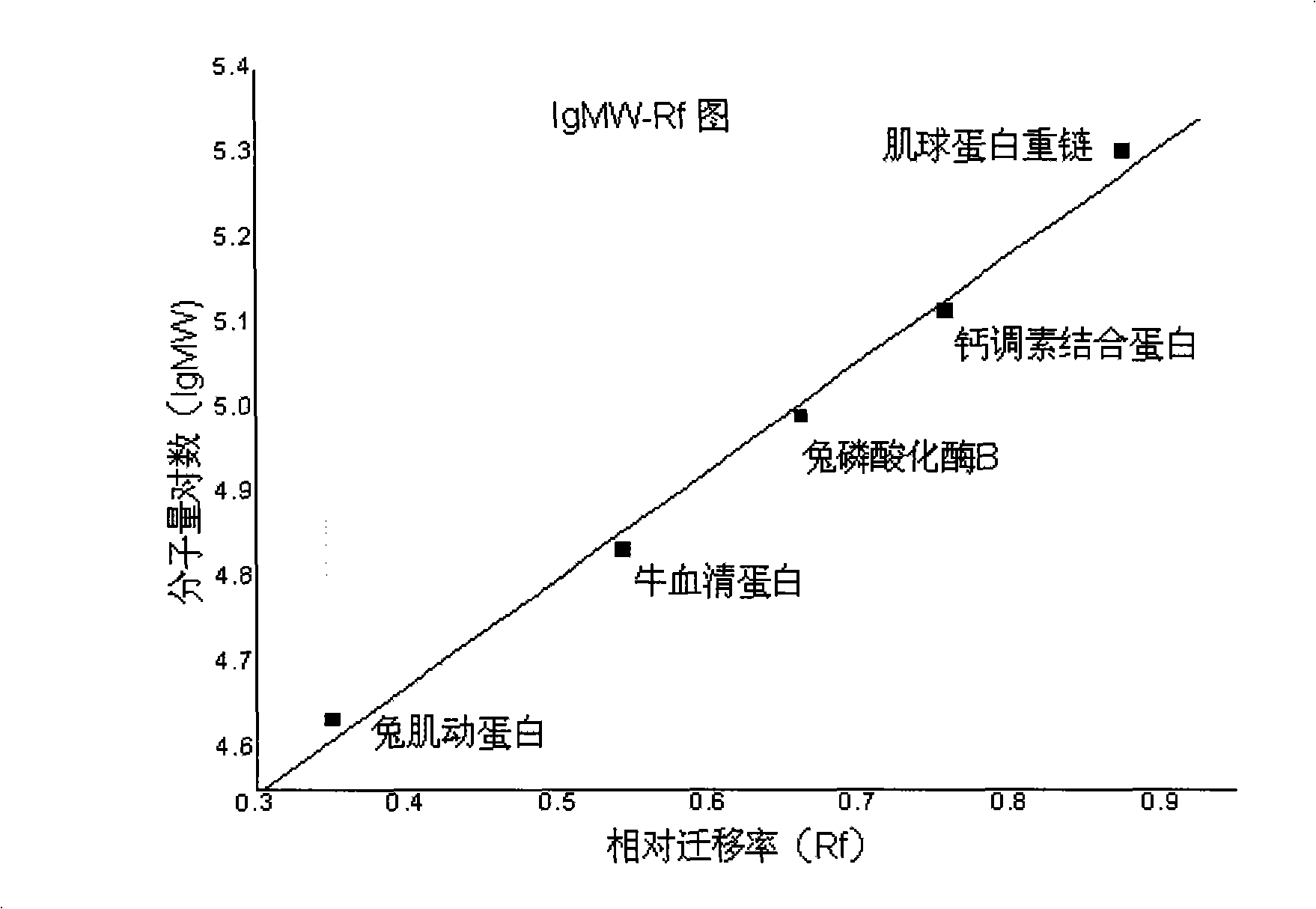

InactiveCN101307092AThe synthesis steps are simpleThe synthetic step worksSerum albuminPeptide preparation methodsBovine serum albuminCarrier protein

A synthetic method for the general artificial antigen of a beta-lactam medicine belongs to the biochemical technical field. The invention adopts 6-amino penicillanic acid as hapten, couples the hapten with the carrier protein of bovine serum albumin BSA through an N-(m-maleimide group benzene methanoyl) succinimides MBS method, and determines the coupling ratio of the coupled matter through a gel electrophoresis method. The method successfully synthesizes the 6-APA general artificial antigen with a simple and effective synthesis process. The method which can completely be used for immune analysis provides necessary artificial antigen for future study and meets the requirements of domestic study on the artificial antigen.

Owner:JIANGNAN UNIV

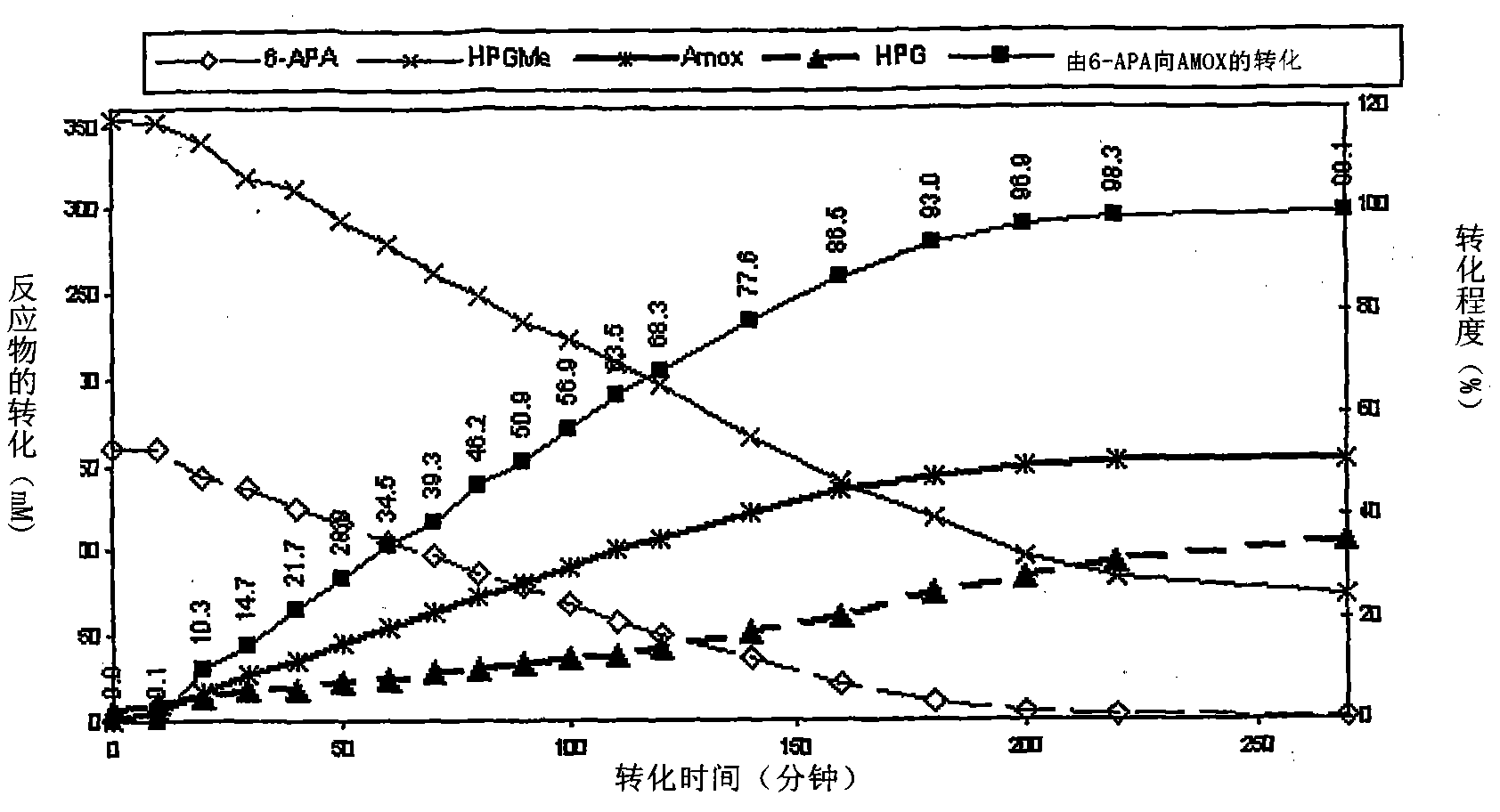

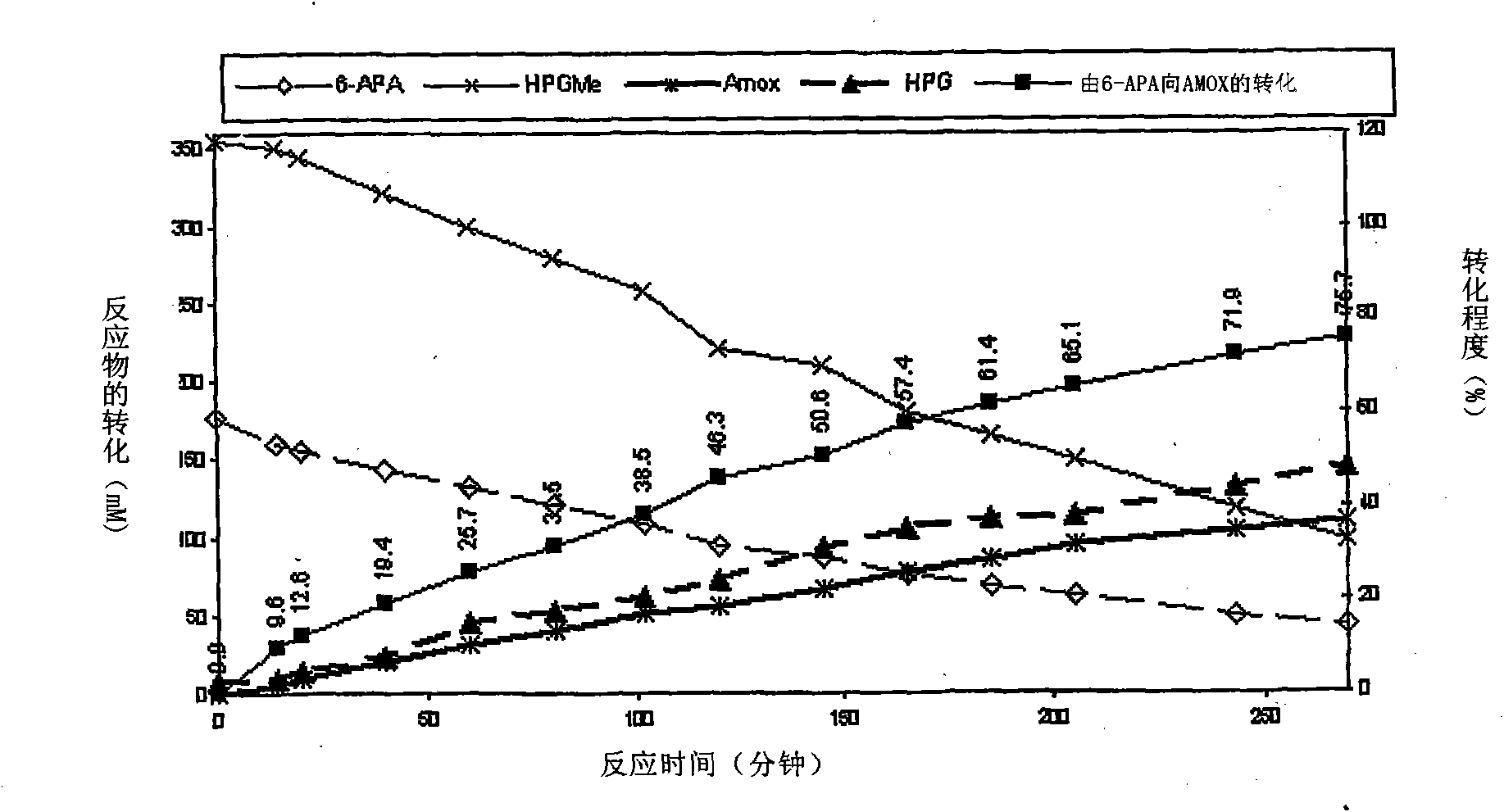

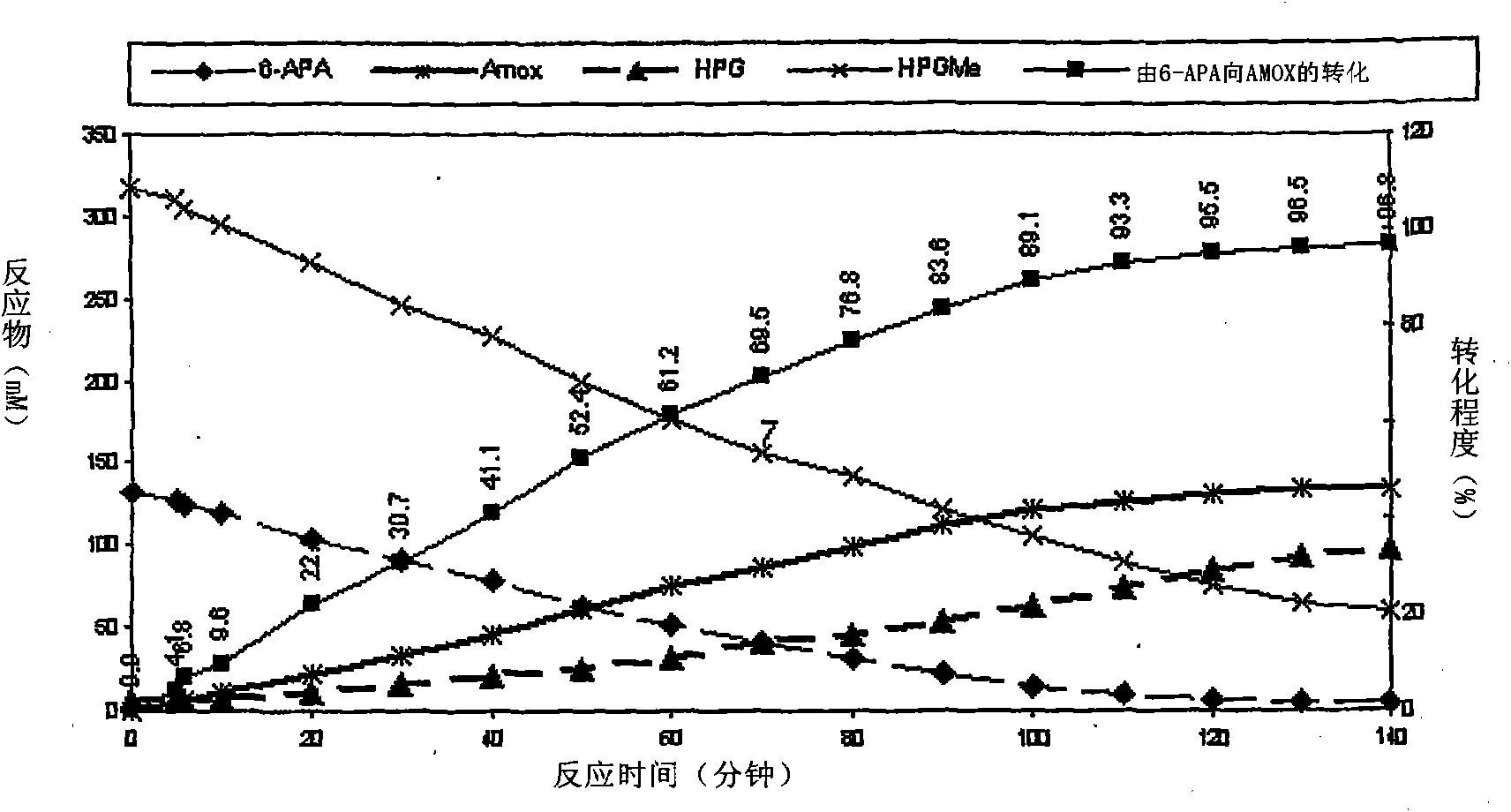

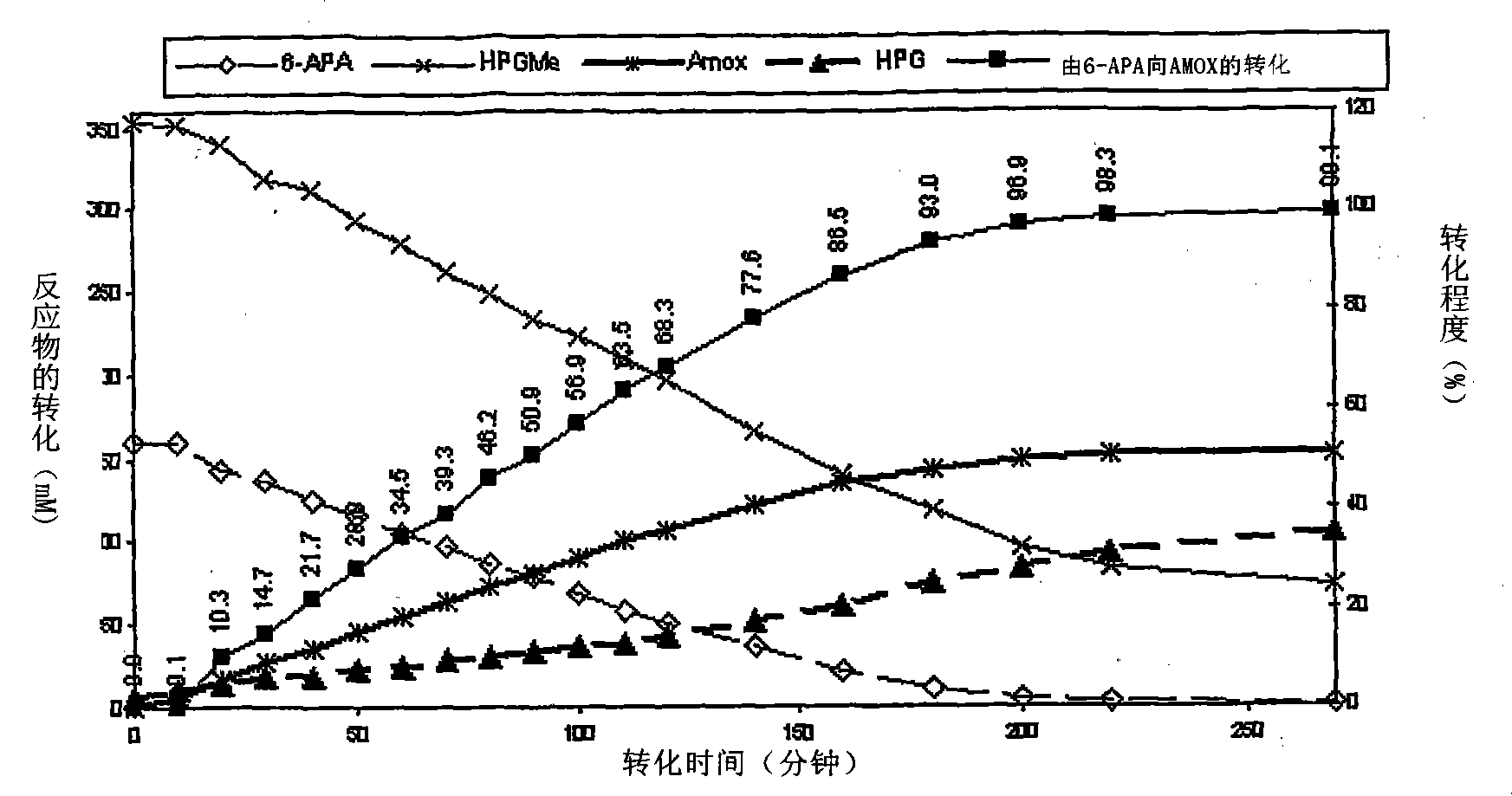

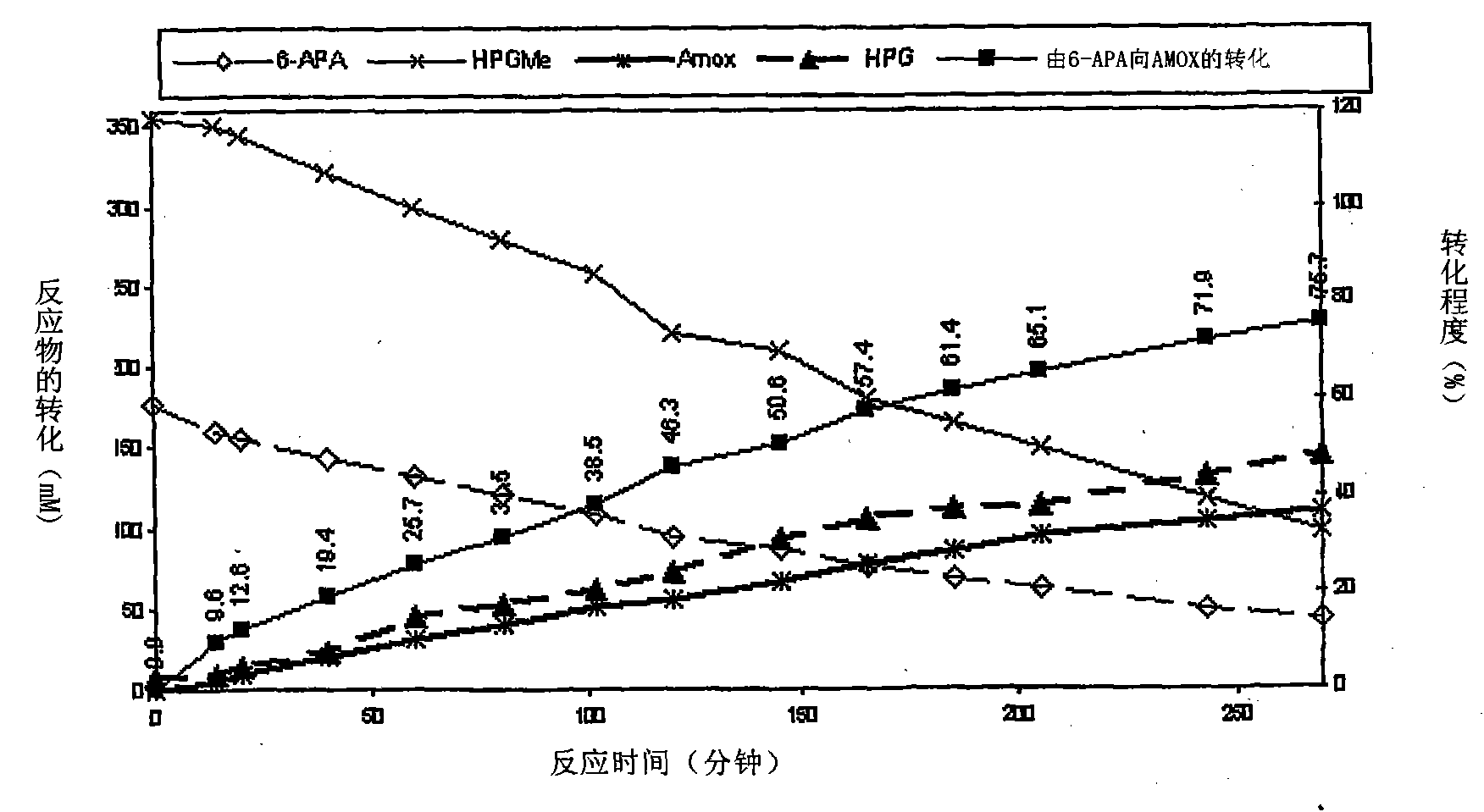

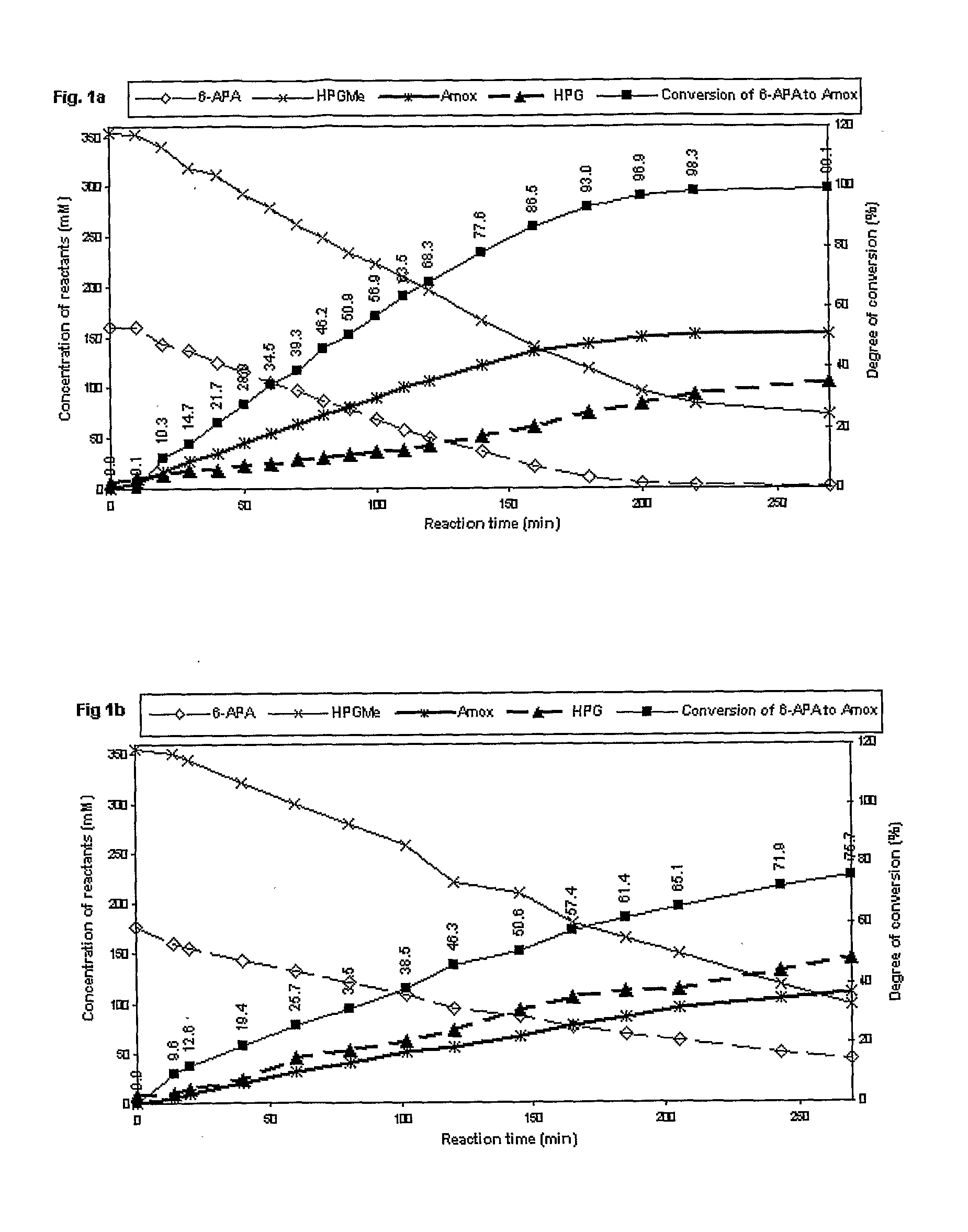

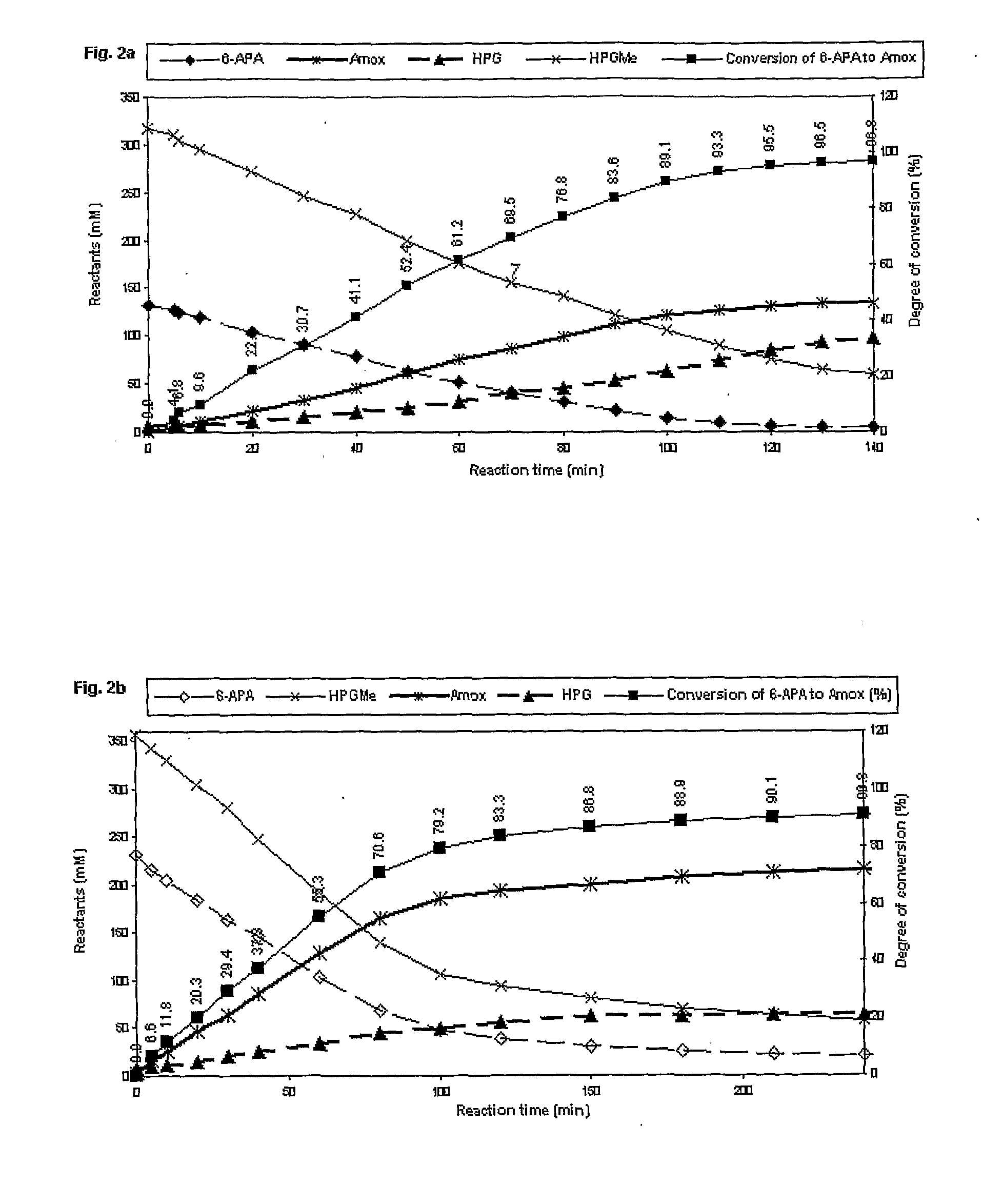

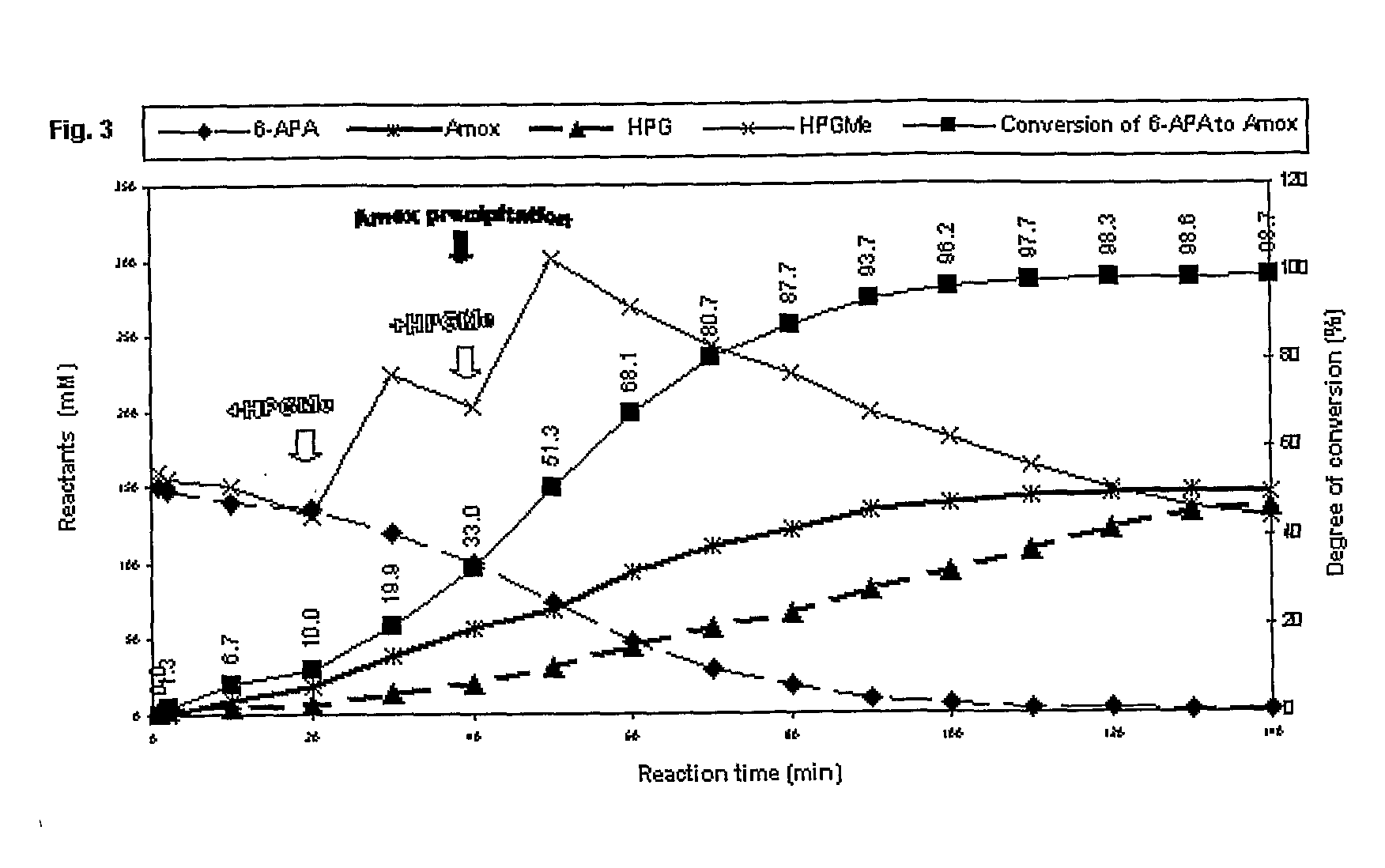

Process for the preparation of immobilized recombinant penicillin acylase catalyst from Achromobacter sp. CCM 4824 expressed in E. coli BL 21 CCM 7394 and its use for the synthesis of beta-lactam antibiotics

ActiveCN101802212AImprove synthesis abilityExtended active timeFermentationAmpicillinBeta lactam antibiotic

The present invention discloses isolation of Penicillin Acylase (PA) from Achromobacter sp CCM 4824 expressed in recombinant strain E. coli BL21 CCM 7394 bearing the recombinant plasmid pKXIP1 and processing of PA into biocatalyst useful for the industrial synthesis of antibiotics. More particularly the invention discloses a synthesis of semi-synthetic [beta]-lactam antibiotics in the reaction mixture consisting of activated acyl-donor (D-p-hydroxyphenylglycine methyl ester or amide for Amoxicillin and Cefadroxil; D-phenylglycine methyl ester or amide for Ampicillin and Cephalexin) and nucleophile (6-APA or 7-ADCA) catalyzed by PA obtained from recombinant E. coli BL21 CCM 7394 as the biocatalyst.

Owner:FERMENTA BIOTECH

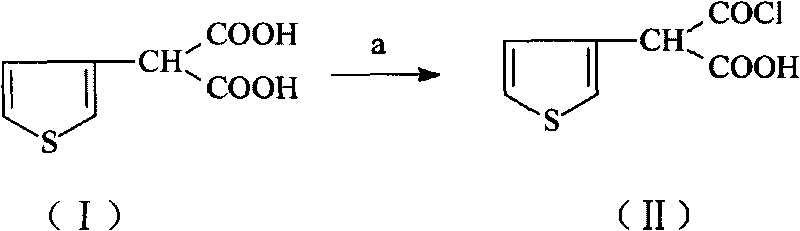

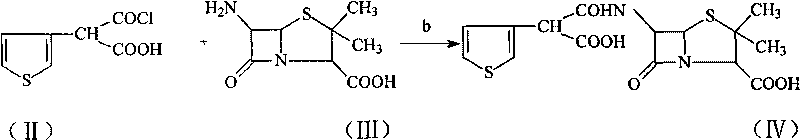

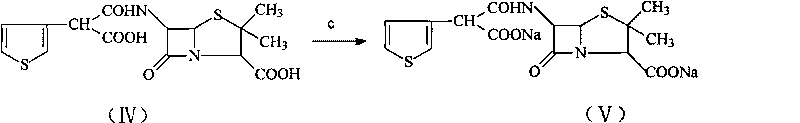

Method for preparing broad-spectrum penicillin antibiotic ticarcillin sodium

ActiveCN101735244AThe reaction route is simpleEasy to operateAntibacterial agentsOrganic chemistryTicarcillin sodiumReaction temperature

The invention relates to a novel method for preparing broad-spectrum penicillin antibiotic ticarcillin sodium. The method is characterized in that the method comprises the following steps of: (1) directly carrying out chlorination on 3-thiophenemalonic acid used as raw material and thionyl chloride in the presence of a catalyst, without protecting carboxyl, and chloridizing one carboxyl to obtian a compound (II); (2) carrying out condensation reaction with 6-aminopenicilanic acid (6-APA), controlling the reaction temperature and pH value, dripping the compound (II) and sodium bicarbonate solution, dispensing liquid after reaction, adjusting pH value to wash, adjusting pH value again to 2.0, extracting reaction solution, and drying to obtain a compound (IV); using sodium iso-octoate to salify, and refining crude products, to obtian the ticarcillin sodium salt.

Owner:LUNAN PHARMA GROUP CORPORATION

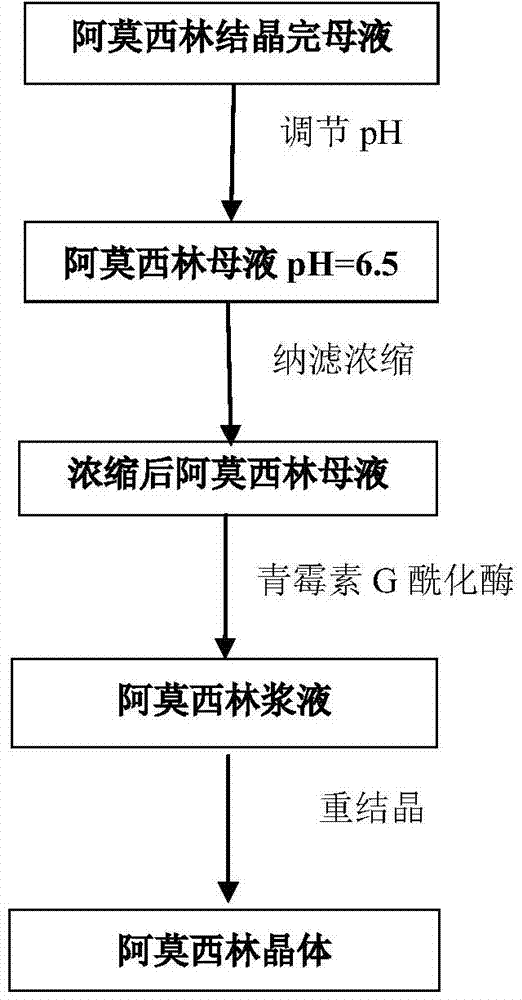

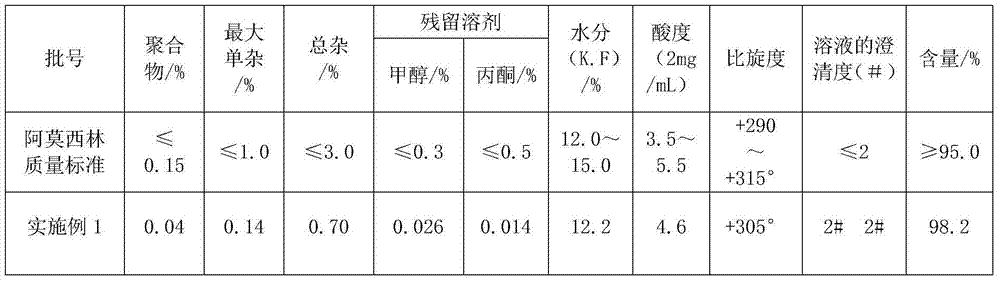

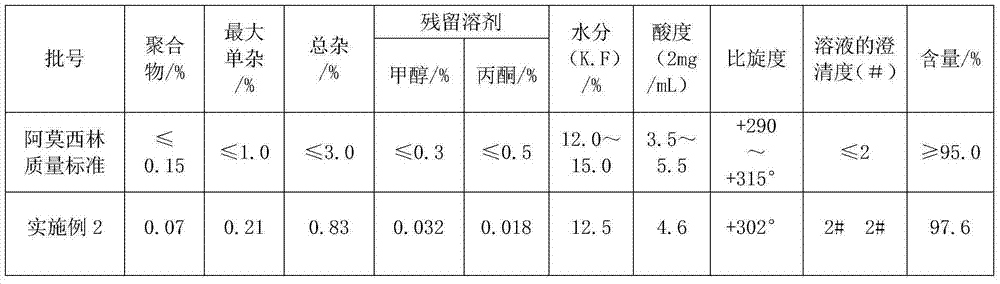

Recycling process of amoxicillin in enzymatically synthesized amoxicillin mother liquor

The invention discloses a recycling process of amoxicillin in enzymatically synthesized amoxicillin mother liquor. The process comprises the following steps: concentrating the amoxicillin mother liquor through the adoption of nanofiltration membrane high-power concentration equipment, feeding the concentrated liquor in a reaction tank, sufficiently reacting the 6-APA in the concentrated liquor with methyl D-(-)-4-hydroxy-phenylglycinate under the effect of penicillin G acylase so as to generate the amoxicillin. The recycling process disclosed by the invention has the advantages that through the nanofiltration concentration, not only the amoxicillin in the mother liquor is recycled, but also the 6-APA contained in the mother liquor participates the enzymatic synthesis reaction to be translated into the amoxicillin, the aim of extremely recycling the amoxicillin in the mother liquor is achieved, and the recycling process has more economy.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

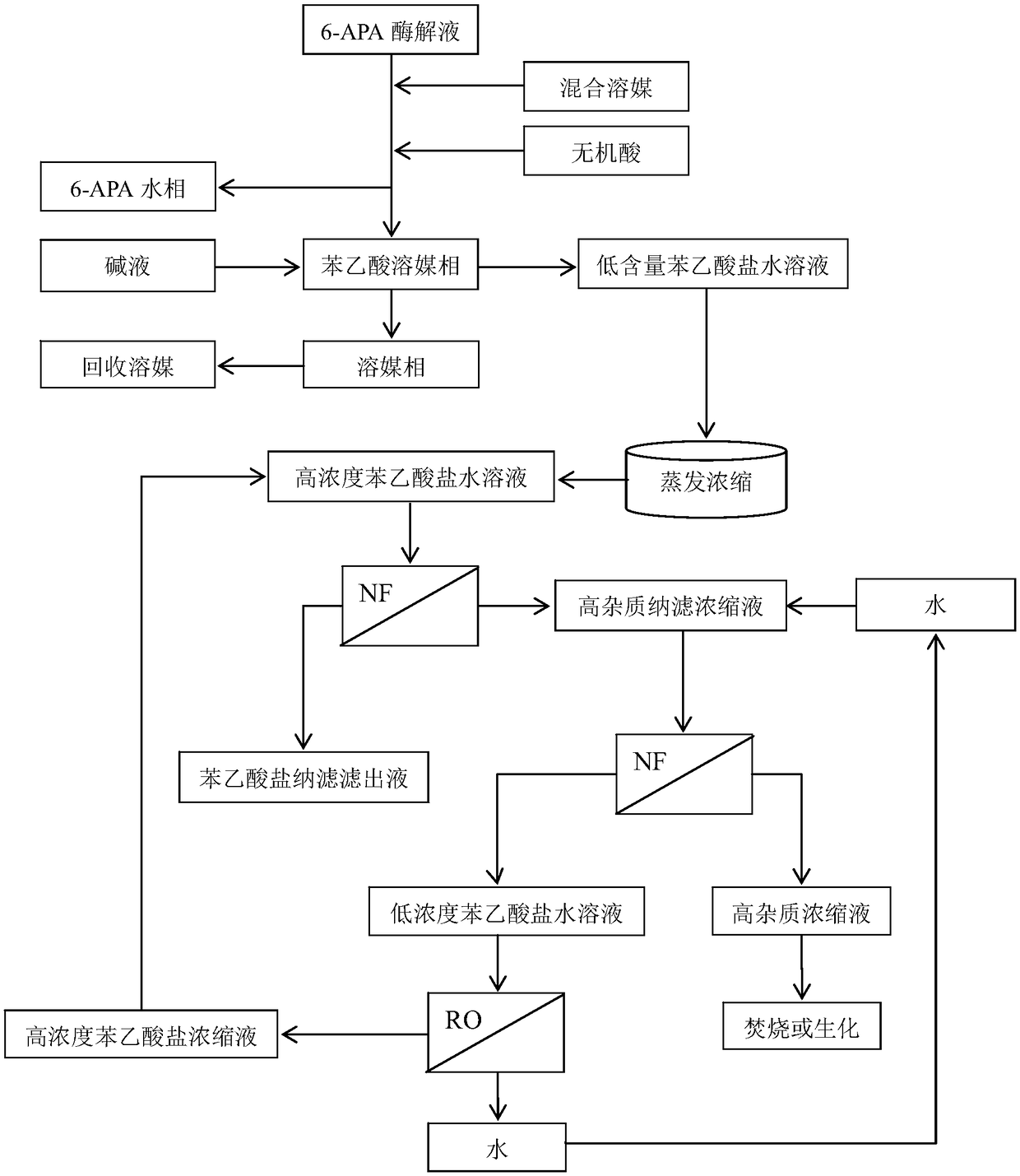

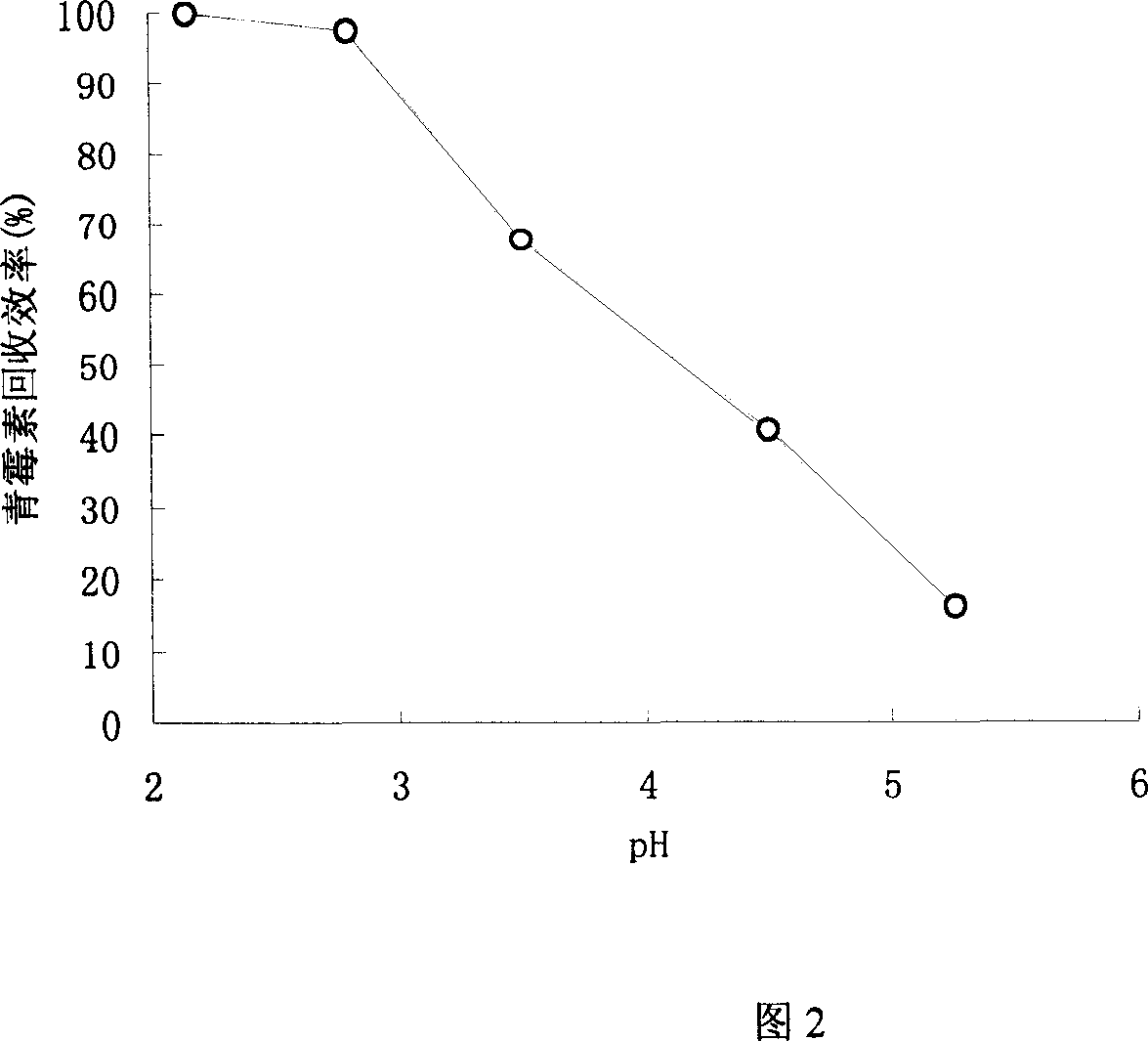

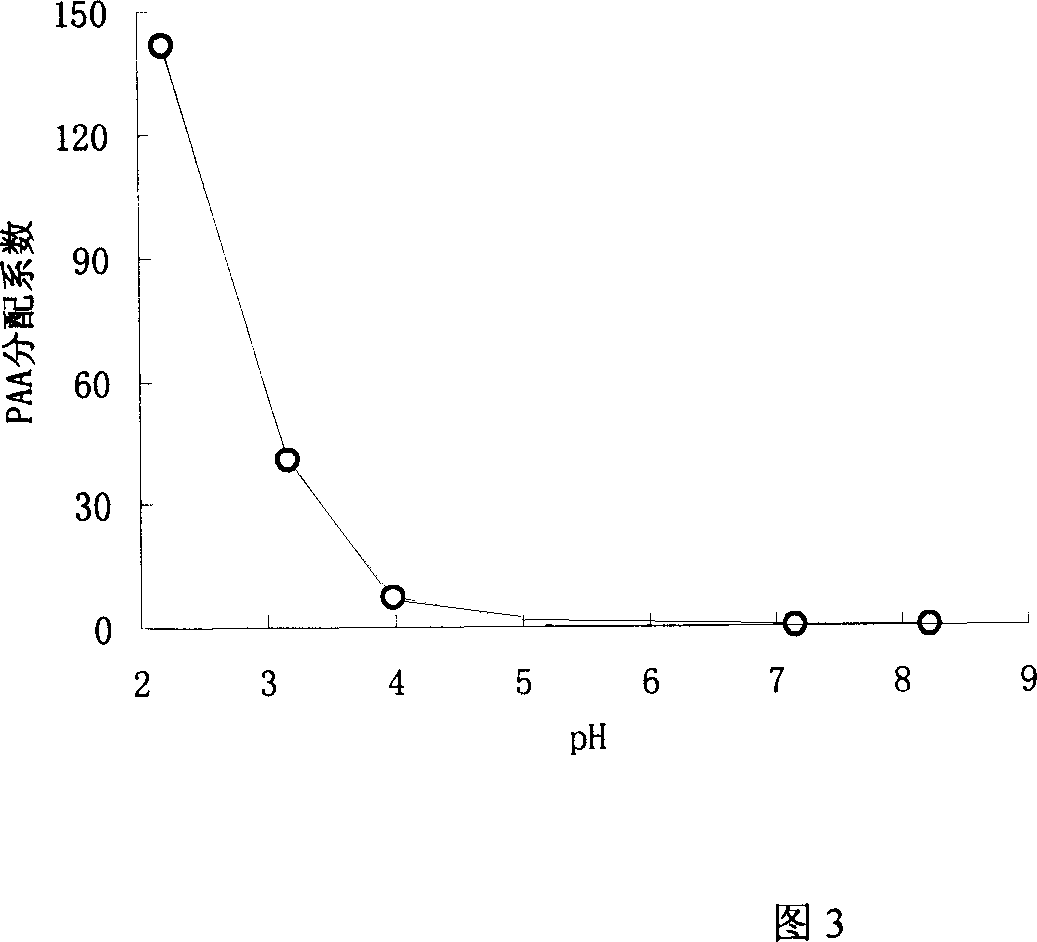

Method for recovering phenylacetic acid in enzymatic aqueous solution of 6-aminopenicillanic acid

ActiveCN108658757ALess dischargeReduce usageCarboxylic compound separation/purificationPhenylacetic acidEvaporation

The invention relates to a method for recovering phenylacetic acid (PAA) in an enzymatic aqueous solution of 6-aminopenicillanic acid (6-APA). The method comprises the following steps: firstly, usinga mixed solvent to extract PAA from the enzymatic aqueous solution of 6-APA to a solvent phase, so as to enable 6-APA to be separated from PAA; then, performing lye stripping and evaporation concentration on the solvent phase to obtain an aqueous solution containing phenylacetate; and finally, recovering PAA in the aqueous solution in a manner of combining secondary nanofiltration with reverse osmosis. The method provided by the invention can directly separate and obtain high-quality aqueous solution of phenylacetate from the enzymatic aqueous solution of 6-APA in a manner of combining extraction, stripping, concentration and nanofiltration, can be directly used for fermentation to produce penicillin, further treats high-impurity nanofiltration concentrate in a manner of combining water dilution, nanofiltration and reverse osmosis, realize zero discharge of PAA, and minimizes discharged wastes by recycling of a solvent and water in the process.

Owner:SHANXI WEIQIDA PHARMA IND

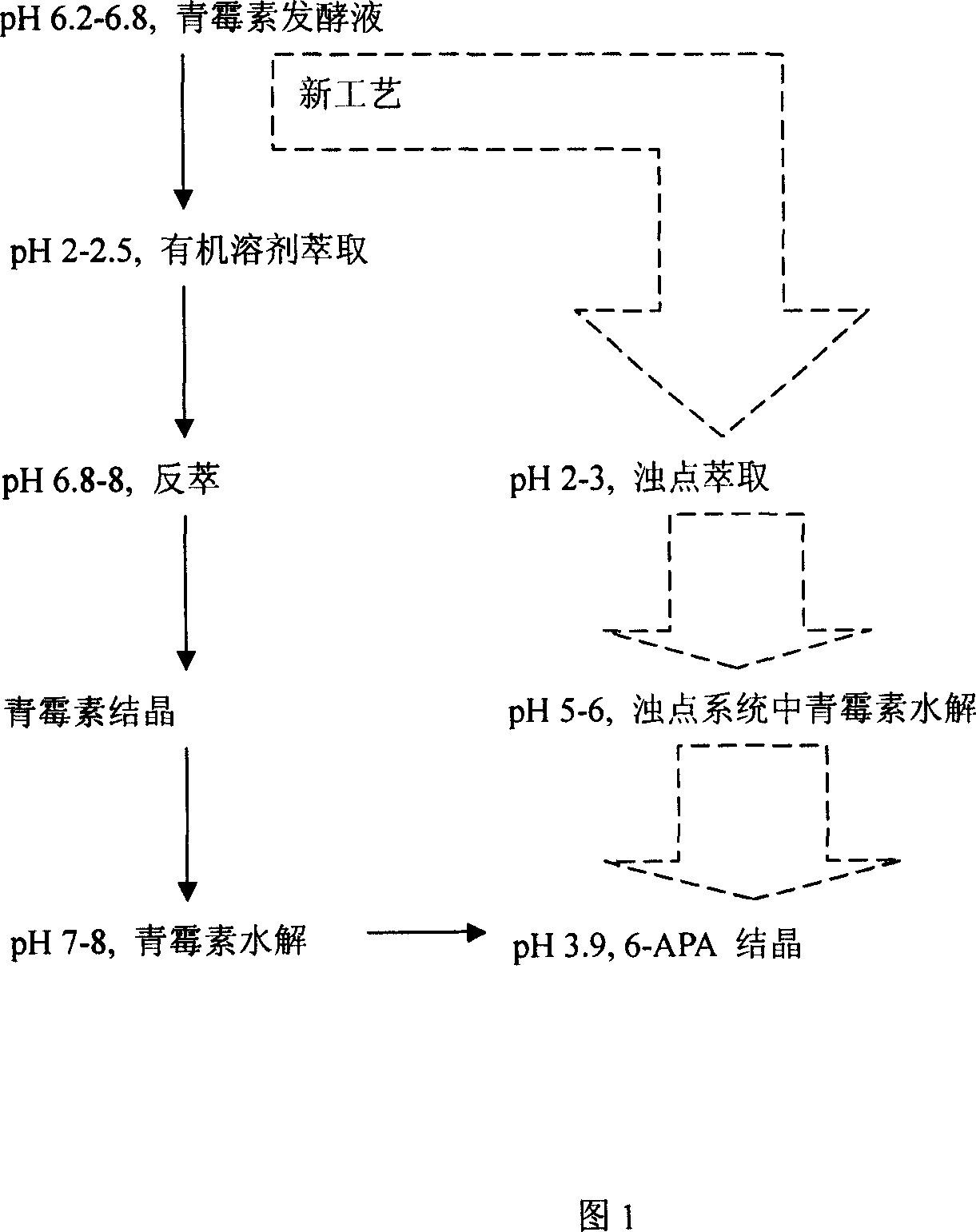

Application of cloud point system two-phase distribution bioreactor in 6-APA preparation by hydrolyzing penicillin with enzyme

The present invention discloses the application of cloud point system in enzymati hydrolysis of penicillin to prepare 6-amino cefo alkanoic acid. By means of two phase distributing bioreactor technology with cloud point system, penicillin acylating enzyme is used in enzymati hydrolysis of penicillin G to prepare semi-synthesized 6-amino cefo alkanoic acid as the key intermediate for beta-lactam antibiotic. The process has direct extraction of penicillin from the fermented liquid without need of penicillin crystallization, direct extraction of phenylacetic acid in hydrolysis without needing addition acid or alkali to control pH value, and less produced wastes.

Owner:YICHENG GOTO PHARMA

Enzymatic conversion in a solvent mixture containing water and flourinated, non-chlorinated solvent

InactiveUS6383772B1Reduce capacityOrganic compound preparationOn/in organic carrierPhenylacetic acidFiltration

A first compound is converted to a second compound enzymatically in a solvent mixture containing water and a fluorinated, non-chlorinated alkane, alkene, or alkyne having up to 4 carbon atoms. Lactams, for example 6-aminopenicillanic acid (6-APA), may be prepared by enzymatic conversion of a first compound, for example penicillin-G, in a solvent mixture comprising water and a non-aqueous organic solvent, for example 1,1,1, 2-tetrafluoroethane. The 6-APA can be caused to precipitate, isolated by filtration and optionally derivatized to produce a desired compound. A by-product of the enzymatic conversion, for example phenylacetic acid, can be isolated by solvent extraction, suitably using a solvent which also comprises 1, 1, 1, 2-tetrafluoroethane.

Owner:ADVANCED PHYTONICS OSSET

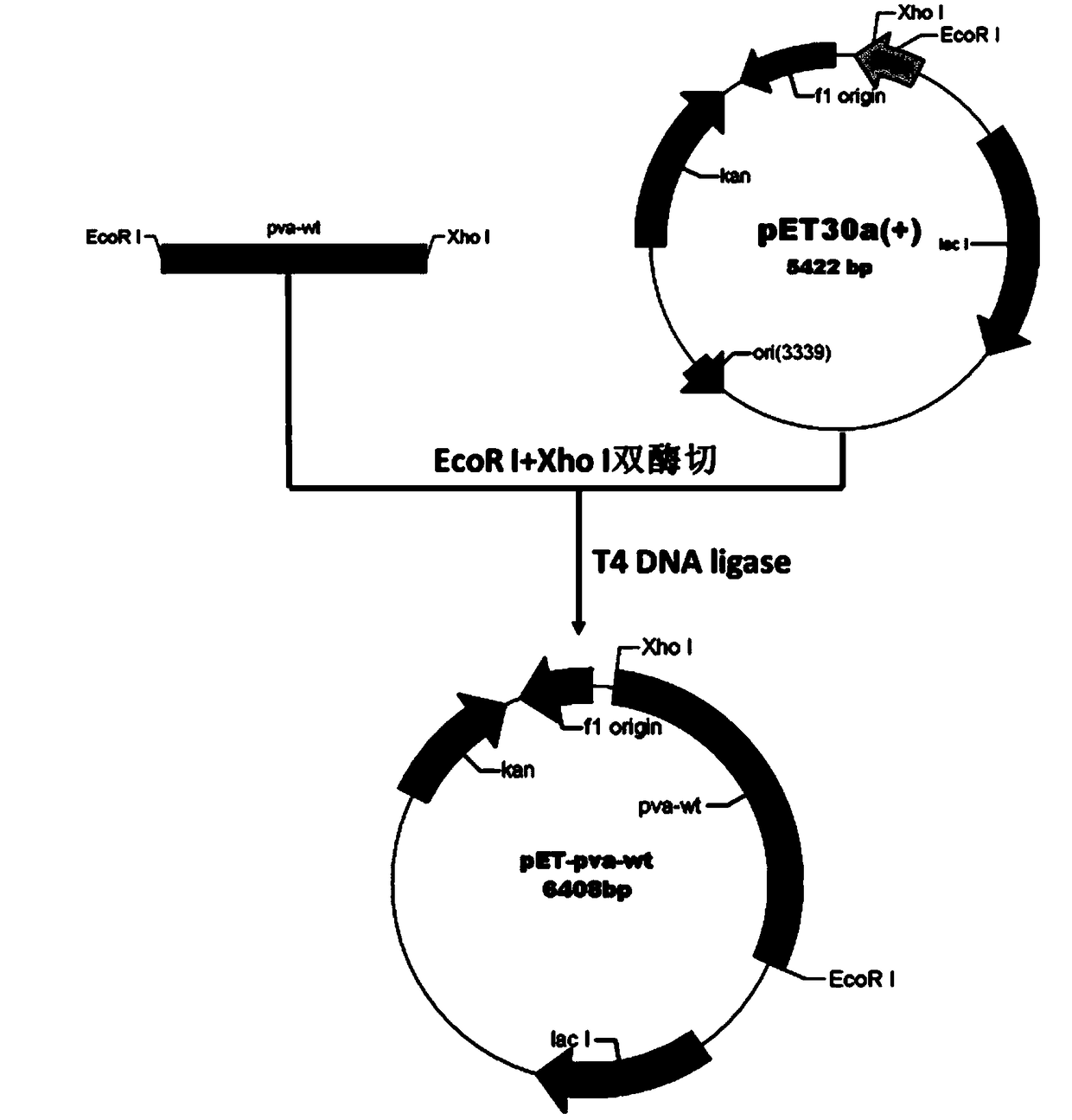

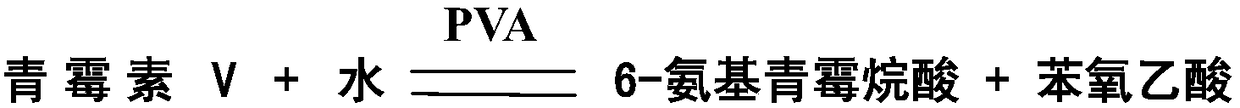

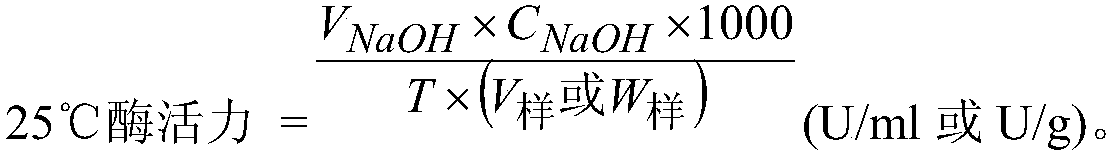

Penicillin V acylase mutant, encoding array, recombinant expression vector, genetically engineered bacterium and application

ActiveCN109161540AHigh catalytic activityRapid catalytic hydrolysisHydrolasesOn/in organic carrierContinuous useMutant

The invention provides a penicillin V acylase mutant, an encoding array, a recombinant expression vector, a genetically engineered bacterium and application. Penicillin V acylase derived from Bacillussphaericus is mutated, the specific activity of the obtained mutant PVA-3 is improved by nine times, the immobilization activity is improved to 820U / g from 92U / g, and after being incubated for one hour under a condition of 30% penicillin V sylvite, the mutant has activity residue of 89.1%; the reaction time that the immobilized mutant PVA-3 is adopted to prepare 6-APA (6-Aminopenicillanic Acid) by splitting 25% penicillin V under a condition that the pH value is 6.0 at 25 DEG C is shortened to 60 minutes from 180 minutes, a substrate conversion rate is increased to 99.5% or greater, the activity is not greatly lost after continuous use for 600 times or greater, and good operation stability can be achieved. By adopting the mutated PVA-3, the production cost can be greatly reduced, the production efficiency can be improved, and the mutant is applicable to industrial application.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

Process for the preparation of immobilized recombinant penicillin acylase catalyst from Achromobacter sp. CCM 4824 expressed in E. coli BL 21 CCM 7394 and its use for the synthesis of beta-lactam antibiotics

ActiveCN101802212BImprove synthesis abilityExtended active timeFermentationAmpicillinBeta lactam antibiotic

The present invention discloses isolation of Penicillin Acylase (PA) from Achromobacter sp CCM 4824 expressed in recombinant strain E. coli BL21 CCM 7394 bearing the recombinant plasmid pKXIP1 and processing of PA into biocatalyst useful for the industrial synthesis of antibiotics. More particularly the invention discloses a synthesis of semi-synthetic &bgr;-lactam antibiotics in the reaction mixture consisting of activated acyl-donor (D-p-hydroxyphenylglycine methyl ester or amide for Amoxicillin and Cefadroxil; D-phenylglycine methyl ester or amide for Ampicillin and Cephalexin) and nucleophile (6-APA or 7-ADCA) catalyzed by PA obtained from recombinant E. coli BL21 CCM 7394 as the biocatalyst.

Owner:FERMENTA BIOTECH

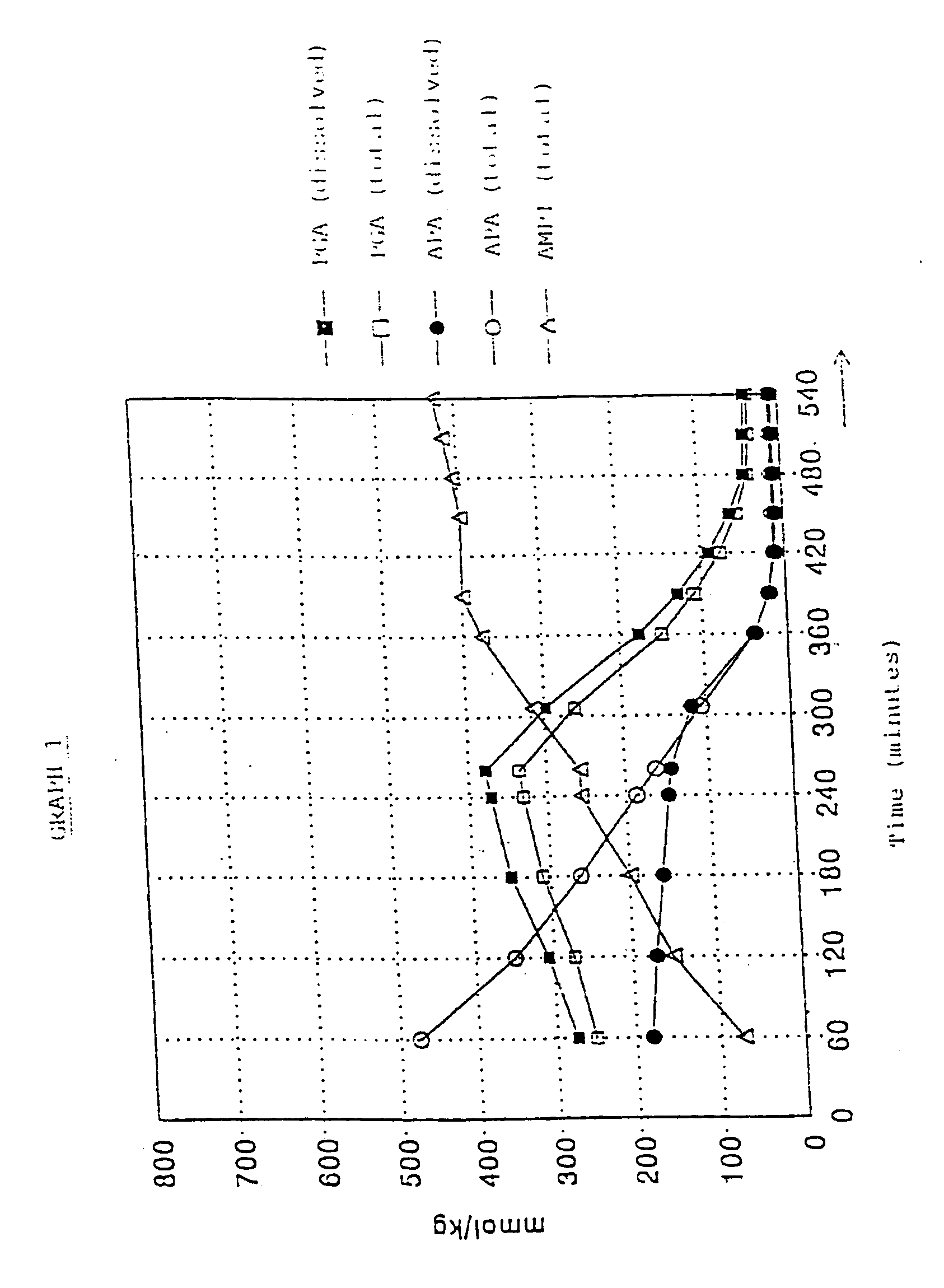

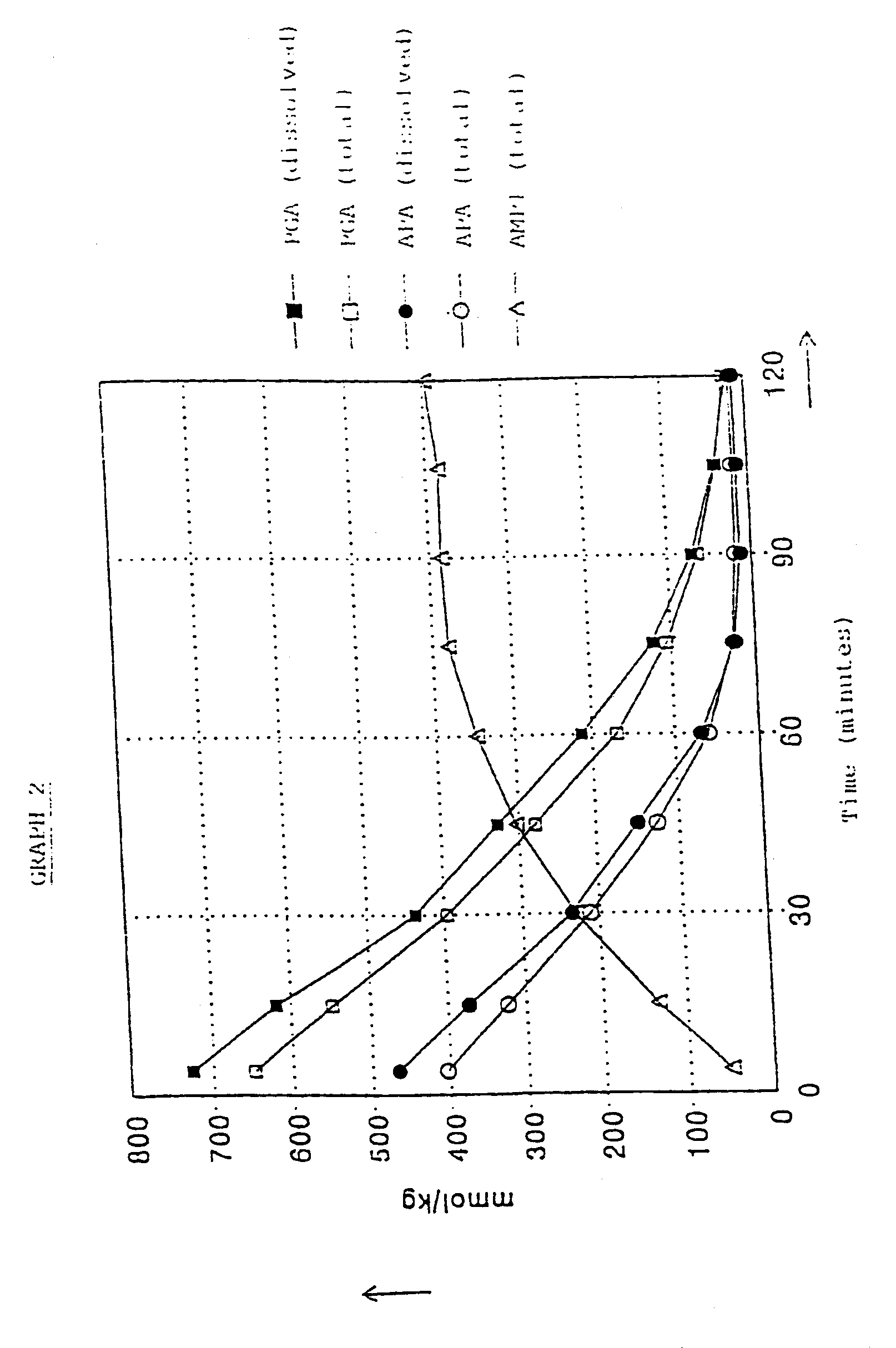

Process for the preparation of ampicillin

InactiveUS7029885B2Speed up the conversion processStirrability is betterEnzymesFermentationAmpicillinBenzylpenicillin

Ampicillin is produced in a batch process by enzymatic acylation of 6-aminopenicillanic acid (6-APA) with the aid of phenylglycine derivative such as D-phenylglycine amide. High conversions of phenylglycine derivative may be achieved by having the total concentration in the reaction mixture of 6-APA and ampicillin greater than 250 mM and the molar ration of total quantity of phenylglycine derivative to total quantity of 6-APA less than 2.5. Higher yields of ampicillin may be achieved when the amount of dissolved 6-APA is kept low, e.g. below 300 mM.

Owner:DSM SINOCHEM PHARMA NETHERLANDS

Improved method for recycling phenylacetic acid waste liquid in 6-APA production

ActiveCN109534983AReduce recycling costsEasy to operateSulfate/bisulfate preparationCarboxylic compound separation/purificationSulfate radicalsPhenylacetic acid

The invention relates the field of pharmacy, and specifically relates to an improved method for recycling phenylacetic acid waste liquid in 6-APA production. The method includes the following steps: (1) performing extraction; (2) performing degreasing; (3) performing heat preservation; (4) performing decolorization and impurity removal; (5) performing crystallization; and (6) processing sulfate radical in mother liquor. The method can perform decolorization under a water phase condition without using a solvent, so that costs can be obviously saved, and the recycling rate of phenylacetic acid can reach more than 90%; and the color of an obtained product is white, and the purity of the product can reach more than 99%. The processing and recycling of the sulfate radical in the mother liquor are also related, so that generated inorganic salt is less, and the pollution on environments is less, and therefore, the products obtained through the method can be applied to penicillin fermentation.

Owner:UNITED LAB INNER MONGOLIA CO LTD

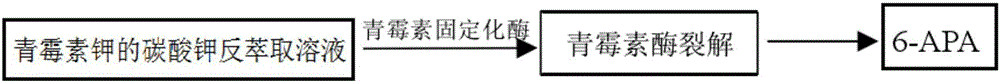

6-APA (6-amino-penicillanic acid) and preparation method thereof

InactiveCN106086151AReduce yieldLight in massOrganic chemistryFermentationBenzylpenicillin potassiumSolvent

The invention provides a preparation method of 6-APA (6-amino-penicillanic acid). 6-APA is prepared from a potassium carbonate reversed-extraction liquid of benzylpenicillin potassium directly, a molecular formula of 6-APA is C8H12N2O3S, and the molecular weight is 216.26. With the adoption of the process, a crystallization step can be omitted, and crystallization yield loss is avoided; extracting and washing processes of a penicillin solvent are optimized in a technical process; with the adoption of the advanced preparation process, the preparation method is higher in yield and lower in cost.

Owner:FARMASINO PHARMA ANHUI

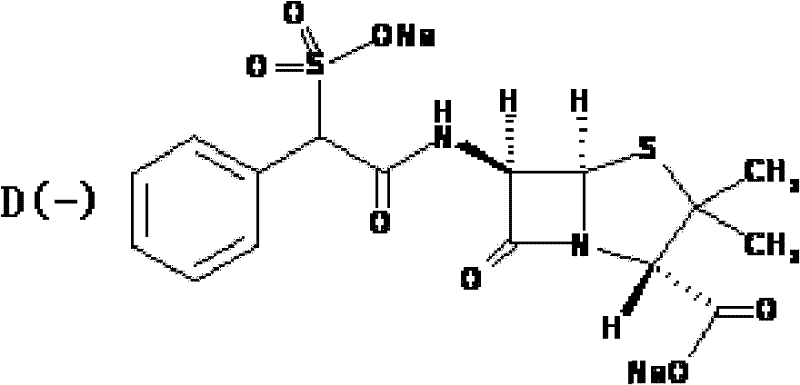

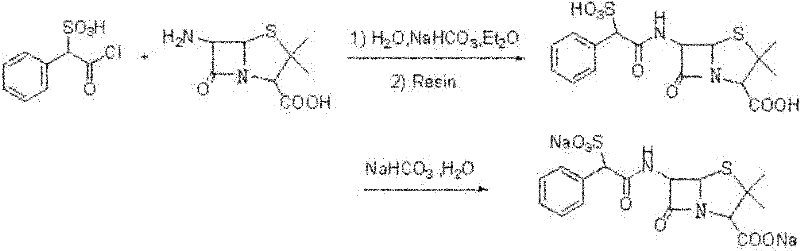

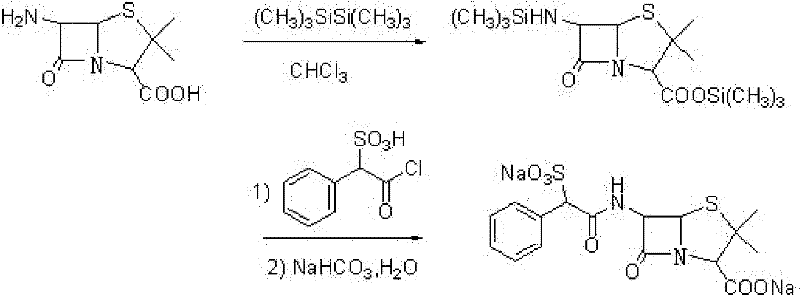

Preparation method of D(-)-sulbenicillin sodium

The invention provides a preparation method of D(-)-sulbenicillin sodium, which comprises the following steps: preparing D(-)-sulfophenylacetyl chloride from D(-)-sulfophenylacetic acid; preparing a D(-)-sulbenicillin sodium crude product from the D(-)-sulfophenylacetyl chloride and 6-APA; and purifying to obtain the final product D(-)-sulbenicillin sodium, wherein the 6-APA and the D(-)-sulfophenylacetyl chloride are added to a mixed solvent of water, ethanol and 2-methyltetrahydrofuran and react at the pH of 5.6-7.0 and the room temperature of 15-25 DEG C for 20-40 minutes. The preparation method has mild reaction condition, high yield and high purity of the obtained product.

Owner:HUNAN SANQING PHARMA +1

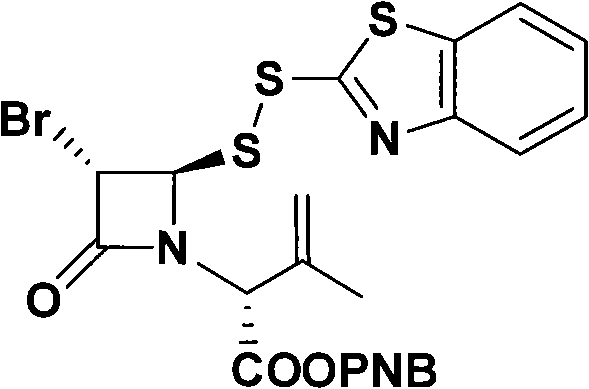

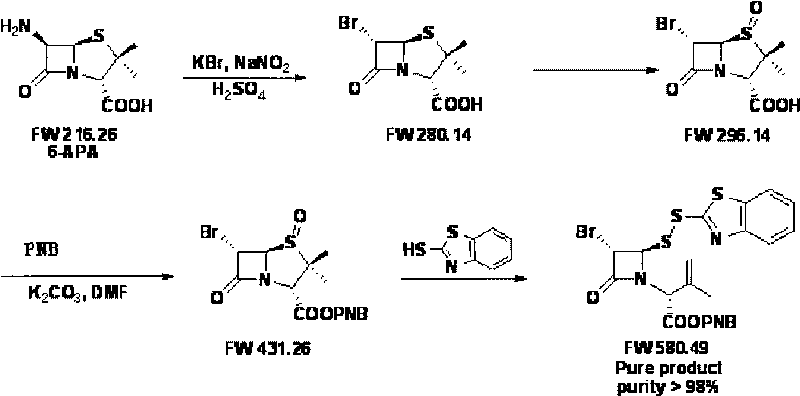

Synthesis method of single-ring imipenem p-nitro benzyl ester

InactiveCN101747328AEasy to makeEasy post-processingOrganic chemistryOrganic solventSynthesis methods

The invention belongs to the technical field of medicines and in particular discloses a synthesis method of single-ring imipenem p-nitro benzyl ester. In the method, 6-APA is used as a raw material, and the single-ring imipenem p-nitro benzyl ester is prepared through reactions of nitration, bromination, oxidation, esterification, ring-opening, and the like. The method is characterized in that noval reagents and catalysts are adopted during synthesis, a single aromatic organic solvent is used as a reaction solvent, and an obtained product is easy to recover and convenient to apply. In the synthesis process, a one-pot synthesis method is adopted, thereby simplifying the process flow and shortening the production period.

Owner:SHANDONG RUNZE PHARMA

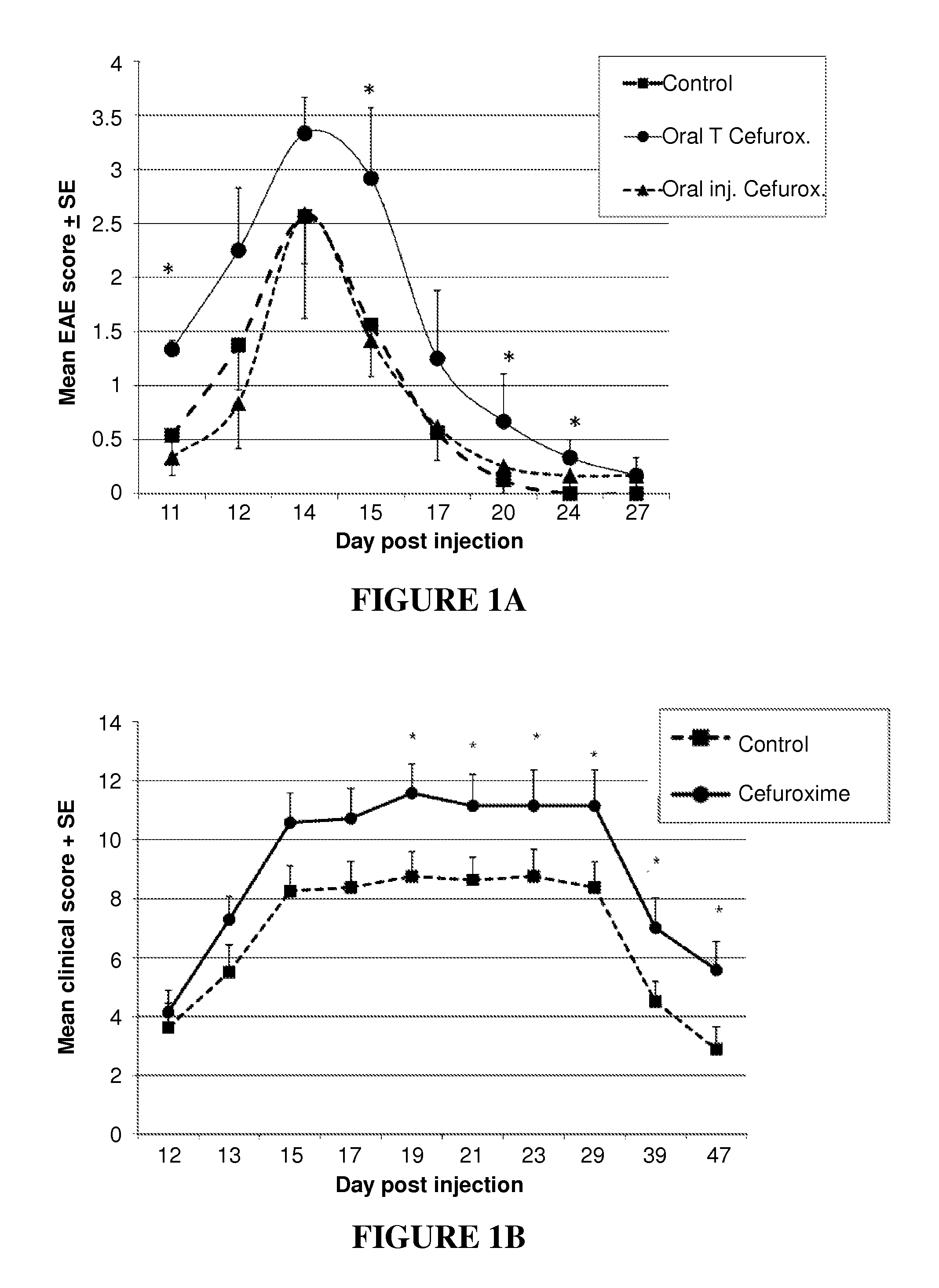

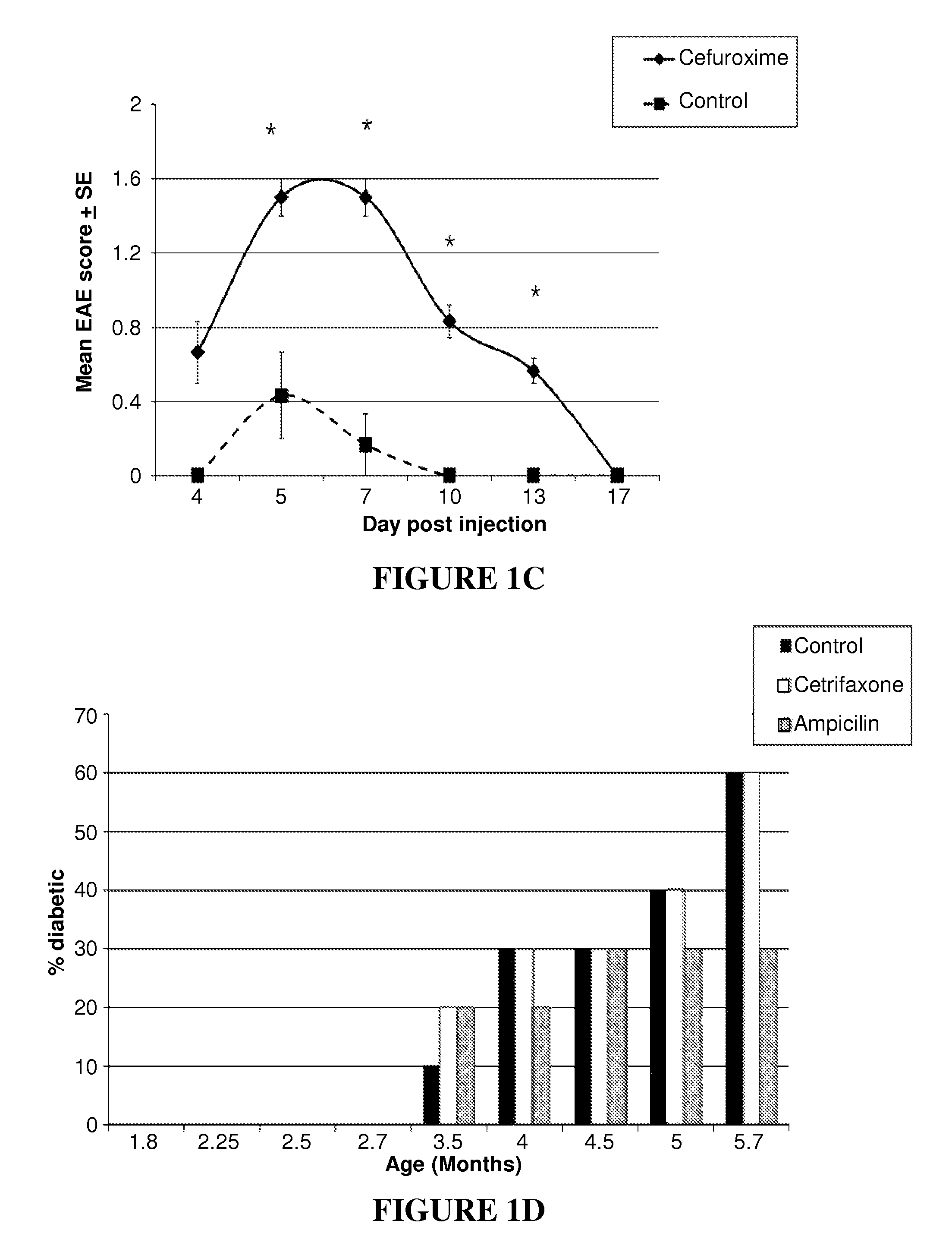

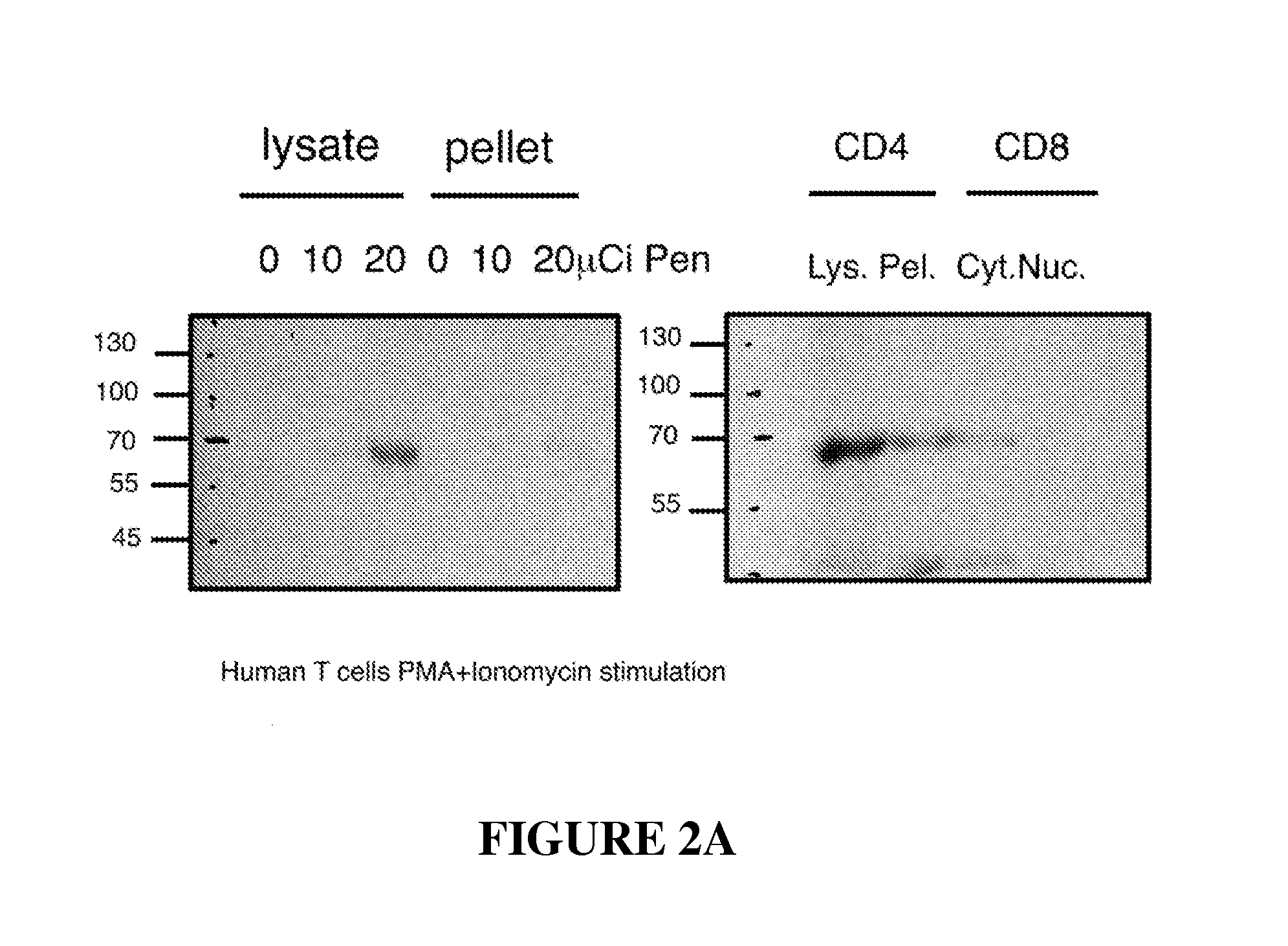

Beta-lactam compounds for enhancing T cell-mediated immune responses

ActiveUS9345691B2Facilitates rejectionInhibit tumor growthPeptide/protein ingredientsMammal material medical ingredientsT cell mediated immunityCefuroxime

Compositions and methods are provided, comprising at least one beta-lactam compound selected from the group consisting of cefuroxime, a penicillin, ceftriaxone, clavulanic acid, 6-aminopenicillanic acid (6-APA) and tazobactam, for enhancing T cell mediated immune responses in a subject, such as anti-tumor and anti-viral immune responses.

Owner:STEM CELL MEDICINE

Process for the preparation of immobilized recombinant penicillin acylase catalyst from achromobacter sp. ccm 4824 expressed in e. coli bl 21 ccm 7394 and its use for the synthesis of beta-lactam antibiotics

The present invention discloses isolation of Penicillin Acylase (PA) from Achromobacter sp CCM 4824 expressed in recombinant strain E. coli BL21 CCM 7394 bearing the recombinant plasmid pKXIP1 and processing of PA into biocatalyst useful for the industrial synthesis of antibiotics. More particularly the invention discloses a synthesis of semi-synthetic β-lactam antibiotics in the reaction mixture consisting of activated acyl-donor (D-p-hydroxyphenylglycine methyl ester or amide for Amoxicillin and Cefadroxil; D-phenylglycine methyl ester or amide for Ampicillin and Cephalexin) and nucleophile (6-APA or 7-ADCA) catalyzed by PA obtained from recombinant E. coli BL21 CCM 7394 as the biocatalyst.

Owner:FERMENTA BIOTECH

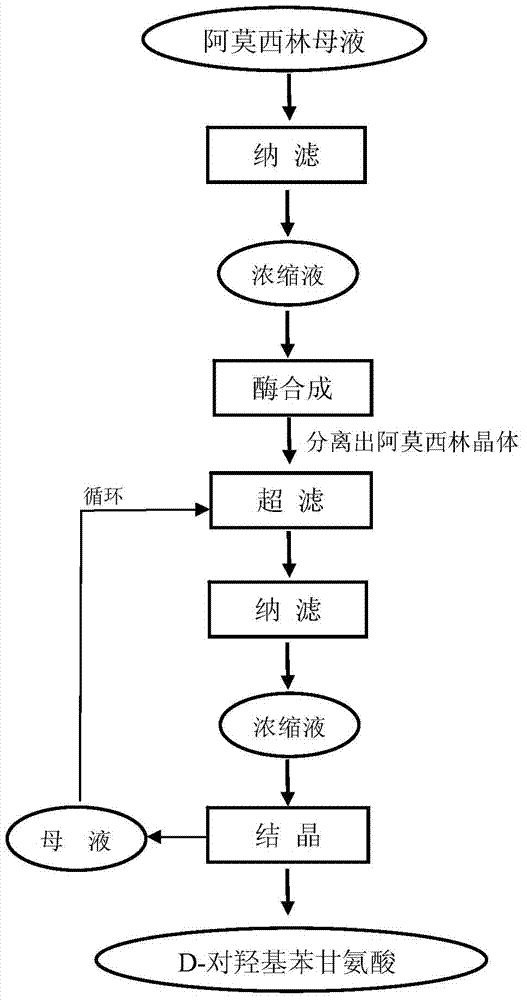

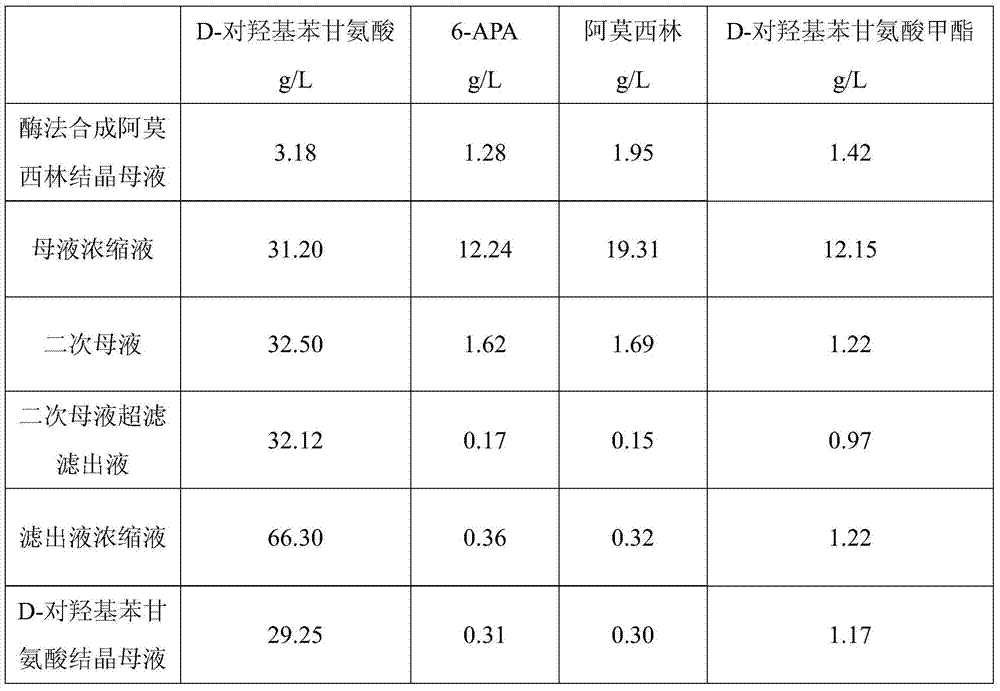

Method for Comprehensive Recovery of Active Components in Enzymatic Amoxicillin Mother Liquor

ActiveCN104357528BImprove product qualityCreate economic growthOrganic compound preparationAmino-carboxyl compound preparationUltrafiltrationBULK ACTIVE INGREDIENT

The invention relates to a method for comprehensively recovering effective ingredients in amoxicillin mother liquid prepared by an enzyme process. The method comprises the following steps: (1) concentrating the amoxicillin mother liquid, namely adjusting the pH value of the amoxicillin mother liquid prepared by the enzyme process to be 8.0-9.5, and performing nanofiltration and concentration to obtain concentrated mother liquid; (2) synthesizing amoxicillin under enzyme catalysis, namely adjusting the pH value of the concentrated mother liquid to be 5.8-7.0, and converting 6-APA (6-amino penicillanic acid) and D-methyl hydroxyphenyl glycinate into amoxicillin in the presence of immobilized penicillin acylase for synthesis; (3) preparing D-hydroxyphenyl glycine concentrated liquid by ultrafiltration and nanofiltration, namely separating after the enzyme catalysis reaction is ended to obtain amoxicillin crystals and secondary amoxicillin mother liquid, and performing ultrafiltration and nanofiltration on the secondary mother liquid to obtain the D-hydroxyphenyl glycine concentrated liquid; (4) crystallizing D-hydroxyphenyl glycine. According to the method, 6-APA and D-methyl hydroxyphenyl glycinate remained in the mother liquid are consumed through an indirect process of synthesizing amoxicillin under enzyme catalysis, the product quality of D-hydroxyphenyl glycine is improved, and the yield of D-hydroxyphenyl glycine is increased.

Owner:SHANXI WEIQIDA PHARMA IND

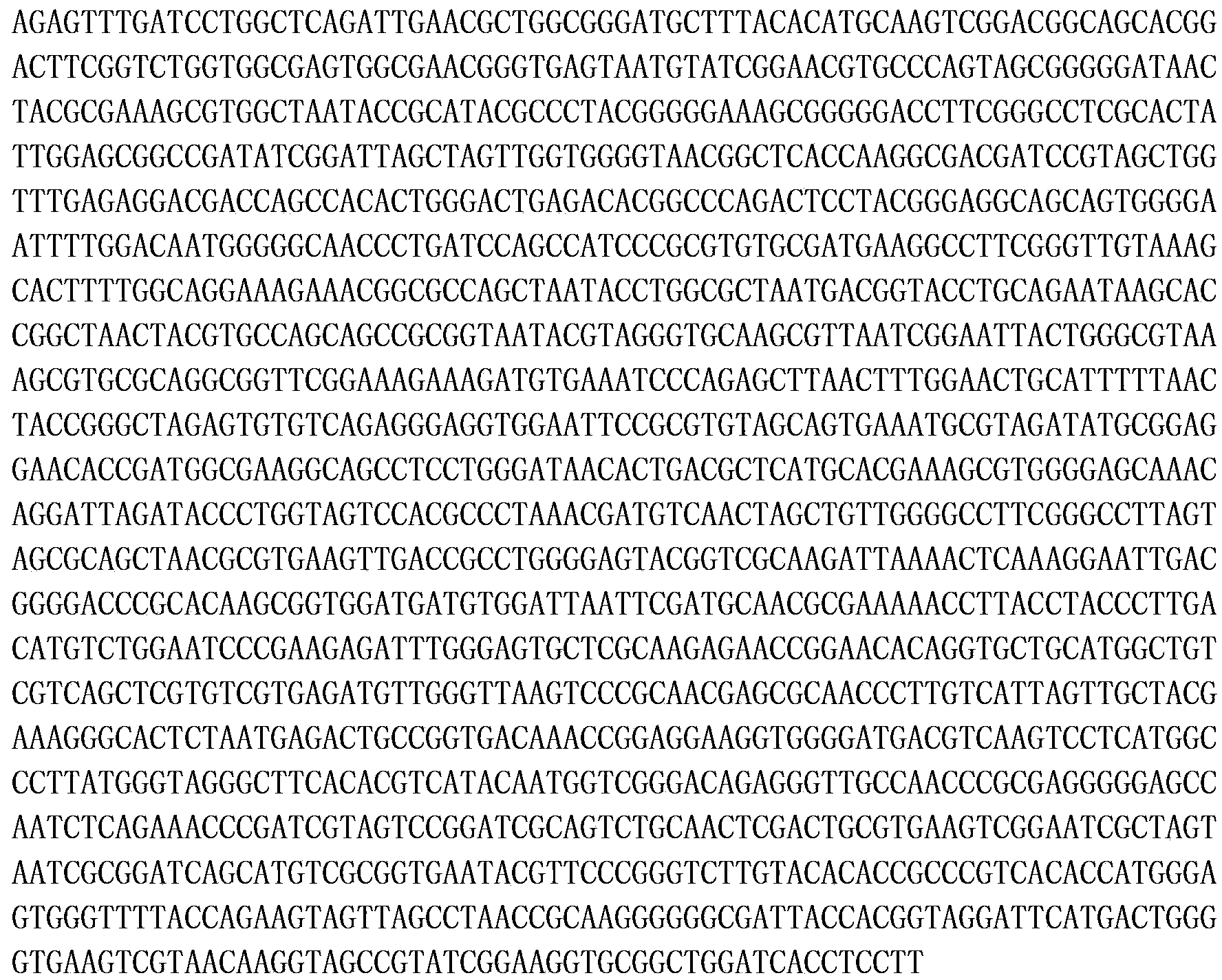

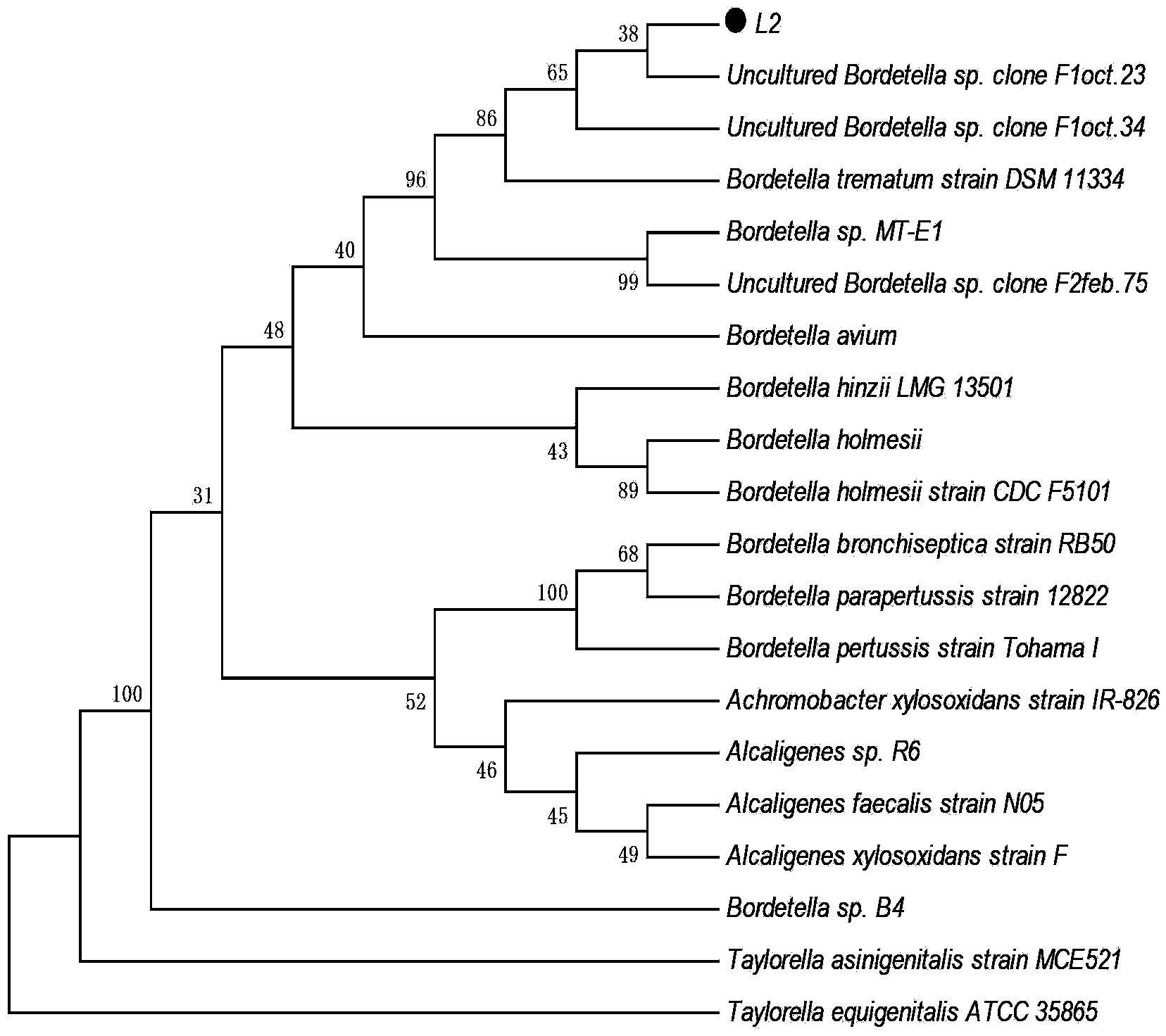

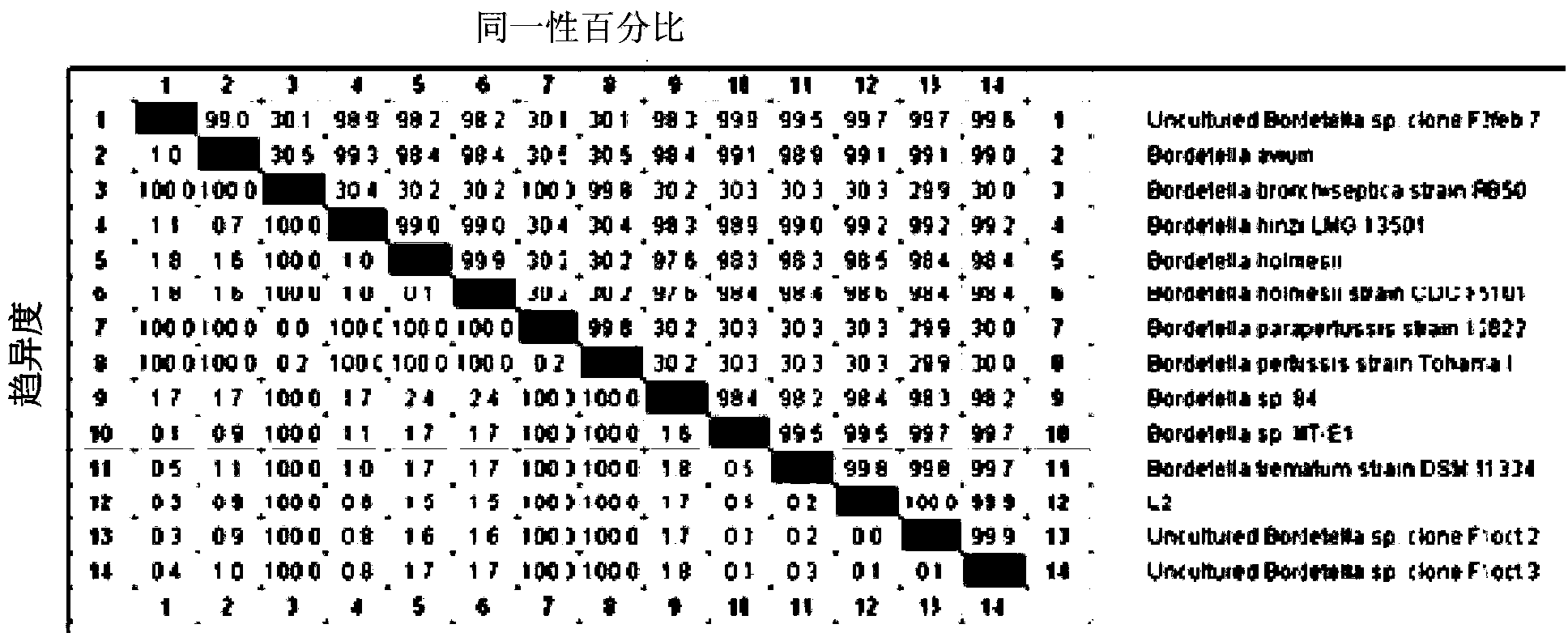

6-aminopenicillanic acid degrading bacterium and screening method thereof

ActiveCN103184177BImprove the ability to hydrolyze 6-aminopenicillanic acidBacteriaWater contaminantsBacteroidesScreening method

The invention relates to a 6-aminopenicillanic acid (6-APA) degrading bacterium and a screening method thereof. Particularly, the invention relates to a strain of 6-APA degrading bacterium Bordetella sp.L2, which is preserved in China General Microbiological Culture Collection Center (CGMCC) on October 18, 2012, with the preservation number of CGMCC No. 6691; and the GenBank registration number of the 16S rRNA gene sequence of the 6-APA degrading bacterium Bordetella sp.L2 is HQ840720. The 6-APA degrading bacterium Bordetella sp.L2 is an aerobic bacillus brevis; and when the pH value is 8.0, the 6-APA degradation rate of the 6-APA degrading bacterium Bordetella sp.L2 is 28%. The strain achieves higher 6-APA degradation capability and has a practical significance and an important engineering application value for treatment of waste water containing 6-APA cephalosporin.

Owner:CHINA THREE GORGES CORPORATION

Process for the fermentative production of penicillin

The present invention discloses an improved process for the preparation of 6-amino penicillanic acid (6-APA) from a fermentatively produced N-substituted penicillin comprising the steps of extraction of the N-substituted penicillin compound as present in a fermentation broth or fluid to an organic solvent, back extraction of the N-substituted penicillin compound to water, treatment of the aqueous phase with a penicillin acylase and isolation of the 6-APA from the thus-obtained conversion solution by crystallization. Further improvements comprise extraction of the side chain to an organic solvent and isolation of 6-APA from the thus-obtained aqueous phase using a specific crystallization process.

Owner:DSM NV

Penicillin amidase immobilized carrier and its preparing method

The invention discloses a preparation method of a penicillin acylase immobilized carrier. In the invention, the surface active agent is used as the dispersant, the vinyl compound is used as the monomer, and the cross-linking polymerization is carried out by adopting the reverse phase suspension technology, so as to obtain the penicillin acylase immobilized carrier. The apparent enzymatic activity of carrier-immobilized penicillin acylase (IME) to hydrolyze penicillin G potassium salt to prepare 6-APA can reach more than 125IU / g. The epoxy group-containing polymer bead carrier obtained by the method of the invention has high apparent enzyme activity, simple process, convenient operation, cheap and easy-to-obtain raw materials, and is easy for industrial scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of technology that straight-through method prepares amoxicillin

The invention discloses a technology for preparing amoxicillin by a straight-through method. The technology takes a penicillin degreasing fluid as a starting raw material; 6-APA (6-amino penicillanic acid) crystallization, suction filtration, washing and drying steps are saved; the amoxicillin can be prepared without obtaining solid 6-APA via separation; and the prepared amoxicillin meets a requirement of a medicinal standard. The technology saves an operation procedure, reduces the labor intensity of production personnel, lowers the production cost, reduces environmental protection pressure, avoids contact between the production personnel and 6-APA dry powder, and reduces anaphylaxis.

Owner:石药集团中诺药业(石家庄)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com