Patents

Literature

48results about How to "Extended active time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt modification silicoaluminophosphate molecular sieve and its preparation and catalytic application in MTO

ActiveCN101259431AImprove catalytic performanceExtended active timeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveStructural formula

The invention relates to a Co-modified silicoaluminophosphate molecular sieve, a preparation method and catalytic application in MTO thereof. The structural formula of the molecular sieve is (0.2-5.0) R: (Si0.01-1 Al0.5-1 P0.1-3):10- 400H2O: (0.01-0.5) Co. Compared with the prior art, the invention provides a Co-SAPO-34 molecular sieve, which is used as a catalyst and applied to prepare light olefins by using methanol, the transformation ratio of the methanol material achieves 100 percent. Due to the selectivity and service life of the light olefins, the Co-modified silicoaluminophosphate molecular sieve, the preparation method and the catalytic application in MTO of the invention is characterized by high selectivity (ethylene plus propylene), high yield rate and long service life of the catalytic agent.

Owner:YANKUANG ENERGY R&D CO LTD

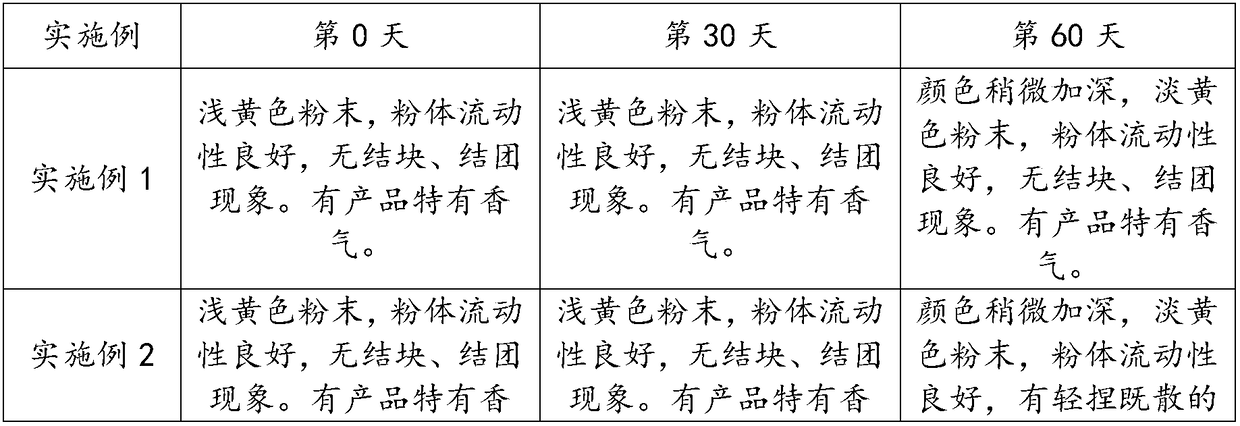

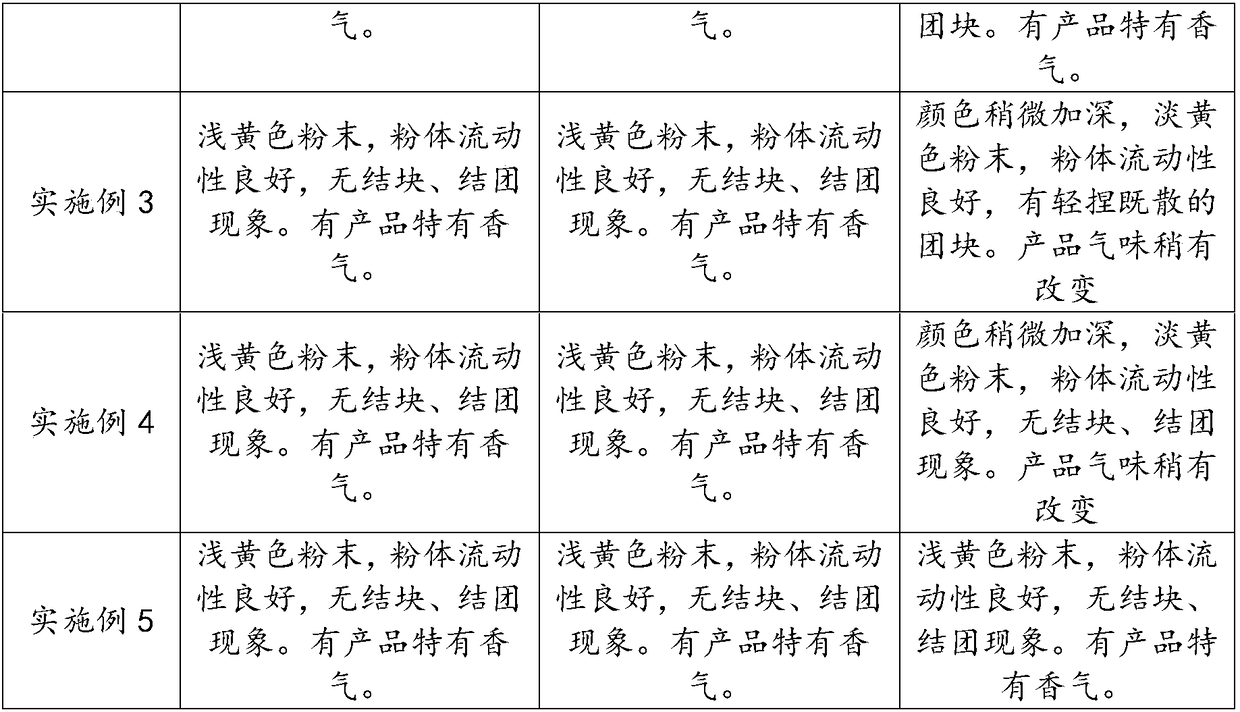

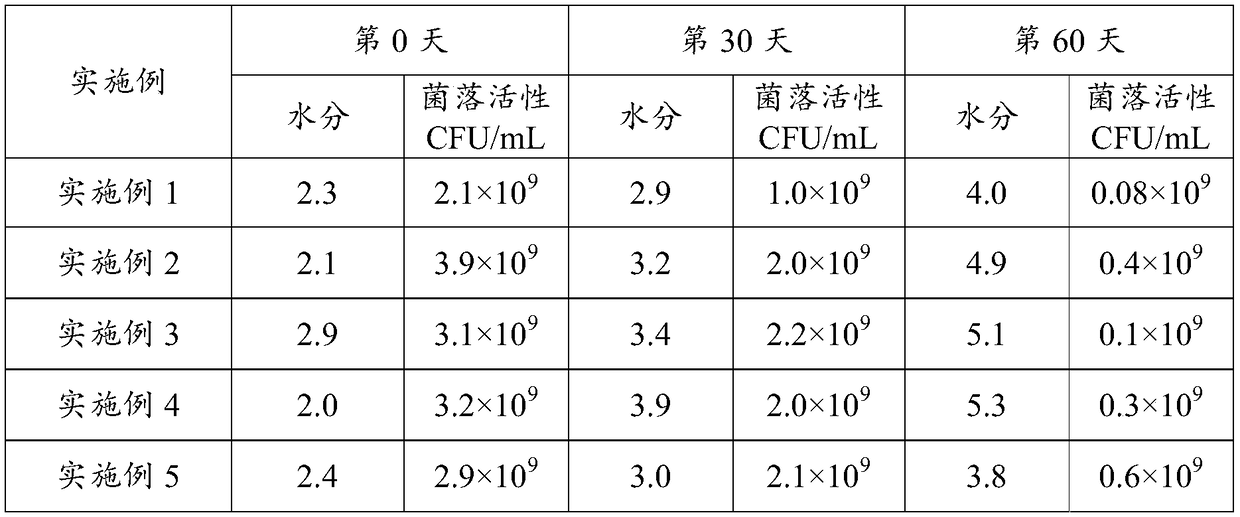

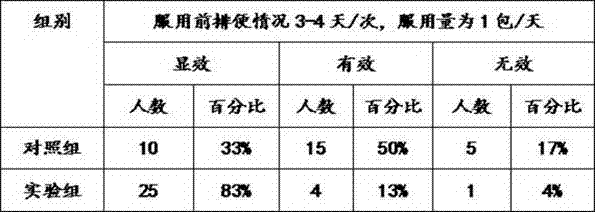

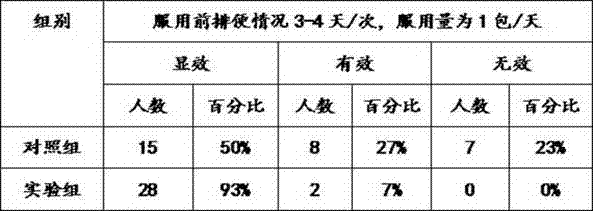

Probiotic powder solid beverage and preparation method thereof

InactiveCN108783167APlay the role of two-way regulationExtended active timeFood dryingFood ingredient functionsBacteroidesLactobacillus rhamnosus

The invention relates to a probiotic solid beverage. The probiotic solid beverage comprises the following components in percentage by weight: 2-10% of lactic acid bacteria powder, 30-50% of fructo-oligosaccharide, 5-15% of xylooligosaccharide, 10-20% of maltodextrin, 5-20% of erythritol and 5-15% of pomegranate fruit powder. According to the probiotic solid beverage disclosed by the invention, thefructo-oligosaccharide has obvious proliferation effect on beneficial bacteria of bifidobacterium lactis, lactobacilli and lactobacillus rhamnosus in gastrointestinal tracts of human bodies; the probiotics are bacteria beneficial to human, can maintain bacterial colonies balanced in the intestinal tracts, can assist in eliminating diarrhea, and can stop constipation; and the fructo-oligosaccharide and the probiotic powder are in collocation for eating, so that diarrhea can be eliminated, constipation can also be stopped, and the fructo-oligosaccharide and the probiotic powder jointly have theeffect of two-way regulation on the intestinal tracts.

Owner:沈通一

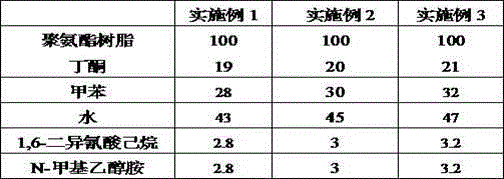

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Nutritional composition for improving oral health and use thereof

PendingCN108514112AAvoid inactivationExtended active timeFood ingredient functionsAlcoholismsIsomaltooligosaccharide

The present invention discloses a nutritional composition for improving oral health. The nutritional composition comprises the following raw materials in parts by weight: 5-30 parts of probiotics, 20-80 parts of prebiotics and 0.1-2 parts of epigallocatechin gallate; the probiotics are selected from at least one of lactobacillus rhamnosus, lactobacillus reuteri, lactobacillus helveticus, and lactobacillus salivarius; and the prebiotics are selected from at least one of inulin, oligofructose, galactooligosaccharide, xylooligosaccharide, stachyose, oligoisomaltose, raffinose, trehalose, and lactitol. At the same time, the present invention also provides a use of the nutritional composition in preparations of oral health-care products. The provided nutritional composition can inhibit colonization of caries inducing streptococcus mutans, reduces adhesion of subgingival gingiva pathogenic bacteria, inhibits bad breath, promotes the proliferation of the oral probiotics, prevents the occurrence and development of dental erosion and oral cancers, and can effectively solve the oral problems caused by alcoholism, smoking, staying up late, irregular diet, long-term consumption of acidic substances, etc.

Owner:广东康侨药业有限公司

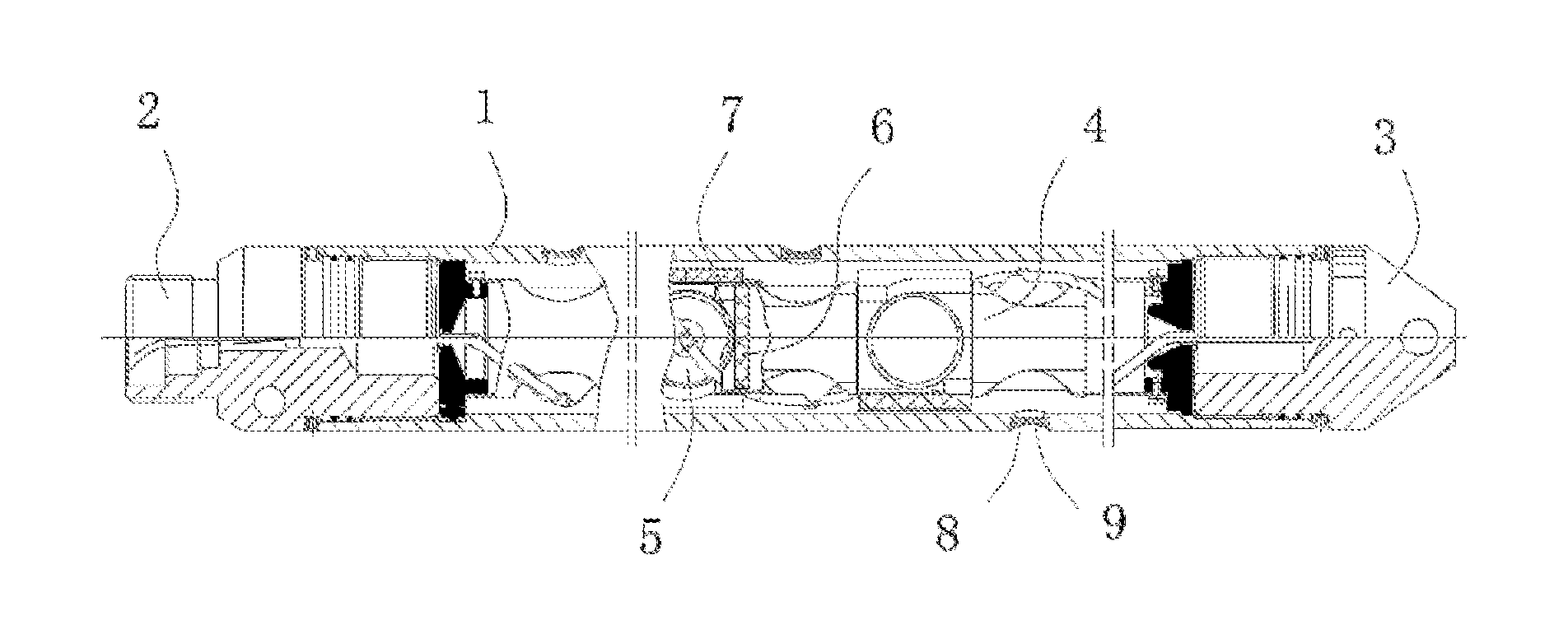

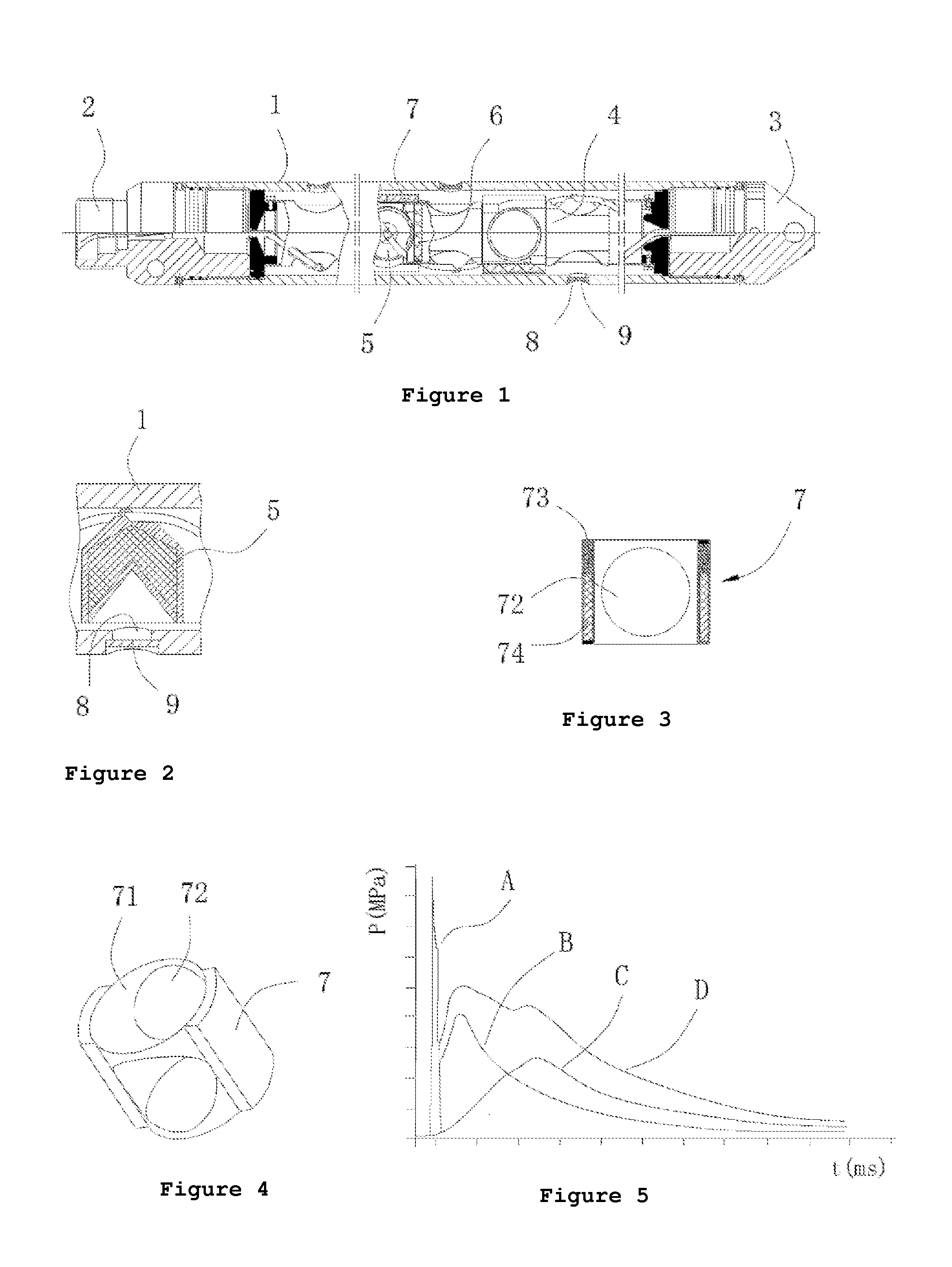

Combined fracturing and perforating method and device for oil and gas well

ActiveUS8960289B2Improve fracturing effectImprove energy efficiencyExplosive chargesNuclear explosivesPetroleum engineeringGunpowder

A combined fracturing and perforating method and device for oil and gas well are disclosed. The method utilizes an explosion of a perforating charge (5) in a combined fracturing perforator to ignite primary gunpowder in the perforator, and burning of the primary gunpowder ignites secondary gunpowder in the perforator. The body of the perforating gun in the combined fracturing and perforating device is provided with pressure releasing hole (8) which is directly facing the jet direction of said perforating charge, and sealing sheet (9) is arranged on said pressure releasing hole (8). Inner gunpowder box (6), which contains the primary gunpowder, and outer gunpowder box (7), which contains the secondary gunpowder, are mounted on the cylindrical charge frame (4).

Owner:TONG OIL TOOLS CO LTD

One alkyl triphenyl substituted group based phosphonium salt preparation method and application

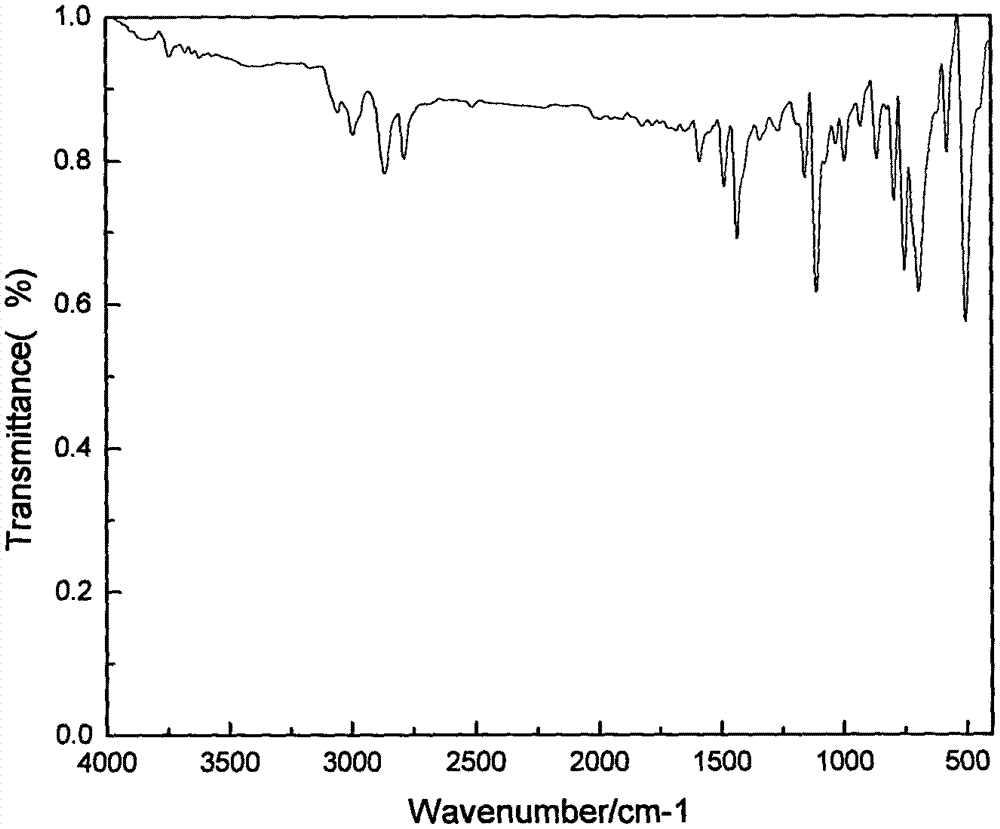

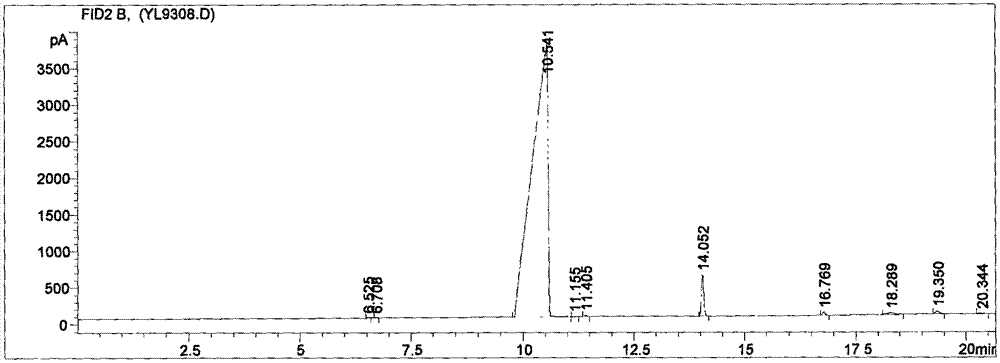

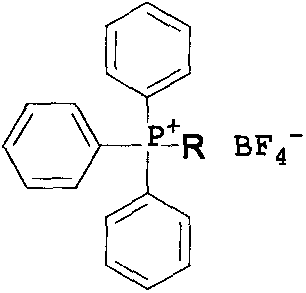

InactiveCN107129511AImprove bindingHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphonium saltSodium tetrafluoroborate

The invention discloses a one alkyl triphenyl substituted group based phosphonium salt preparation method and application. The preparation method includes that a one alkyl triphenyl phosphonium salt halide I is obtained through reaction of several alkyl halides and triphenylphosphine in a DMF (dimethyl formamide) solvent through nucleophilic substitution, and an aqueous solution of a compound I and a sodium tetrafluoroborate aqueous solution are subjected to ion exchange to prepare the phosphonium salt through high yield of recrystallization. The phosphonium salt preparation method and application has the advantages of low cost and easy obtaining of raw materials and low cost, one alkyl triphenyl substituted group containing phosphonium salt II serving as a phase transfer catalyst has the advantages of high catalytic activity, less required dose, long activity time, high thermal stability and low toxicity, high reaction recovery and the like in catalytic fluorine chlorine exchange reaction, and wide commercial application prospect is achieved.

Owner:WUHAN UNIV OF SCI & TECH

Antimicrobial textile

InactiveCN101479425ARetain activityExtended active timeBiochemical fibre treatmentWoven fabricsMicroparticlePolymer chemistry

The invention relates to a textile which is equipped with a biocidal substance. The textile according to the invention is characterized in that 2-n-octyl-4-isothazoline-3-on is contained as the biocidal substance and optionally one or more other biocides, and in that the biocidal substance is embedded in aminoplastic resin microparticles. By embedding the biocidal substance in the microparticles the biocidal substance remains on the textile during drying and condensation while the textile is finished. In practice, the biocidal substance is released only slowly and is not washed out when the textile is exposed to rain or soaked, thereby preventing the biocidal substance from escaping largely already when the textile is finished or preventing it from being washed out from canvas, awnings, filters, tarpaulin, shower curtains and the like after a few downpours.

Owner:THOR GMBH

Methods and nodes in a wireless communication network

InactiveCN106922217ASolve the regeneration problemImprove securityDigital data processing detailsDigital data authenticationComputer networkAir interface

A node (110) and a method (500) therein, for authenticating a mobile device (120) over an air interface are provided. The node (110) comprises a transmitter (630), a processor (620), and a receiver (610). The processor (620) is configured to detect the mobile device (120), to generate a nonce, to determine a key shared with the mobile device (120) and to compute a second MAC based on the generated nonce and the key, and to construct a second training sequence comprising the second MAC. The transmitter (630) is configured to transmit the generated nonce to the mobile device (120). The receiver (610) is configured to receive a first training sequence comprising a first MAC from the mobile device (120) and to tune the receiving circuits of the receiver (610), based on the first and second training sequences; and to receive a further message from the mobile device (120). Further, the processor (620) is configured to decode the further message and authenticate the mobile device (120) when the further message is decoded correctly, otherwise reject the mobile device (120). Also, a mobile device (120) and a method (700) therein are disclosed.

Owner:HUAWEI TECH CO LTD

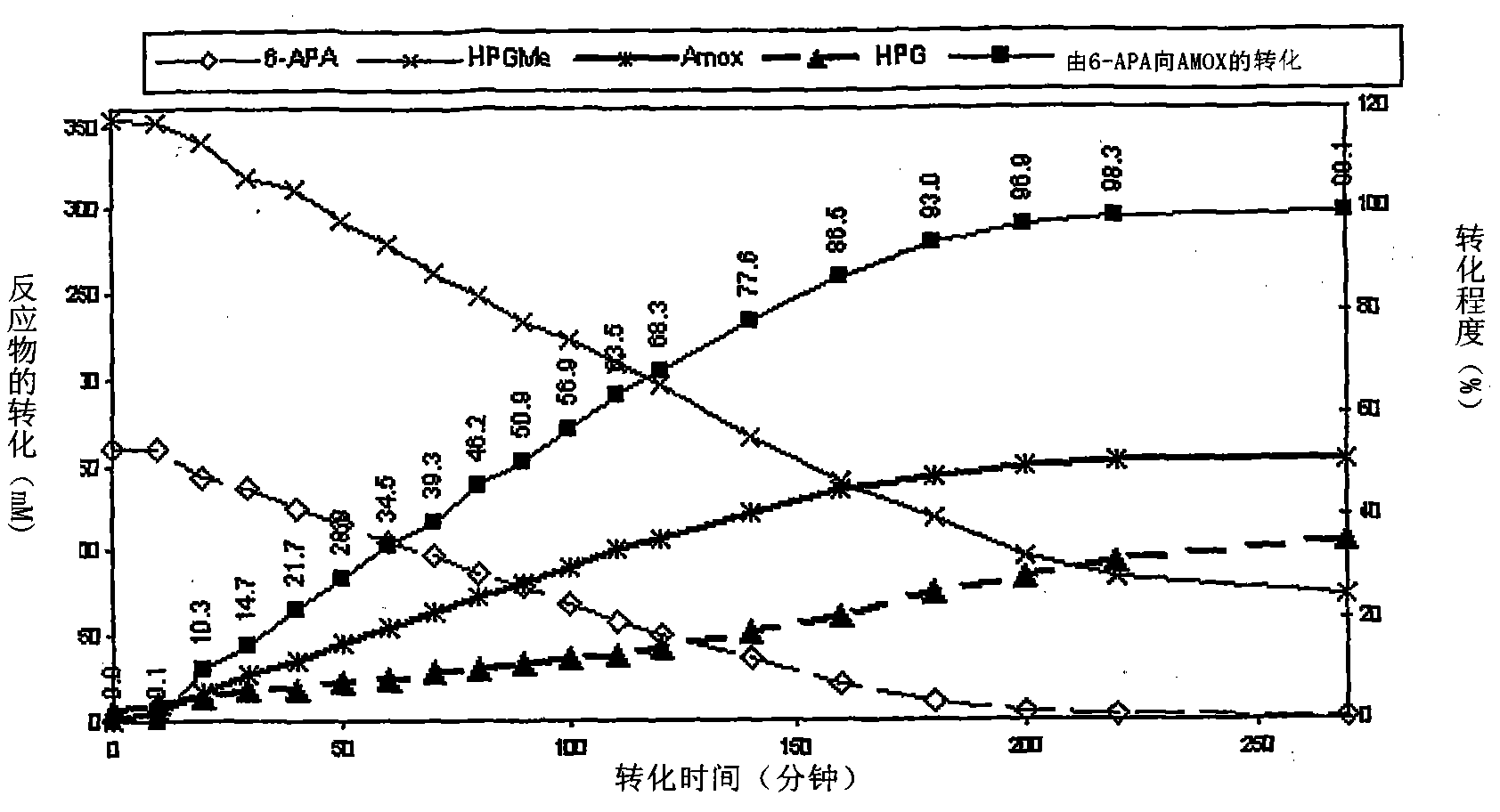

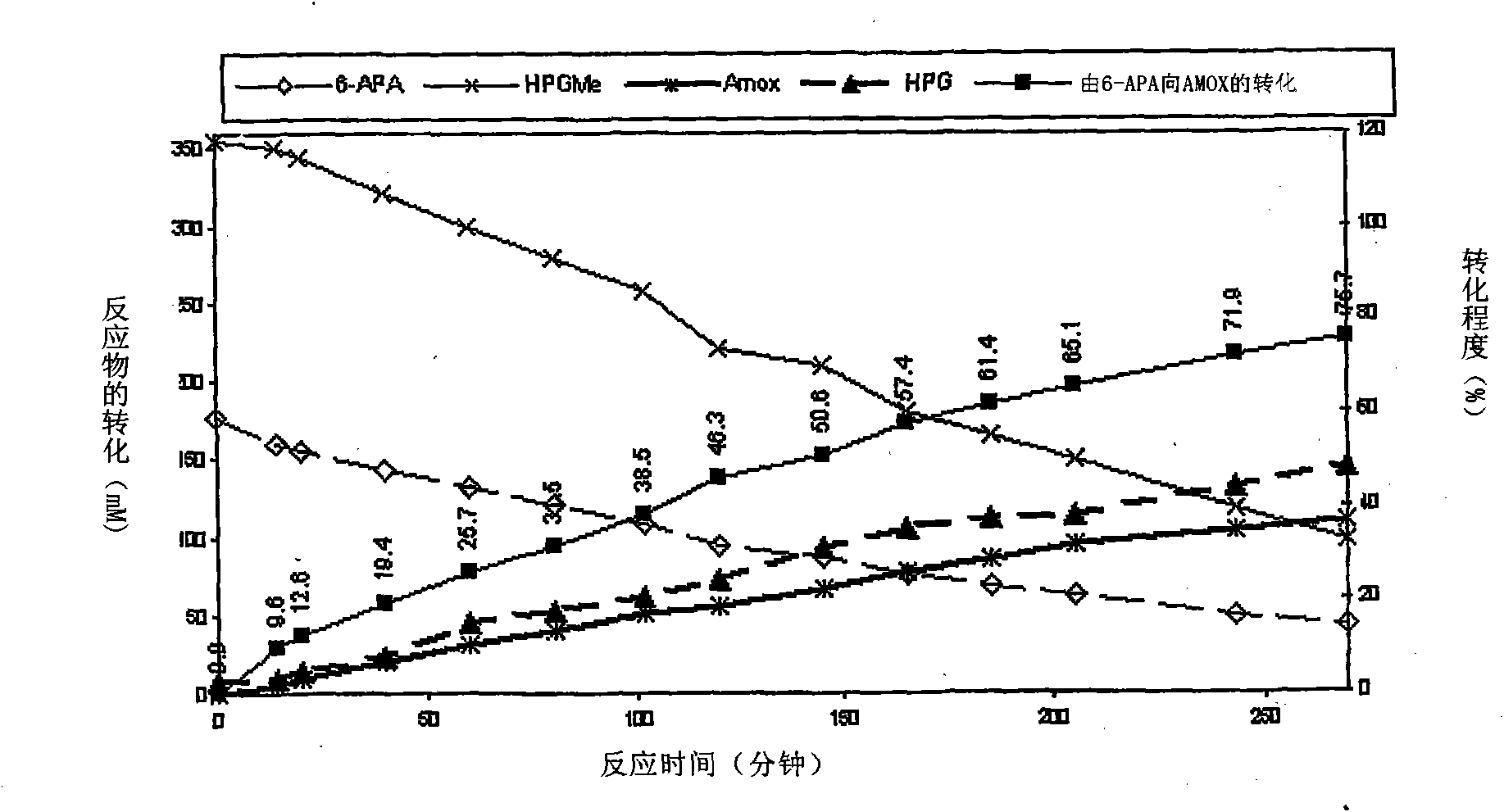

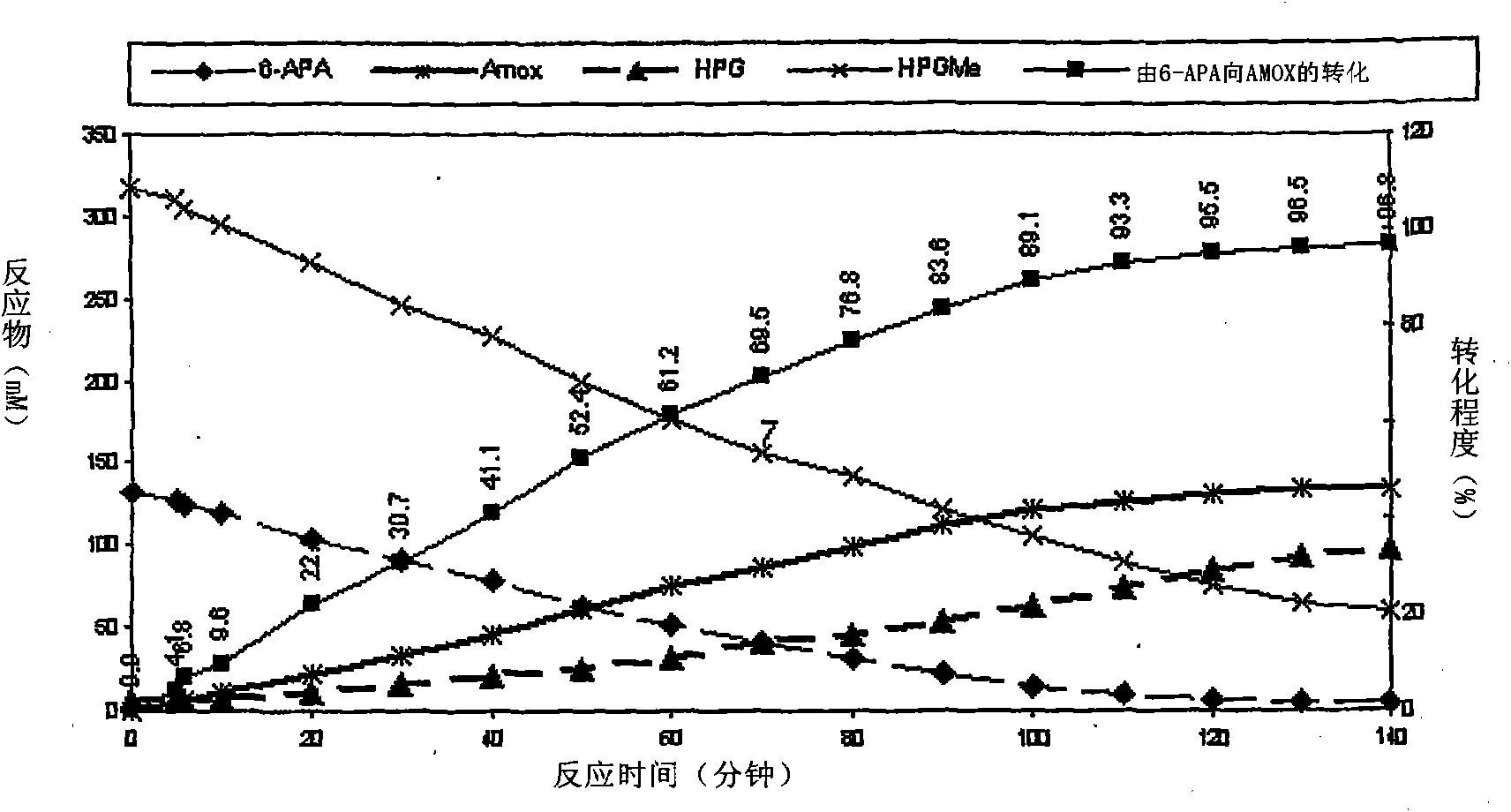

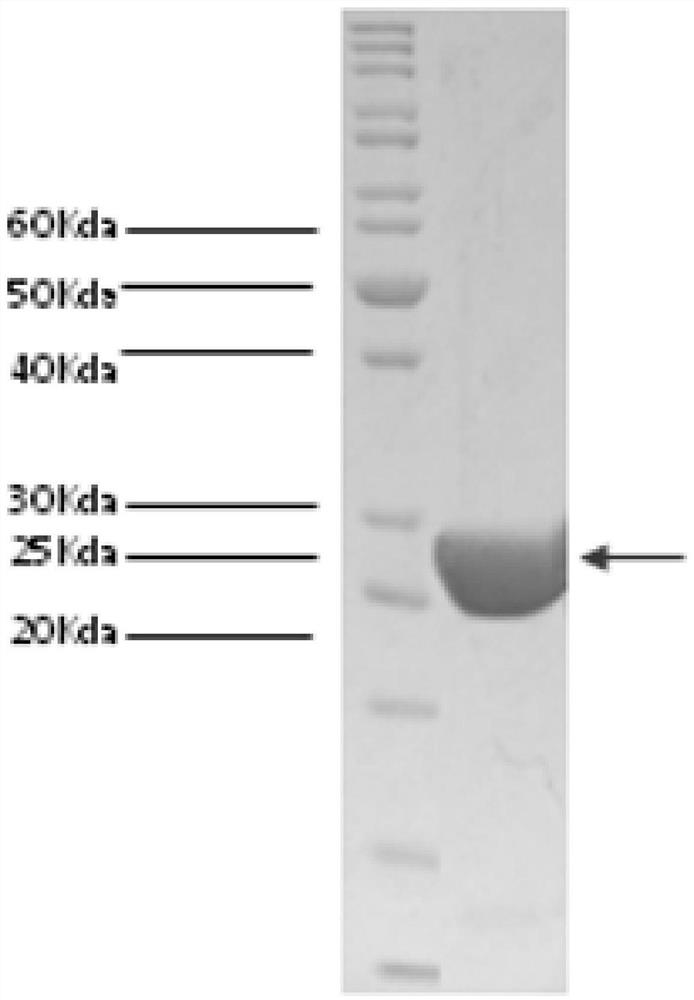

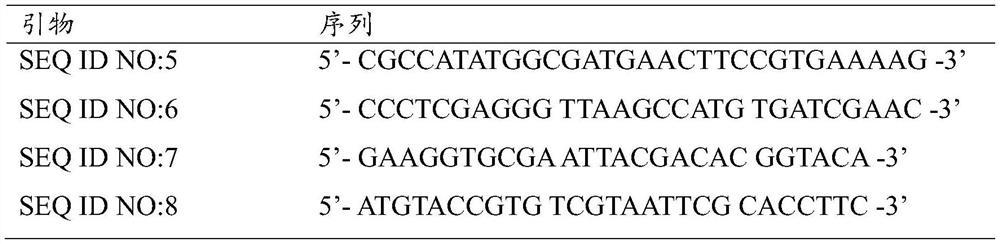

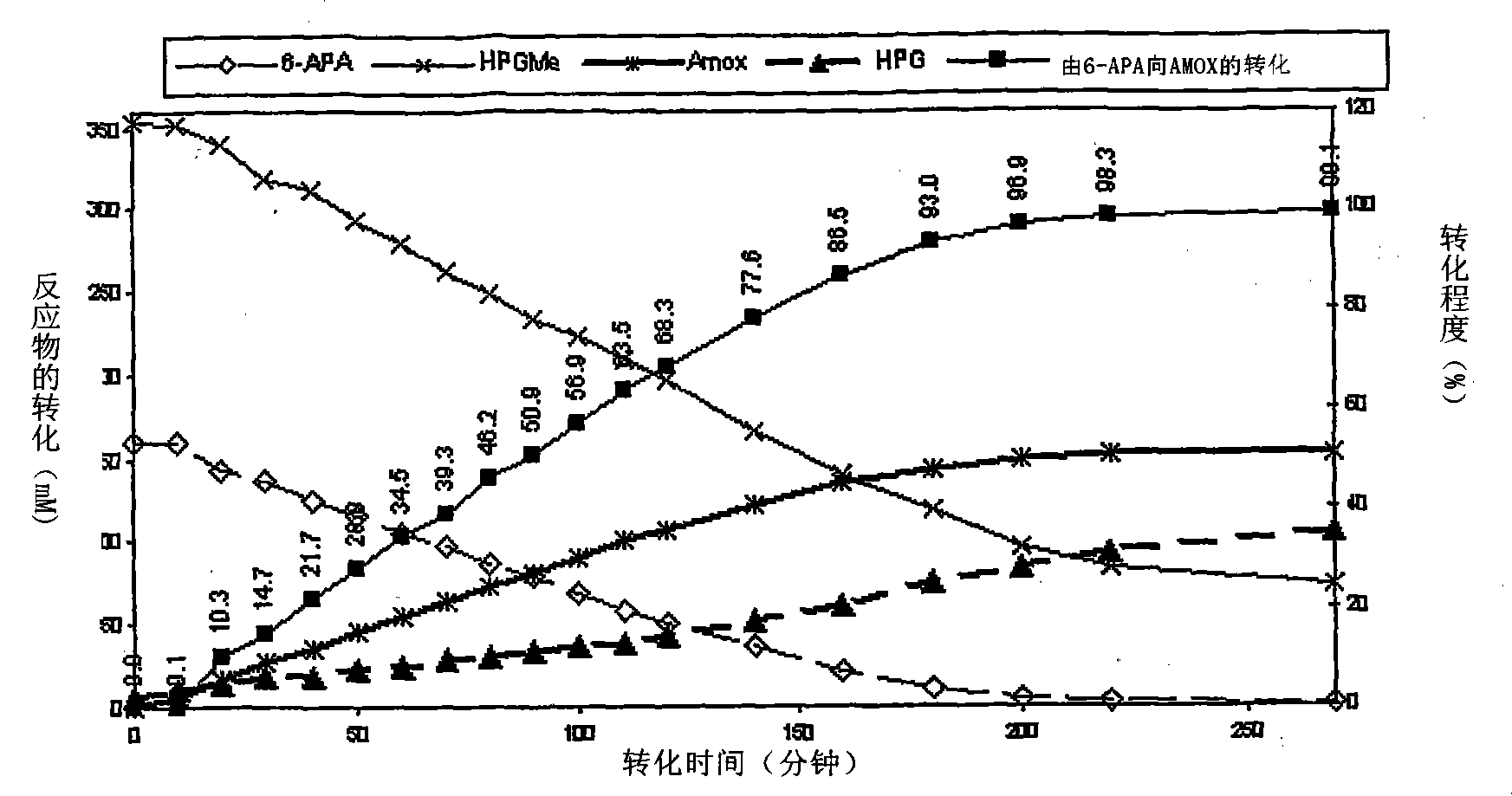

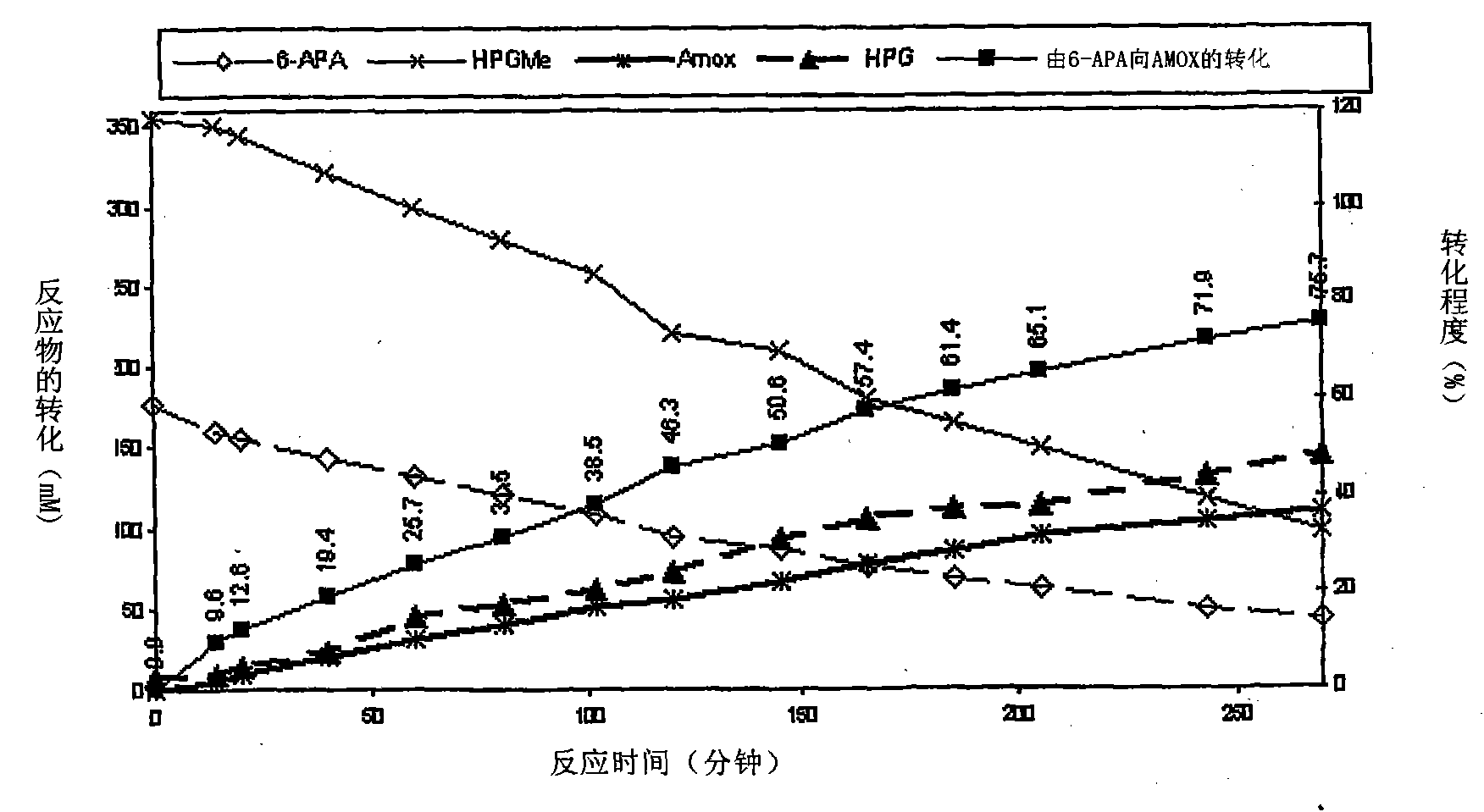

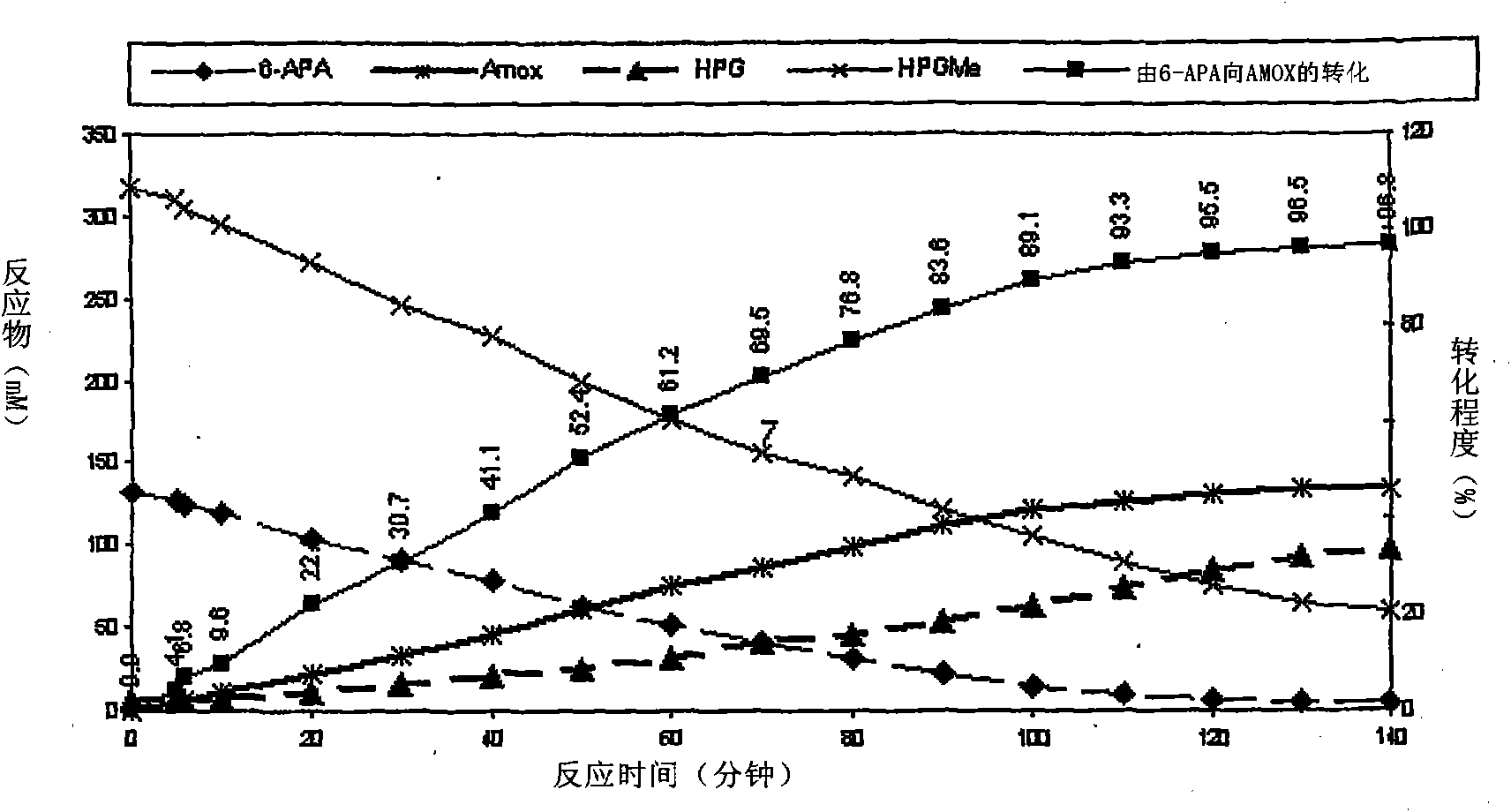

Process for the preparation of immobilized recombinant penicillin acylase catalyst from Achromobacter sp. CCM 4824 expressed in E. coli BL 21 CCM 7394 and its use for the synthesis of beta-lactam antibiotics

ActiveCN101802212AImprove synthesis abilityExtended active timeFermentationAmpicillinBeta lactam antibiotic

The present invention discloses isolation of Penicillin Acylase (PA) from Achromobacter sp CCM 4824 expressed in recombinant strain E. coli BL21 CCM 7394 bearing the recombinant plasmid pKXIP1 and processing of PA into biocatalyst useful for the industrial synthesis of antibiotics. More particularly the invention discloses a synthesis of semi-synthetic [beta]-lactam antibiotics in the reaction mixture consisting of activated acyl-donor (D-p-hydroxyphenylglycine methyl ester or amide for Amoxicillin and Cefadroxil; D-phenylglycine methyl ester or amide for Ampicillin and Cephalexin) and nucleophile (6-APA or 7-ADCA) catalyzed by PA obtained from recombinant E. coli BL21 CCM 7394 as the biocatalyst.

Owner:FERMENTA BIOTECH

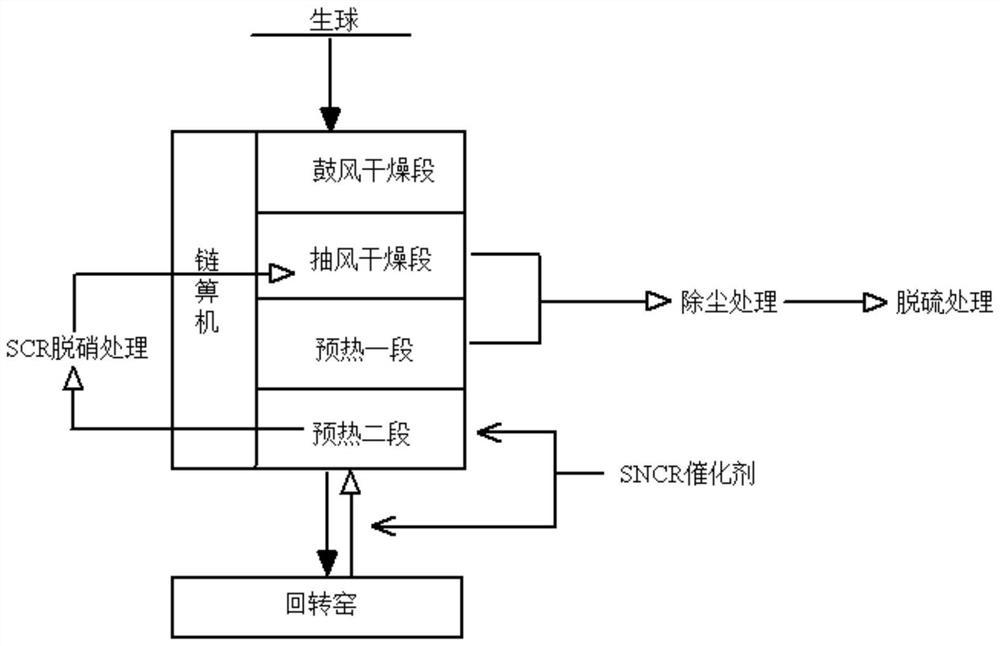

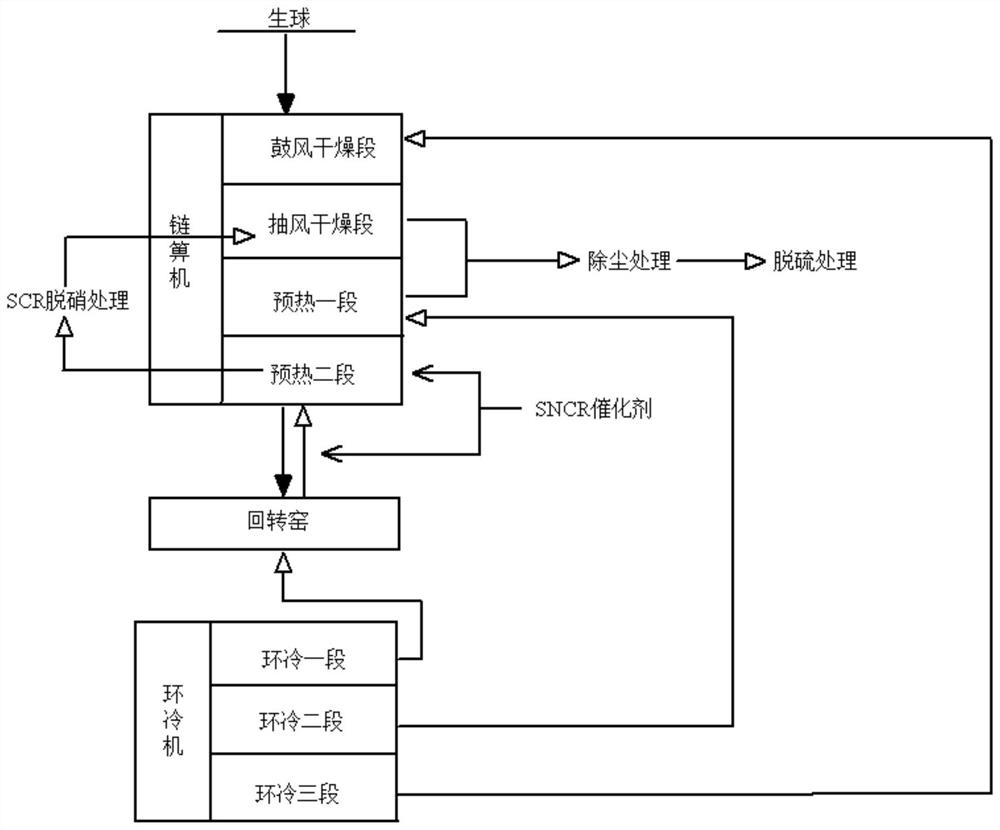

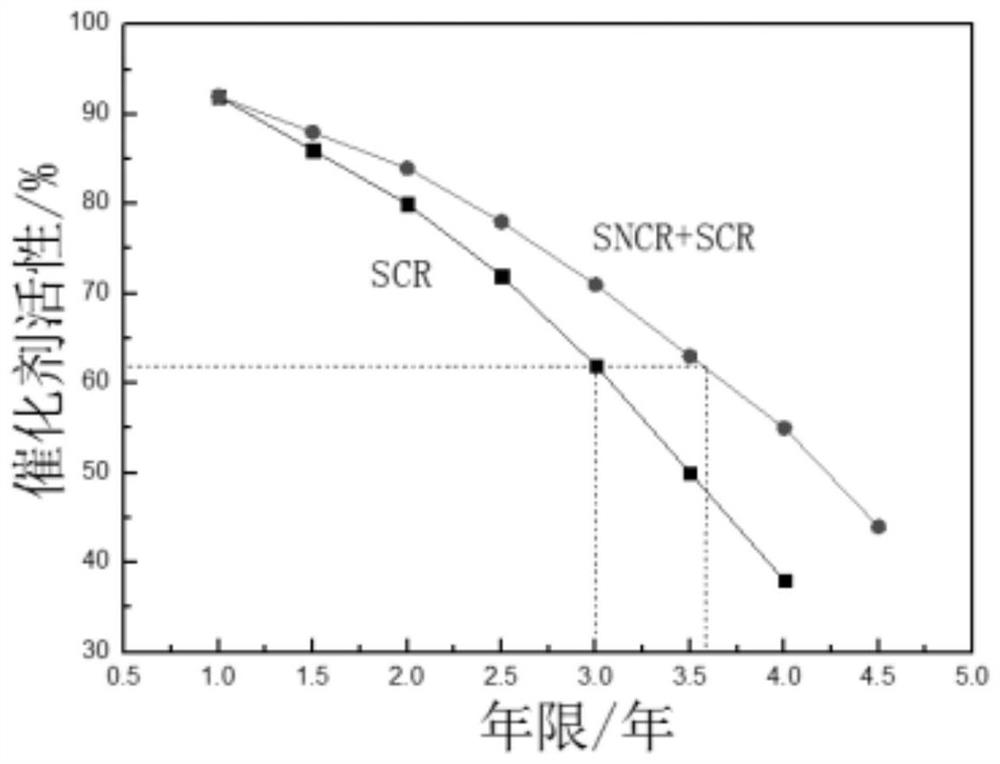

Flue gas treatment process and treatment system

ActiveCN113908677ALow investment costLow running costGas treatmentRotary drum furnacesPtru catalystThermodynamics

The invention discloses a chain grate-rotary kiln flue gas treatment process and treatment system. A control method of an SNCR-SCR coupling denitration system is adopted, a composite additive is added into an SNCR denitration catalyst or a novel SNCR composite ammonia agent is provided; and meanwhile, a movable airflow balance plate is additionally arranged between a PH section and a TPH section of a chain grate, the air pressure of the TPH section is controlled to be larger than or equal to the air pressure of the PH section by utilizing the position change of the airflow balance plate, so that the problem that the content of NOx in flue gas of the TPH section is increased due to the fact that high-NOx-content waste gas of the PH section flees towards the TPH section is prevented. The optimal coupling ultralow NOx emission technology can be formed, the denitration efficiency can be effectively guaranteed on the premise that SNCR ammonia consumption is reduced, meanwhile, the service lifetime of an SCR denitration catalyst can be prolonged, and the denitration operation cost and investment cost of the system are obviously reduced. The utilization efficiency of a flue gas denitration reducing agent is further improved, and the escape amount of NH3 is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Probiotic solid beverage and preparation method thereof

InactiveCN107410812APlay the role of two-way regulationExtended active timeYeast food ingredientsFood ingredient as mouthfeel improving agentLactobacillus rhamnosusActivity time

The invention discloses a probiotic solid beverage. The probiotic solid beverage comprises raw materials, auxiliary materials and probiotic powder, wherein the raw materials comprise the components in grams by weight: 1.2 grams of fructo-oligosaccharide and 0.6 grams of stachyose; the auxiliary materials comprise the following raw materials in grams by weight of 0.1 gram of yeast powder and 0.1 gram of strawberry powder; and the probiotic powder comprises 20 hundred millions of bifidobacterium animalis, 80 hundred millions of bifidobacterium lactis and 80 hundred millions of lactobacillus rhamnosus. The probiotic solid beverage can maintain bacterial colony in intestinal tracts balanced, can facilitate elimination of diarrhoea, can stop constipation, has favorable two-way regulation effect on the intestinal tracts, and is good in mouth feel. The water activity of other raw materials in the probiotic solid beverage is controlled to 0.05 or below, and the activity time of probiotics can be prolonged.

Owner:陈光永

High-effective pleurotus nebrodensis culture medium with algas and preparation method thereof

InactiveCN105237127AShorten the cultivation cycleEasy to passFertilizer mixturesBiotechnologyPhylum Cyanobacteria

The invention discloses a high-effective pleurotus nebrodensis culture medium with algas, which includes the following components, by weight, sugarcane residue, brewer's grain, alginic acid-polyacrylamide composite porous micro-spherical loofah sponge fibers, chlorella powder, sargassum, hydrilla verticillata powder, kelp powder, cyanobacteria powder, algae residue, grateloupia filicina, cellullase, algal polysaccharides, yeast and lactic acid bacteria. The pleurotus nebrodensis culture medium is prepared from the algas, which are rich in nutrients and bio-active substances, as a main material, so that cultivation period of the culture medium is reduced effectively. During the preparation process of the culture medium, the yeast and the lactic acid bacteria are employed to carry out mix-fermentation, thereby enriching fermentation products. The porous substance is used for supporting the fermentation bacteria so that transmission of heat and nutrients are improved and activity time of the fermentation bacteria is increased. The culture medium is increased in decomposition degree of substrates, is improved in abundance and balance of the nutrients and provides fundament to short-period high-effective cultivation of the pleurotus nebrodensis.

Owner:MAANSHAN ANKANG FUNGUS IND

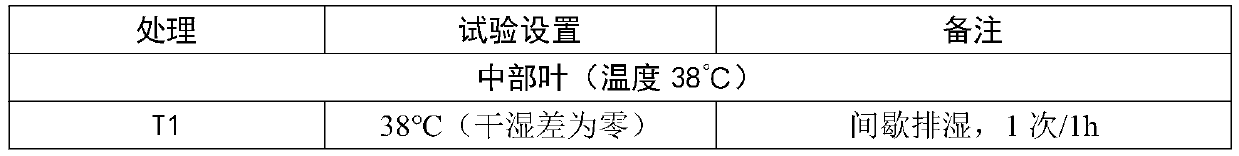

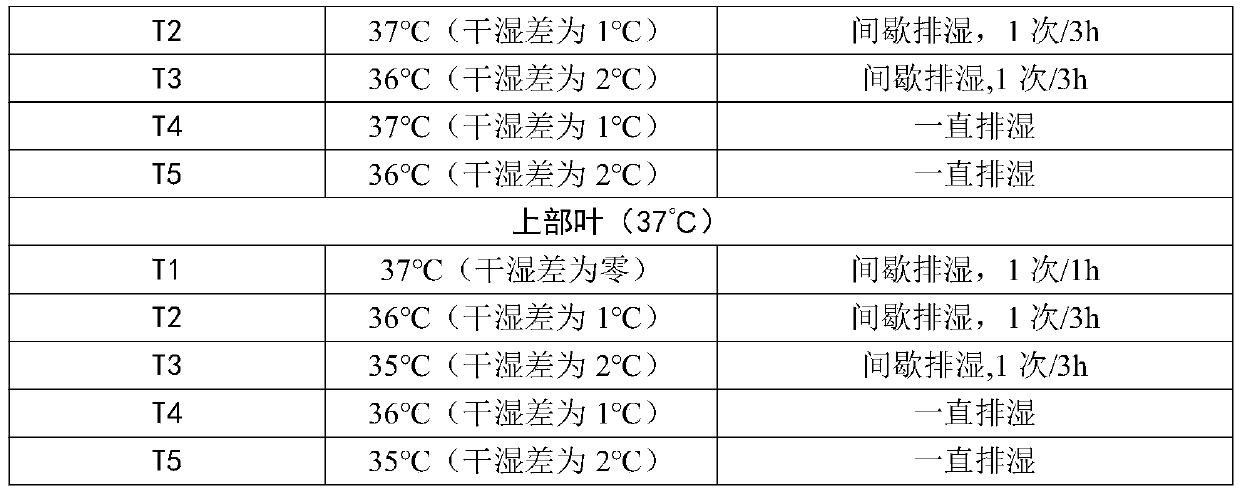

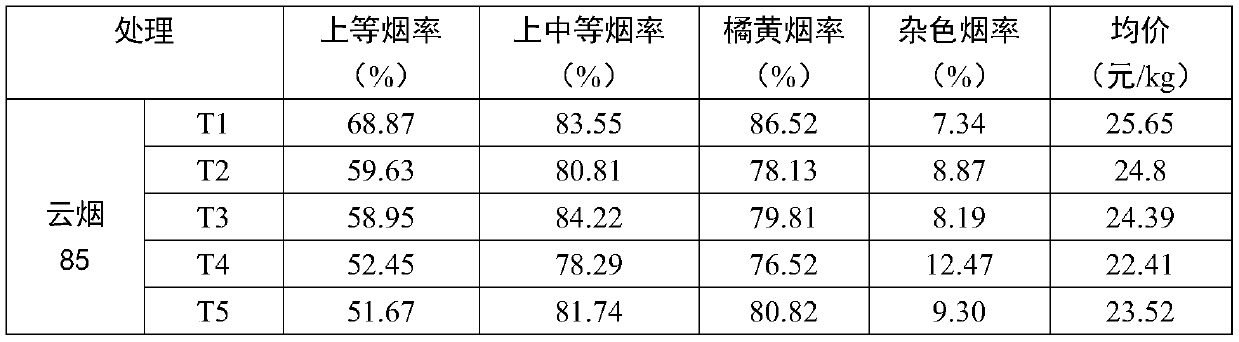

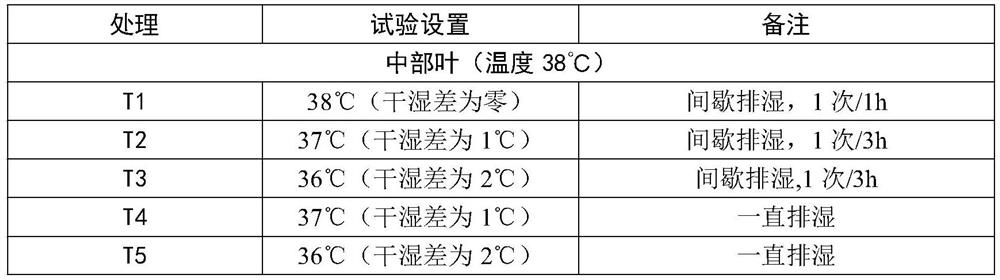

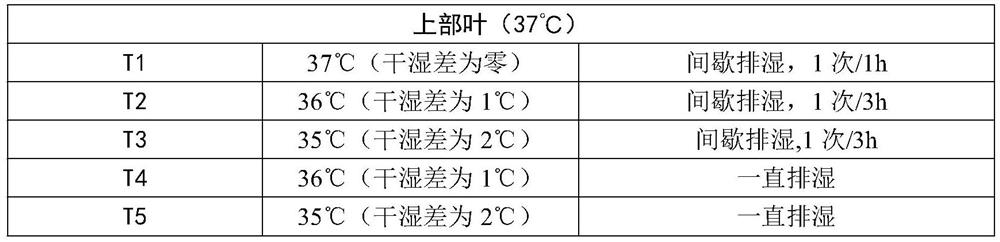

Medium-temperature moisturizing yellowing dense hanging rod baking method for middle-upper tobacco leaves

The invention discloses a medium-temperature moisturizing yellowing dense hanging rod baking method for middle-upper tobacco leaves. The invention belongs to the technical field of flue-cured tobaccothree-section type dense hanging rod baking processes. The method mainly comprises nine steps of three sections. Medium-temperature moisturizing yellowing is adopted in the main yellowing stage of themiddle-upper tobacco leaves, the temperature difference of dry and wet bulbs is kept to be zero, and baking is carried out for 35-50 h at a steady temperature; when the yellowing degree of the tobacco leaves reaches a state with yellow sheet and green tendons, the temperature is slowly increased for dehumidification, so that the first-class tobacco rate, the orange tobacco rate and the average price of the cured middle-upper tobacco leaves are increased, the chemical component coordination and the sensory evaluation quality of the cured tobacco leaves are improved, the quality of the cured tobacco leaves is improved, profits are increased, and income increase of tobacco growers is achieved.

Owner:贵州省烟草公司黔南州公司

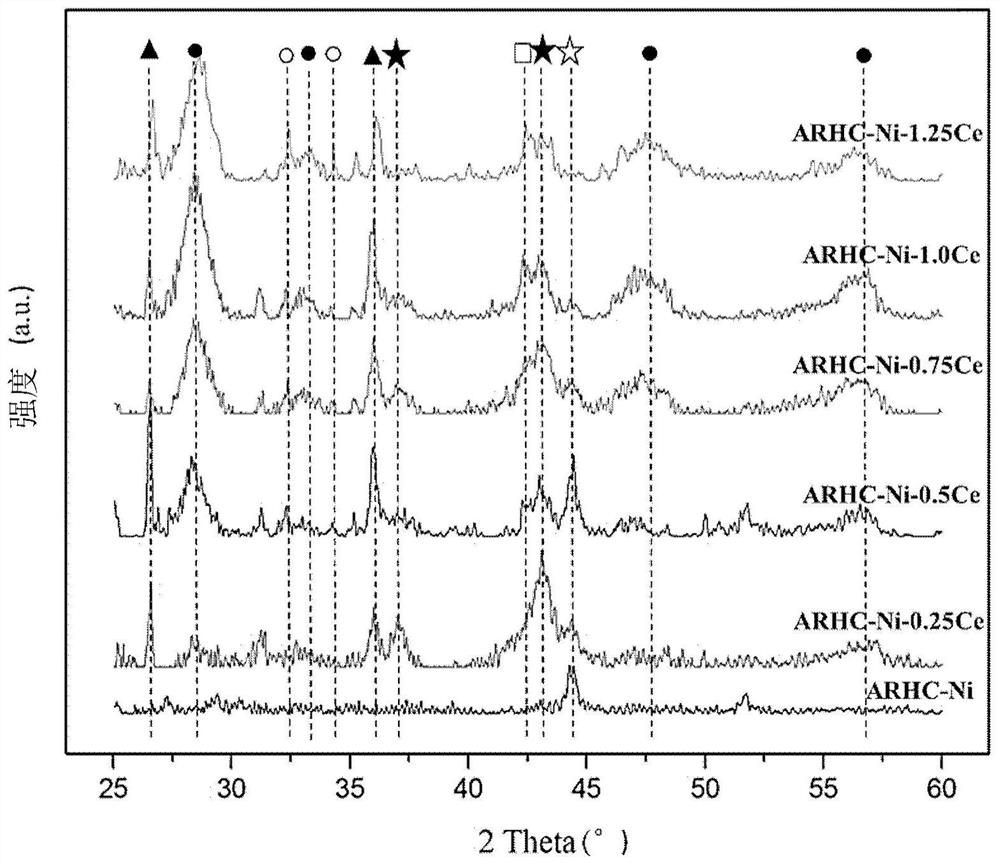

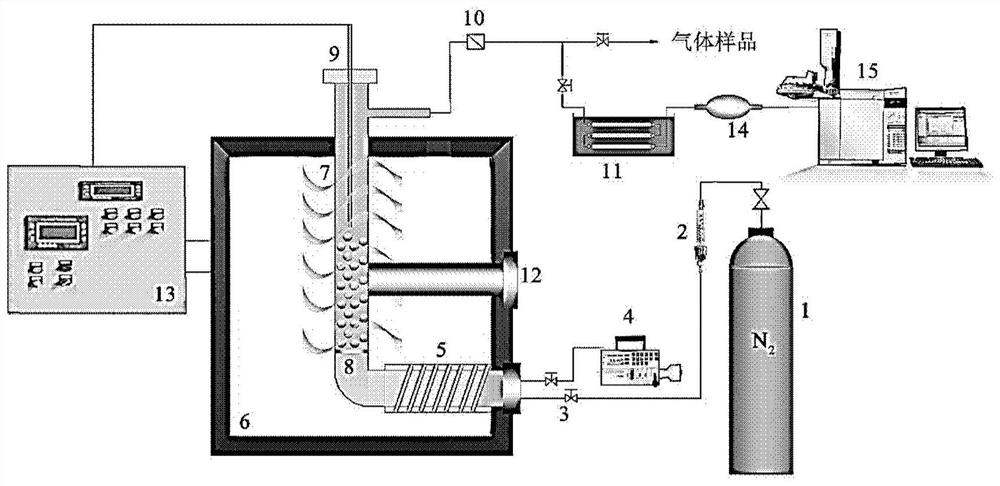

Biomass coke-based bimetallic catalyst as well as preparation method and application thereof

The invention relates to a biomass coke-based bimetallic catalyst as well as a preparation method and application thereof. The biomass coke-based bimetallic catalyst takes biomass coke as a carrier and is loaded with a nickel-cerium intermetallic compound; wherein metal salts of nickel and cerium can be loaded on the biomass coke through an impregnation method, and the biomass coke is calcined ina nitrogen atmosphere for preparation. Due to the cerium, the surface properties of the catalyst carrier can be improved, and a NiCe-Ni5Ce nickel-rich intermetallic compound system is formed; therefore, the product can effectively inhibit the sintering of nickel, and prolongs the activity time of the catalyst.

Owner:TIANJIN UNIV

Preparation process of first coat material with moisture permeable function

ActiveCN104674557ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentPolymer scienceWeakness

The invention discloses a preparation process of a first coat material with the moisture permeable function. The process comprises the following steps: uniformly mixing butanone, water and polyurethane resin in mass ratio of (66-68) to (3-5) to (29-31) to obtain a main resin solution; agitating and uniformly mixing 1,6-diisocyanatohexane and the main resin mixed solution obtained in step 3 in mass ratio of 100 to (1.5-2.5) at the rotating speed of 1000rpm and under the temperature of 25 to 35 DEG C to obtain the regulated main resin mixed solution; filtering the regulated main resin mixing solution through a nylon mesh with 100 to 200 meshes to obtain the filtered main resin mixed solution; standing the filtered main resin mixing solution for at least 2 hours and defoaming, wherein the standing is performed in a vacuum condition for 2 hours. According to the preparation process, the weakness that the first coat material is easily expanded in water is overcome, the moisture permeable performance of a fabric body can be improved, so that the fabric is high in service performance, and the wear resistance is greatly improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Grape planting fertilizer capable of adsorbing microorganisms and preparation method thereof

InactiveCN105175137AIncrease vitalityIncrease microbial contentFertilizer mixturesMicroorganismInsect pest

The invention discloses a grape planting fertilizer capable of adsorbing microorganisms and a preparation method thereof. The fertilizer is prepared from the following raw materials in parts by weight: natural zeolite, 2mol / L diluted HCl, a 6wt% NaCl solution, biomass charcoal granules, glucose, a microorganism agent, urea, potato residues, fowl dung, a bamboo vinegar liquid, selenium powder, diatomite and a proper amount of water. The requirements for various elements are high in grape planting, the requirements are difficultly met by simple nutrient fertilizer supplying, the amount is difficult to control, the environment is easily polluted, the diseases and insect pests of grape are serious throughout the year, and the problems are well solved by the fertilizer.

Owner:ANHUI SHENGNONG AGRI GRP

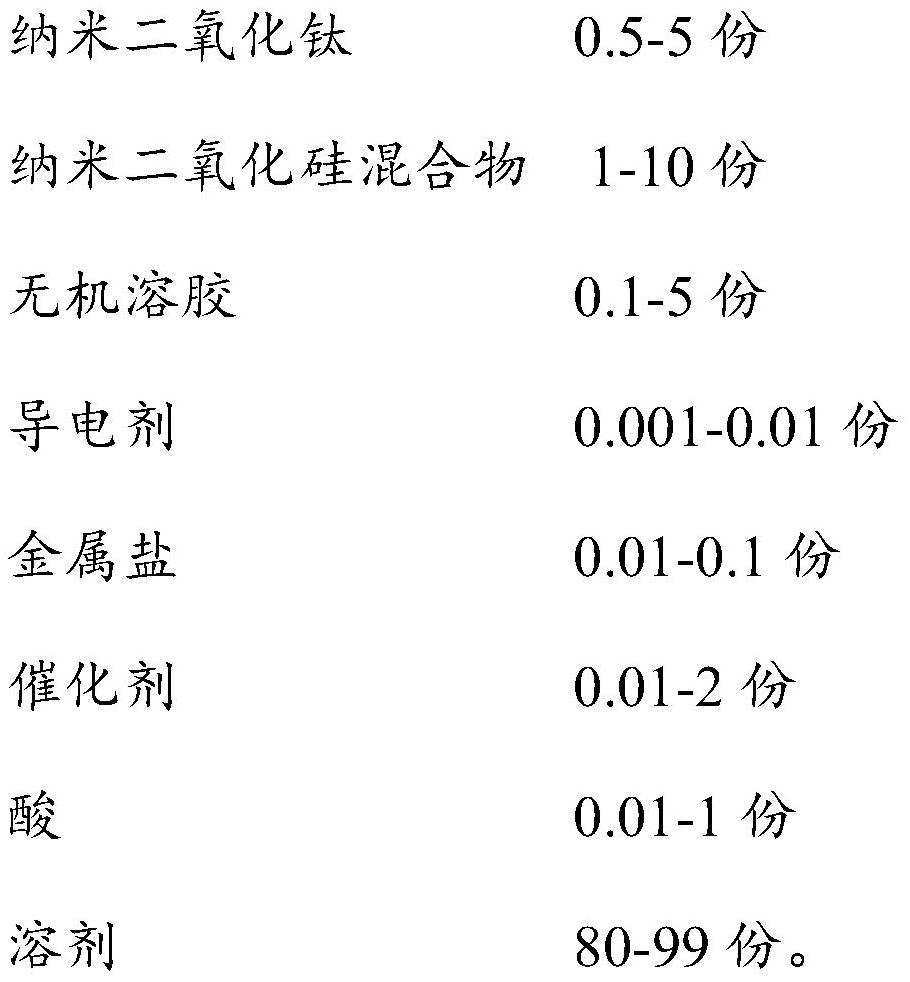

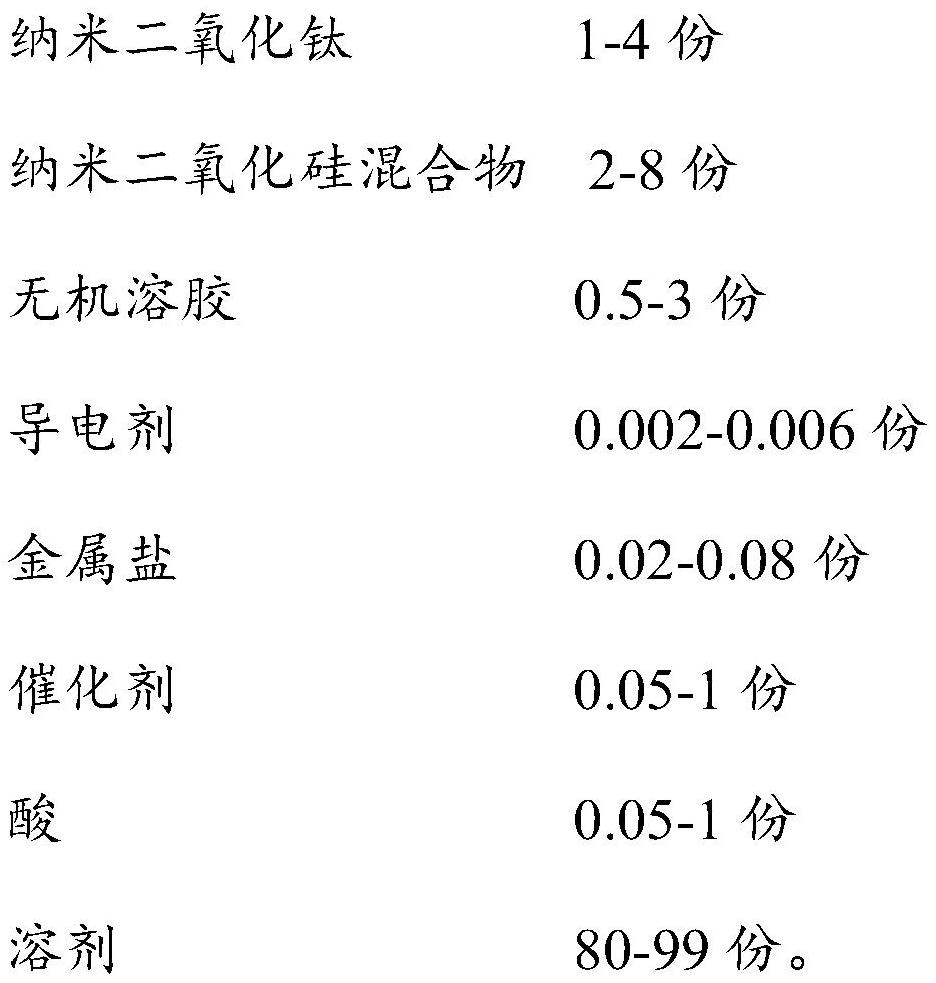

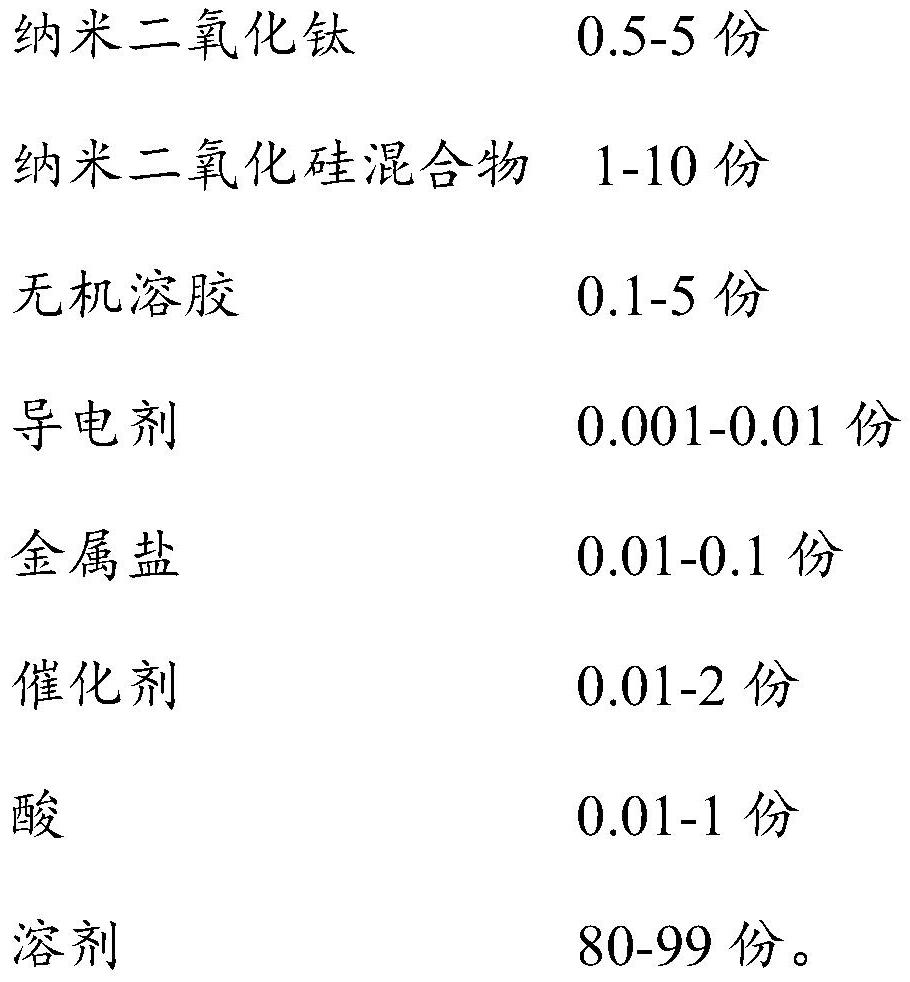

Long-acting self-cleaning composition for glass surface

InactiveCN111826007AExtended active timeKeep Light TransmittanceAntifouling/underwater paintsPaints with biocidesElectrically conductiveTitanium dioxide

The invention discloses a long-acting self-cleaning composition for a glass surface, and aims to provide the long-acting self-cleaning composition for the glass surface, which has the advantages of static resistance, self-cleaning, wide-spectrum reflection reduction, high transmittance, durability and high activity. The technical scheme is as follows: the composition is prepared from the followingsubstances in parts by weight: 0.5 to 5 parts of nano titanium dioxide, 1 to 10 parts of a nano silicon dioxide mixture, 0.1 to 5 parts of inorganic sol, 0.001 to 0.01 part of a conductive agent, 0.01 to 0.1 part of metal salt, 0.01 to 2 parts of a catalyst, 0.01 to 1 part of acid and 80 to 99 parts of a solvent. The invention belongs to the field of glass coatings.

Owner:广州市达三江科技有限公司

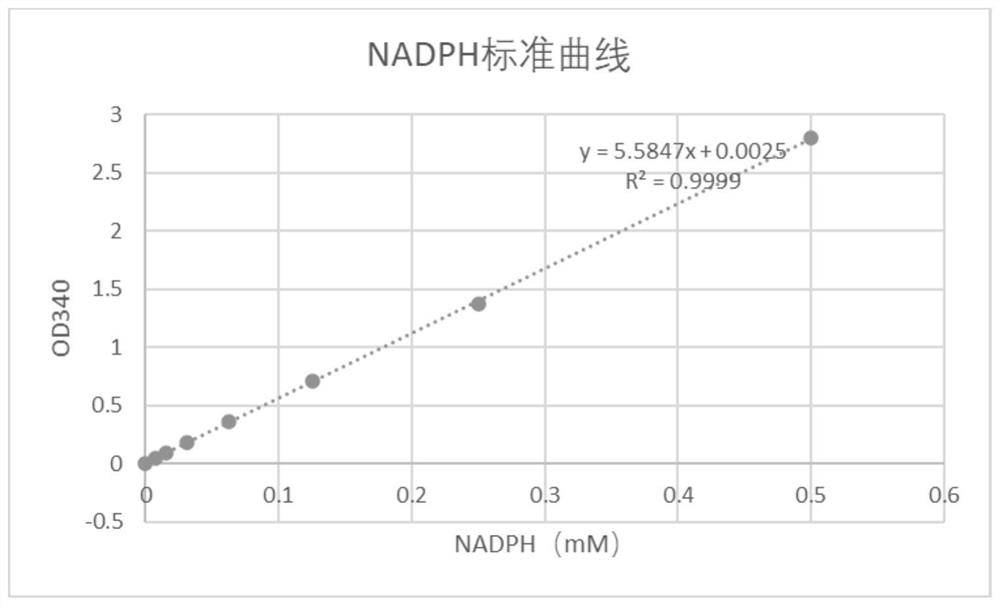

7beta-hydroxysteroid dehydrogenase mutant and application thereof

ActiveCN114231508AExtended active timeChange hydrophobicityBacteriaMicroorganism based processesHydroxysteroid DehydrogenasesHomosteroids

The invention discloses a 7beta-hydroxysteroid dehydrogenase mutant, and belongs to the technical field of biological enzymes. According to the 7 beta-hydroxysteroid dehydrogenase, asparagine at the 115th site of the amino acid sequence of the wild 7 beta-hydroxysteroid dehydrogenase is mutated into valine with stronger nonpolarity, so that the hydrophobicity of the molecular surface is changed, and the thermal stability of the 7 beta-hydroxysteroid dehydrogenase is improved on the premise of not influencing the activity; the method prolongs the activity time of the enzyme in a high-temperature reaction system, avoids the embarrassing situation that the enzyme is high in activity and short in maintenance time at a high temperature and low in activity and long in maintenance time at a low temperature, can effectively solve the problem that the low temperature needs to be controlled by industrial production and is difficult to realize, and is suitable for large-scale industrial production.

Owner:宋建芳

Process for the preparation of immobilized recombinant penicillin acylase catalyst from Achromobacter sp. CCM 4824 expressed in E. coli BL 21 CCM 7394 and its use for the synthesis of beta-lactam antibiotics

ActiveCN101802212BImprove synthesis abilityExtended active timeFermentationAmpicillinBeta lactam antibiotic

The present invention discloses isolation of Penicillin Acylase (PA) from Achromobacter sp CCM 4824 expressed in recombinant strain E. coli BL21 CCM 7394 bearing the recombinant plasmid pKXIP1 and processing of PA into biocatalyst useful for the industrial synthesis of antibiotics. More particularly the invention discloses a synthesis of semi-synthetic &bgr;-lactam antibiotics in the reaction mixture consisting of activated acyl-donor (D-p-hydroxyphenylglycine methyl ester or amide for Amoxicillin and Cefadroxil; D-phenylglycine methyl ester or amide for Ampicillin and Cephalexin) and nucleophile (6-APA or 7-ADCA) catalyzed by PA obtained from recombinant E. coli BL21 CCM 7394 as the biocatalyst.

Owner:FERMENTA BIOTECH

Application of lauric acid modified SOD on prevention of chronic radiation skin lesion

ActiveCN104906562ANo adulterationEasy to see throughPeptide/protein ingredientsEnzyme stabilisationHeat resistanceDistillation

The invention discloses an application of lauric acid modified SOD on prevention of chronic radiation skin lesion. A preparation method of the lauric acid modified SOD comprises the following steps that (1) activated lauric acid modifiers are compounded, wherein lauric acid and thionyl chloride are subjected to reaction at 50-140 DEG C, stable returning is performed after at least 80% of lauric acid is converted, and then cut fractions at 124-127 DEG C are collected through reduced pressure distillation, namely the activated lauric acid modifiers; (2) the lauric acid modified SOD is prepared, wherein ox blood SOD is dissolved in a buffer solution to form an SOD solution, the activated lauric acid modifiers are added into the solution, the mixture is stirred and reacts at 30-50 DEG C and then is quenched to stop reaction, and the lauric acid modified SOD product is obtained. The prepared lauric acid modified SOD easily permeates through the skin and cell membranes compared with natural SOD and is long in activity preservation time and good in heat resistance when stored at normal temperature. Compared with the prior art, toxic catalyst pyridine is eliminated, and the lauric acid modified SOD is suitable for being applied on the aspect of prevention of chronic radiation skin lesion and has a better technical effect.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

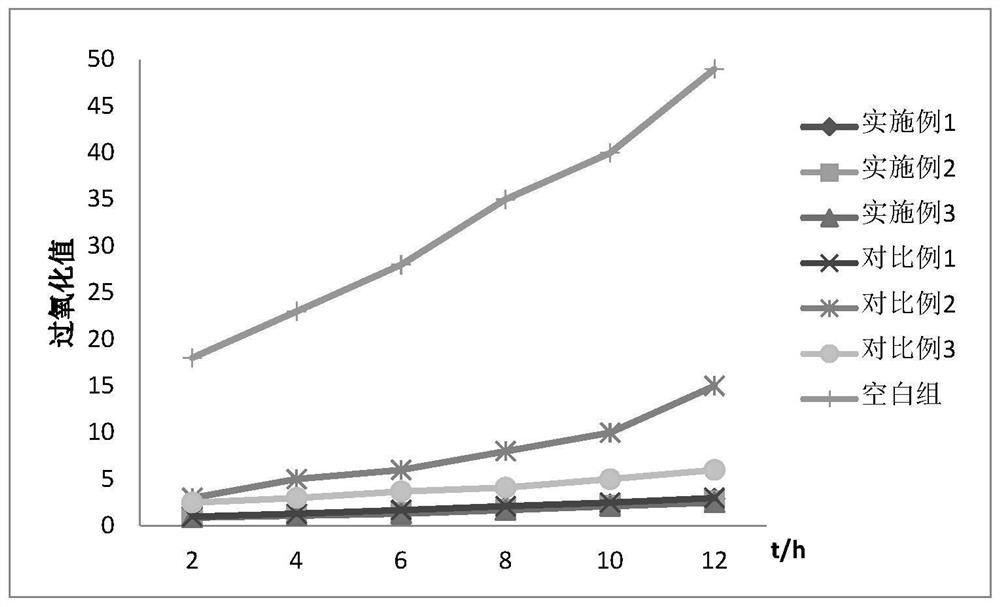

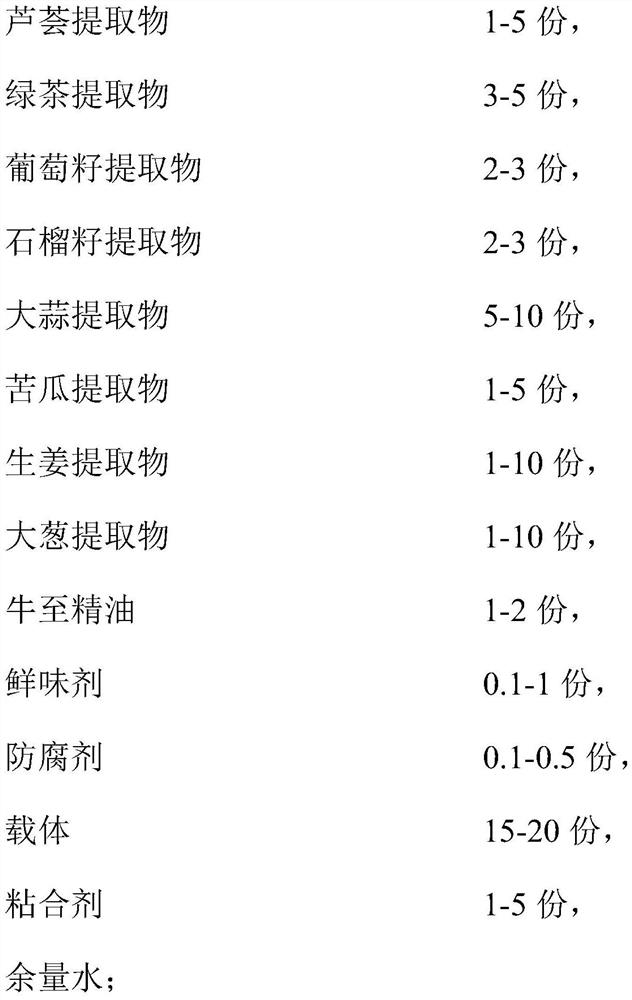

Preparation method of garlic extract and composite natural plant extract additive thereof

InactiveCN112056459AGood antibacterial effectLess irritatingAnimal feeding stuffAccessory food factorsBiotechnologyPharmaceutical drug

The invention provides a preparation method of a garlic extract. The preparation method comprises the following steps: soaking purple garlic in white vinegar, mashing the soaked purple garlic, and performing extracting with supercritical carbon dioxide to obtain the garlic extract. The garlic extract is extracted at a low temperature, allicin is prevented from being damaged by high temperature tothe maximum extent, and the antioxidant activity of garlic soaked with vinegar is remarkably enhanced. The composite extract additive containing the garlic extract contains various extracts, has various regulating functions, improves the immunity of animals, and promotes the healthy growth of animals. The raw materials in the additive come from natural plants, and no chemical medicines are added,so that the problem of medicine residues does not exist, and animals can use the additive more safely.

Owner:TIANJIN NAER BIOTECH

Application of lauric acid modified sod in the protection of chronic radiation skin injury

ActiveCN104906562BNo adulterationEasy to see throughPeptide/protein ingredientsEnzyme stabilisationSkin InjuryCell membrane

The invention discloses an application of lauric acid modified SOD on labor protection of the dye industry and the printing and dyeing industry. A preparation method of the lauric acid modified SOD comprises the following steps that (1) activated lauric acid modifiers are compounded, wherein lauric acid and thionyl chloride are subjected to reaction at 50-140 DEG C, stable returning is performed after at least 80% of lauric acid is converted, and then cut fractions at 124-127 DEG C are collected through reduced pressure distillation, namely the activated lauric acid modifiers; and (2), the lauric acid modified SOD is prepared, wherein ox blood SOD is dissolved in a buffer solution to form an SOD solution, the activated lauric acid modifiers are added into the solution, the mixture is stirred and reacts at 30-50 DEG C and then is quenched to stop reaction, and the lauric acid modified SOD product is obtained. The prepared lauric acid modified SOD has the advantages of easily permeating through the skin and cell membranes compared with natural SOD, being long in activity preservation time and good in heat resistance when stored at normal temperature, being non-toxic and the like. The lauric acid modified SOD is suitable for being applied on labor protection and prevention of occupational dermatosis of staff in the dye industry and the printing and dyeing industry.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

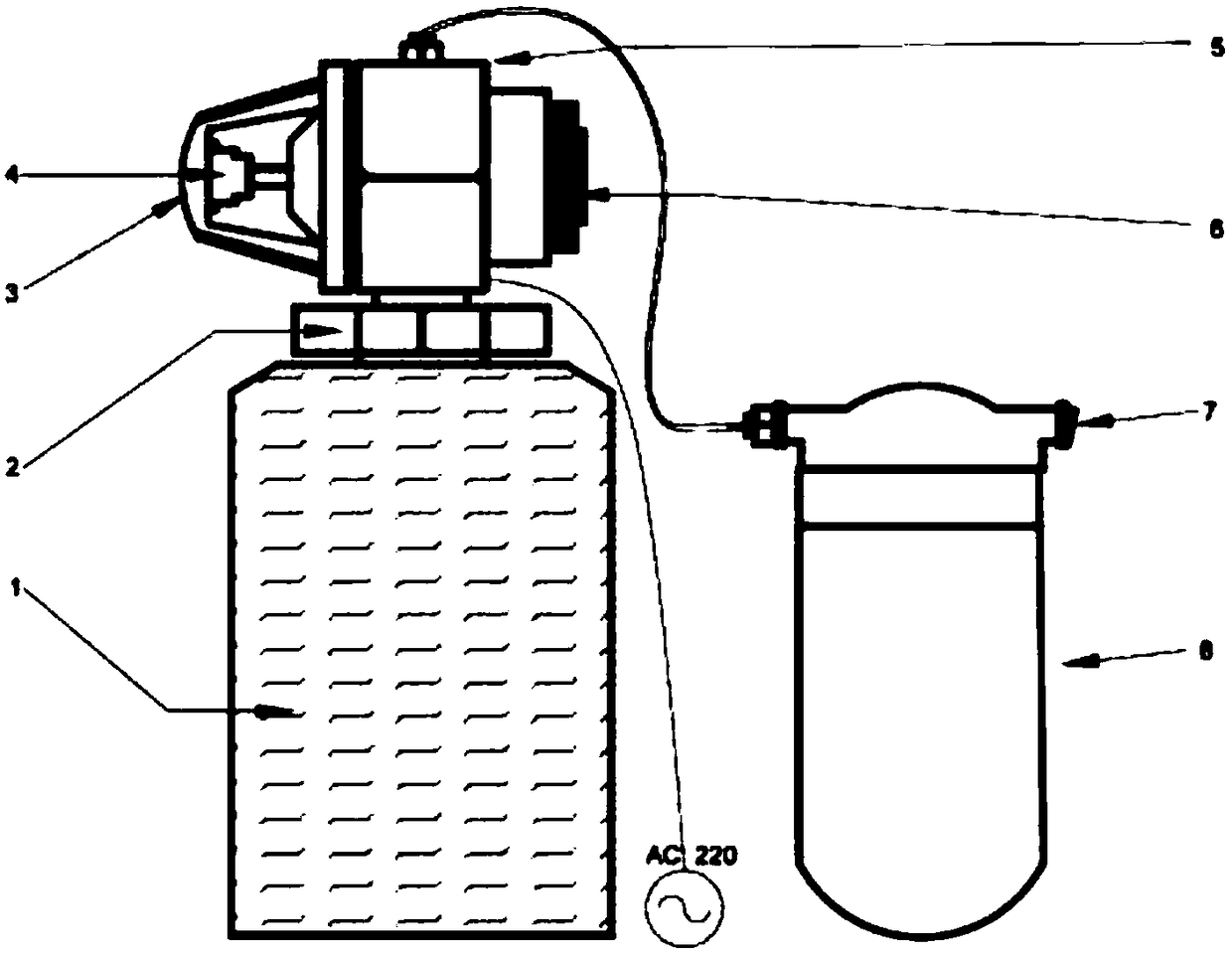

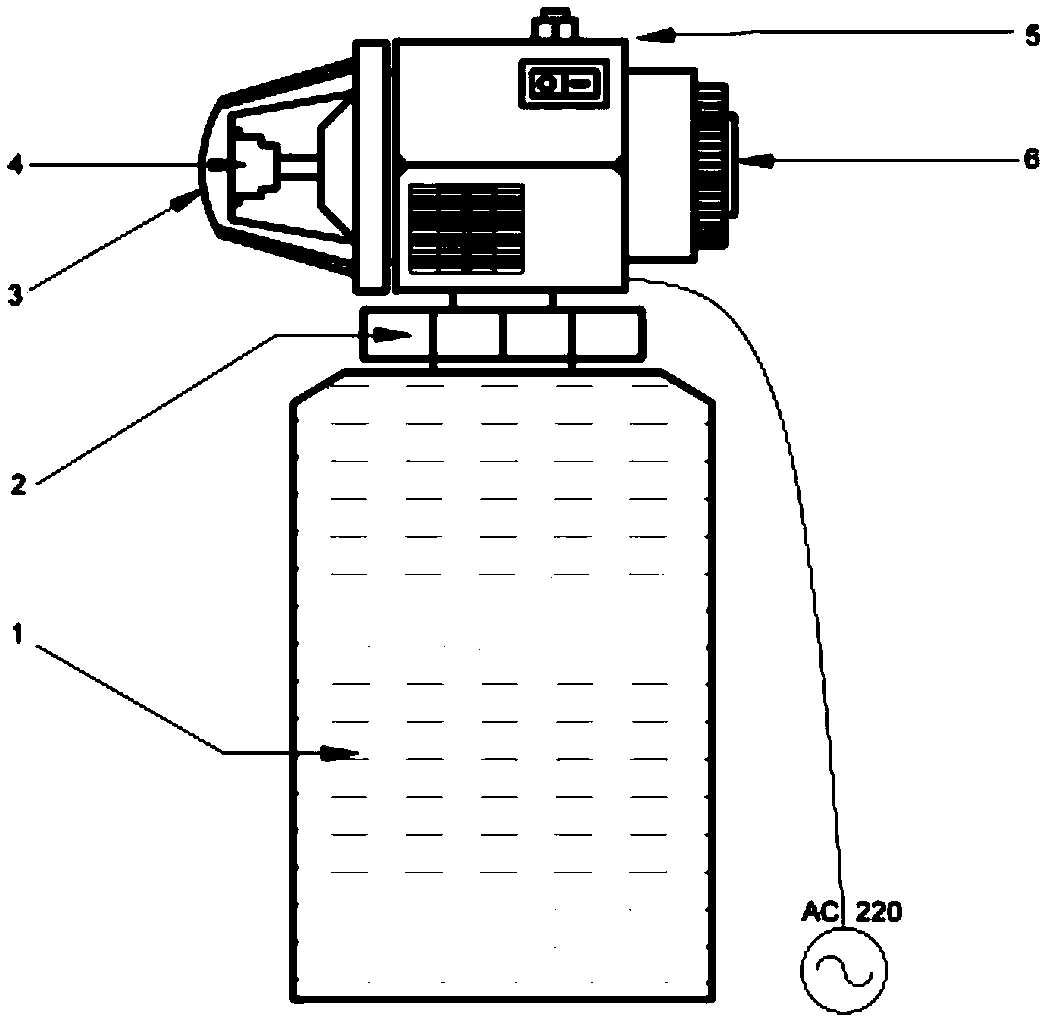

Method for eliminating CO in restricted space through ultrasonic atomizing spray of chemical absorbing solution

InactiveCN108057334AIncrease contact areaGuaranteed response timeGas treatmentDispersed particle separationResonant cavityNon toxicity

A method for eliminating CO in a restricted space through ultrasonic atomizing spray of a chemical absorbing solution belongs o a chemical absorption method of ultrasonic atomizing spray. An ultrasonic atomizing device is combined with the chemical absorption method to achieve the purpose of rapid and effective reduction of the concentration of CO in the restricted space. A CuCl / MgCl2 mixed solution for efficiently absorbing CO at normal temperature under normal pressure is selected, compressed air is used to impact a resonant cavity to generate ultrasonic waves in order to atomize the mixed solution into dense fine fog droplets with the diameter being 50 [mu] or less, and the fog droplets suspend in air for a long time to increase the solution and air contact area and guarantee the absorption efficiency of the chemical absorbing solution. The device can reduce the CO concentration to 20 ppm or less from 400 ppm within 20 min and keep the CO concentration below 20 ppm within 120 h. Thedevice has the advantages of mild application conditions, simplicity in storage, safety, non-toxicity, and meeting of needs of sustainable development. Additionally, the device also has the characteristics of simplicity in operation, low cost, lightness and portability, and provision of a good support for purifying gas in mine rescue capsules, refuge chambers, subway traffic and other restrictedspaces.

Owner:CHINA UNIV OF MINING & TECH

Seed treatment combination

PendingCN108260598AImprove germination rateGood for healthPlant growth regulatorsBiocideCelluloseImidacloprid

The invention provides a seed treatment combination which comprises an active ingredient-sedaxane and a new nicotine compound and further comprises coating polymer coating the active ingredient. The coating polymer is selected from one or multiple of maltodextrin, methylcellulose, ethylcellulose, hydroxyl propyl cellulose, carboxyl propyl / methyl cellulose, and the new nicotine compound is selectedfrom one of imidacloprid, thizmethoxam, thiacloprid and clothianidin. The invention further provides a method for increasing germination rate of seeds treated by a seed treatment agent, improving plant health and protecting the seeds from being invaded by plant pathogenic fungi and harmful organisms.

Owner:JIANGSU ROTAM CHEM

Moisture-permeable waterproof film used for fabric and fabrication process thereof

ActiveCN102555380BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilitySynthetic resin layered productsLaminationSlurryMoisture

The invention discloses a moisture-permeable waterproof film used for a fabric and a fabrication process thereof. According to the invention, a primary coating comprises polyurethane resin, butanone, toluene, water, hexane diisocyanate and N-methylethanolamine, and a first and second surface coatings comprise polyurethane resin, butanone, toluene, water and N-methylethanolamine. The fabrication process comprises the following steps: mixing hexane diisocyanate with main resin; mixing water with butanone to form a solvent which is put into a main resin mixed solution in at least six steps; filtering the mixed solution with a nylon net so as to obtain a filtered main resin mixed solution and carrying out deaeration treatment so as to form a primary coating slurry; preparing a surface coating slurry with the viscosity of a conjugate solution being 3500 to 6000 mpas; coating the primary coating slurry on the surface of release paper to form the primary coating, with coated weight being 4 to 6 g / m<2>; coating the surface coating slurry on the surface of the primary coat to form the surface coatings; and drying the release paper with the surface coatings and peeling the surface coatings off the release paper. According to the invention, the disadvantages that existing hydrophilic moisture permeable processing coating fabrics have nonuniform micropores and easily swell when contacting with water are overcome, and therefore, moisture permeable performance of a fabric itself is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Method for preparing bioreactor for in vitro biological artificial liver

InactiveCN1850967AHas hepatocyte functionEasy accessArtificially induced pluripotent cellsNon-embryonic pluripotent stem cellsArtificial liverFiber

The invention relates to a manufacture method for biology artificial liver biology reactor that includes the following steps: expanding stem cell expanding to 1*10^7 OM, adding into cultivating liquid for suspensoid after assimilating and centrifuging, adding into hollow fiber filterer, and laying into incubator to take continuing expansion and changing inducing type cultivating liquid, the stem cell could have the cell having liver cell function. The invention has stable stem cell resource, and could save cost. It has little immunity source polarity, long time keeping activity, and is benefit for cure.

Owner:THE AFFILIATED DRUM TOWER HOSPITAL MEDICAL SCHOOL OF NANJING UNIV

Application of lauric acid modified sod in chemical industry labor protection

ActiveCN104906561BNo adulterationExtended shelf lifePeptide/protein ingredientsEnzyme stabilisationChemical industryDistillation

The invention discloses an application of lauric acid modified SOD on labor protection of the dye industry and the printing and dyeing industry. A preparation method of the lauric acid modified SOD comprises the following steps that (1) activated lauric acid modifiers are compounded, wherein lauric acid and thionyl chloride are subjected to reaction at 50-140 DEG C, stable returning is performed after at least 80% of lauric acid is converted, and then cut fractions at 124-127 DEG C are collected through reduced pressure distillation, namely the activated lauric acid modifiers; and (2), the lauric acid modified SOD is prepared, wherein ox blood SOD is dissolved in a buffer solution to form an SOD solution, the activated lauric acid modifiers are added into the solution, the mixture is stirred and reacts at 30-50 DEG C and then is quenched to stop reaction, and the lauric acid modified SOD product is obtained. The prepared lauric acid modified SOD has the advantages of easily permeating through the skin and cell membranes compared with natural SOD, being long in activity preservation time and good in heat resistance when stored at normal temperature, being non-toxic and the like. The lauric acid modified SOD is suitable for being applied on labor protection and prevention of occupational dermatosis of staff in the dye industry and the printing and dyeing industry.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

A medium-temperature, moisturizing, yellowing and dense hanging rod baking method for middle and upper tobacco leaves

ActiveCN111084403BHigh average priceImprove coordinationTobacco preparationChemistryCuring of tobacco

Owner:贵州省烟草公司黔南州公司

Primer slurry for moisture-permeable waterproof fabric and its preparation process

ActiveCN103215809BSolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentEthanolaminesSlurry

The invention discloses an under-coating paint used for moisture permeable waterproof fabrics and a preparation technology, the under-coating paint comprises polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methyl ethanolamine; the preparation technology comprises the following steps: uniformly mixing butanone, water and polyurethane resin to form a main resin solution; adding N-methyl ethanolamine in the main resin solution; placing a mixed liquid of butanone and toluene in the main resin solution to form a main resin mixed solution; mixing 1,6-diisocyanatohexane and the main resin mixed solution according to mass proportion of 100:1.5-2.5 to form the adjusted main resin mixed solution; mixing water and butanone to form a solvent, placing the solvent in the adjusted main resin mixed solution by dividing at least six times for uniformly mixing; filtering the adjusted main resin mixed solution through a nylon net; and standing the filtered main resin mixed solution for at least 2 hours for deaeration treatment. The coating fabrics formed by the under-coating paint has uniform micropore, and is difficult to be expanded when contacting water, so that the moisture permeable performance of the fabric can be enhanced.

Owner:KUNSHAN HUAYANG NEW MATERIAL

A method for eliminating CO in confined spaces by ultrasonic atomization and spraying of heme solution

ActiveCN106823758BEasy to operateImprove portabilityGas treatmentDispersed particle separationInternal energyAbsorption efficiency

The invention discloses a method for eliminating CO in a limited space through ultrasonic atomization spraying of a heme solution, and belongs to chemical absorption methods of ultrasonic atomization spraying. With the combination of an ultrasonic atomization device and a chemical absorption method, the purpose of rapidly and effectively reducing the concentration of CO in a limited space can be achieved. According to the method, a heme (He) solution which can be rapidly combined with CO is adopted, a resonant cavity is impacted by using compressed air to generate ultrasonic waves, then a mixed liquid is atomized into micro fog drop of which the diameter is less than 50[mu] u, the fog drop is suspended in air for a long time, then the contact area between the solution and the air can be increased, and the absorption efficiency of the heme solution can be ensured. By adopting the device, 400ppm of carbon monoxide can be reduced to be less than 20ppm within 20 minutes, and the concentration of the carbon monoxide can be kept less than 20ppm within 120 hours. The equipment is gentle in application condition, simple and easy to store, safe and non-toxic and capable of meeting requirements of sustainable development. In addition, the equipment is simple to operate, low in cost and light and portable and provides good support for air purification in limited spaces such as mining escape capsules, refuge chambers and subway traffic.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com