Flue gas treatment process and treatment system

A flue gas treatment and process technology, which is applied in the field of chain grate machine-rotary kiln flue gas treatment, can solve the problems of increased NOx content, difficulty in achieving denitrification and precise control of NOx emission standards, so as to reduce ammonia escape and improve high temperature denitrification efficiency , Optimizing the effect of denitrification process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

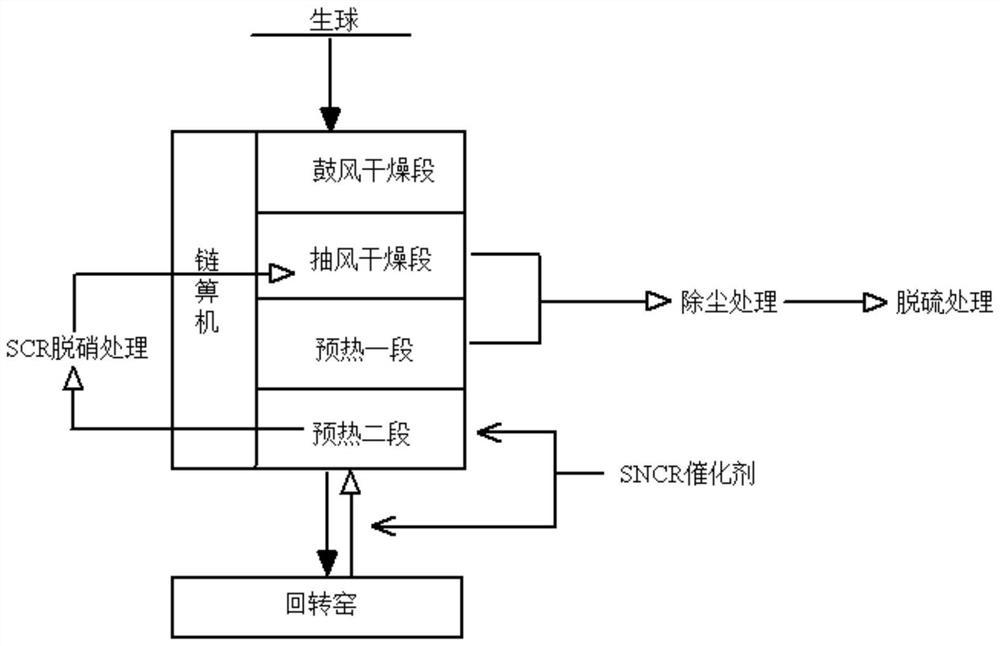

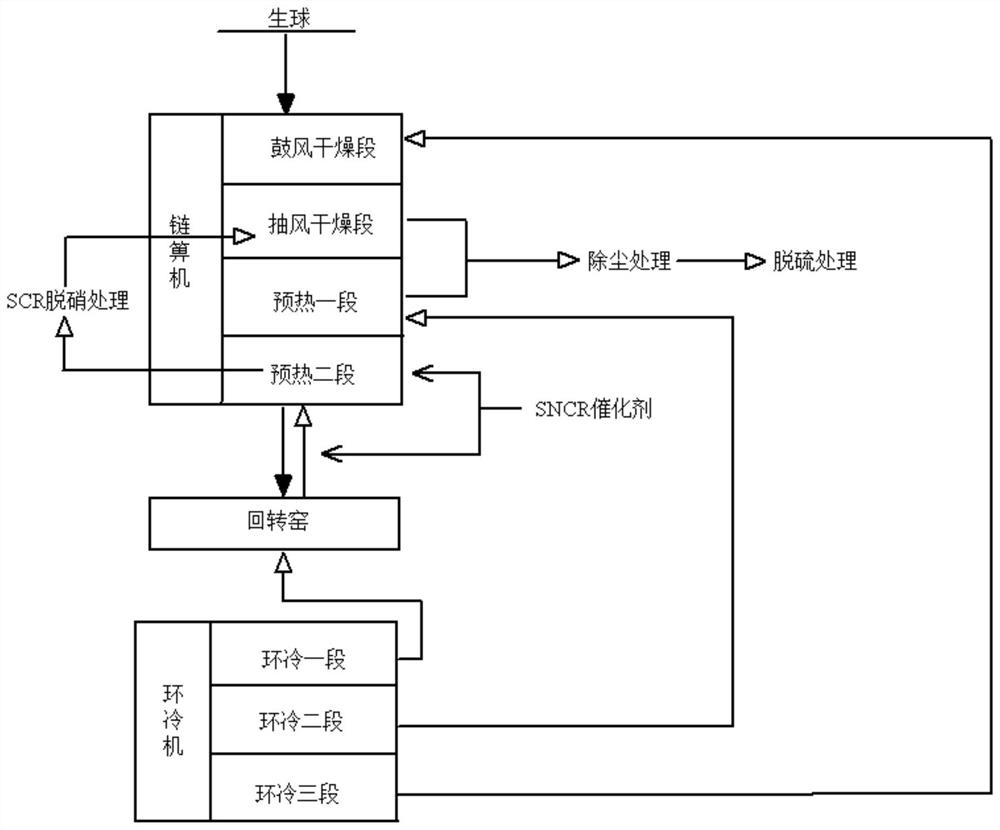

[0360] Such as Figure 6-13 As shown, a flue gas treatment system includes a chain grate machine 1, a rotary kiln 2, a desulfurization device 4, an SCR denitrification device 5, and a dust removal device 6. According to the direction of the material, the chain grate machine 1 is sequentially provided with a blast drying section UDD, a draft drying section DDD, a preheating section TPH and a preheating section PH. The second stage of preheating PH communicates with the flue gas outlet of the rotary kiln 2 through the first pipeline L1. An SNCR denitrification device 8 is installed in the second preheating stage PH and / or the first pipeline L1. The air outlet of the second preheating stage PH is connected to the air inlet of the draft drying stage DDD through the fourth pipeline L4. The air outlet of the exhausting and drying section DDD is connected to the chimney through the fifth pipeline L5. The SCR denitration device 5 is arranged on the fourth pipeline L4. The desulfur...

Embodiment 2

[0362] Repeat Example 1, except that an anti-blow-by wind device 3 is arranged between the first stage of preheating TPH and the second stage of preheating PH.

Embodiment 3

[0364] Embodiment 2 is repeated, except that the anti-channeling device 3 includes an airflow balance plate 301 , a moving platform 302 , rollers 303 and slots 304 . The airflow balance plate 301 is arranged inside the chain grate machine 1 . The mobile platform 302 is arranged on both sides of the outer lower end of the first-stage preheating PH and the second-stage preheating PH. The rollers 303 are arranged at the bottom of the mobile platform 302 . The slots 304 are arranged on both sides of the outer upper ends of the first-stage preheating PH and the second-stage preheating PH. The mobile platform 302 is also provided with a fixed base 30201 . A column 30202 is arranged on the fixing base 30201 . The top of the column 30202 passes through the slot 304 and connects with the top of the airflow balance plate 301 . A mobile motor 30203 is also provided outside the mobile platform 302 . The mobile motor 30203 drives the mobile platform 302 to move on the rollers 303 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com