Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

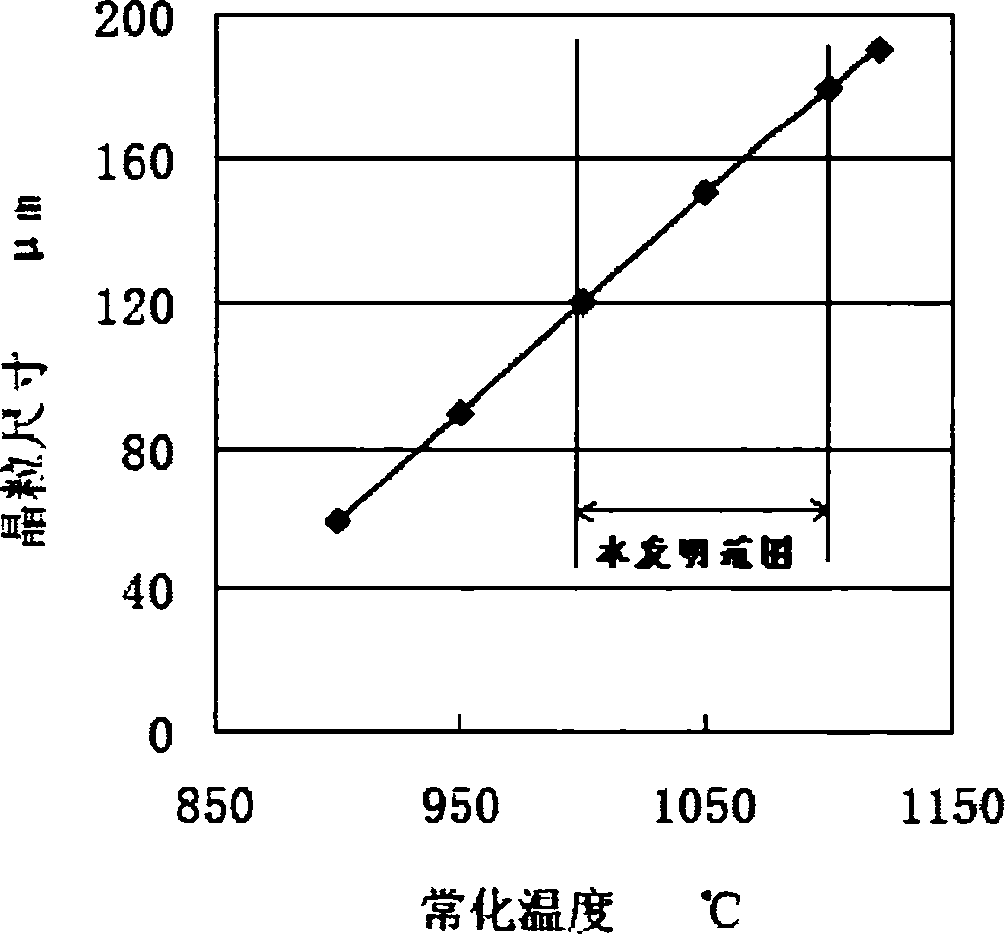

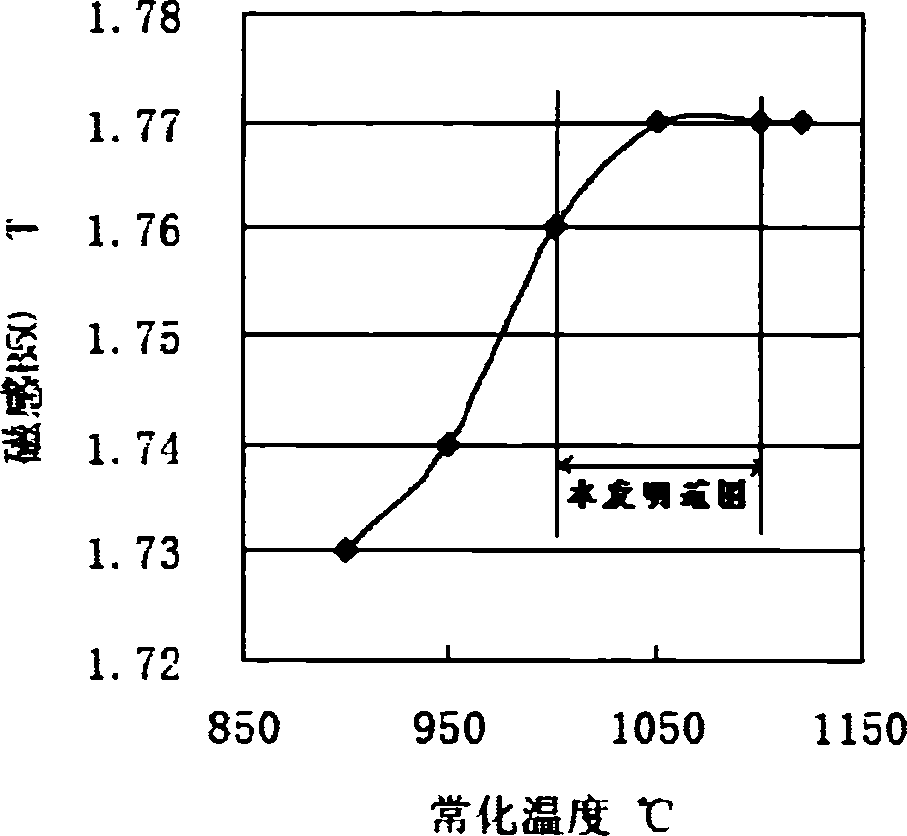

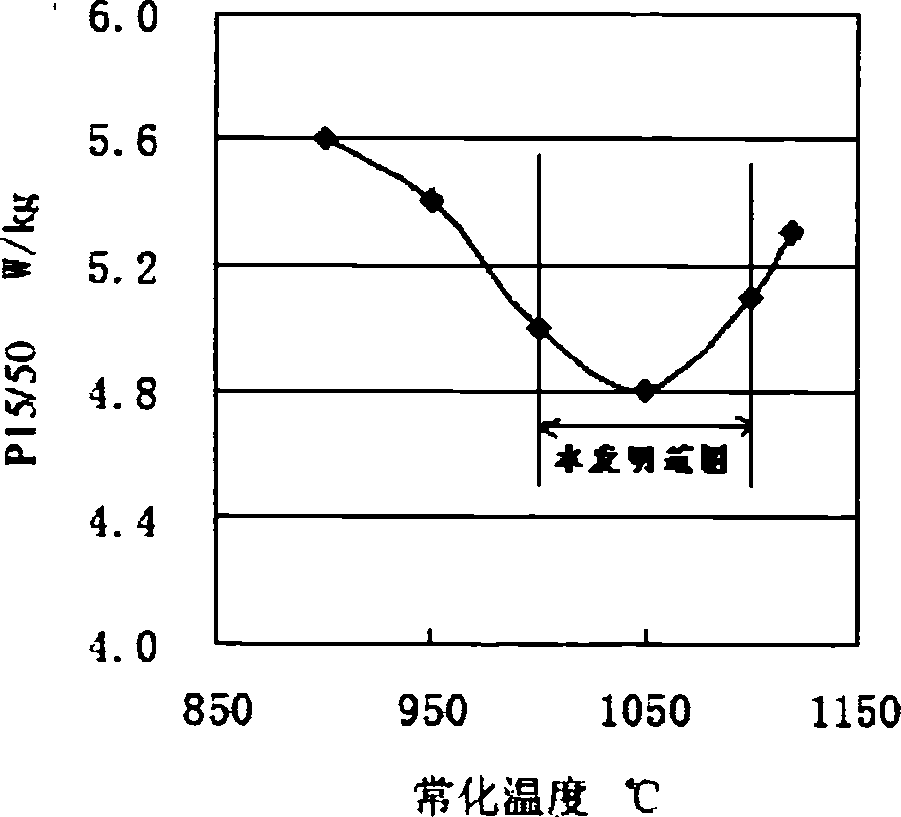

A technology of grain-oriented electrical steel sheet and production method, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of increasing the length of the annealing furnace, long normalization time, large equipment investment, etc., and shorten the normalization time, grain size, etc. The effect of easy growth and high magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Converter, RH vacuum treatment and continuous casting to obtain the continuous casting slab with the composition shown in Table 1, which was hot rolled into a 2.5mm thick hot rolled plate. Perform normalization treatment according to the process shown in Table 2, then wash and cold-roll into a 0.50mm thick cold-rolled sheet, and perform annealing treatment, and then coat the surface with an insulating layer. The magnetic detection results are shown in Table 2.

[0037]

[0038] Normalization conditions of hot rolled sheet

Embodiment 2

[0040] After the component 1 in Table 1 in the embodiment is treated according to the normalization process shown in Table 2, annealing at 700 ° C × 30 s is carried out after the first cold rolling, and then 5% reduction rate is smoothed to 0.5 mm, and the magnetic measurement test The samples were annealed at 780°C×1h, and the magnetic properties were measured. The magnetic properties are shown in Table 3.

[0041] Element

[0042] As can be seen from Table 2 and Table 3, the magnetism of the finished plate obtained by the process of the present invention has obvious advantages over the magnetic of the finished plate obtained by the process of the comparative example (low temperature for a long time or the first stage of faster cooling). Illustrate that the hot-rolled sheet produced by the specified composition and hot-rolling process of the present invention passes through the normalization treatment of high-temperature short-time annealing above the Acl point and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com