Control method of softness of oxide scales on surface of hot-rolling strip steel

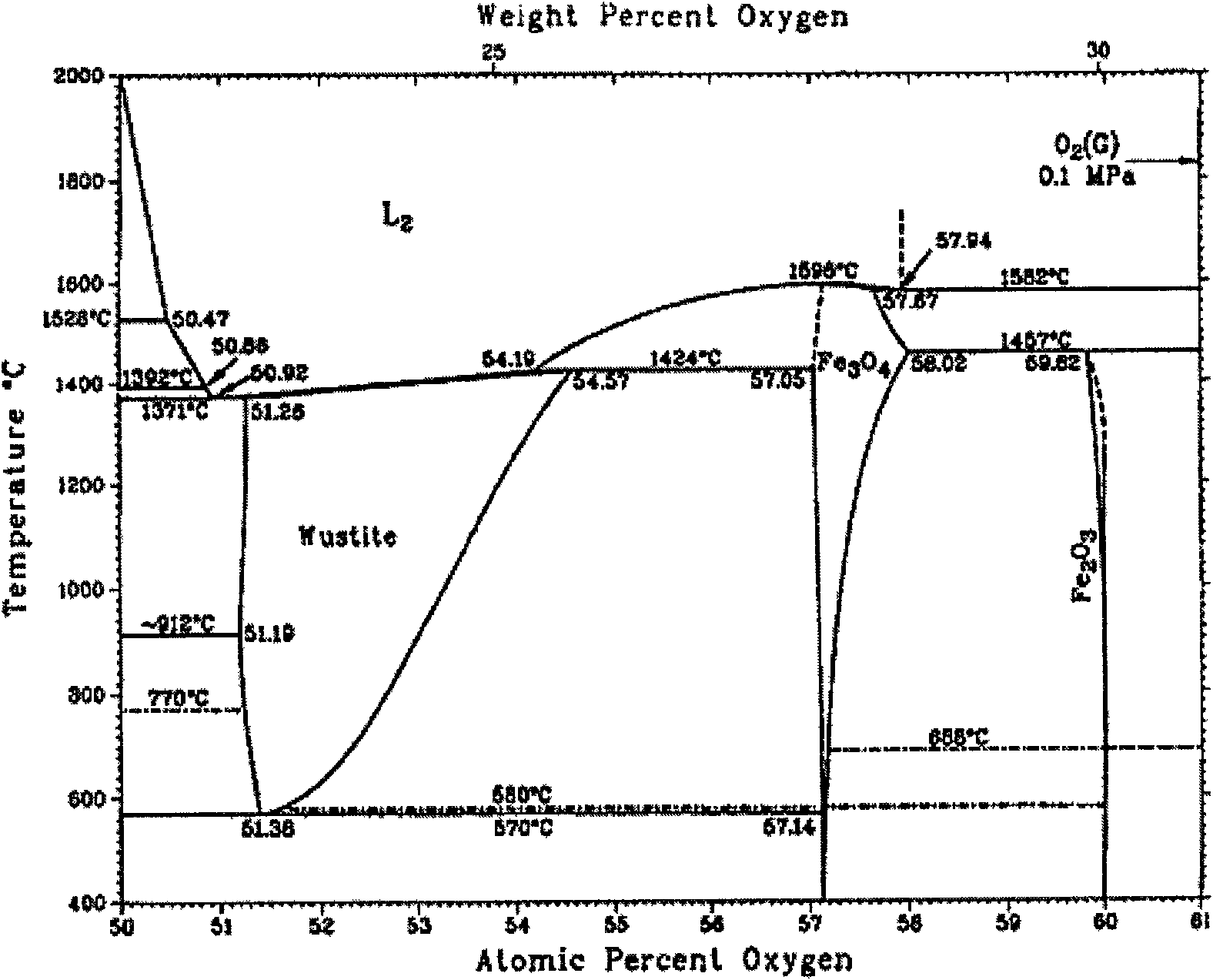

A technology of surface oxidation and hot-rolled strip, applied in metal rolling, metal rolling, temperature control and other directions, can solve the problems of increasing equipment investment, natural cooling can not meet the requirements, etc., to reduce FeO broken, reduce thickness, improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

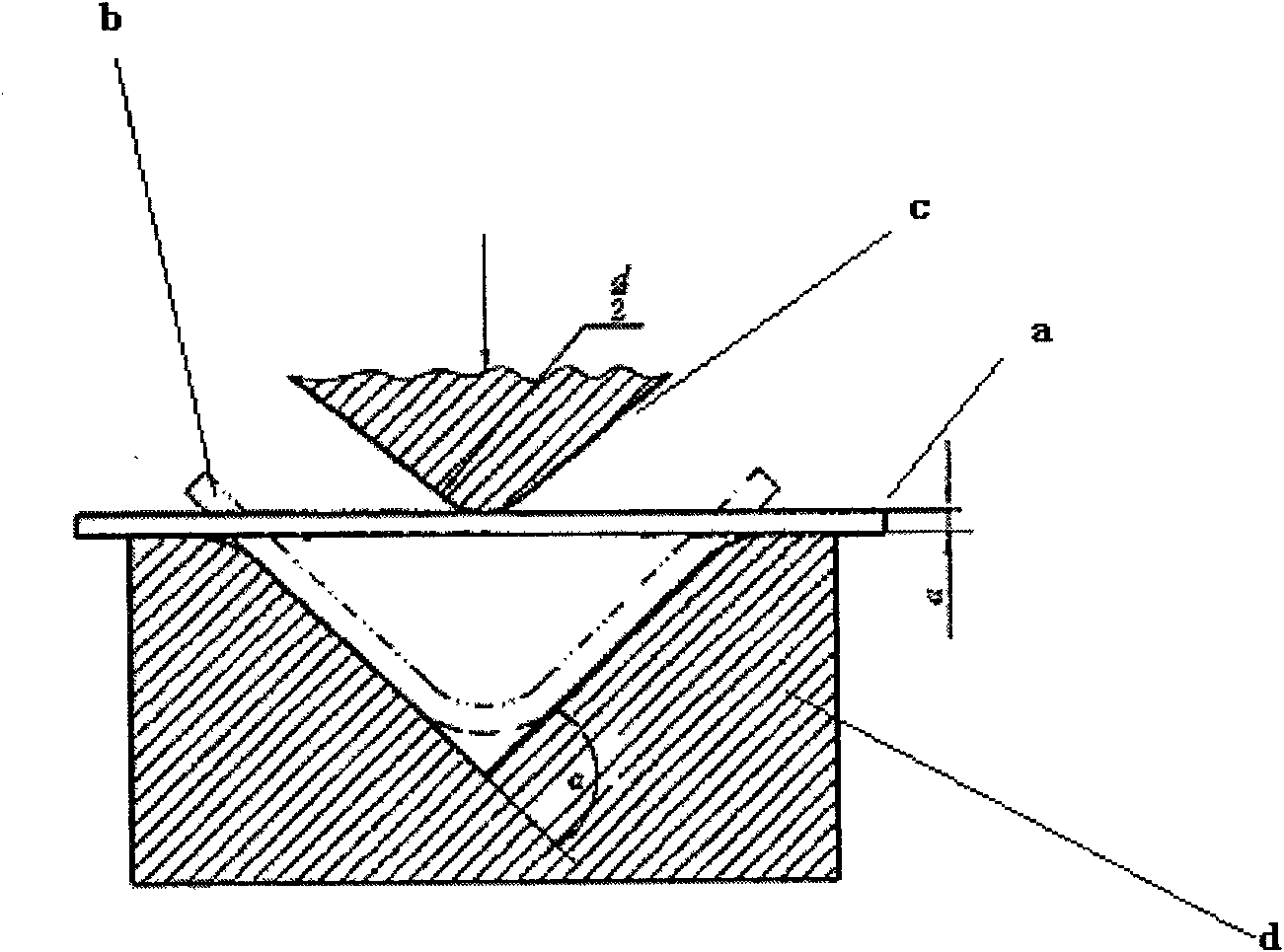

Method used

Image

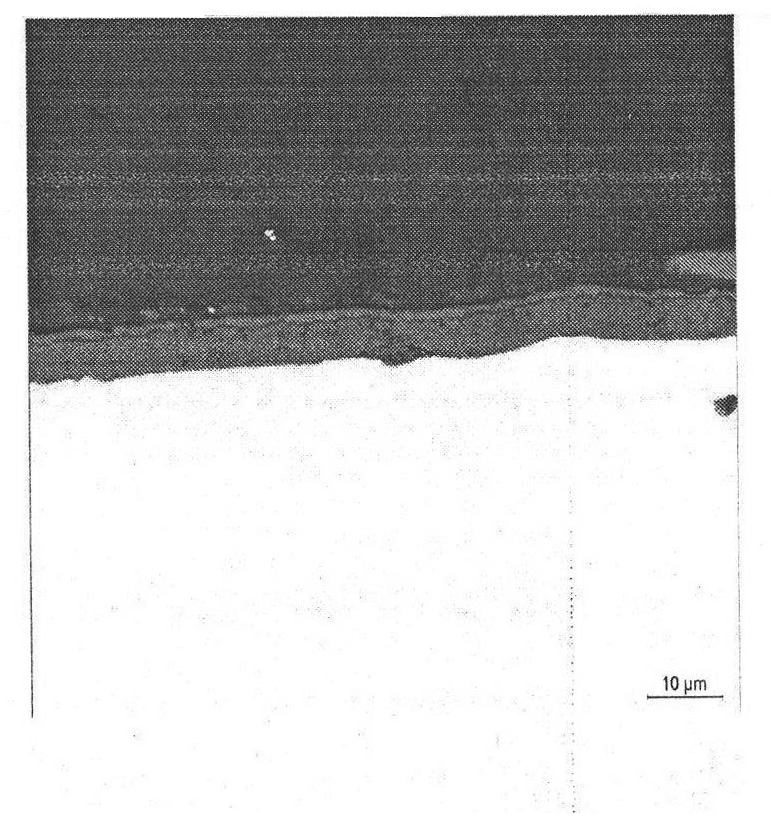

Examples

Embodiment 1

[0044] Smelting molten steel and continuous casting into slabs, its composition by weight percentage is C 0.098%, Si 0.23%, Mn 1.26%, P0.016%, S0.002%, Al 0.032%, Nb 0.020%, V0.001%, Ti0.003%, balance is iron.

[0045] Heat the slab to 1220°C and keep it warm for 40 minutes. Then use high-pressure water to descale, the temperature of descaling is 1200℃, and the water pressure is required to be 20MPa when descaling.

[0046] The descaled slab is subjected to rough rolling, the starting rolling temperature is 1150° C., the finishing rolling temperature is 1030° C., and the accumulated rolling reduction is 78%.

[0047] The slab after rough rolling is descaled before finishing rolling, the descaling temperature is 1050°C, and the water pressure is at least 18MPa during the second descaling; then finish rolling, the finish rolling start temperature is 1020°C, and the final rolling temperature is 870 ℃, the cumulative reduction in finish rolling is 75%, and the rolling speed duri...

Embodiment 2

[0049] Smelting molten steel and continuously casting it into slabs, its composition by weight percentage is C 0.071%, Si 0.131%, Mn 1.485%, P0.006%, S0.003%, Al 0.044%, Nb 0.062%, V0.016%, Ti0.002%, balance is iron.

[0050] Heat the slab to 1250°C and keep it warm for 40 minutes. , and then use high-pressure water to descale, the temperature of descaling is 1220℃, and the water pressure is required to be 20MPa when descaling.

[0051] The descaled slab is subjected to rough rolling, the rolling start temperature is 1180° C., the final rolling temperature is 1060° C., and the cumulative reduction is 85%.

[0052] The slab after rough rolling is descaled after finishing rolling, the descaling temperature is 1080°C, and the water pressure is at least 18MPa during descaling; then finish rolling, the finish rolling start temperature is 1040°C, and the final rolling temperature is 880°C, The cumulative reduction in finish rolling is 75%, and the rolling speed during finish rolli...

Embodiment 3

[0054] Smelting molten steel and continuously casting it into slabs, its composition by weight percentage is C 0.089%, Si 0.074%, Mn 1.282%, P0.007%, S0.002%, Al 0.041%, Nb 0.020%, Ti0.001%, The balance is iron.

[0055] Heat the slab to 1230°C, keep it warm for 30 minutes, and then use high-pressure water to descale. The descaling temperature is 1200°C, and the water pressure is required to be 20-25MPa during descaling.

[0056] The descaled slab is subjected to rough rolling, the starting rolling temperature is 1170°C, the finishing rolling temperature is 1080°C, and the accumulated rolling reduction is 83%.

[0057] The slab after rough rolling is descaled before finish rolling, the descaling temperature is 1100°C, and the water pressure is at least 18MPa during descaling; then finish rolling, the finish rolling start temperature is 1070°C, and the final rolling temperature is 920°C, The cumulative reduction of finish rolling is 95%, and the rolling speed during finish rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com