Patents

Literature

59results about How to "Acts as a lubricant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method of softness of oxide scales on surface of hot-rolling strip steel

ActiveCN101856669AImprove adhesionReduce FeO fragmentationTemperature control deviceWork treatment devicesOxideRolling speed

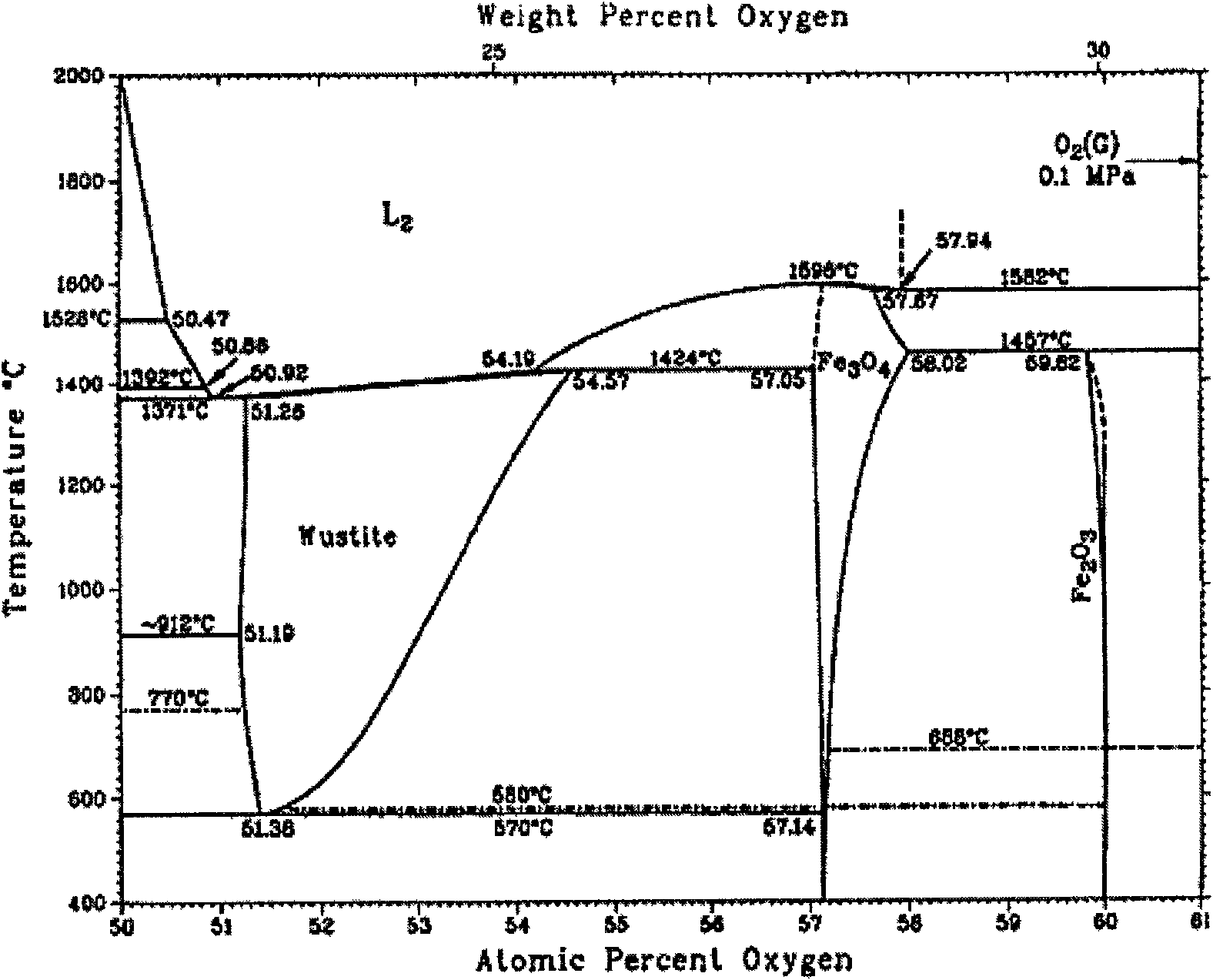

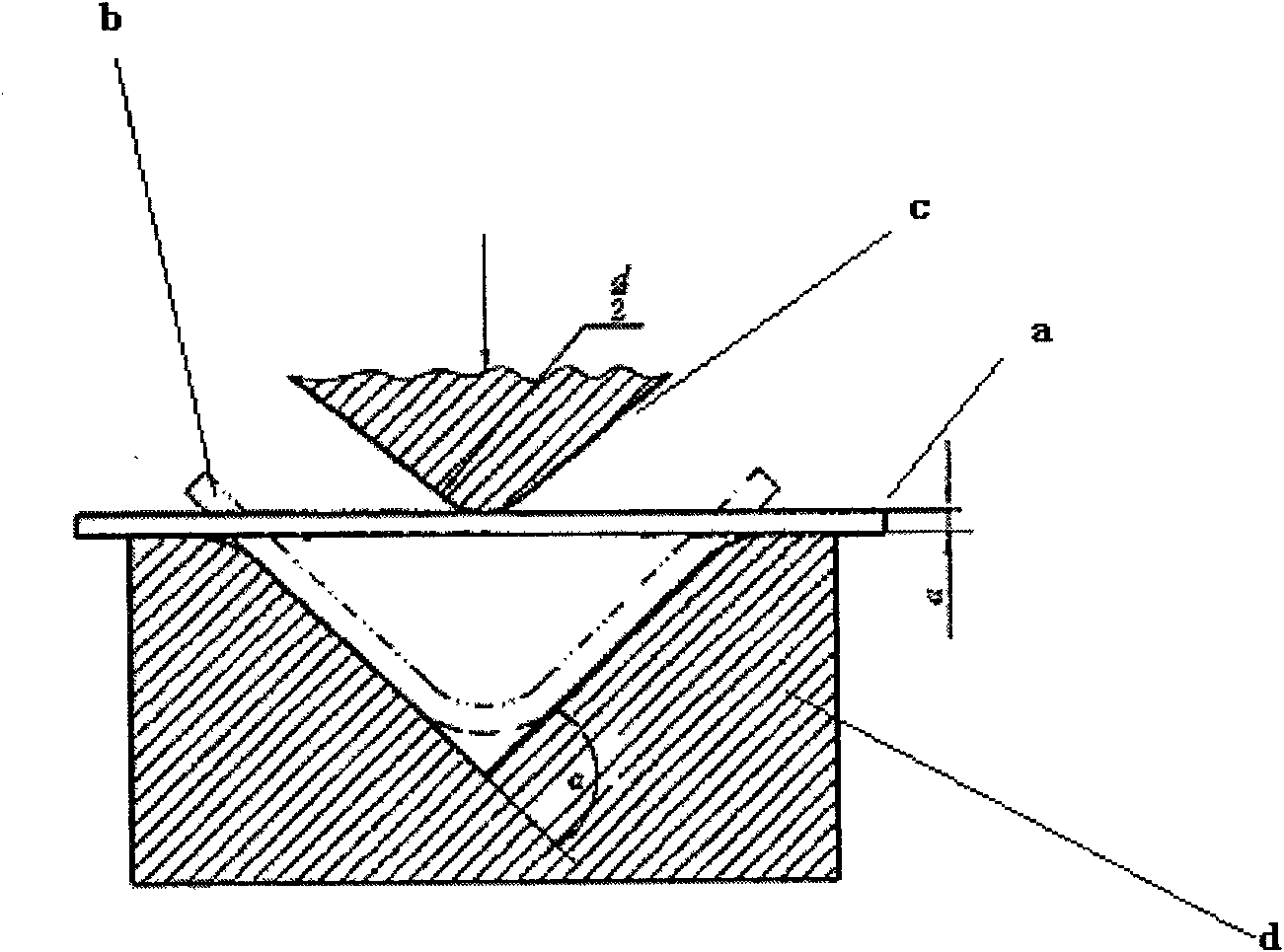

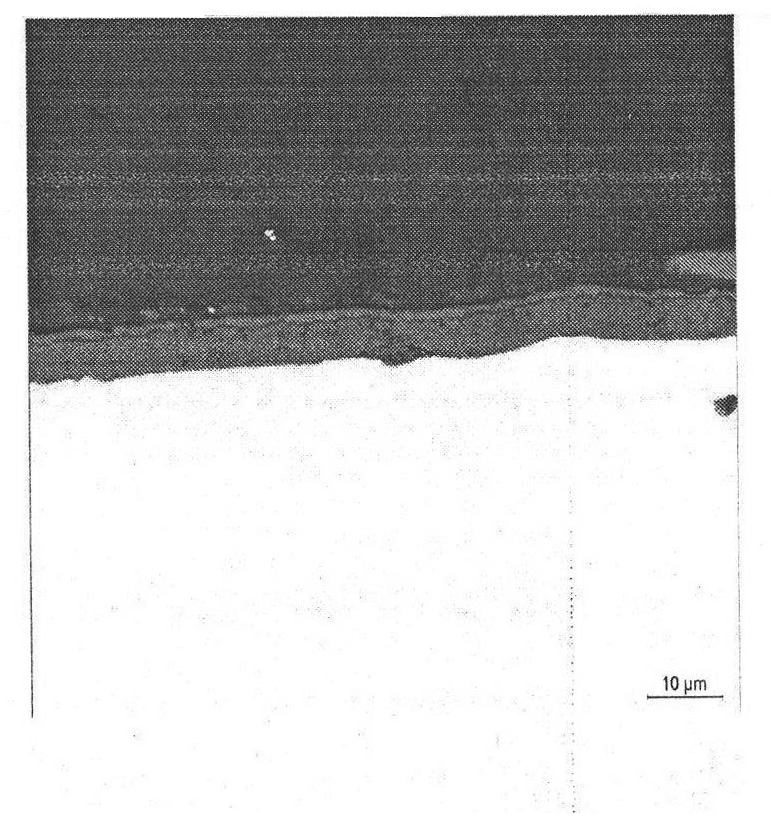

The invention provides a control method of softness of oxide scales on the surface of hot-rolling strip steel, belonging to the technical field of metallurgy. The method comprises the following steps: smelting liquid steel and continuously casting into plate blanks, heating and conducting thermal insulation on the plate blanks, then descaling, and rough rolling; and descaling again, and then finish rolling, wherein the initial rolling temperature is 1020-1070 DEG C, the finish rolling temperature is 870-920 DEG C, the rolling reduction is 75-95%, and the rolling speed is 3.5-12 m / s; cooling to 500-650 DEG C at the speed of 8-25 DEG C / s; and coiling. Aiming to different oxide scales structures, a hot-rolling process regulation scheme is provided in the method. In the hot-rolling process regulation scheme, by controlling the cooling speed and coiling temperature and the degree of a eutectoid reaction of FeO, reasonable control of the structure of the oxide scales is achieved, and loss of mechanical properties of products, which is caused by high temperature rolling, is compensated. The production efficiency is improved by using the existing devices and process conditions in a steel plant, surface quality is improved on the premise of ensuring mechanical properties of the steel plate and flexible production of oxide scale control.

Owner:NORTHEASTERN UNIV

Phosphogypsum water hard road base, road base material and preparation method thereof

The invention discloses a phosphogypsum water hard road base, a road base material and a preparation method thereof, relating to the field of road engineering construction. The preparation method of the road base material comprises the following steps: weighing 85-92 percent of phosphogypsum and 15-8 percent of ordinary portland cement, uniformly mixing and stirring, thereby obtaining a preliminary mixture; weighing 99.7-99.95 percent of preliminary mixture and 0.3-0.05 percent of a phosphogypsum water hard curing agent, uniformly mixing and stirring, thereby obtaining a premix; controlling the moisture content of the premix to be 14-18 percent, thereby obtaining a base material, wherein the phosphogypsum water hard curing agent is prepared by mixing the following components in percentage by mass: 40-60 percent of elastic styrene-acrylic emulsion, 30-20 percent of nanometer alumina sol and 30-20 percent of nanometer silica sol. The road base is prepared from the road base material according to a standard road base construction method. The road base material is produced by utilizing phosphogypsum, the environmental pollution is reduced, and wastes are changed into valuable materials; and moreover, the formed road base is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

Weatherproof and wear-resisting cable sheath material

InactiveCN104231600AImprove wear resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsEpoxyCopper oxide

The invention discloses a weatherproof and wear-resisting cable sheath material which comprises the following raw materials in parts by weight: 40-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of chloroprene rubber, 20-30 parts of chlorinated polyethylene, 30-45 parts of nano-titanium dioxide / graphene oxide, 10-15 parts of modified nano talcum powder, 20-35 parts of coupling-agent-modified attapulgite, 3-5 parts of activated zinc oxide, 4-9 parts of stearic acid, 10-18 parts of expansible graphite, 3-7 parts of copper oxide, 5-12 parts of ferric oxide, 5-9 parts of coupling-agent-modified ammonium polyphosphate, 3-6 parts of sulfur, 2-3.5 parts of tricresyl phosphate, 0.5-2 parts of oxidic polyethylene, 3.5-4.5 parts of an accelerant TMDT, 2-5 parts of an anti-aging agent, 1-2.8 parts of epoxy flaxseed oil and 1-1.8 parts of triethyl O-acetylcitrate. The weatherproof and wear-resisting cable sheath pipe has the advantages of good weather resistance, high wear resistance, good mechanical property and long service life.

Owner:无为县华祥电缆材料有限公司

LED lampshade material and preparation method thereof

ActiveCN104788869AImprove toughnessImprove heat resistancePoint-like light sourceGlobesPolyethylene glycolThermal expansion

The invention relates to a lampshade material. The lampshade material comprises the following raw materials in parts by mass: 100 parts of PMMA, 4-6 parts of an organic silicon material, 1-2 parts of methylacryloyl methoxyl silane, 0.5-1 part of polyethylene glycol, 0.4-0.8 part of an organic silicon photodiffusion agent, 1-1.5 parts of carboxymethylcellulose, 1-2 parts of nano negative ion powder, 0.5-1.5 parts of nano yttrium oxide, 2-5 parts of polytetrafluoroethylene ultrafine powder, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a light stabilizing agent. The invention further relates to a preparation method of the lampshade material. The lampshade material is good in light permeability and gentle in light, the thermal expansion coefficient of the lampshade material is matched with an LED chip, and the wafer of an LED lamp is not bent because of temperature change in normal operation, so that the LED lamp is solid and stable in overall structure in the use process, the service life can be prolonged, the lampshade material has an air purification function, the preparation method of the lampshade material is simple, the dispersing property of the lampshade material can be remarkably improved, the light transmittance rate and the haze degree are remarkably increased, and the mechanical property and the surface hardness are remarkably improved.

Owner:NINGBO LAIHE CHRISTMAS GIFTS

Red mud phosphogypsum hydraulic road base course, red mud phosphogypsum hydraulic road base course material and preparation method of red mud phosphogypsum hydraulic road base course material

The present invention discloses a red mud phosphogypsum hydraulic road base course, a red mud phosphogypsum hydraulic road base course material and a preparation method of the red mud phosphogypsum hydraulic road base course material, and relates to the field of road engineering construction. The preparation method comprises: weighing 10-50% of phosphogypsum and 90-50% of red mud, and uniformly mixing and strring to obtain a primary mixing material; weighing 85-92% of the primary mixing material and 15-8% of ordinary Portland cement, and uniformly mixing and strring to obtain a premix; and weighing 99.7-99.95% of the premix and 0.3-0.05% of a hydraulic curing agent, uniformly mixing and strring to obtain a mixture, and controlling the water content of the mixture to 14-18% to obtain the base course material, wherein the hydraulic curing agent is obtained by mixing the following components by mass: 40-80% of an elastic styrene-acrylic emulsion, and 60-20% of nanometer silicon sol. According to the present invention, the road base course is prepared by using the road base course material according to the standard road base course construction method; the red mud and the phosphogypsum are used to produce the road base course material, such that the pollution of the red mud and the phosphogypsum on the environment is reduced, and the waste is turned into treasure; and the formed road base course has characteristics of strong cracking resistance, corrosion resistance, and long service life.

Owner:湖北炼石环保科技有限公司

Red mud water hard roadbase, roadbase material and preparation method of roadbase material

ActiveCN104926230AHigh mechanical strengthStrong crack resistanceSolid waste managementRoads maintainenceEmulsionTO-18

The invention discloses a red mud water hard roadbase, a roadbase material and a preparation method of the roadbase material, relating to the field of road engineering construction. The preparation method of the roadbase material comprises the steps of weighing 80% to 95% of red mud and 20% to 5% of ordinary portland cement, and mixing and stirring evenly to obtain an elementary mixed material; weighing 99.5% to 99.9% of the elementary mixed material and 0.5% to 0.1% of red mud water rigidness curing agent, mixing and stirring evenly to obtain a gunk, and controlling the moisture content of the gunk to be 14% to 18% to obtain the roadbase material, wherein the red mud water rigidness curing agent is formed by mixing the following components in mass percent: 40% to 80% of elastic styrene acrylic emulsion and 60% to 20% of nano alumina sol, and the solid content of the elastic styrene acrylic emulsion is greater than 55%. The roadbase adopts the roadbase material and is prepared according to a standard roadbase construction method. The red mud is used for producing the roadbase material, thus turning waste into wealth; the formed roadbase is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

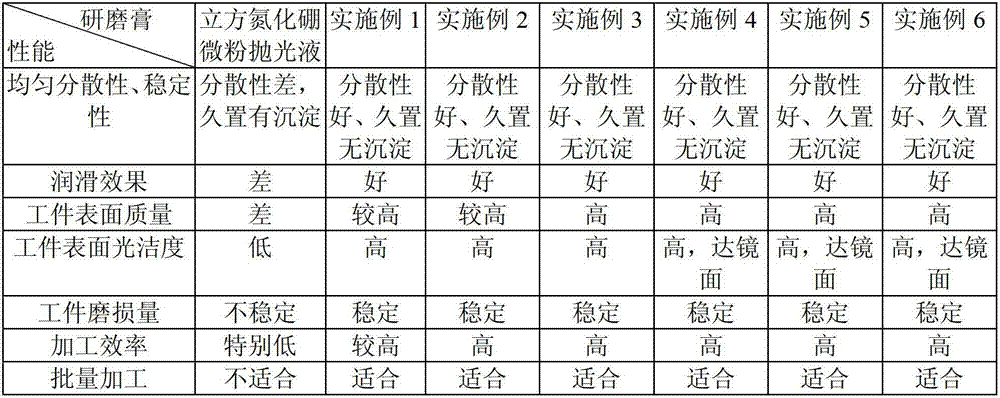

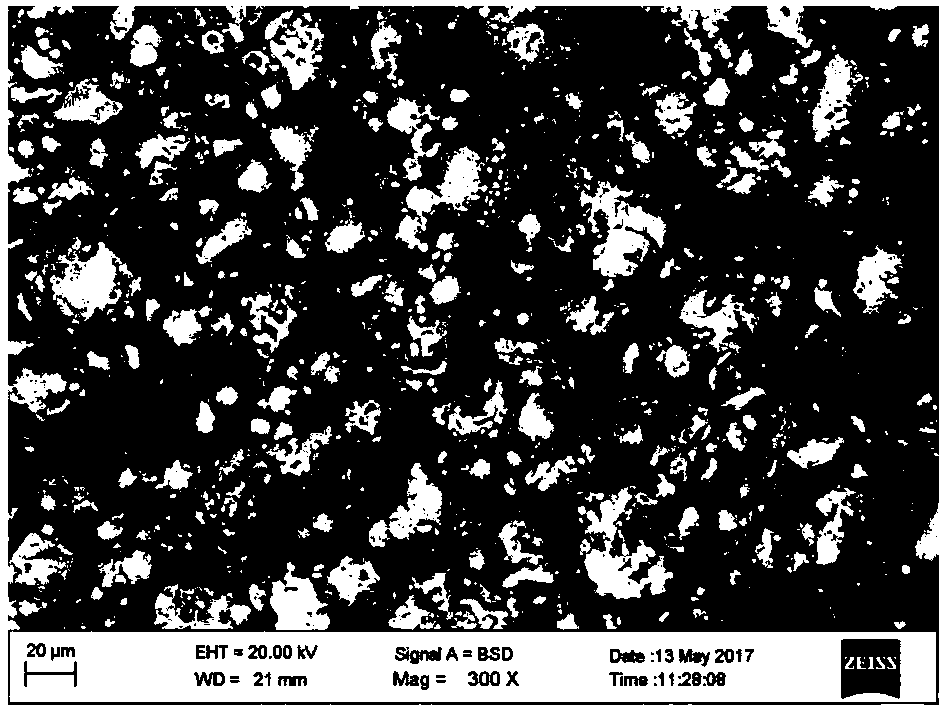

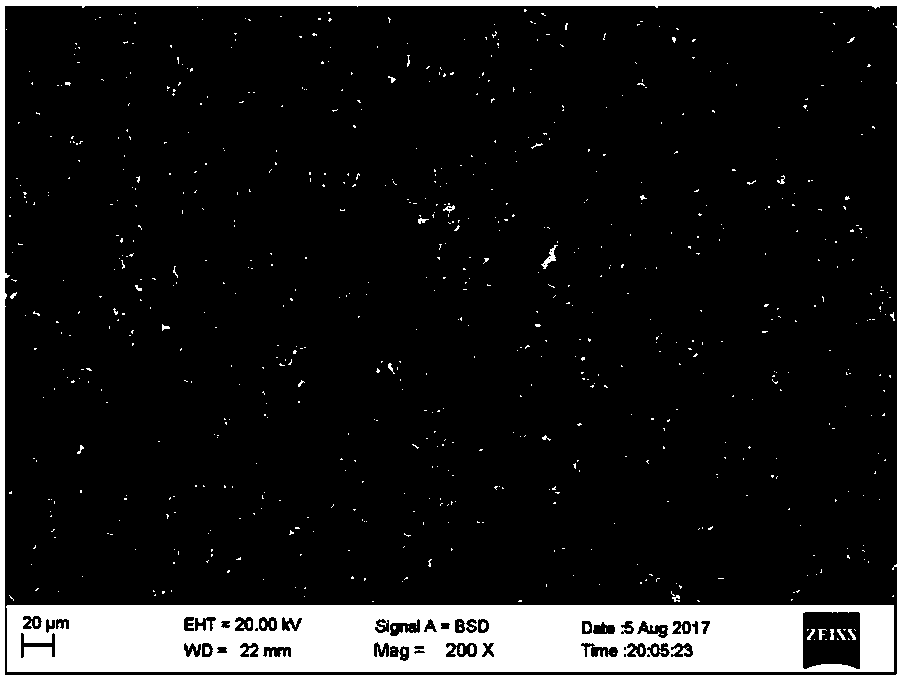

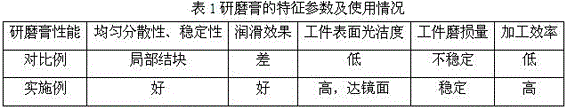

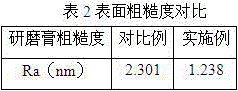

Man-made diamond grinding paste

InactiveCN103160208AActs as a lubricantQuality improvementPolishing compositions with abrasivesSurface finishBatch processing

The invention provides a man-made diamond grinding paste, and the problem that existing polishing solution is prone to generating scrape and damage on the surface of a precision mold. The man-made diamond grinding paste is composed of man-made diamond powder, mixed fat, oleic acid and lubricant. By weight, the man-made diamond grinding paste comprises 15-55 parts of the man-made diamond powder, 25-40 parts of the mixed fat, 20-30 parts of the oleic acid and 3-11 parts of the lubricant. The preparation method of the man-made diamond grinding paste includes the following steps: (1), each component is weighted according to the parts by weight; (2), all the components are mixed evenly under the temperature above 60 DEG C; and (3), the evenly mixed components are cooled to zero DEG C, and the man-made diamond grinding paste is prepared. The grinding paste is matched with a pneumatic polishing machine to be used for carrying out polishing treatment on the surface machining of the precision mold, the surface quality and the surface finish are high, experience and technological level of an operator are not required highly, the production efficiency can be greatly improved, the cost can be reduced and the method is suitable for batch processing.

Owner:QINGDAO HENGHUI MOLD TECH

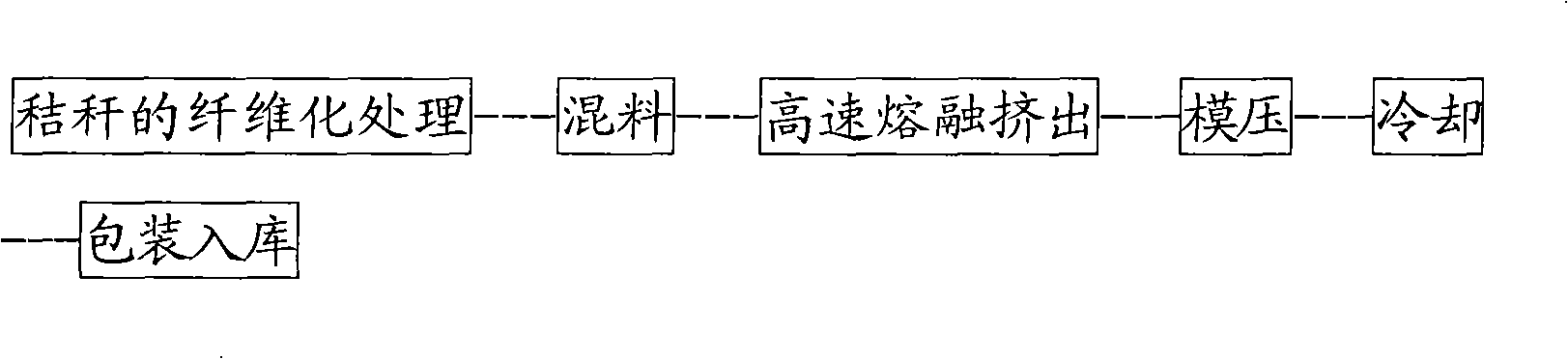

Straw fiber silicon plastic composite building form board and method for making same

InactiveCN101307641AReduce land occupationSolve the problem that the price is too high and difficult to promoteFlat articlesDomestic articlesFiberPlastic waste

The invention discloses a straw fiber silicon-plastic composite building formwork and a method for preparing the same. The proportion of the formulation of per 100 kilogram of straw fiber silicon-plastic composite building formworks is as follows: 28 to 39 kilograms of plastic waste, 35 to 55 kilograms of plant straw short fibers, 15 to 25 kilograms of fly ash and 1 to 2 kilograms of auxiliary agent. The preparation method comprises the following steps of: fiber treatment of straws; mixing; high-speed fusing and extruding; mould pressing; cooling; and product package and storage. The straw fiber silicon-plastic composite building formwork and the method have the advantages of low production cost, high cost performance, good product quality, waste recycling, energy conservation and environmental protection, accordance with the development requirements of recycling economy and so on.

Owner:绍兴一普塑业有限公司

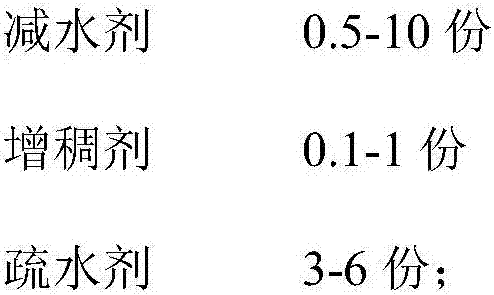

High freezing resistance water permeable concrete additive and preparation method thereof

The invention belongs to the technical field of concrete additives and relates to a high freezing resistance water permeable concrete additive and a preparation method thereof. The high freezing resistance water permeable concrete additive consists of the following components in parts by weight: 5-10 parts of mixing materials, 0.5-10 parts of a water reduction agent, 0.1-1 part of a thickening agent and 3-6 parts of a water repellent agent, wherein the mixing material is silicon ash or coal ash; and the granularity of the mixing material is 300-400 meshes. The preparation method comprises thefollowing steps: mixing the mixing material, the water reduction agent, the thickening agent and the water repellent agent according to the parts by weight, grinding, stirring the mixed material at amedium speed till the components are uniform, and discharging. The additive provided by the invention is capable of enriching fine capillary cavities and micro cracks in a cementing layer of water permeable concrete, improving the strength of a cement adhesive layer, and improving the strength of the water permeable concrete, so that the freezing resistance of the concrete is improved. In addition, due to adoption of the water repellant agent, a water repellant surface is formed on the surface of the cementing layer of concrete, so that water inside the concrete can be well discharged, and thefreezing resistance and the water permeability of the concrete are improved.

Owner:长春市城建维护集团股份有限公司

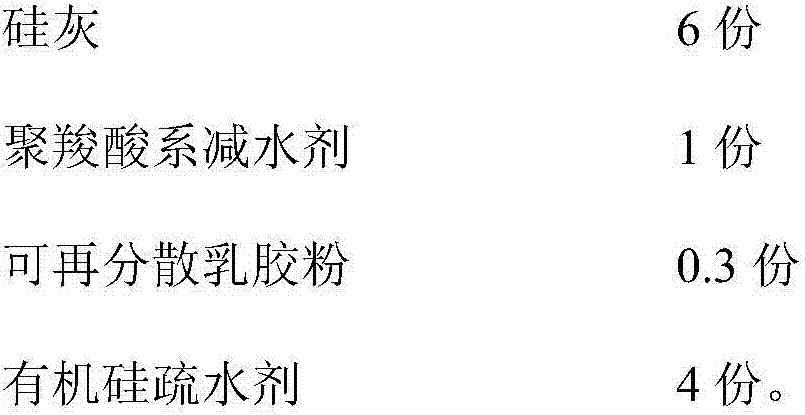

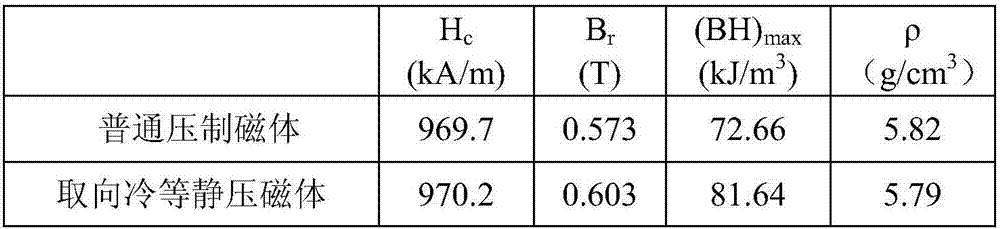

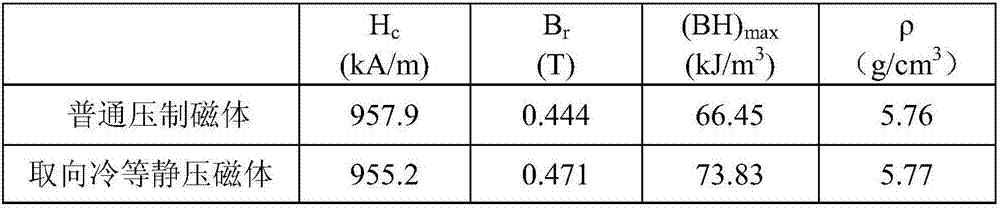

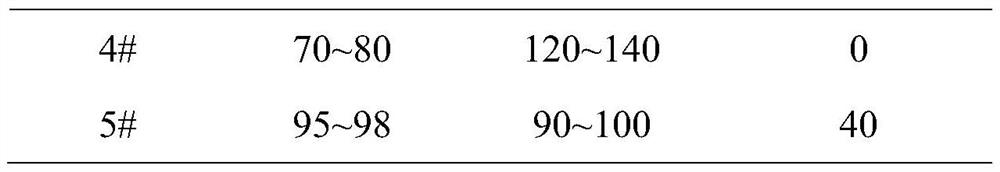

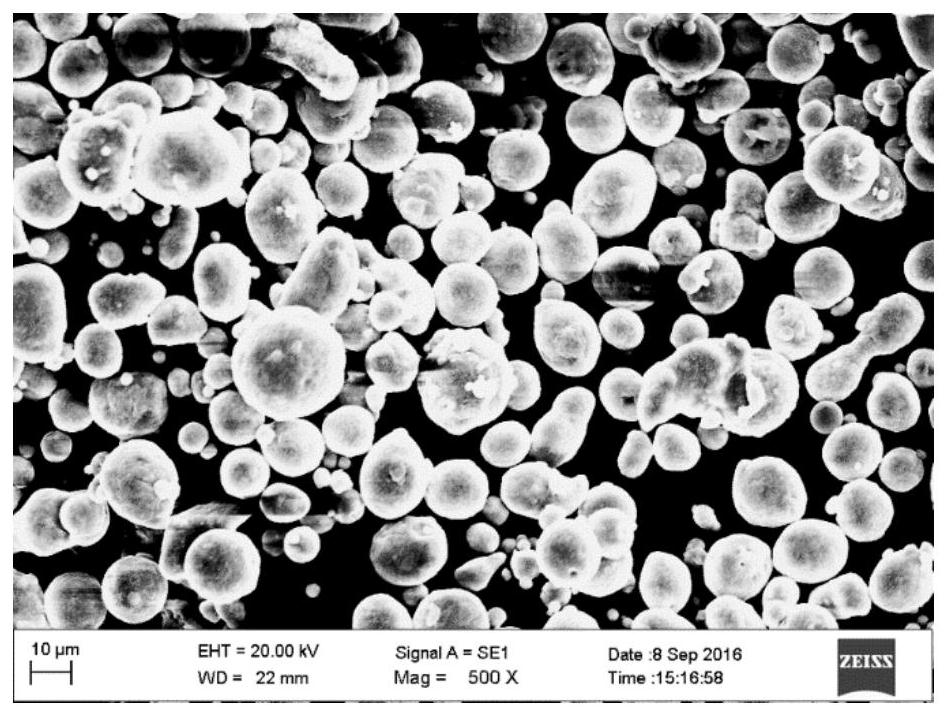

Isostatic cool pressing method for preparing anisotropic bonded magnet with high degree of orientation

ActiveCN107393709ANot easy to damageEasy to prepareInductances/transformers/magnets manufactureRare earthSlurry

The invention discloses an isostatic cool pressing method for preparing an anisotropic bonded magnet with high degree of orientation, and belongs to the technical field of rear-earth magnetic materials. The method comprises the following steps: dissolving a certain amount of thermosetting resin and a certain amount of curing agent into an organic solvent to prepare a bonding machine, then adding anisotropic bonded magnetic powder into a bonder solution, sufficiently stirring to prepare a uniform suspended state low viscosity magnetic slurry, injecting the uniform suspended state low viscosity magnetic slurry into a silicon rubber mold, carrying out vacuum sealing, carrying out orientation under a magnetic field of 1.5 to 2 T, carrying out isostatic cool pressing molding on the magnet after orientation, then curing the formed magnet to obtain high-performance bonded neodymium iron boron magnet. By using in situ orientation of the silicon rubber mold and the bonded magnet, the bonder solution can serve as a lubricating agent among the magnetic powder, complete orientation of the magnetic powder during orientation is guaranteed, and due to the fact that isostatic cool pressing pressure is isotropous after orientation, the degree of orientation of the magnetic powder which has been orientated cannot be damaged. A complicated silicon rubber mold is prepared through mold reversing, so that the bonded magnet with complicated shape is prepared. The mold is simple and easy to prepare, the magnet is high in degree of orientation, and the performance is higher than that of a bonded magnet prepared through ordinary pressing and injection molding.

Owner:UNIV OF SCI & TECH BEIJING

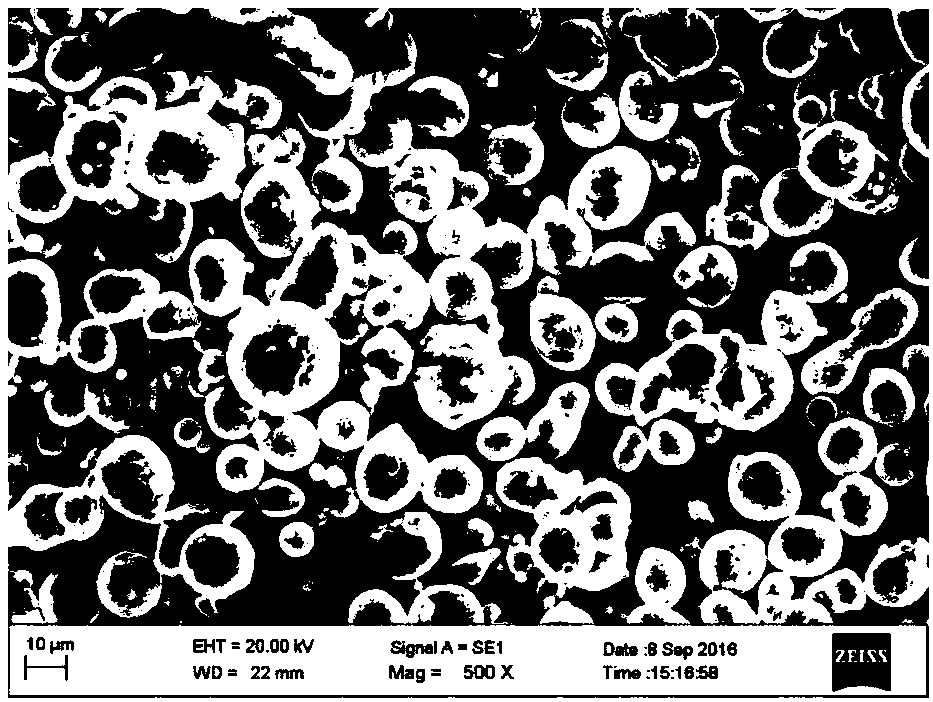

Composition for preparing high porosity particle trap honeycomb ceramic

The invention belongs to a manufacturing technology of honeycomb ceramics and aims to provide a compound used to prepare high-porosity granule trap honeycomb ceramics. The compound generates less heat during the burning stage of honeycomb ceramics, thereby reducing the reject rate of the honeycomb ceramics. Moreover, the compound is characterized in that: the compound comprises foaming resin powder, wherein the diameter of foaming resin granule is 0.1 micron to 30 micron; the weight of foaming resin occupies 0.4 to 17 percent of that of the inorganic matters in the entire compound.

Owner:北京创导奥福科技发展有限公司

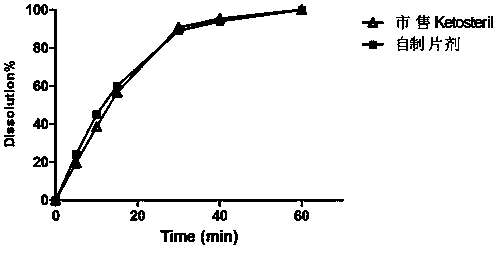

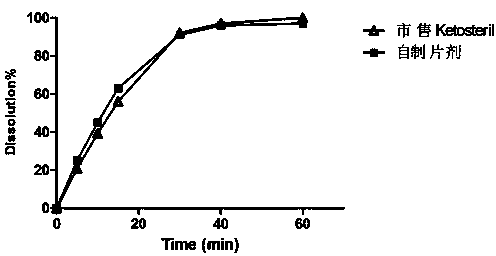

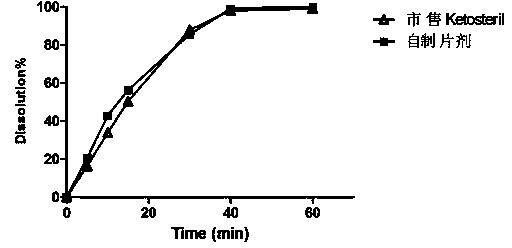

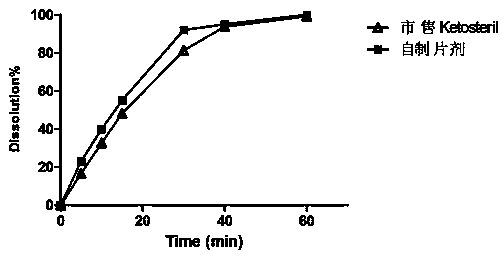

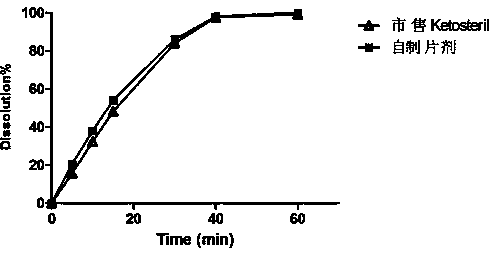

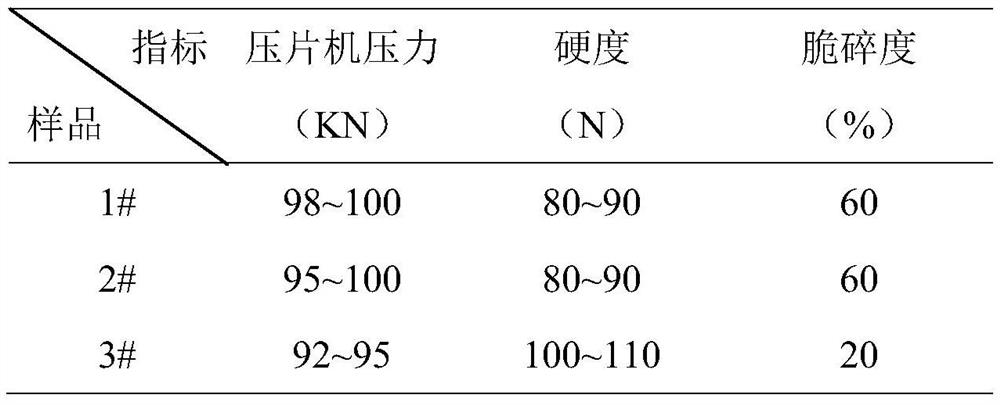

Compound alpha-ketoacid tablet and preparation method thereof

ActiveCN103463014AImprove liquidityAvoid clumpingPharmaceutical non-active ingredientsUrinary disorderPolyethylene glycolDissolution

The invention relates to a compound alpha-ketoacid tablet free from talcum powder and a preparation method of the tablet. The tablet prepared by using the preparation method is good in compressibility, beautiful in appearance, high in disintegration speed, high in dissolution rate and high in long storage stability. According to the preparation method provided by the invention, a dry granulation method is used, all the ingredients are prevented from contacting water or other wetting agent, and therefore, the tablet can be stably stored for long time, and the content of effective ingredient is ensured. The content of the polyethylene glycol in the prescription is optimized, the talcum powder or the analogue with composition similar with that of the talcum powder are not contained in the prescription, no disintegrating agent needs to be added, the problems of clustering phenomenon and quite large viscidity in a wet granulation process in the traditional production are solved, the medication safety is ensured, and the product can be stably produced with quality and high safety.

Owner:SHENYANG PHARMA UNIVERSITY +1

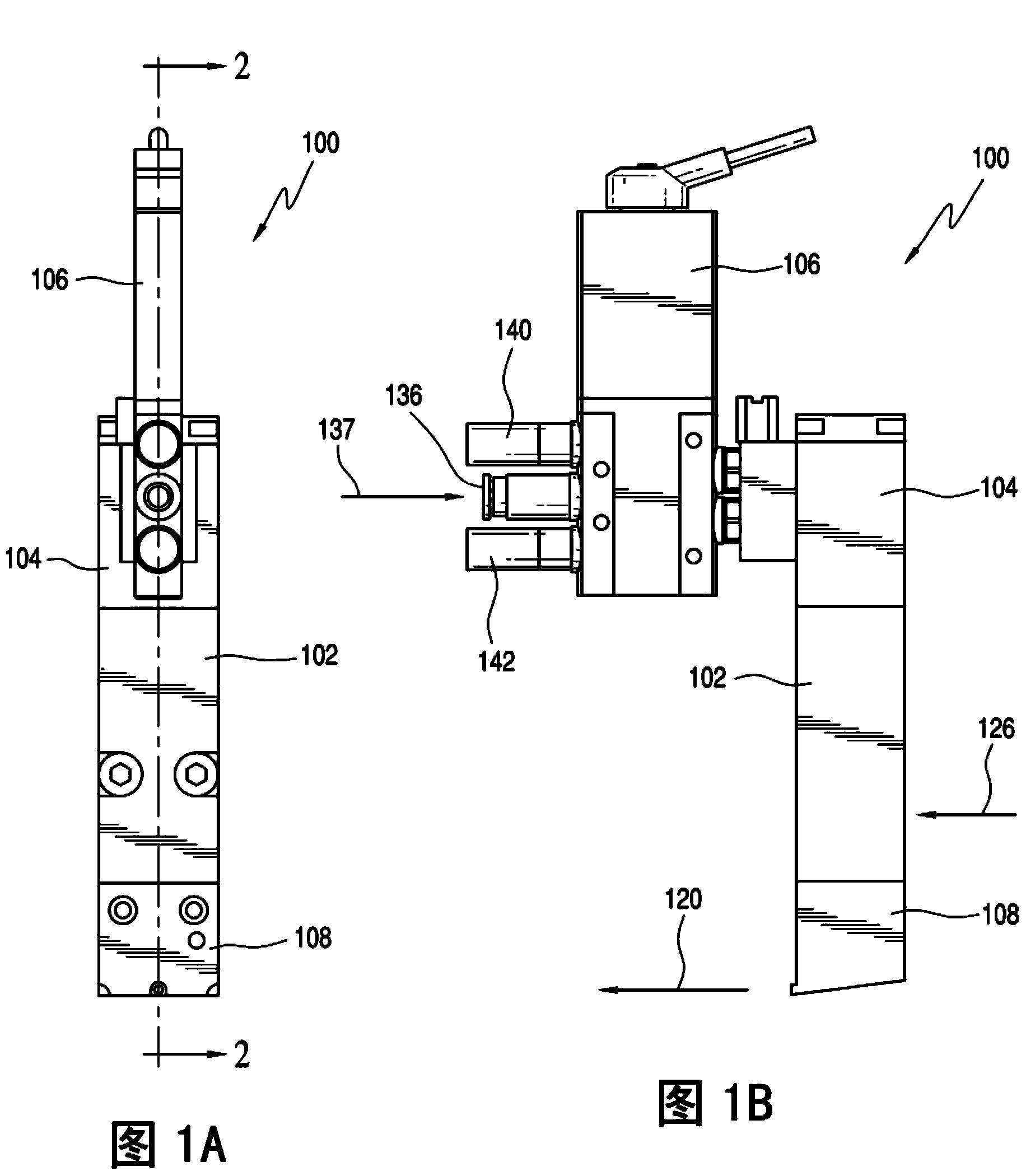

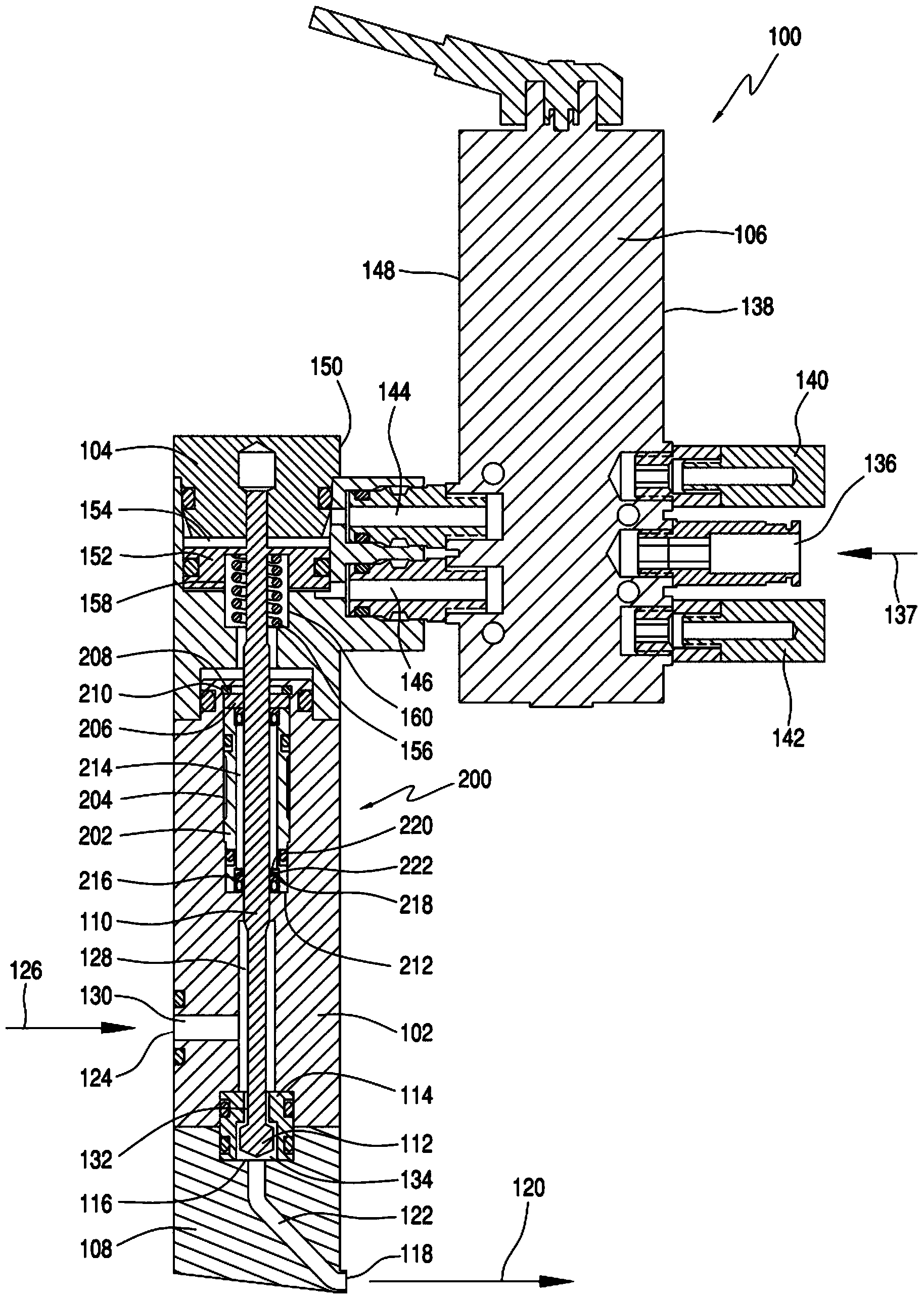

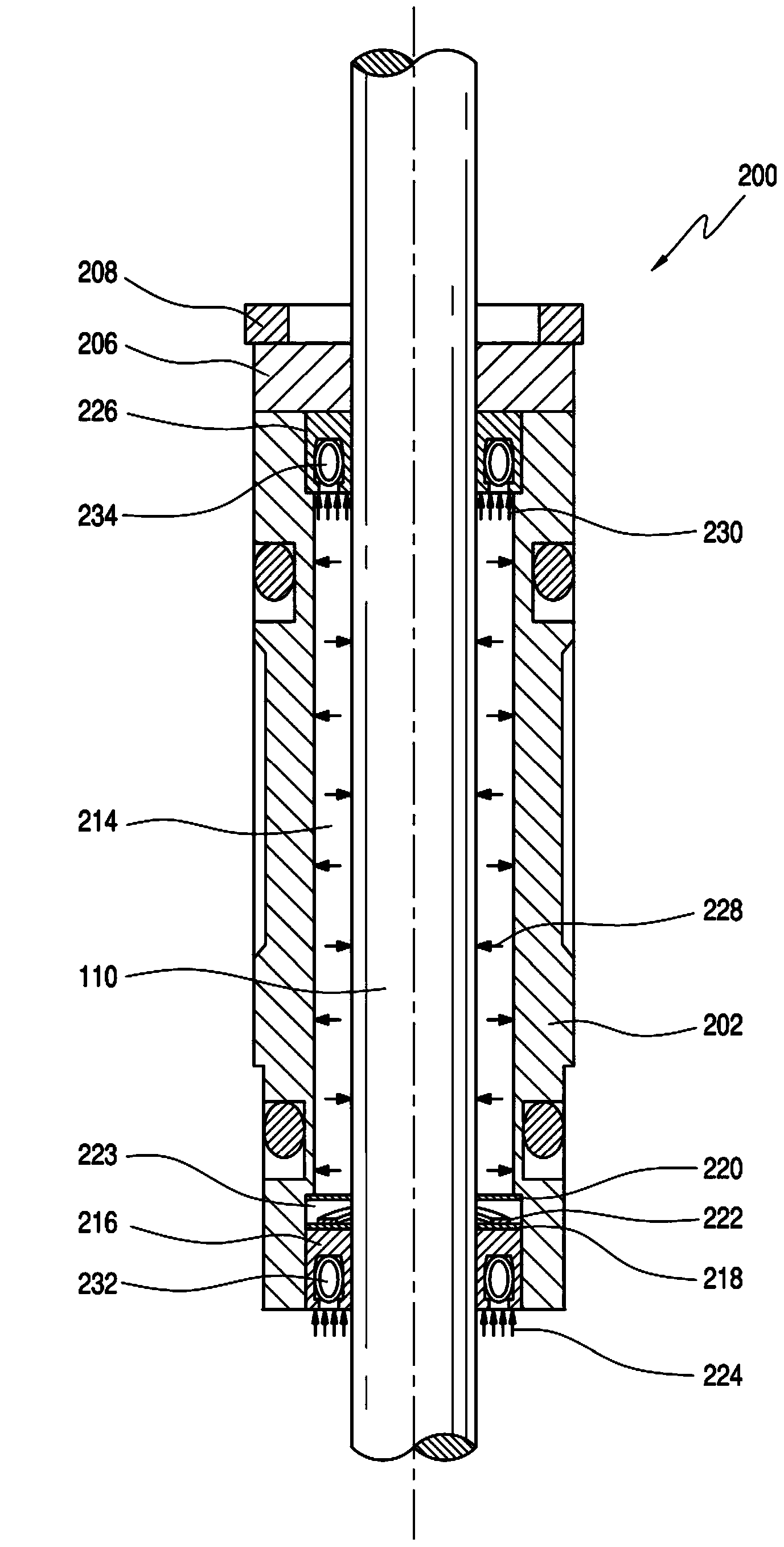

Hydraulic seal assembly for a thermoplastic material dispensing valve assembly

InactiveCN103748389AEliminate differential pressureReduce frictionEngine sealsLiquid surface applicatorsInternal pressureEngineering

A seal assembly, for use within a hot melt adhesive or other thermoplastic material dispensing valve assembly, comprises a sealing cartridge comprising a first primary seal, a secondary seal, and a viscous incompressible silicone grease disposed internally within the sealing cartridge. The viscous silicone grease effectively distributes the pressure forces such that internal pressure forces within the silicone grease are substantially equal to the external pressure forces of the hot melt adhesive whereby a pressure differential across the primary seal member is effectively eliminated thereby effectively eliminating the tendency for leakage of the hot melt adhesive or other thermoplastic materials.

Owner:ILLINOIS TOOL WORKS INC

Roller for rolling large profile steel and manufacturing technology of roller

ActiveCN103341492AActs as a lubricantSolve the sticky steel problemRollsMetal rolling arrangementsManufacturing technologyCarbide

The invention discloses a roller for rolling large profile steel and a manufacturing technology of the roller. A base body of the roller for rolling the large profile steel contains evenly-distributed spheroidal graphite, and the base body is composed of granulous carbide, tempered sorbite and pearlite. When the roller for rolling the large profile steel rolls the large profile steel, the small graphite is crashed under the effect of squeezing, heating and the like, the effect of lubricant can be achieved during rolling material hole punching, the problem of steel sticking is solved, and the surface of a rolled piece is bright and clean.

Owner:江苏凯达重工股份有限公司

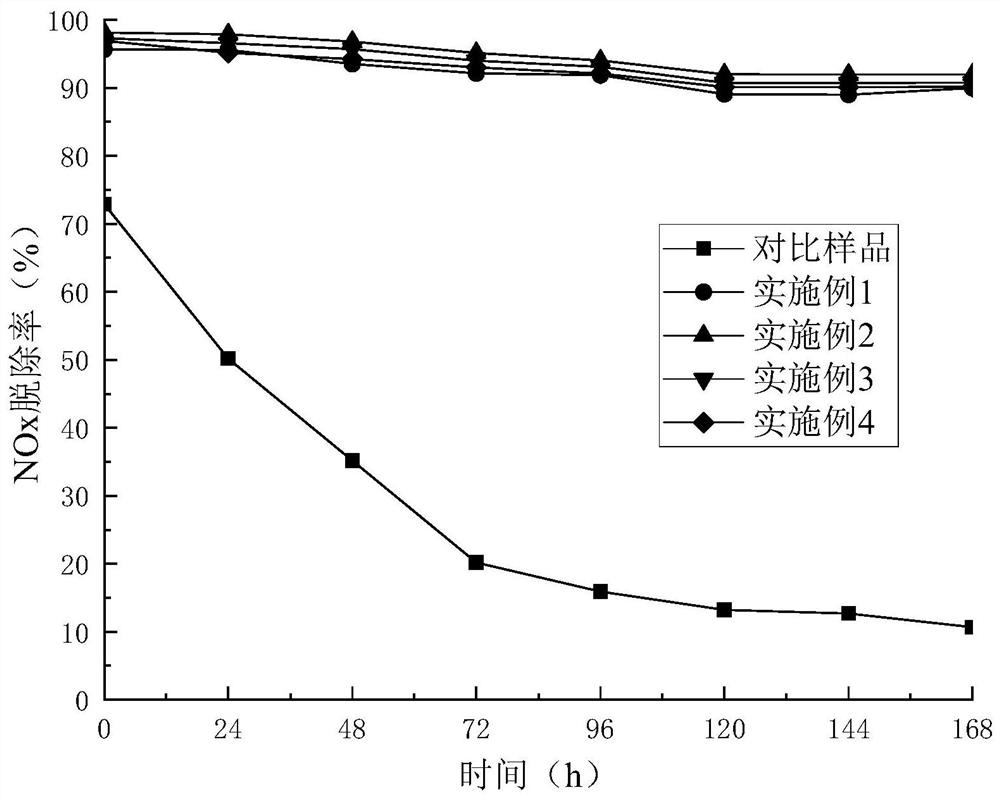

Thin-wall flat plate type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN111715230APromote decompositionImprove denitrification activityHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The embodiment of the invention provides a thin-wall flat plate type low-temperature sulfur-resistant SCR denitration catalyst and a preparation method thereof. The catalyst is prepared by taking TiO2-Nb2O5-Fe2O3 composite nano oxide as a carrier, V2O5 as an active component and MoO3 and MnSO4 as active aids, adding organic and inorganic structural aids, and performing multi-stage rolling, dryingand the like. According to the catalyst disclosed by the invention, the low-temperature denitration performance and sulfur poisoning resistance are improved by developing a carrier for accelerating denitration reaction, promoting decomposition of ammonium sulfate salt, optimizing active ingredients and active aids, optimizing forming aids, a preparation process and the like so that the catalyst has excellent denitration activity and stability within a temperature range of 150-250 DEG C. Due to the plate thickness of 0.35-0.40 mm, the catalyst has relatively low sulfur dioxide oxidation rate and relatively strong sulfur poisoning resistance, the raw material cost required by production is greatly reduced, and the operation cost of an SCR denitration system is saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

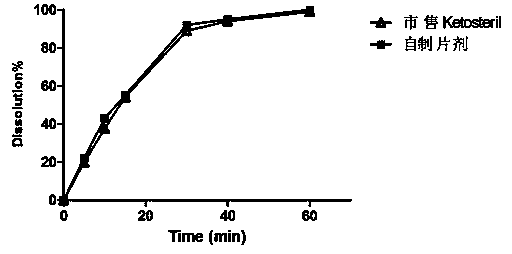

Compound alpha-ketoacid tablet free of talcum powder and preparation process thereof

ActiveCN103520156AGuaranteed stabilityGuaranteed contentMetabolism disorderUrinary disorderPolyethylene glycolDissolution

The invention relates to a compound alpha-ketoacid tablet free of talcum powder and a preparation process thereof. The conventional preparation process is changed without adding the talcum powder; the tablet prepared by the method has good compressibility, attractive appearance, high disintegrating speed, high dissolution rate, high stability in long-term placement and high medicinal safety. Wet granulation is performed separately according to the acidic and alkaline ingredients and the mass balance ratio of main medicines, i.e., a meta-alkaline ingredient, a meta-acidic ingredient and a nearly neutral ingredient are subjected to wet granulation separately, and then mixing, tabletting and coating are performed, so that the direct contact among the ingredients is avoided, long-term stable placement can be realized and the contents of the active ingredients are guaranteed. A disintegrating agent internal and external addition method is adopted in the formula, the content of polyethylene glycol is optimized, and no talcum powder or analogs with ingredients similar to the talcum powder are included in the formula, so that the problems of agglomeration phenomenon and larger viscosity in the granulation process are solved, and the safety in medication is guaranteed.

Owner:SHENYANG PHARMA UNIVERSITY +1

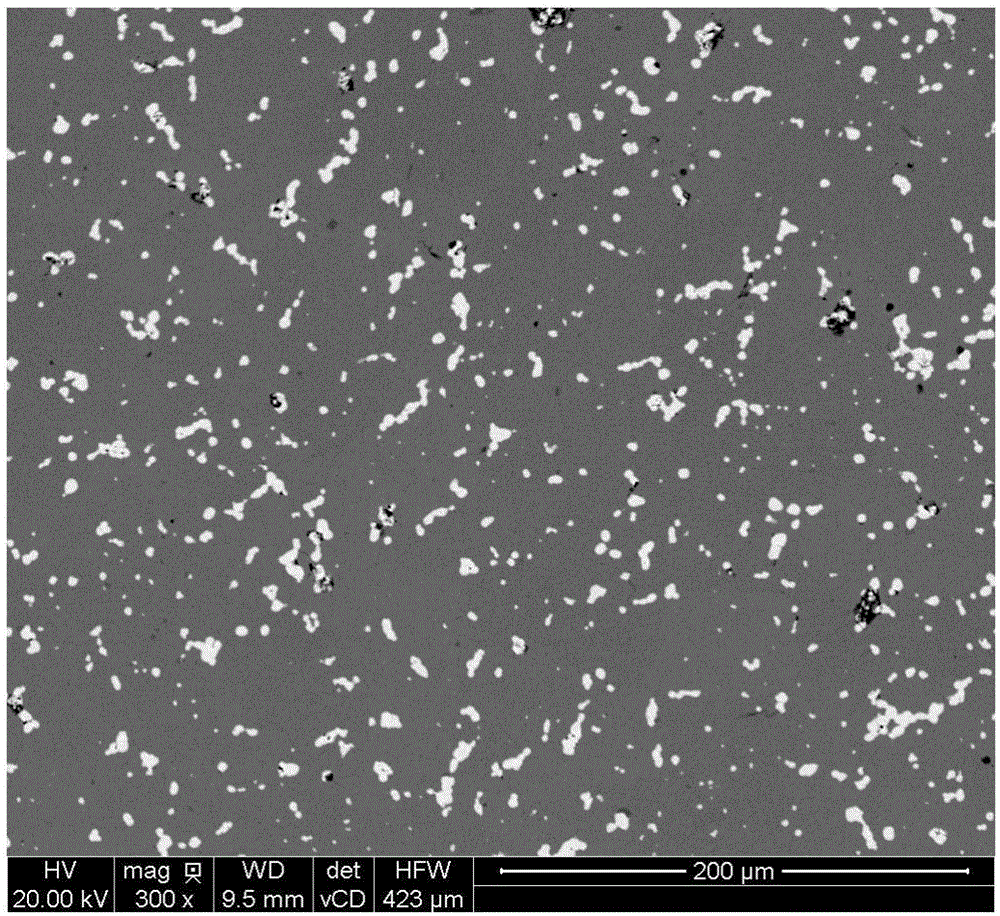

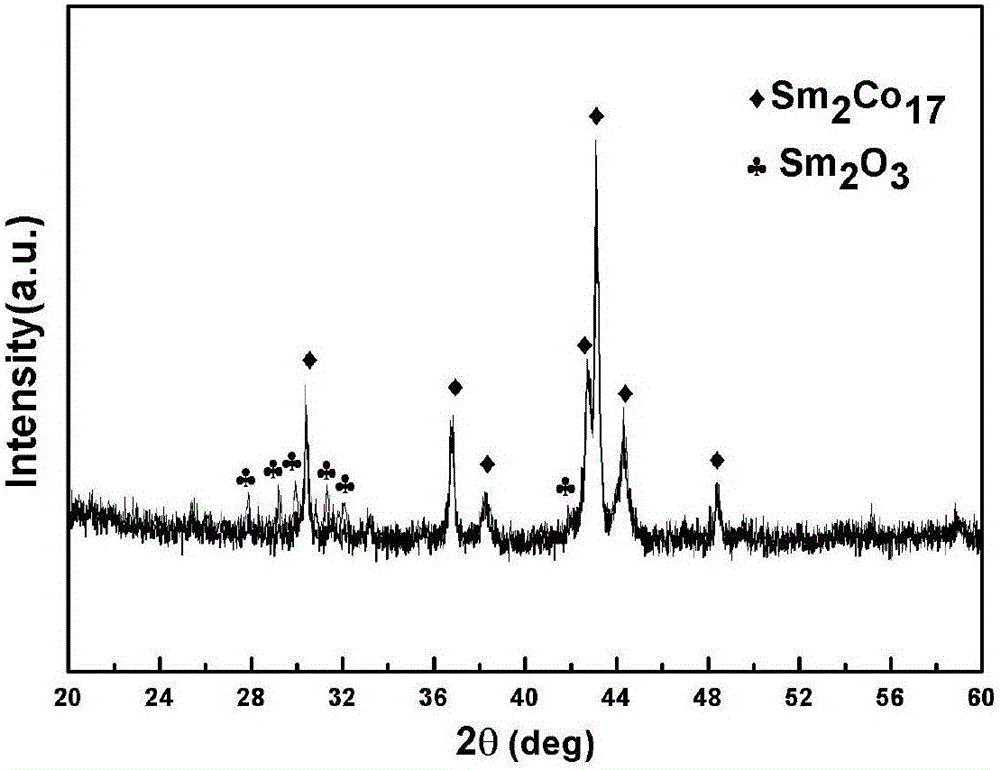

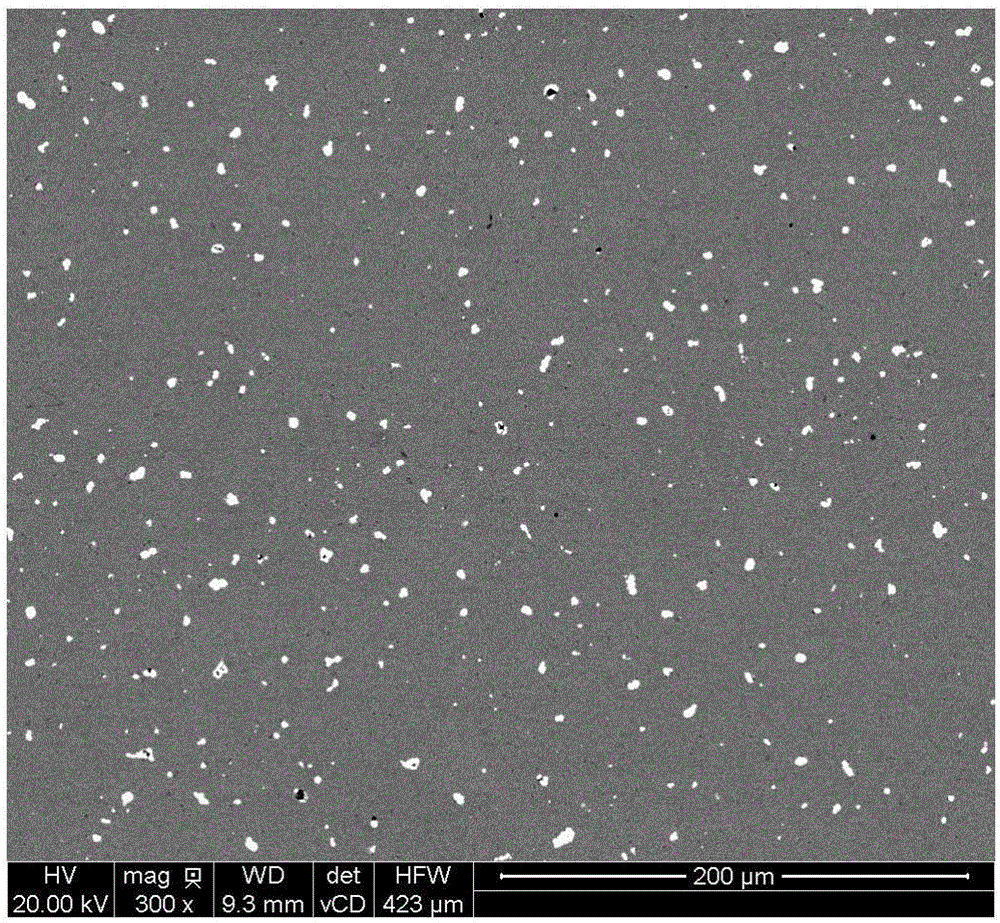

Rare-earth-cobalt-based composite material

ActiveCN106531384AImprove mechanical propertiesImprove coercive forceInorganic material magnetismRare-earth elementCobalt

The invention discloses a rare-earth-cobalt-based composite material. The rare-earth-cobalt-based composite material is prepared from, by mass, 40 wt%-98.55 wt% of matrixes and the balance additional rare earth oxide, the matrixes are samarium-cobalt-based composite materials, and the rare earth oxide in the rare-earth-cobalt-based composite material comprises endogenous rare earth oxide and the additional rare earth oxide which are oxidized by rare earth elements in the samarium-cobalt-based composite materials. According to the rare-earth-cobalt-based composite material, the amount of second-phase oxide is increased through the additional rare earth oxide to improve the mechanical performance of the rare-earth-cobalt-based composite material and reduce the raw material cost, and meanwhile magnetic performance deterioration caused by rare earth oxide increasing is greatly reduced by adjusting ingredients and the preparing technology.

Owner:NINGBO STAR MATERIALS HI TECH

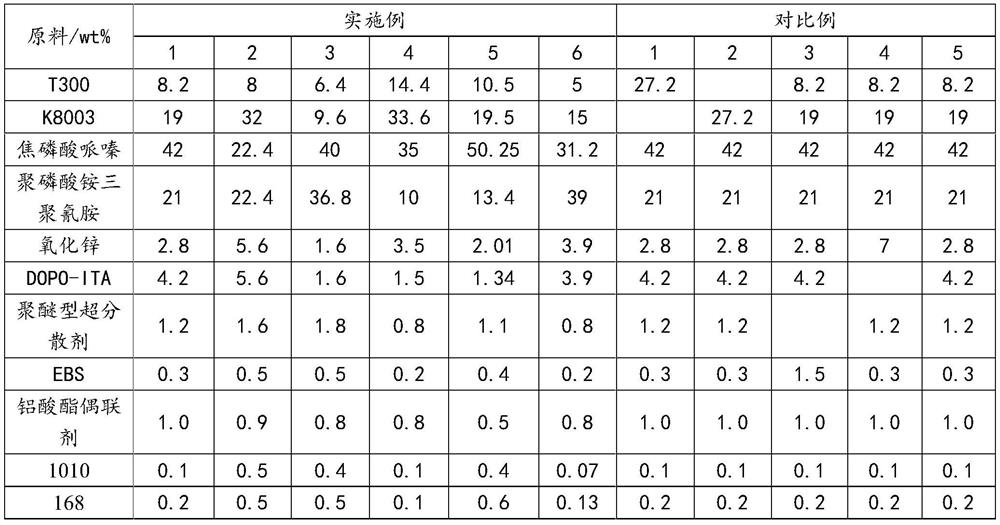

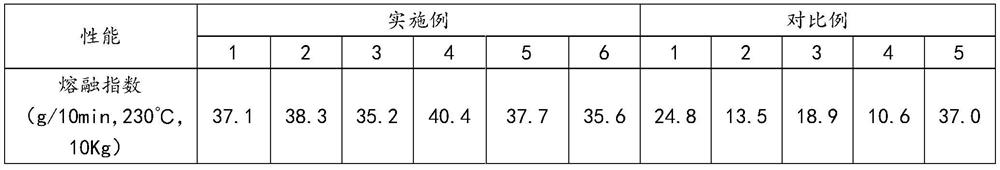

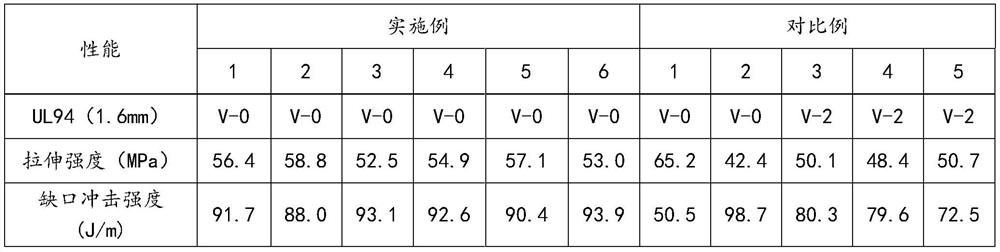

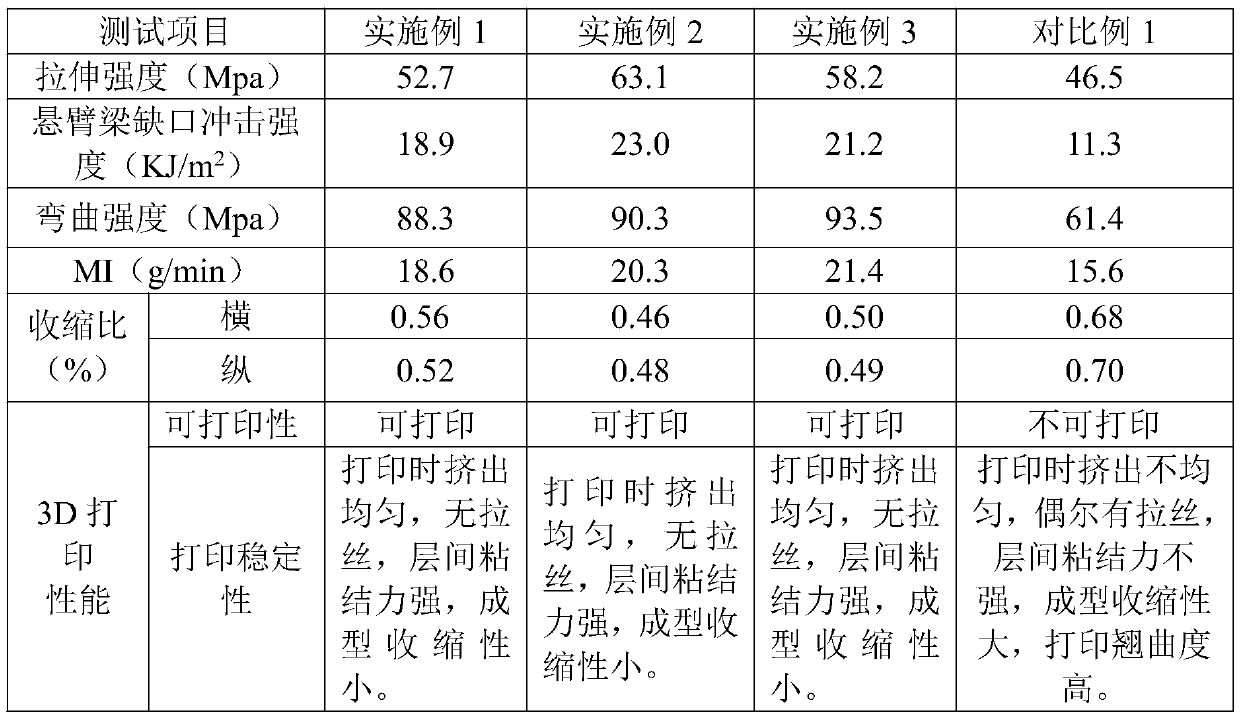

Halogen-free flame-retardant master batch for continuous long glass fiber reinforced polypropylene and preparation method of halogen-free flame-retardant master batch

The invention discloses a halogen-free flame-retardant master batch for continuous long glass fiber reinforced polypropylene and a preparation method of the halogen-free flame-retardant master batch. The halogen-free flame-retardant master batch consists of a polypropylene carrier, a halogen-free flame retardant, a hyperdispersant, a lubricant, a coupling agent and an antioxidant. The polypropylene carrier is a mixture of homo-polypropylene and co-polypropylene resin. The halogen-free flame retardant comprises a low-melting-point lubricating flame-retardant auxiliary agent, and the low-melting-point lubricating flame-retardant auxiliary agent is one or a mixture of several of a phosphaphenanthrene derivative or a phosphazene derivative with the melting point lower than 170 DEG C. The halogen-free flame-retardant master batch for the continuous long glass fiber added polypropylene is extruded at the extrusion temperature of 170 DEG C-210 DEG C, and is granulated by a special long strip granulator for LFTPP under the tension action of a traction machine to obtain the halogen-free flame-retardant master batch for the continuous long glass fiber added polypropylene. The halogen-free flame-retardant master batch can improve the processing fluidity of the continuous long glass fiber reinforced polypropylene material and the uniform dispersion of powder, so that a product prepared from the continuous long glass fiber reinforced polypropylene material has better uniformity. The invention also provides a preparation method of the halogen-free flame-retardant master batch.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD +1

Coral sand hydraulicity road base, road base material and preparation method thereof

The invention discloses a coral sand hydraulicity road base, road base material and preparation method thereof, and relates to the field of a road engineering construction. The preparation method of the road base material comprises the following steps: measuring 80 to 95 percent of coral sand and 20 to 5 percent of ordinary Portland cement, uniformly mixing and stirring the coral sand and ordinary Portland cement to obtain a primary mixture; then measuring 99.5 to 99.95 percent of the primary mixture and 0.5 to 0.05 percent of coral sand hydraulicity curing agent, uniformly mixing and stirring the primary mixture and coral sand hydraulicity curing agent to obtain a pre-mixed material, and controlling the water content of the pre-mixed material at 6 to 8 percent; the coral sand hydraulicity curing agent is formed by mixing the following components: 40 to 60 percent of elastic styrene-acrylic latex, 30 to 20 percent of nano aluminum sol and 30 to 20 percent of nano silicon sol, and the solid content of the elastic styrene-acrylic latex is more than 55 percent. The road base is formed by adopting the road base material according to a standard road base construction method. The coral sand is used for producing the road base material, thereby tailoring measures to suit local conditions; the formed road base is high in crack resistance, unlikely to corrode and long in service life.

Owner:湖北炼石环保科技有限公司

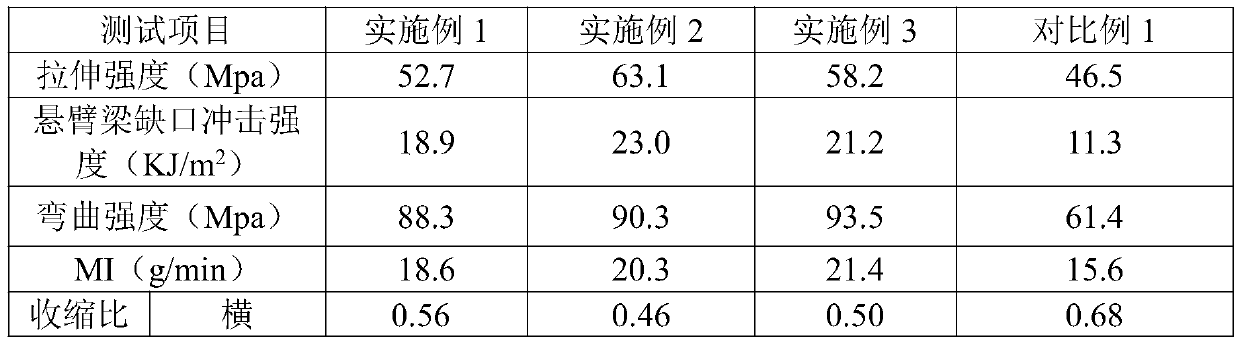

Method for preparing recycled regenerated plastic for 3D printing

InactiveCN110698806AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a method for preparing a recycled regenerated plastic for printing. The recycled and regenerated plastic for 3D printing, which is disclosed by the invention, comprises 60-70 parts of a recycled plastic, 5-20 parts of glass fibers, 3-10 parts of graphenoid, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, recycled and regenerated plastic may also comprise 10-60 parts ofEVA (ethylene vinyl acetate), and the content of VA (vinyl acetate) of EVA is 20-55%. The graphenoid is one of silicene, germanene and molybdenum disulfide surface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and an acrylonitrile-butadiene-styrene copolymer. The recycled and regenerated plastic is one or more of ABS (acrylonitrile butadiene styrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

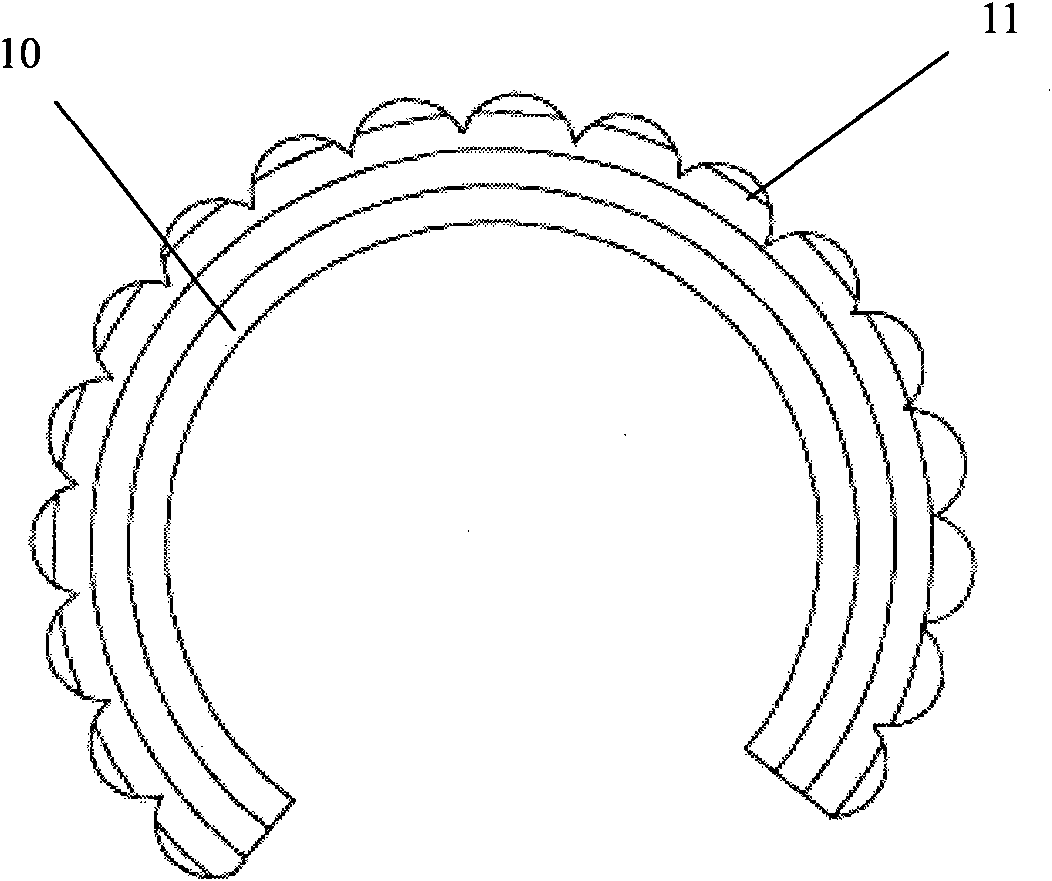

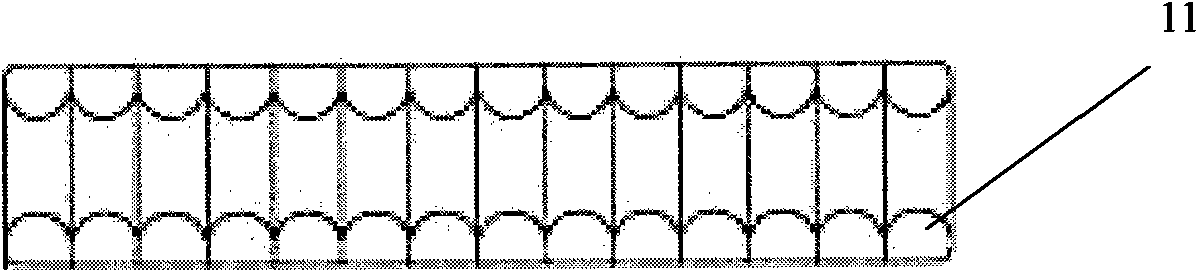

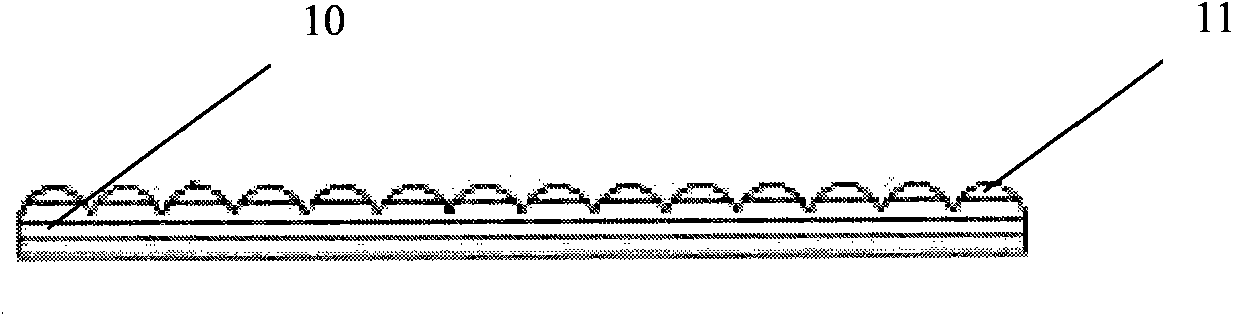

Penis implant and preparation method thereof

The invention relates to a penis implant. The penis implant has a laminar structure comprising a plurality of puffed polytetrafluoroethylene flakes; the laminar structure comprises an outermost layer with a plurality of arc protrusions and a plurality of smooth inner layers arranged below the outermost layer by laminating or adhesive; and the cross section of the laminar structure is arc-shaped. The invention also relates to a preparation method for the penis implant. The penis implant prepared by adopting the method has good biocompatibility; tissue cells can be grown in by controlling the size of micropores in prosthesis so that the penis implant can be implanted permanently, and slippage or shift of the prosthesis and the corresponding complication are not caused; the laminar structureof the penis implant is convenient for an operation doctor to perform repair according to the requirement of a patient; and after the penis implant is used, the appearance is more natural, and the penis implant can meet the requirement of the patient on physiology and psychology.

Owner:叶明

Method for preparing high-performance aluminum alloy by means of powder injection molding technology

ActiveCN107790729AUniform microstructureLow costTransportation and packagingMetal-working apparatusWaxBinary alloy

The invention discloses a method for preparing high-performance aluminum alloy by means of a powder injection molding technology and belongs to the technical field of powder injection molding. The technological process provided by the invention comprises the steps that an Al-Cu-MG-Si alloy system serves as the basis, and a small amount of the alloy element Sn is contained; pure aluminum powder serves as the main raw material, the other alloy elements are added in the form of elemental powder or binary alloy powder; the aluminum alloy powder containing specific components is mixed uniformly, then the aluminum alloy powder and a wax-based binder are arranged on a roller mixer for mixing, then injection molding is performed, and an aluminum alloy billet is prepared; and solvent degreasing andthermal debinding are performed, sintering is performed under the high-purity N2 atmosphere, and then an aluminum alloy product is prepared. By controlling the particle size of the raw material powder, optimizing the binder, adding the trace alloy elements, optimizing a sintering system and taking other means, densification sintering of the injection molded aluminum alloy is achieved. The invention provides a technology for preparing high-performance aluminum alloy components in complex shapes at a low cost on a large scale, the density of the prepared aluminum alloy is greater than 98%, andthe tensile strength is greater than or equal to 300 MPa.

Owner:UNIV OF SCI & TECH BEIJING

Water-oil soluble nanocarbon crystal abrasive paste and preparation method thereof

InactiveCN106010441ANo reunionUniform and stable dispersionOther chemical processesPolishing compositions with abrasivesKeroseneAlloy

The invention discloses water-oil soluble nanocarbon crystal abrasive paste. The water-oil soluble nanocarbon crystal abrasive paste is mainly prepared from, by weight, 10-25 parts of nano carbon crystals, 1-10 parts of water, 20-30 parts of oleic acid, 10-20 parts of vaseline, 15-30 parts of kerosene, 15-25 parts of peanut oil, 5-15 parts of fungicide, 0.2-2 parts of sorbitan fatty acid ester and 0.2-2 parts of an OP-emulsifier. The invention further discloses a preparation method of the water-oil soluble nanocarbon crystal abrasive paste. The prepared abrasive paste has the advantages of being green, environmentally friendly, non-corrosive, low in cost and good in grinding effect and is applicable to measuring tools, cutting tools and optical instruments made from glass, ceramic, hard alloy, natural diamonds, precious stones and other hard materials and machining of other high-finish-degree workpieces.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Recycled regenerated plastic for 3D printing and preparation method of recycled regenerated plastic

InactiveCN110698807AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention relates toa recycled regenerated plastic for 3D printing. The recycled regenerated plastic comprises 60-70 parts of recycled regenerated plastic, 5-20 parts of glass fiber, 3-10 parts ofa graphene-like material, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, the recycled regenerated plastic may also comprise 10-60 parts of EVA (an ethylene-vinyl acetate copolymer), and the content of VA (vinyl acetate) inEVA is 20-55%. The graphene-like material is one of silicene, germanene and molybdenum disulfide which are subjected tosurface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and acrylonitrile-butadiene-styrene copolymer grafted oxazoline. The recycled regenerated plastic is one or more of ABS (acrylonitrile butadienestyrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

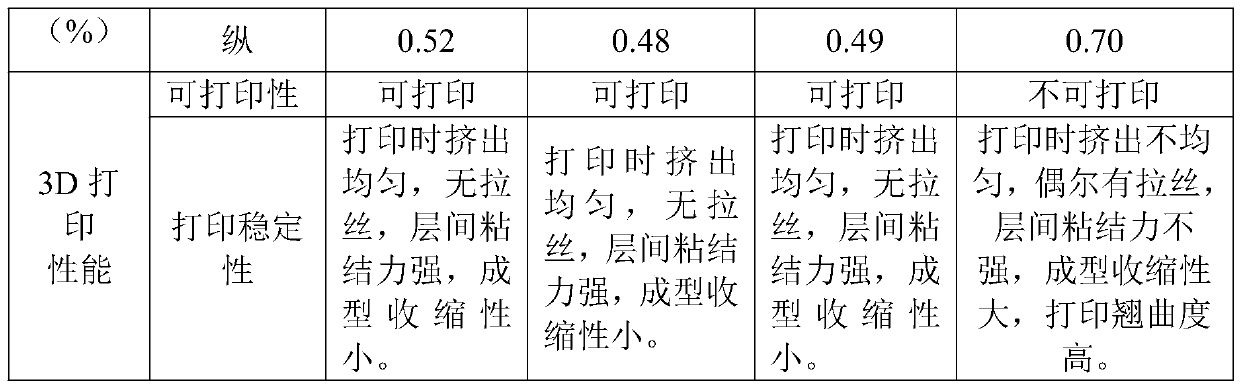

Water-lubricated bearing material and preparation method thereof

The invention discloses a water-lubricated bearing material and a preparation method thereof, and belongs to the technical field of composite materials. The problem that an existing bearing has poor adaptability, large wear and the like under severe working conditions is solved. The water-lubricated bearing material is prepared from the following components in parts by weight: 20-30 parts of phenolic resin, 40-50 parts of nitrile rubber, 1-10 parts of graphene powder, 20-30 parts of basalt fiber, 0.1-1 part of a vulcanizing agent, 5-10 parts of a softener and 10-20 parts of a lubricating agent. The water-lubricated bearing material has the advantages of self-lubrication, high load-bearing, anti-fouling adhesion, green and pollution-free and the like through the synergistic action of the components, is suitable for working in internal navigation vessels with poor water quality and containing sediment, can work without water in short time, is low in noise, good in shock absorption effect, easy in formation of a water film and low in friction coefficient of water lubrication, and can directly and completely replace imported products.

Owner:CHANGCHUN A&Z SCI CO LTD

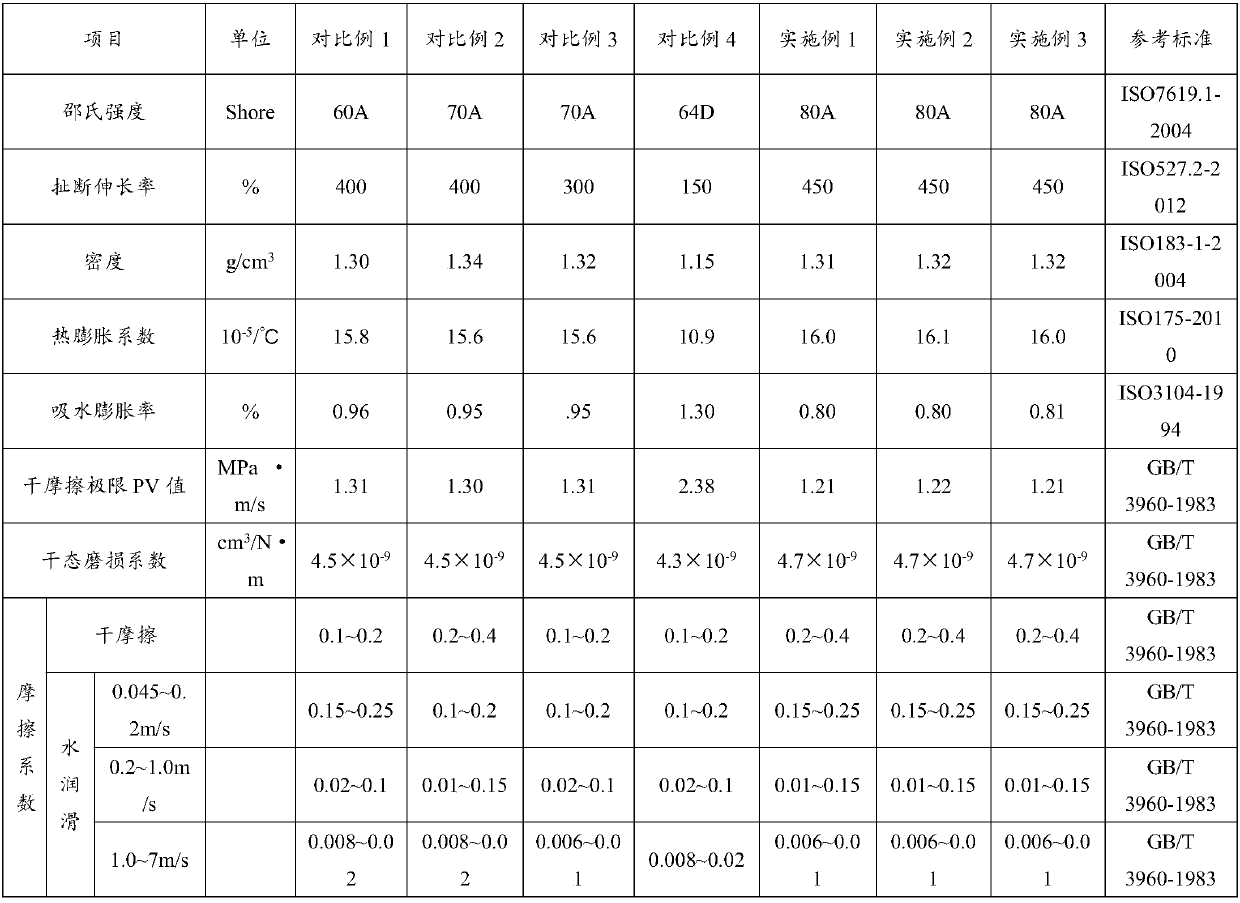

Acerola cherry tabletted candies and preparation method thereof

PendingCN113973964AImprove fluidity and compressibilityImproves hardness and friabilityConfectionerySweetmeatsSucroseMagnesium stearate

The present invention relates to acerola cherry tabletted candies and a preparation method thereof. The candies consist of cherry powder, an excipient, a sweetening agent, an adhesive and a lubricant; the acerola cherry tabletted candies specifically comprise 25-33.35% of acerola cherry powder, 28.6-29.3% of sorbitol, 15-25% of microcrystalline cellulose, 1-8% of D-mannitol, 0.1-1% of stevioside, 10.65-20% of blueberry powder, 0.01-0.05% of sucralose and 0.3-1% of magnesium stearate. The tabletted candies are obtained by adopting the technologies of sieving, weighing, premixing, total mixing and direct pressing. The acerola cherry tabletted candies are simple in preparation process, stable in hardness, friability and taste, have blueberry flavor, are moderate in sourness and sweetness and convenient to eat, and have the beneficial effects of enhancing immunity, improving skin state, whitening, regulating intestinal flora and the like.

Owner:富诺健康股份有限公司

Preparing method of scalded leech medicine granule

The present invention relates to preparation process of leech medicine granule. The preparation process includes preparing scalded leech piece, decoction, filtering, decompression concentrating the filtrate to obtain extractum, spray drying to obtain powder, mixing with magnesium stearate and one of dextrin, lactose and maltodextrin in certain weight proportion, and pelletizing with roller to form 18-40 mesh granule. The leech medicine granule contains amino nitrogen not less than 10 mg / g, active antitrombase not less than 16.0 U / g and sarkin not less than 2 mg / g.

Owner:JIANGYIN TIANJIANG PHARMA

No-water stemming material for blast furnace taphole and its prepn

InactiveCN100453509CShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsCarbide siliconSlag

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Environment-friendly type wool fabric scale-stripping treatment process

InactiveCN105780444AActs as a lubricantEasy to handlePhysical treatmentBiochemical treatment with enzymes/microorganismsFiberUltrasound - action

The invention discloses an environment-friendly type wool fabric scale-stripping treatment process. According to the process, under the action of ultrasonic waves and dual treatment of enzyme treatment and calcium carbonate grinding, the scale-stripping uniformity on the surface of wool is effectively improved, cell damage to inner fiber layers is reduced, and the wearing property and durability of a wool blended fabric are improved. As no substance such as heavy metals and halides which can do harm to human bodies and the environment is used, the process is an environment-friendly type fiber treatment process.

Owner:德清县新鑫达丝绸炼染有限公司

A method for preparing high-performance aluminum alloys using powder injection molding technology

ActiveCN107790729BIncrease profitIncrease productivityTransportation and packagingMetal-working apparatusBinary alloyAl powder

The invention discloses a method for preparing high-performance aluminum alloy by using powder injection molding technology, which belongs to the technical field of powder injection molding. The technological process of the invention is as follows: based on the Al-Cu-Mg-Si alloy system, it contains a small amount of alloy element Sn. Pure aluminum powder is used as the main raw material, and other alloying elements are added in the form of elemental powder or binary alloy powder. The aluminum alloy powder with specific components is mixed and mixed with wax-based binder on a roller mixer, and then prepared into an aluminum alloy green body by injection molding, after solvent degreasing and thermal degreasing, and then in high-purity N 2 Aluminum alloy products are obtained after sintering under atmosphere. By controlling the particle size of the raw material powder, optimizing the binder, adding trace alloy elements, and optimizing the sintering system, the densification and sintering of injection molded aluminum alloys has been realized. The invention provides a low-cost and mass-preparation technology for high-performance and complex-shaped aluminum alloy parts. The density of the prepared aluminum alloy is greater than 98%, and the tensile strength is greater than or equal to 300MPa.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com