Roller for rolling large profile steel and manufacturing technology of roller

A type of steel and roll technology, applied in the field of roll and its production process, can solve the problems of less grinding times, large hardness drop, and low rolling volume, and achieve smooth and bright surface of the rolled piece, strong thermal fatigue resistance, and high hardness. even drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

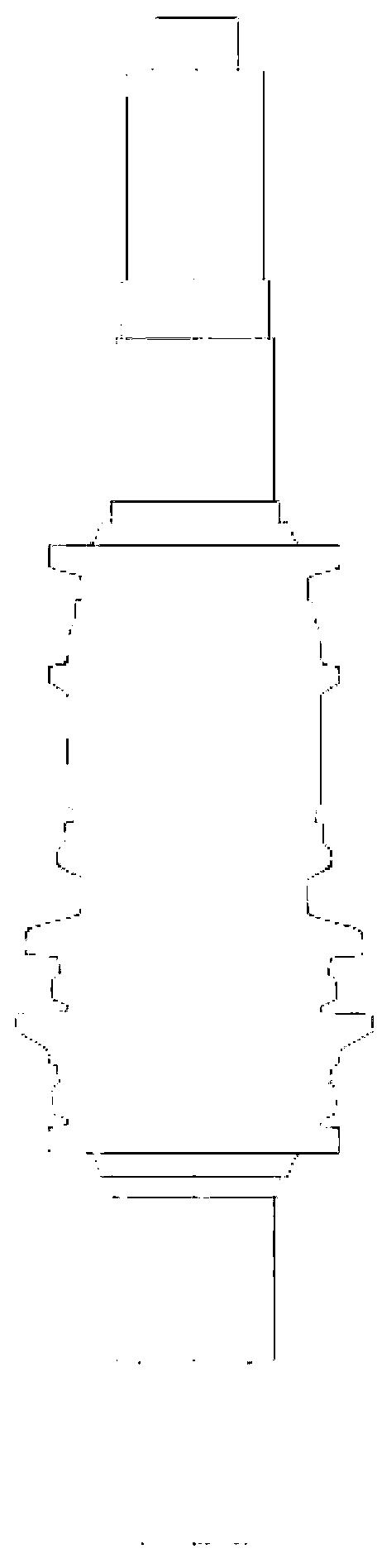

[0018] See figure 1 , The roll used for rolling large section steel in this embodiment contains evenly distributed spherical graphite in the matrix, and the matrix structure is granular carbide, tempered sorbite, and pearlite.

[0019] The drop between the roller surface and the bottom of the deep hole is ≦0.5~1.5 degrees, and the hardness drop is small and uniform. The tensile strength of the roll neck is ≧550MPa.

[0020] When rolling large section steel, the fine graphite is crushed under the action of extrusion and heat, and it can act as a lubricant when the rolled material is pierced to solve the problem of sticking steel, and the surface of the rolled piece is smooth and shiny.

[0021] The production technology of the roll that is used for rolling large section steel of the present embodiment comprises the following steps:

[0022] ①Heat 80-100°C on the basis of the liquidus temperature of the semi-steel, add 0.03% aluminum, and calm down for more than 10 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com