Patents

Literature

403results about How to "Improve thermal fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

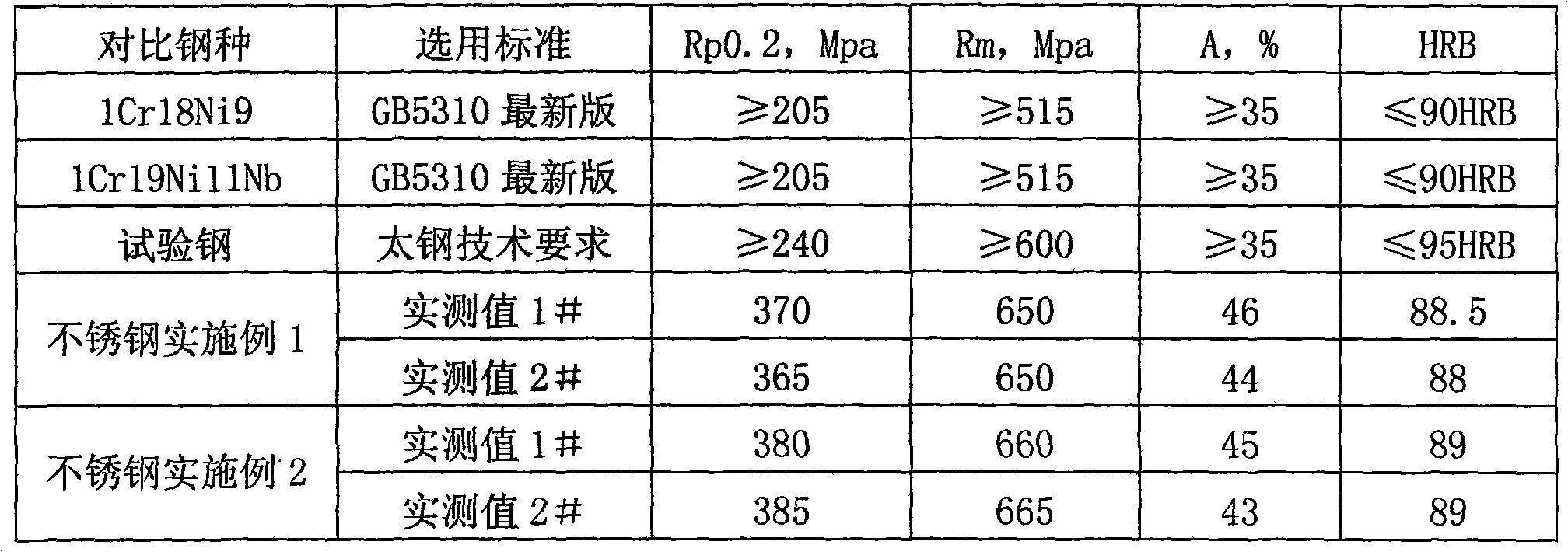

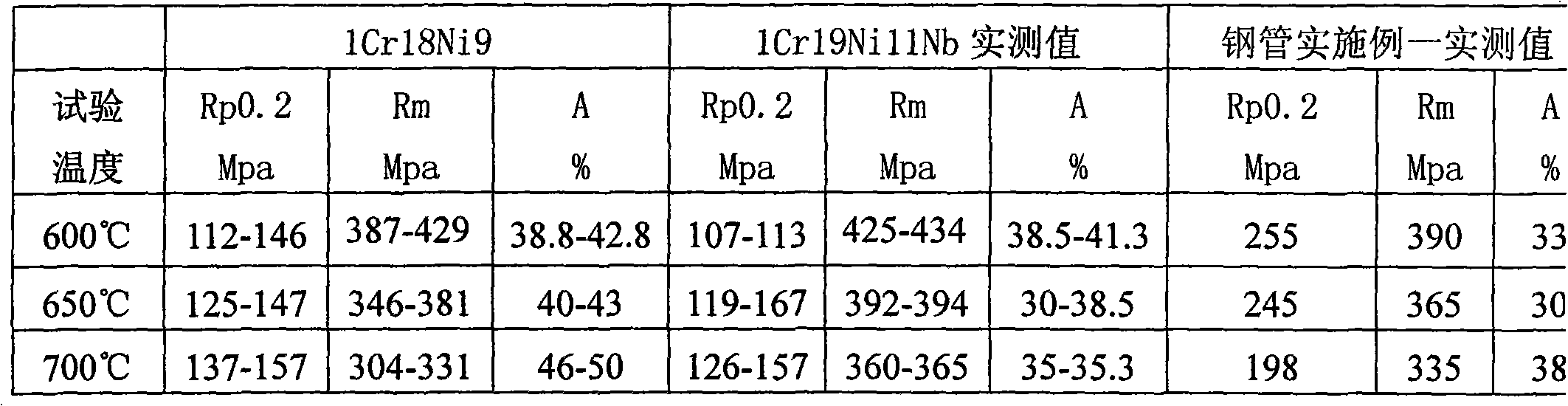

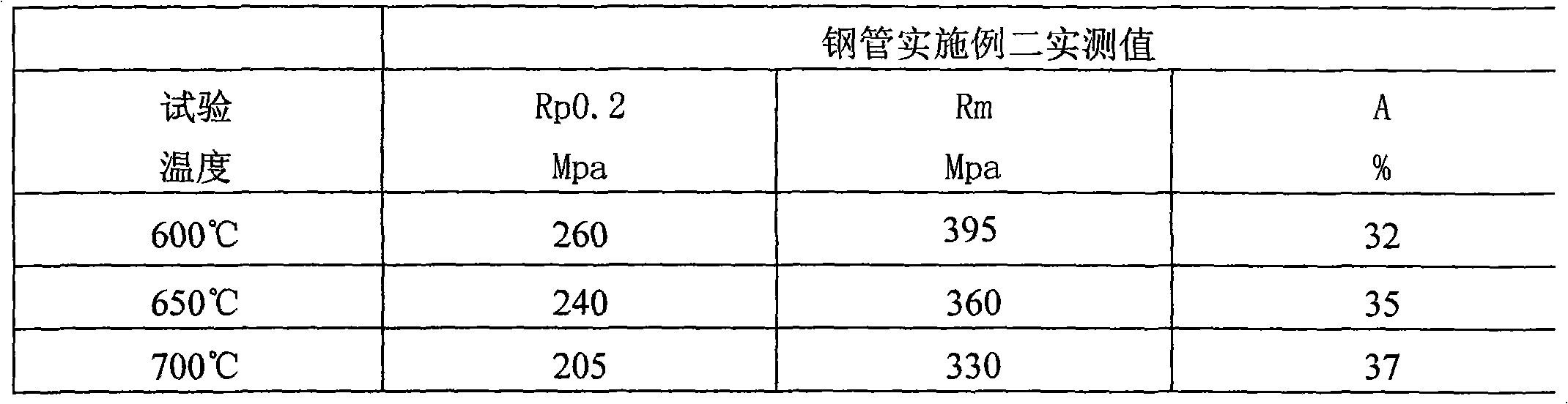

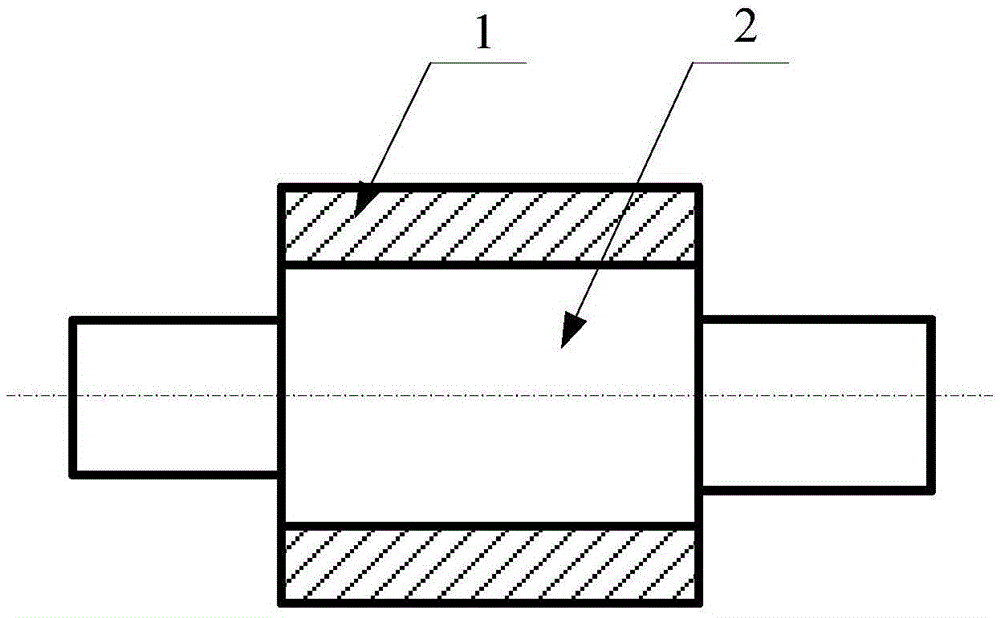

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

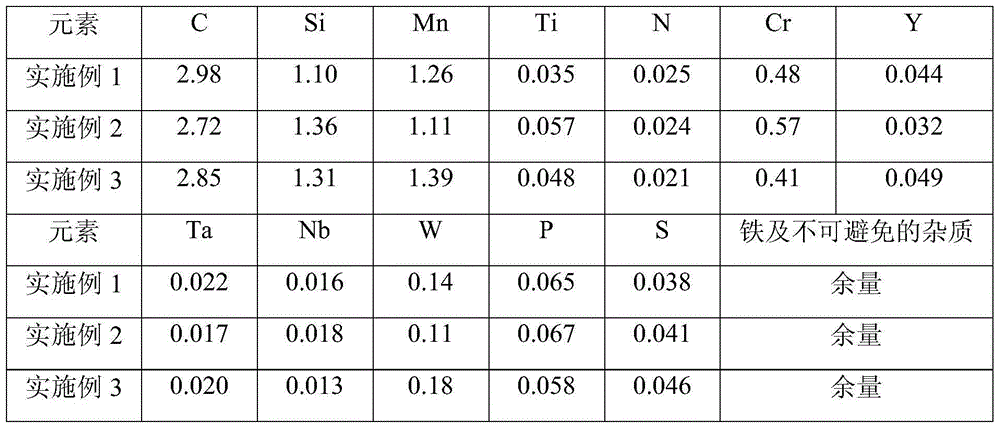

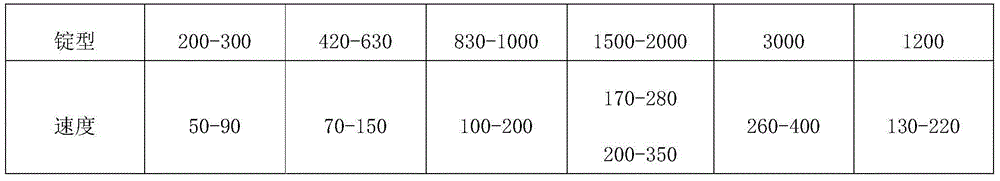

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

Abrasion-resistance high-speed steel composite roller and preparation method thereof

The invention discloses an abrasion-resistance high-speed steel composite roller and a preparation method thereof, and belongs to the technical field of rollers. The composite roller forms a whole through roller body high-speed steel and roller core nodular cast iron by means of centrifuge composite casting. The roller body molten steel is controlled to comprise, by mass, 1.5%-2.4% of C, 3.5%-6.0% of Cr, 3.5%-6.0% of Mo, 3.5%-6.0% of V, 1.5%-3.5% of W, 0.6%-1.2% of Nb, 0.5%-1.2% of Ni, 0.3%-0.8% of Si, 0.3%-0.8% of Mn, 0-0.04% of S, 0-0.04% of P and the balance Fe. The roller body molten steel is deoxidized, external-furnace modification treatment is conducted on the molten steel through multi-element micro-alloy wires, and then pouring is conducted on a centrifugal machine to form the roller; the roller core is made of nodular cast iron, tempering is conducted on the roller after quenching, and therefore the characteristics of being high in hardness, high in toughness, good in abrasive resistance and the like are realized, and an excellent using effect is achieved.

Owner:安徽环渤湾高速钢轧辊有限公司

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Alloy steel for braking discs

ActiveCN101519754AImprove mechanical propertiesImprove thermal fatigue resistanceFriction liningNiobiumManganese

The invention relates to alloy steel for braking discs. Chemical compositions of the alloy steel comprise in percentage by weight: 0.21 to 0.26 percent of carbon, 0.8 to 1.0 percent of silicon, 0.5 to 1.0 percent of manganese, 1.2 to 1.55 percent of chromium, 1.95 to 1.99 percent of nickel, 0.34 to 0.41 percent of molybdenum, 0.1 to 0.2 percent of vanadium, 0.05 to 0.06 percent of niobium, less than 0.01 percent of tungsten, less than 0.02 percent of titanium, less than 0.02 percent of aluminum, 0.05 to 0.09 percent of copper, 0.02 to 0.03 percent of zirconium, and the balance of Fe and unavoidable impurities. The alloy steel provided by the invention is steel for casting, has higher mechanical strength and thermal fatigue resistance, also has better thermal cracking resistance, stable friction property and good thermal conductivity at the same time, and is particularly suitable for producing the braking discs used for rail transit vehicles such as city rail transit vehicles, railway locomotive vehicles, motor vehicles, high-speed trains, and the like.

Owner:BEIJING ZONGHENG ELECTROMECHANICAL TECH DEV

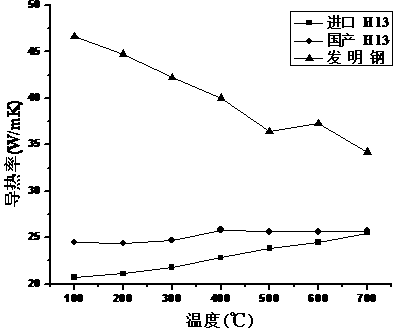

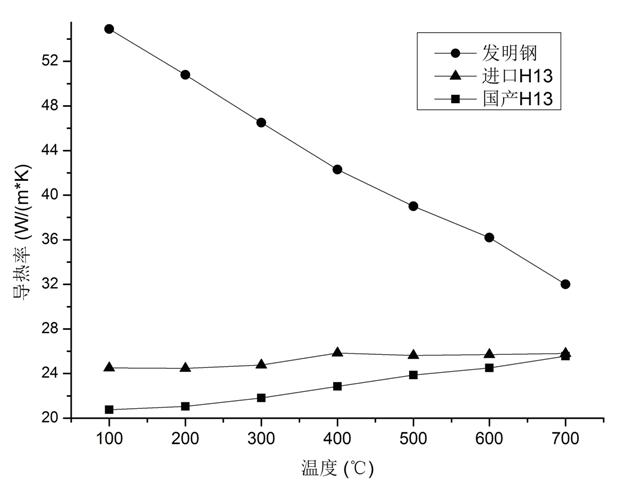

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

Wide-band laser-induced hybrid cladding restoration and surface strengthening method for dies

InactiveCN102373468AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesRepair timeLaser scanning

A wide-band laser-induced hybrid cladding repairing and surface strengthening method for dies is characterized in that a Ni based alloy powder for wide-band laser-induced hybrid cladding is used to repair damaged areas of dies or strengthen the surface of dies. By the adoption of a wide-band scanning system, different dies such as plastic die, hot work die, cold work die and the like can be repaired and undergo surface strengthening. The width of a single track laser-induced hybrid cladding layer reaches 20-30mm; the thickness of each track cladding can reaches 3mm; laser scan speed reaches 10m / min; the powder flow reaches 15kg / h; the powder utilization rate is 90%; the efficiency is raised by 5-10 times in comparison with simple laser cladding; repairing time is shortened by 30%; energy is saved by 10-40%; defects such as pores and crack in the coating are eliminated; wear resistance, corrosion resistance, antioxidation performance and fatigue resistance of dies are greatly raised; and the service life of dies can be increased by 3-10 times.

Owner:XIAOGAN KELONG INDAL

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

Aluminum piston manufacturing method

InactiveCN102943192AHigh temperature strengthImprove thermal fatigue resistancePlungersTrunk pistonsFiberPiston

The invention relates to an aluminum piston manufacturing method, which is characterized by comprising the following steps: (1) preparing an aluminum alloy for a piston; (2) carrying out a smelting treatment, wherein the prepared piston alloy is placed into a melting furnace to carry out melting, and the melted aluminum alloy liquid is subjected to primary refining, modification, refinement and secondary refining to provide a spare use for casting; (3) manufacturing an alumina ceramic short fiber preform; (4) preheating the alumina ceramic short fiber preform; (5) preheating a mold; (6) carrying out extrusion casting; (7) carrying out solidification piece taking; (8) carrying out a heat treatment on an aluminum piston blank; and (9) carrying out mechanical processing and a surface treatment on the aluminum piston blank to obtain the aluminum piston finished product. Compared to the aluminum piston in the prior art, the aluminum piston of the present invention has advantages of high strength and good ablation resistance.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Grinding roller manufacturing/remanufacturing abrasion-resistant material and preparation method thereof

InactiveCN106238709AWide adjustment of hardnessWidth adjustment toughnessFurnace typesWelding/cutting media/materialsCouplingBoron containing

The invention discloses a grinding roller manufacturing / remanufacturing abrasion-resistant material and a preparation method thereof. A grinding roller is formed by a core roller body, a substrate abrasion-resistant layer, a transition layer and a roller face abrasion-resistant shape layer in a coupling mode. A core material is provided with the highly-abrasion-resistant modified boron-containing high-chromium cast iron substrate abrasion-resistant layer through casting and compounding. The substrate abrasion-resistant layer comprises, by mass, 1.75%-3.0% of C, 12.0%-18.0% of Cr, 0.2%-2.0% of B, 0.4%-0.8% of Mn, 0.4%-1.2% of Si, 0.30%-0.80% of Ni, 0.02%-0.04% of Mg, 0.03%-0.05% of Ce, 0.05%-0.10% of Ti, 0.006%-0.015% of N, 0-0.04% of S, 0-0.04% of P, and the balance Fe. Then surfacing of materials of the roller face abrasion-resistant shape layer is conducted on the surface of the transition layer. The roller face abrasion-resistant shape layer is formed by flux-cored wires through surfacing. The flux-cored wires comprises, by mass, 2.3%-3.5% of C, 14.0%-26.0% of Cr, 1.5%-2.0% of Ni, 0.8%-2.0% of Nb, 1.3%-2.0% of Mo, 1.2%-2.3% of Si, 1.0%-1.7% of Ti, 0.3%-1.0% of V, 0.2%-1.5% of B, 0-<0.007% of S, 0-0. 015% of P, and the balance Fe.

Owner:镇江富华轧辊有限公司

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

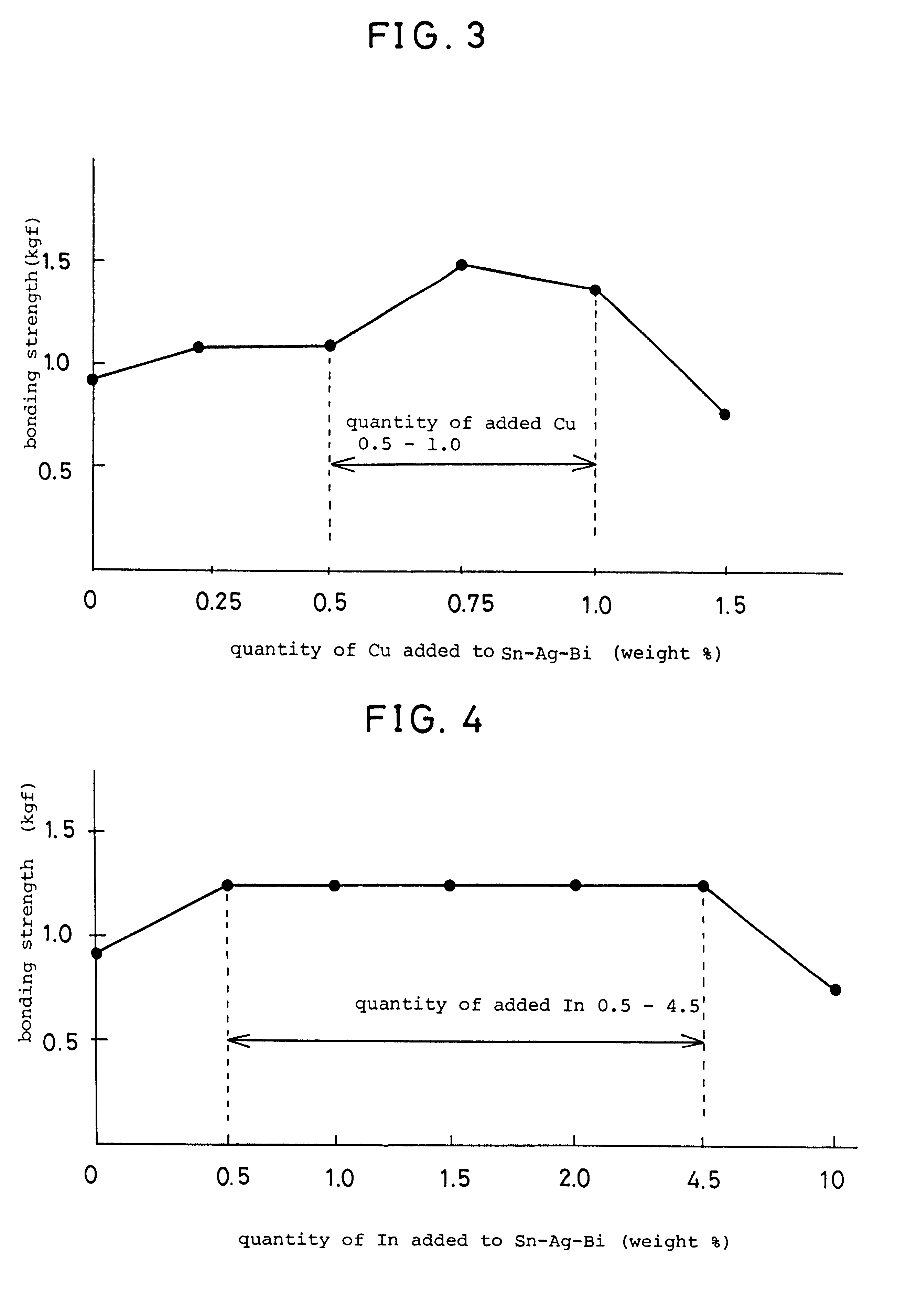

Method for preparing heat-fatigue-resistance wear-resistance laminated particle reinforced composite material

The invention provides a method for preparing a heat-fatigue-resistance wear-resistance laminated particle reinforced composite material. The method prepares the wear-resistance laminated particle reinforced composite material consisting of a heat-fatigue-resistance laminated composite wear-resistance layer, a metallurgical transitional layer and a substrate metal layer by the following steps: mixing nickel-based self-melting alloy powder and hard ceramic particle uniformly, adding an adhesive, and forming a prefabricated block; and performing common sand mold coating or lost foam casting, namely melting a substrate metal material to a pouring temperature, pouring the molten substrate metal material into a molding cavity in which the prefabricated block is placed, allowing the molten substrate metal material to cool and condense at room temperature, and removing sand. The combined preparation process disclosed by the invention has the characteristics of high controllability, simple operation, high yield, high overall performance and stable production quality; and the heat-fatigue-resistance laminated composite wear-resistance layer and the substrate metal layer are metallurgically combined, and the composite material can be used in heat-fatigue-resistance and wear-resistance fields of mines, power, metallurgy, coal, building materials and the like. The method is suitable for industrial large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

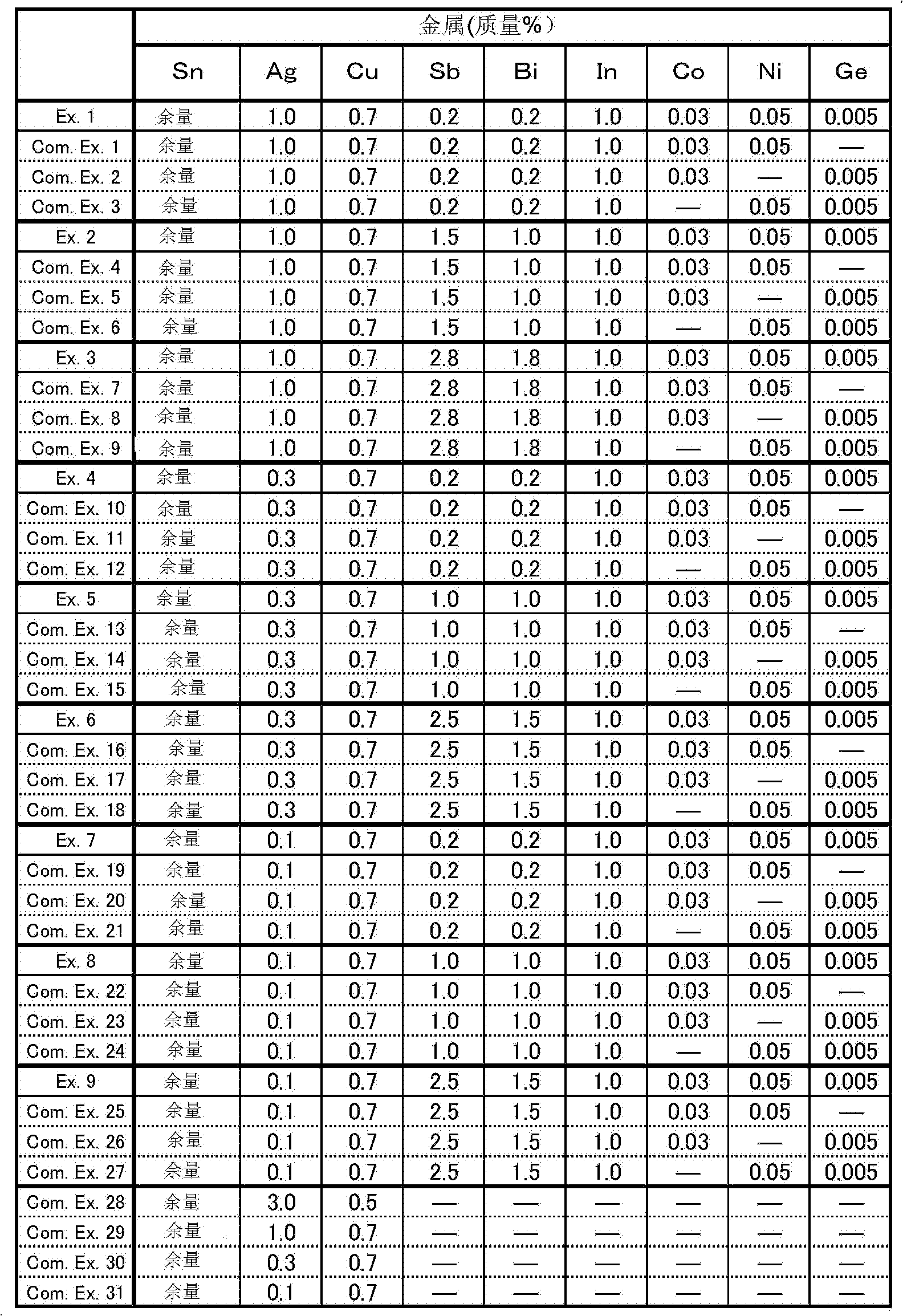

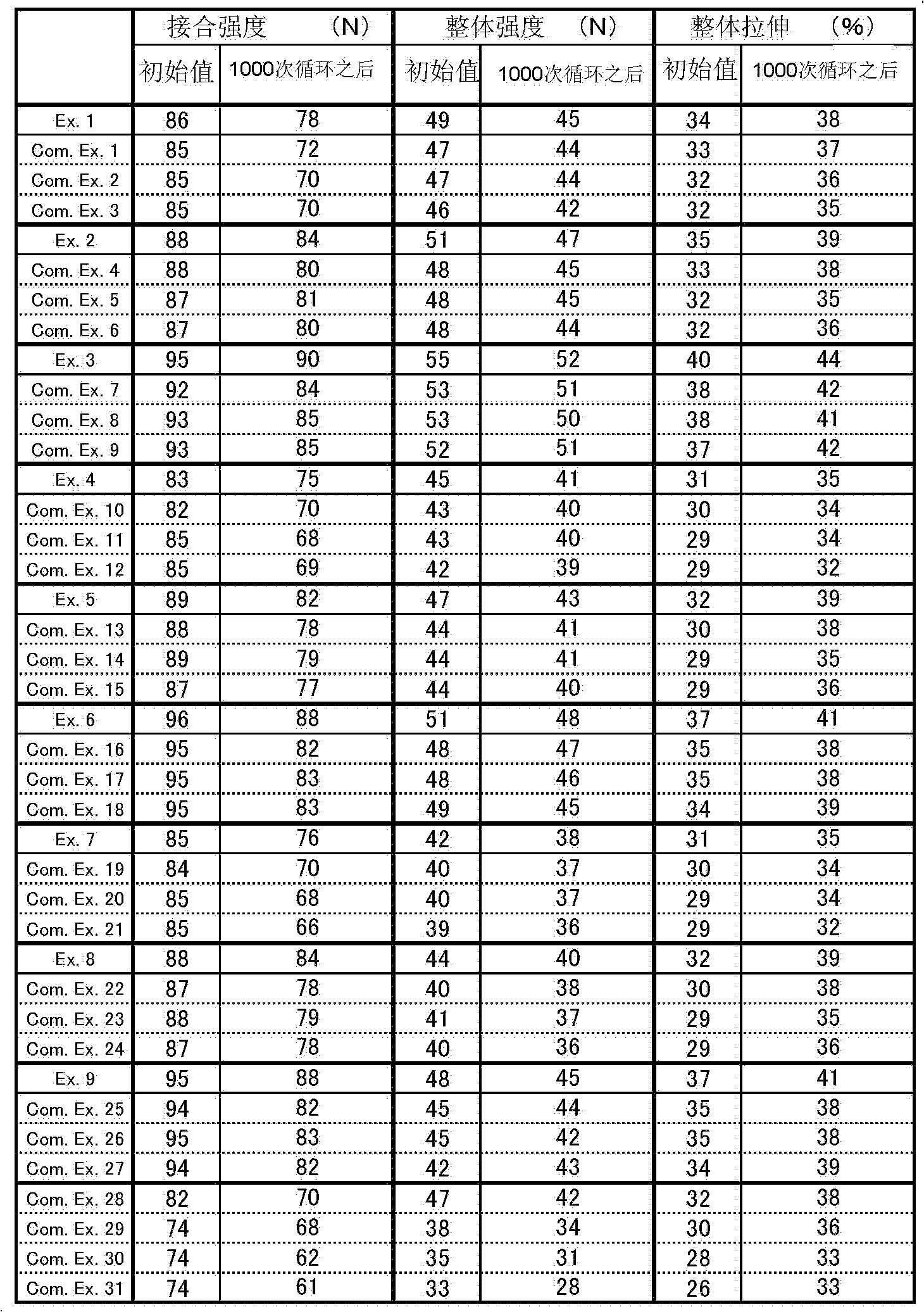

Low-silver-content solder alloy and solder paste composition

InactiveCN102574251AReduce Ag contentLow costTransportation and packagingWelding/cutting media/materialsIndiumCobalt

This low-silver-content solder alloy comprises 0.05-2.0 mass% of silver, 1.0 mass% or less of copper, 3.0 mass% or less of antimony, 2.0 mass% or less of bismuth, 4.0 mass% or less of indium, 0.2 mass% or less of nickel, 0.1 mass% or less of germanium and 0.5 mass% or less of cobalt (wherein the content of each of the above-mentioned elements copper, antimony, bismuth, indium, nickel, germanium and cobalt is not 0 mass%), with the remainder being tin. According to the present invention, it becomes possible to provide a low-silver-content solder alloy which has a reduced Ag content and therefore can be produced at reduced cost, has excellent stretching properties, an excellent melting point, excellent strength and the like, and also has high fatigue resistance (cold thermal fatigue resistance) and long-lasting reliability.

Owner:HARIMA CHEM INC

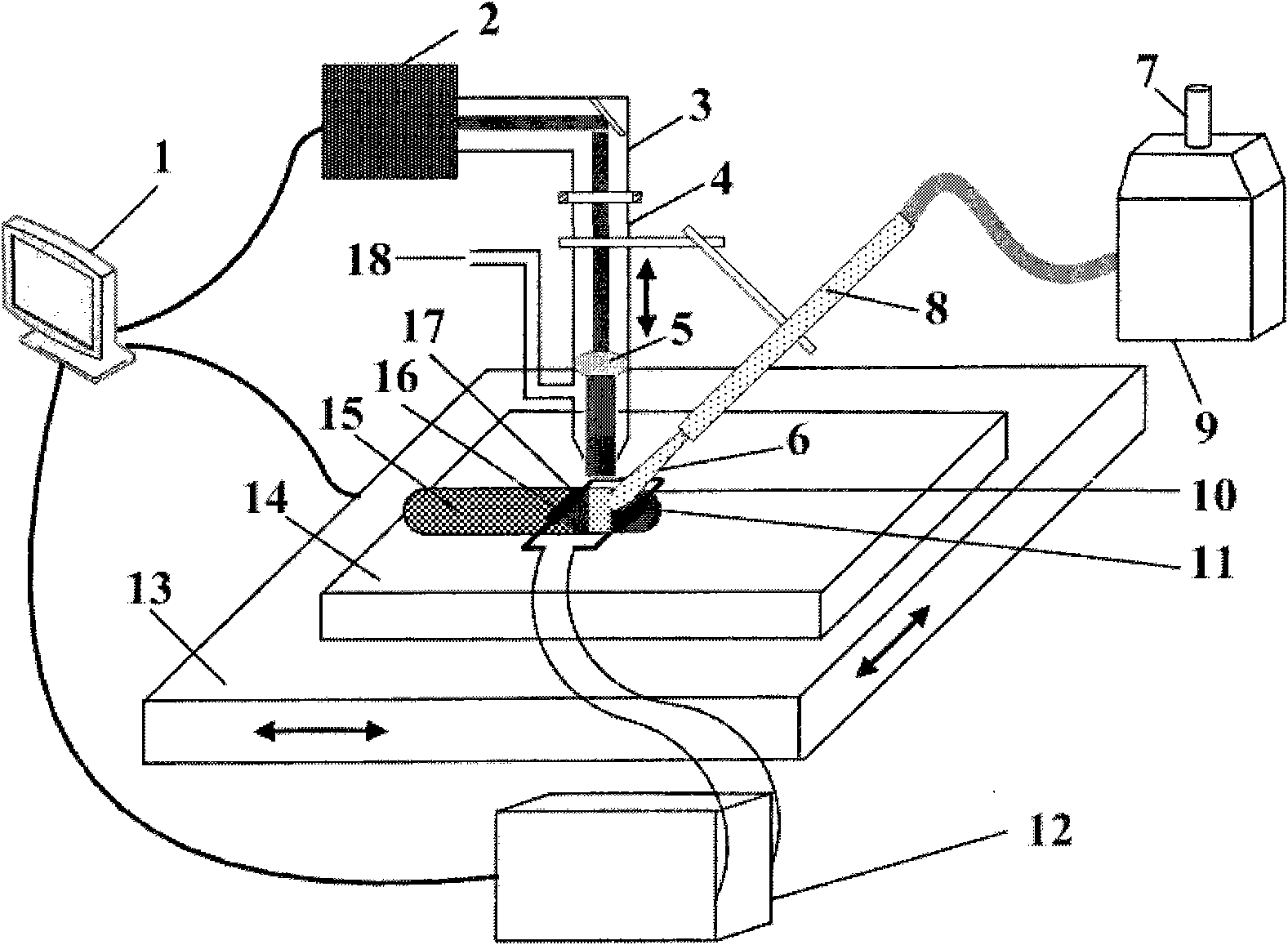

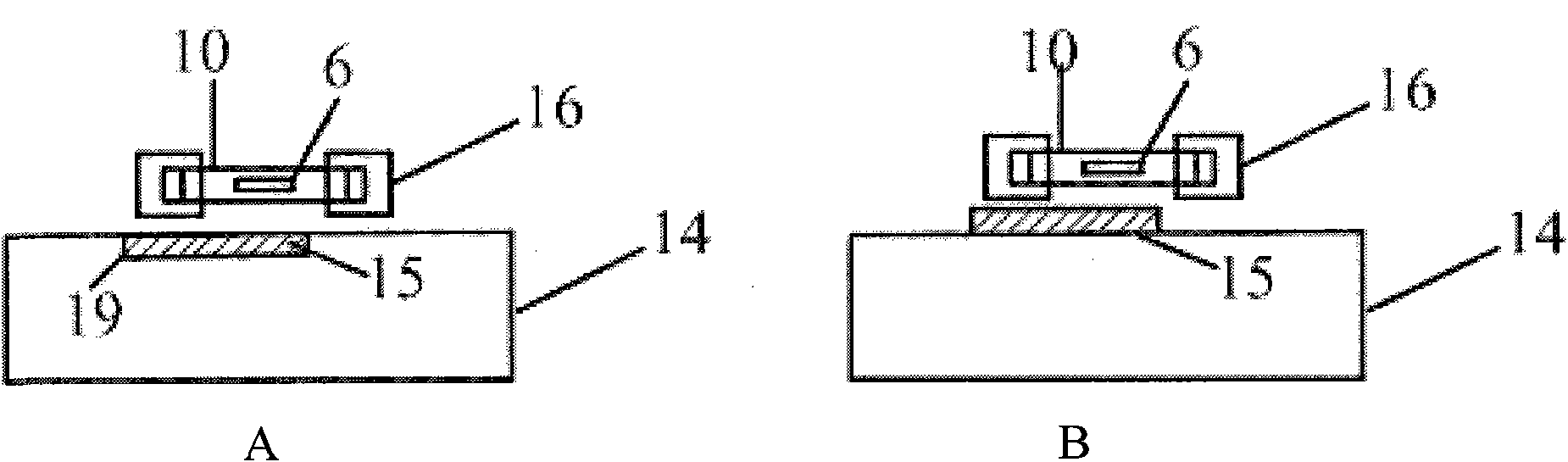

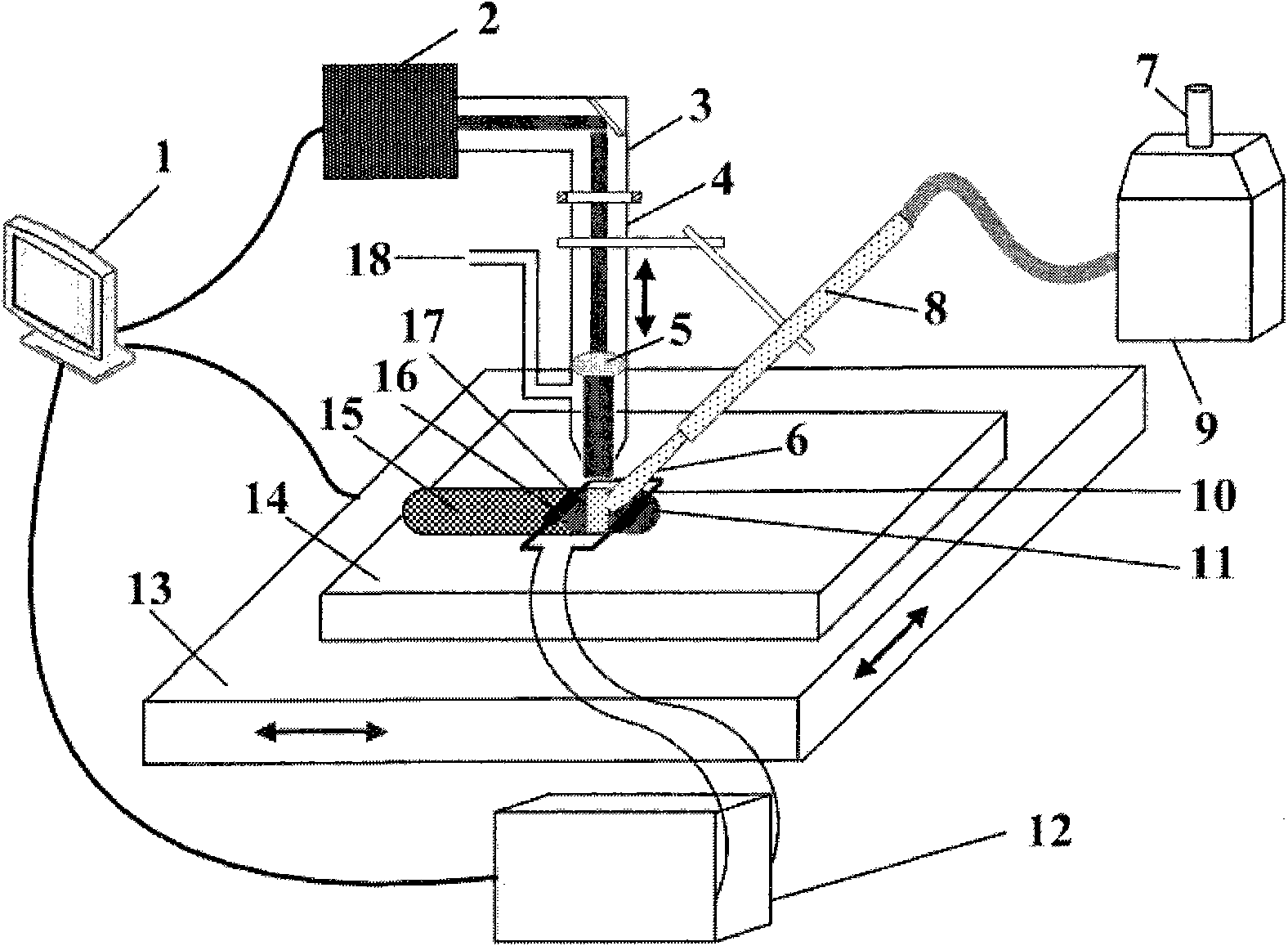

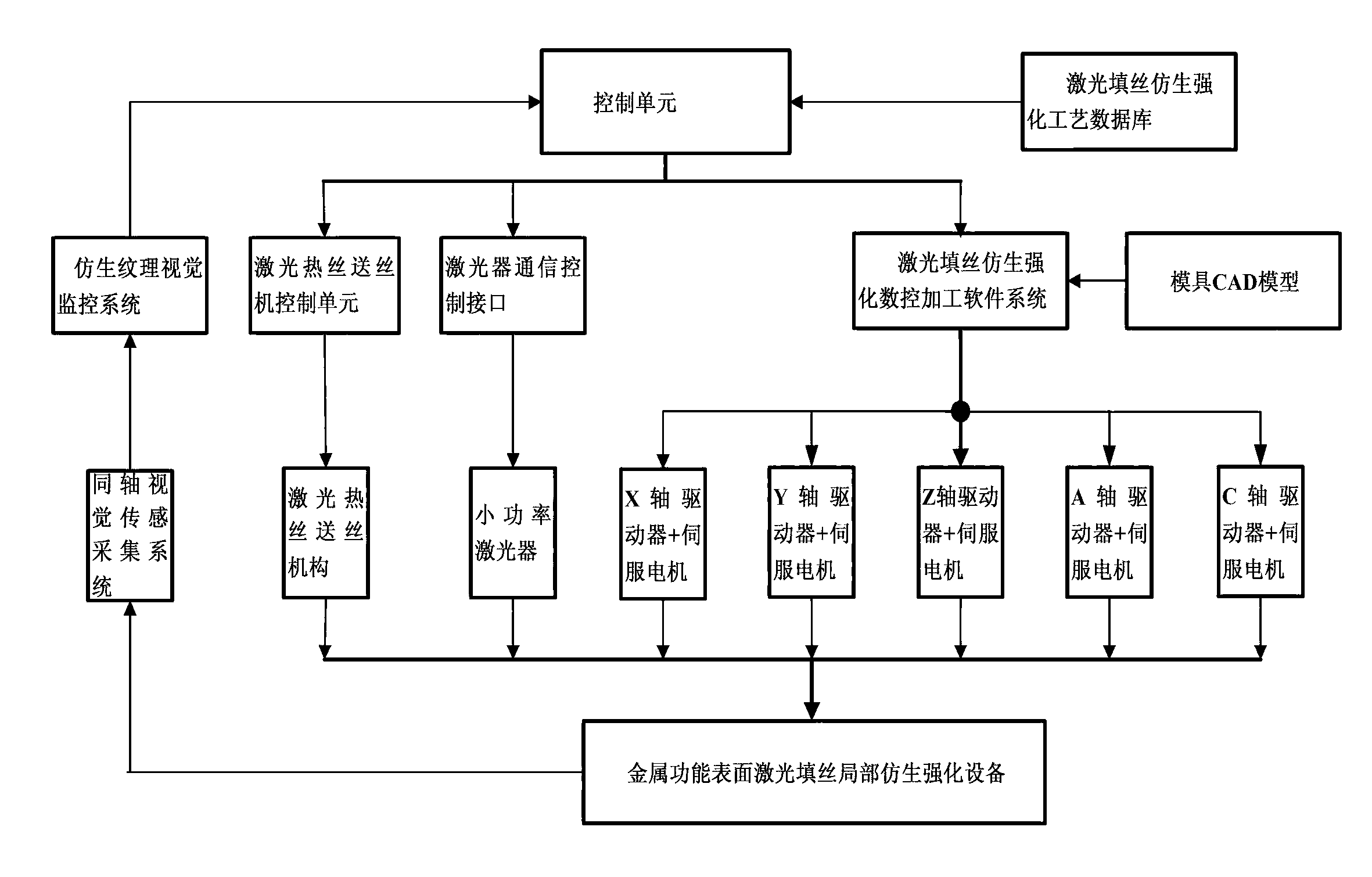

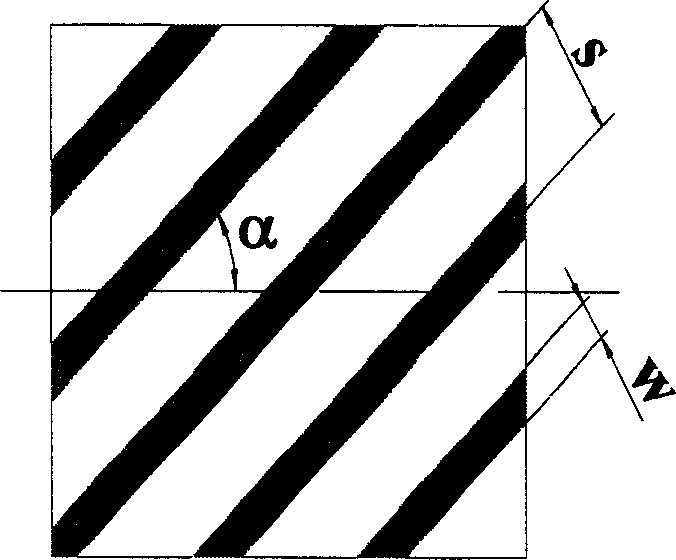

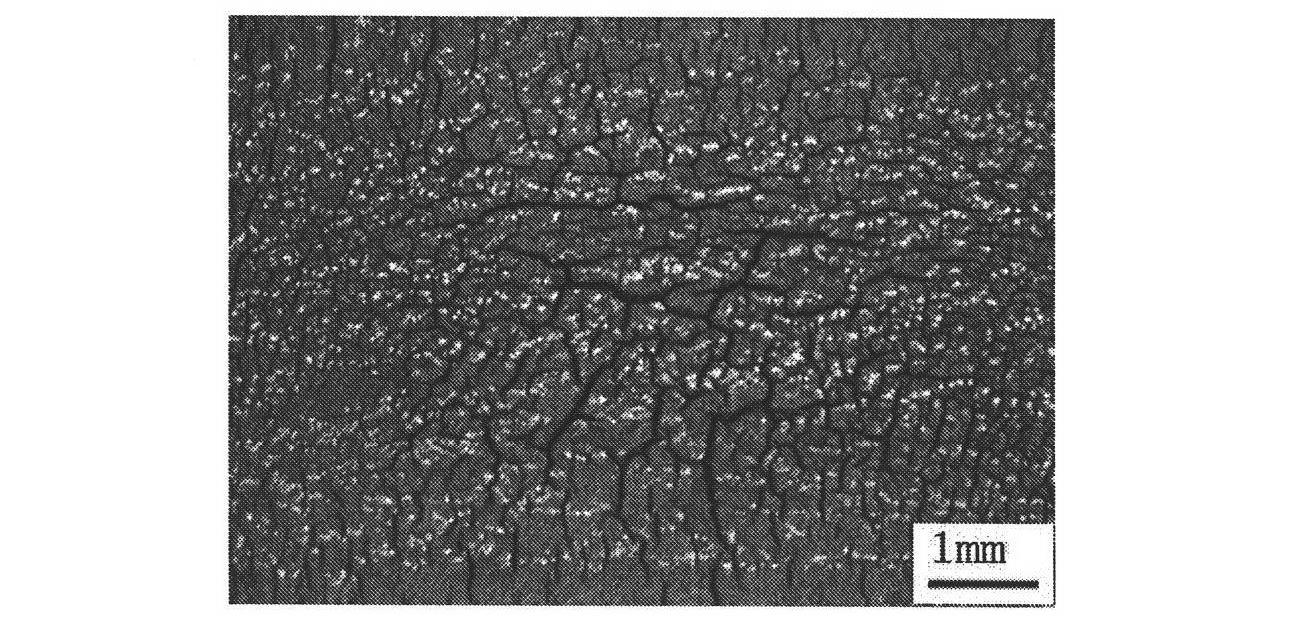

Laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces

InactiveCN103252582AImprove toughnessReduce microcracksLaser beam welding apparatusFive freedomsCost performance

The invention relates to laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces, belongs to the field of processing of metal materials and aims to provide a technical method and a manufacturing device which are capable of effectively improving thermal fatigue resistance and wear resistance on the metal functional surfaces. For different metal base materials, by combining the automatic wire filling technology with the vision sensing and small-power laser technology, a novel method for manufacturing bionic texture on metal functional spatial curved surfaces is provided. In order to implement the mentioned technical method, strengthening equipment composed of a control unit, a vision system, an adjustable temperature heating wire feeding machine, a laser and a five-freedom-degree numerical-control worktable is researched, thermal fatigue resistance and wear resistance of the metal functional surfaces are effectively improved, cost performance is good and production efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

High-carbon gray cast iron automobile brake disk and production method thereof

ActiveCN103225037AShorten the lengthConvenient lengthBraking discsFriction liningChemical compositionHigh carbon

The invention relates to a high-carbon gray cast iron automobile brake disk and a production method thereof. The high-carbon gray cast iron automobile brake disk comprises the following chemical components in percentage by weight: 3.7-3.8% of C, 0.5-0.8% of Mn, 0.3-0.5% of Cu, 0.1-0.2% of Cr, 0.2-0.4% of Mo, 1.6-2.0% of Si, 0.1-0.2% of N, 0.01-0.12% of P, 0.05-0.12% of S and the balance of Fe. The brake disk provided by the invention has the outstanding characteristics of small brake temperature rise, abrasion resistance, favorable heat fatigue resistance effect and the like; the performance of an automobile brake system can be obviously improved, and the service life can be obviously prolonged; and meanwhile, the potential safety hazard caused by ineffective brake due to high temperature can be effectively eliminated. Thus, the high-carbon gray cast iron automobile brake disk has high economic value.

Owner:河南淮海精诚工业科技有限公司

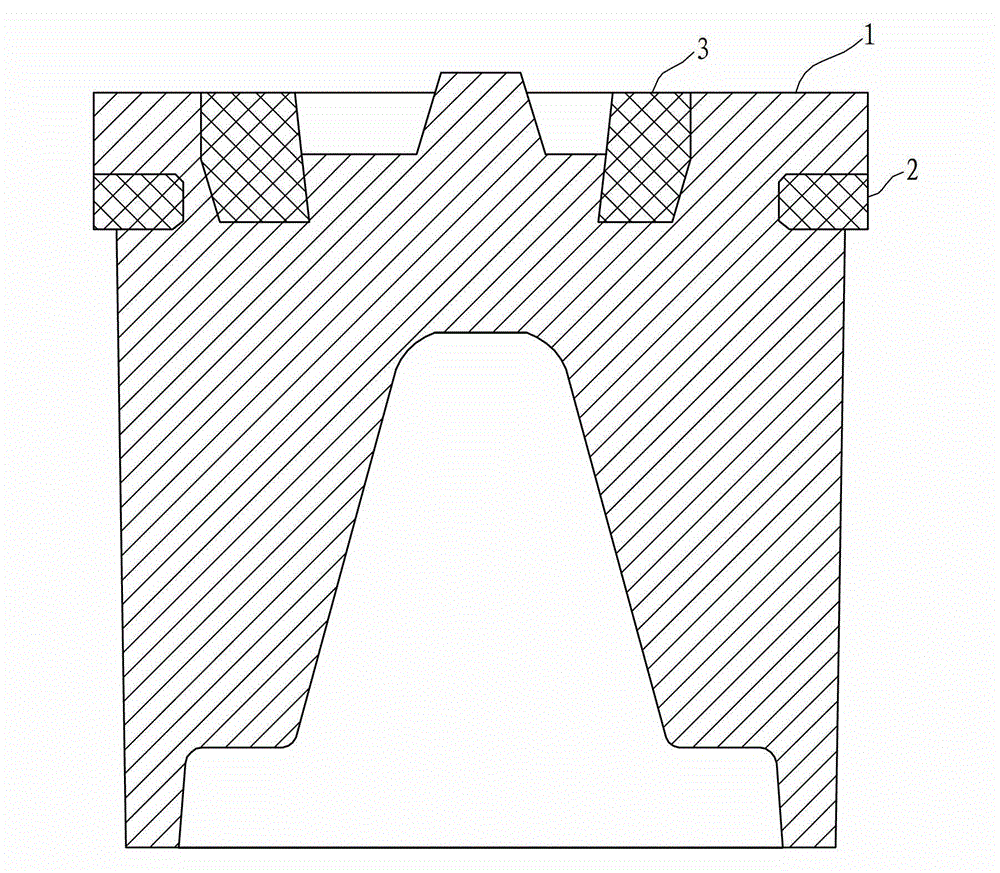

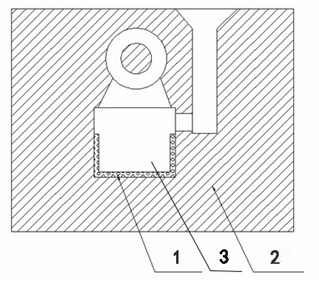

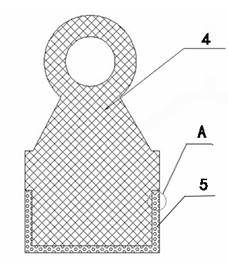

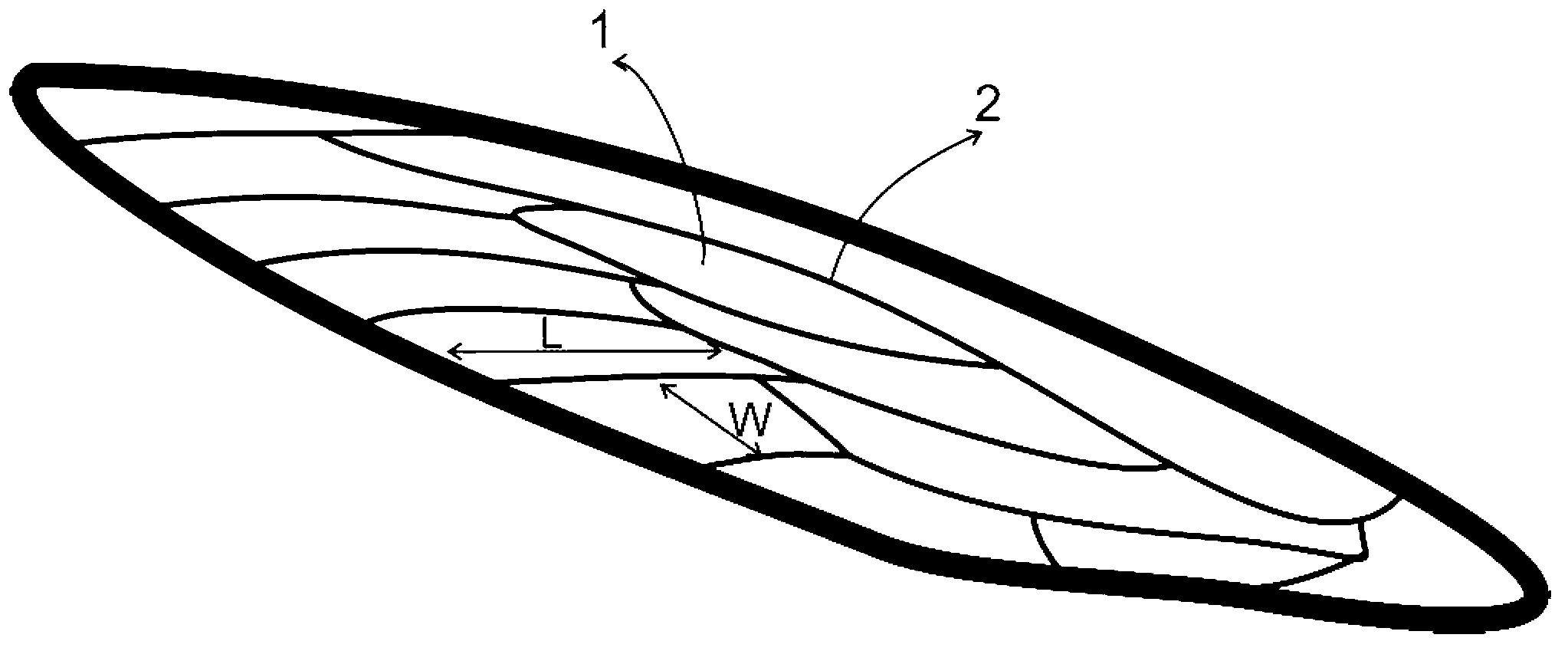

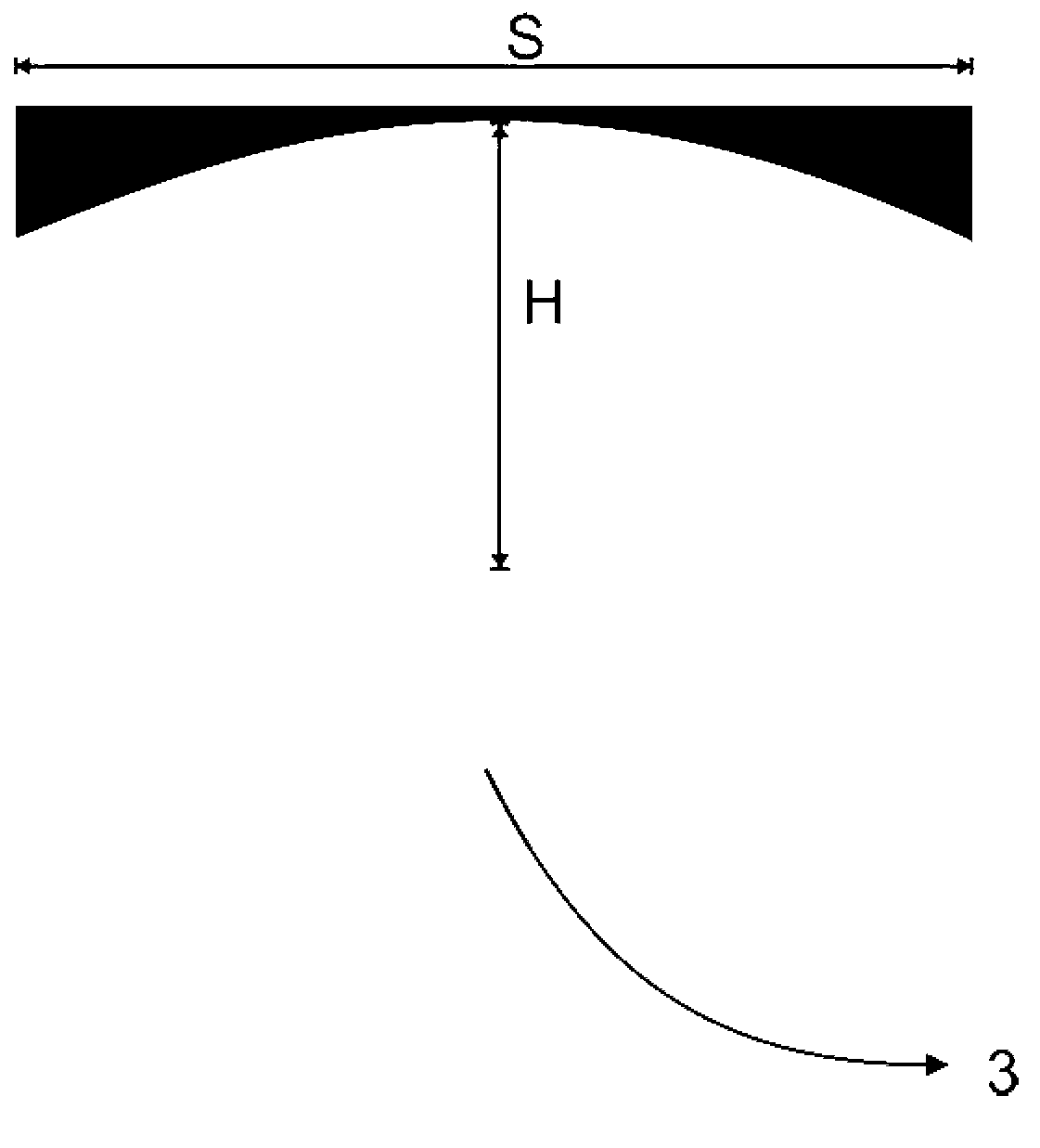

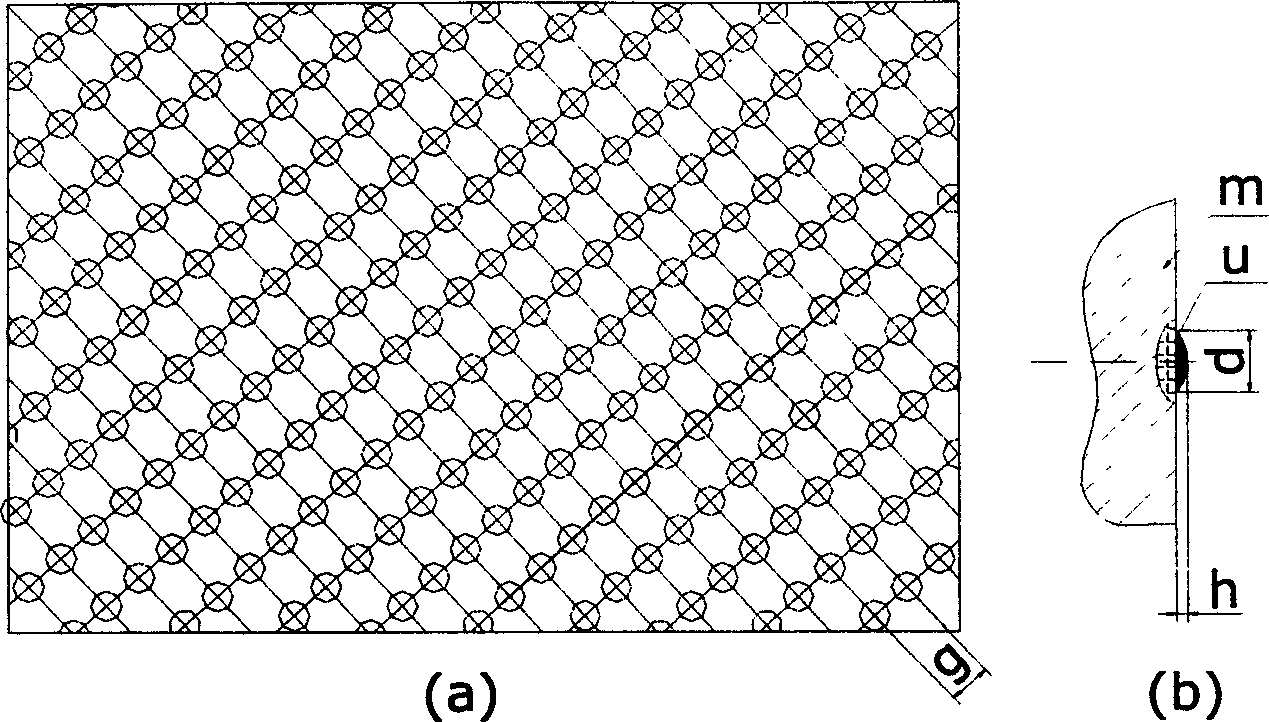

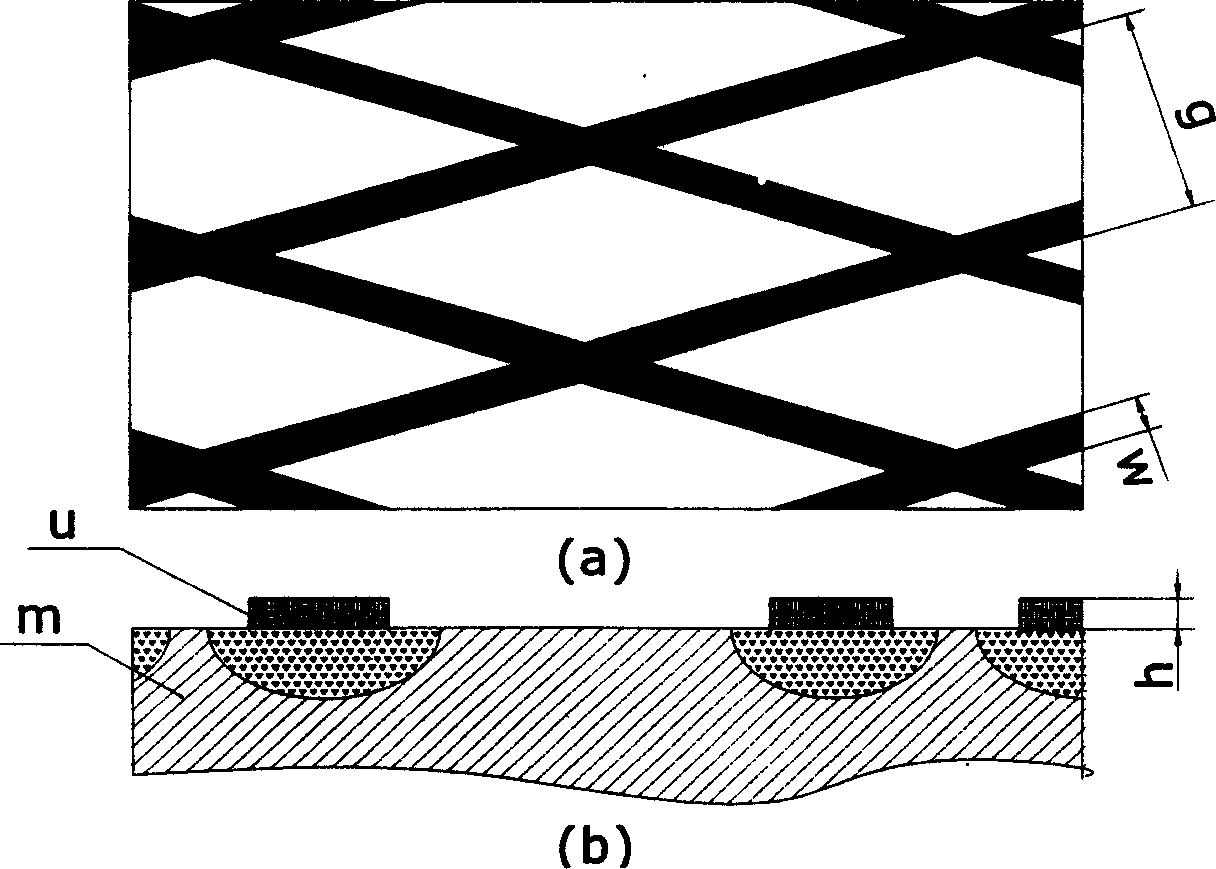

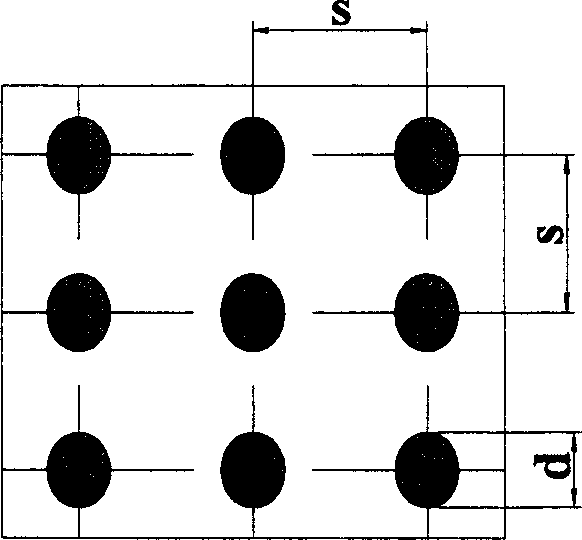

Mould having bionic non smooth surface

InactiveCN1597241AImprove wear resistanceImprove thermal fatigue resistanceSmooth surfaceMaterials science

A die with bionic non-smooth surface for high antiwear and thermal fatige resistant properties and easy demoulding features that the concave and convex unit bodies with the shapes of spherical crown, crater, or parelles or lattic strips are arranged on its working surface.

Owner:JILIN UNIV

Steel with ultra-high thermal conductivity for hot-stamping die and preparation method of steel

The invention relates to a novel material with ultra-high thermal conductivity for a hot-stamping die. The steels in the market for the hot-stamping die are mainly various types of improved H13 and H11 high-alloy hot work die steels. The steel in the invention comprises the following compositions in percentage by mass: 0.150-0.35% of C, less than or equal to 0.25% of Si, 0.08-0.20% of Mn,1.0-2.0% of W,2.0-4.5% of Mo, less than or equal to 0.30% of Cr,less than or equal to 0.02% of V and the balance of Fe and inevitable impurity elements, wherein S in the impurity elements is less than or equal to 0.005%, P in the impurity elements is less than or equal to 0.01 and O in the impurity elements is less than or equal to 30 ppm (parts per million). The invention is characterized in that simple elements i.e. C, Mo and W are used as the main elements, and proper proportion of carbide is adopted; the contents of Mn and Cr are maintained low, and the content of Si is maintained ultra-low; the steel has superior machining property after being subjected to electro-smelting, electro-slag remelting, annealing, high-temperature homogenization, forging and annealing; through thermal treatment (1060-1100 DEG C quenching and high-temperature annealing), the toughness of the steel can reach the toughness of common hot-stamping die steel such as H13, and the hardness, annealing stability and the fatigue property of the steel are more superior; particularly, the steel with lower coefficient of thermal expansion and ultra-high thermal conductivity is more suitable for hot stamping.

Owner:SHANGHAI UNIV

Wear-resisting roll used for steel rolling intermediate mill frame and manufacturing method thereof

ActiveCN104148399ASimple heat treatment processShort heat treatment timeRollsMetal rolling arrangementsSocial benefitsAlloy

A wear-resisting roll used for a steel rolling intermediate mill frame and a manufacturing method thereof belong to the technical field of steel rolling. The wear-resisting roll is composed of outer layer alloy nodular cast iron, inner layer high strength gray iron and a hot rolled middle carbon round steel roll shaft with high strength. The outer layer alloy nodular cast iron and the inner layer high strength gray iron are formed through centrifugal casting in a composite mode, and the inner layer high strength gray iron is integrated with the hot rolled middle carbon round steel roll shaft with high strength, and the composite wear-resisting roll with high strength is obtained. The wear-resisting roll has the advantages of being simple and convenient in production process, long in service life, low in production cost and the like. In addition, good economic and social benefits are achieved through application and popularization.

Owner:枣庄瑞兴机械制造有限公司

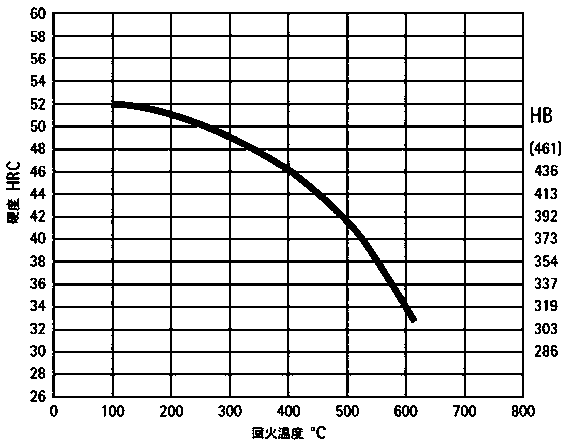

High-performance hot stamping die steel and manufacturing process thereof

The invention relates to high-performance hot stamping die steel and a manufacturing process thereof. The high-performance hot stamping die steel comprises the following components of, in percentage by mass, 0.66% - 0.80% of C, 0.80% - 1.20% of Si, 0.20% - 0.50% of Mn, 5.00% - 6.50% of Cr, 1.50% - 2.00% of Mo, 0.40% - 0.80% of V, less than 0.015% of P, less than 0.015% of S and the balance Fe. Themanufacturing process of the die steel comprises the following steps of carrying out burdening, smelting, casting, electroslag remelting; carrying out high-temperature diffusion thermal treatment, multi-direction forging and hot machining and cooling control after forging; then carrying out secondary carbide refining thermal treatment and isothermal annealing treatment; and finally carrying out quenching and tempering thermal treatment. The high-performance hot stamping die steel and the manufacturing process thereof has the advantages that the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of the hot-work die steel are superior to the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of H13 steel,and the hot-work die steel can be machined into a large-scale hot stamping die with the single-piece weight reaching 5 tons or above, and the usability is good.

Owner:RUGAO HONGMAO HEAVY FORGING

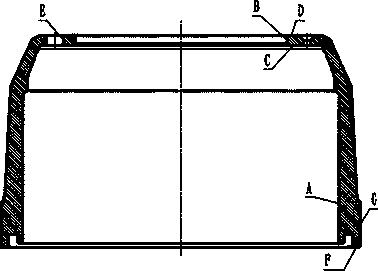

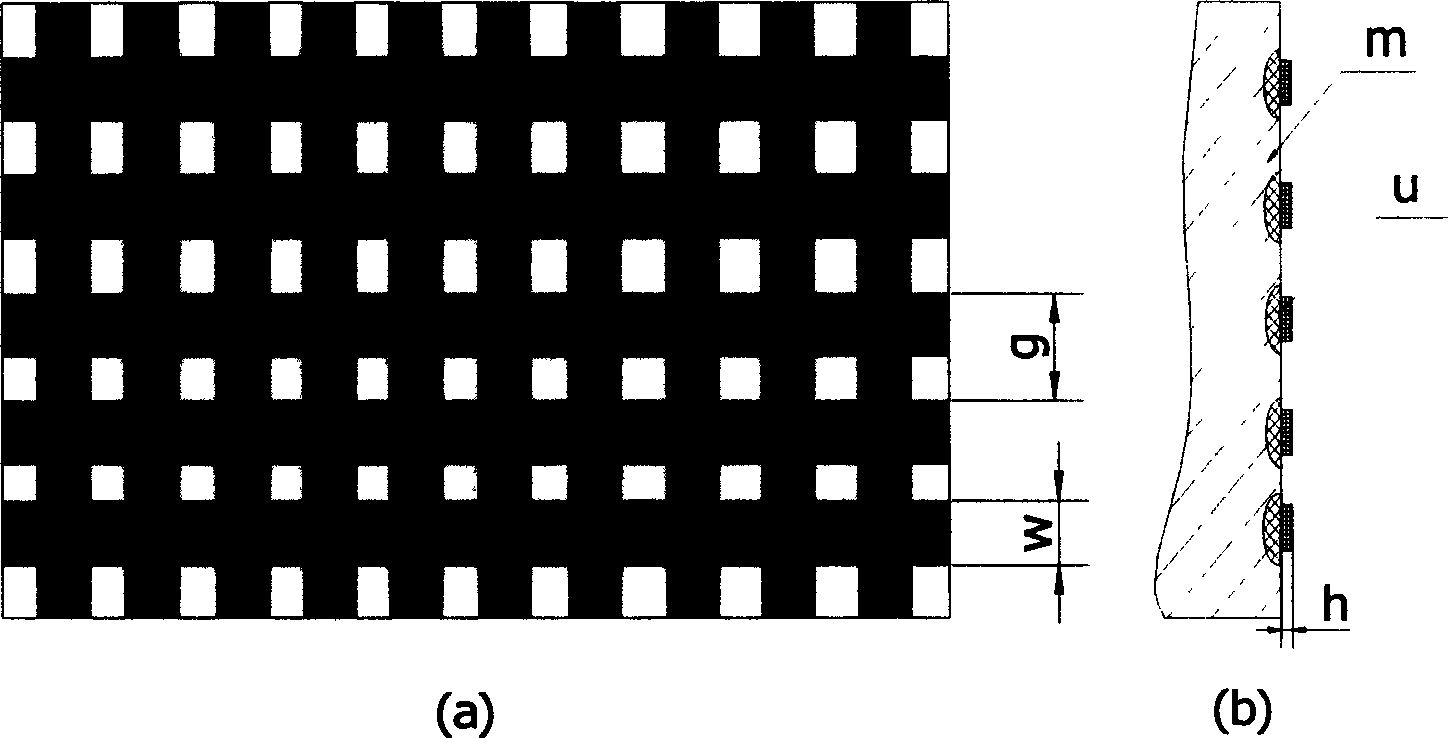

Braking drum with bionic non-smooth surface

InactiveCN1644950AIncrease coefficient of frictionImprove wear resistanceBraking drumsRough surfaceEngineering

A drum break with bionic rough surface characters high friction index, anti-wear, anti-heat fatigue. On the surface of the drum break distribute knaggy units of height 0.15-0.5 mm in parallel or net. The structure and chemical components of the knaggy units increase the ability of anti-friction and anti-heat fatigue of the drum break. The structure of the knaggy units changes a surface friction to point friction therefore reduce wearniess of the drum break. The life this knagg drum break is 1.5-3 times of that of same material in smooth.

Owner:JILIN UNIV

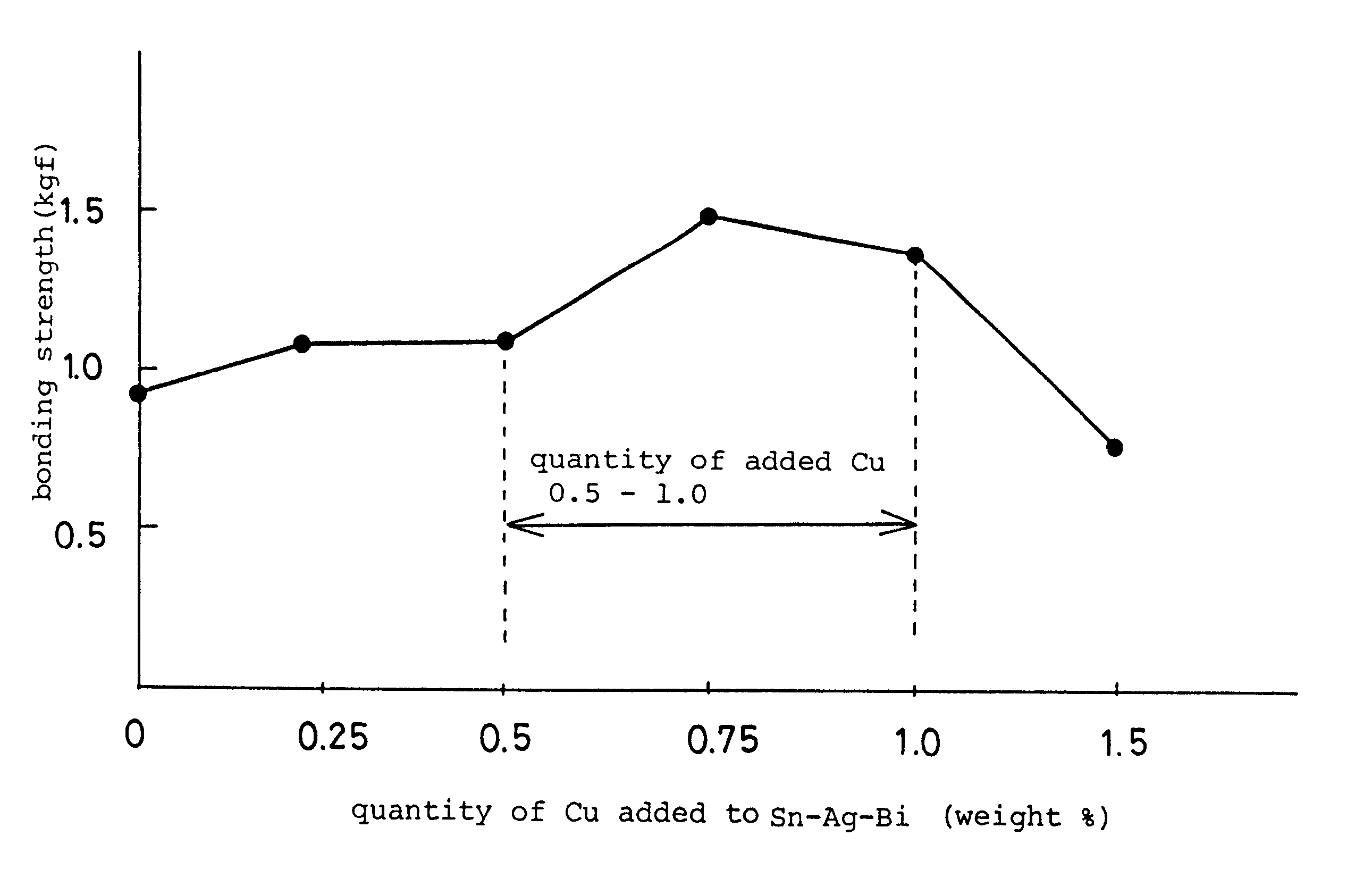

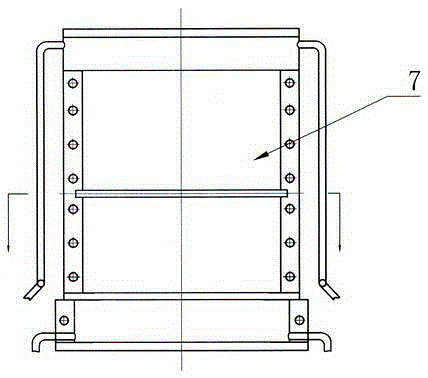

Soldering alloy, cream solder and soldering method

InactiveUS6371361B1Minimize changesImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaThermal fatigueToxic material

The present invention relates to a soldering alloy composed mainly of Sn and free from lead, a toxic substance. Adding a small quantity of Ag to the soldering alloy can make the alloy structure fine, minimize structural changes of the alloy and increase its thermal fatigue resistance. Adding a small quantity of Bi to the soldering alloy lowers the melting point and improves the alloy's wettability. Further, adding a small quantity of Cu restrains the growth of intermetallic compounds in the bonding interface between a copper land and the solder. Furthermore, addition of a small quantity of In improves the elongation property and thermal fatigue resistance of the alloy.

Owner:PANASONIC CORP

Corrosion-resistant welding rod and its preparing method

InactiveCN101148008AWill not cause short supplyAvoid corrosionLiquid surface applicatorsWelding/cutting media/materialsNiobiumBoron carbide

The present invention belongs to the field of welding material technology, and is especially one kind of anticorrosive welding rod. The welding rod includes one core wire and one welding rod coating comprising tungsten carbide 2-10 wt%, boron carbide or boron nitride 2-8 wt%, nickel powder 2-10 wt%, copper 0.30-0.85 wt%, RE elements 0.2-4.60 wt%, Mn-N alloy and / or V-N alloy in any ratio 0.20-2.80 wt%, ferromolybdenum 0.6-3.2 wt%, marble 25-38 wt%, titanium white powder 2-8 wt%, fluorite 1-6 wt%, low carbon ferromanganese 3-8 wt%, ferrovanadium 0.35-4 wt%, ferroniobium or ferrotitanium 0.35-4 wt%, and low carbon ferrochrome for the rest. The welding rod has high corrosion resistance, high wear resistance, good welding performance and other advantages.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

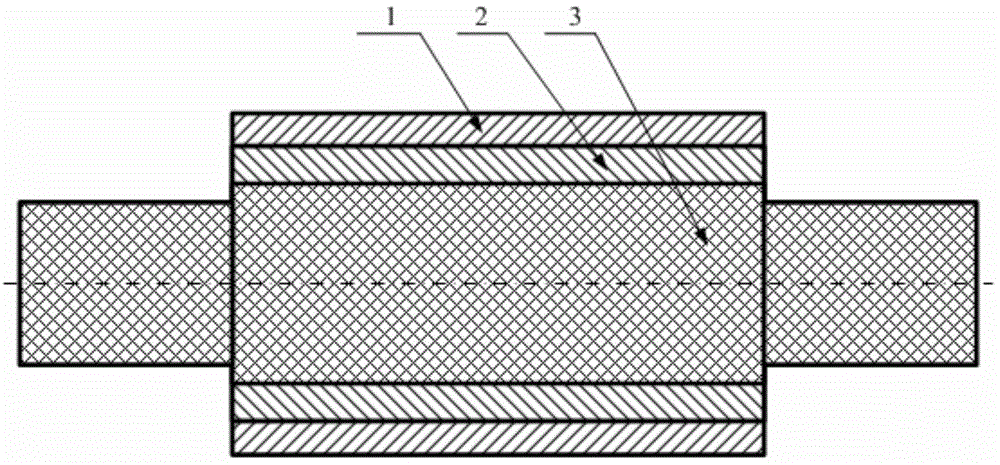

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

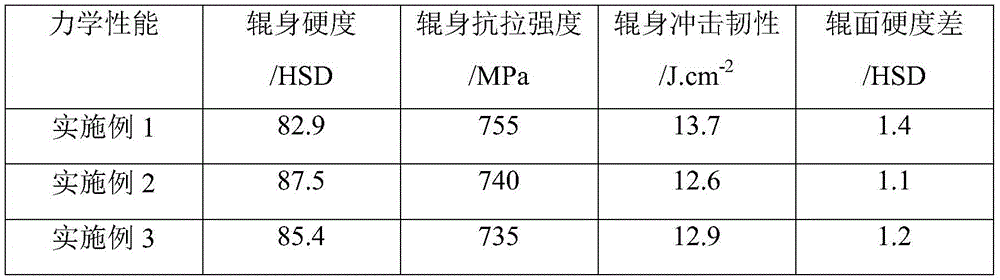

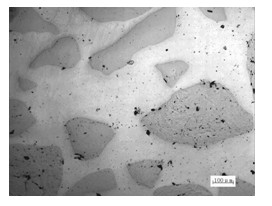

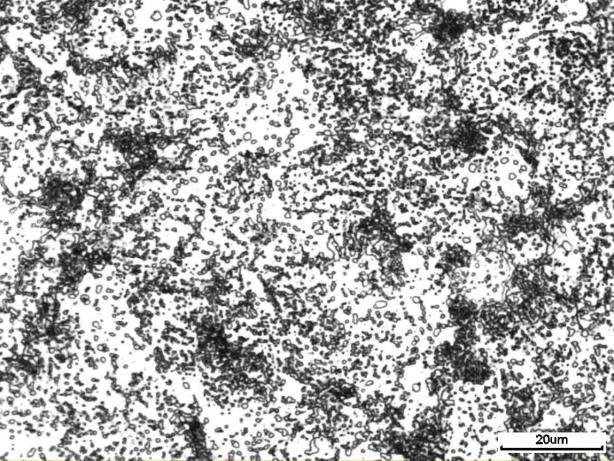

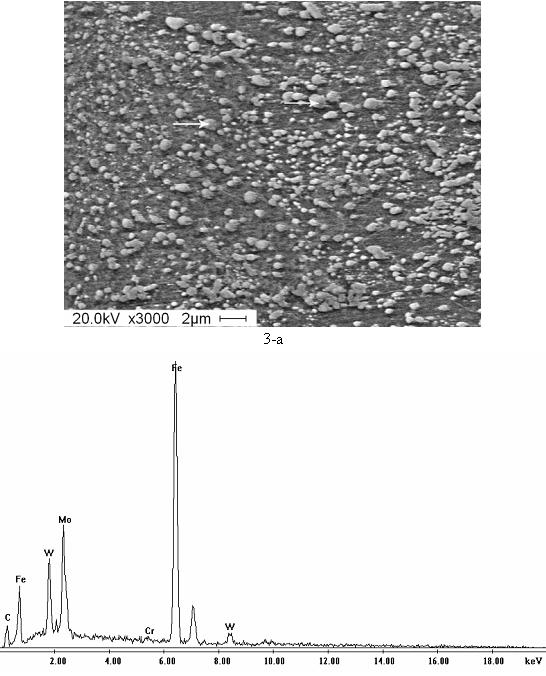

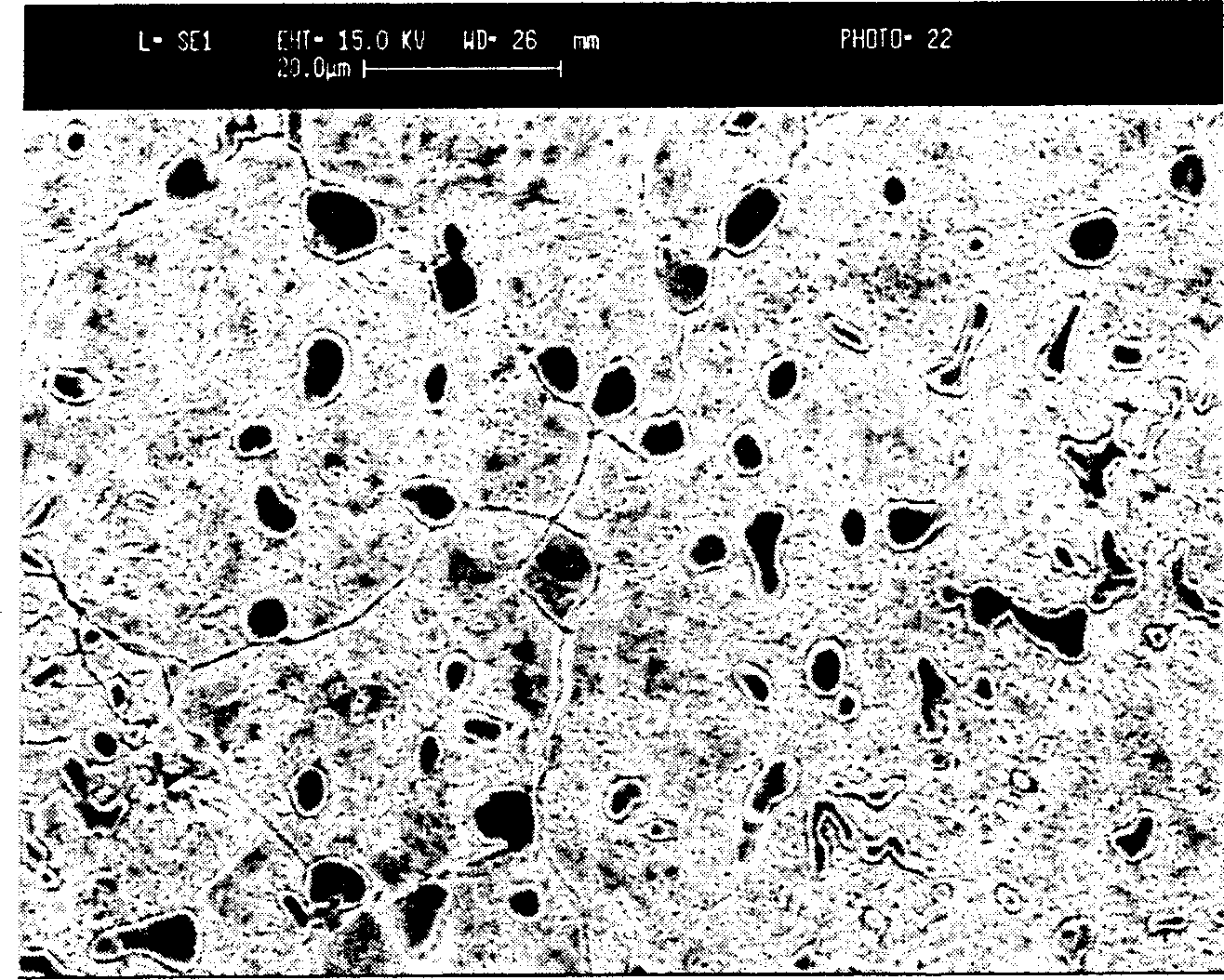

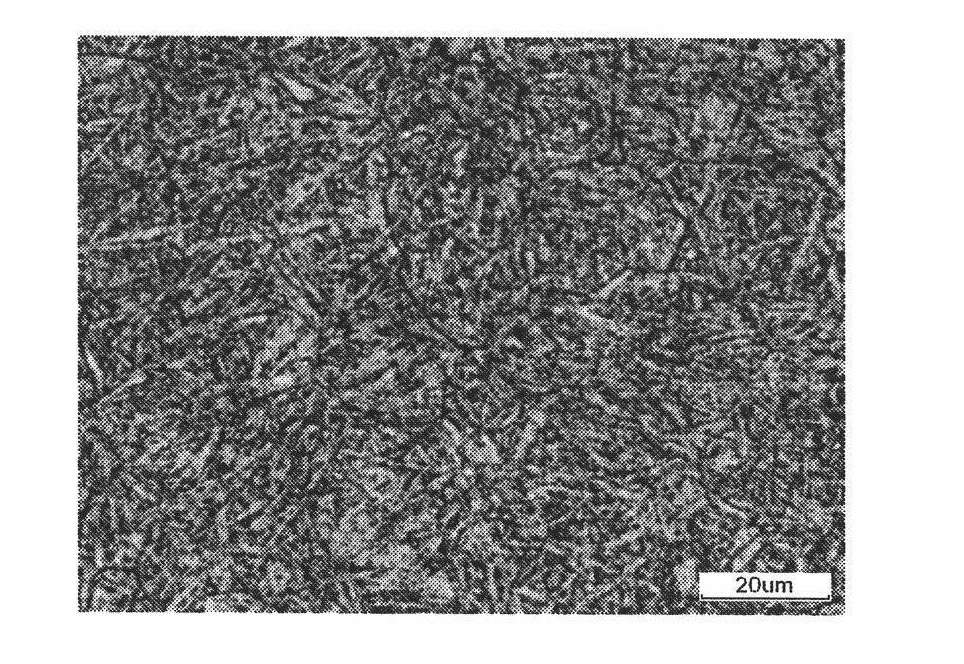

High carbon high-speed steel of containing granular carbide, and preparation method

InactiveCN1916219AImprove mechanical propertiesImprove thermal fatigue resistanceHeat treatment process controlThermal fatigueChemical composition

This invention discloses a method for preparing particular carbide-texile high-carbon high-speed steel, which is composed of: C 1.5-3.0 wt.%, V 3.0-6.0 wt.%, W 4.0-8.0 wt.%, Mo 2.0-6.0 wt.%, Cr 4.0-8.0 wt.%, Nb 0-5.0 wt.%, Co 0-5.0 wt.%, RE 0.05-0.20 wt.%, Ti 0.1-0.3 wt.%, N 0.06-0.18 wt.%, Zn 0.01-0.05 wt.%, Mg 0.02-0.12 wt.%, Ni 0-1.0 wt.%, Si 0-2.0 wt.%, Mn 0-2.0 wt.%, P 0-0.05 wt.%, S 0-0.05 wt.% and Fe, wherein the total content of Nb and Co is within 2.5-5.0 wt.%. The method comprises: casting in an electric furnace, heating at 1020-110 deg.C for 2-4 h, air-cooling, normalizing, heating at 500-580 deg.C for 4-8 h, and air-cooling or furnace-cooling to room temperature to obtain martensite-based particular carbide-texile high-carbon high-speed steel. The steel has improved mechanical properties with tensile strength of 930-980 MPa, impact toughness of 12-15 J / cm2 and fracture toughness of 48-55 MPa, improved thermal fatigue resistance and excellent wear resistance.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

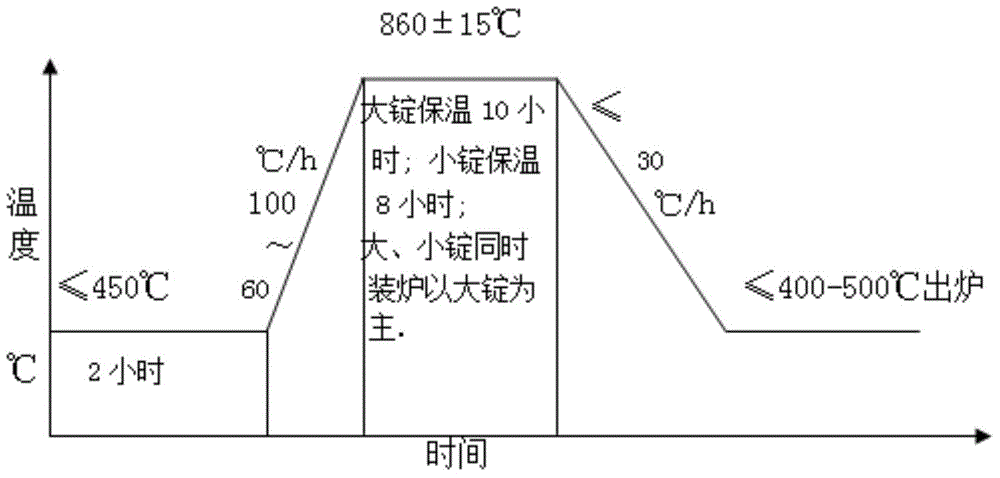

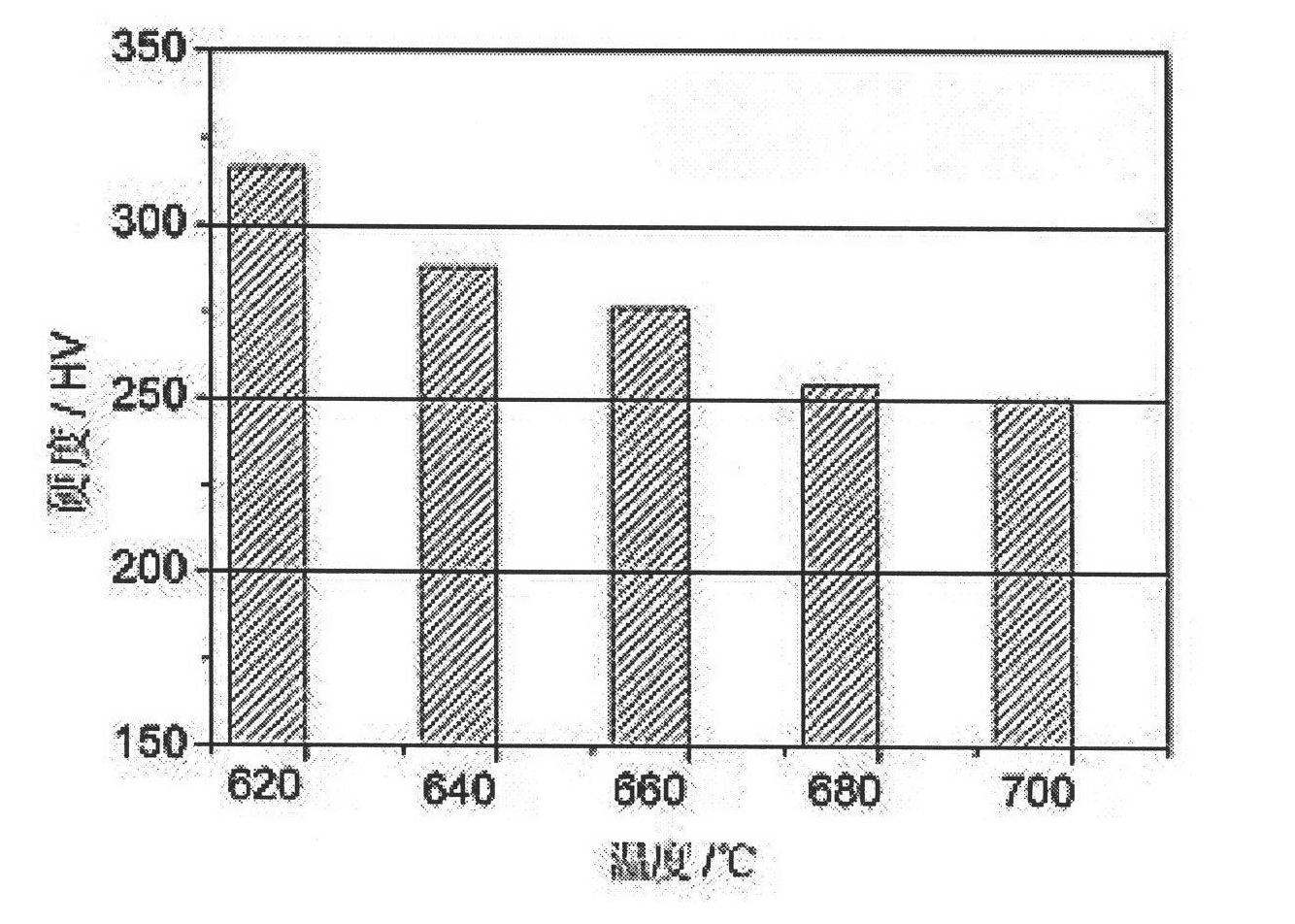

Process for producing H13 hot work die steel

The invention relates to a process for producing H13 hot work die steel, aiming to solve the problem that the present H13 hot work die steel universally has problems of 'good heat resistance and poor toughness or good toughness and poor heat resistance'. The chemical components of the 4Cr5MoSiV1(H13) hot work die steel are reasonably designed and adjusted to control the content of alloy elements such as Cr, Mo, V and Si and exert the interaction of the alloy elements, so that grains are thinned and distributed uniformly; meanwhile, by optimizing an electroslag remelting technology, a forging technology and a thermal treatment technology, the purity and compactness of the steel are improved, segregation is reduced, the mechanical property and isotropy of the steel are further improved, the heat uniformity of a forged part is ensured, a carbide ball structure with stable size and uniform distribution is obtained, and therefore the mechanical property and service life of a product are improved.

Owner:南平市双友金属有限公司

Large-size mandril structure property control method

ActiveCN101787420AImprove purityImprove impact toughnessFurnace typesHeat treatment furnacesThighThermal fatigue

The invention relates to a large-size steel mandril structure thinning control method for improving the performance of a base body, belonging to the field of steel material manufacturing technique control technology. The method mainly comprises structure thinning treatment for mandril billet in the production process of a mandril by a thigh channel as well as quenching treatment-thinned and hardened structure of finished products of the mandril, namely, all performances of the mandril can be improved by technical way of double thinning structure. The large-size steel mandril manufactured by the method has higher impact toughness, better heat stability and higher thermal fatigue resistance.

Owner:SHANGHAI UNIV

Valve finisher surface modified processing method

InactiveCN1570192AHigh hardnessImprove stress resistanceMetal-working apparatusSolid state diffusion coatingThermal fatiguePlasma technology

The invention relates to a surface modification processing method for the engine critical component, which belongs to the field of the steel surface chemistry thermal treatment processing technology. The processing method comprises: nitriding for the air valve finisher by using the plasma technology, adding carbon-containing gas in the nitrogen-containing gas at the late stage of nitriding and carrying out the nitrocarburizing, and placing the mould in the steam oxidizing furnace for surface oxidizing treatment. The mould treated by said technology has excellent mechanical property, improved surface hardness, improved compression resistance, improved wear resistance and improved thermal fatigue resistance.

Owner:SHANGHAI UNIV

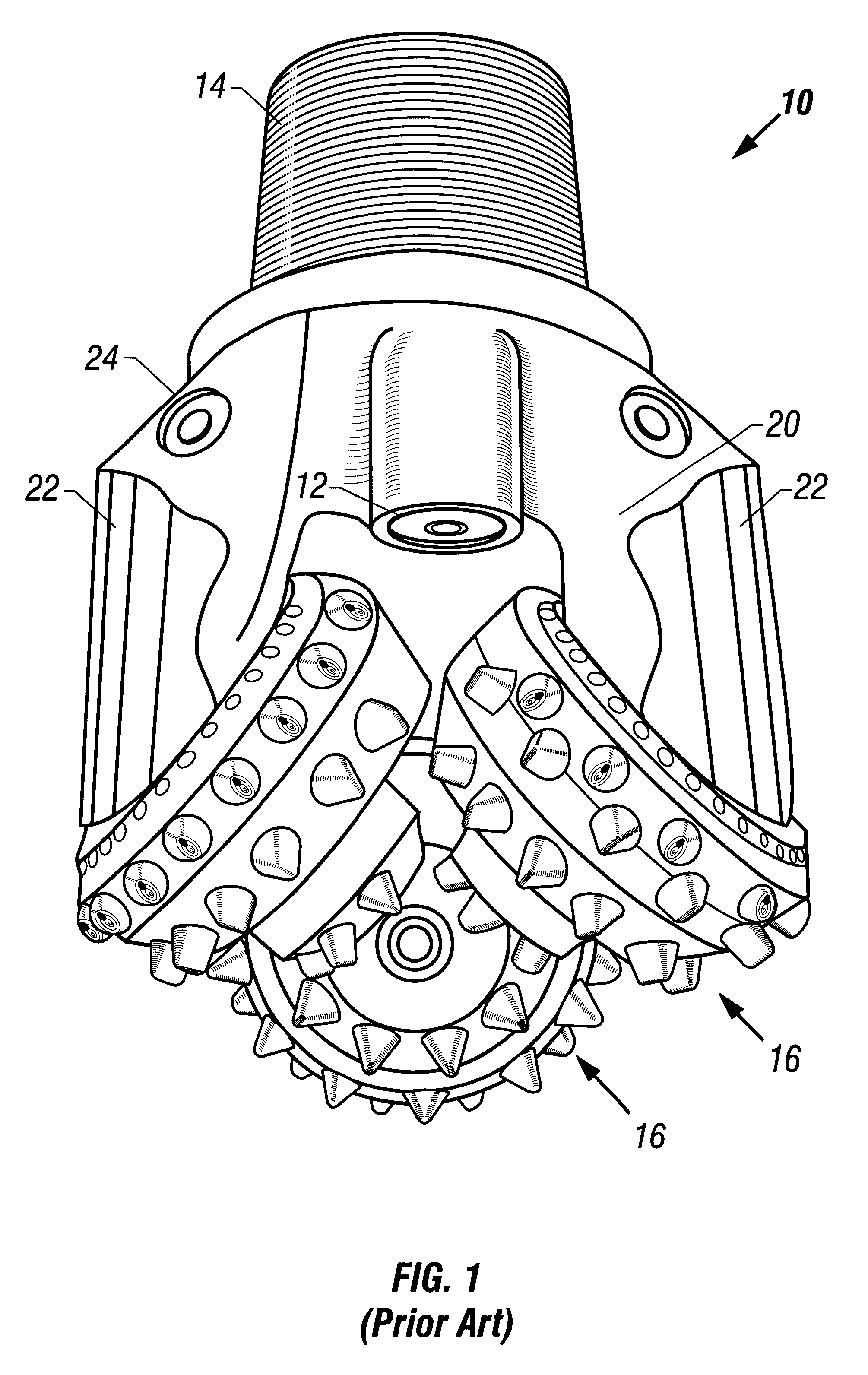

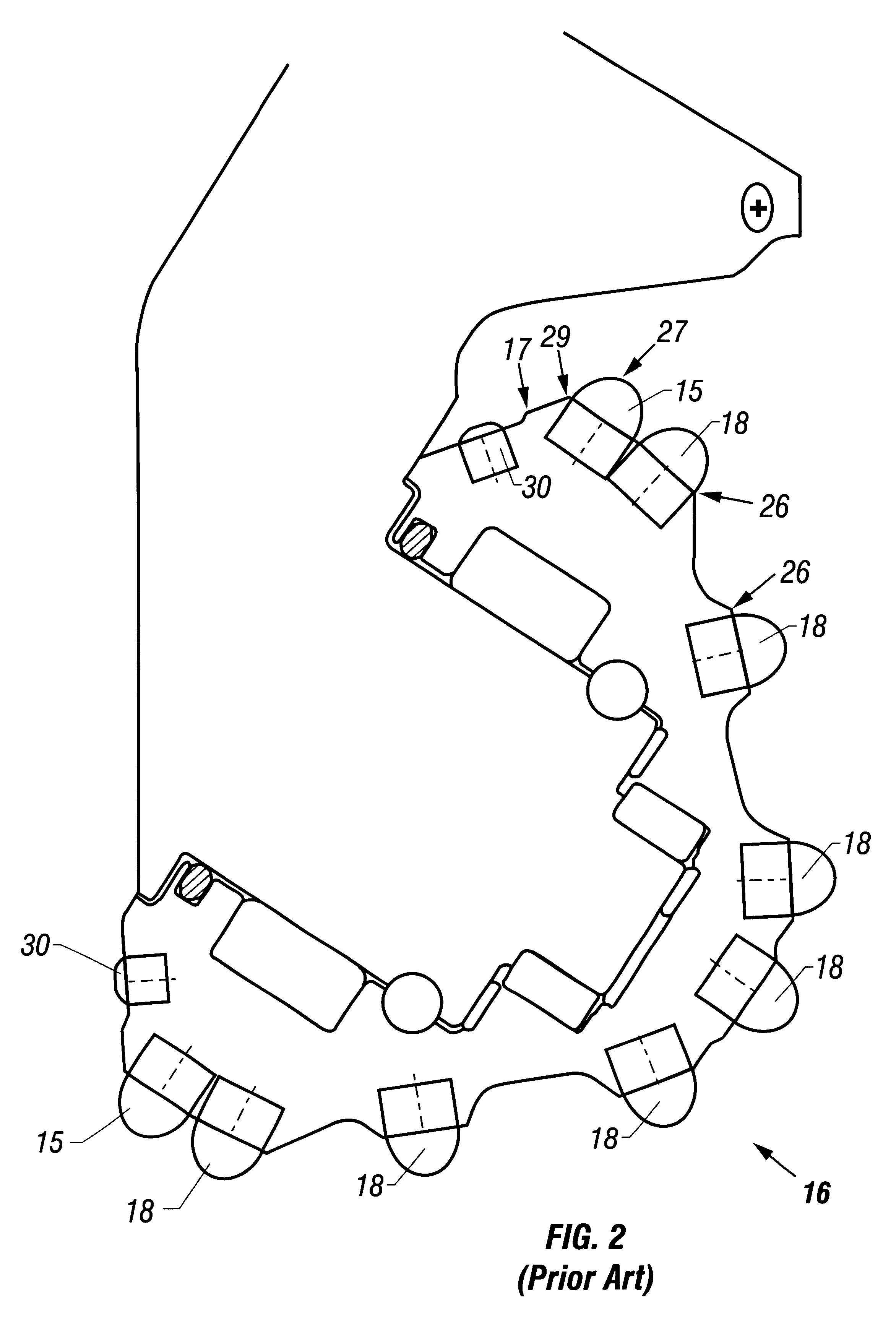

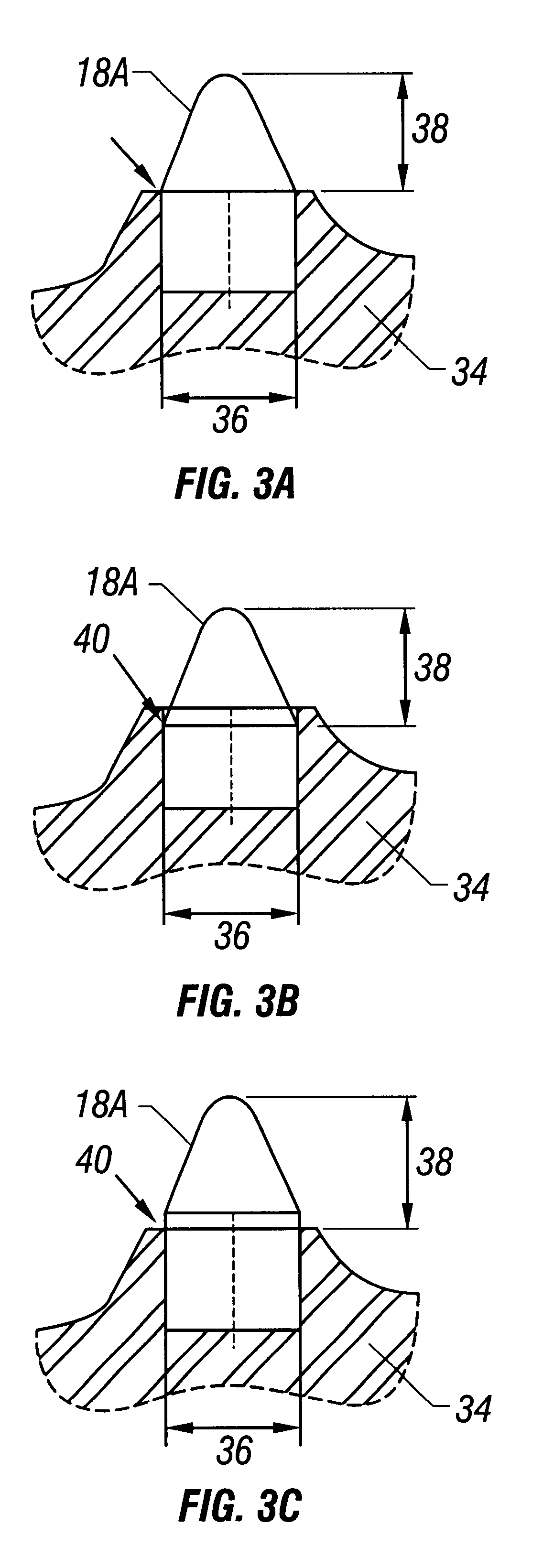

Earth-boring bit having cobalt/tungsten carbide inserts

InactiveUS6244364B1Improve thermal fatigue resistanceDecreasing resistanceDrill bitsConstructionsHardnessCobalt

An earth-boring device such as a drill bit is disclosed. The earth boring device includes a rotary main cutting structure, an insert on the main cutting structure. The insert is formed of a composition having tungsten carbide and cobalt. The cobalt makes up less than approximately 9% by weight of the composition. The composition has a Rockwell A hardness greater than approximately an Hmin as determined by the following formula: Hmin=91.1-0.63X, where X represents a cobalt content by weight of the composition.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com