Low-silver-content solder alloy and solder paste composition

A technology of silver solder and composition, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of rising melting point, increased cost, poor connection, etc., to achieve good stretching, cost reduction, high The effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 9

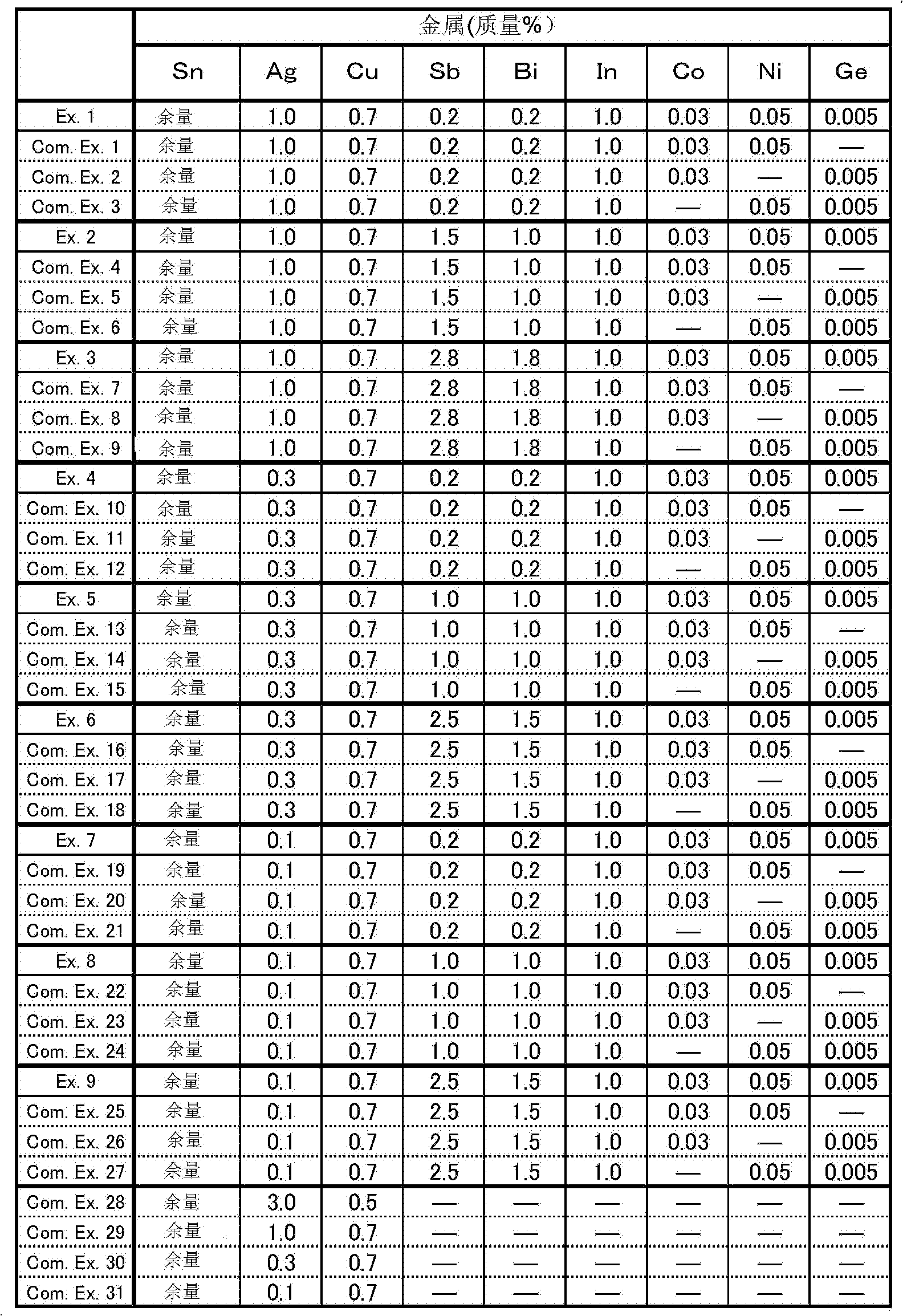

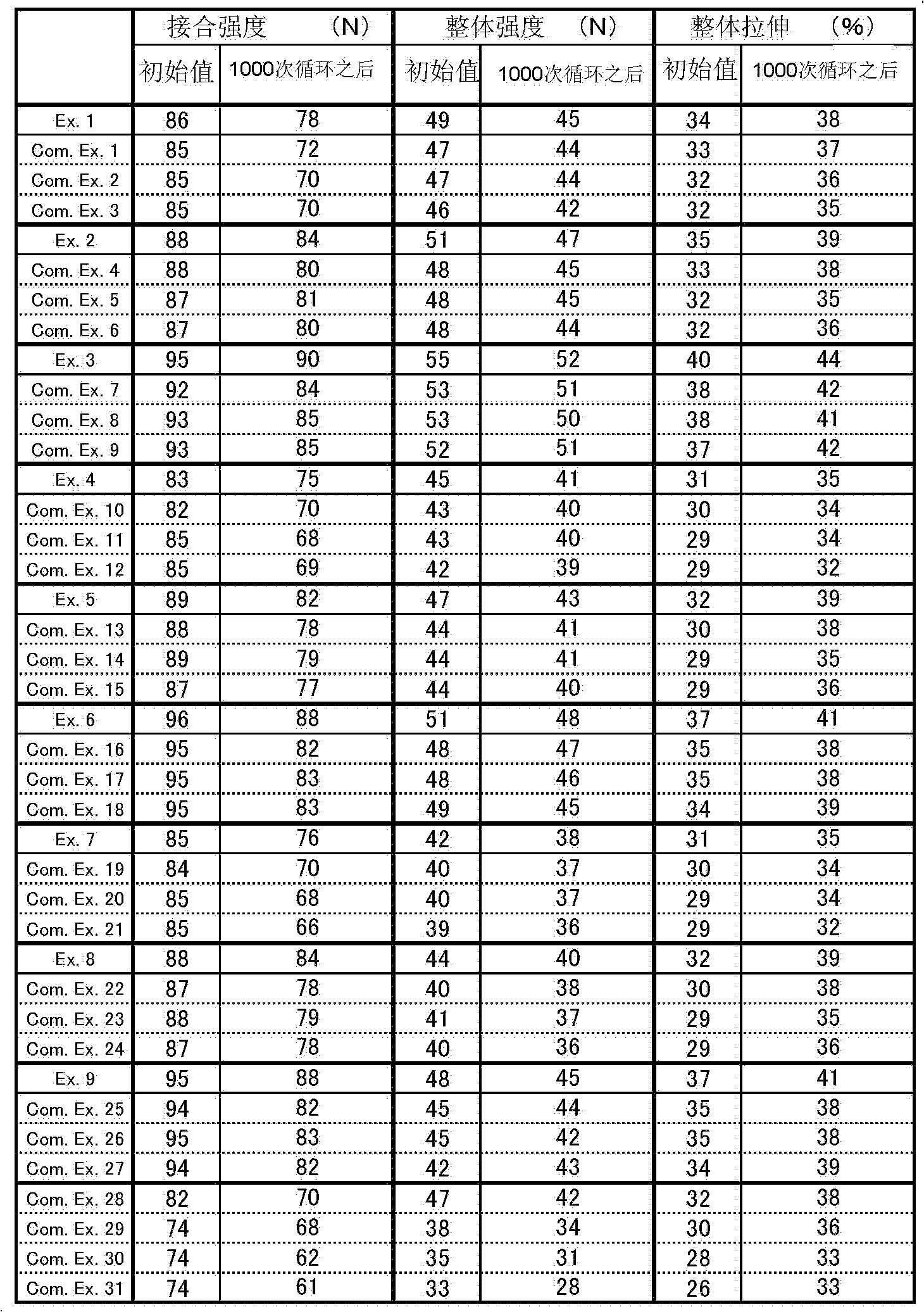

[0071] The metal powders shown in Table 1 were each mixed in the proportions shown in Table 1. Low-silver solder alloys are each prepared by melting and homogenizing these metal mixtures in a furnace.

[0072] The low-silver solder alloys obtained in Examples 1 to 9 were each powdered by a well-known method (the particle diameter of these powders was 25-38 μm). Then, 88% by mass of each of the obtained solder powders and 12% by mass of a known flux were mixed together to obtain each solder paste composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com