Patents

Literature

438results about How to "Reduce microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

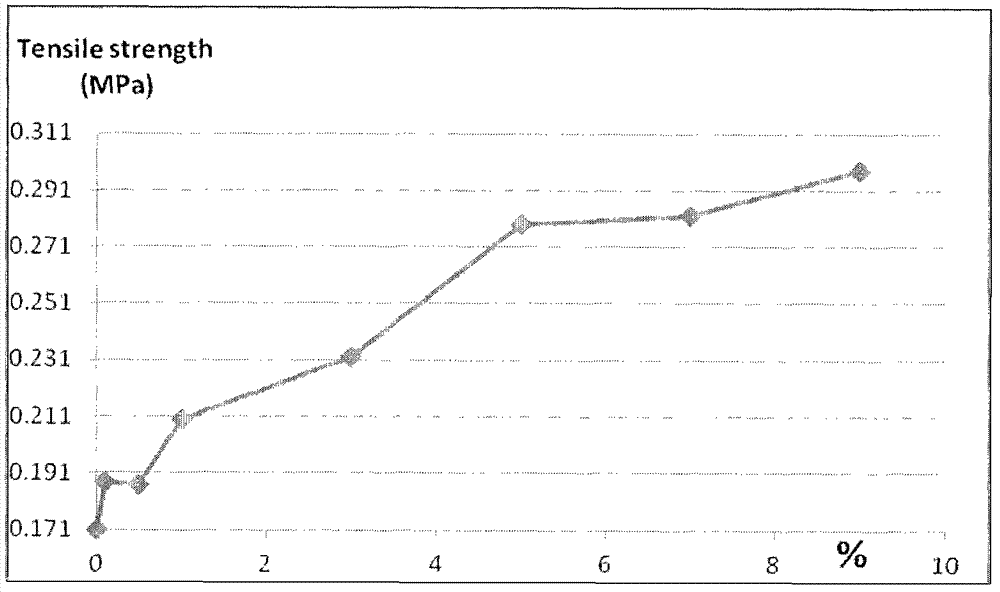

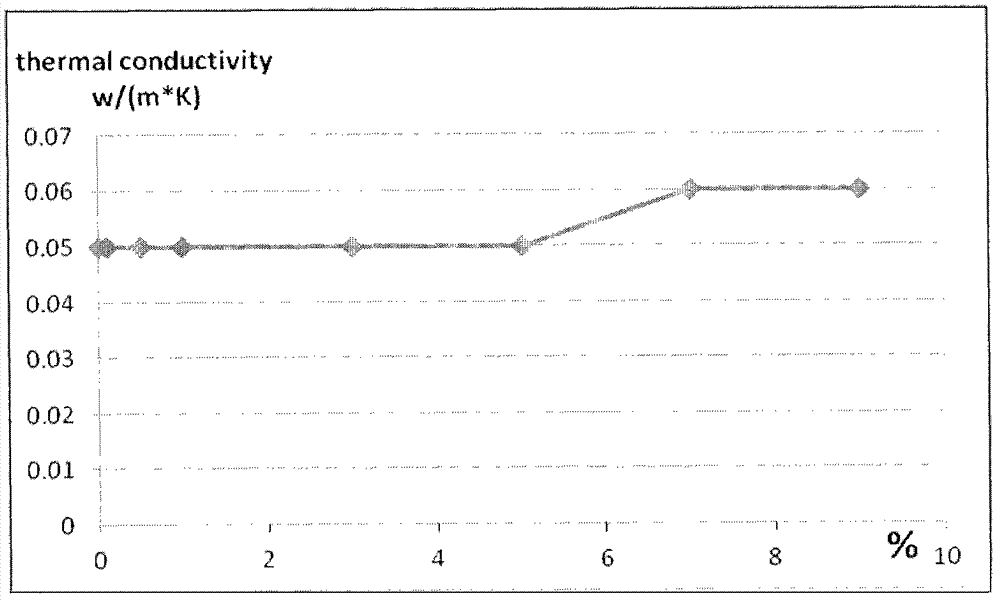

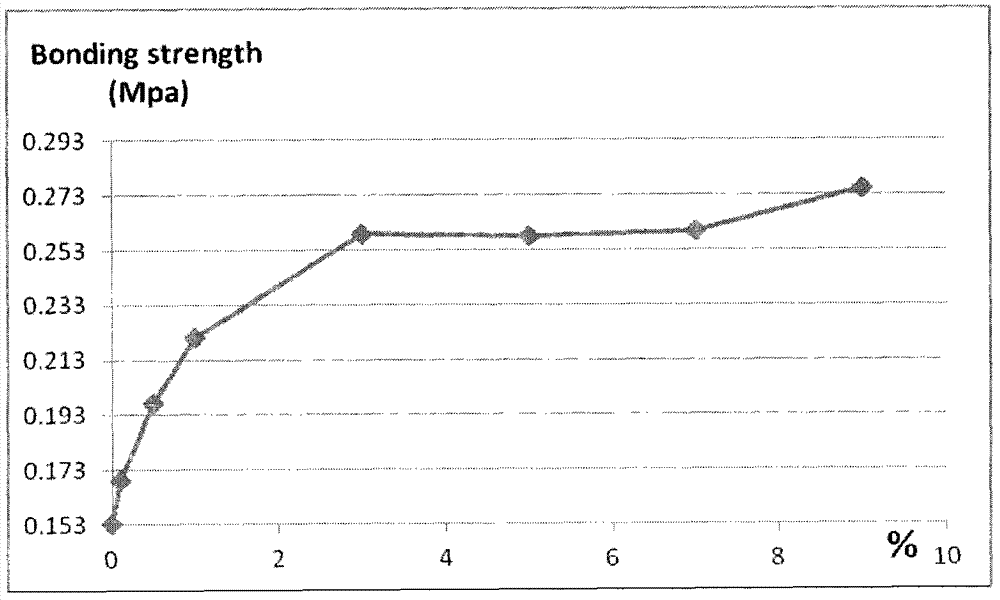

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

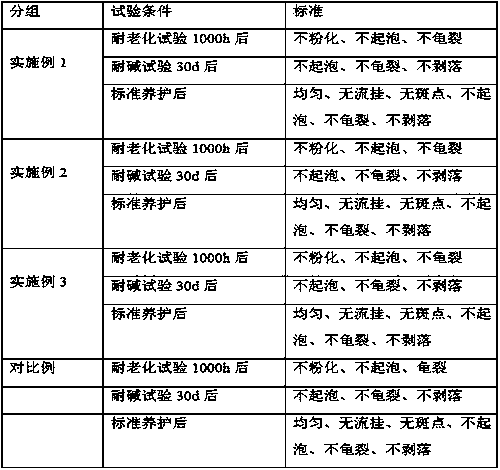

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

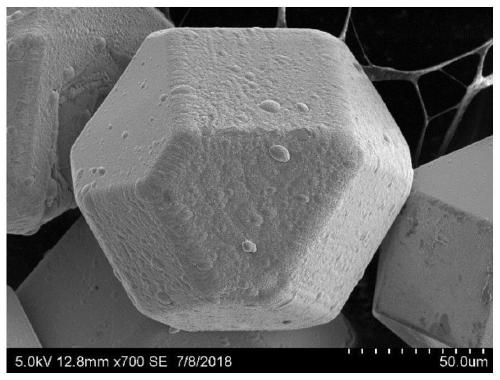

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

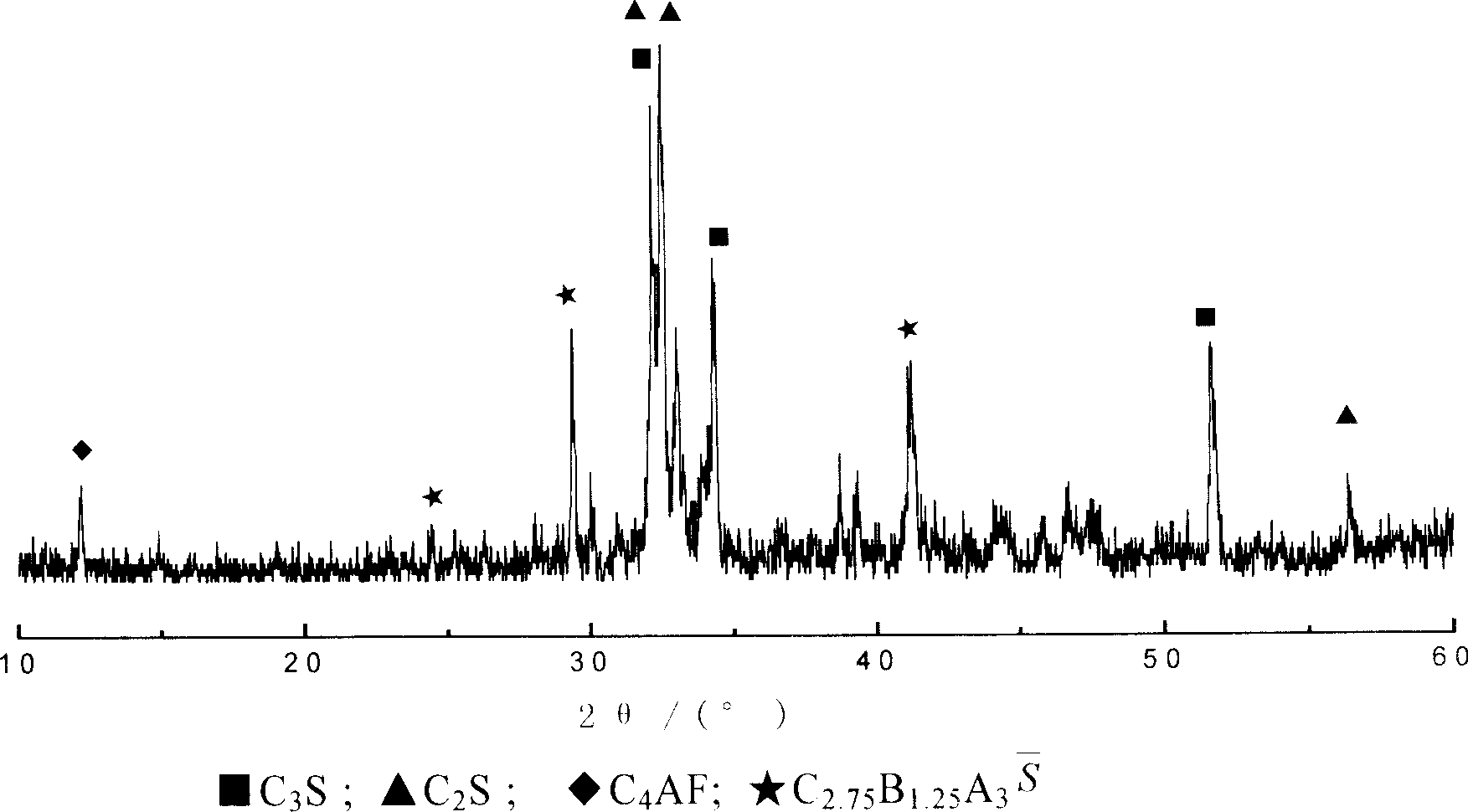

Belite-calcium barium sulphoaluminate cement

InactiveCN1887766ALower firing temperatureReduce dosageCement productionMaceralCalcium aluminoferrite

The present invention belongs to the field of cement material technology, and is especially one kind of Belite-calcium barium sulphoaluminate cement. The cement clinker is mainly one mineral phase system of C2S-CBAS-C3S-C3A-C4AF comprising calcium barium sulphoaluminate 5-45 wt%, dicalcium silicate 30-70 wt%, tricalcium silicate 10-45 wt%, tricalcium aluminate 2-20 wt%, and calcium aluminoferrite 2-20 wt%, where calcium barium sulphoaluminate has the molecular expression of (3-x)CaO .xBaO .3Al2O3 .CaSO4 with x=0.25-3. The present invention has the available of lower firing temperature, utilization of low quality limestone resource, high cement early strength, etc.

Owner:UNIV OF JINAN

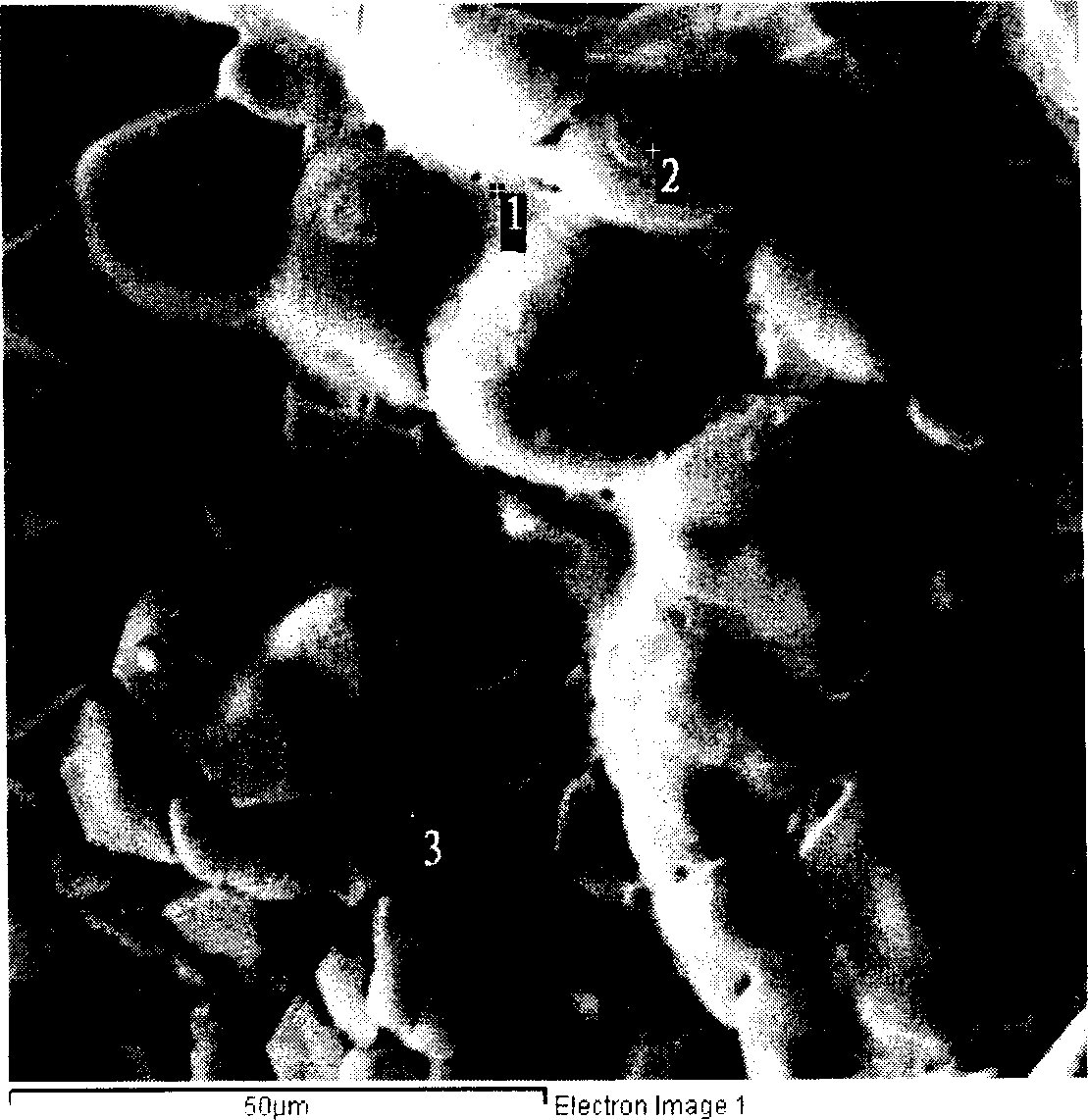

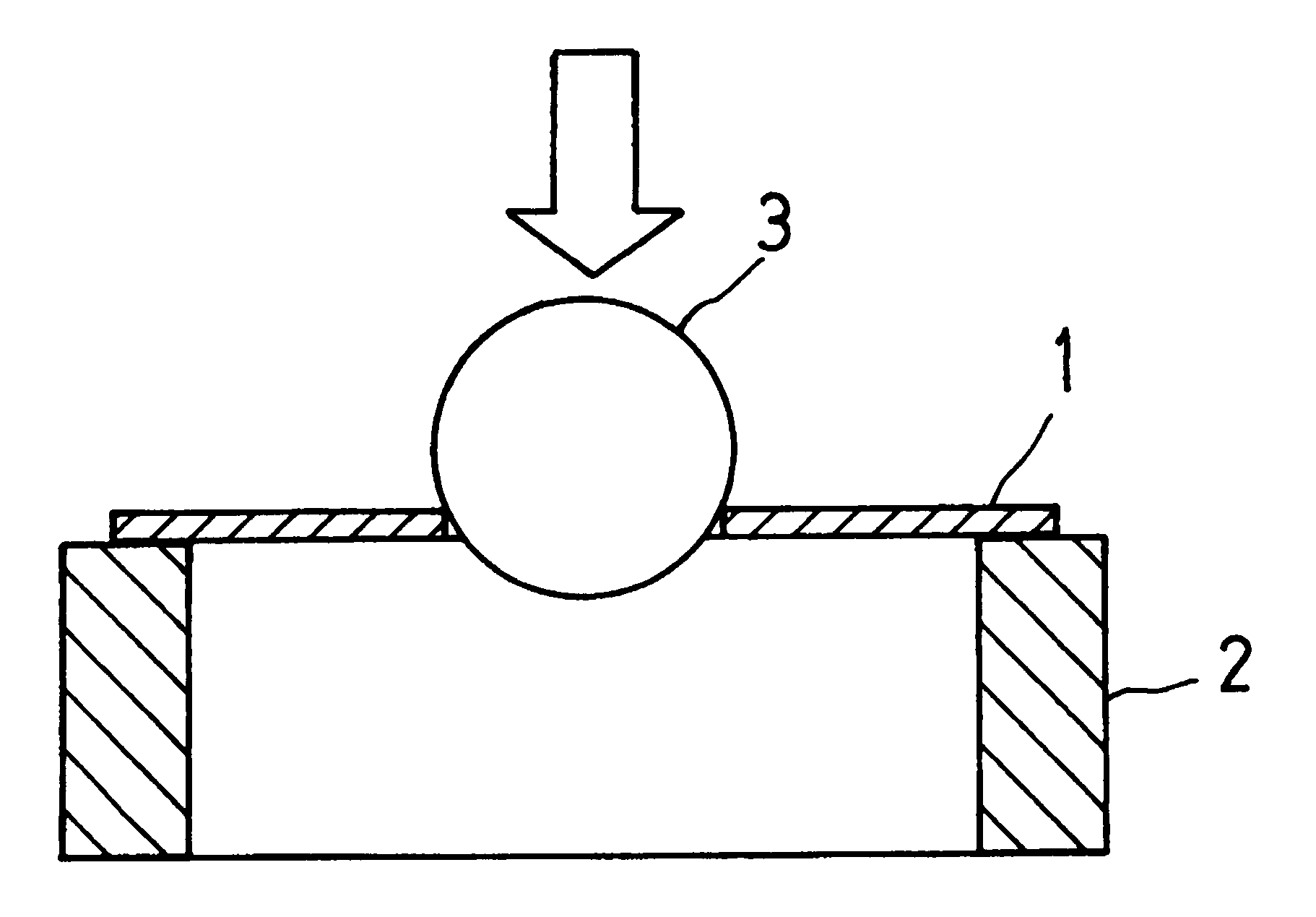

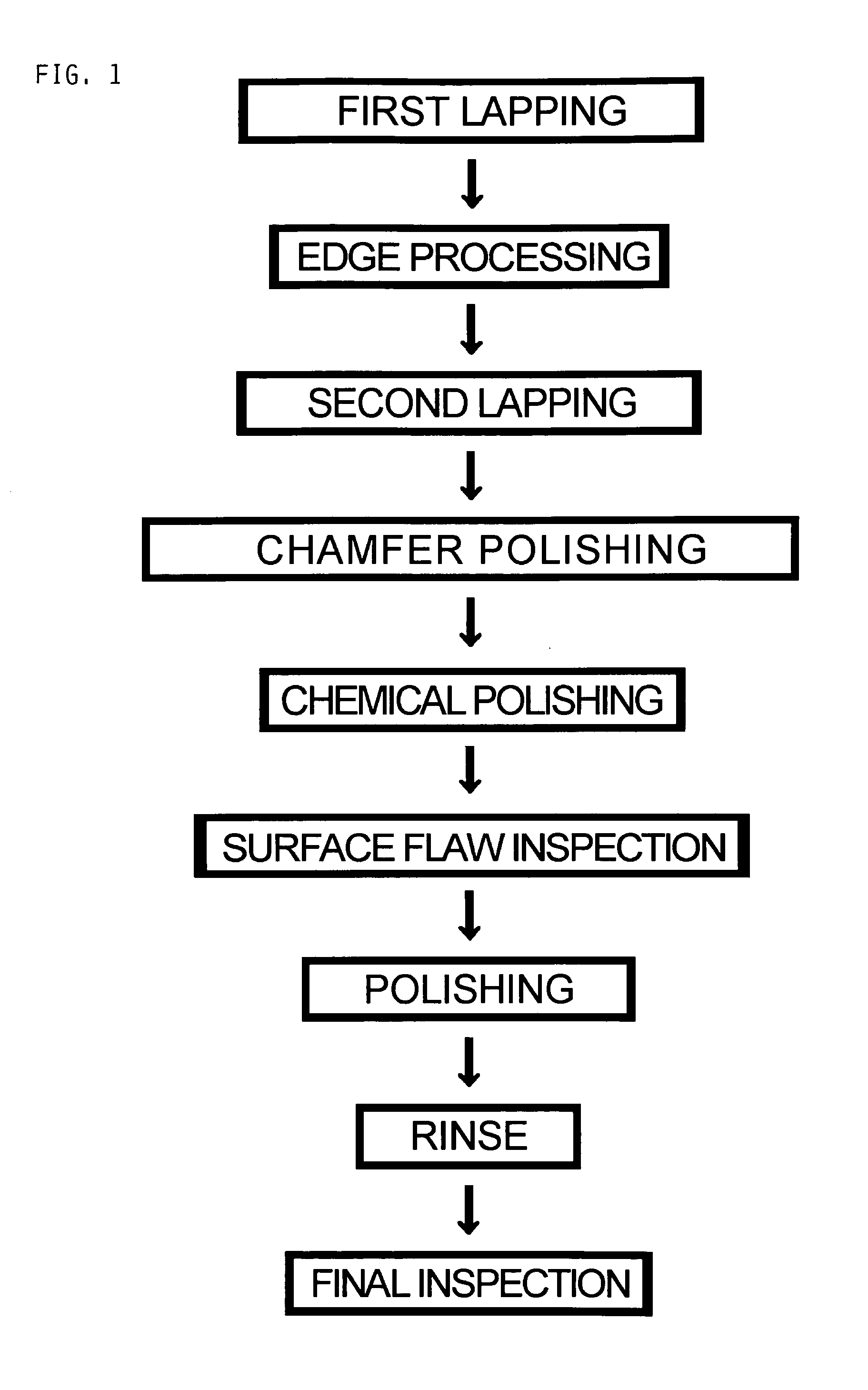

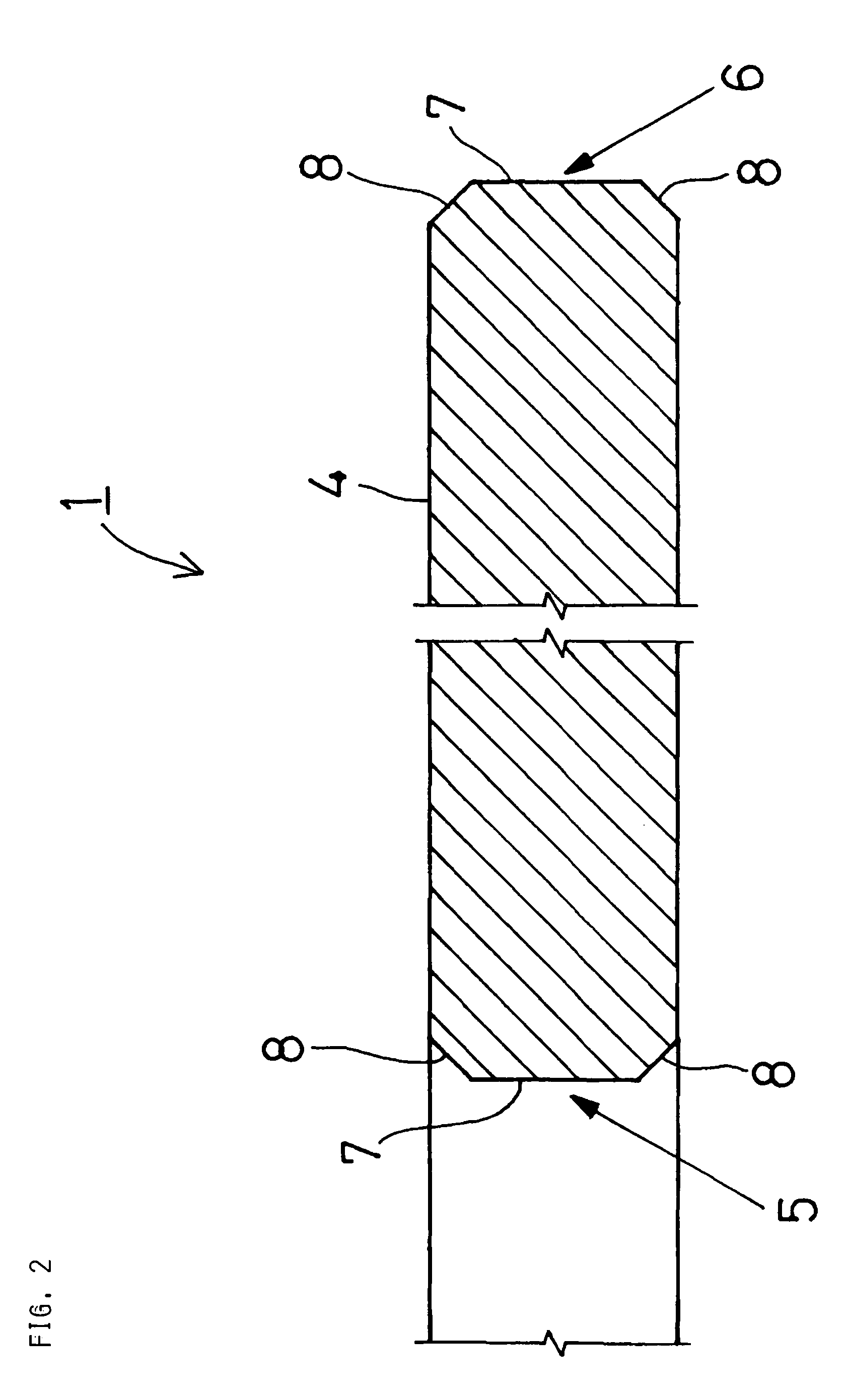

Method of surface-finishing glass substrate for magnetic disks and glass substrate for magnetic disks

InactiveUS20100266874A1Maintain dimensional accuracyMaintain roundnessEdge grinding machinesMagnetic materials for record carriersSurface finishSurface layer

An inner peripheral edge of a toroidal glass substrate for a magnetic disk is subjected to mechanical polishing in such a manner that the surface roughness is no greater than 9 nm in terms of Rmax. Then, the inner peripheral edge is subjected to chemical polishing to remove at least 2 μm of a surface layer. The inner peripheral edge has a non-conventional mirror-finished surface obtained by mechanical polishing. Thus, sufficient ring strength is obtained even when the chemical polishing depth is smaller than in the past. A polishing depth of less than 5 μm is sufficient.

Owner:TOYO KOHAN CO LTD

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

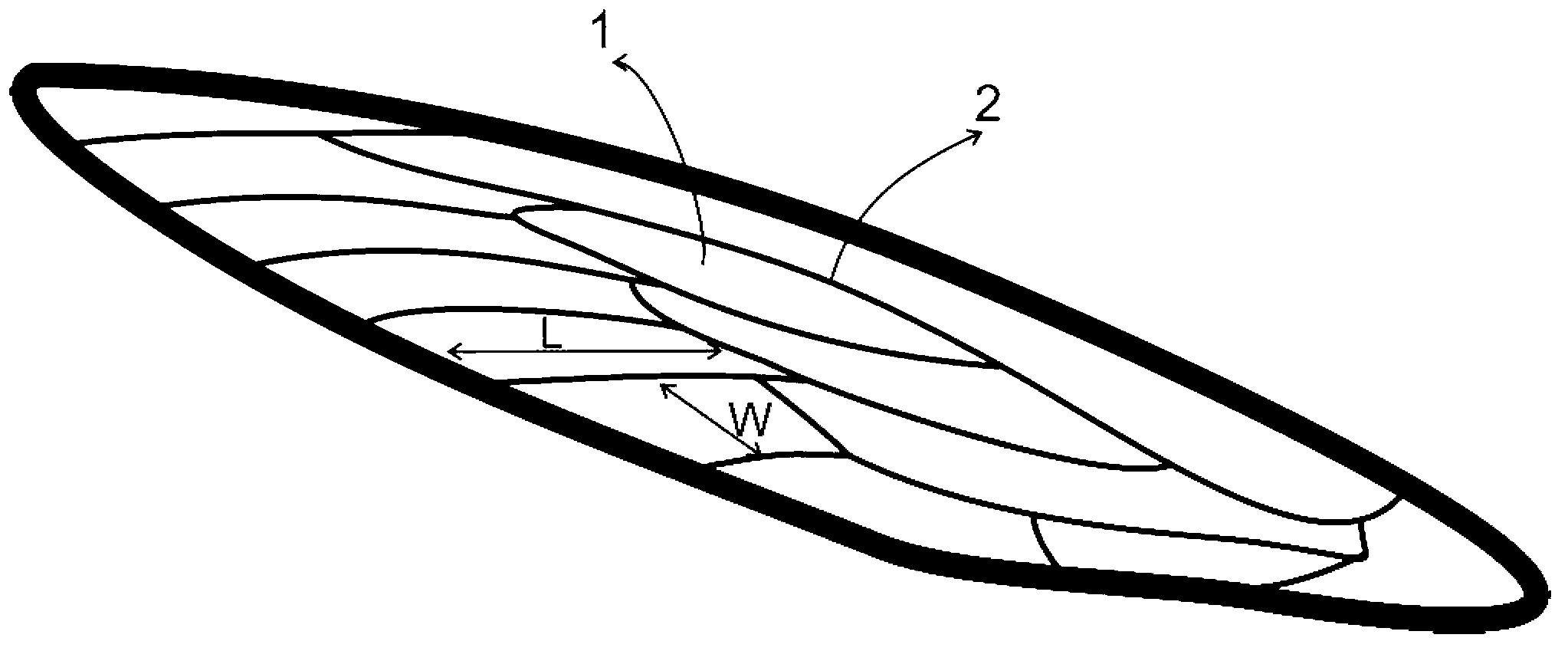

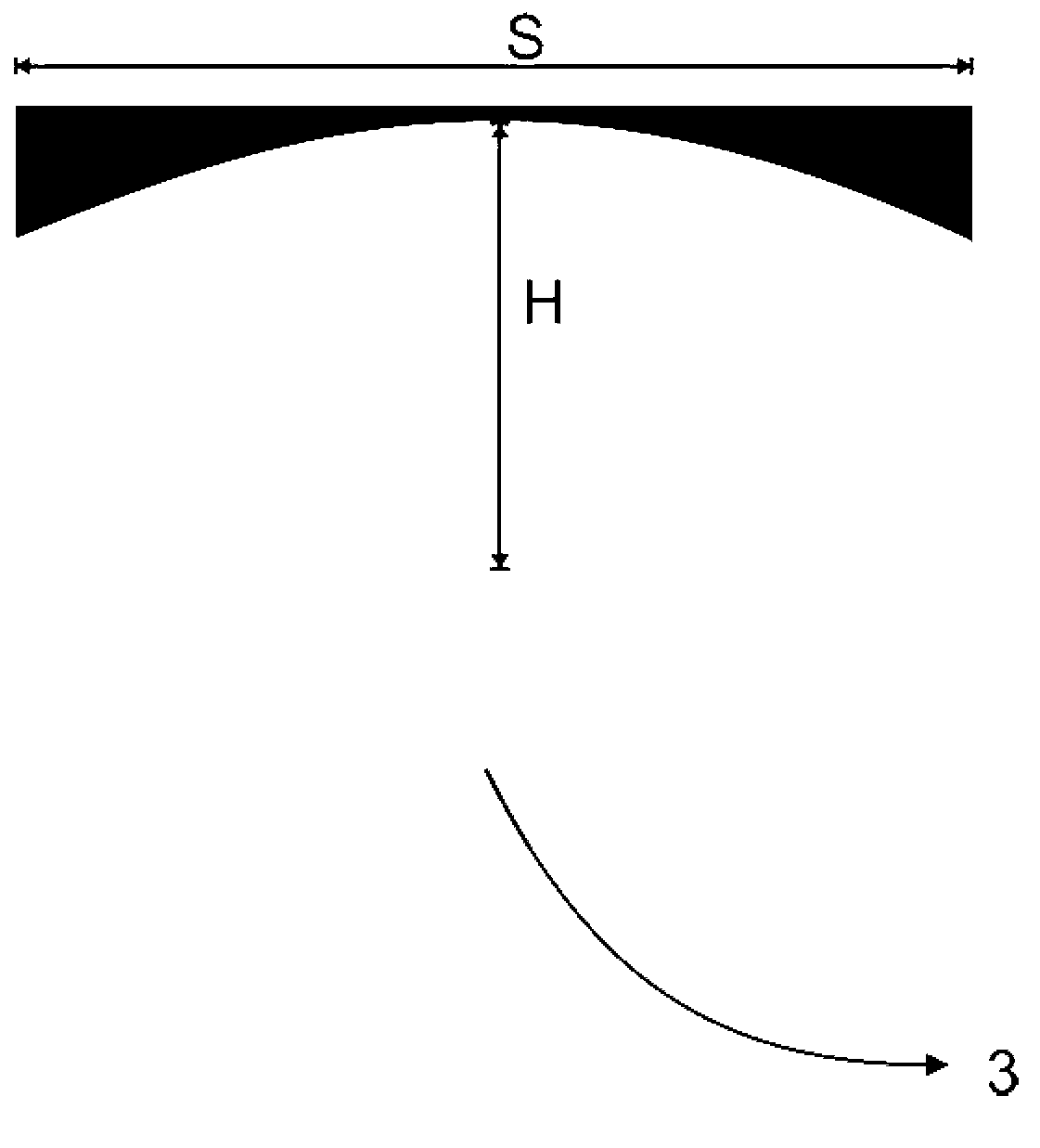

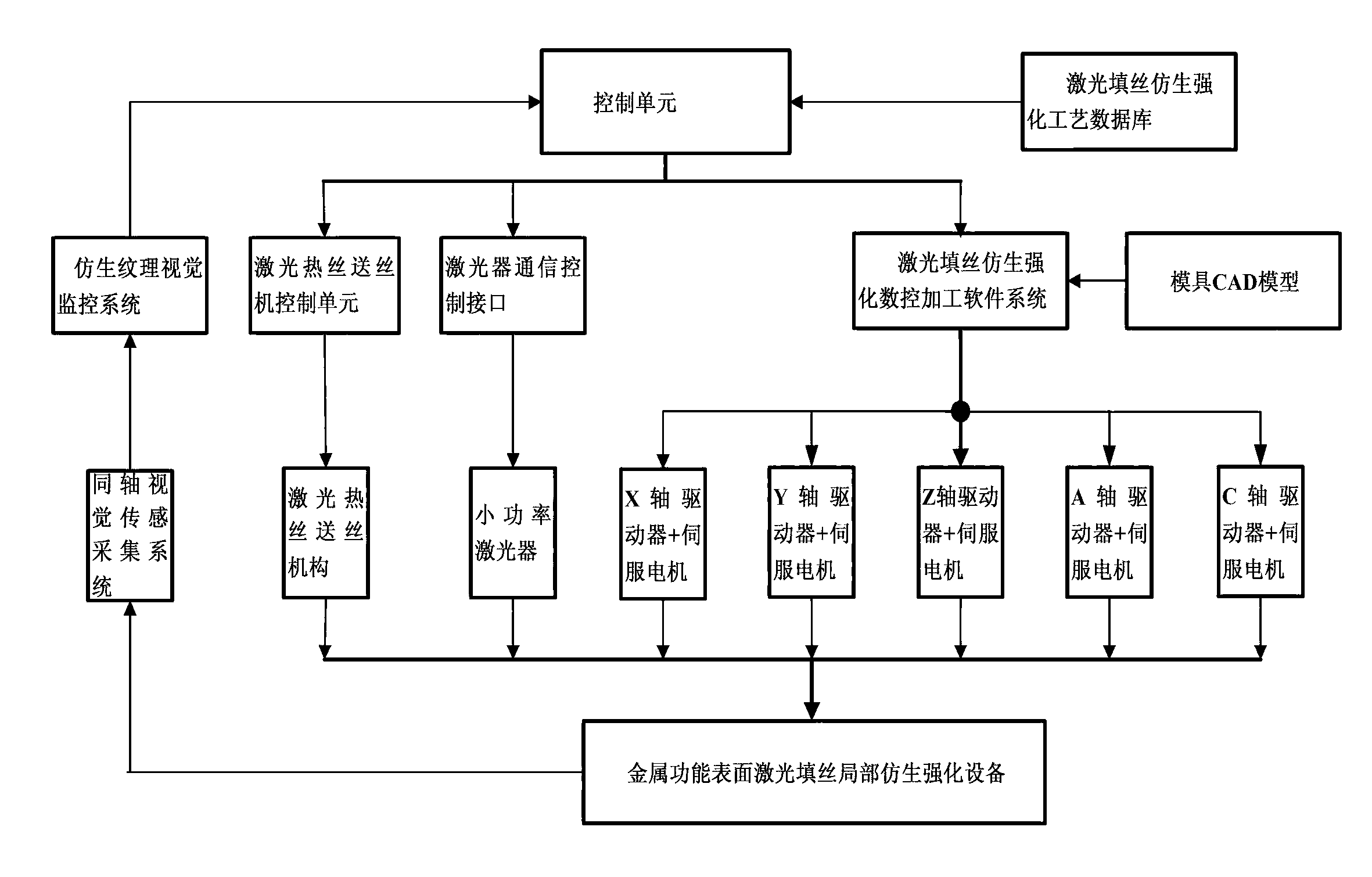

Laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces

InactiveCN103252582AImprove toughnessReduce microcracksLaser beam welding apparatusFive freedomsCost performance

The invention relates to laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces, belongs to the field of processing of metal materials and aims to provide a technical method and a manufacturing device which are capable of effectively improving thermal fatigue resistance and wear resistance on the metal functional surfaces. For different metal base materials, by combining the automatic wire filling technology with the vision sensing and small-power laser technology, a novel method for manufacturing bionic texture on metal functional spatial curved surfaces is provided. In order to implement the mentioned technical method, strengthening equipment composed of a control unit, a vision system, an adjustable temperature heating wire feeding machine, a laser and a five-freedom-degree numerical-control worktable is researched, thermal fatigue resistance and wear resistance of the metal functional surfaces are effectively improved, cost performance is good and production efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

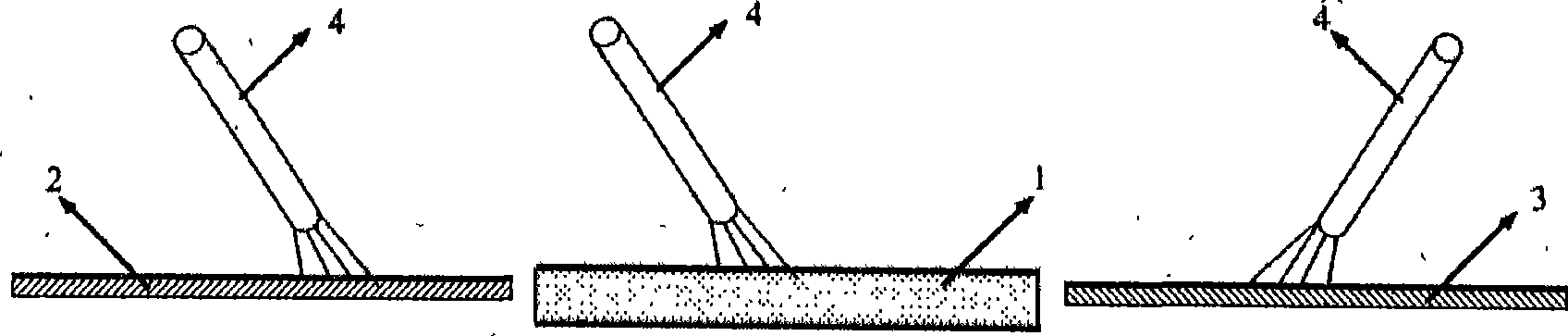

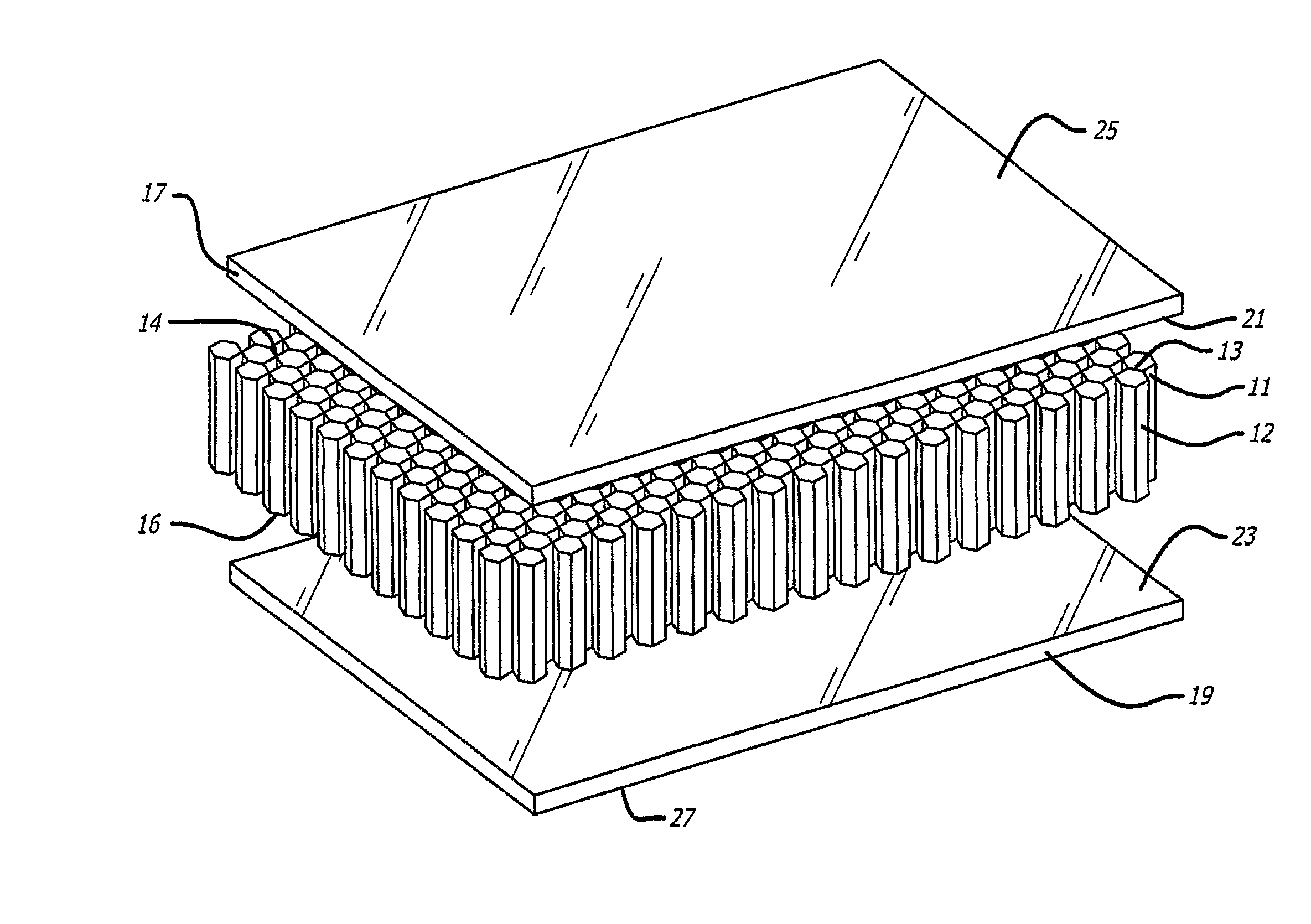

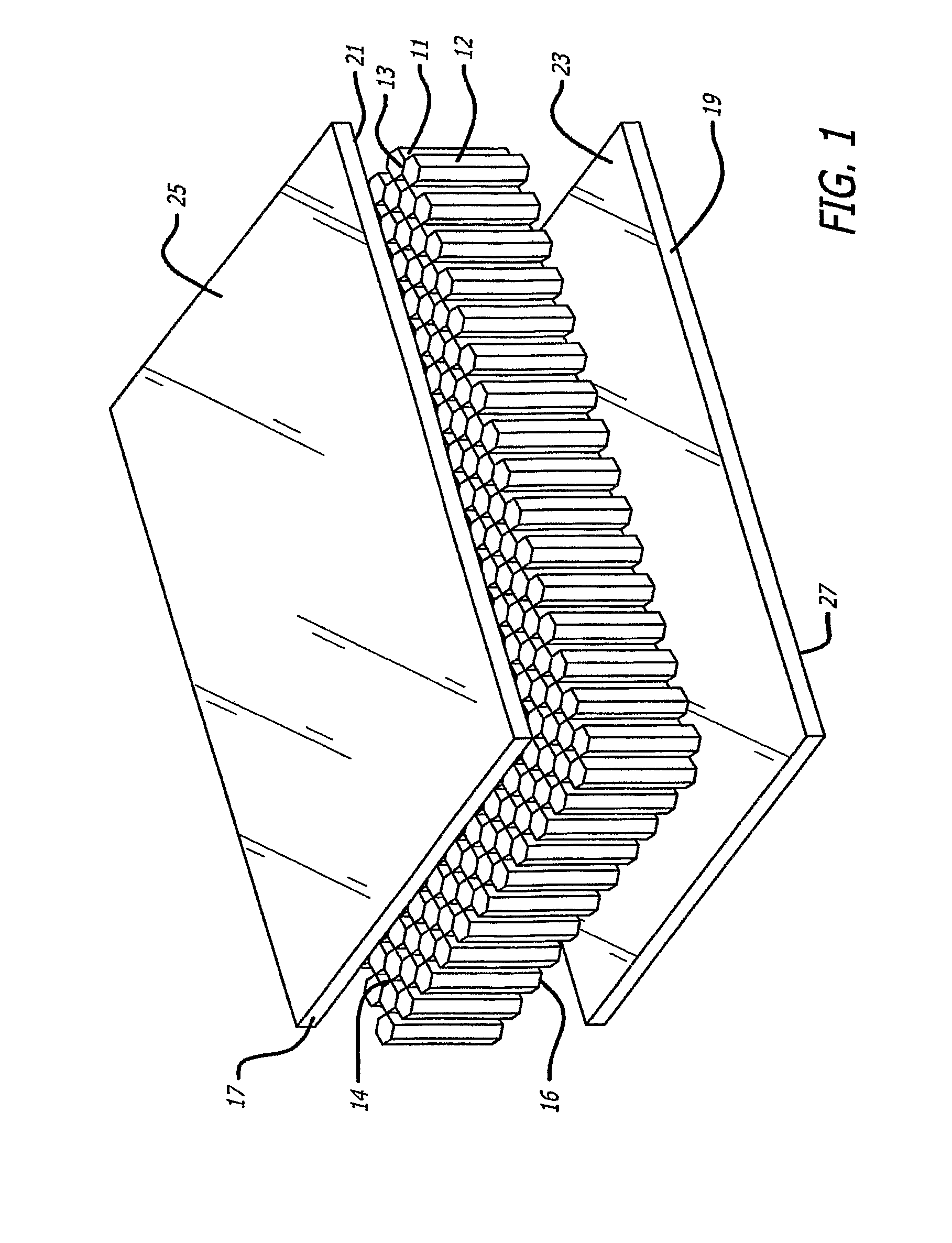

Scraping, vibrating and soldering method for preparing foamed aluminum sandwich structure

InactiveCN101530942AHigh strengthGive full play to the advantages of light weightSoldering apparatusWelding/soldering/cutting articlesSolderingMetal

The invention aims to provide a scraping, vibrating and soldering method for preparing a foamed aluminum sandwich structure, which adopts a wire brush to scrape so that oxide films on the surfaces of aluminum plates and a foamed aluminum plate are broken, pure aluminum surfaces are exposed, and a brazing material can be fully fused into aluminum and can be fully contacted and reacted with an aluminum parent metal to form a good reaction binding layer. The invention achieves the aims as follows: the scraping, vibrating and soldering method for preparing the foamed aluminum sandwich structure comprises the following four steps: cleaning, drying and heating the foamed aluminum plate and two aluminum plates; scraping the brazing material coating surfaces of the aluminum plates by adopting the wire brush; removing the redundant brazing material floating on two surfaces of the aluminum plates and the foamed aluminum plate; and compounding two brazing material coating surfaces of the aluminum plates and the brazing material coating surface of the foamed aluminum plate. The method gives full play to the advantage of foamed aluminum with lightweight, and has special significance in the aerospace field and the like sensitive to weight.

Owner:HARBIN INST OF TECH

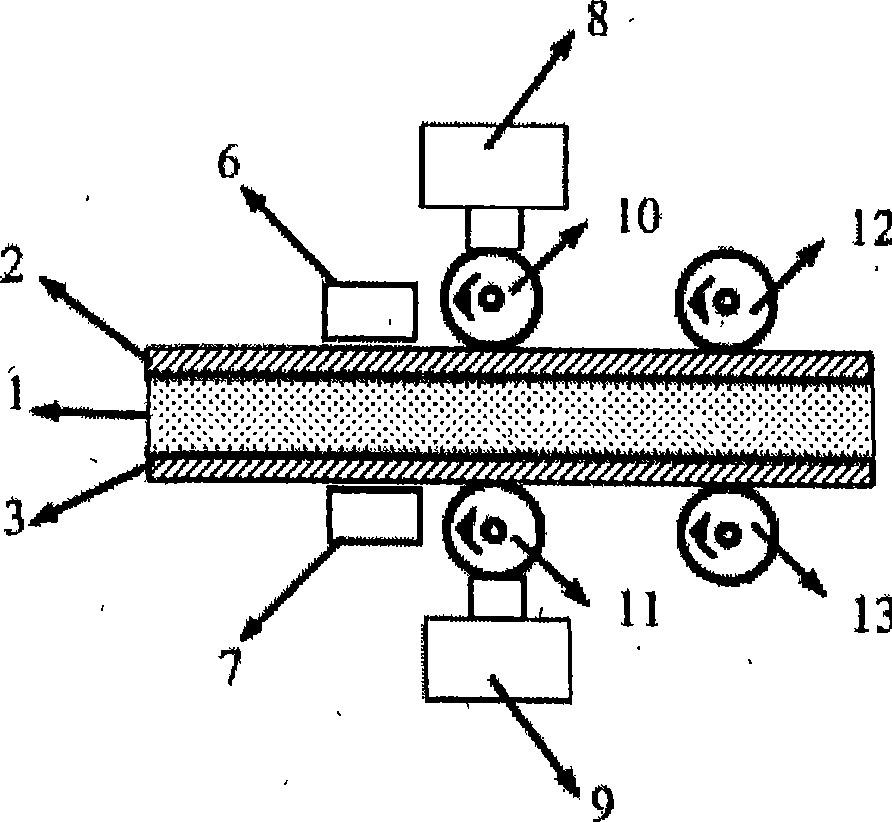

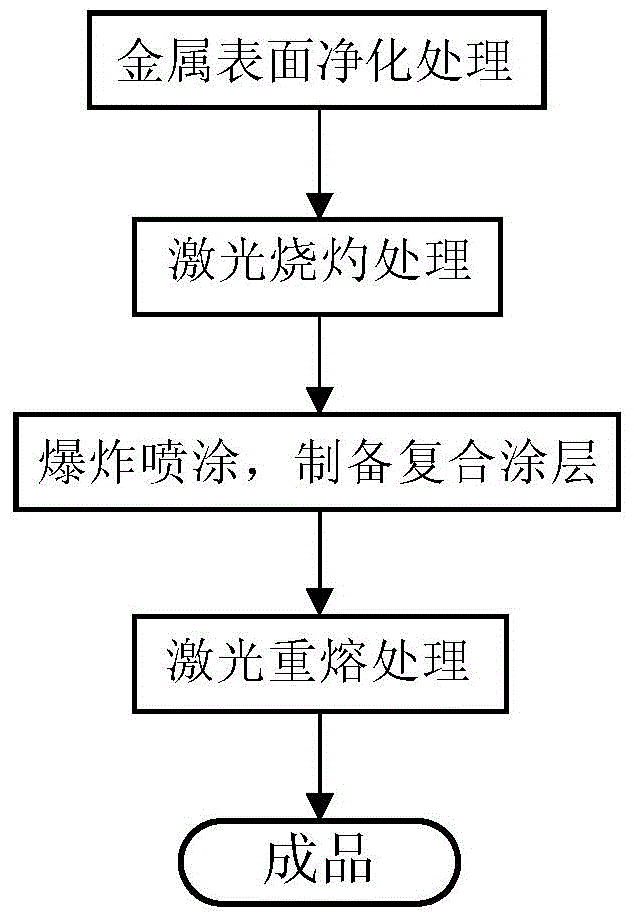

Process for spraying composite coating on metal surface

InactiveCN104789921AReduce porosityImprove microstructureMolten spray coatingWear corrosionLaser burn

The invention discloses a process for spraying a composite coating on a metal surface. The process comprises the following steps: carrying out purification treatment on the metal surface; carrying out laser burning treatment on the metal surface; carrying out explosion spray treatment on the metal surface, and preparing the composite coating; carrying out laser re-melting treatment on the composite coating prepared by an explosion spray process, on the metal surface. According to the combined process for spraying the composite coating on the metal surface, the explosion spray process is compounded with two laser heat treatment processes, so that the binding force of the coating and a matrix can be effectively improved, and the performances of corrosion resistance, wear corrosion and the like of the coating can be further improved.

Owner:上海市机械制造工艺研究所有限公司

Modified cement-based self-leveling mortar and preparation method and application thereof

The invention relates to improved cement-based self-leveling mortar and a preparation method and application thereof. The improved cement-based self-leveling mortar comprises the following components in percentage by weight: 50%-70% of aggregate, 31%-40% of cement, 13%-15% of anhydrite, 5%-15% of ground calcium carbonate, 0.05%-0.3% of water-retaining agent, 0.05%-0.2% of carbonate, 0.4%-0.9% of retarder, 0.3%-0.9% of lignocellulose, 0.2%-0.3% of antifoaming agent, 0.6%-0.9% of water reducer and 1.5%-4.5% of pure acrylic emulsion powder. The invention has the advantages of simple preparation and application methods, good construction peaceability, good waterproofness, greatly reduced microcracks, high mechanical physics property, good self-leveling performance and impact resistance, and excellent flexibility; no cracking and shrinkage occur to constructed ground; and in addition, the invention can effectively solve the problems of complex site operation process, unstable mortar performance, environmental pollution and the like of the existing dual-component cement-based self-leveling mortar, thus the self-leveling mortar is a green building material because no toxic and harmful matter is contained.

Owner:北京天维宝辰化学产品有限公司

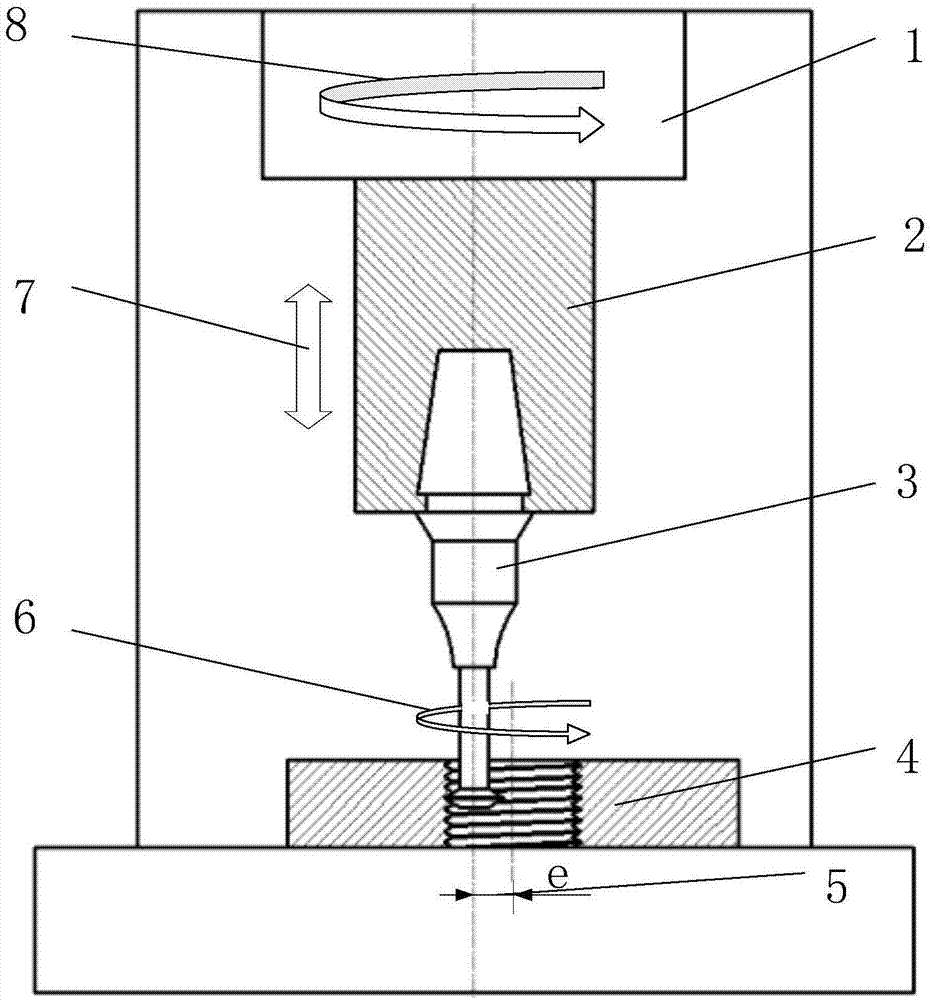

Ultrasonic vibration assisted spiral thread milling and grinding method

InactiveCN107442873AReduce cutting forceImprove use reliabilityThread cutting machinesUltrasonic vibrationCutting force

The invention provides an ultrasonic vibration assisted spiral thread milling and grinding method, and belongs to the technical field of machining and tools. A profiling grinding wheel tool is used in the method, and the tool is mounted on a spindle of an ultrasonic machine tool by an ultrasonic vibration hilt. In the method, the axis of the tool is parallel to the center of the axis of a threaded hole, and a spiral milling mode which is formed by compounding four movements including rotation of the grinding wheel tool, revelation of the profiling grinding wheel tool around the axis of the threaded hole, axial feeding of the profiling grinding wheel tool and axial vibration of the profiling grinding wheel tool along with the ultrasonic vibration hilt is adopted. By the method, a cutting force of hard and crisp materials difficult to machine in a thread machining process can be reduced effectively, the circumstance that a screw tap is broken in a tapping process due to insufficient strength to cause scrapping of parts is avoided, the thread machining quality and machining efficiency are improved, and abrasion of the tool is improved.

Owner:TSINGHUA UNIV

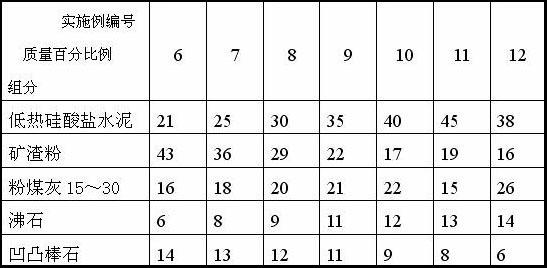

High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

InactiveCN102169737AStrong adsorption capacityIncrease retention capacityRadioactive decontaminationSlagCoal

The invention discloses a high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body which is composed by mixing the following components: high-salt high-alkali medium-low-level radioactive liquid waste and, solidification material, water glass and cellulose ether, wherein the high-salt high-alkali medium-low-level radioactive liquid waste to the solidification material is 0.55-0.75: 1 in mass proportion; the modulus of the water glass is 2.5-3.5 based on Na2O in the water glass and the mass of the solidification material is 1-3% of the mass of the water glass ; the mass of the solidification material is 0.05-0.5% of the mass of the cellulose ether; the component mass percent of the solidification material is as follows: 20-40% of low-heat Portland cement, 15-50% of slag powder, 15-30% of coal ash, 5-15% of zeolite and 5-15% of attapulgite; and the cement solidification body with various properties meeting the requirements is obtained by carrying out normal-temperature maintenance on the mixed slurry which obtained by mixing and stirring. The high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body is suitable for the solidification of the medium-low-level radioactive liquid waste, which has the total salt concentration being 100-400g / L, the pH value being larger than 13 and the nuclide being 90Sr or / and 137 Cs.

Owner:SOUTHWEAT UNIV OF SCI & TECH

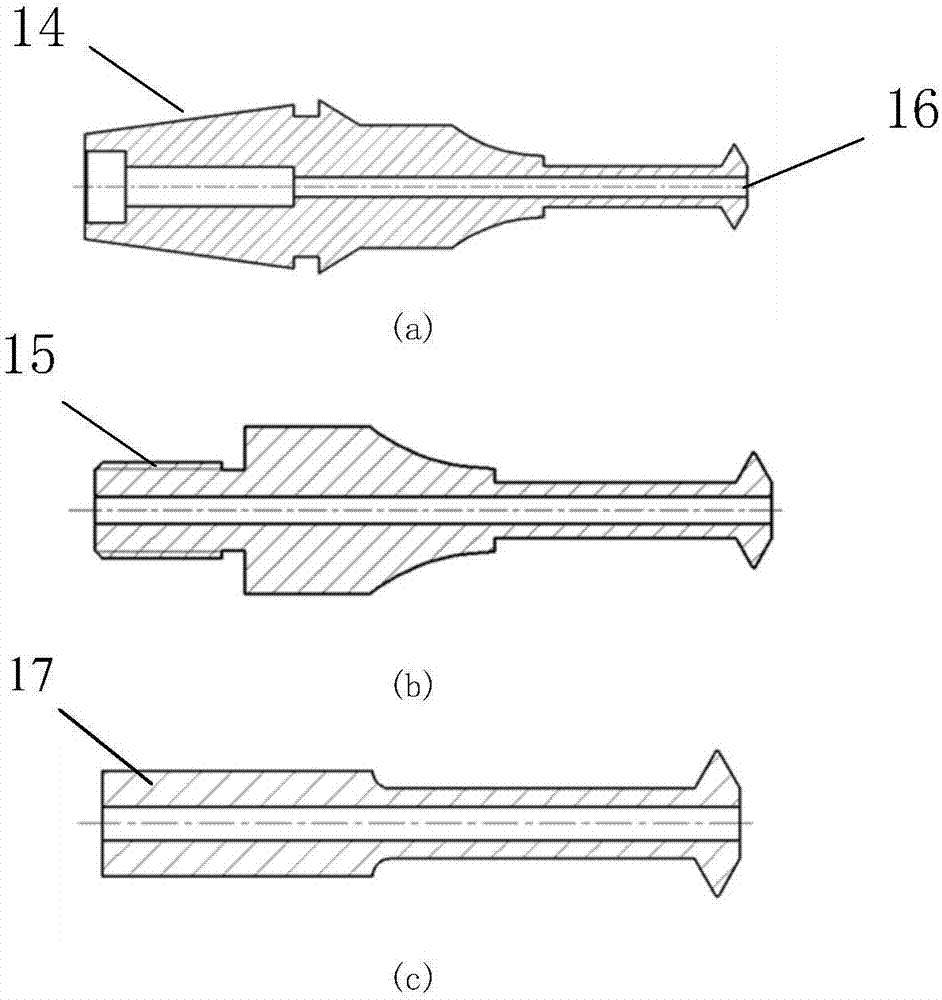

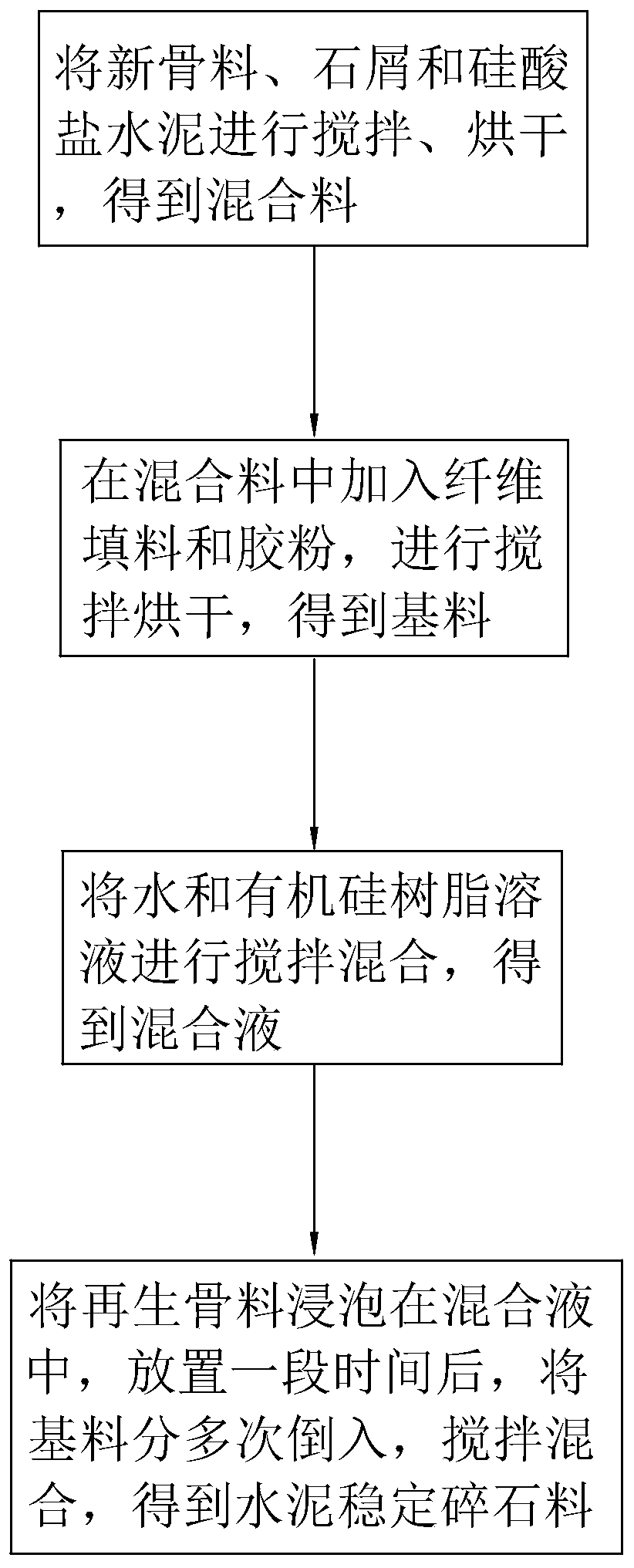

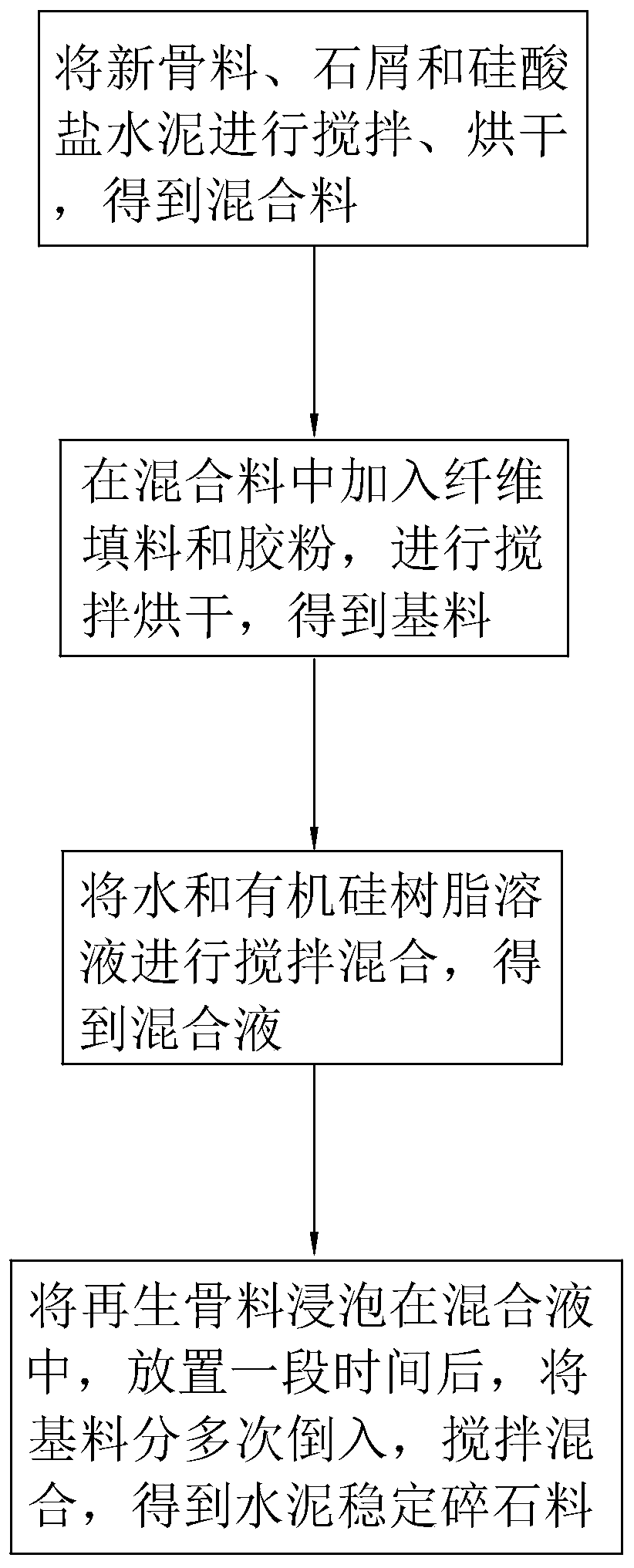

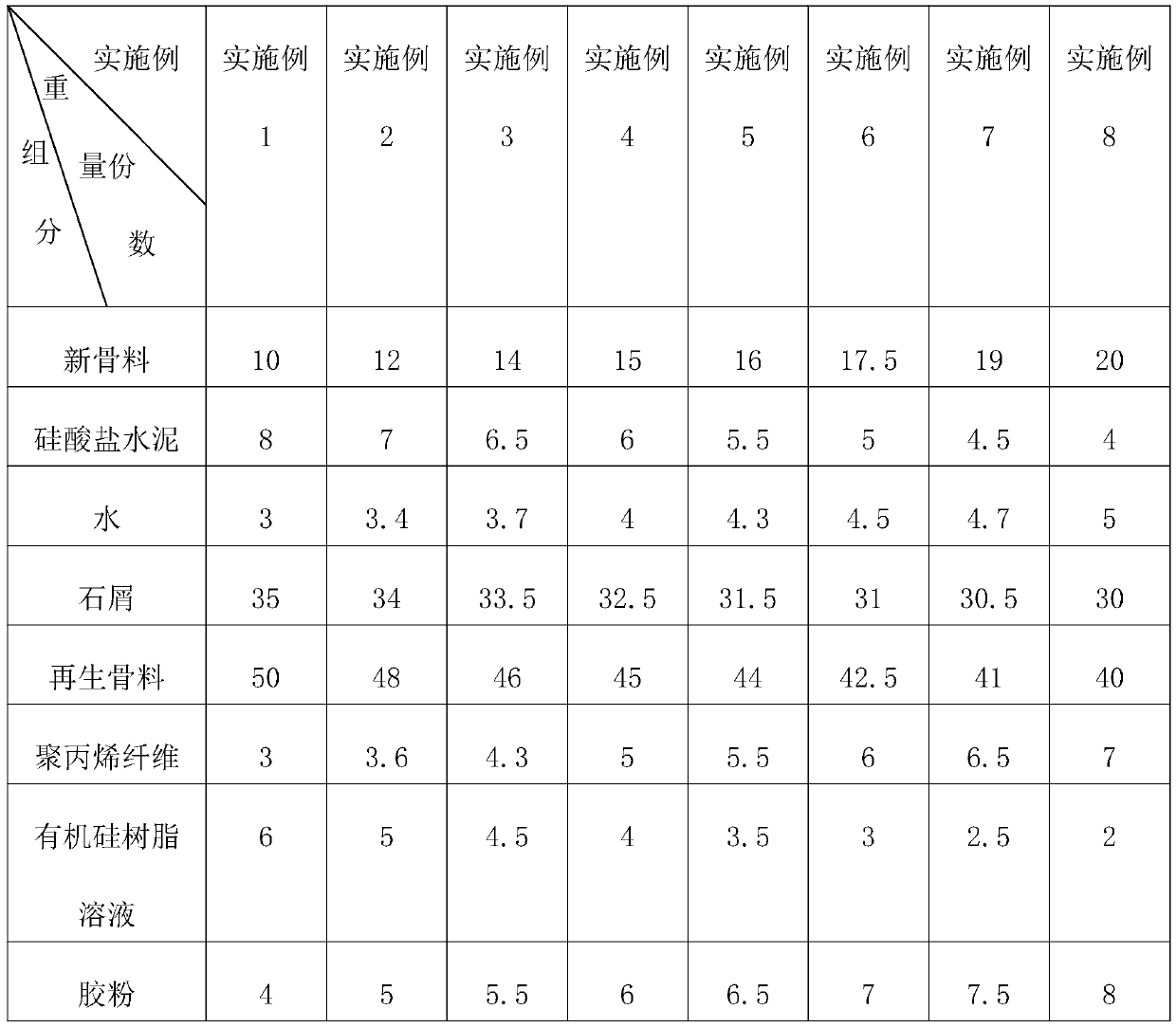

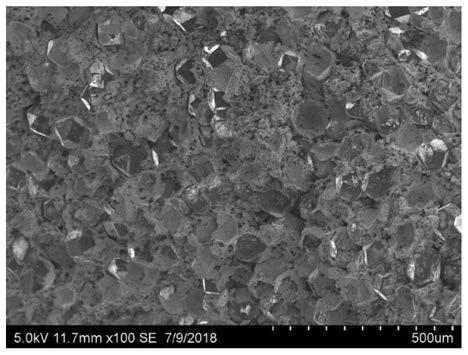

Cement stabilized macadam material and preparation process thereof

The invention discloses a cement stabilized macadam material and a preparation process thereof, relates to the technical field of roadbed materials, and solves the problem that the overall quality ofcement stabilized macadam is greatly reduced due to direct mixing of cement and recycled aggregates with voids and microcracks. The cement stabilized macadam material is prepared from the following components in parts by weight: 10-20 parts of new aggregate, 4-8 parts of silicate cement, 3-5 parts of water, 30-35 parts of aggregate chips, 40-50 parts of recycled aggregate, 3-7 parts of fiber filler, 2-6 parts of an organic silicon resin solution and 4-8 parts of rubber powder. The cement stabilized macadam material is mainly prepared from the recycled aggregate, is green and environmentally friendly, has good structural strength integrally after use, is less likely to produce dry shrinkage cracks during use and has good quality.

Owner:上海家根路基材料有限公司

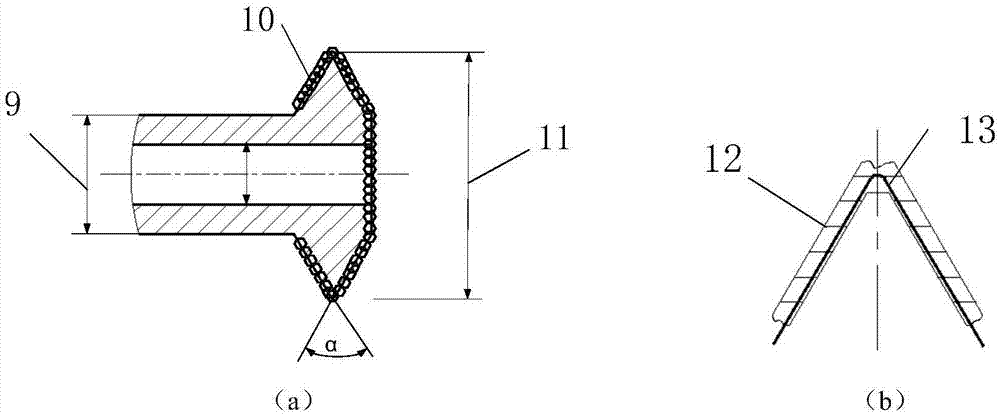

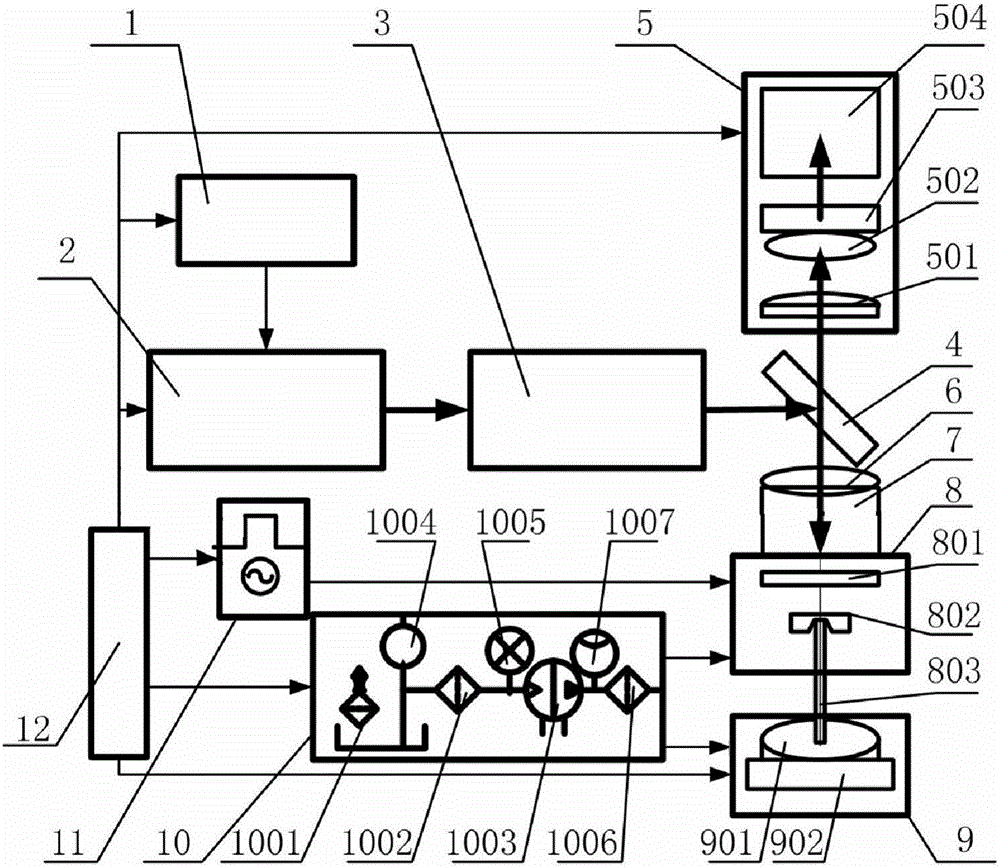

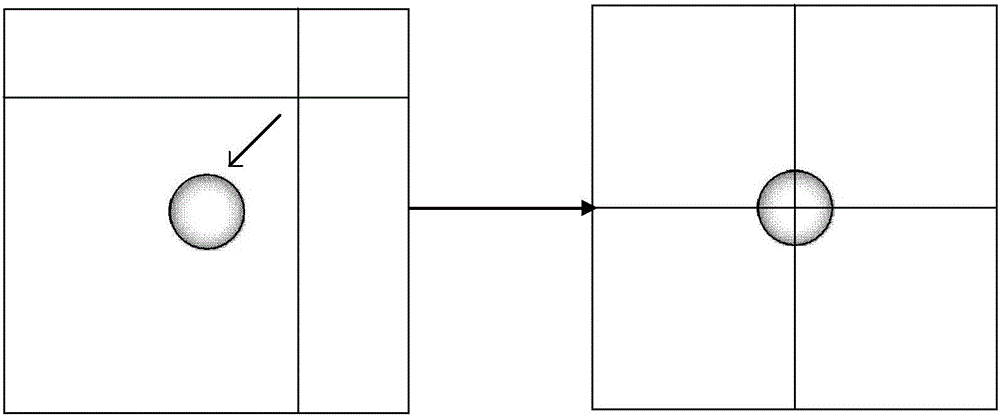

Micro-nano machining method and device for laser composite ejection liquid beam

InactiveCN105880849AIncrease instantaneous powerReduce microcracksNanotechnologyLaser beam welding apparatusMicro nanoControl system

The invention discloses a micro-nano machining method and a micro-nano machining device for a laser composite ejection liquid beam, and belongs to the technical field of micro-nano processing techniques. The micro-nano machining device comprises a laser pulse sequence regulator (1), a laser system (2), a laser beam adjusting system (3), a visible light transmission reflector (4), a laser beam and ejection liquid beam coaxial observation regulation system (5), a focusing lens (6), a regulating and control device (7), an ejection device (8), a micro-nano working table (9), an ejection liquid filtering circulation system (10), a laser power supply (11) and an overall control system power supply (12). The micro-nano machining method comprises a step of implementing micro-nano machining on a workpiece by taking laser beams generated from the laser system (2) and ejection liquid beams generated from the ejection device (8). The micro-nano machining method and the micro-nano machining device are applicable to machining of engine blade film holes.

Owner:HARBIN INST OF TECH

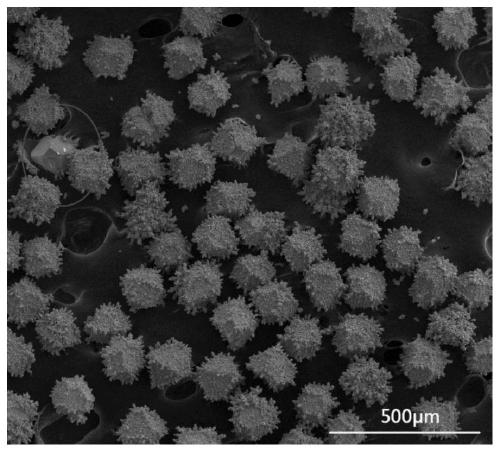

Tungsten-plated diamond particle, tungsten plating method, application of tungsten-plated diamond particle used as copper-based reinforced phase, and obtained diamond/copper composite material

ActiveCN110438444AHigh surface energyPromote infiltrationTransportation and packagingMetal-working apparatusUltrasonic vibrationCopper

The invention discloses a tungsten-plated diamond particle, a tungsten plating method, application of the tungsten-plated diamond particle used as a copper-based reinforced phase, and an obtained diamond / copper composite material, and belongs to the field of composite materials. According to the tungsten plating method of the diamond particle provided by the invention, an ultrasonic vibration manner is adopted, diamond particles continuously keep at a vibration state in the plating process, and meanwhile, the plating speed is controlled, so that each surface of the particles are uniformly plated. According to the tungsten-plated diamond particle obtained by utilizing the tungsten plating method provided by the invention, the bonding between plating layers and the surfaces of the diamond particles is perfect, the compactness is high, the problem that the plating layers are easy to fall off in the prior art is solved, and the interface resistance between the diamond particles and a matrix can be greatly reduced.

Owner:XI AN JIAOTONG UNIV

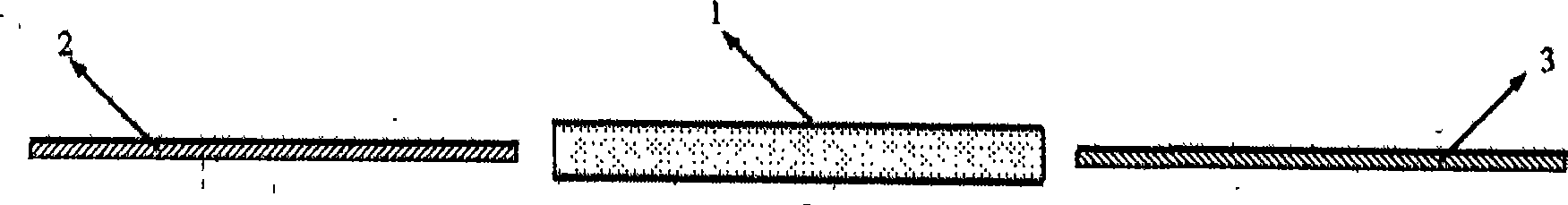

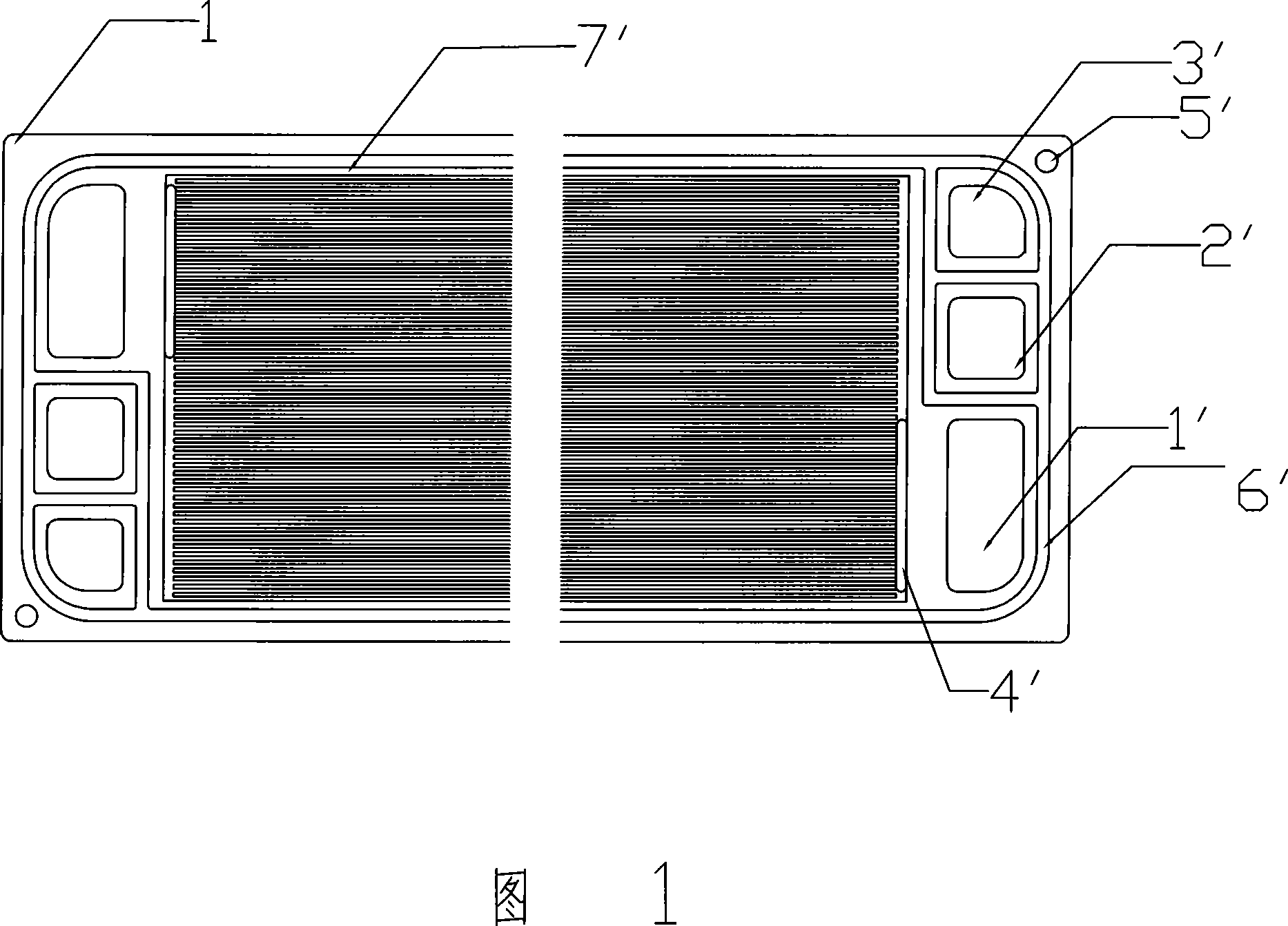

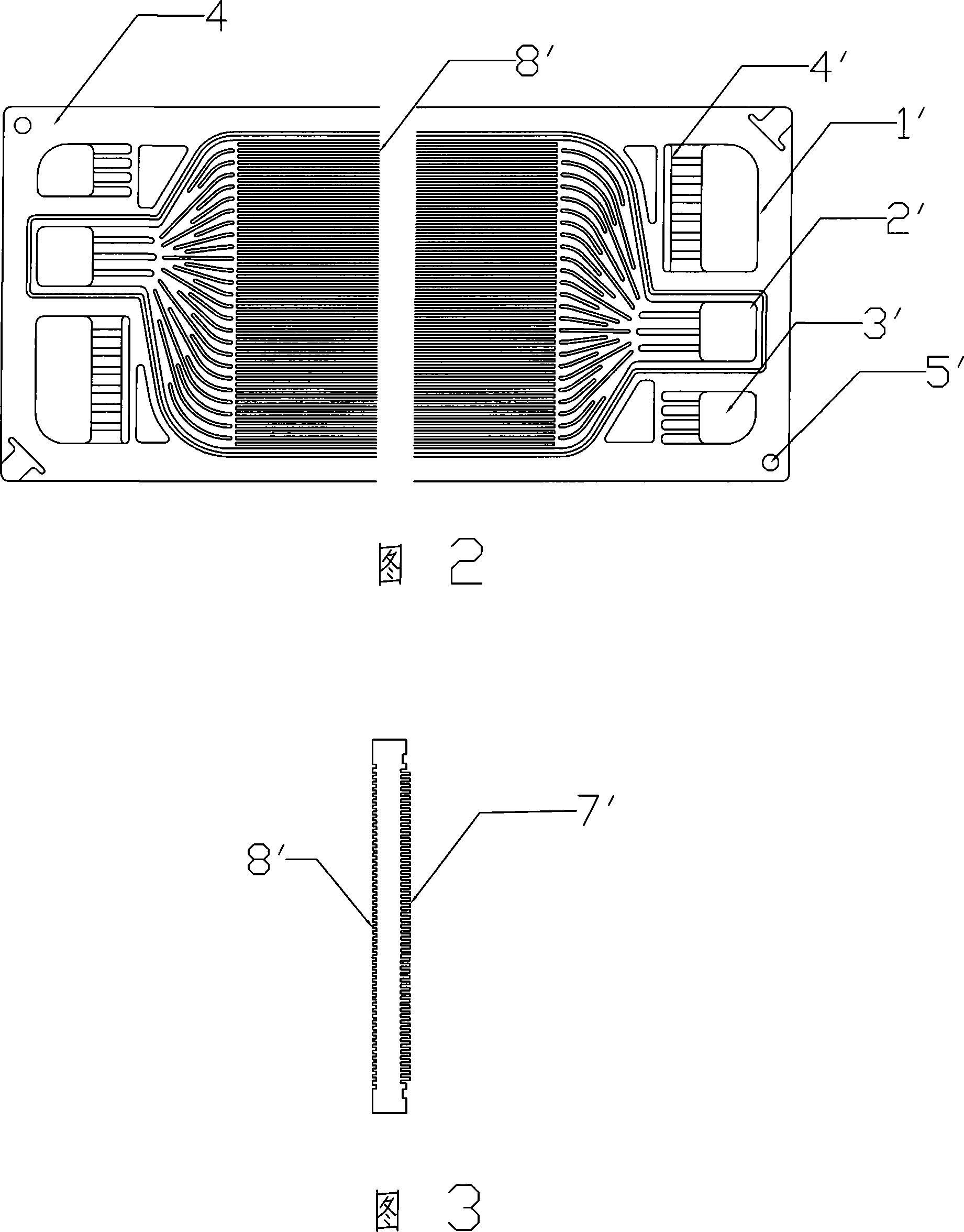

Production method for flexible graphite polar plate with plough groove on both faces

The invention relates to a manufacturing method for a flexible graphite pole plate both surfaces of which are provided with grooves, comprising the following steps: firstly, expandable graphite raw materials are rolled or extruded into a low density graphite plate with thickness of 1.5 to 8 millimeters and density of 0.15 to 0.5 gram per cubic centimeter; secondly, the low density graphite plate is infused into a low viscosity resin solution until grain in weight of resins is 15 to 50 percent of weight of the low density plate; the low density graphite plate is dried after being taken out and solvent in an infused plate is removed, and then a drying plate is obtained; thirdly, the drying plate is extruded into the pole plate both surfaces of which are provided with the grooves; fourthly, the pole plate both surfaces of which are provided with the grooves is solidified. The invention is characterized in that: the step in which the drying plate is extruded into the pole plate both surfaces of which are provided with the grooves is that the dried low density graphite plate after infusion in the low viscosity resin solution is extruded into the pole plate both surfaces of which are provided with the grooves under the condition of vacuum. The invention has the advantages that: thickness of the flexible graphite double pole plate is reduced; isotropy degree of particle orientation of the expandable graphite materials is improved; longitudinal resistivity of the expandable graphite plate materials is reduced.

Owner:SUNRISE POWER CO LTD

Thermosetting resin adhesive containing irradiated thermoplastic toughening agent

InactiveUS20120282434A1Lower Level RequirementsReduction in solvent-induced micro crack formationPretreated surfacesCoatingsHigh energyGamma ray

Thermosetting resins are provided that are toughened with an irradiated thermoplastic toughening agent. The resins have reduced levels of solvent-induced micro crack formation and do not lose their adhesiveness when attacked by solvent. The thermoplastic toughening agent is treated with a sufficient amount of high-energy radiation (e.g. electron beam or gamma rays) to cause reductions in solvent-induced micro crack formation and solvent-induced loss of adhesiveness when compared to the same toughened thermosetting resin in which a non-irradiated version of the thermoplastic toughening agent is used.

Owner:HEXCEL COMPOSITES LTD (GB)

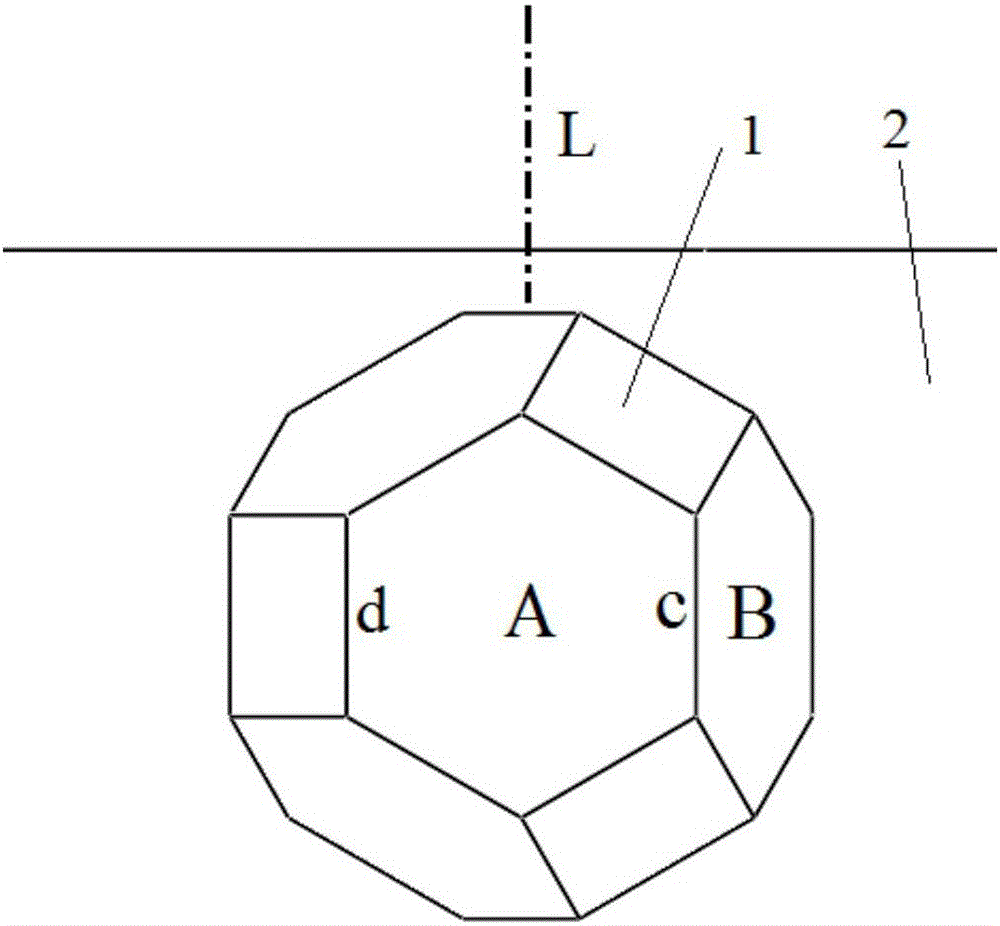

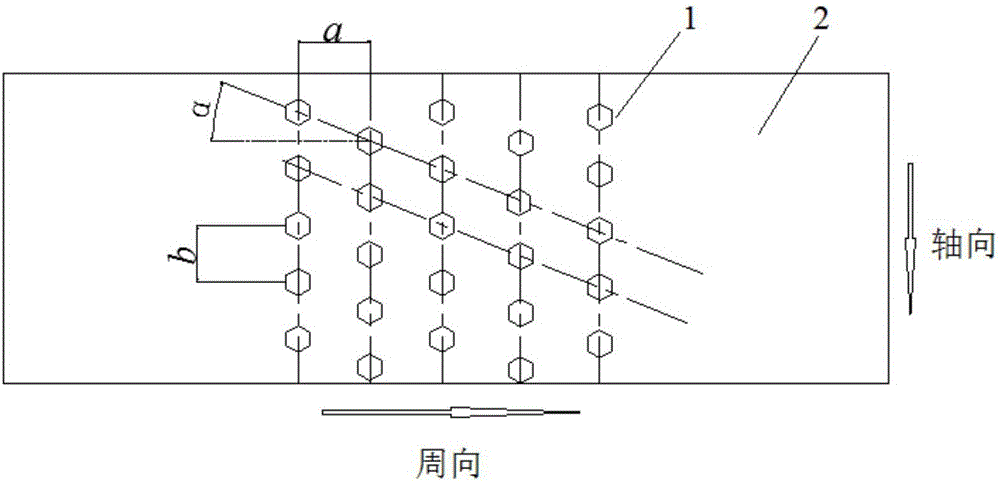

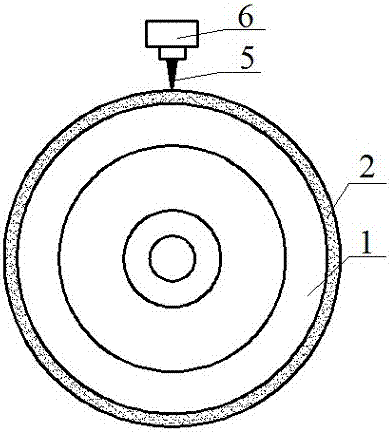

Pulse laser processing-based novel positive rake diamond abrasive tool manufacturing method

ActiveCN105728961AReduce microcracksReduce residual stressGrinding devicesWelding apparatusLaser processingPhase change

The invention relates to a pulse laser processing-based novel positive rake diamond abrasive tool manufacturing method, being characterized in that a diamond grinding wheel with orderly-arranged abrasive particles is eroded by pulse laser, so that a vertex angle of the diamond abrasive particles is changed from being greater than 90 degrees to being smaller than 90 degrees, thus a traditional negative rake grinding method of a diamond abrasive tool is changed, and the abrasive particles taking part in the grinding are changed into a positive rake machining mode during grinding. Compared with traditional grinding (namely negative rake grinding), when the positive rake diamond grinding wheel is used for grinding, three processes of scratching, plowing and cutting are not needed, cutting is directly performed, and the traditional grinding machining mode is changed. When the diamond grinding wheel performs positive rake grinding on a hard and brittle material, normal grinding force is less than tangential grinding force, and the normal grinding force and the tangential grinding force during positive rake grinding are both less than those during negative rake grinding, so that surface / subsurface damages, such as microcracks, residual stress, phase change, dislocation and ripple, of the hard and brittle material subjected to grinding are effectively reduced, and the surface completeness of the material can be greatly improved.

Owner:HUNAN UNIV

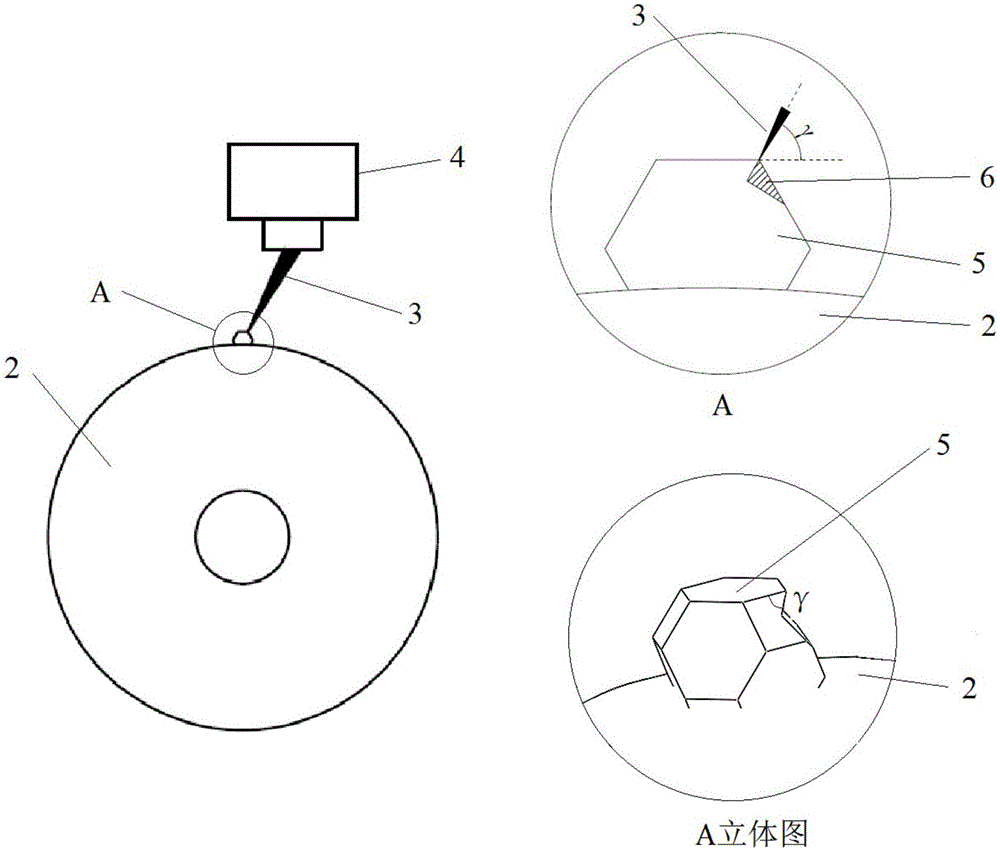

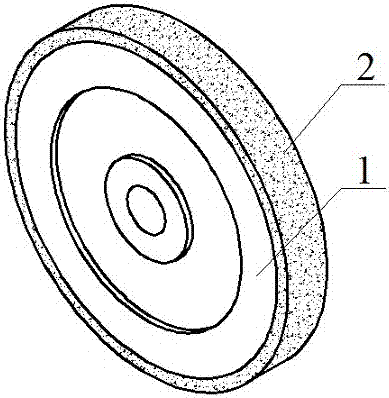

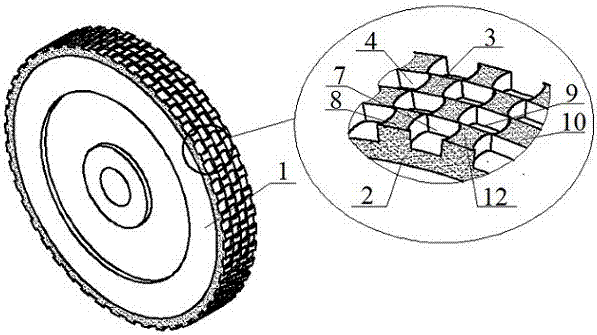

CVD diamond grinding wheel with ordered micro-structured surface and making method thereof

ActiveCN107962510AIncrease the number of effective sharpeningImprove surface qualityBonded abrasive wheelsGrinding devicesMaterial removalGas phase

The invention discloses a CVD diamond grinding wheel with an ordered micro-structured surface and a making method thereof. The grinding wheel is characterized in that a layer of diamond film is deposited on the outer circumferential face of a grinding wheel hub, a large number of staggered in-order micro grinding units are machined on the whole outer circumferential face of the diamond film, and the top ends of the grinding units are in kidney shapes. The making method is characterized in that through the chemical vapor deposition that is CVD, the diamond film is deposited on the outer circumference face of the grinding wheel hub, a pulse laser beam is adopted to machine the large number of micro grooves with the same geometric dimensioning in the outer circumference face of the whole diamond film, and the large number of micro grinding units are formed; the grinding units are arranged in a staggered and in-order manner, the top face of each grinding unit is in a kidney shape, according to the grinding wheel, the effective sharpening number of the grinding wheel during grinding can be improved, the chip formation efficiency and the surface material removal rate are improved, the cutting performance is improved, the surface machining quality and the cutting efficiency can be improved, the holding force of the grinding wheel hub to the grinding units can be increased, and the service life of the grinding wheel can be obviously prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

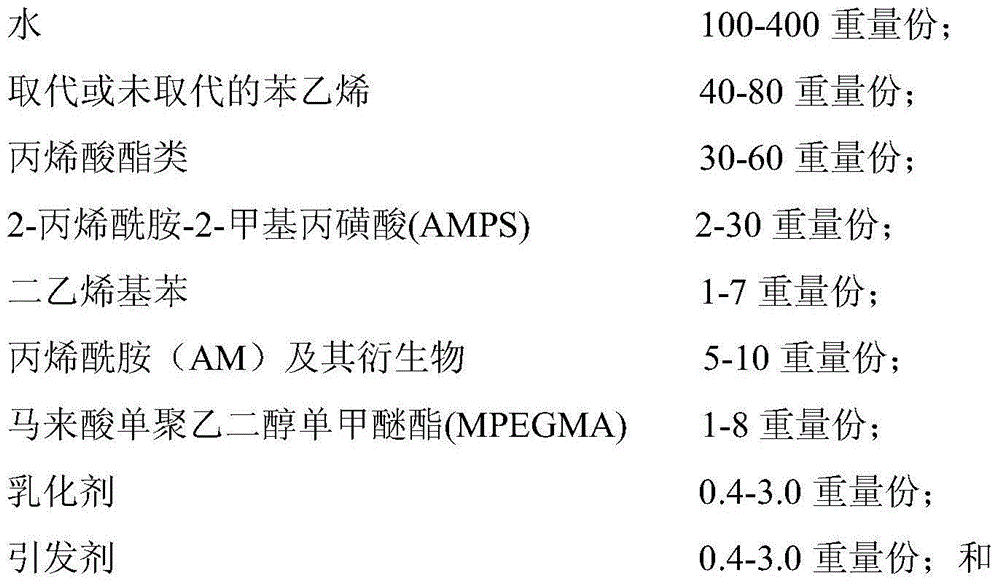

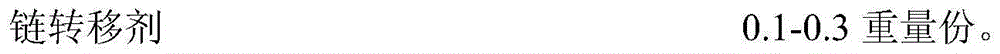

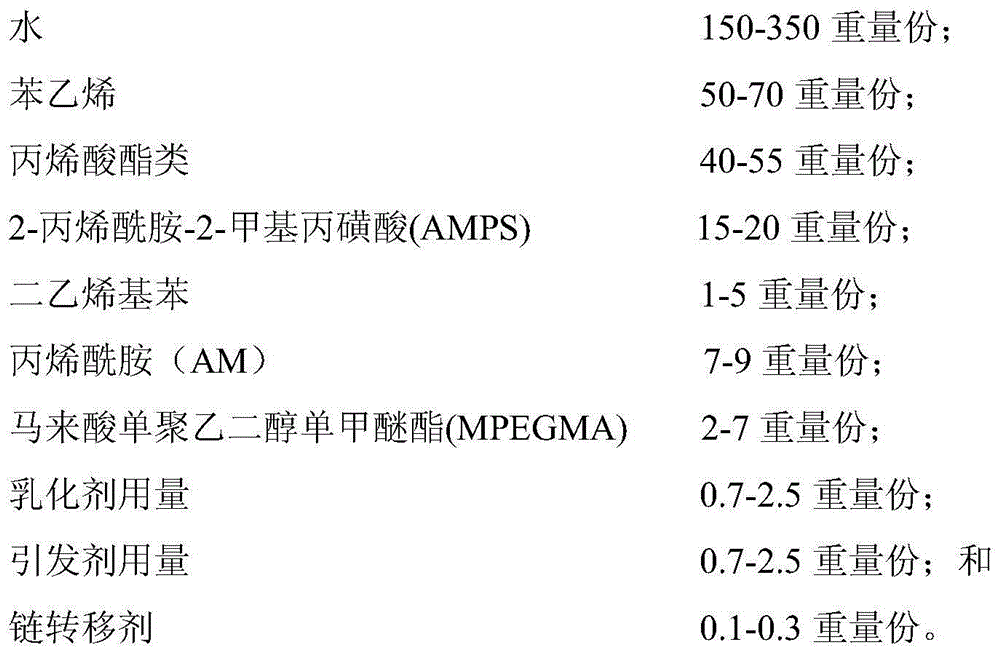

Preparation method of self-healing agent for oil well cement, well cementation self-healing cement slurry and application

ActiveCN104418965ATo achieve the effect of oil expansionEasy construction pumpingDrilling compositionSelf-healingPolyethylene glycol

The invention discloses a preparation method of a self-healing agent for oil well cement. The preparation method comprises the following steps: i) mixing substituted or unsubstituted styrene, acrylates, 2-acrylamide-2-methyl propane sulfonic acid, divinyl benzene, acrylamide and derivatives thereof, mono polyethylene glycol maleate, an emulsifier and a chain transfer agent with water and pre-emulsifying to obtain a pre-emulsion A; ii) preparing an initiator solution B by water and an initiator; iii) heating a part amount of the pre-emulsion A to 70-90 DEG C and then adding a part amount of the initiator solution B; then, further adding the residual amount of the pre-emulsion A and the initiator solution B; and iv) after reaction, adjusting the pH value to 7-9 to obtain the self-healing agent for oil well cement. The invention further relates to well cementation self-healing cement slurry which contains the self-healing agent prepared by the method as well as an application of the self-healing agent or the well cementation self-healing cement slurry in oil gas well cementing operation.

Owner:CHINA PETROLEUM & CHEM CORP +2

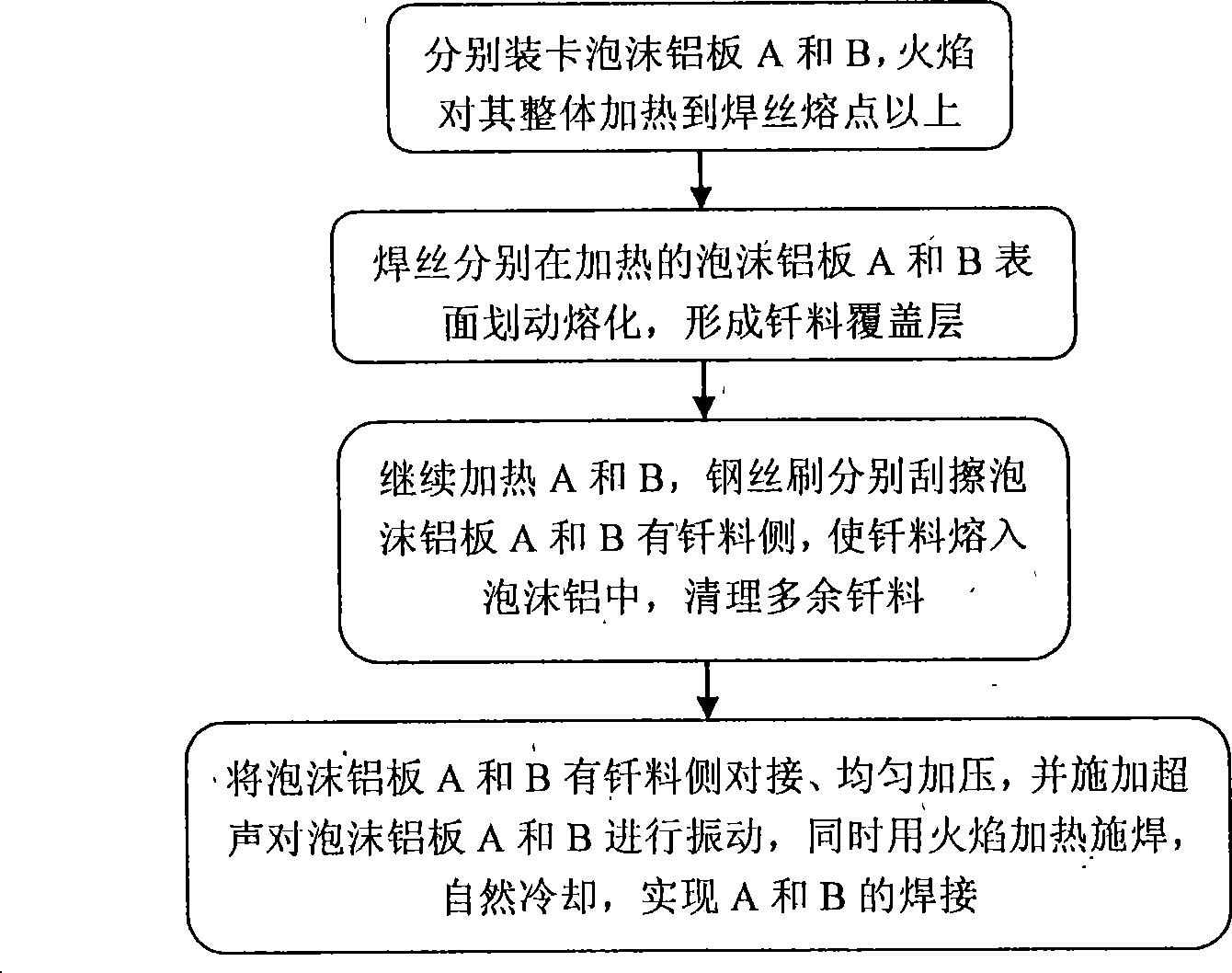

Vibration welding method for foamed aluminium scraper

InactiveCN101434012AGood removal effectReduce microcracksWelding apparatusWeld seamUltrasonic vibration

The invention aims to provide a scraping and vibrating welding method for foamed aluminum, which comprises: the foamed aluminum is heated until the temperature is higher than the melting point temperature of a soldering wire or brazing alloy; the soldering wire is respectively stroke on one surface of a foamed aluminum plate A and one surface of a foamed aluminum plate B, so that molten metals are uniformly laid on the surfaces of the foamed aluminum plates; one surface of foamed aluminum plate A and one surface of the foamed aluminum plate B which are provided with the brazing alloy are opposite to each other and clamped on a clamper, and pressure which is perpendicular to the welding surfaces is exerted; and the foamed aluminum plate A and the foamed aluminum plate B are vibrated by means of ultrasonic vibration and simultaneously heated by flame, so that the two foamed aluminum plates are welded together. The scraping and vibrating welding method for the foamed aluminum adopts wire brushes or steel wires for scraping, makes the brazing alloy capable of fully contacting aluminum parent metals and reacting with the aluminum parent metals, exerts ultrasonic vibration so as to be favorable to remove oxide films on the surfaces of the foamed aluminum in weld zones, cleans away superfluous brazing alloy, can reduce filled brazing alloy, makes the welded seams reach optimum clearance value, reduces the overall weight after welding, gives full play to light weight advantage of the foamed aluminum, and has special significance in the fields of aerospace and so on which are sensitive to weight.

Owner:HARBIN INST OF TECH

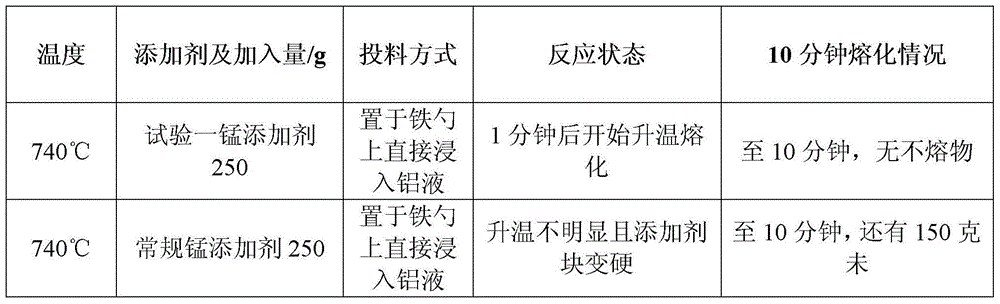

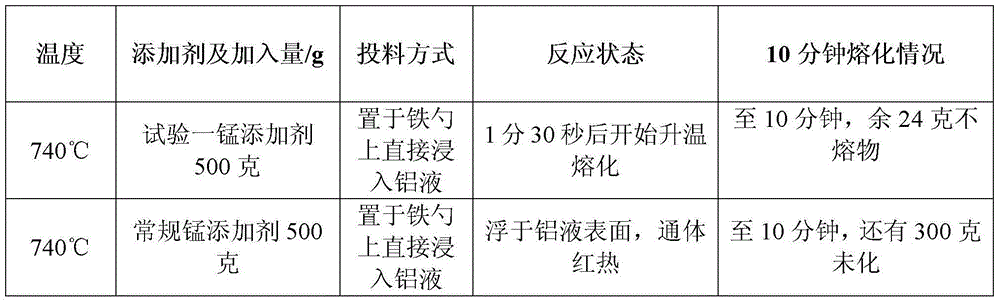

Manganese additive for casting aluminum magnesium alloy and preparation method of manganese additive

The invention discloses a manganese additive for casting aluminum magnesium alloy and a preparation method of the manganese additive, relates to an additive for casting aluminum magnesium alloy and a preparation method of the additive, and aims at solving the problems that a conventional manganese additive is low in melting rate or infusible, low in casting yield, high in smelting temperature, long in smelting time and high in energy consumption under the existing environment with high content of magnesium. The manganese additive disclosed by the invention is prepared from manganese powder and a fluxing agent. The method disclosed by the invention comprises the following steps: mixing the manganese powder with the fluxing agent, and pressing into a cake at the pressure intensity of 7-8MPa, so as to obtain the manganese additive. The manganese additive is low in melting temperature, high in melting rate and high in casting yield, and can be completely molten at 740 DEG C; the melting rate is over 50% greater than that of the conventional manganese additive; the additive which is fed to molten aluminum magnesium alloy over 740 DEG C can be rapidly molten and can be absorbed by molten aluminum within 8-10 minutes; and the casting yield of a manganese element within 20 minutes can be up to over 90%.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

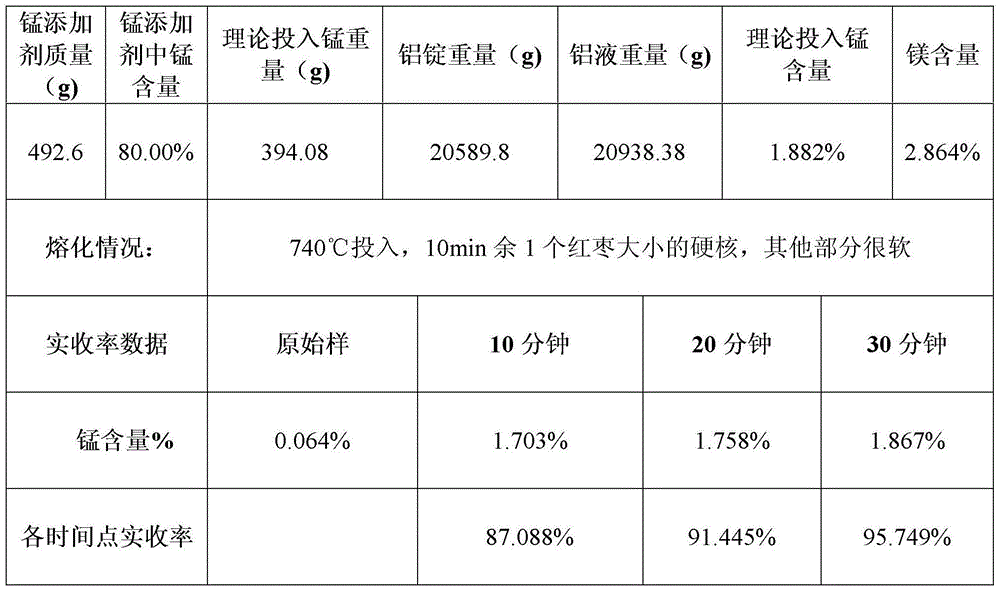

Preparation method for graphene oxide modified polymer cement-based anti-corrosive paint

ActiveCN109666360AReduce reunionImprove mechanical propertiesAnti-corrosive paintsPolymer scienceMechanical property

The invention provides a preparation method for graphene oxide modified polymer cement-based anti-corrosive paint. The preparation method comprises the following steps: performing carboxylation of a graphene oxide; synthesizing graphene oxide modified polyacrylate emulsion; and preparing the graphene oxide modified polymer cement-based anti-corrosive paint. The paint prepared by the preparation method has the advantages of high toughness, high bonding strength and high compactness and the like of an organic polymer, and has high mechanical strength and high weather resistance and durability ofa special cement-based material. The graphene oxide is used for modifying the polymer cement-based anti-corrosive paint, a mechanical property of a polymer film is further optimized, interface compatibility and a bonding force of a polymer organic component and a cement-based inorganic component are improved, thereby a paint microscopic structure is optimized, and anti-corrosion performance and stability are improved.

Owner:青岛伟力商品混凝土有限公司

Steel bar for high-ductility and superhigh-strength pre-stressed concrete and machining method thereof

ActiveCN103484789AReduce intensityImproved resistance to hysteresis fractureUltra high pressurePre stress

The invention discloses a steel bar for high-ductility and superhigh-strength pre-stressed concrete and a machining method of the steel bar. The steel bar comprises, by weight, 0.3-0.5% of C, 0.3-1.8% of Si, 0.6-1.5% of Mn, 0.02-0.2% of Nb, 0.01-0.1% of V, 0.01-0.2% of Ni, 0.1-0.5% of Cr, 0.01-0.1% of Mo, 0.001-0.005% of B and the balance Fe, wherein the Ceq is smaller than 0.8%. Because an online continuous superhigh-pressure quenching control technology is adopted, the strength of the steel bar can be larger than 1860MPa or even larger than 2000MPa; because an online continuous quenching heat insulation and control technology is adopted, the ductility of the steel bar can be larger than 7%, the structural state of few ultra fine ferrites and tempered troostite is kept, and the steel bar has the advantages of being good in ductility and resistant to delayed fractures.

Owner:江苏森林建筑新材料股份有限公司

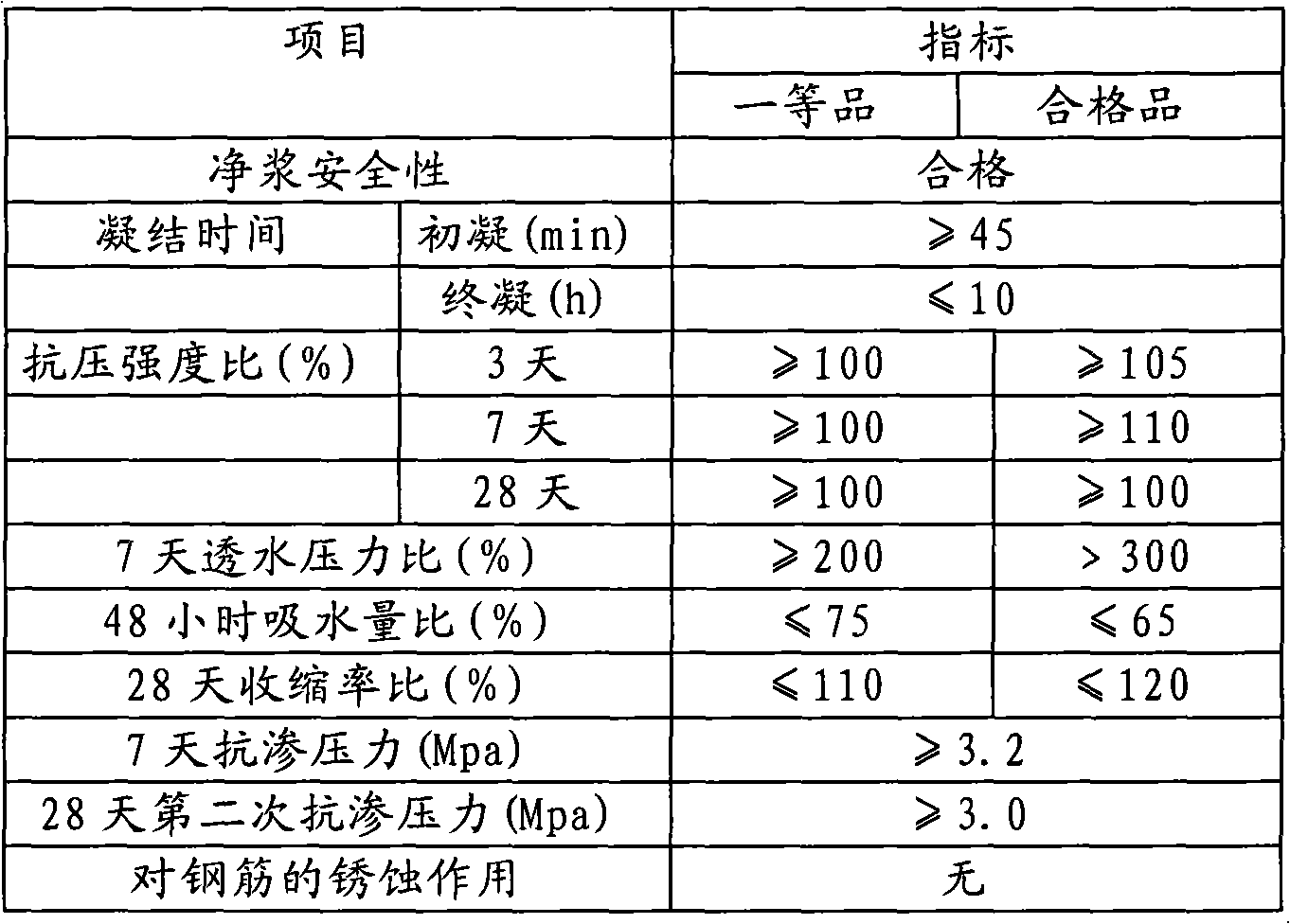

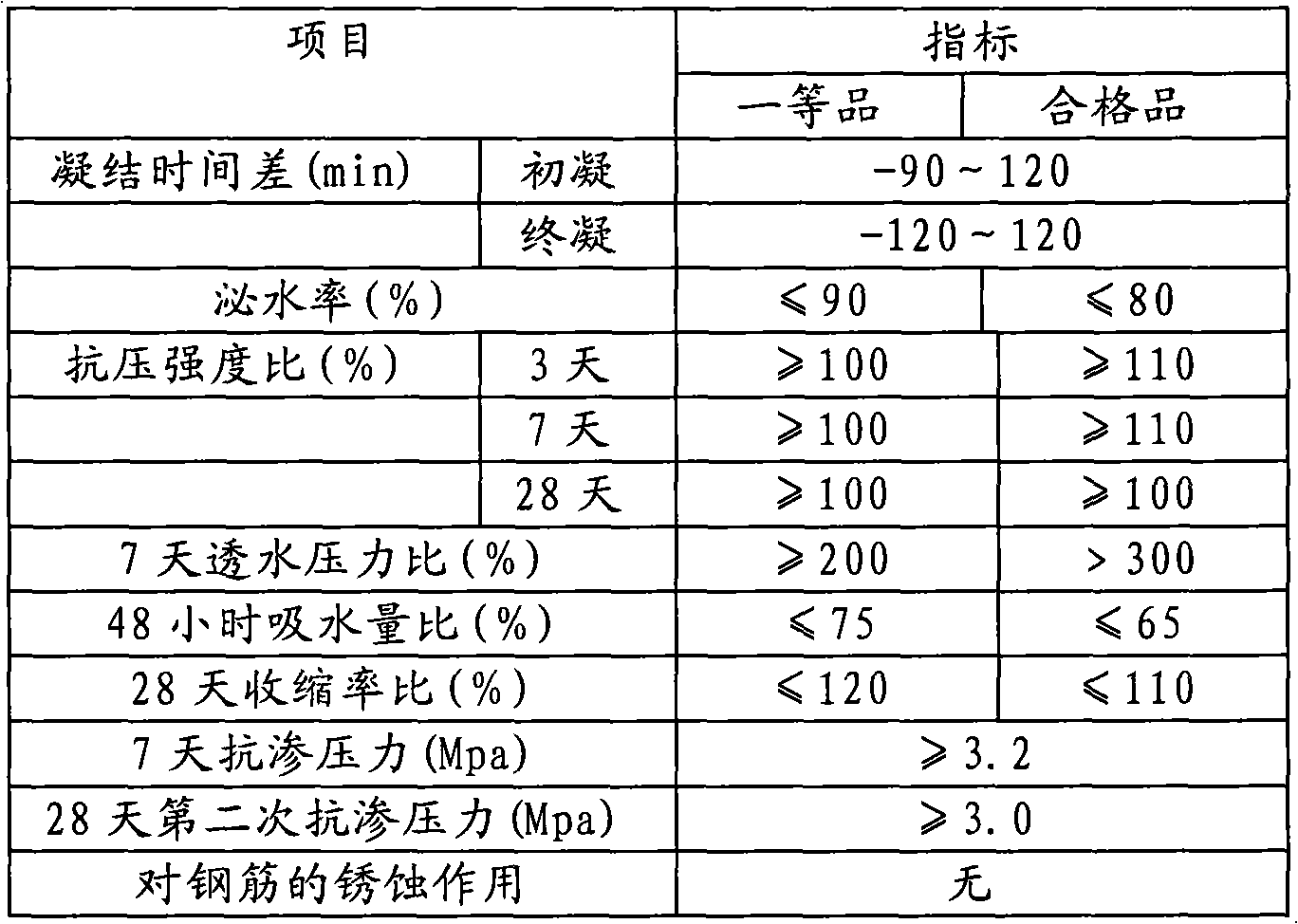

High-impervious microcrystal self-curing type cement additive

The invention discloses a high-impervious microcrystal self-curing type cement additive, which relates to the filed of concrete additive and can be used for preparing high-impervious motar or microaggregate concrete by being mixed with cement. The high-impervious microcrystal self-curing type cement additive comprises the following components in percentage by weight: 30-50% of active silicon oxide, 32-55% of levigated mineral powder or coal ash or quartziferous silicon epitaxy materials or limestone powder, 5-8% of phosphate and 7-11% of water reducer. The additive of the invention can be used for preparing high-impervious flaw self-curing type motar or the microaggregate concrete by being mixed with cement.

Owner:施无我

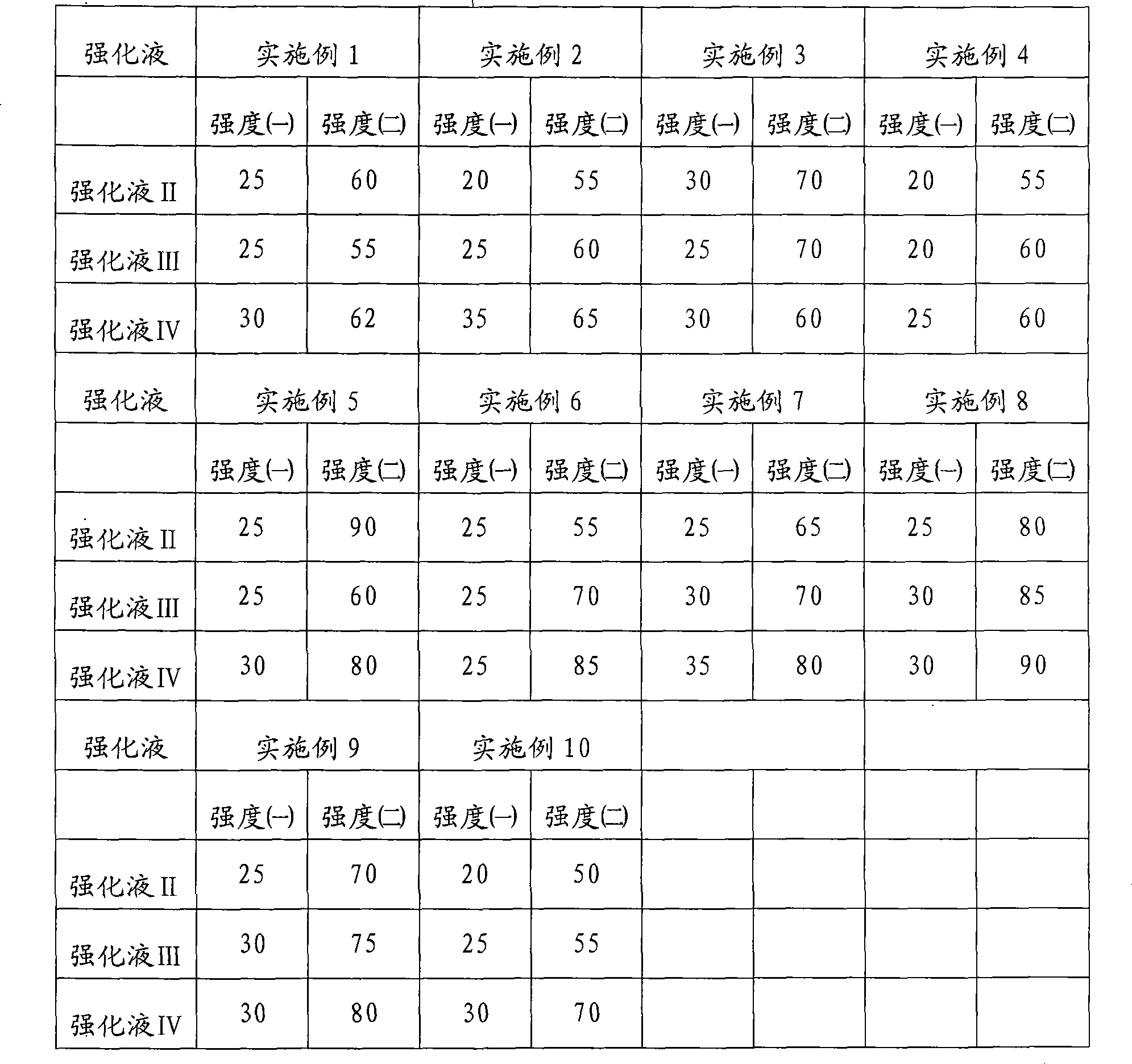

Glass reinforced solution and use thereof

The invention discloses a glass strengthening solution and the application thereof. The solution comprises potassium silicate, accelerator and water, wherein, the accelerator is potassium hydroxide and / or potassium phosphate. The glass strengthening solution provided by the invention can repair the cracks on the surfaces of the glass after being strengthened primarily, the smoothness of glass surface can be improved greatly, the strengthening process is simple, and raw material is available with low price.

Owner:BYD CO LTD

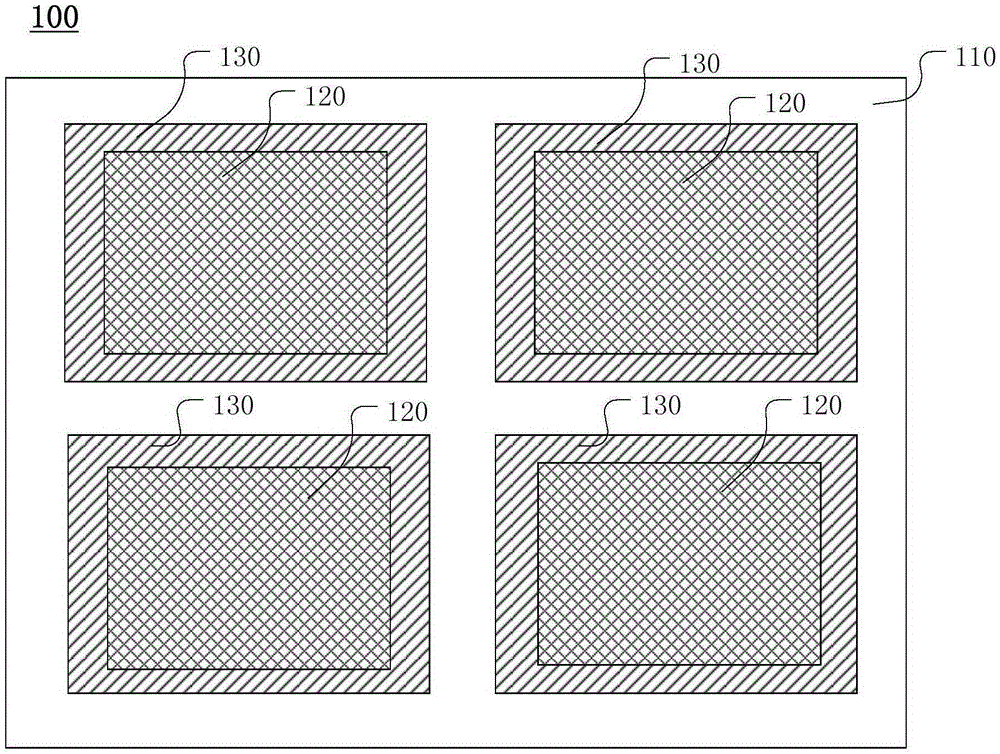

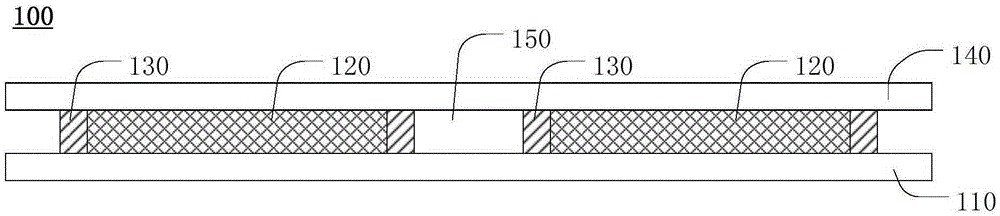

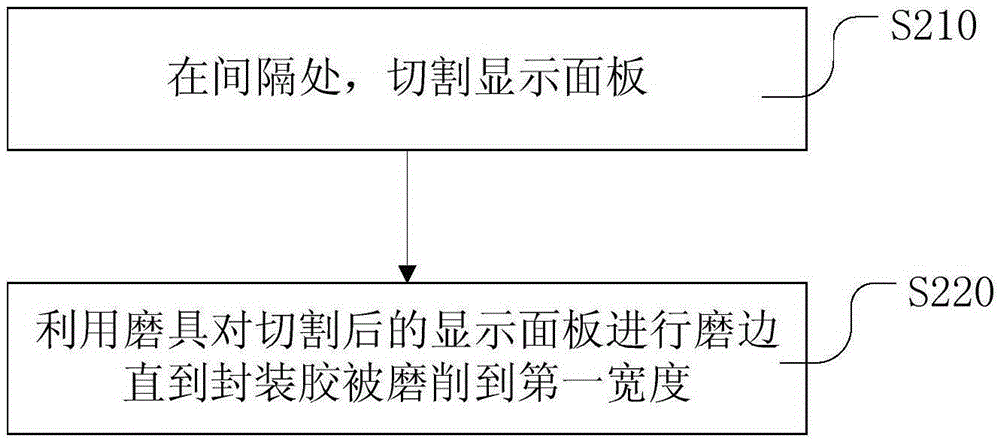

Cutting method for display panel

ActiveCN106541310AAchieve narrow bezel designReduce widthEdge grinding machinesWorking accessoriesAdhesiveEngineering

The invention provides a cutting method for a display panel. The display panel comprises a substrate, a cover plate opposite to the substrate, a plurality of display components located between the substrate and the cover plate and a packaging adhesive located between the substrate and the cover plate and respectively arranged around the plurality of display components. The cutting method comprises the steps: cutting the substrate and the cover plate of the display panel between two adjacent display components to form a plurality of display modules; and grinding the edges of the cut display modules by using an edge grinding device, and grinding the edges of the display modules into the packaging adhesive until the packaging adhesive is ground to the preset width. By using the cutting method for the display panel, provided by the invention, the design of a narrow frame of the display panel can be precisely realized.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com