Scraping, vibrating and soldering method for preparing foamed aluminum sandwich structure

A technology of sandwich structure and brazing method, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of hindering the spread and wetting of solder, difficulty in removing oxide film, and inability of solder to spread, etc., to achieve improved The effect of comprehensive mechanical properties, improving strength and reducing microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

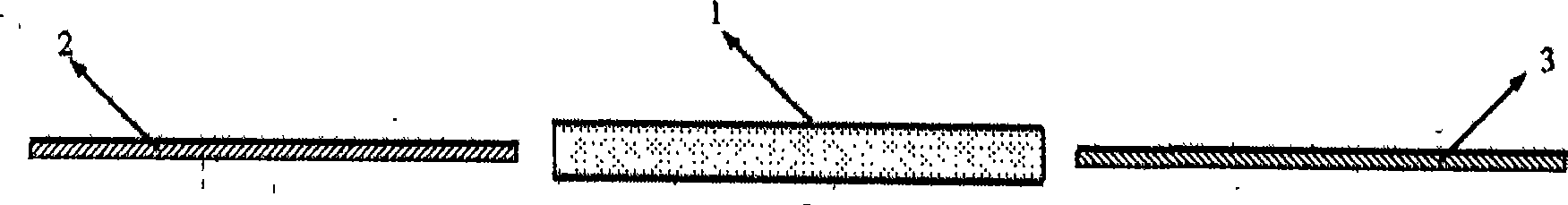

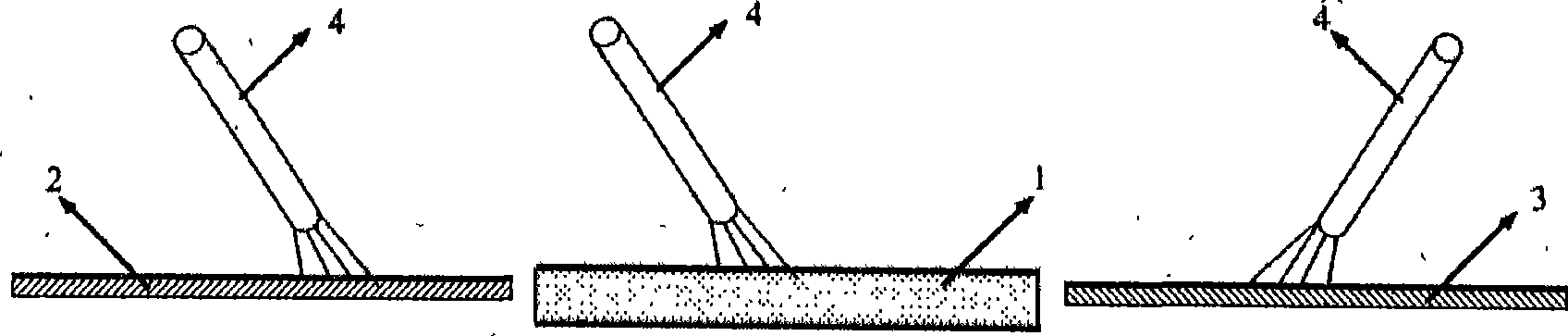

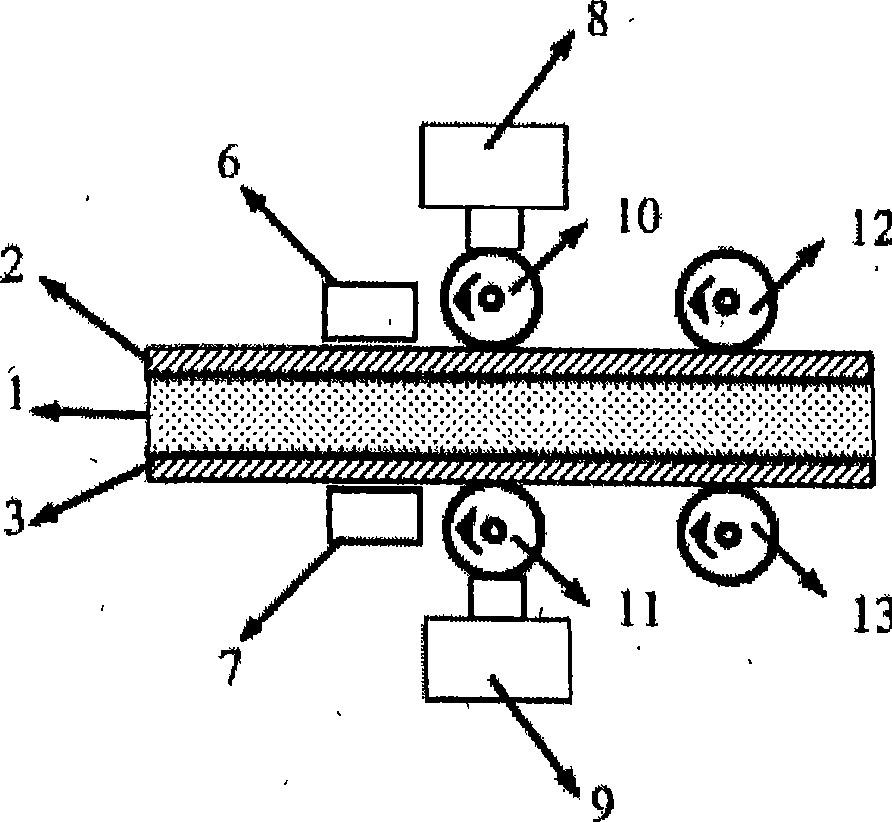

[0017] Embodiment 1, combining figure 1 , the present invention prepares a kind of scraping vibration brazing method of aluminum foam sandwich structure, concrete steps are as follows:

[0018] Step 1: Ultrasonic cleaning and drying the aluminum foam plate with a thickness of 20mm and a porosity of 80% and an aluminum plate with a thickness of 2mm, respectively heating the foamed aluminum plate and the aluminum plate with a propane flame to make the temperature reach 390°C, and evenly spread the solder Coated on both sides of aluminum foam and one side of two aluminum plates;

[0019] Step 2: Continue to heat, keep the aluminum foam board and the aluminum board warm, and use a wire brush (or steel wire) to scrape the side of the workpiece with the brazing filler metal, so that the brazing filler metal gradually melts into the foam aluminum and the surfaces of the two aluminum boards to form a layer Solder adsorption layer;

[0020] Step 3: Clean up the excess solder on both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com