Patents

Literature

60 results about "Calcium aluminoferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium aluminoferrite (Ca₂(Al,Fe)₂O₅) is a dark brown crystalline phase commonly found in cements. In the cement industry it is termed ferrite. It also exists in nature as the rare mineral brownmillerite.

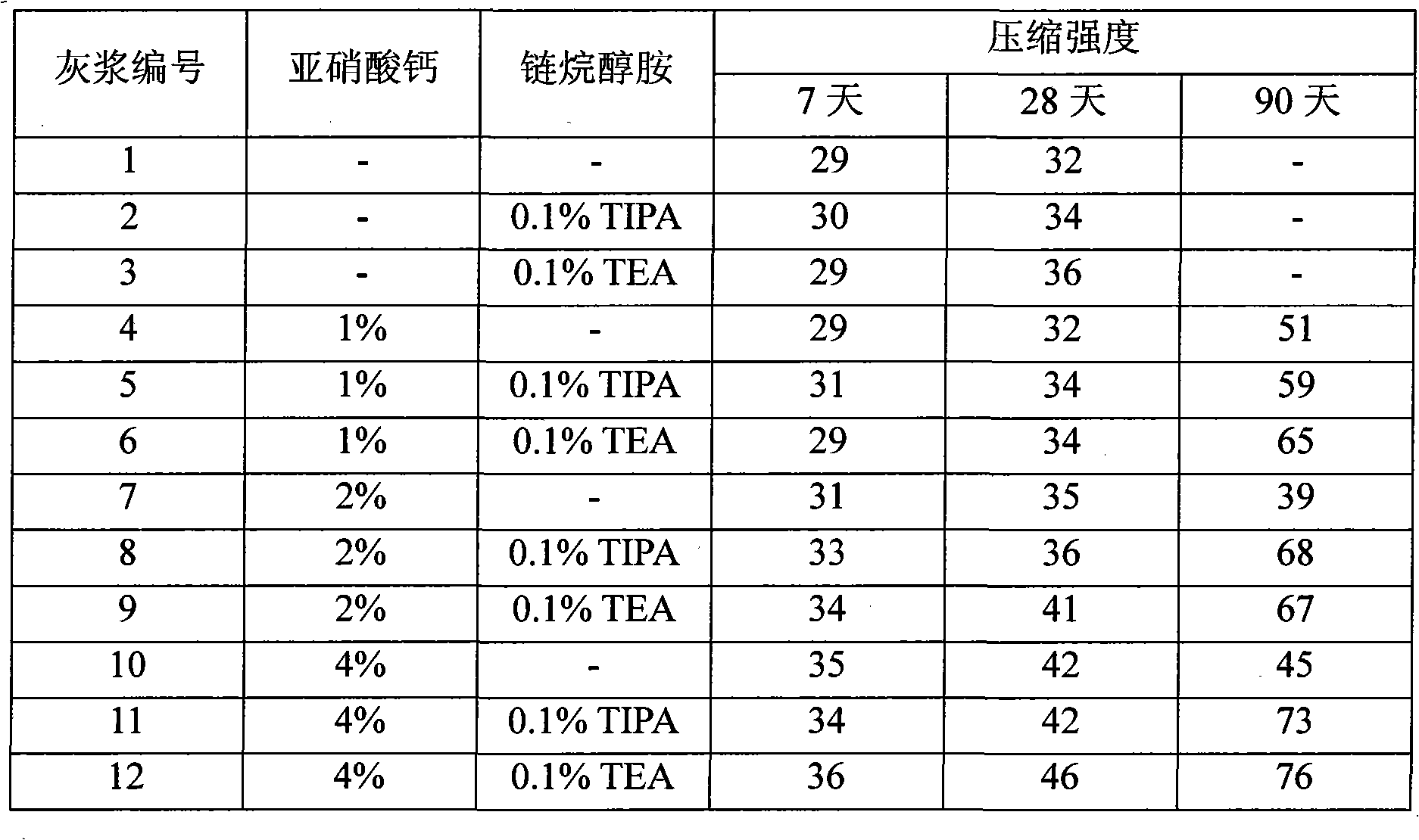

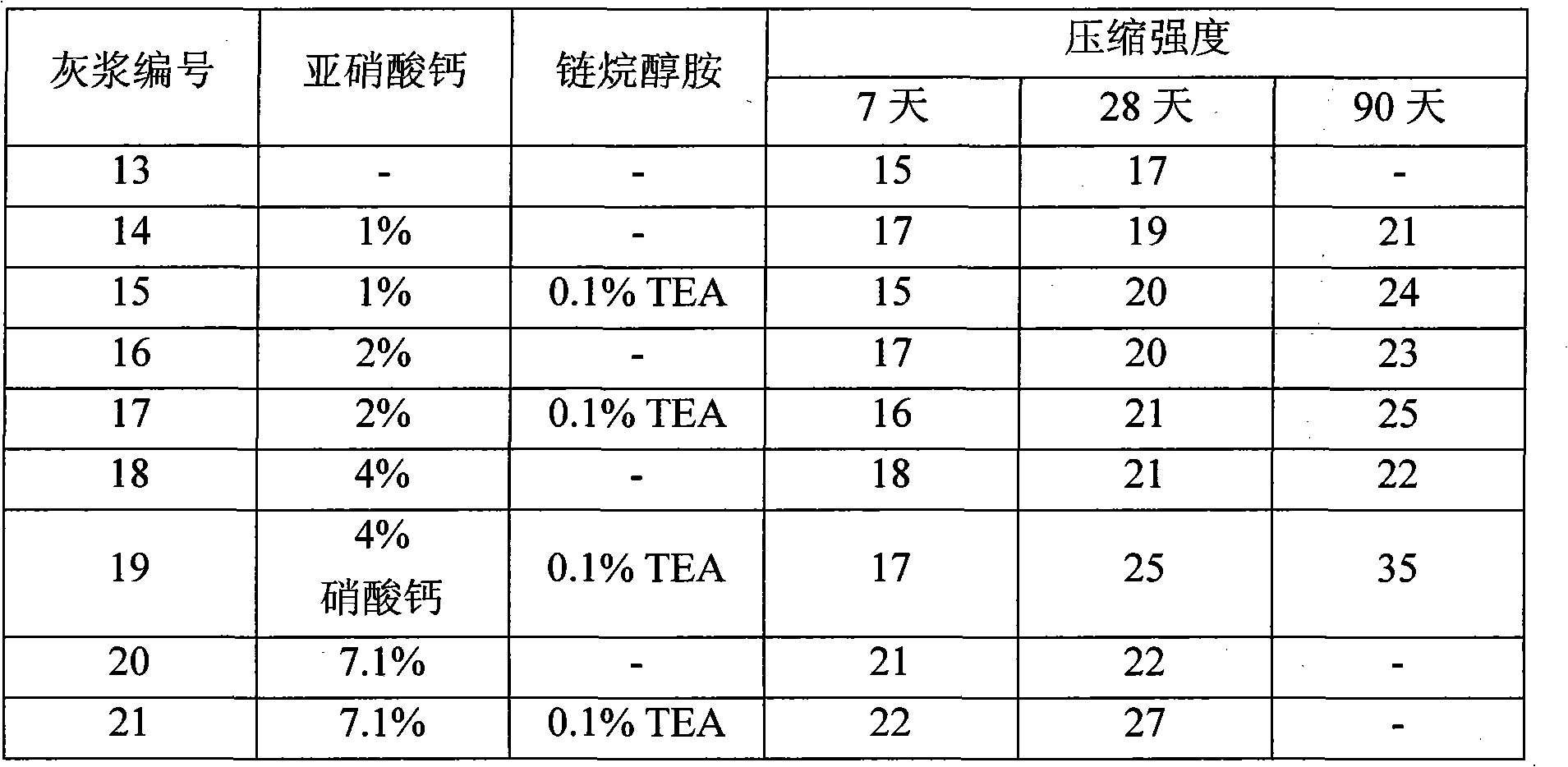

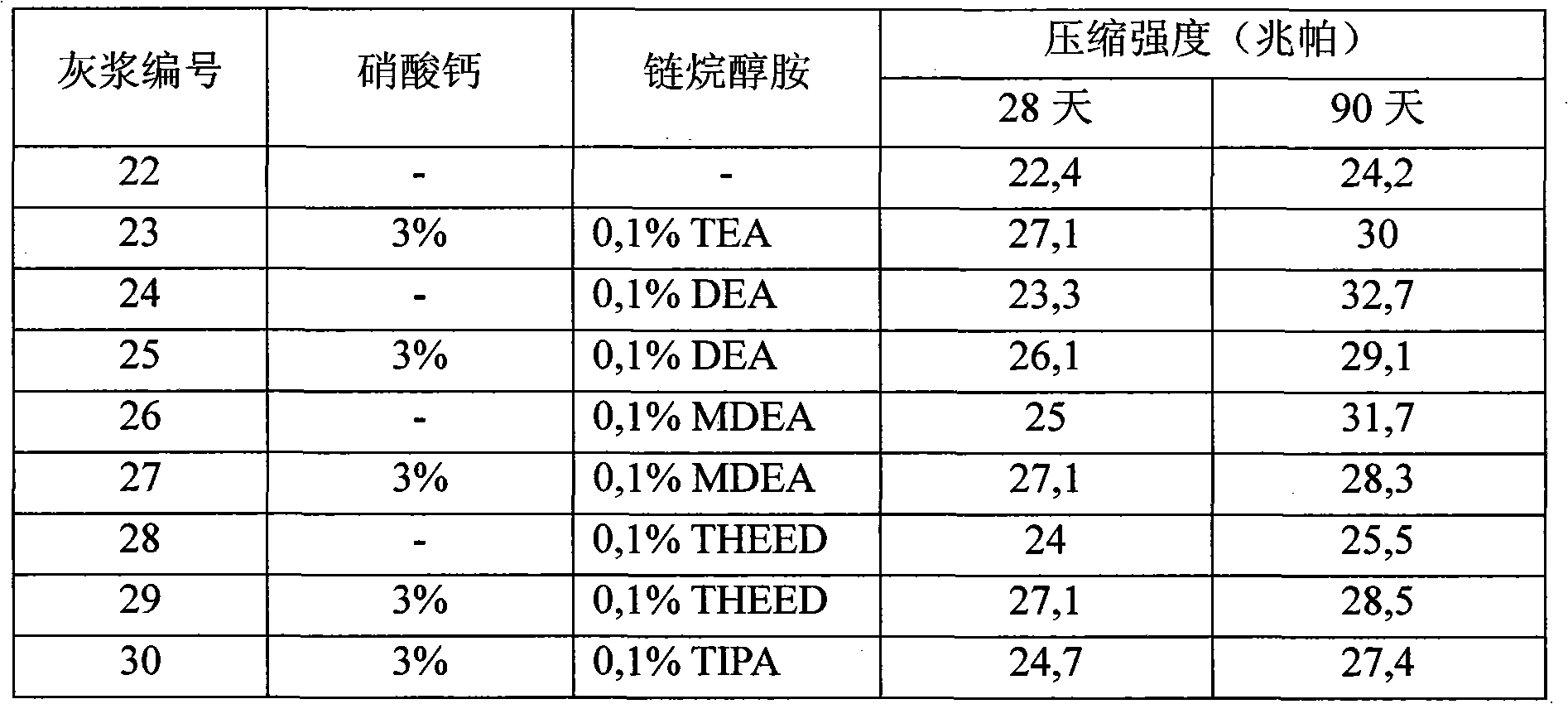

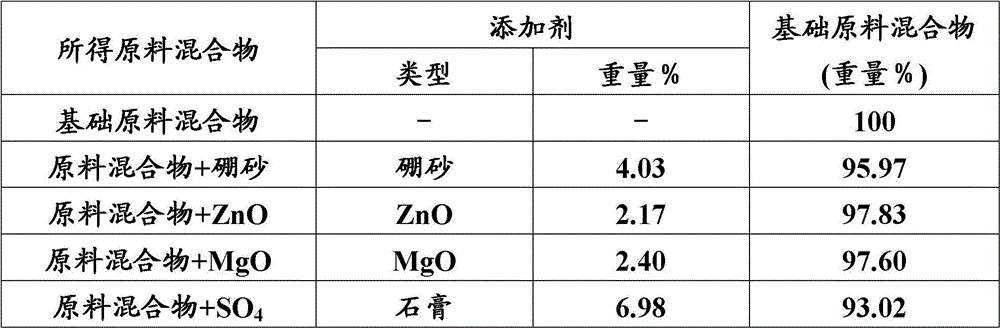

Additives for cement

The invention provides a belite-calcium sulphoaluminate-ferrite (BCSAF) cement composition comprising: a BCSAF clinker which clinker has the following mineralogical composition, based on the total weight of the clinker: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase having the general formula C2AxF(1-X), wherein X is from 0.2 to 0.8; 15 to 35% of a calcium sulphoaluminate phase; 40 to 75% of belite (C2S); from 0.01 to 10% in total of one or more minor phases selected from calcium sulphates, alkali metal sulphates, perovskite, calcium aluminates, gehlenite, free lime and periclase and / or a vitreous phase; and an alkanolamine.

Owner:HOLCIM

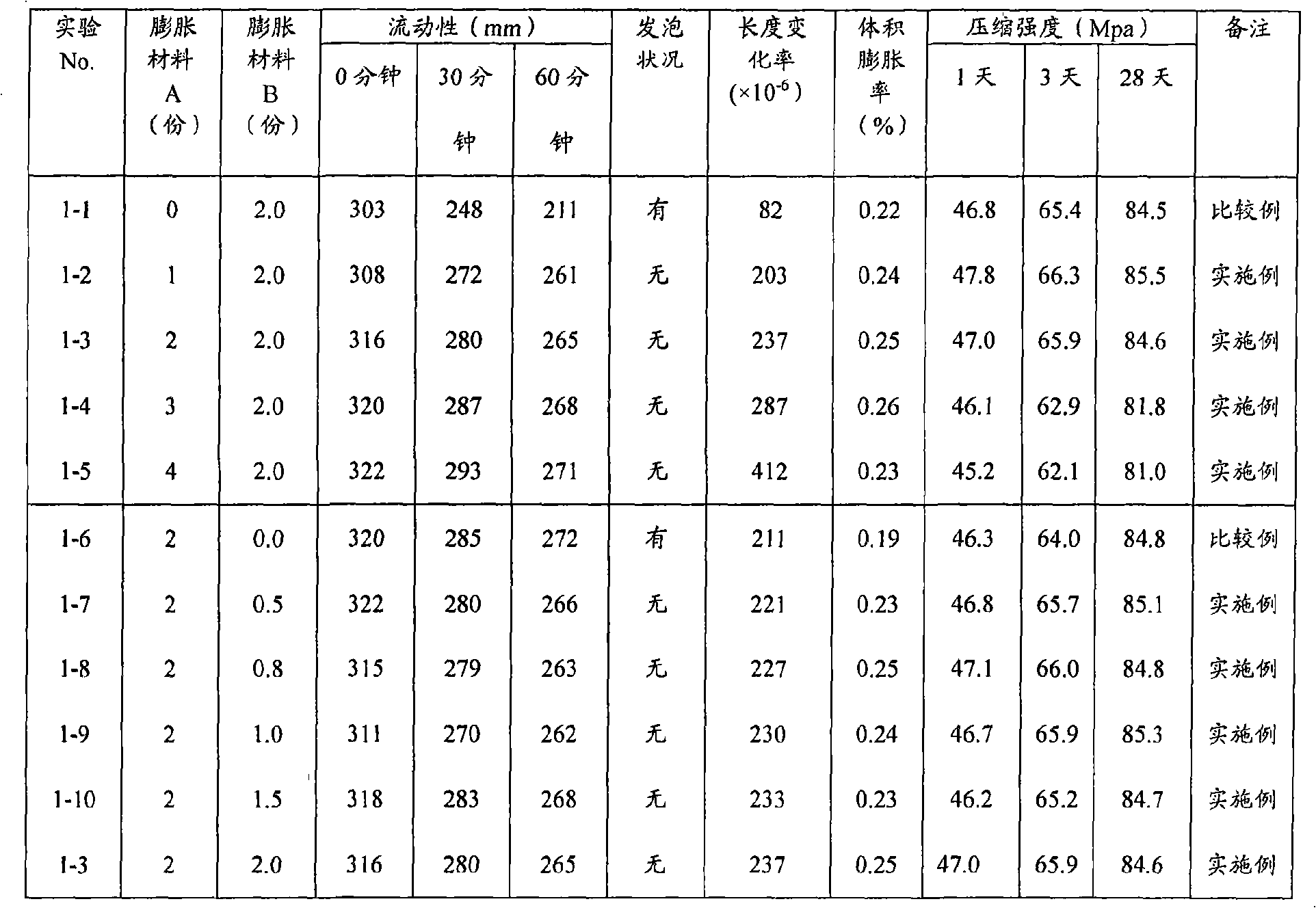

Cement composition for grouting and grout material comprising the same

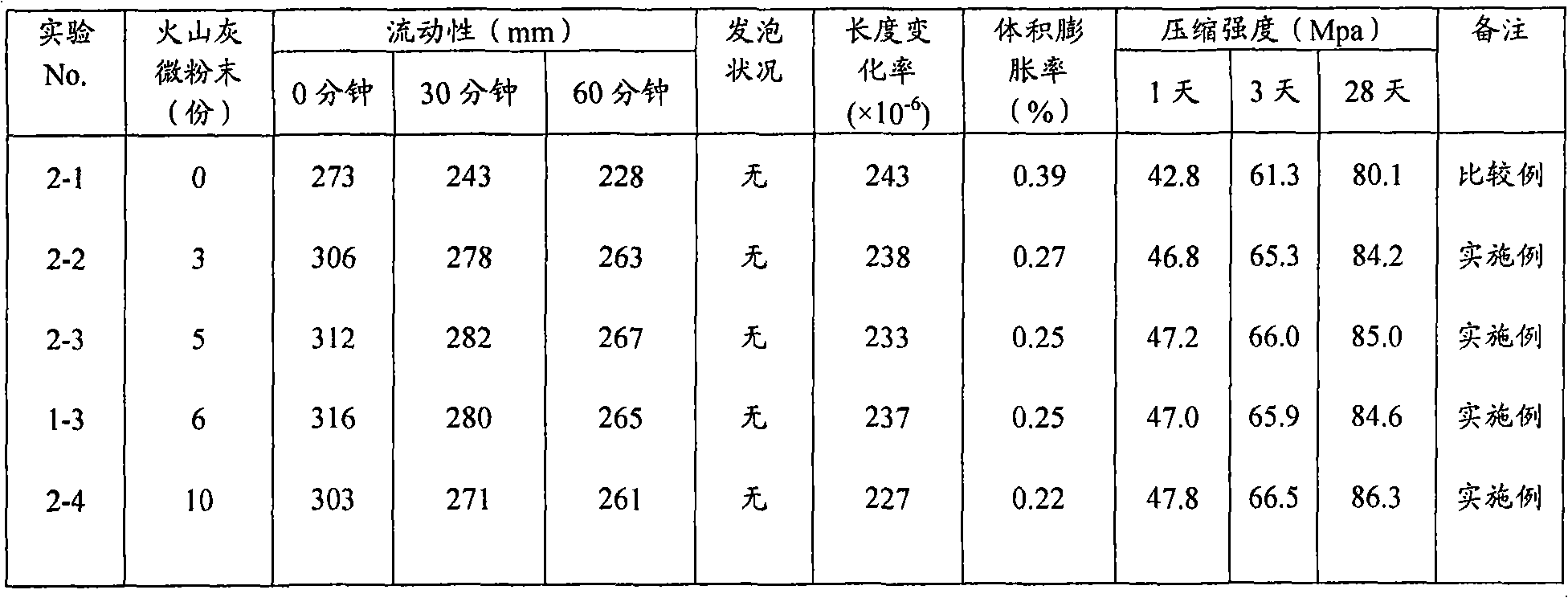

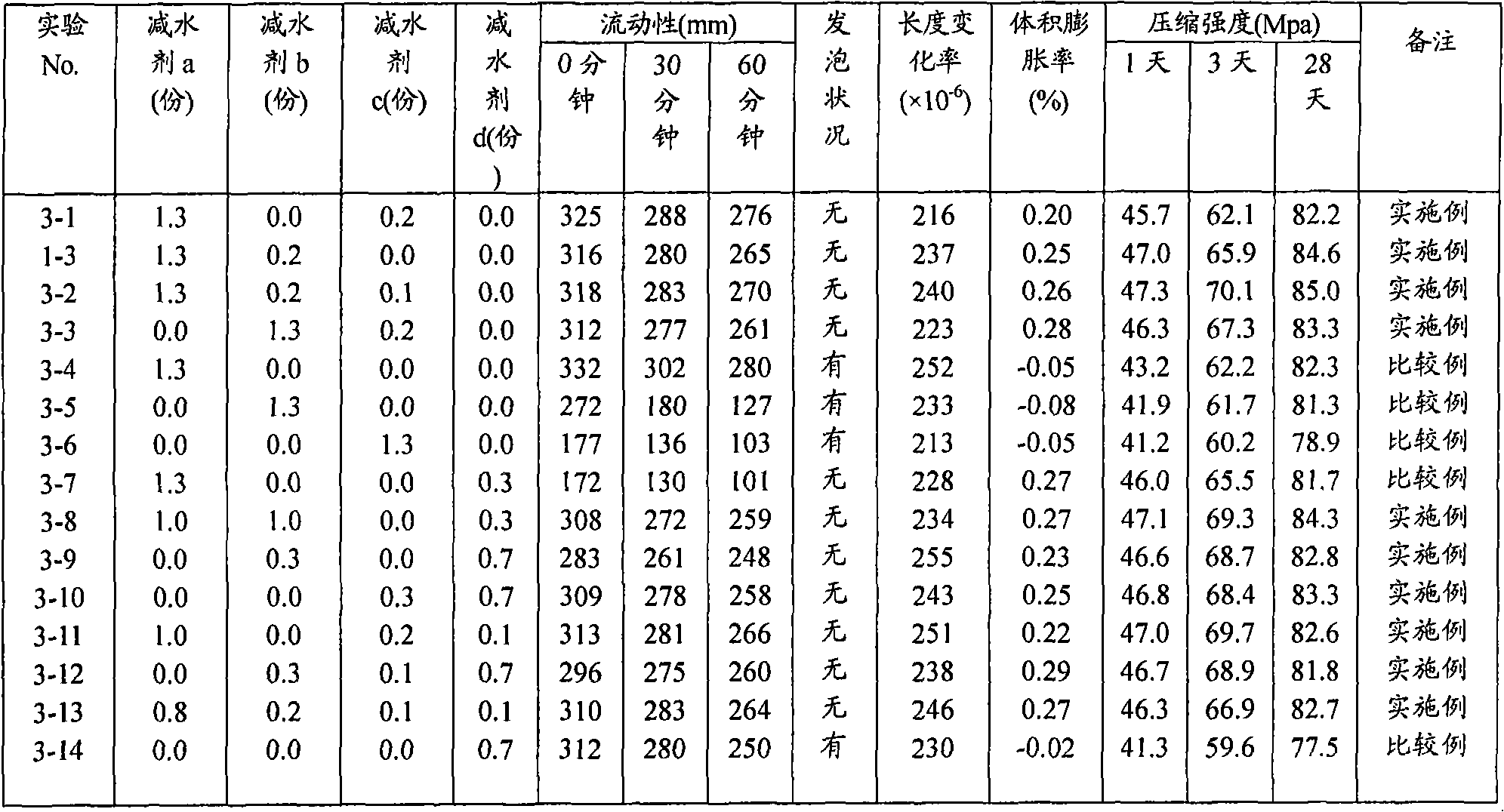

A cement composition for grouting which has excellent flowability, is prevented from bubbling, retains an appropriate length change and volume expansion, and has high-strength performance; and a grout material comprising the cement composition. The cement composition for grouting comprises a cement, expanding materials, a fine pozzolan powder, a blowing agent, and two or more water-reducing agents selected from the group consisting of naphthalenesulfonic acid water-reducing agents, melaminesulfonic acid water-reducing agents, lignoesulfonic acid water-reducing agents, and polycarboxylic acid water-reducing agents (provided that a combination of a naphthalenesulfonic acid water-reducing agent and a polycarboxylic acid water-reducing agent is excluded), and is characterized in that the expanding materials comprise a calcium aluminoferrite expanding material having a Blaine specific surface area of 2,000 cm<2> / g or larger and a calcium sulfoaluminate expanding material having a Blaine specific surface area exceeding 4,500 cm<2> / g.

Owner:DENKA CO LTD

Low-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 40 to 70 percent of dicalcium silicate, 10 to 35 percent of tricalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 340m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 13MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.0MPa, the 3-day hydration heat is less than or equal to 220KJ / kg, and the 7-day tensile strength is less than or equal to 250KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

Endogenous toughened corrosion-resistant cement mortar system

ActiveCN105967600AGood settlement stabilityReduce water lossDrilling compositionPorosityPolyvinyl alcohol

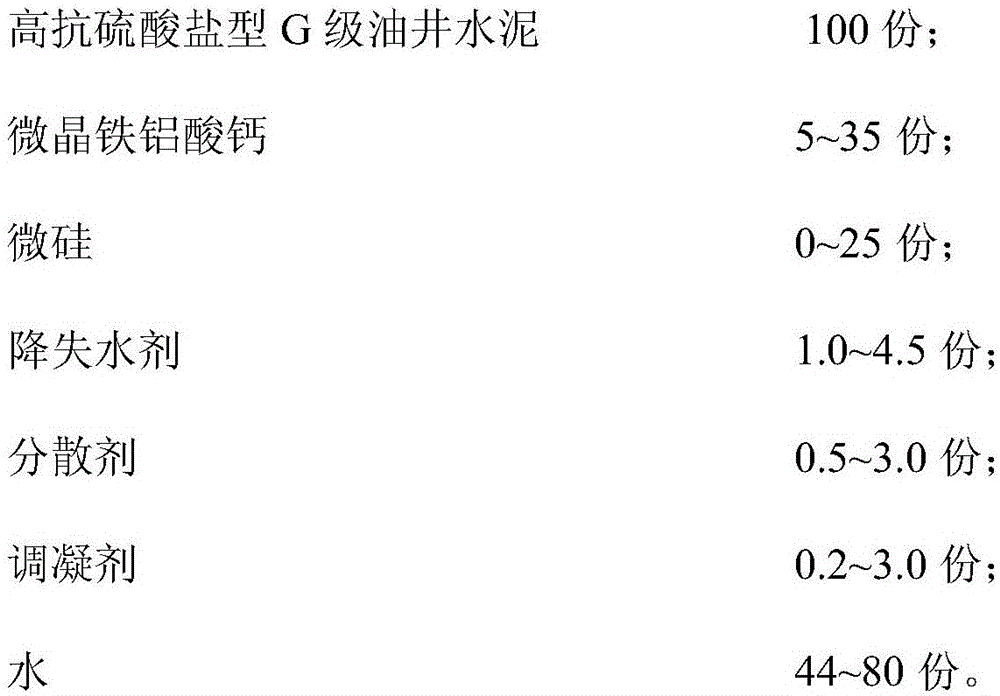

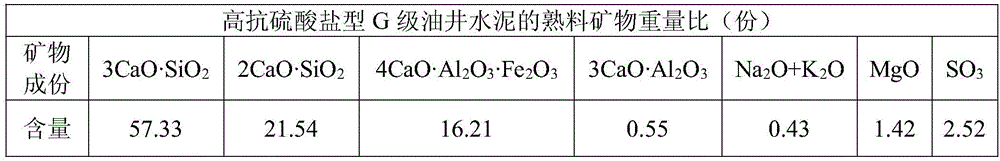

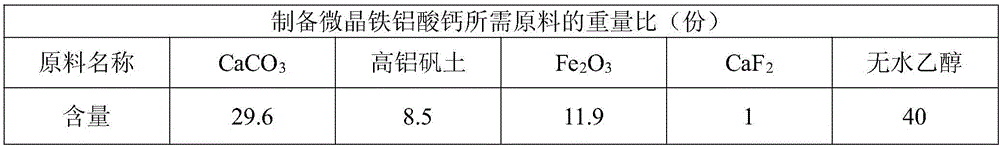

The invention discloses an endogenous toughened corrosion-resistant cement mortar system which is composed of the following components in parts by weight: 100 parts of high-sulfate-resistance Grade-G oil well cement, 5-35 parts of microcrystal calcium aluminoferrite, 0-25 parts of micro silicon, 1.0-4.5 parts of water-loss control agent, 0.5-3.0 parts of dispersing agent, 0.2-3.0 parts of thickening time control agent and 44-80 parts of water. The microcrystal calcium aluminoferrite is prepared by high-temperature calcination and shock cooling. The micro silicon is a density regulator. The water-loss control agent is polyvinyl alcohol, polyacrylamide or carboxymethyl cellulose. The dispersing agent is sodium hexametaphosphate, melamine formaldehyde resin, sodium lignosulfonate or methyl cellulose. The thickening time control agent is boric acid, gypsum, sodium borate or a mixture thereof. The endogenous toughened corrosion-resistant cement mortar system has the advantages of excellent impact resistance, higher compression strength, high volume stability and small changes of porosity and permeability, has important meanings for ensuring safe and efficient development of shale gas, and thus, has broad market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

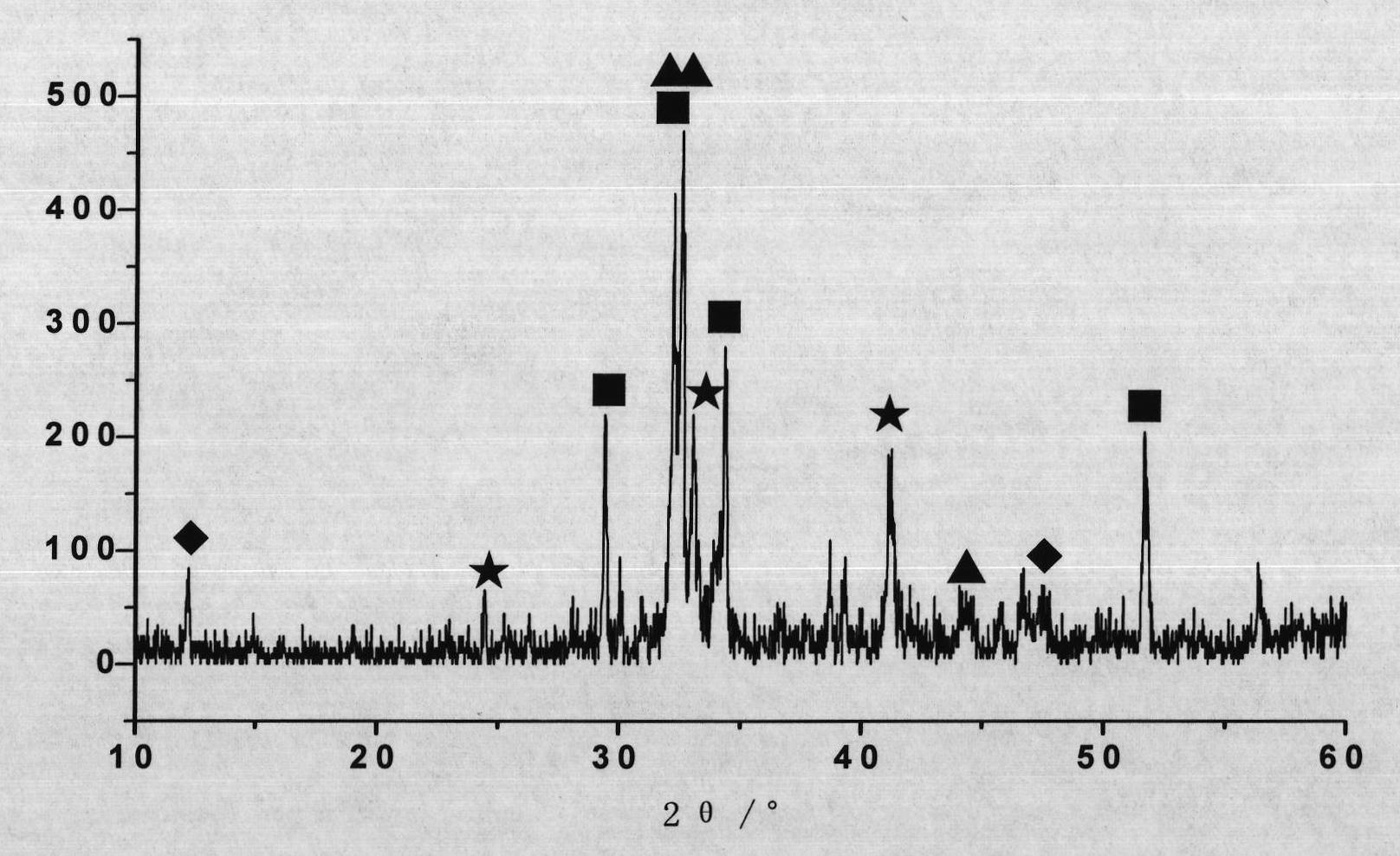

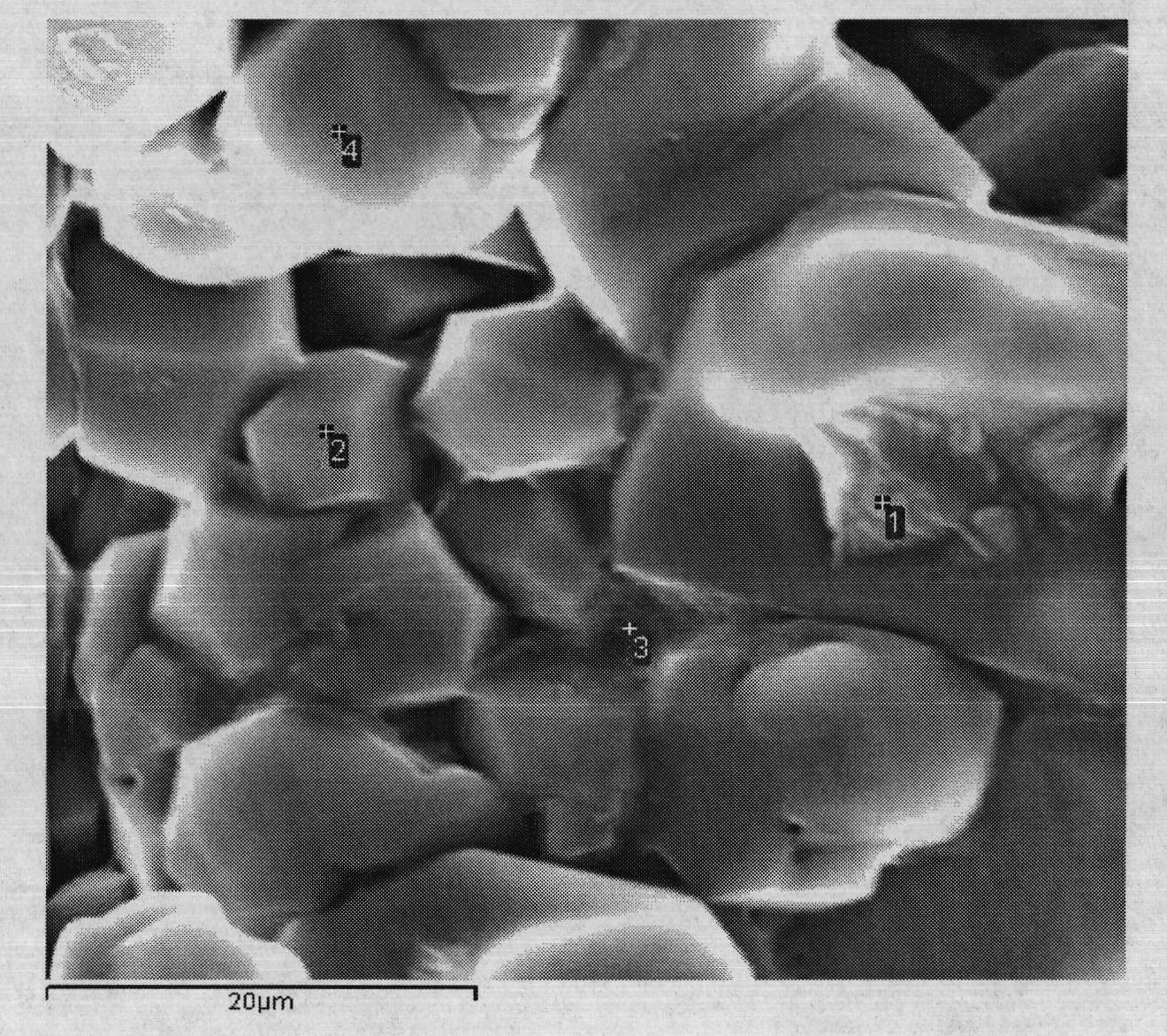

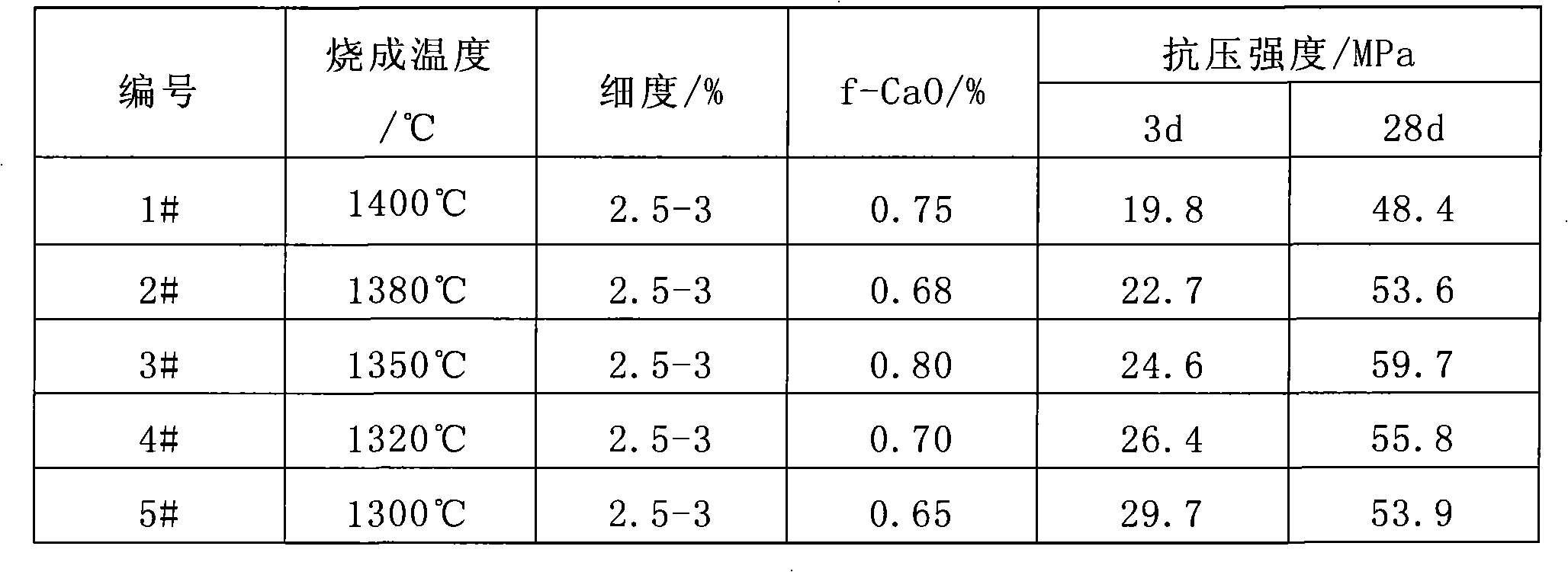

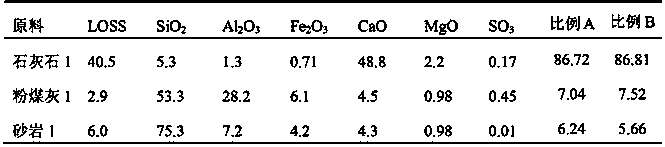

Method for preparing low-carbon cement clinker by utilizing iron tailings

ActiveCN103373826ARaise the intensity levelReduce intensity levelCement productionCement mortarMaterials science

The invention provides a method for preparing low-carbon cement clinker by utilizing iron tailings. The method for preparing the low-carbon cement clinker comprises the step of firing the iron tailings and limestone as main raw materials at the temperature lower than 1400 DEG C. The low-carbon cement clinker comprises the following mineral compositions: 70-85% of dicalcium silicate, 5-15% of tricalcium silicate, 0-5% of tricalcium aluminate and 4-15% of tetra calcium aluminoferrite. The method has the advantages that the proportion of iron tailings in the raw materials can be up to 32%; in addition, compared with the firing temperature 1450 DEG C of traditional portland cement clinker, the firing temperature is reduced by 50-150 DEG C; compared with the emission of the greenhouse gases in traditional cement production, the emission of CO2 and other NOx-based greenhouse gases is reduced by about 20%. The cement prepared by utilizing the low-carbon cement clinker has the advantages that the 28-day strength can be up to 65-75 MPa; the strength grade is up to 62.5; the cement mortar dispersion degree can be up to 135-200mm; the cement is low in the hydration heat, good in safety and excellent in working performance.

Owner:承德金隅水泥有限责任公司

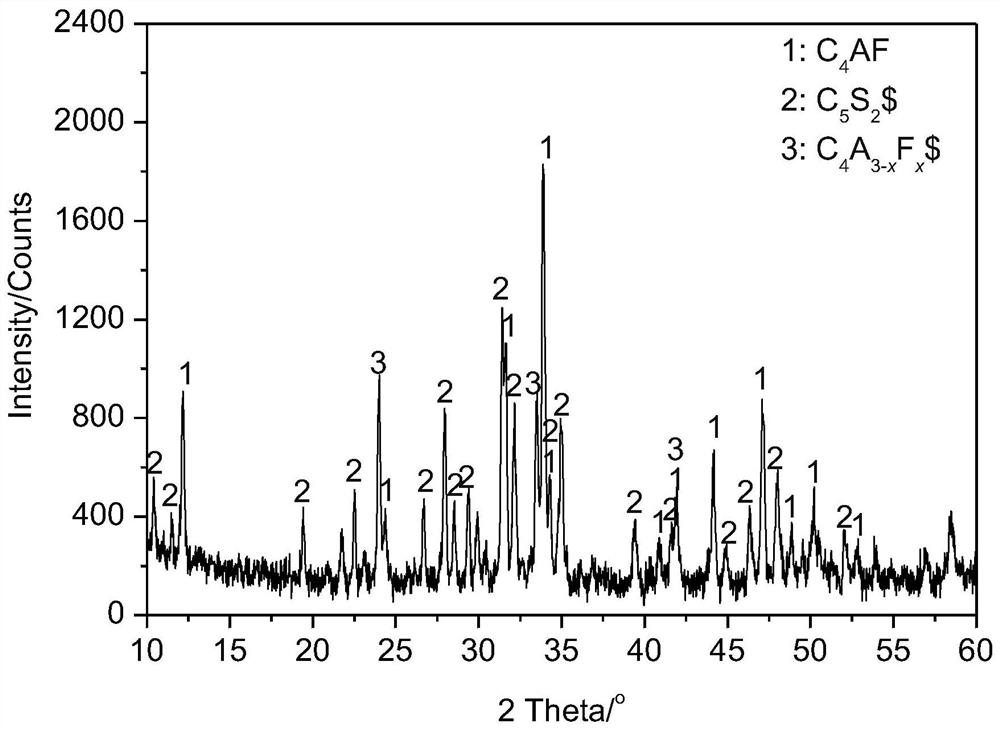

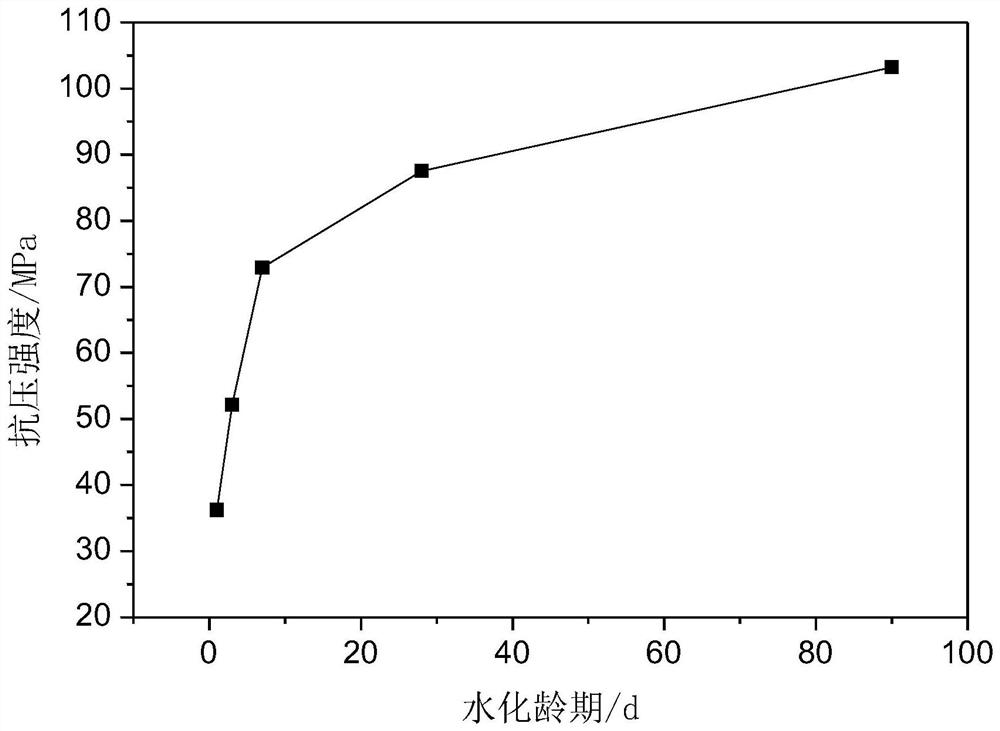

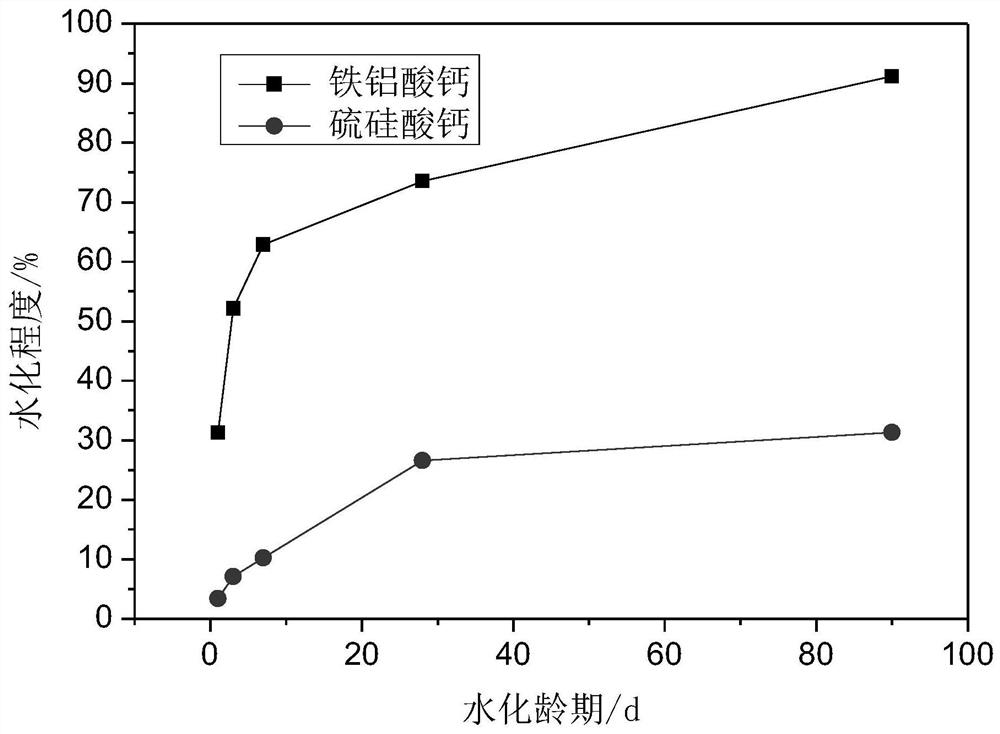

Red mud-based calcium sulphosilicate-calcium aluminoferrite cement raw material, cement clinker, cement and preparation method thereof

ActiveCN111943533AEnhanced solid solution abilityImproved solid solution capacityCalcium silicateRed mud

The invention relates to the technical field of cement, in particular to a red-mud-based calcium sulphosilicate-calcium aluminoferrite cement raw material, cement clinker, cement and a preparation method thereof.The cement raw material is prepared from, by weight, 30-50 parts of calcium raw materials, 20-50 parts of red mud, 10-25 parts of barium and / or strontium containing raw materials, 20-30 parts of aluminum raw materials and 5-20 parts of gypsum. According to the invention, the cement clinker with high content of calcium aluminoferrite is sintered at a low temperature, the phenomena of skinning and even blockage of a cement kiln caused by melting of the cement clinker are avoided, and the hydration activity of calcium aluminoferrite is significantly improved. Detection shows that thecontent of calcium aluminoferrite in the cement clinker is as high as 25-60%, the 28-day hydration degree of calcium aluminoferrite in the cement clinker is greater than or equal to 70%, the 28-day hydration degree of calcium sulphosilicate is greater than or equal to 25%, and the radioactivity of the cement clinker meets the conditions that IRa is less than or equal to 1.0 and Ir is less than orequal to 1.0.

Owner:UNIV OF JINAN

Super-early-strength and super-high-strength inorganic grouting material based on ordinary Portland cement and preparation method of grouting material

ActiveCN112939503AImprove early strengthSatisfy workabilitySolid waste managementMonocalcium aluminateWater reducer

The invention discloses a super-early-strength and super-high-strength inorganic grouting material based on ordinary Portland cement and a preparation method of the grouting material. The grouting material comprises the following components in parts by weight: 300-500 parts of ordinary Portland cement, 10-50 parts of silica fume, 400-600 parts of fine aggregate, 50-200 parts of a rapid hardening agent, 3-15 parts of a water reducing agent, 0.1-5 parts of a water-retaining agent and 0.1-5 parts of a defoaming agent. The rapid hardening agent comprises the following components in parts by weight: 20-100 parts of calcium aluminate mineral, 5-50 parts of anhydrous gypsum and 1-50 parts of light calcined magnesia. The calcium aluminate mineral is selected from one or more of anhydrous calcium sulphoaluminate mineral, calcium fluoroaluminate mineral, calcium aluminoferrite mineral, monocalcium aluminate and dodecacalcium heptaaluminate. The super-early-strength inorganic grouting material provided by the invention has ultrahigh hour strength while meeting workability, and the early strength of the grouting material is greatly improved; and the ordinary Portland cement and the anhydrite are used as basic raw materials, so that the material cost is low, and production and popularization are easy.

Owner:四川省佳宇建设集团有限公司

Method for preparing microcrystal calcium aluminoferrite by using red mud

The invention discloses a method for preparing microcrystal calcium aluminoferrite by using red mud. The method comprises the following steps: mixing 20-55 parts by weight of a calcium raw material, 3-15 parts by weight of an aluminum raw material, 100 parts by weight of red mud and 2-3 parts by weight of a fluxing agent, then preparing the mixture into a raw material, and grinding the raw material to enable the average grain size to be less than or equal to 8 microns; drying the ground raw material to remove free water in the raw material; containing the raw material with a platinum crucible, and placing the crucible in a high temperature furnace for heating until the raw material is fused; taking out clinker, and quenching the clinker; and drying the quenched clinker, and grinding the clinker until the average grain size is 30-50 microns, thereby obtaining microcrystal calcium aluminoferrite powder. Combined with high-temperature fusing and quenching processes, the method can utilize the red mud in large quantity and solve the problem of environmental pollution caused by red mud piling, and the method is short in production cycle; and the prepared microcrystal calcium aluminoferrite is high in uniformity, good in chemical stability, strong in hydratability and suitable for large-scale industrial production, and has broad market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Expanded perlite modified activated carbon automobile exhaust desulfurizing agent, and preparation method thereof

InactiveCN103566879AReduce pollutionFast adsorptionOther chemical processesDispersed particle separationFiberHigh concentration

The invention discloses an expanded perlite modified activated carbon automobile exhaust desulfurizing agent which is prepared from the following raw materials in parts by weight: 100-120 parts of activated carbon, 5-7 parts of tricalcium aluminate, 4-6 parts of tetra calcium aluminoferrite, 8-10 parts of dolomite clay, 7-9 parts of montmorillonite, 15-20 parts of expanded perlite, 12-16 parts of calcium hydroxide, 15-20 parts of wood fiber, 4-5 parts of modified diatomite and a suitable amount of water. According to the expanded perlite modified activated carbon automobile exhaust desulfurizing agent disclosed by the invention, the expanded perlite is used for modifying the activated carbon to form loose porous powder, so high adsorption speed and larger adsorption amount are realized; quick and efficient desulfuration as well as longer effect can be realized by using tricalcium aluminate, tetra calcium aluminoferrite, dolomite clay, montmorillonite clay and calcium hydroxide as a desulfurizing agent. The expanded perlite modified activated carbon automobile exhaust desulfurizing agent disclosed by the invention has the advantages of low cost, simple technique, less environmental pollution, high desulfuration speed, easiness for regeneration, and suitability for high-concentration desulfuration of automobile exhaust and the like.

Owner:BENGBU HUAFANG FILTER

Quick-setting quick-hardening high-strength low-carbon cement clinker as well as preparation method and application thereof

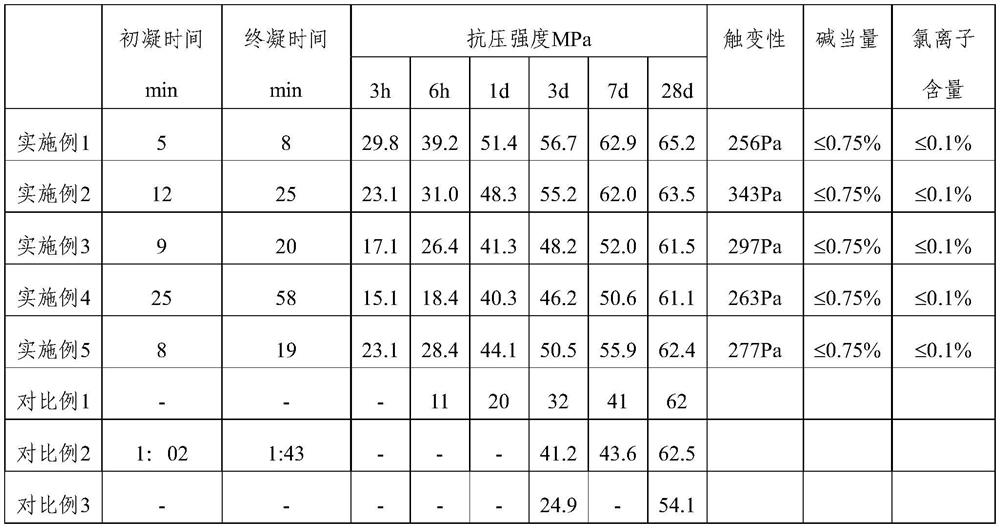

ActiveCN111925137ASignificantly low alkaliHigh compressive strengthCement productionCalcium silicateCompressive resistance

The invention belongs to the technical field of cement clinker, and particularly relates to quick-setting quick-hardening high-strength low-carbon cement clinker as well as a preparation method and application thereof. The low-carbon cement clinker comprises the following components in percentage by mass: more than or equal to 85% of a crystalline phase and less than or equal to 15% of an amorphous phase. In the crystalline phase, in terms of the low-carbon cement clinker, the content of tricalcium silicate is 15-45%; the content of calcium oxide is 0-5%; the content of calcium sulphosilicatedoped with ferric oxide is 5-50%; and the content of calcium sulphoaluminate is 15-45%; the content of calcium aluminoferrite is 2-15%. The amorphous phase is a CaO-Al2O3-SiO2-SO3-Fe2O3 solid solutionglass body. By designing five specific crystalline phase structures and controlling the content ratio of the five crystalline phase structures, a low-carbon cementing material prepared from the obtained low-carbon cement clinker has higher compressive strength in a short time, and the compressive strength is remarkably superior to existing similar cement clinkers; and meanwhile, the low-carbon cement clinker disclosed by the invention also has the excellent characteristics of remarkable thixotropy, low alkali and low chloride ion content.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

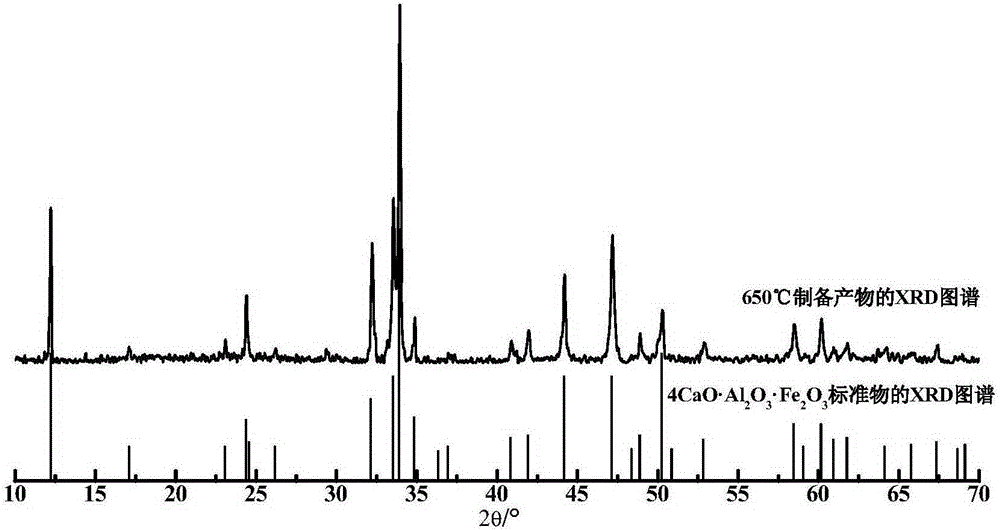

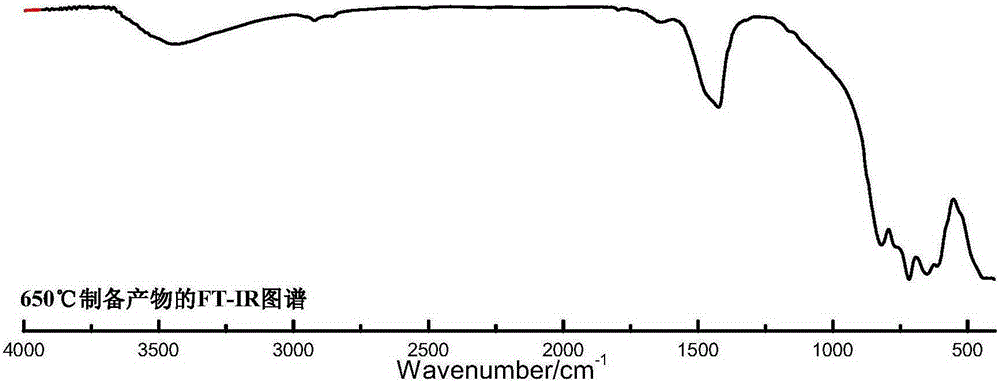

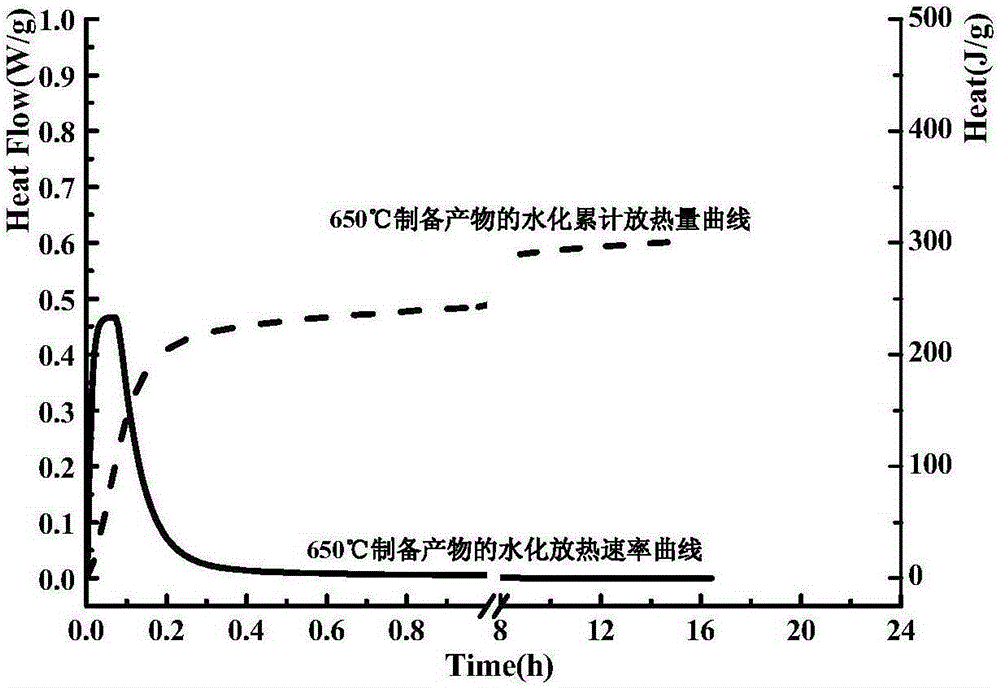

Method for fast preparing polycrystalline tetra calcium aluminoferrite

ActiveCN105271427ALow preparation temperatureLess power consumptionChemical industryIron compoundsAir atmosphereTetra

The invention discloses a method for fast preparing polycrystalline tetra calcium aluminoferrite. The method includes the steps that firstly, raw materials including calcium nitrate terahydrate, aluminum nitrate nonahydrate, iron nitrate nonahydrate and urea are weighed according to the mass ratio of 1:0.7942:0.8554:2.0413-2.1923; secondly, a proper amount of deionized water is added, and dispersion liquid with the concentration ranging from 0.5 mol / L to 0.8 mol / L is prepared and continuously stirred for 1.5 hours to 2 hours till the raw materials are completely dissolved; thirdly, the dispersion liquid is moved into a high temperature stove and heated to 500 DEG C to 510 DEG C in air atmosphere, after the constant temperature is kept for two hours, the dispersion liquid is taken out and grinded into particles with the particle size smaller than or equal to 0.15 mm, and the particles serve as a precursor ready for use; fourthly, the precursor is pressed into a thin piece with the diameter of 35 mm and the thickness smaller than or equal to 5 mm under the pressure of 25 MPa to 30 MPa; finally, the pressed precursor thin piece is heated to 650 DEG C to 950 DEG C at the heating rate of 10 DEG C / min, after the constant temperature is kept for 7 hours, the pressed precursor thin piece is taken out, fast cooled in the air and grinded, and the polycrystalline tetra calcium aluminoferrite with the hydration activity is obtained. The method is small in working procedure number, short in period and high in efficiency, the sintering temperature is 300 DEG C to 600 DEG C lower than the sintering temperature of a traditional method, and the method has the advantages of being fast, efficient and capable of saving energy, and is suitable for industrial large-scale application.

Owner:WUHAN UNIV

High-iron-phase Portland cement product and preparation method thereof

ActiveCN113200692AWide variety of sourcesSimple methodCement productionSilicic acidTricalcium aluminate

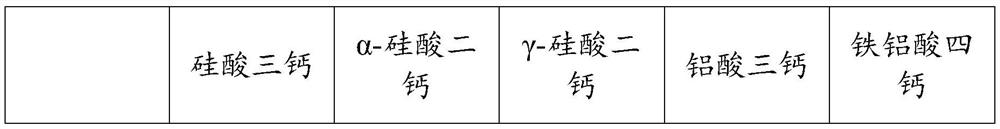

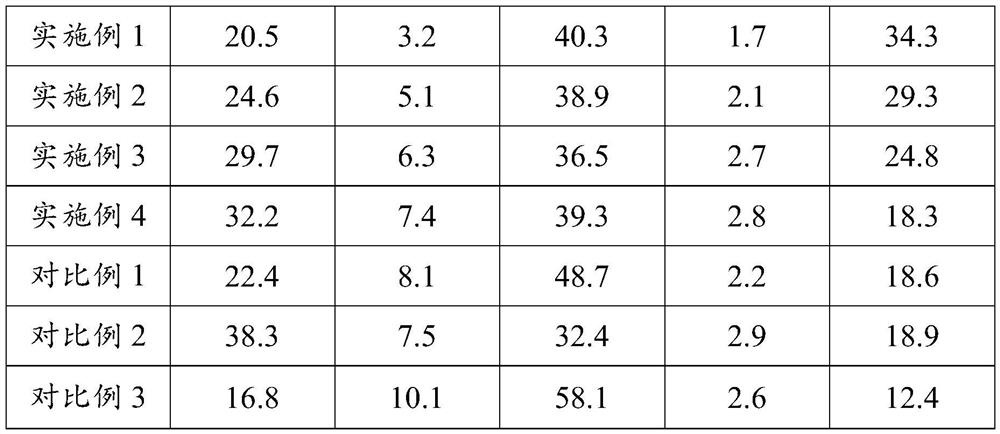

The invention discloses a high-iron-phase Portland cement product and a preparation method thereof. The preparation method comprises the following steps of mixing high-iron-phase Portland cement clinker and water according to a mass ratio of 1: (0.15-0.25), uniformly stirring to prepare a wet material, putting the wet material into a mold, pressing into a green body, putting the green body into a carbonization curing chamber, and carrying out accelerated carbonization treatment to obtain a high-iron-phase Portland cement product. The high-iron-phase Portland cement clinker is prepared from the following minerals in percentage by weight: 20 to 33 percent of tricalcium silicate, 3 to 8 percent of alpha-dicalcium silicate, 36 to 41 percent of gamma-dicalcium silicate, 1 to 3 percent of tricalcium aluminate and 18 to 35 percent of tetra calcium aluminoferrite. The high-iron-phase Portland cement product is prepared by selecting the cement clinker with specific composition, and the high-iron-phase Portland cement product with ultrahigh strength and corrosion resistance is formed under the combined action of mineral phase carbonization and hydration; and the method is simple, wide in raw material source and short in production period.

Owner:WUHAN UNIV OF TECH

Filling material for reinforcing joint and construction method of filling reinforcing joint

ActiveUS8080104B2High compressive strengthIncrease the lengthSolid waste managementPozzolanaHydrogen-Ion Concentrations

A filler for reinforcement joint that ensures excellent fluidity and retention thereof, exhibiting appropriate length change ratio and high strength performance; and a method of reinforcement joint filling operation using the same. There are provided a filler for reinforcement joint containing a cement, an expanding material, a pozzolana micropowder, a water reducing agent and a sand, and a method of reinforcement joint filling operation using the same, characterized in that the expanding material is a calcium aluminoferrite expanding material, and that the pozzolana micropowder is a silicious micropowder having a silicon dioxide (SiO2) content of 90% or higher and having a hydrogen ion concentration falling in an acid region, and that the water reducing agent is a polycarboxylic acid water reducing agent. The calcium aluminoferrite expanding material preferably has a value of Brain specific surface area of 2000 to 6000 cm2 / g. The sand is preferably a weighty sand of 3.0 g / cm3 or higher density.

Owner:DENKA CO LTD +1

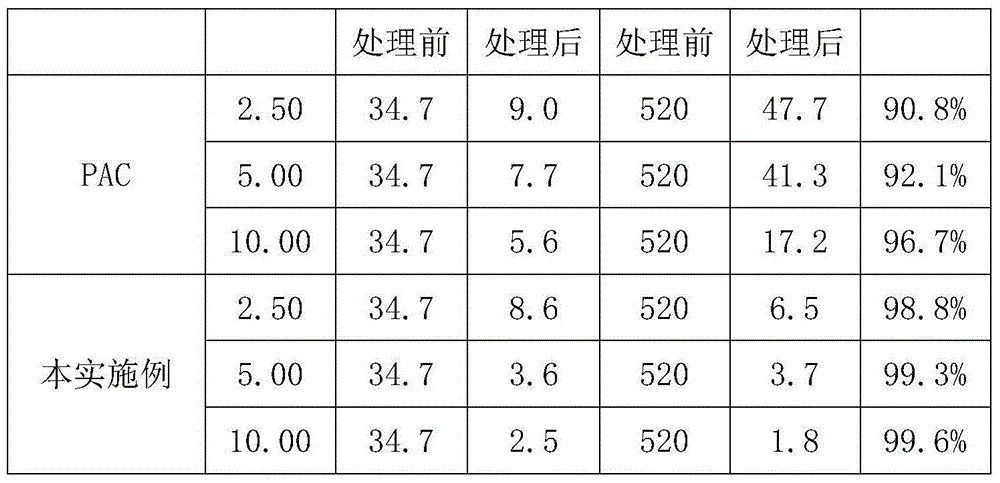

Deoiling powdery blue-green algae treatment agent and preparation method thereof

InactiveCN104445495AImprove adsorption capacityHigh nitrogen contentWater/sewage treatment by sorptionWater/sewage treatment by oxidationWater qualityCatalytic oxidation

The invention relates to a deoiling powdery blue-green algae treatment agent which is prepared from the following raw materials in parts by weight: 14-18 parts of tetra calcium aluminoferrite, 5-7 parts of hydroxyethyl cellulose, 10-15 parts of filter powder, 10-14 parts of expanded graphite, 20-24 parts of vermiculite, 14-19 parts of calcium carbonate, 3-5 parts of ligneous calcium sulphonate, 6-9 parts of titanium dioxide, 8-12 parts of iron oxide red powder, a proper amount of water, 13-16 parts of tea dregs, 13-16 parts of astragalus smicus and 3-4 parts of an adsorption auxiliary. By using astragalus smicus, the deoiling powdery blue-green algae treatment agent after high-temperature treatment is not only good in suspension property and good in adsorption on blue-green algae, but also is high in nitrogen content of astragalus smicus; the n / p ratio of water quality can be improved, the growth of blue-green algae is inhibited, and by match of expanded graphite and vermiculite, the deoiling powdery blue-green algae treatment agent can adsorb blue-green algae, is good in suspension property and easy to gather and fish. Moreover, the expanded graphite is good in oil absorption. By adding titanium dioxide and iron oxide red powder, ecological balance is not affected while the blue-green algae are killed by catalytic oxidation.

Owner:WUHU XIANGRONG FOOD

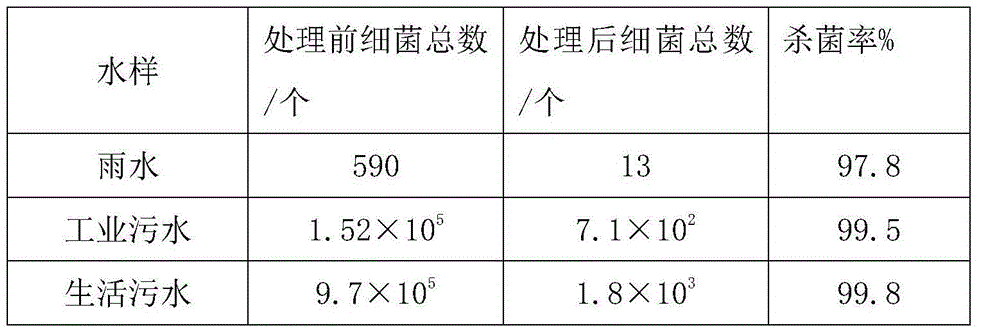

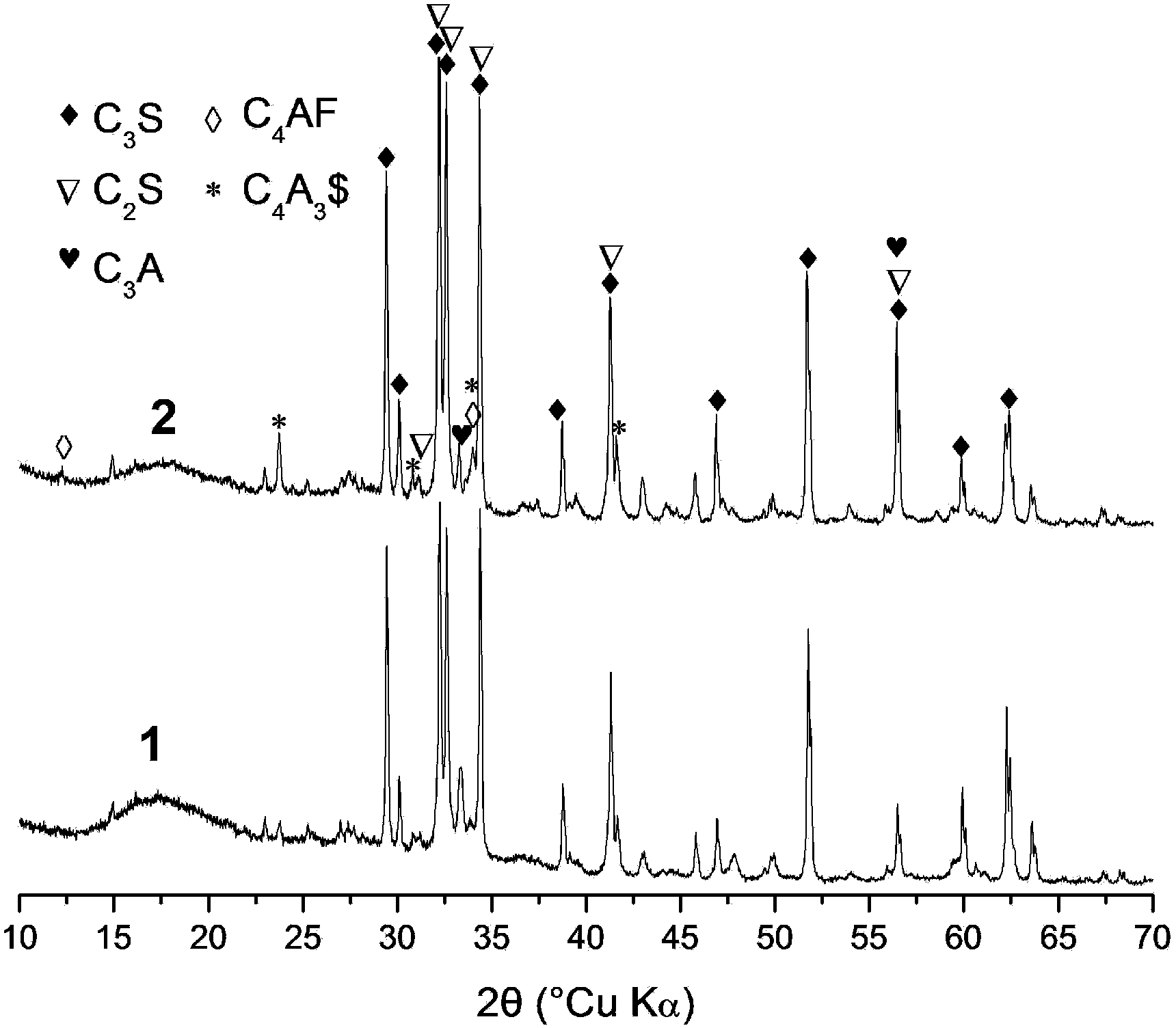

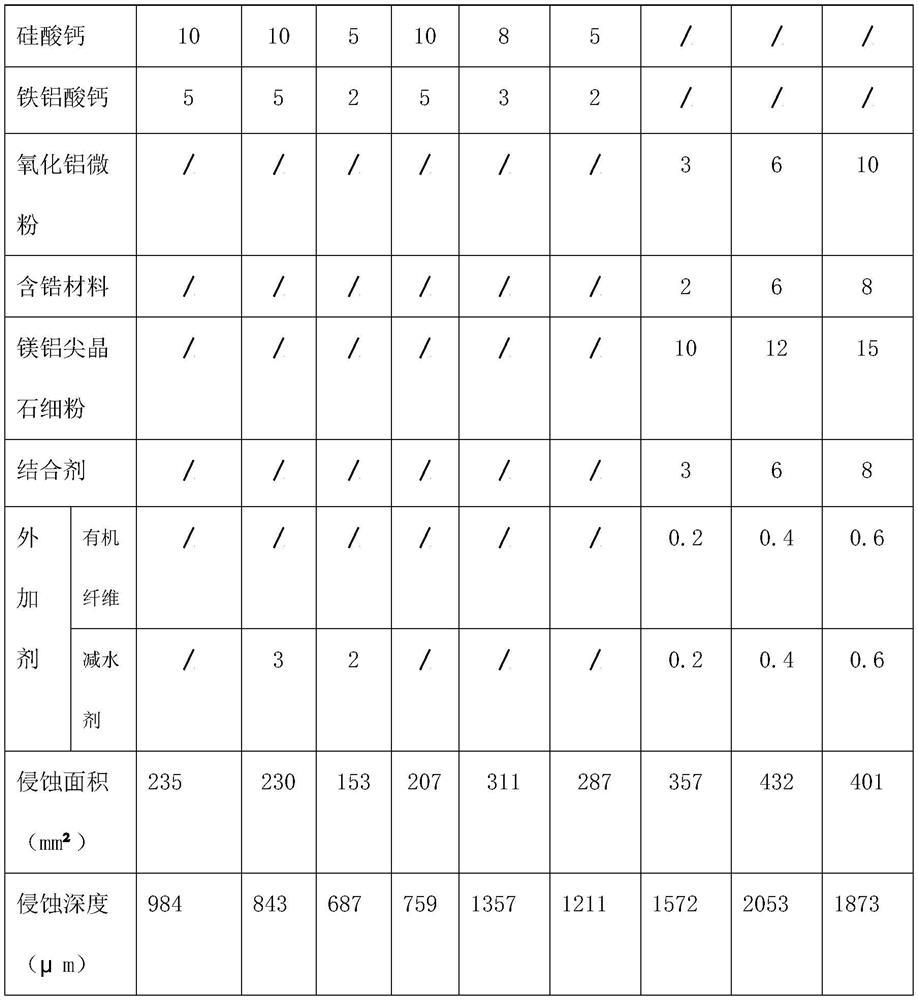

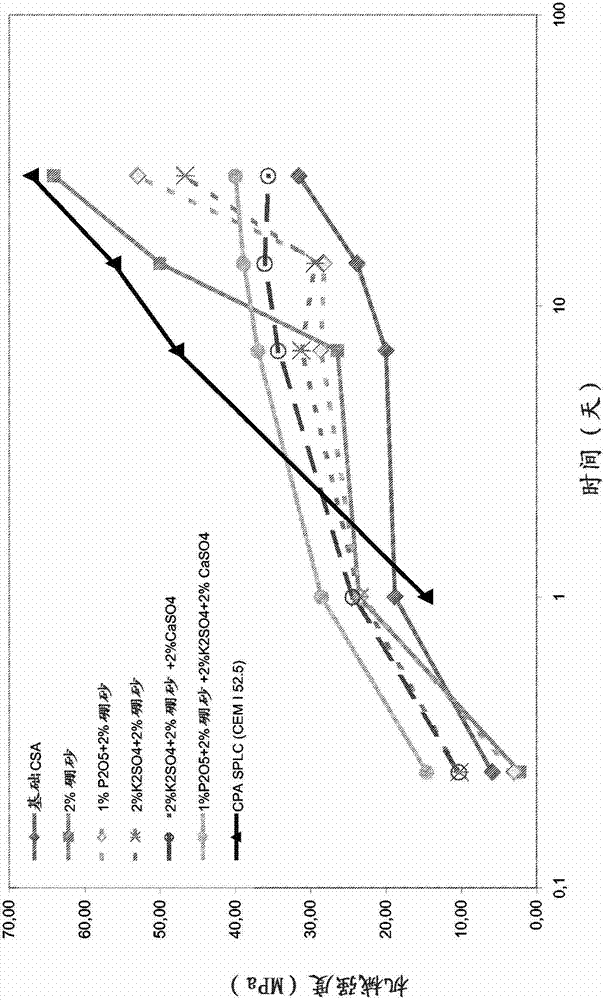

High belite-containing sulfoaluminous clinker, method for the production and the use thereof for preparing hydraulic binders

InactiveCN102745918AHelps develop long-term strengthReduce industrial emissionsSolid waste managementCement productionManganesePotassium

The present invention concerns a belite-rich sulphoaluminous clinker, a method for producing such a clinker and its use for preparing hydraulic binders, and comprising as a mineralogical formulation: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase with a formulation corresponding to the general formula C2AXF(1-X), with X comprised between 0.2 and 0.8. 15 to 35%, preferably 20 to 30%, of a calcium sulphoaluminate phase 'yee' limite' (C4A3$), 40 to 75%, preferably 45 to 65% belite (C2S), from 0.01 to 10% of one or several minor phases selected from calcium sulphates, alkaline sulphates, perovskite, calcium aluminates, gehlenite, free limestone and periclase, and / or a vitreous phase, and at least one or several secondary elements selected from sulphur, magnesium, sodium, potassium, boron, phosphorus, zinc, manganese, titanium, fluorine, chlorine, the total content of these secondary elements being less than or equal to 15%.

Owner:LAFARGE SA

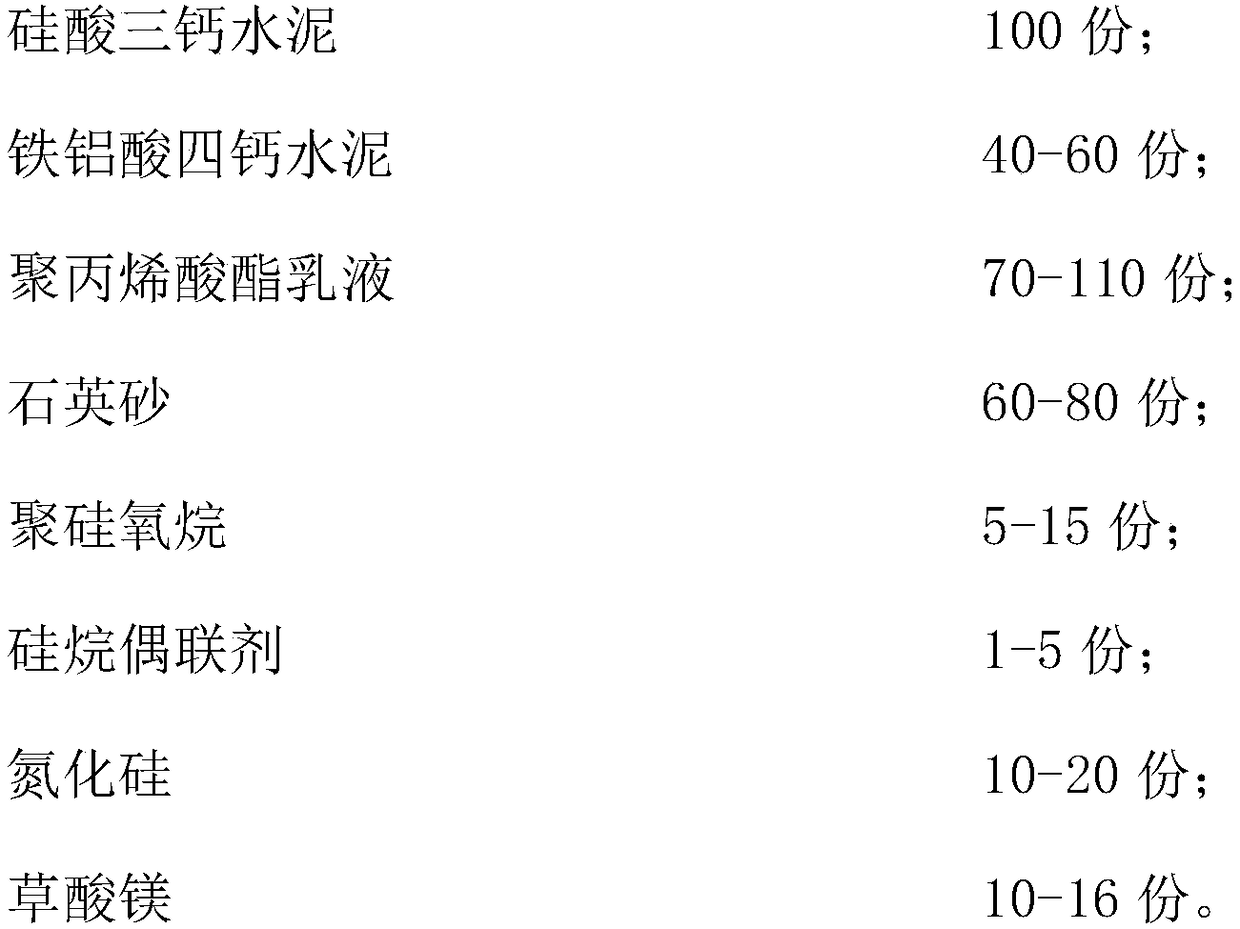

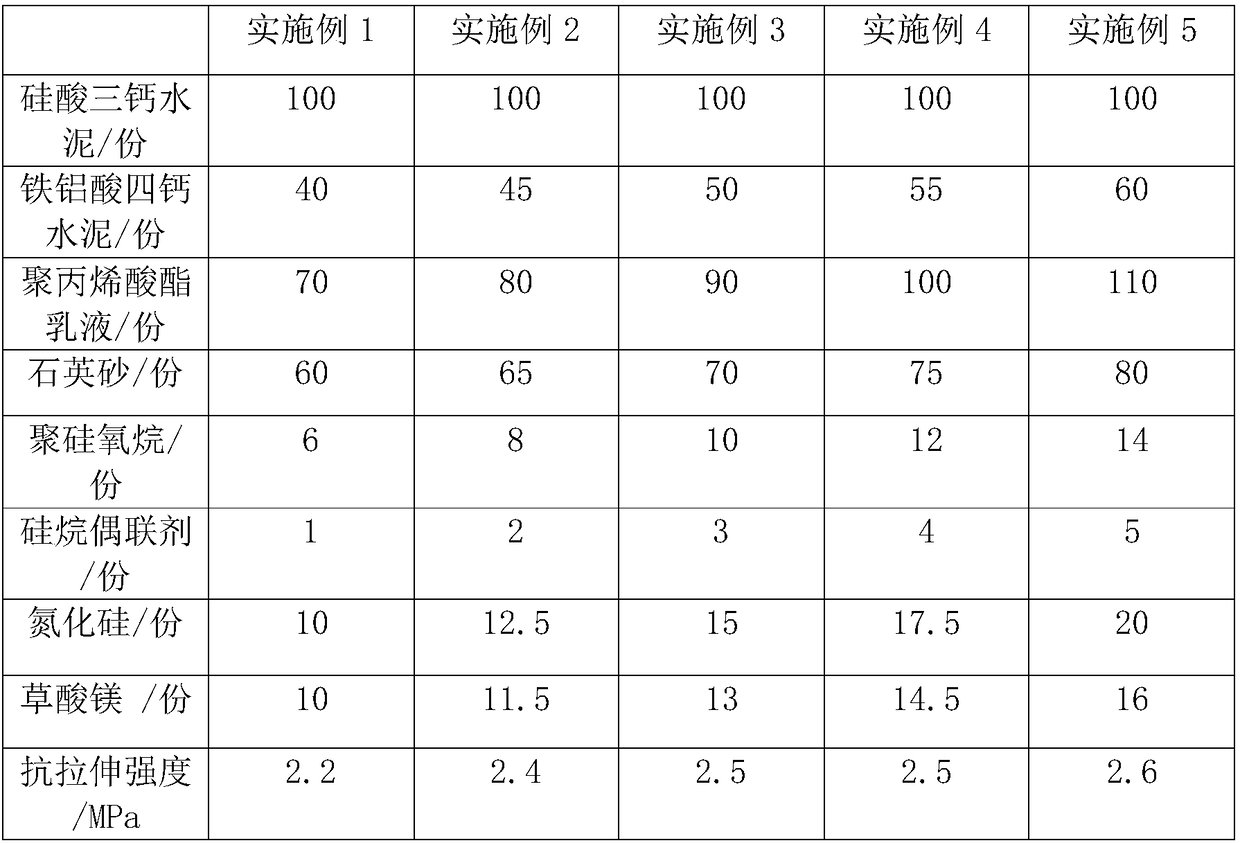

Polyacrylic ester polymer cement-based waterproof paint and preparation method thereof

The invention discloses polyacrylic ester polymer cement-based waterproof paint and a preparation method thereof. The paint is prepared from the following ingredients in parts by weight: 100 parts oftricalcium silicate cement, 40 to 60 parts of tetra-calcium aluminoferrite cement, 70 to 110 parts of polyacrylic ester emulsion, 60 to 80 parts of quartz sand, 5 to 15 parts of polysiloxane, 1 to 5 parts of silane coupling agents, 10 to 20 parts of silicon nitride and 10 to 16 parts of magnesium oxalate. The preparation method comprises the following steps of mixing the tricalcium silicate cement, the tetra-calcium aluminoferrite cement, the quartz sand, the silicon nitride and the silicon carbide; dispersing the mixture into the polyacrylic ester emulsion; heating the materials to 85 DEG C;then, adding the polysiloxane and silane coupling agents; performing stirring reaction; when the quantity of Si-C, Si-O-C, Si-C-N and Si-O-Si in the reaction system is unchanged, and after the cooling, adding the magnesium oxalate; performing homogeneous treatment. The produced polyacrylic ester polymer cement-based waterproof paint can be fast cured and coagulated; the space structure is compact;excellent mechanical property and waterproof and acid-alkali resistant performance are realized.

Owner:安徽朗凯奇科技股份有限公司

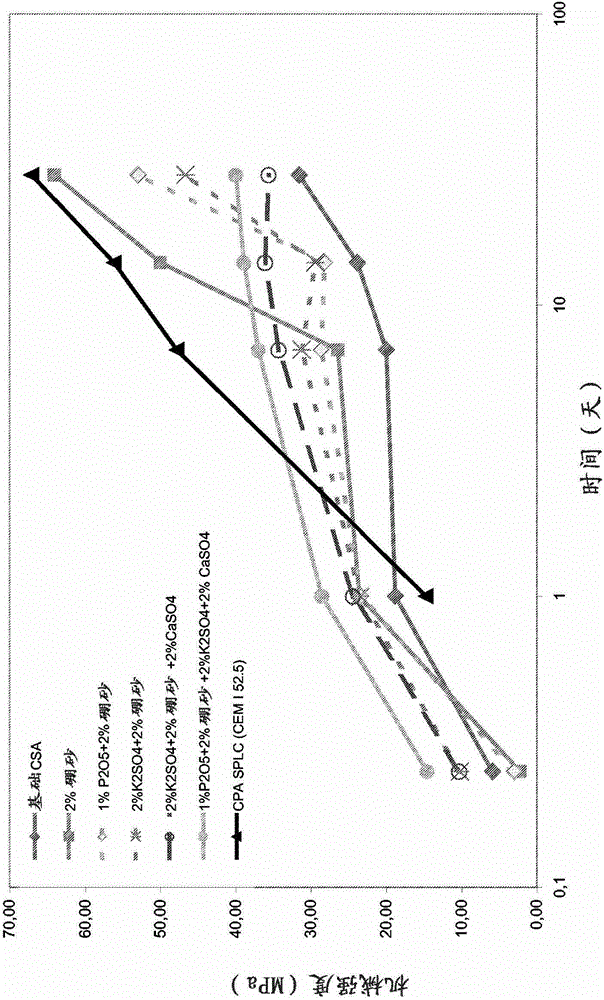

Phosphoaluminate early strength cement clinker being high in content of calcium aluminoferrite

A phosphoaluminate early strength cement clinker being high in content of calcium aluminoferrite includes, by mass, 1-10% of SiO2, 10-50% of Al2O3, 9-15% of Fe2O3, 35-55% of CaO, 10-30% of P2O5 and the balanced being impurities, wherein the raw materials are mixed and are calcined at 1500-1800 DEG C to sinter the phosphoaluminate early strength cement clinker being high in the content of calcium aluminoferrite. The cement clinker is low in sintering temperature and cost and is better in mechanical performance and anti-erosion performance.

Owner:HUANGSHI YONGMING ENVIRONMENTAL PROTECTION TECH CO LTD

Magnesium oxychloride wall

The invention provides a magnesium oxychloride wall. The magnesium oxychloride wall is prepared from raw materials in parts by weight as follows: 80-100 parts of magnesium chloride, 50-70 parts of magnesium oxide, 5-20 parts of fly ash, 6-12 parts of perlite, 5-10 parts of quartz sand, 5-20 parts of tetra calcium aluminoferrite, 5-20 parts of maize straw, 1-10 parts of a stearic acid-polyvinyl alcohol emulsion, 3-5 parts of phosphorus slag powder, 5-10 parts of graphite powder, 1-5 parts of talc powder, 2-6 parts of ferrous sulfate, 1-4 parts of 307 resin, 5-10 parts of sawdust, 1-2 parts of polypropylene fibers and 5-12 parts of silicon carbide whiskers. According to the raw material formula of the wall, magnesium chloride and magnesium oxide are used as the main raw materials and matched with various functional components, and all the components are matched for use as a whole, so that the prepared magnesium oxychloride wall has excellent performance such as high strength, heat resistance, water resistance, heat insulation, freezing resistance, corrosion resistance, acid and alkali resistance and avoidance of efflorescence.

Owner:广东晶盈环保建材实业有限公司

Belite-strontium calcium sulphoaluminate cement

InactiveCN101857388AImprove early strengthImprove volume stabilityCement productionCalcium silicateStrontium

The invention discloses belite-strontium calcium sulphoaluminate cement. Cement clinker comprises the following mineralogical phase systems in percentage by weight: 1-20% of strontium calcium sulphoaluminate, 30-60% of dicalcium silicate, 10-45% of tricalcium silicate and 2-20% of calcium aluminoferrite, wherein a chemical formula of the strontium calcium sulphoaluminate is (3-x) CaO.xSrO.3Al2O3.CaSO4, wherein x is equal to 1-3. The invention enhances the early strength of the belite cement, saves the energy and resources, improves the volume stability of the belite cement, and has waste reclamation, environment improvement and low production cost.

Owner:UNIV OF JINAN

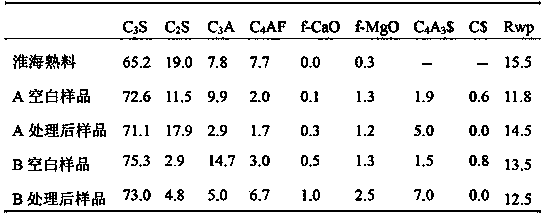

A kind of high-strength Portland cement clinker and its preparation method

The invention relates to high-strength silicate cement clinker and a preparation method thereof. The mineral constituents of the clinker are as follows in percentage by weight: alite (50%-75% of tricalcium silicate C3S), belite (2%-25% of dicalcium silicate C2S), tricalcium aluminate (2%-10% of C3A), tetra calcium aluminoferrite (2%-8% of C4AF), calcium sulphoaluminate (2%-9% of C4A3S), free calcium oxide (0.5%-3% of f-CaO), periclase (1%-6% of f-MgO) and bassanite (0-3% of CS). 1-day stand mortar strength, 3-day stand mortar strength and 28-day standard mortar strength are respectively 25MPa-35MPa, 38MPa-45MPa and 65MPa-75MPa; the clinker has certain expansibility after being hydrated; and the hydrated sample volume porosity is 10%-12%. The preparation method of the clinker comprises the following steps of: introducing gypsum to raw materials; improving content of SO3 in the materials to form calcium sulphoaluminate; properly improving aluminum ratio in dosing to control liquid phase amount in the clinker, and reducing the content of iron in the clinker; and sintering the materials into clinker under 1400 DEG C to 1500 DEG C, cooling and thermally treating the cooled clinker, quenching after the treatment is finished, wherein the clinker with high alite content is mainly formed in the first sintering process, and the secondary formation of calcium sulphoaluminate is promoted by the thermal treatment.

Owner:NANJING TECH UNIV

Curing gent for building material

The invention discloses a curing gent for a building material. The curing agent comprises the following ingredients in formula: sulfoaluminate, silica, tetra calcium aluminoferrite, fine-grained gypsum, calcium sulfate, sodium chloride, calcium chloride, ammonium bicarbonate, potassium carbonate, sodium carbonate and water. The curing agent prepared from the formula is nontoxic, free of any toxic and side effects on a human body after being used for a long time, has the curing effect of a common curing agent and also has the effect of decomposing harmful substances; meanwhile, the potassium carbonate, sodium carbonate and sodium chloride in the formula have the effects of regulating the pH value and resisting freezing and ageing. The curing agent has good economic benefits and social values.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

Moderate heat anti-crack type Portland cement

The invention discloses moderate heat anti-crack type Portland cement. The moderate heat anti-crack type Portland cement is characterized in that cement clinker of the moderate heat anti-crack type Portland cement comprises the following mineral components in weight percent: 20-30% of tricalcium silicate, 40-60% of dicalcium silicate, 7-11% of tricalcium aluminate, 5-10% of tetra calcium aluminoferrite and 1-8% of free calcium oxide, wherein the content of magnesium oxide in the cement is 0.5-1.0%, the alkali content is not more than 0.5%, the content of sulfur trioxide is not more than 2.0%, and all the percents are weight percents. The moderate heat anti-crack type Portland cement can obviously improve the crack resistance of hydraulic concrete.

Owner:关勇河

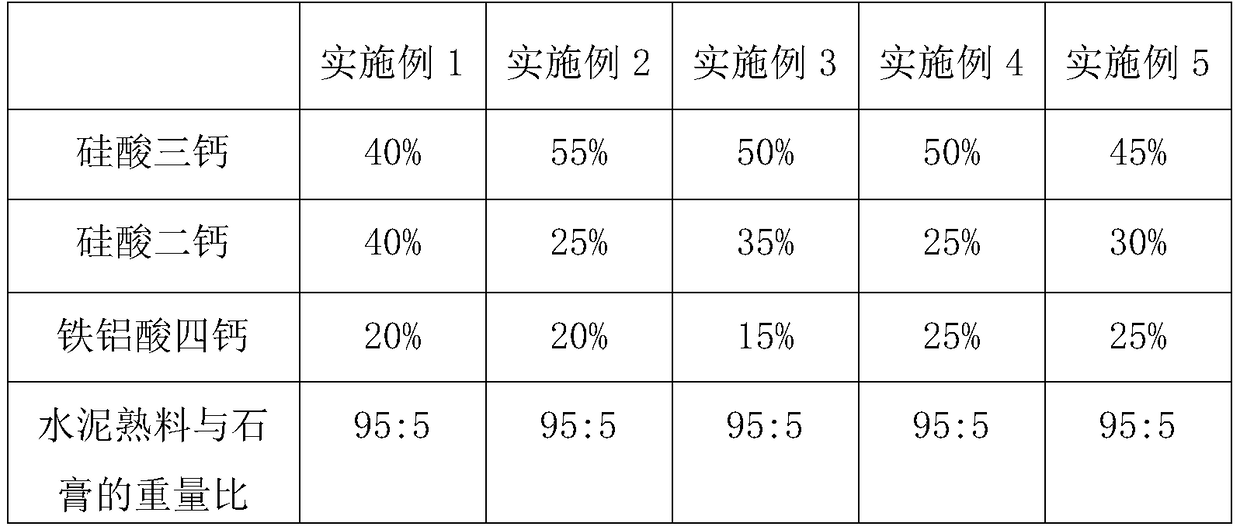

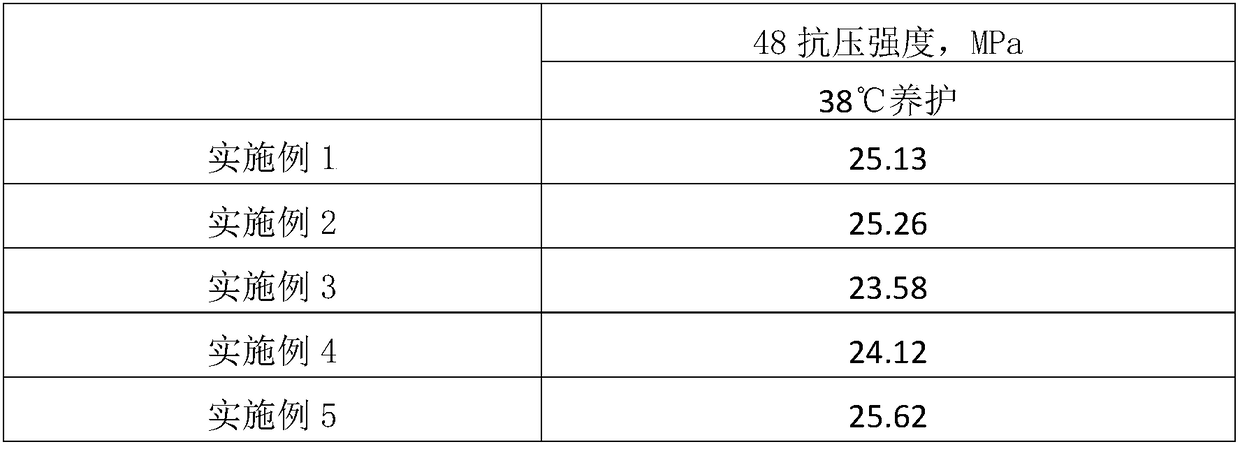

Shale gas horizontal well cementating cement and shale gas horizontal well cementating cement paste

ActiveCN108793783AExtended service lifeImprove performanceCement productionDrilling compositionCement pasteShale gas

The invention relates to shale gas horizontal well cementating cement and shale gas horizontal well cementating cement paste. The shale gas horizontal well cementating cement is prepared from cement clinker and gypsum. In percentage by weight, the cement clinker is prepared from the following mineral compositions: 40-55% of tricalcium silicate, 25-40% of dicalcium silicate, and 15-25% of tetra calcium aluminoferrite. The shale gas horizontal well cementating cement is capable of solving a problem in a shale gas horizontal well cementating project that set cement is brittle failure, a preparation method is simple and easy to operate, the current shale gas horizontal well cementating cement can be replaced, and the shale gas horizontal well cementating cement is beneficial to the structuraldurability and safety of the shale gas horizontal well cementating project.

Owner:CHINA BUILDING MATERIALS ACAD

A method for preparing low-carbon cement clinker from iron tailings

ActiveCN103373826BIncrease the blending ratioEmission reductionCement productionCement mortarMaterials science

The invention provides a method for preparing low-carbon cement clinker by utilizing iron tailings. The method for preparing the low-carbon cement clinker comprises the step of firing the iron tailings and limestone as main raw materials at the temperature lower than 1400 DEG C. The low-carbon cement clinker comprises the following mineral compositions: 70-85% of dicalcium silicate, 5-15% of tricalcium silicate, 0-5% of tricalcium aluminate and 4-15% of tetra calcium aluminoferrite. The method has the advantages that the proportion of iron tailings in the raw materials can be up to 32%; in addition, compared with the firing temperature 1450 DEG C of traditional portland cement clinker, the firing temperature is reduced by 50-150 DEG C; compared with the emission of the greenhouse gases in traditional cement production, the emission of CO2 and other NOx-based greenhouse gases is reduced by about 20%. The cement prepared by utilizing the low-carbon cement clinker has the advantages that the 28-day strength can be up to 65-75 MPa; the strength grade is up to 62.5; the cement mortar dispersion degree can be up to 135-200mm; the cement is low in the hydration heat, good in safety and excellent in working performance.

Owner:承德金隅水泥有限责任公司

Medium-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 35 to 55 percent of tricalcium silicate, 15 to 35 percent of dicalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 percent and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 320m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 22MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.5MPa, the 3-day hydration heat is less than or equal to 241KJ / kg, and the 7-day tensile strength is less than or equal to 283KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

Multipurpose anti-lighting waterproof sealant

The invention relates to a multipurpose anti-lighting waterproof sealant belonging to sealants and aiming to provide a power system external equipment surface sealant resisting pollution flashover, lightning, permeability, corrosion, aging, freezing and low temperature and having strong weatherability. The multipurpose anti-lighting waterproof sealant is prepared by mixing the following components in parts by weight: 10-20 parts of anti-pollution flashover coating, 20-30 parts of permeability-reducing agent and 15-25 parts of preservative, wherein the anti-pollution flashover coating is vulcanized silicone rubber, the permeability-reducing agent is anhydrous calcium sulphoaluminate, tetra calcium aluminoferrite or a mixture of the two substances, and the preservative is pentachlorophenol, copper naphthenate or a mixture of the two substances. The multipurpose anti-lighting waterproof sealant of the invention is directly sprayed on the surface of the power system equipment to be protected, is convenient to use and operate, is suitable for the maintenance need of various kinds of power system external equipment, is particularly suitable for needs under adverse weather conditions, has long service life and can greatly lighten the workload of power maintenance staff.

Owner:刘志强

Ethylene propylene rubber catalyst composition

The invention discloses an ethylene propylene rubber catalyst composition which comprises, by weight, 10-30 parts of calcium silicate, 10-35 parts of tetra-calcium aluminoferrite, 10-20 parts of sodium oxide, 8-20 parts of isoprene, 10-20 parts of ethane, 5-15 parts of 3,5-di-tert-butyl salicylaldehyde, 10-25 parts of nanometer titanium dioxide, 10-20 parts of titanium isopropoxide, 15-25 parts of alkyl aluminum compound solution, 10-30 parts of tridecyl trimethyl ammonium bromide, 10-25 parts of butadiene alkane solution and 5-15 parts of organic rare earth compounds. The ethylene propylene rubber catalyst composition is simple in production process, a preparation process is environmentally friendly and free from contamination, a prepared catalyst is good in stability, low in reaction temperature, short in reaction time and high in activity, and the conversion rate of ethylene propylene rubber can be increased.

Owner:SHANDONG CHENGTAI CHEM IND

Curing agent for building material

The invention discloses a curing agent for building material which comprises the following main components: sulfoaluminate, silicon dioxide, tetra calcium aluminoferrite, grinded gypsum, calcium sulfate, sodium chloride, calcium chloride, hydroxyethyl cellulose, sodium polyphosphate, ammonium bicarbonate, potassium carbonate, sodium carbonate and the balance of water. The curing agent has the advantages that the curing agent prepared according to the formula is non-toxic, free of toxic or side effect on human bodies in long-term use and has effects of decomposing harmful substances in addition to a hardening function of a common curing agent, in addition, the potassium carbonate, the sodium carbonate and the sodium chloride in the formula have the effects of adjustment on power of hydrogen, freezing resistance and aging resistance, and good economic benefits and social values can be made.

Owner:南通盛赫园林古建筑工程有限公司

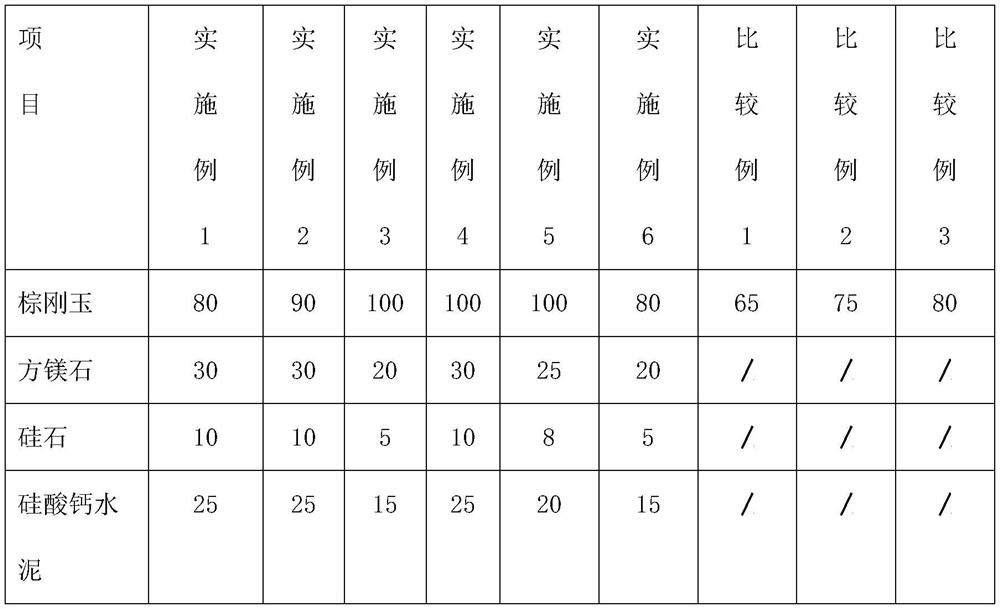

Anti-erosion refractory castable for waste medical incinerator lining and preparation method of anti-erosion refractory castable

The invention provides a waste medical incinerator lining anti-erosion refractory castable and a preparation method thereof, and relates to the technical field of refractory castable, The waste medical incinerator lining anti-erosion refractory castable and the preparation method thereof comprise the following raw materials by weight: 80-100 parts of brown fused alumina, 20-30 parts of periclase, 5-10 parts of silica, and 15-25 parts of calcium silicate cement. The preparation method comprises the following steps: respectively crushing the brown fused alumina, periclase, silica, calcium silicate and calcium aluminoferrite into powder according to the weight ratio, and uniformly mixing to obtain the refractory castable; the refractory castable prepared by the invention is located in a severe environment of the same incinerator, the erosion area is small, the erosion depth is shallow, and the prepared refractory castable has a strong anti-erosion effect.

Owner:郑州汇鑫隆耐火材料有限公司

High belite-containing sulfoaluminous clinker, method for the production and the use thereof for preparing hydraulic binders

The present invention concerns a belite-rich sulphoaluminous clinker, a method for producing such a clinker and its use for preparing hydraulic binders, and comprising as a mineralogical formulation: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase with a formulation corresponding to the general formula C2AXF(1-X), with X comprised between 0.2 and 0.8. 15 to 35%, preferably 20 to 30%, of a calcium sulphoaluminate phase 'yee' limit' (C4A3$), 40 to 75%, preferably 45 to 65% belite (C2S), from 0.01 to 10% of one or several minor phases selected from calcium sulphates, alkaline sulphates, perovskite, calcium aluminates, gehlenite, free limestone and periclase, and / or a vitreous phase, and at least one or several secondary elements selected from sulphur, magnesium, sodium, potassium, boron, phosphorus, zinc, manganese, titanium, fluorine, chlorine, the total content of these secondary elements being less than or equal to 15%.

Owner:LAFARGE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com