Belite-strontium calcium sulphoaluminate cement

A technology of sulfoaluminic acid and calcium aluminate ferrite, which is applied in the field of cement materials, can solve the problems of unimproved shrinkage and cracking of cement, increased energy consumption of cement manufacturing, and increased consumption of high-quality resources, so as to realize waste utilization and reduce Effects of consumption and saving energy and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

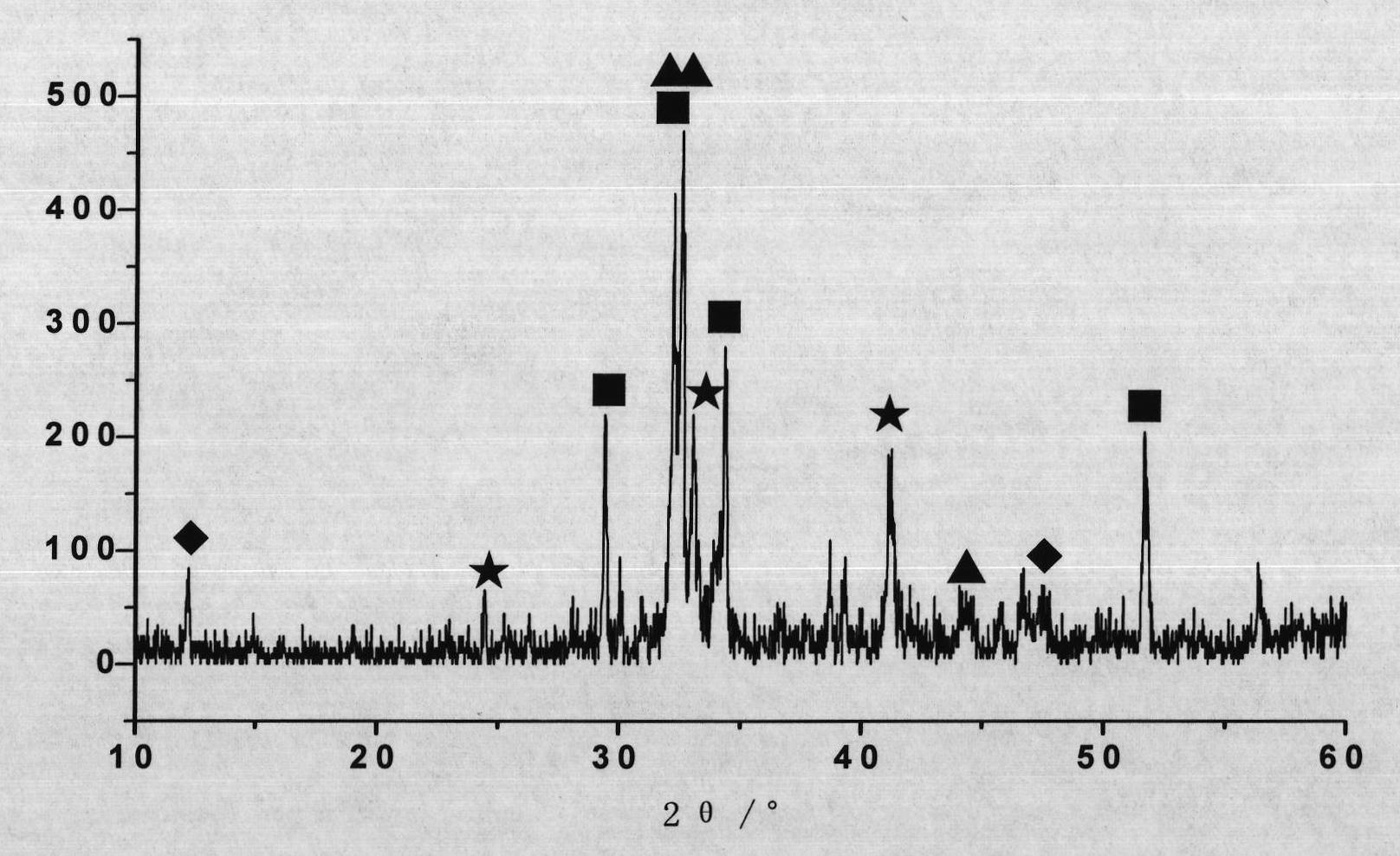

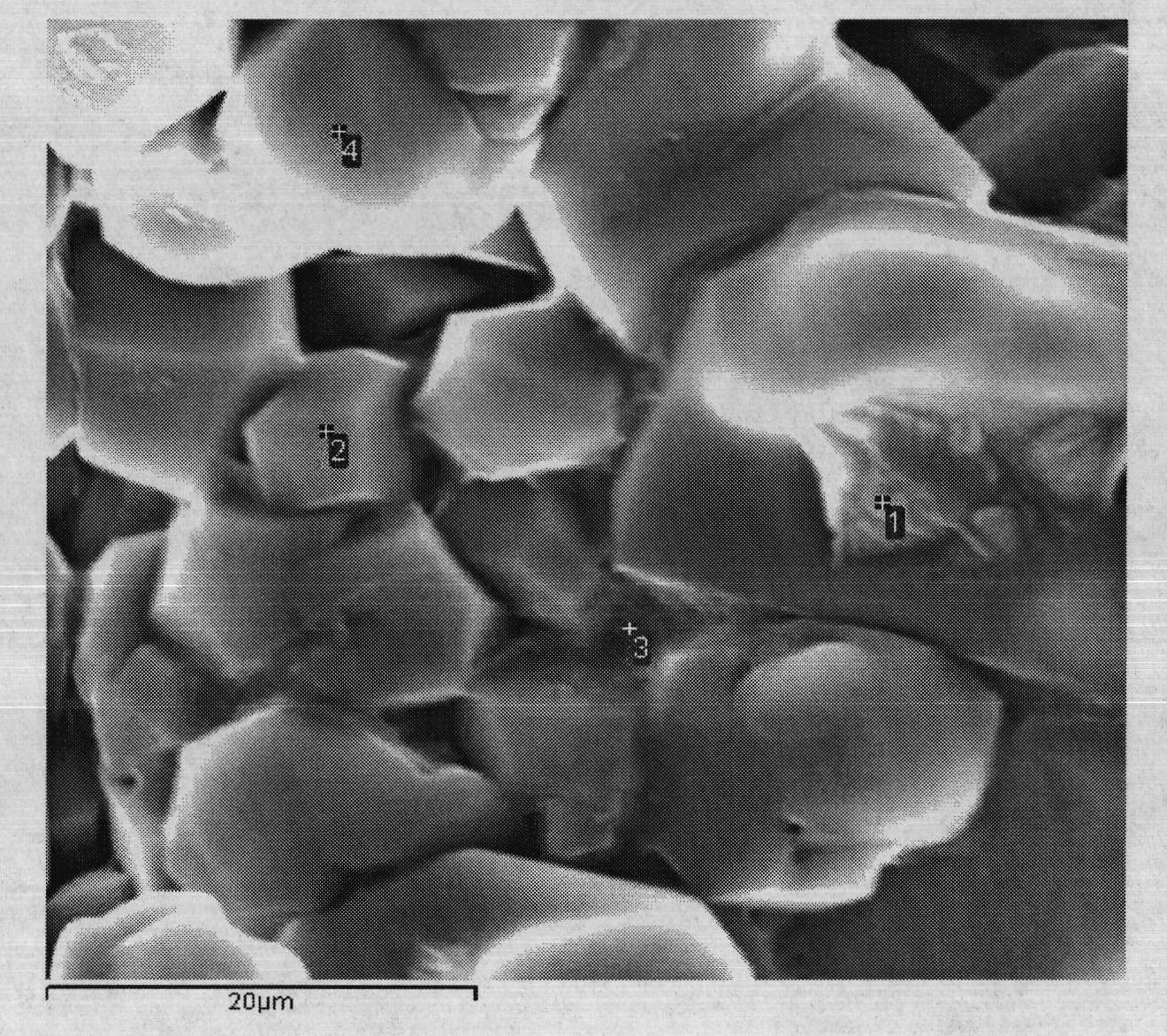

Image

Examples

Embodiment Construction

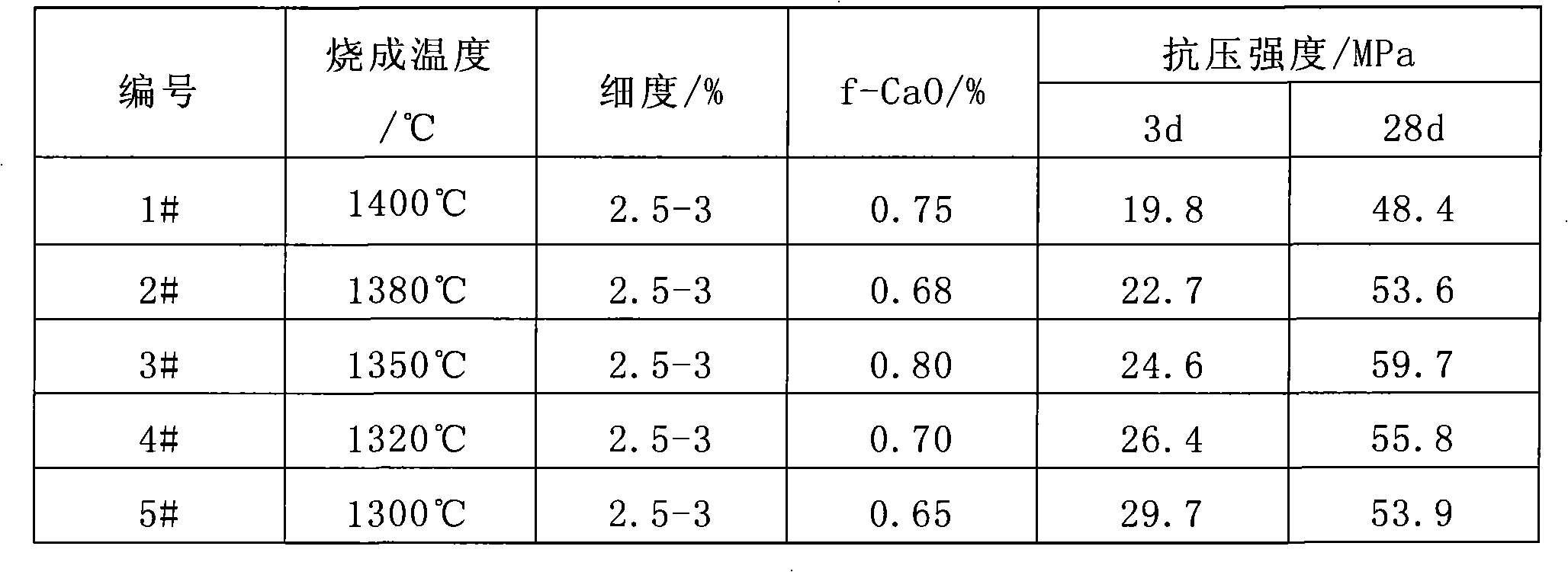

[0037] See Table 1 for specific examples of the Belite-calcium strontium sulfoaluminate cement of the present invention.

[0038] Table 1 Cement raw meal chemical composition / weight%

[0039] Numbering

loss

CaO

SiO 2

al 2 o 3

Fe 2 o 3

SO 3

SrO

CaF 2

1#

34.08

43.35

16.73

3.05

2.32

0.15

0.19

0.13

2#

33.64

42.28

16.63

3.01

2.3

0.56

1.31

0.27

3#

32.96

41.94

16.21

2.93

2.27

0.77

2.5

0.42

4#

32.37

41.2

15.91

2.89

2.25

1.33

3.46

0.59

5#

31.26

39.78

15.37

2.78

2.15

2.2

5.71

0.75

[0040] According to the proportioning of the above-mentioned embodiment 1-5# according to the proportion of 1-5#, the present invention will reactant raw material CaO, SiO 2 , Al 2 o 3 , Fe 2 o 3 , SrO, SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com