Patents

Literature

38 results about "Alite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

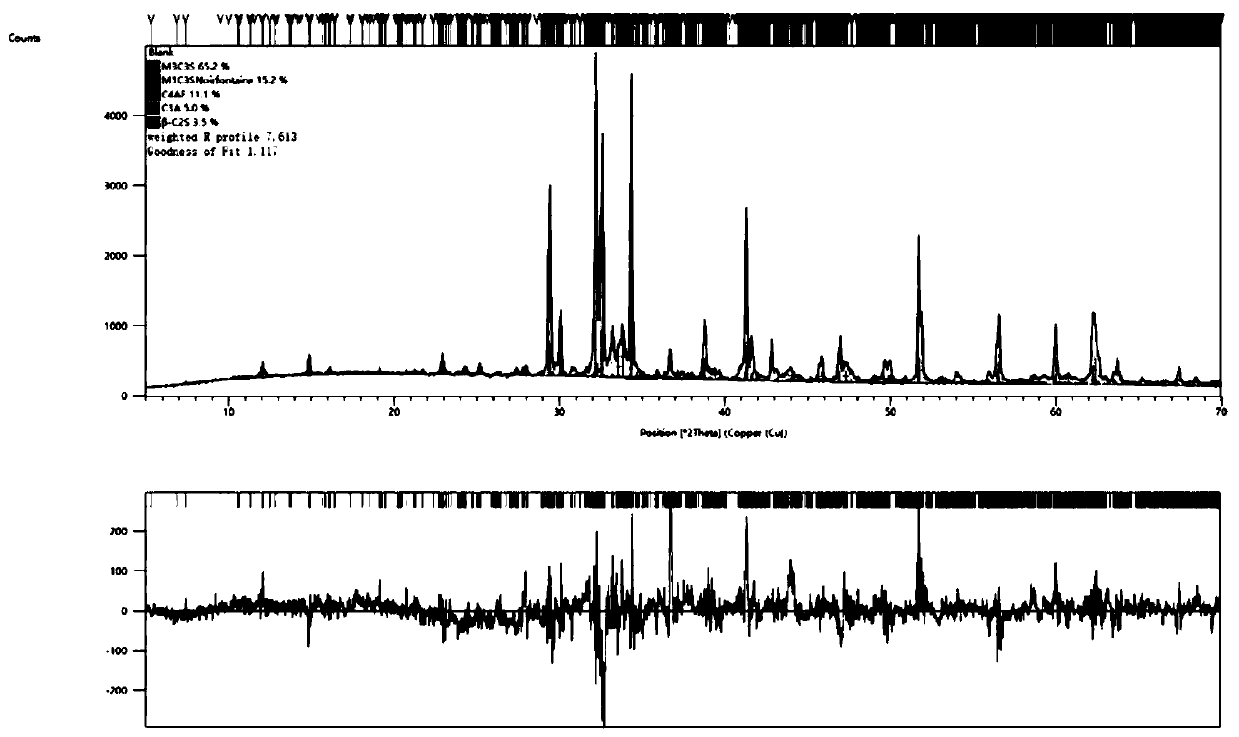

Alite is an impure form of tricalcium silicate, Ca₃SiO₅, sometimes formulated as 3CaO·SiO₂ (C₃S in cement chemist notation, CCN) with typically 3-4% of substituent oxides. It is the major, and characteristic, mineral phase in Portland cement. The name was given by Törnebohm in 1897 to a crystal identified in microscopic investigation of Portland cement. Alite is a name in common use in the cement industry, but it is very rare in nature (known as hatrurite).

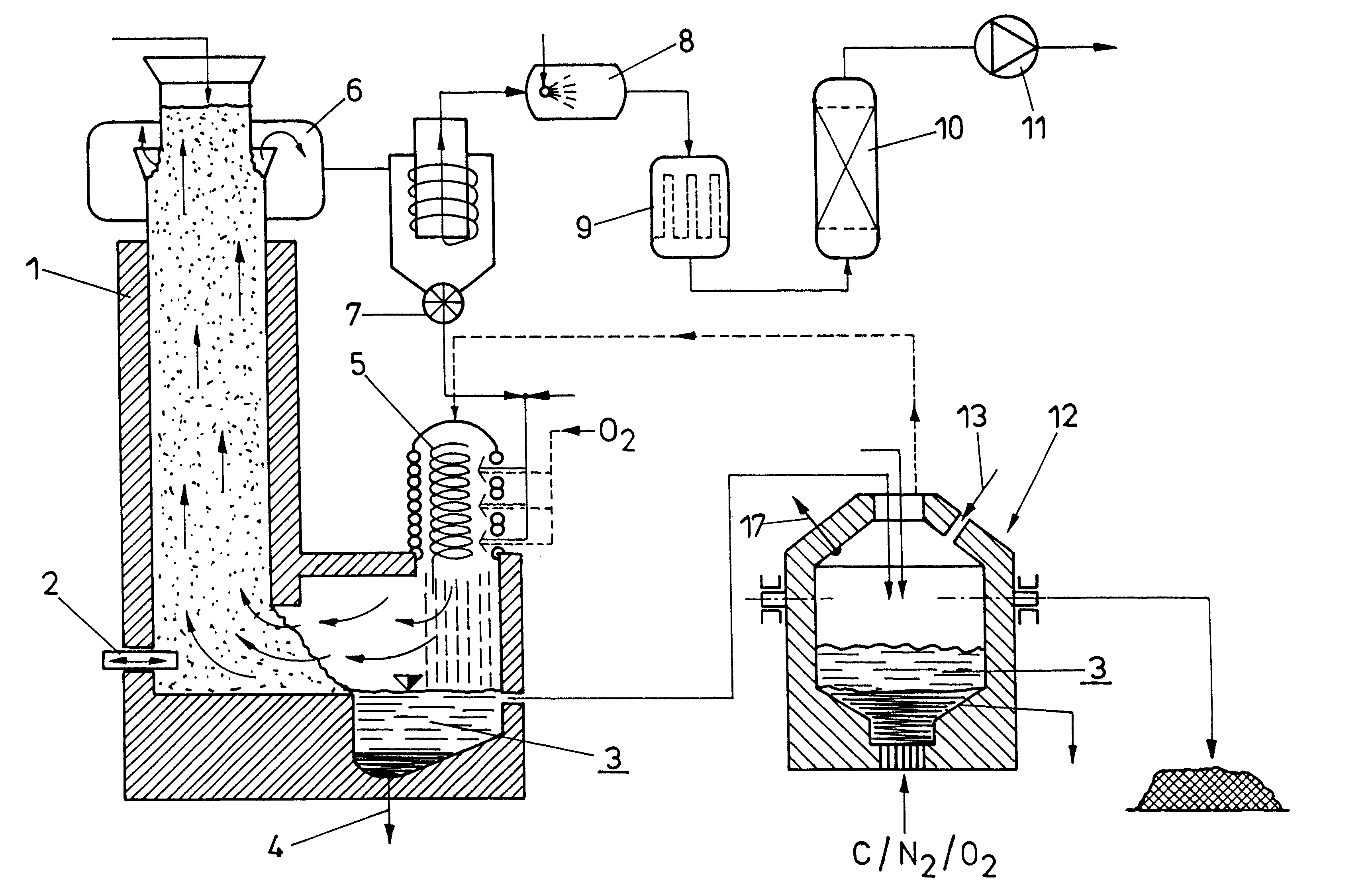

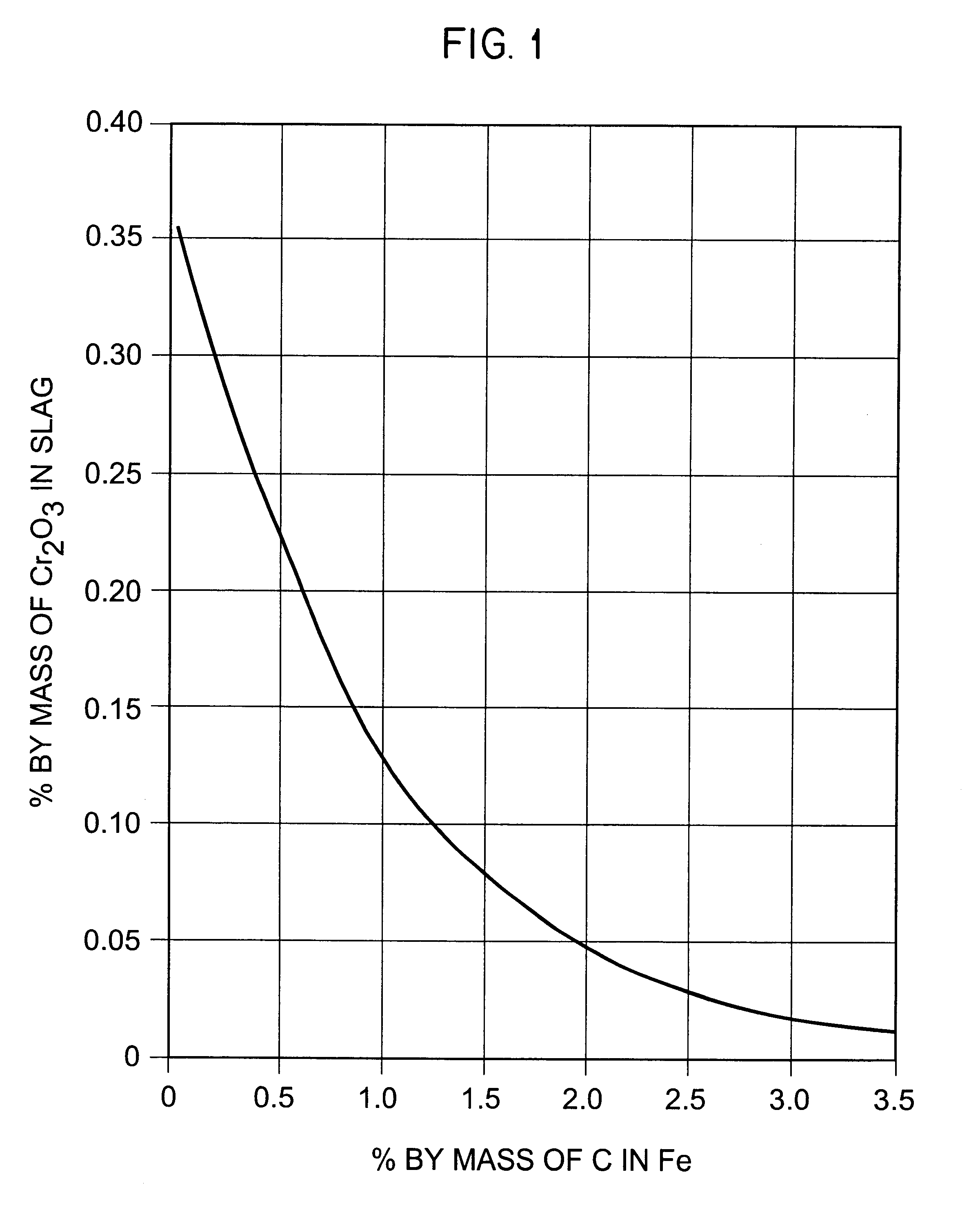

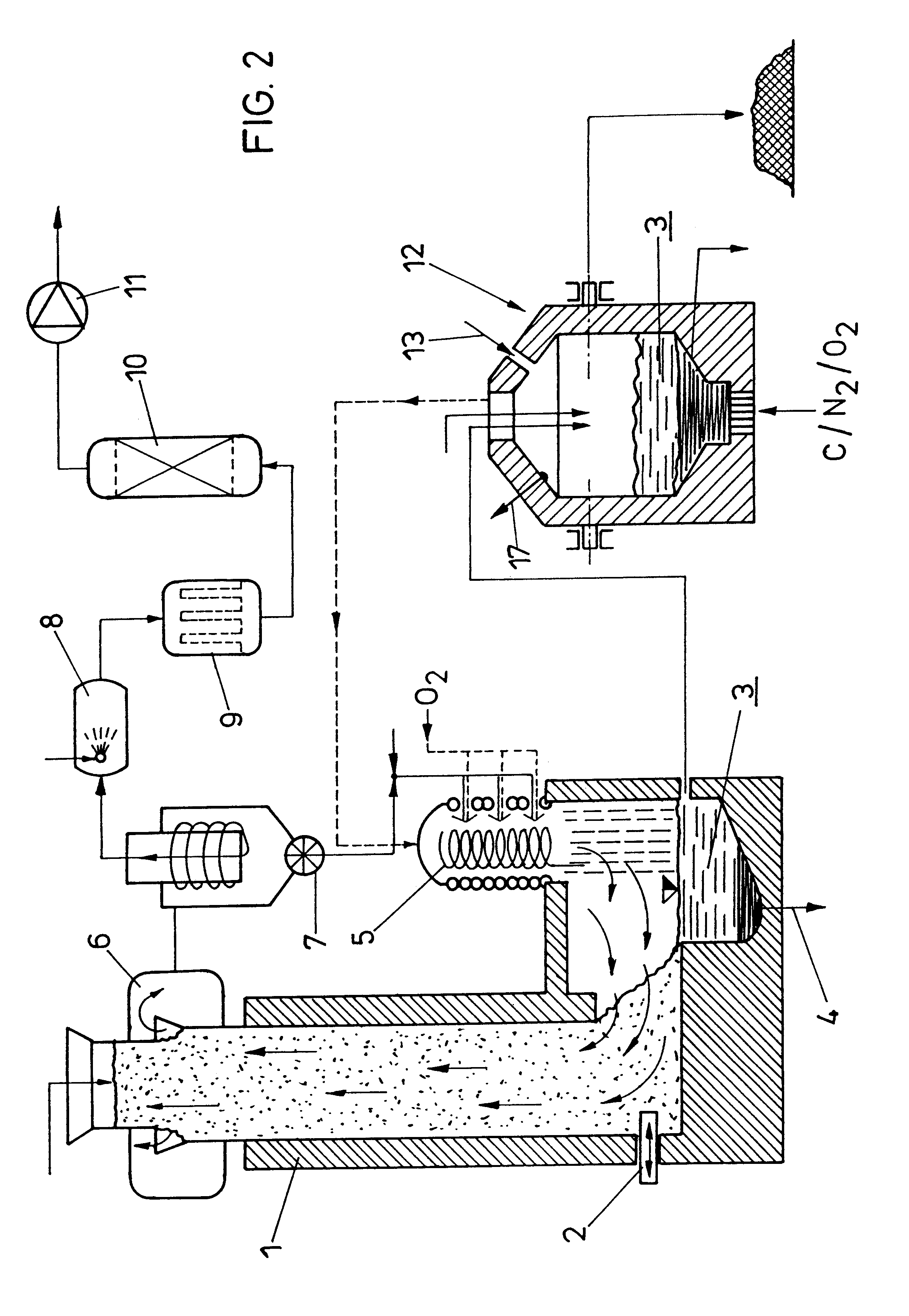

Process for producing pozzolanes, synthetic blast furnace slags, belite or alite clinkers, or pig iron alloys from oxidic slags

InactiveUS6395054B1Little structural expenditureOperational securityGlass furnace apparatusGlass shaping apparatusAlloyBelite

A process that produces pozzolanes, synthetic blast furnace slags, belite, or alite clinkers, as well as pig iron alloys, from oxidic liquid slag. The oxidic liquid slag is reduced above an iron bath in a reactor containing submerged tuyeres. Carbon is blown through the submerged tuyeres and into the iron bath to maintain the iron bath at a carbon content of between 2.5 wt % and 4.6 wt %.

Owner:HOLCIM

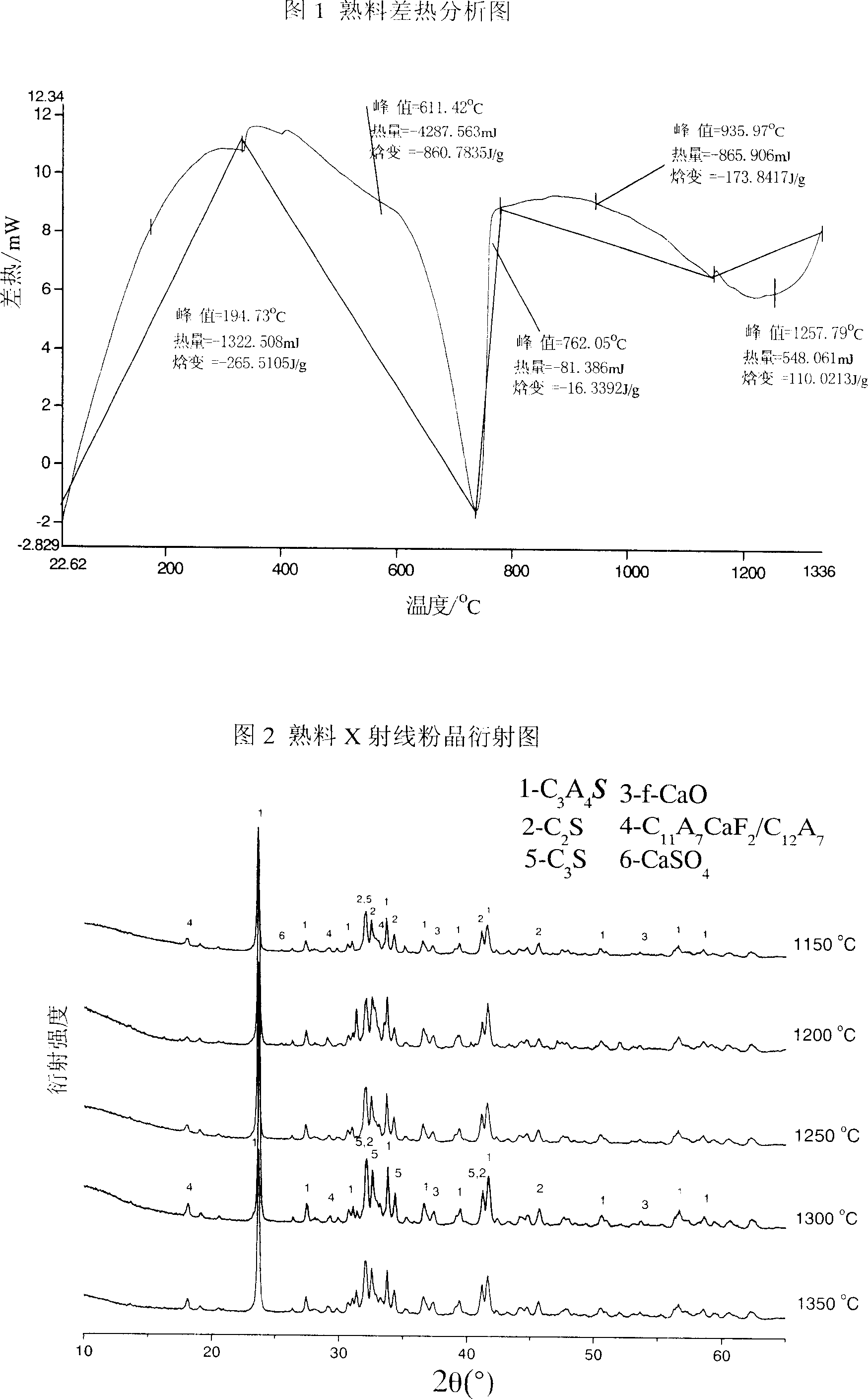

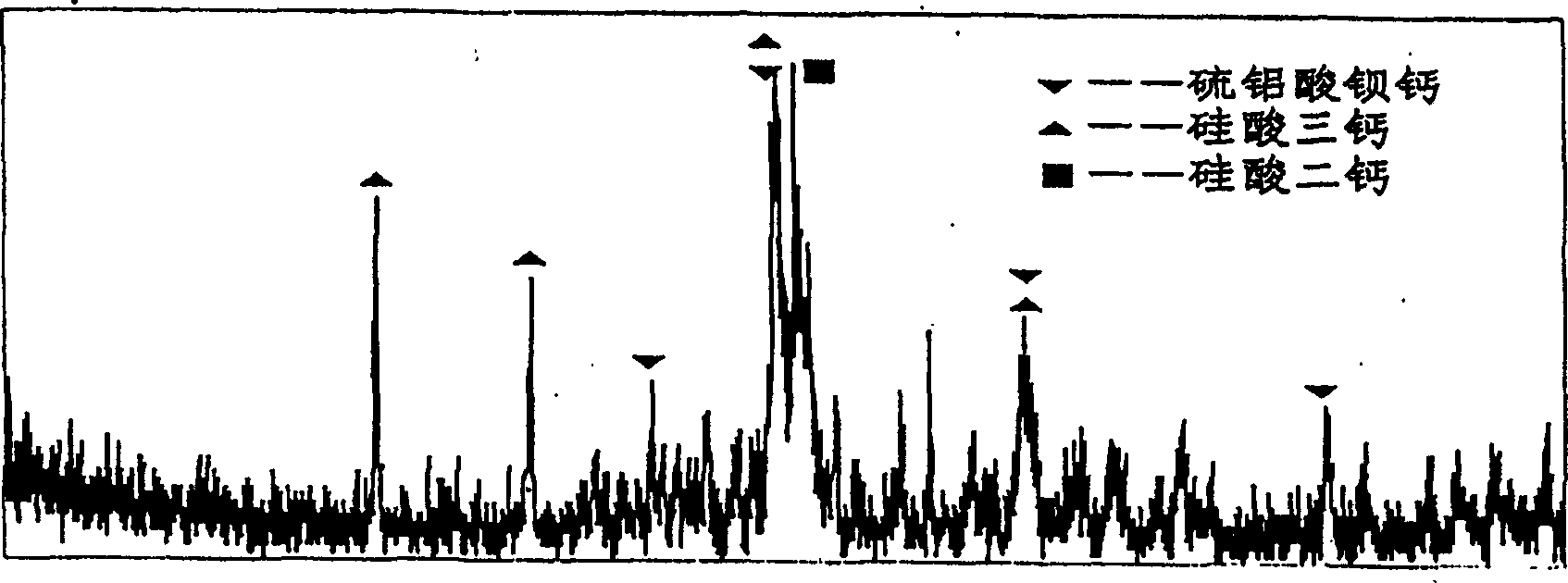

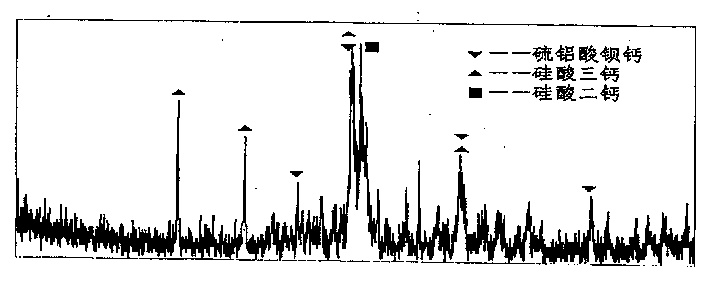

Calcium sulphoaluminate-alite composite mineral phase cement clinker and its preparation method

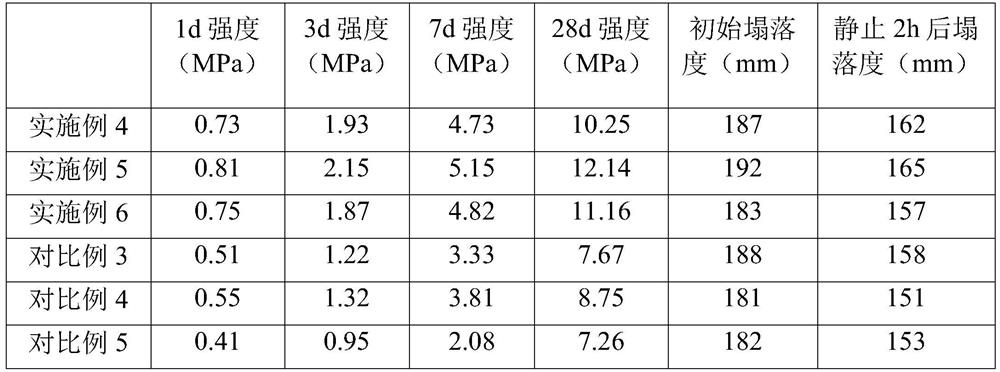

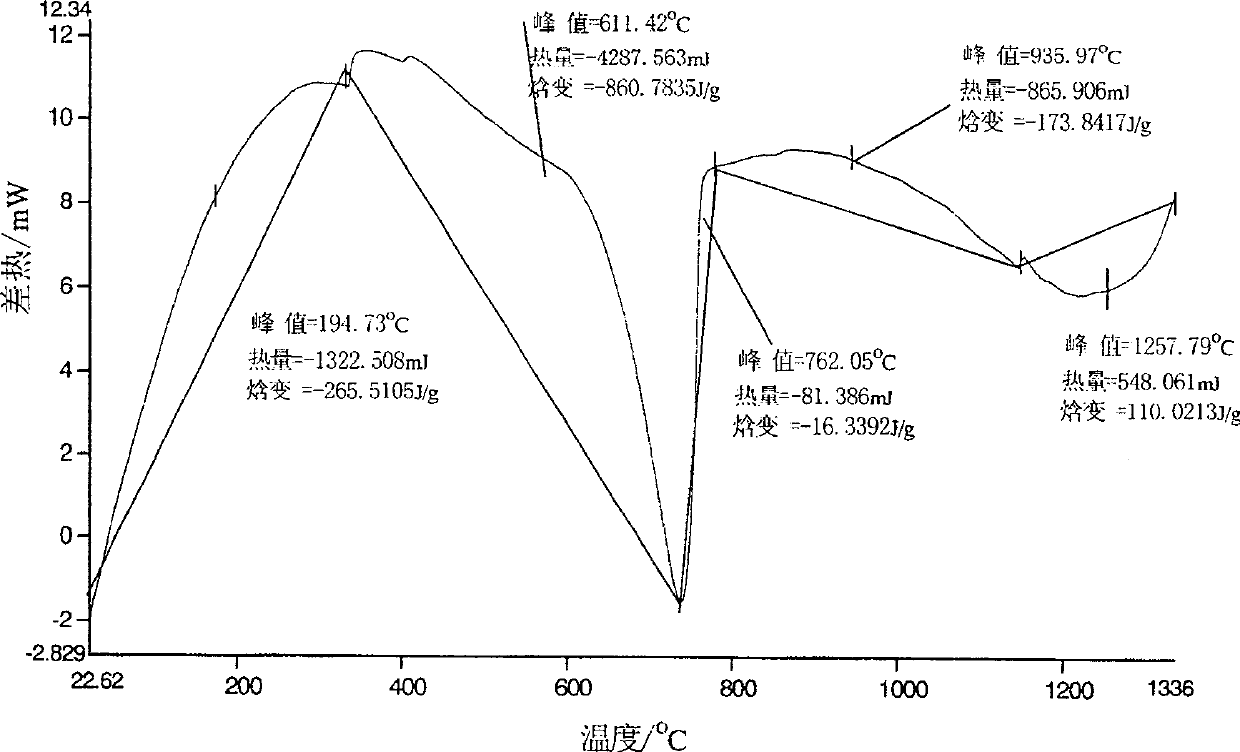

The invention discloses calcium sulphoaluminate-Relit composite mineral phase cement and preparing method, which is characterized by the following: adopting coal ash, alumina, limestone and plaster as raw material and fluorite as mineralizer; designing MG and MS value; introducing new Relit mineral in the preparing course of common aluminium sulfate cement; preparing new clinker of new calcium sulphoaluminate-Relit composite mineral phase cement under 1200-1330 deg.c with 45%-65% C4A3S, 20%-36% C3S and residual C2S.

Owner:李金洪

Alite-barium calcium sulfur aluminate cement

An Alinty-barium calcium thioaluminate cement contains barium calcium thioaluminate (3-38 wt.%), tricalcium aluminate (3-20), tricalcium silicate (30-60), dicalcium silicate (15-40), and ferroaluminate (3-20). Its advantages are low burning temp, high early strength and hardening speed, and low cost.

Owner:UNIV OF JINAN

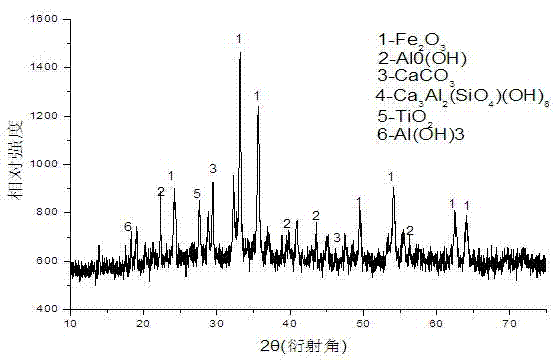

Coagulating/flocculating method for processing nanofiltration concentrate reject stream of early percolate at refuse landfills

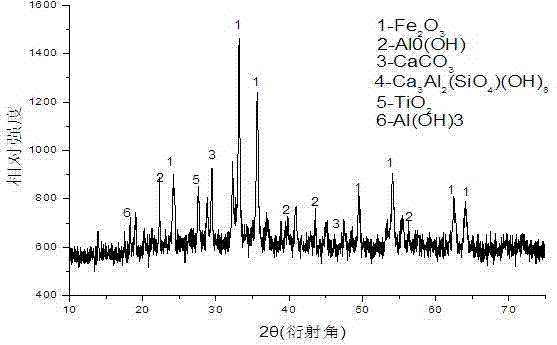

InactiveCN101767854AGood coagulation/flocculation effectEasy to operateWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationLitterNational standard

The present invention relates to a coagulating / flocculating method for processing nanofiltration concentrate reject stream of early percolate at refuse landfills, which belongs to the technical field of environment protection. The present invention uses reasonable coagulating / flocculating agent kinds, coagulating / flocculating agent dosage, pH-value processing time and stirring time to adjust the pH-valve range of the nanofiltration concentrate reject stream to 7.5 to 10. Polymerization aluminum salt, polymerization alite, or composite salt is used as coagulating / flocculating agent. The feeding amount of the coagulating / flocculating agent is 50 to 1000 mg / L accounted by Al2O3. The coagulating / flocculating agent is stirred rapidly first at 100 to 280 r / min for 0.5 to 5 min; then, the coagulating / flocculating agent is stirred slowly at 20 to 100 r / min for 3 to 30 min; and solid-liquid separation is done. By the processing of the coagulating / flocculating method, the nanofiltration concentrate reject stream of early percolate can be discharged within controlling index of national standard.

Owner:KUNMING UNIV OF SCI & TECH

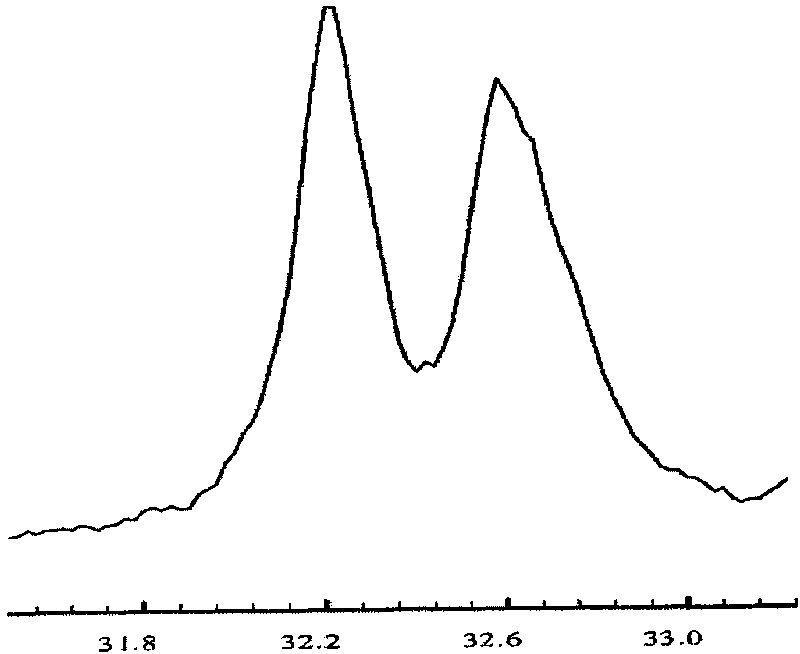

Ocean engineering repair mortar and preparation method thereof

The invention discloses an ocean engineering repair mortar and a preparation method thereof. The repair mortar is prepared from, by weight, 20-30 parts of alite-sulphoaluminate cement, 15-25 parts ofmaritime work Portland cement, 1.5-3 parts of an ultra-disperse shrinkage-reducing water reducer, 0-5 parts of a thickening time control agent, 1-5 parts of a reinforcing powder, 1-4 parts of an anticorrosion compacting agent, 6-8 parts of a crack-proof and waterproof expanding agent, 5-30 parts of ultrafine mineral powder, 0.1-0.6 part of an antifoaming agent, 0.5-2 parts of redispersible latex powder and 50-80 parts of quartz sands. The ocean engineering repair mortar has the advantages of short setting time, fast strength development, high bonding strength with concrete, good stability andno cracking, and can improve the seawater erosion resistance of repaired concrete, prevent secondary damage, prolong the service life of buildings and save a large amount of reconstruction funds.

Owner:广西云燕特种水泥建材有限公司

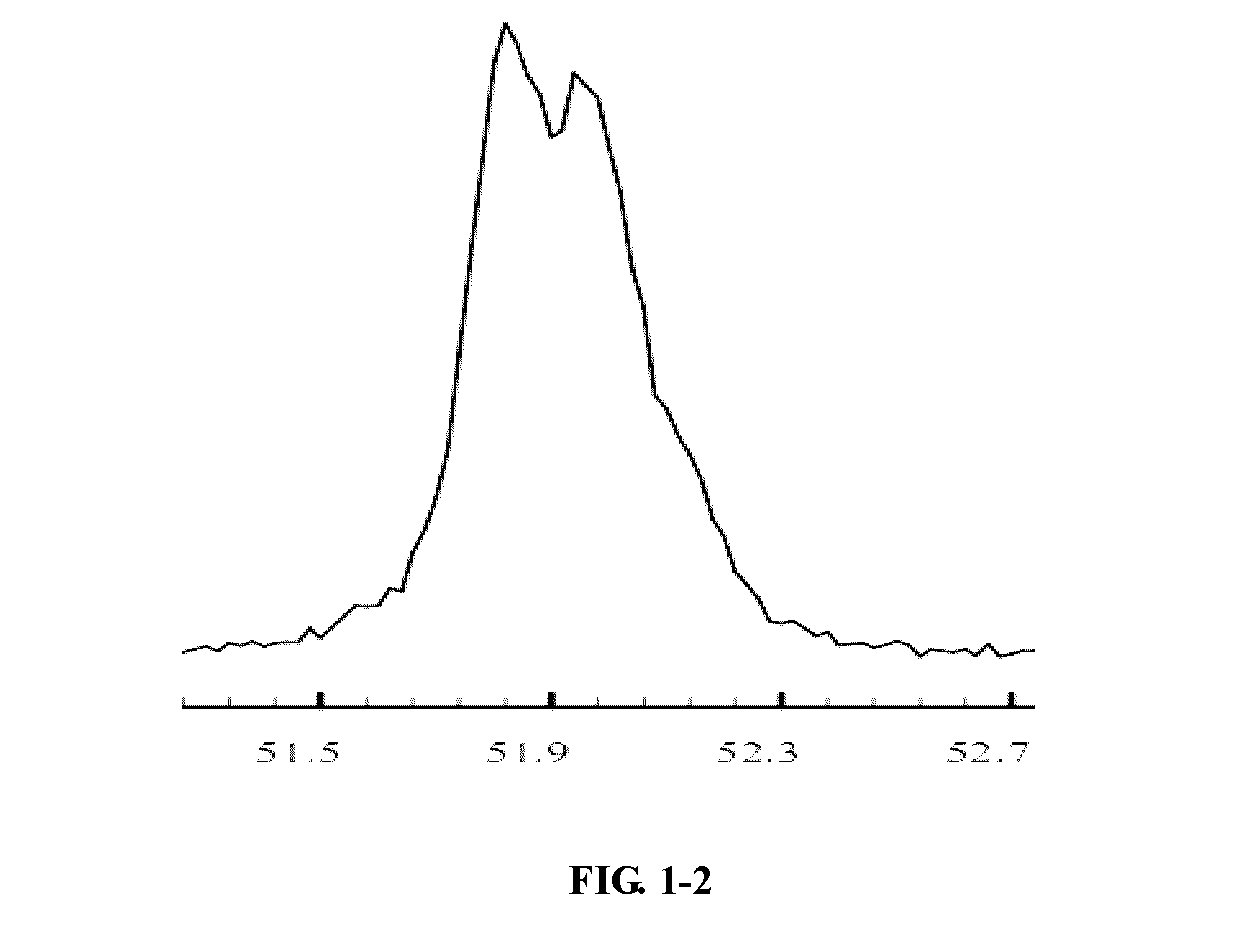

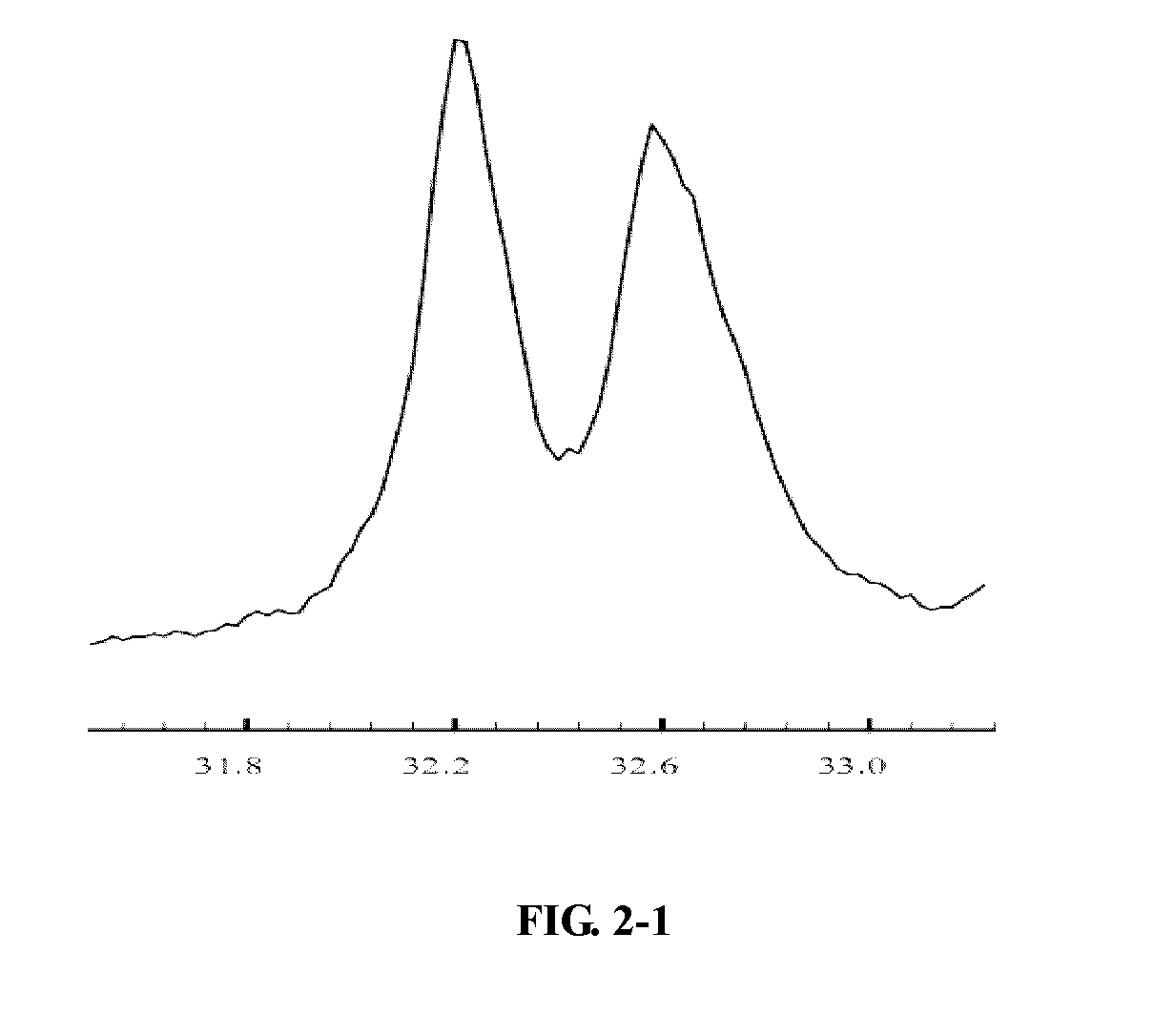

Alite crystal modulation process in metasilicate cement clinker

ActiveCN101717210AImprove clinker performanceSimple processClinker productionThermal treatmentMaterials science

Owner:NANJING TECH UNIV

Method for preparing sulfoaluminate cement clinker by using five-component mineral phase system

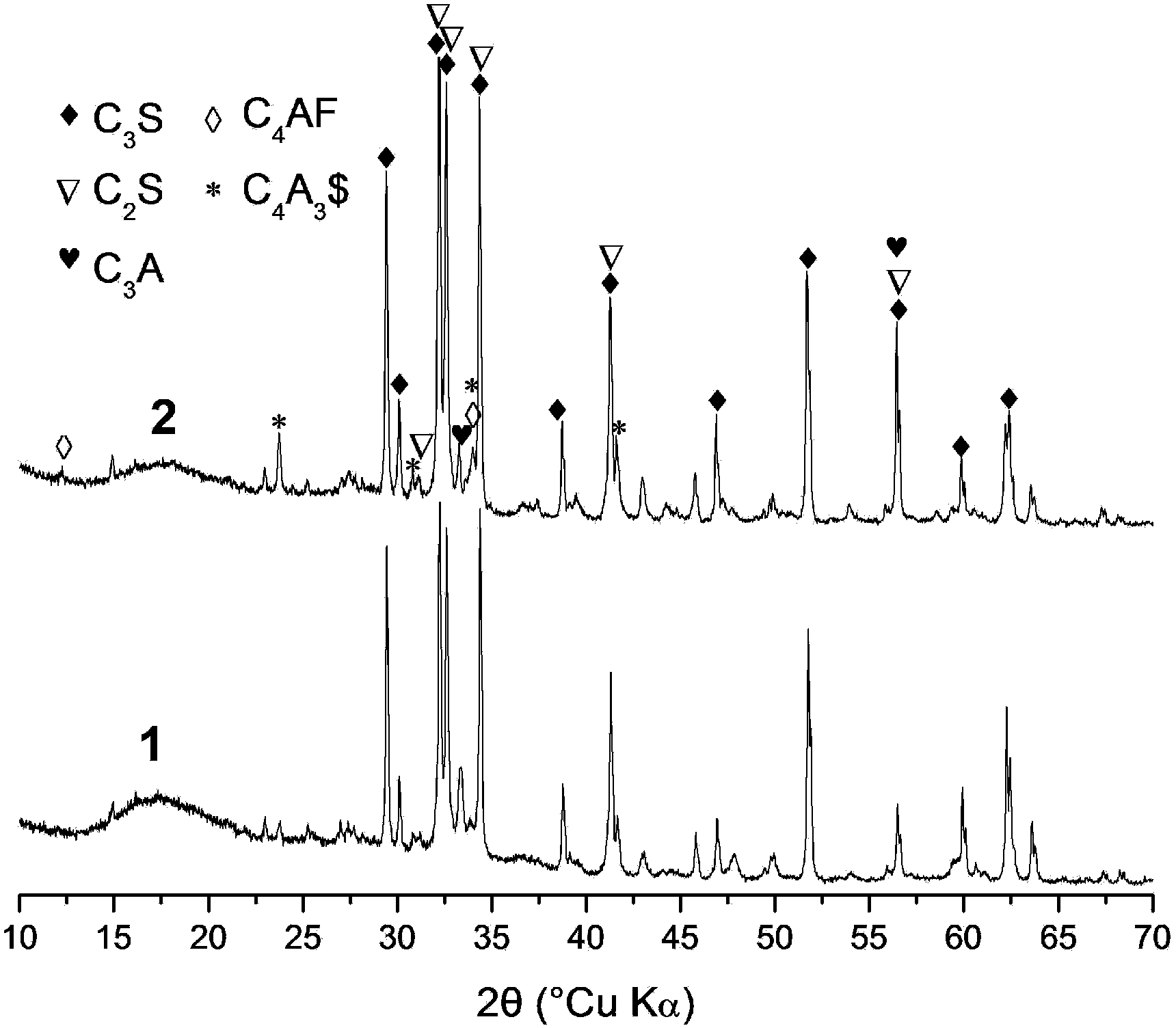

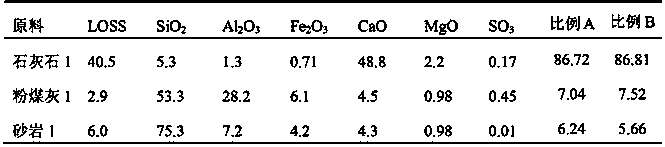

The invention relates to a method for preparing sulfoaluminate cement clinker by using a five-component mineral phase system. The alite-sulphoaluminate cement clinker is prepared by using a CaO-SiO2-Al2O3-Fe2O3-SO3 multicomponent system under the condition of not adding fluorite. The method comprises the following steps: (1) achieving the conditions that the basicity factor [(CaO+MgO) / (SiO2+Al2O3)] is 1.42 and the aluminum and sulfur ratio Al2O3 / SO3 is 1.73; (2) uniformly mixing and tabletting 75-80% of limestones, 5-7% of sandstones, 1-2% of coal ash, 6-10% of low-grade bauxite and 5-8% of gypsum, putting in a high-temperature furnace and sintering; and (3) insulating at 950 DEG C in a low-temperature furnace for 30 minutes, directly transferring to a high-temperature furnace at 1450 DEG C, insulating for 40 minutes, cooling along with the furnace to 1300 DEG C, insulating for 40 minutes, and cooling to room temperature after taking for 30 minutes to room temperature so as to obtain the CaO-SiO2-Al2O3-Fe2O3-SO3 multicomponent system cement clinker with coexisting C3S and C4A3S. The cement clinker has the advantages of high early strength and no shrinkage of long-term strength.

Owner:BEIJING UNIV OF TECH

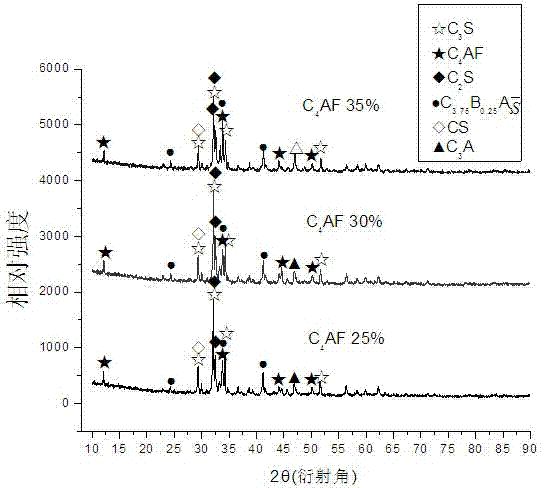

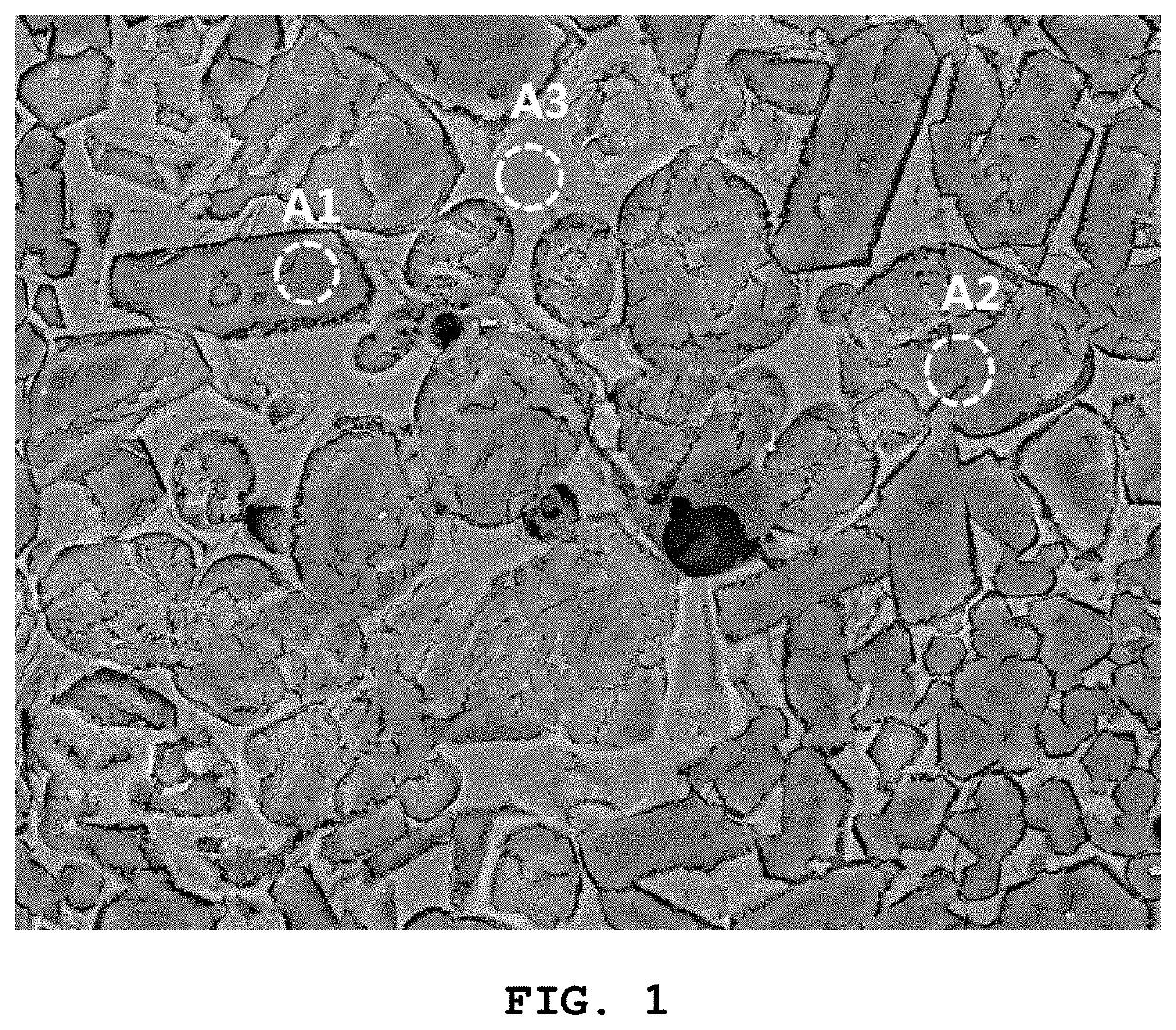

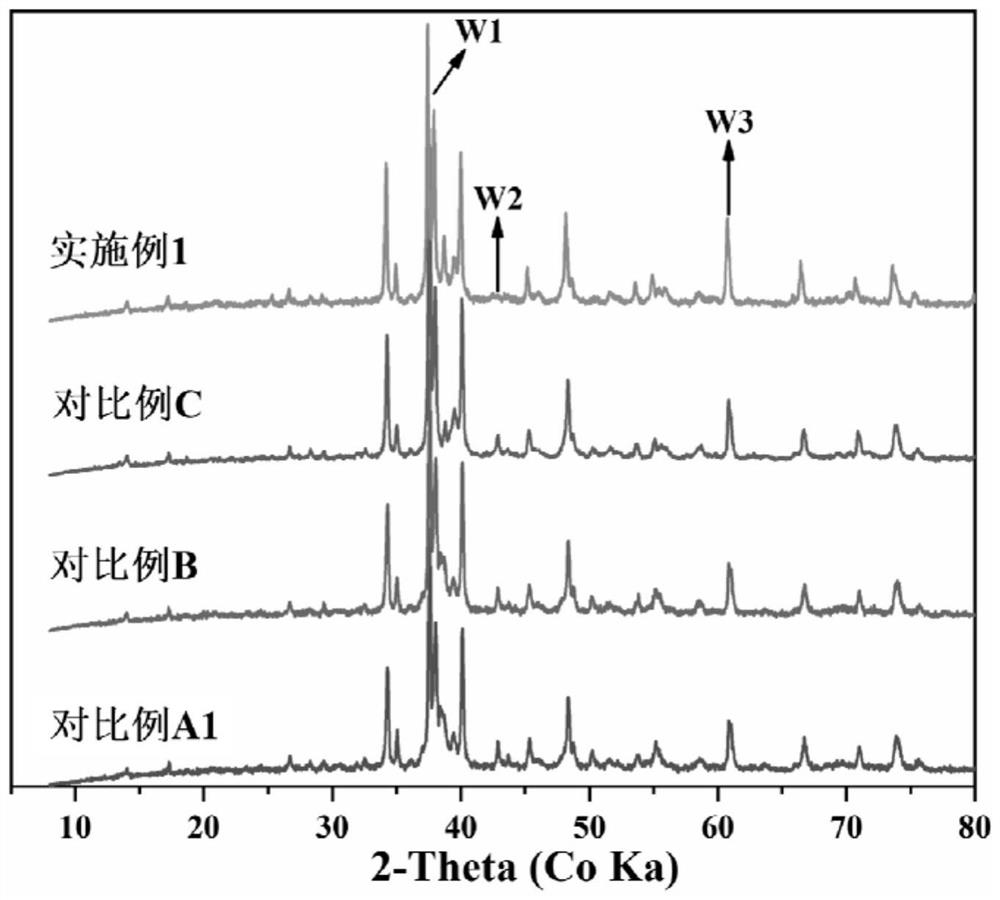

Method for preparing high-ferric Alite-calcium barium sulphoaluminate cement by using red mud and barium mud

The invention discloses a method for preparing high-ferric Alite-calcium barium sulphoaluminate cement by using red mud and barium mud. The mineral phases are as follows in percentage by weight: 5-8% of C(4-x)BxA3S, 15-19% of C2S, 30-45% of C3S, 25-45% of C4AF and 4-8% of C3A; the raw materials are as follows in percentage by weight: 10-20% of clay, 8-30% of red mud, 55-65% of limestones, 3-5% of gypsum, 0.3-0.5% of barium mud, 0-2% of bauxite and 0.4-1% of fluorite. The method comprises the following steps: crushing and homogenizing the raw materials and drying and polishing; preparing a round cake-shaped test sample which is 5cm in radius and 2cm in thickness, and calcining and cooling; and (6) crushing, and doping 8-12% of gypsum or dihydrate gypsum based on the total mass of the material, wherein the grinding fineness is 350m<2> / kg-450m<2> / kg or residue on sieve is 5% by a 200mesh sieve. The high-ferric Alite-calcium barium sulphoaluminate cement disclosed by the invention has the characteristics of low sintering temperature and small volume shrinkage, low cost and durability and the like as high-ferric or high-ferric aluminum industrial wastes and barium-containing industrial waste residues are used as raw materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Dental composition and preparation method therefor

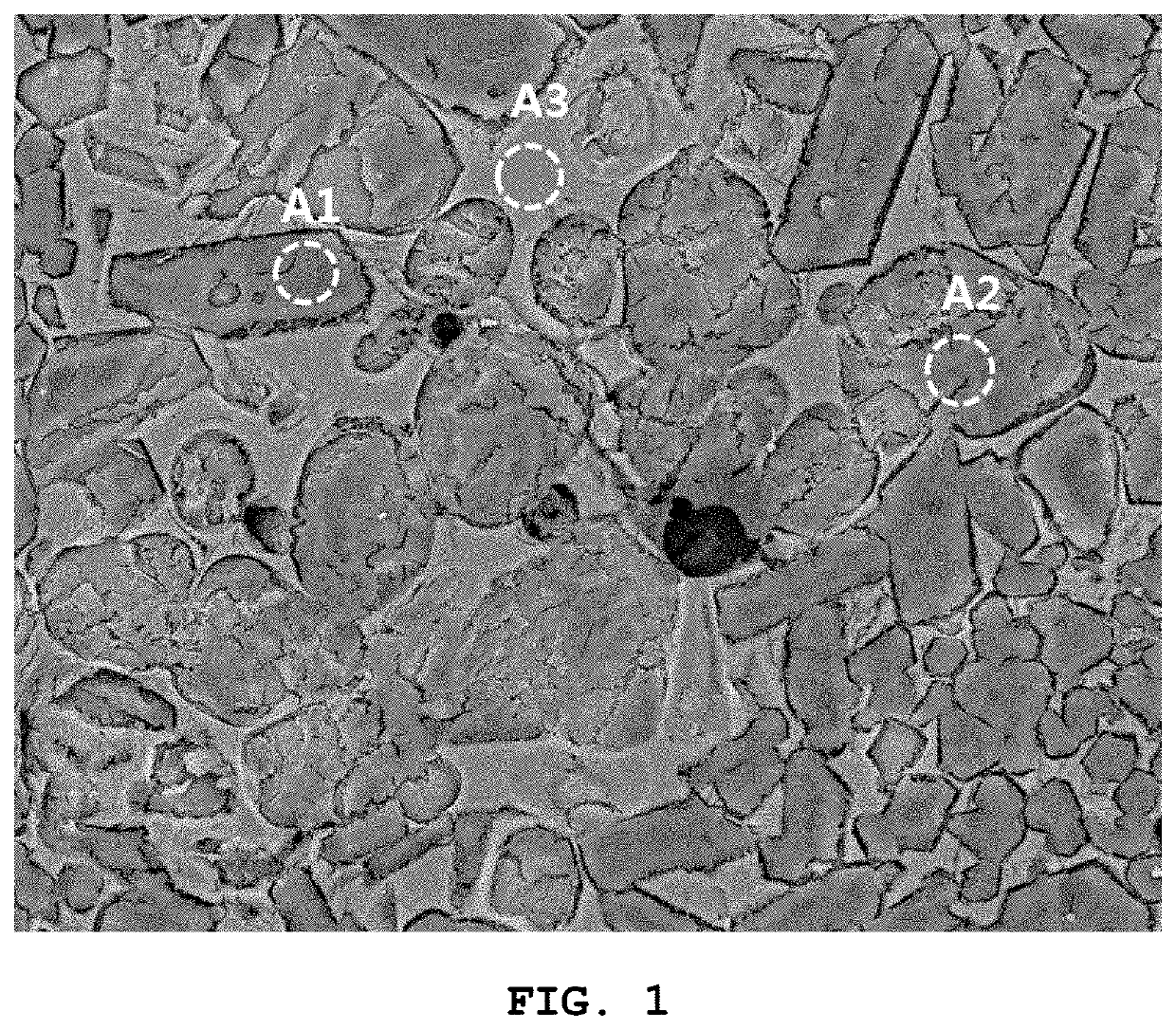

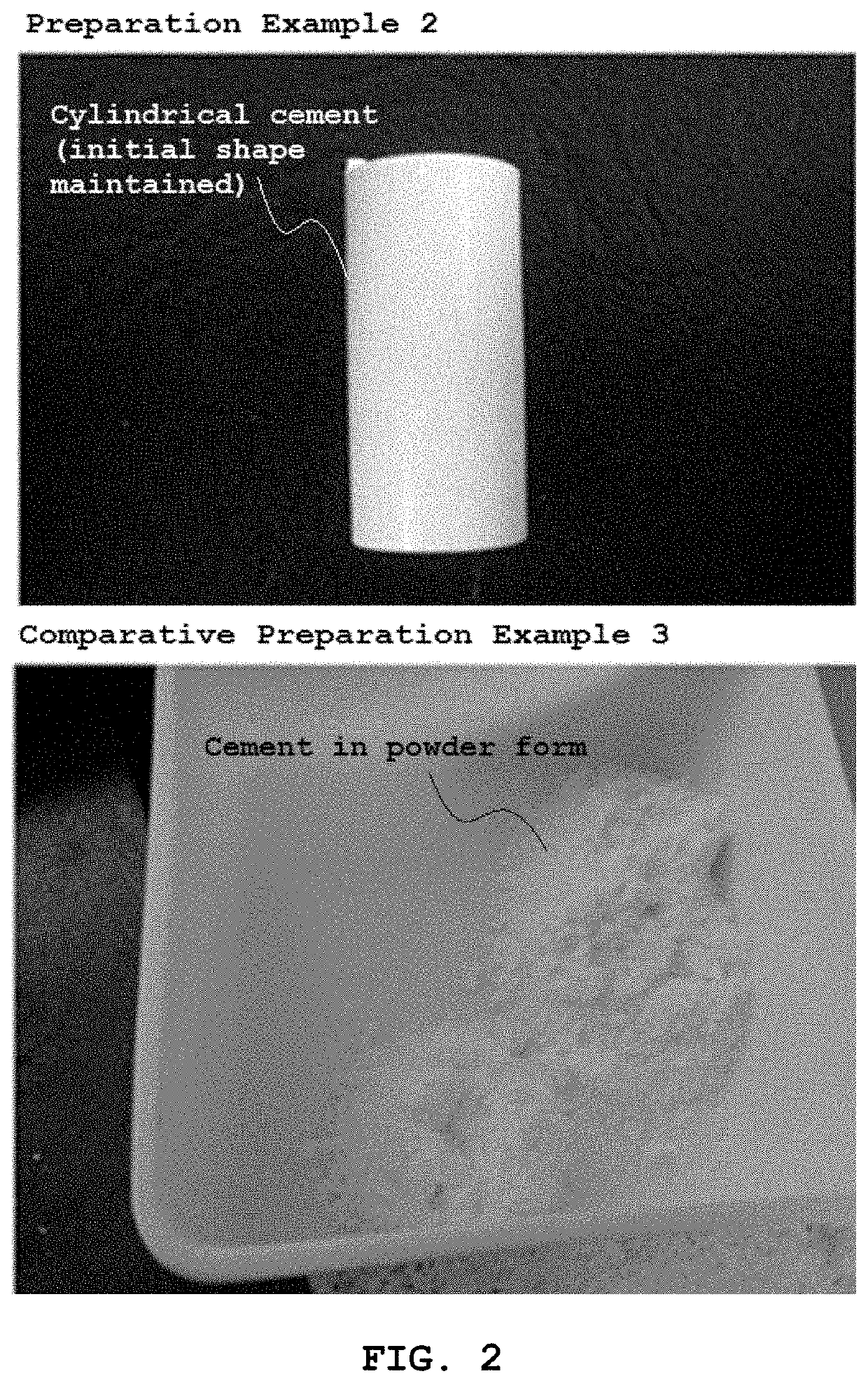

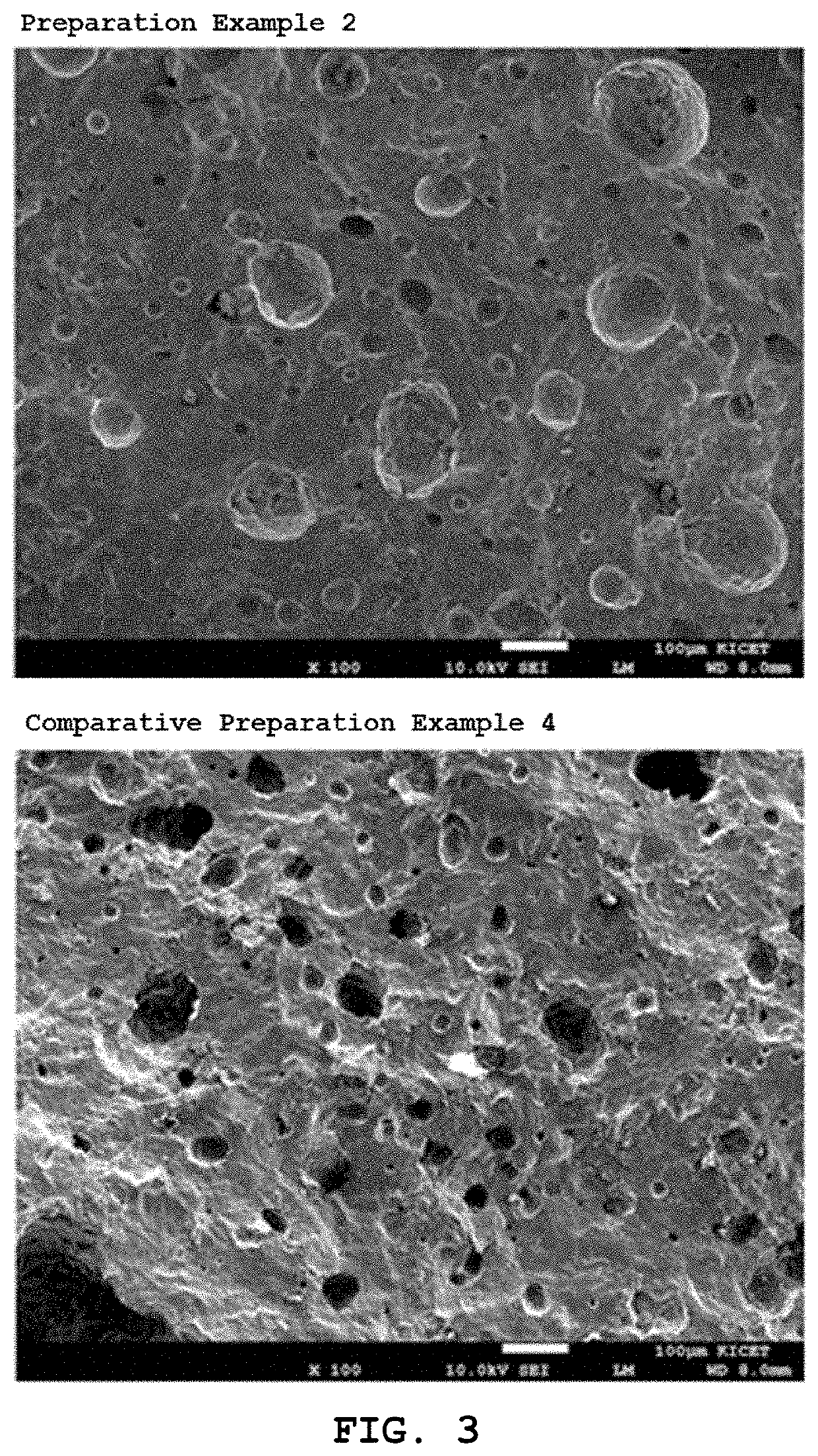

The present invention relates to a dental composition including cement and a non-aqueous liquid, wherein the cement includes a first domain including alite, a second domain including belite, and a matrix located between one or more selected from the group consisting of the first domain and the second domain and configured to include silicon (Si)-atom-doped tricalcium aluminate (3CaO.Al2O3). A dental hydraulic composition according to the present invention is a single ointment-type composition, and is thus easy to use and exhibits a good aesthetic appearance, high curability and high biocompatibility.

Owner:VERICOM

Alite-sulphoaluminate cement concrete crack-resistant admixture

The present invention provides an Alite-sulphoaluminate cement concrete crack-resistant admixture. In percentage by weight, the Alite-sulphoaluminate cement concrete crack-resistant admixture mainly comprises the following components: 20-30% of ground quartz sand; 20-30% of polycarboxylic acid water reducing mother liquor, 10-20% of sodium tetraborate, 4-10% of redispersible latex power, 2-8% of polyvinyl alcohol, 3-7% of aluminum hydroxide, 5-10% of mannitol, and 2-7% of calcium formate. The crack-resistant admixture has the prominent advantages of high initial slump and no loss of slump for4h under the construction condition of 35 DEG C; no effect on early and late strength of the Alite-sulphoaluminate cement concrete; good adaptability to cement; excellent crack resistance and no concrete cracks due to concentrated heat release of Alite-sulphoaluminate cement concrete. The crack-resistant admixture is also applicable to sulphoaluminate cement-based materials.

Owner:UNIV OF JINAN

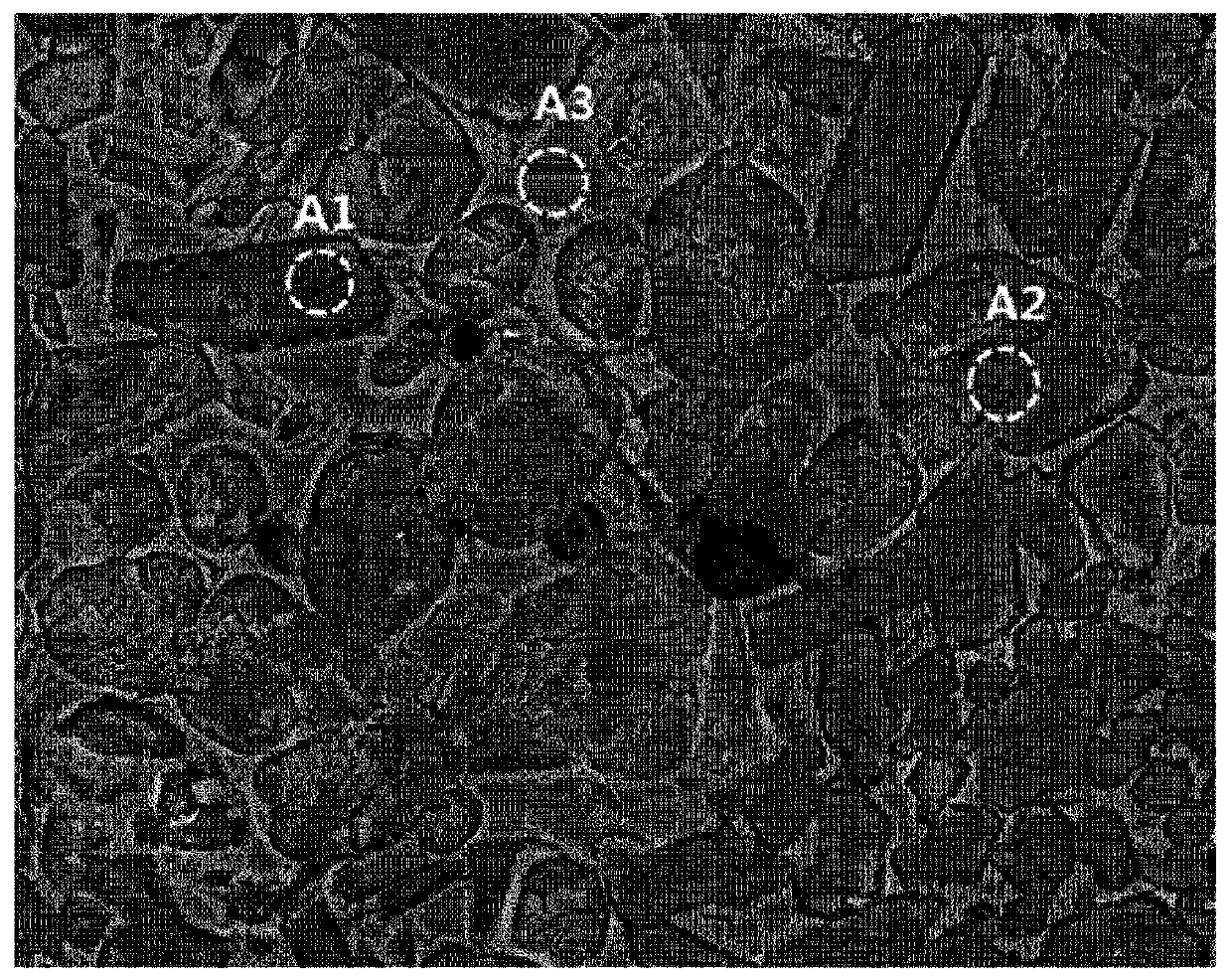

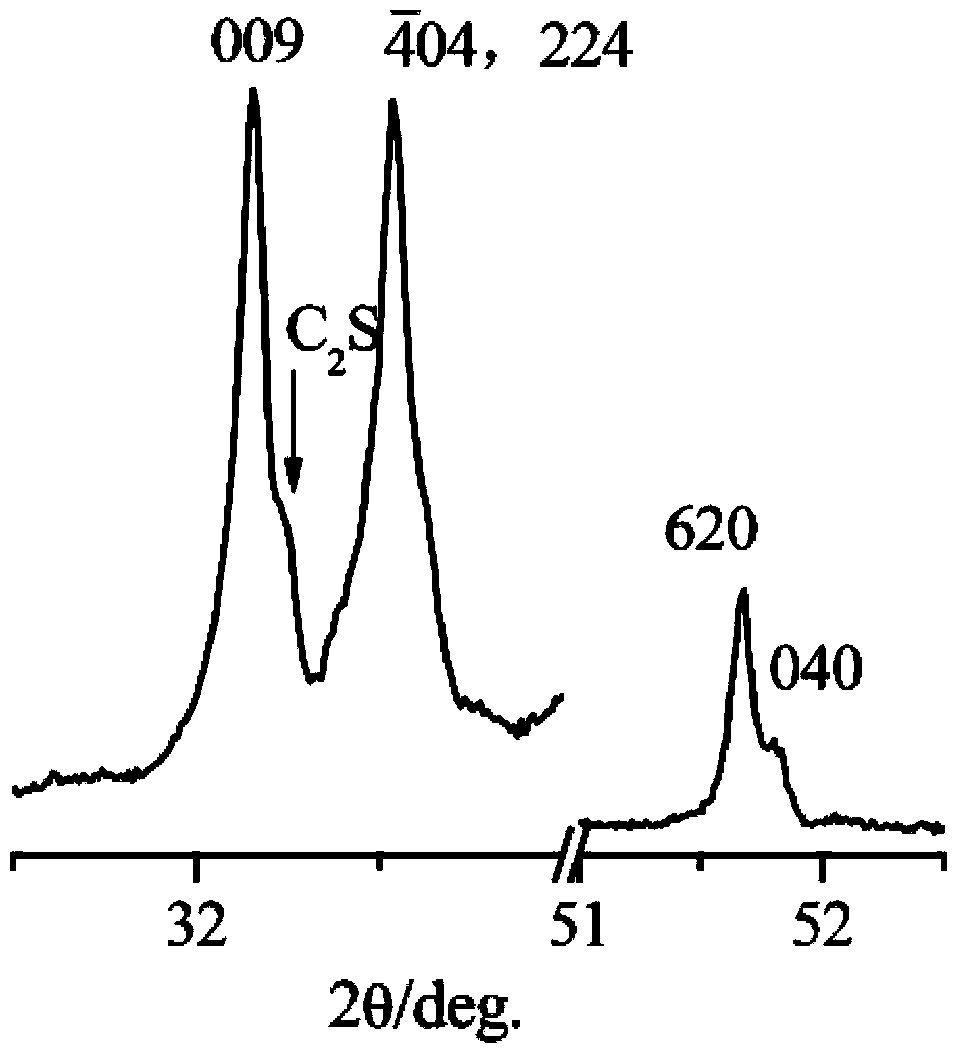

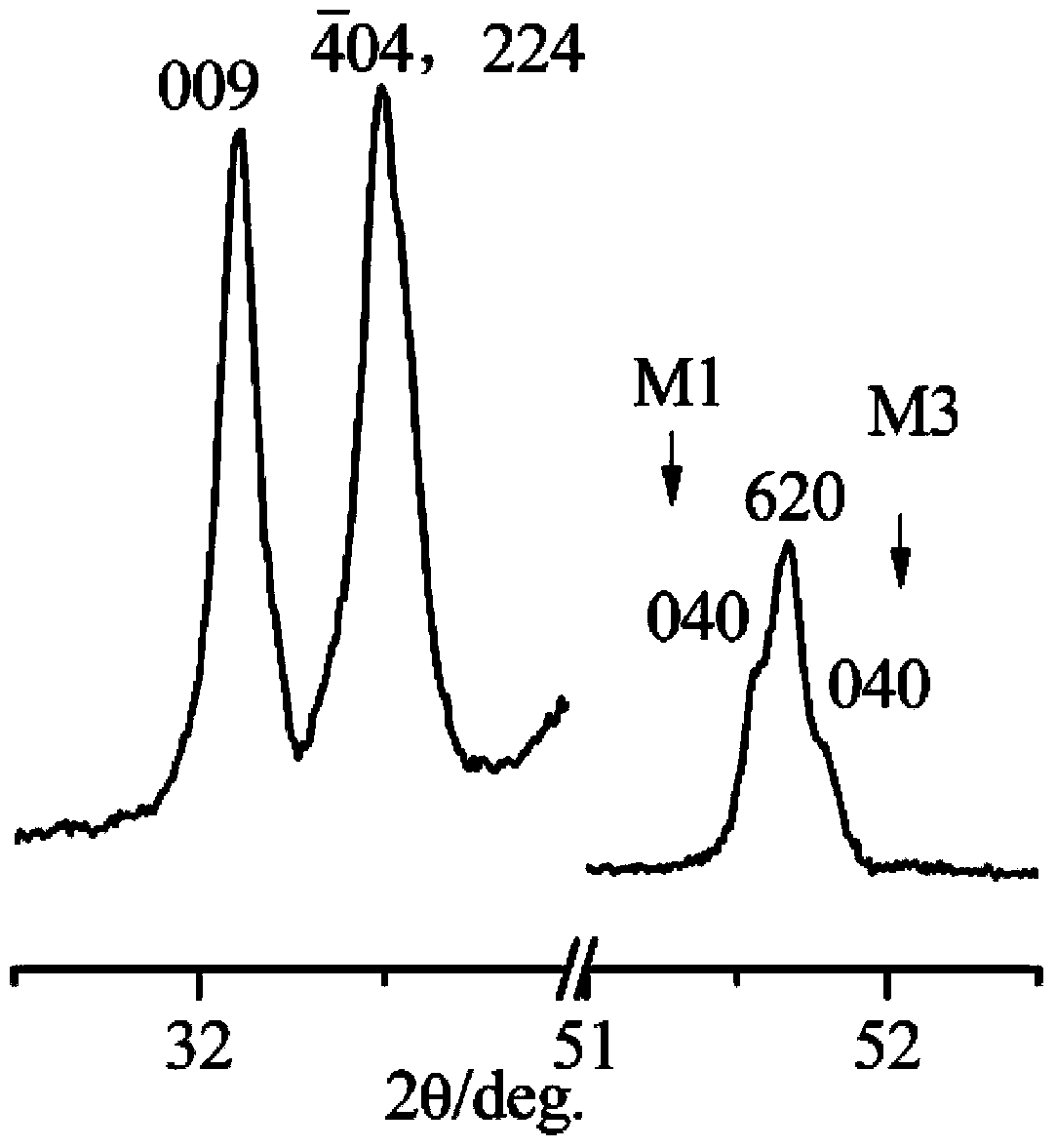

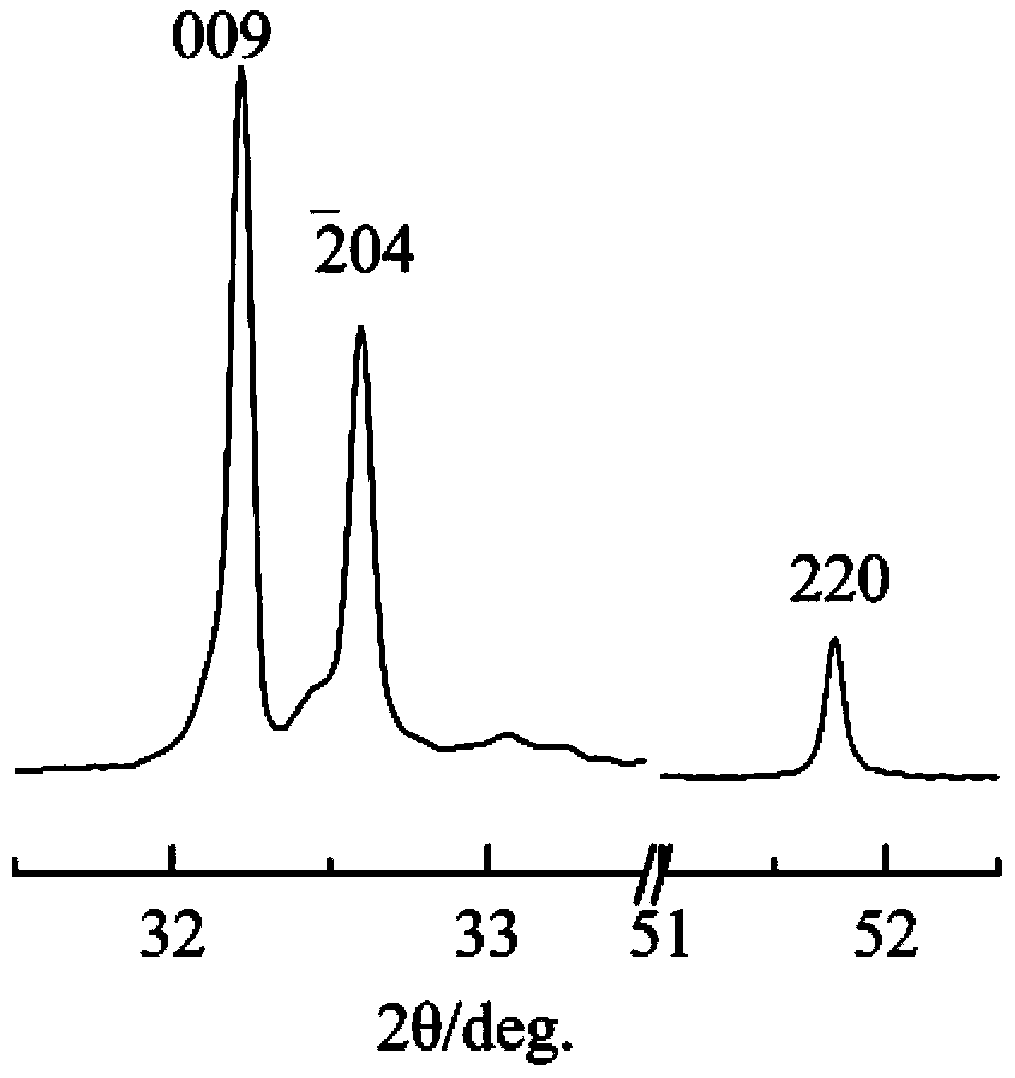

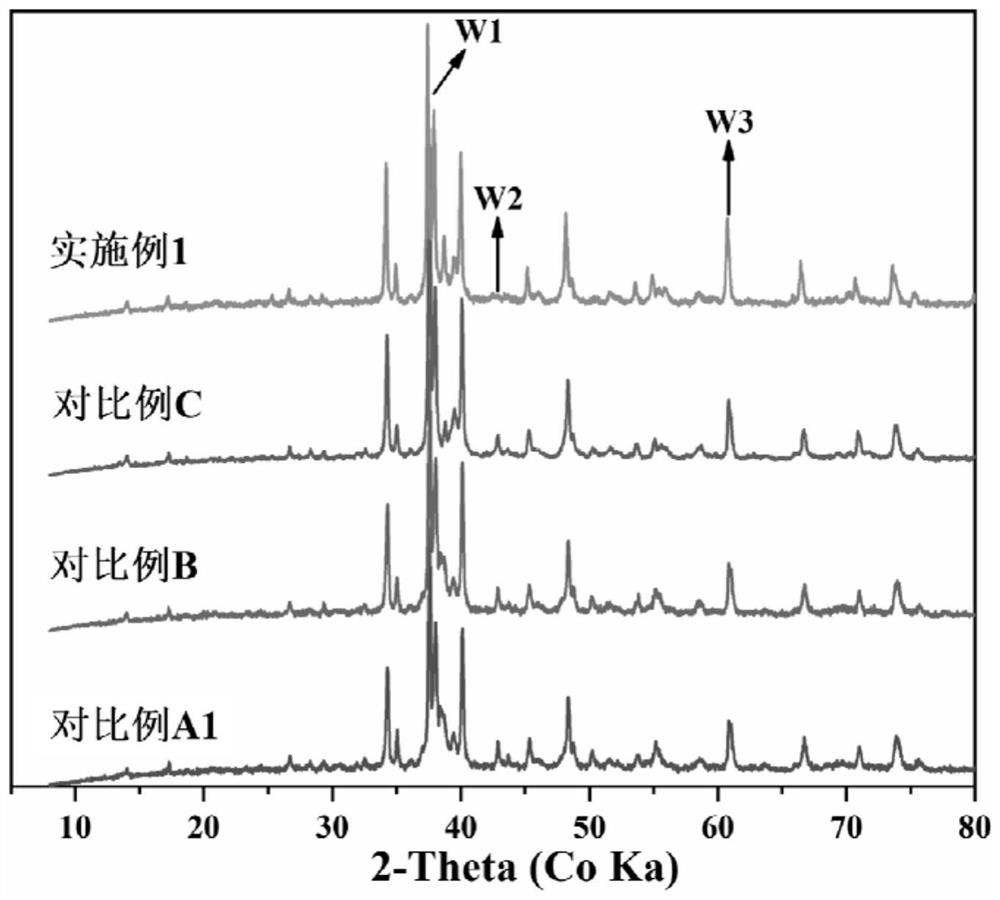

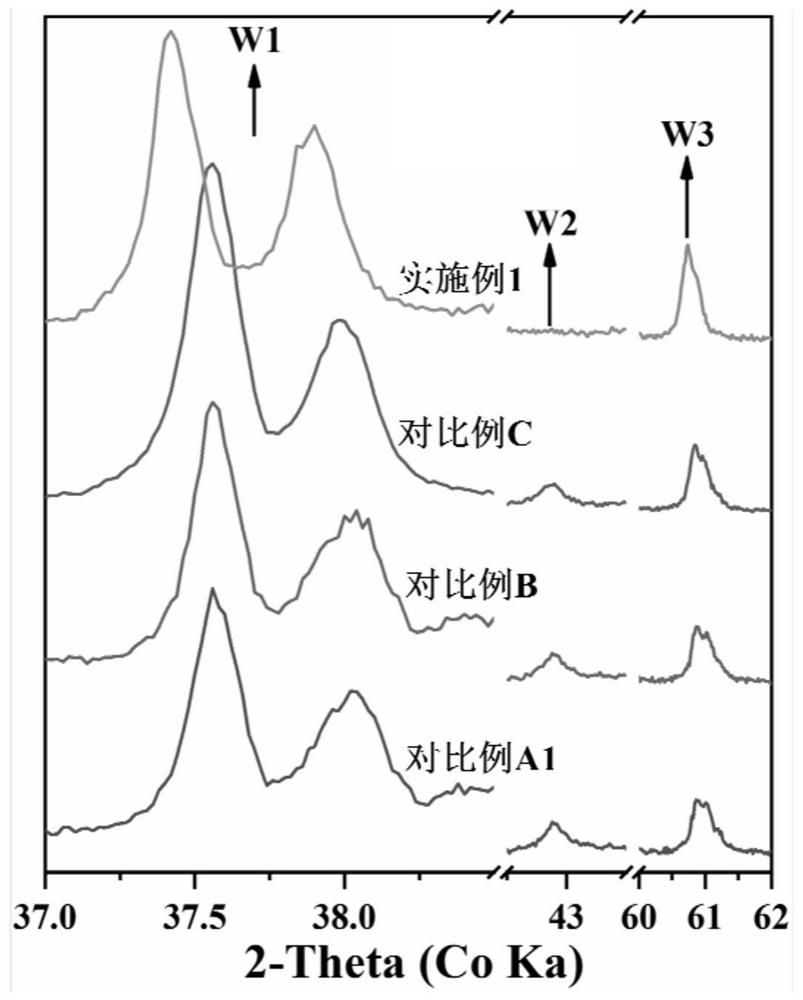

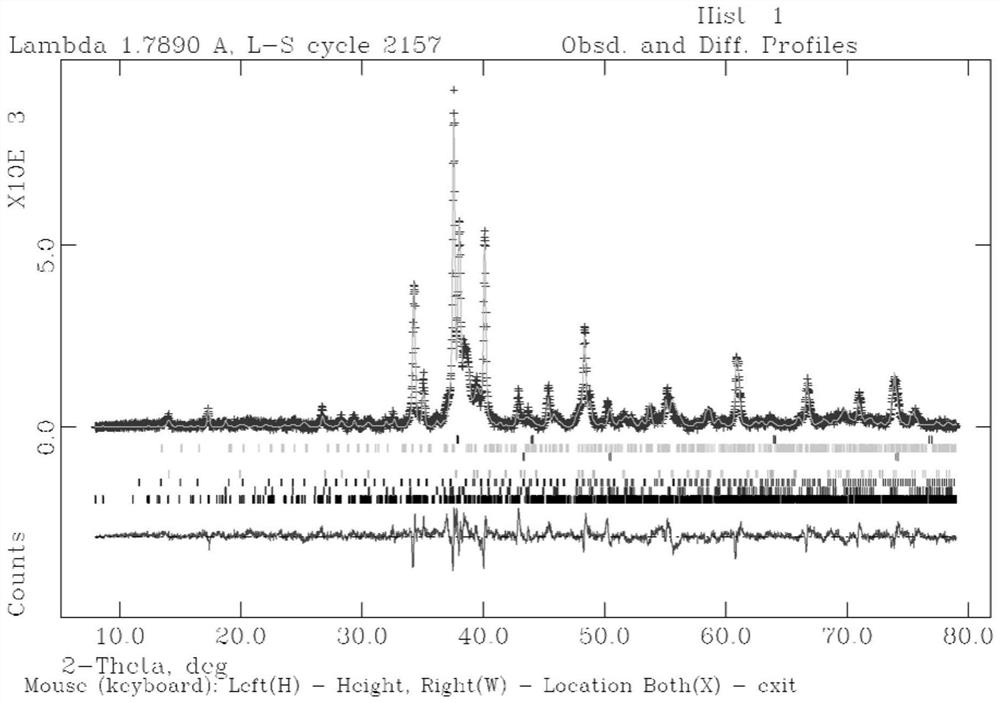

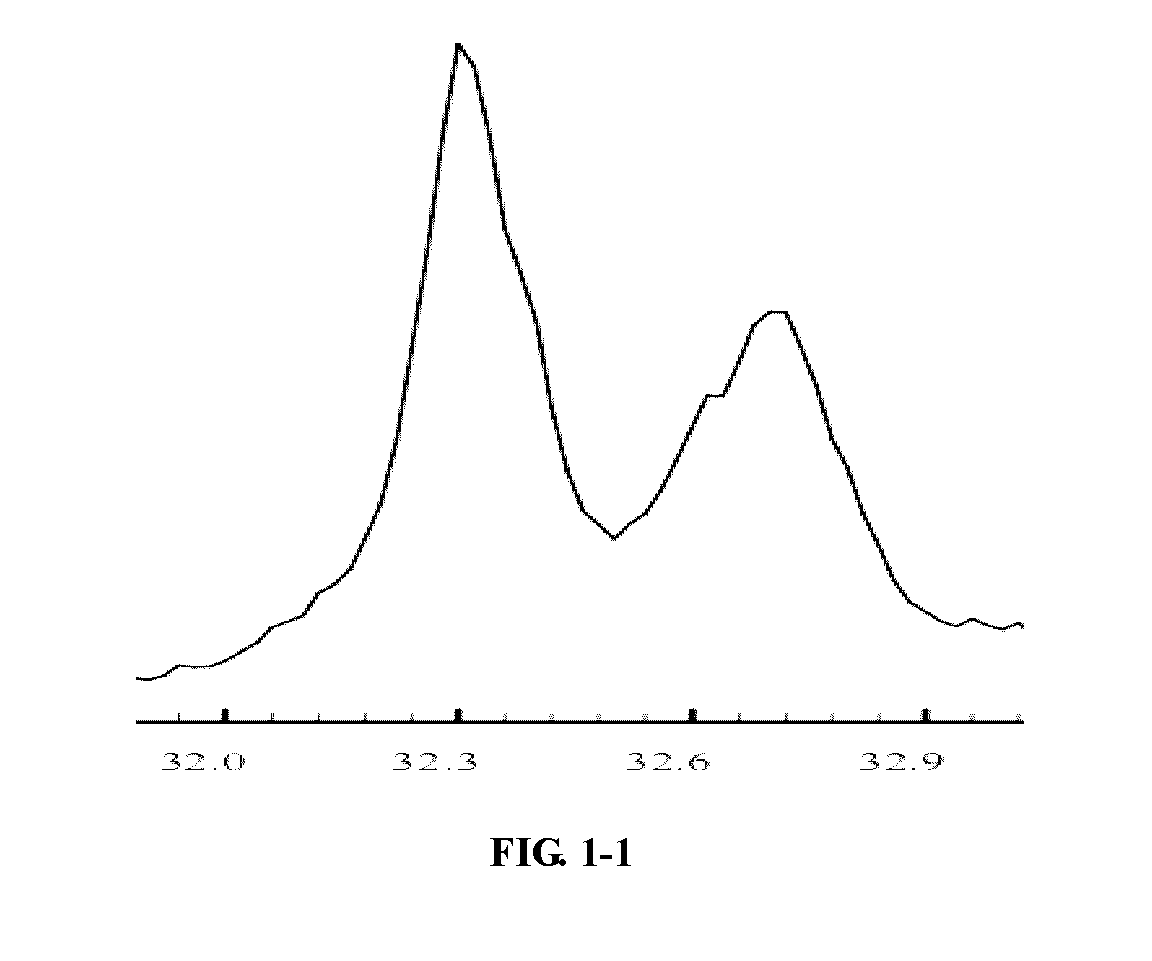

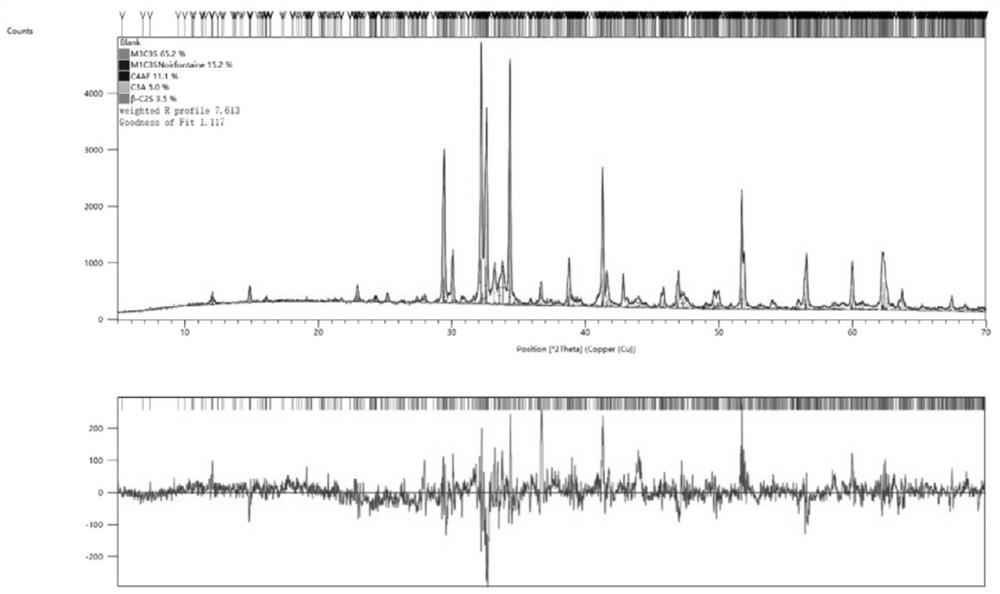

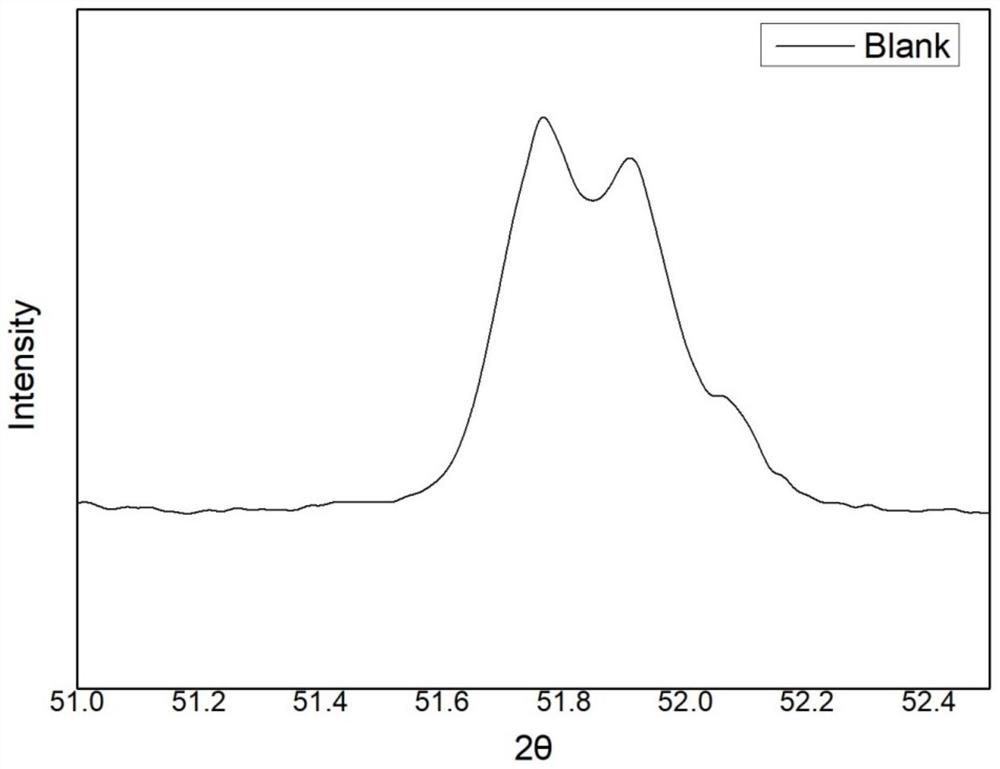

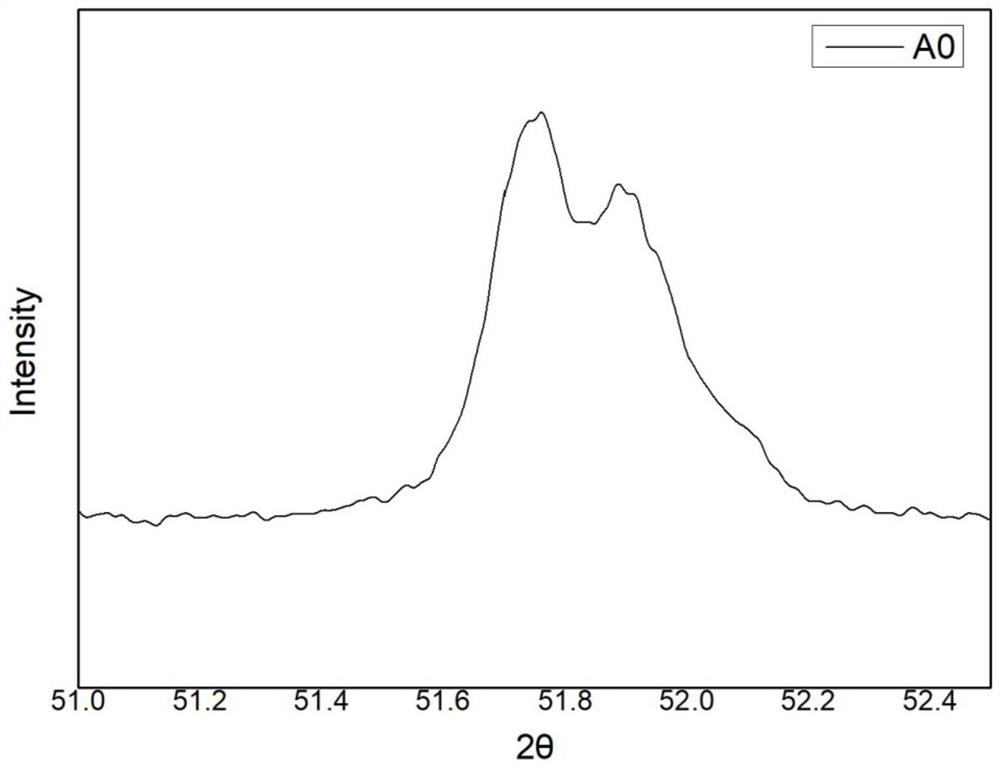

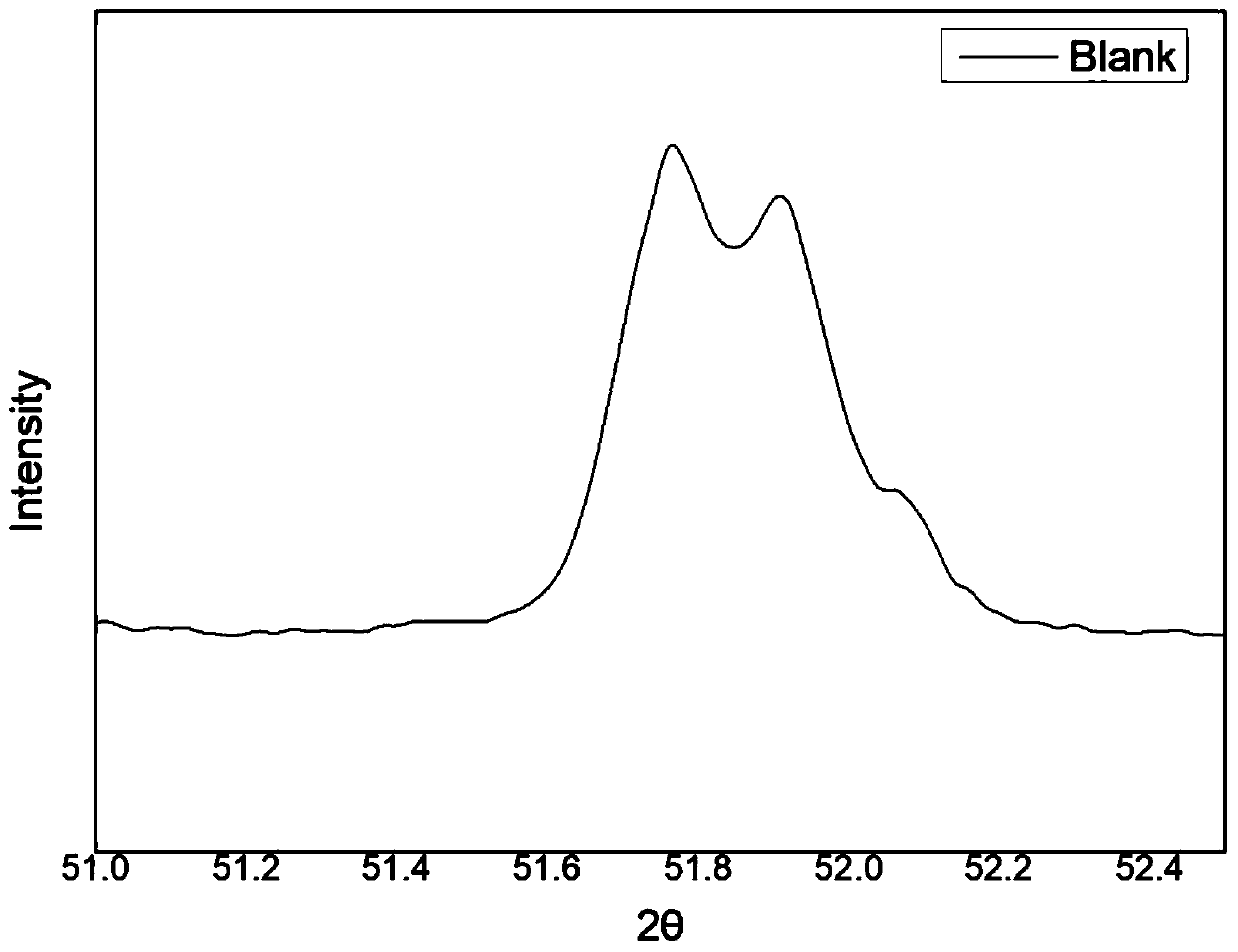

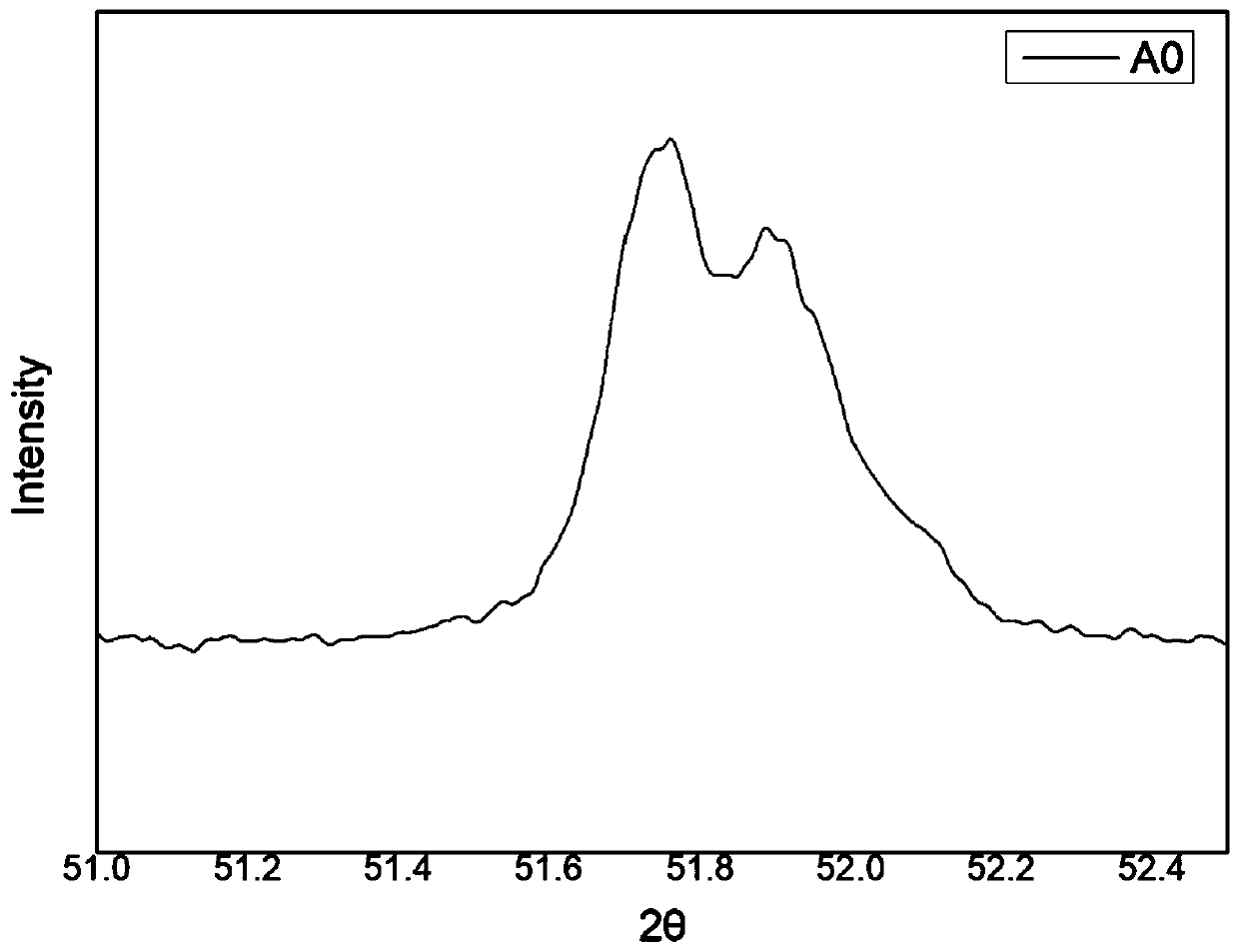

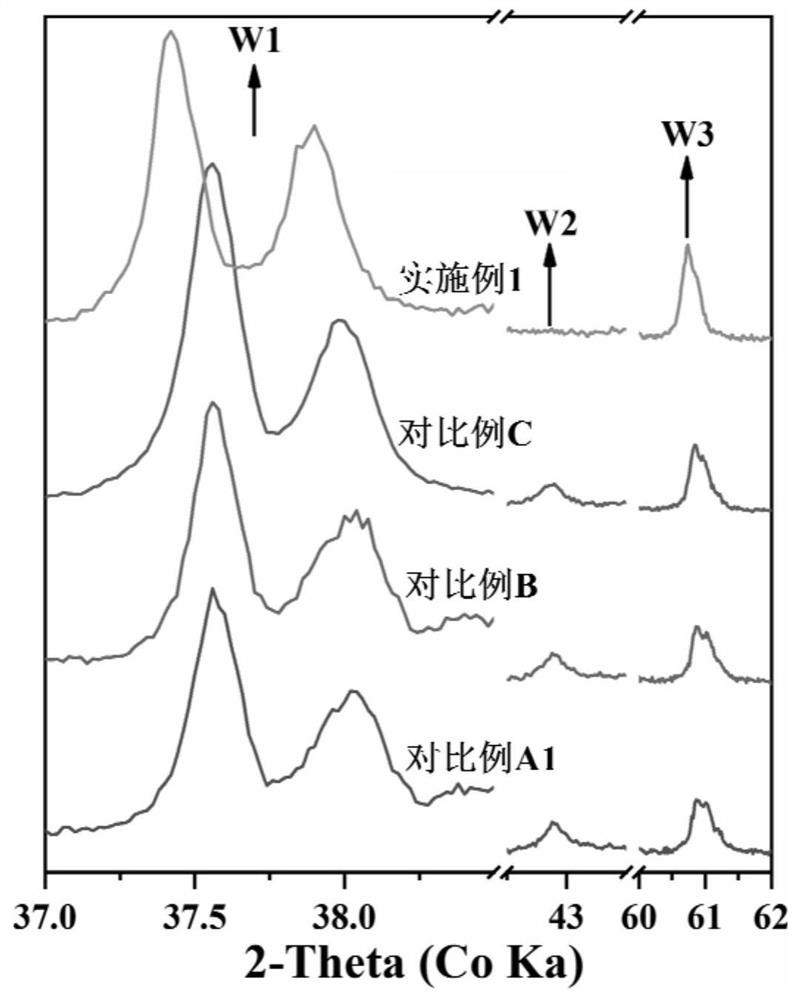

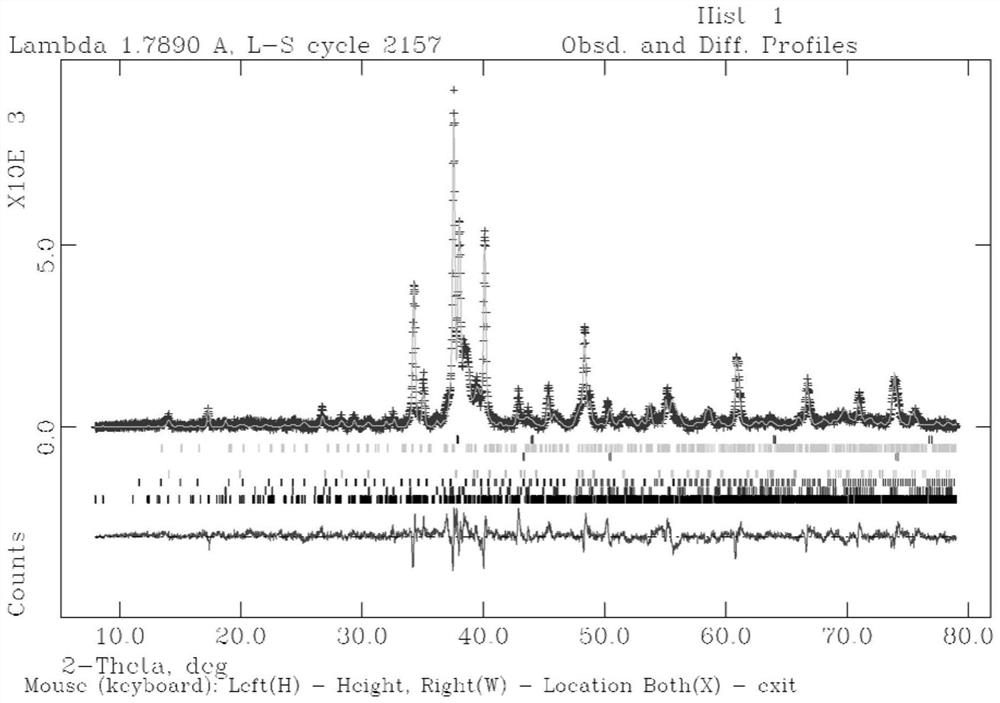

Method for regulating and controlling alite crystal structure in cement clinker

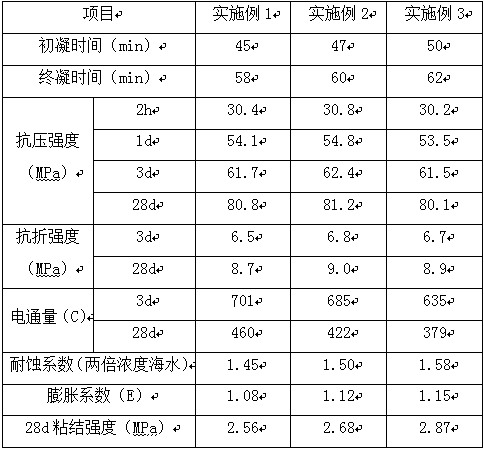

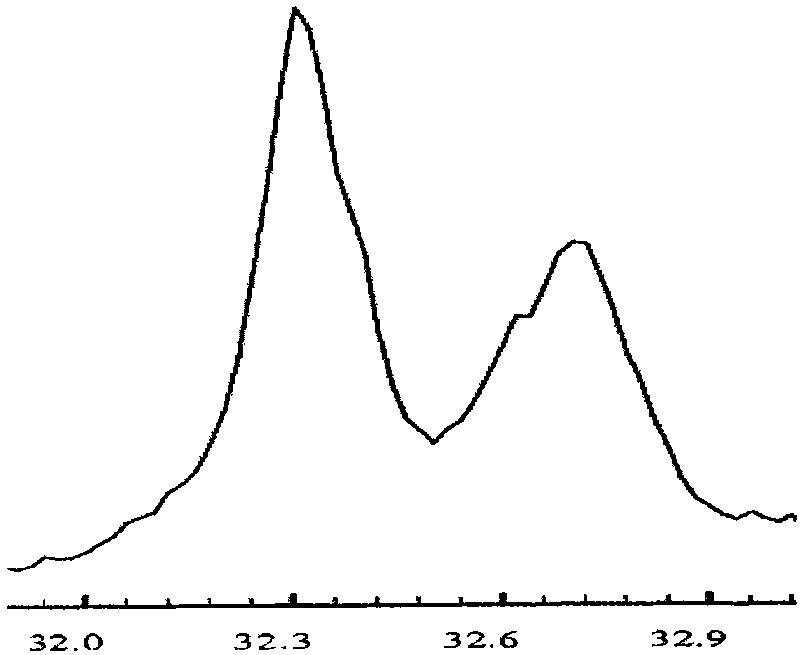

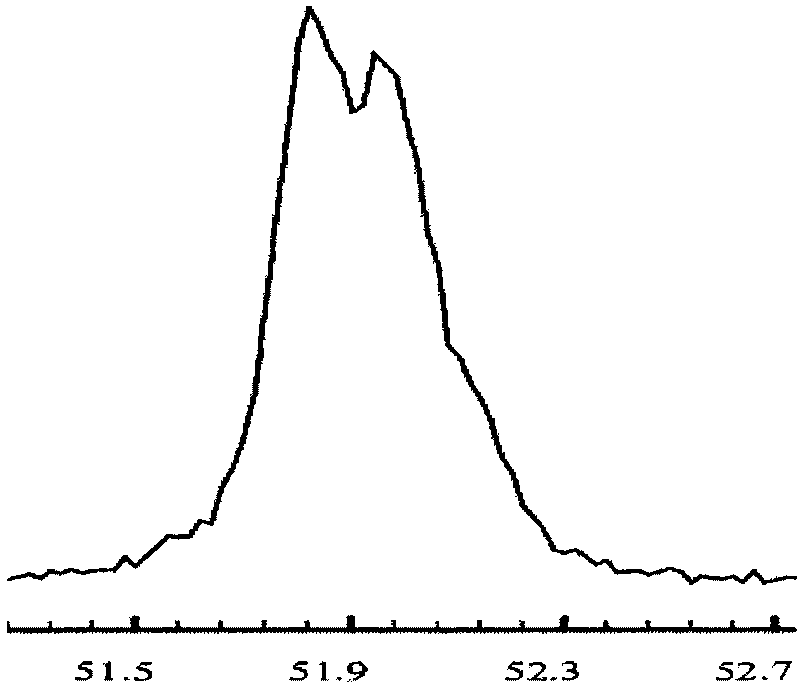

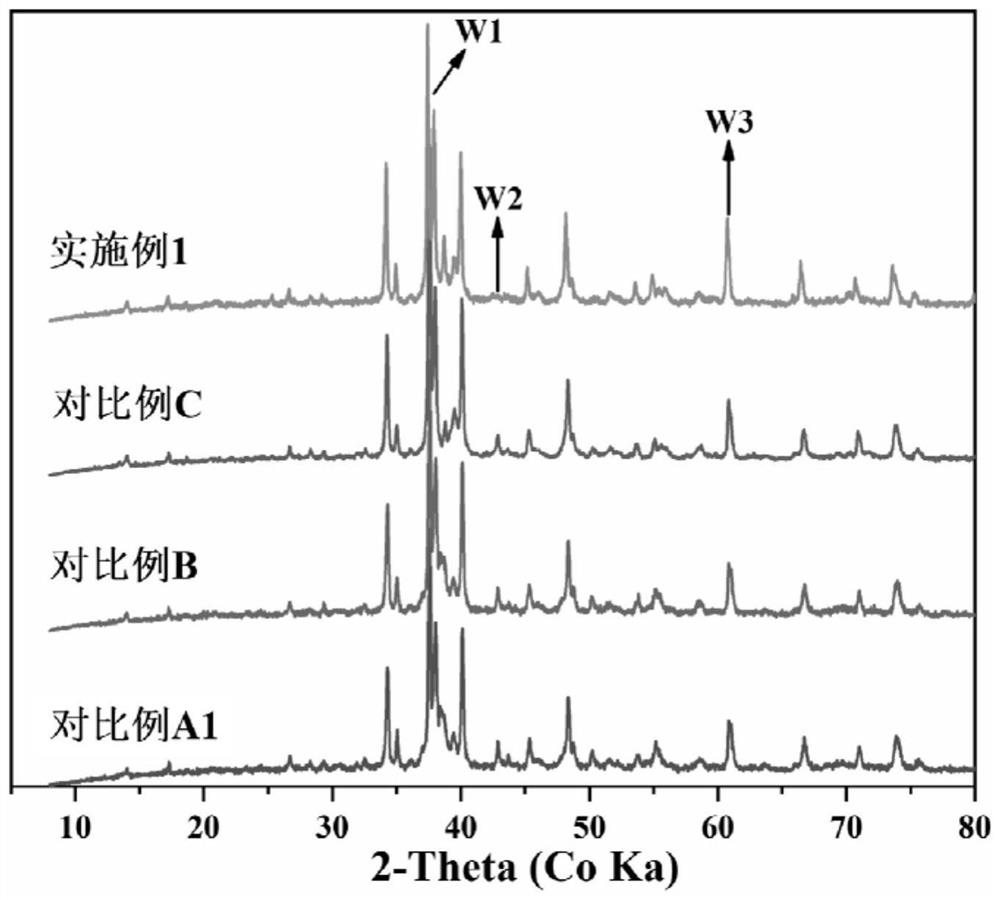

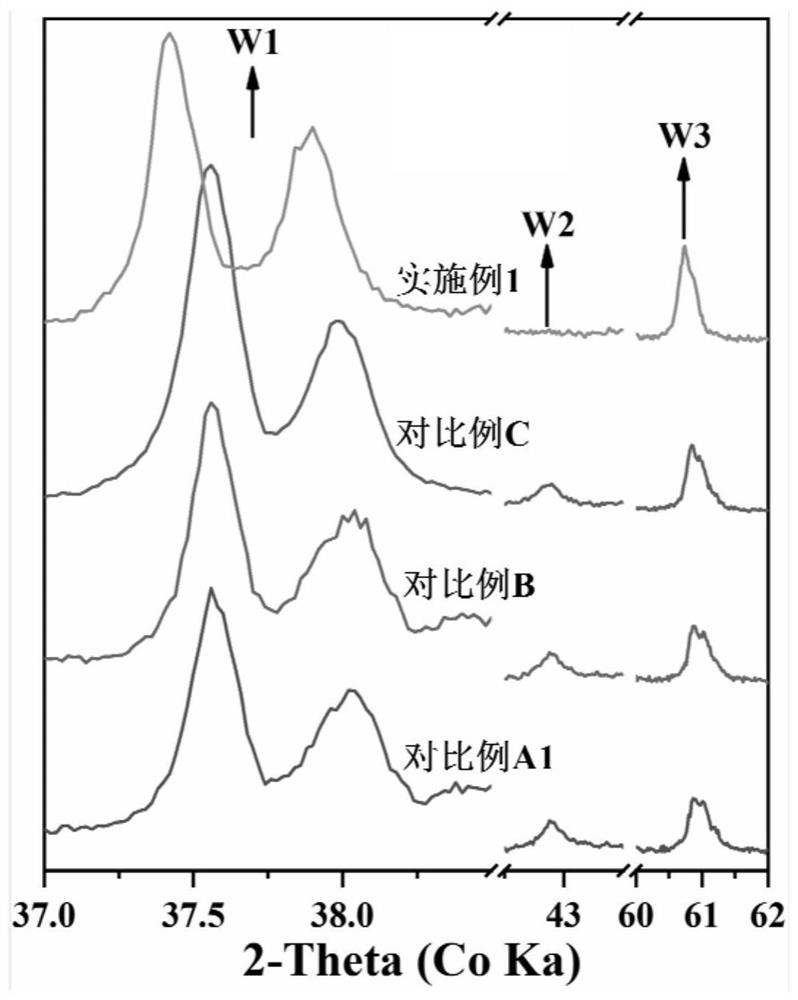

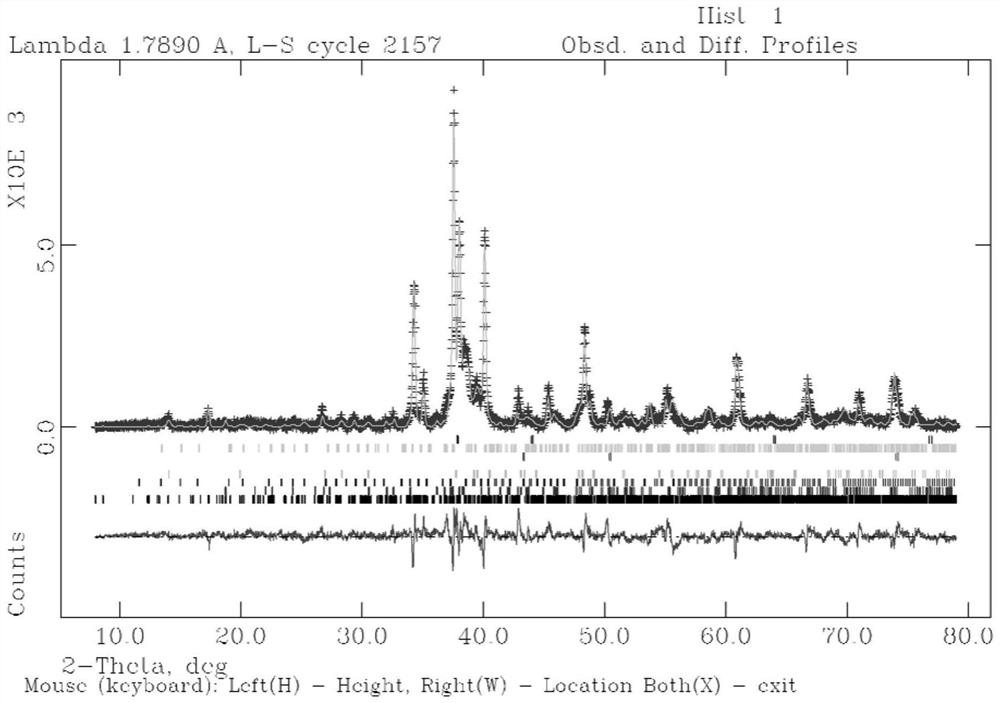

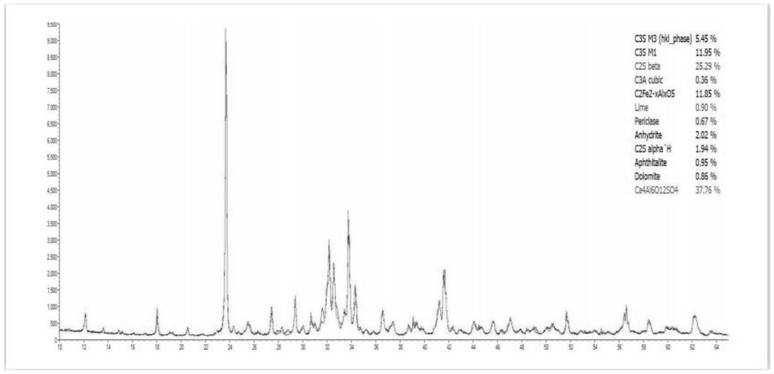

The invention discloses a method for regulating and controlling an alite crystal structure in cement clinker. Th method comprises the following steps: simultaneously introducing a magnesium element and a sulfur element in the preparation process of a Portland cement raw material, and completely converting M3-type alite in the clinker into M1-type alite under the combined action of the magnesium element and the sulfur element. The raw materials used in the crystal structure regulation and control method are easy to obtain, and the method is simple, easy to operate and high in universality. In actual production, desulfurized gypsum, phosphogypsum and the like can be used as sulfur sources, so that the comprehensive utilization value of industrial by-products is increased. The magnesium source can be selected from low-quality limestone, no additional ingredient components need to be added, the operation is convenient, the use of the low-quality limestone is increased, and the production cost is reduced. After being regulated and controlled by the method, the alite crystal structure in the Portland cement clinker can be completely converted from M3 type or M1 / M3 mixed type into M1 type.

Owner:NANJING UNIV OF TECH +1

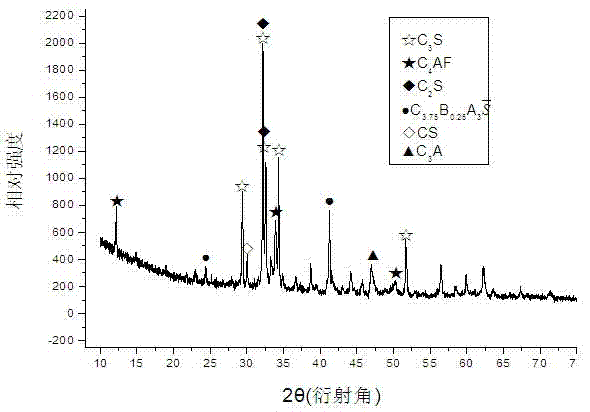

Method for preparing Alite-barium calcium sulphoaluminate cement from red mud

The invention discloses a method for preparing Alite-barium calcium sulphoaluminate cement from red mud. The method comprises the following steps: (1) adopting a mineral phase of Alite-barium calcium sulphoaluminate cement prepared from red mud, wherein the mineral phase consists of the following components in percentage by mass: 5%-8% of C3.75B0.25A3S, 15%-19% of C2S, 40%-60% of C3S, 10%-20% of C4AF and 4%-8% of C3A; (2) according to the mineral phase composition of Alite-barium calcium sulphoaluminate cement, calculating the mixing amount of the following raw materials in percentage by mass: 6%-10% of red mud, 0.3%-0.5% of barium mud, 65%-75% of lime stone, 0.3%-1% of bauxite, 15%-25% of clay, 3%-5% of gypsum and 0.4%-1.5% of fluorite, wherein the fluorite is taken as a mineralizer; (3) crushing, homogenizing, drying, grinding, uniformly mixing, roasting and cooling the raw materials; and (4) adding and grinding gypsum or dihydration gypsum powder which accounts for 5-12% of the total mass until the specific surface area is 350-450m<2> / kg. The method disclosed by the invention is low in sintering temperature, high in early strength, stable in later strength and low in cost, can be used for providing an effective utilization way for comprehensively utilizing the red mud.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

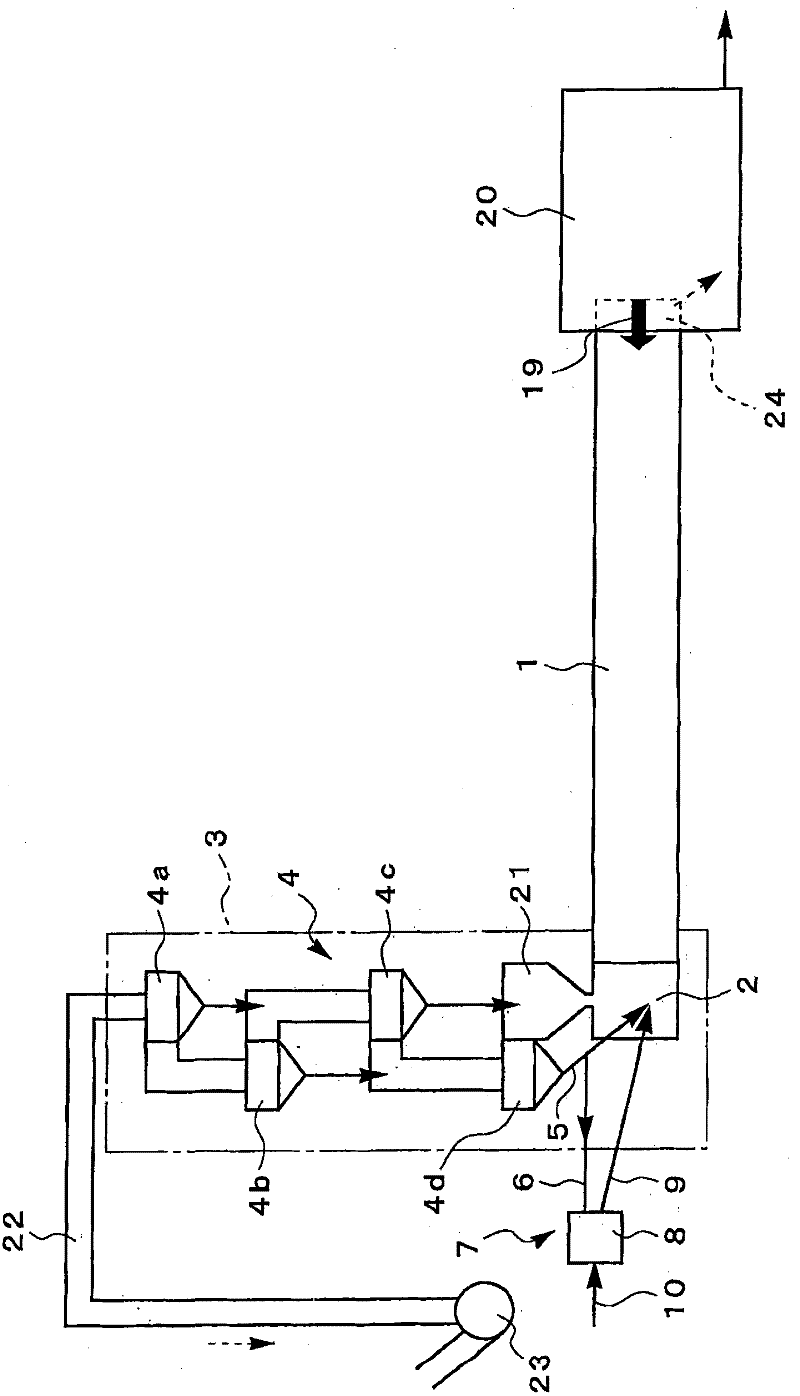

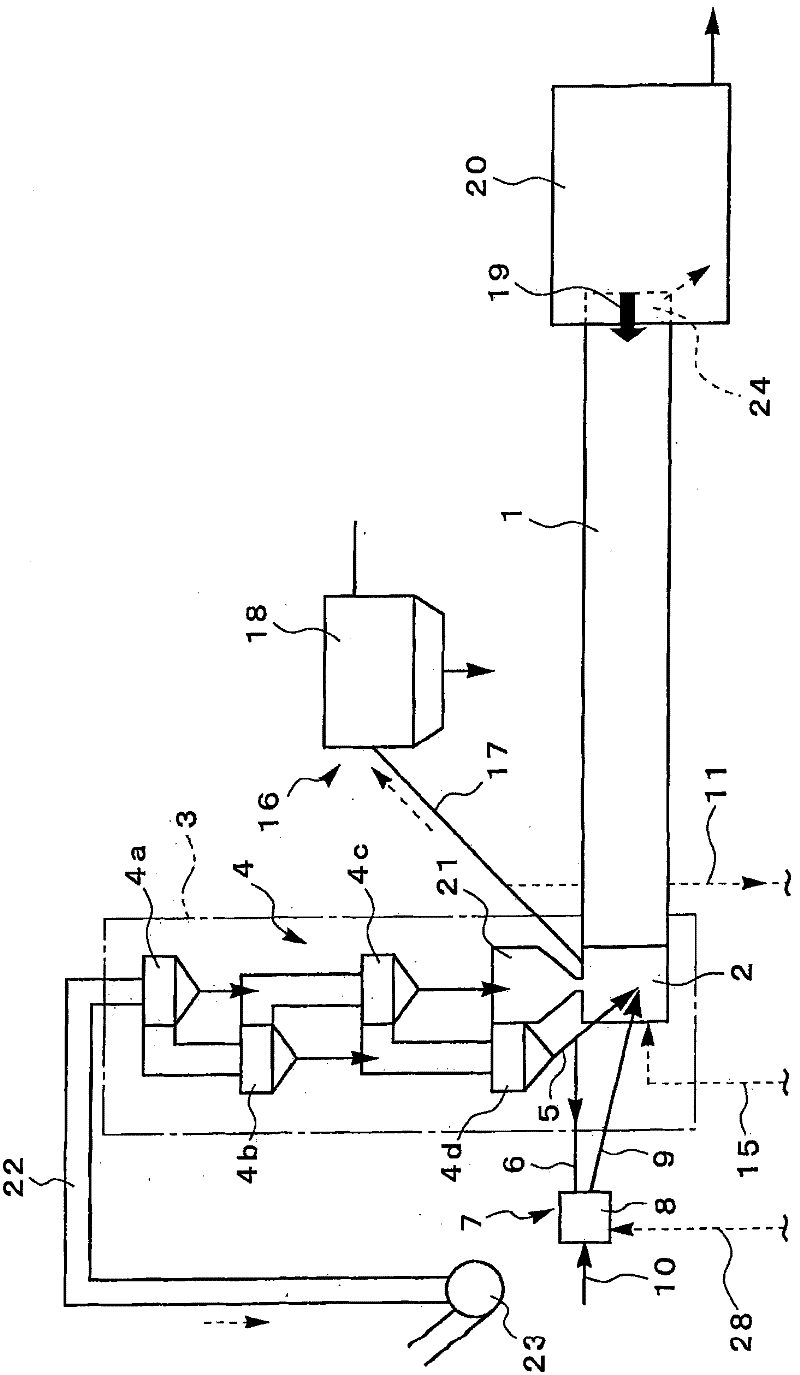

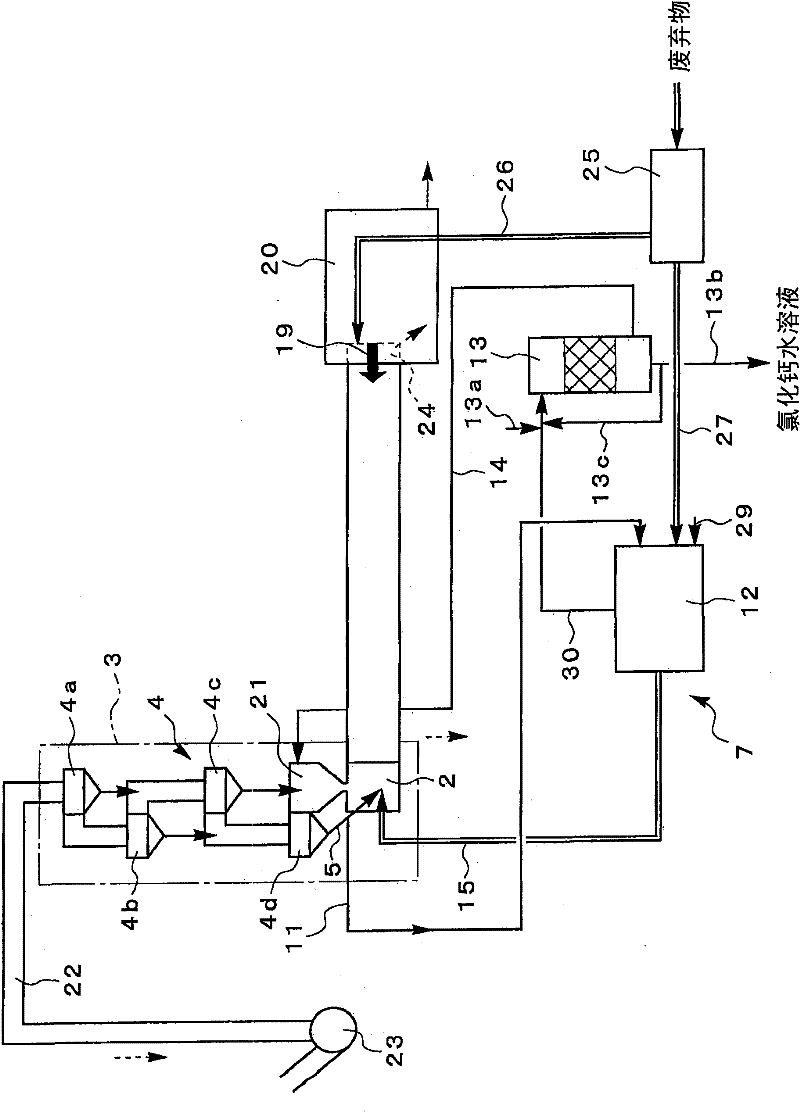

Cement clinker manufacturing device and manufacturing method

ActiveCN102219412AReduce the heat of firingDoes not change the chemical compositionHeat lossesMaterials science

The invention provides a cement clinker manufacturing device and a manufacturing method, which facilitates generation of alite after extracting and sintering a part of cement raw materials having halogen elements and / or fuel and prevent a heat loss from being generated during the high-temperature sintering process and thus reduce the sintering heat of the cement clinkers. The cement clinker manufacturing device comprises a preheater for preheating by mean of cement raw materials having halogen elements and / or fuel, and a rotary kiln for sintering the cement raw materials on the downstream side of the preheater. The cement clinker manufacturing device further comprises an extraction pipeline (6) for extracting a part of the cement raw materials from a sliding chute (5) of a cyclone separator (4) of the preheater (3), a sintering device (7) for sintering the cement raw materials extracted from the extraction pipeline (6), and a returning pipeline (9) located in the rotary kiln (1) and used for a part of the cement raw materials sintered in the sintering device (7) to return.

Owner:MITSUBISHI MATERIALS CORP

Dental composition and preparation method therefor

InactiveCN110446483AEasy to useImprove aestheticsImpression capsDentistry preparationsDentistryBiocompatibility

Owner:(株)倍丽康

A kind of high-strength Portland cement clinker and its preparation method

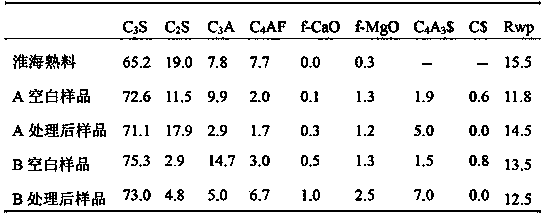

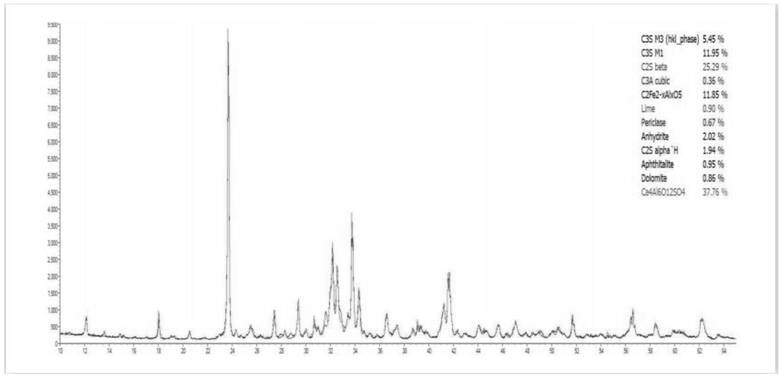

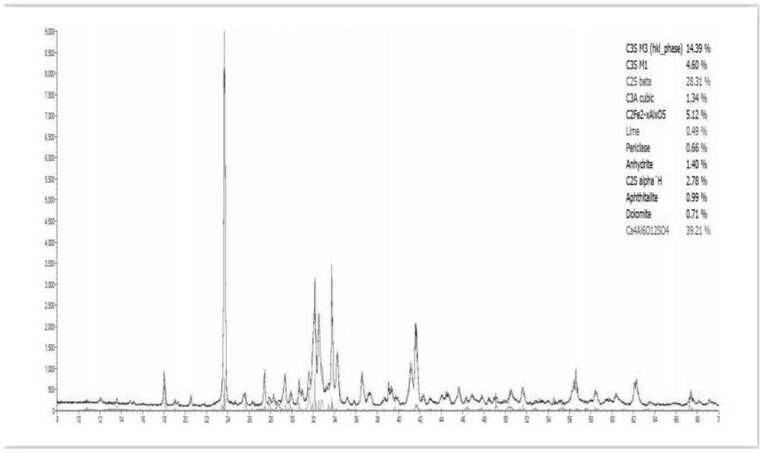

The invention relates to high-strength silicate cement clinker and a preparation method thereof. The mineral constituents of the clinker are as follows in percentage by weight: alite (50%-75% of tricalcium silicate C3S), belite (2%-25% of dicalcium silicate C2S), tricalcium aluminate (2%-10% of C3A), tetra calcium aluminoferrite (2%-8% of C4AF), calcium sulphoaluminate (2%-9% of C4A3S), free calcium oxide (0.5%-3% of f-CaO), periclase (1%-6% of f-MgO) and bassanite (0-3% of CS). 1-day stand mortar strength, 3-day stand mortar strength and 28-day standard mortar strength are respectively 25MPa-35MPa, 38MPa-45MPa and 65MPa-75MPa; the clinker has certain expansibility after being hydrated; and the hydrated sample volume porosity is 10%-12%. The preparation method of the clinker comprises the following steps of: introducing gypsum to raw materials; improving content of SO3 in the materials to form calcium sulphoaluminate; properly improving aluminum ratio in dosing to control liquid phase amount in the clinker, and reducing the content of iron in the clinker; and sintering the materials into clinker under 1400 DEG C to 1500 DEG C, cooling and thermally treating the cooled clinker, quenching after the treatment is finished, wherein the clinker with high alite content is mainly formed in the first sintering process, and the secondary formation of calcium sulphoaluminate is promoted by the thermal treatment.

Owner:NANJING TECH UNIV

Portland cement clinker and preparation method thereof

The invention discloses a Portland cement clinker which contains trace magnesium and trace phosphorus, and R type Alite accounting for 52wt%-65wt%. The invention also discloses a preparation method of the Portland cement clinker; the preparation method comprises the following steps: step 1, selecting raw material components according to the composition of the desired cement clinker and determining the weight proportion of each raw material component, wherein the raw material components include at least one magnesium raw material and at least one phosphorus raw material; step 2, thoroughly mixing the raw material components, and then performing high-temperature calcination on the mixture, and then quickly cooling to a room temperature, thereby obtaining the cement clinker; in the cement clinker, the weight percentage of the phosphorus content in terms of the oxide P2O5 is 0.5%-1.2%, while the weight percentage of the magnesium in terms of the oxide MgO is 1%-5%. The Portland cement clinker prepared by the preparation method contains R type tricalcium silicate, and the compressive strength of the clinker can be greatly improved in contrast with the clinker prepared by use of other methods.

Owner:CHINA BUILDING MATERIALS ACAD

Portland cement clinker and preparation method thereof

ActiveCN112341010AReduce symmetryReduced structural symmetryCement productionFossil fuel consumptionSilicate Cement

The invention discloses a Portland cement clinker and a preparation method thereof. According to the Portland cement clinker, M1 type alite accounts for 99% or more of the mass of all alite crystal forms; and the clinker contains a trace amount of magnesium and a trace amount of sulfur, the mass percentage of magnesium is 0.5%-5% in terms of MgO, and the mass percentage content of sulfur is 0.36%-2.94% in terms of SO3. From the perspective of ion regulation and control, magnesium and sulfur elements are introduced simultaneously in the preparation process of a Portland cement raw material, andM3 type alite in the clinker is completely converted into the M1 type alite under the combined action of the magnesium and sulfur elements, so the Portland cement clinker with a higher M1 type alitecontent is stably sintered; and a clinker sintering temperature is reduced, fossil fuel consumption is lowered, greenhouse gas emission is decreased, the multiple effects of energy conservation, emission reduction, consumption reduction and quality improvement are achieved, and an application value is extremely high.

Owner:NANJING UNIV OF TECH +1

Cement Clinker and Process for Producing the Save

A cement clinker which necessitates no considerable change in the main chemical components and mineral components of cement, is free from preheater coating problems and adverse influences on cement properties, and is effective in reducing the heat quantity required for burning; and a process for producing the cement clinker. In the process for cement clinker production a substance having a melting point higher than the temperature of a liquid phase of the cement clinker and serving as crystal nuclei for C3S is incorporated include a fine powder of refractory brick, particles of an ordinary Portland cement clinker, a fine powder of a high-early-strength Portland cement clinker, a high-early-strength Portland cement, and a fine powder of quicklime. Due to this, alite generation is accelerated even at a low temperature. As a result, high-quality clinker can be produced through burning using a small unit heat quantity and no decrease in cement quality results. The process contributes to a reduction in preheater coating amount and prolongation of the life of the refractory bricks.

Owner:MITSUBISHI MATERIALS CORP

Process for controlling a crystal form of alite in portland cement clinker

The present invention relates to a process of controlling crystal form of Alite in Portland cement clinker, wherein the said Portland cement clinker is thermally treated in order to change the crystal form of Alite in Portland cement clinker, so as to improve performance of resulting Portland cement clinker. The said process of present invention is easy and feasible.

Owner:NANJING UNIV OF TECH

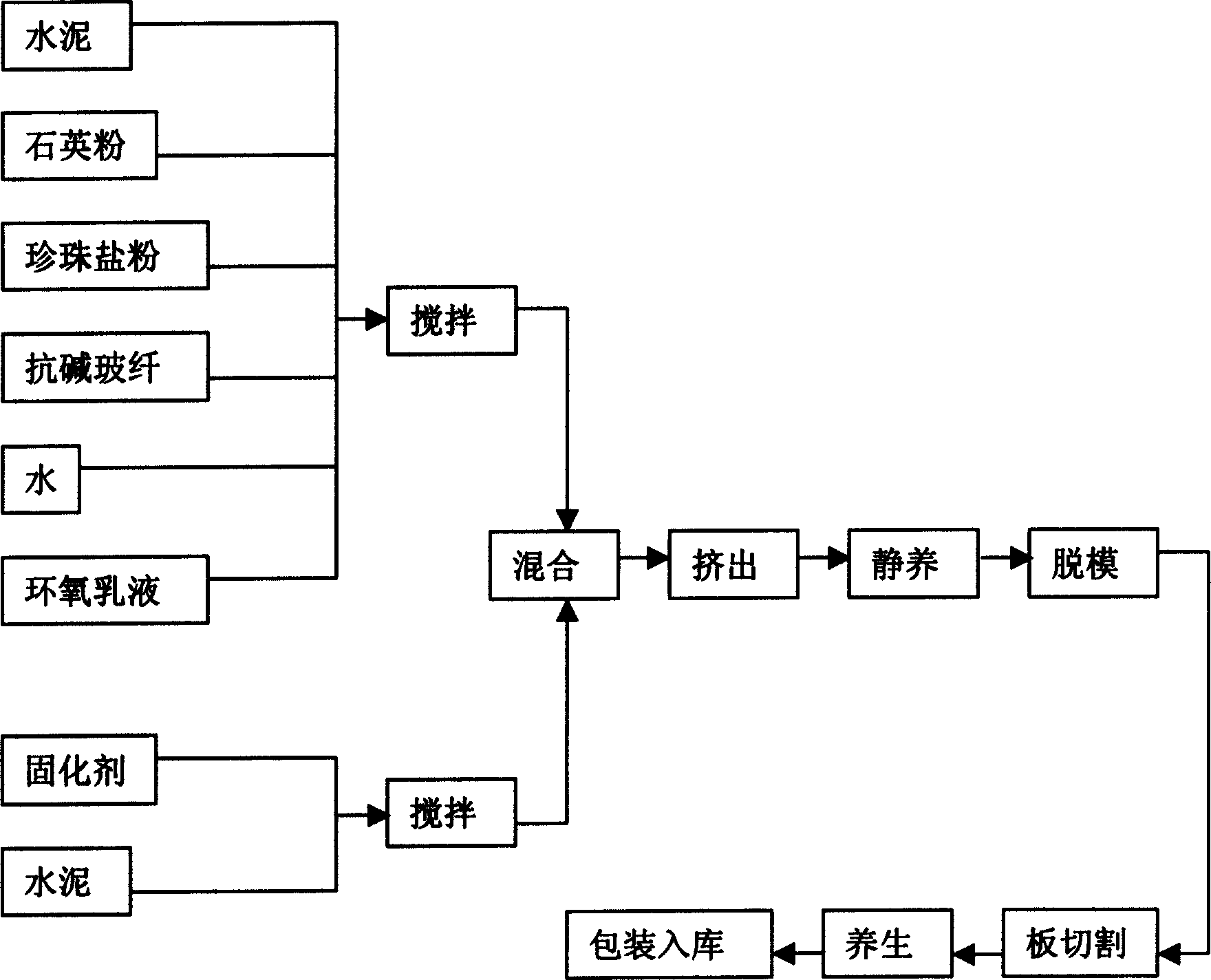

Method for fabricating plates made from fine concrete modified by epoxy emulsion

By this method, epoxy can be cross-linked, solidified, formed to film in early stage to make cement fine concrete form epoxy net layer slotting structure when cement concrete is modified in board material producing. The method is to mix epoxy emulsion and water according to polyash ratio 20:100-45:100 and water ash ratio 33:100 into cement, fine aggregate andp earlstone powder to be stirred to form epoxy cement paste, then to put room-temp. stype amines curing agent into the epoxy cement paste to fully stir to make cement concrete forming asphalt alite with epoxy net layer slotting structure, finally asphalt alite is processed to board material.

Owner:珠海市豪瑞森建材有限公司

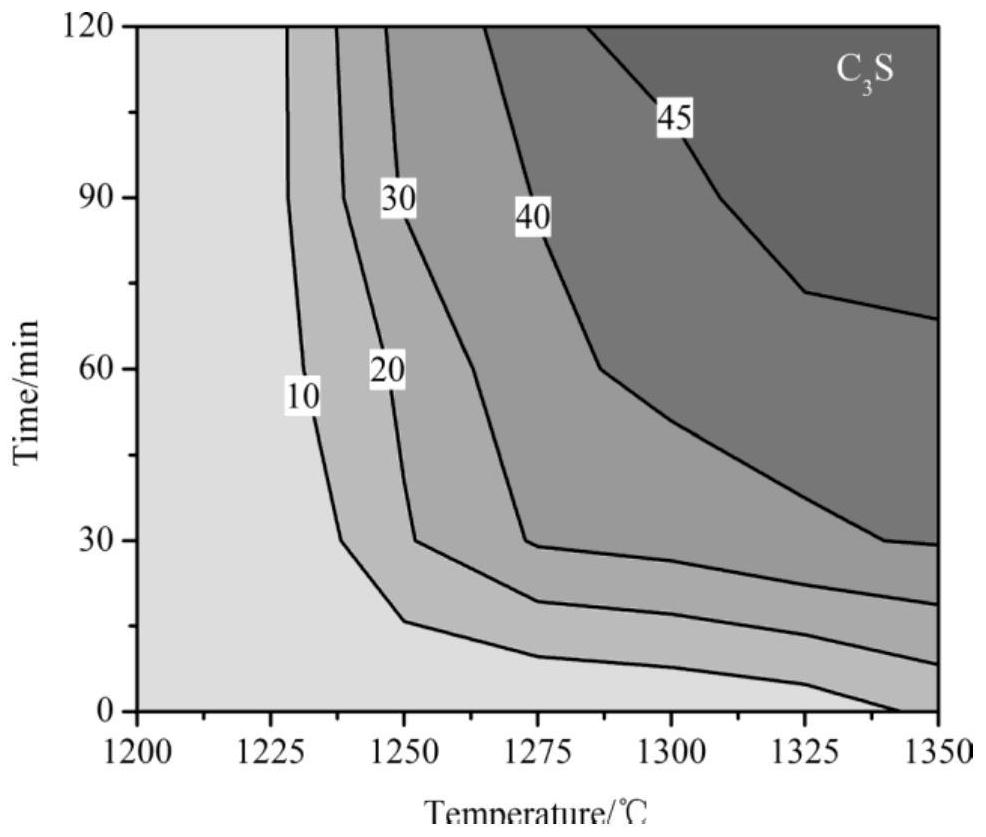

Alit-leaf liter cement and preparation method thereof

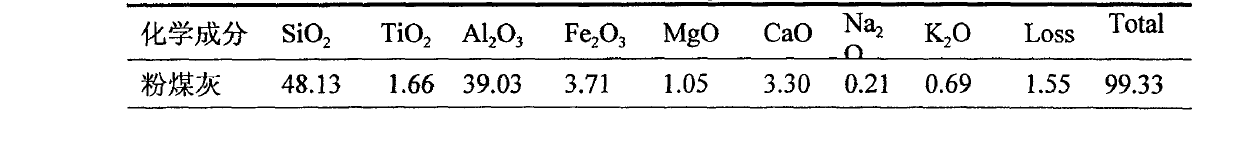

PendingCN114409283AReduce the formation temperatureEasy to manufactureCement productionSilicon oxideFly ash

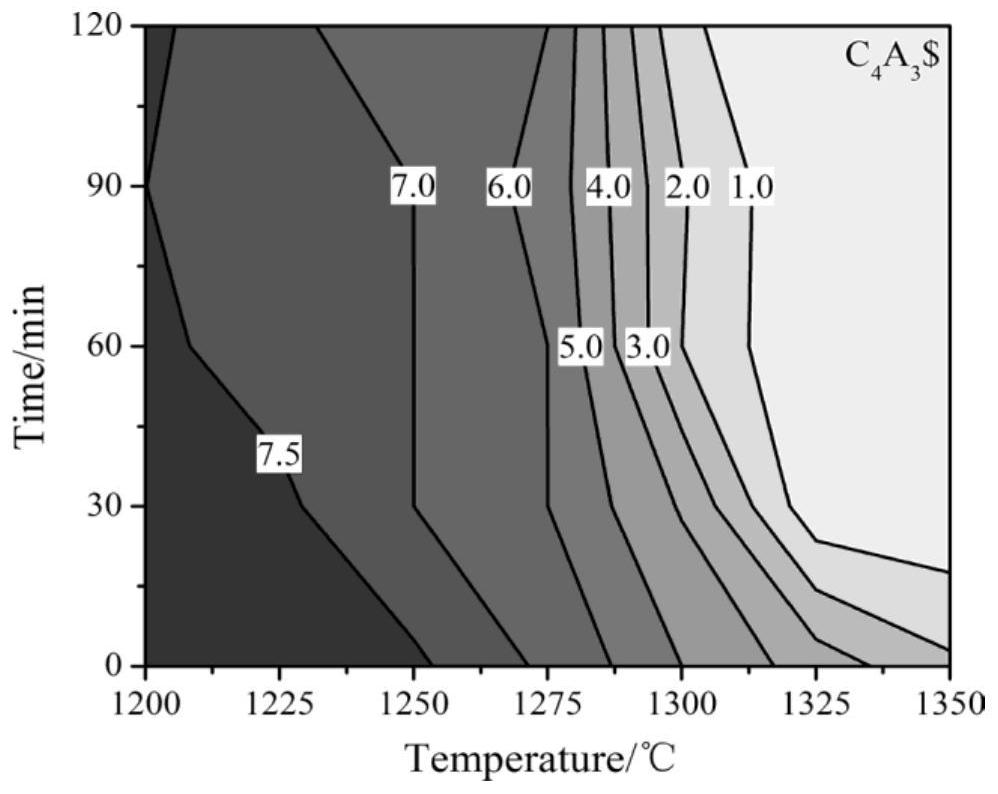

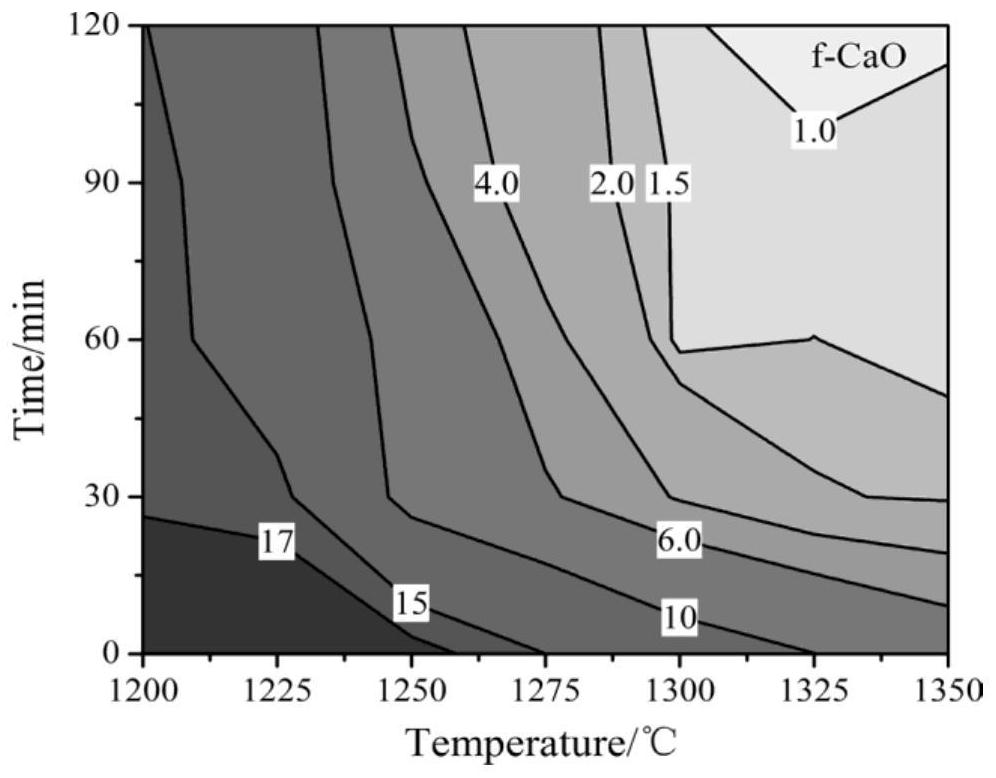

The invention discloses alite-leaf liter cement and a preparation method thereof, and the alite-leaf liter cement comprises: limestone; according to the formula, the raw materials comprise, by weight, 70%-72% of the raw materials, 6.5%-7.5% of sandstone, 6.8%-7.0% of fly ash, 9.2%-9.4% of gypsum, 1.4%-1.6% of copper slag, 2.2%-2.4% of phosphorus slag, 0.7%-0.9% of aluminum oxide and 1.1%-1.3% of silicon oxide. The preparation method of the alite-leaf liter cement comprises the following steps: mixing the raw materials together for a certain time, pressing the homogenized mixture into a mixture in a parallel epitaxial wafer shape by using water, and sintering the mixture at different temperatures of 1200-1350 DEG C at different time intervals, the samples are taken out at different heat preservation time of 0 h, 0.5 h, 1 h, 1.5 h and 2 h respectively.

Owner:CHUZHOU UNIV

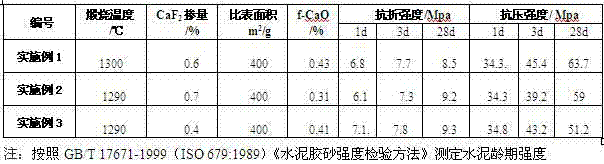

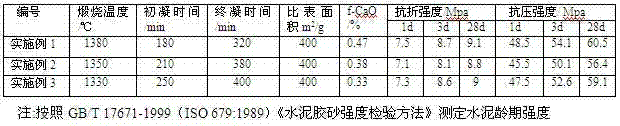

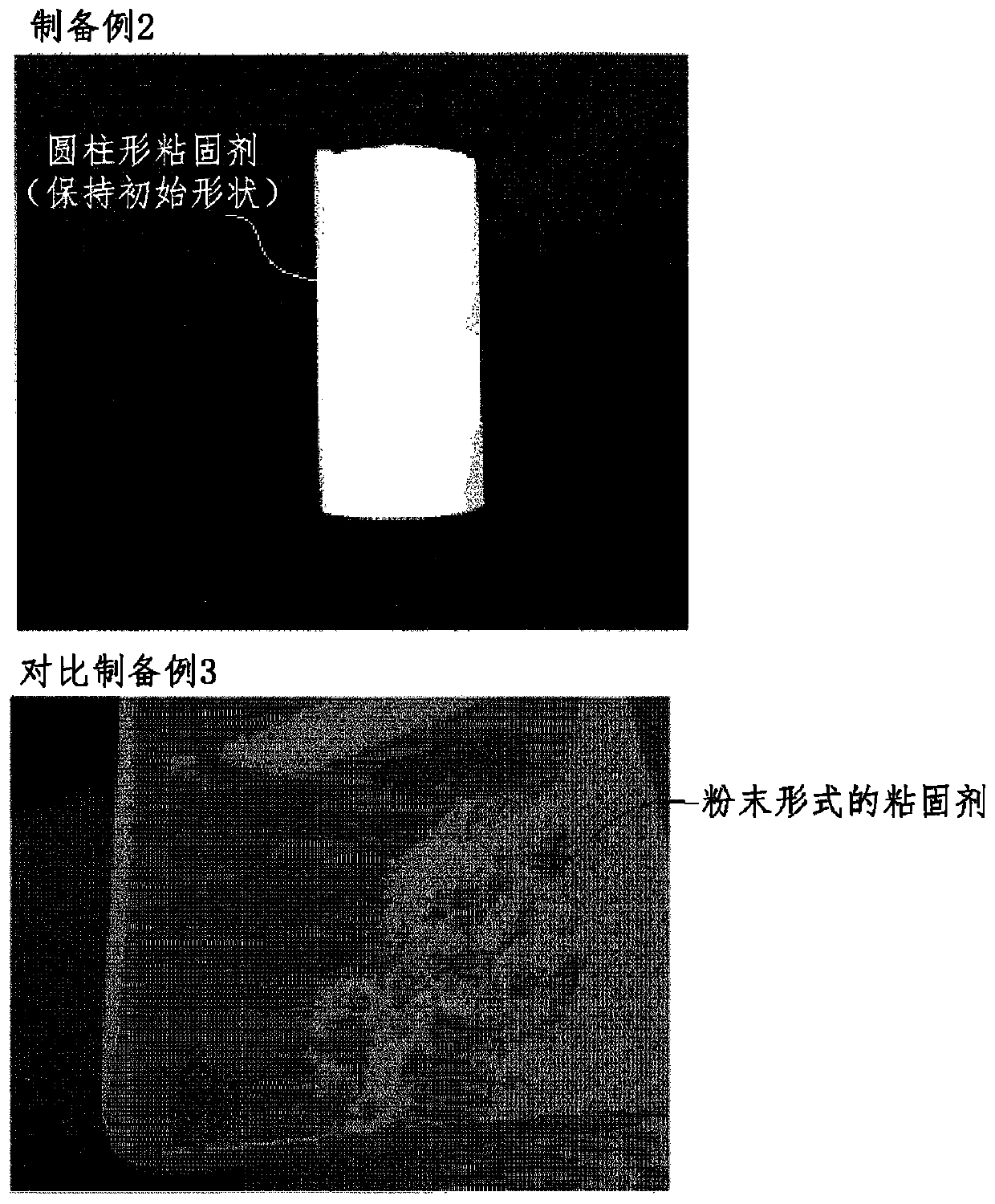

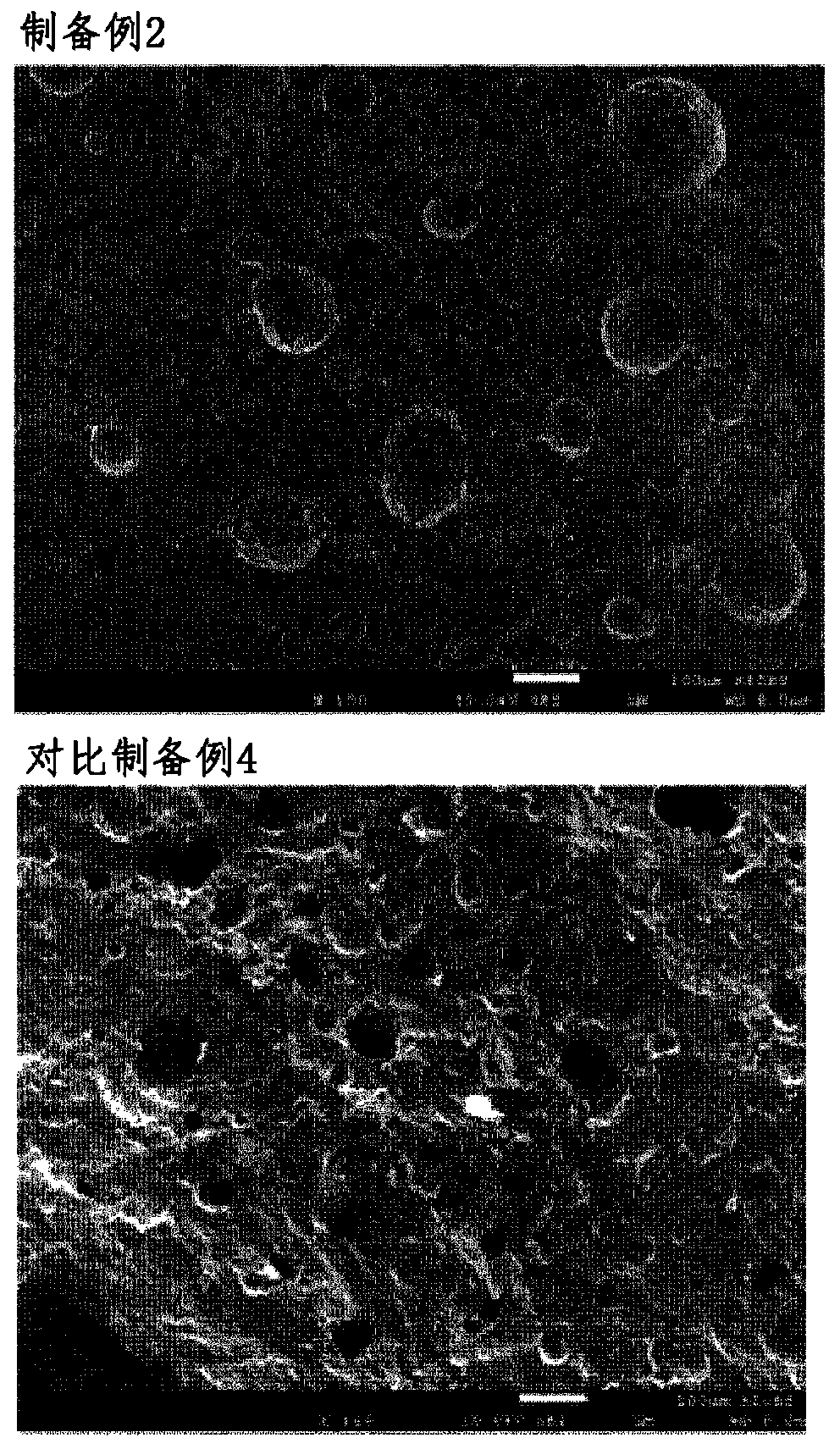

High-alite sulphoaluminate cement clinker and preparation method and application thereof

The high-alite sulphoaluminate cement is energy-saving cement which is high in early strength, has micro-expansion and erosion resistance, can be constructed in winter and is stable in strength increase, and is characterized in that the clinker comprises the following components in percentage by weight: 5-20% of SiO2, 10-20% of Al2O3, 1-10% of Fe2O3, 30-60% of CaO and 2-13% of SO3. The saturationratio coefficient of clinker lime is 0.90 + / -0.05; the aluminum rate is 4.5 + / -0.5; the silicon rate is 2.0 + / -0.5, and the sulfur-aluminum ratio is 1.2 + / -0.1. The invention is characterized in thatthe sulphoaluminate cement clinker containing high-content tricalcium silicate can be sintered at 1,250-1,350 DEG C while the burdening scheme is adopted, and the amount of tricalcium silicate in thesulphoaluminate cement clinker sintered within the temperature range is basically zero.

Owner:YAOBAI SPECIAL CEMENT TECH R&D CO LTD

Cement clinker and process for producing the same

Owner:MITSUBISHI MATERIALS CORP

Paste filling cementing material and paste filling slurry

The invention relates to the technical field of mining engineering, and particularly discloses a paste filling cementing material and a paste filling slurry. The paste filling cementing material is prepared from, by mass, 55-65% of high alite Portland cement clinker, 25-35% of steel slag, 2-5% of nano SiO2, 2- 3% of nano CaCO3, 2-6% of modified gypsum and 0.1-0.5% of a compound additive. The industrial solid waste steel slag is used as the raw material, the process is simple, the production cost is greatly reduced, a guarantee is provided for green mining of mines, and a new way is provided for comprehensive utilization of industrial solid wastes. The paste filling cementing material is used for preparing paste filling slurry, and the problems that the paste filling material is low in early strength, poor in slurry fluidity, high in cost and energy consumption and the like are solved.

Owner:河北充填采矿技术有限公司 +1

Calcium sulphoaluminate-alite composite mineral phase cement clinker and its preparation method

The invention discloses calcium sulphoaluminate-Relit composite mineral phase cement and preparing method, which is characterized by the following: adopting coal ash, alumina, limestone and plaster as raw material and fluorite as mineralizer; designing MG and MS value; introducing new Relit mineral in the preparing course of common aluminium sulfate cement; preparing new clinker of new calcium sulphoaluminate-Relit composite mineral phase cement under 1200-1330 deg.c with 45%-65% C4A3S, 20%-36% C3S and residual C2S.

Owner:李金洪

A method for controlling the alite crystal form in Portland cement clinker by gas-solid reaction

Owner:NANJING TECH UNIV

Method for regulating and controlling alite crystal form in Portland cement clinker through gas-solid reaction

The invention discloses a method for regulating and controlling an alite crystal form in Portland cement clinker through a gas-solid reaction. The method comprises the following steps: crushing Portland cement clinker to obtain a Portland cement clinker particle material, heating the Portland cement clinker particle material to 600-1100 DEG C in a mixed gas atmosphere of SO2 and air, carrying outheat preservation reaction for 0.5-2 hours, and cooling to room temperature after the reaction is finished. According to the method, the mixed gas of SO2 and air is introduced in the high-temperatureheat preservation process, and the content of M1 type alite is increased under the action of SO2 in the mixed gas and cement clinker minerals, so that the performance of the portland cement clinker isimproved. Compared with a traditional process for regulating and controlling the alite crystal form in Portland cement clinker, the method has the advantages that a certain amount of SO2 gas can be consumed, a feasible solution is provided for cement and other enterprises possibly generating SO2 waste gas, and the M1 type alite conversion rate of the alite crystal form regulated and controlled through gas-solid reaction is higher.

Owner:NANJING UNIV OF TECH

A kind of Portland cement clinker and preparation method thereof

ActiveCN112341010BImprove use valueRaw materials are easy to getCement productionFossil fuelSilicate Cement

The invention discloses a portland cement clinker and a preparation method thereof, wherein the M1 type alite accounts for more than 99% of the mass of all alite crystal forms; the clinker contains trace amounts of magnesium and sulfur, wherein the mass of magnesium is The content of sulfur is 0.5%~5% in terms of MgO; the mass percentage of sulfur is in terms of SO 3 Calculated as 0.36% to 2.94%. From the perspective of ion regulation, the present invention introduces magnesium and sulfur elements simultaneously during the preparation of Portland cement raw materials, and through the joint action of magnesium and sulfur elements, the M3 type alite in the clinker is completely converted into M1 Type Alite, so as to stably burn Portland cement clinker with high M1 Alite content, which not only reduces the clinker firing temperature, reduces the consumption of fossil fuels, but also reduces the emission of greenhouse gases, reaching The multiple effects of energy saving, emission reduction, consumption reduction, and quality improvement have extremely high application value.

Owner:NANJING TECH UNIV +1

Alite-barium calcium sulfur aluminate cement

An Alinty-barium calcium thioaluminate cement contains barium calcium thioaluminate (3-38 wt.%), tricalcium aluminate (3-20), tricalcium silicate (30-60), dicalcium silicate (15-40), and ferroaluminate (3-20). Its advantages are low burning temp, high early strength and hardening speed, and low cost.

Owner:UNIV OF JINAN

Dental composition and preparation method therefor

The present invention relates to a dental composition including cement and a non-aqueous liquid, wherein the cement includes a first domain including alite, a second domain including belite, and a matrix located between one or more selected from the group consisting of the first domain and the second domain and configured to include silicon (Si)-atom-doped tricalcium aluminate (3CaO.Al2O3). A dental hydraulic composition according to the present invention is a single ointment-type composition, and is thus easy to use and exhibits a good aesthetic appearance, high curability and high biocompatibility.

Owner:VERICOM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com