Patents

Literature

103results about How to "Reduce the formation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

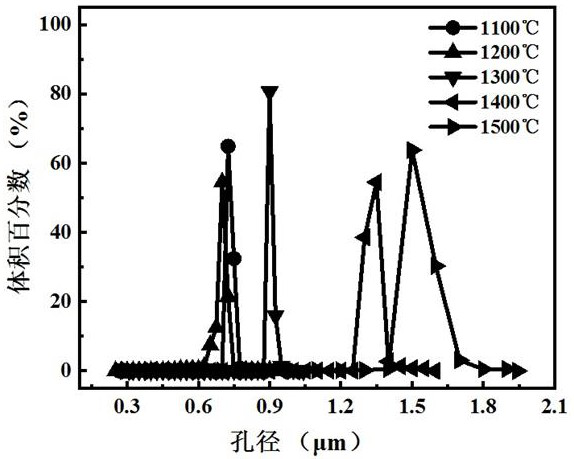

Method for preparing porous mullite

InactiveCN101759430AHigh strengthImprove high temperature resistanceCeramicwarePore distributionMullite

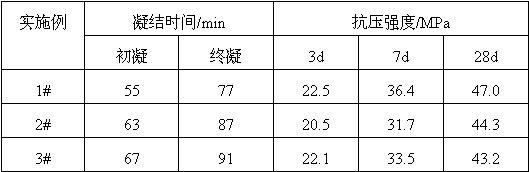

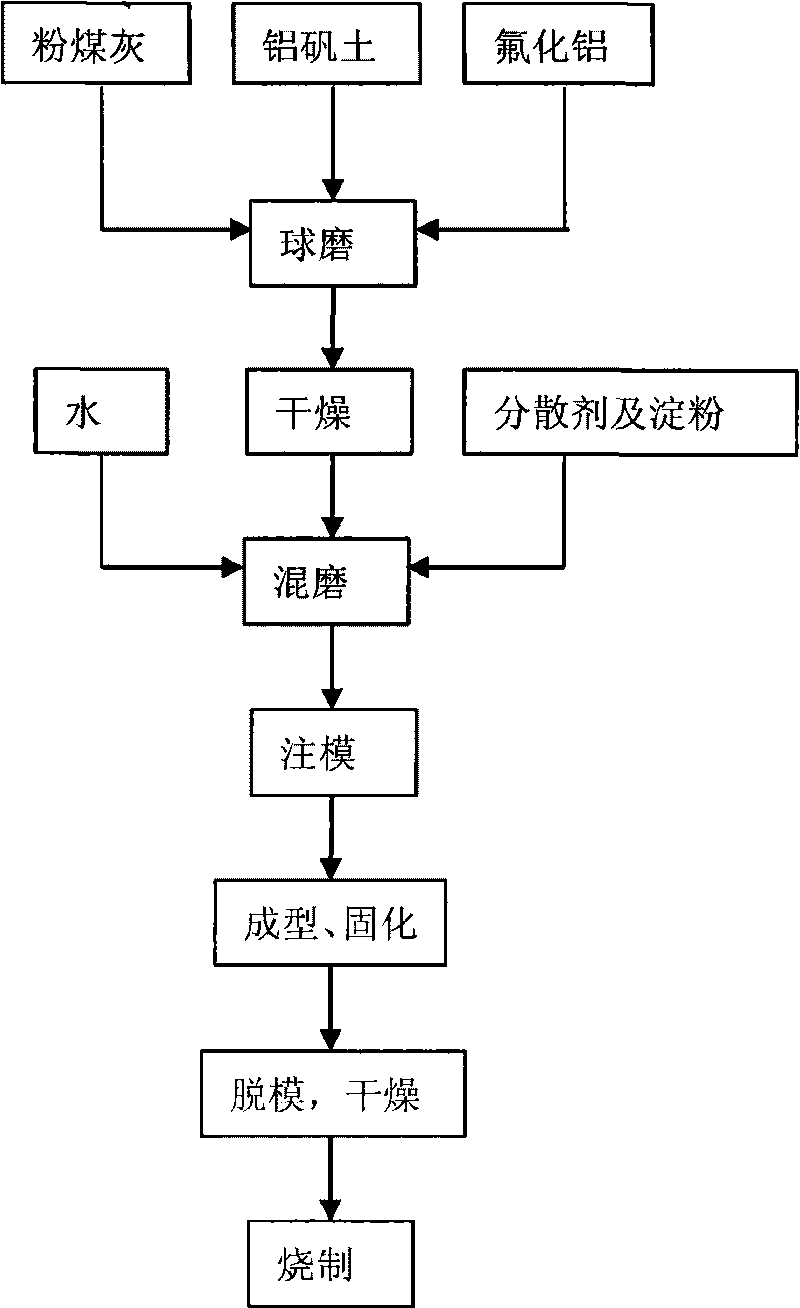

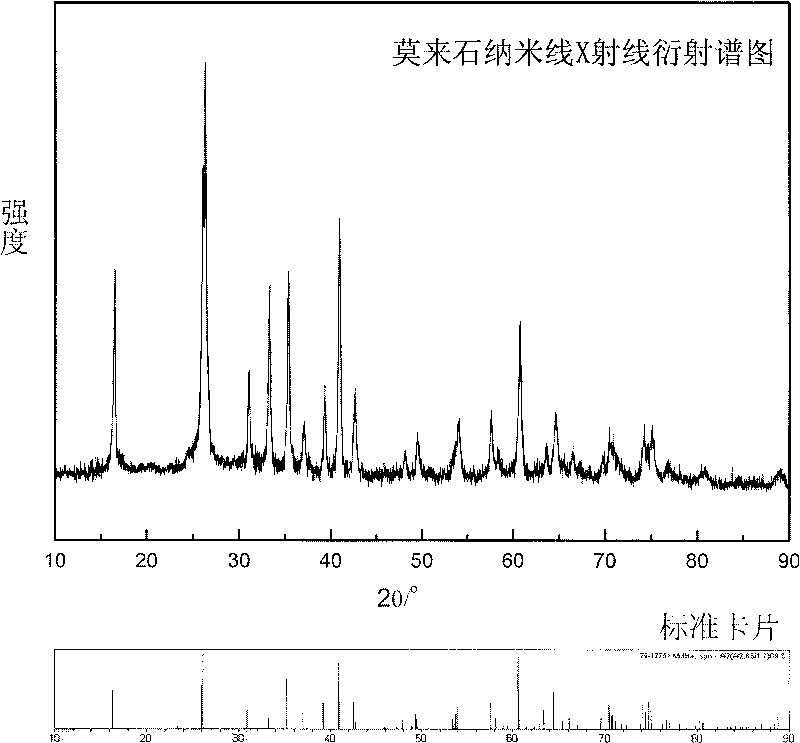

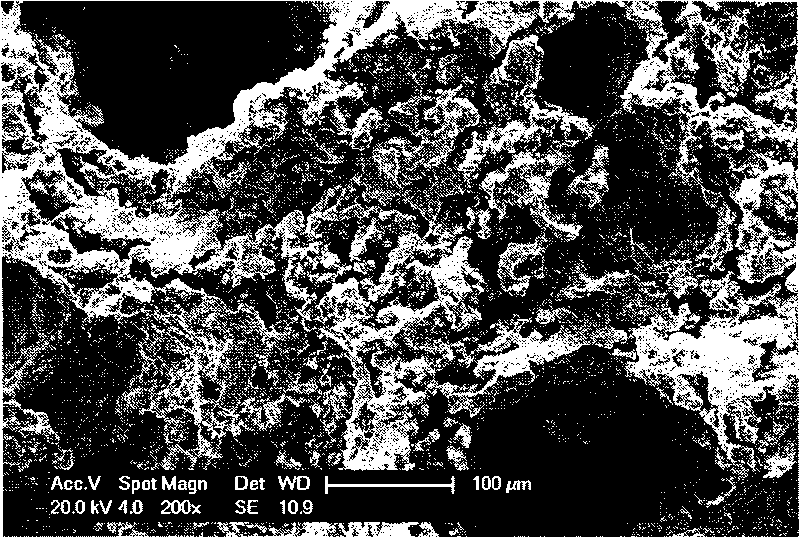

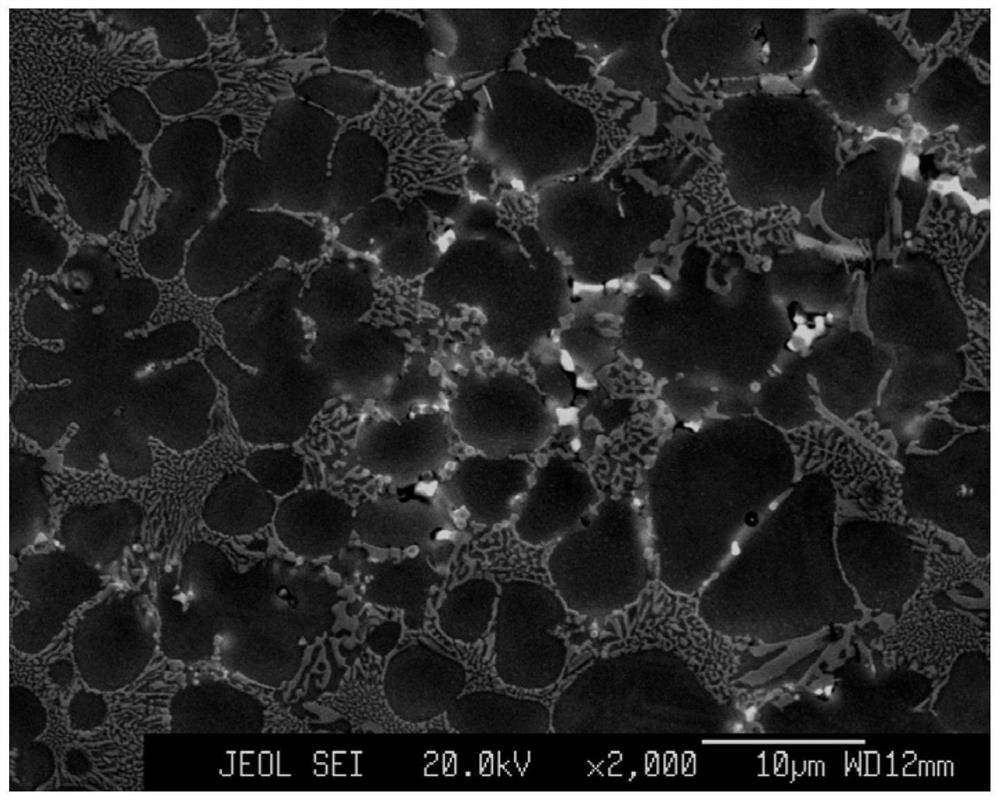

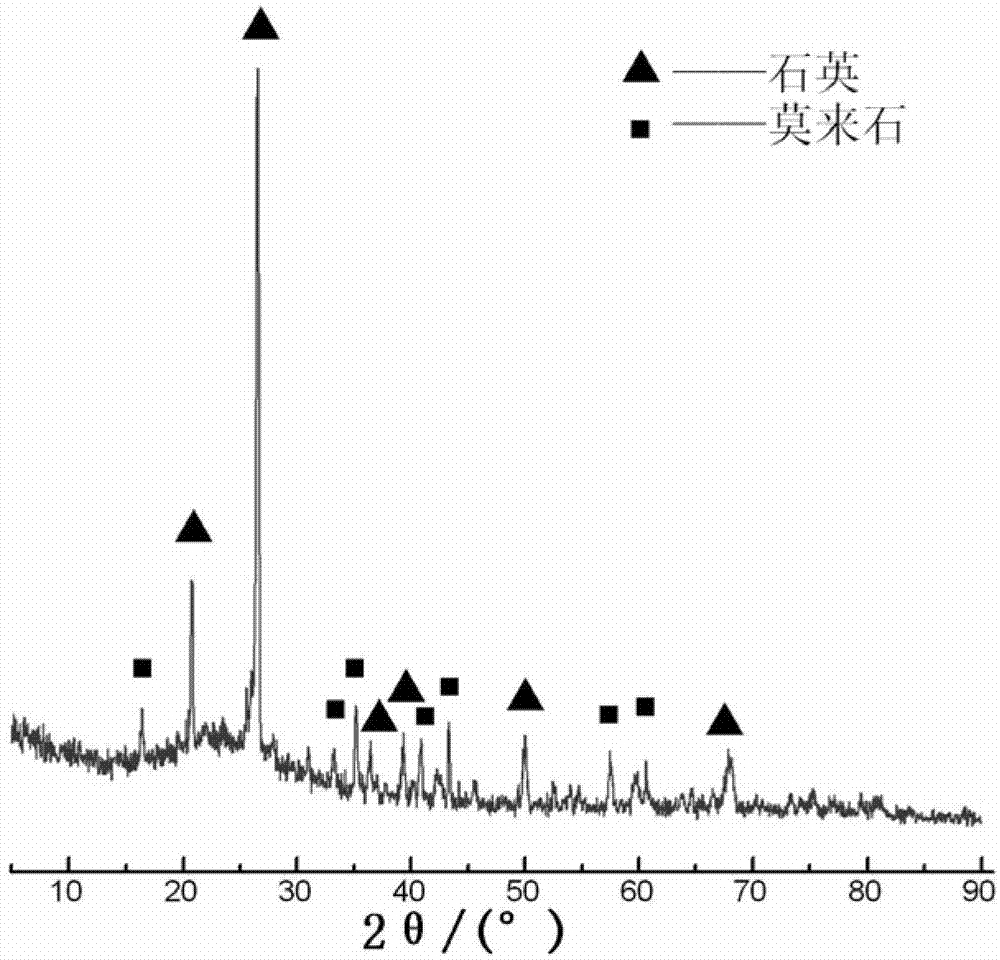

The invention discloses a method for preparing porous mullite, which comprises the following steps of: (1) performing magnetic separation to fly ash to remove iron; (2) proportioning the iron-removed fly ash, bauxite and aluminium fluoride; (3) adding a dispersing agent and a firming agent to prepare a mixed sizing agent; (4) pouring into a mold, and demolding after heating and curing; (5) preserving the demolded dry blank at the temperature of 350-400 DEG C for 0.5-2 h; (6) preserving the temperature at 1300-1500 DEG C for 2-4 h, and cooling. The method not only greatly utilizes fly ash which is a solid pollutant to achieve the purposes of energy saving, pollution reduction and environmental protection, but also has simple technology. The prepared porous mullite ceramics have reasonable pore diameter distribution, even pore distribution, high mullite content and great high-temperature resistance, and are applicable to multiple application requirements on high and low temperatures.

Owner:TIANJIN UNIV

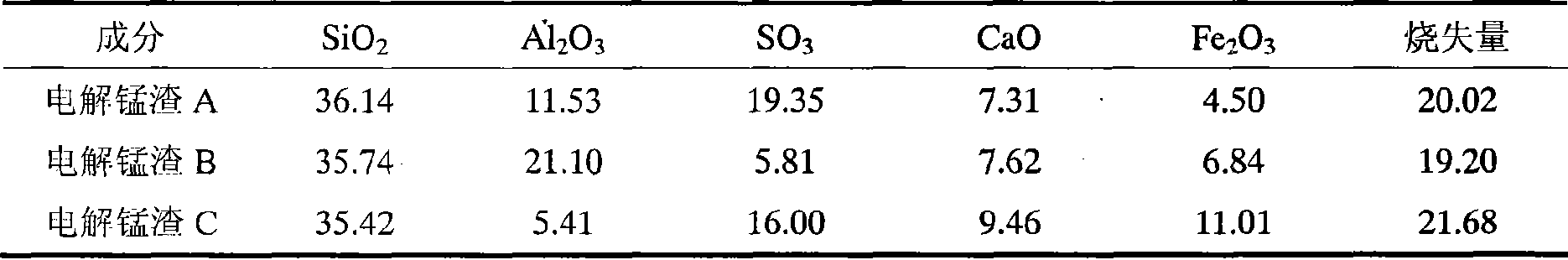

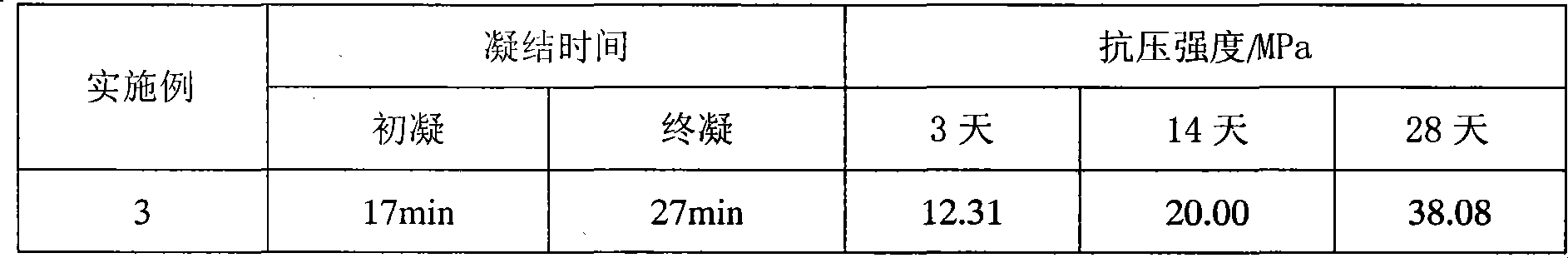

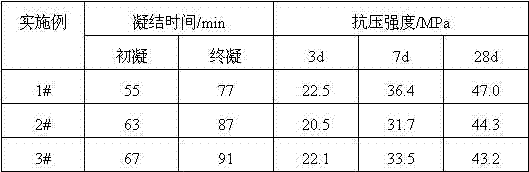

Manufacture of sulphur aluminate cements with electrolytic manganesium residue and method of manufacturing the same

A sulphate-aluminium-like cement produced by using electrolytic manganese slag and the preparation method of the cement relate to the production of the sulphate-aluminium-like by using industrial wastes and the preparation method of the cement. The raw materials of the cement clinker of the invention contain limestone, electrolytic manganese slag, kaolin and soft coal, and dihydrate gypsum is added to the fired cement clinker; the preparation method comprises the following steps: using the limestone, electrolytic Manganese slag, kaolin and soft coal as the raw materials of the clinker; first, levigating and homogenizing the raw materials, and calcining the raw materials into the clinker at a relatively low temperature; then adding the dihydrate gypsum to the clinker according to the requirement and then levigating the mixture to be the finished product. The cement is characterized in that the firing temperature ranges from 150 DEG C to 200 DEG C which is lower than that of the common Portland cement, and the energy-saving advantage is obvious; the mixture proportion range of the components is wide; the mixing amount of the manganese slag is great; and the fired cement has wide application, and so on. The preparation method can be widely used for producing the sulphate-aluminium-like cement by using electrolytic the manganese slag, and is in particular applicable to the production of early strength cement, rapid-hardening high-strength cement, expansive cement and low-alkali cement, and the like.

Owner:CHONGQING UNIV

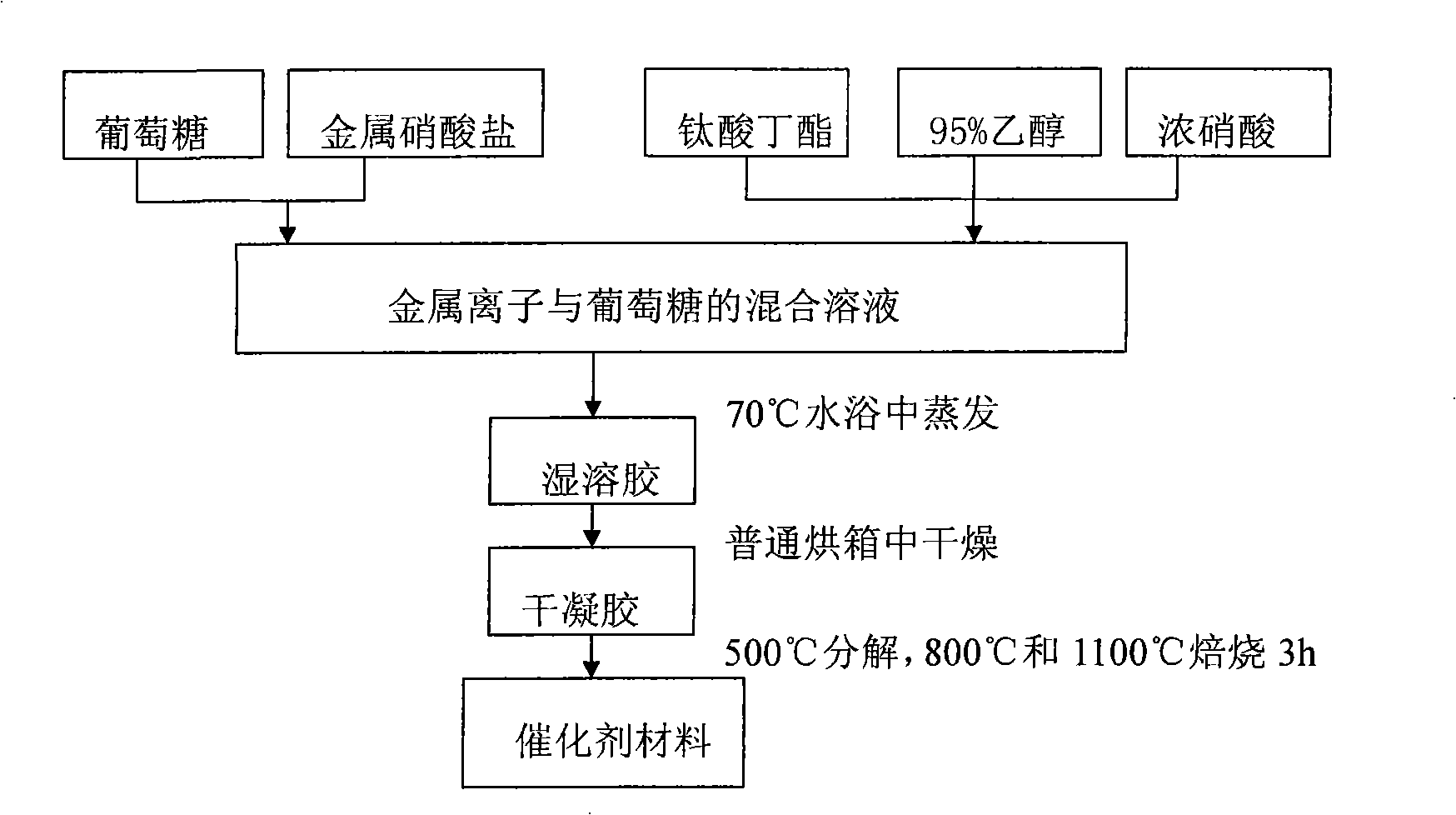

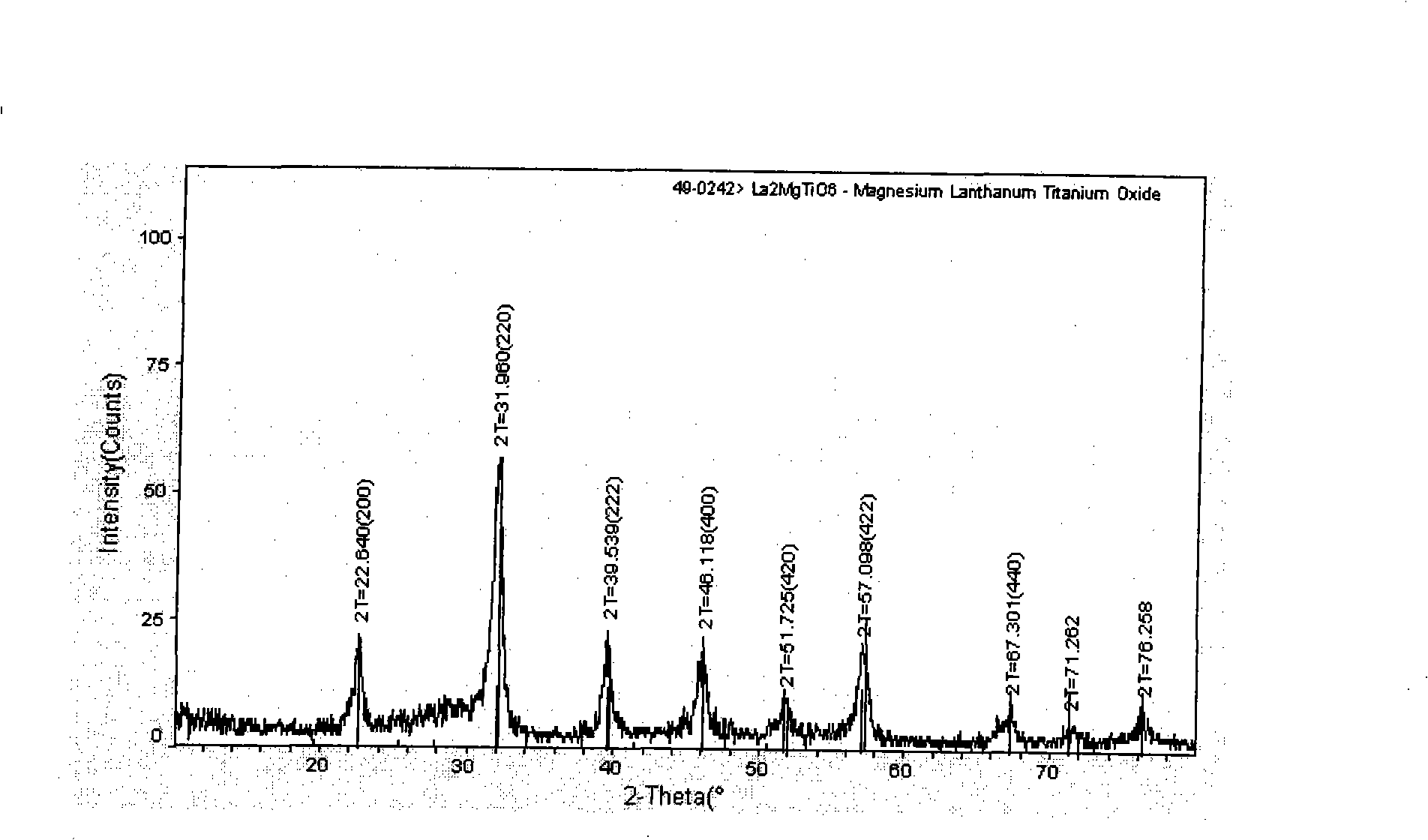

Method for preparing dual-perovskite type methyl hydride combustion catalyst containing titanium

InactiveCN101293200ASimple structureHigh catalytic activityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsEvaporationCoordination complex

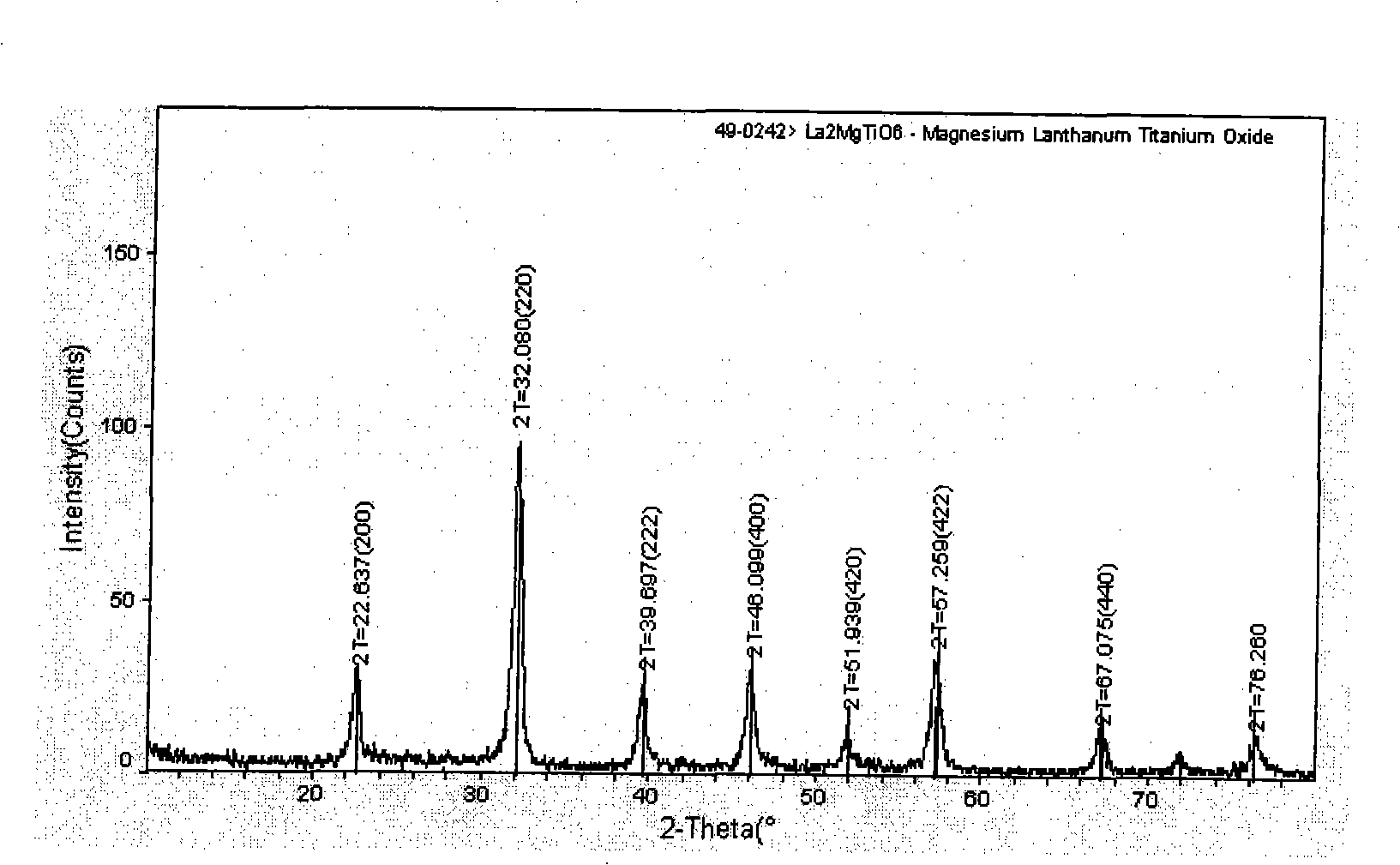

The present invention relates to a preparation method of titanium-containing double perovskite type methane combustion catalyst. The process is characterized in that a certain amount of butyl titanate is added into ethanol to produce white sediment; concentrated nitric acid is added until the sediment is totally dissolved and transparent solution is obtained; lanthanum nitrate and magnesium nitrate are weighed and dissolved in the deionized water and a certain amount of dextrose is added, thus completely forming composition solution; then gel is formed by constant-temperature stirring and evaporation; the gel obtained is dried and sintered at the temperature of 500 DEG C, 800 DEG C and 1,100 DEG C in the air for three hours to obtain the catalyst La2MgTiO6. The present invention is characterized in that the Sol-Gel Preparation Method with the dextrose as the complexing agent is adopted and the single-phase double layer perovskite type composite oxide catalyst is prepared at lower temperature. The preparation method is simple and low in cost. The catalyst used in methane catalytic combustion reaction has the characteristics of low initiation temperature and low whole transformation temperature.

Owner:INNER MONGOLIA UNIVERSITY

Preparation technology of low-cost high-strength ceramic floor tile

InactiveCN103819176AAlleviating the crisis of scarcityReduce dependenceManufacturing technologyRed mud

The invention relates to a preparation technology of a low-cost high-strength ceramic floor tile, which comprises the following steps: 1)taking 30-40% of steel slag, 40-55% of bayer process red mud and 20-30% of talcum according to weight percentage for standby; 2)crudely crushing the steel slag into the particles with size below 10mm; 3)respectively performing ball milling on the steel slag particles and the bayer process red mud by a ball mill for 8 hours, and sieving through a sieve with 250 meshes; 4)placing the sieved raw material in a three-dimensional stereo feed mixer for mixing for 10 hours; and 5)adding water in a mixture, and preparing a green compact by an oil hydraulic press under 25MPa pressure, placing the dried green compact in a muffle furnace, and roasting to obtain the ceramic floor tile. The ceramic floor tile provided by the invention takes red mud and steel slag as main raw materials, and the red mud and steel slag substitute the rear kaolin with high cost and high quality, so that dependence of ceramic industry in our country to kaolin is reduced, and crisis of high-quality kaolin scarcity due to rapid development of industrial can be alleviated.

Owner:HENAN UNIV OF SCI & TECH

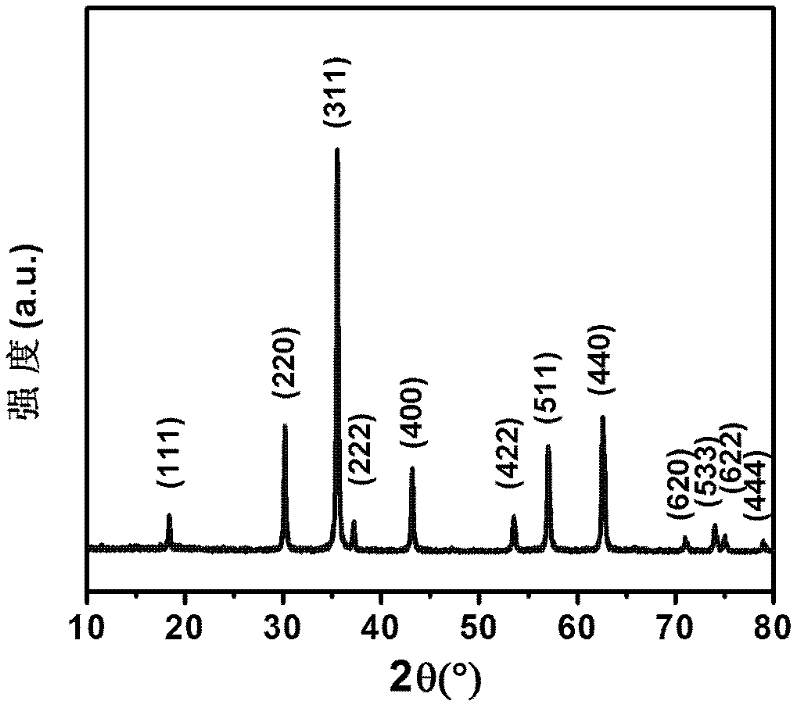

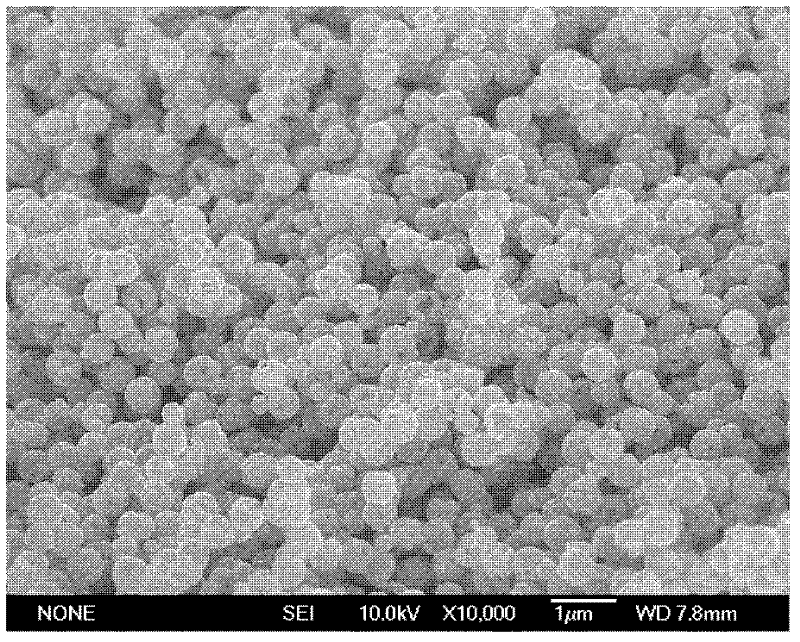

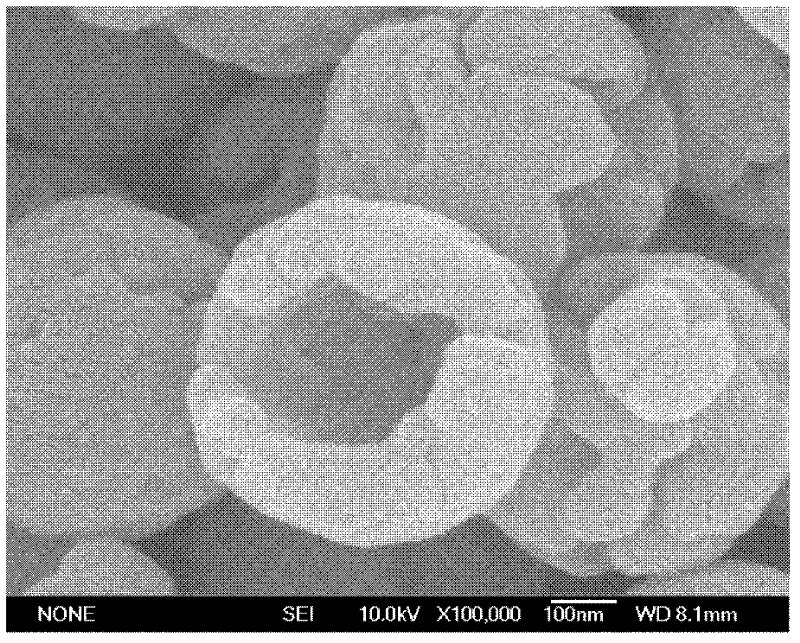

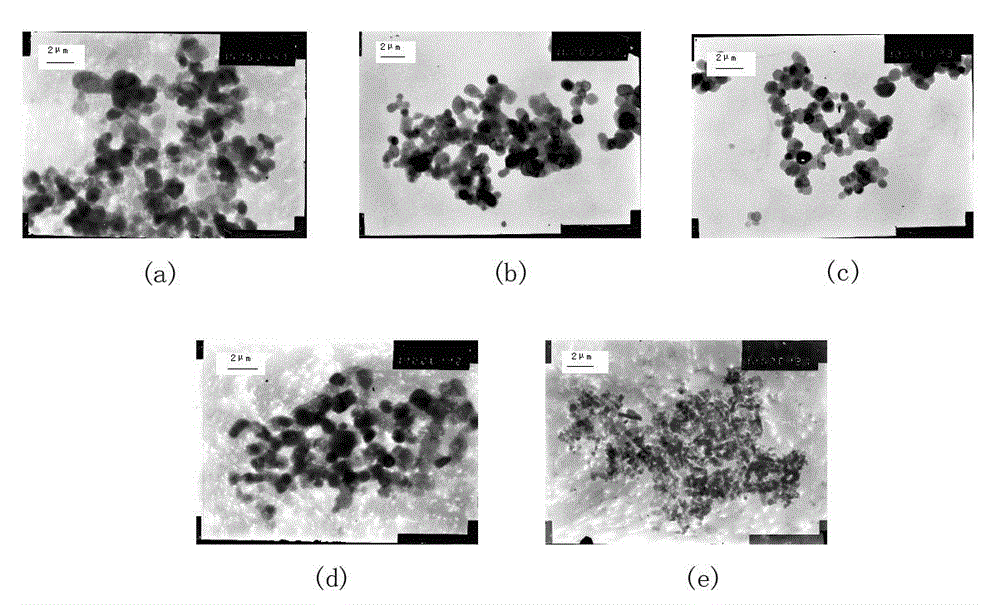

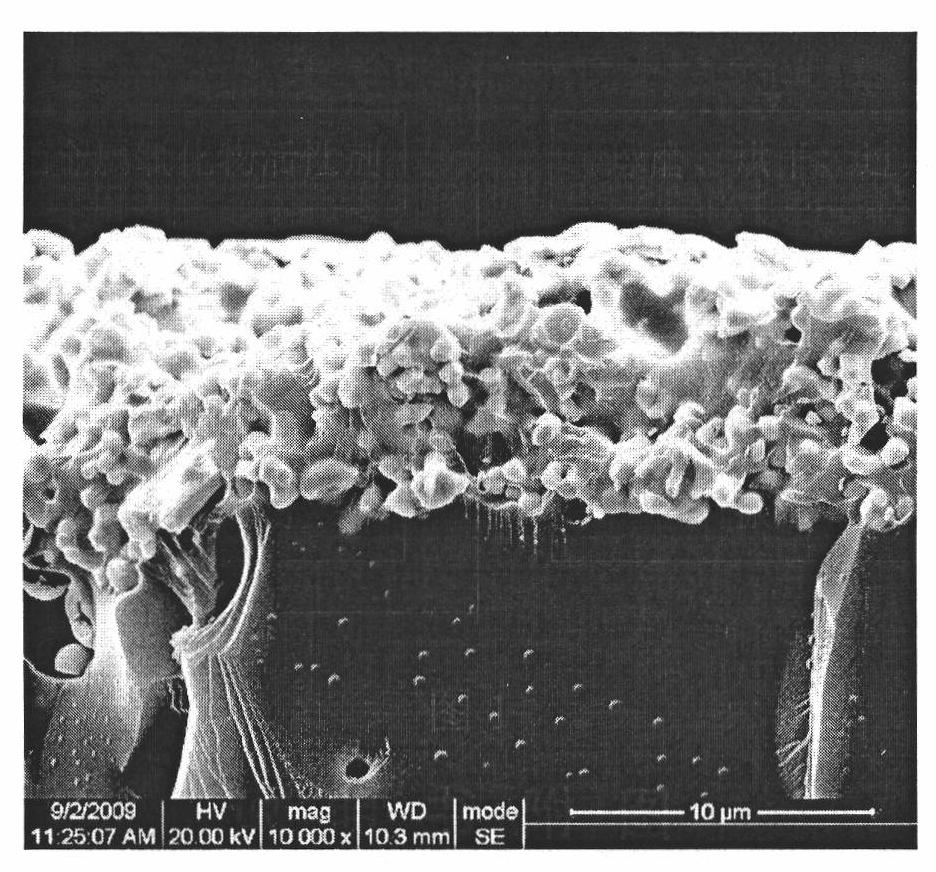

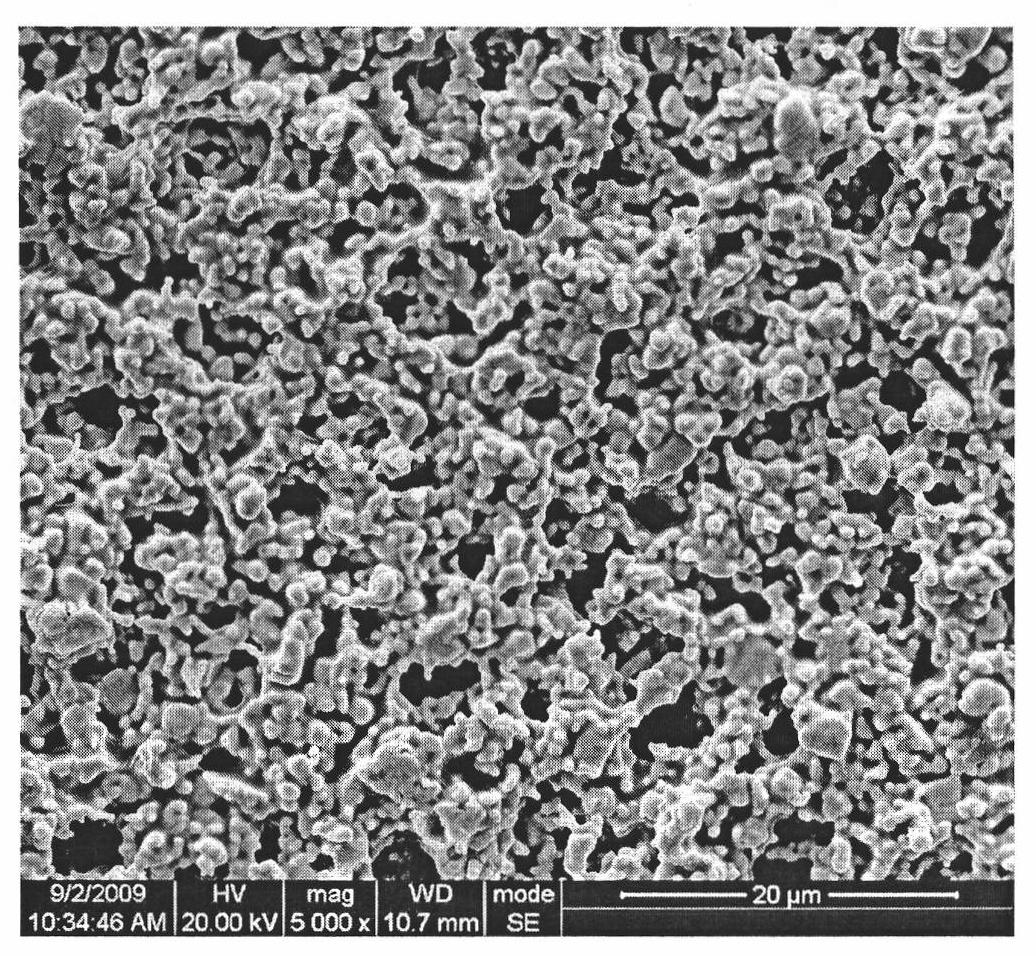

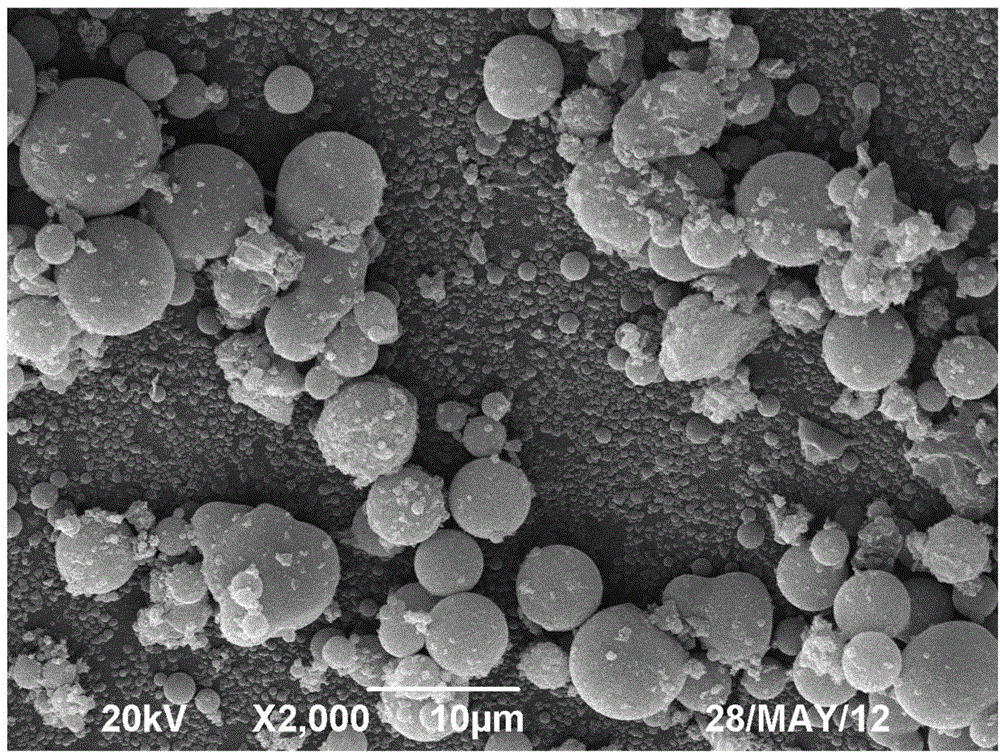

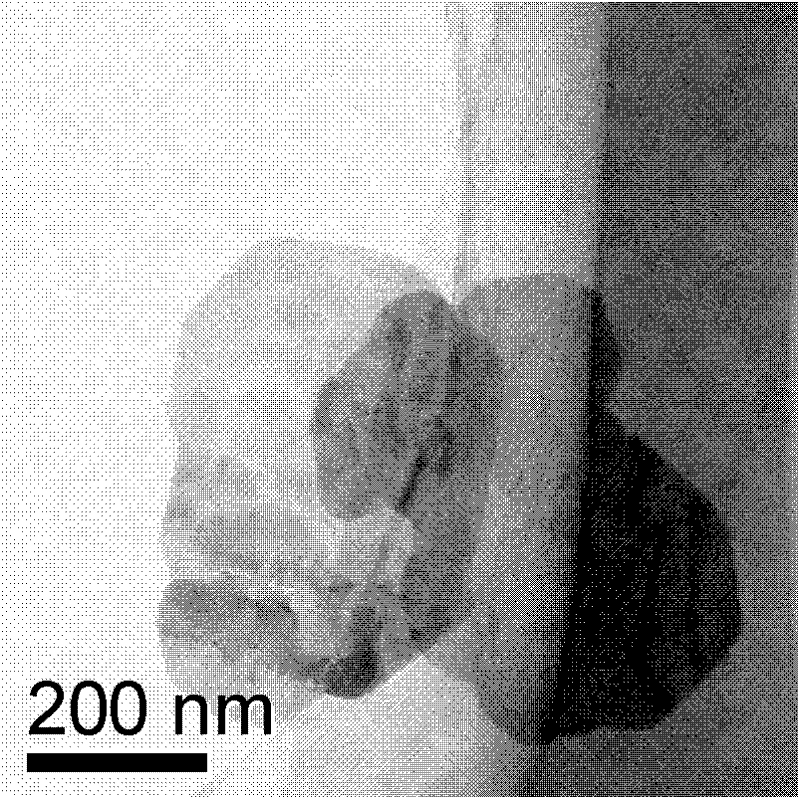

Spherical ferrate having hollow structure and preparation method thereof

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

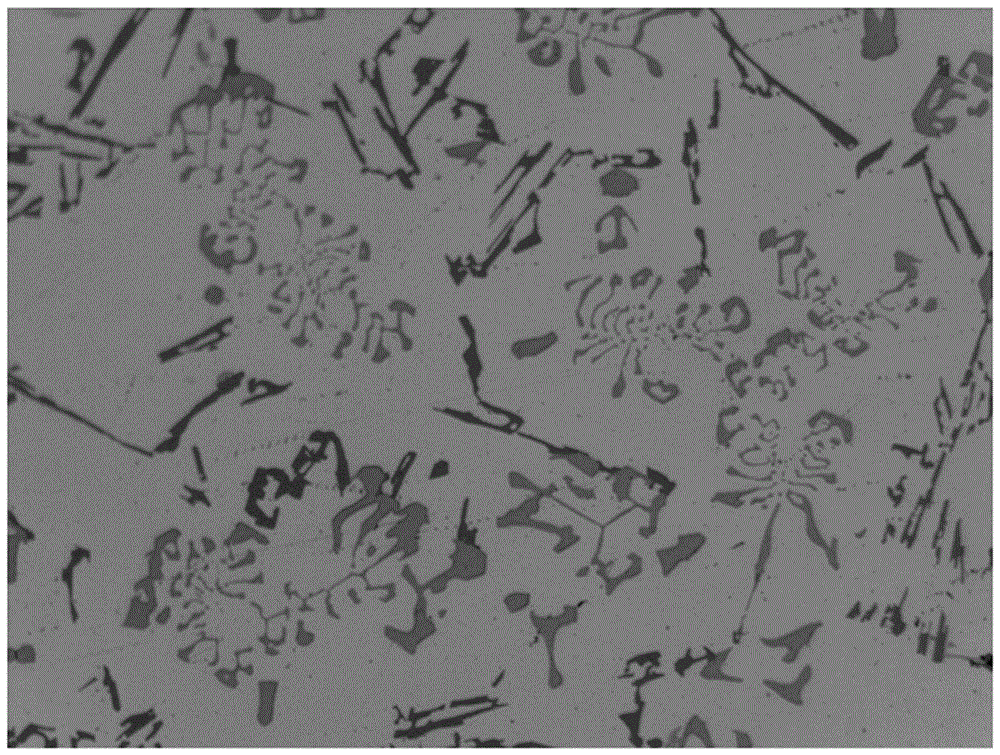

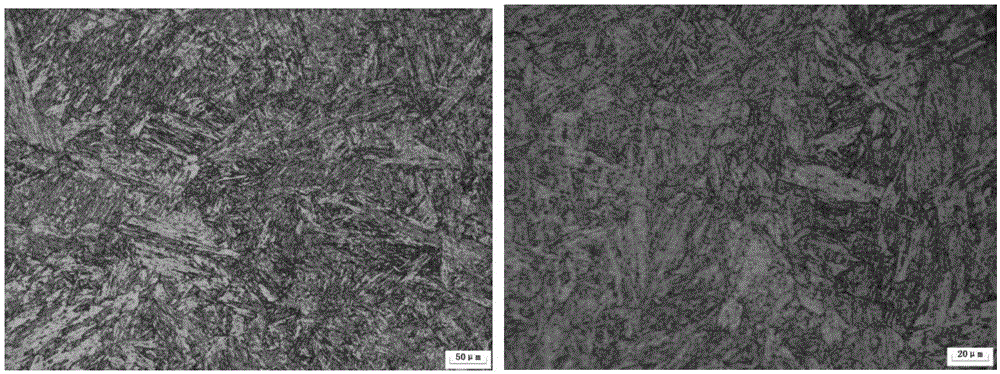

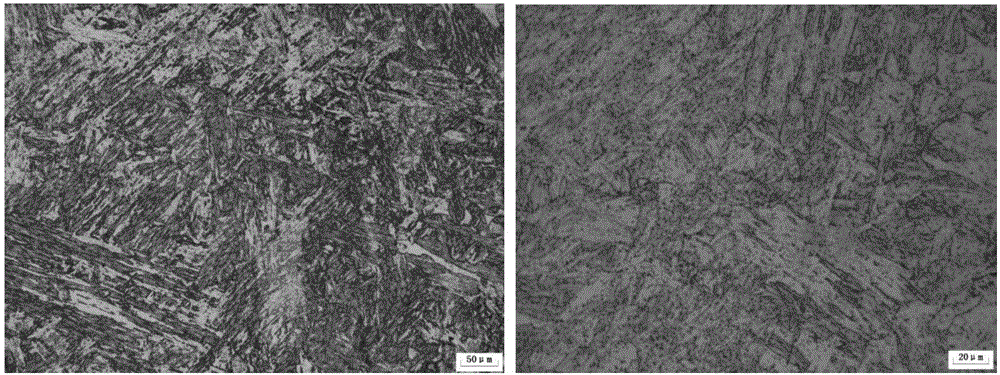

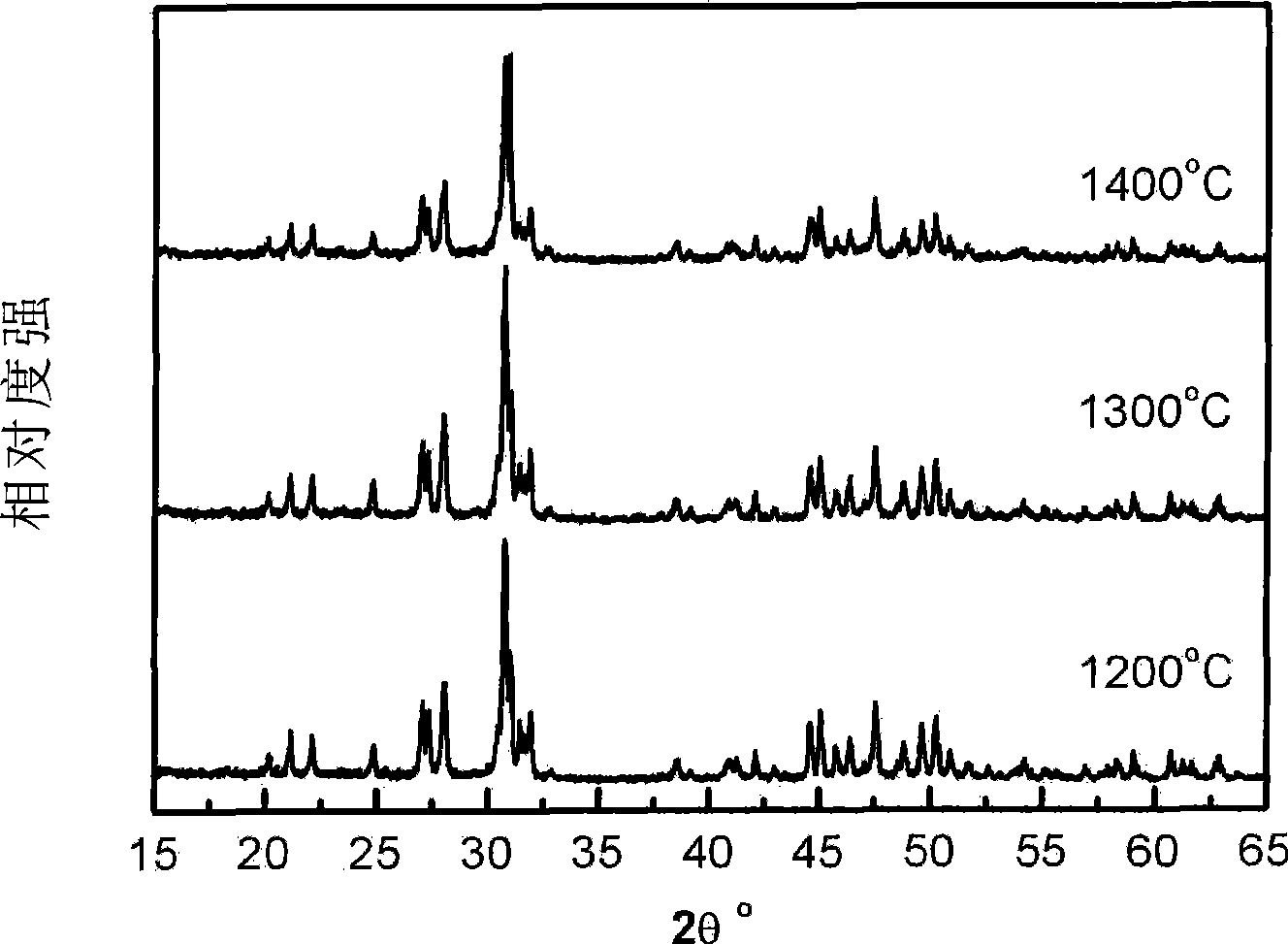

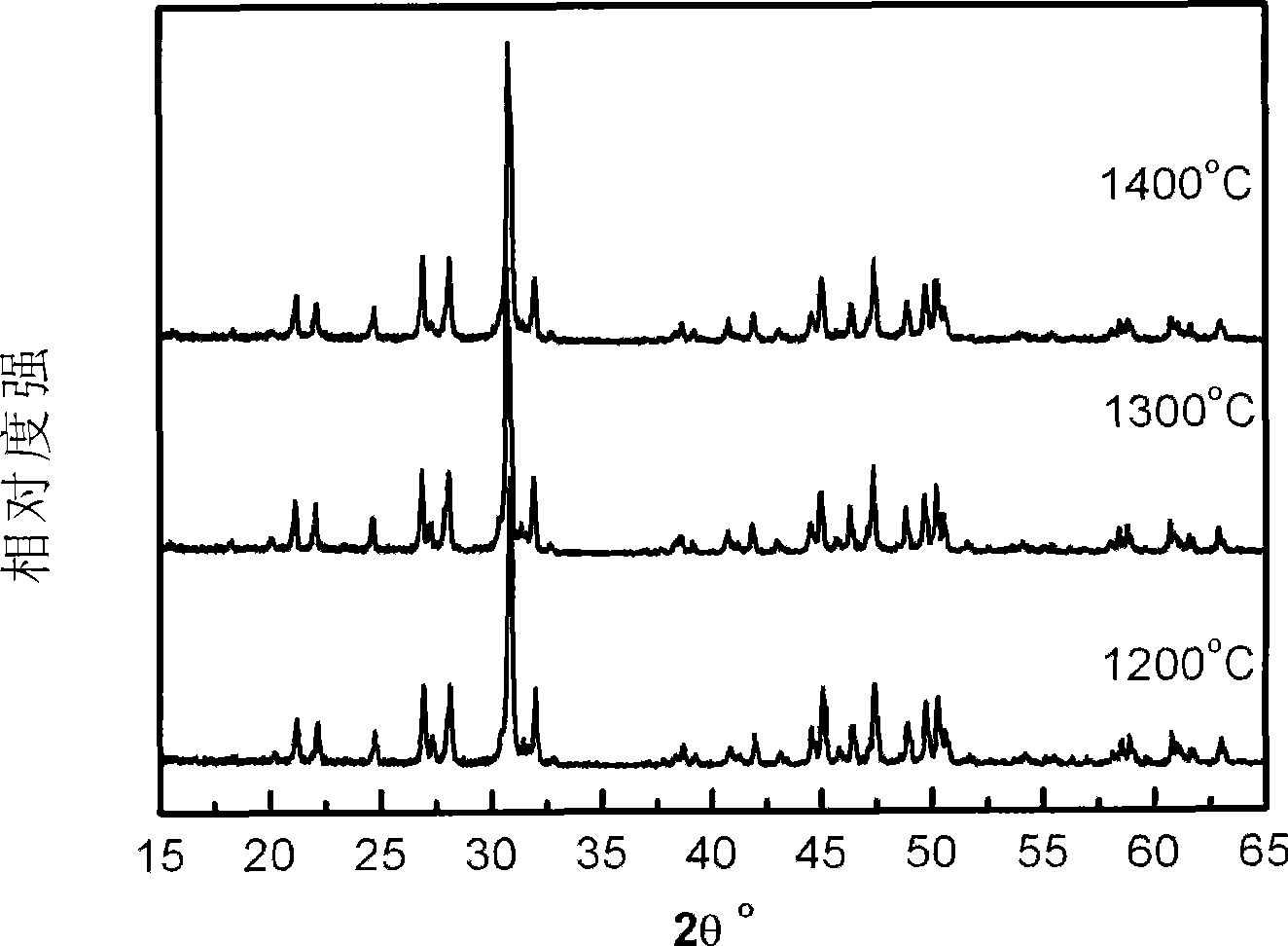

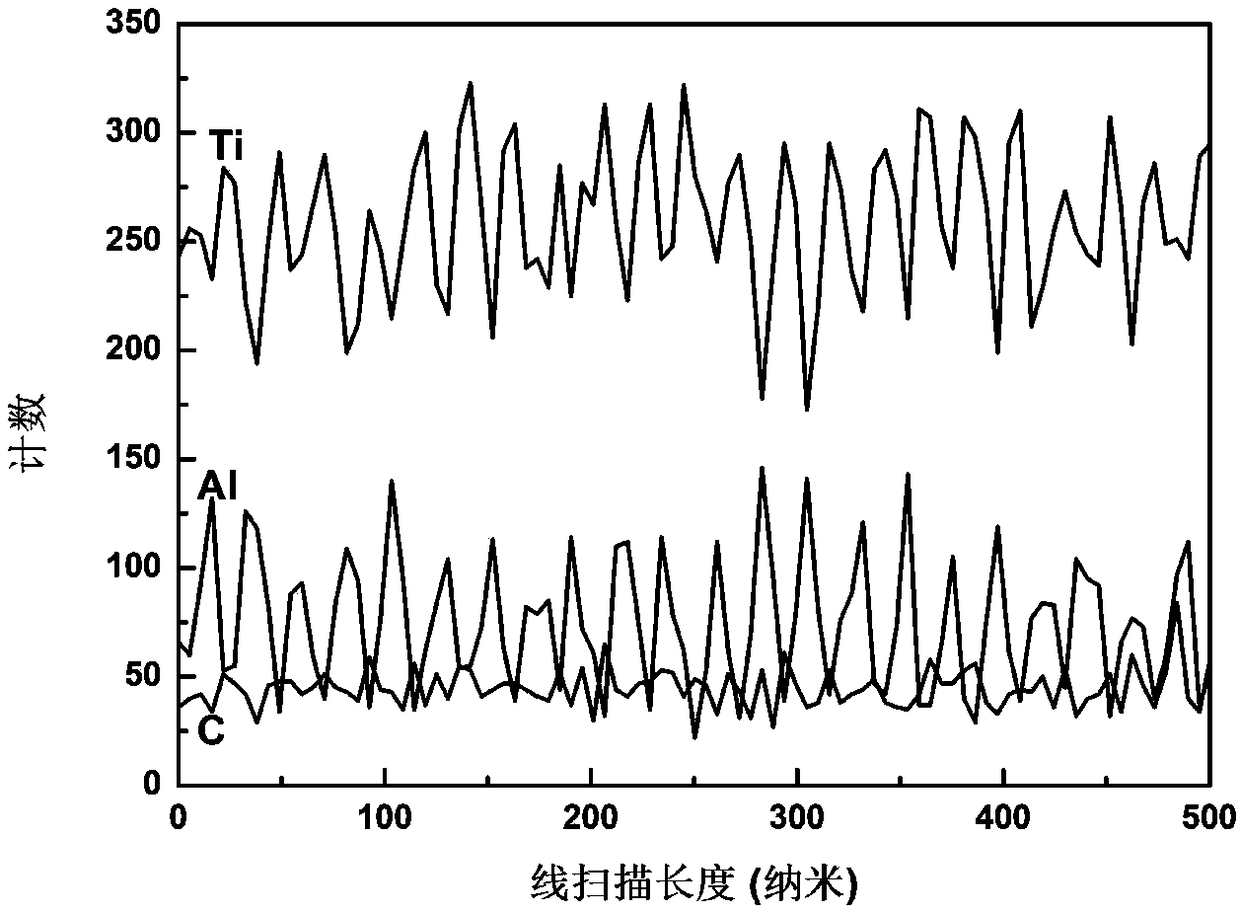

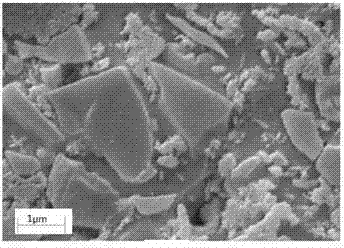

Alterant of iron-rich phase in secondary aluminum and alteration method

The invention relates to an alterant of an iron-rich phase in secondary aluminum and an alteration method. The alterant is composed of a [Mn] agent and a [B] agent. The alteration method includes the steps that part of secondary aluminum is heated to form a melt, then the [Mn] agent is added, the remaining secondary aluminum is added after the [Mn] agent melts, the [B] agent is added, refining is carried out after the [B] agent melts, pouring is carried out after standing is carried out for a period of time, and the secondary aluminum obtained after alteration treatment is obtained. According to the alterant and the alteration method, the Fe element in the iron-rich phase can be replaced through the [Mn] agent, the advantage growth orientation of the iron-rich phase is changed, and therefore a needle-like beta-Fe phase is eliminated; meanwhile, the forming temperature of the iron-rich phase can be reduced through B in the [B] agent, the growth time of a primary iron-rich phase is shortened, the growth space of the primary iron-rich phase is reduced, the B can also serve as a surface-active element, and is absorbed to the surface of the iron-rich phase in the initial phase of formation of the iron-rich phase, and growth of the iron-rich phase is restrained, so that through the combined action of the [Mn] agent and the [B] agent, existence of the needle-like iron-rich phase and the primary iron-rich phase can be completely eliminated, the uniform Chinese character type iron-rich phase is obtained; and in addition, the adding amount of the Mn can be greatly reduced, and the mechanical performance and the machining performance of the secondary aluminum can be greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

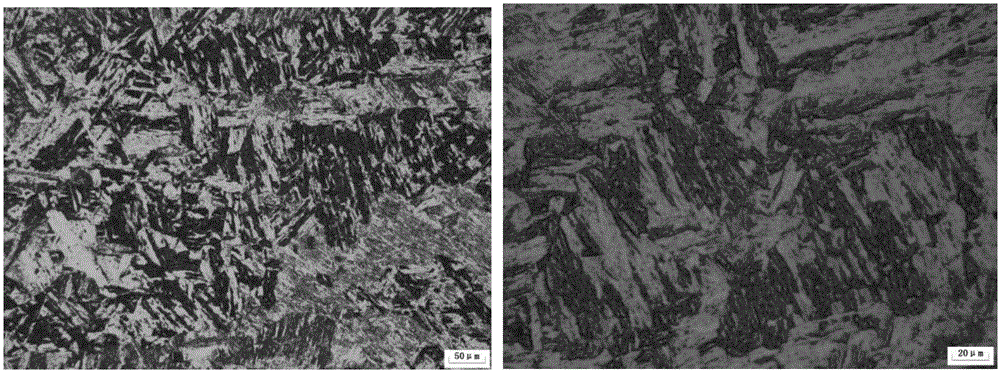

Method for improving structure and performance of T92 steel welding joint and T92 steel welding joint

InactiveCN106624416AGood welding performanceImprove toughnessWelding apparatusMechanical propertyHeat treated

Owner:中国大唐集团科学技术研究总院有限公司

Process for producing medium-temperature solid-oxide fuel battery electrolyte material lanthanum silicate powder

InactiveCN101508437AReduce dosageReduce manufacturing costSolid electrolyte fuel cellsSilicon compoundsApatiteSlurry

The invention relates to a method for preparing lanthanum silicate powder-an electrolyte material for a mesothermal solid oxide fuel cell, and belongs to the field of preparation of inorganic materials. The method comprises the following steps: firstly, preparing a nitrate raw material into a saturated solution and nano silicon dioxide into uniform suspension according to the stoichiometric ratio of the target lanthanum silicate powder, and uniformly mixing and stirring the saturated solution and the suspension; secondly, adding an organic monomer-acrylamide and a crosslinking agent-N,N'-methylene-bisacrylamide into the mixture for uniformly stirring; thirdly, adding an initiator-a ammonium persulfate aqueous solution into the mixture, keeping the mixture stand at the temperature of between 60 and 80 DEG C for 30 to 80 minutes after uniformly stirring the mixture, curing slurry into gel, and performing dehydration or thermal treatment on the gel to obtain a plastery precursor; and fourthly, calcining the precursor at high temperature, and obtaining the electrolyte material-the lanthanum silicate powder with high purity and an apatite structure.

Owner:SHANDONG UNIV

Green pellet and pellet ore preparation method

ActiveCN101649391AReduce the formation temperatureHigh strengthRotary drum furnacesProcess efficiency improvementContinuous productionRotary kiln

The invention provides a green pellet prepared from ferrous raw materials, an adhesive and an additive, wherein the diacidic alkalinity of the green pellet is 0.2-0.4, the ferrous raw materials comprise at least 80 weight percent of hematite and / or sulphuric acid residue. Compared with the prior art, when the pellet is roasted, because the pellet comprises partial CaO, the CaO reacts with Fe2O3 togenerate a calcium ferrite system compound, the roasting temperature of the hematite pellet in a rotary kiln can be reduced to 1280-1330 DEG C, and a ring forming problem cause by overhigh roasting temperature is avoided, therefore, the high-intensity pellet ore can be prepared, and the continuous production can be ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

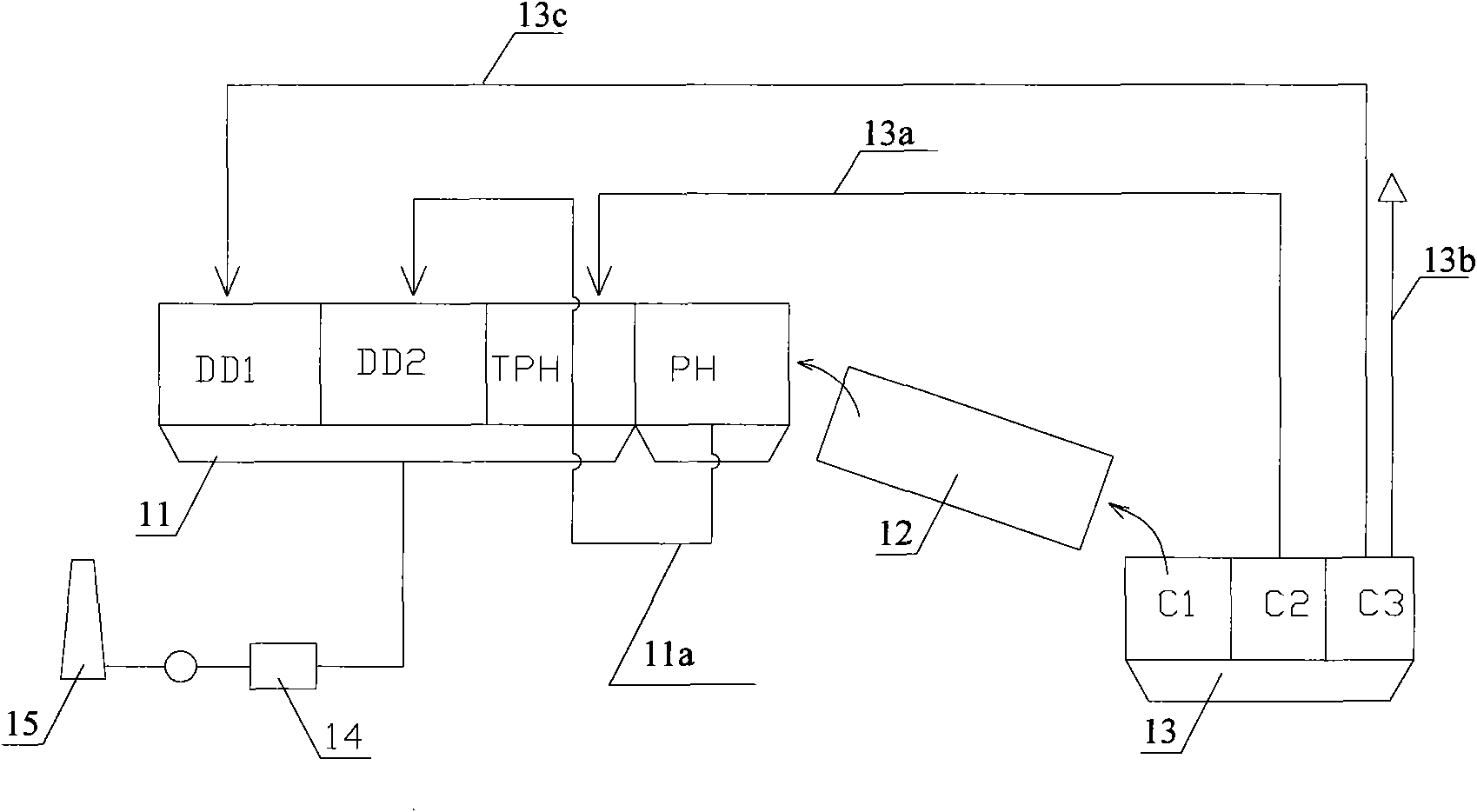

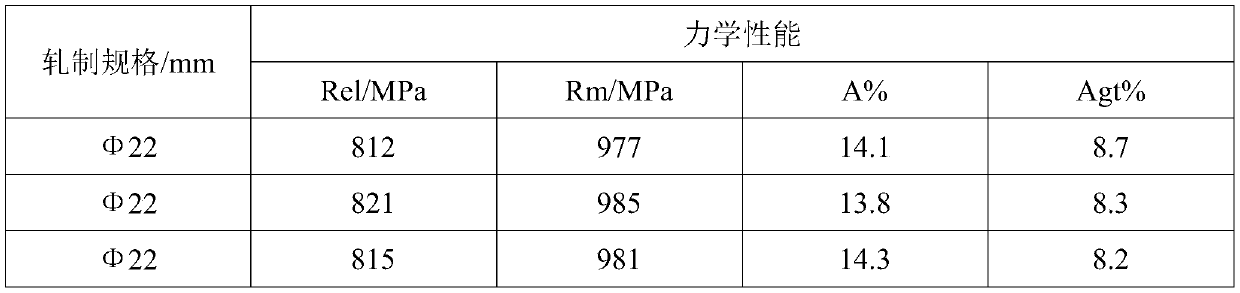

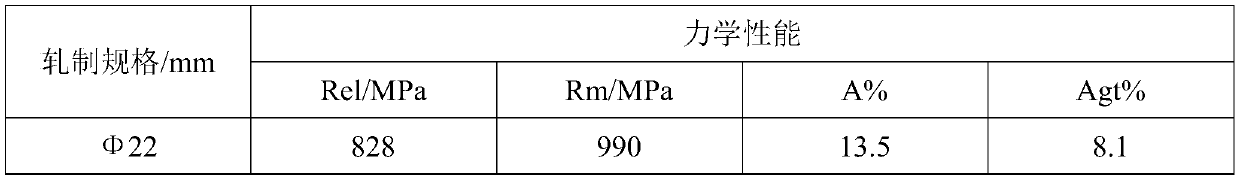

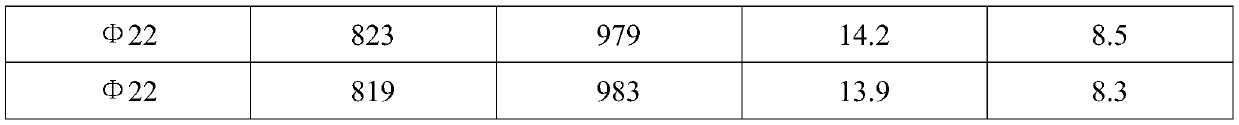

800 MPa level hot-rolled threaded steel bar and production method

The invention discloses an 800 MPa level hot-rolled threaded steel bar and a production method. The high-strength threaded steel bar is composed of following elements including, by weight percent (%),0.15%-0.25% of C, 1.00%-3.00% of Si+Mn, 0.01%-0.04% of Nb, 0.01%-0.20% of Ti, 0.50%-1.50% of Mo+Cr, 0.001%-0.01% of B, 0.01%-0.20% of Cu and the balance Fe and inevitable impurities. Through adding of Nb, Mo, Cr and B, the bainite forming temperature is reduced, and forming of granular bainite good in tenacity is promoted; the high-temperature heating and low-temperature initial rolling combinedtechnology is adopted, Nb plays an effective solid solution role, dispersed Nb (C and N) nanoscale precipitation is formed in the subsequent rolling and cooling process, and the precipitation strengthening effect is good. A threaded steel microscopic structure produced through the above components and technology is ferrite + bainite, and the lower yield strength is larger than or equal to 800 MPa.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

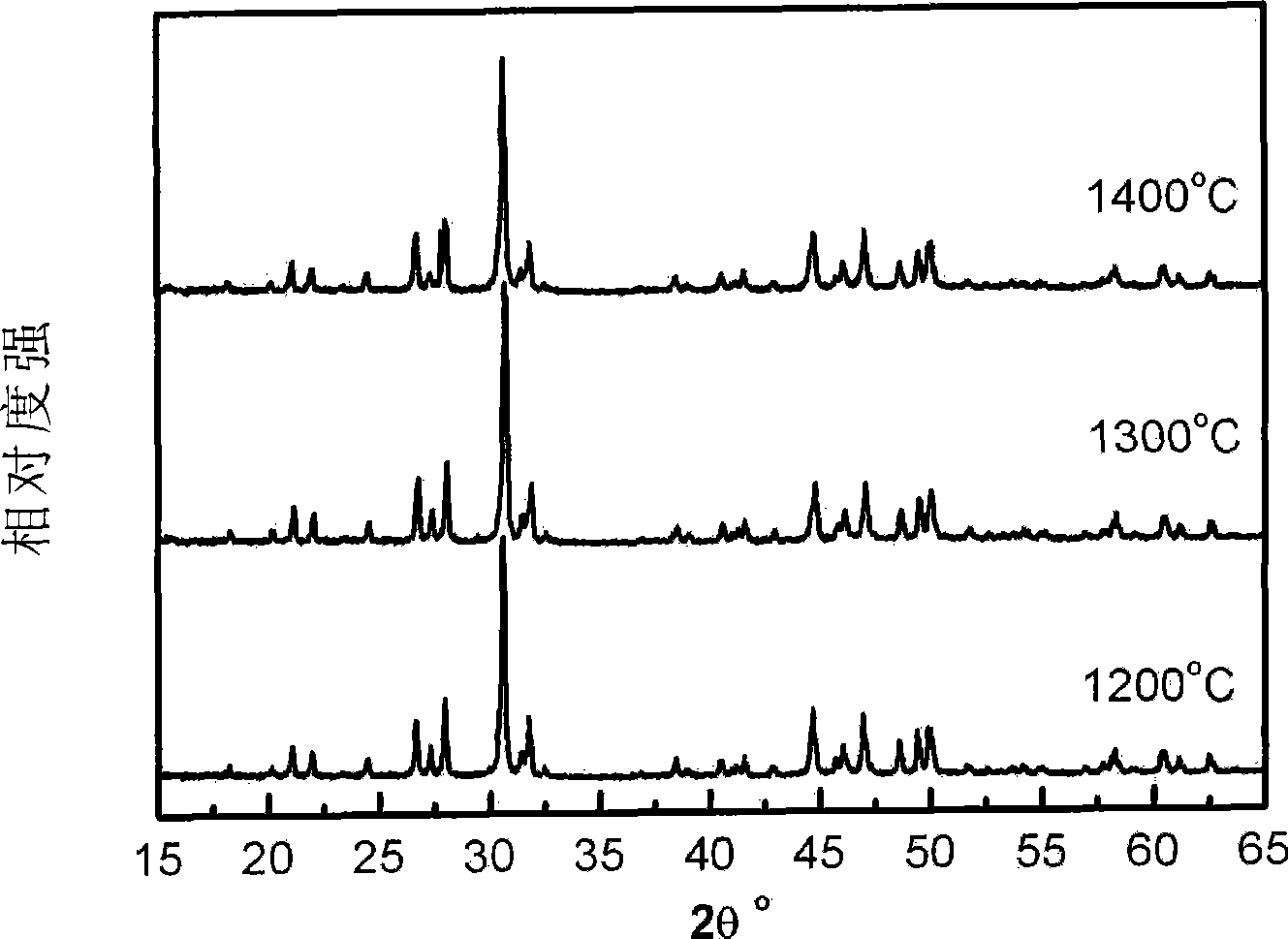

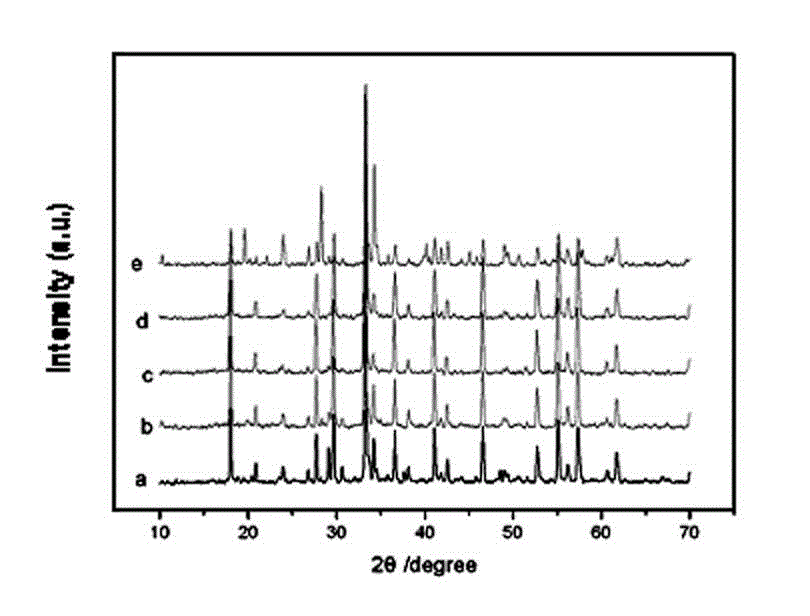

Preparation method of yttrium aluminum garnet (YAG): Ce<3+> fluorescent powder using chlorides as fluxing agents

InactiveCN102863962AHigh light conversion efficiencyReduce the formation temperatureLuminescent compositionsChlorideCrystallinity

The invention relates to a preparation method of yttrium aluminum garnet (YAG): Ce<3+> fluorescent powder using chlorides as fluxing agents and belongs to the field of light-emitting materials. According to the preparation method, Y2O3 (99.99%), CeO2 (99.99%), Al2O3 (analytical pure, namely AR) and the fluxing agents which contain LiCl, NaCl, KCl and SrCl2 are weighted in the stoichiometric ratio according to fluorescent powder composition (Y0.98)3Al5O12:Ce0.06, wherein the fluxing agents account for 1%-13% of the total weight. By adding the fluxing agents, the light conversion efficiency of the YAG:Ce<3+> fluorescent powder can be increased and the formation temperature of the single-phase YAG can be reduced; improvement of the crystallinity and morphology of the YAG:Ce<3+> fluorescent powder is beneficial to absorption and emission of the light; and the preparation method adopts a high temperature solid state method, chlorides used as the fluxing agents, namely LiCl, NaCl, KCl and SrCl2 are added to prepare the YAG:Ce<3+> fluorescent powder and the obtained YAG:Ce<3+> fluorescent powder maintains the structure, regular morphology and narrow particle size distribution of YAG, thus the light conversion efficiency of the YAG:Ce<3+> fluorescent powder is greatly increased.

Owner:CHANGCHUN UNIV OF TECH

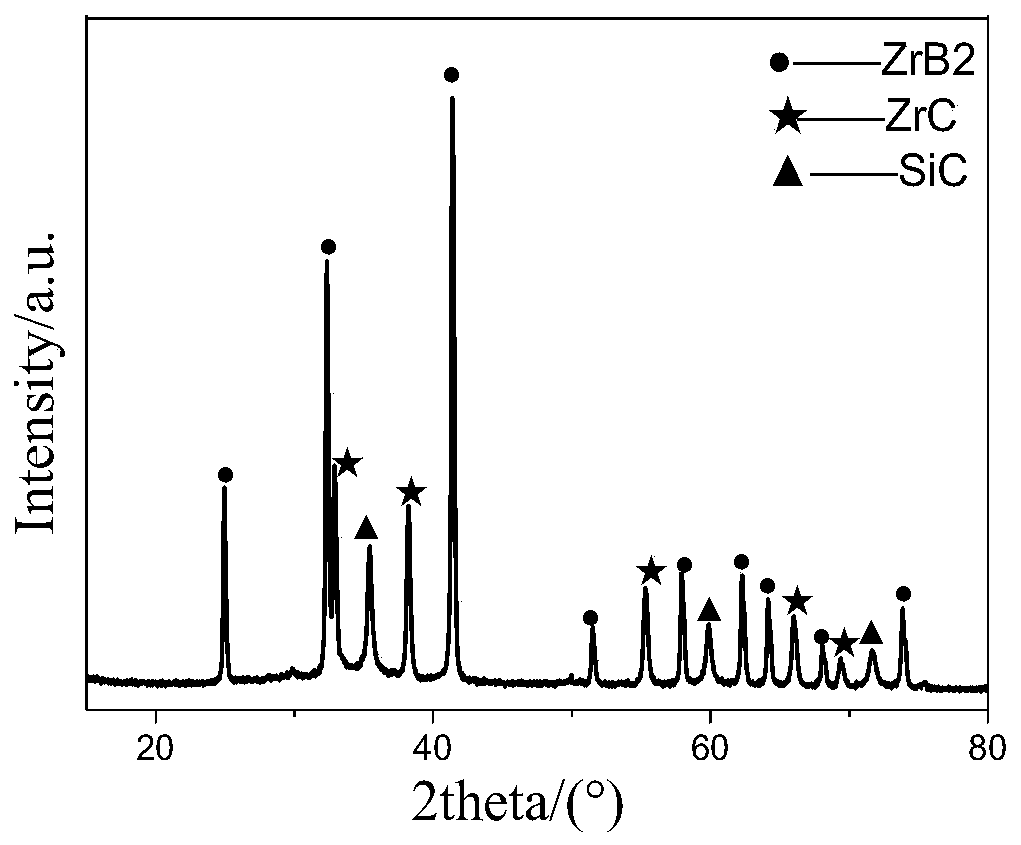

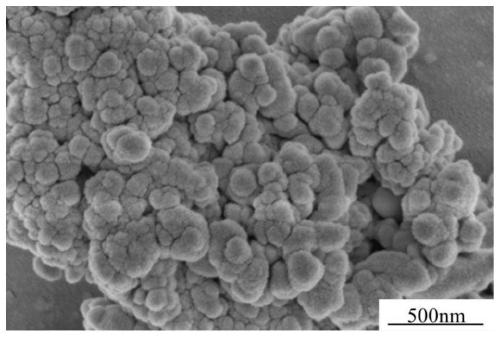

Preparation process of ZrC-ZrB2-SiC ceramic composite powder by precursor conversion method

The invention discloses a preparation process of ZrC-ZrB2-SiC ceramic composite powder by a precursor conversion method. Zirconium oxychloride octahydrate, boric acid, ethyl orthosilicate and glucoseare used as starting raw materials, and absolute ethyl alcohol and deionized water are used as solvents, wherein the molar ratio of the boric acid to the zirconium oxychloride octahydrate to the ethylorthosilicate is (1-5):1:(0.5-5), and the mass ratio of the glucose to the ethyl orthosilicate is (1-4):1. A zirconium precursor solution, a boric acid solution, an ethyl orthosilicate solution and aglucose solution are prepared separately, the solutions are uniformly mixed to obtain a boron-silicon-zirconium precursor solution, the boron-silicon-zirconium precursor solution is dried, and heat treatment is carried out at 1450-1600 DEG C for 1-2 hours under the protection of an argon atmosphere to obtain the ZrC-ZrB2-SiC ceramic powder. The prepared ceramic powder is uniform in particle sizeand the average particle size is about 150 nm. The preparation process has the characteristics of simple process, short period, low energy consumption and low cost, and the obtained ceramic phase is uniform and fine in particle size and high in purity.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Cell cryopreservation liquid containing antifreeze proteins

InactiveCN107333751AInhibition formationInhibition of recrystallizationDead animal preservationCytotoxicityAntifreeze protein

The invention relates to the field of cell freezing liquids, and concretely relates to a cell cryopreservation liquid containing antifreeze proteins. AFP134 proteins are added to the cell cryopreservation liquid in order to effectively improve the cell recovery rate; and the cell cryopreservation liquid contains no DMSO, so the influences of the DMSO on the cytotoxicity are reduced.

Owner:昆明医科大学第二附属医院

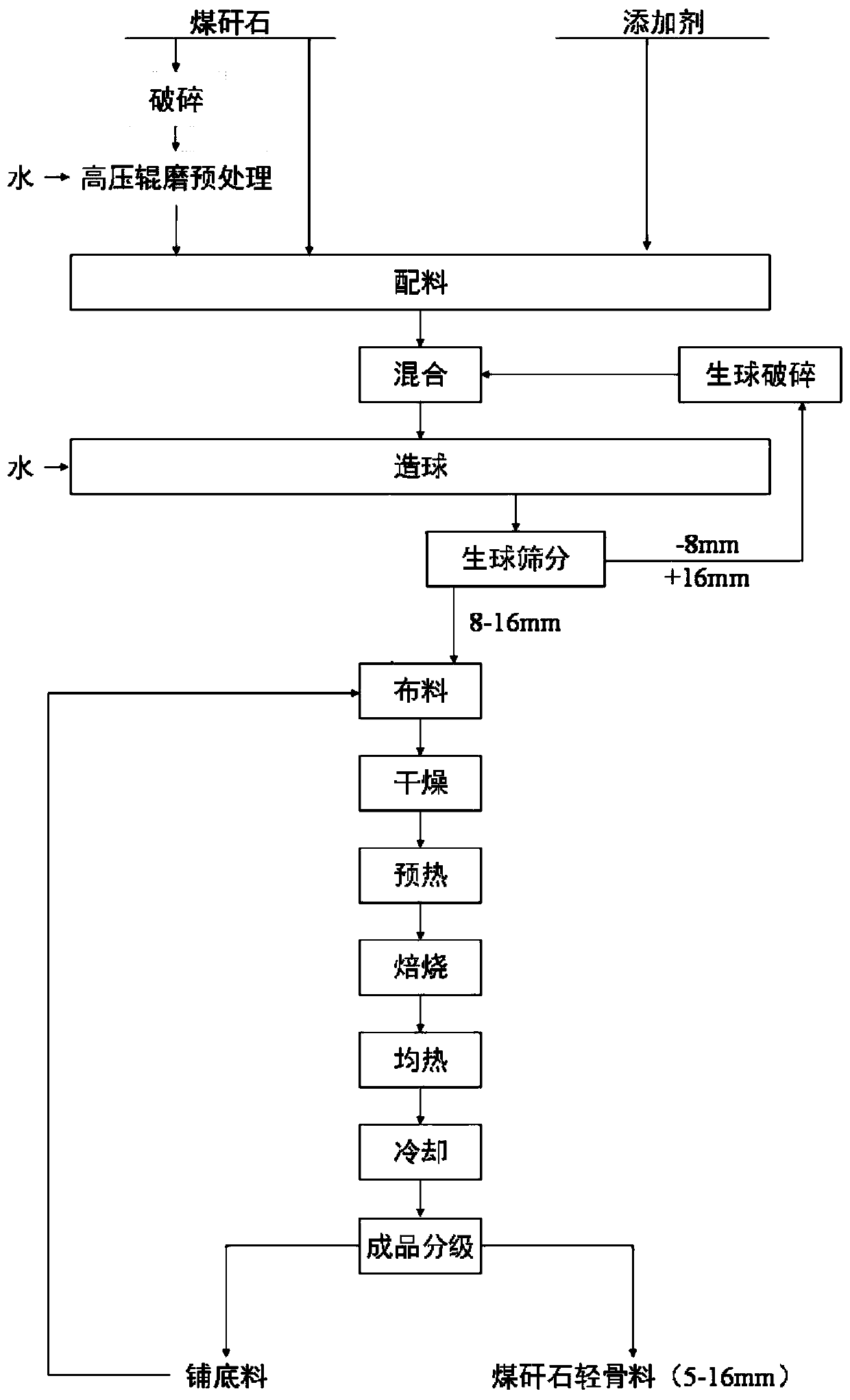

Technology for preparing coal-gangue lightweight aggregate with pelletizing method through belt-type roasting machine

ActiveCN110104975AHigh strengthUniform qualitySolid waste managementFoaming agentUltimate tensile strength

The invention discloses a technology for preparing coal-gangue lightweight aggregate with a pelletizing method through a belt-type roasting machine. The technology includes the following steps of 1) breaking and ore grinding; 2) preparing and even mixing; 3) pelletizing and screening; 4) roasting in the belt-type roasting machine; 5) finished-product grading. The coal-gangue-lightweight-aggregatepelletizing-method preparing technology of the belt-type roasting machine is suitable for large-scale production of high-quality coal-gangue lightweight aggregate, and the obtained product is high instrength, even in mass, low in energy consumption and environmentally friendly; a huge amount of coal gangue may be thoroughly eliminated, the environment problem caused by the coal gangue is solved,and the high-performance lightweight aggregate is produced and provides a high-quality raw material for construction industry; a specific additive is prepared in the technology, the functions of improving the strength of green balls and increasing the yield and the effects of a fluxing agent and a foaming agent are both achieved, the formation temperature of a liquid phase of a system is lowered,swelling of coal-gangue pellets is promoted, the organizational structure of the lightweight aggregate is optimized accordingly, the strength of the lightweight aggregate is remarkably improved, and energy consumption is reduced.

Owner:CENT SOUTH UNIV

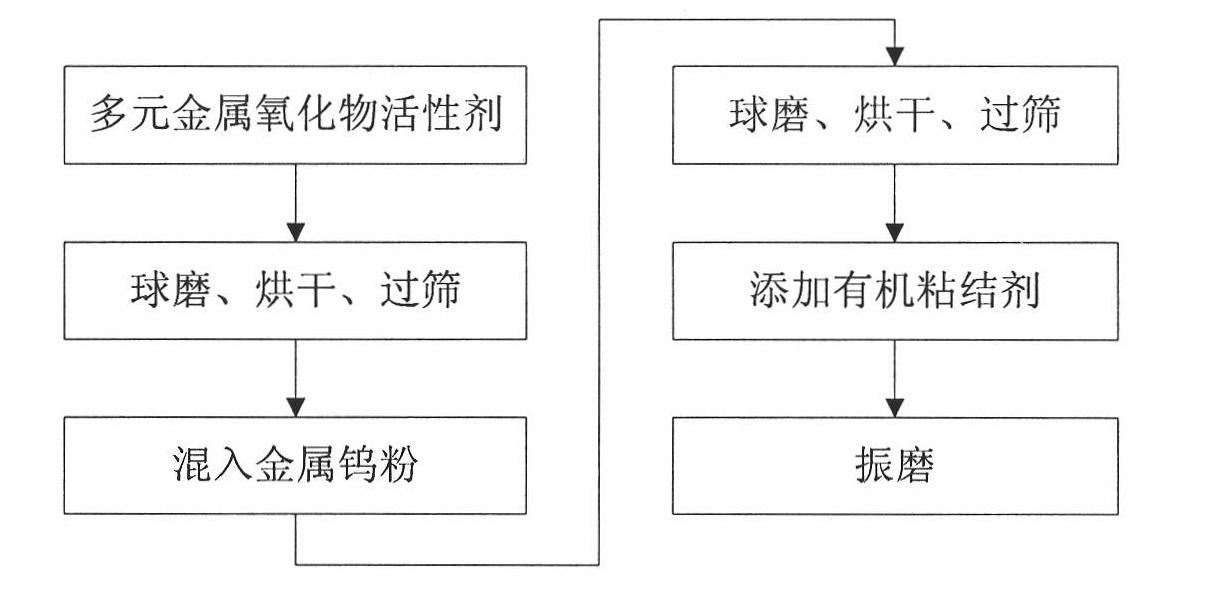

99BeO ceramic metallizing slurry and preparation method thereof

The invention discloses a 99BeO ceramic metallizing slurry and a preparation method thereof, belonging to the technical field of electronic material. The 99BeO ceramic metallizing slurry consists of 60-70% of metallizing raw material by mass and 30%-40% of organic adhesive. The metallizing raw material consists of 70-90% of metal W by mass and 10-30% of multi-element metal oxide active agent by mass. The multi-element metal oxide active agent consists of MgO, Al2O3, SiO2 and more than one oxides containing Sm, Nd, Pr or Tb. The preparation method comprises the steps: at first, preparing the multi-element metal oxide active agent with raw materials like MgO, Al2O3, SiO2, etc. by ball milling; then mixing the multi-element metal oxide active agent with metal tungsten powder, followed by ball milling and drying so as to obtain the metallizing raw material; and finally mixing the metallizing raw material with the organic adhesive, followed by vibration milling so as to obtain the metallizing slurry. When the metallizing slurry provided by the method is used to metallize the surface of 99 beryllium oxide ceramic, the sintering temperature of metallization can be lowered, and the metallized layer on the surface of beryllium oxide ceramic devices has higher tensile strength and thermal conductivity; and simultaneously, the preparation method thereof is simple in process, low in cost, excellent in repeatability and suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Synthetic method of aluminium zinc phosphate nanocrystal

InactiveCN102225751AGood corrosion inhibitionFew reaction stepsMaterial nanotechnologyPhosphorus compoundsChemical reactionPhosphate

A synthetic method of an aluminium zinc phosphate nanocrystal adopts a direct synthetic method of low-heating solid-state chemical reaction, uses zinc salt powder, aluminium salt powder, and phosphate powder as raw materials, and comprises the following steps: adding a template, mixing and grinding under a condition with room temperature and normal pressure, allowing the reaction mixture to standat a temperature from room temperature to 90 DEG C, washing the reaction mixture with water to remove by products of soluble inorganic salts, filtering, drying the filter cake at 100 DEG C to obtain a product of a zinc phosphate nanocrystal with a microcrystal particle size of 35 nm. Compared with the prior art, the aluminium zinc phosphate product obtained by the method of the invention has better corrosion inhibition performance than traditional zinc phosphate or aluminium phosphate products, and is a antirust material with excellent performance. Additionally, the method has the advantages of no solvent required, mild reaction conditions, easy control, simple process, extensive raw material sources, etc.

Owner:广西冶金研究院有限公司 +1

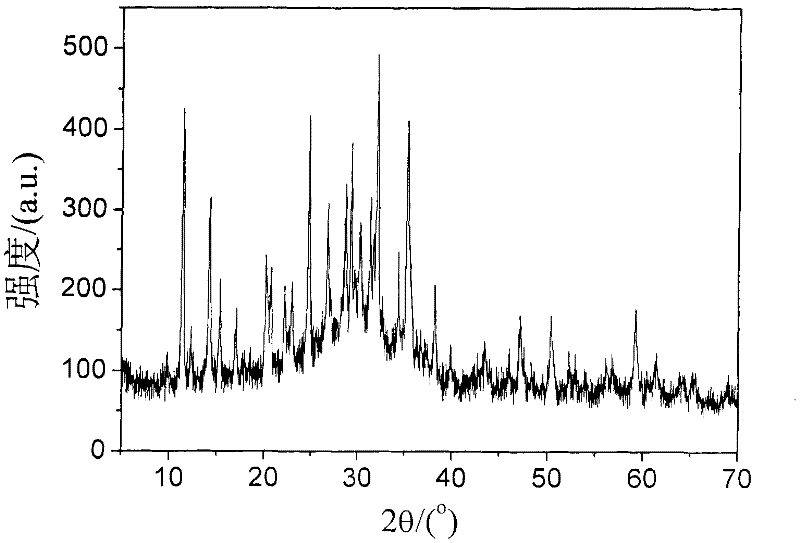

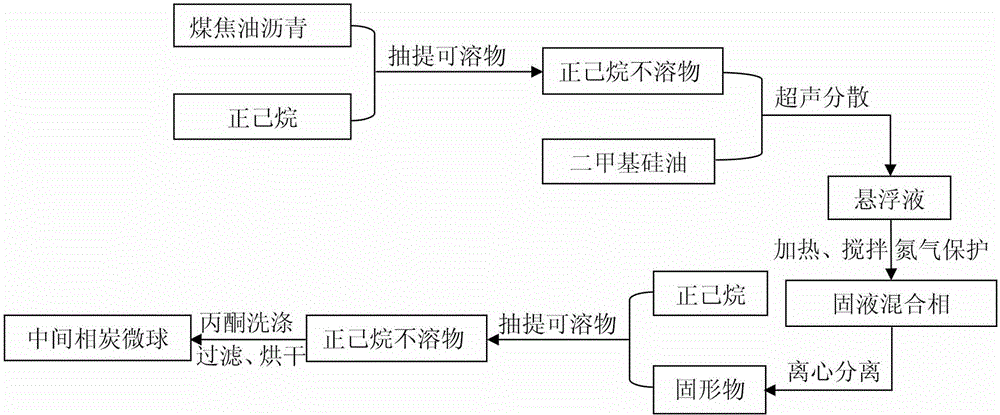

Raw material composition capable of being used for preparing mesocarbon microbeads (MCMB), preparation method thereof and preparation method of MCMB anode material

ActiveCN102942172AThe production process steps are simpleReduce manufacturing costCell electrodesCarbon preparation/purificationSilicone fluidCoal Tar Pitches

The invention discloses a raw material composition capable of being used for preparing MCMB. The composition is a suspension formed by coal tar pitch extracts after dispersed on dimethicone, and the coal tar pitch extracts are insoluble substances obtained by coal tar pitch powder after dissolution and impurity removal by n-hexane or toluene. The preparation method of the raw material composition includes filling the coal tar pitch powder into a Soxhlet extractor, performing repeated extracting, dissolving and impurity removing to obtain the insoluble substances through n-hexane or toluene; and then drying and grinding, and subjecting the substances to ultrasonic dispersion on the dimethicone. The method for preparing the MCMB anode material through the raw material composition includes heating the raw material composition to subject the material to a thermal condensation reaction to form micron-sized spherulite; and then subjecting the solid-liquid mixed phase after the thermal condensation to centrifugation, n-hexane extraction, repeated scrubbing and drying sequentially to obtain the MCMB anode material. The material and the methods are simple in process steps, low in cost and capable of being used for preparing high-quality MCMB.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

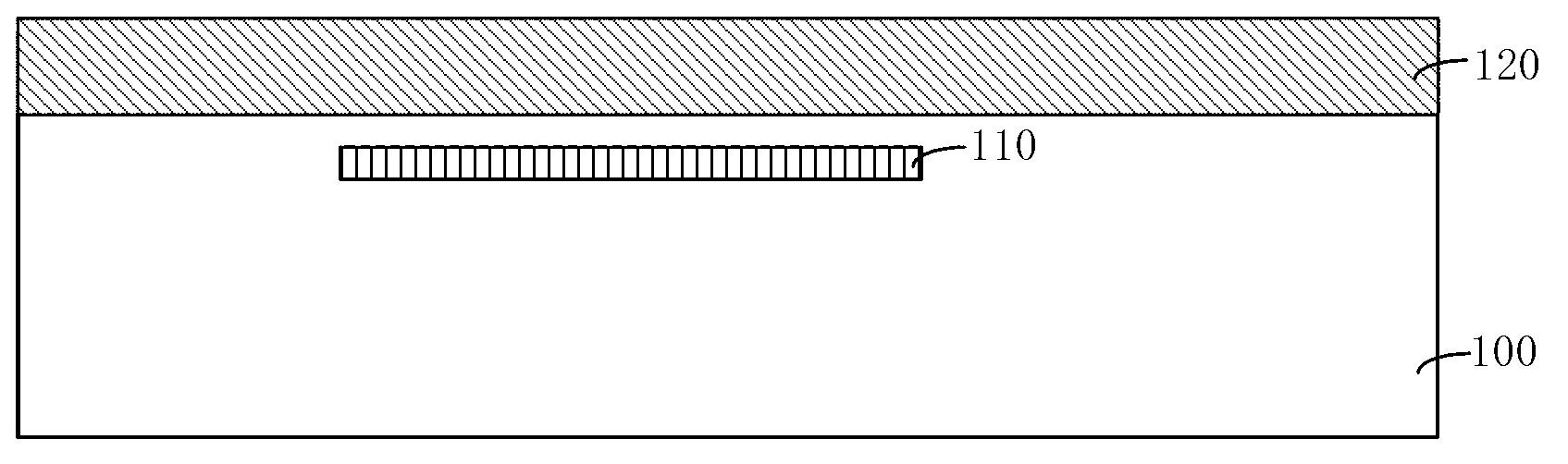

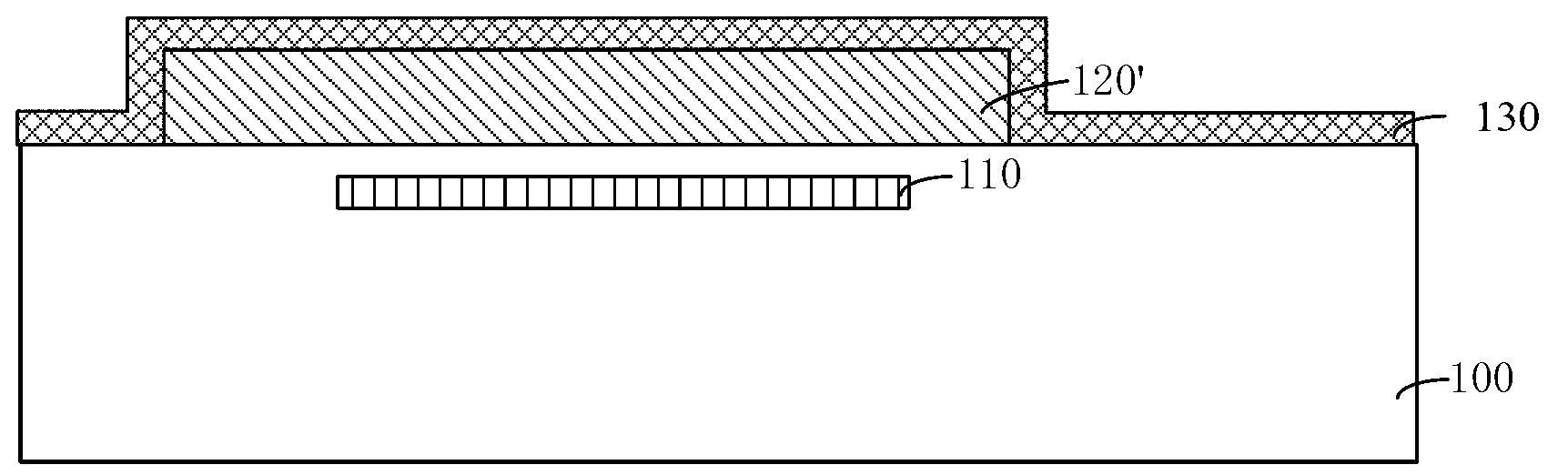

Sacrificial layer of MEMS (Micro-Electro-Mechanical-System) device, MEMS device and manufacturing method thereof

InactiveCN103011052AAvoid pollutionWide selection of materialsDecorative surface effectsSolid-state devicesDecompositionOptoelectronics

Different from the scheme that an organic material layer is separately used as a sacrificial layer of an MEMS (Micro-Electro-Mechanical-System) device, the invention adopts the following scheme that after the organic material layer is patterned, a covering layer with the decomposition temperature higher than that of the organic material layer covers the surface of the patterned organic material layer, so that a subsequent deposited structural material layer is isolated from the organic material layer to play a role of preventing a machine cavity from being polluted due to the decomposition and escape of the organic material layer in the high-temperature deposition process. In addition, the covering layer provides a larger material selection range for the organic material layer. Based on the sacrificial layer, the invention also provides the MEMS device comprising the sacrificial layer and a manufacturing method of the MEMS device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

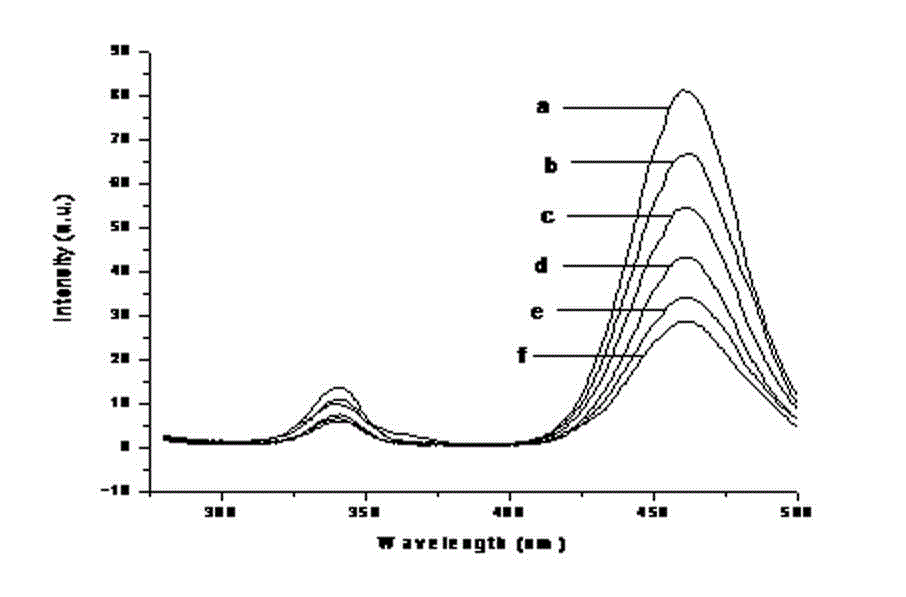

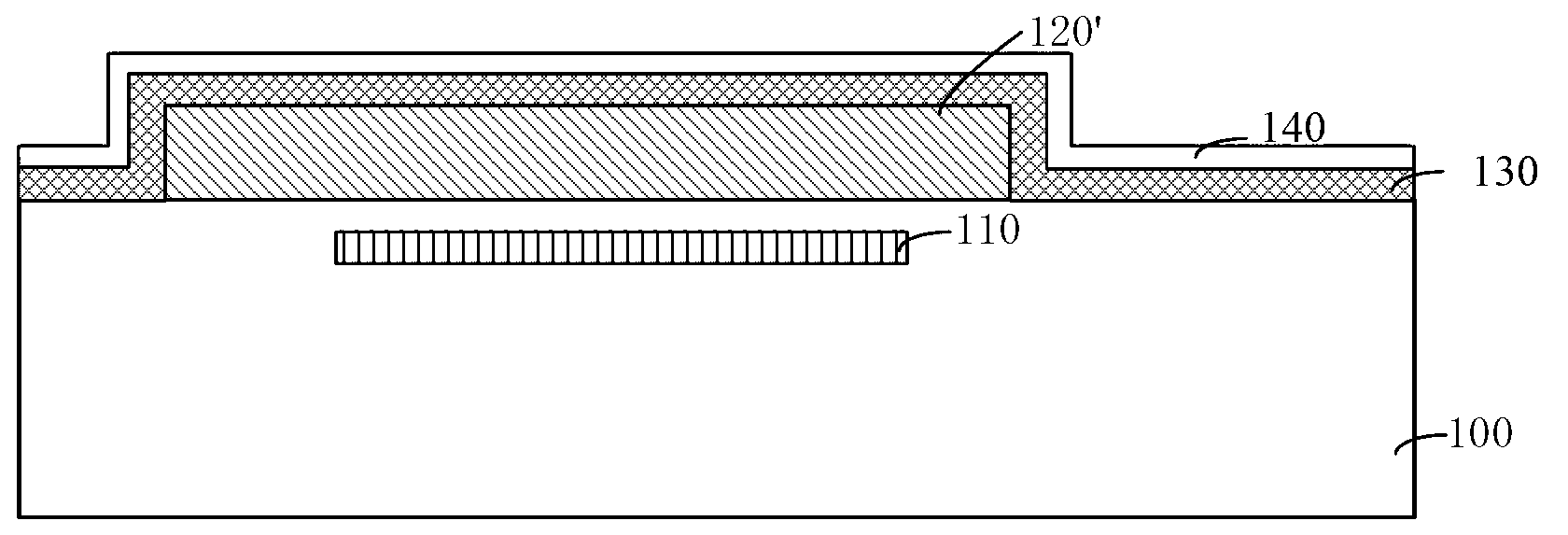

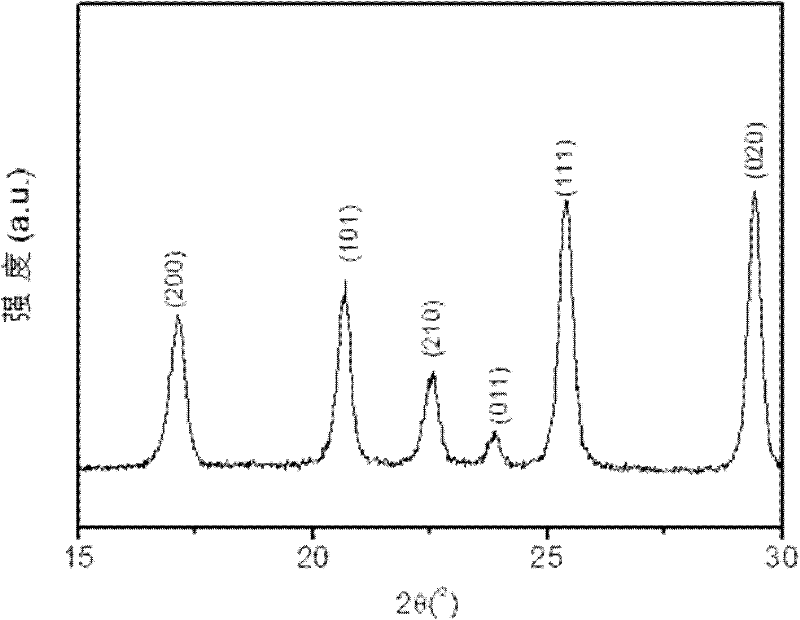

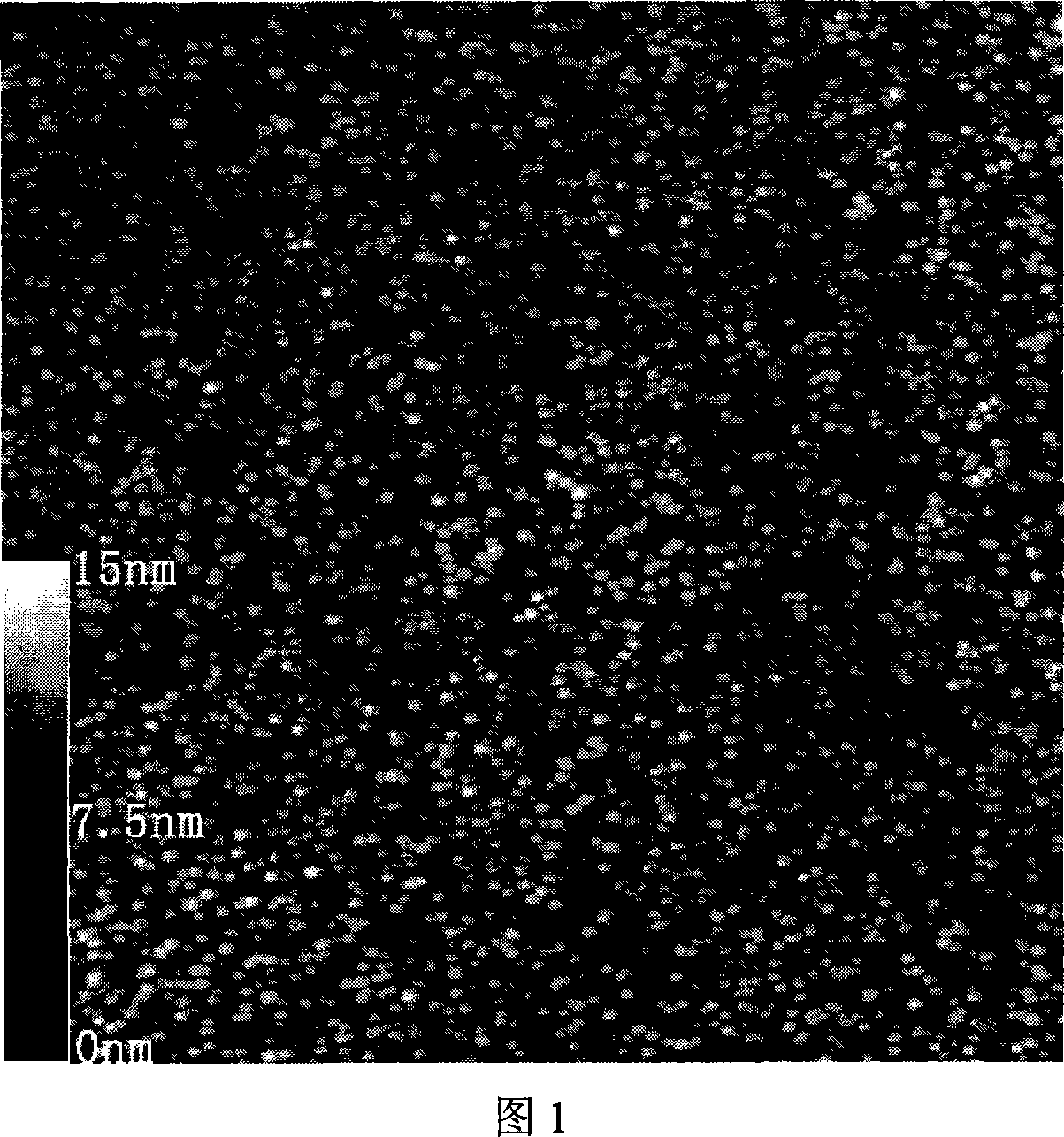

Lamellar manganese lithium phosphate (LiMnPO4) nano-crystal with high-proportion 020 crystal face and method for preparing lamellar LiMnPO4 nano-crystal

ActiveCN102544484AReduce the formation temperatureControl facet growthCell electrodesManganeseLITHIUM PHOSPHATE

The invention discloses a lamellar manganese lithium phosphate (LiMnPO4) nano-crystal with a high-proportion 020 crystal face and a method for preparing the lamellar LiMnPO4 nano-crystal. The LiMnPO4 nano-crystal has a lamellar shape, 80 to 95 percent of 020 crystal face of the LiMnPO4 nano-crystal is exposed, a lamella along the [020] direction has a thickness of 10 to 30 nm and a size of 100 to 300 nm, and the tap density of powder is 1.2 to 1.6 g / cm<3>. Lamellar LiMnPO4 nano-crystal powder can serve as a cathode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

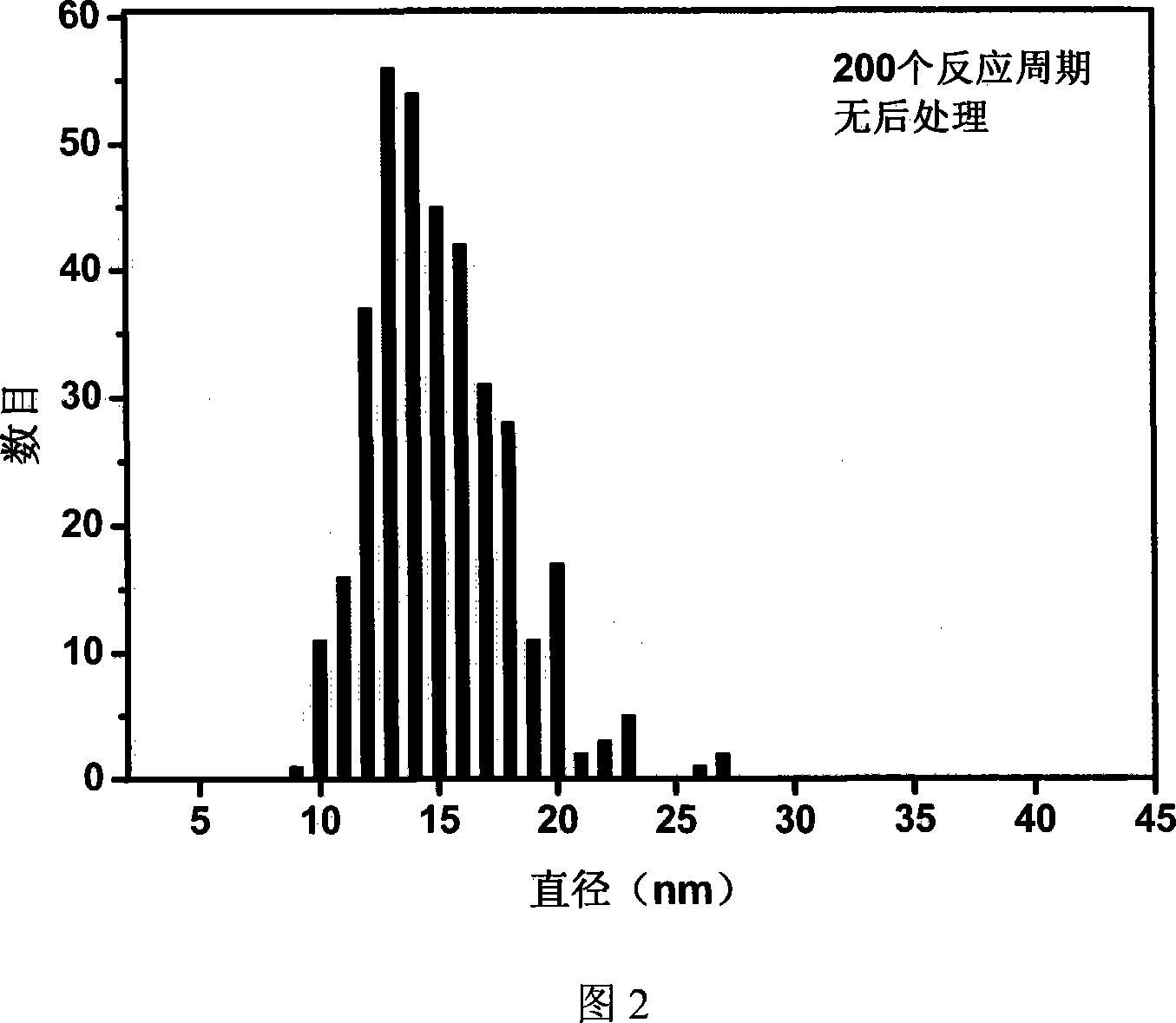

Manufacture method of HD Ru nanocrystalline atomic layer deposition for flash memory

InactiveCN101060077AReduce the formation temperatureLower thermal budgetSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricHigh density

The atomic-layer pulse deposition preparation method for high-density nano-Ru crystal comprises: heat growing SiO2 layer or film with high dielectric constant on the Si surface, depositing 2-5nm Ru film with atomic-layer pulse deposition, and fast annealing at high temperature. This invention is compatible to CMOS technique, and operates simply.

Owner:FUDAN UNIV

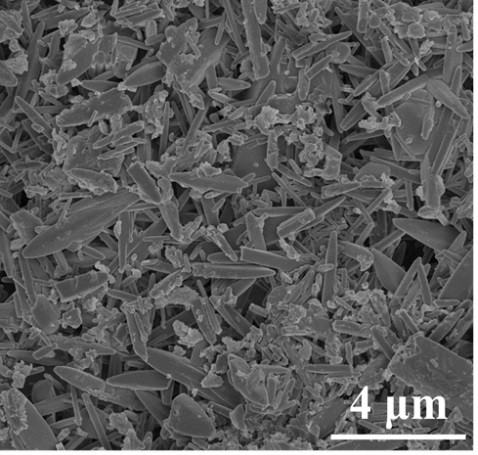

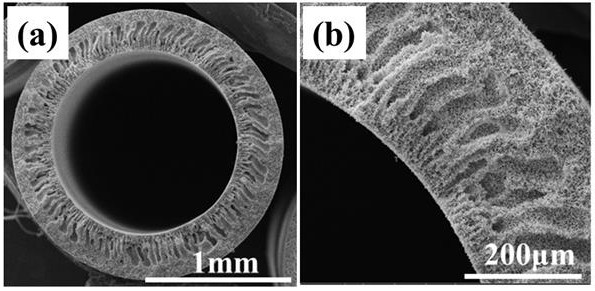

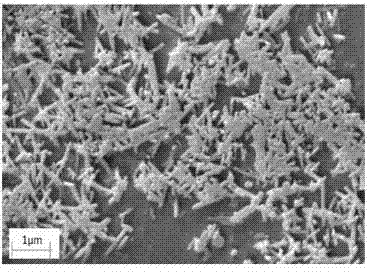

Preparation and application of whisker-shaped ceramic membrane with low cost and high permeability

ActiveCN113105223ALow costImprove permeabilitySemi-permeable membranesHigh concentrationOil retention

The invention discloses preparation and application of a whisker-shaped ceramic membrane with low cost and high permeability, and belongs to the technical field of preparation of high-permeability membranes. According to the method, tungsten oxide is added to form thewhisker-shaped ceramic membrane; the ceramic membranehas lower mullite forming temperature, and the sintering cost is greatly reduced; higher porosity, higher mechanical strength and better mechanical strength are achieved, and the permeability is improved; and the surface is rougher, so that the wettability of the membrane is effectively enhanced, and the membrane has higher oil pollution resistance in the oil-water separation process. In the preparation process, a phase inversion method or an extrusion molding method is adopted, so that hollow fibrous, tubular or hollow flat-plate-shaped and large-size tubular or flat-plate-shaped whisker structure mullite ceramic membranes can be respectively obtained, and can be used for large-scale industrial application. The whisker-shaped mullite ceramic membrane shows stable high permeation flux and high oil retention rate for oil-water separation (such as high-concentration and high-acid-base environments and complex oily wastewater), and has a wide application prospect.

Owner:DALIAN UNIV OF TECH

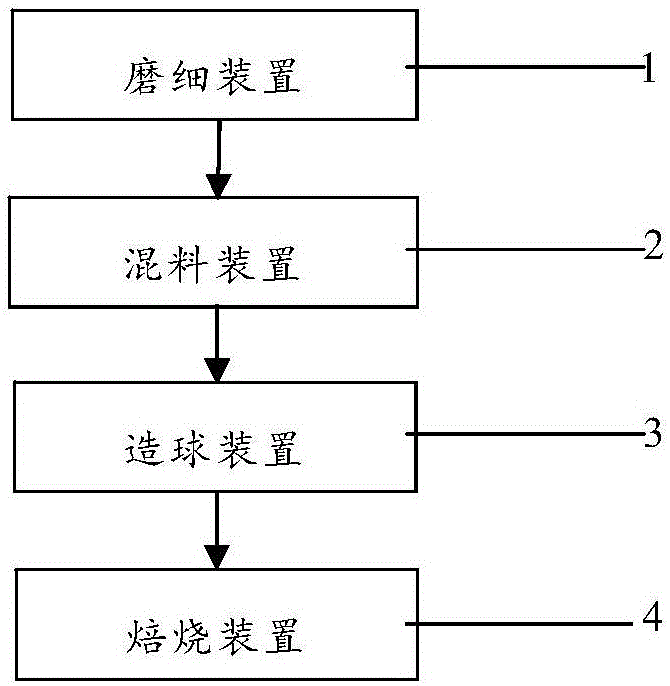

Method and system for reducing reduction degradation of vanadium-titanium magnet pellets

The invention discloses a method and system for reducing reduction degradation of vanadium-titanium magnet pellets. The method for reducing reduction degradation of the vanadium-titanium magnet pellets includes the following steps that firstly, vanadium-titanium magnetite is ground to be fine, and vanadium-titanium magnetite powder is obtained; secondly, the vanadium-titanium magnetite powder is mixed with bentonite, and a mixture is obtained; thirdly, the mixture is pelletized, and green pellets are obtained, wherein a boric acid water solution is added in the pelletizing process to serve as water for pellet pelletizing; and fourthly, the green pellets are roasted, and the vanadium-titanium magnet pellets are obtained. The invention further discloses a system implementing the method, and the system includes a fine grinding device, a material mixing device, a pelletizing device and a roasting device. According to the method and the device, in the pelletizing process, the boric acid water solution is evenly sprayed into the green pellets, the reduction degradation rate of the vanadium-titanium magnet pellets is effectively reduced, and the metallurgical performance in the pellet smelting reduction process is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

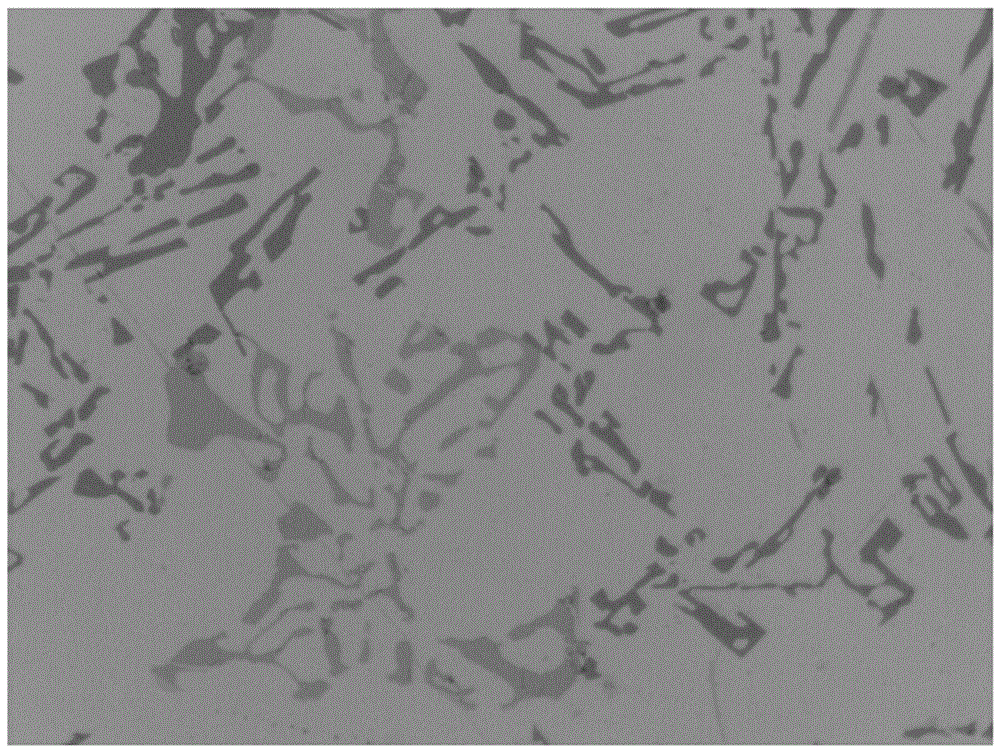

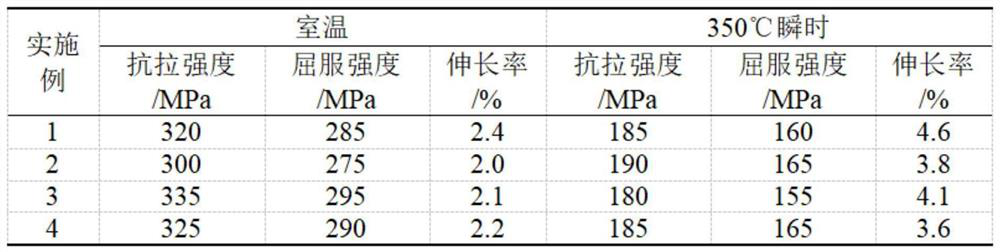

Heat-resistant regeneration die-cast aluminum alloy and preparation method thereof

The invention discloses a heat-resistant regeneration die-cast aluminum alloy and a preparation method thereof, and belongs to the field of regeneration die-cast aluminum alloy preparation. The invention provides the heat-resistant regeneration die-cast aluminum alloy capable of reducing the preparation cost and the preparation method of the heat-resistant regeneration die-cast aluminum alloy. Chemical components of the heat-resistant regeneration die-cast aluminum alloy include 10.0%-12.0% of Si, 0.50%-0.75% of Ni, 0.95%-1.35% of Mg, 0.9%-1.4% of Fe, 0.20%-0.30% of Mn, 0.08%-0.12% of Cr, 0.015%-0.03% of B, smaller than or equal to 0.15% of an impurity element and the balance Al. The preparation method includes the steps that smelting is conducted; sampling is conducted to adjust the alloycomponents; refining is conducted after low-melting-point alloy addition; slag removal is conducted; and casting is conducted. According to the heat-resistant regeneration die-cast aluminum alloy andthe preparation method, Ni and Cu are replaced with the low-cost impurity element Fe, and the alloy cost is effectively reduced; and by means of the compound modification technology of the Mn, the Cr, the B and the like, the size of the iron-rich phase is refined, and the high-temperature strength of the alloy is ensured.

Owner:肇庆南都再生铝业有限公司 +2

Preparation method of light metal surface compound coating

ActiveCN103710694AImprove surface propertiesImprove microstructureHeat inorganic powder coatingChemical compoundLaser peening

The invention discloses a preparation method of a light metal surface compound coating, and relates to the technical field of a material surface. The method is characterized by comprising the following steps: firstly, processing a light metal surface by using a laser fused method, and then putting the alloying metal powder on the laser-fused light metal surface; finally processing the light metal surface with preset powder in a laser peening manner under the condition of medium temperature; accelerating diffusion reaction of the preset powder and metal matrix, so as to prepare the surface compound coating. By adopting the preparation method of the light metal surface compound coating, the formation temperature of the compound coating is reduced, the thickness of the surface compound coating is increased, a microstructure of the surface compound coating is refined, and the light metal surface performance is significantly improved. The preparation method is simple in craft process, easy to operate, and applicable to large-scale mass production.

Owner:苏州仁和商用设备有限公司

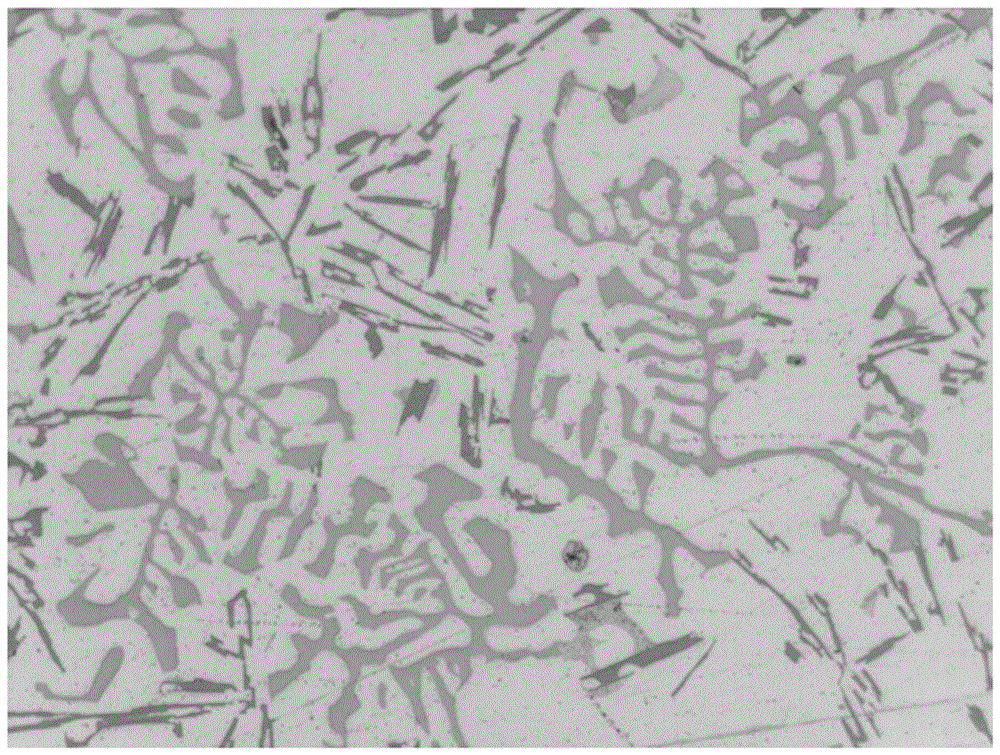

A kind of high wear-resistant secondary aluminum alloy and its preparation method and application

The invention provides high-wear-resistance regenerative aluminum alloy and a preparation method and application thereof, and relates to the technical field of aluminum alloy. The high-wear-resistanceregenerative aluminum alloy mainly comprises the following components: 7.0-12.0% of Si, 1.2-5.0% of Fe, 0.5-1.5% of Mn, 0.1-0.4% of Mg, 0.03-0.06% of B, 0.05-0.30% of RE, 0.01-0.06% of Sr, 0-0.15% ofimpurity elements and the balance of Al. The preparation method of the high-wear-resistance regenerative aluminum alloy comprises the following steps: melting waste aluminum materials; adjusting components of molten aluminum according to the requirements for the components; then adding intermediate alloy such as Al-B, Al-Sr and Al-RE according to the ratio; and refining and standing, and then pouring into ingots or tundish. By a composite modification technology, regenerated aluminum which contains an iron-rich phase with high volume fraction is prepared, and the wear resistance of the alloyis greatly improved. The high-wear-resistance regenerative aluminum alloy has the advantages of simple process, low cost and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

Preparation method for expanded graphite

InactiveCN104789981AReduce the formation temperatureEnergy savingElectrolysis componentsGraphiteHigh-level wastePhosphate

The invention belongs to the field of chemistry and particularly relates to a preparation method for expanded graphite. The method comprises the following steps: taking sulfate, phosphate or nitrate as an electrolyte solution, taking a simulated spent fuel ball as an anode, and taking an inert electrode as a cathode; performing electrolysis under a condition that the current is 25-70 A. Collected graphite particles have the specific surface area being 20-50 m<2> / g and the expansion volume of 20-70 mL / g. Due to the adoption of electrochemical intercalation and oxidation coupling methods, graphite oxide containing various free radical groups is easily formed under the action of high current, and graphite particles are refined, so that the formation temperature of the expanded graphite is reduced, energy resources are saved, the breakage rate of a simulated fuel core is reduced, reutilization of a large amount of matrix graphite is improved, and disposal space of high-level wastes is reduced.

Owner:TSINGHUA UNIV

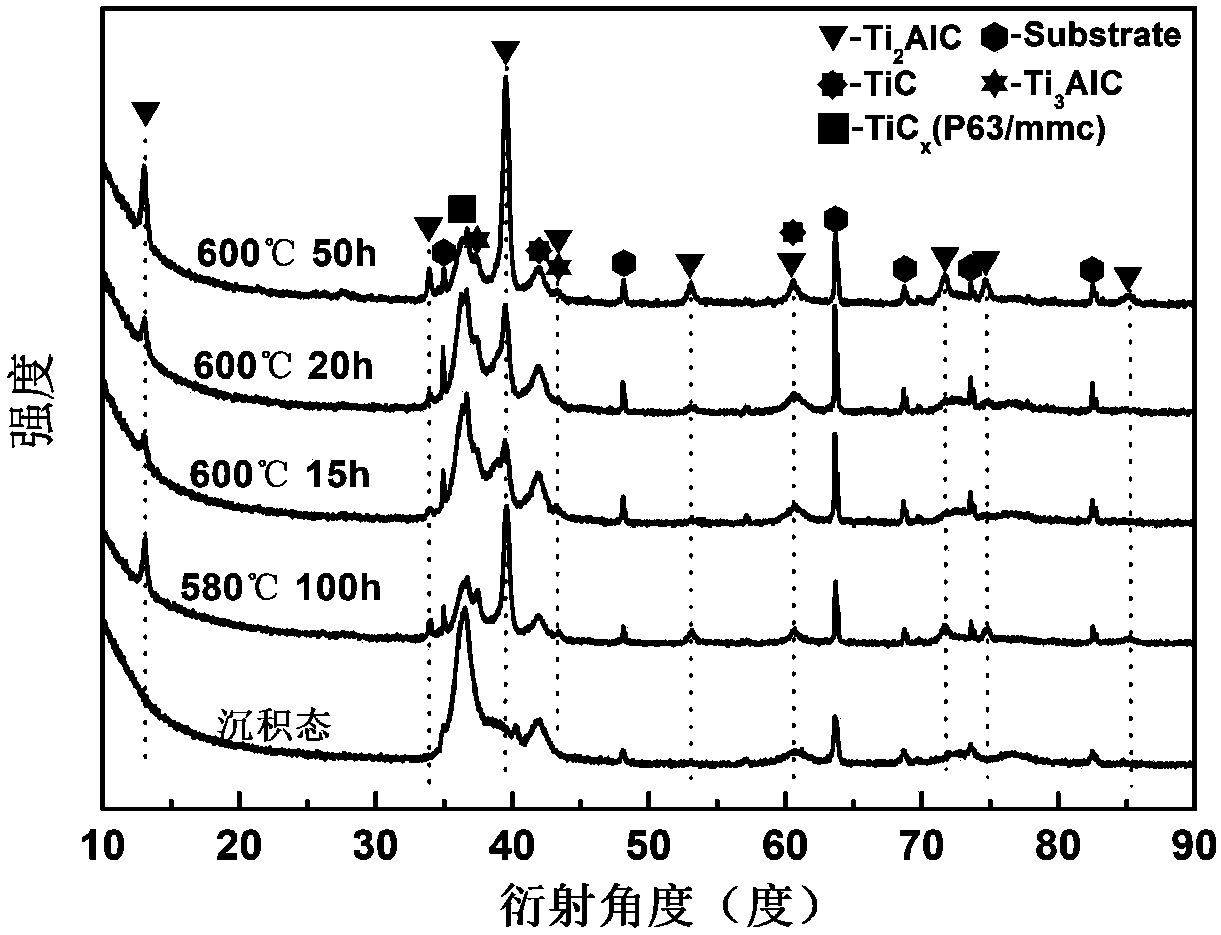

Preparation method of MAX-phase coating

InactiveCN108330452AReduce the formation temperatureAvoid damageVacuum evaporation coatingSputtering coatingCrystal structureProduct gas

The invention relates to a preparation method of an MAX-phase coating. The preparation method comprises the following steps: providing a substrate; depositing an M-A-X coating on the surface of the substrate by combining a cathode arc ion plating method with a magnetron sputtering method, wherein an M source is provided by a cathode arc target, M in the M source stands for a transition metal element, an A source is provided by a magnetron sputtering target, A in the A source stands for an Al element or a Si element, an X source is provided by a reaction gas, and X in the X source stands for aC element or a N element; and carrying out annealing treatment on the substrate with the deposited M-A-X coating, so as to obtain the MAX-phase coating. According to the preparation method provided bythe invention, an M-element-rich coating and an A-element-rich coating are alternately formed by combining the cathode arc ion plating method with the magnetron sputtering method; M atoms in the M-element-rich coating are of a close-packed hexagonal structure; C atoms or N atoms are dissolved in the close-packed hexagonal structure; the prepared MAX-phase coating has a similar crystal structure with a conventional MAX-phase coating; and consequently, the MAX phase forming temperature can be lowered during the annealing process, and then the damage to the substrate can be reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphoaluminate cement. Limestone, phosphogypsum, low-grade bauxite and coke are formulated into cement raw meal in a certain proportion, and calcined at high temperature after grinding and mixing. Promote the decomposition of phosphogypsum as much as possible, and the calcium oxide generated by the decomposition can replace part of the limestone. The sulfur dioxide gas can be collected to prepare sulfuric acid. The obtained cement clinker is mixed with natural dihydrate gypsum and ground to make cement products. Compared with the existing traditional production method, the method of the present invention can greatly improve the utilization rate of phosphogypsum, avoid the concentration of sulfur dioxide emitted by a small amount of decomposition of gypsum in the production process, which cannot reach the concentration used, and can also reduce the amount of limestone and carbon dioxide emissions. Burnt cement has wide adaptability and can be widely used in the production of sulphoaluminate cement using phosphogypsum, and is also suitable for the production of rapid hardening cement and expansive cement.

Owner:CHONGQING UNIV

Method for preparing anorthite toughened ceramic by utilizing desulfurized gypsum

The invention discloses a method for preparing anorthite toughened ceramic by utilizing desulfurized gypsum. The method comprises the following steps of: uniformly mixing 5wt%-30wt% of desulfurized gypsum and 70wt%-95wt% of ceramic blank in a wet-process ball milling manner, wherein the desulfurized gypsum is calcium sulfate type flue gas desulfurization waste residue; grinding and drying the slurry, and preparing the ceramic green blank by dry-pressing and forming; sintering the ceramic green blank in a kiln, controlling the sintering temperature at 1180 -1260 DEG C, and preserving the heat for 30-90 minutes to prepare the anorthite toughened ceramic. The ceramic test sample which is prepared from the method disclosed by the invention adopts anorthite and mullite as the principal crystalline phase, and adopts cristobalite as the secondary crystalline phase, so that the crystalline phase structure is matched with the thermal expansion coefficient of the feldspathic glass which is used as the binding phase better, and therefore, the micro cracks generated in a ceramic sintering process can be reduced, and the impact strength of the ceramic product is improved. Besides, the method can be used for achieving the purposes of utilizing the waste, saving the ceramic production energy consumption and improving the product performance.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com