99BeO ceramic metallizing slurry and preparation method thereof

A ceramic metallization and metallization technology is applied in the field of metallization slurry formulation and preparation of high-purity BeO ceramic surface metallization treatment, which can solve the problem of low sealing performance of electronic components or components and difficult product dimensional accuracy. control, the easy growth of ceramic grains, etc., to achieve the effect of low glass phase formation temperature, good fluidity, and lower metallization sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

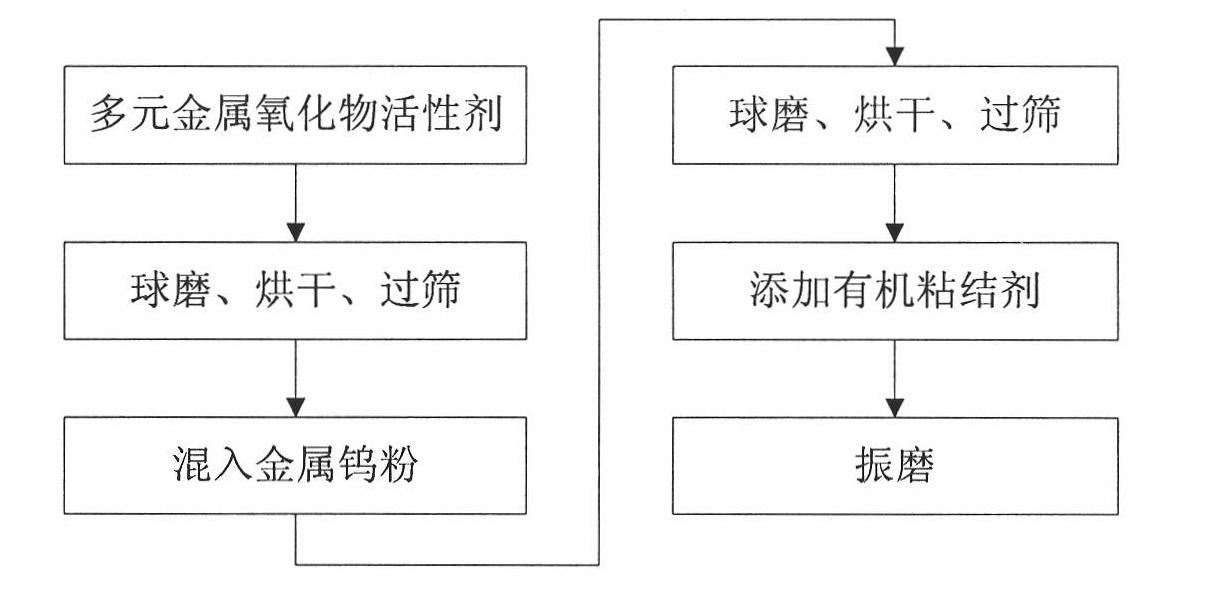

[0019] Take 15-35% by mass of MgO, 15-35% by mass of Al 2 o 3 , 30-60% SiO by mass 2 and 3% to 10% mass of Sm 2 o 3 Put into the ball mill jar that agate ball is housed, add deionized water, water: material: the mass ratio of ball is 5:1:5; After the end, separate the agate balls with a filter, put the material into a hot air circulation oven for drying, and keep it warm at 120°C for 4 hours; pass the dried material through a 250-300 mesh sieve for two to three times to obtain a multi-element metal oxide active agent . Mix 10%-30% mass multi-element metal oxide activator with 70-90% mass tungsten powder, put into a ball mill jar equipped with agate balls, add alcohol, the mass ratio of alcohol:material:ball is 5: 1:5, put the ball mill tank on the ball mill for ball milling, the ball milling time is 15-25 hours; after the ball milling, filter out the agate balls and put the material in the oven, keep it warm for 3 hours at 70°C, and dry it The raw materials are passed th...

specific Embodiment 2

[0021] Take 20-40% by mass of MgO and 15-35% by mass of Al 2 o 3 , 30-60% SiO by mass 2 , 2.5% to 8% mass of Sm 2 o 3 and 0.5 to 2% by mass of Nd 2 o 3Put into the ball mill jar that agate ball is housed, add deionized water, water: material: the mass ratio of ball is 5:1:5; After the end, separate the agate balls with a filter, put the material into a hot air circulation oven for drying, and keep it warm at 120°C for 4 hours; pass the dried material through a 250-300 mesh sieve for two to three times to obtain a multi-element metal oxide active agent . Mix 10%-30% mass multi-element metal oxide activator with 70-90% mass tungsten powder, put into a ball mill jar equipped with agate balls, add alcohol, the mass ratio of alcohol:material:ball is 5: 1:5, put the ball mill tank on the ball mill for ball milling, the ball milling time is 15-25 hours; after the ball milling, filter out the agate balls and put the material in the oven, keep it warm for 3 hours at 70°C, and dr...

specific Embodiment 3

[0023] Take 15-35% by mass of MgO, 15-35% by mass of Al 2 o 3 , 30-60% SiO by mass 2 , 2.5% to 8% mass of Sm 2 o 3 and 0.5-2% mass of Pr 6 o 11 Put into the ball mill jar that agate ball is housed, add deionized water, water: material: the mass ratio of ball is 5:1:5; After the end, separate the agate balls with a filter, put the material into a hot air circulation oven for drying, and keep it warm at 120°C for 4 hours; pass the dried material through a 250-300 mesh sieve for two to three times to obtain a multi-element metal oxide active agent . Mix 10%-30% mass multi-element metal oxide activator with 70-90% mass tungsten powder, put into a ball mill jar equipped with agate balls, add alcohol, the mass ratio of alcohol:material:ball is 5: 1:5, put the ball mill tank on the ball mill for ball milling, the ball milling time is 15-25 hours; after the ball milling, filter out the agate balls and put the material in the oven, keep it warm for 3 hours at 70°C, and dry it T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com