Patents

Literature

356 results about "Beryllium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beryllium oxide (BeO), also known as beryllia, is an inorganic compound with the formula BeO. This colourless solid is a notable electrical insulator with a higher thermal conductivity than any other non-metal except diamond, and exceeds that of most metals. As an amorphous solid, beryllium oxide is white. Its high melting point leads to its use as a refractory material. It occurs in nature as the mineral bromellite. Historically and in materials science, beryllium oxide was called glucina or glucinium oxide.

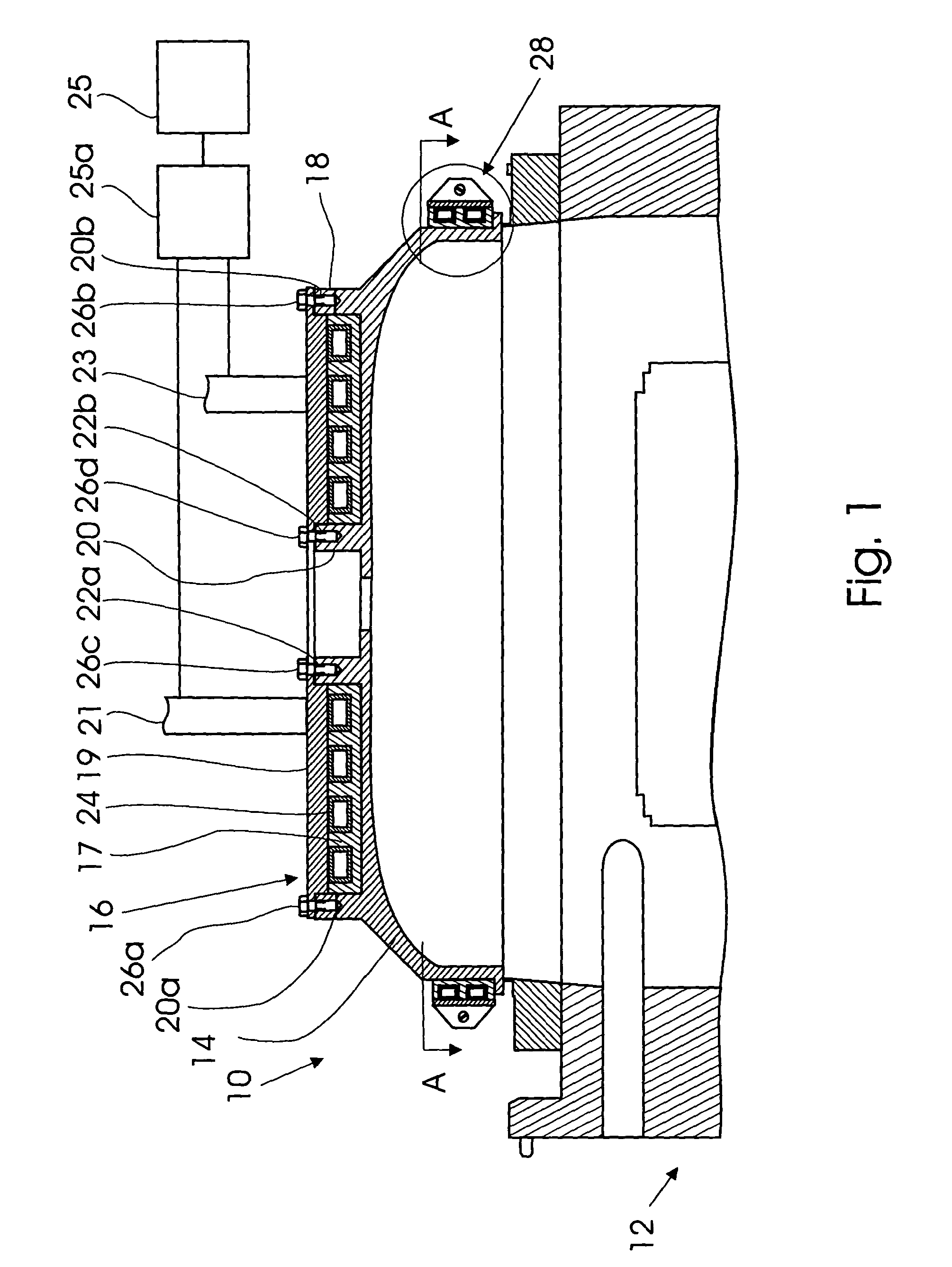

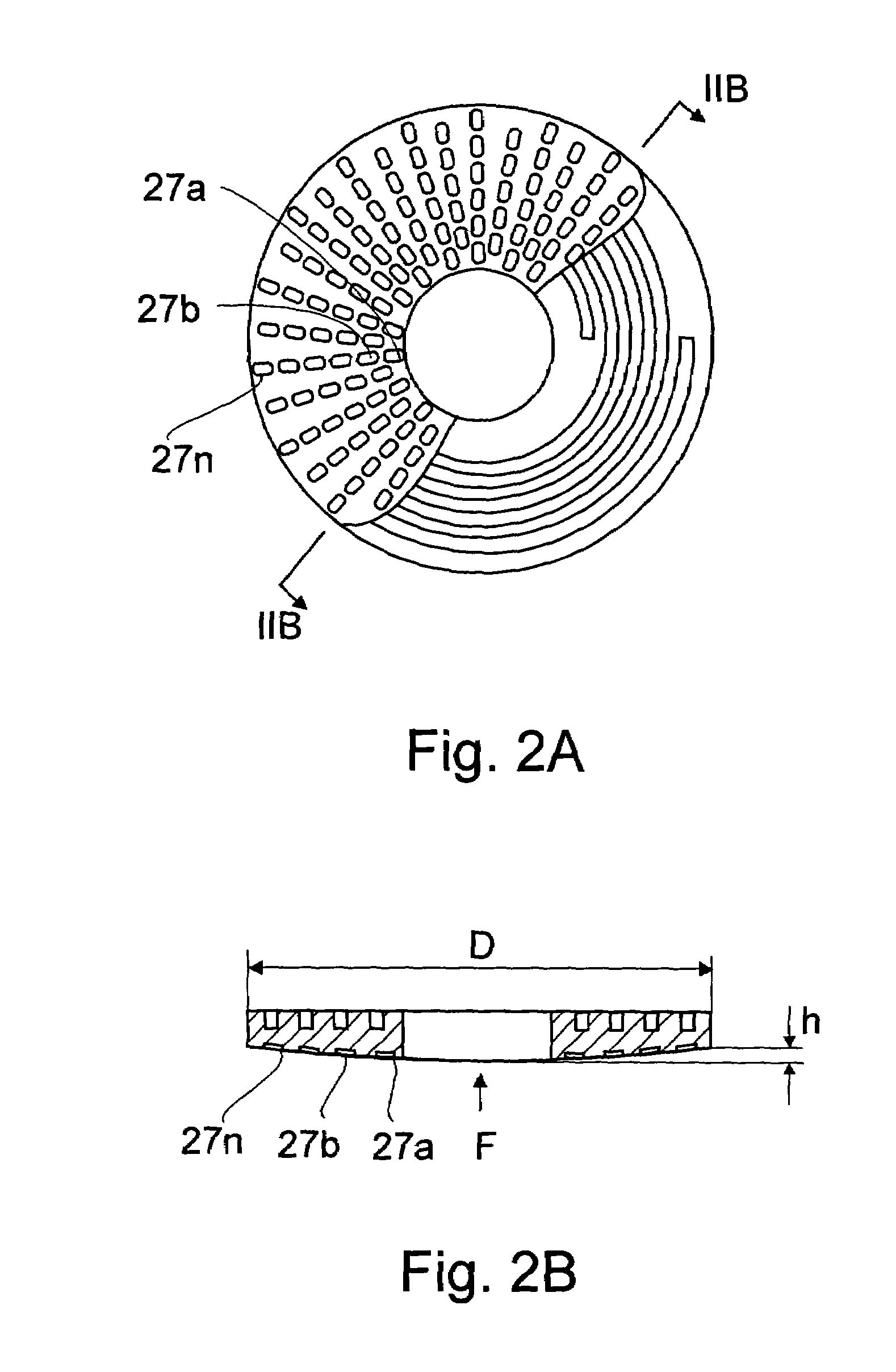

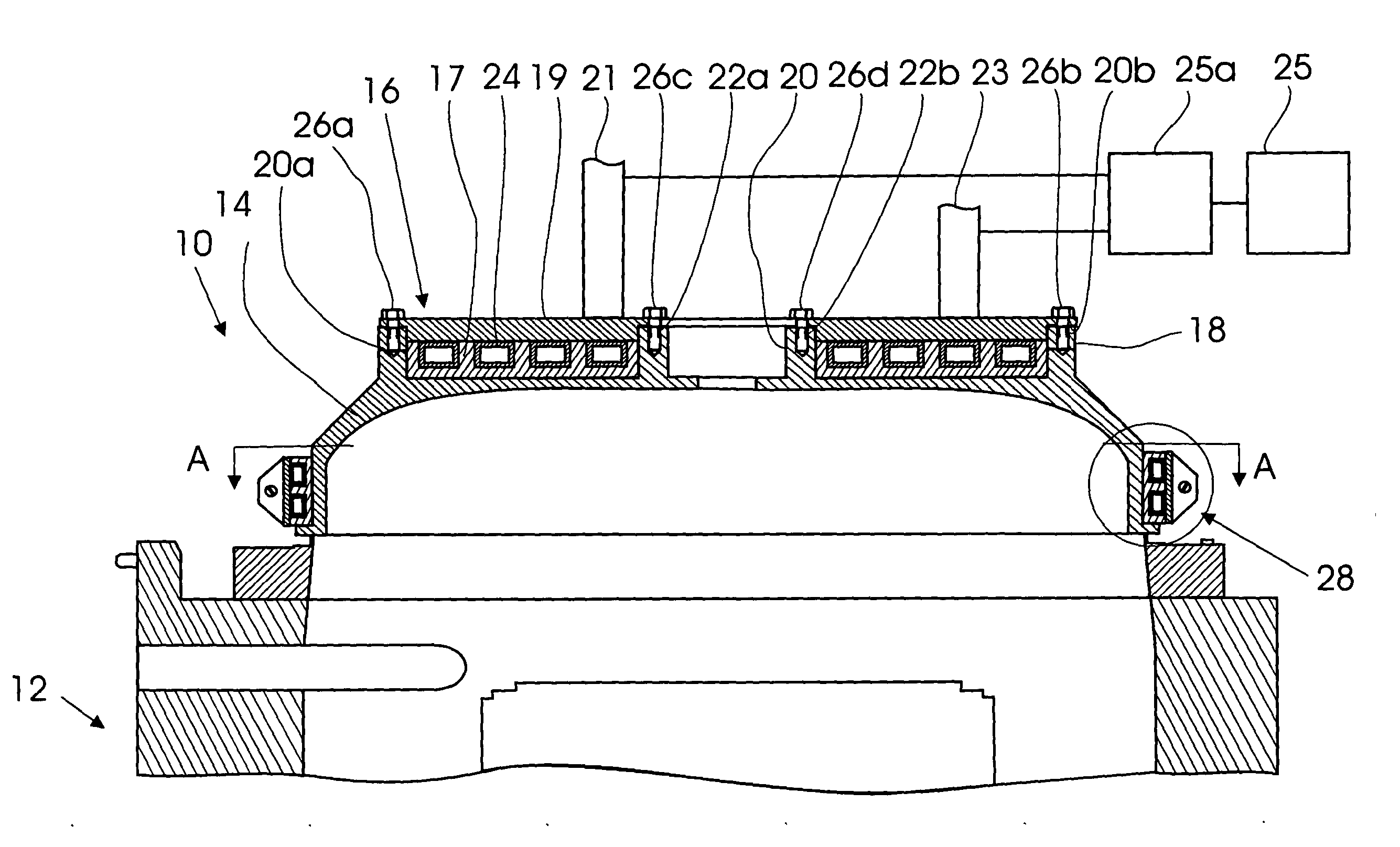

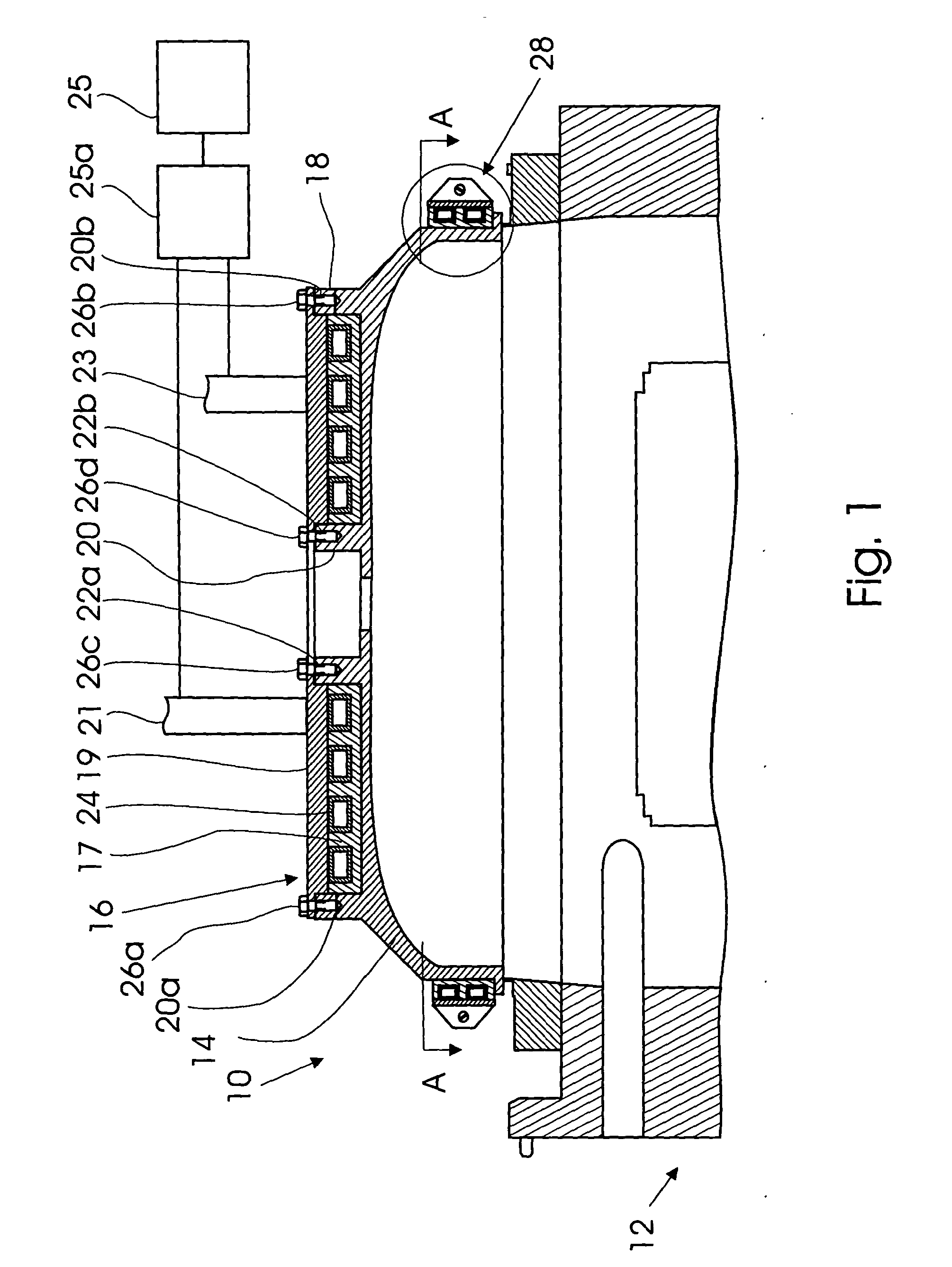

Heat-transfer interface device between a source of heat and a heat-receiving object

InactiveUS7137444B2Reliable and stable thermally-conductiveImproving and stabilizing a heat-transfer interfaceElectric discharge tubesSynthetic resin layered productsElastomerWorking temperature

Owner:PACIFIC RUBBER & PACKING

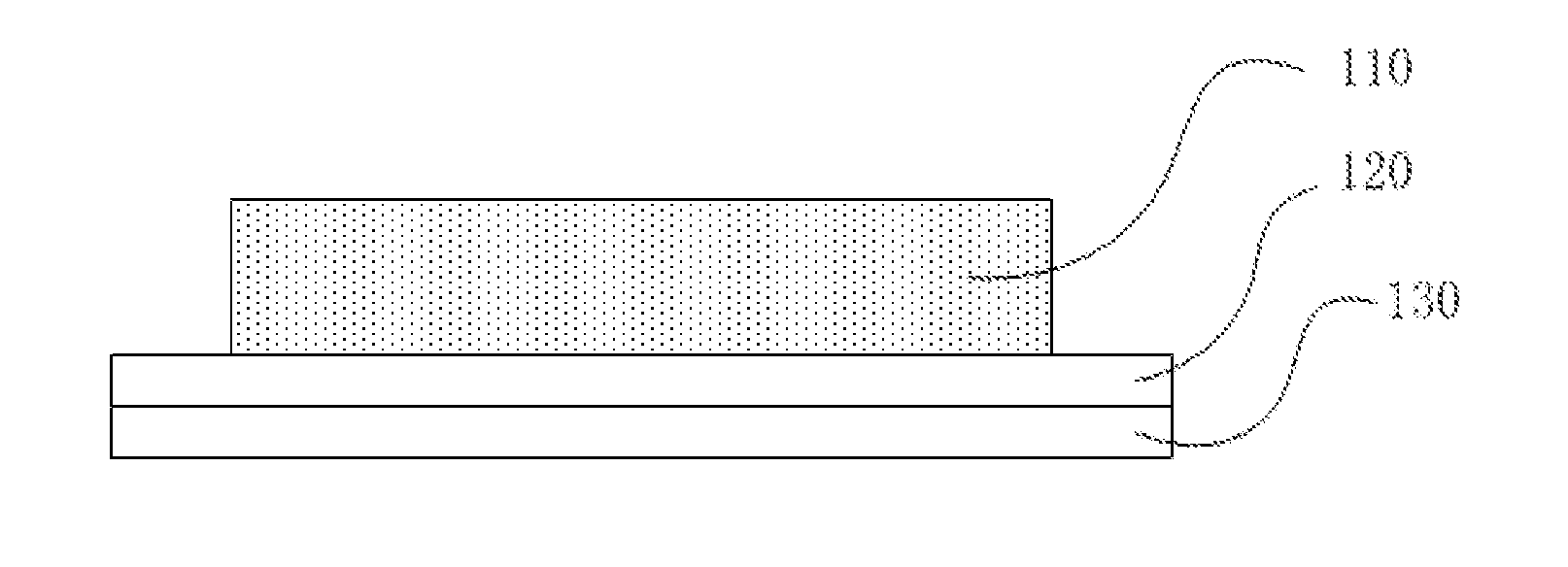

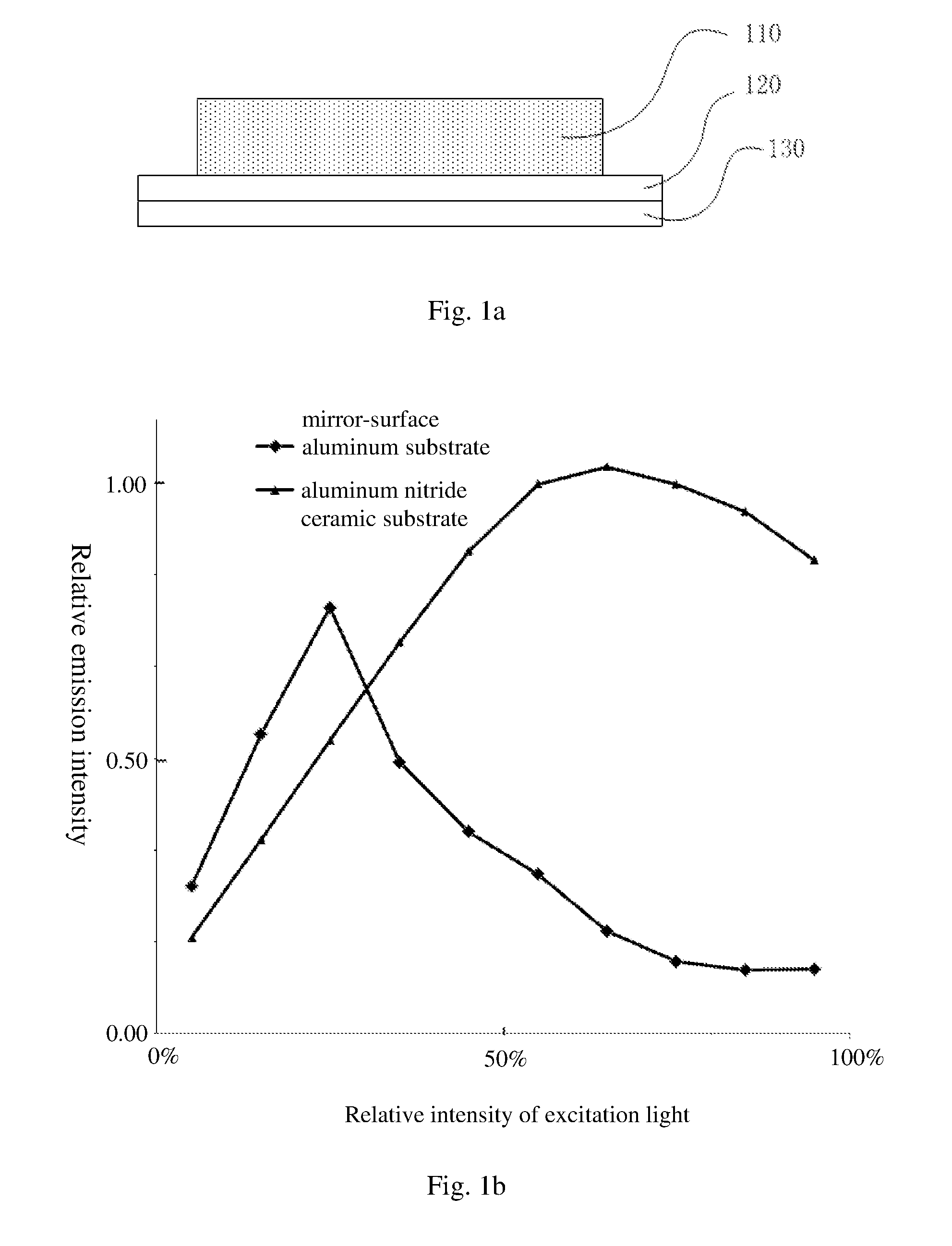

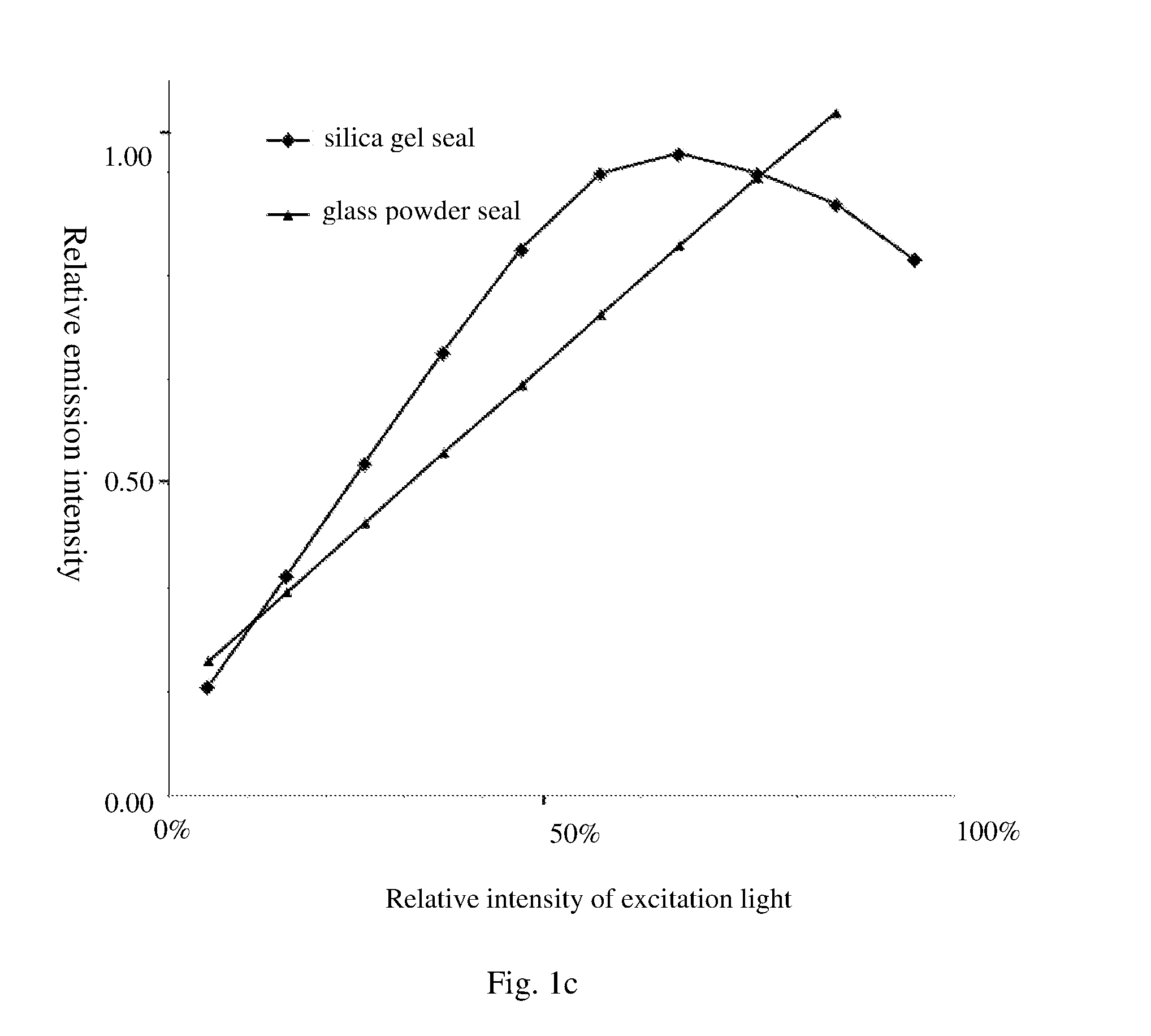

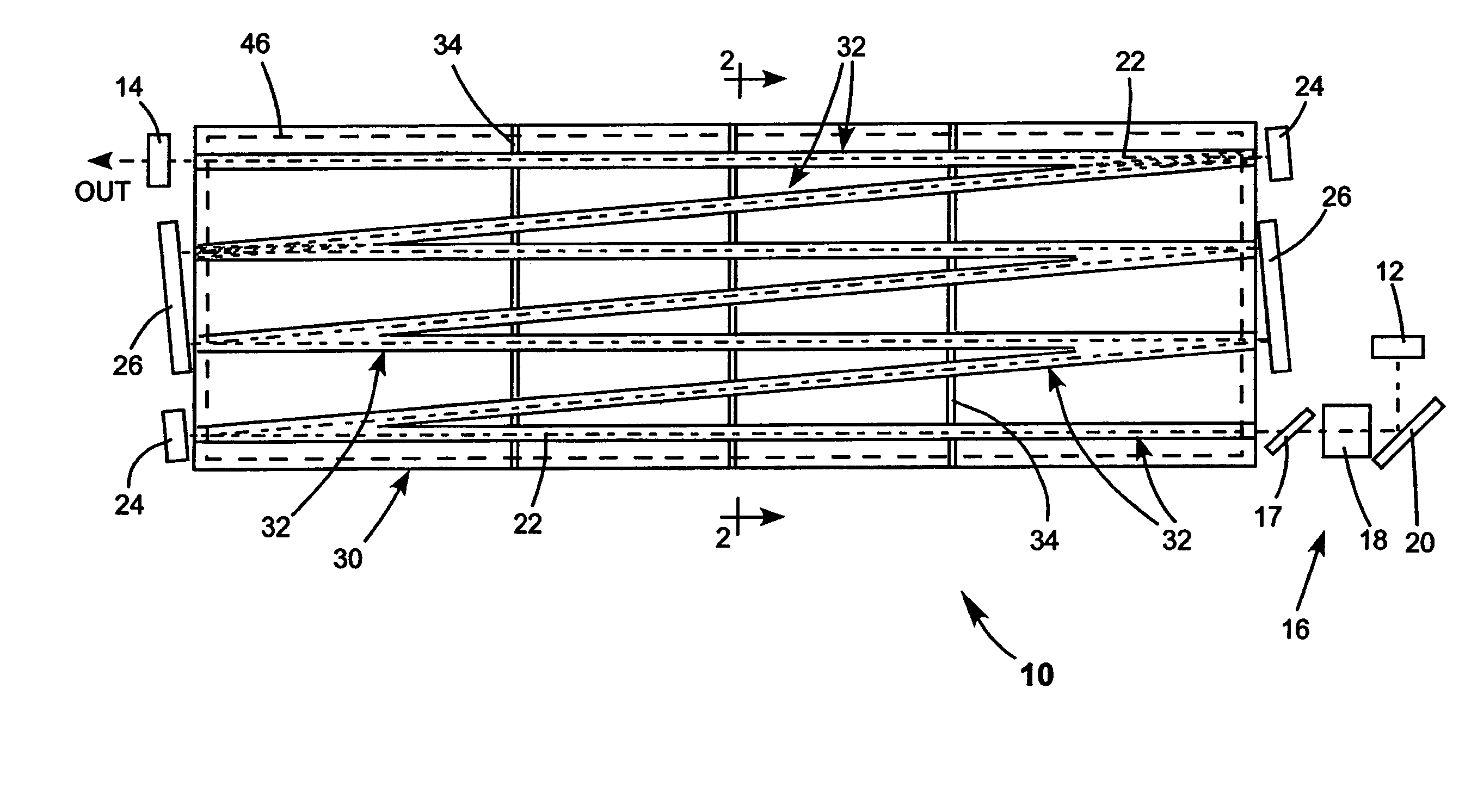

Wavelength conversion device, manufacturing method thereof, and related illumination device

ActiveUS20160123557A1Reduce reflectivityImprove thermal conductivityLighting heating/cooling arrangementsProjectorsDiffuse reflectionBoron nitride

A wavelength conversion device, a manufacturing method thereof, and a related illumination device. The wavelength conversion device comprises a fluorescent powder layer (110) that is successively stacked, a diffuse reflection layer (120), and a high-thermal-conductivity substrate (130). The diffuse reflection layer (120) comprises white scattered particles for scattering the incident light; the high-thermal-conductivity substrate (130) is one of an aluminum nitride substrate, a silicon nitride substrate, a silicon carbide substrate, a boron nitride substrate, and a beryllium oxide substrate. The wavelength conversion device has good reflectivity and thermal stability.

Owner:APPOTRONICS CORP LTD

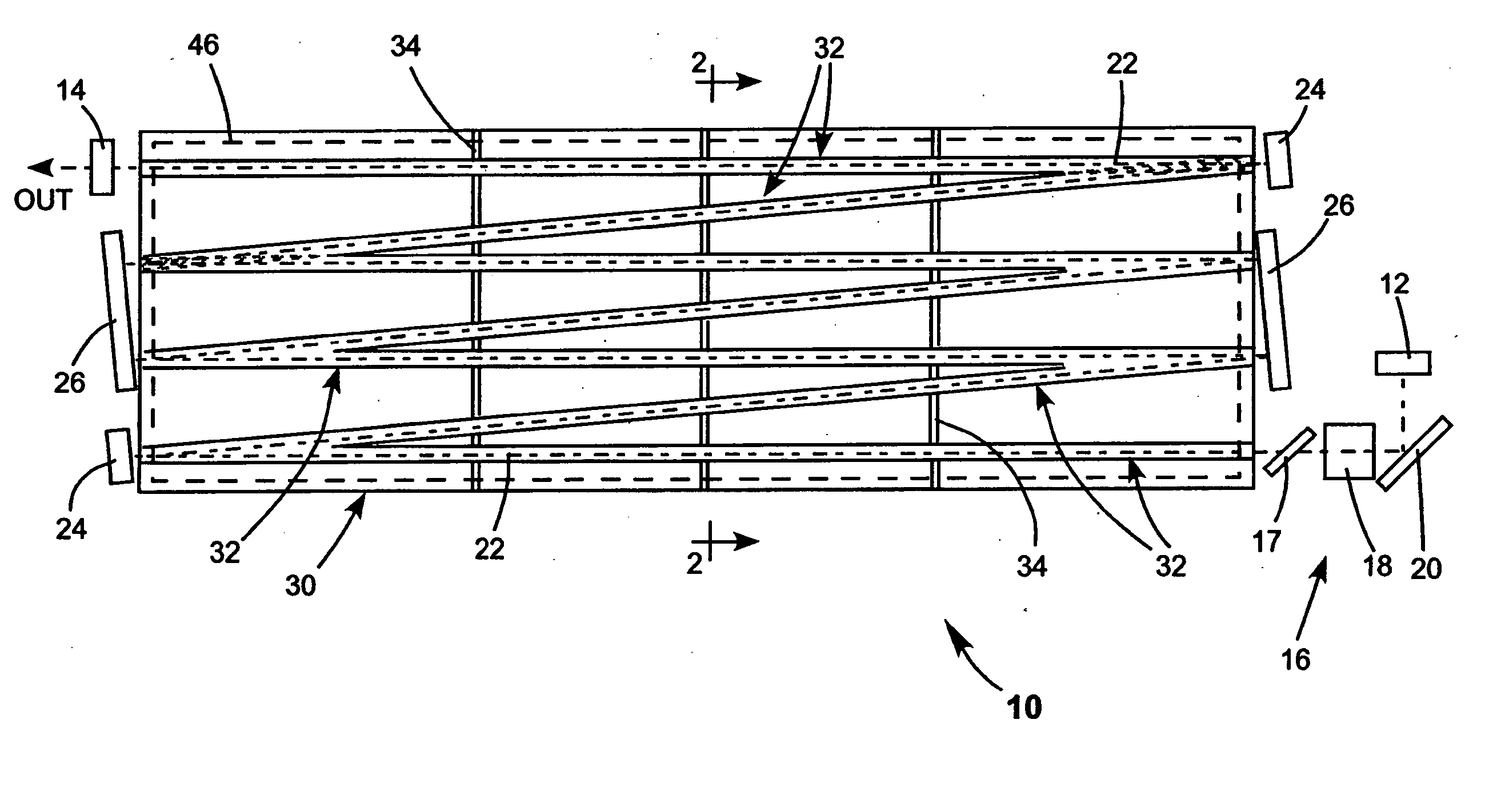

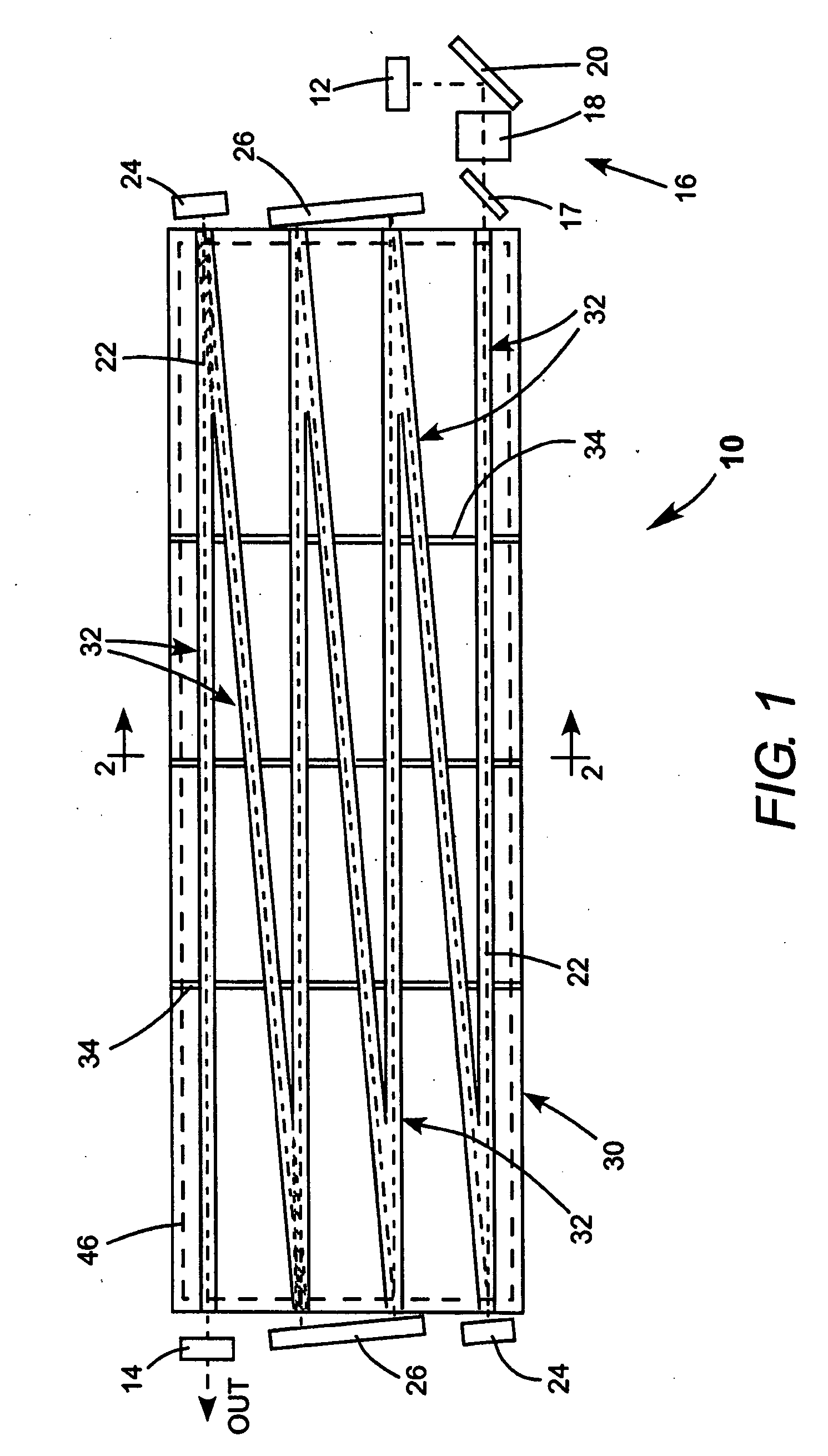

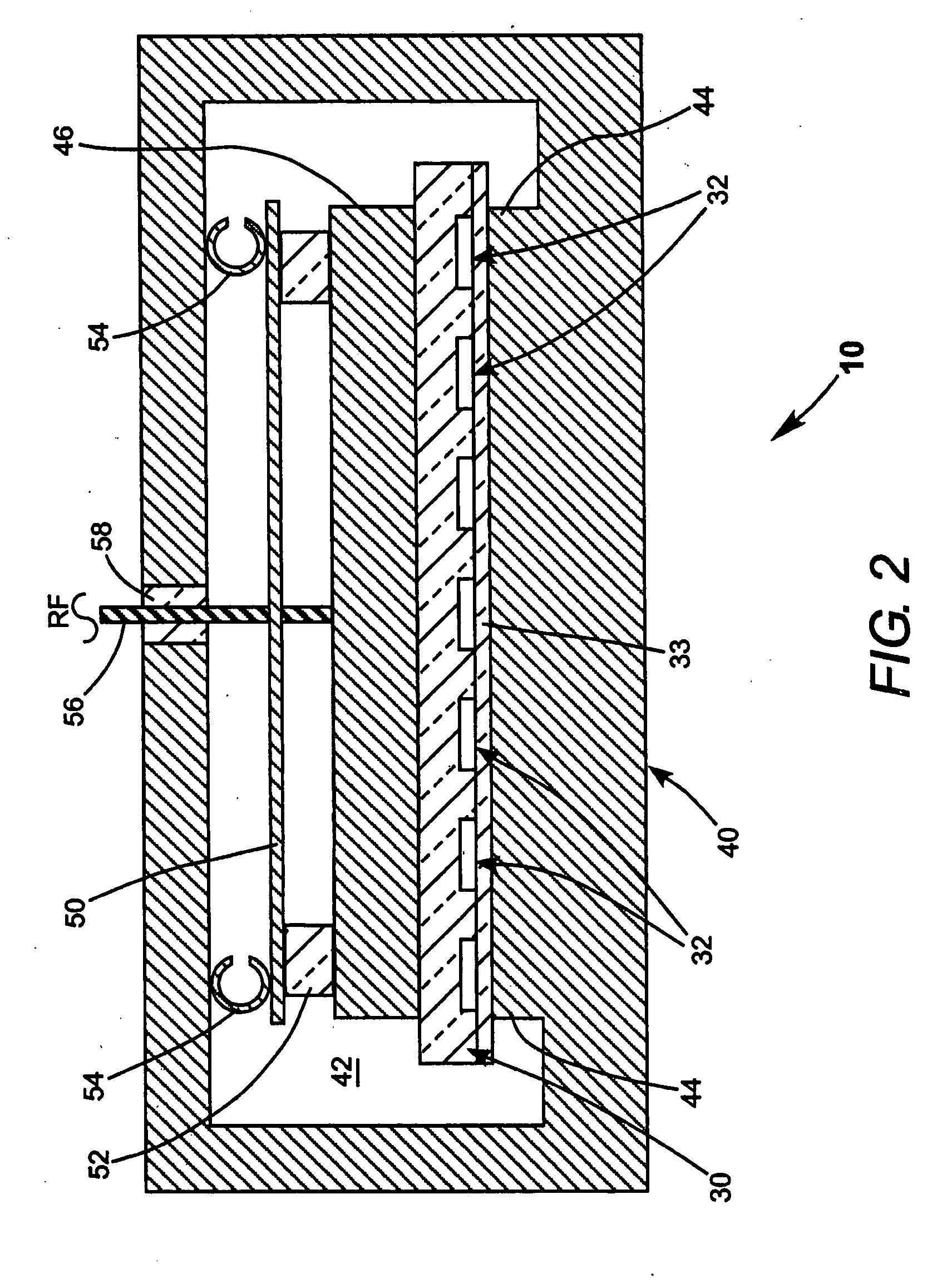

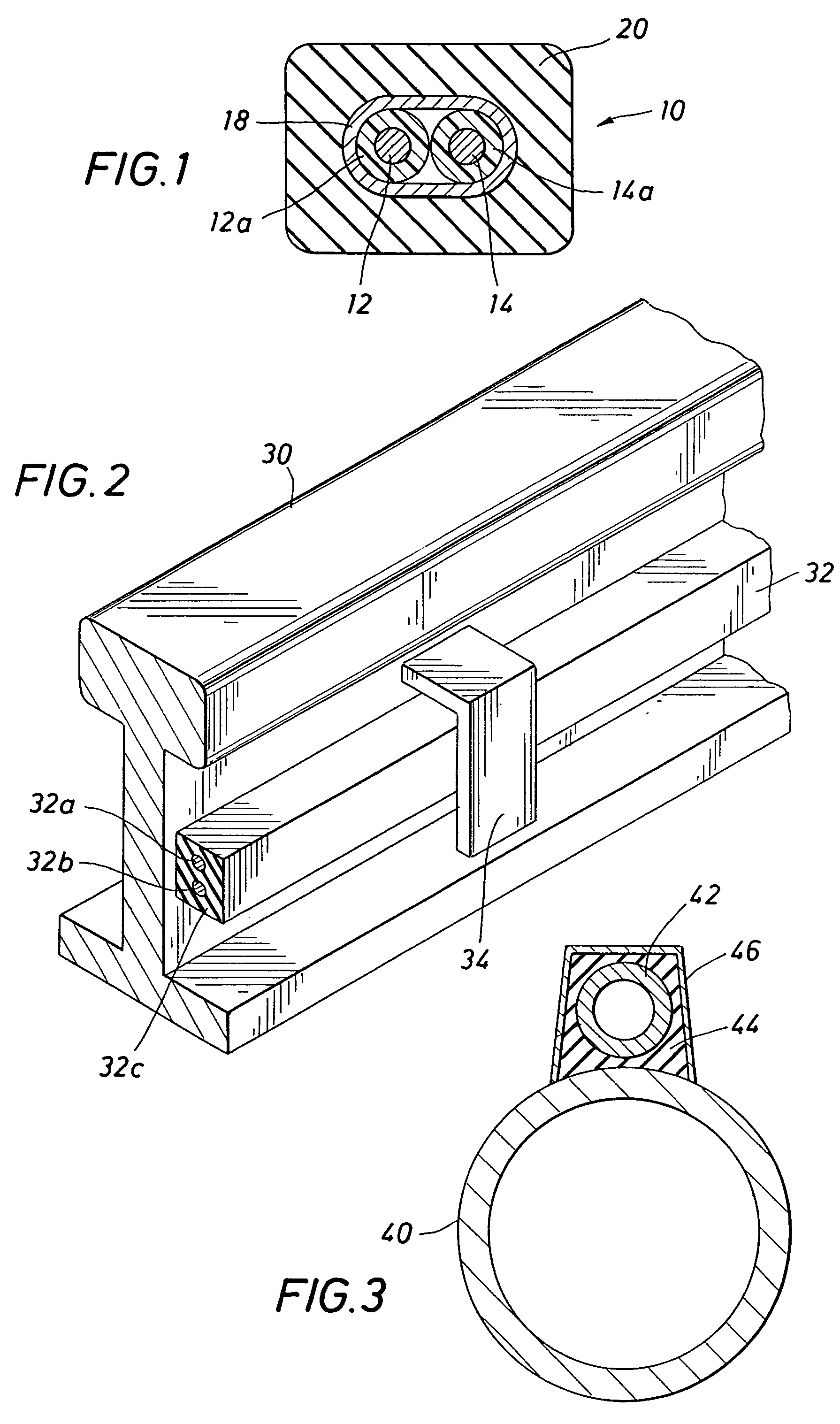

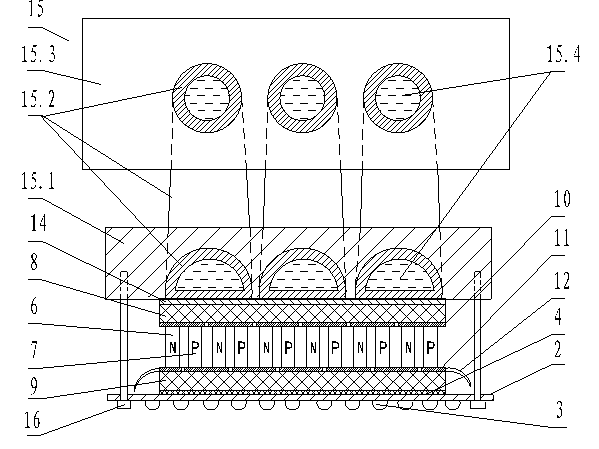

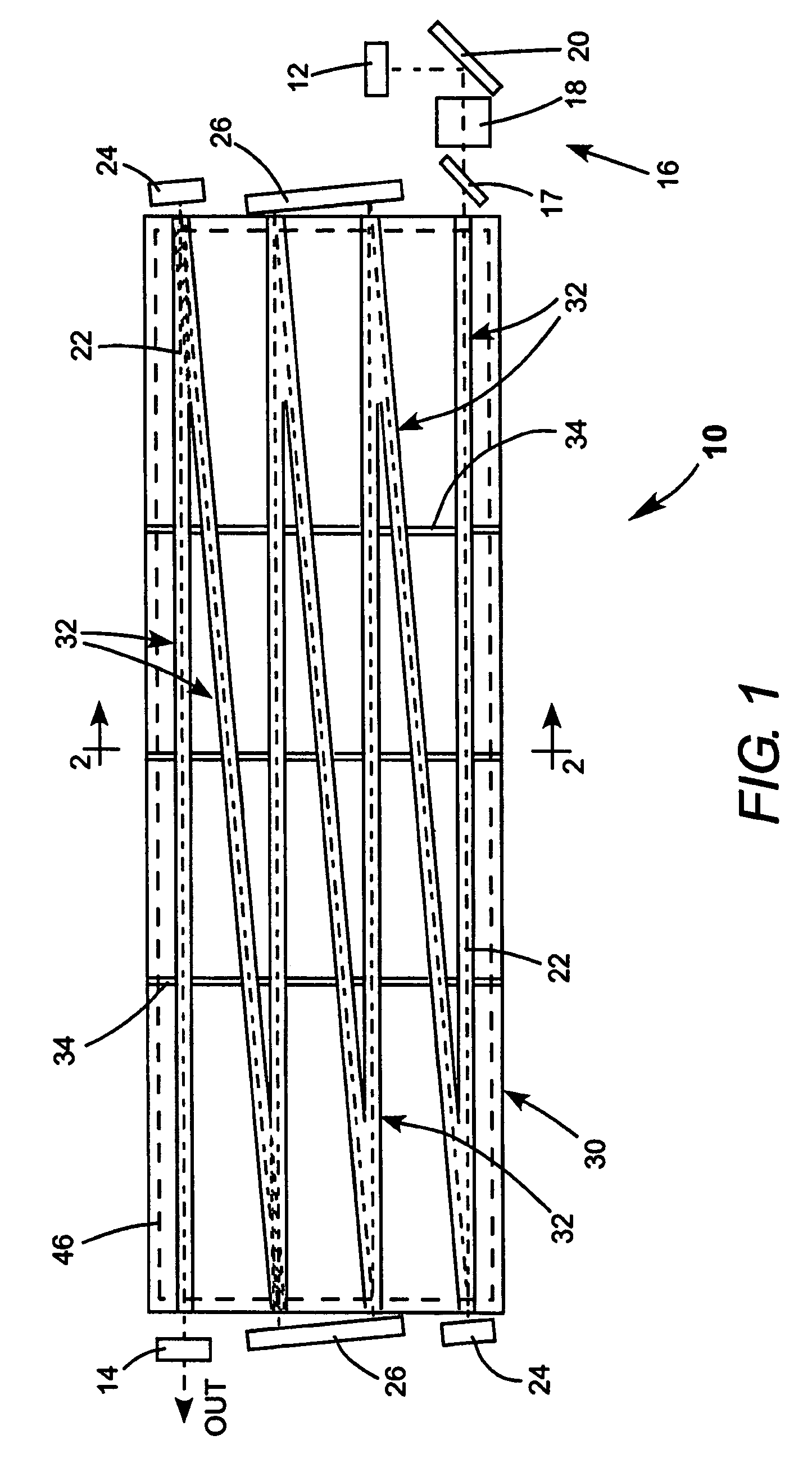

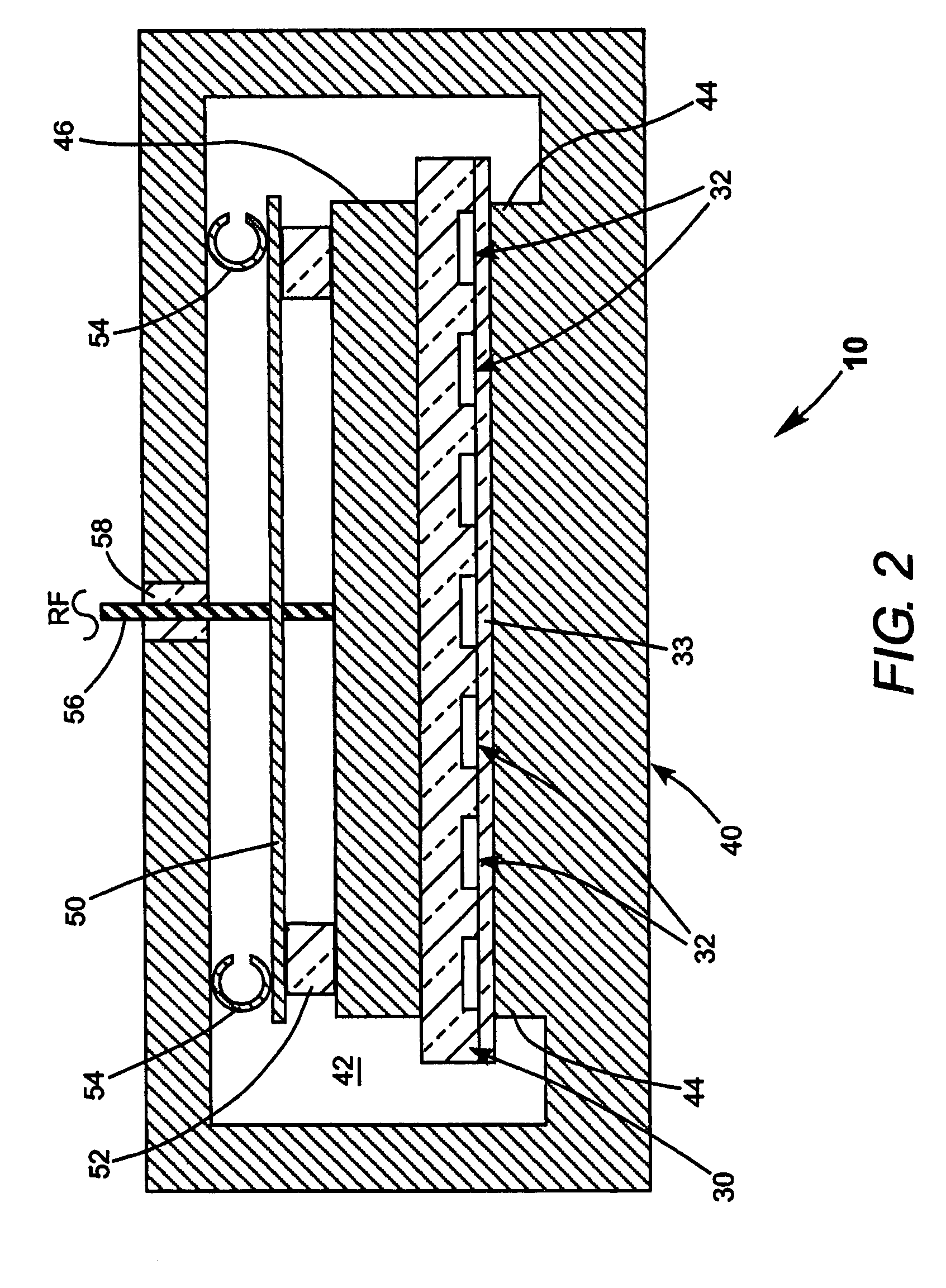

CO2 waveguide laser with beryllium oxide waveguides

ActiveUS20050105581A1Active medium materialActive medium shape and constructionMicrometerWaveguide lasers

A pulsed, Q-switched, waveguide CO2 laser includes a plurality of waveguide channels formed in a block of a beryllium oxide ceramic material and is operated at a wavelength between about 9.2 and 9.7 micrometers. The laser has an output power up to 55% greater than that of a similarly configured laser, operated at the same wavelength and pulse conditions, but wherein the waveguide channels are formed in a block of an alumina ceramic material.

Owner:COHERENT INC

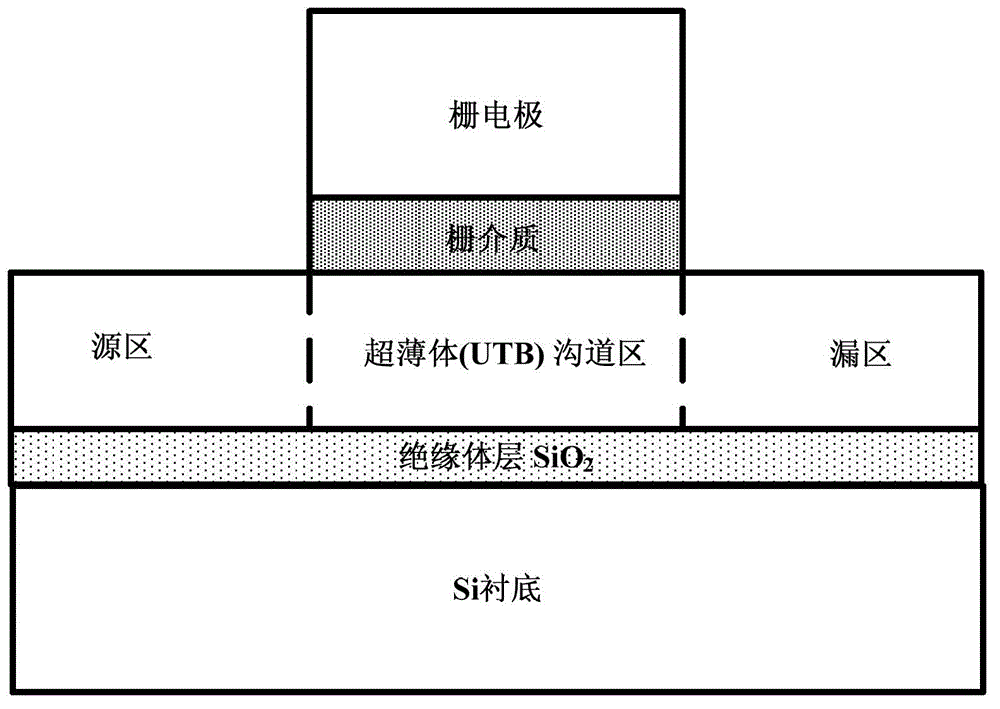

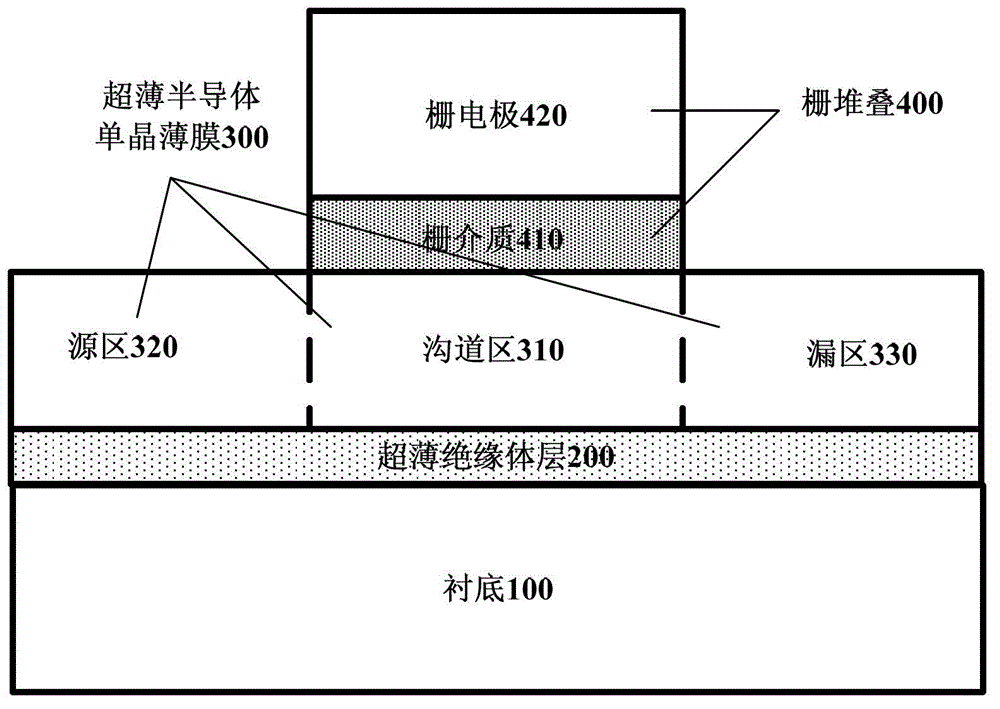

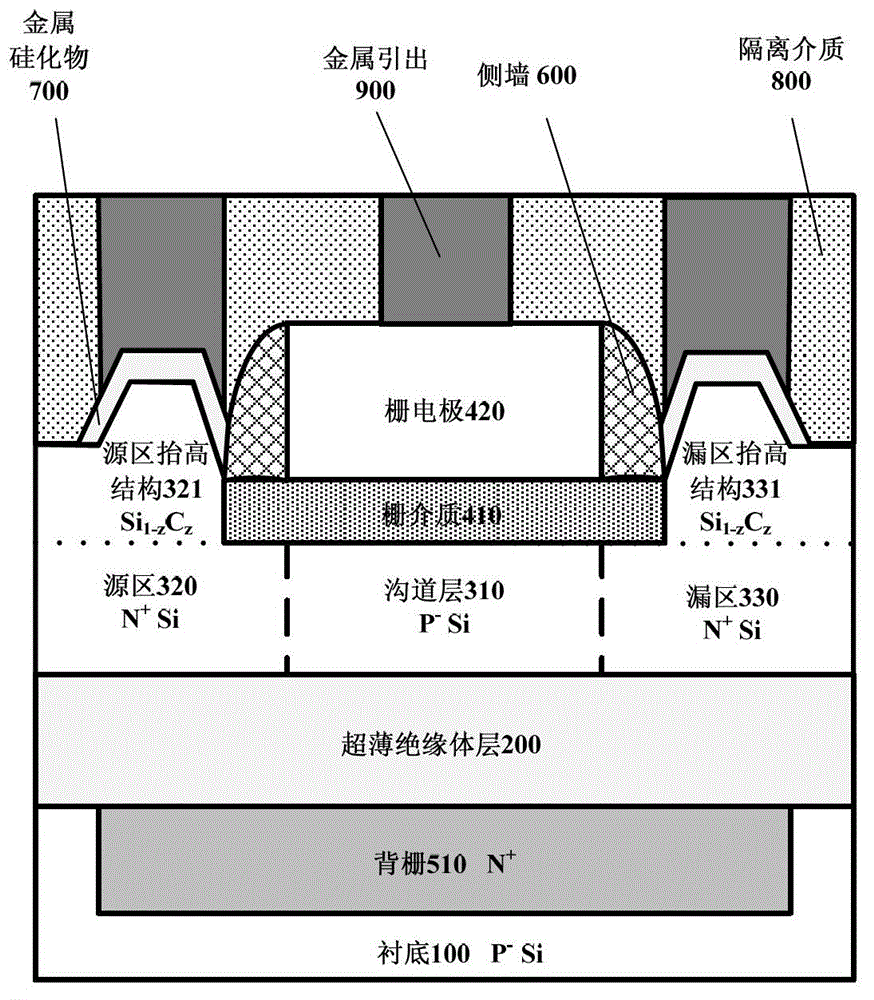

Field effect transistor and forming method thereof

InactiveCN103337519AEasy to implementSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesOxideField-effect transistor

The invention discloses a field effect transistor and a forming method thereof, wherein the field effect transistor comprises a substrate, an ultrathin insulator layer formed on the substrate, an ultrathin quasi-conductor monocrystal thin film formed on the ultrathin insulator layer, and a grid stack formed on the ultrathin quasi-conductor monocrystal thin film, wherein the ultrathin insulator layer is made of monocrystal tombarthite oxide or monocrystal beryllia; the grid stack comprises a grid medium and a grid electrode formed above the grid medium. The field effect transistor and the forming method, provided by the invention, have the advantages of simple structure, compatibility in process, low off-state current, excellent heat dissipation and the like.

Owner:TSINGHUA UNIV

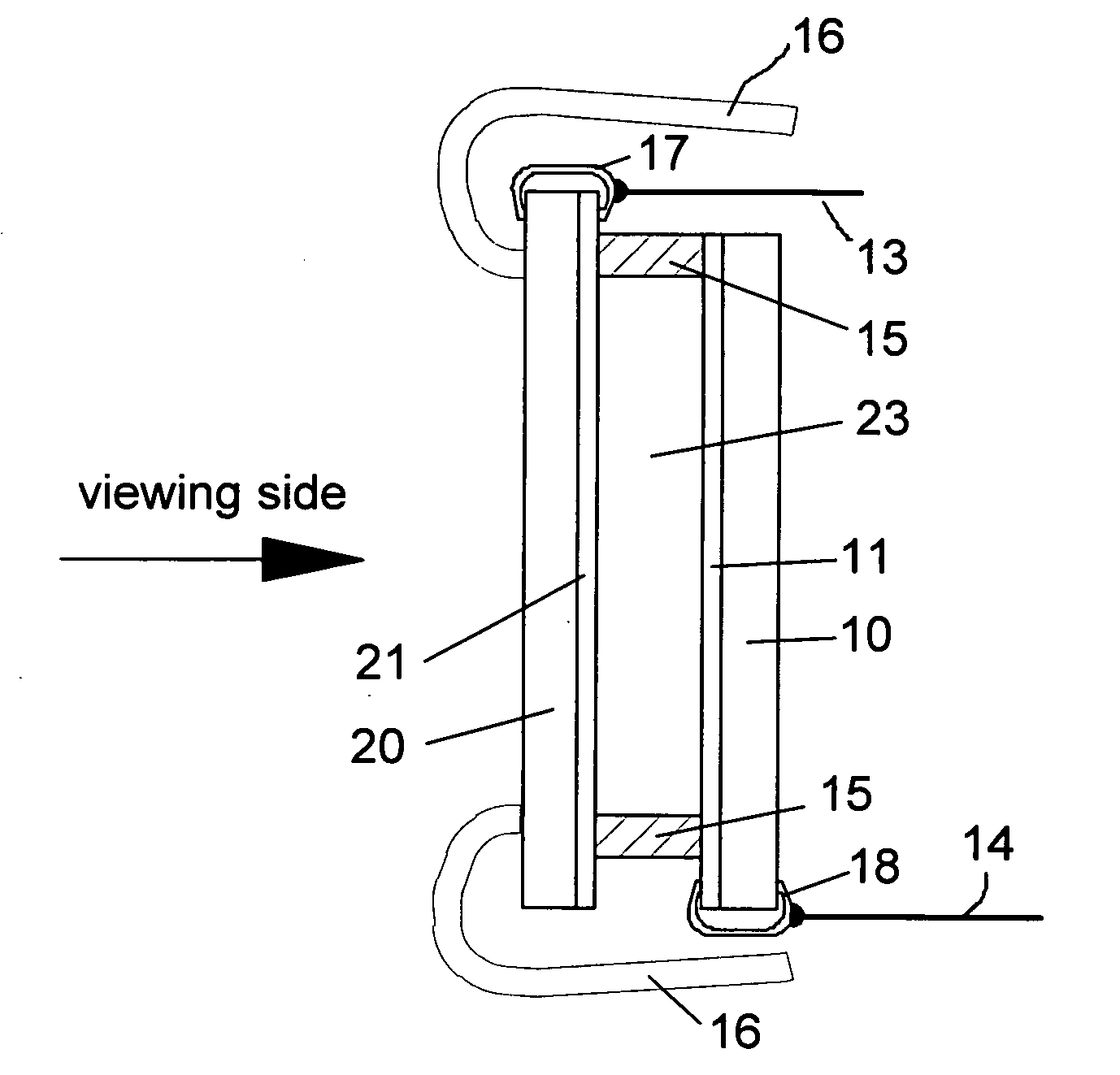

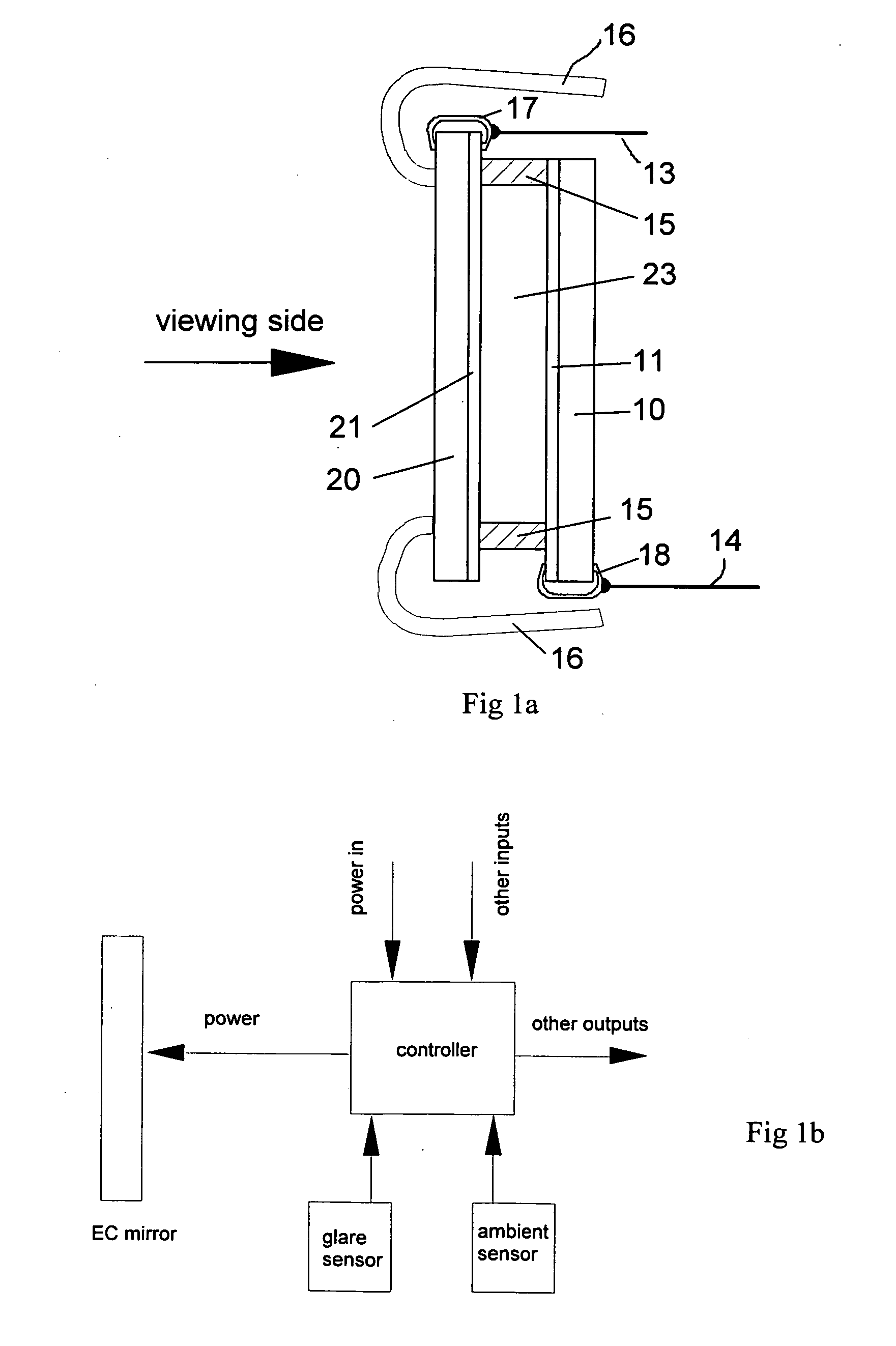

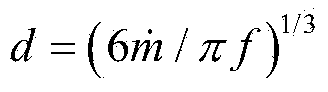

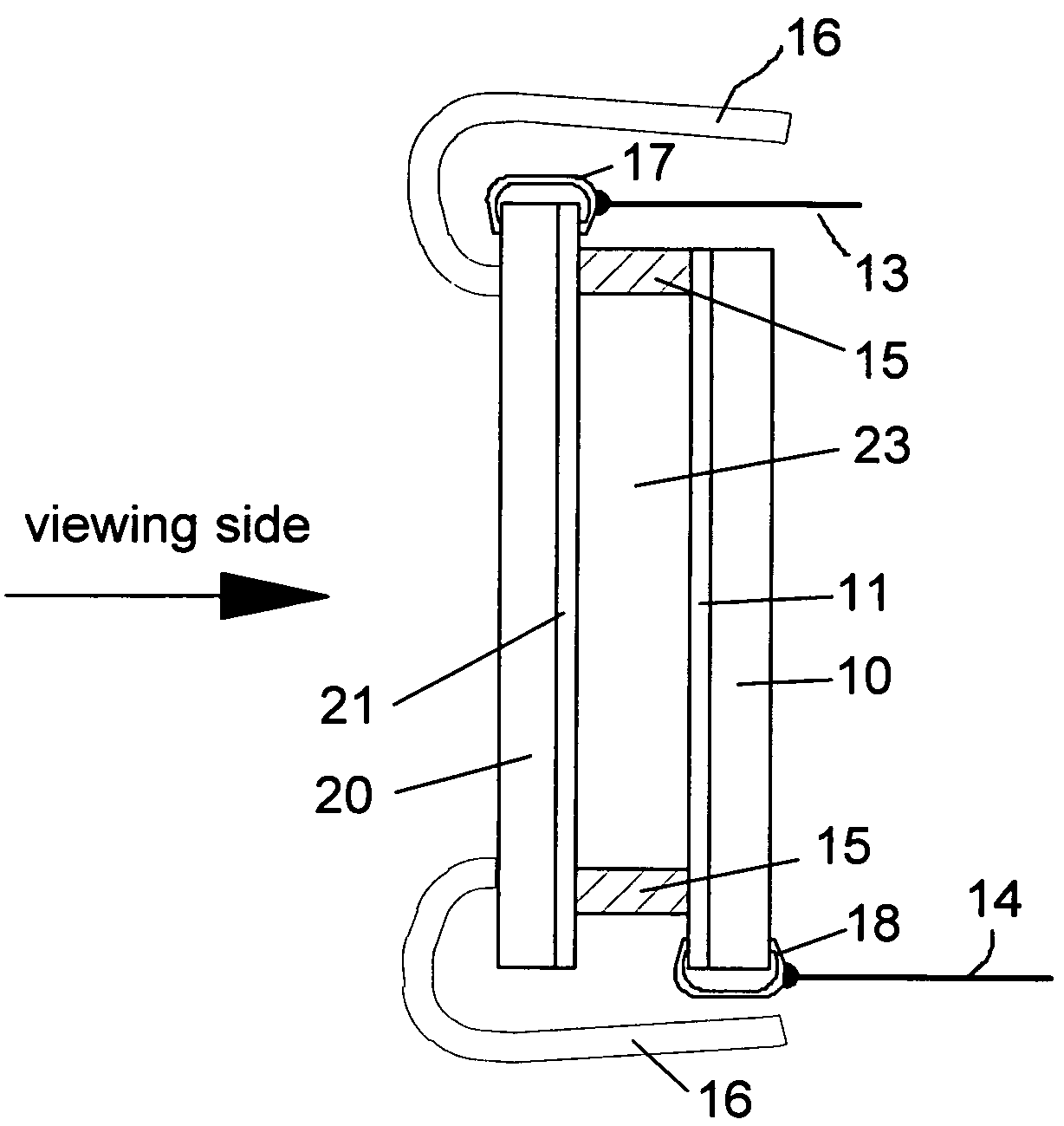

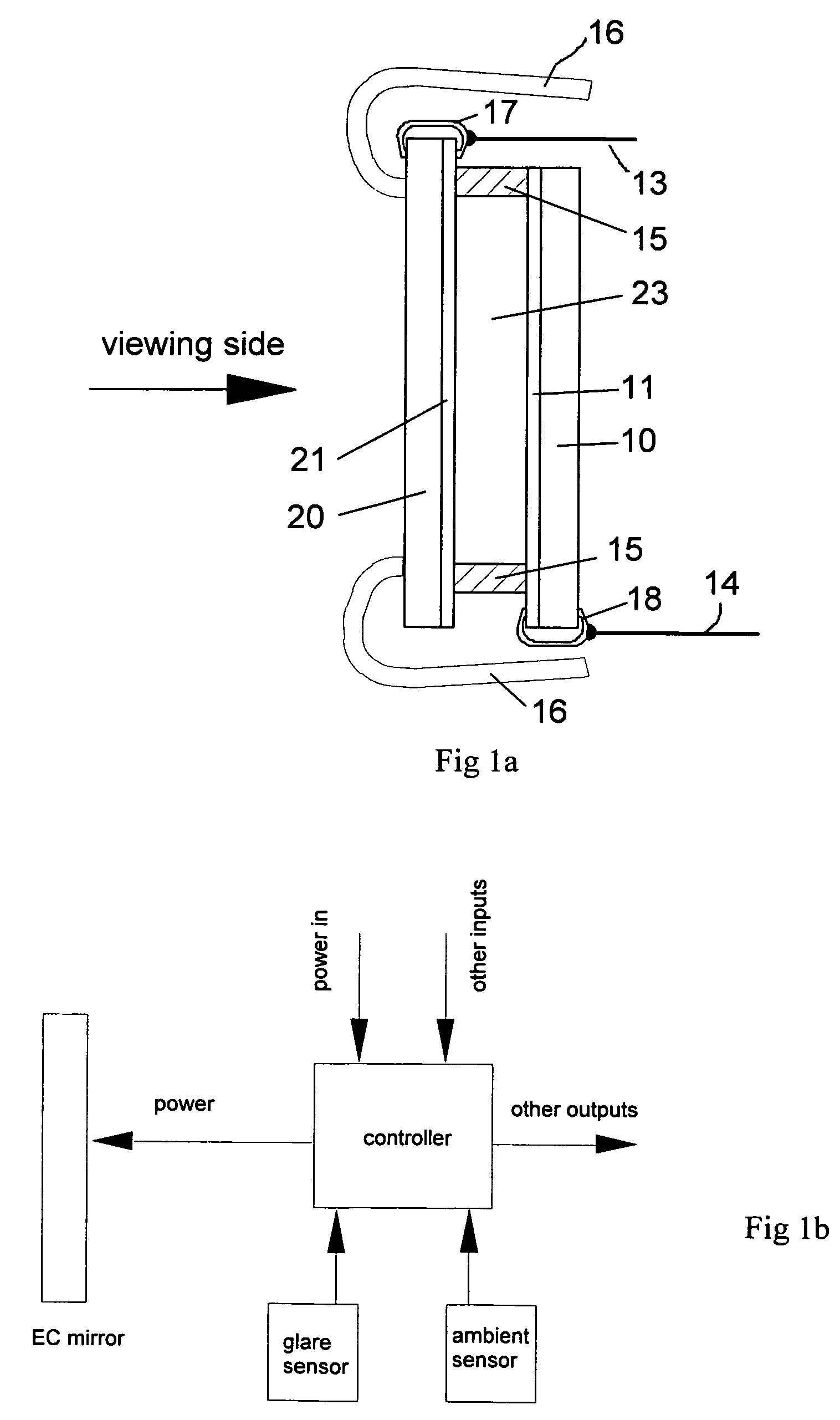

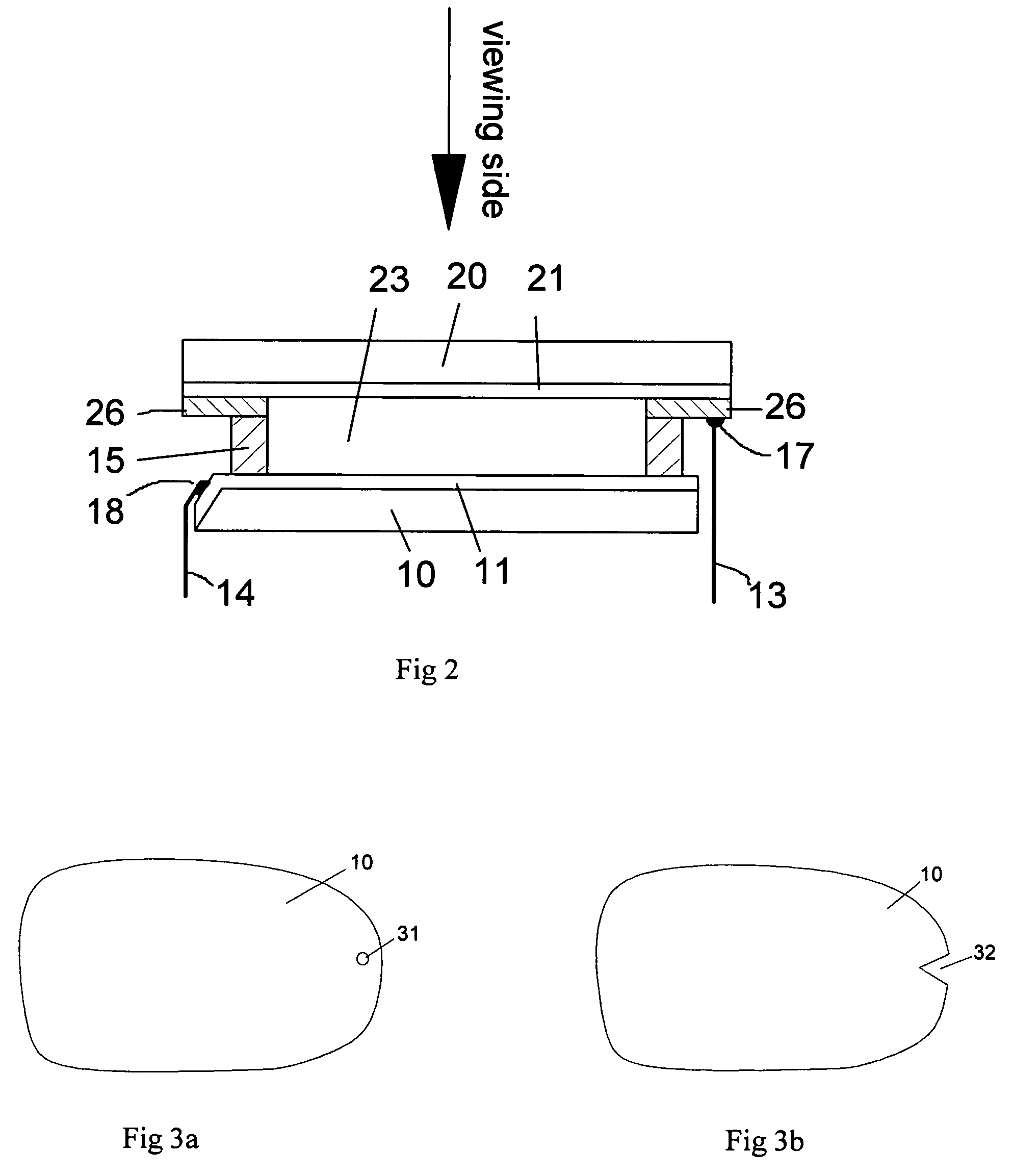

Environmentally safe electrochromic mirrors

This invention recognizes the hazards of beryllium and beryllium oxide in automotive applications and offers alternative material solutions. In particular, commercial electrochromic mirrors use beryllium comprising alloys for busbars and may also use beryllium oxide for the electronics used to power and control these mirrors. Further, this can be combined by reducing other known hazards such as mercury, cadmium, lead and antimony compounds.

Owner:AJJER

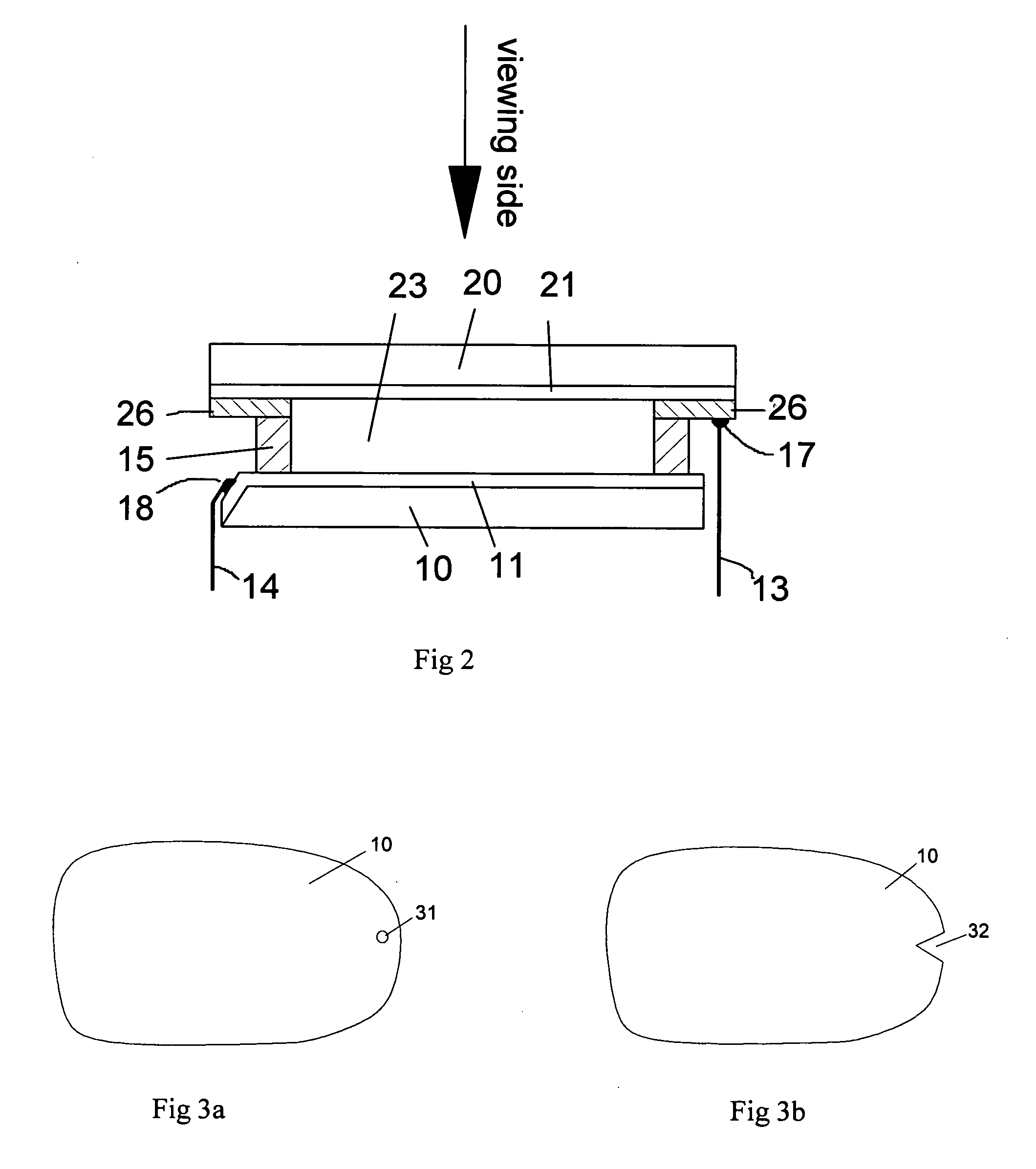

High thermal conductivity polyimide film and preparation method thereof

InactiveCN105111739AHigh thermal conductivityThe steps of the preparation method are clearSlurryBoron nitride

The invention relates to a high thermal conductivity polyimide film. The high thermal conductivity polyimide film is prepared from 80-99 wt% of reaction monomer mixtures and 1-20 wt% of nanometer material slurry; the reaction monomer mixtures are composed of amine monomers and anhydride monomers, and the mole ratio of the amine monomers to the anhydride monomers is 1:1-1.15; the nanometer material slurry is prepared from 30-40 wt% of aprotic polar solvent, 50-66 wt% of inorganic nano-materials, 2-5 wt% of dispersing agents and 2-5 wt% of coupling agents, wherein the inorganic nano-meterials adopt one of or several of beryllium oxide, mica, boron nitride, aluminum oxide, diamond, magnesium oxide and graphite; the thermal conductivity coefficient of the high thermal conductivity polyimide film is set as 1-5 Wm-1k-1, and the glass transition temperature is set at 300-380 DEG C. The inorganic nano-materials with the high thermal conductivity are added in the formula of the polyimide film, therefore, the thermal conductivity performance of the polyimide film is improved, the thermal conductivity coefficient of the polyimide film is increased to 1-5 Wm-1k-1 from the original 0.2 Wm-1k-1, and meanwhile the glass transition temperature is lowered to 300-380 DEG C from 400-420 DEG C.

Owner:苏州嘉银新材料科技有限公司

Highly fire-resistant foundry sand for steel casting and preparation method of highly fire-resistant foundry sand

The invention discloses highly fire-resistant foundry sand for steel casting and a preparation method of the highly fire-resistant foundry sand. The highly fire-resistant foundry sand is prepared from the following raw materials in parts by weight: 50-80 parts of fused ceramite, 10-15 parts of high-alumina cement, 17-23 parts of sludge dry powder, 20-30 parts of volcanic tuff, 15-25 parts of dickite, 16-22 parts of natural manganese sand, 8-12 parts of nacrite, 10-15 parts of asbestos powder, 5-10 parts of aluminum dihydrogen tripolyphosphate, 10-15 parts of modified bentonite, 4-8 parts of alumn powder, 3-6 parts of cellulose glycolate, 2.5-4.5 parts of corn syrup, 4.5-6.5 parts of beryllium oxide, 3-5 parts of China wood oil, 4-6 parts of sodium metasilicate, 2-4 parts of polyethylene glycol and an appropriate amount of water. Compared with conventional foundry sand, the highly fire-resistant foundry sand provided by the invention is not only excellent in fire-resistant performance, can maintain a higher strength and relatively low thermal expansion coefficient under high temperature, does not easily cause expansion and breakage, has excellent plasticity, air permeability and collapsibility, can remarkably improve the surface quality of castings and improve the finished product rate of castings.

Owner:江守仲

Low Temperature Method For Hermetically Joining Non-Diffusing Ceramic Materials

ActiveUS20150108203A1Material gluingSemiconductor/solid-state device manufacturingHermetic sealBeryllium oxide

A method for the joining of ceramic pieces with a hermetically sealed joint comprising brazing a layer of joining material between the two pieces. The wetting and flow of the joining material is controlled by the selection of the joining material, the joining temperature, the joining atmosphere, and other factors. The ceramic pieces may be on a non-diffusable type, such as aluminum nitride, alumina, beryllium oxide, and zirconia, and the pieces may be brazed with an aluminum alloy under controlled atmosphere. The joint material is adapted to later withstand both the environments within a process chamber during substrate processing, and the oxygenated atmosphere which may be seen within the shaft of a heater or electrostatic chuck.

Owner:WATLOW ELECTRIC MFG

Thermally-conductive, electrically non-conductive heat transfer material and articles made thereof

InactiveUS7321107B2Improve conductivityLower core temperatureHeater elementsHeating element shapesPlasticizerBoron nitride

A heat transfer material comprised of a polymeric material and a nitride or oxide is provided and is thermally conductive, but electrically non-conductive. The polymeric material may be silicone rubber, and the nitride or oxide may be aluminum nitride, boron nitride, silicon nitride, aluminum oxide or beryllium oxide. The material is made flexible by adding plasticizer and remains flexible after an extended period of use. A dielectric jacket for an electrical heating cable is thermally conductive and remains flexible so that it can be reused. The heat transfer material can be used on heating devices such as steam tubes and panels, where the heat transfer material does not bond to or adhere to the heated surface, which allows the heating device to be reused.

Owner:THERMON INC

Alumina fiber reinforced alumina ceramic matrix composite and preparation method thereof

The present invention discloses an alumina fiber reinforced alumina ceramic matrix composite and a preparation method thereof, the alumina fiber reinforced alumina ceramic matrix composite is characterized by comprising the following raw materials by weight: 40-60 parts of alumina, 20-30 parts of clay, 10-15 parts of modified alumina fiber, 2-3 parts of antimony sulfide, 1-3 parts of beryllium oxide, 0.03-0.05 part of methyl ethyl ketone peroxide, 3-5 parts of vinyl acetate, 0.2-0.4 part of silane coupling agent KH550, 1-2 parts of microcrystalline wax, 1-2 parts of carboxymethyl cellulose, 20-30 parts of ethanol, and 30-40 parts of deionized water; the antioxidant treated alumina fiber added in the alumina fiber reinforced alumina ceramic matrix composite is used as a ceramic reinforcing phase, and has the characteristics of ceramic toughness reinforcing properties, mechanical properties, abrasion resistance, hardness and high temperature resistance, the gel casting technology used in the method can reduce the production cost, and improve the material integrity and machinability, and any shape and size of ceramic structural workpieces can be convenient to produce.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Method for extracting beryllium oxide from low-grade beryllium ore

InactiveCN102168184AIncrease concentrationLow firing temperatureProcess efficiency improvementKeroseneSlag

The invention discloses a method for extracting beryllium oxide from low-grade beryllium ore. The method is characterized by comprising the following steps of: grinding the low-grade beryllium ore, pelletizing, drying, roasting, and crushing to obtain a roasted material; adding concentrated sulfuric acid, stirring, leaching, and separating to obtain acidified liquid and acidified slag; adding the acidified liquid into the other roasted material, and stirring and leaching to obtain primary steep and primary leaching residue; adding concentrated sulfuric acid into the primary leaching residue, adding water, and stirring and leaching to obtain secondary steep and secondary leaching residue, wherein the acidified liquid is replaced by the secondary steep for recycling; extracting the primary steep by adopting an extracting agent in a volume ratio of phosphors extracting agents: alkanol: kerosene of (25-45):(5-1):(50-70) to obtain a beryllium-loaded organic phase and raffinate; washing the beryllium-loaded organic phase by adopting solution of oxalic acid, and performing back extraction by using solution of NaOH to obtain a blank organic phase and stripping solution; and regulating the concentration of hydroxyl ions in the stripping solution to ensure that beryllium is hydrolyzed and precipitated, and calcining a precipitate to obtain the beryllium oxide. The method is easy to operate, the cost is low, the beryllium oxide with the content of over 97 percent is obtained, and the recovery rate of the beryllium is about 80 percent. The method is suitable for extracting the beryllium oxide from low-grade beryllium ore with low BeO content and high CaF2 content.

Owner:广东省资源综合利用研究所

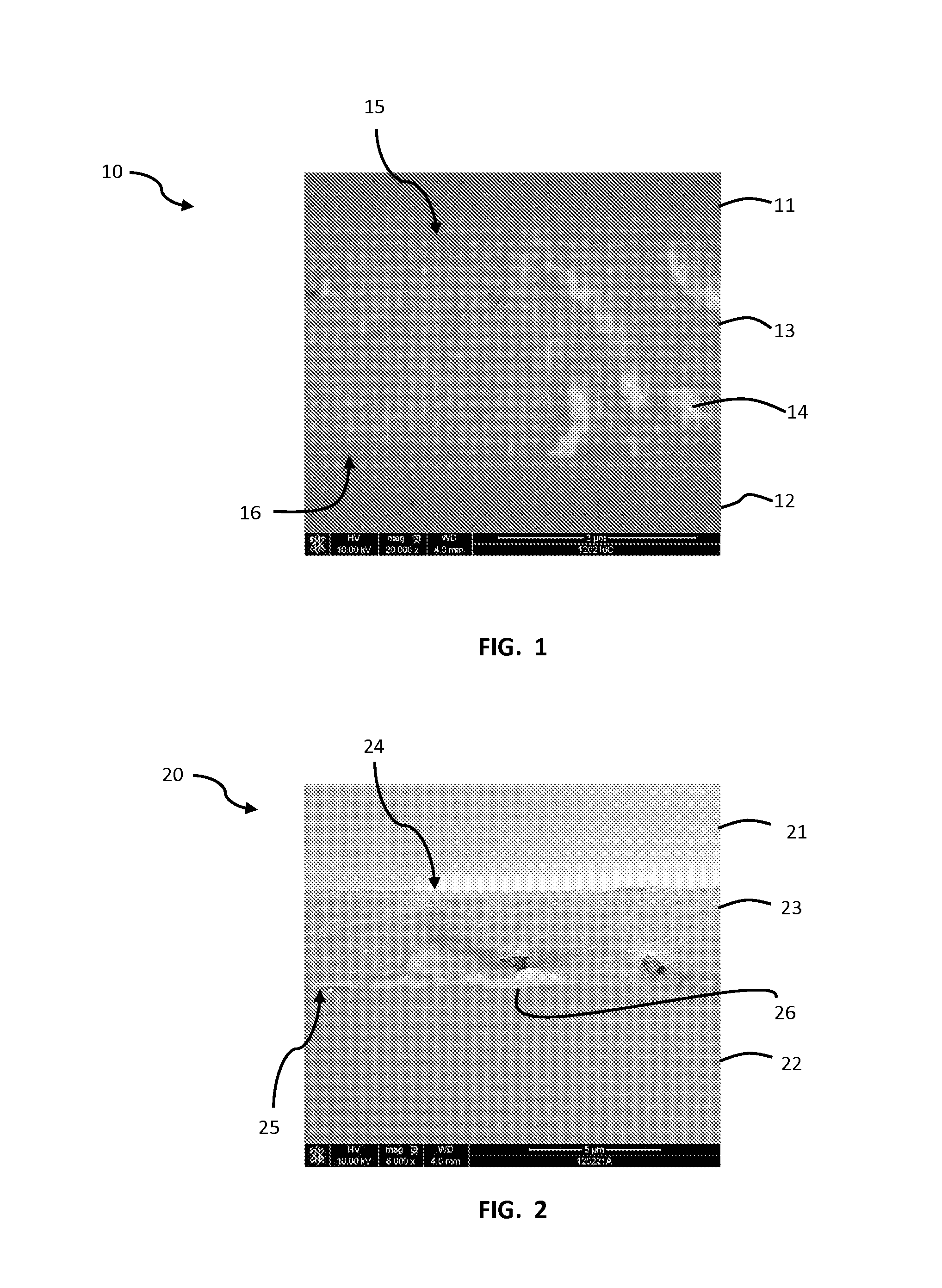

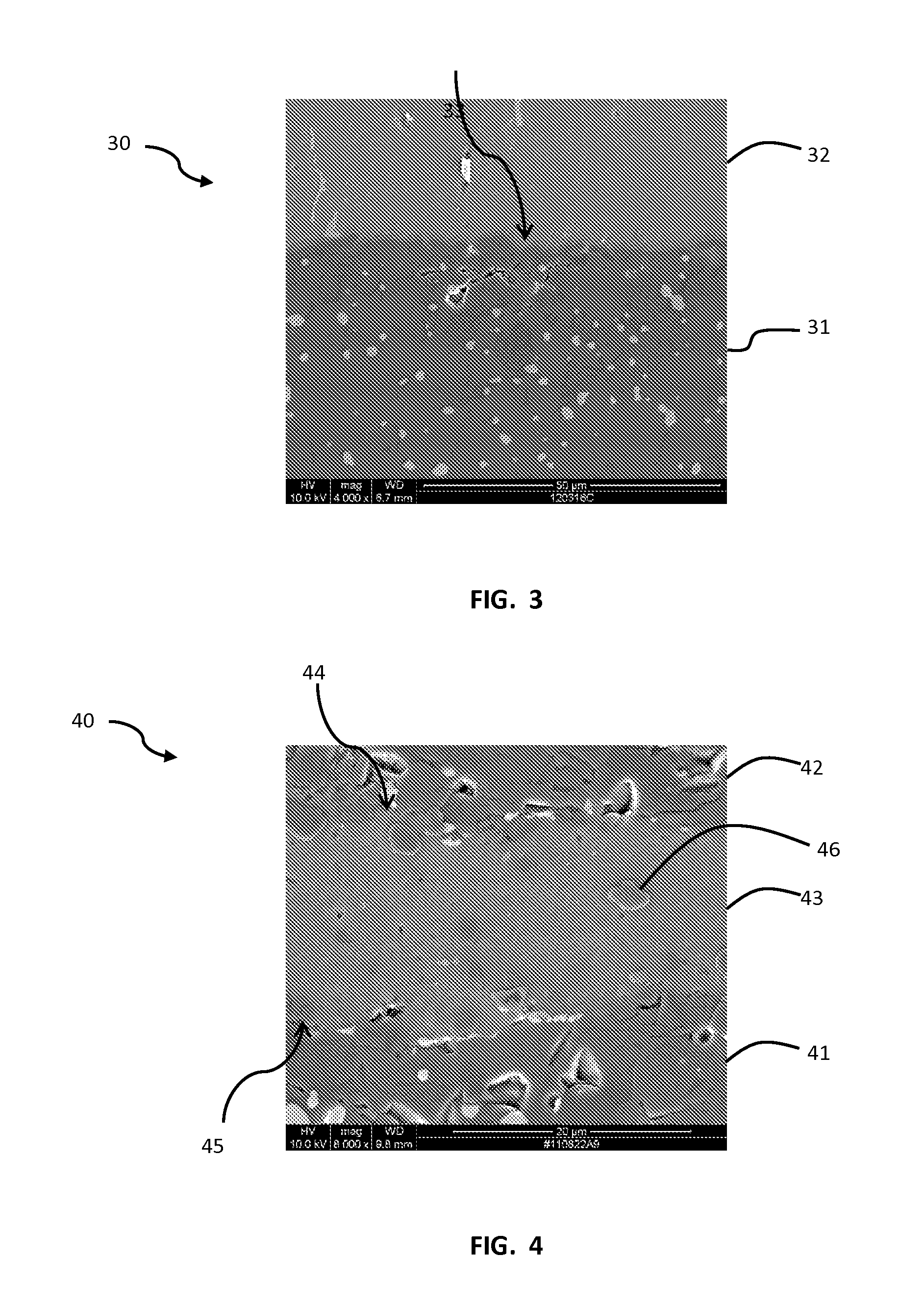

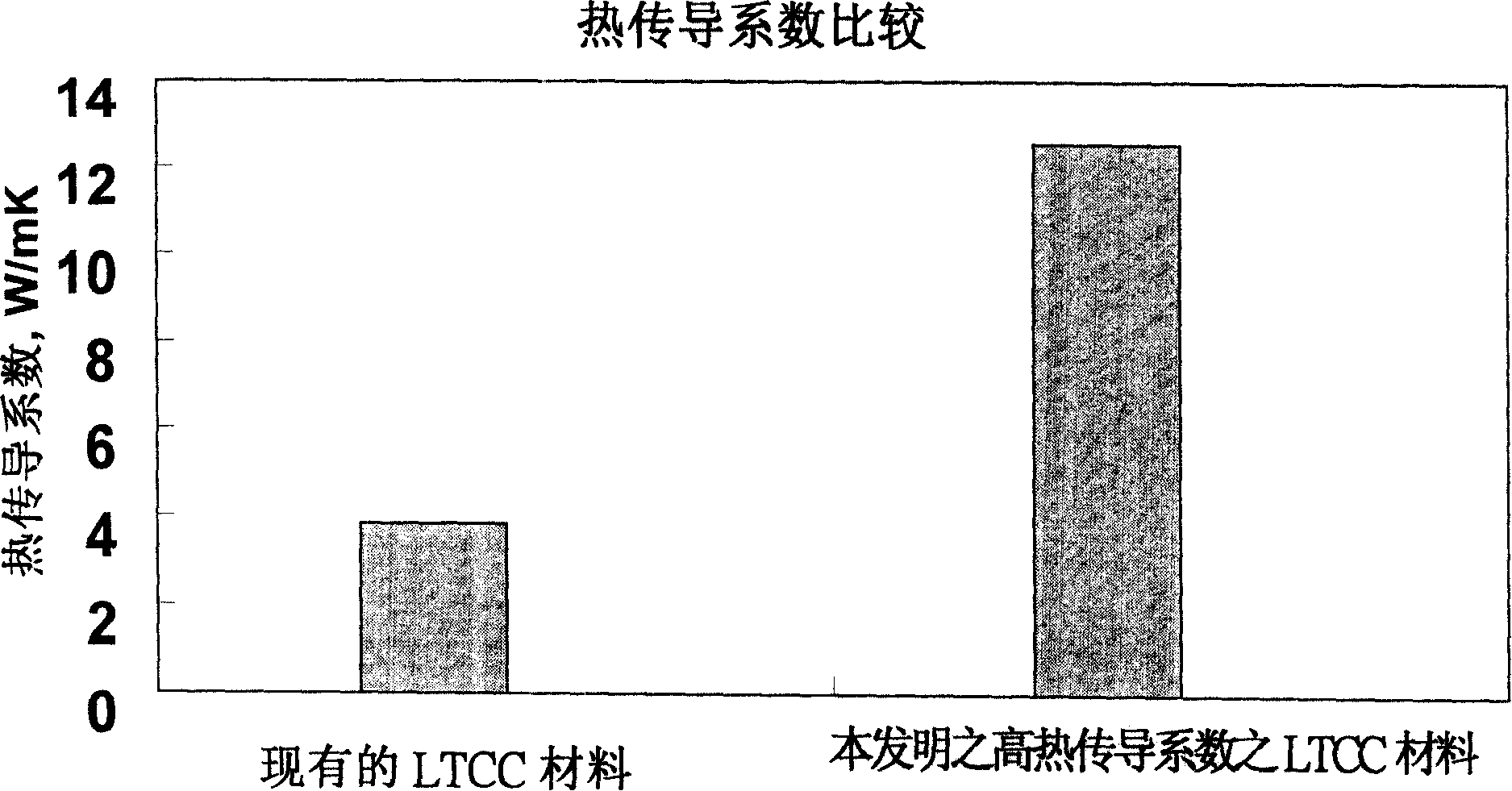

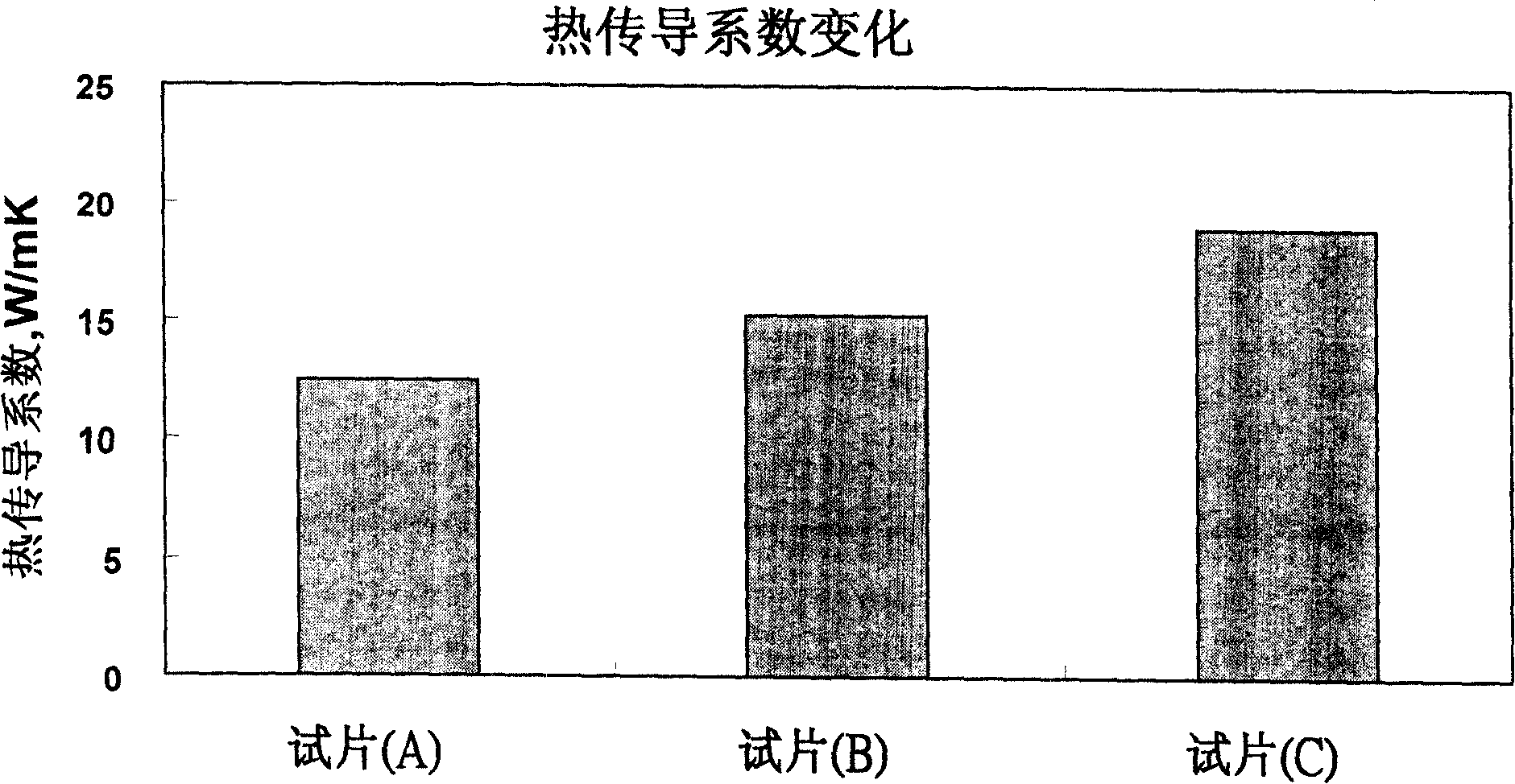

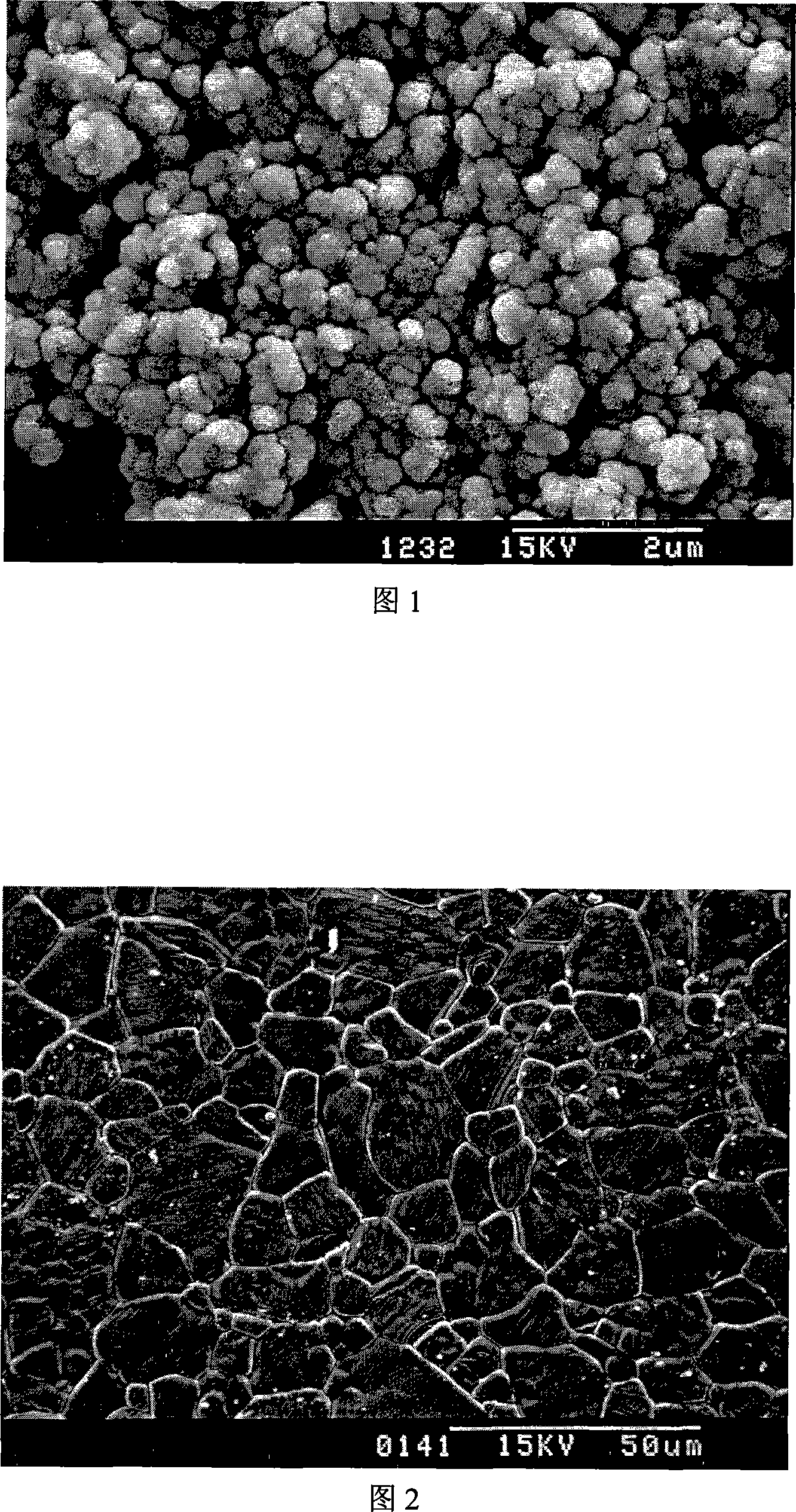

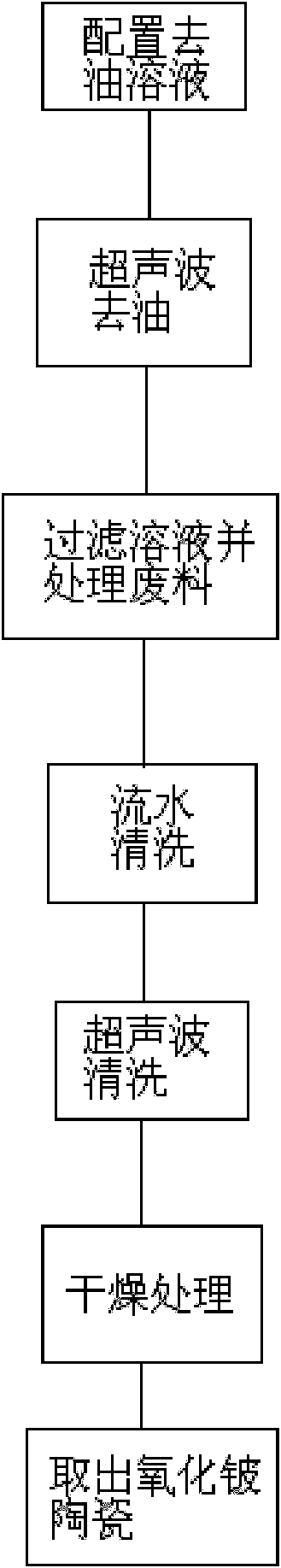

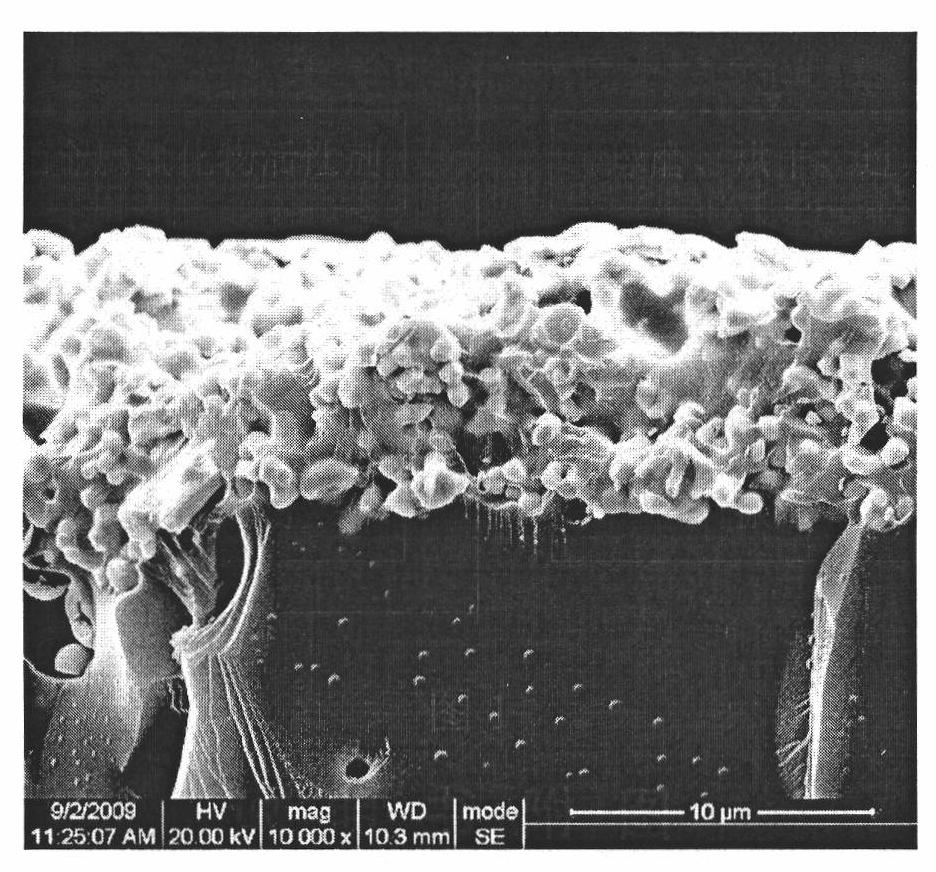

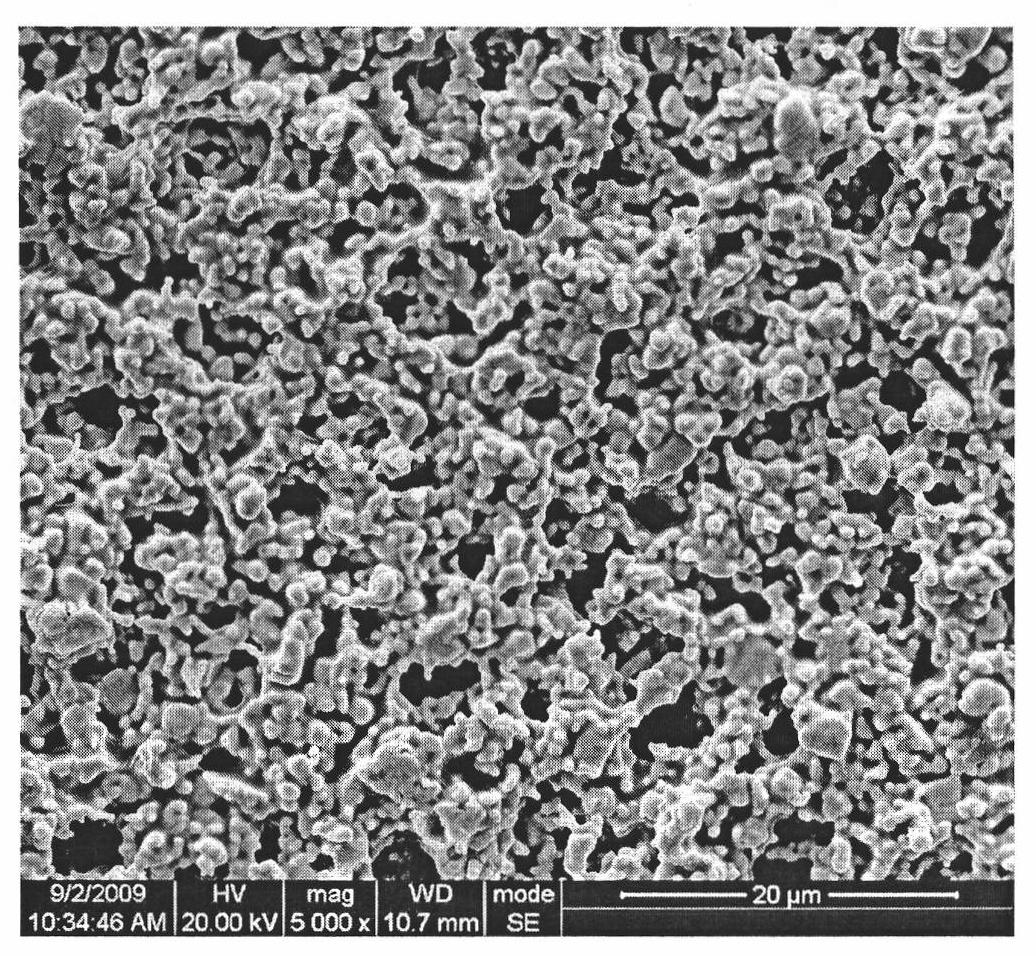

Multi-component doping high-performance beryllium oxide ceramic material and preparation method

The invention belongs to the technical field of electronic materials. Multi-element doped high-performance beryllium oxide ceramic material, in addition to beryllium oxide, also includes 0.2-0.6% by mass of multi-element dopant; said multi-element dopant is composed of MgO, Al2O3, SiO2, CaO, ZnO and rare earth oxides , the mass percentage content of each component is: MgO: 5-60%, Al2O3: 0-40%, SiO2: 20-95%, CaO: 0.1-0.5%, ZnO: 0-0.5%, containing Y, La, Single or random mixed rare earth oxides of Ce or Sm: 0.01-0.5%. The multi-element dopant is prepared by a sol-gel method, and then mixed with a high-purity beryllium oxide raw material, shaped and sintered at a high temperature to obtain the multi-element doped high-performance beryllium oxide ceramic material of the present invention. The multi-component doped high-performance beryllium oxide ceramic material provided by the invention has lower sintering temperature, higher density, thermal conductivity and mechanical properties; its microstructure has the characteristics of compactness, uniform crystal grains and few pores. The preparation method has simple process, low production cost and good repeatability, and is suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Chemical metallurgy method for extracting beryllium oxide from chrysoberyl

InactiveCN103088206AFully consider the protectionFully consider the comprehensive utilizationProcess efficiency improvementWater vaporDump leaching

The invention discloses a chemical metallurgy method for extracting beryllium oxide from chrysoberyl. The chemical metallurgy method is a comprehensive treatment technology for carrying out chemical metallurgy on refractory chrysoberyl with not more than 0.5% of Be. The chemical metallurgy method is characterized by comprising the following steps of: carrying out structural transformation roasting on the minerals by using ammonium fluosilicate as a structural transforming agent in the presence of activator limestone; cooling the roasted minerals and using water to spray dump leaching beryllium; precipitating beryllium for the ammonium fluoroberyllate solution by using ammonium bicarbonate to obtain basic beryllium carbonate; calcining the basic beryllium carbonate to release carbon dioxide and water vapor to obtain the product beryllium oxide; and concentrating and crystallizing a beryllium-precipitated solution which is the beryllium fluoride solution under reduced pressure, and drying the concentrated and crystallized solution in air flow to obtain the product ammonium fluoride. The chemical metallurgy method disclosed by the invention is simple in process, low in price, free of pollution, high in metal recovery rate, low in production cost and capable of effectively separating and extracting beryllium in the chrysoberyl.

Owner:戴元宁

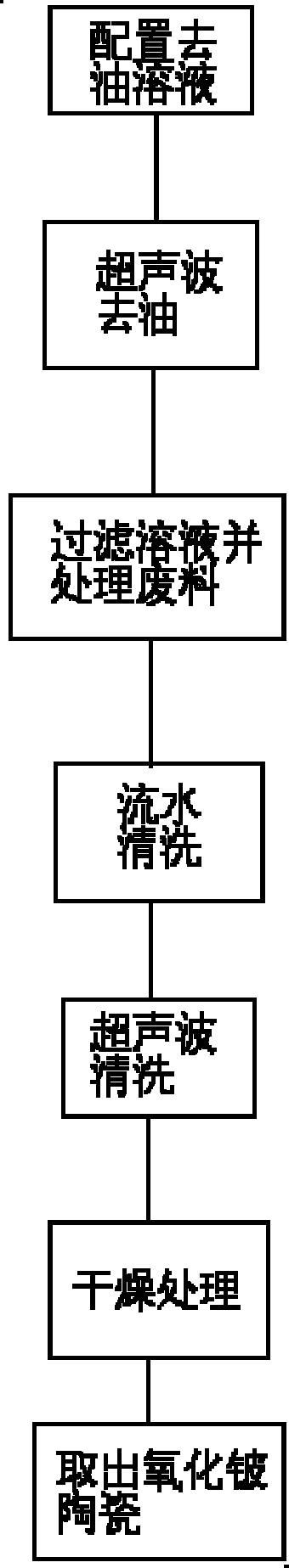

Cleaning process of beryllium oxide ceramic

ActiveCN102166575AEffectively wash offReduce harmDrying gas arrangementsCleaning using liquidsBeryllium oxideMaterials science

The invention discloses a cleaning process of beryllium oxide ceramic. The process has the following process flow of: preparing oil-removing solution, removing oil with ultrasonic waves, filtering the solution and treating scrap materials, cleaning with flowing water, cleaning with the ultrasonic waves, drying, and taking the beryllium oxide ceramic out. The cleaning process is simple, easy to realize and low in cost; toxic dust attached to the beryllium oxide can be effectively washed off; and the hurt to a human body caused by the beryllium oxide is reduced.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

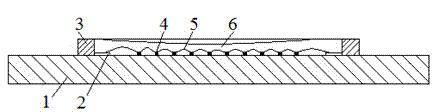

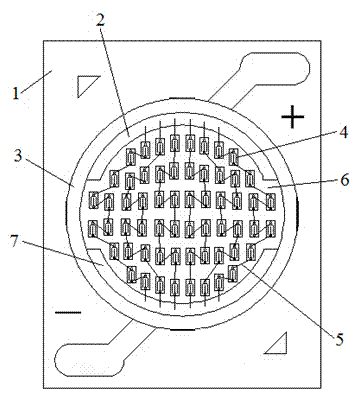

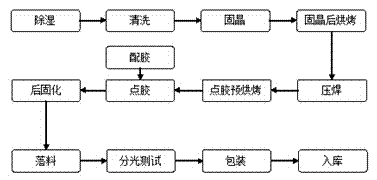

COB type LED packing piece based on beryllium oxide ceramic substrate and production method

ActiveCN104332550AImprove cooling effectReduce volumeSolid-state devicesSemiconductor devicesHemt circuitsBeryllium oxide

The invention provides a COB type LED packing piece based on beryllium oxide ceramic substrate and production method, and the packing piece comprises a substrate made of the beryllium oxide ceramic board, a box dam and two symmetrical electrodes are formed on the substrate; a plurality of series circuits not crossed to each other and composed of light-emitting diode are formed in the substrate solid crystal region, two ends of each series circuit are respectively connected to two electrodes, the fluorescent powder glue is fixedly sealed in the box dam. The COB type LED packing piece based on beryllium oxide ceramic substrate is prepared by the steps as follows: cleaning beryllium oxide ceramic board, screen-printing the electrode, high temperature sintering, manufacturing the box dam, baking and dehumidifying, plasma cleaning, pasting LED chip, baking, bonding, baking, coating fluorescent powder glue in the box dam and solidifying, blanking, spectral testing, packaging and putting in storage. The beryllium oxide substrate is applied to the LED in the LED packing piece with good heat radiation capability, the high power LED packing product is small in volume, light in weight and high in reliability.

Owner:广东韶华科技有限公司

Preparation method of beryllium oxide modified uranium dioxide nuclear fuel

ActiveCN107221359AImprove high temperatureImprove stabilityNuclear energy generationReactor fuel susbtancesNetwork structureBeryllium oxide

The invention discloses a preparation method of a beryllium oxide modified uranium dioxide nuclear fuel. The preparation method comprises the following steps: extremely uniformly coating the surfaces of UO2 particles with BeO micro-powder through a spheroidizing and cladding technology, shaping the coated UO2 particles to make BeO extremely uniformly dispersed in a UO2 matrix, and carrying out high temperature sintering for a long time to locally melt the BeO in UO2 particle gaps and realize intercommunication in order to form a three-dimensional network structure and finally obtain the BeO modified UO2 nuclear fuel containing uniform distributed BeO and having a BeO and UO2 matrix formed interpenetrating network structure. The BeO enhancement phase of the three-dimensional network structure provides a rapid channel for heat conduction, so the heat conductivity of a BeO / UO2 composite core is maximally improved; and the UO2 matrix and the BeO of the three-dimensional network structure are interlaced, and can well support and constrain the BeO enhancement phase in a high temperature radiation environment, so the high temperature stability and the radiation resistance of the core are well guaranteed.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

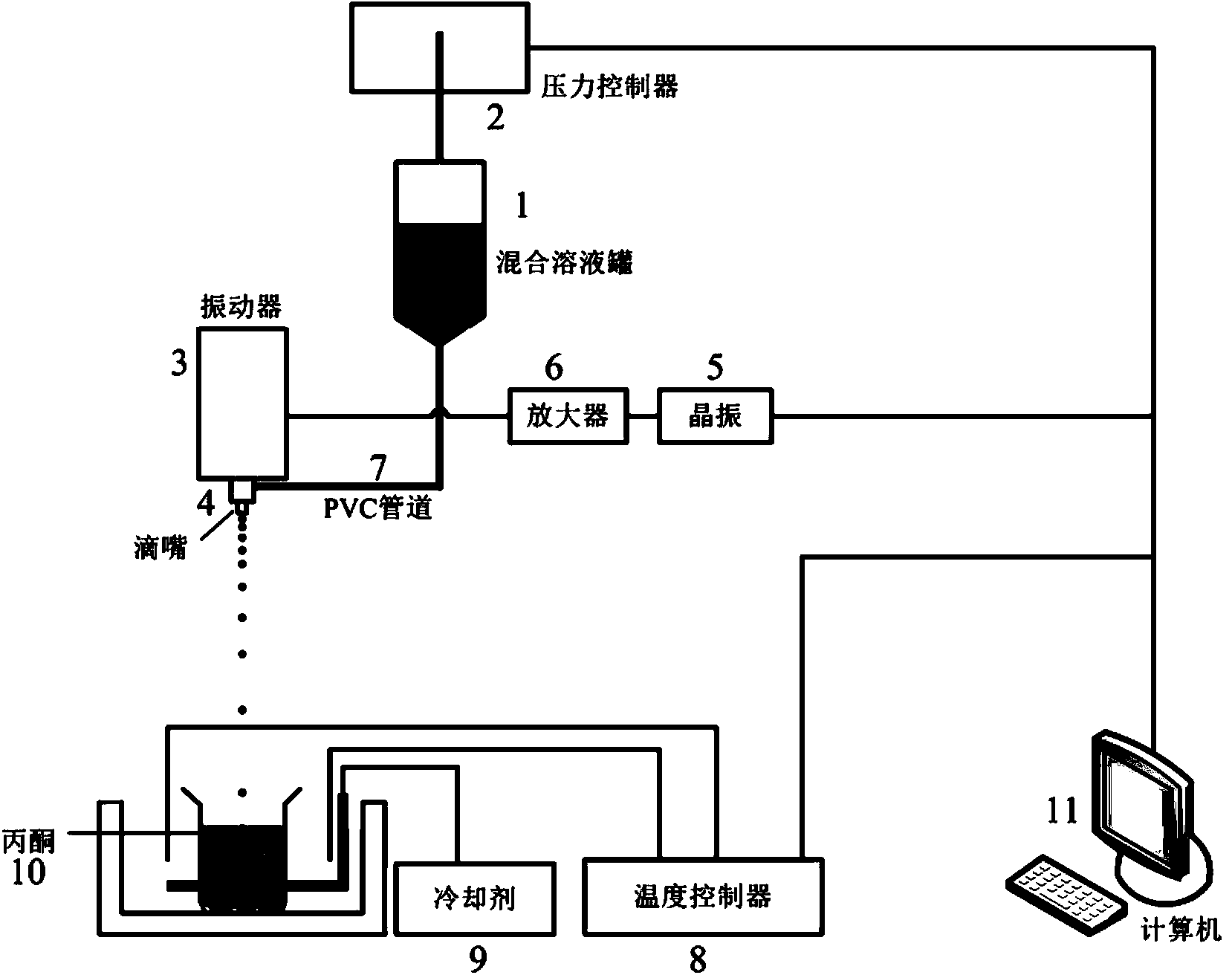

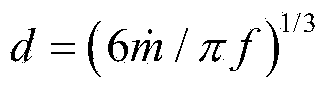

Preparation method of fusion reactor cladding neutrons and tritium breeding agent beryllium acid lithium pellets

InactiveCN103854706ASolve self-sustaining problemsImprove utilization efficiencyNuclear energy generationThermonuclear fusion reactorLithium hydroxideLithium titanate

The invention discloses a preparation method of fusion reactor cladding neutrons and tritium breeding agent beryllium acid lithium pellets. The preparation method of the fusion reactor cladding neutrons and tritium breeding agent beryllium acid lithium pellets comprises the following steps: preparing a beryllium acid lithium material, representing, preparing beryllium acid lithium pellets with the diameter of 1mm, detecting performances, preparing lithium hydroxide and beryllium oxide raw materials at room temperature, putting into a container according to the proportion of 1 of Li / Bi molecule mole ratio, rotating and stirring for about 20 hours, mixing fully and uniformly, putting dried gel in a sintering furnace, warming to 1073K under an air environment, forging for 5 hours, and carrying out solid phase reaction fully; taking a beryllium acid lithium sample, grinding fully into particles, analyzing the formation of components by adopting XDR (external data representation; analyzing the Li / Bi mole ratio by adopting ICP-AES (inductively coupled plasma-atomic emission spectrometry). According to the invention, the problem that when lithium silicate or lithium titanate pellets are originally adopted as breeding agents, a plurality of layers of beryllium zone breeding neutrons are required to be arranged in a cladding is overcome, so that the utilization efficiency of breeding agents in a limited space of the cladding is improved extremely, and the fusion reactor tritium self-sustaining difficulty can be solved effectively.

Owner:中国人民解放军陆军军官学院

Rapid preparation method of beryllium oxide-enhanced uranium dioxide nuclear fuel

ActiveCN107274936ALow densityReduce intensityNuclear energy generationReactor fuel susbtancesBeryllium oxideCore shell

The invention discloses a rapid preparation method of beryllium oxide-enhanced uranium dioxide nuclear fuel. The preparation method comprises preparing BeO-coated UO2(UO2 / BeO) core-shell structure particles through SPS low-temperature rapid pre-sintering granulation, spheroidization and coating processes, and carrying out SPS rapid sintering on the core-shell structure particles to obtain a UO2 / BeO composite nuclear fuel pellet. The preparation method is fast and efficient. The beryllium oxide-enhanced uranium dioxide nuclear fuel can solve the problem that the existing UO2 fuel pellet has low thermal conductivity.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Ceramic substrate for LEDs

The invention discloses a ceramic substrate for LEDs. Various raw materials used in the LTCC preparation technology are optimized, aluminum nitride, boron nitride, alumina and beryllium oxides serve as the main raw materials, meanwhile, glass sintering additives, copper and aluminum alloy nano-particles, rare earth oxides, solvents, plasticizer, dispersant, binder and other additives are added, and the physical and chemical properties of the ceramic substrate are further optimized. The thermal conductivity of the ceramic substrate is larger than 400 W / (m*k), the bending strength is larger than 300 Mpa, and the dielectric constant is smaller than 2. Meanwhile, due to a conventional LTCC preparation method, the main raw materials and the additives can be prepared into the high-conductivity ceramic substrate, the preparation technology is simple, and industrialization is facilitated.

Owner:GANSU RONGBAO IND GRP

Environmentally safe electrochromic mirrors

InactiveUS7733555B2Increase surface areaGood lookingNon-linear opticsOptical viewingElectricityAntimony compounds

This invention recognizes the hazards of beryllium and beryllium oxide in automotive applications and offers alternative material solutions. In particular, commercial electrochromic mirrors use beryllium comprising alloys for busbars and may also use beryllium oxide for the electronics used to power and control these mirrors. Further, this can be combined by reducing other known hazards such as mercury, cadmium, lead and antimony compounds.

Owner:AJJER

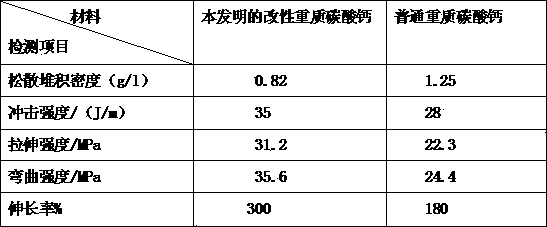

Modified calcium carbonate for floor tiles and preparation method thereof

ActiveCN103408797AUniform particle sizeLarge specific surface areaInorganic pigment treatmentSodium phosphatesModified carbon

The invention provides a modified calcium carbonate for floor tiles, which is prepared from the following raw materials in parts by weight: 95-100 parts of 400-mesh ground calcium carbonate, 0.2-0.4 part of magnesium oxide, 0.1-0.4 part of sodium tripolyphosphate, 0.1-0.2 part of silane coupling agent, 2-4 parts of fatty glyceride, 0.3-0.5 part of beryllium oxide, 1-3 parts of EVA (ethylene-vinyl acetate) resin, 0.2-0.4 part of molybdenum oxide, 0.6-0.8 part of hollow glass microsphere and 0.8-1.0 part of bamboo charcoal. The preparation method comprises the following steps: mixing part of materials, drying calcium carbonate, mixing, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable heat insulation property, and can lower the cost and enhance the working properties and heat insulation property of the product when being used in floor tiles.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

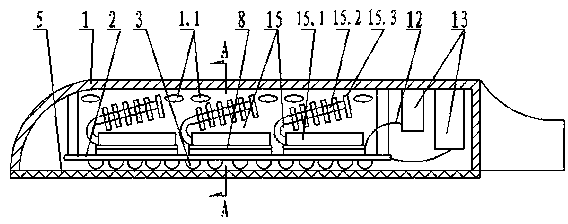

Low-light-degradation and high-power LED street lamp and manufacturing method thereof

ActiveCN103398358AEasy to identifyAvoid the phenomenon of reduced work efficiencyMechanical apparatusPoint-like light sourceEngineeringGraphene

The invention discloses a low-light-degradation and high-power LED street lamp and a manufacturing method thereof. According to the low-light-degradation and high-power LED street lamp and the manufacturing method thereof, color code marks are arranged on the tail end faces of N type semiconductor elements or on the tail end faces of P type semiconductor elements, wherein the N type semiconductor elements and the P type semiconductor elements are manufactured in advance; the N type semiconductor elements and the P type semiconductor elements are arranged between an upper beryllium oxide ceramic wafer with a conductive circuit and a lower beryllium oxide ceramic wafer with a conductive circuit in a matrix mode, and the head end of each N type semiconductor element is made to be connected with the tail end of a corresponding P type semiconductor element or the tail end of each N type semiconductor element is made to be connected with the head end of a corresponding P type semiconductor element, wherein the N type semiconductor elements and the P type semiconductor elements are connected in series; the lower beryllium oxide ceramic wafer is then attached to the back side of a circuit board through a graphene heat conductive grease layer, wherein LED bulbs are installed on the circuit board; a radiator is installed on the upper beryllium oxide ceramic wafer; the circuit board together with the radiator is installed in a street lamp shade. The low-light-degradation and high-power LED street lamp and the manufacturing method thereof have the advantages that the radiating effect is good, light degradation is avoided when an LED light source works, the service life is long, cost is low, and the energy-saving effect is obvious.

Owner:陈志明 +2

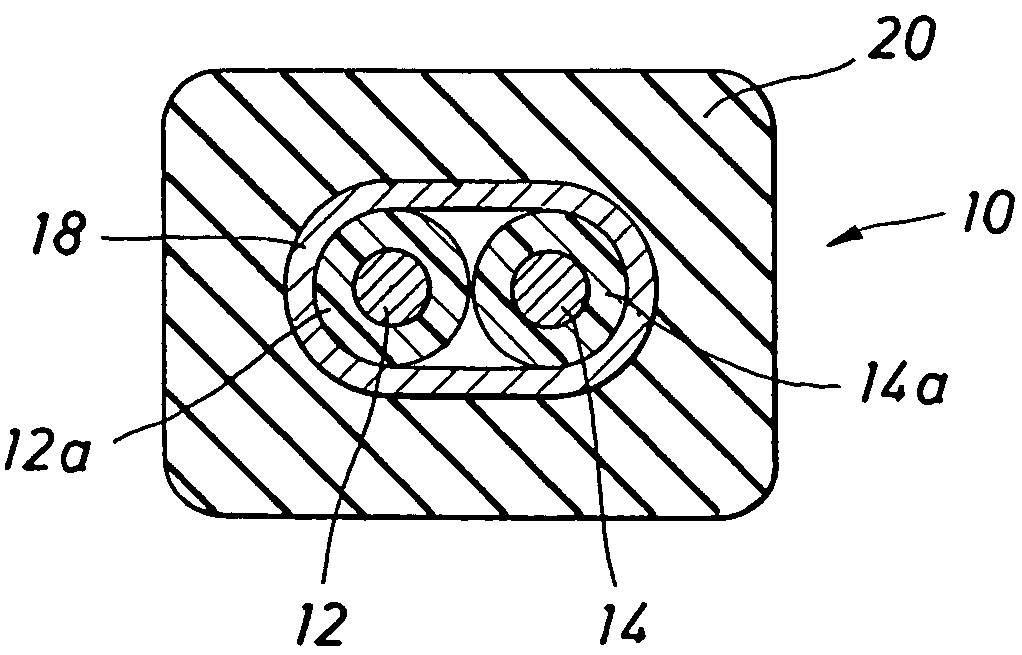

CO2 waveguide laser with beryllium oxide waveguides

ActiveUS7046709B2Active medium materialActive medium shape and constructionMicrometerWaveguide lasers

A pulsed, Q-switched, waveguide CO2 laser includes a plurality of waveguide channels formed in a block of a beryllium oxide ceramic material and is operated at a wavelength between about 9.2 and 9.7 micrometers. The laser has an output power up to 55% greater than that of a similarly configured laser, operated at the same wavelength and pulse conditions, but wherein the waveguide channels are formed in a block of an alumina ceramic material.

Owner:COHERENT INC

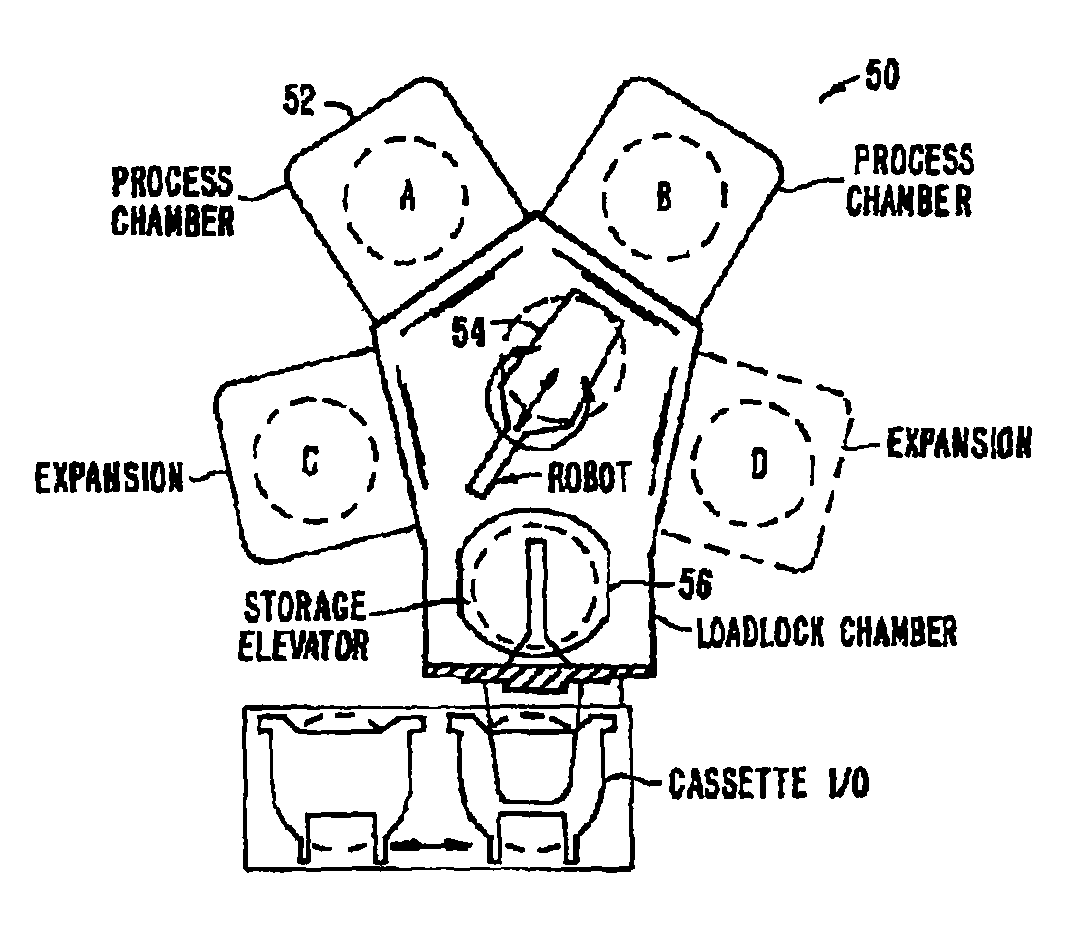

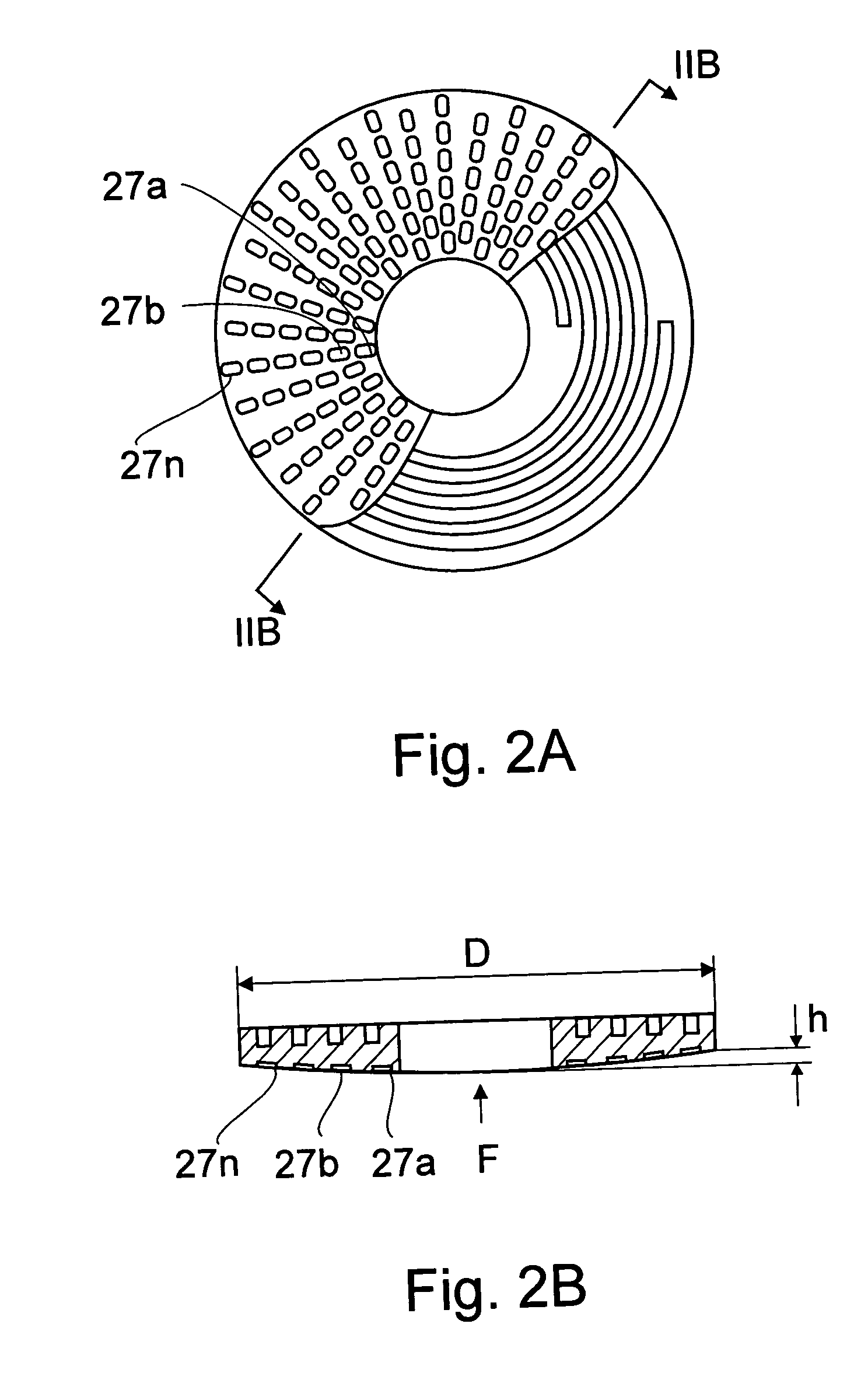

Ceramic cover wafers of aluminum nitride or beryllium oxide

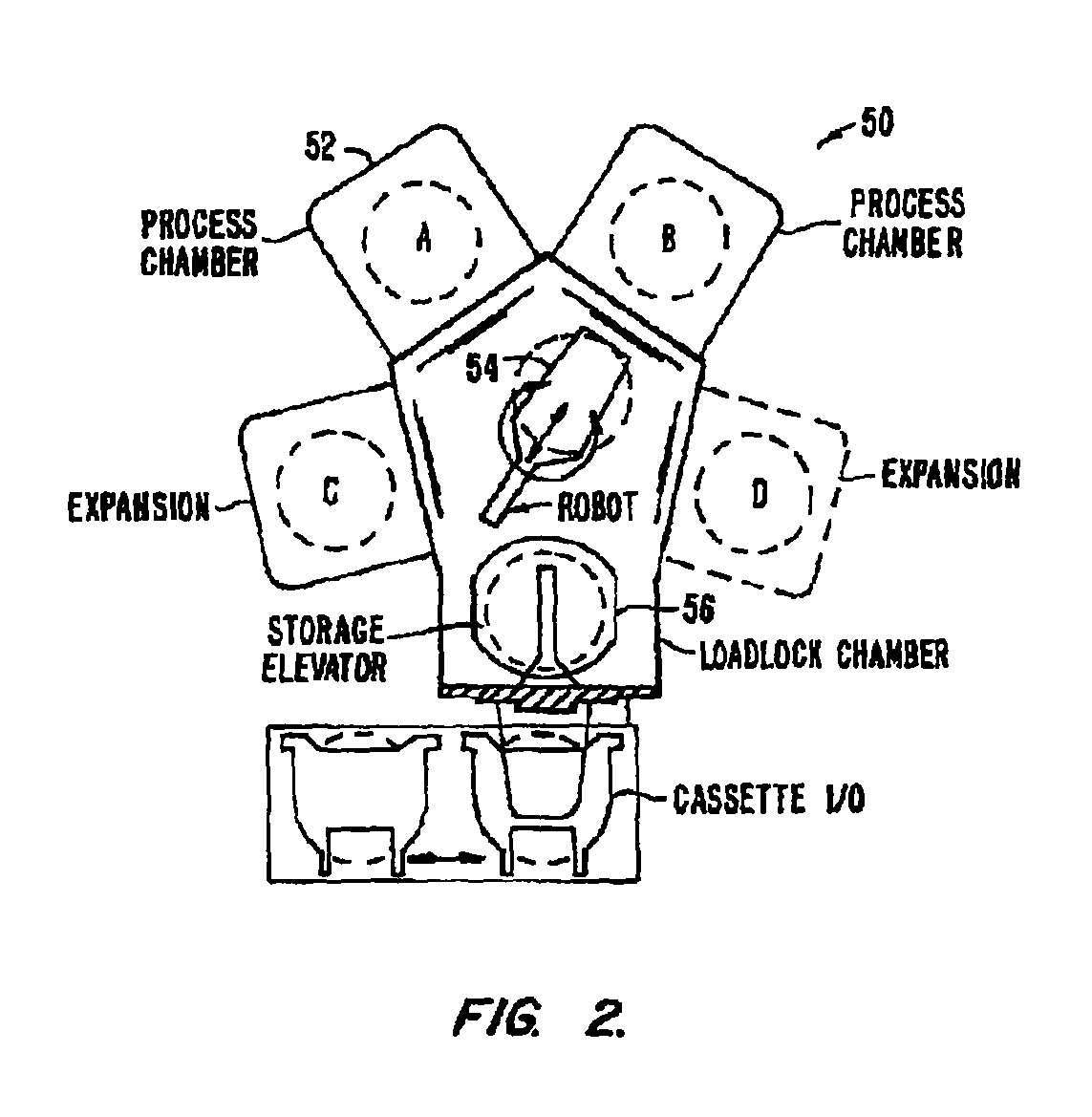

ActiveUS8252410B2Extended service lifeReduce the number of timesSynthetic resin layered productsSemiconductor/solid-state device manufacturingSusceptorCleansing Agents

Embodiments of the invention provide a method and apparatus for protecting a susceptor during a cleaning operation by loading a ceramic cover substrate containing either aluminum nitride or beryllium oxide onto the susceptor before introducing the cleaning agent into the chamber. In one embodiment, an aluminum nitride ceramic cover substrate is provided which includes an aluminum nitride ceramic wafer having a thermal conductivity of greater than 160 W / m-K, a circular-shaped geometry having a diameter within a range from about 11 inches to about 13 inches, a thickness within a range from about 0.030 inches to about 0.060 inches, and a flatness of about 0.010 inches or less. The thermal conductivity may be about 180 W / m-K, about 190 W / m-K, or greater. The thickness may be within a range from about 0.035 inches to about 0.050 inches, and the flatness may be about 0.008 inches, about 0.006 inches, or less.

Owner:APPLIED MATERIALS INC

Self-lubricating wear-resistant ceramic for cutting tools and preparation method thereof

ActiveCN104387071AImprove high temperature resistanceImprove carrying capacityPolyoxyethylene castor oilWear resistant

The invention relates to a self-lubricating wear-resistant ceramic for cutting tools, which is prepared from the following raw materials in parts by weight: 2-3 parts of bismuth sulfide, 2-3 parts of diethanolamine, 2-3 parts of ammonium sulfate, 2-3 parts of magnesium chloride, 2-3 parts of calcium carbide sludge, 2-3 parts of graphene oxide, 0.6-0.8 part of KOH, 0.2-0.3 part of polyoxyethylene castor oil, 3-4 parts of magnesium oxide, 36-40 parts of titanium boride, 4-5 parts of nano tungsten trioxide, 30-35 parts of titanium carbide, 3-5 parts of beryllium oxide, 1-2 parts of silver powder, a right amount of ethanol, a right amount of deionized water, 1-1.5 parts of polyacrylic acid, 1.2-1.6 parts of polyethyleneglycol and 4-5 parts of antiwear assistant. The added nano tungsten trioxide enhances the high temperature resistance of the ceramic. The ceramic has the characteristics of high temperature resistance, high carrying capacity, self lubrication, thermal shock resistance, high wear resistance and the like, and is suitable for manufacturing cutting tools. The antiwear assistant can enhance the wear resistance and heat resistance of the ceramic.

Owner:枣庄科顺数码有限公司

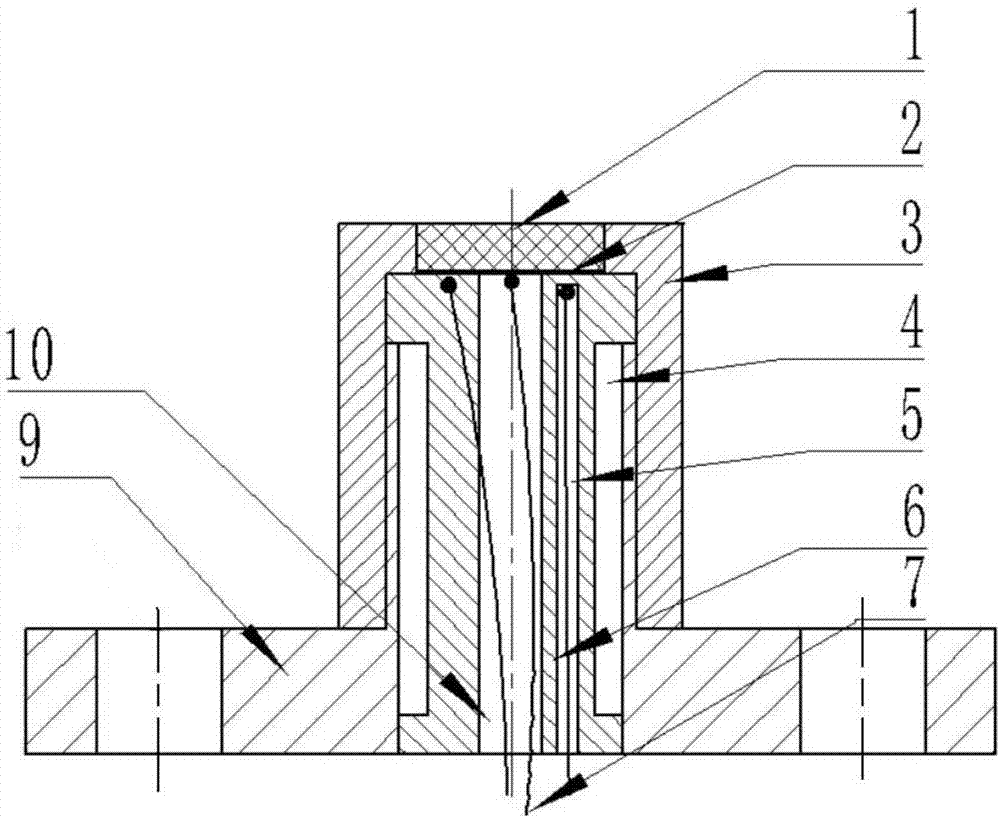

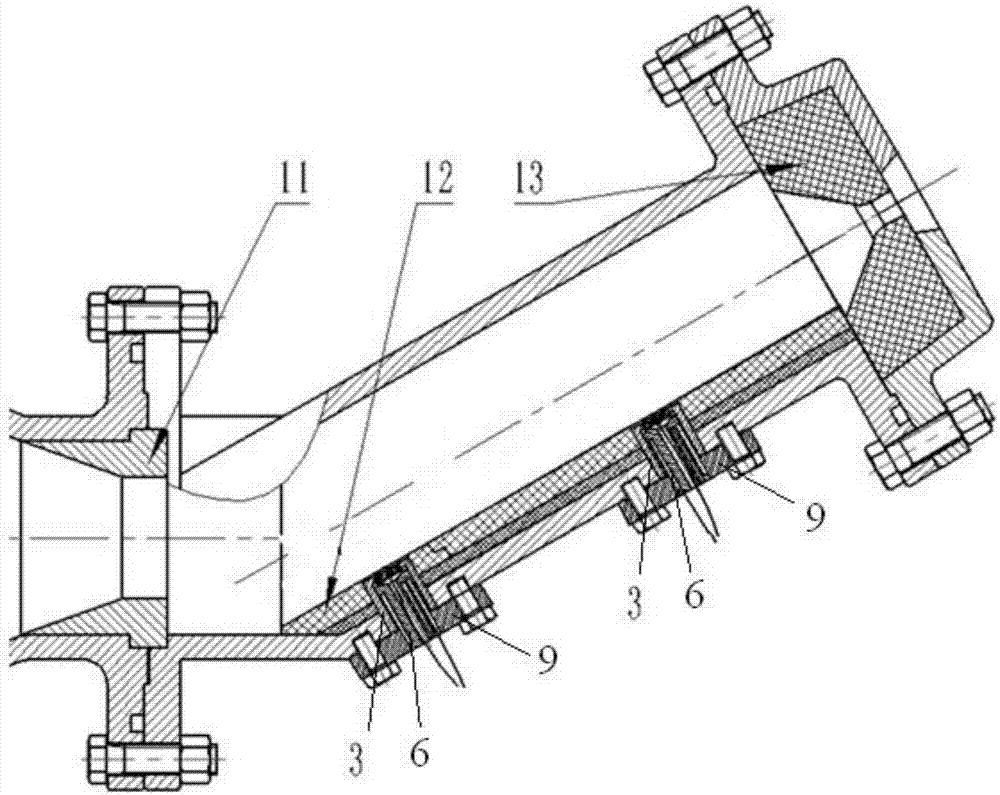

Heat-flow meter for measuring heat flux of aluminium oxide inside solid rocket engine dynamically in real-time

The invention discloses a heat-flow meter for measuring heat flux of aluminium oxide inside a solid rocket engine dynamically in real-time. The heat-flow meter comprises a heat-flow meter body including a cylindrical heat-sink copper piece and a constantan piece that are arranged coaxially. A thermal-insulation ceramic plate that is used for cooling high-temperature heat flux at the surface of the constantan piece is arranged at the top of the constantan piece coaxially; and the outer sides of the thermal-insulation ceramic plate, the constantan piece, and the heat-sink copper piece are coated with a beryllium-oxide ceramic housing and the thermal-insulation ceramic plate is fixed at the top of the constantan piece by the beryllium-oxide ceramic housing. The beryllium-oxide ceramic housing is used for guiding one part of heat flux to the matrix of the heat-sink copper piece. A heat-sink copper hole is formed along the axis direction inside the heat-sink copper piece; and a thermocouple for measuring the top temperature of the heat-sink copper piece is installed approaching the constantan piece inside the heat-sink copper hole. Therefore, a problem that condensed-phase particle washing or density measurement of disposition heat flux inside a solid rocket engine can not be realized on the high-temperature, high-pressure, and high-heat-flux conditions can be solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

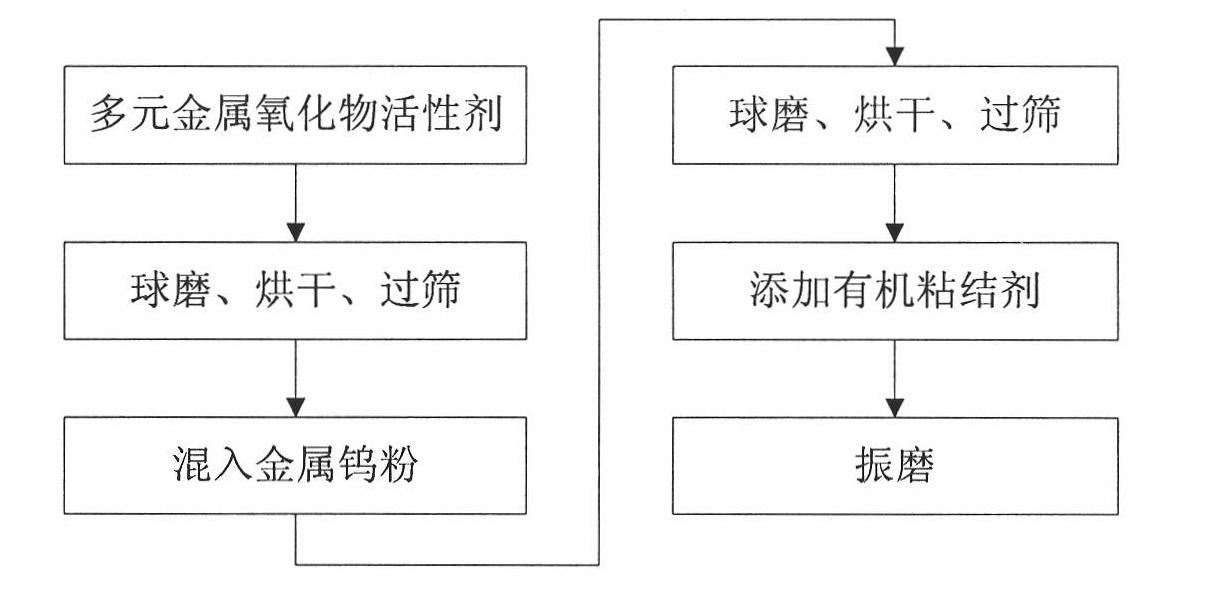

99BeO ceramic metallizing slurry and preparation method thereof

The invention discloses a 99BeO ceramic metallizing slurry and a preparation method thereof, belonging to the technical field of electronic material. The 99BeO ceramic metallizing slurry consists of 60-70% of metallizing raw material by mass and 30%-40% of organic adhesive. The metallizing raw material consists of 70-90% of metal W by mass and 10-30% of multi-element metal oxide active agent by mass. The multi-element metal oxide active agent consists of MgO, Al2O3, SiO2 and more than one oxides containing Sm, Nd, Pr or Tb. The preparation method comprises the steps: at first, preparing the multi-element metal oxide active agent with raw materials like MgO, Al2O3, SiO2, etc. by ball milling; then mixing the multi-element metal oxide active agent with metal tungsten powder, followed by ball milling and drying so as to obtain the metallizing raw material; and finally mixing the metallizing raw material with the organic adhesive, followed by vibration milling so as to obtain the metallizing slurry. When the metallizing slurry provided by the method is used to metallize the surface of 99 beryllium oxide ceramic, the sintering temperature of metallization can be lowered, and the metallized layer on the surface of beryllium oxide ceramic devices has higher tensile strength and thermal conductivity; and simultaneously, the preparation method thereof is simple in process, low in cost, excellent in repeatability and suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

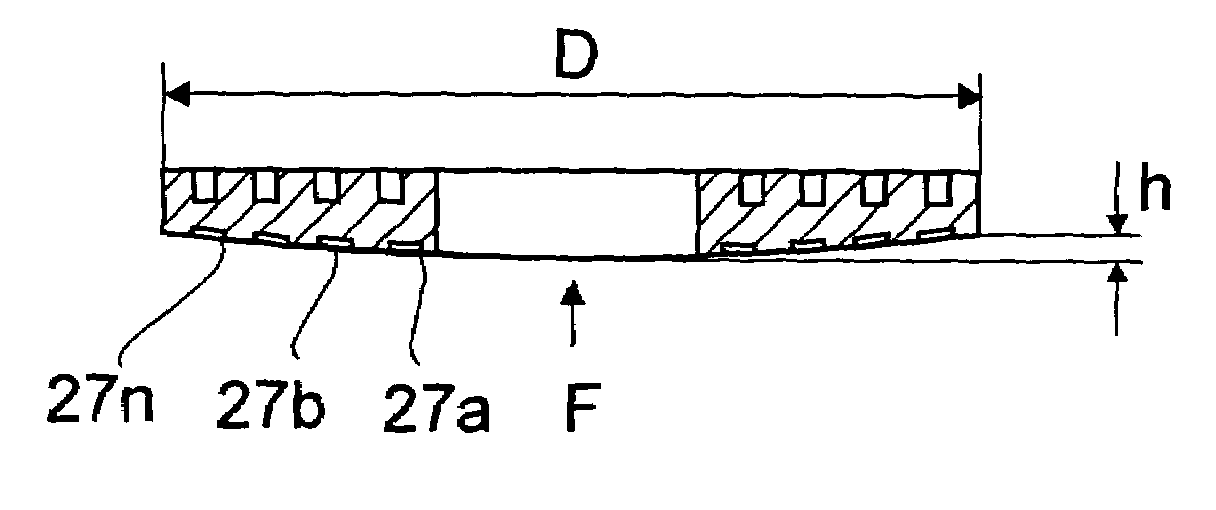

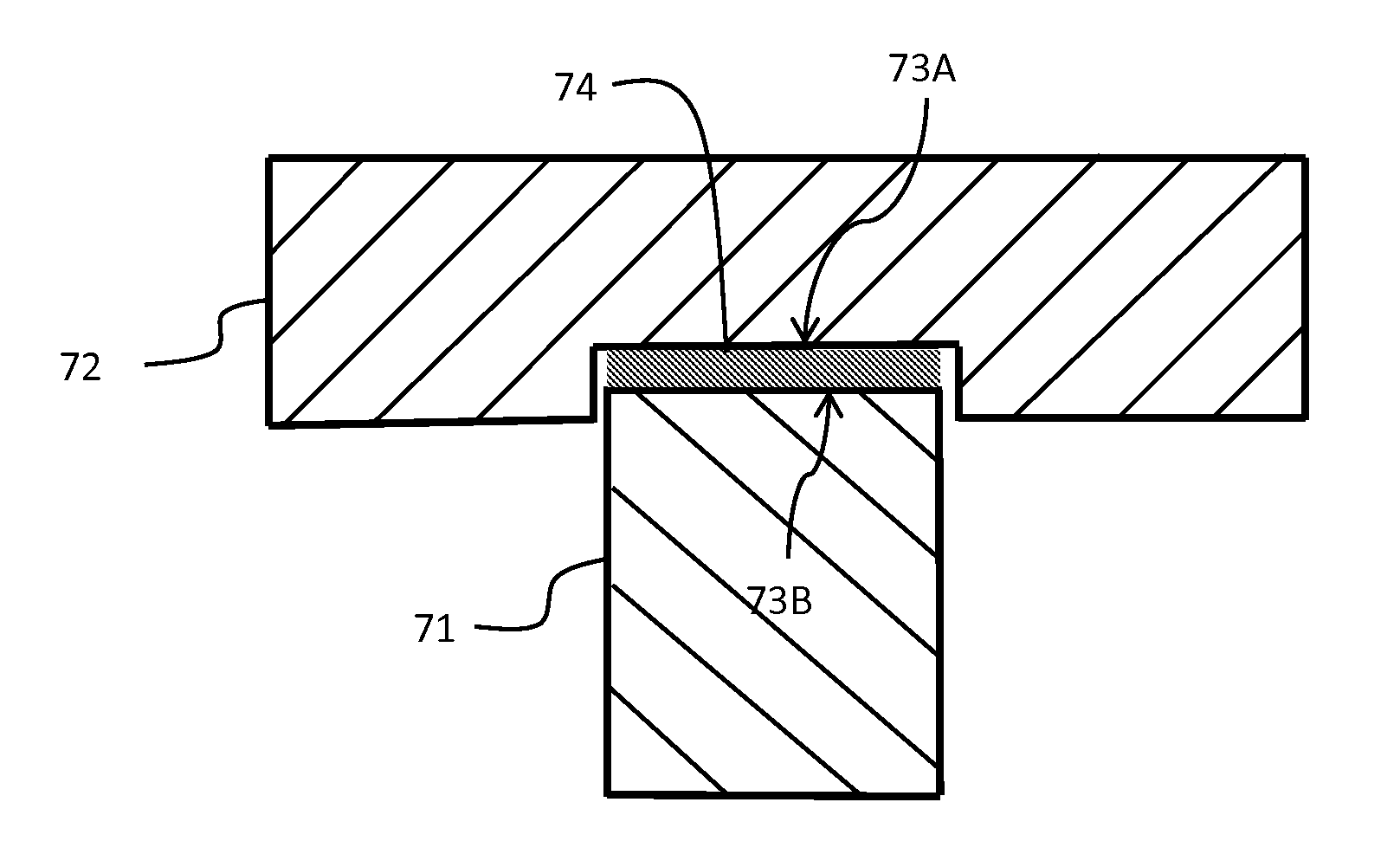

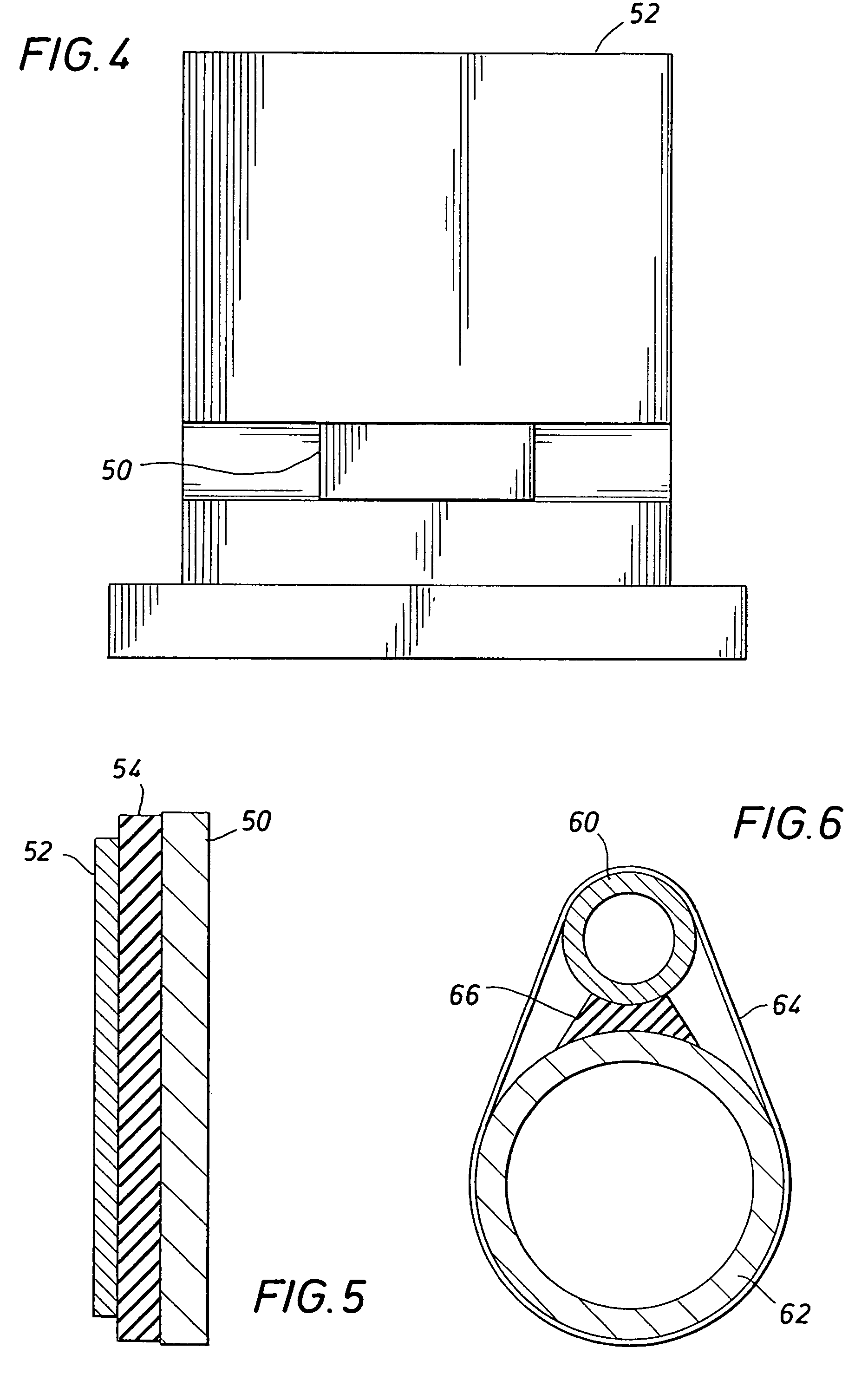

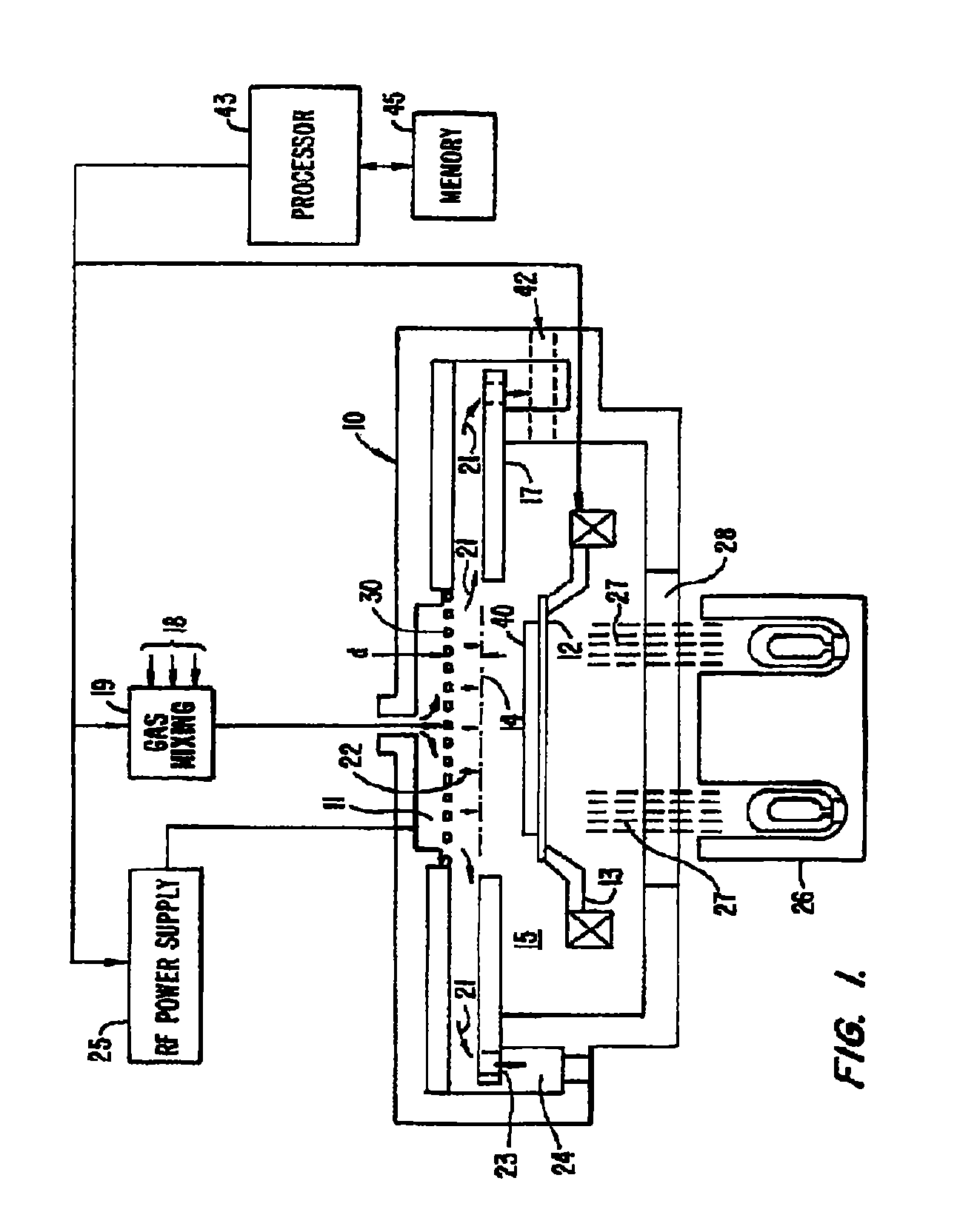

Heat-transfer interface device between a source of heat and a heat-receiving object

InactiveUS20050067157A1Stable heat-transfer conditionReliable and stable thermally-conductiveElectric discharge tubesSynthetic resin layered productsElastomerPerfluoropolyether

What is proposed is a heat-transfer interface device for use in a range of up 320° C. working temperatures for transfer of heat from a source of heat to a heat-receiving object under severe conditions. The device comprises an elastomeric material filled with an electrically-nonconductive and thermally-conductive filler material. The elastomeric material may have recesses on the surface or the surface may be curved, e.g., on the side facing the source of heat for forming a space between the surface of the device and the mating surface of the source of heat. The elastomeric material is clamped between the heat source and heat receiver in a compressed state so that when it is expanded under the effect of an increased temperature, the material is redistributed and the recesses are flattened. The elastomeric material comprises perfluoroelastomer polymer, and the filler can be selected from boron nitride, aluminum nitride, beryllium oxide, etc. If necessary, a combined mixing-assisting and compression-set reducing agent in the form of perfluoropolyether can be added.

Owner:PACIFIC RUBBER & PACKING

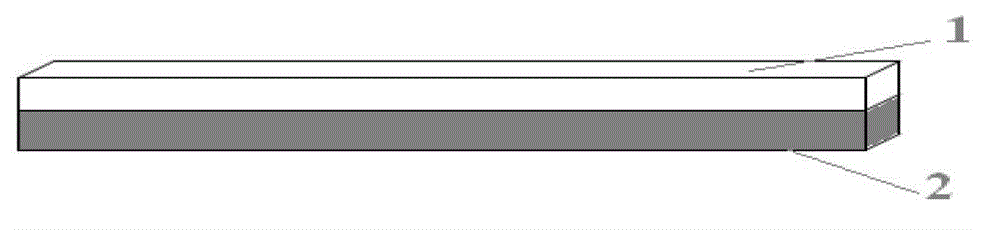

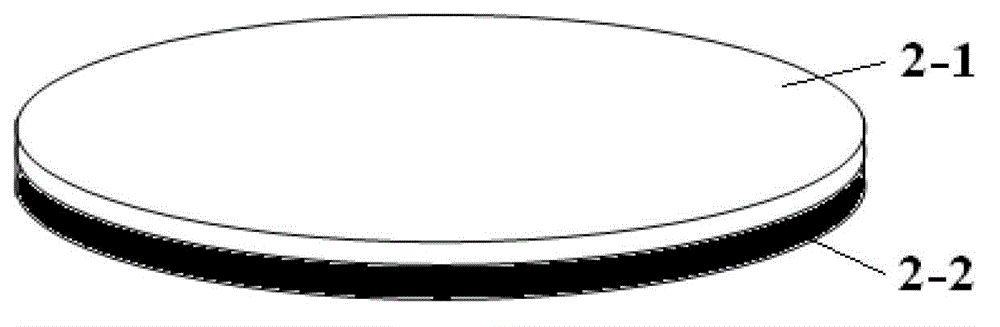

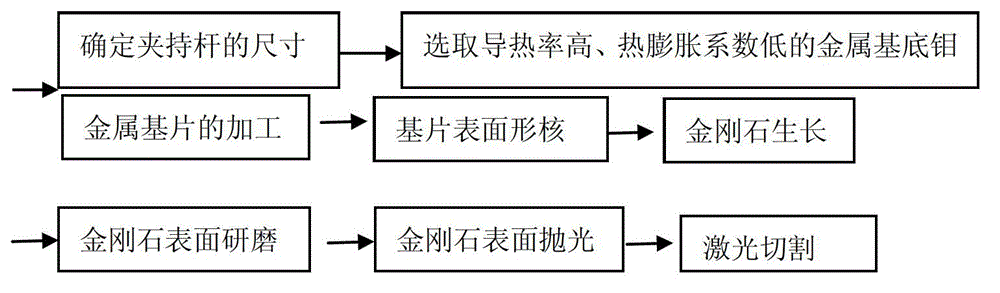

Diamond-metal compound type clamping rod for travelling wave tube and manufacture method of diamond-metal compound type clamping rod

InactiveCN102867716AHigh strengthIncrease output powerTransit-tube vessels/containersVessels or leading-in conductors manufactureGas phaseChemical vapor deposition

The invention discloses a diamond-metal compound type clamping rod for a travelling wave tube and a manufacture method of the diamond-metal compound type clamping rod, belonging to the technical field of vacuum electronics. The diamond-metal compound type clamping rod is used as one part in a travelling wave tube and high-frequency structure and comprises an artificially synthesized diamond and a metal substrate. The manufacture method of the diamond-metal compound type clamping rod comprises the following steps of: firstly forming a diamond crystal nucleus on the surface of the metal substrate, then artificially synthesizing a diamond layer by using a chemical vapor deposition method, then grinding and polishing the surface of the diamond, and cutting and processing into the diamond-metal compound type clamping rod by using laser. The diamond-metal compound type clamping rod has the advantages of greatly shortening the growing time of diamond, reducing the cost, improving the strength of the clamping rod, and remarkably improving the output power of the travelling wave tube compared with that when a beryllium oxide clamping rod is used.

Owner:NO 12 RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com