Diamond-metal compound type clamping rod for travelling wave tube and manufacture method of diamond-metal compound type clamping rod

A diamond and clamping rod technology, applied in the field of diamond-metal composite clamping rod components and their manufacturing, can solve the problems of low clamping rod strength, difficult assembly, high cost, shortened time, increased strength, and increased output. The effect of power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

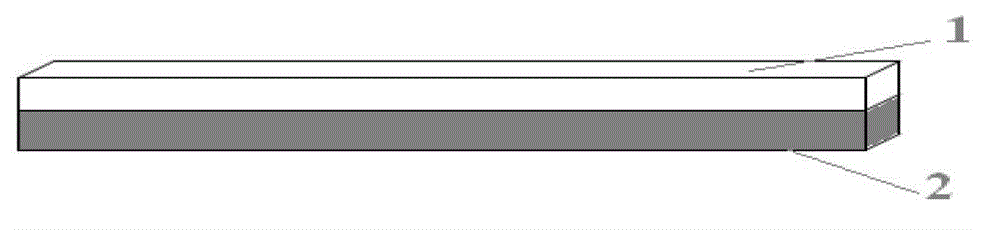

[0012] refer to figure 1 , represents a schematic diagram of a rectangular cross-section diamond-metal composite clamping rod. In the figure, 1 is a polished diamond whose surface is close to the clamped helix, and 2 is a molybdenum metal substrate. As a practical application example for a traveling wave tube, the length of the diamond-metal composite clamping rod is 52mm, the height is 0.7mm, the width is 0.2mm, and the thickness of the diamond is 0.2mm; Mo is used as the metal substrate.

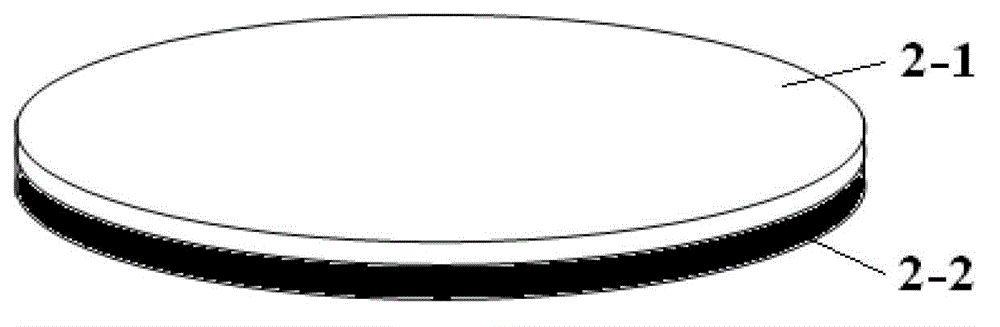

[0013] refer to figure 2 , represents a schematic diagram of a metal substrate for growing diamond. In the figure, 1 is a diamond, and 2 is a molybdenum substrate with a thickness of 0.5 mm and a diameter of 60 mm. The surface of the molybdenum substrate is first mechanically polished and nucleated with diamond powder, and then diamonds are grown by microwave plasma chemical vapor deposition. figure 1 The diamond-metal composite clamping rod shown.

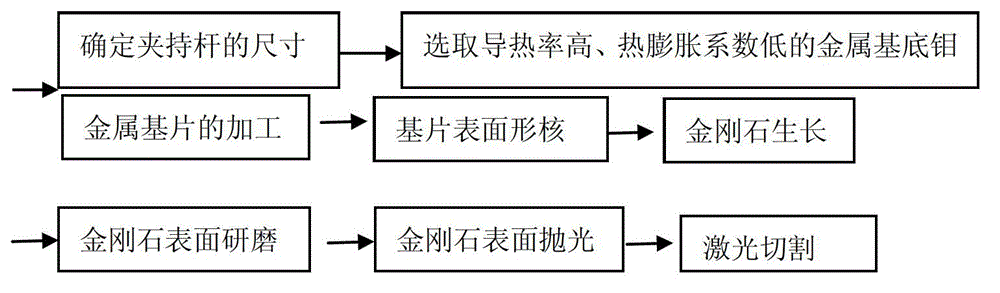

[0014] refer to image 3 , repre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com