High thermal conductivity polyimide film and preparation method thereof

A technology of polyimide film and polyimide resin, which is applied in the field of high thermal conductivity polyimide film and its preparation, can solve the problems of easy accumulation of heat, poor thermal conductivity, safety, etc., and achieve simple operation, clear steps, Effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides a high thermal conductivity polyimide film, which is prepared through the following steps:

[0018] (a) Configure nanomaterial slurry: disperse 2g vinyltrimethoxysilane, 2g silane coupling agent, and 50g nano-graphite powder evenly in 46gN, N-dimethylformamide (DMF) to form nanomaterial slurry ;

[0019] (b) Preparation of polyimide resin: Take 0.6mol pyromellitic dianhydride (PMDA), 0.4mol3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), 0.7mol4,4'- After mixing diaminodiphenyl ether (ODA) and 0.3mol 2,2-bis[4(4-aminophenoxy)phenyl]propane (BAPP) evenly, add them to the reaction kettle, condense and reflux at room temperature for 2 hours to obtain Polyimide resin;

[0020] (c) Preparation of composite polyimide resin: get 2g of the nanomaterial slurry in step (a) and add it to 98g of the above polyimide resin under constant stirring, fully disperse, and continue to react until the viscosity of the system is 80Pa. S / 25°C;

[0021] (d) Fo...

Embodiment 2

[0023] This embodiment provides a high thermal conductivity polyimide film, which is prepared through the following steps:

[0024] (a) Configure nanomaterial slurry: uniformly disperse 5g vinyltriethoxysilane, 5g titanate coupling agent, 40g nano-alumina powder, 10g carbon black powder, and 10g ferric oxide (iron oxide) In 30gN, in N dimethylacetamide (DMAc), form nano material slurry;

[0025] (b) Preparation of polyimide resin: Take 0.6mol pyromellitic dianhydride (PMDA), 0.4mol3,3',4,4'-diphenyl ether tetraacid dianhydride (ODPA), 0.7mol4,4' -diaminodiphenyl ether (ODA), 0.3mol1,3-bis(4-aminophenoxy)benzene (TPE-R) mixed evenly, then added to the reaction kettle, condensed and refluxed at room temperature for 5 hours to obtain polyamide imide resin;

[0026] (c) Preparation of composite polyimide resin: get 20g of the nanomaterial slurry in step (a) and add it to 80g of the above polyimide resin under constant stirring, fully disperse, and continue to react until the vis...

Embodiment 3

[0029] This embodiment provides a high thermal conductivity polyimide film, which is prepared through the following steps:

[0030] (a) Configure nanomaterial slurry: uniformly disperse 5g of vinyltriethoxysilane, 5g of titanate coupling agent, and 60g of nano-alumina powder in 30g of N,N dimethylacetamide (DMAc) to form nano Material slurry;

[0031] (b) Preparation of polyimide resin: Take 0.6mol pyromellitic dianhydride (PMDA), 0.4mol3,3',4,4'-diphenyl ether tetraacid dianhydride (ODPA), 0.7mol4,4' -diaminodiphenyl ether (ODA), 0.3mol1,3-bis(4-aminophenoxy)benzene (TPE-R) mixed evenly, then added to the reaction kettle, condensed and refluxed at room temperature for 5 hours to obtain polyamide imide resin;

[0032] (c) Preparation of composite polyimide resin: get 20g of the nanomaterial slurry in step (a) and add it to 80g of the above polyimide resin under constant stirring, fully disperse, and continue to react until the viscosity of the system is 120Pa. S / 25°C;

[0...

PUM

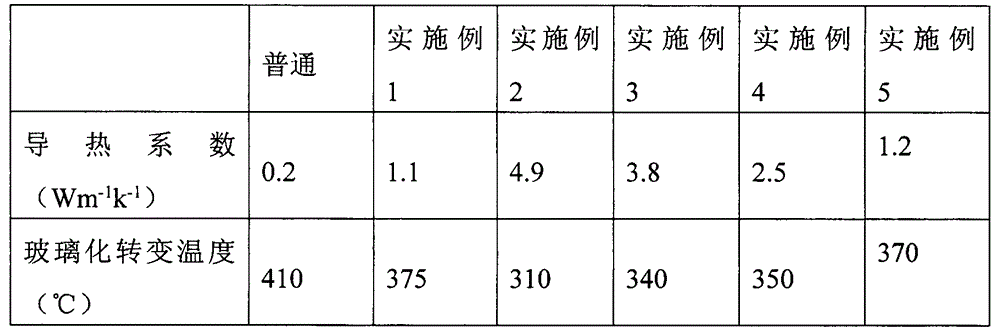

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com