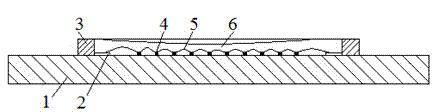

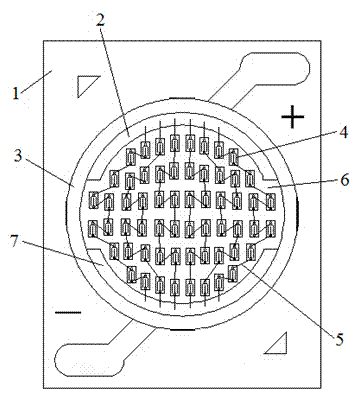

COB type LED packing piece based on beryllium oxide ceramic substrate and production method

A technology of LED package and beryllium oxide ceramics, which is applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., to achieve the effect of light weight, small size and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

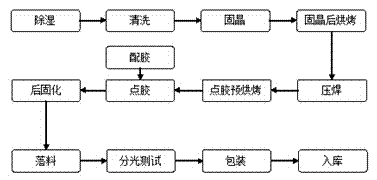

Method used

Image

Examples

Embodiment 1

[0053] Put the beryllium oxide ceramic plate into the ceramic cleaning agent, heat it to boiling state and cook for 20 minutes, take it out and rinse it alternately with cold-hot-cold deionized water for 15 minutes each (the temperature of hot deionized water is 30°C), and then place it in acetone Ultrasonic cleaning in the solution for 10 minutes, after taking it out, rinse it alternately with cold-hot-cold deionized water for 15 minutes each (the temperature of hot deionized water is 30°C), and dry it under an infrared lamp to form a substrate; place the substrate on a 300-mesh nylon screen Under the plate, align the position between the substrate and the screen according to the electrode pattern to ensure that the distance between the substrate and the screen is 0.1mm, and use a 45° scraper to scrape the silver paste from the screen to the surface of the substrate to complete the electrode printing; Afterwards, bake the printed electrode substrate in a high-temperature sinte...

Embodiment 2

[0055] Put the beryllium oxide ceramic plate into the ceramic cleaning agent, heat it to boiling state and cook for 20 minutes, take it out and rinse it alternately with cold-hot-cold deionized water for 15 minutes each (the temperature of hot deionized water is 30°C), and then place it in acetone Ultrasonic cleaning in the solution for 10 minutes, after taking it out, rinse with cold-hot-cold deionized water alternately for 15 minutes each (hot deionized water temperature is 30°C), and dry to form a substrate; place the substrate under a 300-mesh nylon screen plate, Align the position between the substrate and the screen according to the electrode pattern, ensure that the distance between the substrate and the screen is 0.11mm, use a 45° scraper to scrape the silver paste from the screen to the surface of the substrate to complete the printing of the electrode; after that, place The printed electrode substrate is baked in a high-temperature sintering furnace at 955°C for 60 mi...

Embodiment 3

[0057]Put the beryllium oxide ceramic plate into the ceramic cleaning agent, heat it to boiling state and cook for 20 minutes, take it out and rinse it alternately with cold-hot-cold deionized water for 15 minutes each (the temperature of hot deionized water is 30°C), and then place it in acetone Ultrasonic cleaning in the solution for 10 minutes, after taking it out, rinse it alternately with cold-hot-cold deionized water for 15 minutes each (the temperature of hot deionized water is 30°C), and finally dry it under an infrared lamp to complete cleaning and form a substrate; place the substrate in Under the 300-mesh nylon screen, align the position between the substrate and the screen according to the electrode pattern, and ensure that the distance between the substrate and the screen is 0.99mm, use a 45° scraper to scrape the silver paste from the screen to the substrate The electrode is printed on the surface; after that, bake the substrate with the printed electrode in a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com