Patents

Literature

288results about How to "Dense microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High permittivity silicate gate dielectric

InactiveUS6841439B1Great ratioHigh densitySemiconductor/solid-state device manufacturingSemiconductor devicesState densityHigh dielectric permittivity

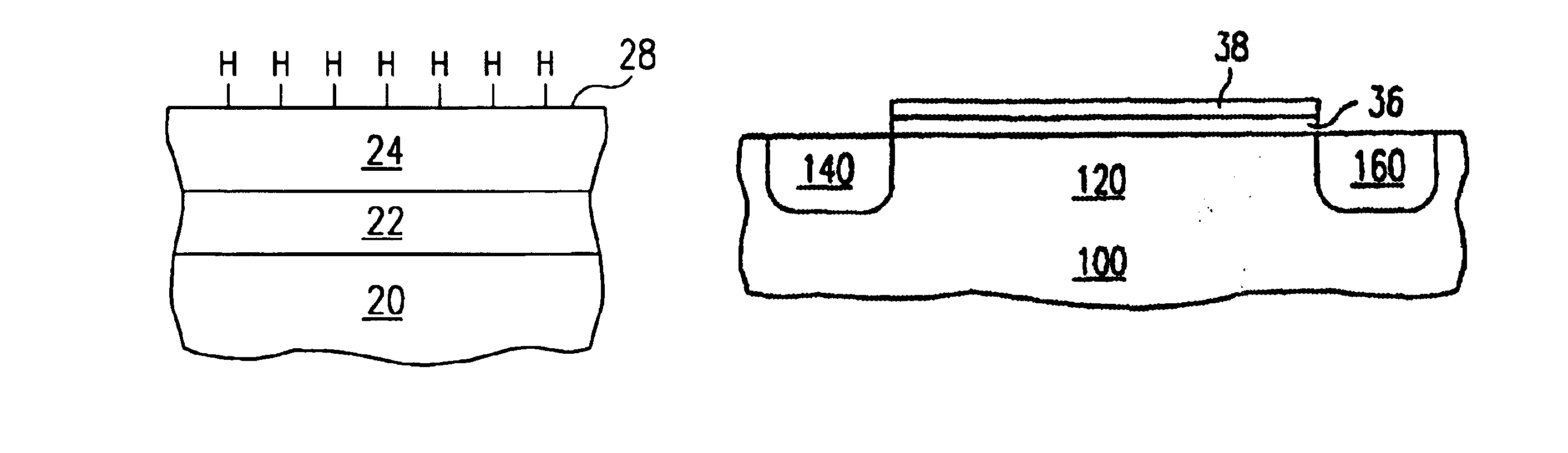

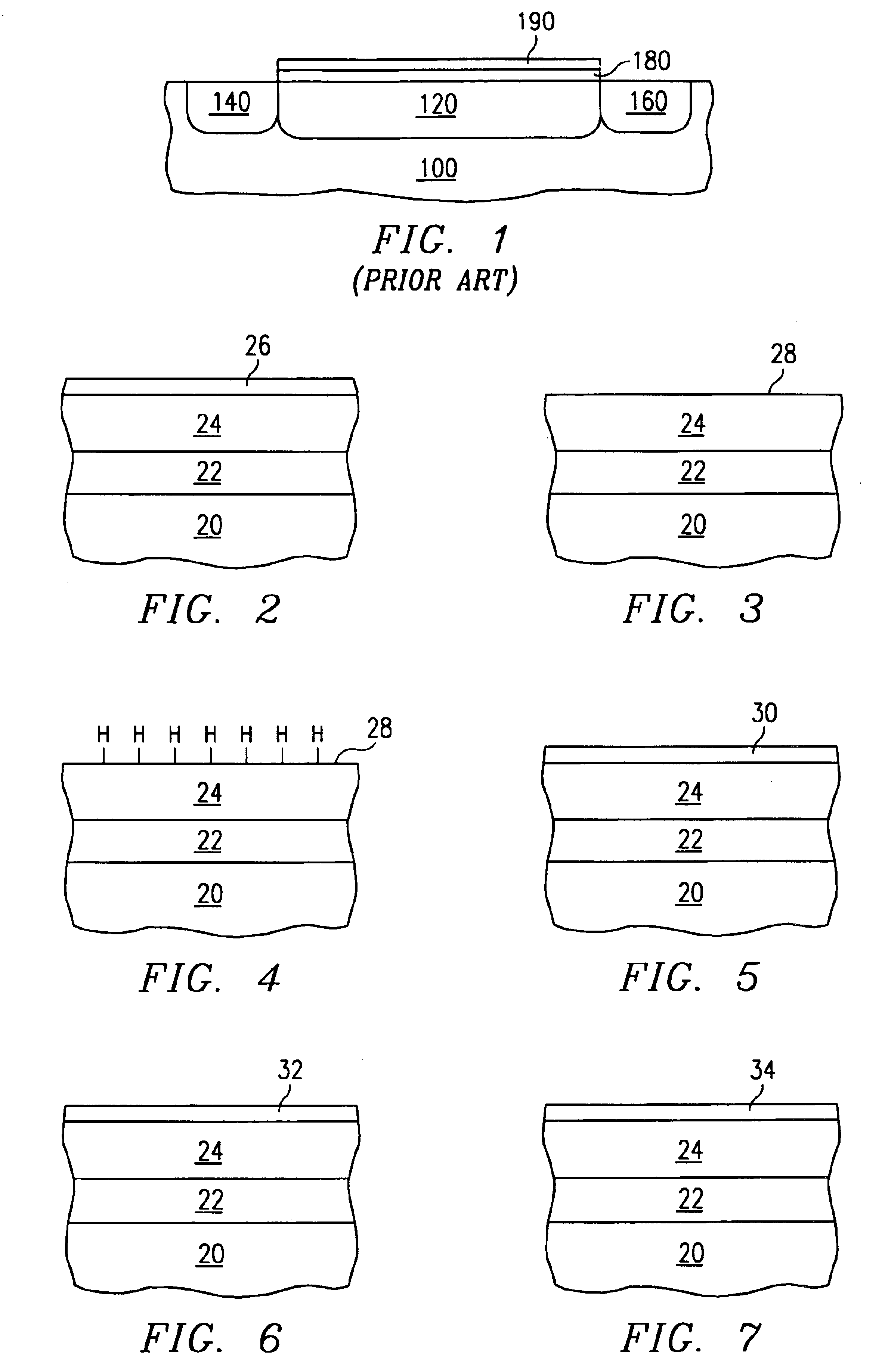

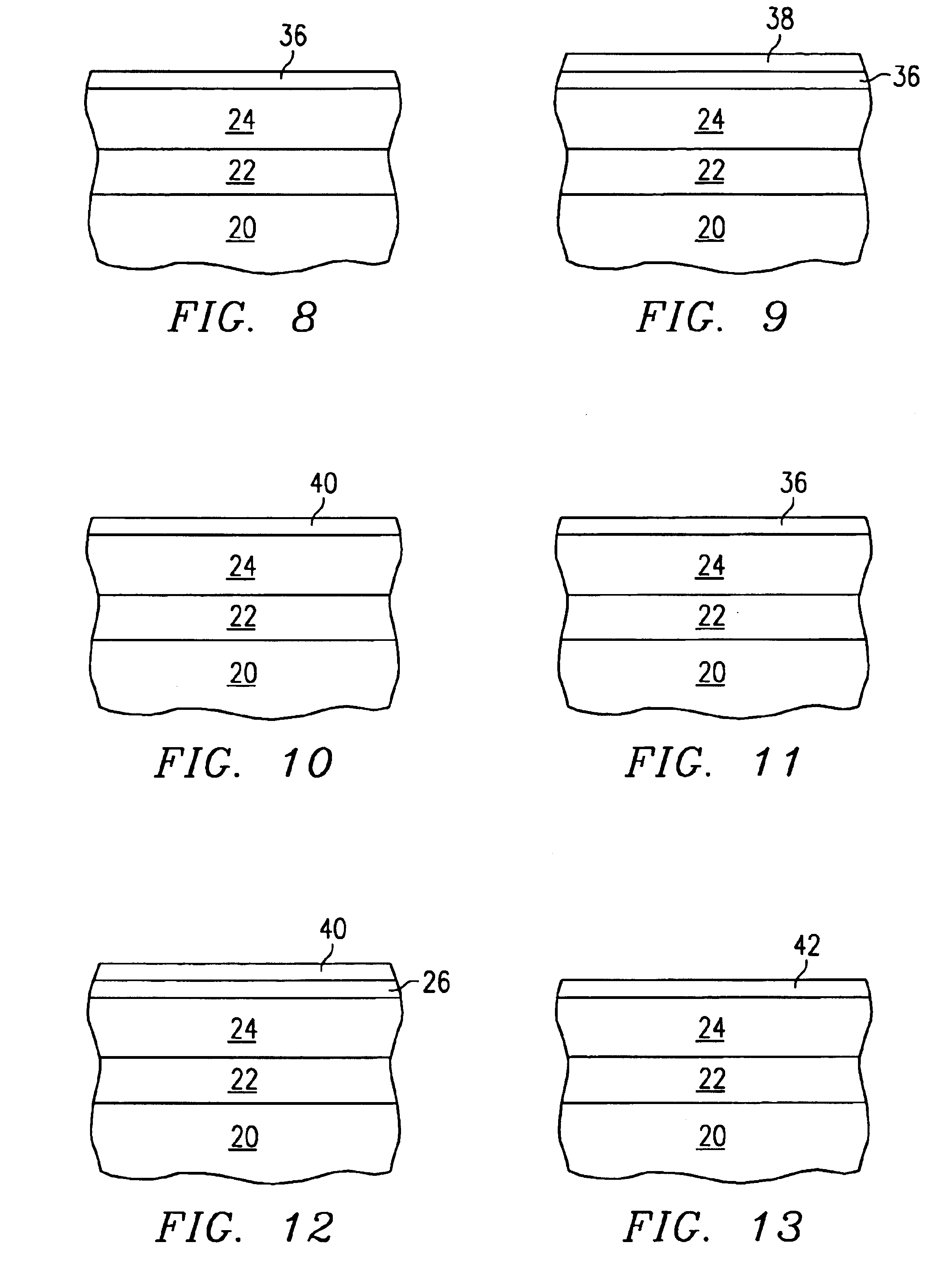

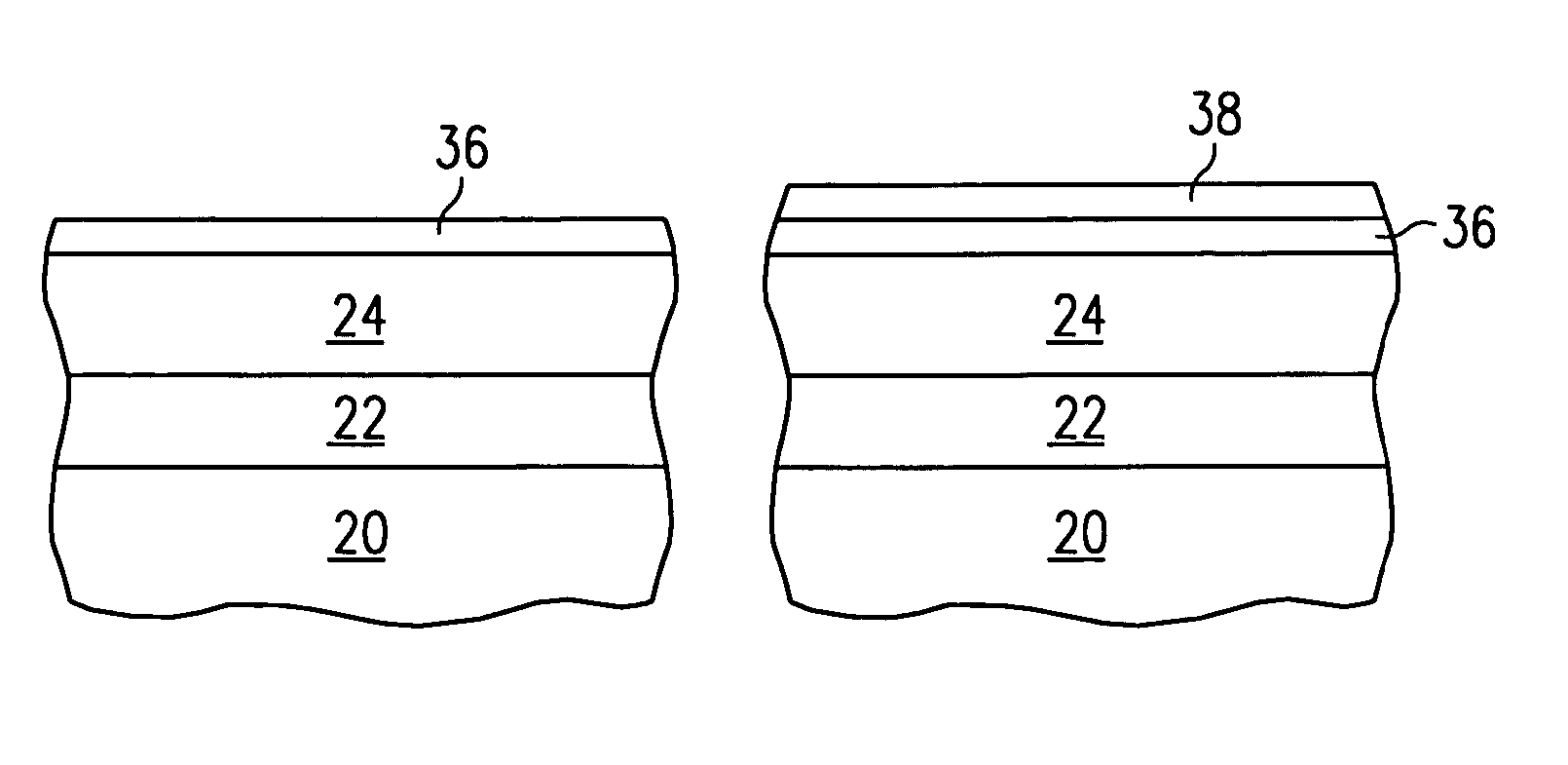

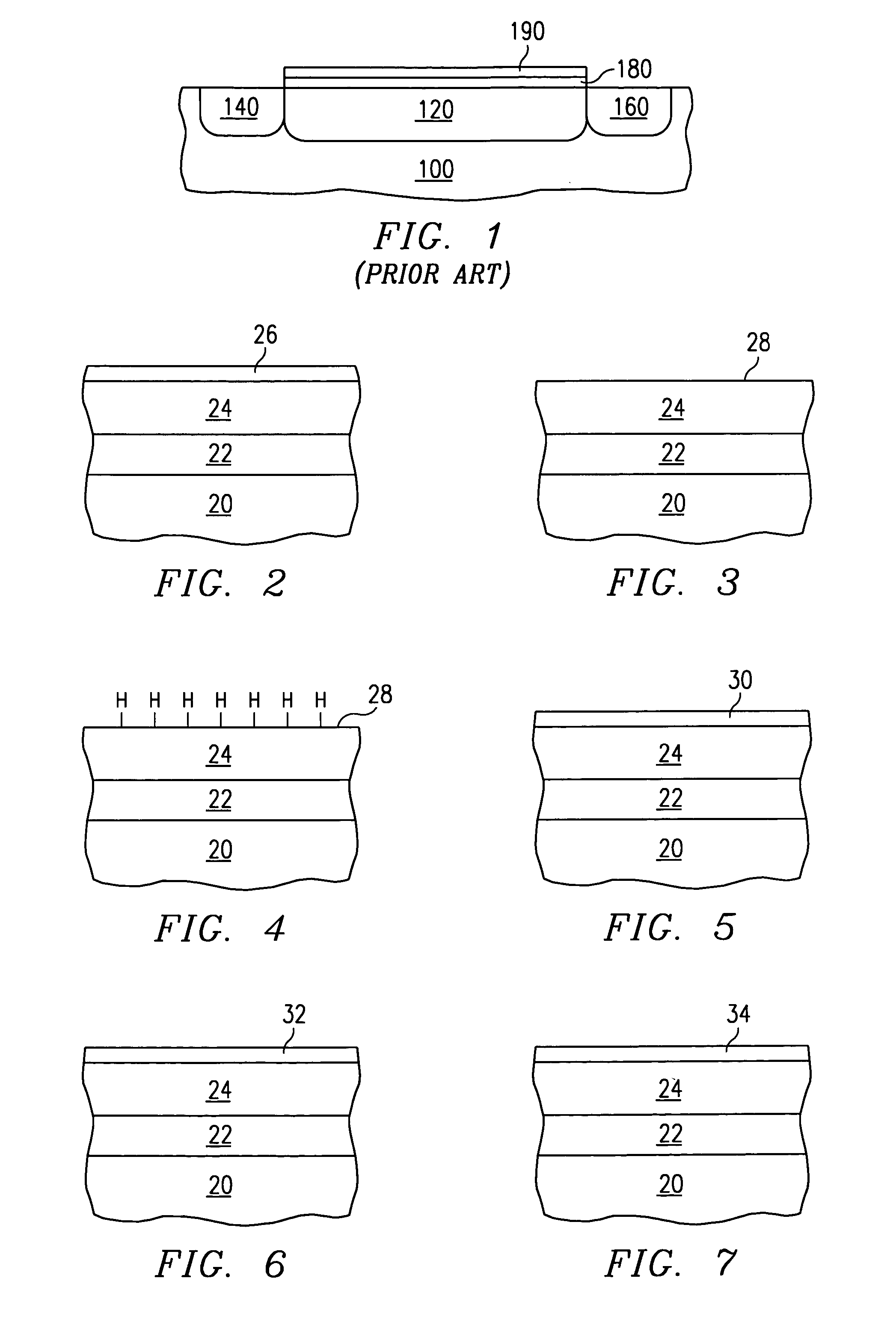

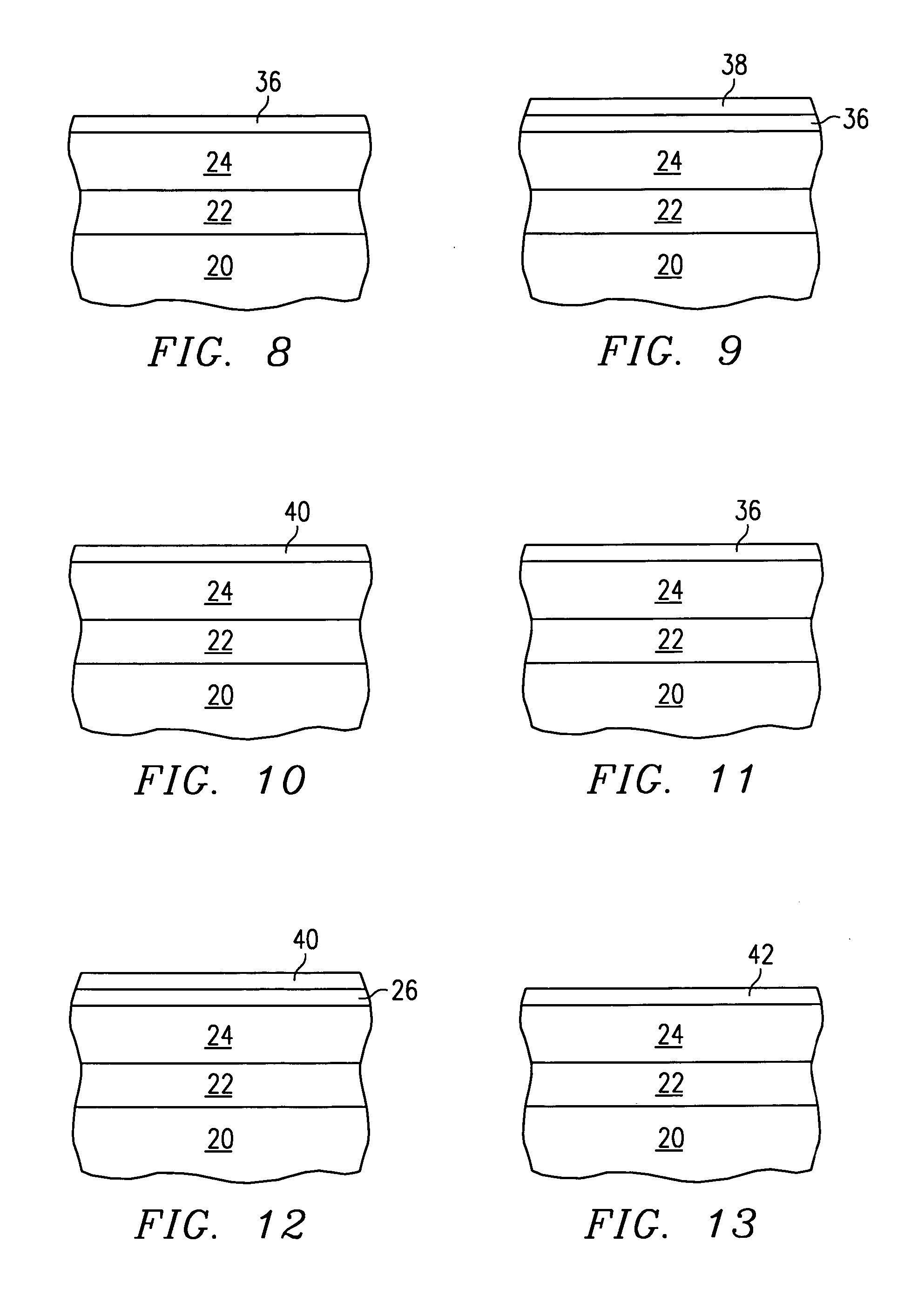

A field effect semiconductor device comprising a high permittivity silicate gate dielectric and a method of forming the same are disclosed herein. The device comprises a silicon substrate 20 having a semiconducting channel region 24 formed therein. A metal silicate gate dielectric layer 36 is formed over this substrate, followed by a conductive gate 38. Silicate layer 36 may be, e.g., hafnium silicate, such that the dielectric constant of the gate dielectric is significantly higher than the dielectric constant of silicon dioxide. However, the silicate gate dielectric may also be designed to have the advantages of silicon dioxide, e.g. high breakdown, low interface state density, and high stability. The present invention includes methods for depositing both amorphous and polycrystalline silicate layers, as well as graded composition silicate layers.

Owner:TEXAS INSTR INC

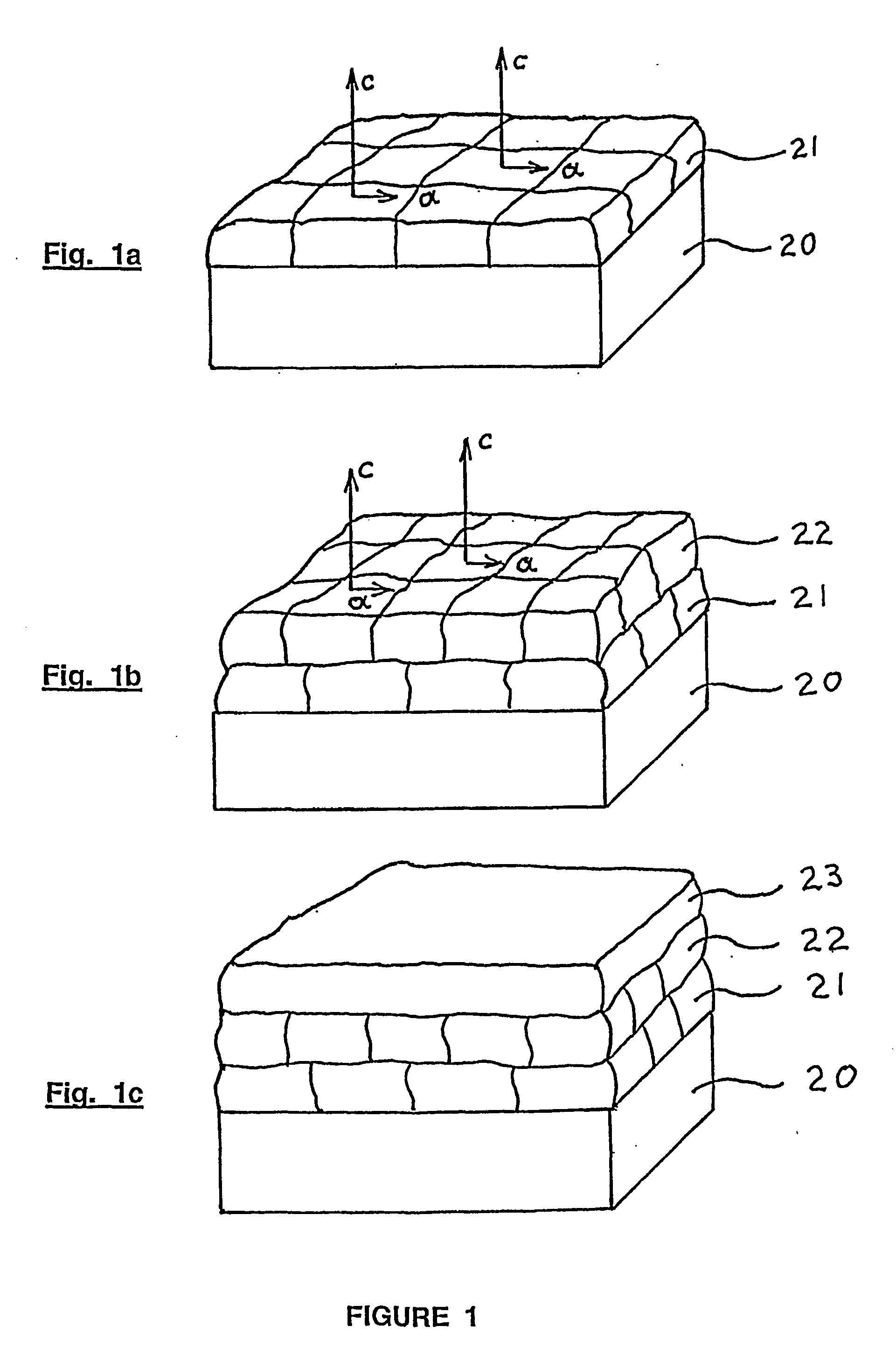

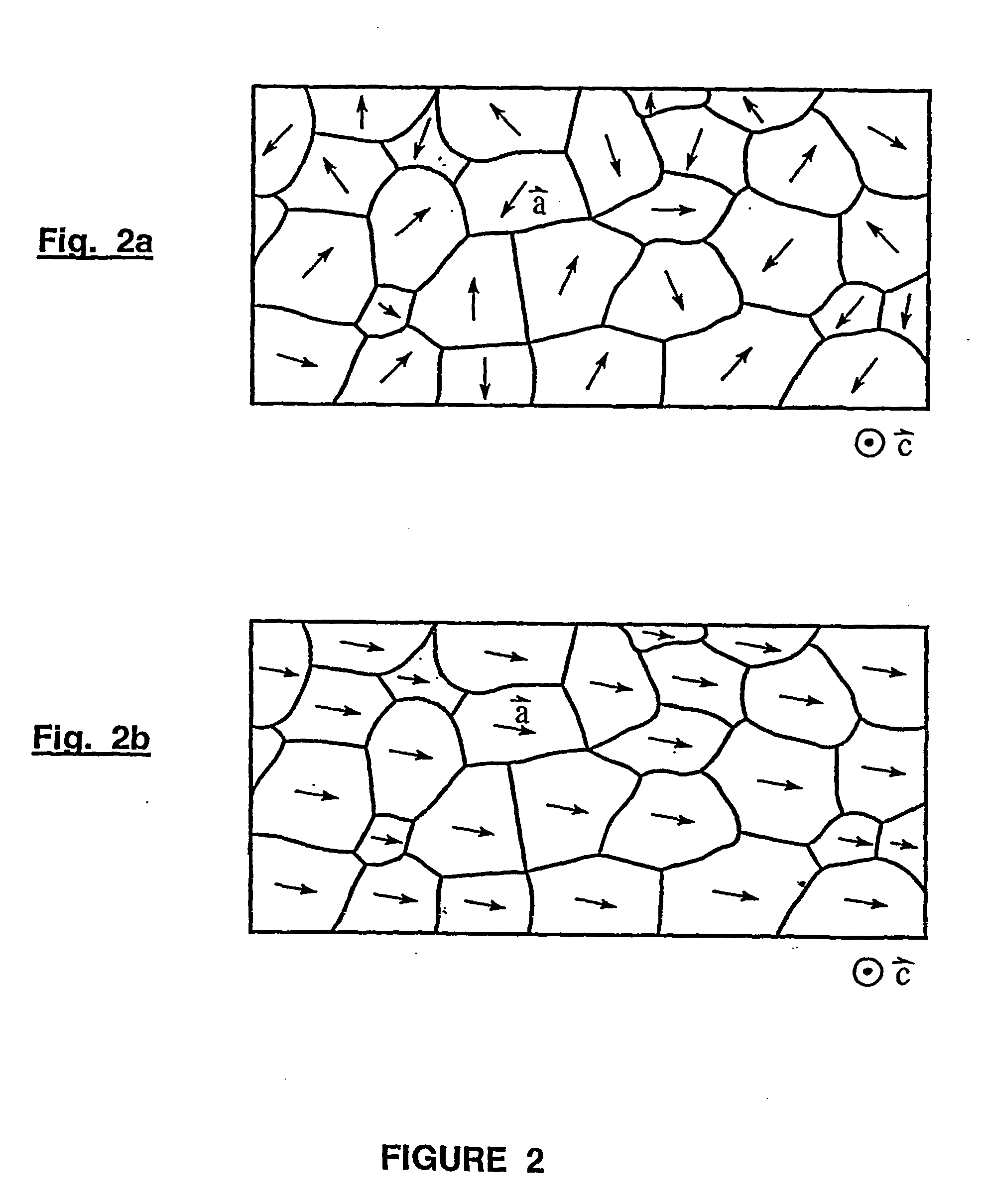

Process and apparatus for producing cystalline thin film buffer layers and structures having biaxial texture

InactiveUS20040168636A1Increase deposition rateEasy alignmentPolycrystalline material growthElectric discharge heatingIon beamOptoelectronics

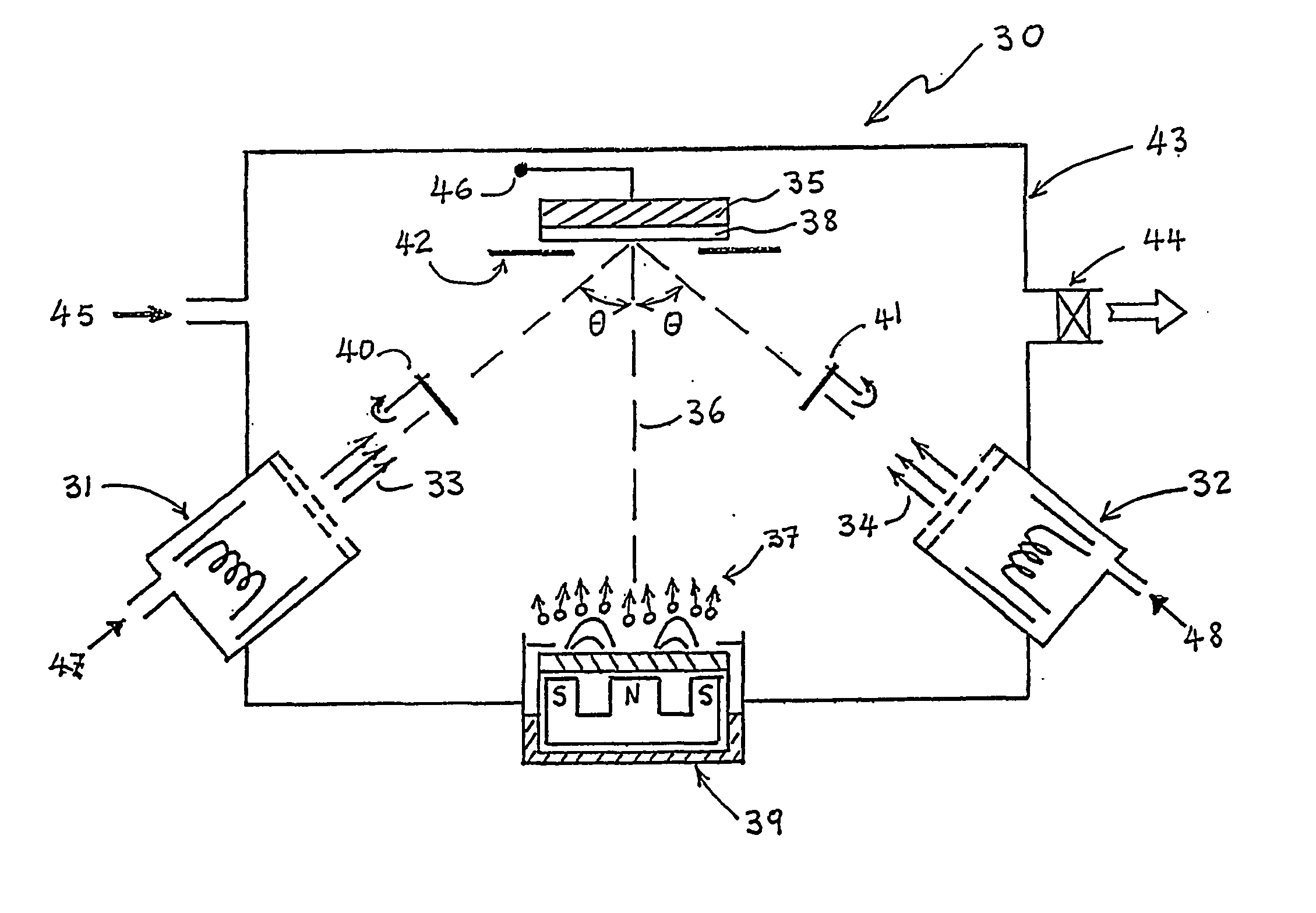

The invention provides a method of depositing a buffer layer or film onto a surface of a substrate. The method includes providing the substrate in a controlled atmosphere and exposing the substrate to a vapour comprising a film forming species. While the substrate is exposed to the vapour, two or more ion beams are provided incident upon the surface of the substrate to assist formation of the film. The respective axes of incidence of the two or more ion beams are distinct and are selected and controlled in order to maintain the arrival rate ratio, maximise the deposition rate, and maximise the biaxial alignment of the layer so formed.

Owner:COMMONWEALTH SCI & IND RES ORG

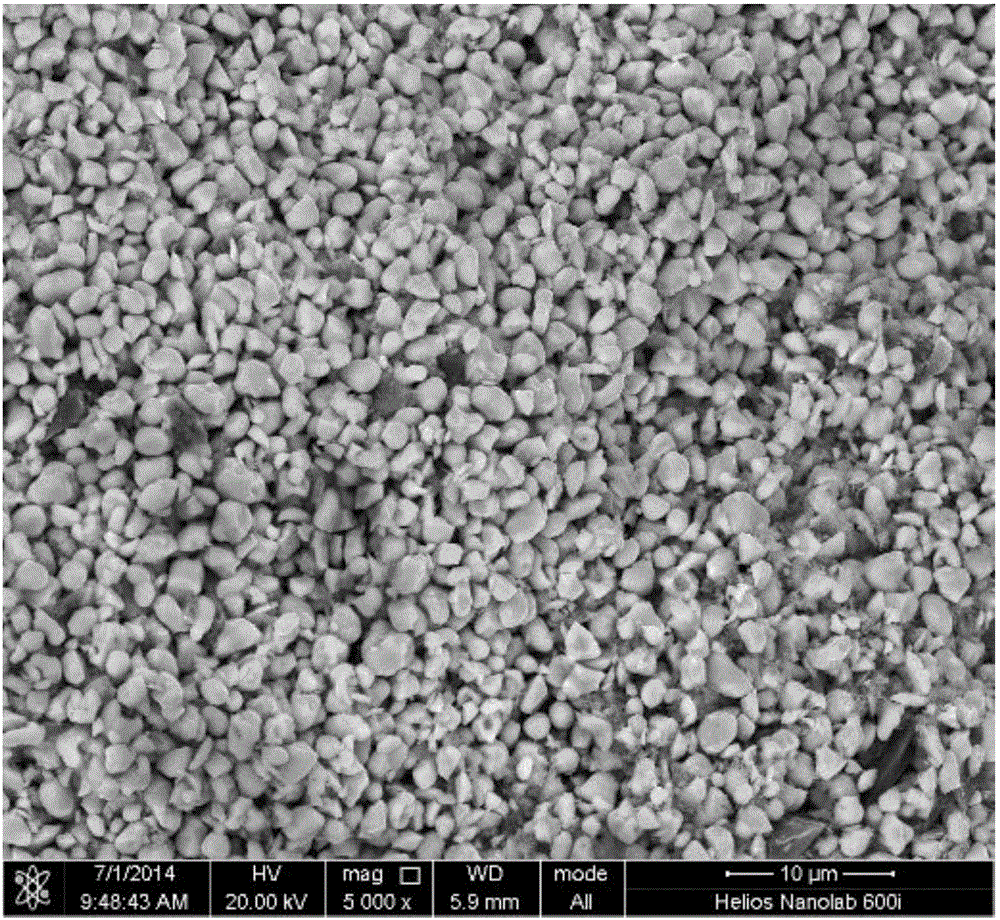

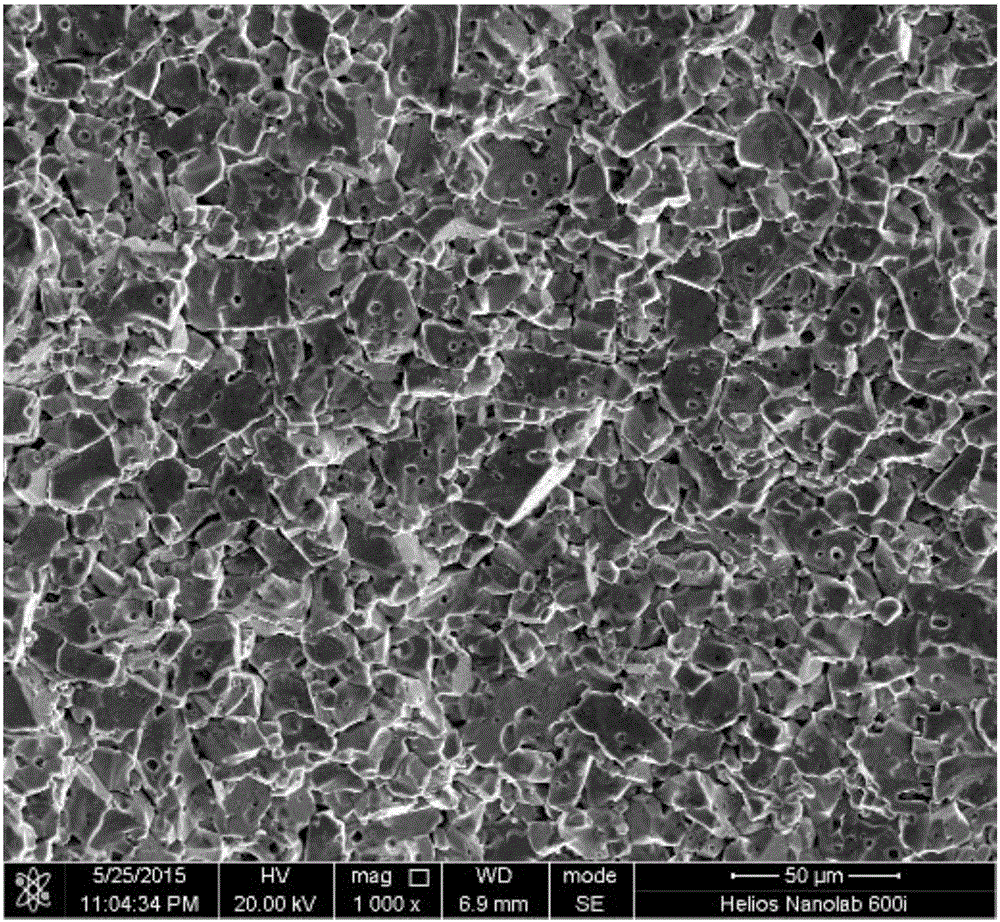

Preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide

ActiveCN107475548AUniform particle sizeNarrow normal distribution of particle sizePorosityFlexural strength

The invention discloses a preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide comprises the following steps of that 0.1-0.5 micron ultra-fine powder of WC hard phase and Co binder phase is prepared by adopting an airflow crushing classification method and a high-pressure water atomization method correspondingly, and the ultra-fine grain cemented carbide is prepared through material matching and nano-metal mixed additives adding, airflow mixed powder sieving, ball milling waxing and drying sieving, mold pressing and cold isostatic pressing molding and pressure sintering and heat treating, wherein the nano-metal mixed additives are prepared by adopting vacuum electric arc smelting ingot casting plus rapid-in-situ packaging plasma arc process discharging method. The nano-metal mixed additives play the role of refining the cemented carbide granules, improving the material wettability, reducing the porosity and enhancing the local grain boundary strength, so that macro performances such as hardness, flexural strength and fracture toughness of the alloy are improved greatly. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide has the advantages of being high in production efficiency, low in production cost, high in product quality and purity, and a great deal of man-hour and energy consumption are saved.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

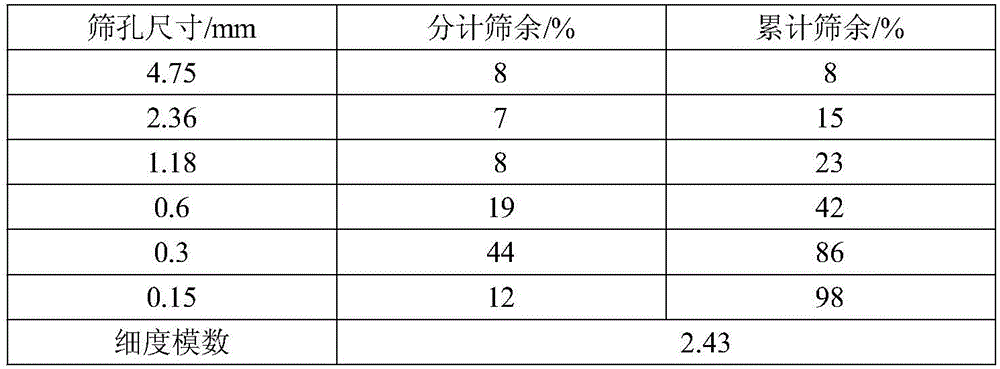

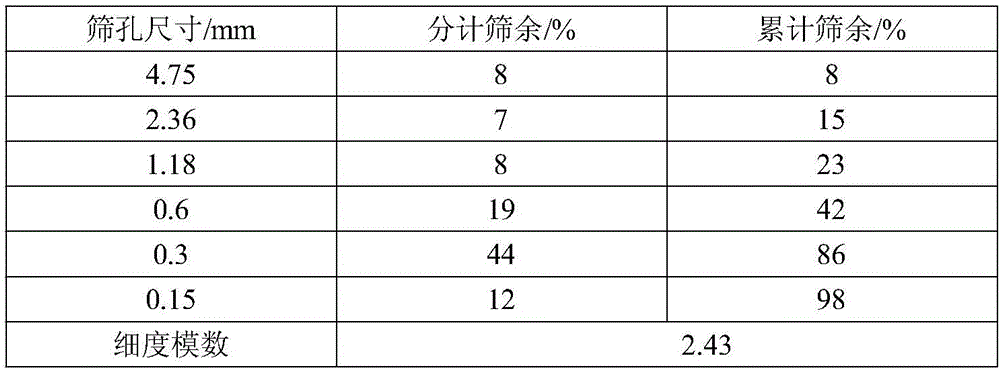

Exterior wall facing mortar with inorganic characteristic and excellent crystalline bloom resistant performance

The invention provides exterior wall facing mortar with an inorganic characteristic and excellent crystalline bloom resistant performance. The facing mortar comprises double components, wherein a component A is an acrylic emulsion, and a component B mainly comprises 5 to 15 percent of high alumina cement, 0 to 2 percent of gypsum, 70 to 75 percent of quartz sand, 0 to 12 percent of ultrafine calcium carbonate and 0.1 to 1 percent of additive. The exterior wall facing mortar provided by the invention has the advantages that through using the acrylic emulsion, a continuous film layer is formed after the mortar is solidified, so that the mortar is guaranteed to have high bonding strength and good anti-aging performance; the migration of salt can also be effectively prevented or reduced, so that crystalline bloom is controlled; and besides, the selection of the ratio of the high alumina cement to portland cement can also achieve a control effect on crystalline bloom. A template coating obtained through the mortar is detected according to a JC / T1024-2007 wall body facing mortar standard, and all performance indexes meet the requirements, so that the exterior wall facing mortar can be widely applied to the decoration of building wall bodies.

Owner:KAINUO QINGDAO CHEM BUILDING MATERIALS

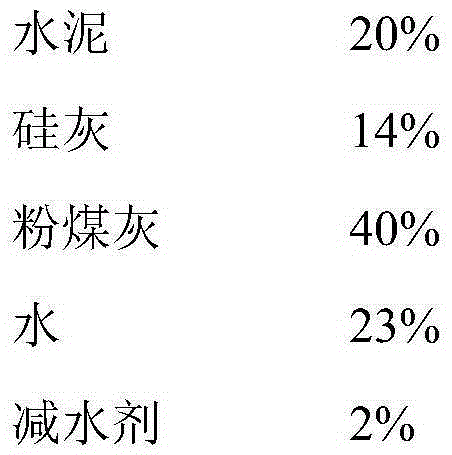

High-strength and high-toughness geopolymer material and preparation method thereof

ActiveCN111018435AHigh bonding strengthImprove mechanical propertiesCement productionFiberKaolin clay

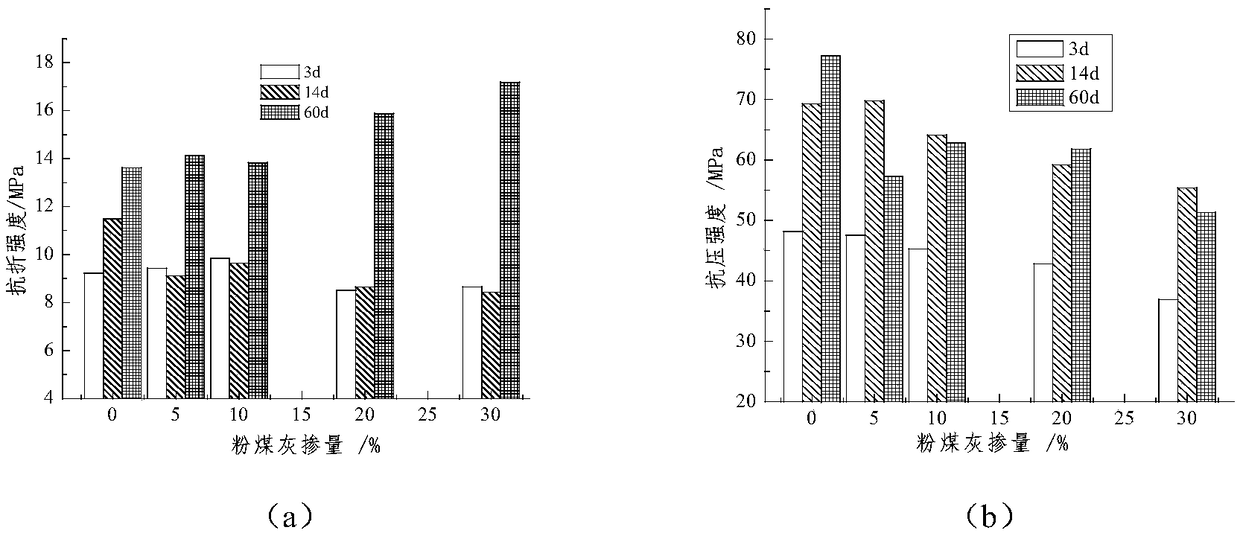

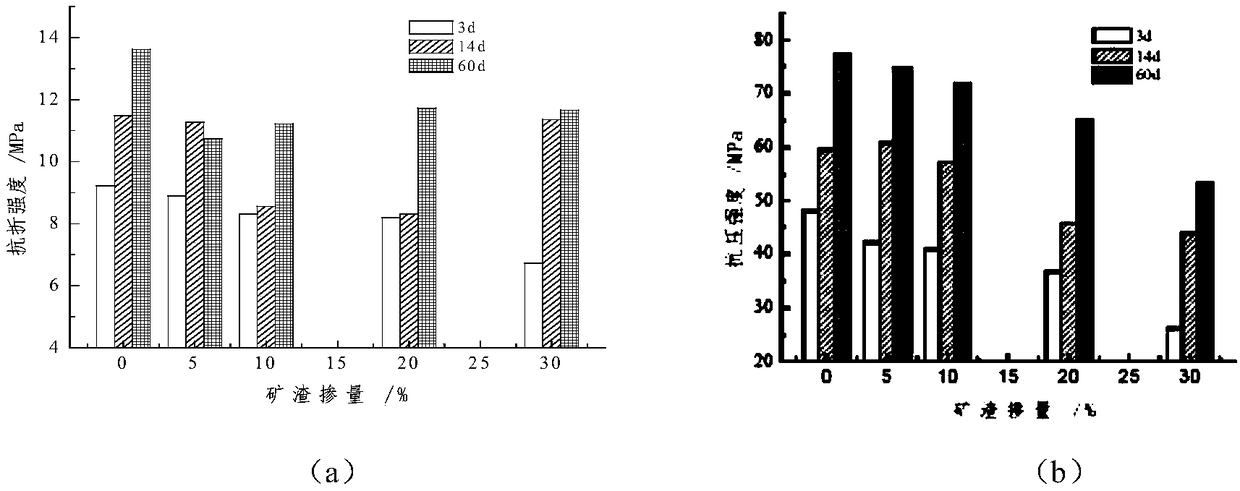

The invention discloses a high-strength and high-toughness geopolymer material. The high-strength and high-toughness geopolymer material comprises, by weight, 500-700 parts of silicon-aluminum mineralraw materials, 600-800 parts of an alkali activator, 70-150 parts of a nanoscale efficient modifier, 2-5 parts of super absorbent resin, 2-6 parts of a hybrid fiber, 4-10 parts of a surfactant, 700-1000 parts of fine aggregates and 100-150 parts of deionized water, the silicon-aluminum mineral raw materials comprise 200-300 parts of metakaolin, 150-200 parts of fly ash, 50-100 parts of red mud, 40-60 parts of mineral slag, 40-60 parts of silica fume and 20-40 parts of Portland cement, and the nanoscale efficient modifier comprises 20-50 parts of condensed phosphate, 20-40 parts of nano-silica, 20-40 parts of nano-alumina and 10-20 parts of zeolite. The invention further discloses a preparation method of the high-strength and high-toughness geopolymer material. The problems of large earlyself-shrinkage and easy cracking of the geopolymer are solved, and the obtained geopolymer has strong toughness and high strength.

Owner:ZHEJIANG UNIV

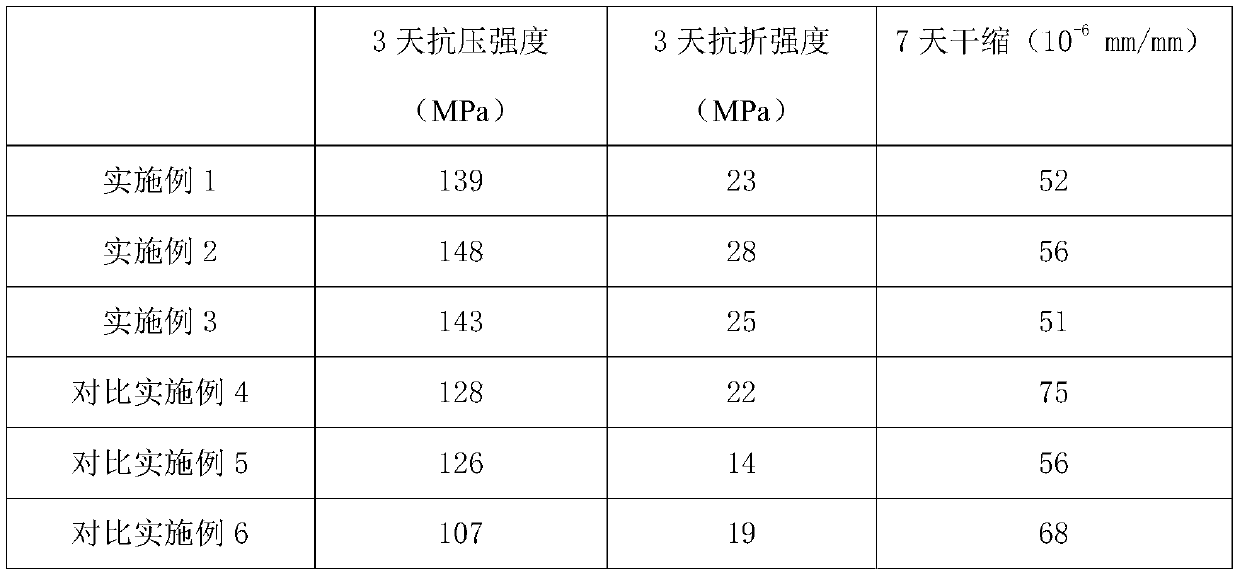

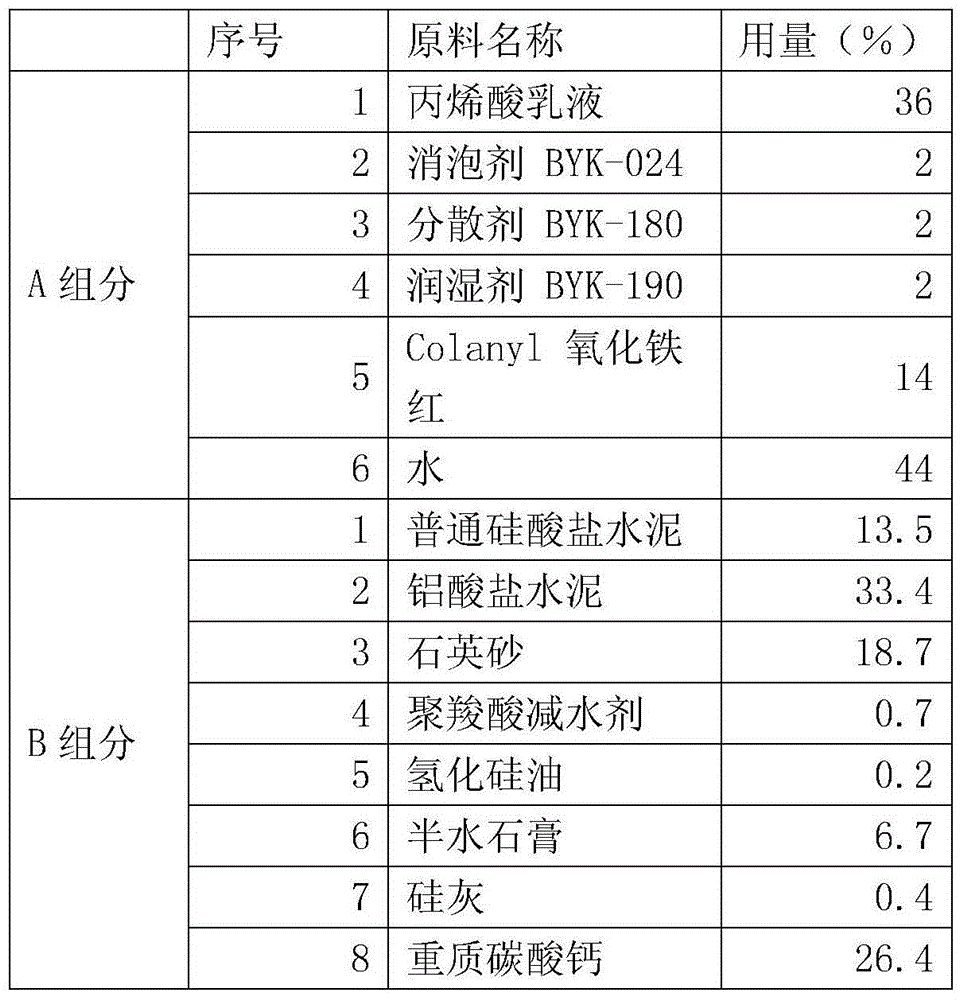

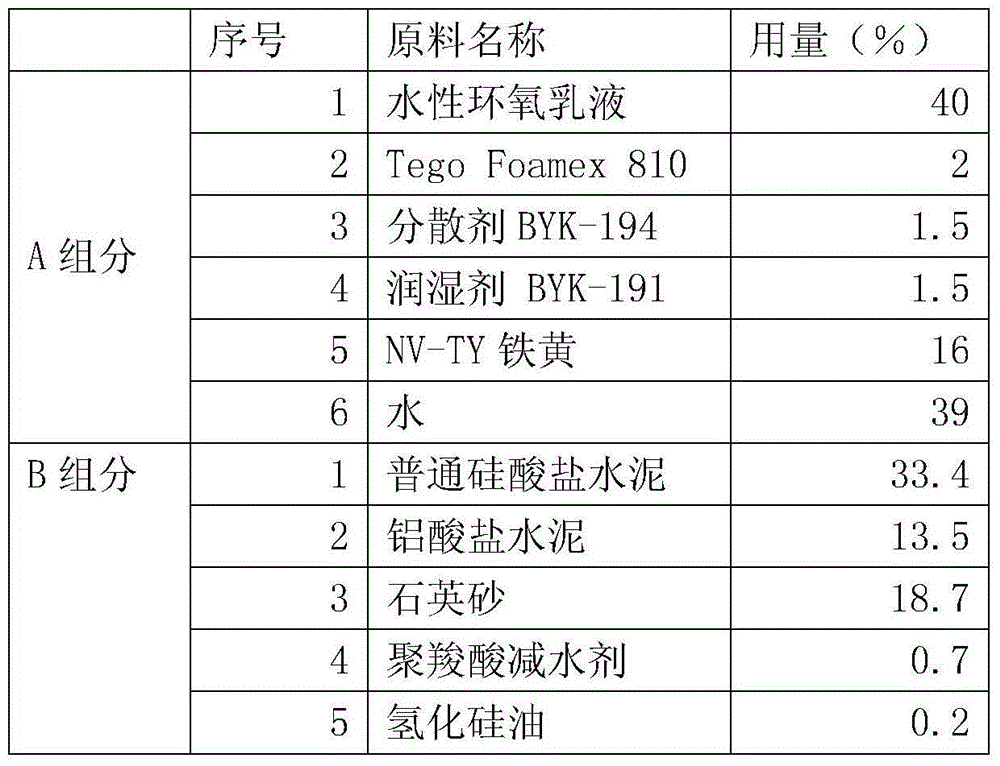

Color floor prepared by automatic leveling of color terrace coating mixed high-strength cement and construction method of color floor

ActiveCN104356811AHigh strengthDense microstructureConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsAluminatePortland cement

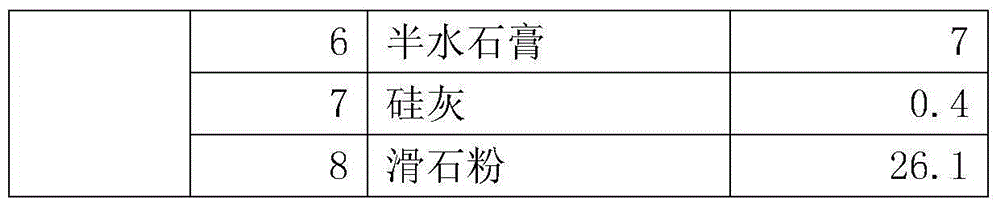

The invention provides a color floor prepared by automatic leveling of color terrace coating mixed high-strength cement and a construction method of the color floor. The color floor is formed by mixing a component A with a component B, then paving the obtained mixture on the ground for automatically leveling, drying and polishing sequentially by using abrasive discs with different meshes until the ground is light, wherein the component A is color terrace coating which is formed by adding 20-75% of water-based emulsion, 1-10% of additives and10-30% of concentrated water-based color paste into 10-60% of water, and the component B consists of 10-45% of ordinary Portland cement, 10-45% of aluminate cement, 1-12% of semi-hydrated gypsum, 15-60% of quartz sand, 0.1-1% of a polycarboxylate water reducing agent, 0.1-1% of hydrogenated silicon oil, 0.1-3% of silica fume and 15-50% of fillers. The prepared color floor are fast in material setting and hardening, and is firm and wear-resistant; the floor is smooth and attractive and flat, natural and is soft and attractive in color, overload-resistant, highly pressure-resistant, and highly wear-resistant.

Owner:武汉菲凡士建材有限公司

Evacuating agent of vermicelli foodstuff and the vermicelli foodstuff thereof

ActiveCN101081065AEvenly distributedDraw downFood preservationFood preparationSodium bicarbonateAdditive ingredient

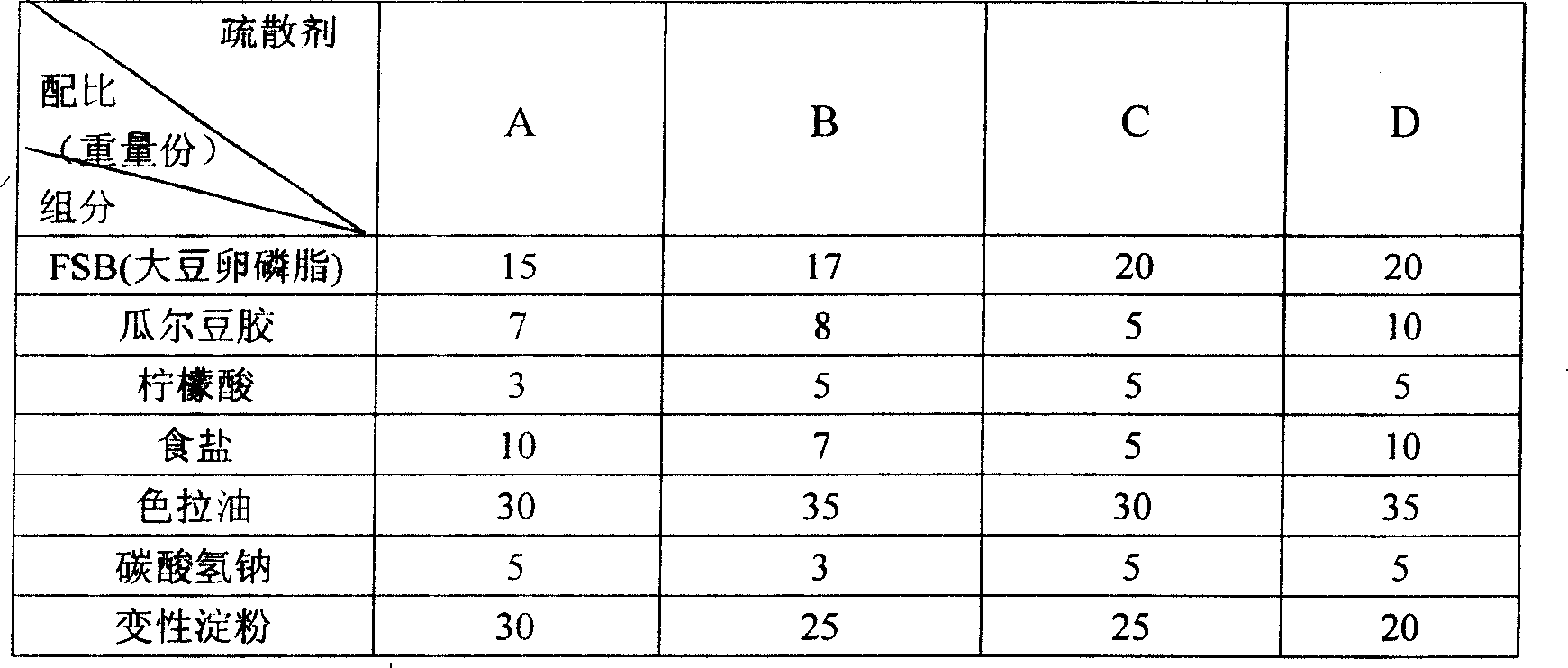

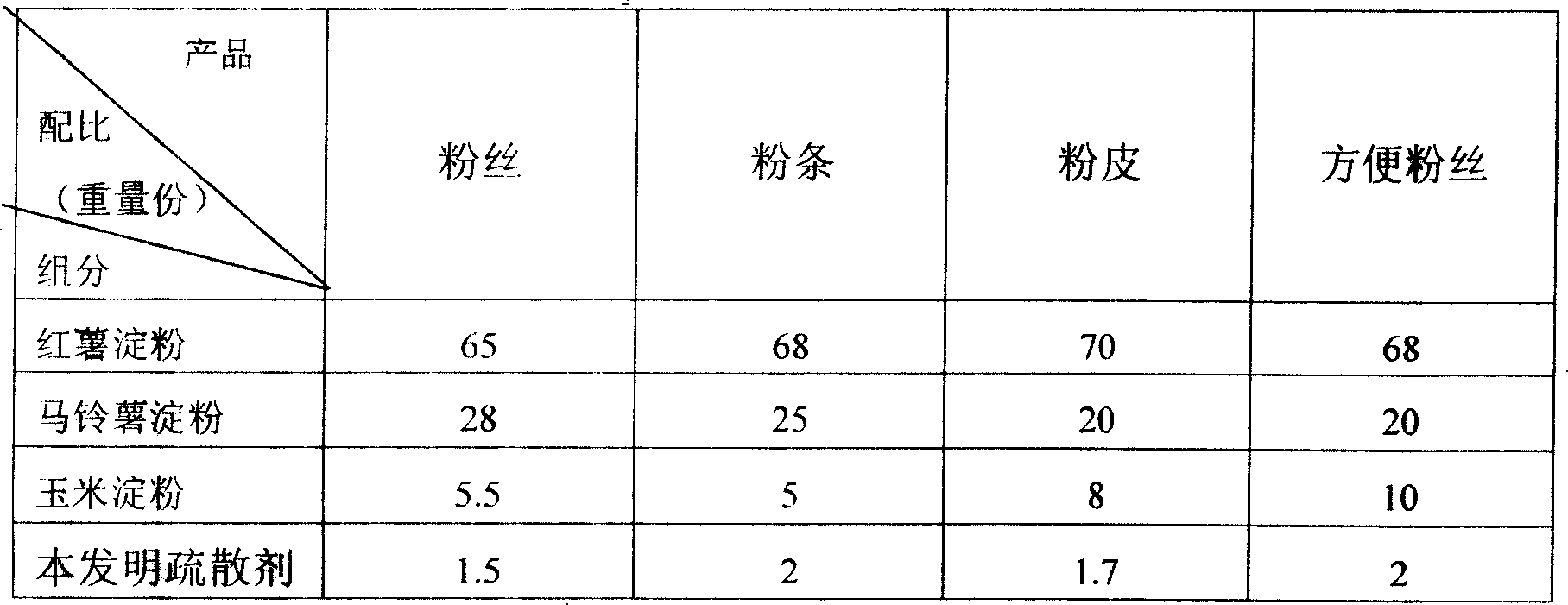

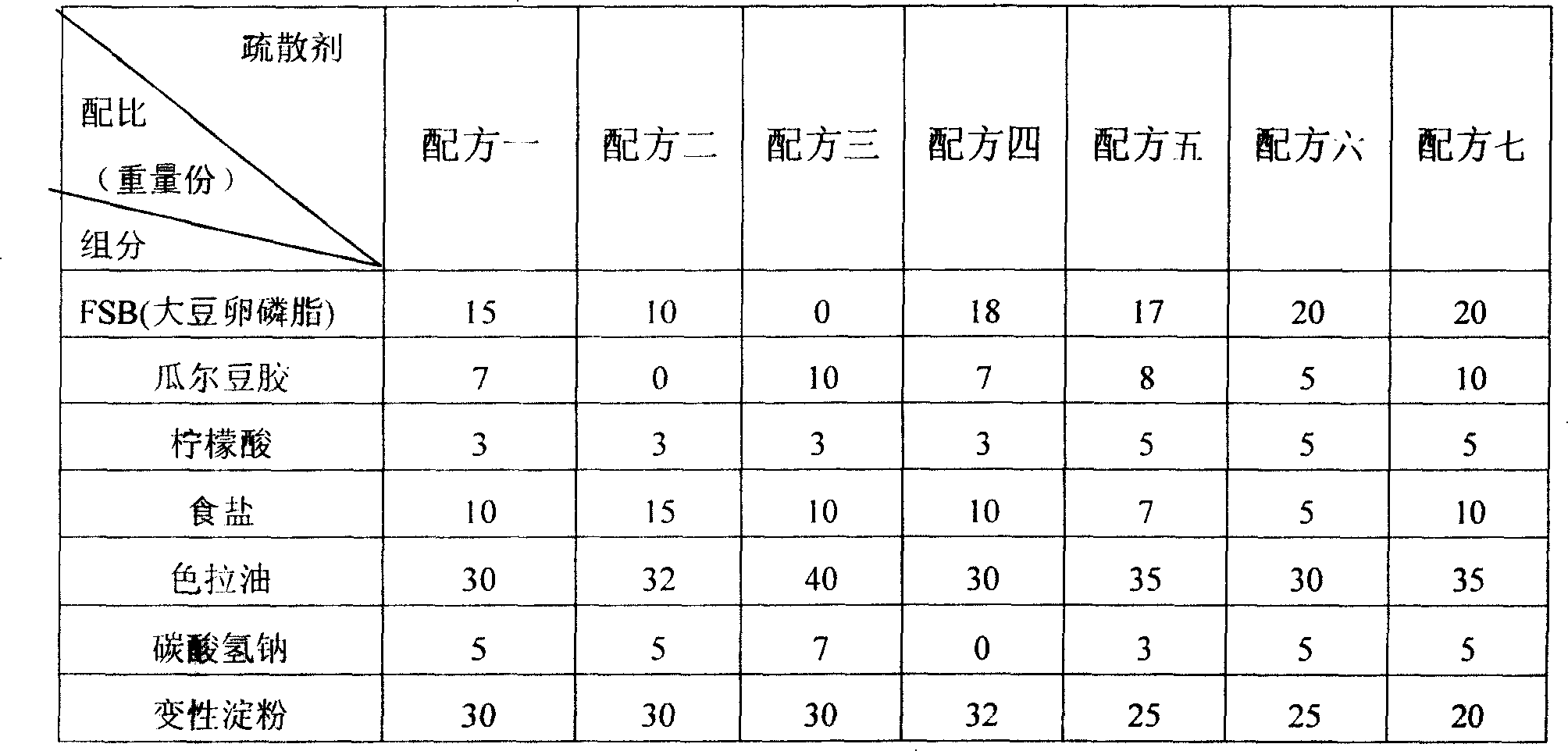

The present invention belongs to the field of food producing technology, and is especially one kind of dispersant for vermicelli. The dispersant for vermicelli consists mainly of soybean lecithin 15-25 weight portions, salad oil 20-40 weight portions, sodium bicarbonate 3-8 weight portions, guar gum 5-15 weight portions, citric acid 3-8 weight portions, table salt 5-15 weight portions, and modified starch 15-30 weight portions. The present invention also provides corresponding vermicelli, which consists of the dispersant 1.5-2 weight portions and plant starch 80-120 weight portions. Experiment shows that the dispersant for vermicelli has no harmful matter contained and effect similar to traditional dispersant. The vermicelli with the dispersant is one kind of health food possessing high safety, good look, good taste, physical, chemical and hygienic indexes meeting relevant requirements, balanced and rich nutrients and high marketability.

Owner:四川白家阿宽食品产业股份有限公司

Sintering aid for yttrium aluminum garnet-based fluorescent transparent ceramic and using method thereof

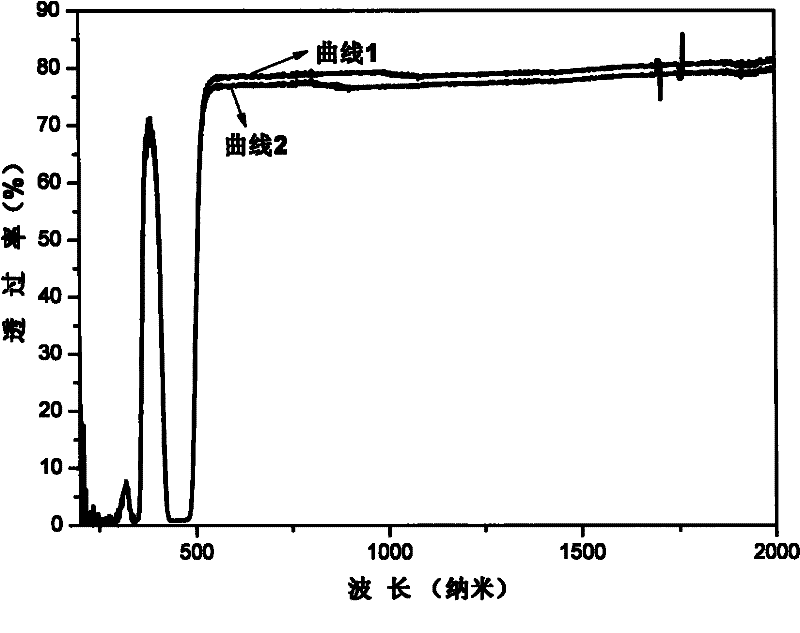

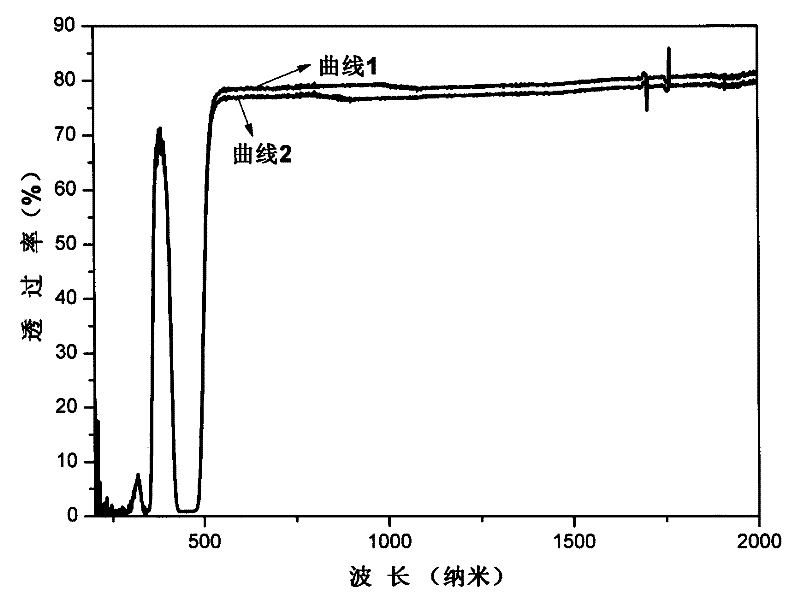

The invention relates to a sintering aid for yttrium aluminum garnet-based fluorescent transparent ceramic and a using method thereof. The sintering aid particularly comprises tetraethoxysilane and magnesium oxide, wherein the using amount of the tetraethoxysilane with the silicon oxide content of not less than 28.4 percent is 0.3 to 0.7 weight percent of the garnet-based transparent ceramic fluorescent powder raw material; and the using amount of the magnesium oxide with the purity of not less than 99.9 percent is 0.01 to 0.8 weight percent of the garnet-based transparent ceramic fluorescent powder raw material. The garnet-based transparent ceramic fluorescent material prepared from the sintering aid has a compact microstructure and is uniform in crystallite dimension distribution.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

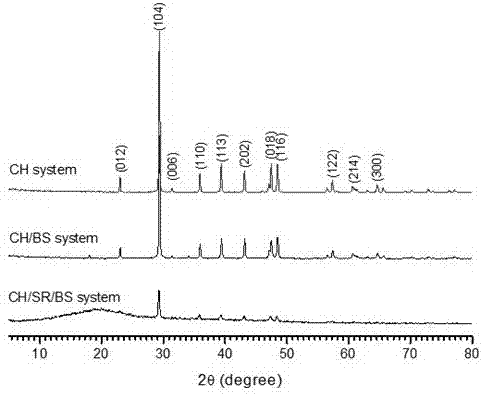

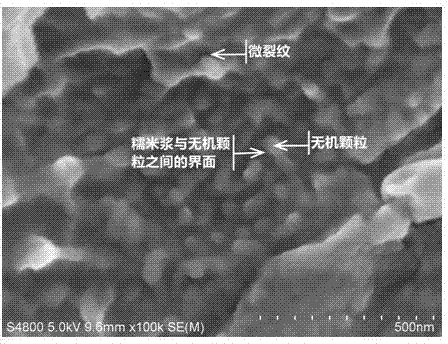

High-performance historic site repair material and preparation method thereof

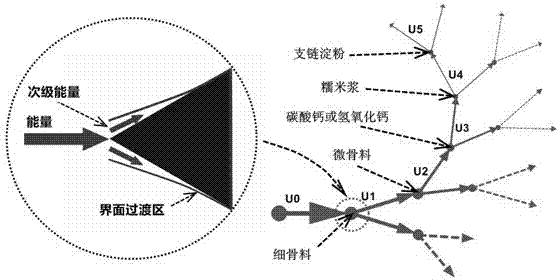

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

High permittivity silicate gate dielectric

InactiveUS7115461B2High densityHigh dielectric constantSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricHafnium

A field effect semiconductor device comprising a high permittivity silicate gate dielectric and a method of forming the same are disclosed herein. The device comprises a silicon substrate 20 having a semiconducting channel region 24 formed therein. A metal silicate gate dielectric layer 36 is formed over this substrate, followed by a conductive gate 38. Silicate layer 36 may be, e.g., hafnium silicate, such that the dielectric constant of the gate dielectric is significantly higher than the dielectric constant of silicon dioxide. However, the silicate gate dielectric may also be designed to have the advantages of silicon dioxide, e.g. high breakdown, low interface state density, and high stability. The present invention includes methods for depositing both amorphous and polycrystalline silicate layers, as well as graded composition silicate layers.

Owner:TEXAS INSTR INC

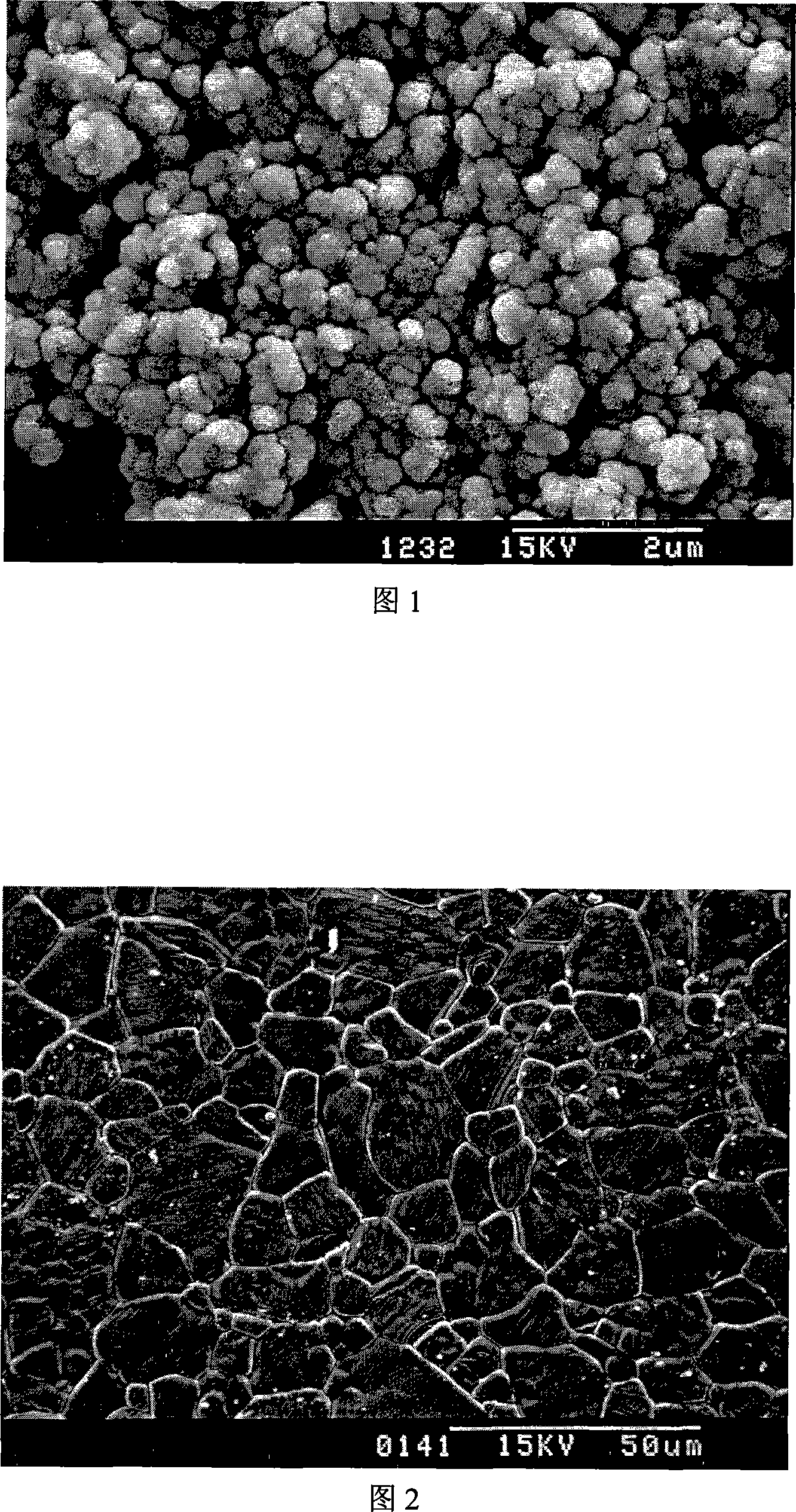

Method for preparing ceramic through micro-nano grain-size grading

The invention discloses a method for preparing ceramic through micro-nano grain-size grading and relates to a ceramic preparing method. The method aims at solving the problems that in an existing ceramic powder forming technology, high-density ceramic green bodies and sintering bodies are difficult to obtain, and the comprehensive performance of ceramic materials cannot be effectively promoted. The method includes the steps that firstly, an even mixing solution is prepared; secondly, single-phase or multi-phase ceramic slurry is prepared; thirdly, a ceramic body is prepared; fourthly, sintering densification is conducted, and therefore the ceramic is completed. The method is started with the combination of the problem of micro-nano powder grading in ceramic particle stacking under the centrifugal gel-casting technology, and ceramic materials good in performance are obtained by selecting proper particle size grading proportions. According to the method, the requirement for equipment in the whole preparing technology is low, operation is simple, and the method is suitable for centrifugal gel-casting forming of various ceramic materials through a grading technology.

Owner:HARBIN INST OF TECH

Multi-component doping high-performance beryllium oxide ceramic material and preparation method

The invention belongs to the technical field of electronic materials. Multi-element doped high-performance beryllium oxide ceramic material, in addition to beryllium oxide, also includes 0.2-0.6% by mass of multi-element dopant; said multi-element dopant is composed of MgO, Al2O3, SiO2, CaO, ZnO and rare earth oxides , the mass percentage content of each component is: MgO: 5-60%, Al2O3: 0-40%, SiO2: 20-95%, CaO: 0.1-0.5%, ZnO: 0-0.5%, containing Y, La, Single or random mixed rare earth oxides of Ce or Sm: 0.01-0.5%. The multi-element dopant is prepared by a sol-gel method, and then mixed with a high-purity beryllium oxide raw material, shaped and sintered at a high temperature to obtain the multi-element doped high-performance beryllium oxide ceramic material of the present invention. The multi-component doped high-performance beryllium oxide ceramic material provided by the invention has lower sintering temperature, higher density, thermal conductivity and mechanical properties; its microstructure has the characteristics of compactness, uniform crystal grains and few pores. The preparation method has simple process, low production cost and good repeatability, and is suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

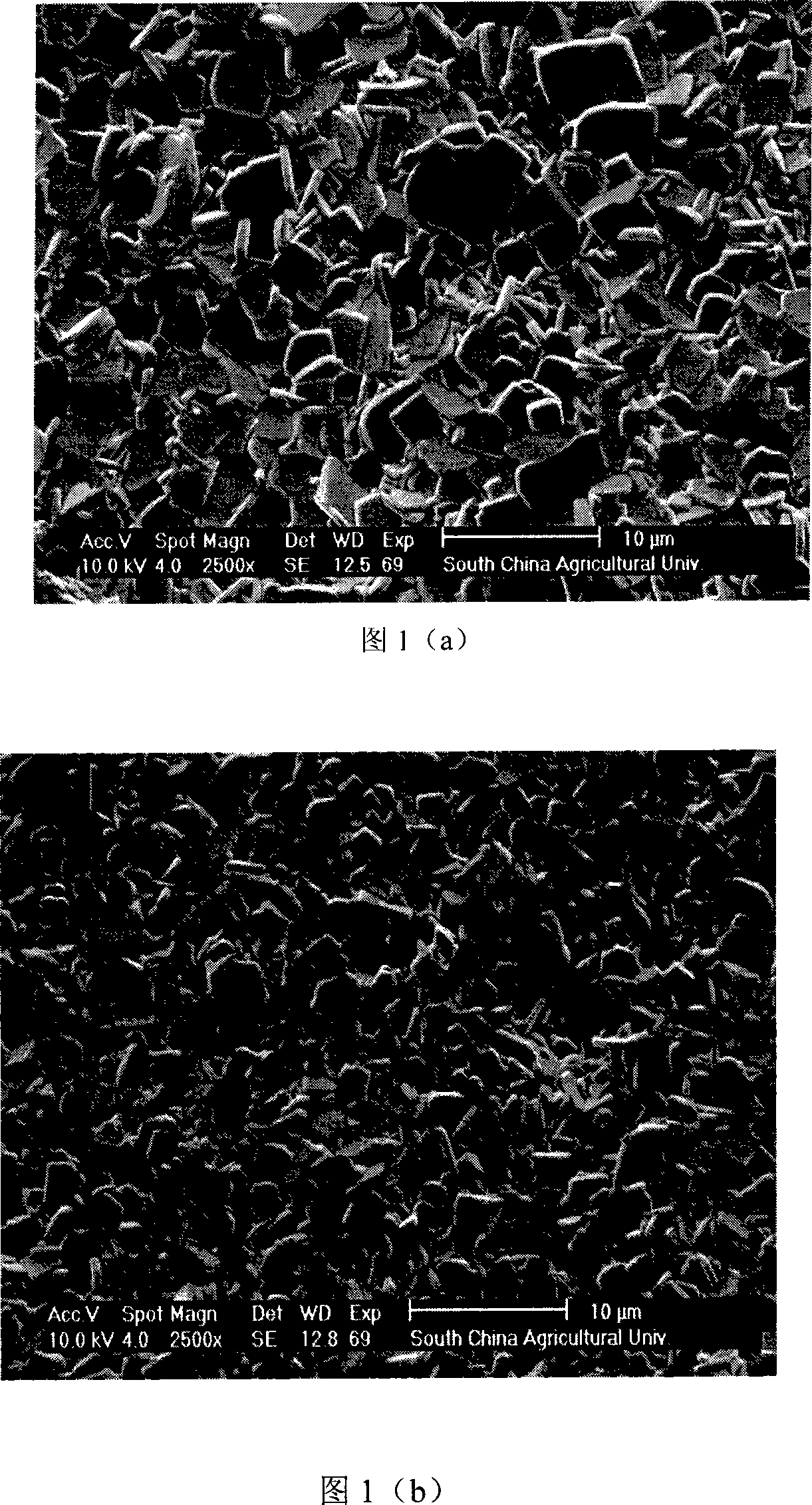

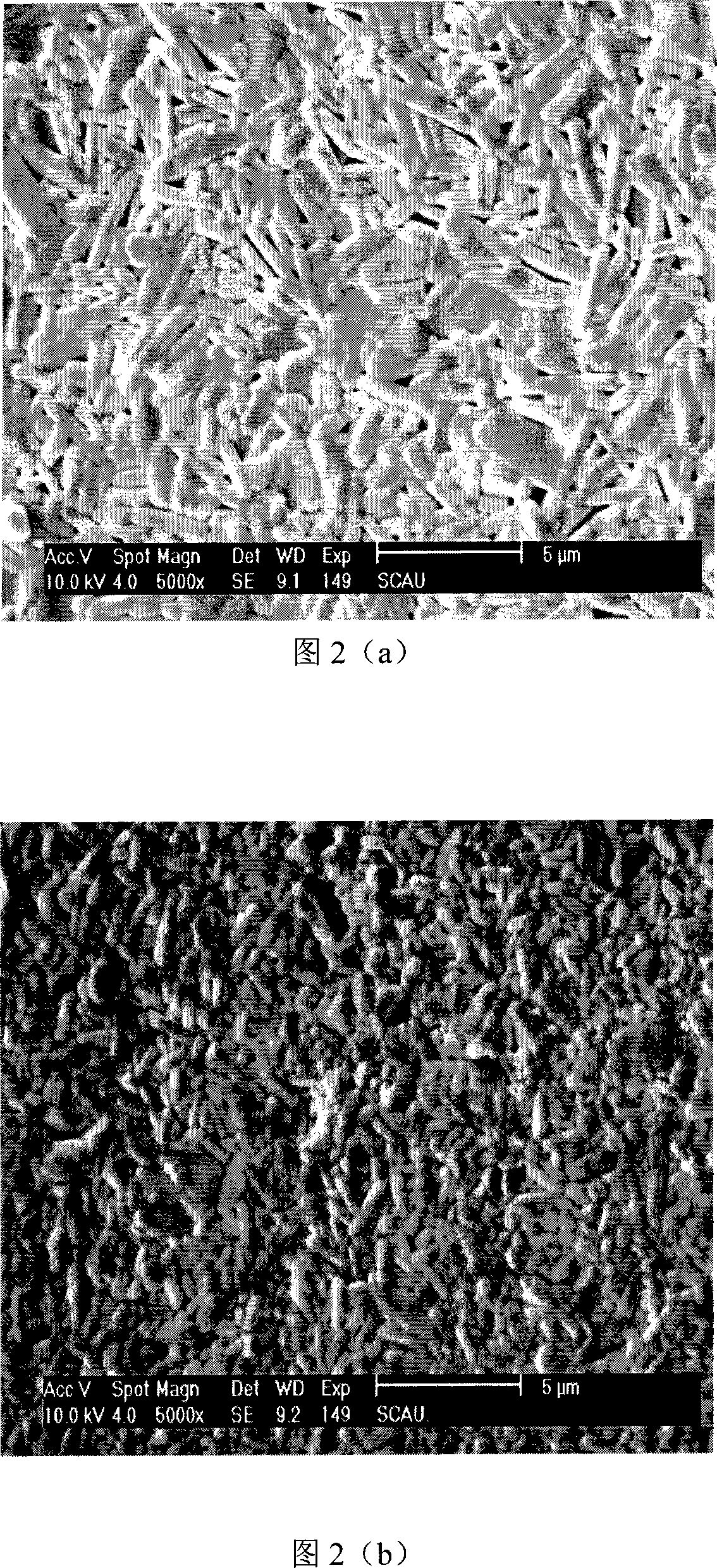

Method for increasing bismuth layer structure piezoelectricity ferroelectric ceramic material density

InactiveCN101186493AInhibit migrationGrowth inhibitionPiezoelectric/electrostrictive/magnetostrictive devicesVolumetric Mass DensityMaterial density

The invention discloses a density enhancing method of piezoelectric ferroelectric ceramic materials with bismuth layer structure. According to a chemical formula: (Am-1BmO3m+1) <2-> (Bi2O2) <2+>; and molar ratio A: B: Bi = m-1: m : 2, materials are calculated and weighted, wherein, the A is univalent, bivalent, trivalent or quadrivalent metal ion that is suitable for dodecahedral coordination; the B is trivalent, quadrivalent, pentavalent or sexivalent metal ion that is suitable for octahedral coordination; the production processes are that: mixing, pre-synthesizing, grinding, forming and sintering; the sintering process is that: the temperature of the obtained material from the last step is raised to 1100 to 1250 DEG C at a speed of 2 to 5 DEG C per minute, and is lowered to 50 to 150 DEG C within 1 to 5 minutes; under the temperature of 950 to 1150 EDG C, insulation at the low temperature is done for 5 to 20 hours; then the temperature is lowered to 500 DEG C at a speed of 3 to 7 DEG C per minute, and the obtained material is naturally cooled with a furnace. The invention can obtain the piezoelectric ferroelectric ceramic materials with grain-refining and density bismuth structure.

Owner:SOUTH CHINA UNIV OF TECH

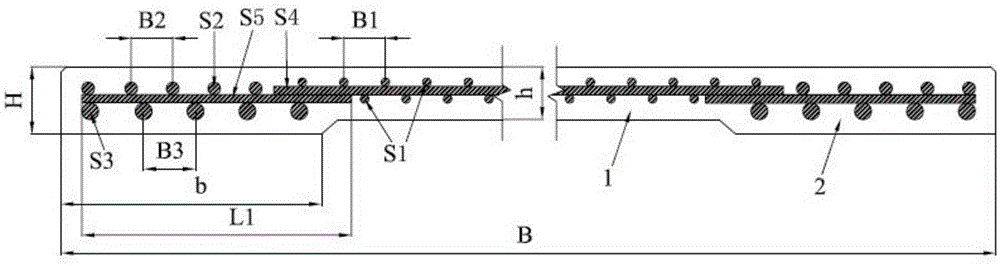

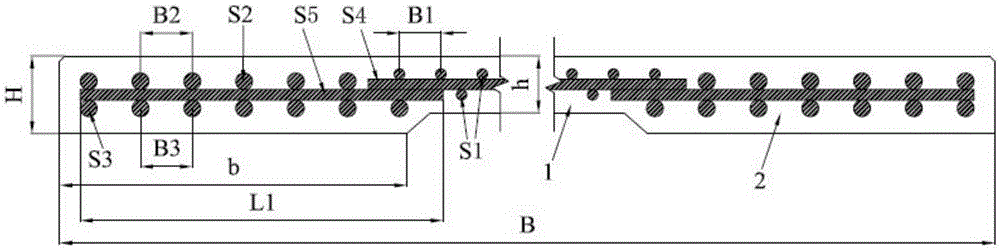

Ultra-high-performance cement-based bridge deck slab poured with ultra-high-performance cement-based composite materials

InactiveCN105254249ALight weightEasy to manufactureBridge structural detailsBridge materialsReinforced concreteBridge deck

The invention relates to an ultra-high-performance cement-based bridge deck slab poured with ultra-high-performance cement-based composite materials. The cement-based bridge deck slab meets the conditions that H / B<=0.03, h / B<=0.025, H>=h+15 mm, 1<=L / B<=4, B1, B2 and B4>=30 mm, B3>=40 mm, b / B=0.05-0.15, b<=L1<=b+B1, the reinforcement ratio of the middle section of the bridge deck slab is 1%-10%, the reinforcement ratio of the reinforcing sections on the two sides of the bridge deck slab is 5%-15%, the rib material yield strength is larger than or equal to 400 MPa, and the self weight is smaller than or equal to 240 kg / m<2>. According to the ultra-high-performance cement-based bridge deck slab poured with the ultra-high-performance cement-based composite materials, due to the fact that the cement-based composite materials with the ultra-high strength and high-strength rib materials are adopted, not only is the high bearing capacity achieved, but also the advantages that the self weight is small (only accounts for 20%-40% of that of an ordinary reinforced concrete bridge deck slab), the fatigue resistance, the corrosion resistance and the long life (the theoretical life can be more than 150 years) are achieved, installation is quick, time and labor are saved (the construction amount and the construction period are both reduced by 50%-70% than those of the ordinary reinforced concrete bridge deck slab) are achieved, and the cement-based bridge deck slab can be applied to new projects of small-medium bridges or existing bridge upgrading projects in the fields of roads, railways and the like.

Owner:浙江宏日泰耐克新材料科技有限公司

Production method of carbon fiber composite graphene-reinforced recycled concrete

InactiveCN106116362ASolve the reuse problemMeet the requirementsSolid waste managementBreaking strengthFiber

A production method of carbon fiber composite graphene-reinforced recycled concrete includes: first, preparing the materials: cement, sand, coarse aggregate, water, a nanomaterial, a water reducer, and a fiber material according to the ratio of 1:(1.4-1.6): (2.6-3): (0.28-0.32): (0.0001-0.0005): (0.01-0.05): (0.012-0.016); second, mixing the nanomaterial, the water reducer and the water, and ultrasonically dispersing to obtain a suspension; third, placing the cement, fiber material, sand and coarse aggregate in a stirring unit, and stirring well to obtain a mixture; adding the suspension into the mixture, stirring to obtain the carbon fiber composite graphene-reinforced recycled concrete; the nanomaterial is graphene, the fiber material is nano carbon fiber, and the concrete produced herein is more compact and has greatly improved breaking strength and compressive strength.

Owner:XIJING UNIV

Bridging particle for shallow casing blind hole

The invention discloses a bridging particle for a shallow casing blind hole. The bridging particle is suitable for the leakage stoppage of a shallow casing blind hole in an oil field, and comprises 1 to 3% of nano-zirconia, 10 to 20% of silica micropowder, 10 to 15% of light calcium carbonate, 25 to 40% of superfine cement, 0.2 to 2% of glass fiber, 1 to 2% of drag reducer, 0.5 to 2% of early strength agent and 30 to 45% of water. The slurry of the bridging particle has good thixotropy; the multiviscosity time is adjustable; the strength is high and the volume does not shrink after solidification; and no micro-cracks are generated. The invention can effectively solve technical problems of oil field leakage stoppage, such as severe casing leakage after a casing of an oil-water well is corroded and holed, while improving construction safety.

Owner:CHINA PETROLEUM & CHEM CORP +1

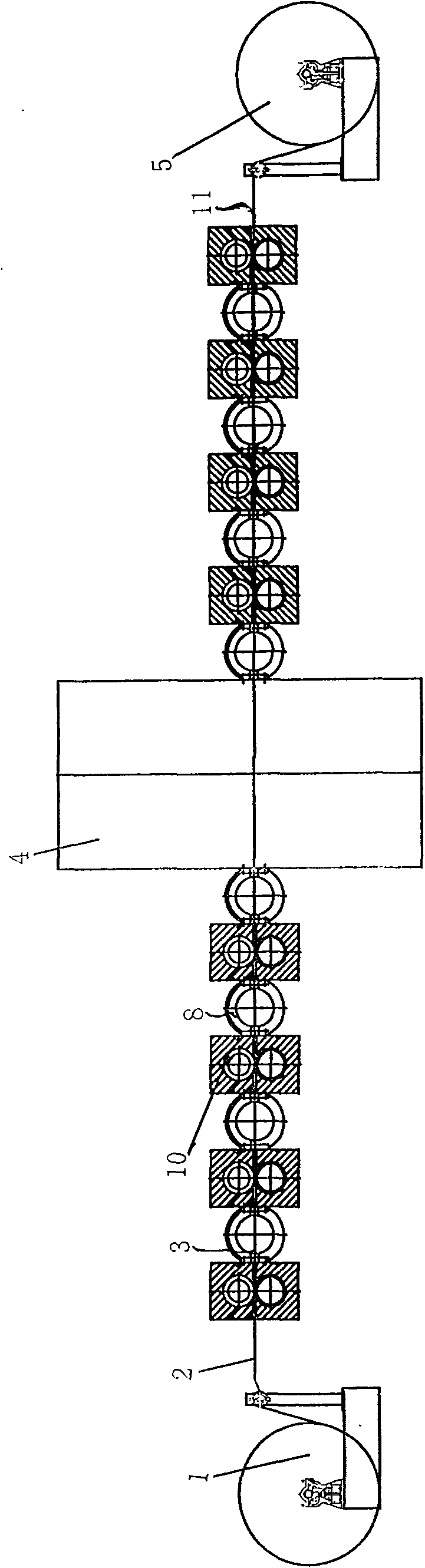

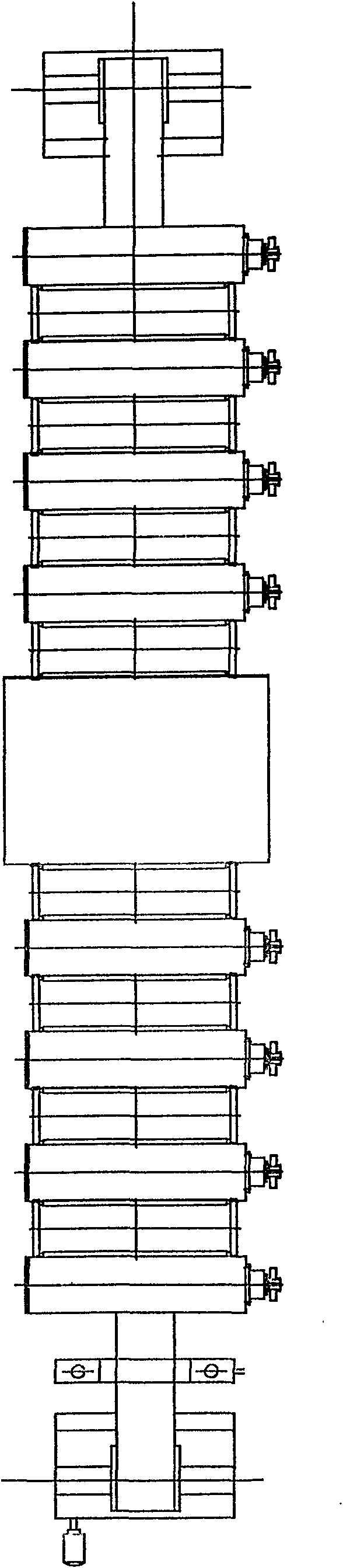

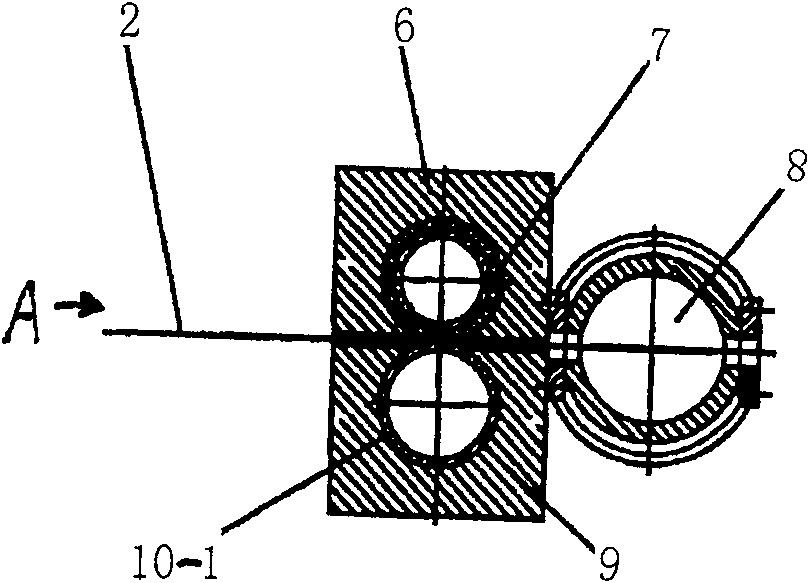

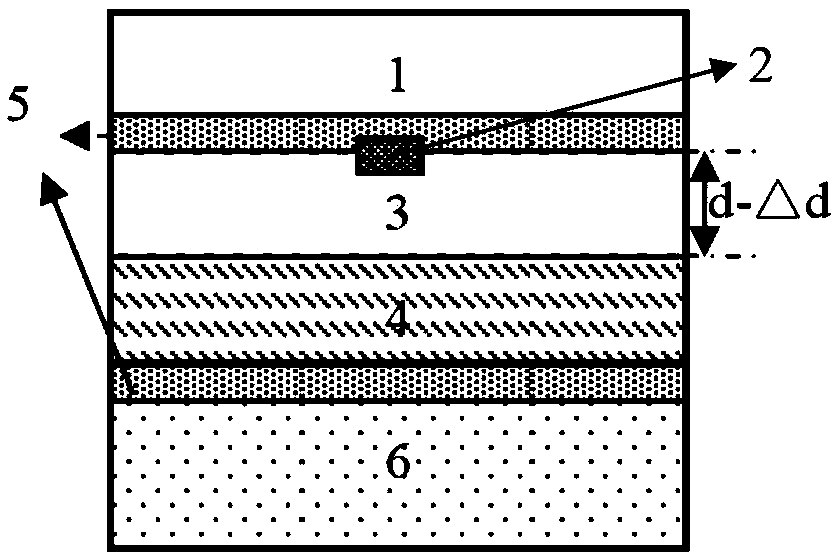

Strip film plating machine

ActiveCN102021527AImprove sealingSolution to short lifeVacuum evaporation coatingSputtering coatingEngineeringMetal sheet

The invention provides a strip film plating machine, which comprises at least one film plating vacuum chamber, and a coiled material unreel mechanism and a coiled material take-up mechanism which are positioned outside the film plating vacuum chamber. The strip film plating machine is characterized in that: a vacuum channel for at least one strip is formed between the film plating vacuum chamber and the coiled material unreel mechanism; a vacuum channel for at least one strip is formed between the film plating vacuum chamber and the take-up mechanism; and the vacuum channels each consist of at least one group of arc-shaped narrow silt damping mechanisms formed by two arc-shaped cavities and two rollers positioned in the two arc-shaped cavities and a vacuum lock with a vacuum aspirating chamber. In the strip film plating machine, the coiled material unreel mechanism and the coiled material take-up mechanism are arranged outside the vacuum chamber; the vacuum lock and a narrow silt damping channel are hermetic and reliable and have long service life, and the manufacturing cost of the equipment is low; and the strip film plating machine can perform continuous production and perform monolayer or multilayer film plating on surfaces of plastic films and metal sheets, and the surfaces of the obtained plating films have compact microstructures and are smooth.

Owner:SICHUAN GOLDSTONE-ORIENT NEW MATERIAL TECH CO LTD

High thermal conductivity silica brick for coke oven and preparation method thereof

ActiveCN104119081ADense microstructureImprove thermal conductivitySilica particleCarboxymethyl cellulose

The invention relates to a high thermal conductivity silica brick for coke oven and a preparation method thereof. The high thermal conductivity silica brick for a coke oven comprises the following components by weight: 68.0%-82.0% of natural silica particles, 13.0%-26.0% of natural silica powder, 0.5%-2.0% of an additive containing dispersant, 1.5%-5.0% of siliceous non oxide, 1.0%-3.0% of a mineralization agent, and an additional binder in the weight 1.5%-3.0% of the total weight of the previous materials. The additive comprises a dispersant carboxymethyl cellulose (CMC) with granularity less than 0.088 mm and siliceous non-oxide Si with granularity less than 0.043 mm, wherein the content of Si is greater than 96 wt.%. The silica brick provided by the invention has high thermal conductivity and keeps other comprehensive excellent performances of silica brick, and can satisfy the demands of coke oven for longevity, energy saving and high efficient production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

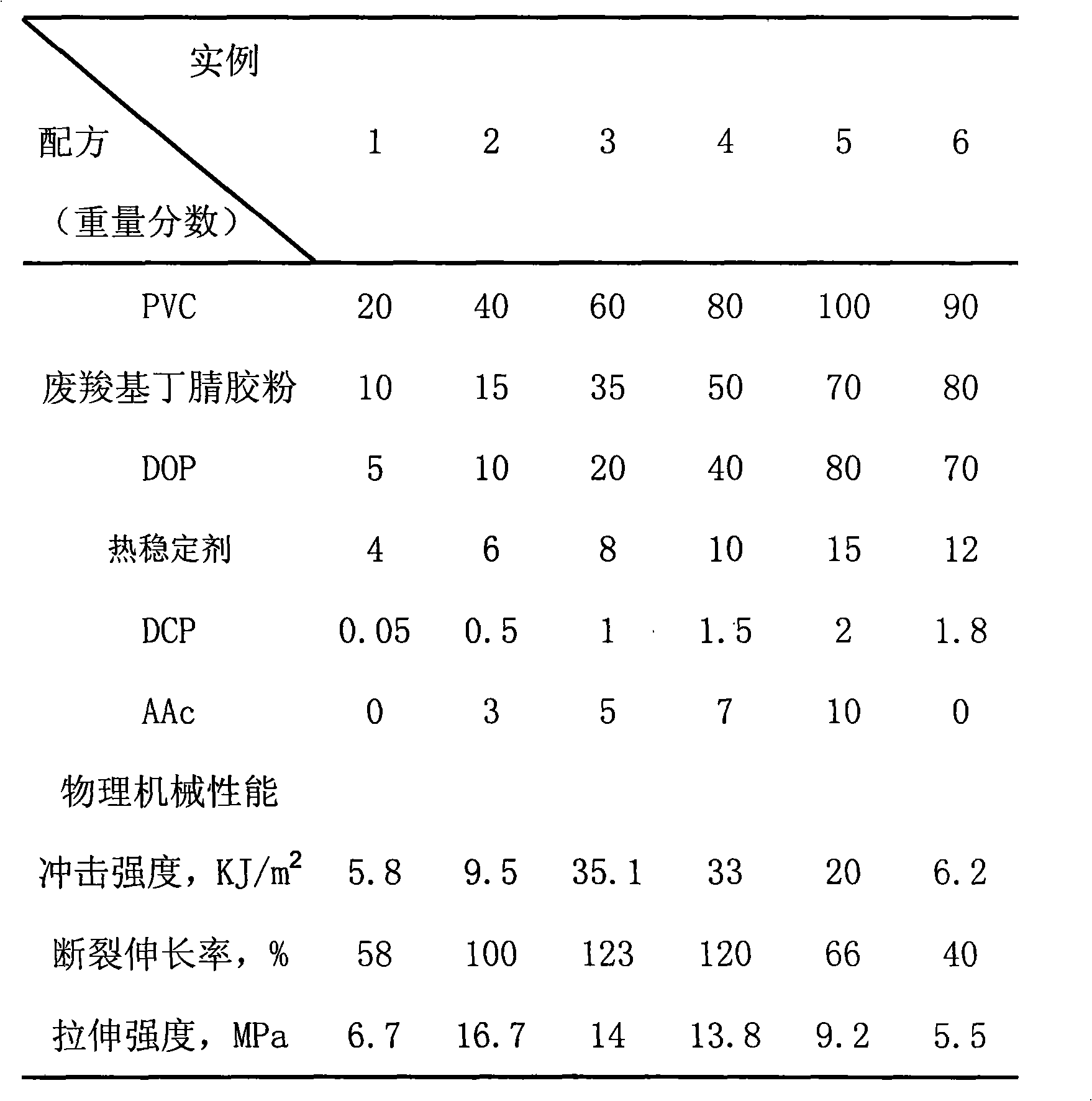

Method for preparing waste carboxylbutyronitrile adhesive powder and PVC mixture

The invention discloses a preparation method for waste carboxyl nitrile gelatine powder and PVC blend. The preparation method comprises the following steps that: plasticizer, heat stabilizer and PVC mixture are added in a double-roller feed mill to carry out preplasticizing, and then initiator, modifier and crushed waste carboxyl nitrile gelatine powder are added in turn to carry out milling; then, after stem pressing is completed inside a flat vulcanizing machine, a test block is quickly moved to a chilling press and demoulding is carried out after the test block is cooled down to room temperature, thereby obtaining the waste carboxyl nitrile gelatine powder / PVC blend. The blend not only has substantially increased impact strength and elongation at break, but also has a compact microstructure; moreover, the blend has wide application, simple manufacturing process, low cost and less environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

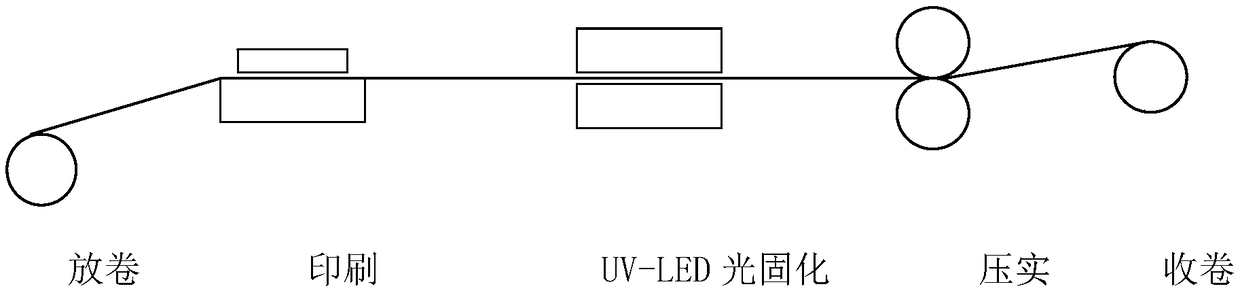

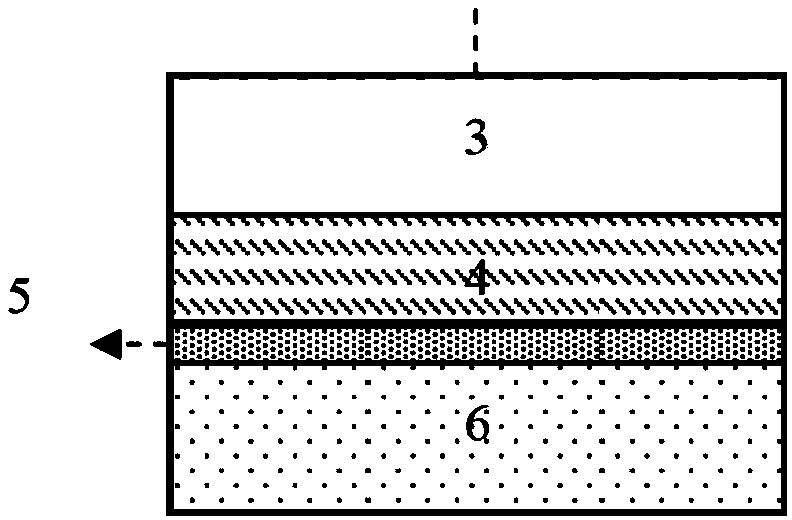

Radio frequency identification antenna and preparation method thereof

InactiveCN108615971AImprove performanceNon-volatileRadiating elements structural formsInksEngineeringRadio frequency

The invention discloses a radio frequency identification antenna and a preparation method thereof. According to the radio frequency identification antenna, an antenna pattern is printed and compactedon a fragile paper substrate through light-curable conductive ink; the thickness of the antenna pattern ranges from 3 to 15 microns. The antenna is compact in structure, has excellent performance, andcan be used for making a fragile, anti-tear and anti-transfer electronic label. The radio frequency identification antenna has the advantages of low manufacturing process difficulty, high productionefficiency and high industrial applicability.

Owner:XIAMEN XINDECO IOT & OPTPELECTRONICS TECH INST CO LTD

Geopolymer-based artificial flood control stone prepared from all wastes and preparation method thereof

The invention discloses a geopolymer-based artificial flood control stone prepared from all wastes and a preparation method of the geopolymer-based artificial flood control stone. The geopolymer-basedartificial flood control stone comprises the following raw materials in parts by weight: 288-412 parts of a waste silicon-aluminum material; 85-150 parts of alkali-containing waste; 29-75 parts of waste sulfate mineral; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; and 0-5 parts of crop waste. The process is simple, the prepared artificial flood control stone has no appearance defect; the stone has the advantages of large volume density, high strength (more than 34 MPa), good weathering resistance, freezing resistance and abrasion resistance and the like, is convenient to throw, good in integrity, strong in stability, freeze-thaw resistance, weathering resistance and high-speed sand-containing water flow abrasion resistance in the usingprocess, is not easy to lose under high-speed water flow, and is an ideal substitute product for natural stone standby stone prevention.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

Recycled concrete with highly effective damping property

The invention relates to a recycled concrete with highly effective damping property, which includes screening of fine aggregate and preprocessing of coarse aggregate. According to a weight ratio, each component is weighed; all of highly effective water-reducing agent and carbon nanofibers and half weight of water are poured into an agitator and agitated at high speed, so that suspension is obtained; the other half of water, thinner and polymer emulsion are mixed, so that a mixed solution is obtained; all of cement, fine aggregate and coarse aggregate are poured into an agitator and agitated uniformly, so that a mixture is obtained; the suspension prepared in Step 4 and the mixed solution in Step 5 are added into the mixture uniformly agitated in Step 6 and agitated sufficiently, so that the recycled concrete is obtained. The invention has the advantage that while sufficiently utilizing discarded concrete, the invention also can effectively increase the physicomechanical properties of the recycled concrete.

Owner:XIJING UNIV

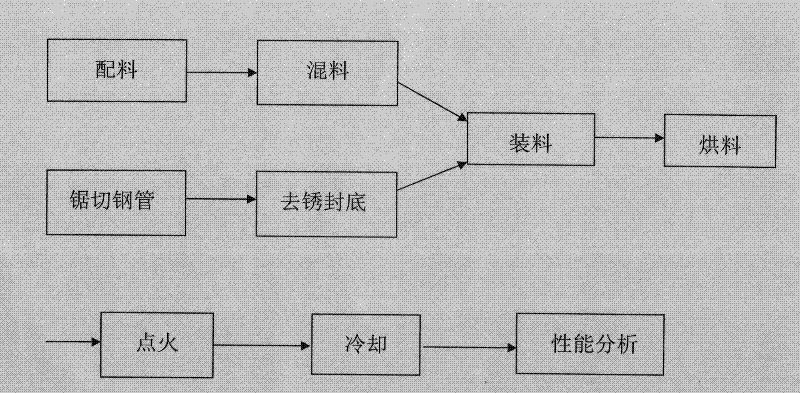

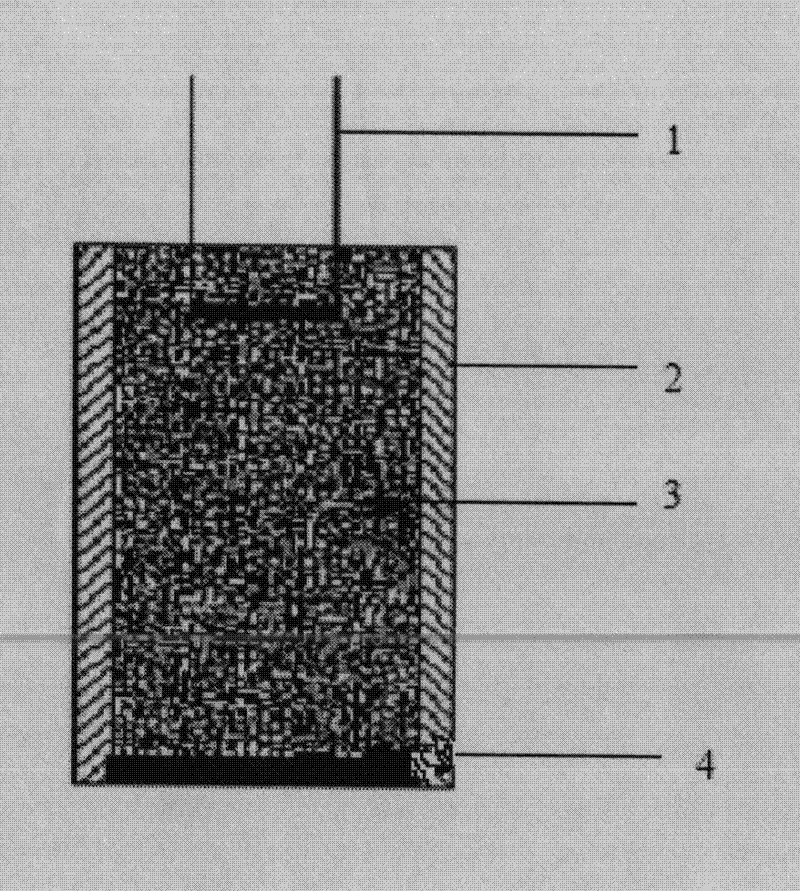

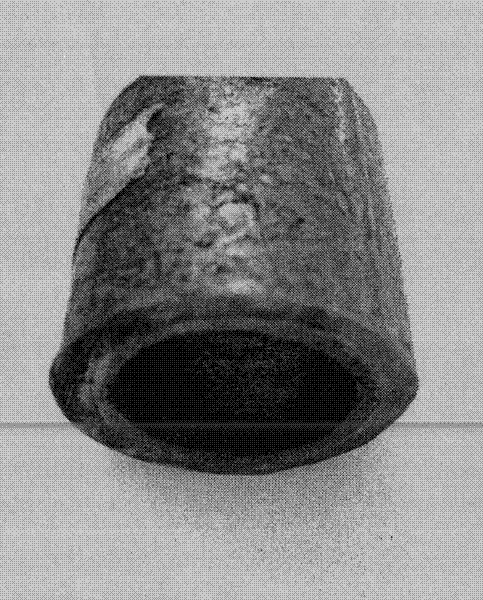

Manufacturing method for ceramic-lined composite steel pipe

InactiveCN102505117AHigh application valueSimple processMetallic material coating processesWear resistantCorrosion

The invention relates to a manufacturing method for a ceramic-lined composite steel pipe, and belongs to the field of pipeline transportation materials. The invention provides an additive, wherein the additive consists of rare earth oxide Y2O3 or La2O3 and silicon dioxide SiO2; the rare earth oxide Y2O3 or La2O3 and the silicon dioxide SiO2 are added into a thermit according to a proportion; the additive accounts for 1-3 percent of the total weight of reaction materials; and after drying, the ceramic-lined composite steel pipe is synthesized by a self-propagating process. The method has the advantages of increasing the compactness of a ceramic layer, improving the hardness of the composite steel pipe, enhancing the wear resistance, improving the corrosion resistance and prolonging the service life, along with fine and smooth inner surface and good texture. The overall performance of the ceramic-lined composite steel pipe is improved, so that the ceramic-lined composite steel pipe becomes an ideal wear-resistant pipeline transportation material; meanwhile, the rare earth resource advantage of China is brought into full play; and the application value of rare earth in the ceramic-lined composite steel pipe is effectively improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

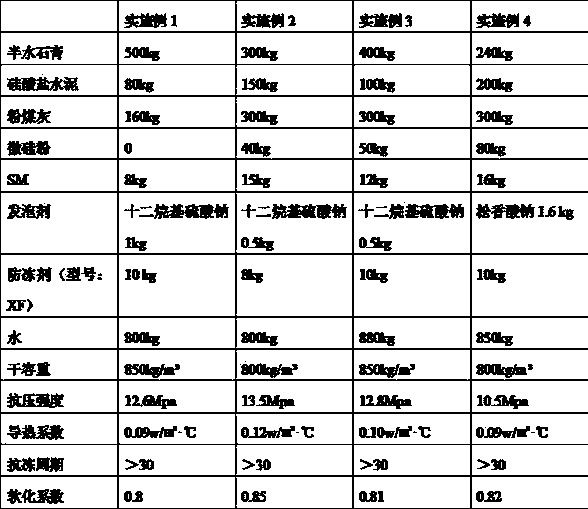

Composite-based self-heat-insulation building block and preparation method thereof

InactiveCN103553532AReduce intensityHigh strengthSolid waste managementCeramicwareFoaming agentCompressive strength

The invention relates to a composite-based self-heat-insulation building block. The composite-based self-heat-insulation building block comprises the following components in parts by weight: 240 to 500 parts of semi-hydrated gypsum, 80 to 200 parts of silicate cement, 160 to 300 parts of coal ash, 8 to 16 parts of a high-efficiency water reducing agent SM, and 0.5 to 1.6 parts of foaming agent. The composite-base self-heat-insulation building block is prepared by adding the high-efficiency water reducing agent SM and the foaming agent into 800 to 880 parts of water to obtain a mixture; adding the semi-hydrated gypsum, the silicate cement and the coal ash into the mixture; stirring the mixture, casting and molding to harden the mixture; drying or naturally curing to obtain the composite-based self-heat-insulation building block. The prepared composite-based self-heat-insulation building block has light weight, high compressive strength, a good heat insulation effect, high water resistance and a high softening coefficient, and is an excellent material for an energy-saving wall body of a building.

Owner:CHANGSHA YUKANG BUILDING MATERIAL TECH

Mineral modified magnesium-oxysulfate-based composite cementing material

The invention discloses a mineral modified magnesium-oxysulfate-based composite cementing material. The mineral modified magnesium-oxysulfate-based composite cementing material is formed by light calcined magnesia powder, epsom salt, water, a citric acid modifier and a mineral modifier, wherein a specific value of sum of weight parts of the light calcined magnesia powder and the mineral modifier,weight parts of the epsom salt and weight parts of the water is 532:246:216. The weight parts x of the light calcined magnesia powder, the weight parts y of the citric acid modifier and the weight parts z of the mineral modifier meet relational expressions: y / (x+y)+0.04-0.01, z / (x+z)=0.05-0.1. The mineral modifier is capable of reducing formation of a subsulfate phase and Mg(OH)2, has the micro-aggregate effect, and is capable of enabling a microscopic structure to be more compact, apparently delaying a hydration process of the citric acid modified magnesium-oxysulfate-based cementing material, reducing hydration heat of a system, and reducing an internal temperature stress caused by early hydration thereof. The cementing material has a better mechanical property and water resistance, early breaking strength thereof can reach 9.9 MPa maximally, and the water resistance can reach 0.91 maximally.

Owner:NINGBO UNIV

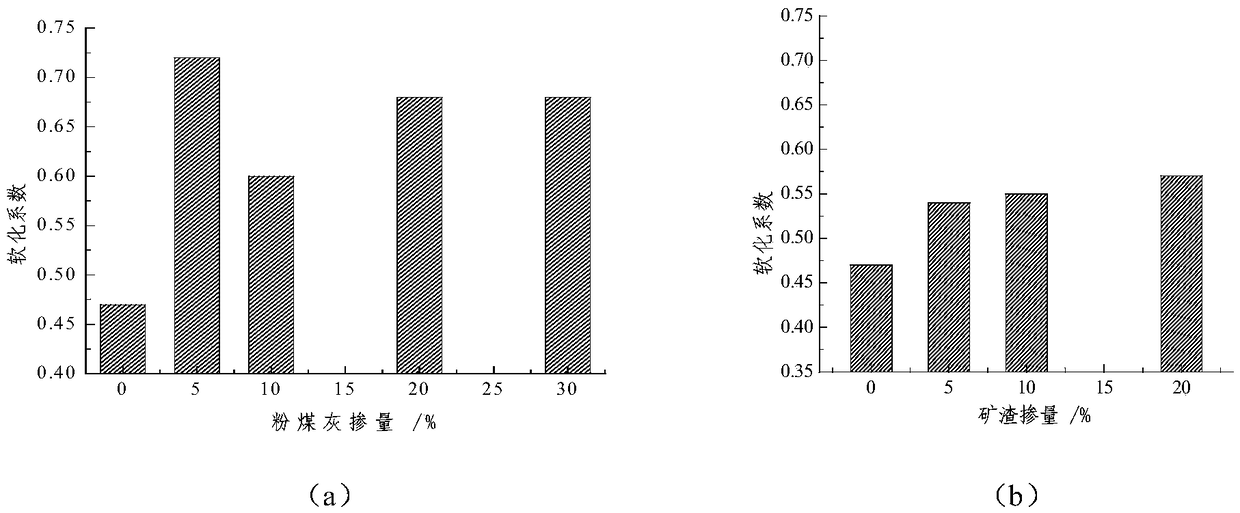

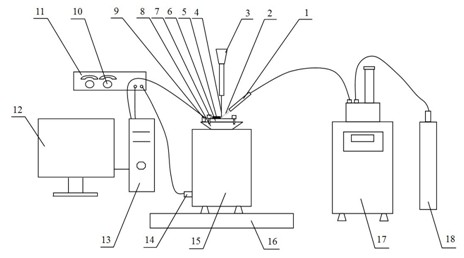

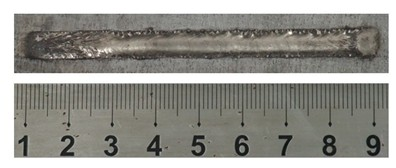

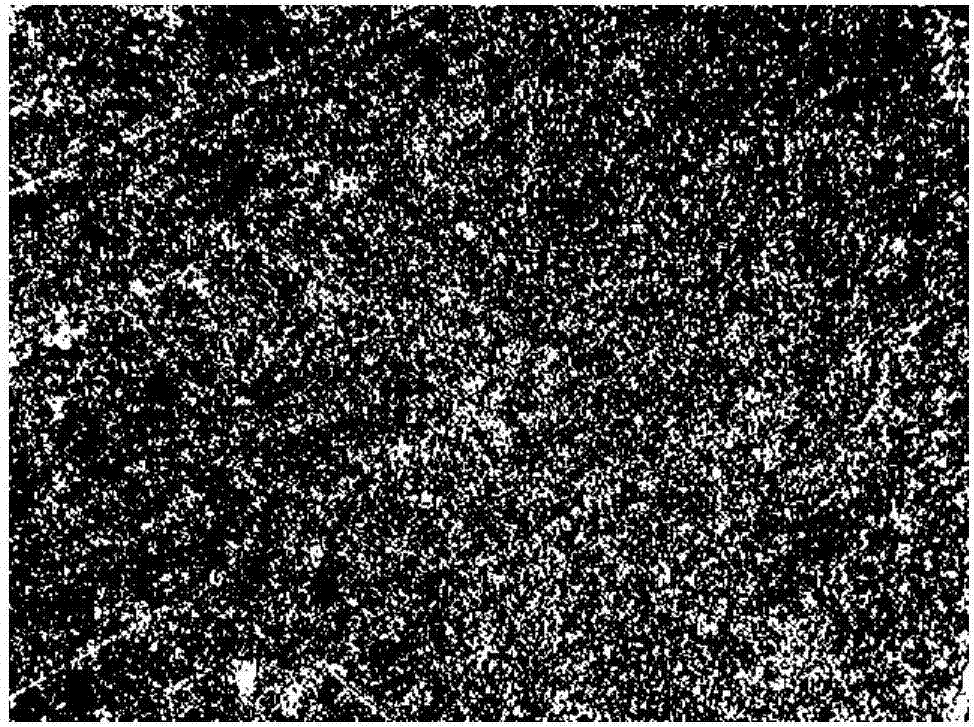

Method for controlling air holes of laser cladding layer by intermittent parking machine

InactiveCN102383124AImprove liquidityAvoid legacyMetallic material coating processesMelting tankEngineering

The invention relates to a method for controlling air holes of a laser cladding layer by an intermittent parking machine, belonging to the technical field of surface treatment. The method comprises the following steps of: fixing a cladding sample on a platform surface of an electromagnetic vibrating platform by a clamp device, adopting a lateral and synchronous powder feeding method, assisting low-amplitude and high-frequency intermittent parking vibration in the laser cladding process, leading metal liquid to be stressed by exciting force provided by mechanical vibration intermittently in the solidification process of a melting pool, and obtaining the high-quality cladding layer. In the method, the formation of a feeding channel can be enhanced, the intermittent vibration accelerates the escaping of residual gas in the cladding process, the residue of microscopic bubbles in the cladding layer is restrained, the macroscopic surface quality after the cladding layer is solidified is improved, the subsequent processing amount is reduced, and the comprehensive surface performance of the cladding layer is improved. The method is applicable to the fields such as strengthening and forming of laser cladding surfaces of metal parts and surface repairing of medium parts and the like, and can improve the quality of the cladding layer.

Owner:KUNMING UNIV OF SCI & TECH

Ultrahigh-strength low-alloy wear-resistant steel used for forging and preparation method thereof

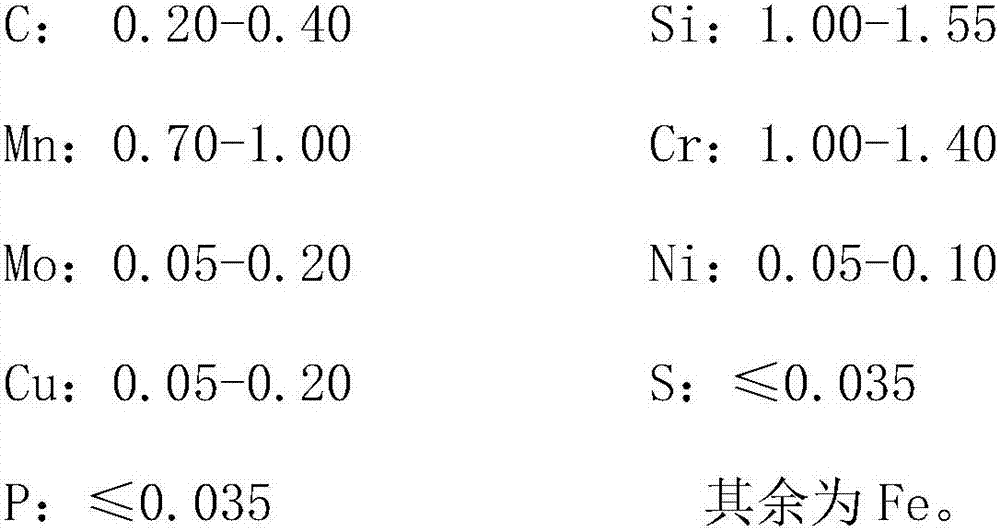

InactiveCN106868420AReduce intensityDense microstructureFoundry mouldsSoil-shifting machines/dredgersChemical compositionWear resistant

The invention provides ultrahigh-strength low-alloy wear-resistant steel used for forging. Main chemical components of the material of the low-alloy wear-resistant steel include 0.20 wt.%-0.40 wt.% of C, 1.00 wt.%-1.55 wt.% of Si, 0.70 wt.%-1.00 wt.% of Mn, 1.00 wt.%-1.40 wt.% of Cr, 0.05 wt.%-0.20 wt.% of Mo, 0.05 wt.%-0.10 wt.% of Ni, 0.05 wt.%-0.20 wt.% of Cu, not larger than 0.035 wt.% of S, not larger than 0.035 wt.% of P and the balance Fe. The ultrahigh-strength low-alloy wear-resistant steel has the beneficial effects that by means of the ultrahigh-strength low-alloy wear-resistant steel, hardenability and wear resistance of the wear-resistant steel can be greatly improved; and the ultrahigh-strength low-alloy wear-resistant steel used for forging has ultrahigh strength, good tenacity, high hardness and good wear resistance at the same time, and the service life of the ultrahigh-strength low-alloy wear-resistant steel can be prolonged by three or more times compared with the service life of ordinary low-alloy wear-resistant steel. The invention further provides a preparation method of the ultrahigh-strength low-alloy wear-resistant steel used for forging, and it is ensured that the process is not complex and is easy to control and the production cost is low.

Owner:HUBEI WANXIN PRECISION CASTING & FORGING INC

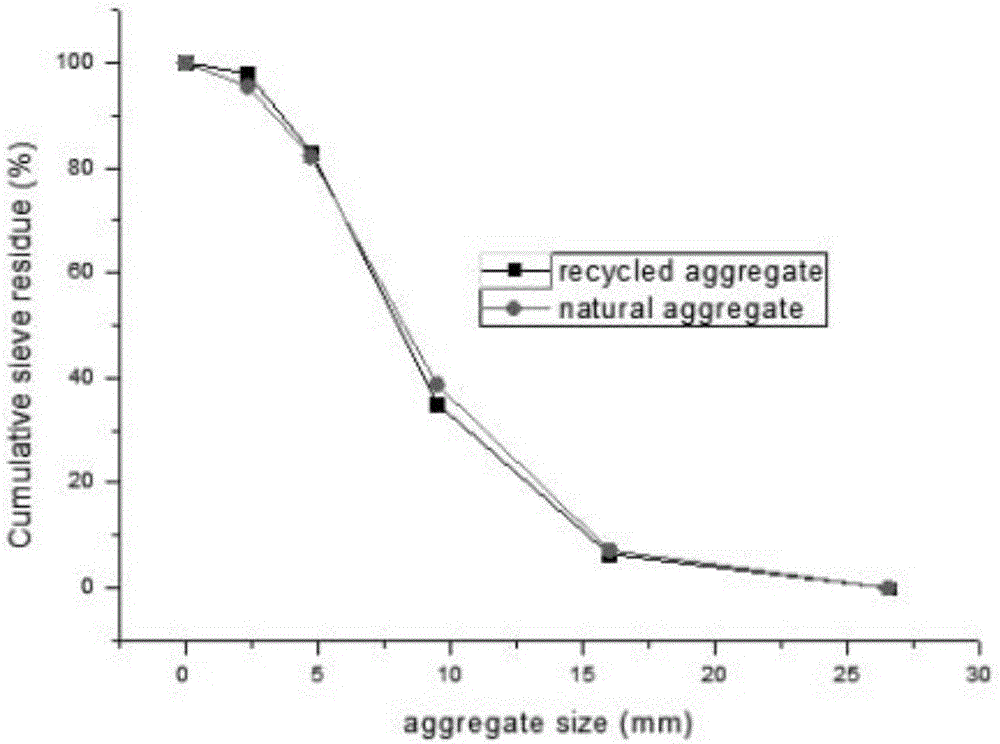

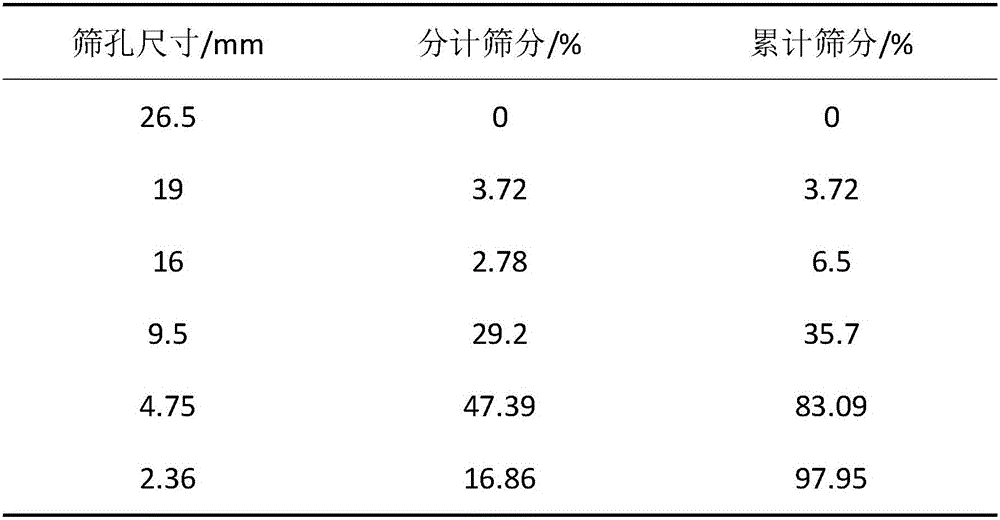

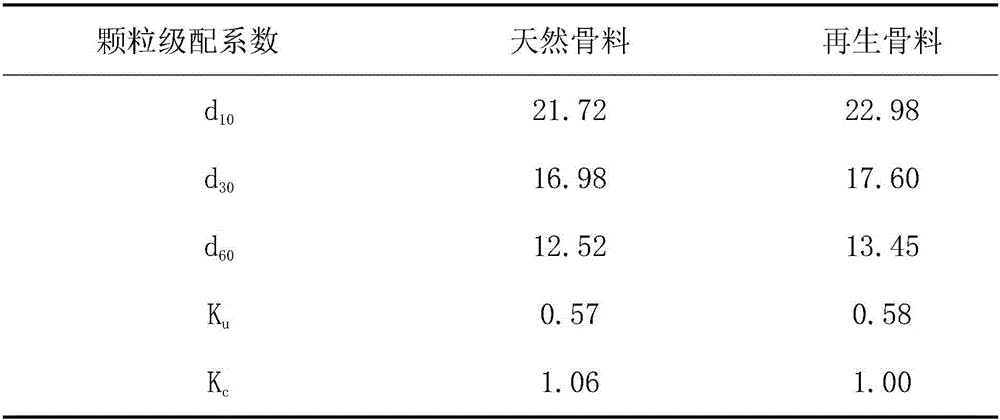

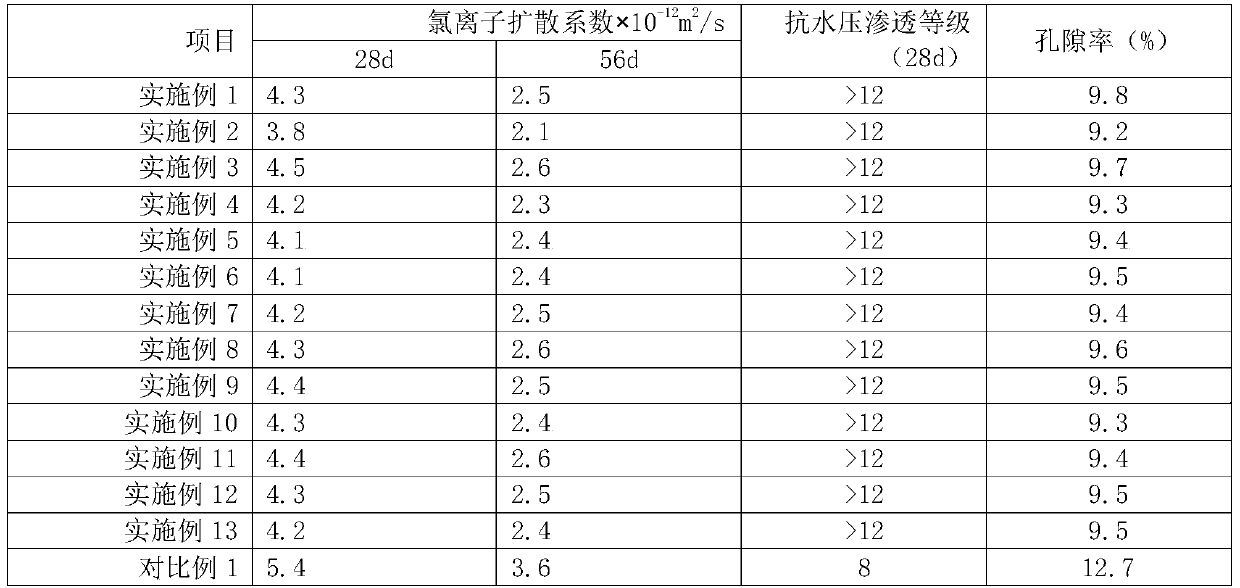

Method for improving performances of recycled concrete by utilizing carbon dioxide

ActiveCN110590260AImprove solubilityDense microstructureSolid waste managementCALCIUM HYDROXIDE SOLUTIONEconomic benefits

An objective of the invention is to provide a method for improving performances of recycled concrete by utilizing carbon dioxide. The method comprises the following steps: mixing Ca(OH)2 powder rich in calcium with water so as to form a calcium hydroxide solution; then introducing carbon dioxide gas into the calcium hydroxide solution until the calcium hydroxide solution is completely carbonized,then adding cement, mixing the cement with the solution produced in the first step under stirring for 60 s, then adding recycled coarse aggregate, carrying out stirring for 60 s, pouring sands and natural coarse aggregate, and carrying out complete mixing under stirring for 120 s so as to obtain a concrete mixture. The recycled concrete prepared by using the method provided by the invention is improved in compressive strength and flexural strength to a certain extent; meanwhile, the method can fix carbon dioxide in the atmosphere. The method provided by the invention provides a direction for promotion and application of CO2 and recycled aggregates, expands the application range of the CO2 and the recycled aggregates, has important theoretical value and significant economic benefits and environmental protection benefits, and has great significance for development of concrete.

Owner:HUNAN UNIV

Construction waste recycled concrete

The invention relates to construction waste recycled concrete, and belongs to the technical field of concrete. The construction waste recycled concrete comprises fly ash, stone powder, recycled coarseaggregate, recycled fine aggregate, an early strength agent, a water reducing agent, an air entraining agent and a reinforcing component, wherein the recycled coarse aggregate is formed by crushing and screening waste bricks; the recycled fine aggregate is formed by crushing and screening waste concrete; and the reinforcing component comprises basalt fibers, polypropylene reticular fibers, metakaolin and a CABR-MS605 corrosion inhibitor. According to the technical scheme, the impermeability of the recycled concrete can be improved.

Owner:BEIJING GAOQIANG CONCRETE

Outside casing channeling-blocking agent

The invention discloses an outside casing channeling-blocking agent which is applicable to the blocking of the outside casing channeling of an oil-water well casing on an oil field. The outside casing channeling-blocking agent is composed of 0.5-2% of nano zinc oxide, 1-3% of nano titanium oxide, 15-30% of silicon micro powder, 0.5-2% of glass fiber, 30-45% of ultra-fine cement, 1-1.5% of complex iron salt, 0.5-2% of retarder and 35-45% of water. Because of the addition of the part of the nano materials, the channeling-blocking agent has good slurry fluidity and high thixotropy, ensures high intensity and non-shrinking volume after being cured, produces no micro crack and has high blocking rate. Besides, the channeling-blocking agent can effectively solve the outside casing channeling problem caused by poor high pressure water injection quality of a water injection well, poor well cementing quality of an oil well or other reasons, and can be also used for secondary well cementing above the top of the cement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com