Strip film plating machine

A coating machine and strip technology, applied in the field of strip coating machines with arc-shaped narrow slit damping mechanism, can solve the problems of unfavorable vacuum pump operation, poor effect, low power, etc., achieve smooth surface, low equipment manufacturing cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

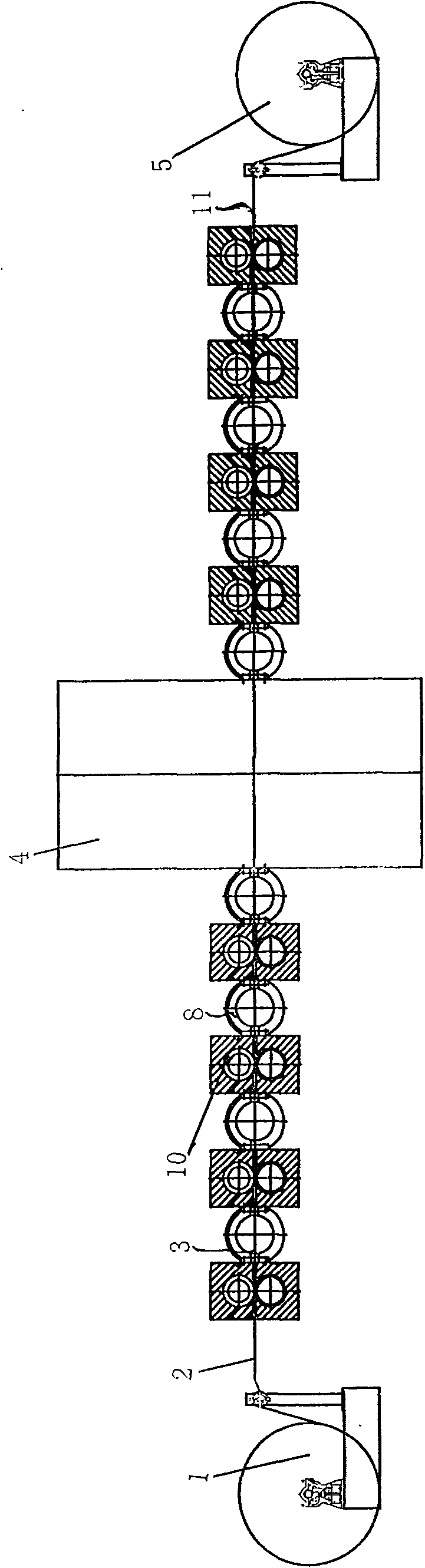

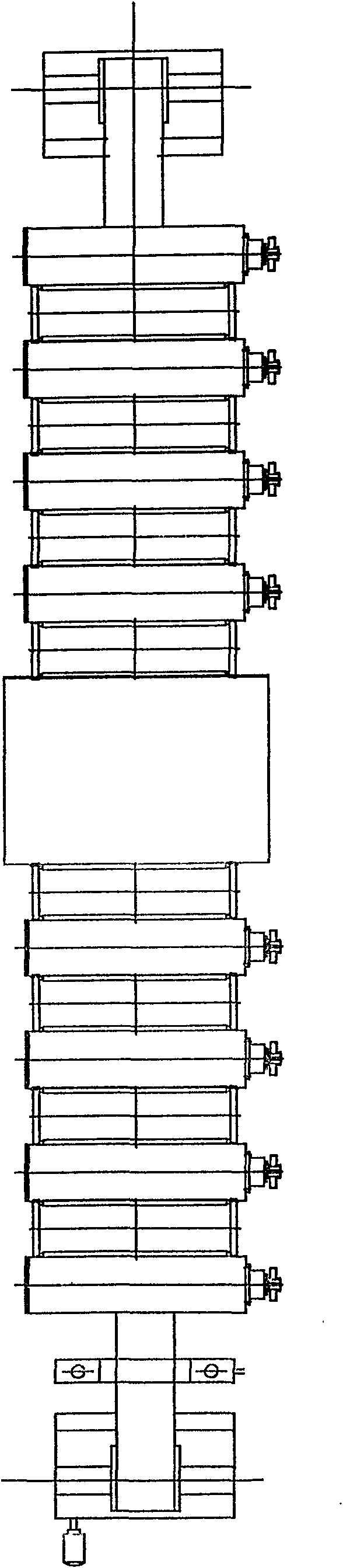

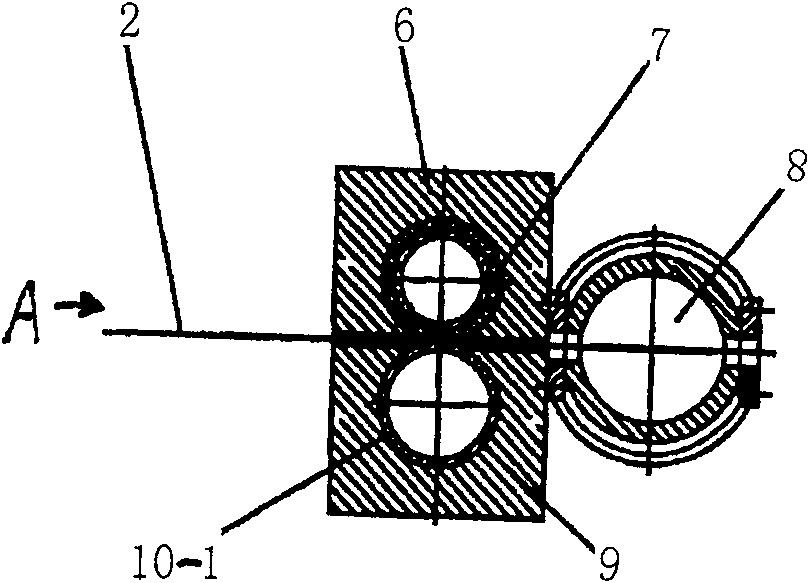

[0016] Figure 1 to Figure 6 Figures of embodiments of the invention are given. see Figure 1 to Figure 6 , Coil material unwinding mechanism 1 and winding mechanism 5, steel strip (or plastic film) 2, plated steel strip finished product coil 11 that are positioned at coating vacuum chamber 4 are arranged in the strip coating machine of the present invention. Between the coating vacuum chamber and the coil unwinding mechanism, and between the coating vacuum chamber and the winding mechanism, there are eight vacuum passages 3 through which strips pass in and out. The vacuum channel consists of two arc-shaped cavities 12 in the damping seat 6, an arc-shaped slit damping mechanism 10 composed of two sticks, the rubber roller 7 and the steel roller 9 located in the arc-shaped cavity, and a vacuum lock composed of a vacuum pumping chamber 8. constitute. The arc-shaped slit 10-1 formed by the stick and the arc-shaped cavity is between 0.01mm and 0.5mm. The cylinder is an active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com