Production method of carbon fiber composite graphene-reinforced recycled concrete

A technology of composite graphene and recycled concrete, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to meet the requirements of use and solve the problem of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of preparation method of carbon fiber composite graphene reinforced recycled concrete comprises the following steps:

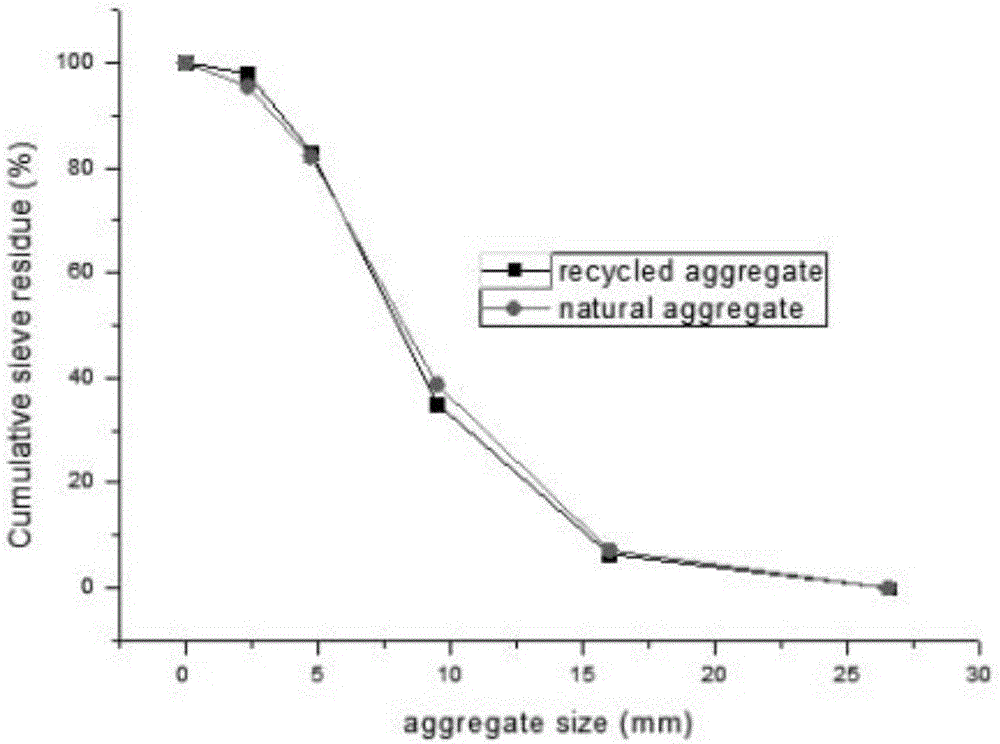

[0038] Step 1: prepare materials according to the following mass ratio, cement: sand: coarse aggregate: water: nano material: water reducer: fiber material = 1: 1.4: 2.6: 0.28: 0.0001: 0.02: 0.012, the cement is 42.5 R ordinary Portland cement, the sand is medium sand, the coarse aggregate is a mixture of natural crushed stone and recycled aggregate with a replacement rate of 30%, and the replacement rate is the weight of waste concrete to the total mass of coarse aggregate The nanomaterial is graphene with a particle size of 0.6-1nm, the water reducer is a carboxylic acid-based high-efficiency water reducer, and the water reducing efficiency is 20% to 30%, and the fiber is nano Carbon fibers with an average diameter of 150nm and a length of 30-100um;

[0039] Step 2: Mix nanomaterials, water reducing agent and water, and perform u...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of carbon fiber composite graphene reinforced recycled concrete comprises the following steps:

[0044] Step 1: prepare materials according to the following mass ratio, cement: sand: coarse aggregate: water: nanomaterial: water reducer: fiber material = 1: 1.5: 2.8: 0.30: 0.0002: 0.01: 0.014, the cement is 42.5 R ordinary Portland cement, the sand is medium sand, the coarse aggregate is a mixture of natural crushed stone and recycled aggregate with a replacement rate of 30%, and the replacement rate is the weight of waste concrete to the total mass of coarse aggregate The nanomaterial is graphene with a particle size of 0.6-1nm, the water reducer is a carboxylic acid-based high-efficiency water reducer, and the water reducing efficiency is 20% to 30%, and the fiber is nano Carbon fibers with an average diameter of 150nm and a length of 30-100um;

[0045] Step 2: Mix nanomaterials, water reducing agent and water, and perform ul...

Embodiment 3

[0049] Embodiment 3, a kind of preparation method of carbon fiber composite graphene reinforced recycled concrete, comprises the following steps:

[0050] Step 1: prepare materials according to the following mass ratio, cement: sand: coarse aggregate: water: nano material: water reducer: fiber material = 1: 1.5: 2.8: 0.28: 0.0003: 0.03: 0.016, the cement is 42.5 R ordinary Portland cement, the sand is medium sand, the coarse aggregate is a mixture of natural crushed stone and recycled aggregate with a replacement rate of 50%, and the replacement rate is the weight of waste concrete to the total mass of coarse aggregate The nanomaterial is graphene with a particle size of 0.6-1nm, the water reducer is a carboxylic acid-based high-efficiency water reducer, and the water reducing efficiency is 20% to 30%, and the fiber is nano Carbon fibers with an average diameter of 150nm and a length of 30-100um;

[0051] Step 2: Mix nanomaterials, water reducing agent and water, and perform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com