Method for preparing modified wood chip hydrothermal charcoal by adopting KOH

A biochar, wood chip technology, applied in water pollutants, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of limited adsorption performance and stability, limited adsorption sites, etc., and achieve far-reaching social significance and economical. Value, improved adsorption performance, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Through the preparation method of KOH modified sawdust hydrothermal biochar, the steps are as follows:

[0027] 1) Sawdust (SD) is crushed into powder, and the particle size is to pass through a 50-mesh sieve;

[0028] 2) Add 5.0g of sawdust and 60mL of distilled water in turn into a 100mL reactor, and seal it;

[0029] 3) Place the reaction kettle in an oven, react at a constant temperature of 200°C for 20 hours, and then cool to room temperature;

[0030] 4) Take out the solid-phase product, wash it with distilled water until it is neutral, dry it at 105°C and store it in a sealed container to obtain sawdust hydrothermal biochar (H-SD);

[0031] 5) Mix 2.0 g of sawdust hydrothermal biochar with 2N KOH solution, stir well for 1 hour, filter, wash with water, and dry to obtain modified sawdust hydrothermal biochar (mH-SD).

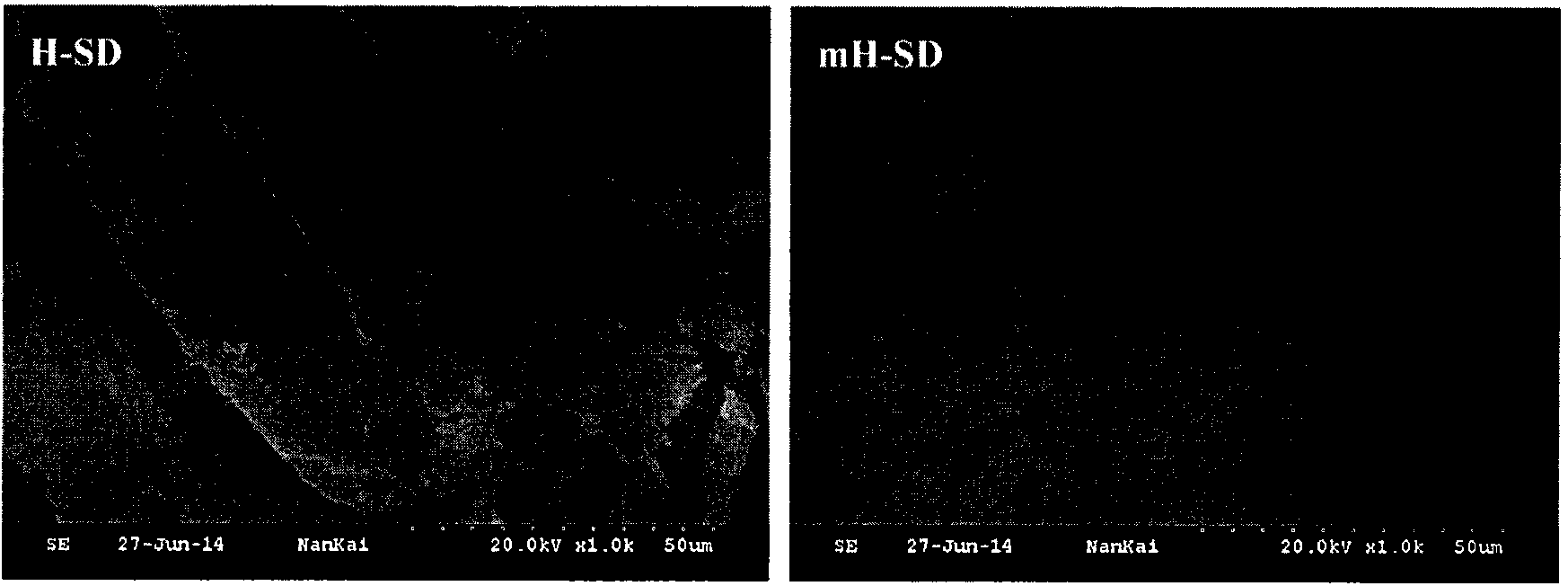

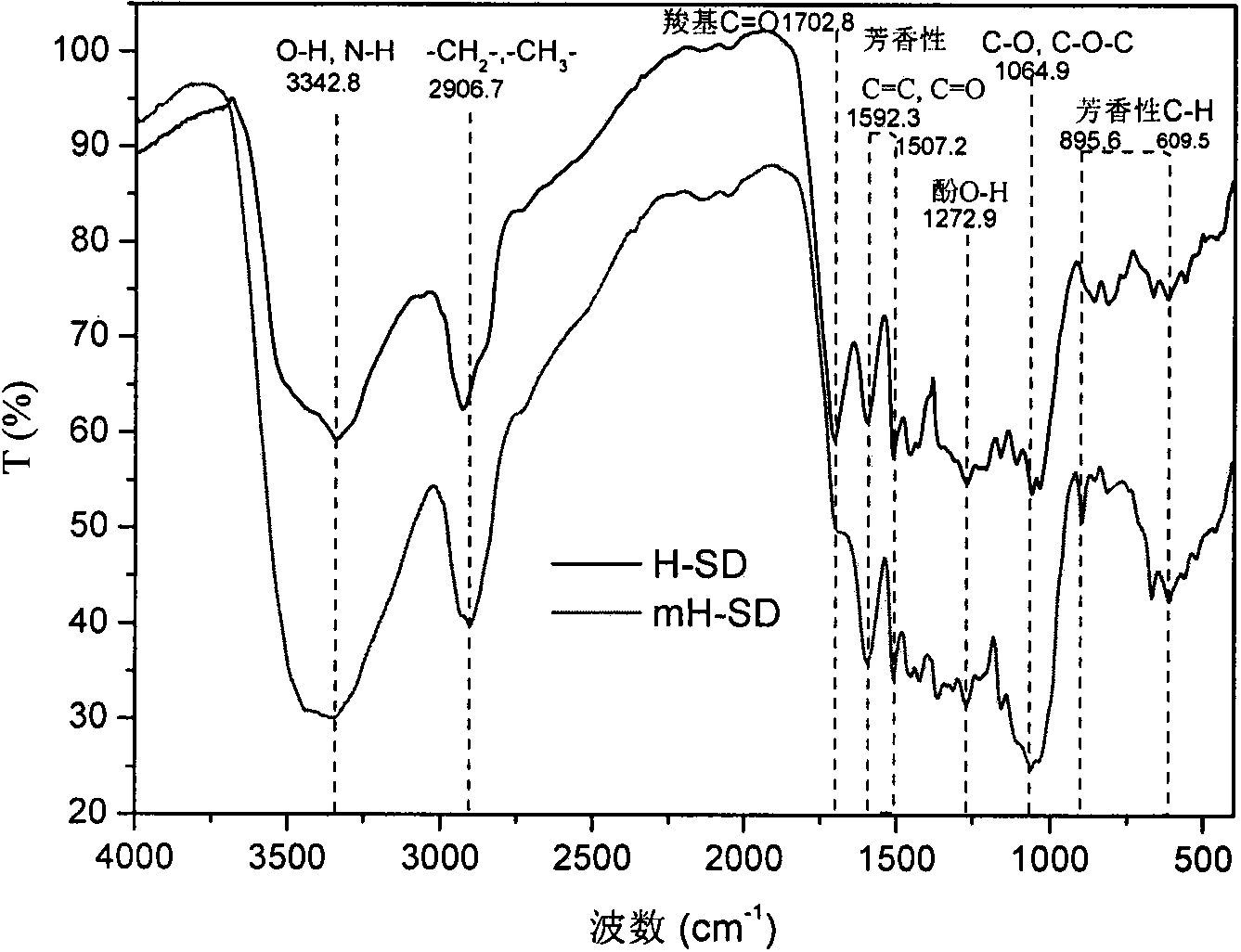

[0032] like figure 1 As shown, before modification, the content of impurities on the surface of wood chip hydrothermal biochar is more, while KO...

Embodiment 2

[0038] Weigh 0.06g of modified sawdust hydrothermal biochar, add 30mL of 20mg / L cadmium solution (containing 0.01mol / L of NaNO 3 As a background solution), adjust the pH of the solution with 0.1mol / L NaOH and nitric acid, place the sample bottle in a shaker at 150r / min, shake at 30°C, take samples at different time periods, filter with a 0.22μm filter membrane, and use Atomic absorption spectrophotometer (AA240FS, VARIAN) was used to measure the concentration of Cd(II) in the filtrate. For the unmodified hydrothermal biochar, the same steps as above were taken for comparison.

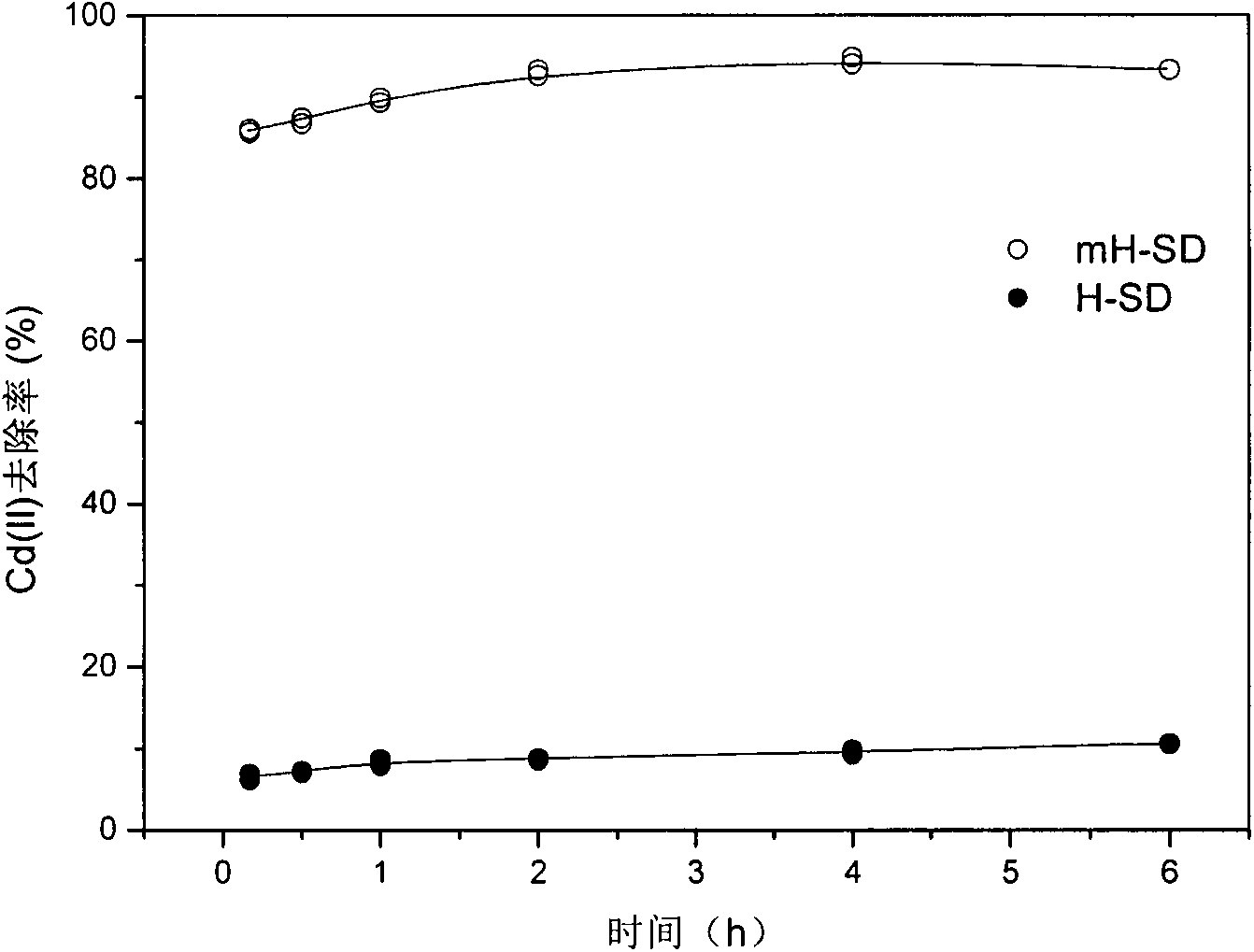

[0039] image 3 It shows that before and after the modification of sawdust hydrothermal biochar, the adsorption equilibrium time is the same, but the removal rate of Cd(II) after modification is significantly improved, from 11% of H-SD to 95% of mH-SD, indicating that the modified water Thermal biochar has good removal ability for heavy metal cadmium.

Embodiment 3

[0041] Weigh 0.06 g of modified sawdust hydrothermal biochar, and add 30 mL of cadmium solutions with different concentrations (containing 0.01 mol / L NaNO 3 As a background solution), adjust the pH of the solution with 0.1mol / L NaOH and nitric acid, place the sample bottle in a shaker at 150r / min, shake at 30°C for 24h, take a sample, filter it with a 0.22μm filter membrane, and use atomic absorption spectrophotometry Meter (AA240FS, VARIAN) was used to measure the concentration of Cd(II) in the filtrate. For the unmodified hydrothermal biochar, the same steps as above were taken for comparison.

[0042] like Figure 4 As shown, the maximum adsorption capacity of sawdust hydrothermal biochar before and after modification was 14.25 and 41.25 mg / L, respectively, and the adsorption capacity of modified hydrothermal biochar to Cd(II) increased by nearly 3 times, indicating that the modified hydrothermal biochar It has good adsorption performance for heavy metal Cd(II).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com