Patents

Literature

228results about How to "Homogeneous microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

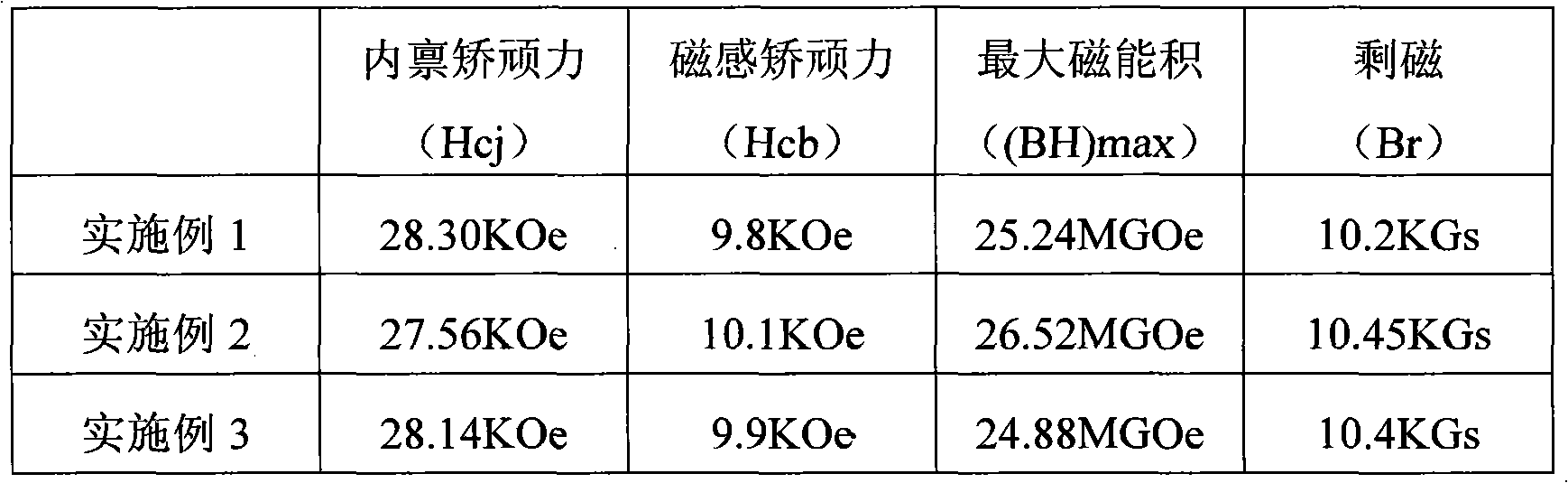

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

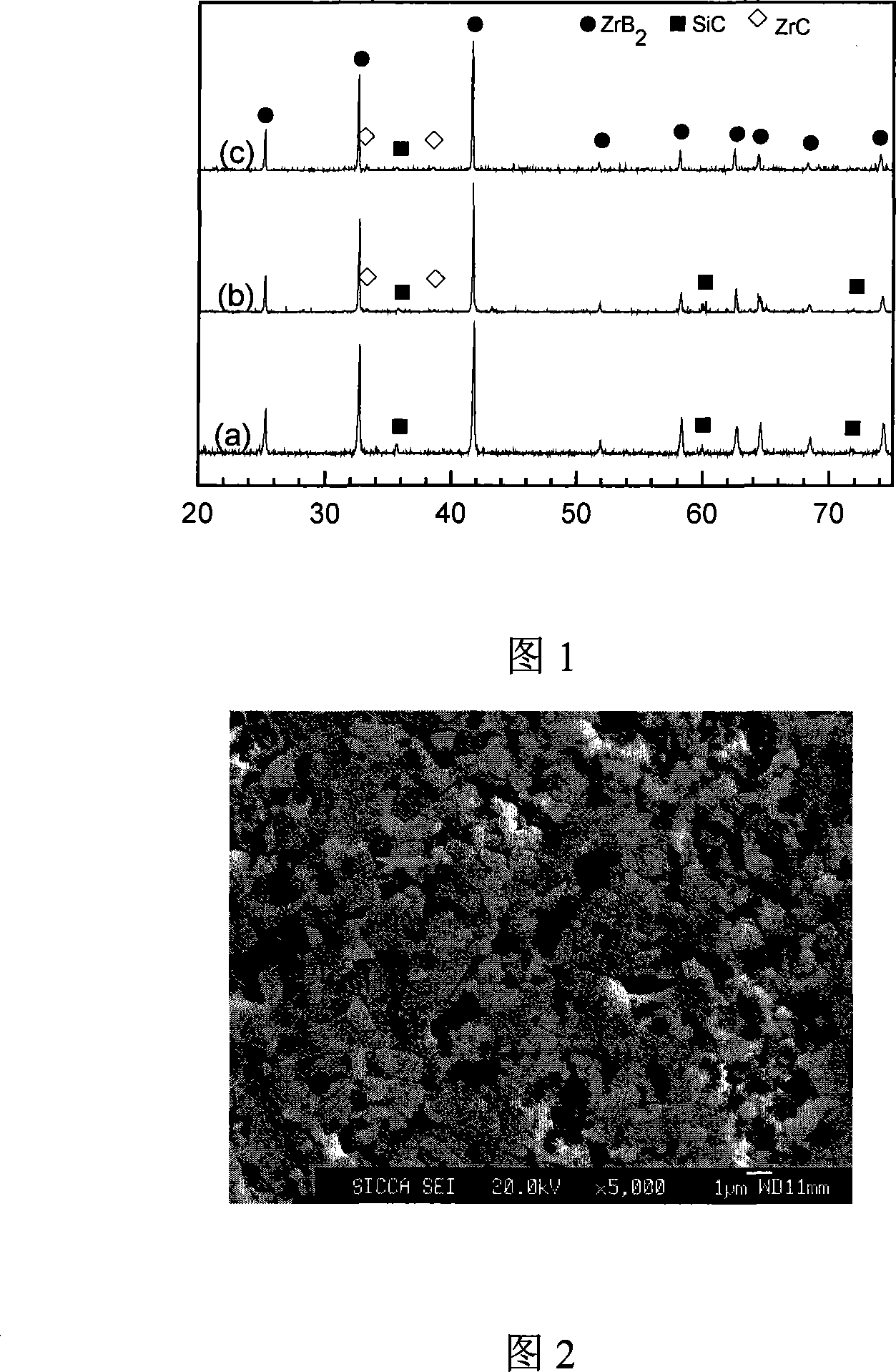

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ceramics of containing powder body of cubic silicon nitride, and preparation method

This invention discloses a ceramic containing cubic nitride powder. The ceramic is composed of: gamma-Si3N4 5-100 wt.%, at least one of Al2O3, ZrO2, alpha- or beta-Si3N4, SiC, BN and AlN 0-95 wt.%, and at least one of Y2O3, Al2O3 and La2O (sintering aid) 0-10 wt.%. The ceramic is prepared by: preparing the raw materials, dry-cooling, grinding by isostatic cool pressing, dry-pressing, assembling the sintering chamber, and sintering under an ultrahigh pressure. The method has such advantages as simple process, easy operation, low sintering temperature, and short sintering time. The ceramic has such advantages as high compactness, uniform microstructure, and good mechanical properties, and can be used in the fields of mechanics, chemical engineering, aviation and photoelectronics.

Owner:SOUTHWEAT UNIV OF SCI & TECH

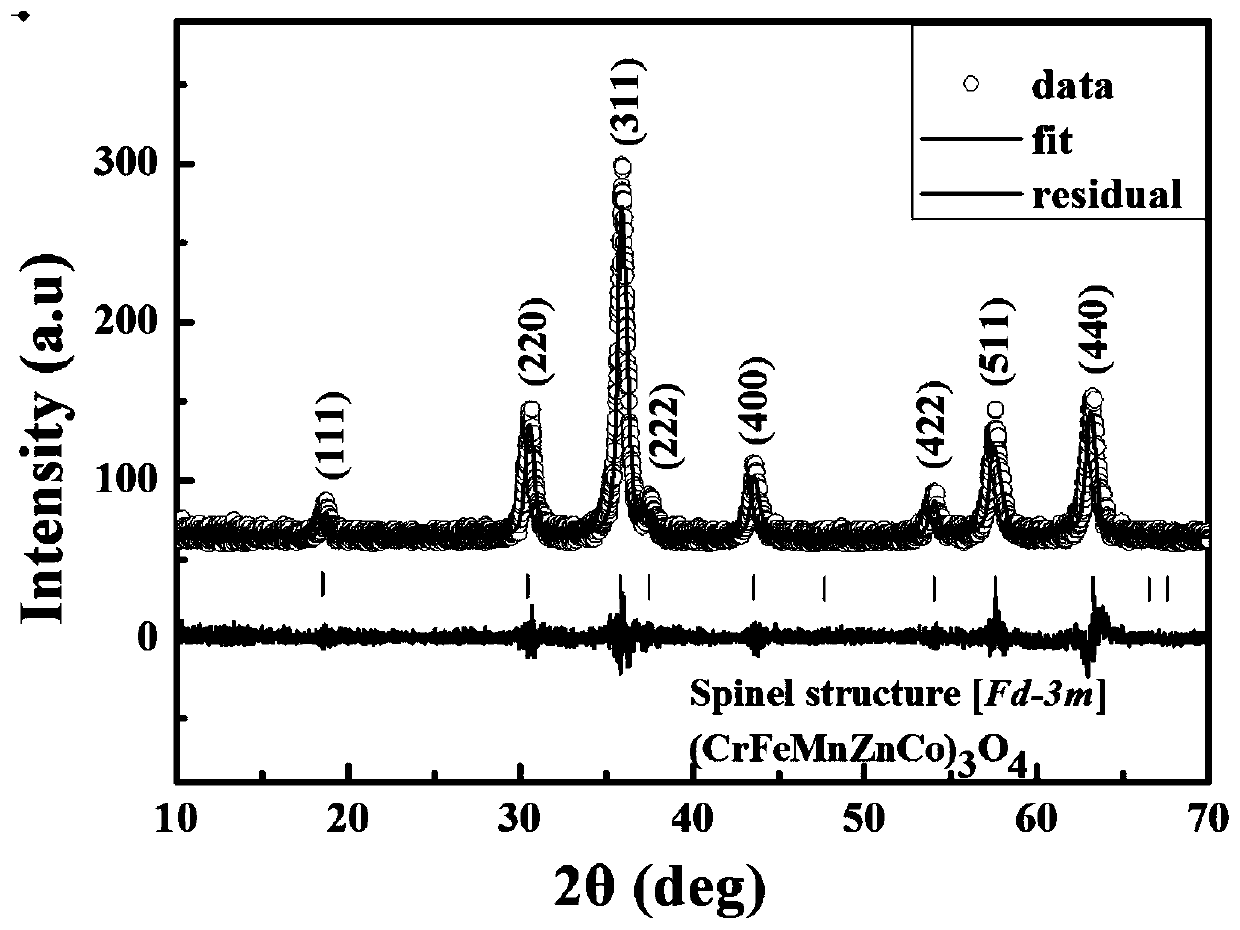

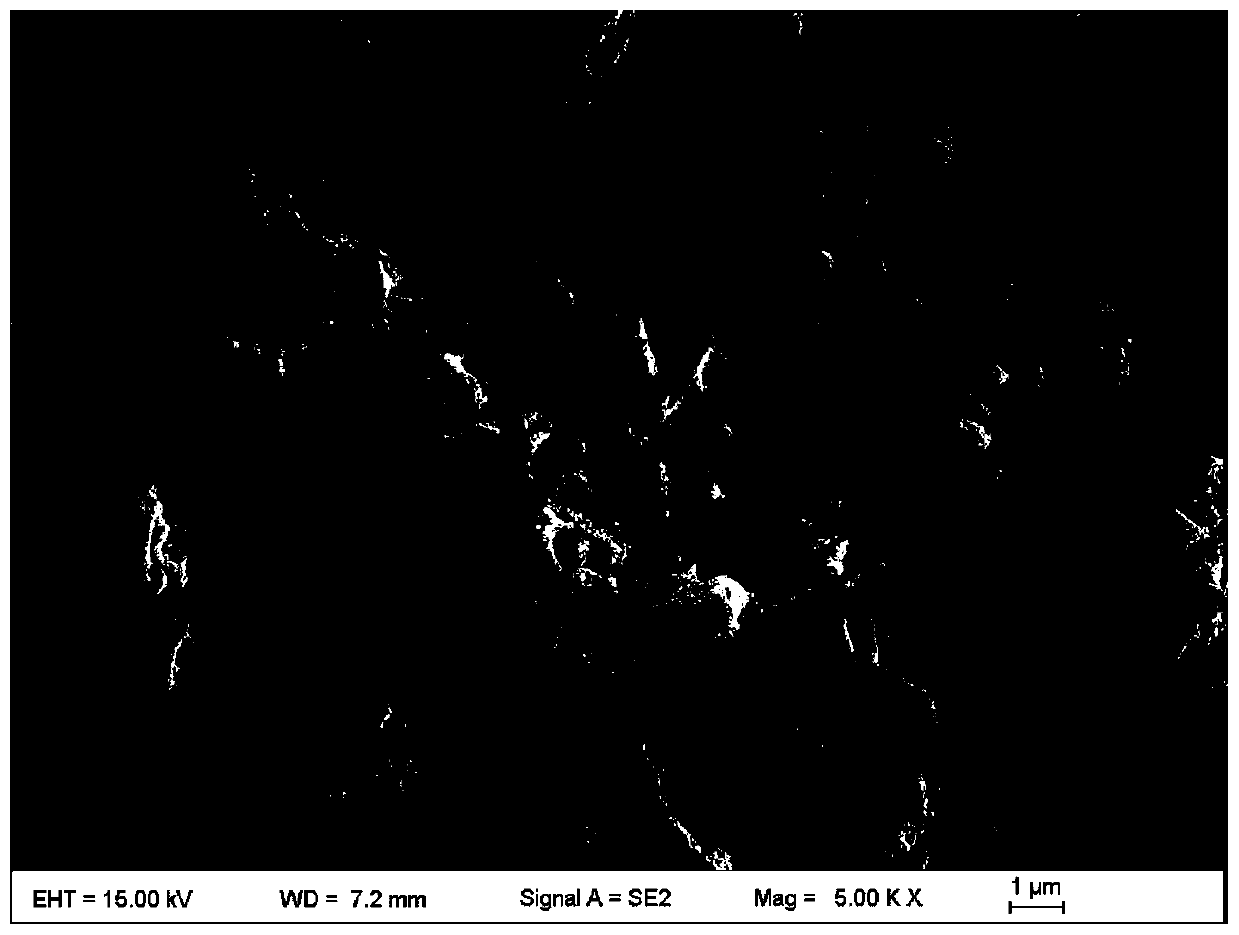

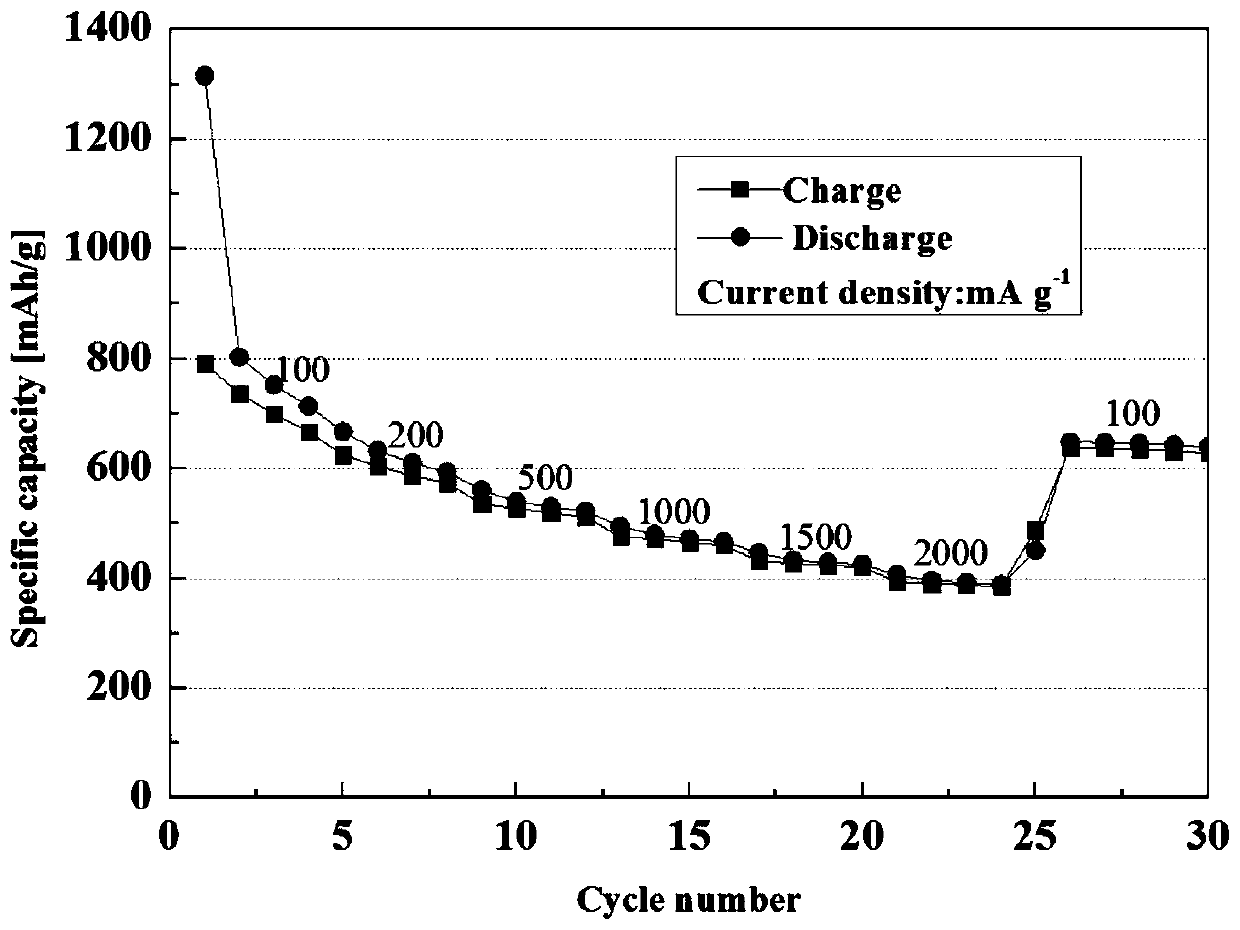

Five-element transition metal oxide high-entropy material for lithium-ion battery

ActiveCN110600703ACustomized electrochemical performanceMeet the needs of useNegative electrodesSecondary cellsSynthesis methodsLithium-ion battery

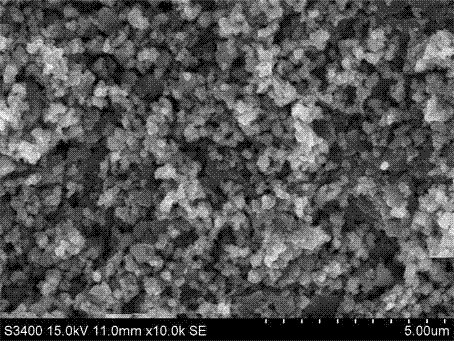

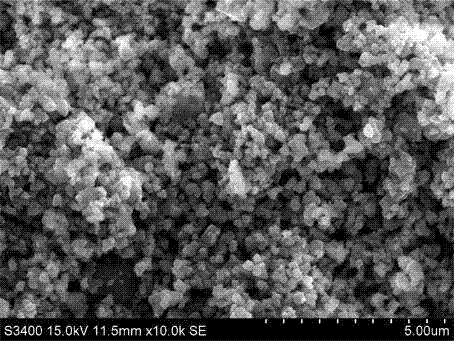

The invention discloses a five-element transition metal oxide high-entropy material for a lithium-ion battery. The high-entropy material is a five-element spinel type oxide high-entropy material formed by five transition metal positive ions, the chemical formula of the high-entropy material is (Cr0.2Fe0.2Mn0.2Zn0.2M0.2)3O4, wherein M is a divalent metal positive ion Co2+ or Ni2+. According to theinvention, a high-entropy oxide material with a spinel structure and different chemical compositions is regulated and controlled by changing the variety of divalent transition metal positive ions, sothat the electrochemical performance of the high-entropy oxide material is customized, and a nanocrystalline powder material with large specific surface area, small grain size and uniform chemical composition and microstructure is prepared through a combustion synthesis method. The five-element transition metal oxide high-entropy material for the lithium-ion battery has the advantages of large initial charge specific capacity, stable reversible specific capacity, good rate capability and good cycling stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High potential gradient zinc oxide pressure-sensitive resistor material and preparation process thereof

InactiveCN102515742AExtended service lifeReduce energy consumptionVaristor coresHigh energyElectric power system

The invention relates to a high potential gradient zinc oxide pressure-sensitive resistor material and a preparation process thereof. The high potential gradient zinc oxide pressure-sensitive resistor material with uniform particle sizes is obtained by weighing a main material ZnO, a doping oxide, and a product rare earth oxide obtained by carrying out thermal decomposition on a rare earth oxalate or / and carbonate or / and hydroxide according to proportions, carrying out high energy wet grinding, drying, presintering at 200-800DEG C, carrying out high energy dry grinding, and sintering at 800-1100DEG C. The preparation process of the invention has the advantages of simplicity, low cost, environmental protection and low energy consumption, and the prepared zinc oxide pressure-sensitive resistor material can be used for preparing high quality lightning arrester products for ultrahigh electric power systems.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

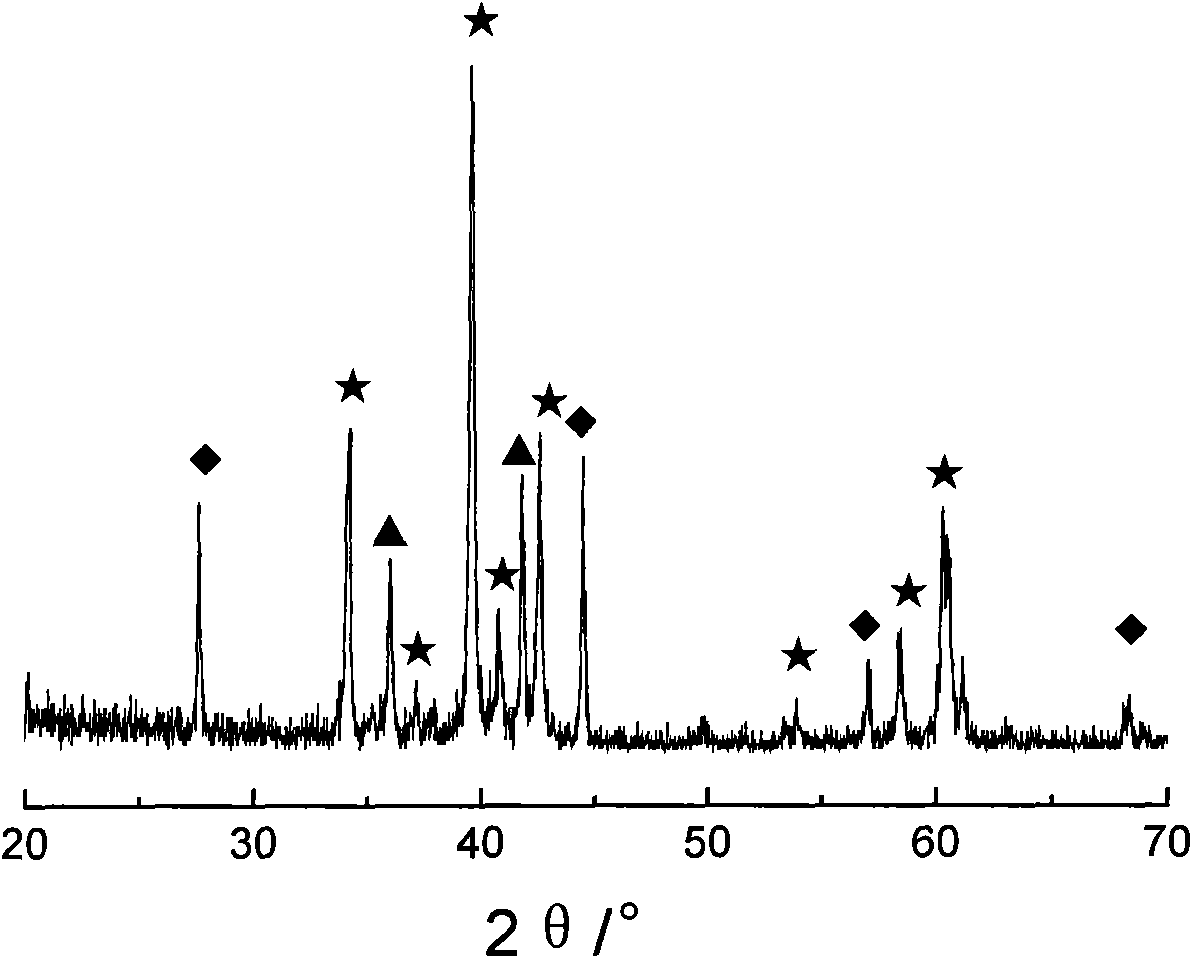

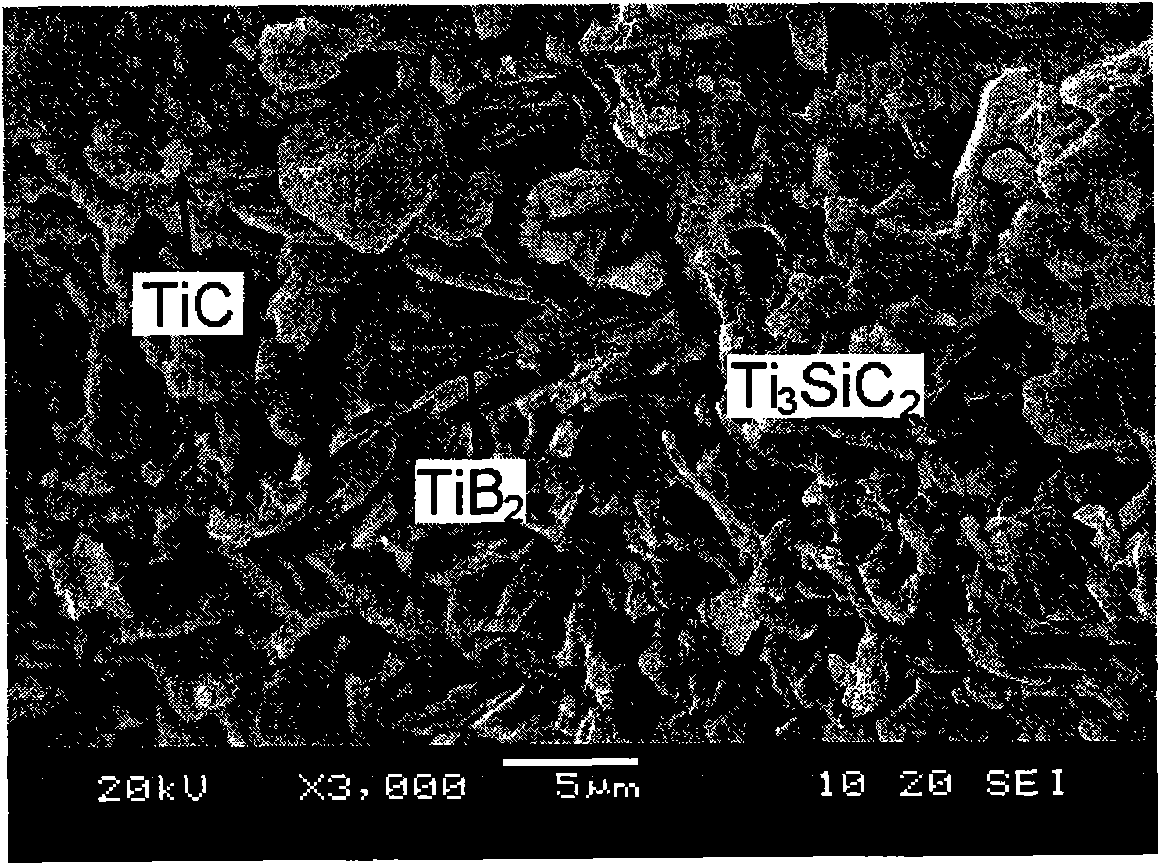

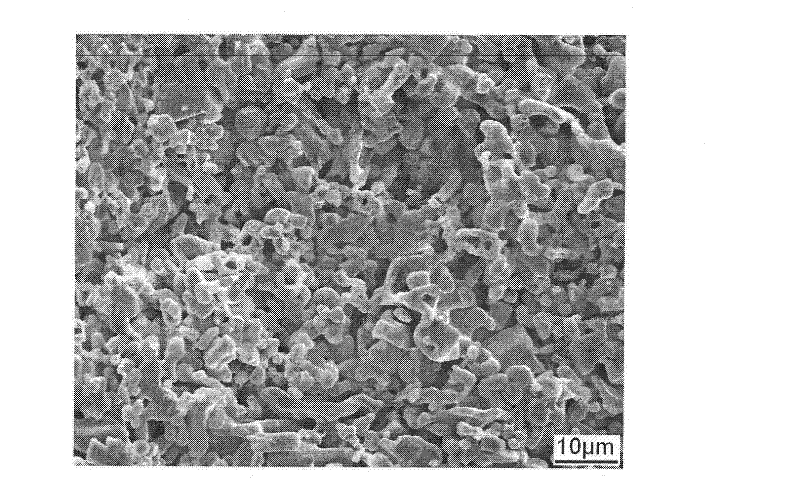

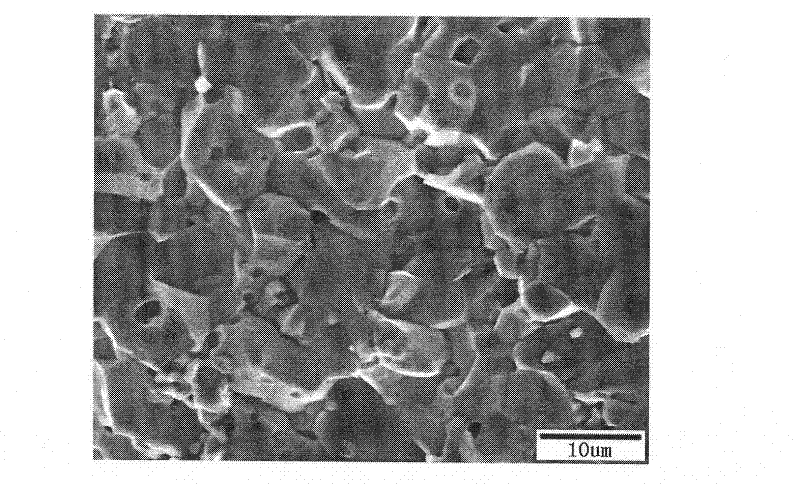

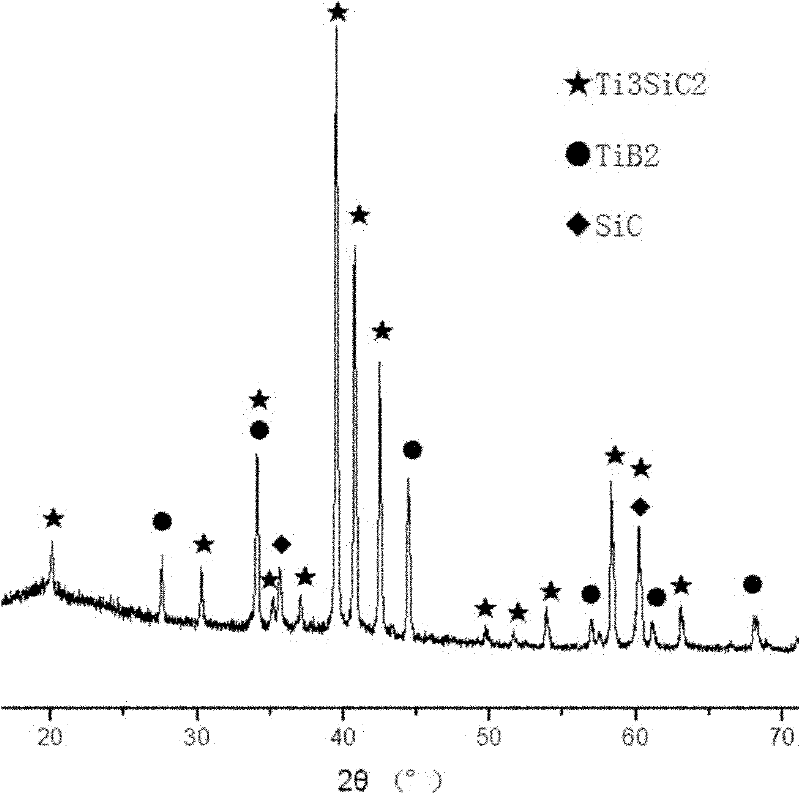

(TiB2 plus TiC)/Ti3SiC2 multi-phase ceramic material and prepration method thereof

The invention relates to a (TiB2 plus TiC) / Ti3SiC2 multi-phase ceramic material and a preparation method thereof. The multi-phase ceramic material consists of plate / columnar TiB2, equiaxed TiC reinforcing phase and a layered Ti3SiC2 substrate, wherein the TiB2 accounts for 5-20 percent of the total volume of the material, and the TiC accounts for 10-15 percent of the total volume of the material. The raw materials such as TiH2 powder, Si powder, graphite powder and B4C powder are weighed according to the molar proportioning of (3.27-4.49): (1.04-1.21): 2: (0.07-0.43), evenly mixed by the physical mechanical method, then arranged in a graphite grinding tool for cold press molding and introduced into a hot-press furnace with shielding gas atmosphere for sintering. The invention has simple process and low sintering temperature, two different toughening phases in the material are synergic with the strengthening and toughening mechanism, and the material performance is excellent.

Owner:NANJING UNIV OF TECH

Zirconia injection molding process and organic carrier for zirconia powder

The present invention is zirconia injection molding process and organic carrier for zirconia powder. Zirconia powder as the main material is added with certain amount of optimized organic carrier, injection molded into biscuit, defatted and sintered to produce high performance zirconia ceramic product. The organic carrier for the zirconia powder consists of polyethylene 10-30 wt%, polypropylene 10-30 wt%, vegetable oil 5-40 wt%, oleic acid1-5 wt%, and paraffin 5-50 wt%; and the weight ratio between the zirconia powder and the organic carrier is 100 to 10-80.

Owner:JIANGSU HENGXIN TECH CO LTD

Preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids

The invention provides a preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids. Two-phase sintering aids capable of being reacted, namely Zr powder and C powder, or Zr powder and B4C powder, are added, and a material is promoted to be compact and crystals of a matrix are inhibited from growing by zirconium carbide / zirconium boride second phase particles with higher sintering activity, which are generated through in-situ reaction between the sintering aids. The ZrB2 or ZrC-based bulk material prepared by the method has the relative density of over 97 percent, the room temperature bending strength of 500-800MPa, the fracture toughness of 3.5-6.5MPa.ml / 2, and the hardness of 14-20GPa. The second phase generated through the in-situ reaction has the same melting point as the matrix, and the sintering acids cannot bring adverse effect to the high temperature mechanical properties of the material.

Owner:江苏先进无机材料研究院

Sintering aid for yttrium aluminum garnet-based fluorescent transparent ceramic and using method thereof

The invention relates to a sintering aid for yttrium aluminum garnet-based fluorescent transparent ceramic and a using method thereof. The sintering aid particularly comprises tetraethoxysilane and magnesium oxide, wherein the using amount of the tetraethoxysilane with the silicon oxide content of not less than 28.4 percent is 0.3 to 0.7 weight percent of the garnet-based transparent ceramic fluorescent powder raw material; and the using amount of the magnesium oxide with the purity of not less than 99.9 percent is 0.01 to 0.8 weight percent of the garnet-based transparent ceramic fluorescent powder raw material. The garnet-based transparent ceramic fluorescent material prepared from the sintering aid has a compact microstructure and is uniform in crystallite dimension distribution.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Mixed powder for electric tool and preparation method thereof

The invention belongs to the field of powder metallurgy, and particularly relates to mixed powder for an electric tool and a preparation method thereof. The mixed powder is characterized by being prepared by mixing and bonding water-atomized diffused alloy powder with water-atomized pure iron powder, graphite powder, copper powder and a lubricating agent in a segregation-free way, wherein the ratio of components by weight percentage as follows: 50-55 percent of water-atomized diffused alloy powder, 0.4-0.5 percent of graphite powder, 0.3-0.35 percent of copper powder, 0.7-0.8 percent of lubricating agent and the rest of water-atomized pure iron powder. The preferable ratio is as follows: 50 percent of water-atomized diffused alloy powder, 0.5 percent of graphite powder, 0.35 percent of copper powder, 0.7 percent of lubricating agent and the rest of water-atomized pure iron powder. Compared with the prior art, the mixed powder has the advantages that 1) the mix powder has over 7.05g / cm3 of compressed density; 2) alloy elements cannot be segregated in the transport and mixing treatment process; and 3) the mechanical performance of sintering parts is effectively improved.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

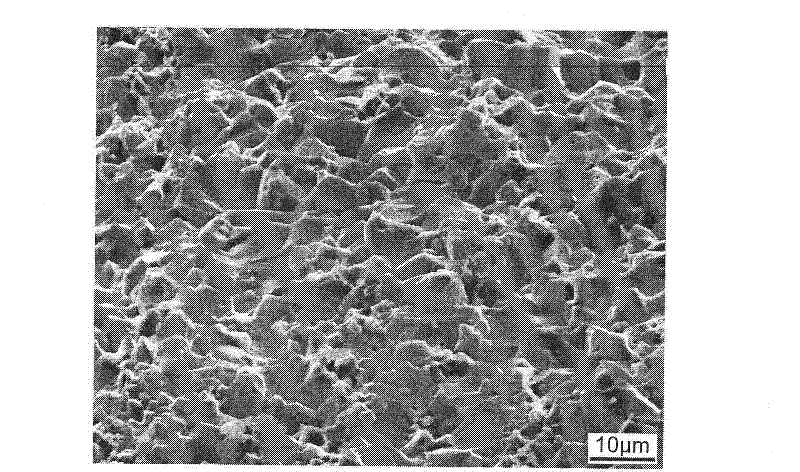

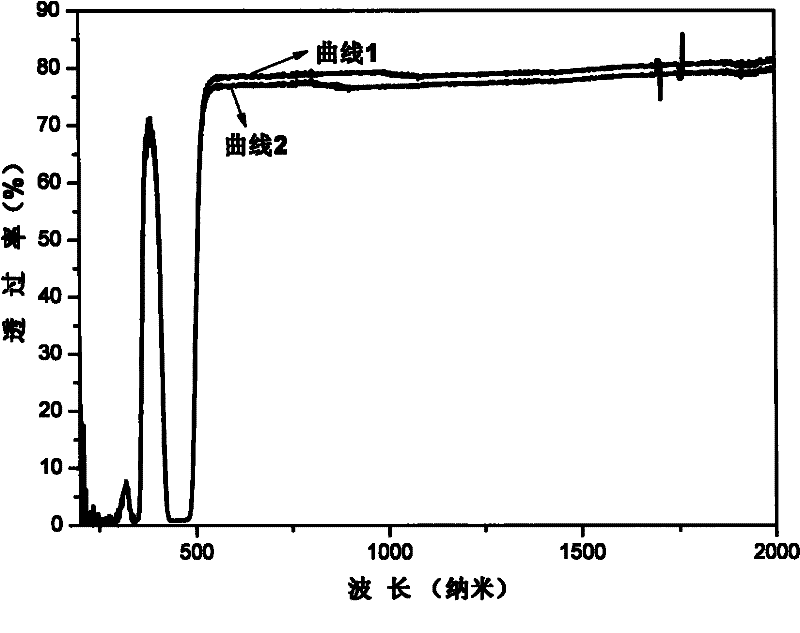

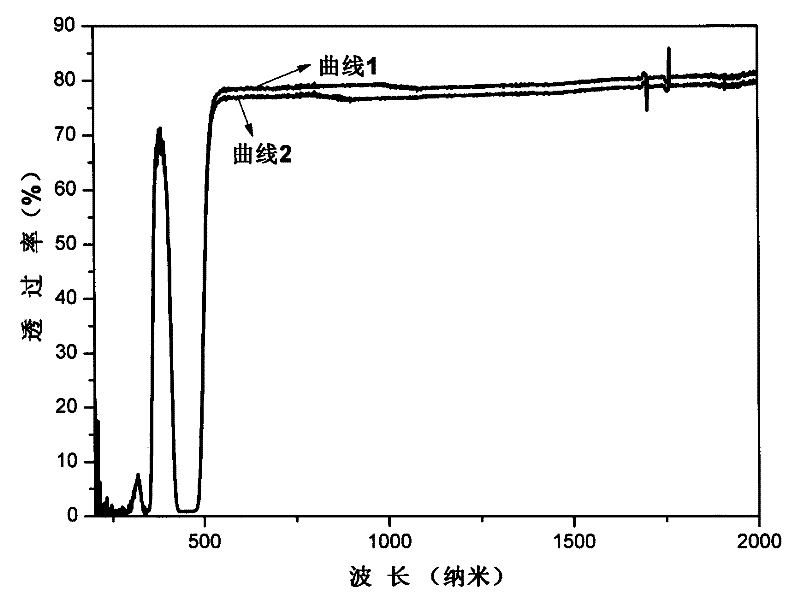

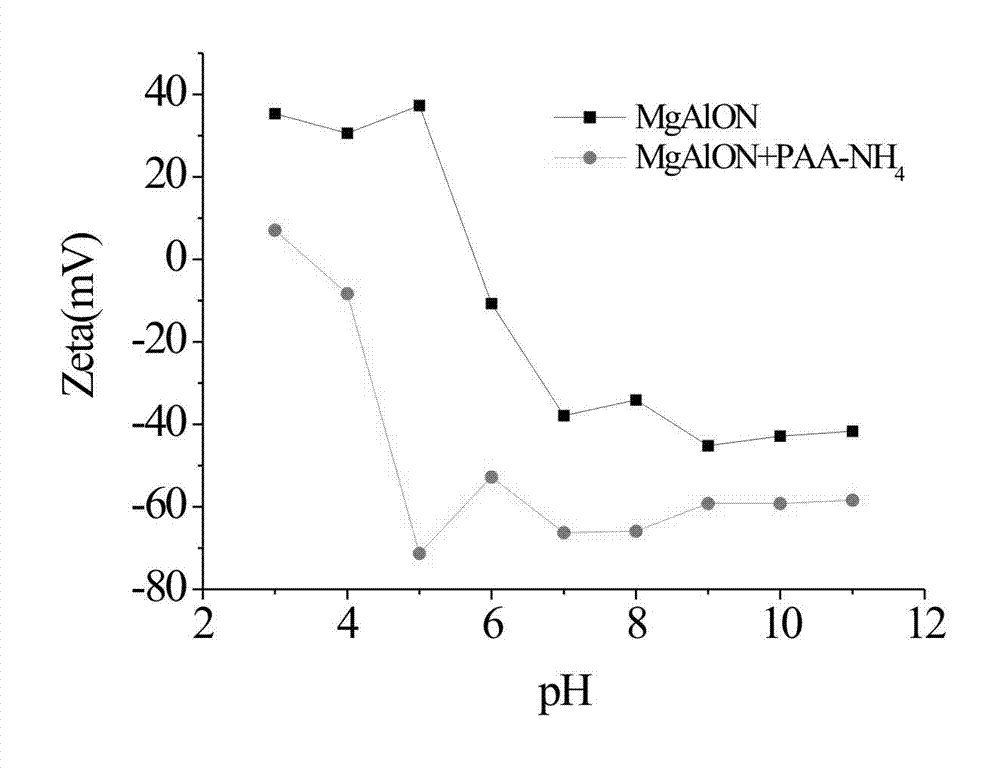

Method for preparing MgAlON transparent ceramic bisque by gel casting and molding

ActiveCN102825649AIn good shapeHomogeneous microstructureCeramic shaping apparatusFlexural strengthMicrostructure

The invention relates to a method for preparing an MgAlON transparent ceramic bisque by gel casting and molding. The method comprises the steps of: 1) preparing a pre-mixed solution; 2) preparing ceramic slurry; 3) casting and molding; 4) drying and degreasing a billet, and finally obtaining the MgAlON ceramic bisque. The MgAlON ceramic bisque prepared by the method is smooth in surface, intact in shape, and uniform in microscopic structure; the bending strength of a dried billet is greater than 10MPa, and the micro-structure and mechanical property of a sample are superior to those of the ceramic bisque prepared by the other traditional ceramic molding methods.

Owner:WUHAN UNIV OF TECH

Silicon nitride ceramic ball preparation method employing glass encapsulating heat and other static pressuring processes

The invention relates a silicon nitride ceramic ball preparation method employing glass encapsulating heat and other static pressuring processes, comprising the following steps: adopting silicon nitride formula material for shaping and cold isostatic pressing to obtain base substrate, coating a layer of graphite isolation layer on the surface of the base substrate by solution dipping process, drying the obtained base substrate, then placing the dry base substrate in a crucible, embedding cullet around the dry base substrate, heating to 1100-1300 DEG C to melt the glass and form complete encapsulating, pressurizing to 100-200Mpa and heating to 1700-1900 DEG C, keeping the temperature for 1-3h to perform hot-isostatic pressing sintering and finally obtaining the product. Compared with the prior art, the method of the invention has the advantages of simple process, good repeatability, quantitative production and the like.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

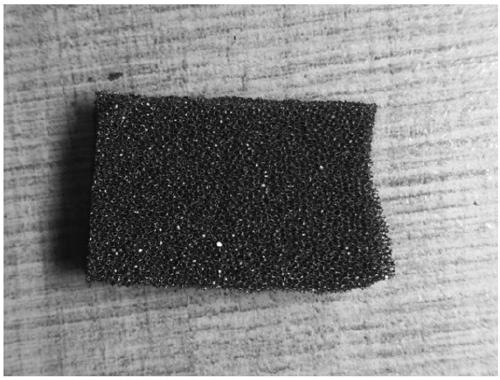

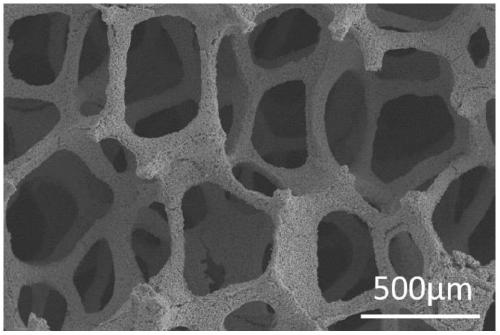

High-strength silicon carbide foam ceramic and one-time pulp hanging carburizing sintering preparation method thereof

The invention discloses high-strength silicon carbide foam ceramic and a one-time pulp hanging carburizing sintering preparation method thereof, and belongs to the technical field of silicon carbide foam ceramic preparation. The method comprises the steps that foamed plastic serves as a template, a one-time pulp hanging carburizing sintering method is adopted, high-char polymer resin, silicon powder, sintering aids and ethyl alcohol are mixed to be prepared into pulp with certain viscosity, the foamed plastic is immersed in the pulp and then taken out, then surplus pulp is removed through a centrifugal method, drying is conducted in the shade, and then pulp hanging is repeated until the needed volume fraction is reached; a foam precursor obtained after pulp hanging is put into a tubular furnace to be subjected to pyrolysis carbonization in a nitrogen or argon atmosphere, a foam ceramic carbon precursor framework formed by pyrolytic carbon, the silicon powder and the sintering aids is obtained, the foam ceramic carbon precursor framework is put in an atmosphere furnace to be sintered, and the high-strength SiC foam ceramic is obtained. Compared with a traditional template method, the method is simple in technology, mild in reaction condition, low in equipment requirement and capable of achieving large-scale production easily.

Owner:XI AN JIAOTONG UNIV

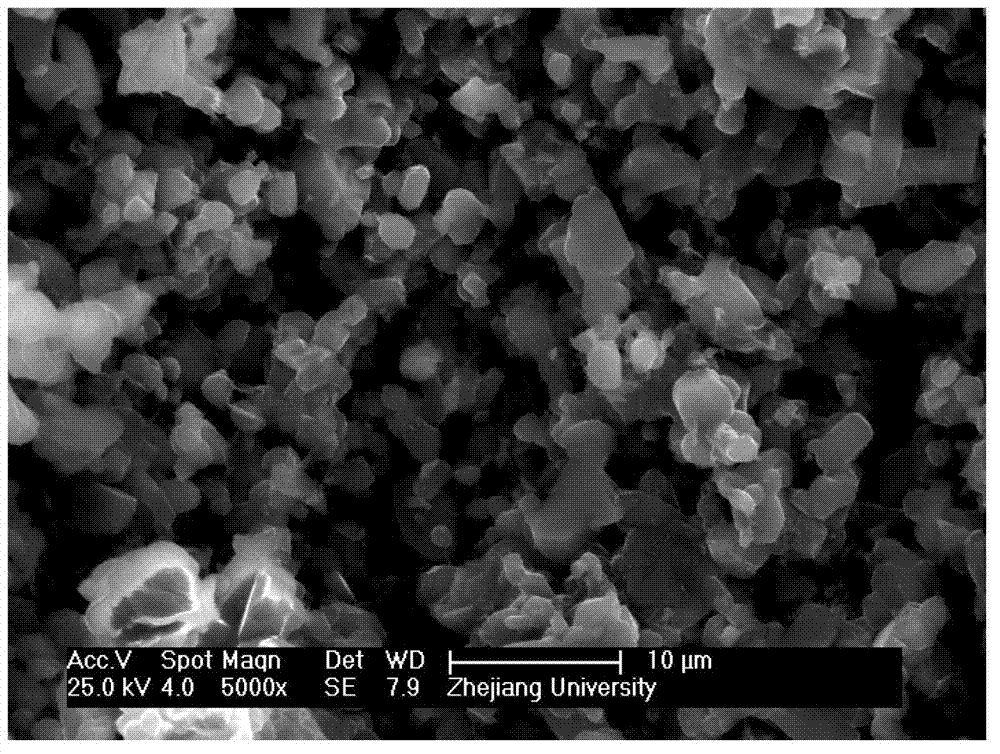

Preparation method of high-porosity silicon-carbide porous ceramics

ActiveCN102807384ALow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

Method for preparing silicon carbide woodceramics

The invention discloses a method for preparing silicon carbide woodceramics, which uses a slip casting method for preparing carbon slurry into carbon billets and then adopts a method of liquid phase siliconizing or gas phase siliconizing to lead the carbon billets and the carbon to form the silicon carbide woodceramics. The carbon slurry contains wooden carbon powder with fineness of 1500 meshes to 10000 meshes and water. The mass ratio of the carbon powder to the water in the carbon slurry is 5: (4-7.5), and the carbon slurry also contains a dispersant and a binding agent; the mass ratio of the dispersant to the wooden carbon powder is 1:(33-300); and the mass ratio of the binding agent to the wooden carbon powder is 1: (120-1000). The method for preparing the silicon carbide woodceramics has cheap and easy-available raw materials, simple and feasible technique and reliable material performance, and can be applied to the industrial production in batches.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

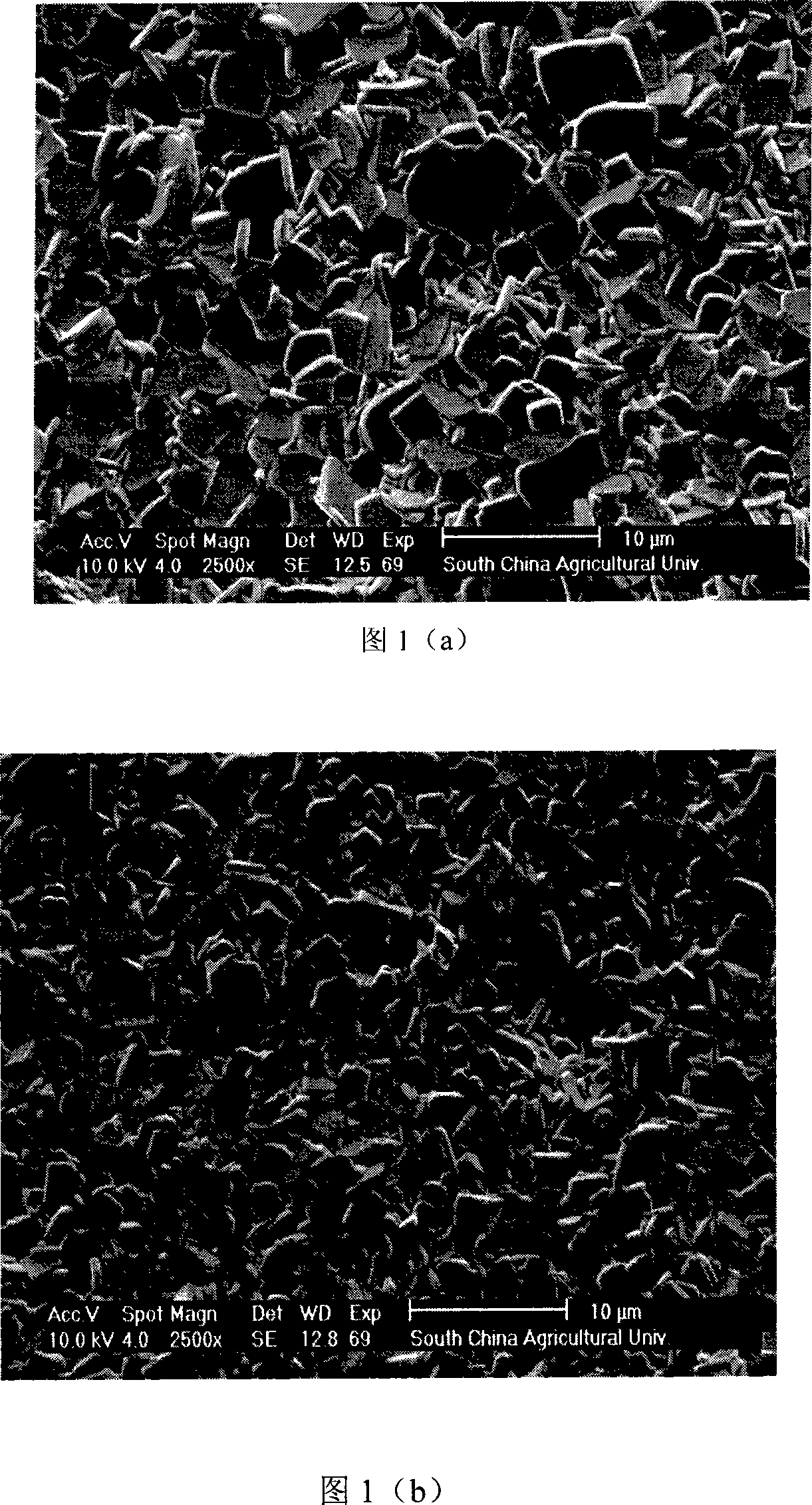

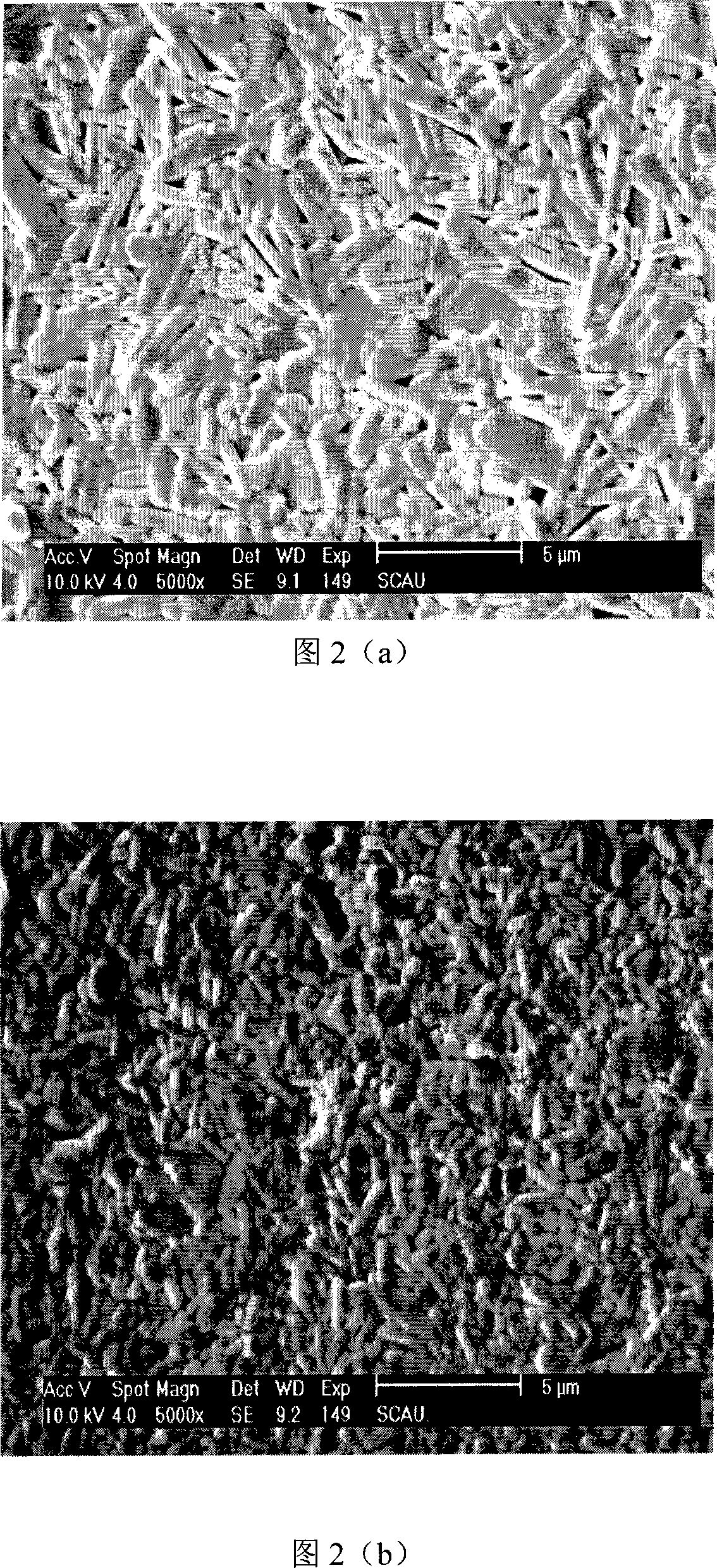

Method for increasing bismuth layer structure piezoelectricity ferroelectric ceramic material density

InactiveCN101186493AInhibit migrationGrowth inhibitionPiezoelectric/electrostrictive/magnetostrictive devicesVolumetric Mass DensityMaterial density

The invention discloses a density enhancing method of piezoelectric ferroelectric ceramic materials with bismuth layer structure. According to a chemical formula: (Am-1BmO3m+1) <2-> (Bi2O2) <2+>; and molar ratio A: B: Bi = m-1: m : 2, materials are calculated and weighted, wherein, the A is univalent, bivalent, trivalent or quadrivalent metal ion that is suitable for dodecahedral coordination; the B is trivalent, quadrivalent, pentavalent or sexivalent metal ion that is suitable for octahedral coordination; the production processes are that: mixing, pre-synthesizing, grinding, forming and sintering; the sintering process is that: the temperature of the obtained material from the last step is raised to 1100 to 1250 DEG C at a speed of 2 to 5 DEG C per minute, and is lowered to 50 to 150 DEG C within 1 to 5 minutes; under the temperature of 950 to 1150 EDG C, insulation at the low temperature is done for 5 to 20 hours; then the temperature is lowered to 500 DEG C at a speed of 3 to 7 DEG C per minute, and the obtained material is naturally cooled with a furnace. The invention can obtain the piezoelectric ferroelectric ceramic materials with grain-refining and density bismuth structure.

Owner:SOUTH CHINA UNIV OF TECH

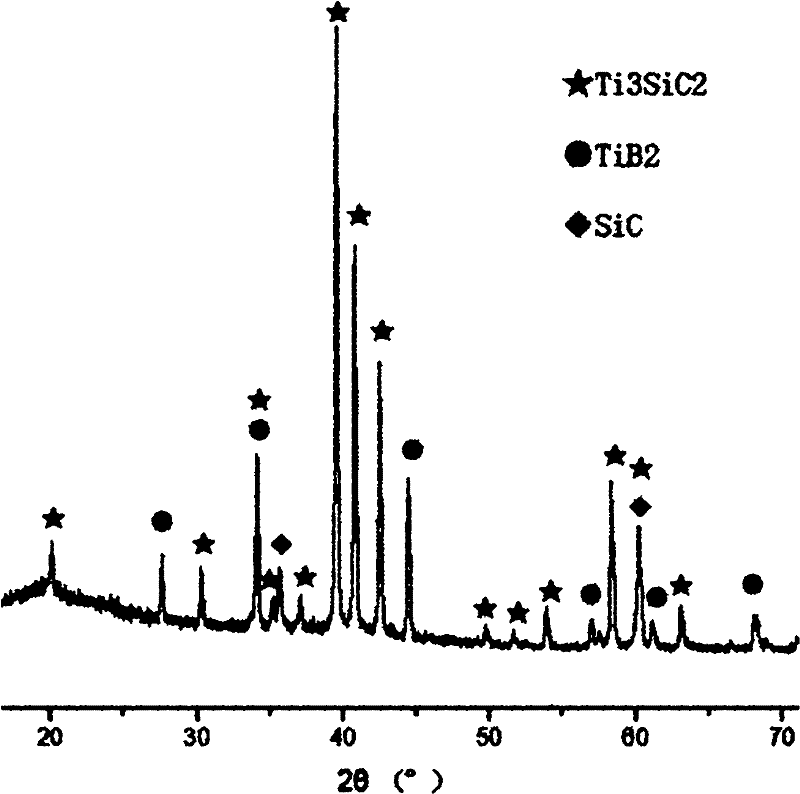

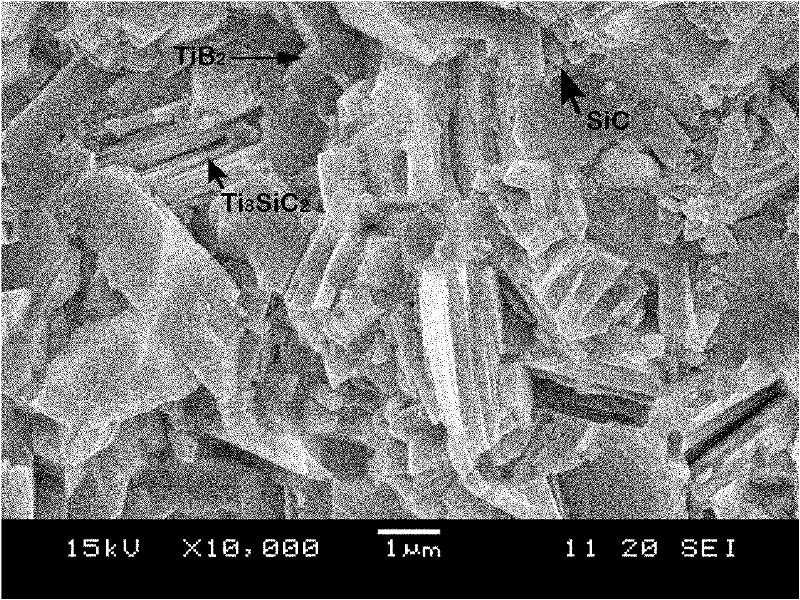

In-situ (TiB2+SiC)/Ti3SiC2 complex phase ceramic material and preparation method thereof

The invention relates to an in-situ (TiB2+SiC) / Ti3SiC2 complex phase ceramic material. The in-situ (TiB2+SiC) / Ti3SiC2 complex phase ceramic material is characterized by consisting of a laminated Ti3SiC2 matrix and two reinforced phases of columnar TiB2 and granular SiC, wherein the TiB2 accounts for 13 to 15 percent of the total volume of the complex phase ceramic material; and the SiC accounts for 5 to 15 percent of the total volume of the complex phase ceramic material. A preparation method of the in-situ (TiB2+SiC) / Ti3SiC2 complex phase ceramic material comprises the following steps of: weighing TiH2 powder, Si powder, TiC powder, B4C powder and Al powder according to the molar ratio of the TiH2 powder to the Si powder to the TiC powder to the B4C powder to the Al powder of (0.9-1.3):(1):(1.4-1.6):(0.15-2.1):(0.13-0.16); mixing the raw materials uniformly; putting the mixture into a graphite mould to perform cold moulding; and performing hot pressed sintering in a graphite resistance furnace under protective atmosphere. The process is simple and the material has excellent properties.

Owner:NANJING UNIV OF TECH

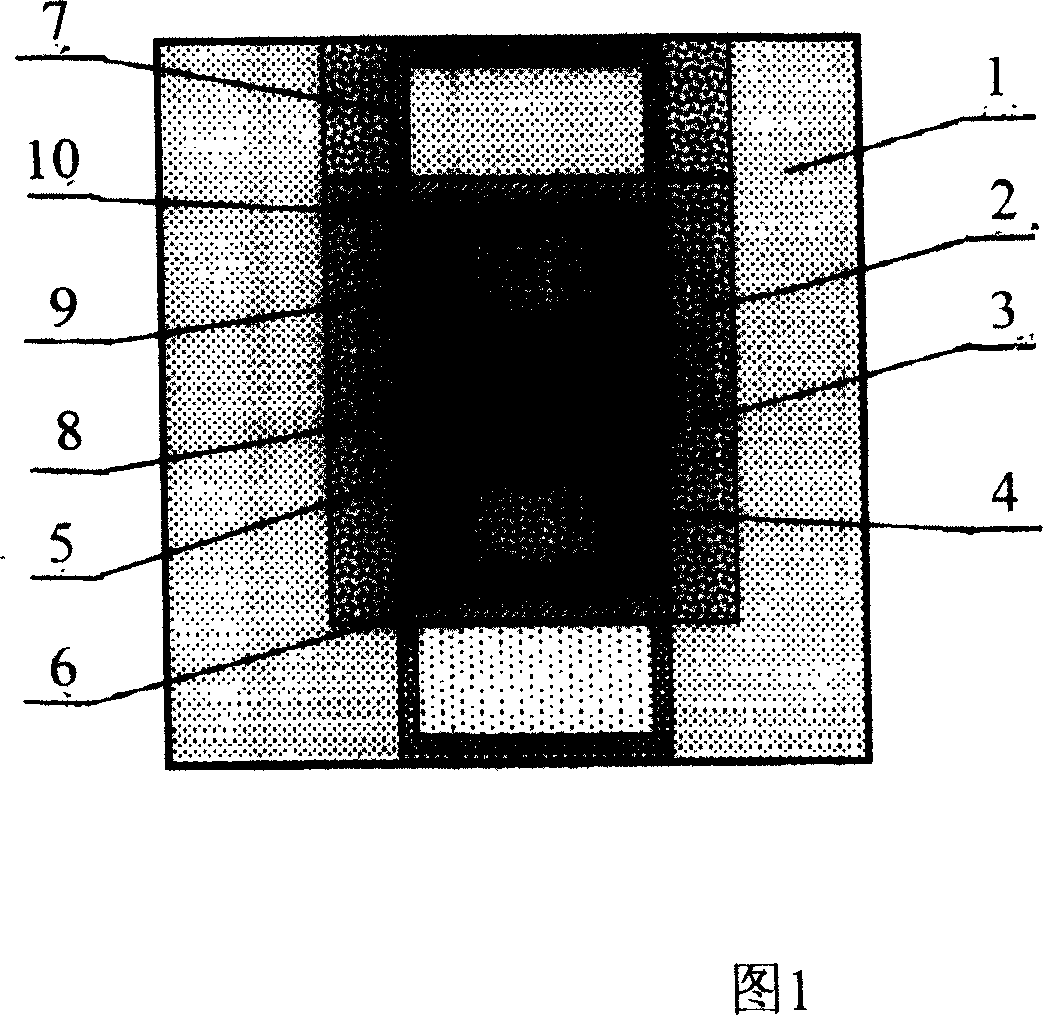

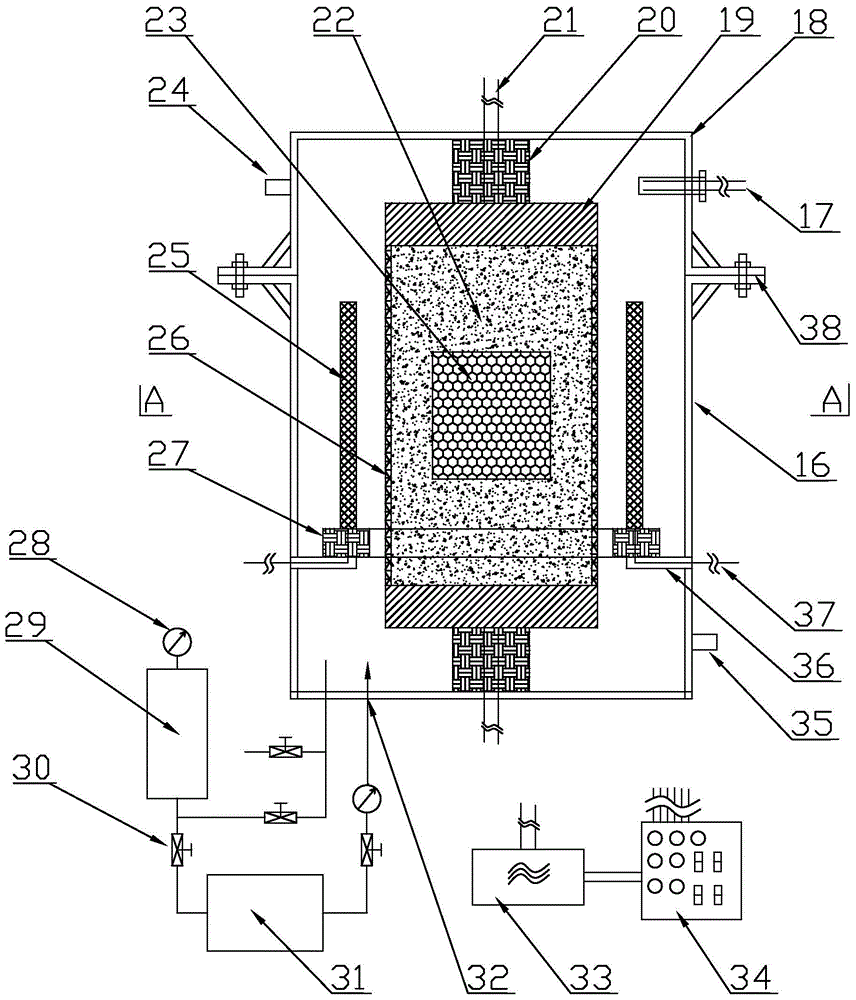

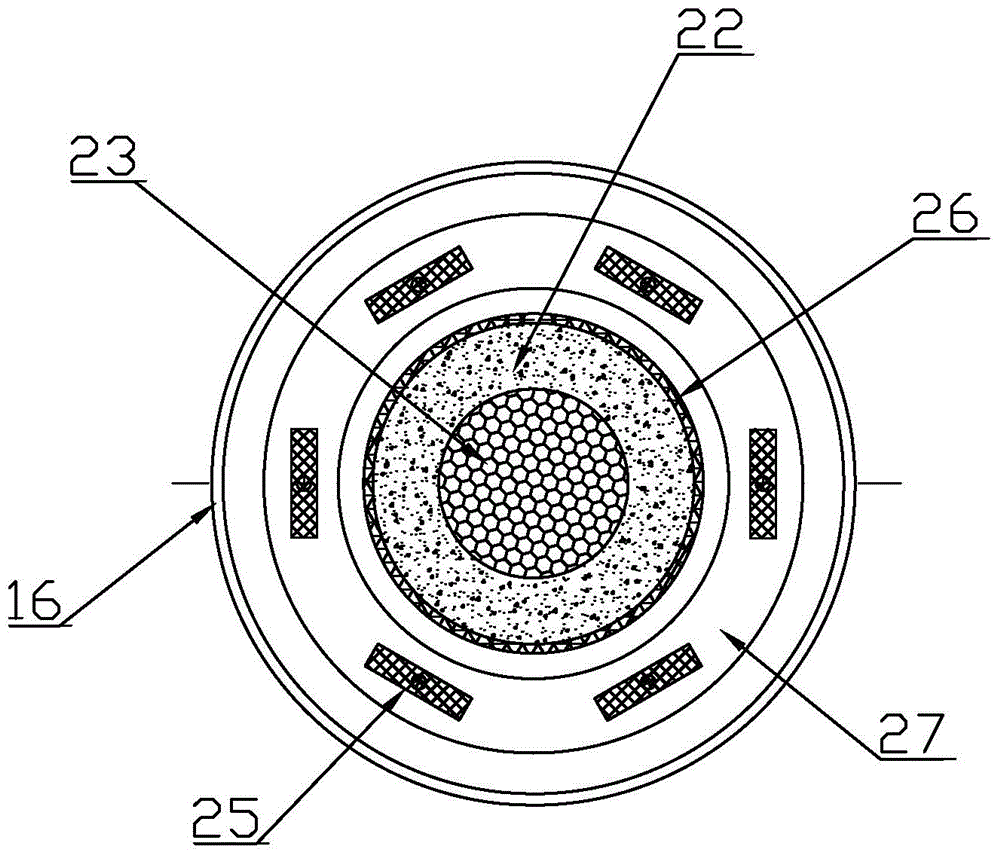

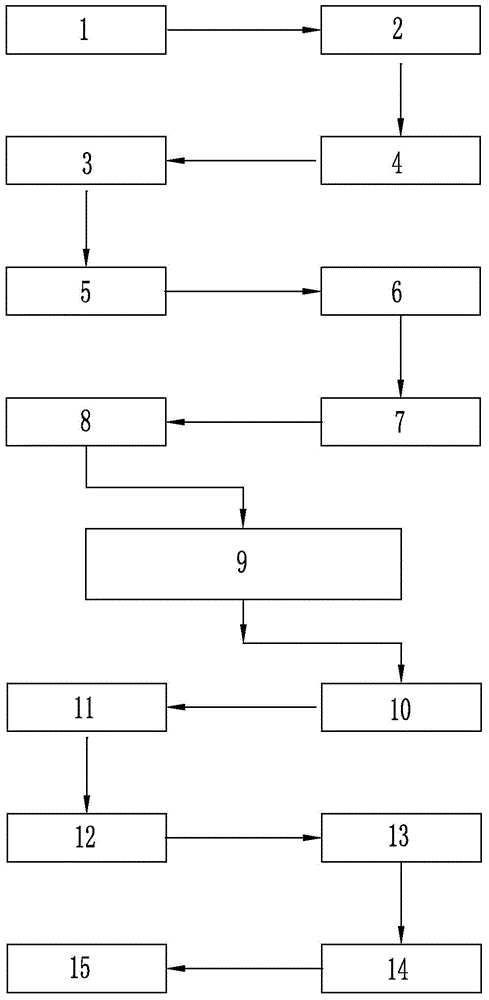

Ceramic material sintering furnace and isostatic pressing field-controlled spark pulse sintering method

ActiveCN103819202AHomogeneous microstructureImprove efficiencyFurnace coolingControl devices for furnacesGrain boundaryGraphite

The invention discloses a ceramic material sintering furnace and an isostatic pressing field-controlled spark pulse sintering method, namely isostatic pressing and spark pulse field controlled sintering for short. The isostatic pressing and spark pulse field controlled sintering is characterized by comprising preparation of a ceramic blank, an isostatic pressing and spark pulse field controlled sintering furnace, processing of a ceramic sintering body, and an isostatic pressing and spark pulse field controlled sintering method, wherein the isostatic pressing and spark pulse field controlled sintering furnace comprises a lower furnace body, a thermocouple, an upper furnace body, an electrode plate, an bench insulator, an electrode lead, a graphite packing, a control electric field, a rubber seal cartridge, an insulating ring adaptor, a pressure gauge, a gas cylinder, a gas valve, a compressor, a gas inlet, a gas outlet, an impulse current generator, a sintering controller and fixing support feet, the isostatic pressing and spark pulse field controlled sintering method enables the transfer and direction of the heat energy, pressure and electromagnetic field of macroscopic and microcosmic ceramic materials to tend to be uniform due to the application of the discharge plasma pulse currents and alternating electromagnetic fields on the blank and the comprehensive action of gas isostatic pressing, the ceramic material is uniformly and isotropously sintered in the microcosmic crystal lattice, the grain boundary and the dot matrix, so that the various performances of the sintered structural ceramic material are improved.

Owner:SUZHOU EVERBEST ENG CERAMICS

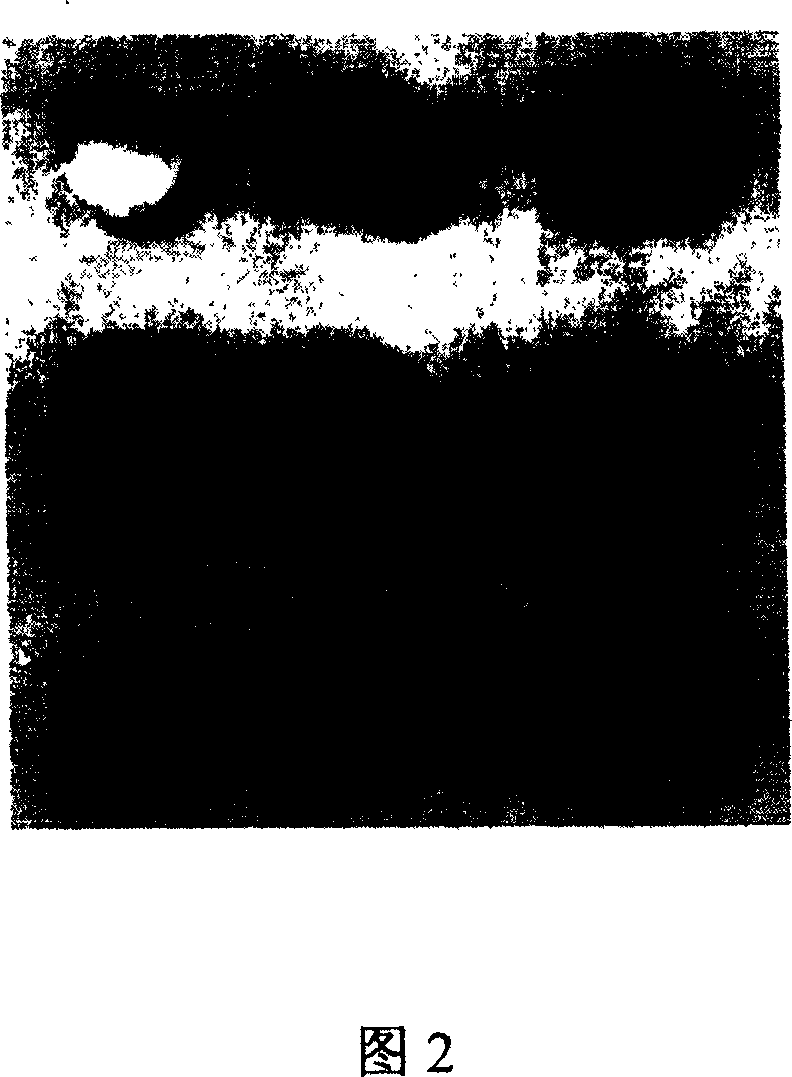

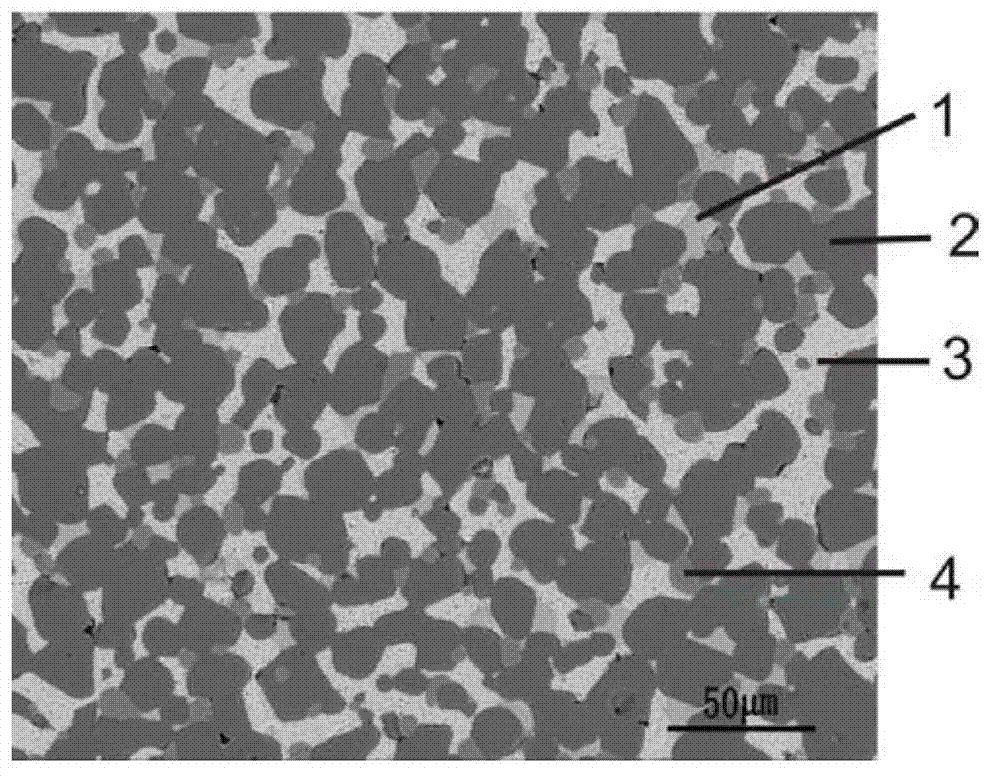

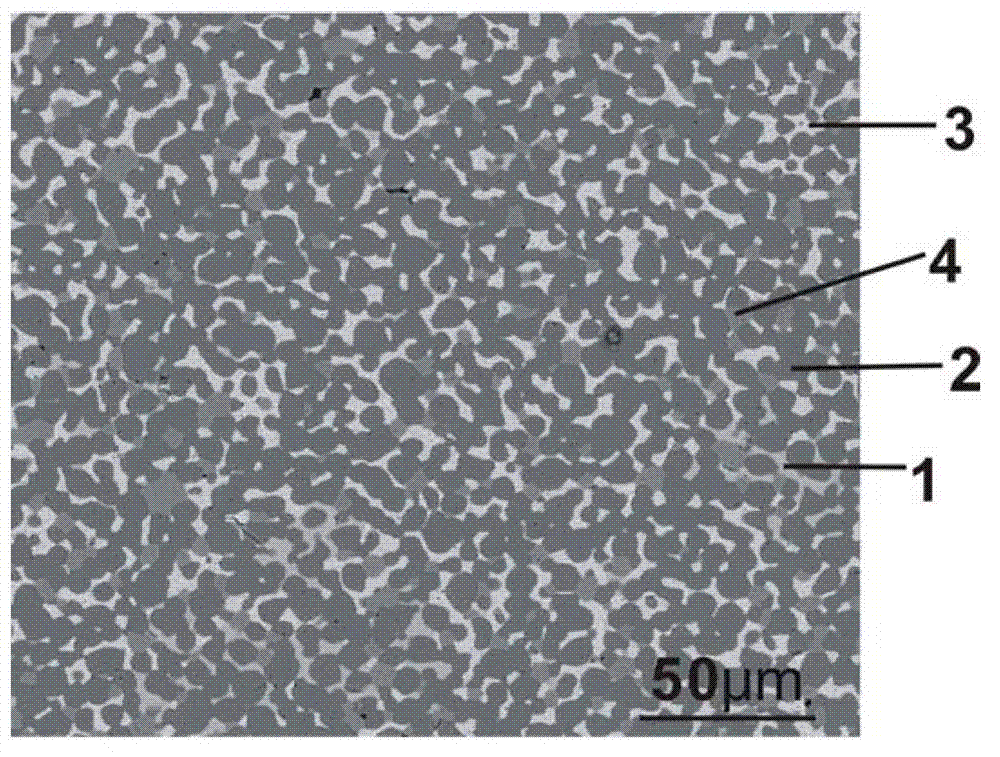

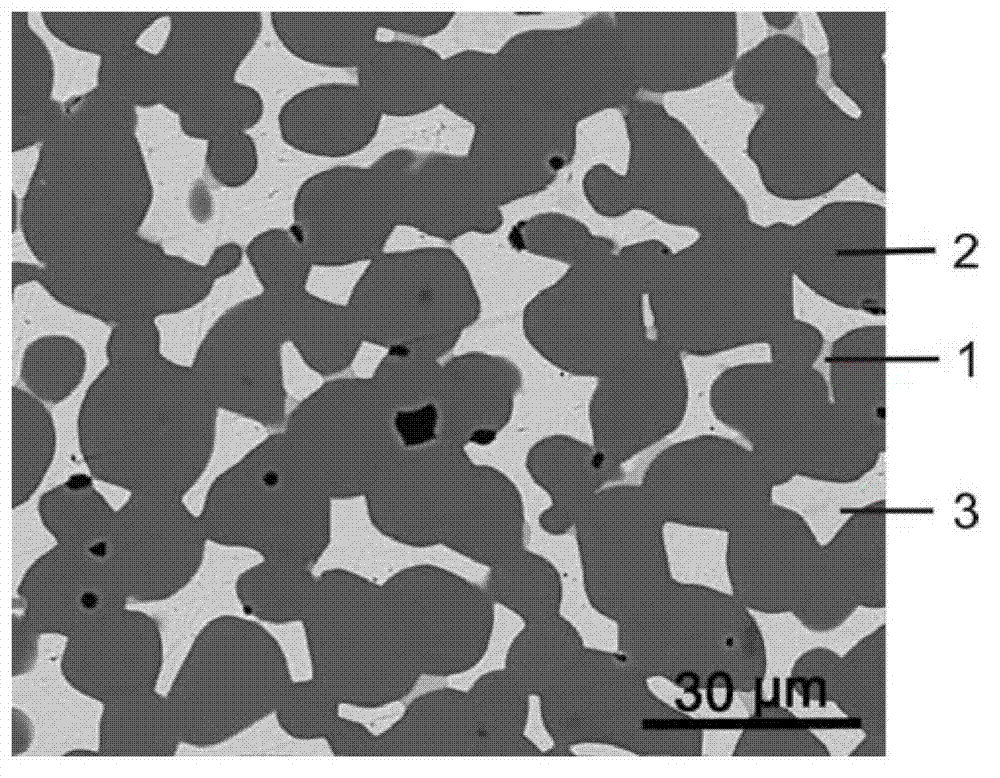

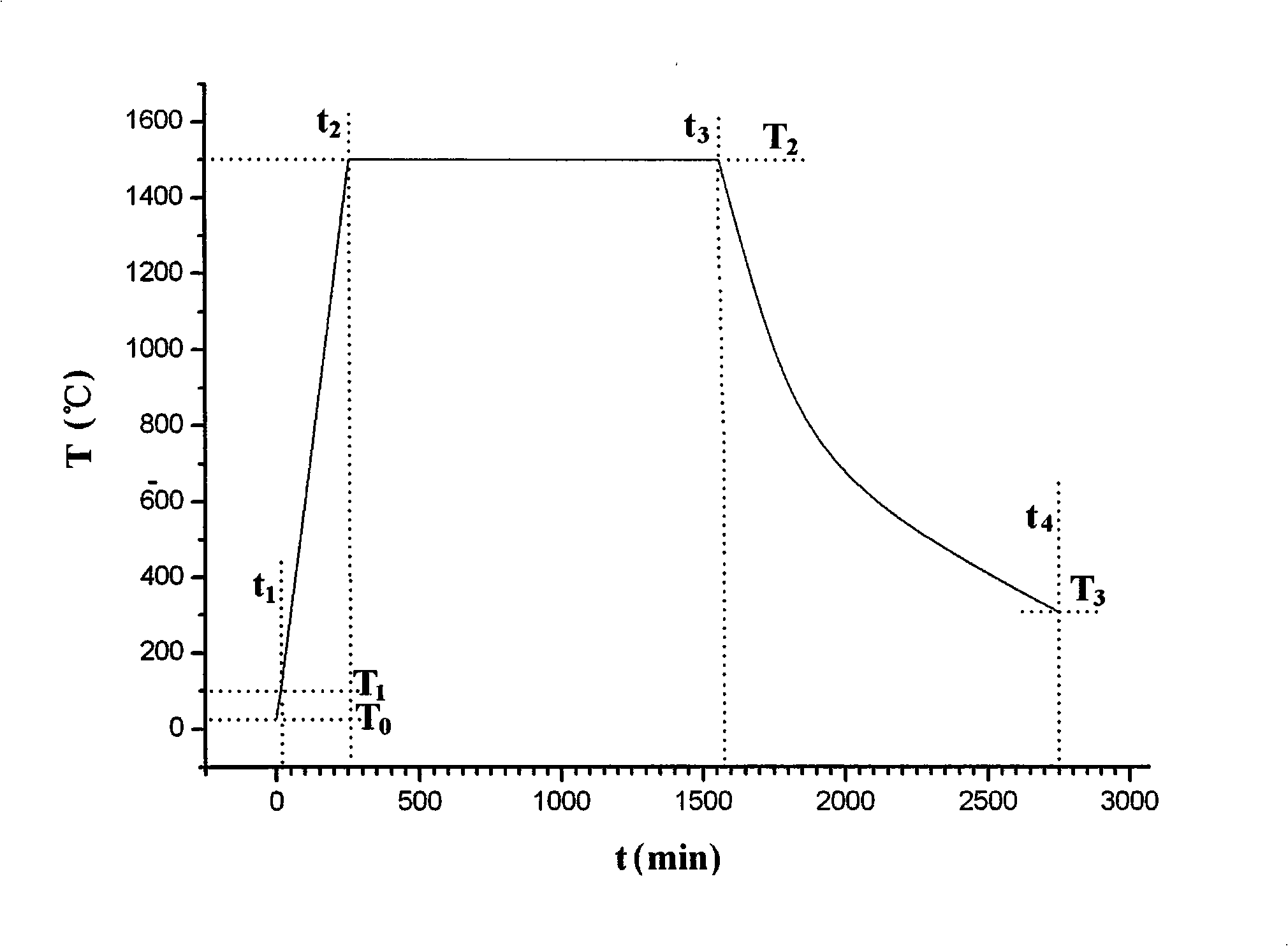

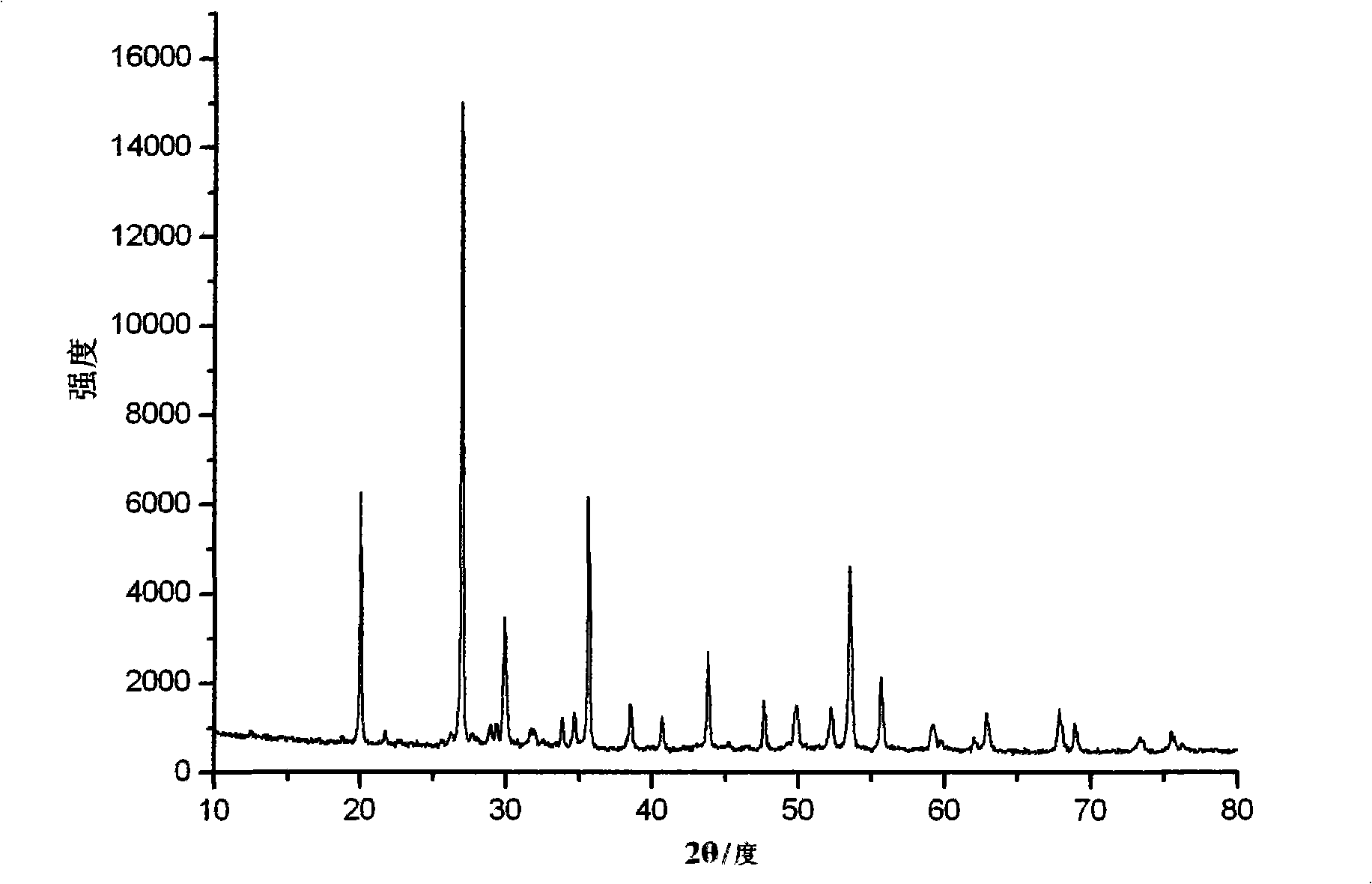

Nickel ferrite-copper metal ceramic inert anode material and preparation method

The invention relates to a nickel ferrite-copper metal ceramic inert anode material which comprises a ceramic phase and a metal phase, wherein the ceramic phase is nickel ferrite or nickel ferrite base composite ceramic; and the metal phase consists of metal copper and cuprous oxide, and the cuprous oxide accounts for 1-20% of the total mass of the metal phase. In the preparation process, the content of the cuprous oxide in the metal phase is controlled through controlling the oxygen partial pressure of a nitrogen protection atmosphere so as to improve the wettability of the nickel ferrite and the copper and achieve the sintering infiltration preparation of the ceramic phase and the metal phase. The metal phase and the ceramic phase of the nickel ferrite-copper metal ceramic inert anode material are in a three-dimensional reticular through structure, wherein the sintering density is higher than 98%, the electric conductivity of the metal ceramic material is more than 200S / cm at a temperature of 900 DEG C, the heat conductivity is up to 40W / (m.K) at the room temperature, and the metal ceramic material cannot be cracked through temperature difference thermal shock at the temperature of 400 DEG C. The problems of difficult sintering densification of the nickel ferrite and the copper, sintering overflow of the metal phase and material thermal shock and cracks are effectively solved, and compared with a material prepared by a conventional mixed powder sintering process, the electric conductivity and the thermal shock resistance of the nickel ferrite-copper metal ceramic material are greatly improved.

Owner:CENT SOUTH UNIV

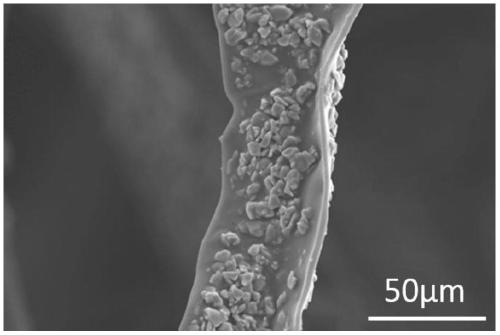

Method for preparing silicon nitride bonding silicon carbide foamed ceramics

The invention discloses a method for preparing silicon nitride bonding silicon carbide foamed ceramics. The method is characterized by comprising the following steps: uniformly mixing SiC, silica powder, a phenolic resin and hydroxypropyl methyl cellulose solution so as to prepare ceramic slurry; dipping the ceramic slurry on polyurethane foam, drying, and firing in a nitrogen atmosphere, thereby obtaining the silicon nitride bonding silicon carbide foamed ceramics. The silicon nitride bonding silicon carbide foamed ceramics prepared by the method are uniform in microstructure, high in strength and uniform in pore size, and residues of carbon and free silicon are avoided, so that the strength, high temperature resistance and thermal shock resistance of the ceramics can be greatly improved.

Owner:SHANDONG UNIV OF TECH

Curing method of active nucleus waste matter simulation substance

InactiveCN101345095AEfficient curingProtection securityRadioactive decontaminationCrystallinityZircon

The invention provides a curing method used for radioactive nuclear waste simulation matter, which is characterized in that the method comprises the steps as follows: SiO2, ZrO2, and Eu2O3 or CeO2 are taken as raw material and compounded, grinded, dried and calcinated for 20-25h under the temperature of 1400-1600 DEG C so as to prepare a solidified body which takes the zircon as the substrate. The preparation method of the invention has the advantages of simple method, easy operation, short production period, high production efficiency, and uniform solidified body microstructure with higher crystallinity; the method of the invention is a new effective curing method provided for processing the radioactive nuclear waste and can be widely used for the processing of the radioactive nuclear waste exhausted by corresponding fields such as nuclear industry, etc.

Owner:SOUTHWEAT UNIV OF SCI & TECH

High energy type zinc oxide piezoresistor material and preparation method thereof

InactiveCN102515740AReduce the residual pressure ratioReduce leakage currentVaristor coresOvervoltage protection resistorsTin dioxideHigh energy

The invention relates to a high energy type zinc oxide piezoresistor material and a preparation method thereof, which belong to the technical field of piezoresistor material preparation. The preparation method comprises (1) enabling manganese carbonate, barium carbonate and strontium carbonate to be mixed, ball-milled and calcined to obtain mixture A; (2) enabling titanium oxide, antimony pentoxide, bismuth trioxide, cobalt oxide, nickel oxide, silica and stannic oxide to be mixed in submicron-sized zinc oxide powder to obtain mixture B which is mixed and ball-milled with the mixture A to obtain mixture C; and (3) adding aluminum nitrate, silver nitrate, magnesium nitrate, a dispersing agent and an antifoaming agent in the mixture C, ball-milling and drying to obtain high energy type zinc oxide piezoresistor composite powders which are formed in a pressing mode and sintered to obtain a high energy type zinc oxide piezoresistor. The high energy type zinc oxide piezoresistor material is simple in preparation method, prepared zinc oxide piezoresistor has high energy density, low leakage current and residual voltage ratio, batch of products is stable, acceptability is high, and the high energy type zinc oxide piezoresistor material is applicable to scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

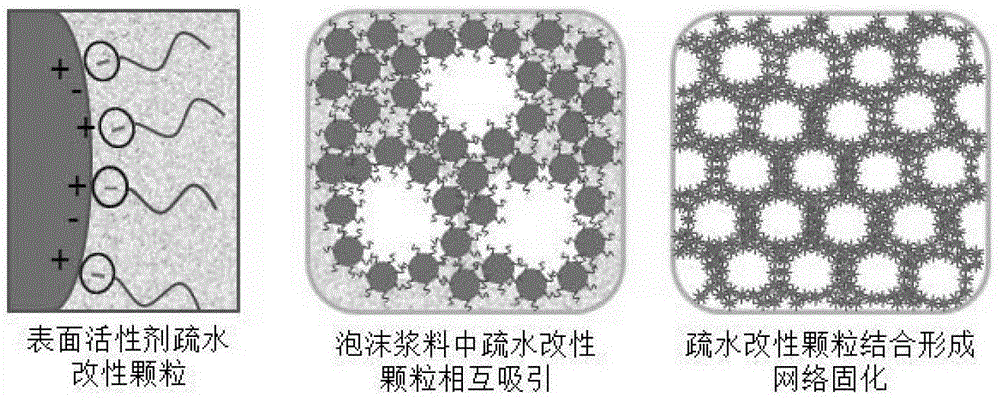

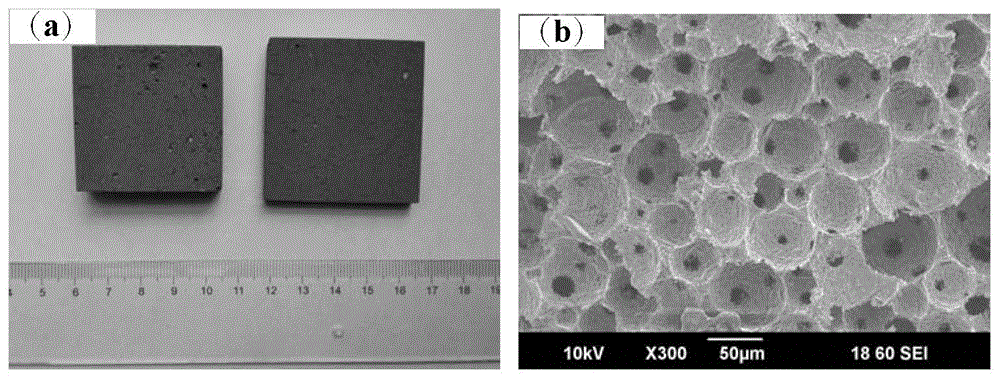

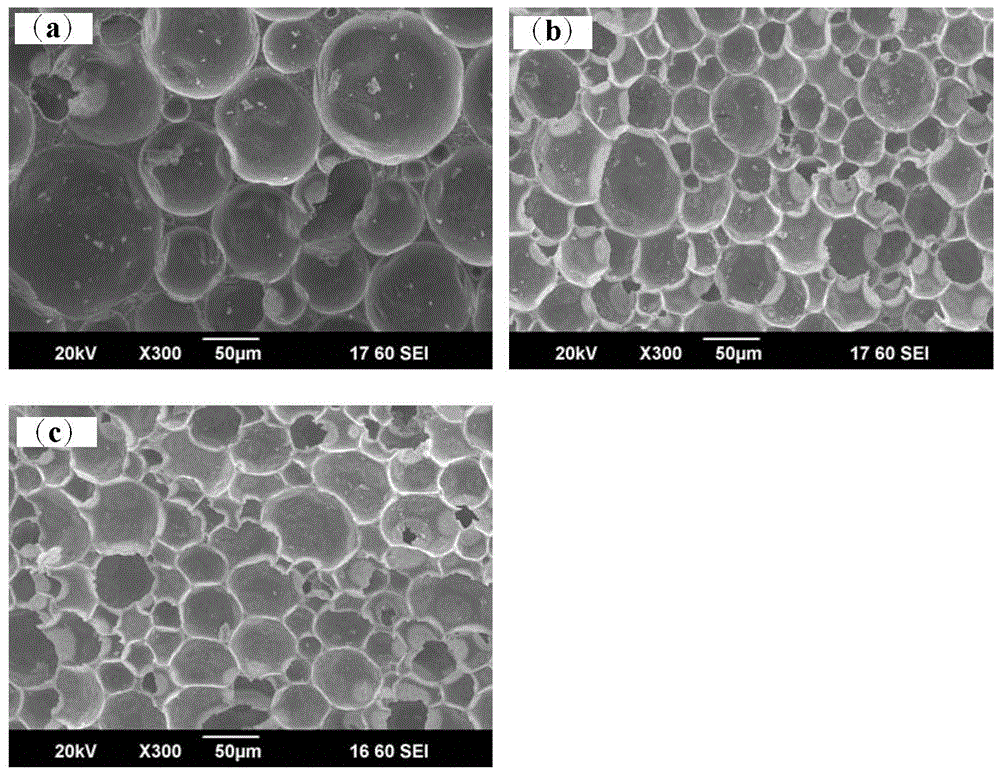

Method for preparing foamed ceramic through hydrophobic flocculation

The invention relates to a method for preparing foamed ceramic through hydrophobic flocculation. The method comprises the steps that the solid content is controlled to be 15-50 vol.%, the pH value of water-based ceramic slurry is regulated to enable the surface of ceramic powder to be electrically charged so as to be uniformly dispersed in an electrostatic repulsion mode; surfactant of which an electric charge type is opposite to that of the ceramic powder surface is added into the water-based ceramic slurry, stirring or ball-mill mixing is conducted to enable the surfactant to be uniformly dispersed or adsorbed on the ceramic powder surface, and surfactant modified partially-hydrophobic ceramic slurry is obtained; the partially-hydrophobic ceramic slurry is subjected to mechanical stirring foaming, foam slurry is directly injected into a mold, the room-temperature in-situ solidification, then demoulding and drying are conducted, and after sintering is conducted, the foam ceramic is obtained. According to the method, by means of electrostatic repulsion, ceramic particles in the slurry reach a good dispersion effect, and the water based ceramic slurry which is low in viscosity and good in flowability is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

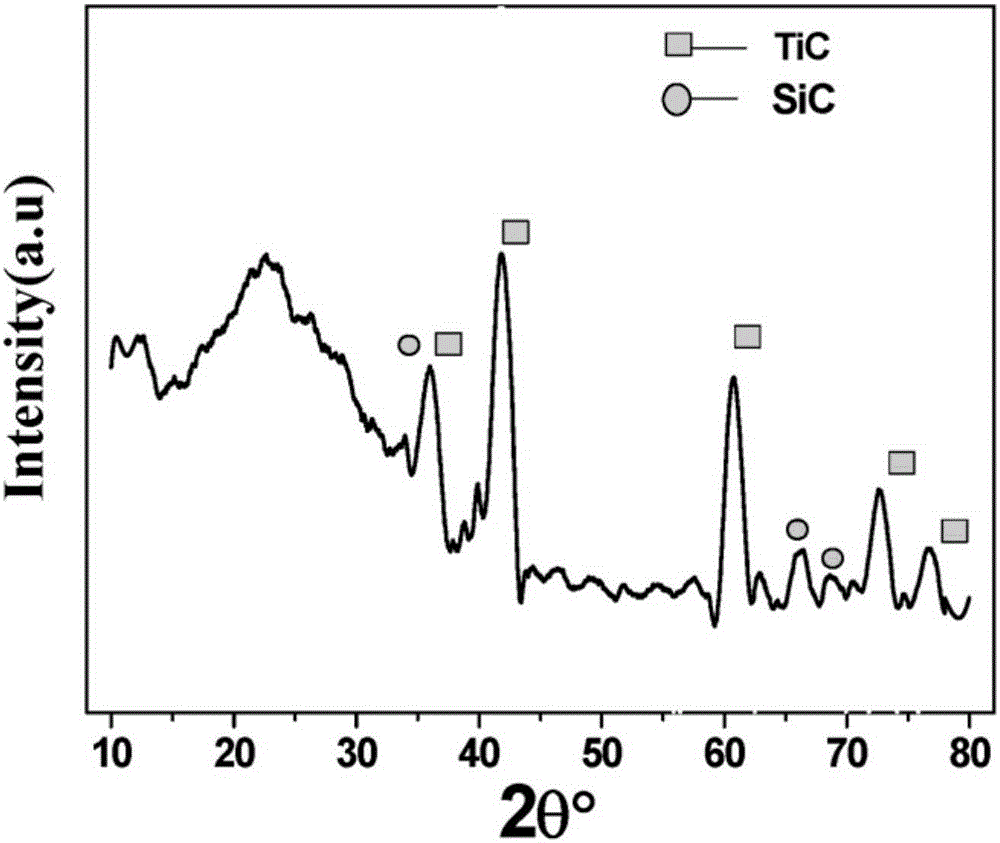

Method for preparing SiC/TiC composite ceramic by precursor method

The invention relates to a method for preparing SiC / TiC composite ceramic by a precursor method. The method of the invention is characterized by comprising the following steps: (1) fully dissolving PCS with a solvent so as to prepare a PCS transparent solution; adding Ti powder; heating, stirring and removing the solvent by steaming until the system is hard to stir; and drying to obtain a mixture of PCS (polycarbosilane) and Ti powder; (2) carrying out high-temperature pyrolysis on the mixture of PCS and Ti powder in a high temperature furnace in the inert atmosphere so as to obtain a SiC / TiC composite powder; and (3) carrying out hot pressed sintering densification on the SiC / TiC composite powder to obtain the SiC / TiC composite ceramic. The technology of the method is simple; sintering temperature is low; and the prepared SiC / TiC composite material has uniform microstructure, fine grain size and high hardness.

Owner:WUHAN UNIV OF TECH

Preparation method of high-purity zirconia refractory product

The invention belongs to the field of refractory materials and provides a preparation method of a high-purity zirconia refractory product. The preparation method is characterized by adopting the pouring process in which the substrates are separated from the aggregates, infiltrating slurry (substrates) into the gaps of particles (aggregates) uniformly under negative pressure and the vibration environment by reasonably selecting grain gradation of the raw particles, precisely grasping the fluidity and solid content of the slurry and utilizing the crosslinking principle of acrylamide polymerization, forming zirconia bodies with uniform structures after curing the slurry (substrates) and obtaining the high-purity zirconia product after proper thermal treatment process. The method has the advantages of wide application range, simple operation, high product purity, zero limitation by the shape and size of the product, etc.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

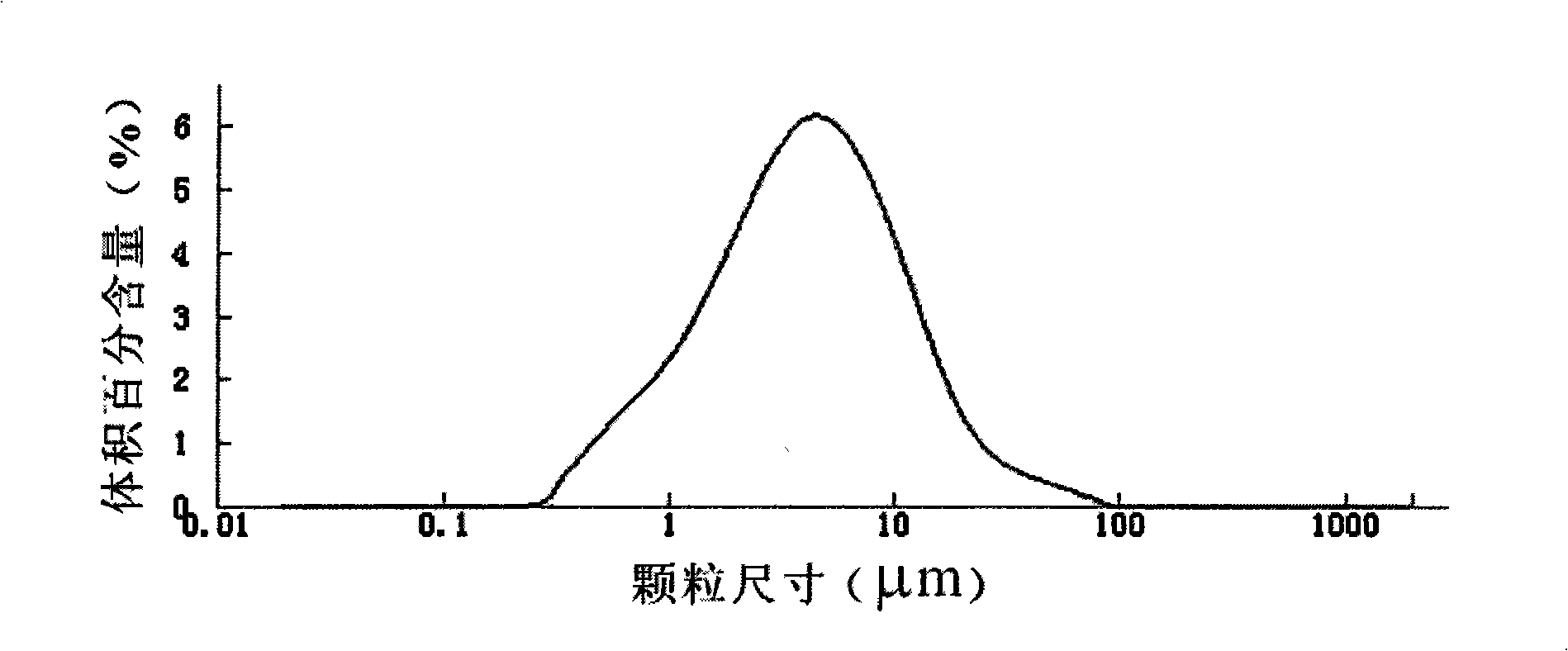

Method for preparing zircon refractory material by using particle size distribution combined with gel injection molding process

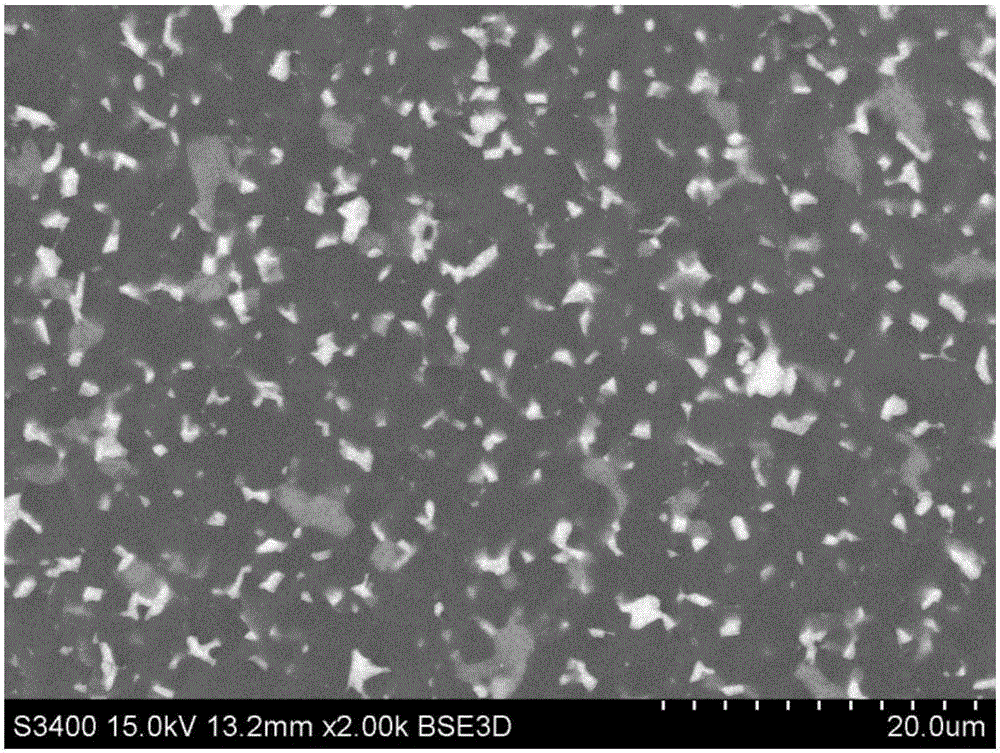

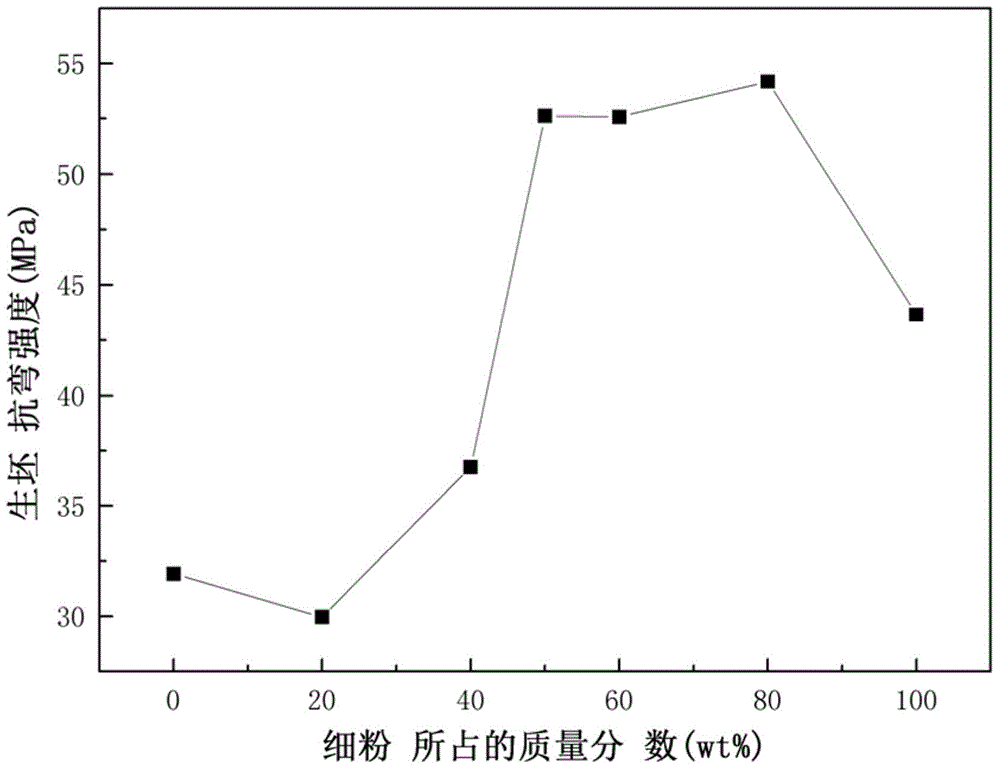

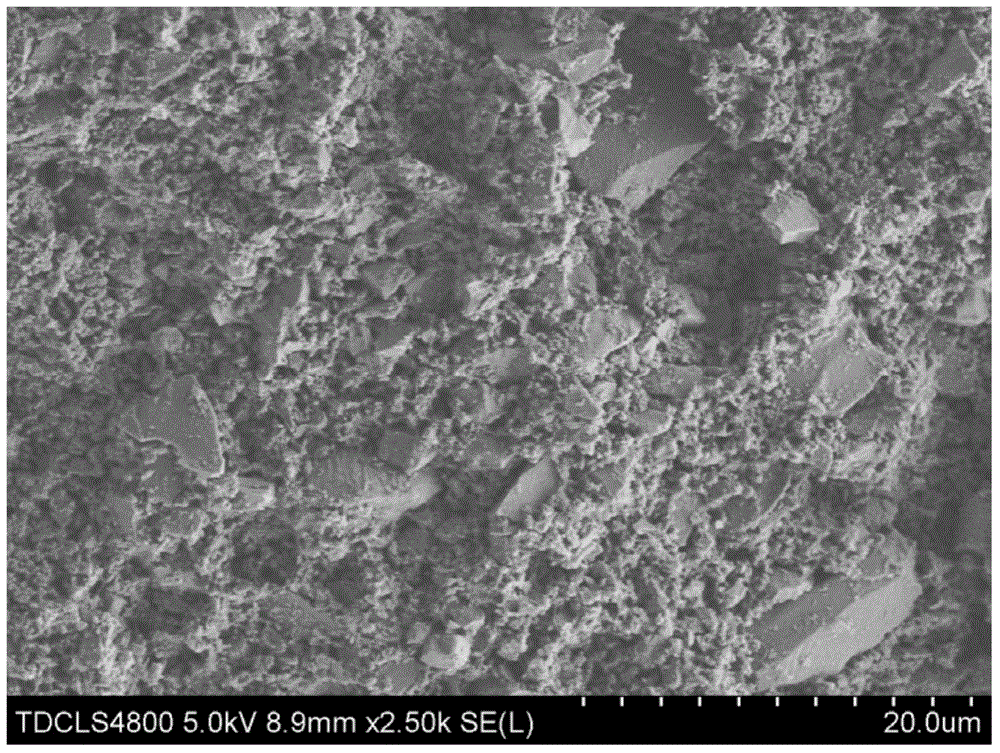

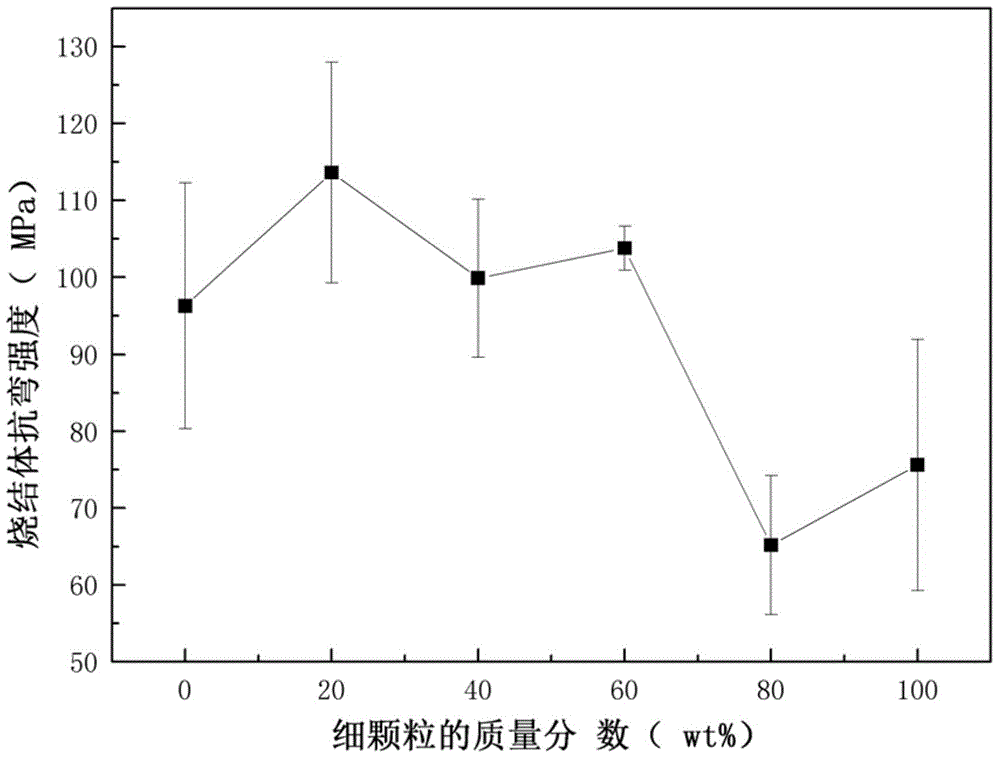

The invention discloses a method for preparing a zircon refractory material by using particle size distribution combined with a gel injection molding process. The method comprises the steps of particle size distribution of powder, preparation of a premixed solution, preparation of ceramic slurry, injection molding, demolding and drying of a wet blank, degreasing of a green body and sintering of a biscuit. The whole process flow is simple, easy to control and suitable for neat size complex forming, and does not need expensive isostatic pressing equipment; under the condition that the solid content is 56vol%, the bending strength of the zircon green body obtained by virtue of particle size distribution can reach 52.6MPa; the bending strength of the compact zircon obtained after degreasing the green body and sintering at 1550 DEG C is 111.9MPa; and compared with a sintered body which is prepared from complete fine powder and complete coarse powder with the same solid content, the strengths are improved by 20.6% and 65.2% as well as 49.1% and 11.8% respectively. The qualitative characterization method of a wet blank drying process does not depend on product sizes and has a wider application scope.

Owner:TIANJIN UNIV

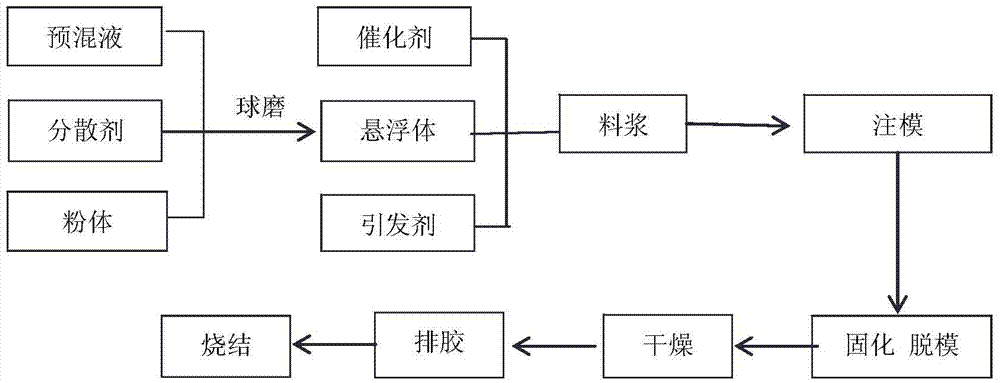

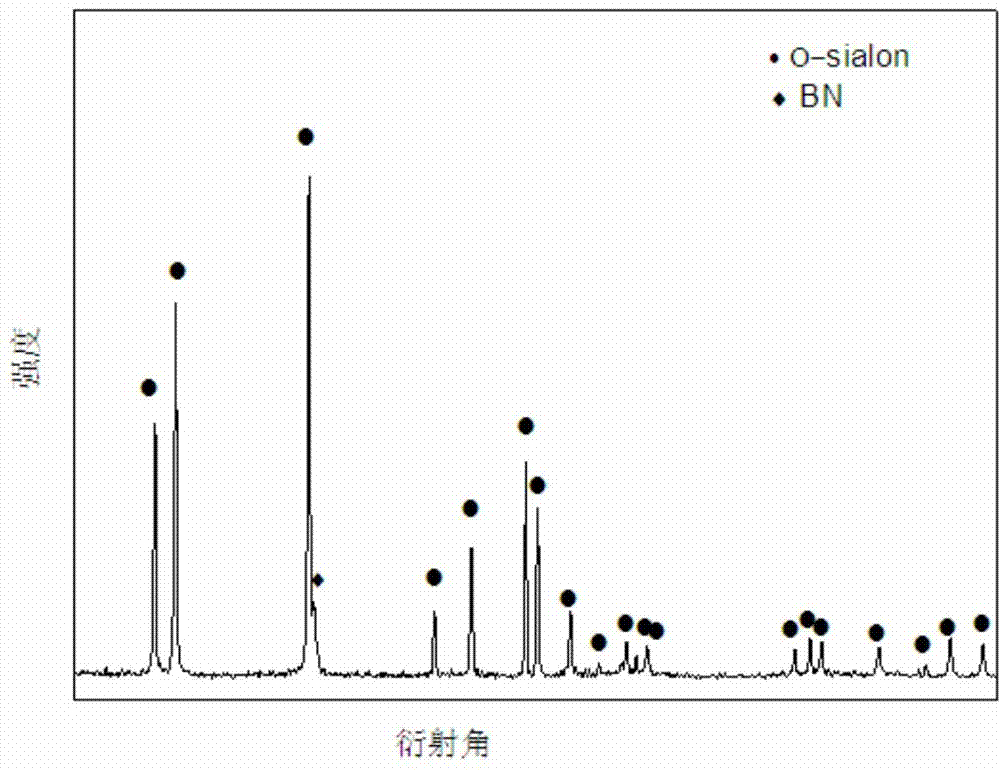

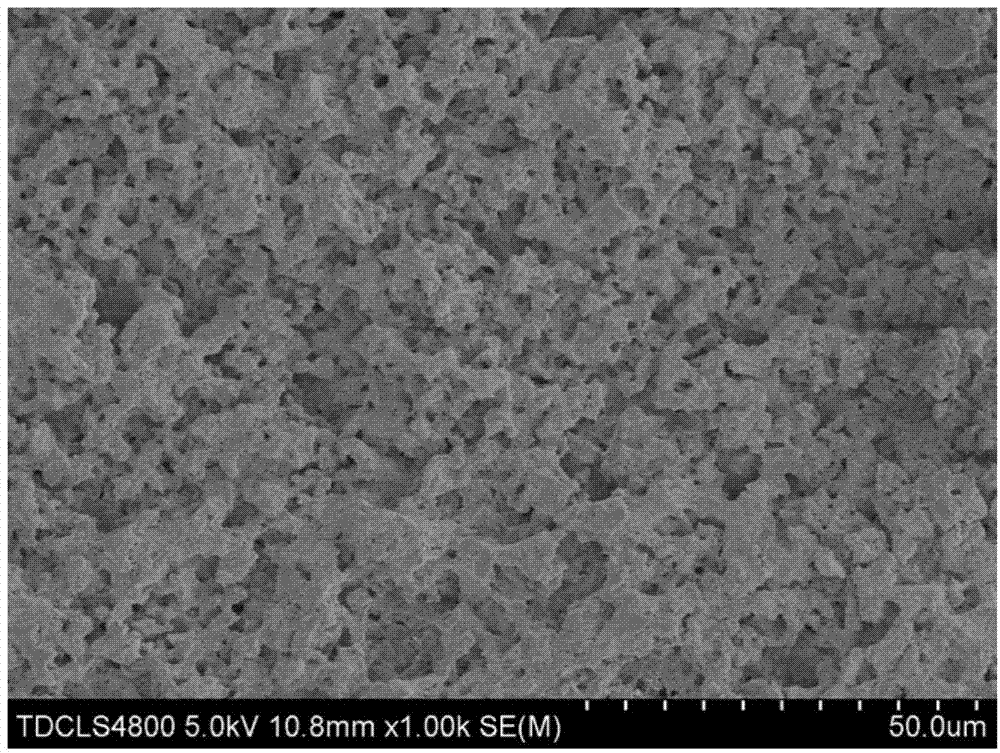

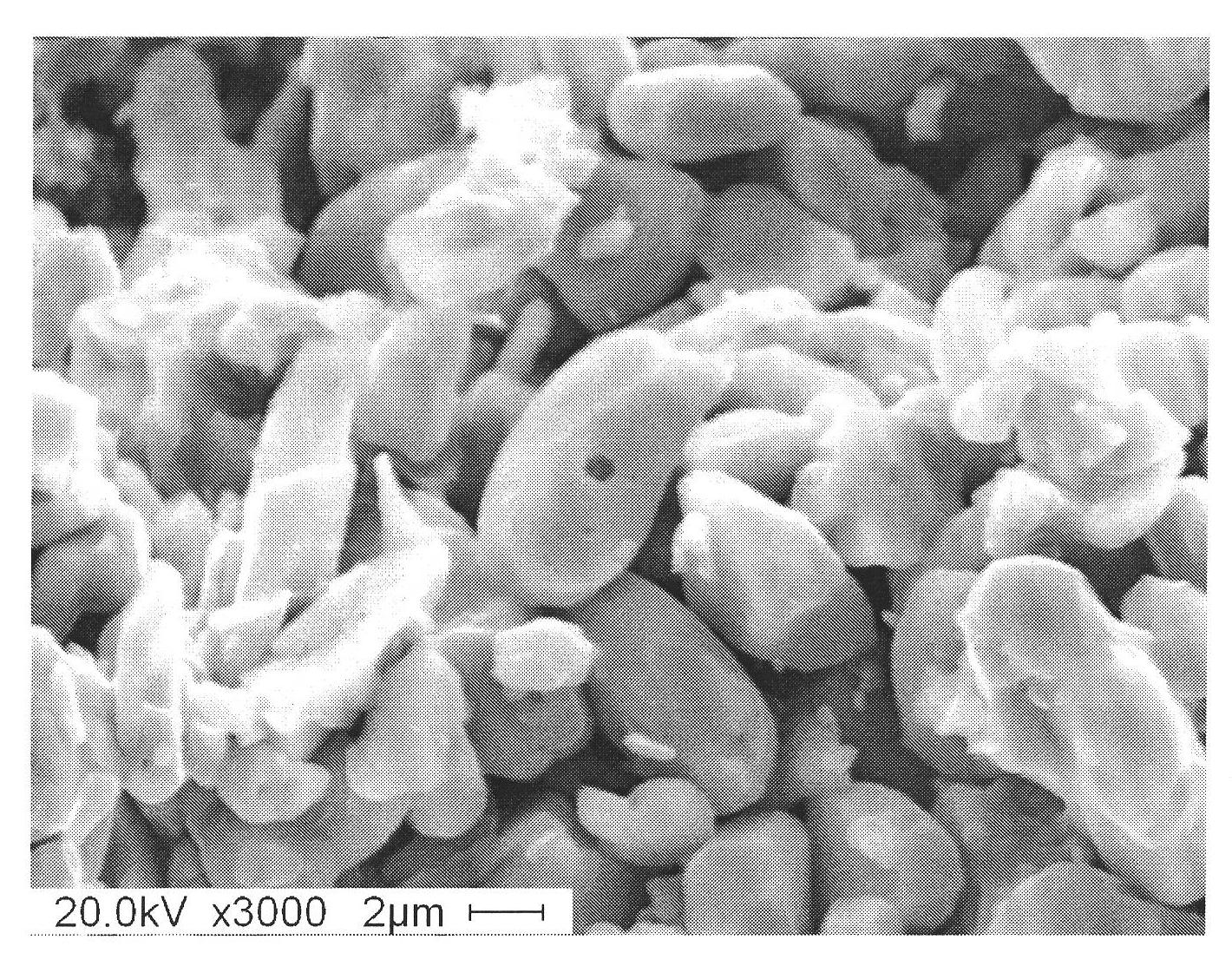

O-Sialon porous material prepared by gel-casting and preparation method thereof

The invention relates to an O-Sialon porous material prepared by gel-casting and a preparation method thereof. The preparation method mainly comprises the following steps: preparing suspensoid slurry, preparing a green body, drying, exhausting rubber and sintering. Alpha-Si3N4, Al2O3, SiO2, Y2O3, MgO and h-BN are taken as raw materials, and the O-Sialon porous material is prepared by a way of combining gel-casting and adding of hard-to-sinter phase (h-BN) of a second phase through an in-situ synthesis technology; the O-Sialon porous material has the density of 1.1 g.cm<-3>-1.6 g.cm<-3>, the porosity between 46% and 64%, the room temperature three-point bending strength between 30 MPa and 82 MPa, a dielectric constant between 2.1 and 4.5, and a tangential value of dielectric loss between 0.112*10<-3>-0.702*10<-3>.

Owner:TIANJIN UNIV

Method for promoting sintering of titanium boride ceramic by using reaction aids

The invention relates to a method for promoting the sintering of titanium boride ceramic by using reaction aids, belonging to the field of structural ceramic. The method comprises the following steps of: adding compound aids Ti and B / B4C / C serving as sintering aids which can react at low temperature; promoting the sintering of TiB2 ceramic by using two-phase particles with high sintering activitygenerated by an in-situ reaction between the sintering adds; and preparing TiB2 ceramic of which the relative density is more than 97 percent by performing hot rolling at the temperature between 1,800 DEG C and 2,000 DEG C. A second phase (titanium boride or titanium carbide) generated by using the method has a melting point as high as that of a substrate, and untoward influence on the high temperature mechanical property of a material caused by the sintering aids is eliminated.

Owner:中科西卡思(苏州)科技发展有限公司

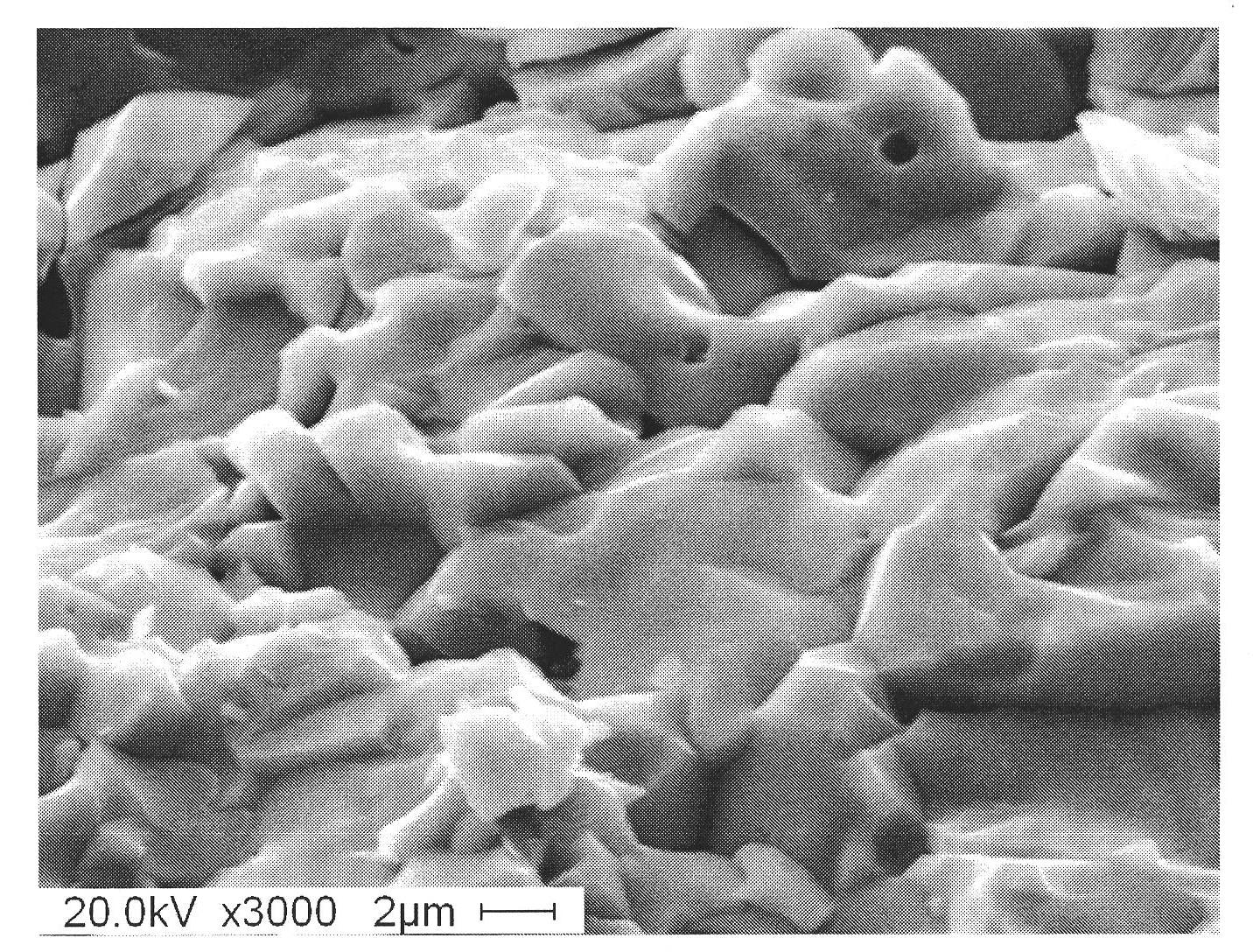

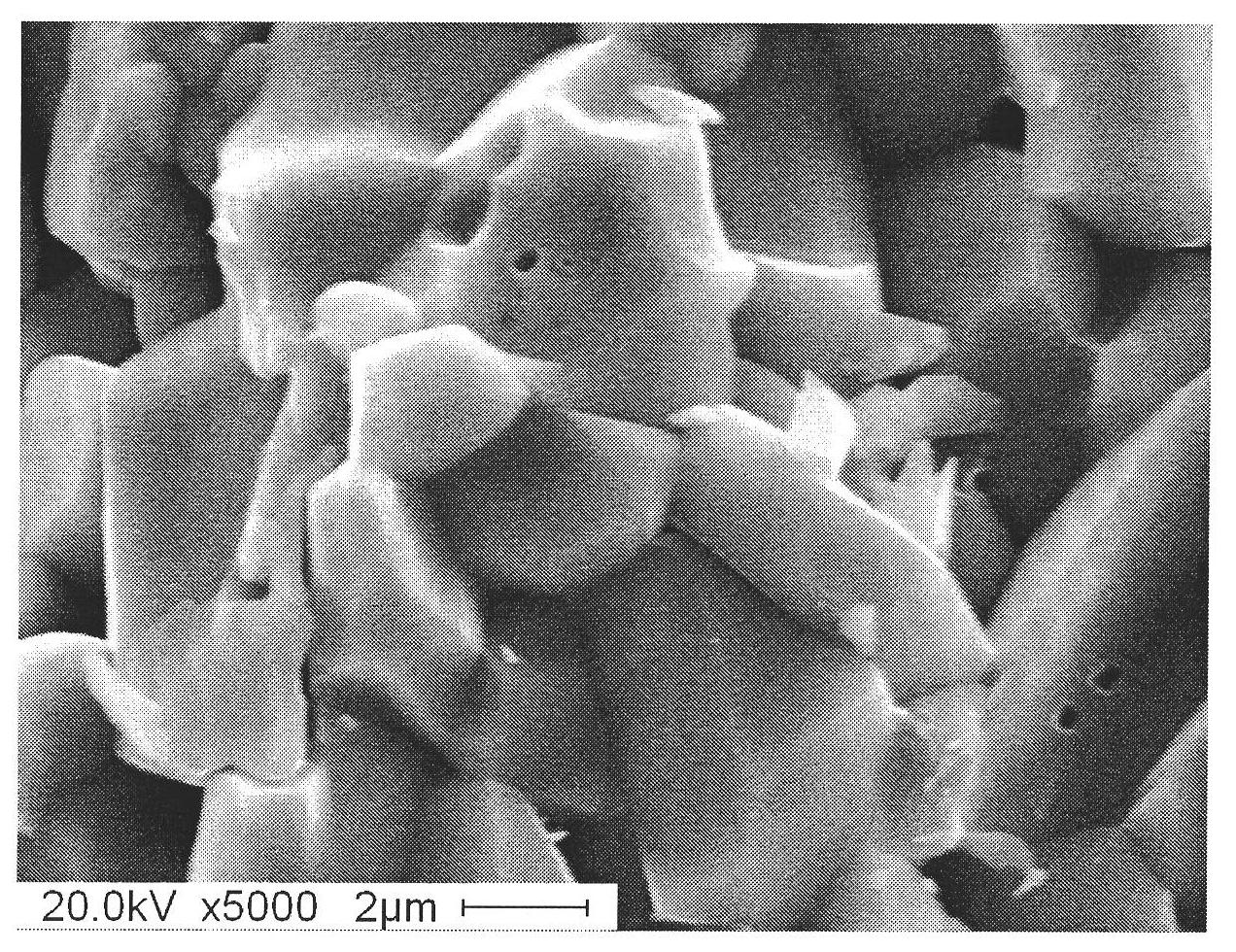

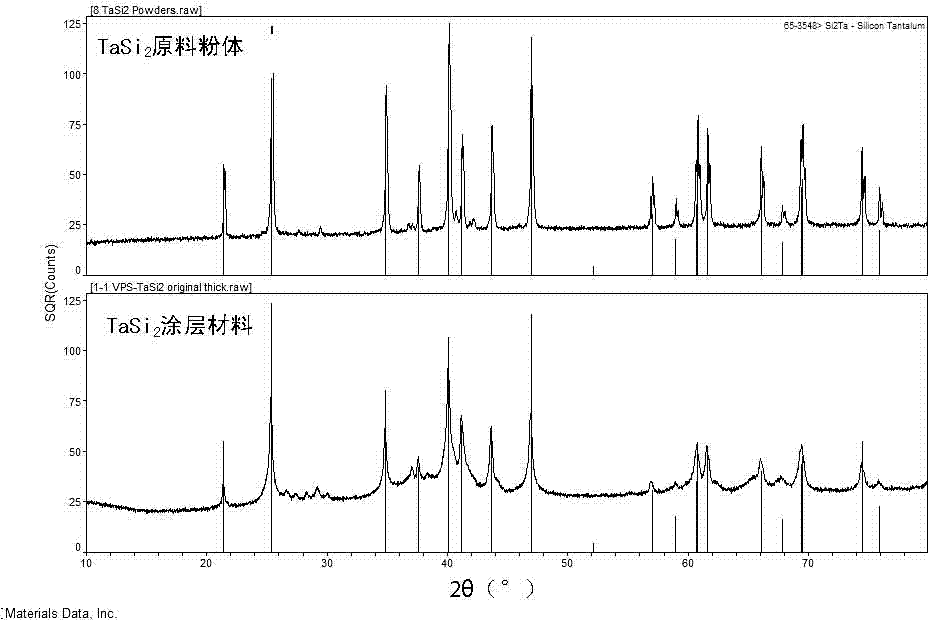

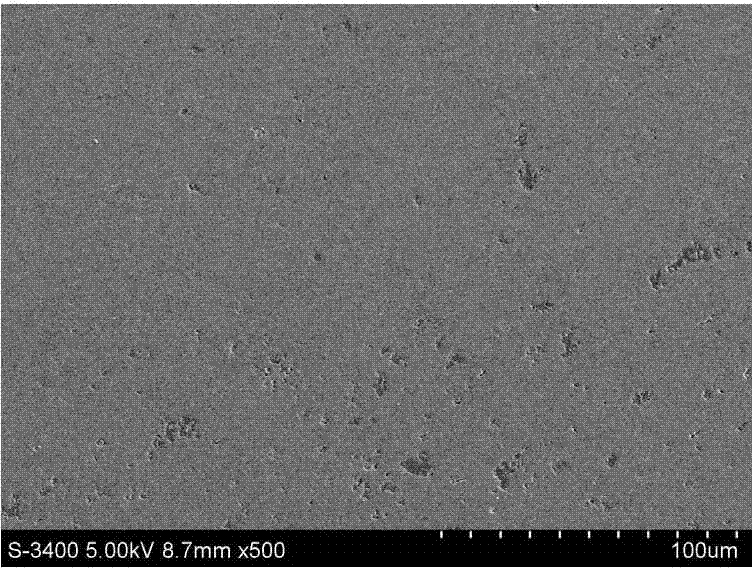

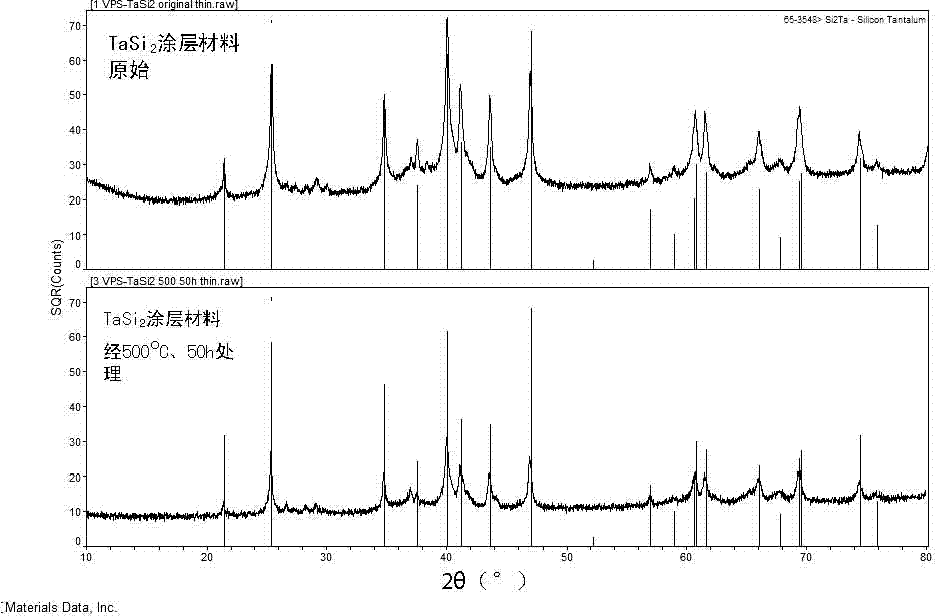

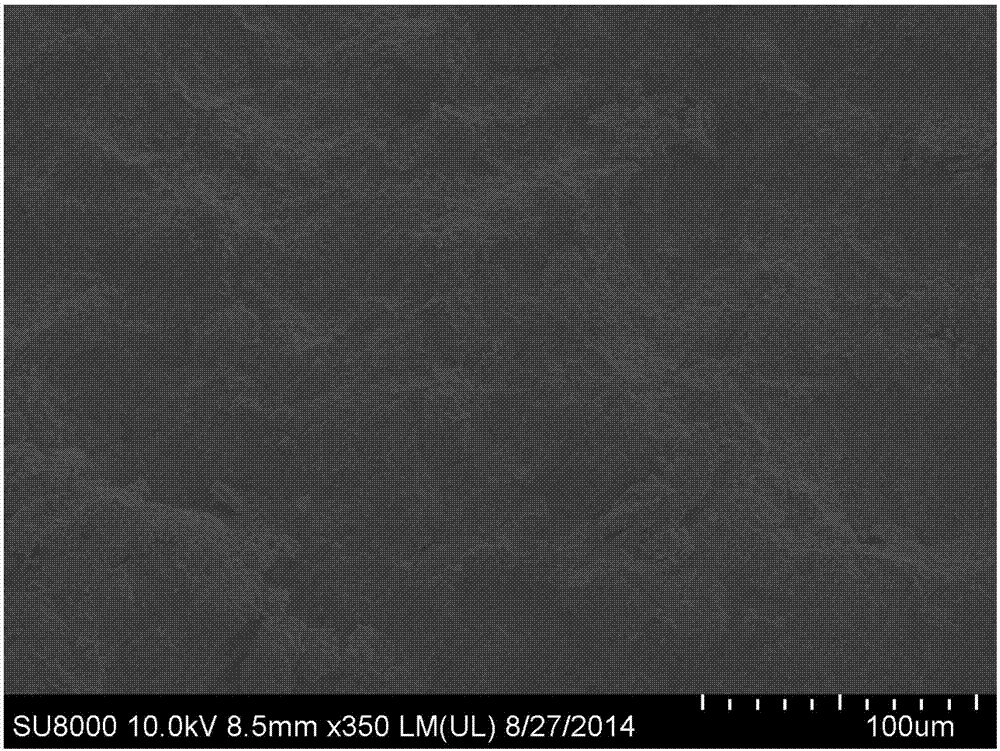

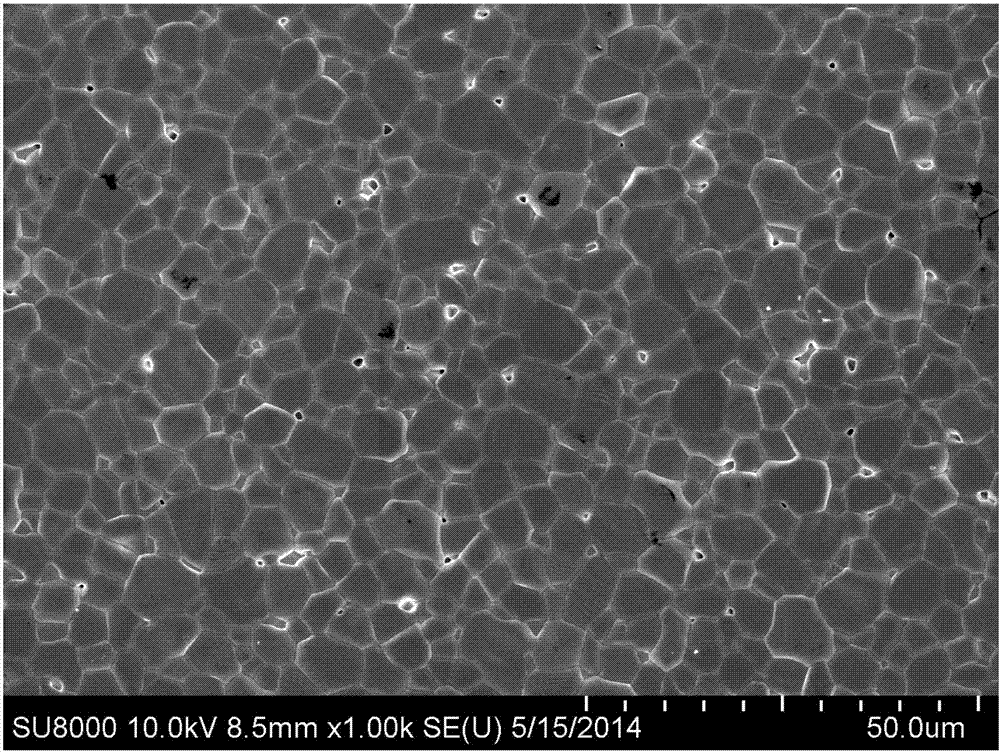

Method for preparing tantalum disilicide coating

InactiveCN103882368AHomogeneous microstructureDense microstructureMolten spray coatingPlasma GasesTantalum

The invention relates to a method for preparing a tantalum disilicide coating. The method comprises the step of spraying tantalum disilicide powder, which has the grain size of 10-120 microns and the purity higher than 95wt%, to the surface of a pretreated high-temperature resistant base material by adopting a vacuum plasma spraying process or low-pressure plasma spraying process, thereby obtaining the tantalum disilicide block material, wherein the plasma spraying process has the parameters as follows: the flow rate of plasma gas Ar is 30-50slpm, the flow rate of plasma gas H2 is 8-18slpm, the flow rate of powder carrying gas Ar is 1.5-5slpm, the spraying distance is 100-350mm, the spraying power is 30-58kW, the powder feeding speed is 8-30g / min, and the spraying pressure is 100-800mbar.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method for slip casting of high-density AZO target material

The invention discloses a preparation method for slip casting of a high-density AZO target material. The preparation method comprises the following steps that zinc oxide powder and aluminum oxide powder are evenly mixed to obtain mixed materials, the mixed materials are added into a nylon tank, a dispersing agent and water are added, and a pH value is regulated to 8.5-10.3 by using ammonia water or acetic acid; the premixed solution is subjected to ball milling to prepare suspension liquid slurry; the slurry obtained through ball milling is subjected to vacuum degassing, the slurry obtained after vacuum degassing is injected into a plaster mold; demolding is performed after slurry sucking and molding, a blank is air-dried for more than 72 hours; degreasing is performed after curing to obtain an AZO blank; the blank is sintered to obtain the AZO target material. A slip casting forming process and a pressure-less AZO target material sintering process are adopted, and the high-density AZO target material can be prepared in a low-cost mode.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com