Method for preparing MgAlON transparent ceramic bisque by gel casting and molding

A technology for gel injection molding and transparent ceramics, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as unreported research, and achieve the effect of uniform microstructure, smooth surface and good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing MgAlON transparent ceramic biscuit by gel injection molding, it comprises the steps:

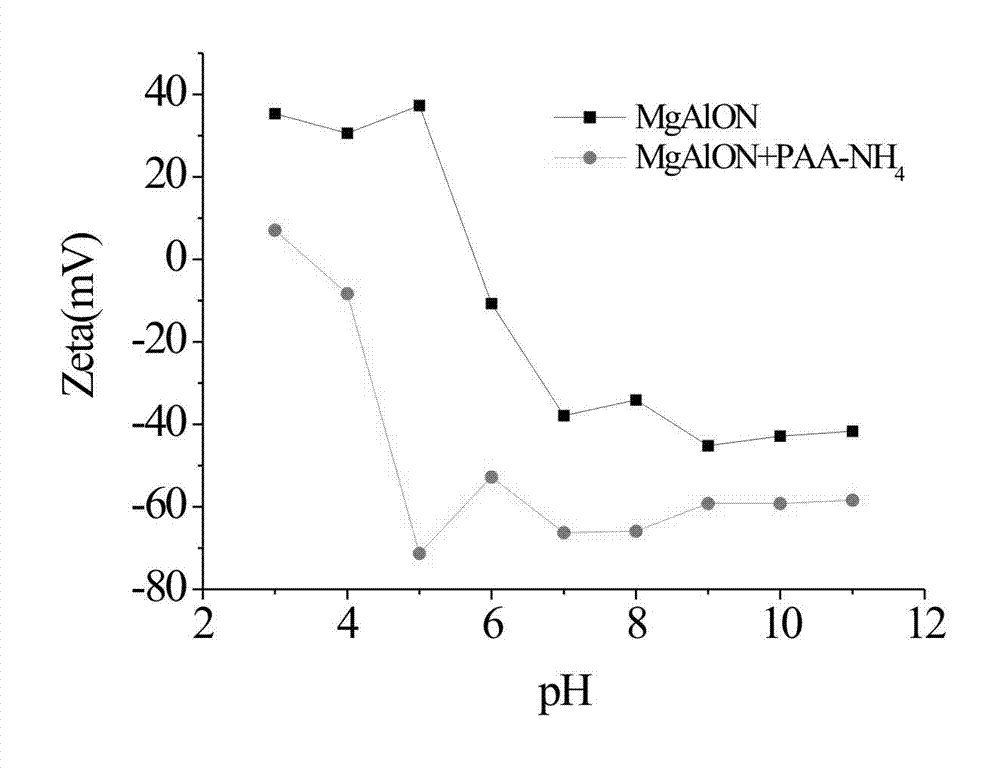

[0038] 1) Preparation of premix solution: Dissolve 3.81g of methacrylamide (abbreviated as MAM) and 0.76g of N,N′-methylene bisacrylamide (abbreviated as MBAM) in 20ml of deionized water to make a MAM concentration of 16wt% solution, add 42.8wt% polyammonium acrylate aqueous solution (referred to as PAA-NH 4 ) 0.29g is a dispersant (the amount of dispersant added is 0.398wt% of the mass of the MgAlON powder to be formed, calculated as 0.4wt%), after stirring evenly, the pH value of the solution is adjusted to 10 with concentrated ammonia water to obtain a premixed solution;

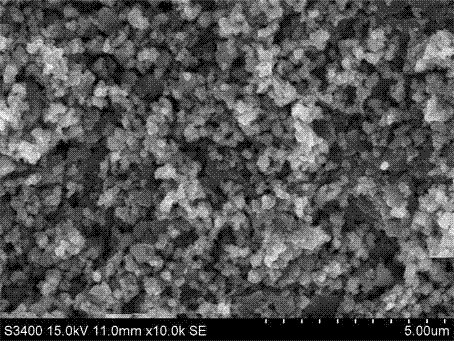

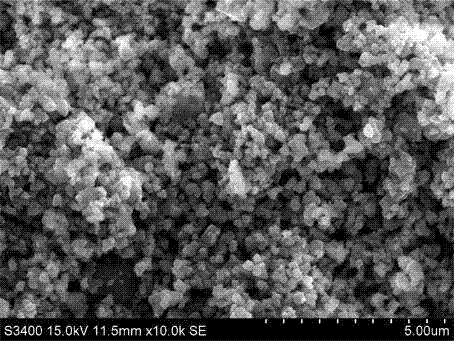

[0039] 2) Preparation of ceramic slurry: add 72.8g of MgAlON powder to the premix prepared in step 1), add alumina balls according to the mass ratio of balls to material 1.5:1, put them in a mixing bottle for mixing, and ball mill for 8 hours to get A ceramic slurry with a solid phase cont...

Embodiment 2

[0044] A method for preparing MgAlON transparent ceramic biscuit by gel injection molding, it comprises the steps:

[0045] 1) Preparation of premix: Dissolve 3.81g of MAM and 0.38g of MBAM in 20ml of deionized water to make a solution with a MAM concentration of 16wt%, and add 0.34g of 42.8wt%PAA-NH 4 As a dispersant, after stirring evenly, adjust the pH value of the solution to 10 with concentrated ammonia water to obtain a premixed solution;

[0046] 2) Preparation of ceramic slurry: Add 74.6g of MgAlON powder to the premix prepared in step 1), add alumina balls according to the mass ratio of balls to materials 1.5:1, put them in a mixing bottle for mixing, and ball mill for 6 hours to get A ceramic slurry with a solid phase content of 50vol%;

[0047] 3) Injection molding: Vacuumize the ceramic slurry prepared in step 2) for 20 minutes to 0.8×10 4 Pa, add 0.37g of 10wt% APS aqueous solution as initiator, 0.37g of TMEDA as catalyst, continue vacuuming for 3min to 0.8×10 ...

Embodiment 3

[0051] A method for preparing MgAlON transparent ceramic biscuit by gel injection molding, it comprises the steps:

[0052] 1) Preparation of premix: Dissolve 3.81g of MAM and 0.25g of MBAM in 20ml of deionized water to make a solution with a MAM concentration of 16wt%, and add 0.38g of 42.8wt% PAA-NH 4 As a dispersant, after stirring evenly, adjust the pH value of the solution to 10 with concentrated ammonia water to obtain a premixed solution;

[0053] 2) Preparation of ceramic slurry: add 76.4g of MgAlON powder to the premix prepared in step 1), add alumina balls according to the mass ratio of balls to material 1.5:1, put them in a mixing bottle for mixing, and ball mill for 4 hours to get A ceramic slurry with a solid phase content of 52vol%;

[0054] 3) Injection molding: Vacuumize the ceramic slurry prepared in step 2) for 5 minutes to 1.2×10 4 Pa, add 0.38g of 10wt% APS aqueous solution as initiator, 0.38g of TMEDA as catalyst, stir well and continue vacuuming for 3mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com